Patents

Literature

79results about How to "Control the amount of glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

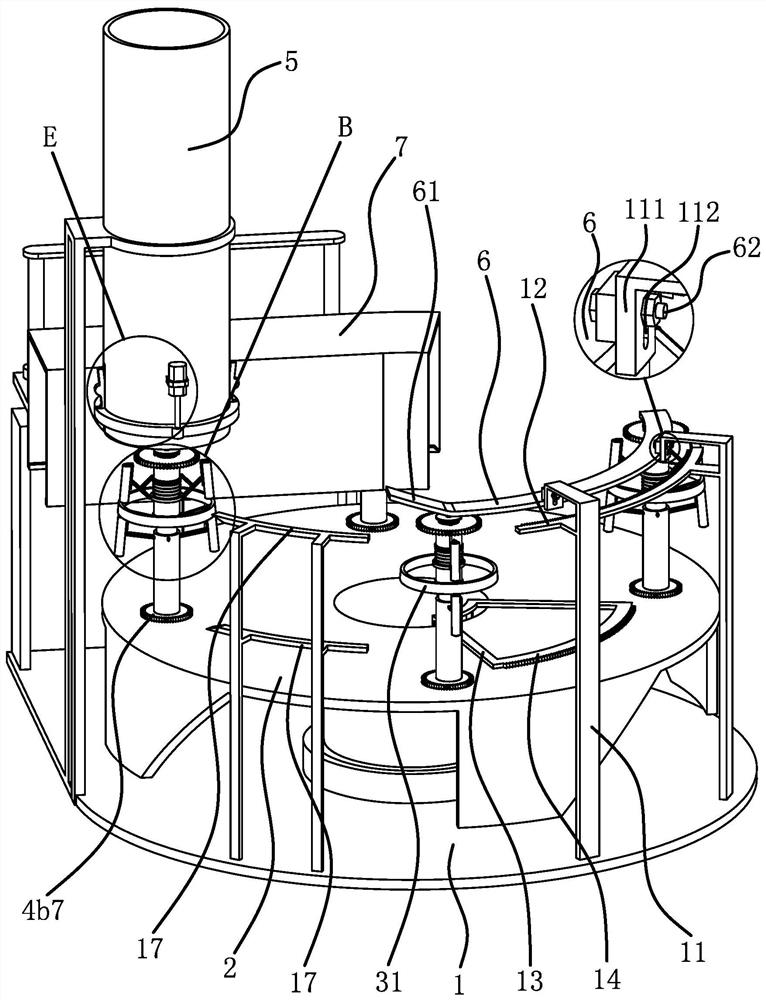

Optical module automatic chip mounting and assembling machine

InactiveCN106239902AHigh precisionIncrease productivityMaterial gluingOptical articlesUV curingOptical Module

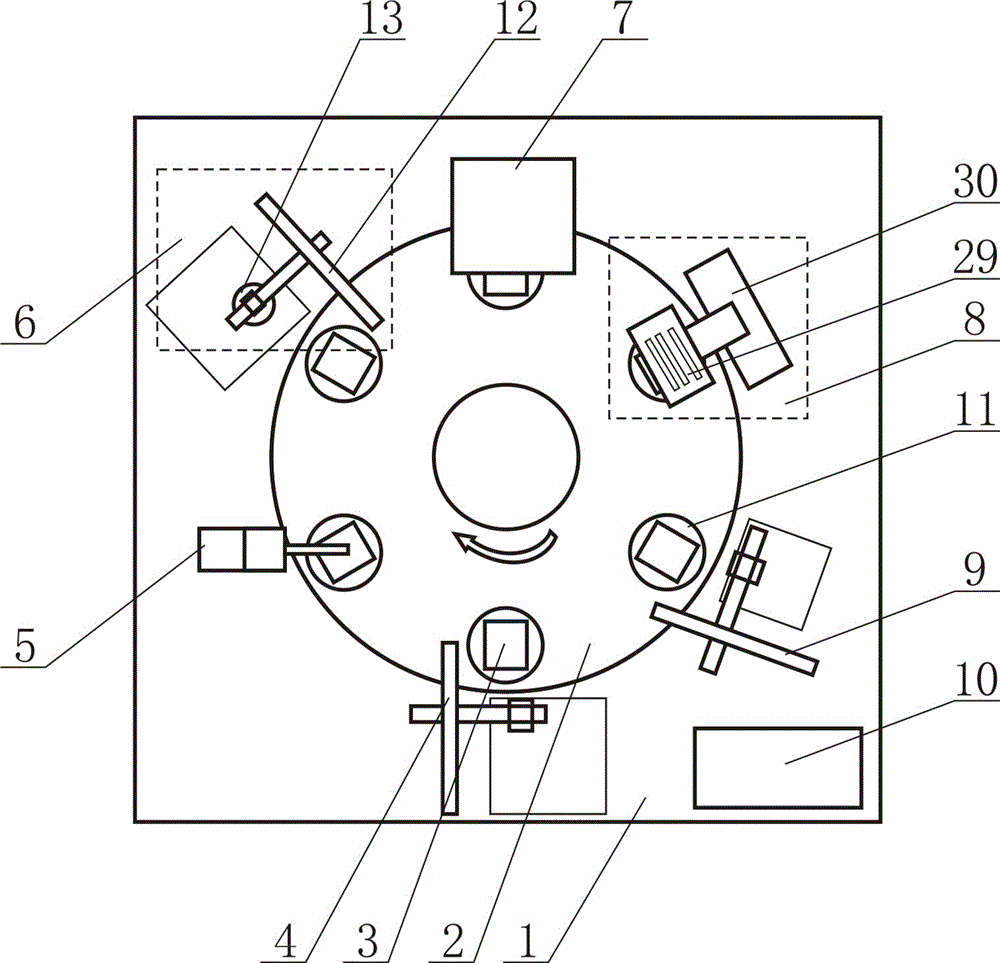

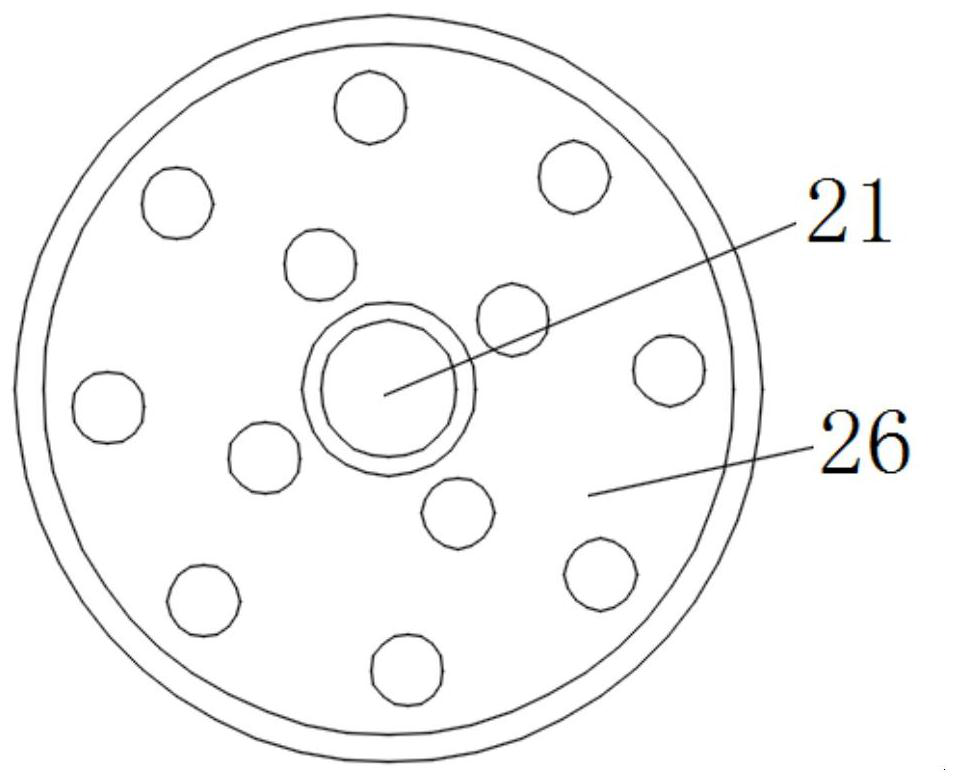

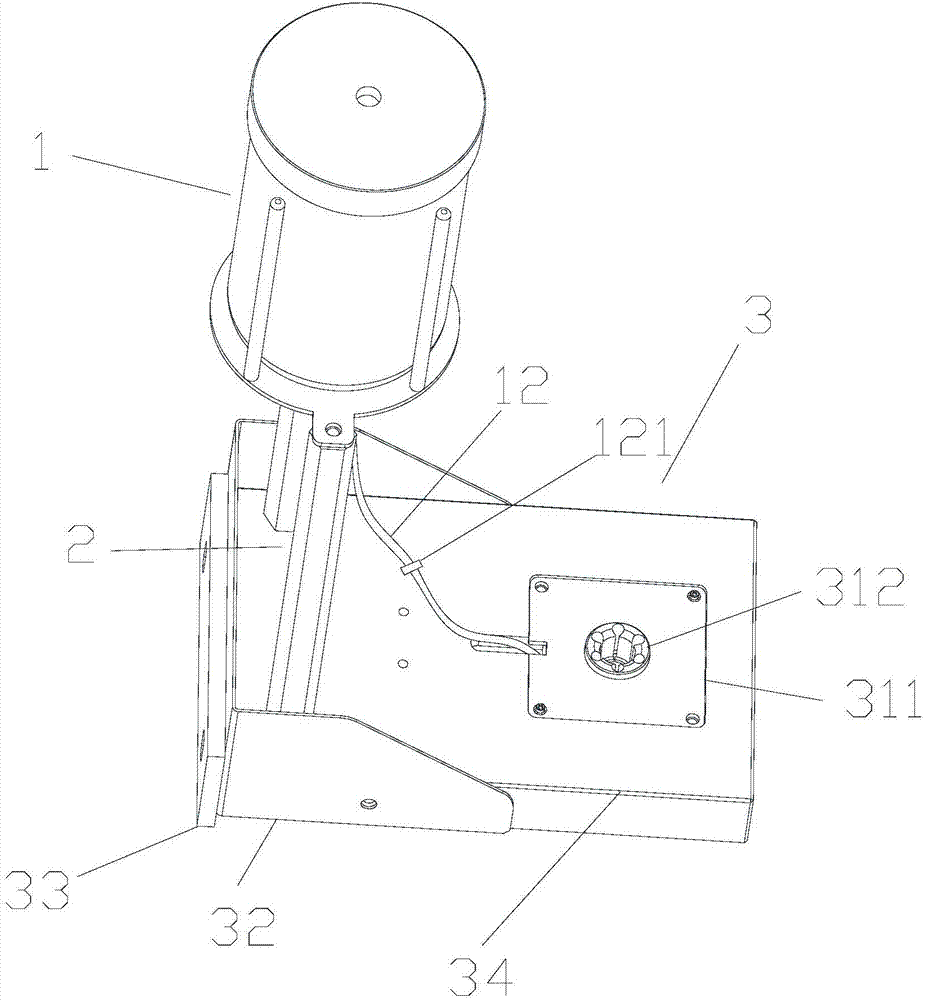

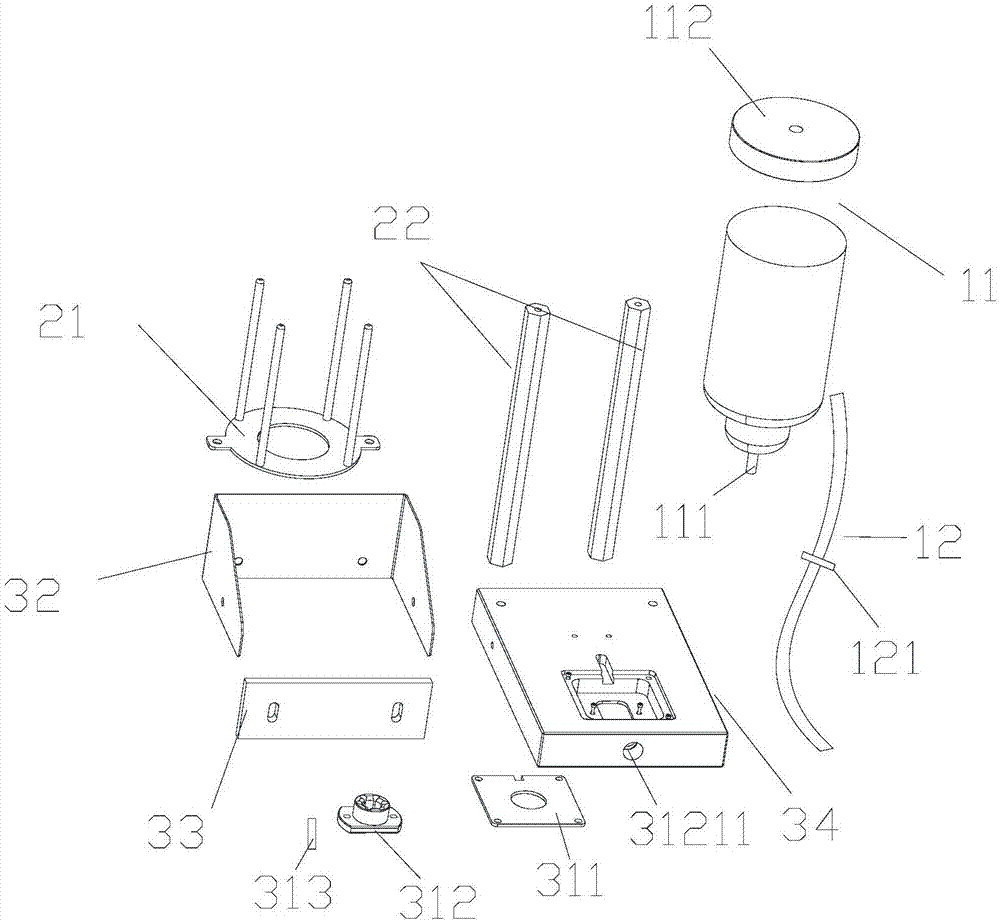

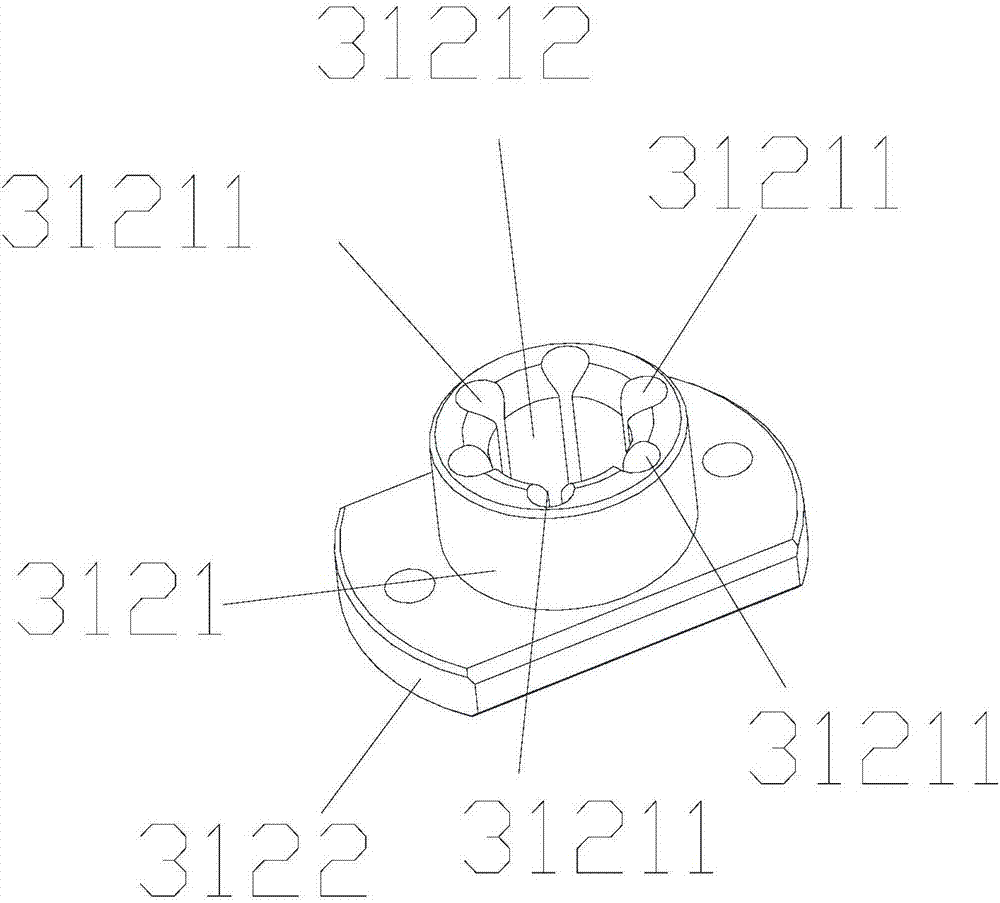

The invention discloses an optical module automatic chip mounting and assembling machine. The optical module automatic chip mounting and assembling machine comprises a worktable and an intermittent rotary plate arranged on the worktable. Six tool clamps are evenly distributed along the periphery of the intermittent rotary plate at intervals. A glass prism feeding manipulator, a glue dispensing device, an optical filter feeding device, a chip mounting press-fitting device, a UV curing device, a finished product taking manipulator and a controller which correspond to the tool clamps are sequentially arranged on the worktable and around the intermittent rotary plate. Linkage of all the processes is realized through the intermittent rotary plate with six stations, glass prism feeding, glue dispensing, optical filter feeding, chip mounting press-fitting, UV curing and finished product taking are carried out in sequence, and automatic operation of all the procedures is realized. Automatic batch production is realized through various sensors and electric element control machines and mechanisms, and the production efficiency, and reliability and consistency of novel products are improved. As the glue outlet amount can be controlled accurately, the accuracy of chip mounting and assembling is greatly improved, and product quality is improved.

Owner:OPTIMAL COATECH GUANGZHOU CO LTD

Method for machining bamboo floor

InactiveCN102729309AHigh strengthImprove the carbonization effectLiquid surface applicatorsDomestic articlesProcess engineeringBamboo floor

The invention relates to the technical field of floor materials and particularly relates to a method for machining a bamboo floor. By improving a carbonization process, a gluing process, a painting process and the like and adding a new process, the total quality of the bamboo floor is improved; the carbonization is good; the bamboo floors with different colors can be produced according to production demands; and the color is uniform. The total quality of the bamboo floor can be further improved by finely polishing; the gluing process is better, so that the integral strength of the floor can be effectively improved with a hot pressing process, the glue using amount is effectively controlled, and the production cost is effectively reduced; and the painting technique is improved, and a coating quantity is reduced, so that the painting amount is greatly reduced, the coating is more stable, and the quality is higher.

Owner:安吉华信竹木制品有限公司

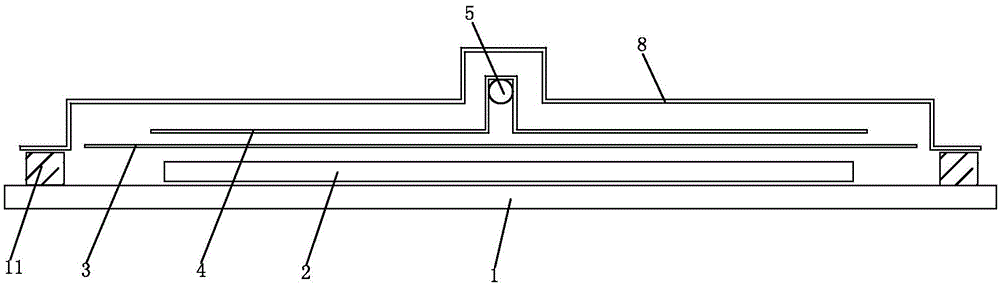

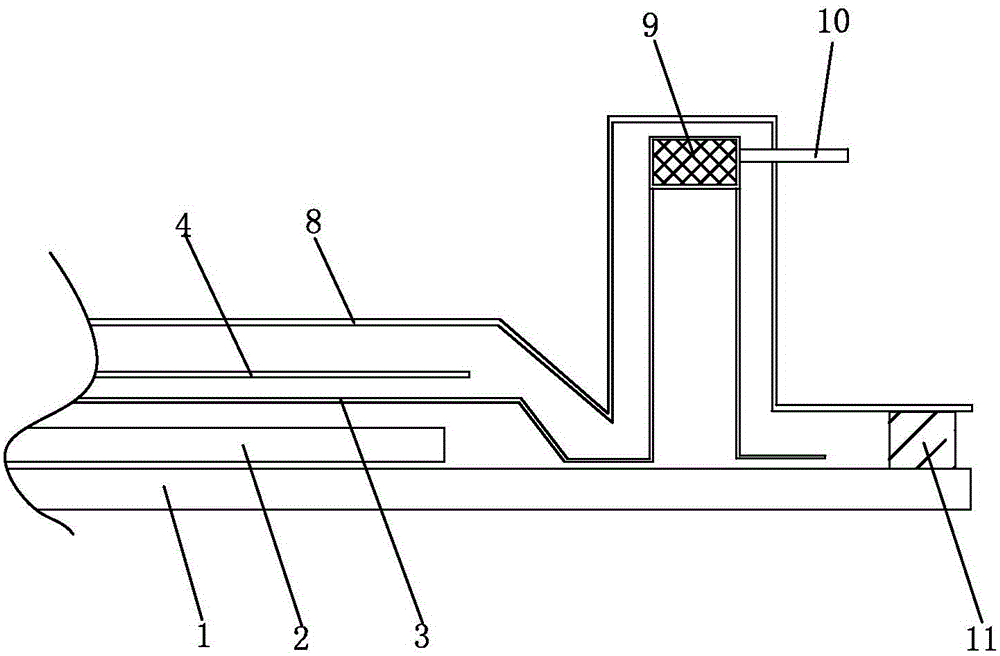

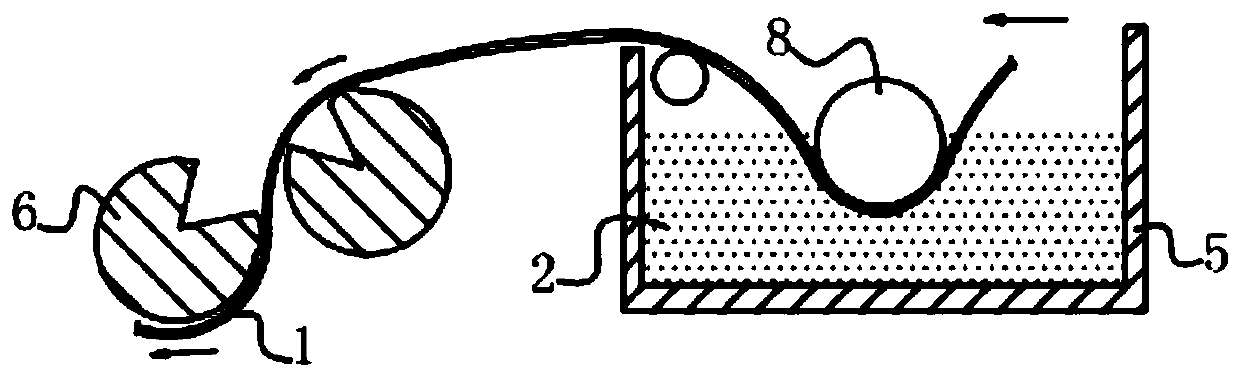

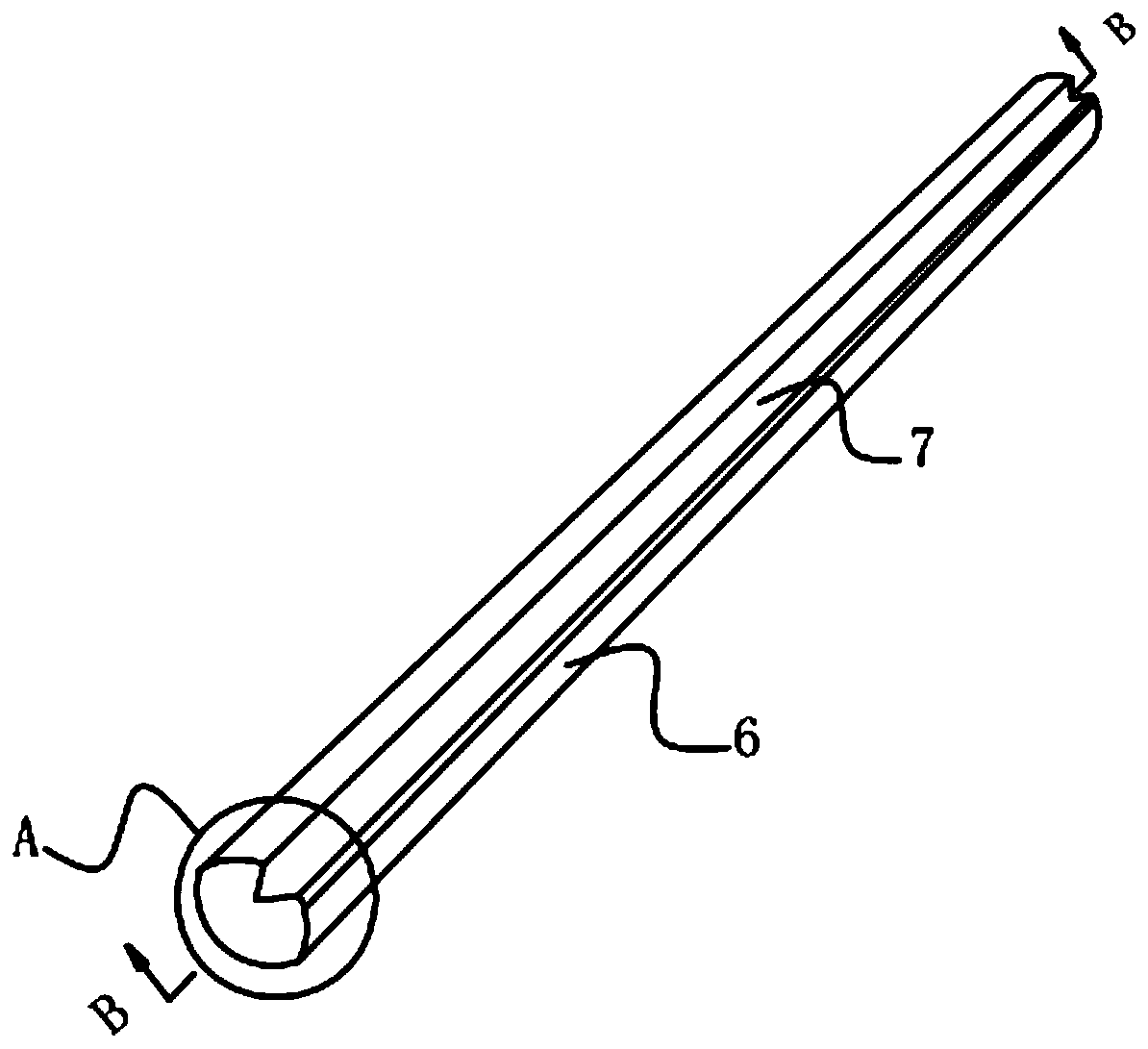

Condulet external-gluing mechanism

InactiveCN102989625ARealize spatial displacementControl the amount of glueLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a condulet external-gluing mechanism. The condulet external-gluing mechanism is characterized in that two sides of a baseboard are provided with linear guide rails, a linear guide rail connection supporting board is formed on the surfaces of the linear guide rails, a horizontal guide rod cylinder is fixedly connected with the baseboard through a guide rod cylinder fixing board, the horizontal guide rod cylinder is connected with a second guide rod cylinder connection board through a first guide rod cylinder connection board, the front portion of the second guide rod cylinder connection board is fixedly connected with a gluing board through an extension board, at least two vertical guide rod cylinders are symmetrically distributed on the bottom of the second guide rod cylinder connection board, and the bottoms of the vertical guide rod cylinders are fixed on the linear guide rod connection supporting board. The condulet external-gluing mechanism which adopts a dual-cylinder driving system realizes the space displacement of a whole support, the gluing plate having a jagged edge enables the glue carrying amount to be effectively controlled, the gaps between teeth can realize the condulet external-gluing, and the condulet external-gluing mechanism has the advantages of reasonable whole design, ingenious conception, stable working state, accurate positioning, convenient operation, simple whole mechanical structure, and very good practicality.

Owner:温岭市泛腾自动化设备有限公司

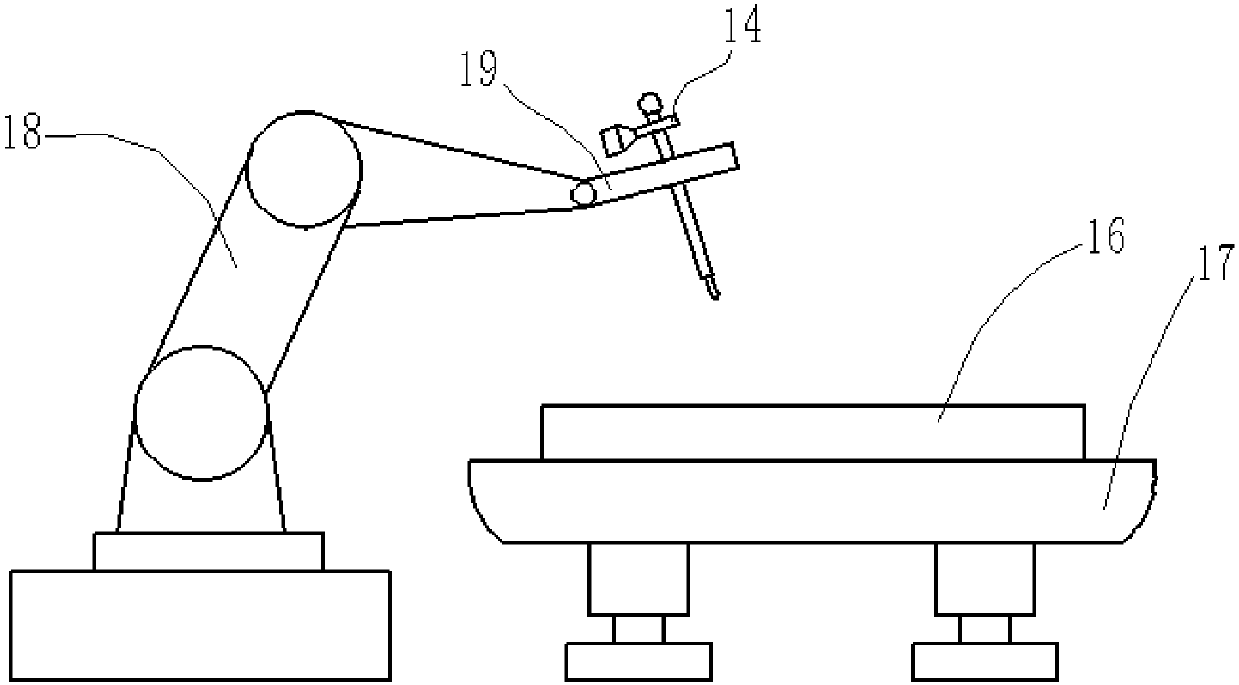

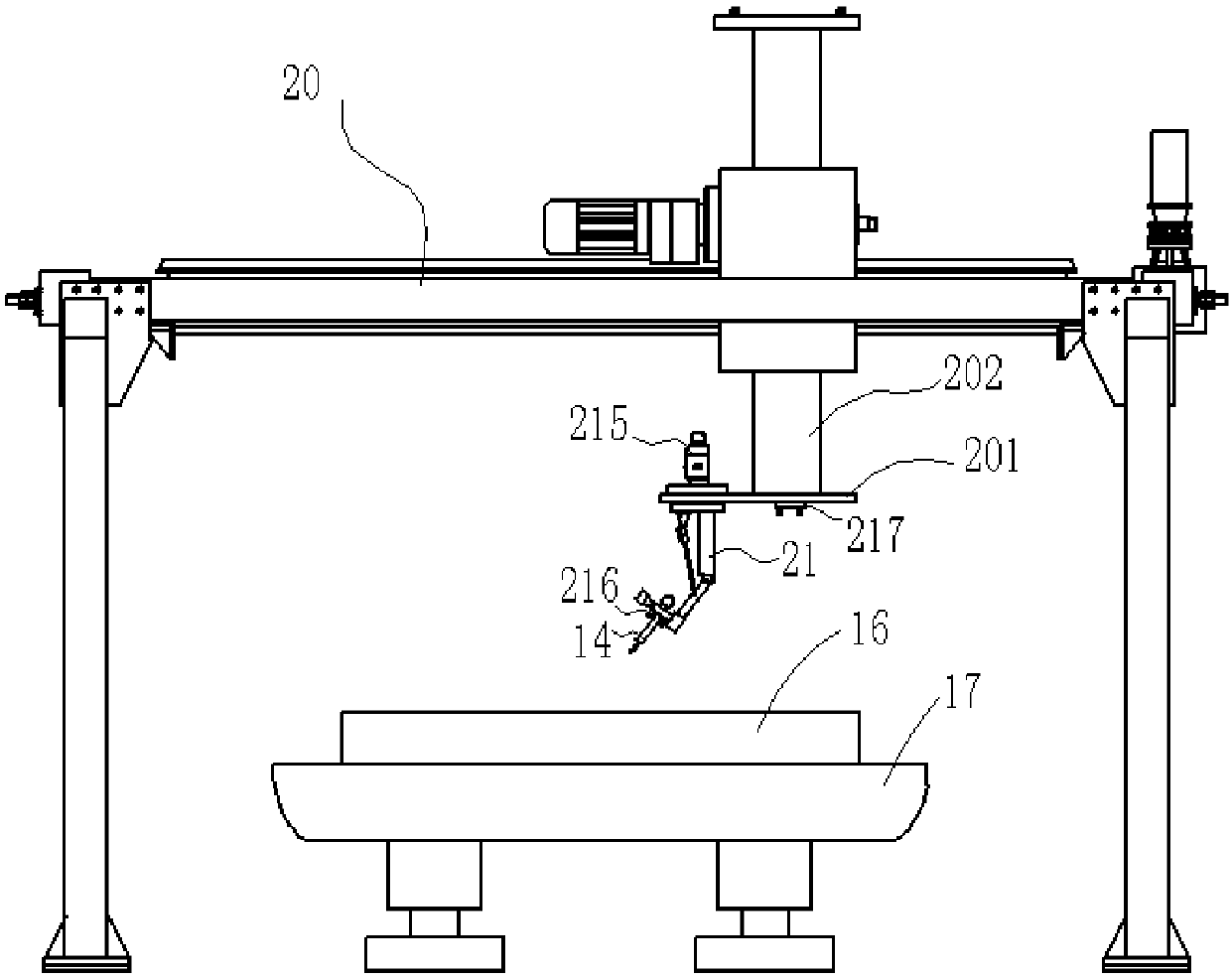

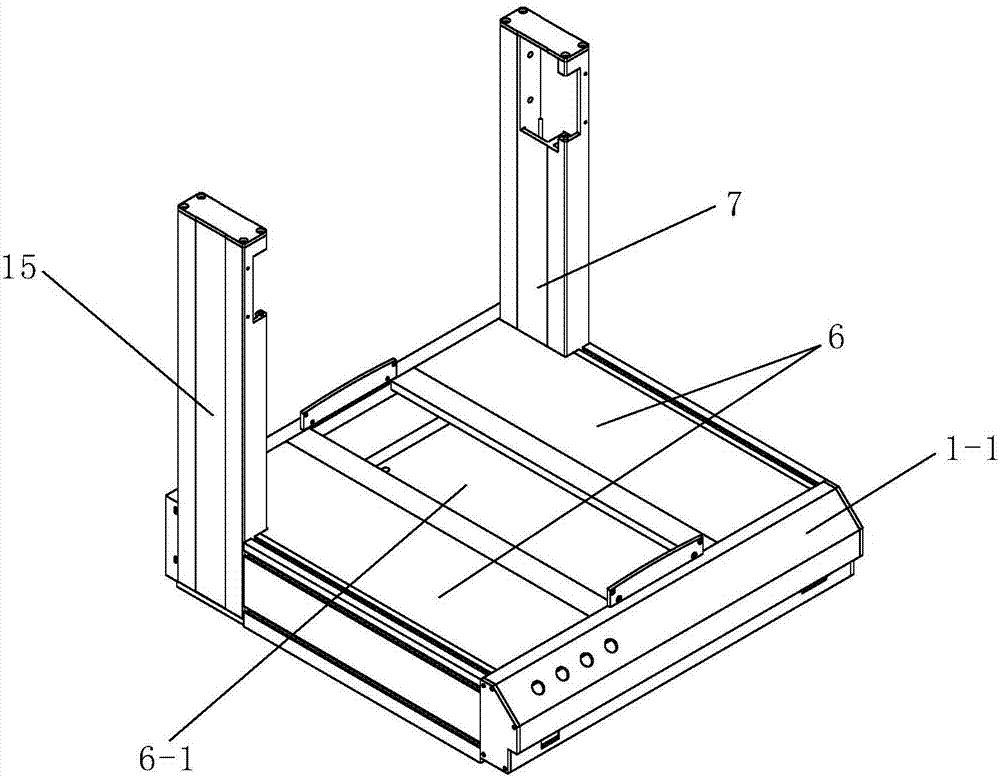

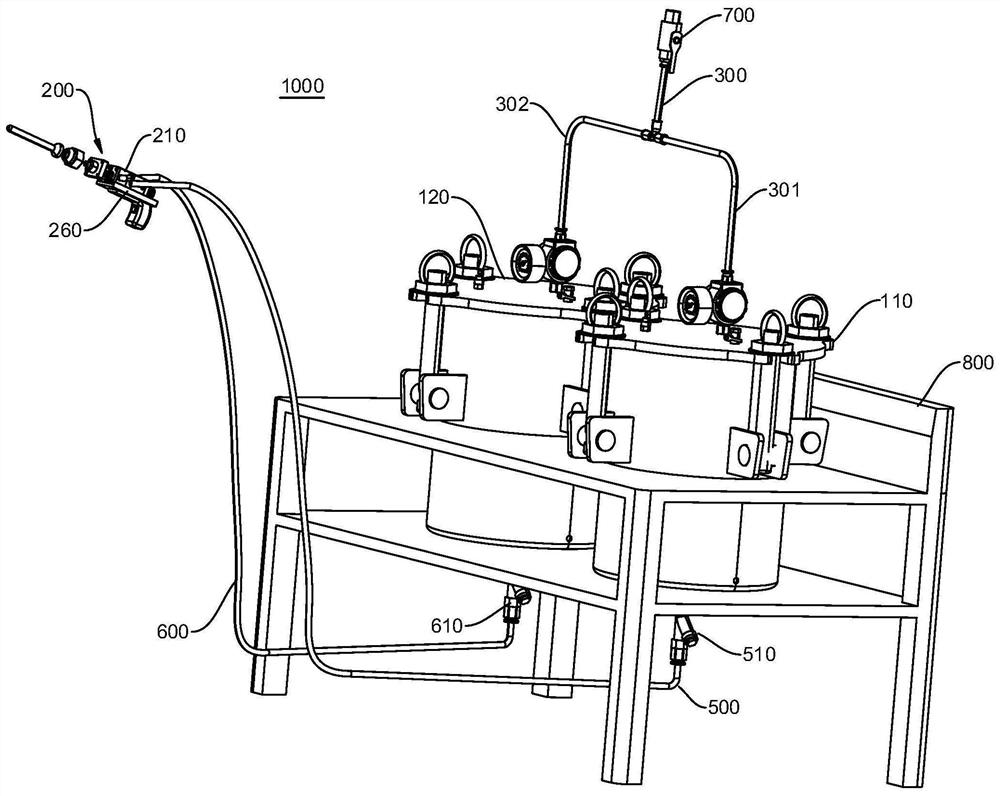

Automatic composite glue coating device and glue gun automatic alignment method

InactiveCN108031577AEasy to useShorten the timeLiquid spraying apparatusEngineeringMechanical engineering

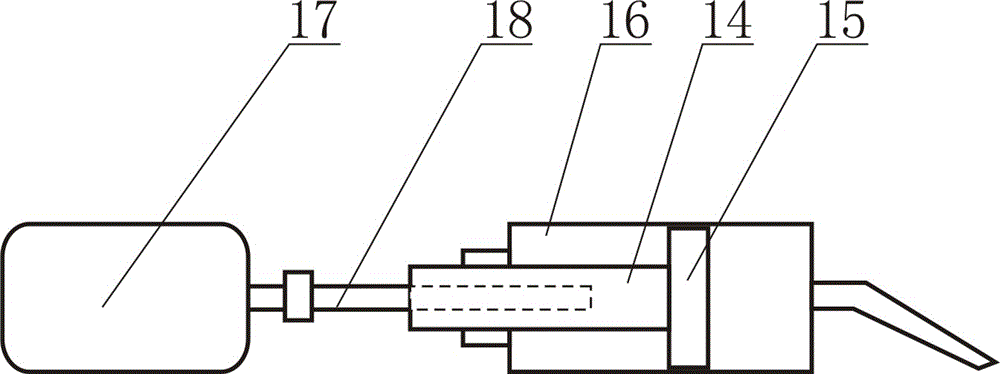

The invention relates to an automatic composite glue coating device and a glue gun automatic alignment method. The automatic composite glue coating device comprises a glue gun, a first glue pump, a second glue pump, a glue gun driving device and a positioning working table. The glue gun is provided with a two-component mixing cavity. The glue gun driving device comprises a base and a driving system. A workpiece to be coated with glue is positioned on the positioning working table. The relative positions of the positioning working table and the base of the glue gun driving device are fixed. Thetwo glue pumps are provided with displacement or speed sensors and deliver two-component glue to the mixing cavity of the glue gun. The glue gun driving device is a robot. The glue gun driving devicecan also be mounted on a sliding block mounted on a bracket and moving along the X-axis, Y-axis and Z-axis. An adjusting device for adjusting the coating angle of the glue gun and two distance measuring instruments are mounted on the sliding block. The glue gun is fixed to a clamping rod of the adjusting device. The glue gun can conduct alignment automatically to be perpendicular to the surface of the workpiece to be coated with glue. The automatic composite glue coating device can quickly complete the glue coating process and is convenient to use.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

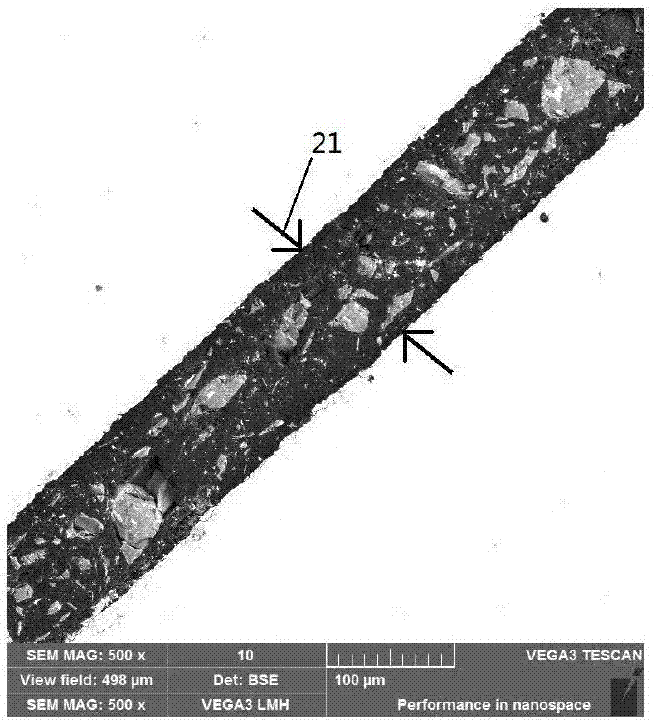

Magnet assembly and preparing method thereof

ActiveCN107578879AChange mobilityAvoid deformationPermanent magnetsInductances/transformers/magnets manufactureEpoxyCooking & baking

The invention discloses a magnet assembly and a preparing method thereof. The magnet assembly is formed by overlapping and attaching a plurality of magnetic pieces which are made of a rare earth permanent magnet material. Attaching layers are arranged between the magnetic pieces. The magnet assembly is characterized in that each attaching layer comprises epoxy resin glue and irregular-shaped particles evenly distributed in epoxy resin glue, and the thickness of each attaching layer is 80-200 micron. The preparing method of the magnet assembly includes the steps of glue mixing, glue dispersing,pressurizing, baking and the like. By means of the magnet assembly and the preparing method, by adding the irregular-shaped particles to the attaching layers, the thickness uniformity of the attaching layers is greatly improved, and the performance of the magnet assembly is improved.

Owner:TIANJIN SANHUAN LUCKY NEW MATERIAL CO LTD +1

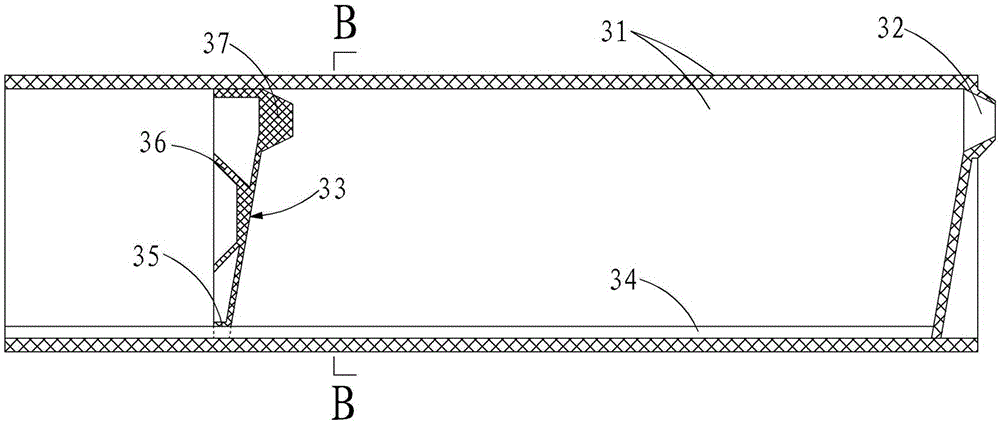

Vacuum assisted resin injection process for preparing fiber composite material

The invention discloses a vacuum assisted resin injection process for preparing a fiber composite material. When a center point injection mode is adopted, a plurality of layers of soft materials are laid under a glue injection seat; when a linear injection mode is adopted, a pipeline is laid among products for reducing the distance of a flowing channel, a glue guide pipe is wrapped with a flow guide net for preventing the glue guide pipe from making indentations on the surfaces of the products, the glue guide pipe is separated from the surface of a prefabricated part, direct contact is avoided, and the height between the glue guide pipe and the prefabricated part is approximately 10-50 mm; at an extracting opening, a layer of narrow strong-core felt strip wrapped with demolding cloth serves as a gas guide channel, the gas guide channel is also separated from the edge of the prefabricated body, and the height between the gas guide channel and the prefabricated body is approximately 50-100 mm. By means of the process, resin glue volume and bubbles in laminated plates can be reduced, and the voidage is reduced.

Owner:HENGSHEN

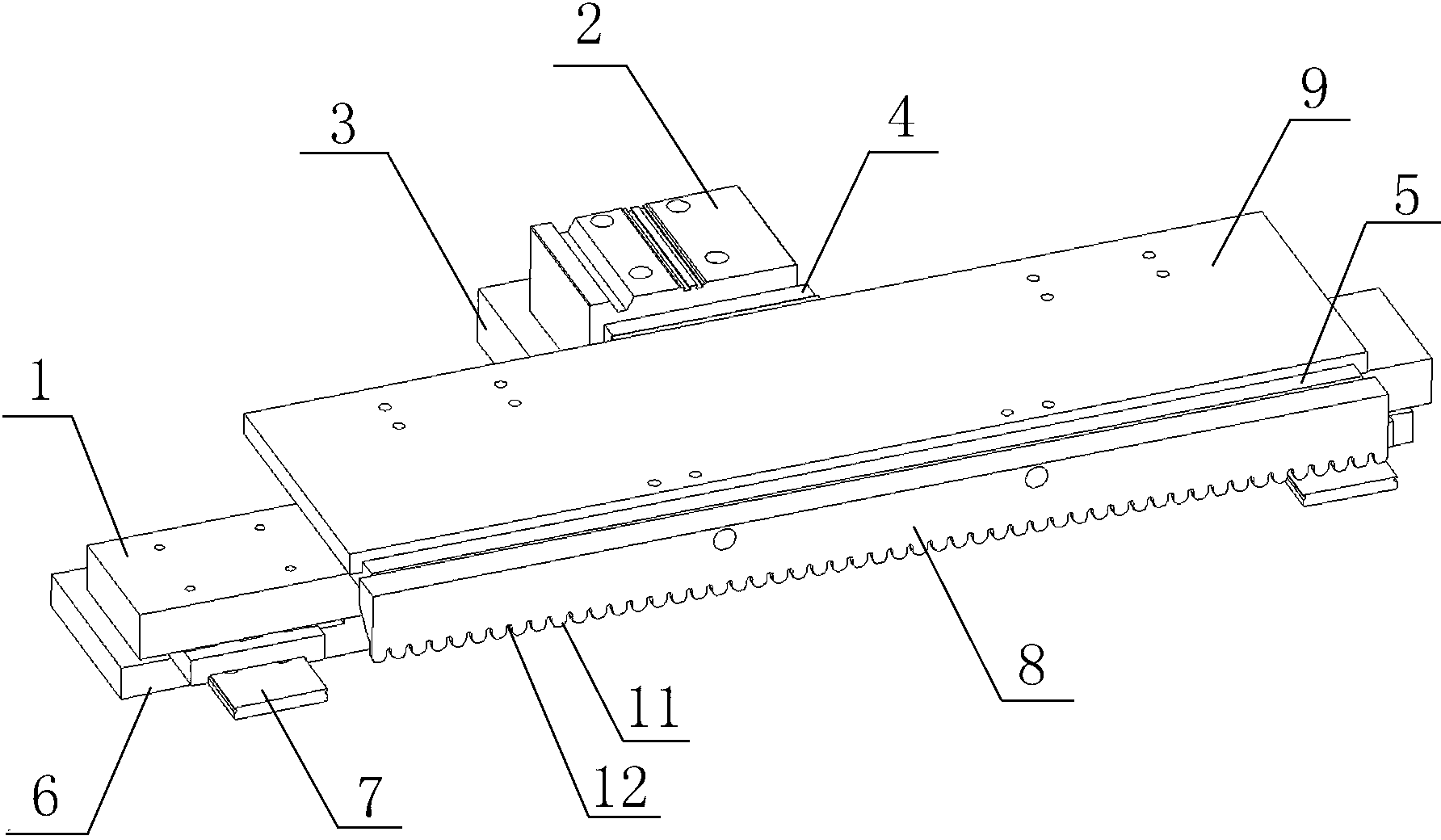

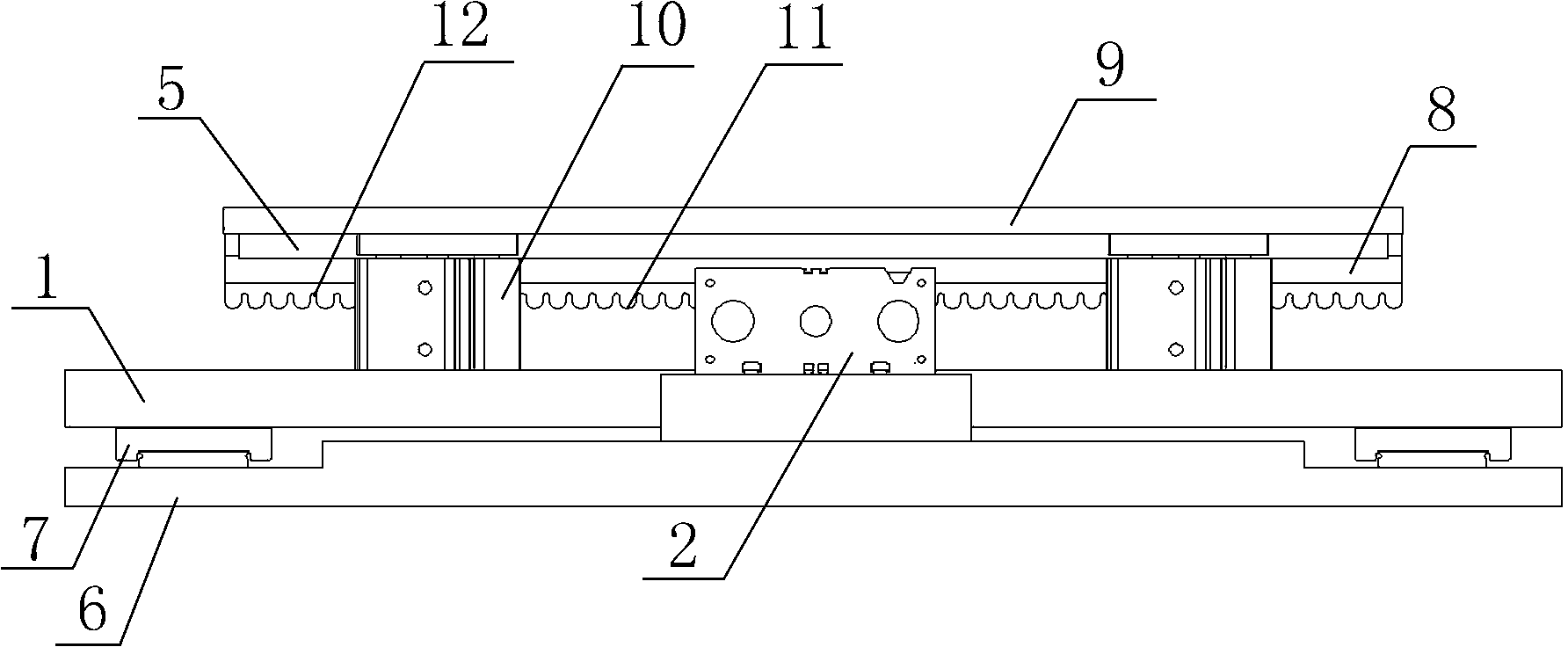

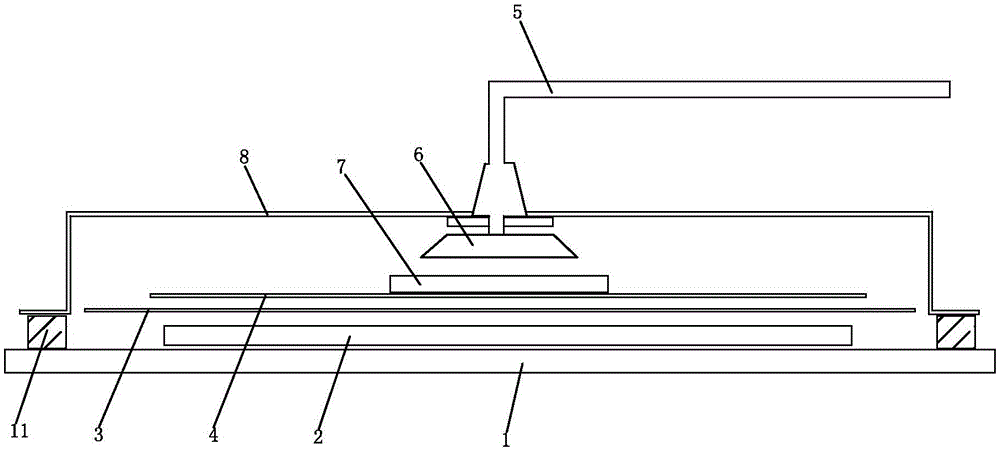

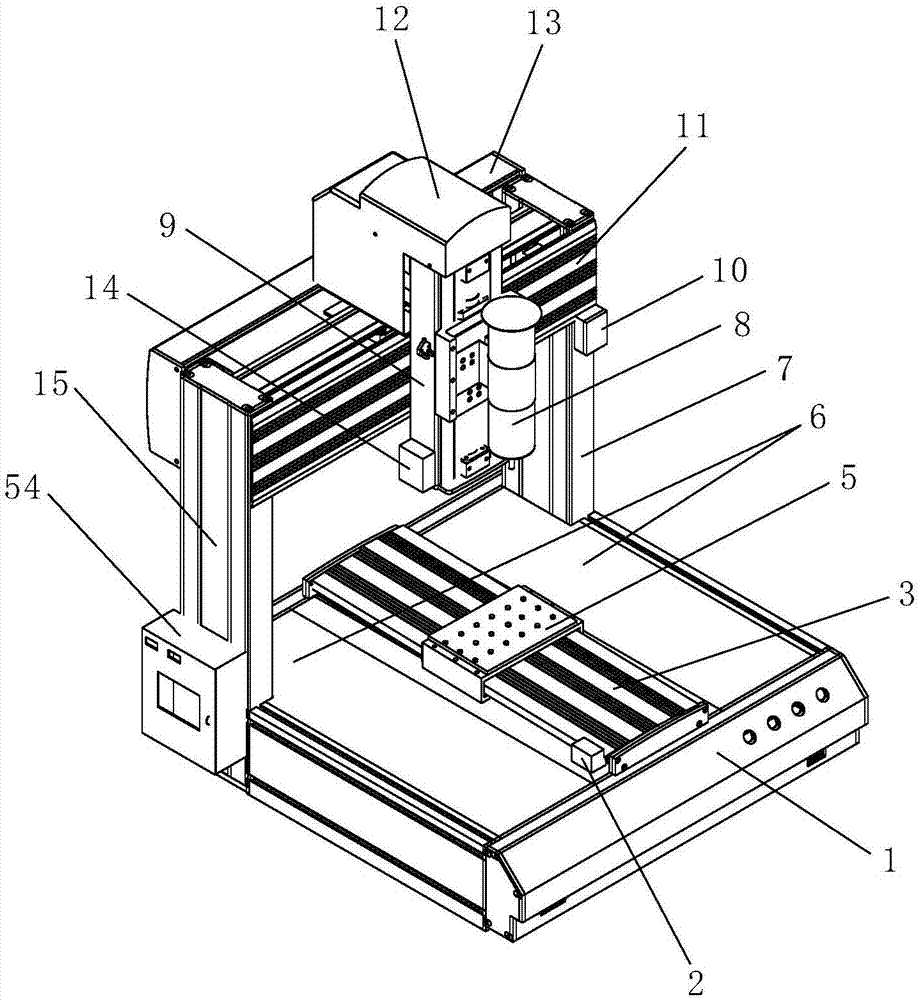

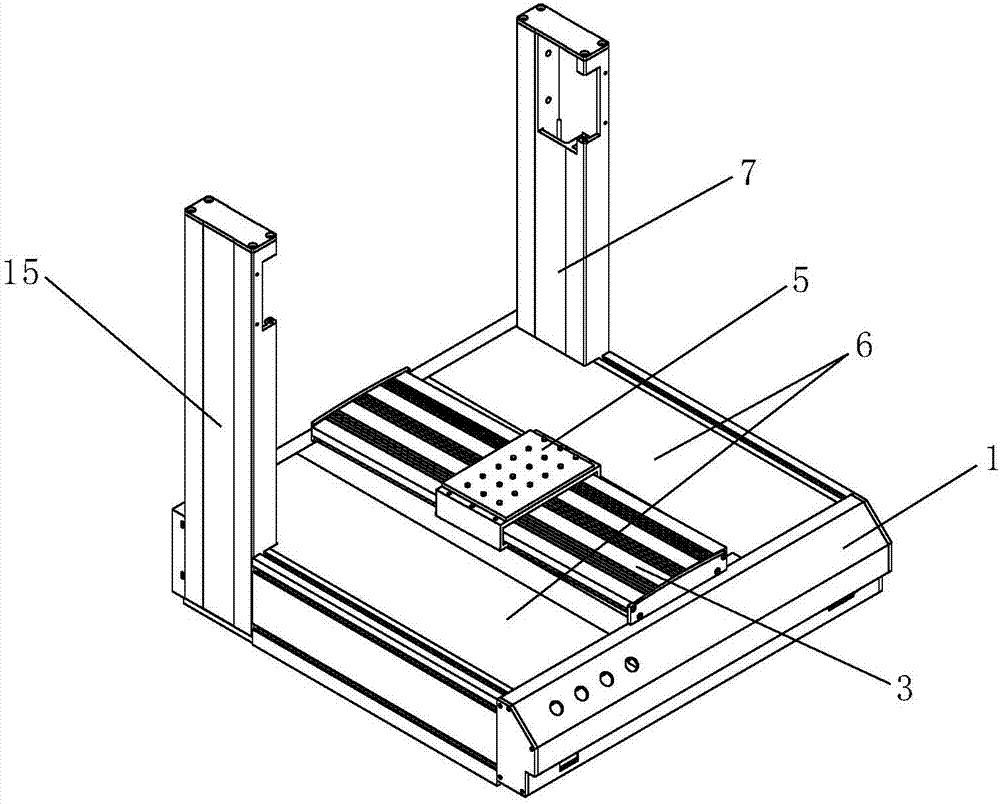

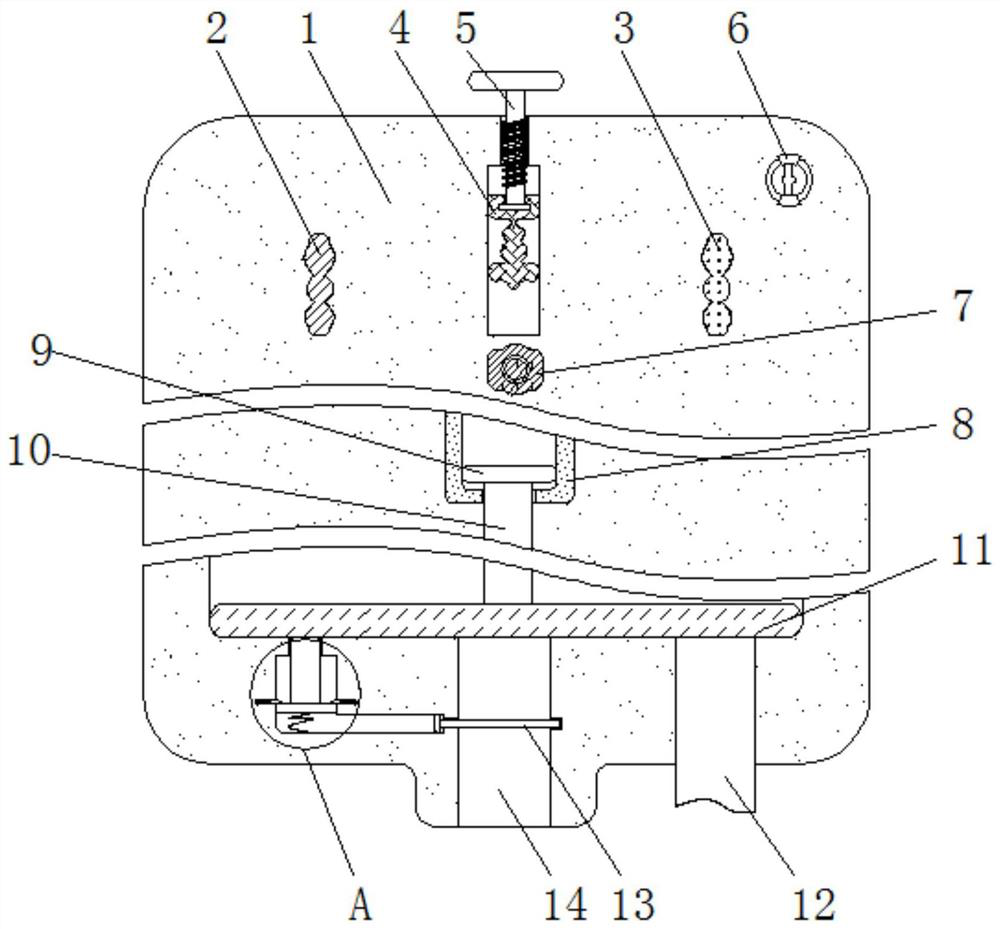

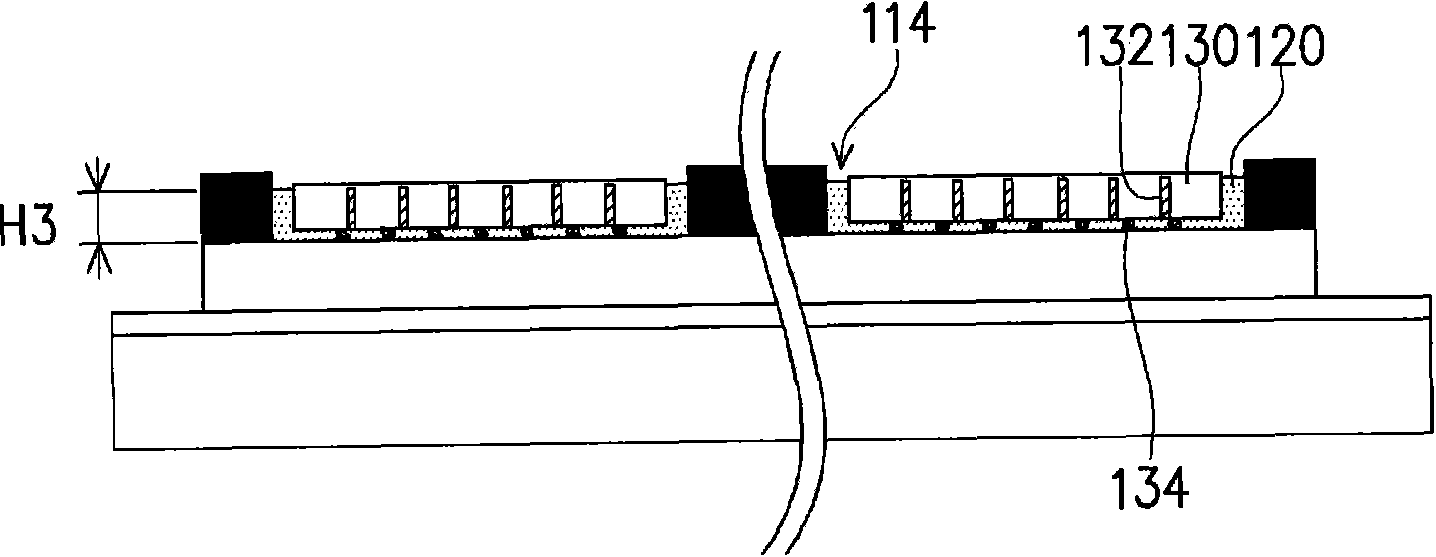

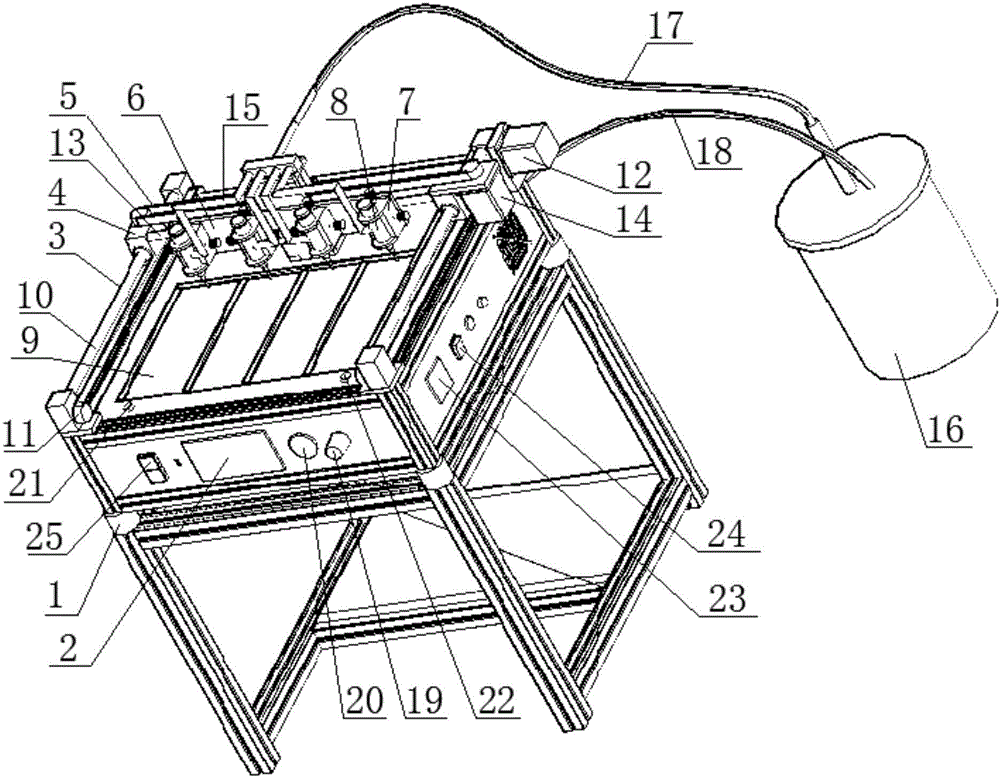

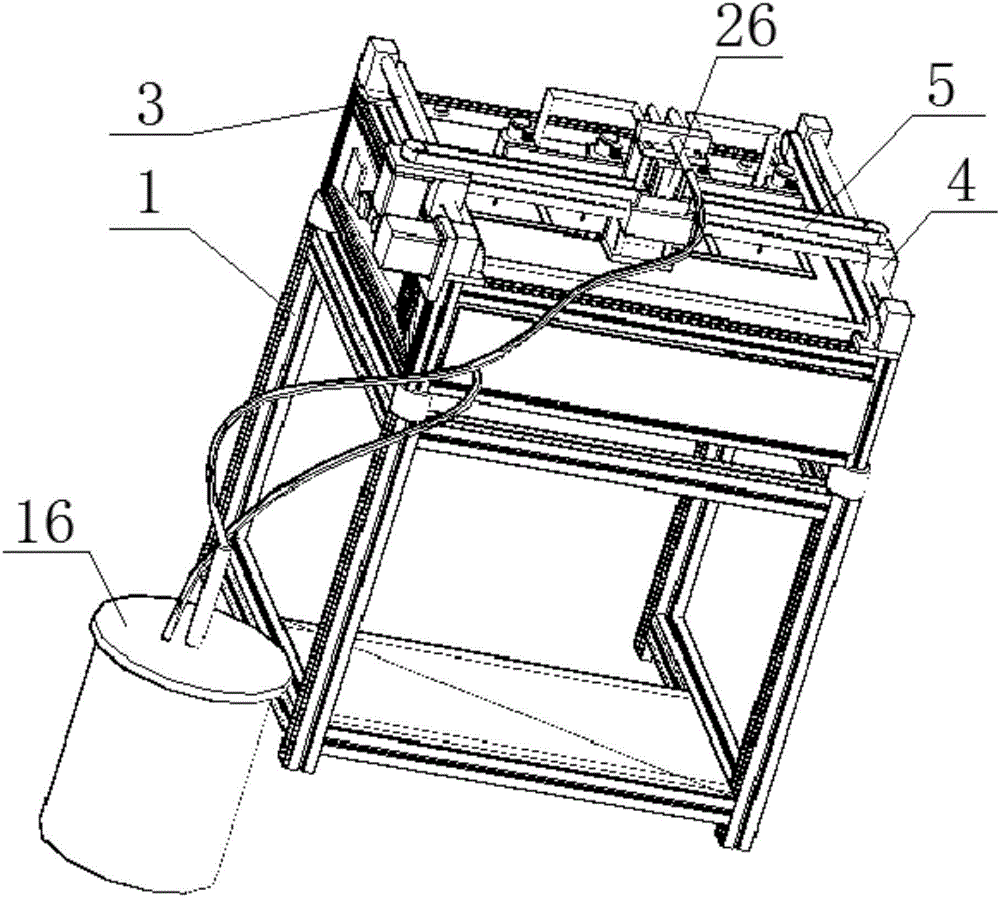

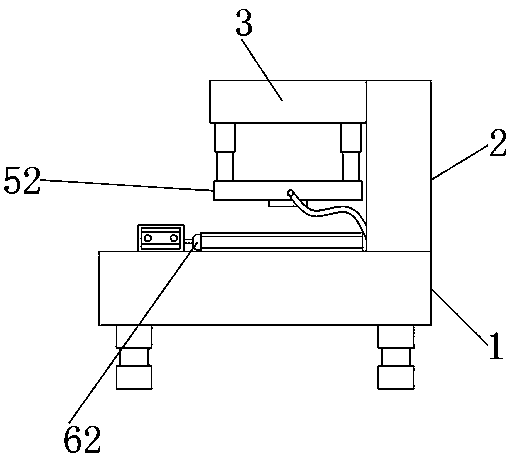

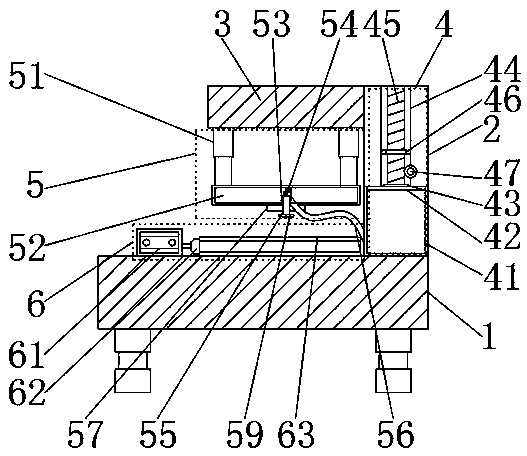

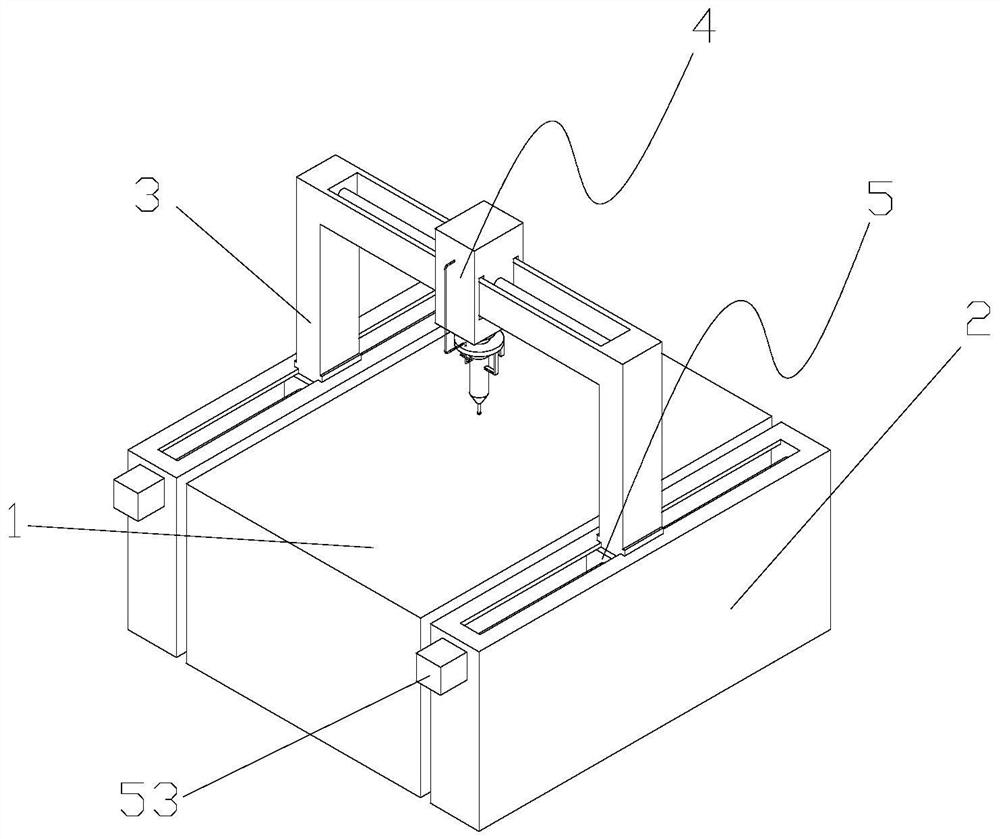

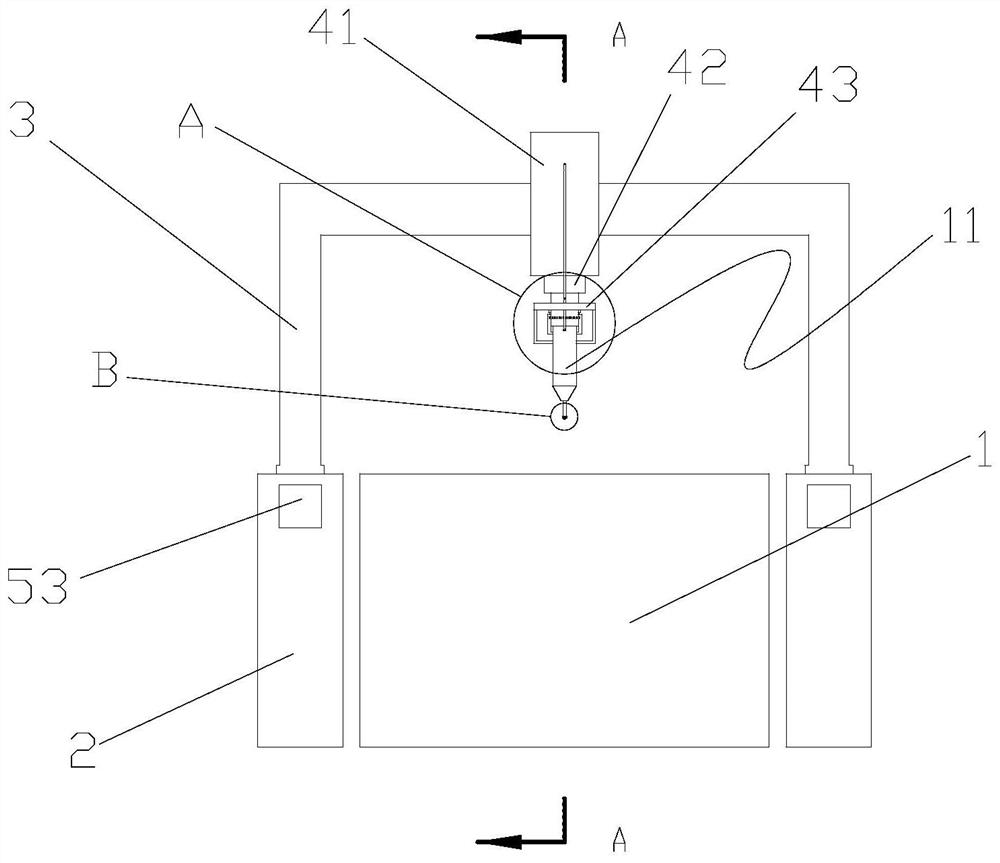

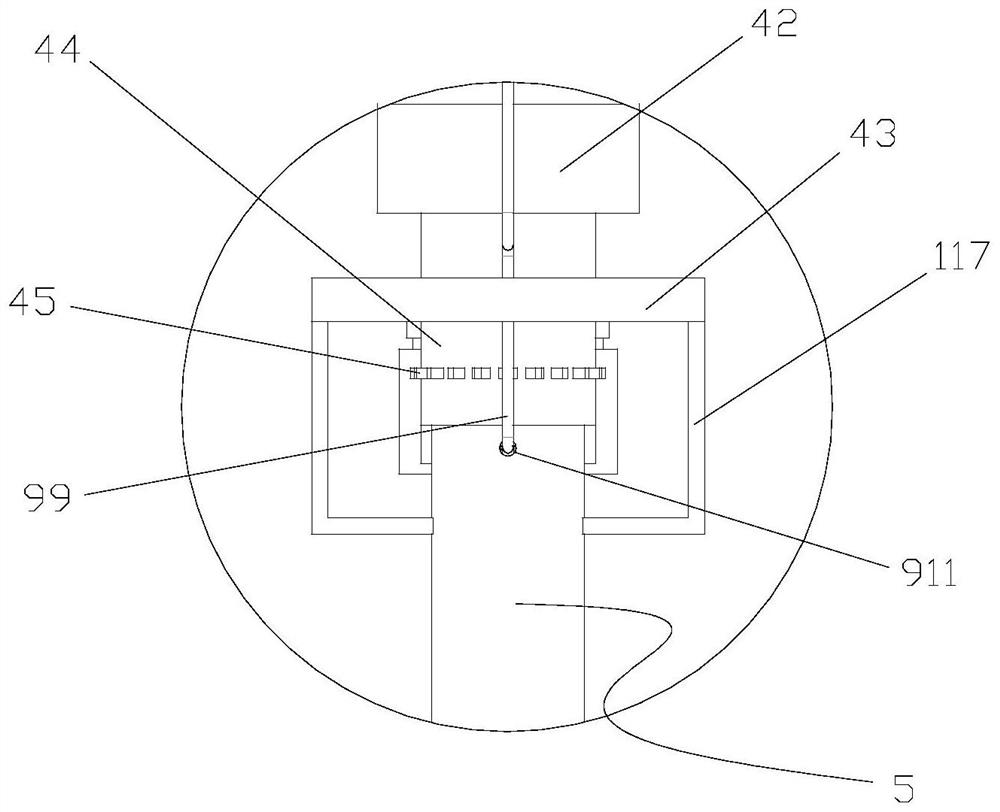

Dispensing machine with accurate positioning performance and consistent dispensing quantity

PendingCN107282370ASimple structureReasonable designLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a dispensing machine with accurate positioning performance and consistent dispensing quantity. The dispensing machine comprises a frame assembly body, an x-axis assembly body, a y-axis assembly body, a z-axis assembly body and a glue outlet assembly body; the frame assembly body comprises a square frame, a left bracket and a right bracket, and the left bracket and the right bracket are mounted on the two sides of the back of the square frame; horizontal operation platforms are mounted on the left and right sides of the square frame, the x-axis assembly body is mounted between the two horizontal operation platforms, the two ends of the y-axis assembly body are connected with the upper end of the left bracket and the upper end of the right bracket respectively, the z-axis assembly body is mounted on the y-axis assembly body, and the glue outlet assembly body is mounted on the front side of the z-axis assembly body; a workpiece platform is mounted on the upper side of the x-axis assembly body, an x-axis displacement sensor is mounted on the left side of the front end of the x-axis assembly body, a y-axis displacement sensor is mounted on the lower side of the right end of the y-axis assembly body, and a z-axis displacement sensor is mounted on the left side of the lower end of the z-axis assembly body. The dispensing machine has the advantages that positioning can be accurate, the dispensing quantity is consistent, the scrap rate of parts is reduced, and the glue is saved.

Owner:XIAN UNIV OF SCI & TECH

Paperboard pretreatment device for corrugated paper forming

InactiveCN112123879AAvoid cloggingExtended service lifeMechanical working/deformationDielectric plateCarton

The invention relates to the technical field of corrugated cartons, and discloses a paperboard pretreatment device for corrugated paper forming. The paperboard pretreatment device comprises a glue boxcasing; a positive plate is fixedly connected to the inner wall of the glue box casing; a screw rod is in threaded connection in the position, close to the right side of the positive plate, of the inner wall of the glue box casing; a dielectric plate is movably connected to the bottom of the screw rod; and a negative plate is fixedly connected in the position, close to the right side of the dielectric plate, of the inner wall of the glue box casing. According to the paperboard pretreatment device for corrugated paper forming, the glue outlet amount of a glue box is controlled through the electromagnetic principle, glue in the glue box can be sprayed out completely and conveniently during glue spraying, residues on the inner wall of the glue box are avoided, resource waste is prevented, the glue box is prevented from being blocked during intermittent use, and the service life of the glue box is prolonged; and the glue outlet amount is convenient to control, the phenomenon of uneven glue outlet is avoided, uneven glue amount routing on a corrugated paperboard is prevented, and the percent of pass of products is increased.

Owner:李悌坚

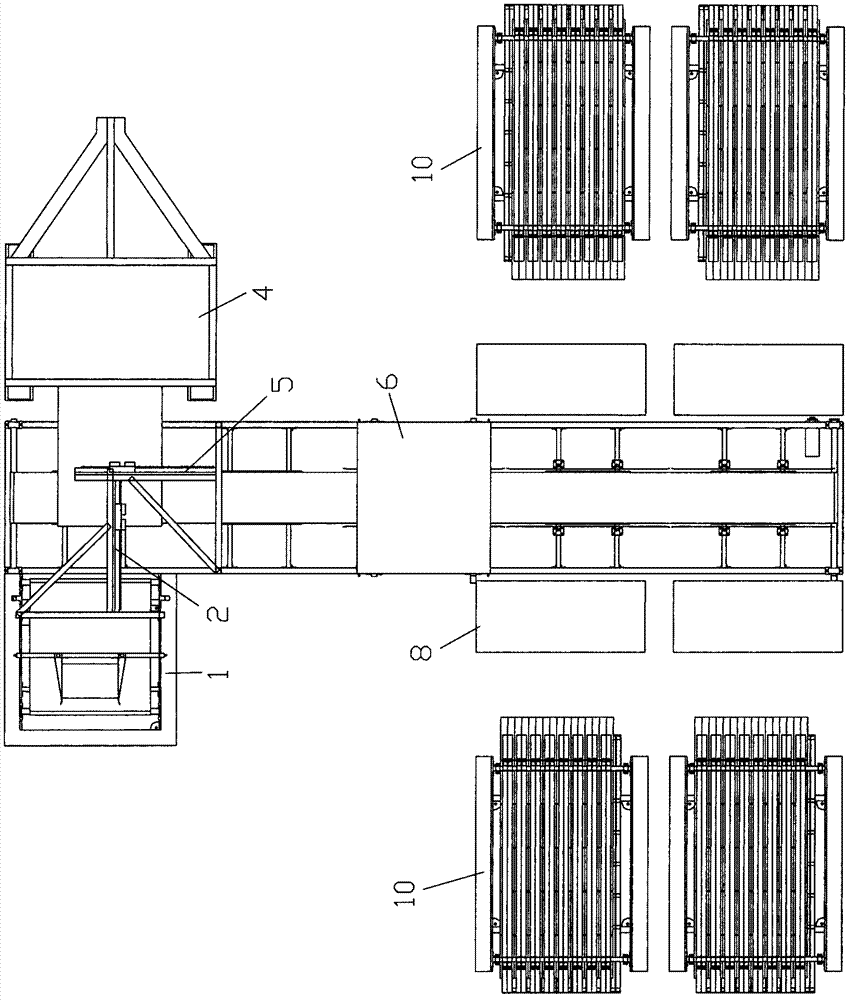

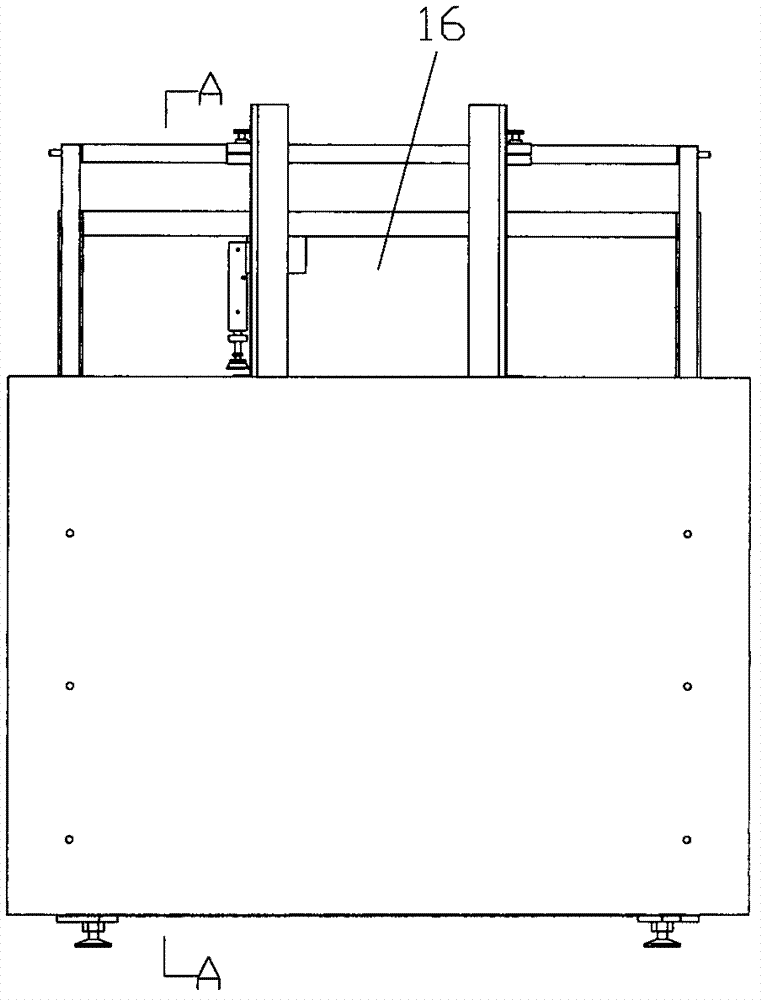

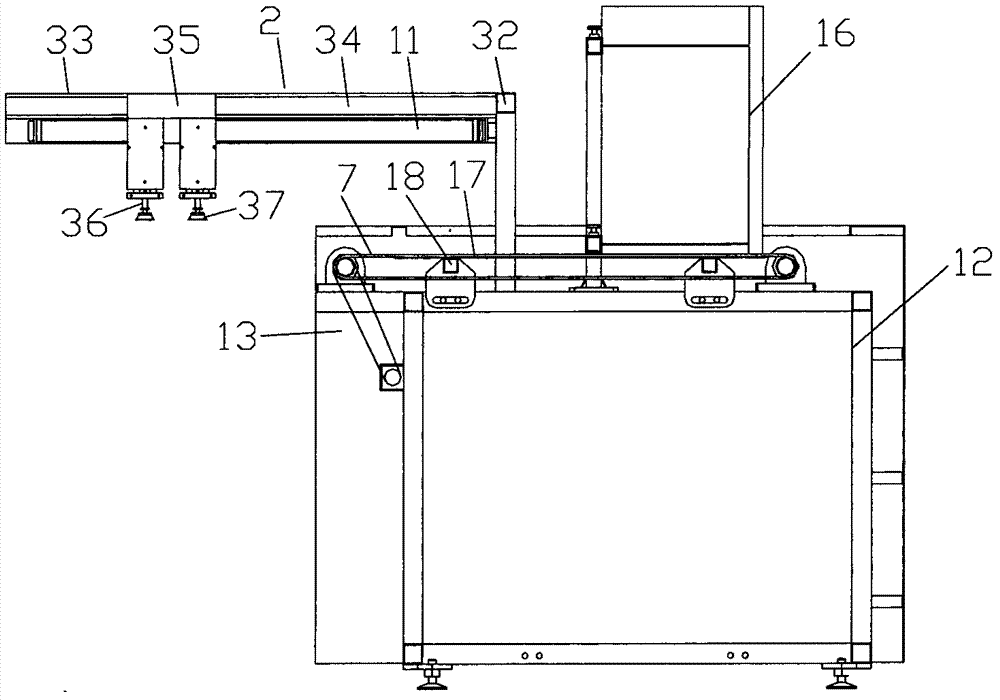

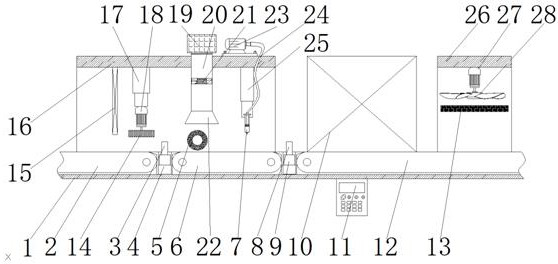

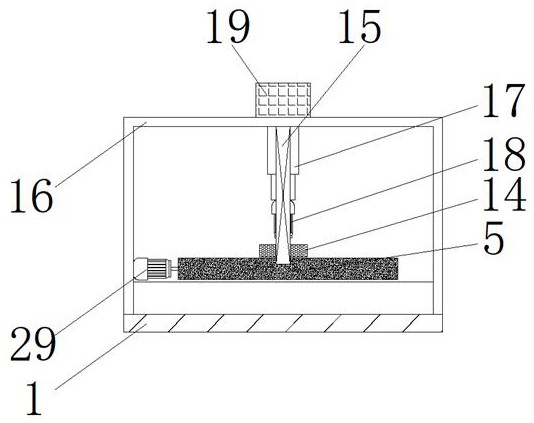

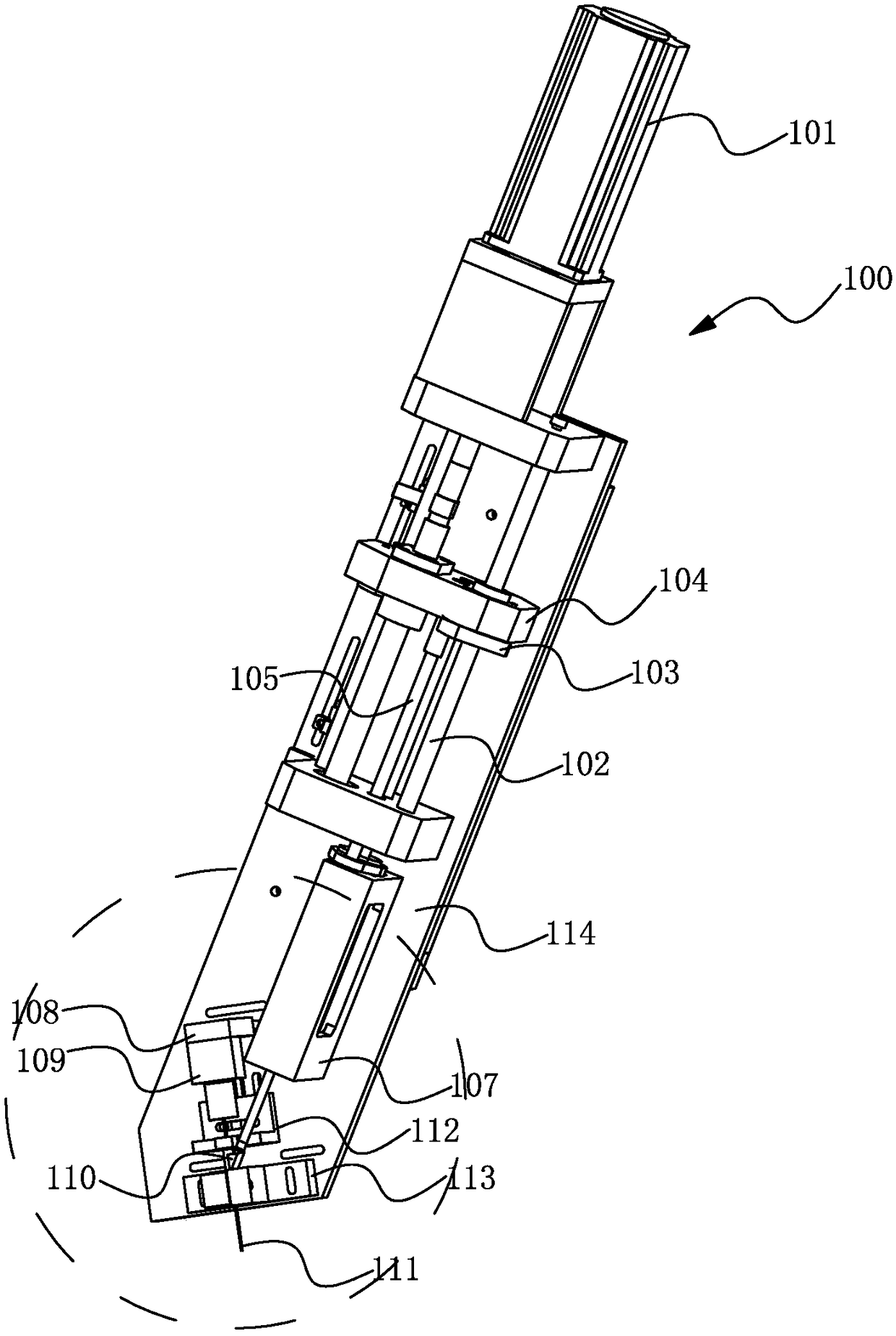

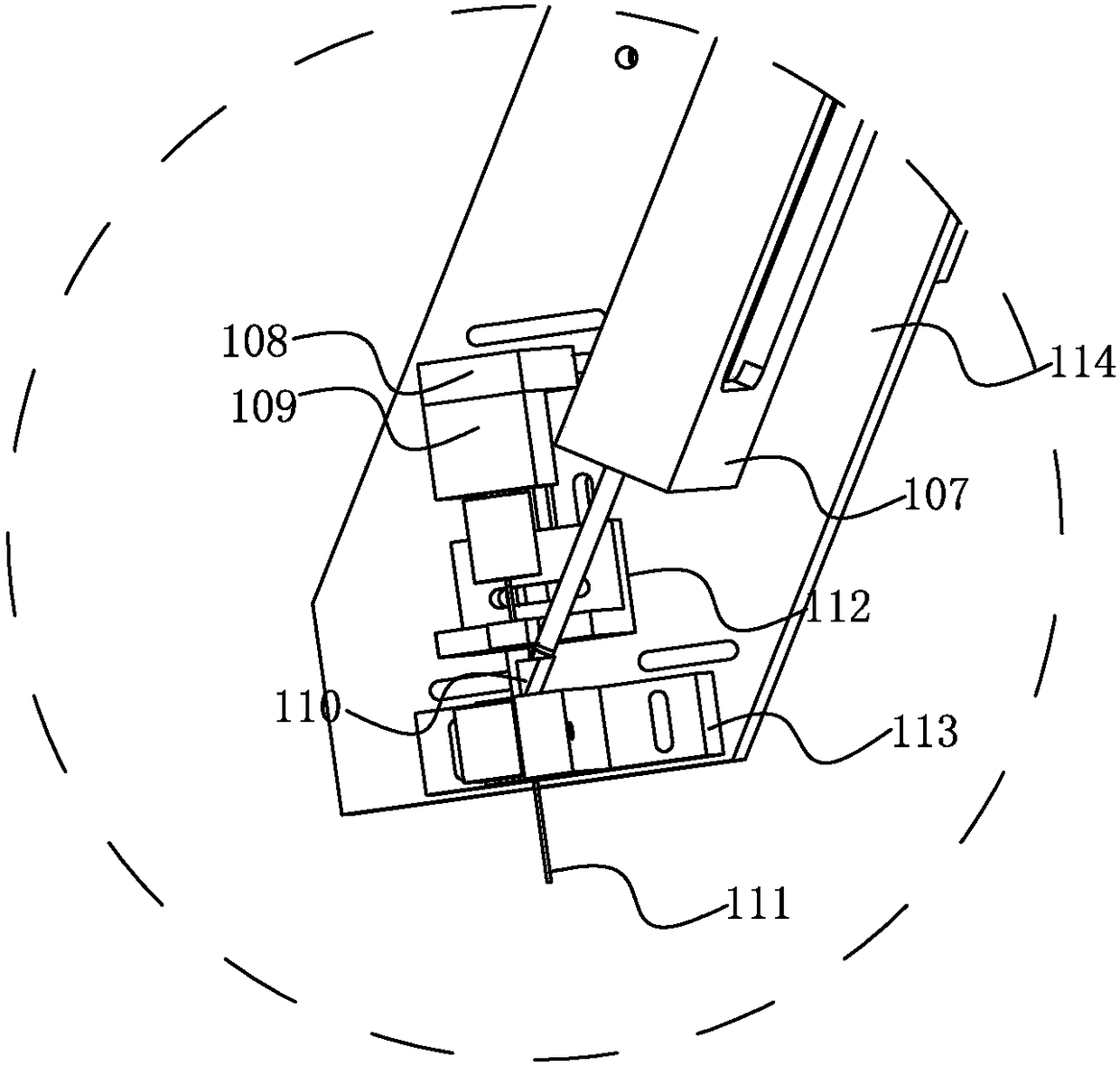

Manufacturing method and production device for production line of corrugated fiberboard cushioning pad

InactiveCN103085341AImprove automated productionPrecise feedingMechanical working/deformationManipulatorCorrugated fiberboard

The invention relates to a manufacturing method and a production device for a production line of corrugated fiberboard cushioning pads. The manufacturing method is achieved in manners of loading, blanking, adhesive injecting, manual folding and piling up and the production device comprises a loading machine, a blanking machine, an adhesive injecting machine and piling-up machines, wherein the loading machine is arranged opposite to the blanking machine. The adhesive injecting machine is strip-shaped and vertically arranged on one side of the loading machine and the blanking machine. The piling-up machines are positioned on both sides behind the adhesive injecting machine side by side. According to the manufacturing method and production machine, effective and rapid automatic loading, blanking and adhesive injecting can be achieved, the processed parts can be transferred in a rapid and accurate way by means of a feeding manipulator arm and a conveying manipulator arm and the automatic production can be improved to the largest extent, so that the loading is accurate, the blanking is rapid, the glue quantity can be controlled accurately and the adhesive injecting position can be convenient to adjust. After folding, the compacting and shaping of corrugated fiberboards can be easy to achieve and the conveying of processed work pieces can be achieved with simultaneous drying adhesive and shaping. The manufacturing method is simple and rapid. The production device has the advantages of being tidy in layout, small in occupied area, simple in structure, high in reliability, low in production cost and capable of being used widely.

Owner:NINGBO GREENS PACKAGE TECH

Novel production method of mica tape with a few glues by reducing organic solvent dosage

ActiveCN102412037AReduce manufacturing costReduce dosageMicaInsulating bodiesCooking & bakingOrganic solvent

The invention relates to a novel production method of a mica tape with a few glues by reducing an organic solvent dosage. The method comprises the following steps that: (1), a reinforcing material is dipped; (2), composition is carried out; (3), baking is carried out; (4), cooling is carried out to manufacture a blank; and (5), slitting and rolling are carried out. According to the method provided in the invention, a gluing method and a glue scraping method are improved as well as a gluing amount is controlled; a baking temperature is controlled in a segment mode and the production speed is enhanced by 1.3 to 1.5 times. When gluing is carried out, a solid content of an adhesive solution reaches 50% to 60% wt. About 120 Kg of organic solvents can be saved to produce one ton of mica tapes with a few glues as well as production costs of the mica tapes are reduced; and pollution of the organic solvents on the environment can be substantially reduced. Moreover, the production speed is improved and the baking temperature is reduced as well as a third of power consumption can be reduced.

Owner:JIANGSU BINGCHENG HYDROGEN ENERGY TECH CO LTD

Shoemaking method through aerial fog glue spraying

InactiveCN106490768AIncrease productivityImprove product qualityMineral oil hydrocarbon copolymer adhesivesEpoxy resin adhesivesAdhesiveEngineering

The invention discloses a shoemaking method through aerial fog glue spraying and belongs to the technical field of shoemaking. The method comprises the steps of assembly unit placing, dedusting, adhesive spraying and bonding, wherein the step of assembly unit placing comprises the procedures of flatly laying one piece or above shoe sole or upper of a shoe on a glue spraying plate according to a suit cut method, and a 2-4 mm gap is left between the assembly units; the step of dedusting comprises the procedures of conducting overall dedusting on glue spraying assembly units through a sparger, and the speed of the overall dedusting is 6-9 s / m<2>; the glue spraying step comprises the procedures of adopting aerial fog glue spraying to conduct spraying and smearing on the glue spraying assembly units, and the interval between a glue spraying device and the glue spraying assembly units is 25-40 cm and the speed of spraying is 3-5 s / m<2>; the step of bonding comprises the procedures of bonding each of the glue-sprayed glue spraying assembly unit together in sequence and conducting drying. According to the shoemaking method through the aerial fog glue spraying, a traditional brush coating is replaced by the aerial fog glue spraying so that the amount of glue using of shoes is effectively controlled, and the brushing and smearing of the glue can be uniform, not only can production efficiency and product quality of the shoes be improved, but also comfort indexes of the shoes can be increased.

Owner:天津百世丹达科技有限公司

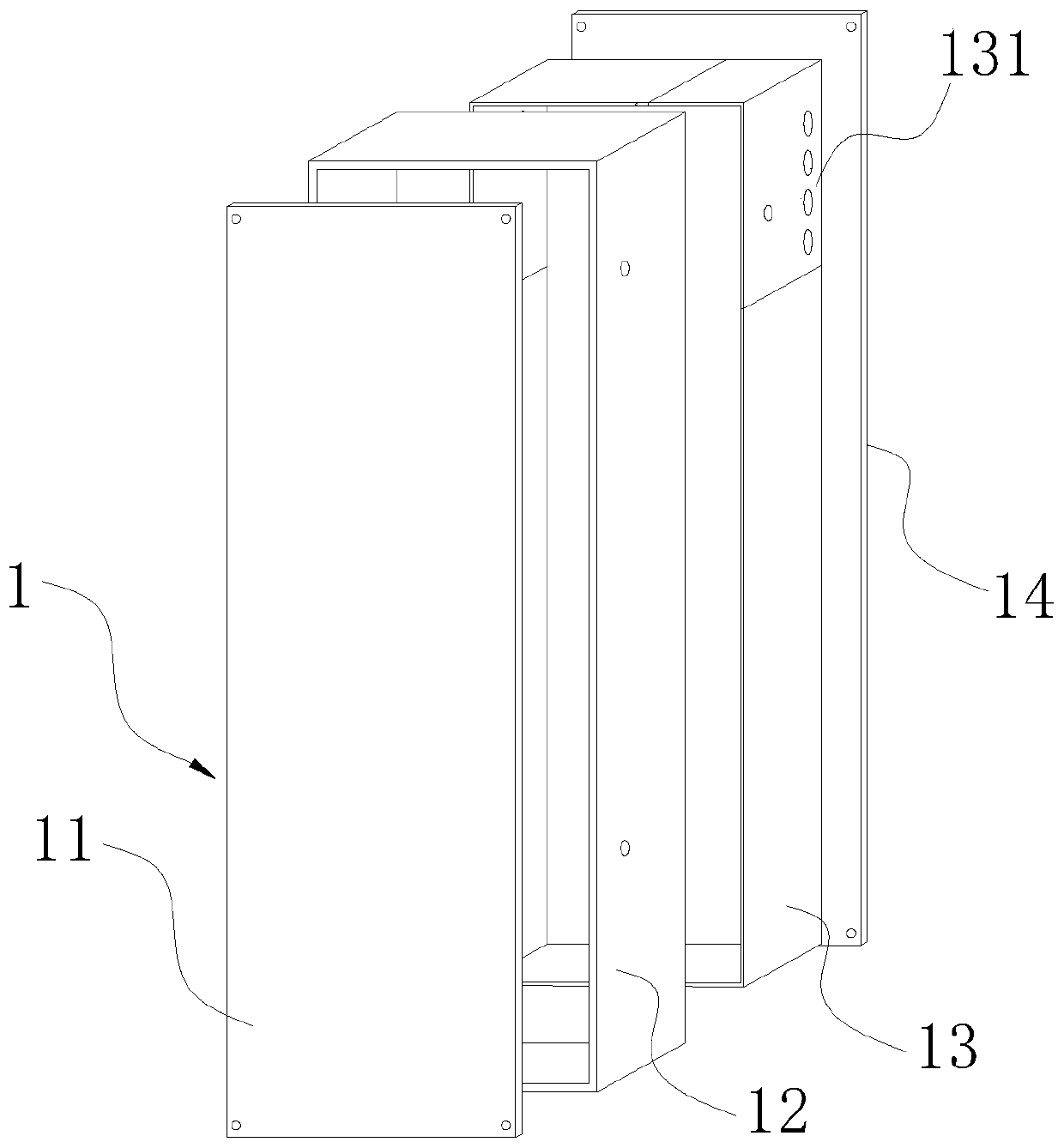

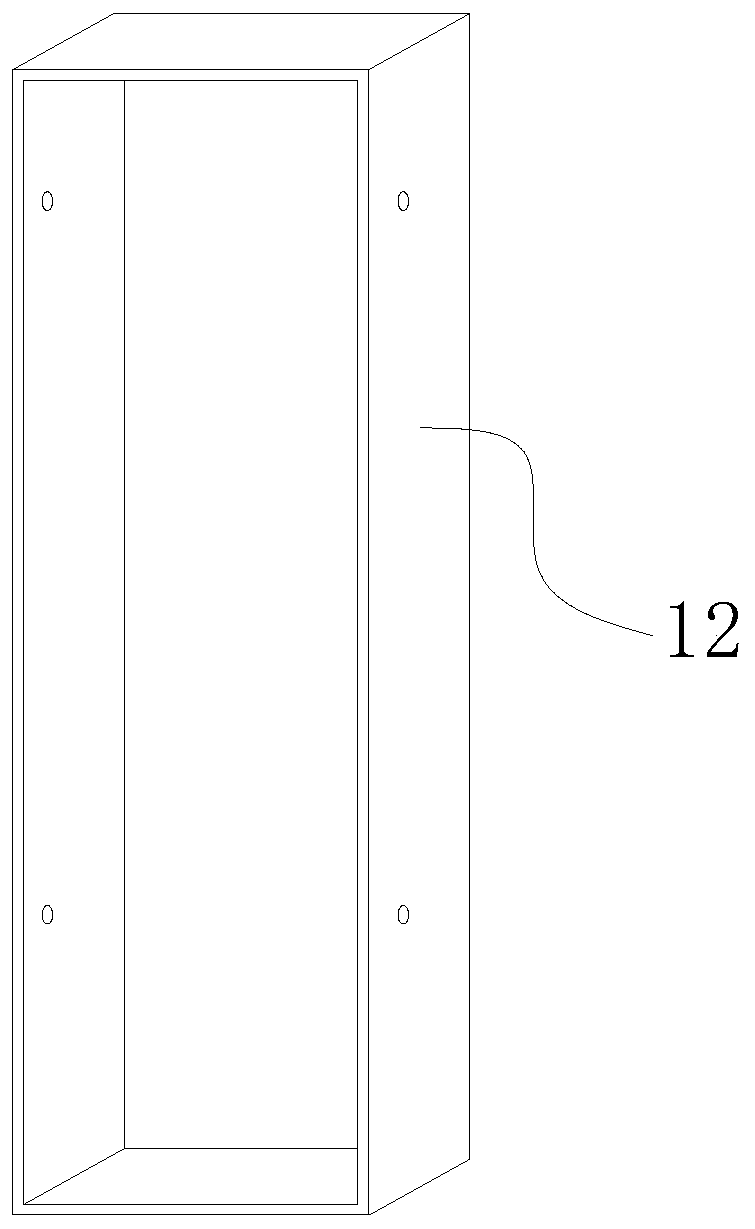

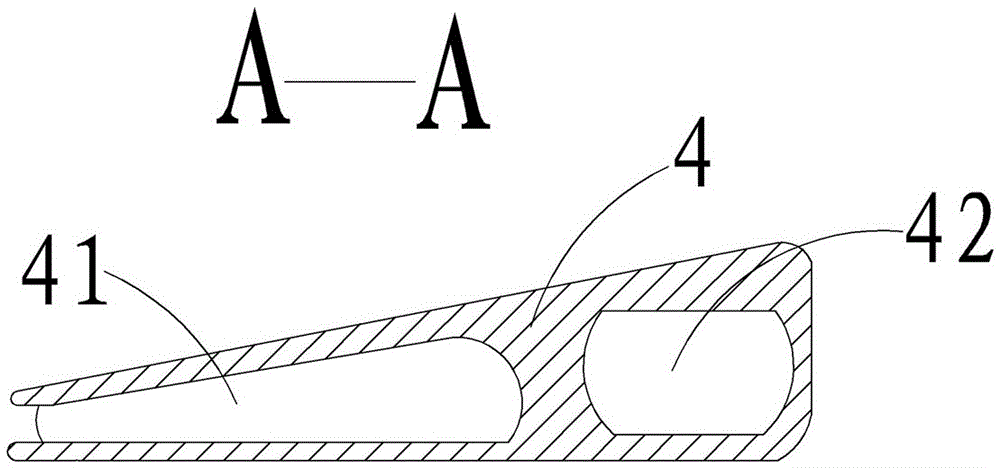

Original-state whole-section soil specimen collecting and manufacturing device and method

ActiveCN111380717AEasy to collectEasy to manufactureWithdrawing sample devicesPreparing sample for investigationSoil scienceAgricultural engineering

The invention belongs to the technical field of soil specimen collection and manufacturing, and particularly relates to original-state whole-section soil specimen collection and manufacturing equipment and method. The equipment comprises a soil specimen box body, a profile knife and a rubber brush device. The soil specimen box body comprises an outer box and a soil containing frame used for containing and shaping soil specimens, the soil containing frame is arranged in the outer box in a sleeved mode, and the soil containing frame is detachably connected with the outer box. By combining a plurality of pieces of soil sample collecting and manufacturing equipment, soil is more convenient to collect and manufacture, the integrity of the soil can be guaranteed, and later soil display and maintenance are better facilitated.

Owner:INST OF SOIL & FERTILIZER ANHUI ACAD OF AGRI SCI

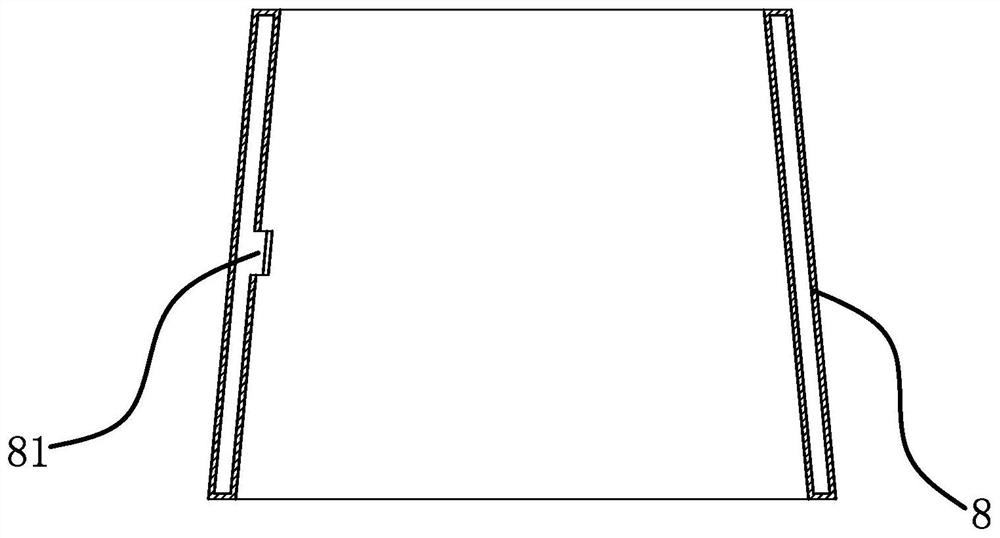

Lampshade gluing device of solar isolation column

ActiveCN111804502APrevent circumferential rotationAvoid problemsLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides a lampshade gluing device of a solar isolation column, which belongs to the technical field of energy-saving and environmental protection equipment. The invention solves the problem of poor gluing quality of the lampshade of the solar isolation column in the prior art. The lampshade gluing device of the solar isolation column includes a bottom plate and a frame body; a turntable is connected to the bottom plate; a number of glue distributing tubes are fixed on the turntable; an upper rotating sleeve and a lower rotating sleeve are rotatablely arranged on the glue distributing tubes; a lower gluing roller is connected to the lower rotating sleeve; the upper rotating sleeve is connected with an upper gluing roller through a swing rod; a pressing part is arranged on theframe body; a glue supply structure is also arranged in the glue distributing tube; and the frame body is provided with a transmission part which can drive the upper rotating sleeve and the lower rotating sleeve to rotate in reverse synchronously when the upper gluing roller abuts against the inner peripheral wall of the lampshade. The lampshade gluing device of the solar isolation column can improve the gluing efficiency and improve the gluing quality.

Owner:瞿少卯

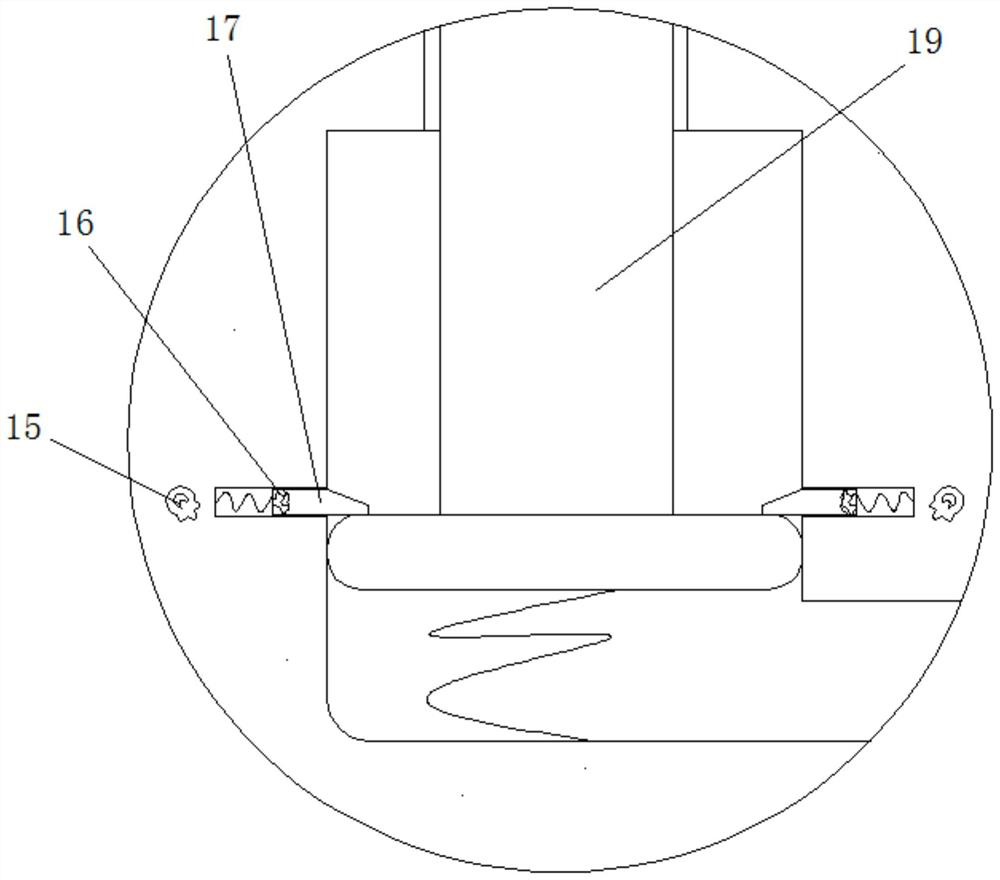

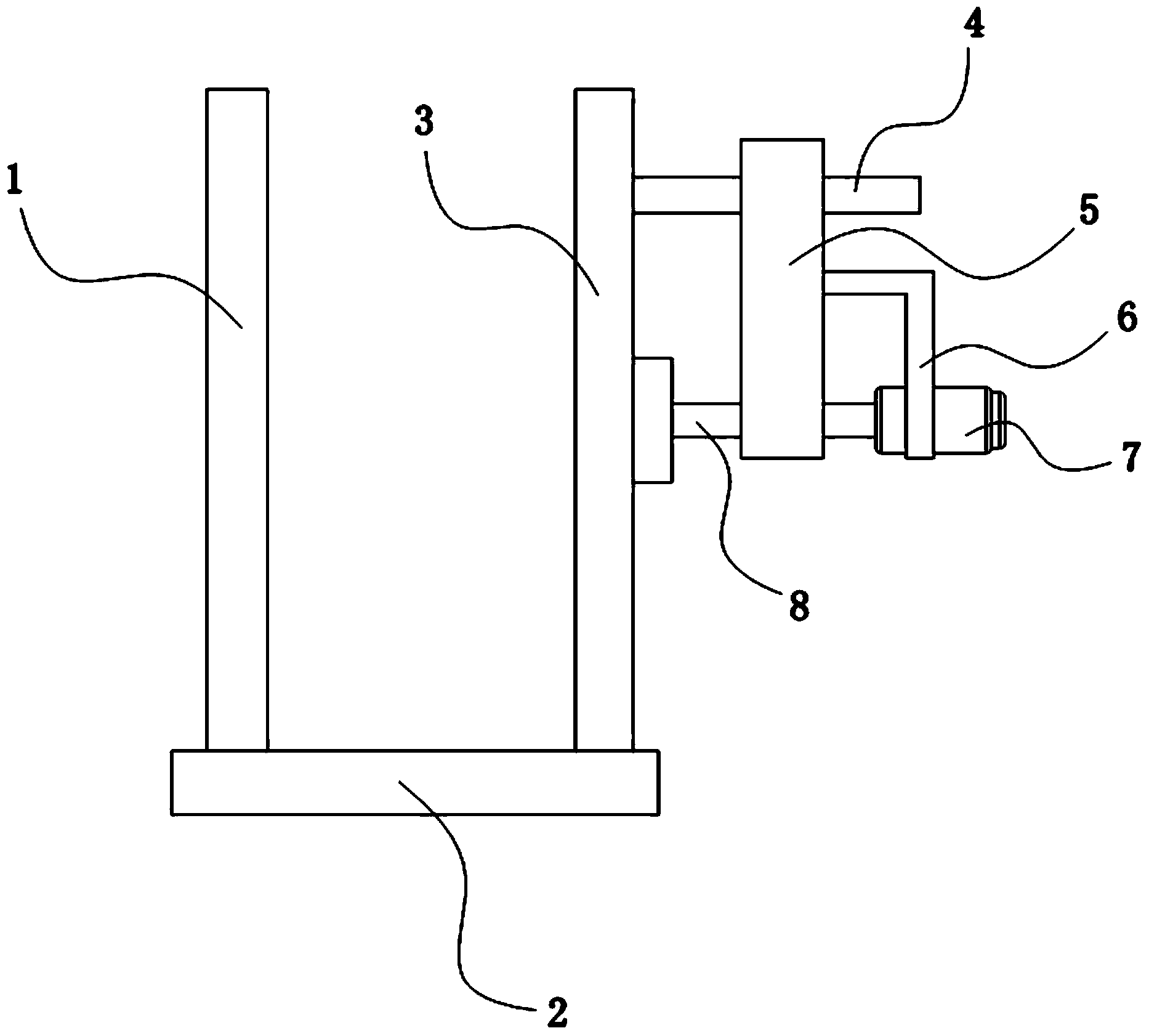

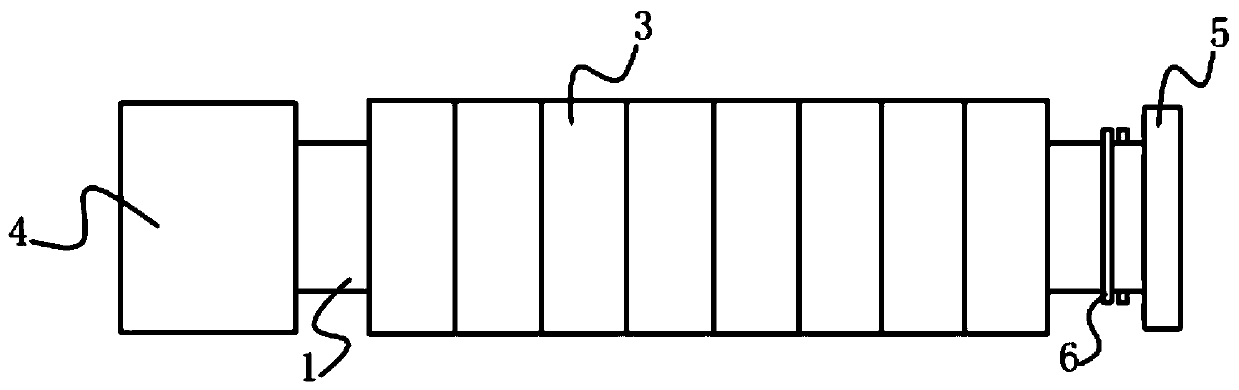

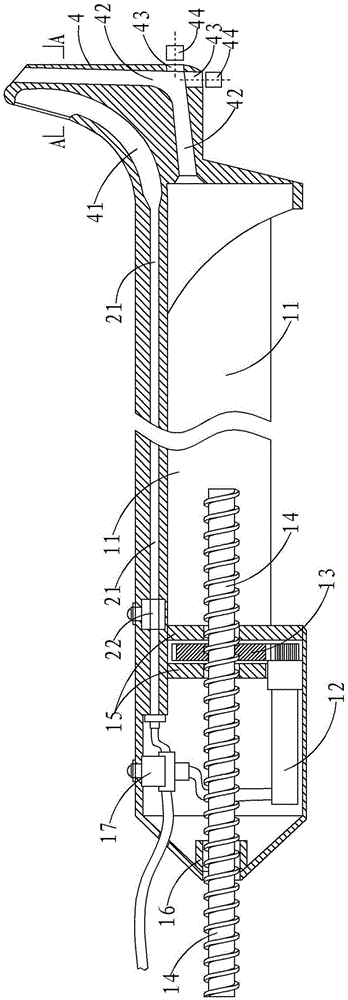

Quantitative motor squeezing device for ultrasonic coupling agent

InactiveCN103462636AAvoid wastingEasy to detectUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsCouplingEngineering

The invention relates to a quantitative motor squeezing device for an ultrasonic coupling agent. The device is characterized by comprising a bracket with a U-shaped structure, wherein the bracket consists of a bottom plate and side plates; a through hole is formed in the middle part of the bottom plate; the side plates comprise a fixed side plate fixedly connected to the bottom plate and a movable side plate connected to the bottom plate in a sliding way; a screw rod is fixedly connected to the outer lateral surface of the movable side plate; a fixed plate is in threaded connection with the screw rod; a guide rod is connected to the upper end of the fixed plate in the sliding way; the movable side plate is fixedly connected to the end part of the guide rod; an L-shaped bracket is fixedly connected to the middle part of the fixed plate; a motor is fixedly connected to the bracket; a motor shaft is fixedly connected with the screw rod. The device is simple in structure; the motor is used for driving a screw rod squeezing structure to accurately control the glue discharging amount of the coupling agent, so that the detection effect of a probe is improved, and the waste of the coupling agent is avoided.

Owner:SUZHOU BIANFENG ELECTRONICS TECH

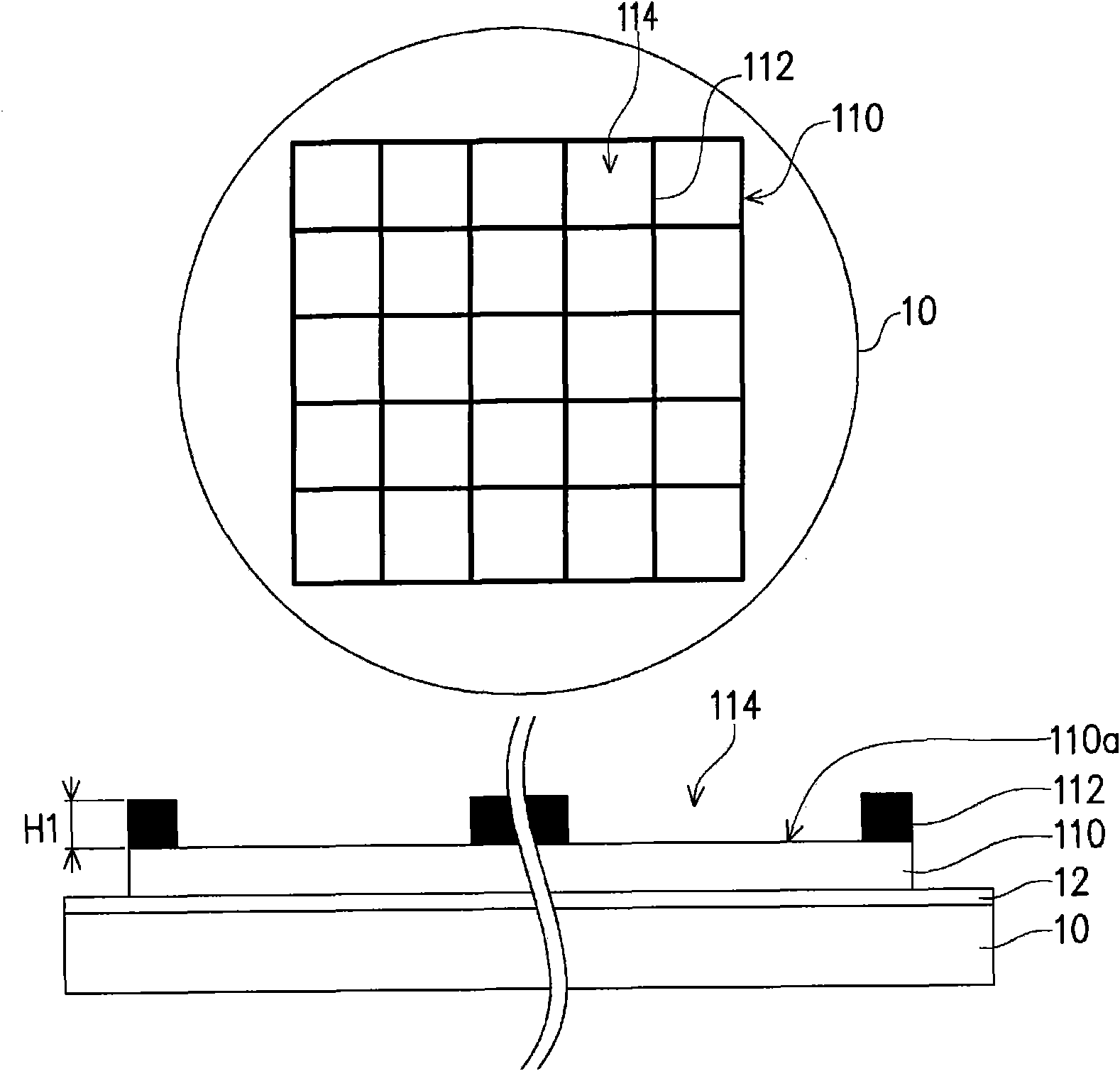

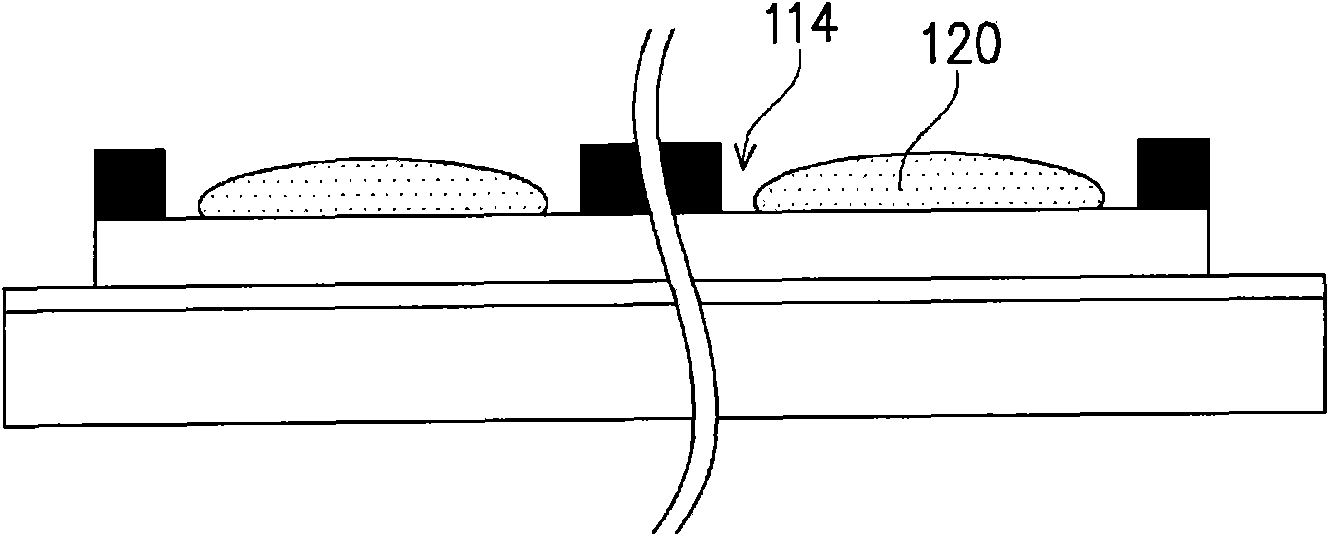

Semiconductor packaging structure and manufacture process thereof

ActiveCN101976652AAvoid pollutionControl the amount of glueSemiconductor/solid-state device detailsSolid-state devicesEngineeringSilicon

The invention discloses a semiconductor packaging structure and a manufacture process thereof. The manufacture process of the semiconductor packaging structure comprises the steps of: configuring a packaging mother board on a support tool, wherein the packaging mother board is provided with a grid wall arranged vertically on the packaging mother board and the grid wall defines a plurality of concave parts on the packaging mother board; respectively jointing a plurality of first chips to the concave parts of the packing mother board, wherein each first chip is provided with silicon penetrating guide holes inside; forming first primer between each first chip and the corresponding packaging mother board; forming a cladding layer on the support tool; thinning the cladding layer and the grid wall from the upside of the support tool until the cladding layer above the grid wall and the first chip is completely removed; jointing a plurality of second chips to the first chips; forming second primer between each second chip and the corresponding first chip; separating the support tool from the packaging mother board, and cutting the packaging mother board to obtain a plurality of packaging units.

Owner:ADVANCED SEMICON ENG INC

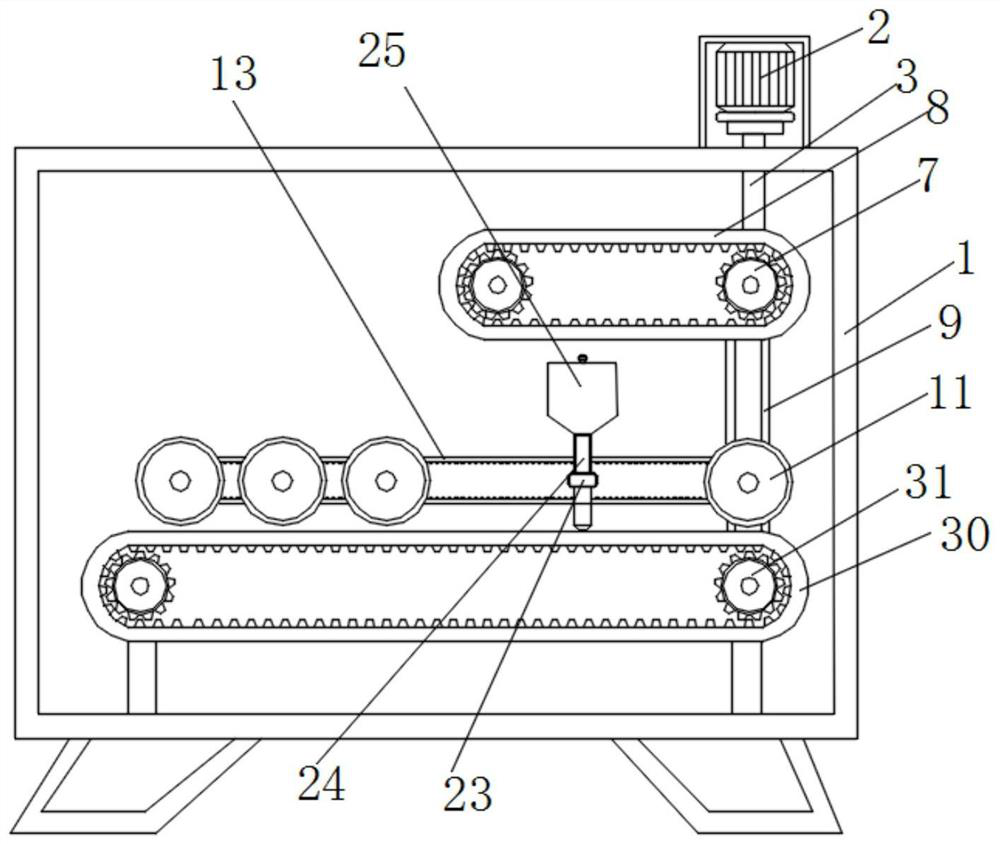

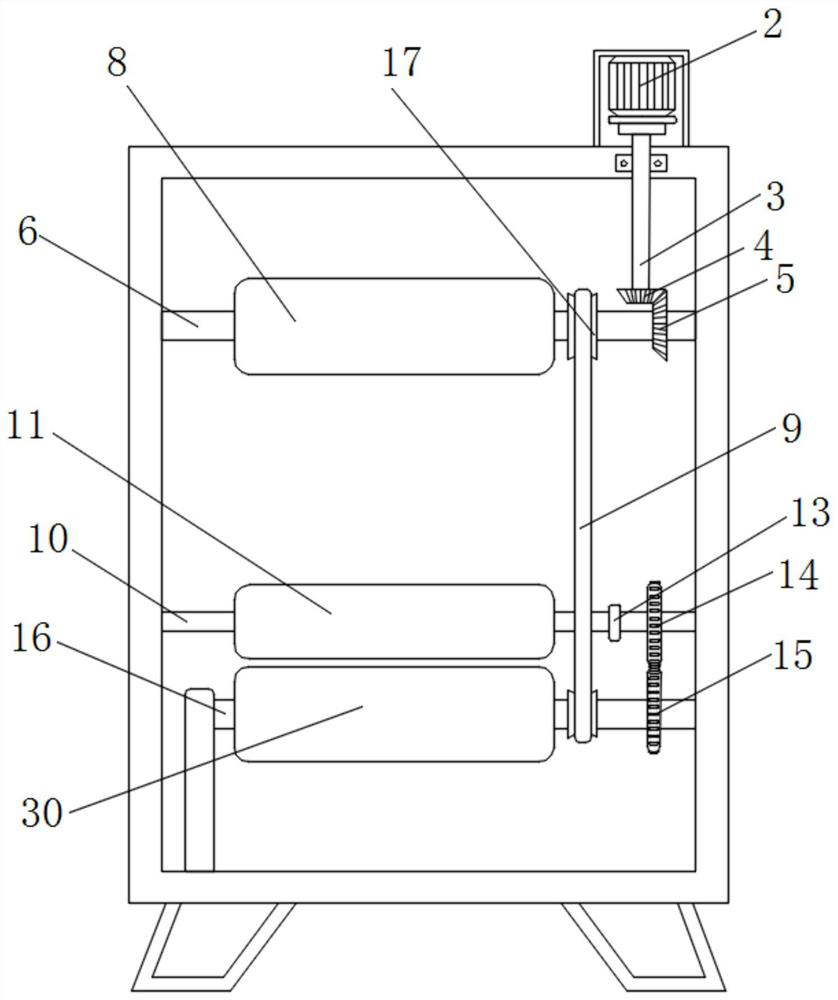

Full-automatic COB glue sealing machine

ActiveCN106179883APrecisely control the glue out timeControl the amount of glueLiquid surface applicatorsCoatingsMotion controllerEngineering

The invention relates to a full-automatic COB glue sealing machine. The full-automatic COB glue sealing machine comprises a machine table, a motion controller, a longitudinal motion mechanism, a movement truss, a transverse motion mechanism, a supporting frame, a vertical rising and falling air cylinder and four dispensing valves. The motion controller is fixedly embedded on the machine table; the longitudinal motion mechanism and the transverse motion mechanism are both connected with the motion controller through lines; the longitudinal motion mechanism is arranged at the upper end of the machine table longitudinally, the movement truss is transversely arranged at the upper end of the longitudinal motion mechanism, and the longitudinal motion mechanism drives the movement truss to longitudinally move; the transverse motion mechanism is transversely arranged at the upper end of the movement truss and driven by the movement truss to move longitudinally, and the supporting frame is arranged at the upper end of the transverse motion mechanism and transversely moves along with the transverse motion mechanism; the vertical rising and falling air cylinder is arranged between the movement truss and the supporting frame; the supporting frame is provided with a three-shaft adjusting frame which is provided with the dispensing valves; and the machine table is provided with a heating platform. By means of the full-automatic COB glue sealing machine, full-automatic running can be achieved, the running stability is improved, and the product quality is improved.

Owner:深圳市拓普微科技开发有限公司

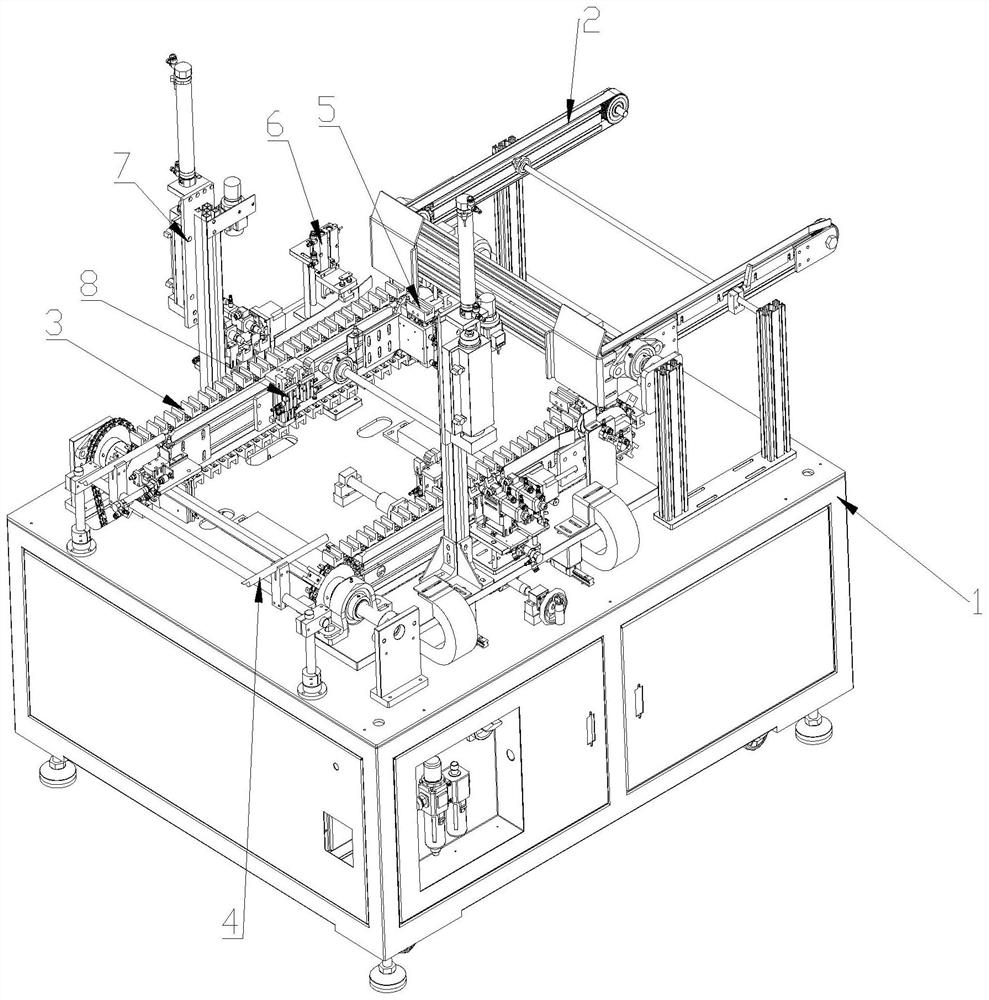

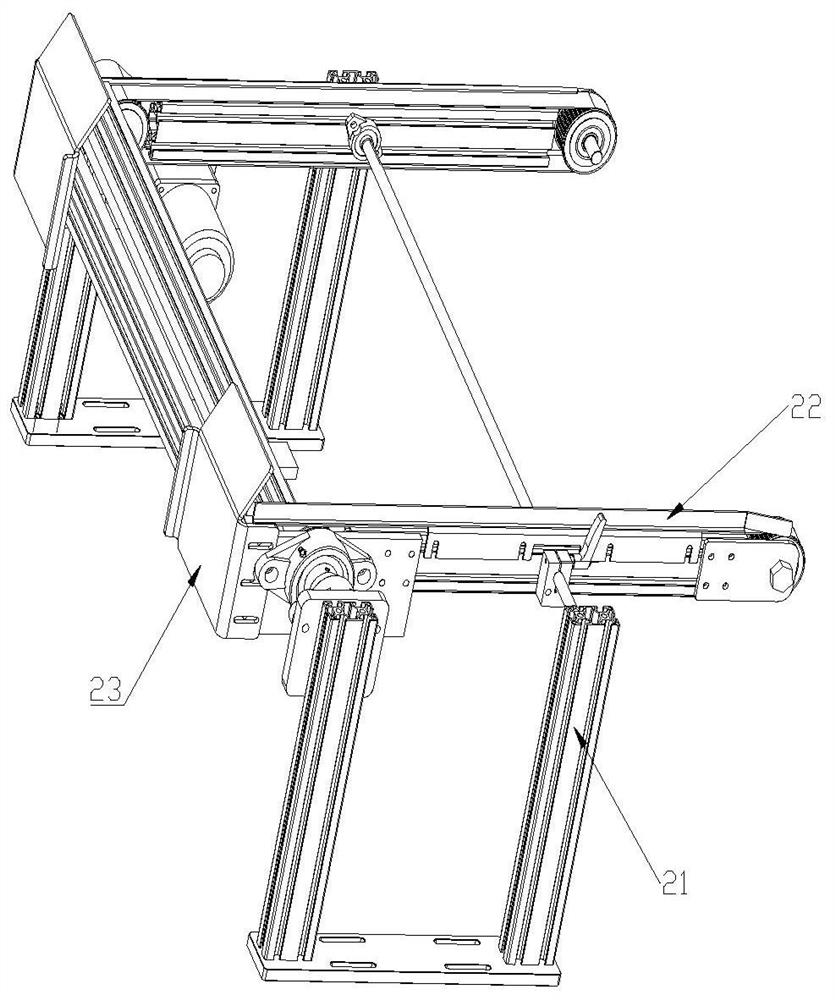

Automatic two-end gluing machine

ActiveCN113289866AShorten the timeImprove work efficiencyLiquid surface applicatorsCoatingsEngineeringMachine

The invention discloses an automatic two-end gluing machine, and relates to the field of gluing. The automatic two-end gluing machine comprises a rack, a dust cover and a control mechanism, wherein the rack is sequentially provided with a feeding mechanism, a conveying mechanism and a discharging mechanism in the flowing direction of products; a material distributing mechanism is arranged between the feeding mechanism and the conveying mechanism; the rack is sequentially provided with a terminal plug opening mechanism and two gluing mechanisms at one side of the conveying mechanism in the flowing direction of the products; the two gluing mechanisms are symmetrically arranged along the conveying mechanism; jacking mechanisms are arranged at the positions, located on the gluing mechanisms, of the inner side of the conveying mechanism; and the rack is provided with first sensors located at one sides of the gluing mechanisms. According to the automatic two-end gluing machine, glue dispensing can be carried out on two ends of the products, a plurality of glue dispensing mechanisms are arranged, and a plurality of products can be glued at the same time, so that the working efficiency is improved; and a glue pushing mechanism and a glue amount precision control table are used, so that the glue outlet amount can be more precisely controlled, gluing is more uniform, and the gluing quality is improved.

Owner:苏州博奕精工科技有限公司

Glass fiber flame-retardant cloth foamed coating one-time forming production line and production process

ActiveCN109759275AControl the amount of glueReduce manufacturing costPretreated surfacesCoatingsWinding machineDyeing

The invention relates to the technical field of flame retardant cloths, and particularly relates to a glass fiber flame-retardant cloth foamed coating one-time forming production line and a productionprocess. The production line comprises a glue coating device, a drying device and a winding machine, wherein the drying device is composed of eight drying boxes, the glue coating device comprises a glue coating groove and a glue amount control device arranged on one side of the discharge direction of the glue coating groove, the glue amount control device comprises a glue scraping roller and an adjusting mechanism, a glue scraping mechanism is arranged on the glue scraping roller, the glue scraping mechanism comprises a glue scraping groove which are arranged along the axis direction of the glue scraping roller in a penetrating mode. The invention further discloses a glass fiber flame-retardant cloth foamed coating one-time forming production process. The production process comprises thefollowing production steps of (1) preparing; (2) dipping the dyeing glue; (3) carrying out glue scraping and spreading; (4) drying; and (5) rolling. The glass fiber flame-retardant cloth produced by the process is good in air permeability, excellent in sound-absorbing effect and soft in fabric hand feeling, dyeing glue dipped on the two surfaces of the glass fiber flame-retardant cloth can be simultaneously spread, the gluing amount is controlled, the coating is uniform, the application range is wide, and the working efficiency is high.

Owner:青岛博时阻燃织物有限公司

Automatic box gluing machine for paper box production

PendingCN111730902AControl the amount of glueMuch valuePaper-makingBox making operationsElectric machineryAir pump

The invention discloses an automatic box gluing machine for paper box production. The automatic box gluing machine comprises a rack, wherein a belt wheel one is arranged on the left side of the top ofa bottom plate, an electric cylinder one is connected to the top of the rack in a bolted mode, and the electric cylinder one is arranged on the right side of the belt wheel one. Through the arrangement of a motor two, a belt wheel two, a brush, a dust suction cover, an air inlet pipe, an exhaust fan and a filter box, dust generated in the paper box grinding process can be collected, so that harmto bodies of workers is avoided, and meanwhile the influence of the dust on the surfaces of paper boxes on the bonding process is reduced; through the arrangement of a PLC body, electric appliances inthe device can achieve semi-automation, so that the production efficiency is greatly improved; and through the arrangement of an air pump, an electric cylinder four, a limiting block two, an infraredsensor two, an air outlet pipe, an electric cylinder three and a needle tube, the device can control the glue dripping amount of each paper box, and the glue dripping amount of each paper box is controlled, so that the production cost is greatly reduced, and the production efficiency is improved.

Owner:鸿昇纸品(惠州)有限公司

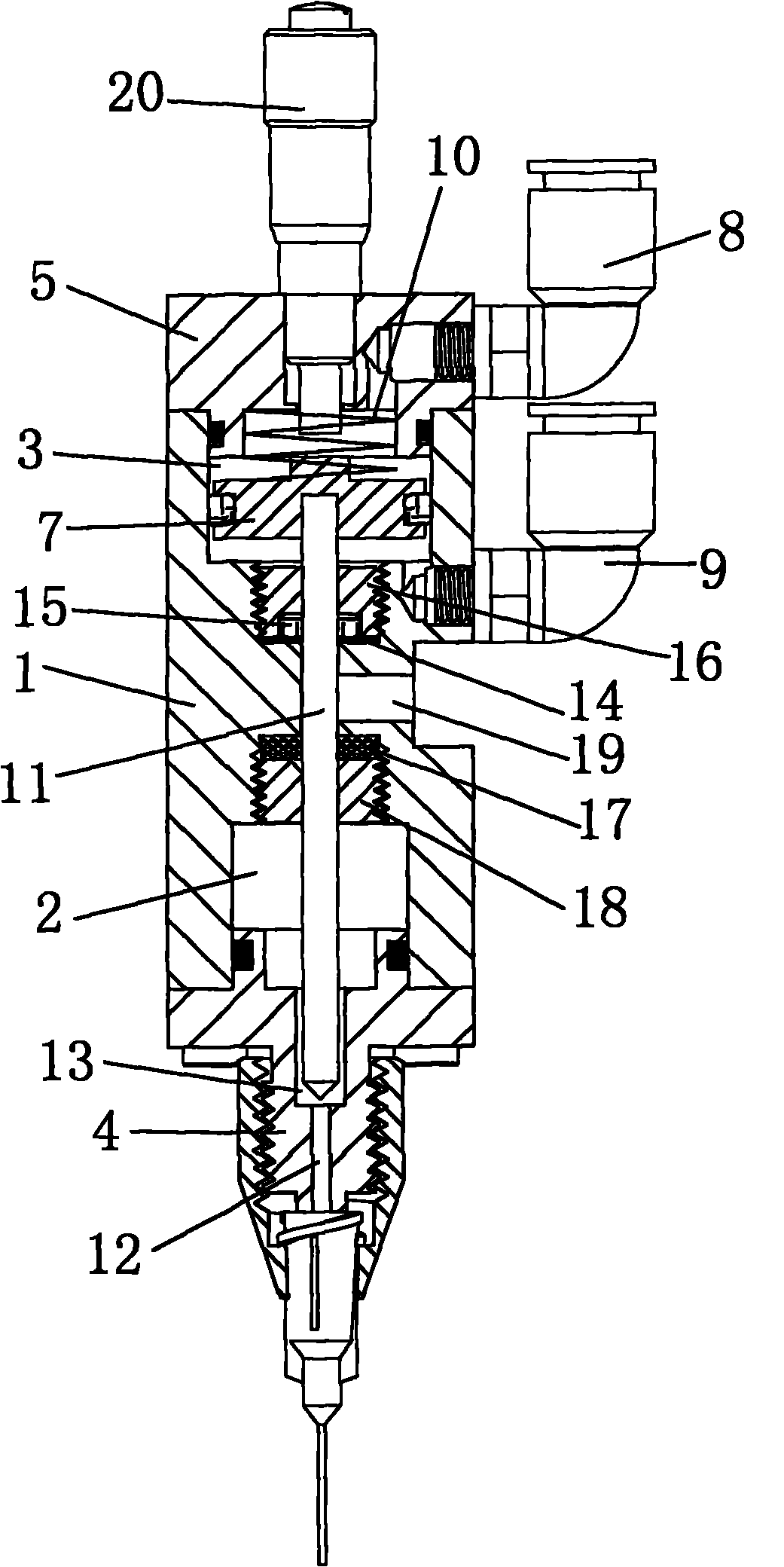

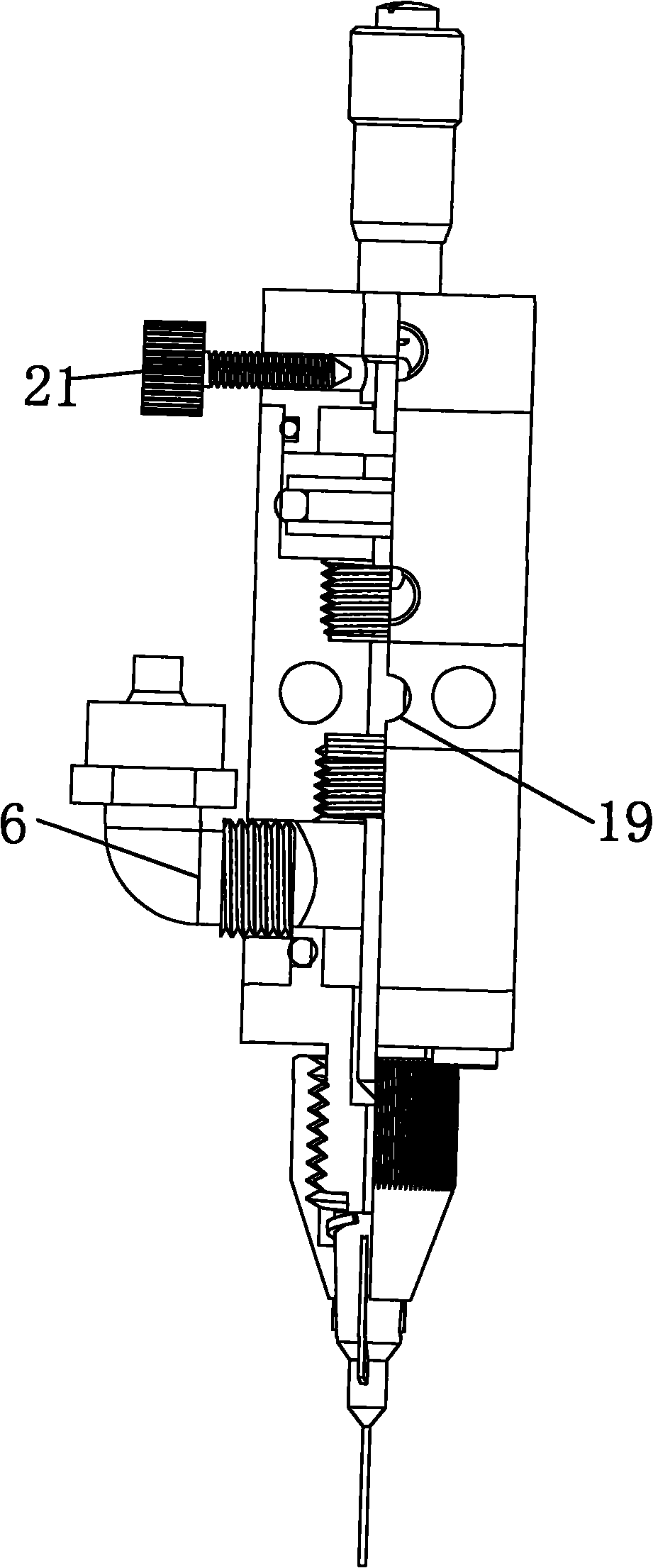

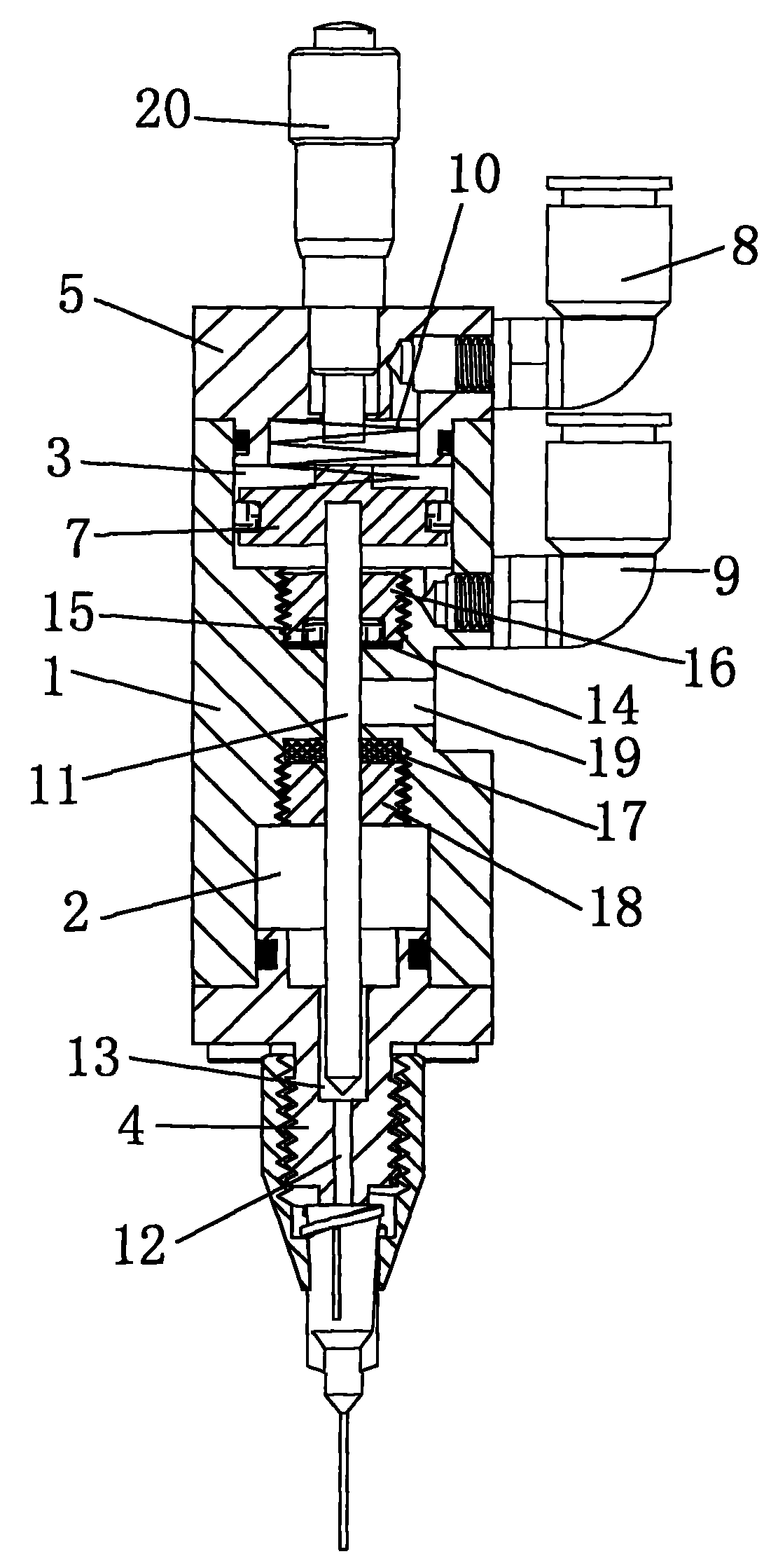

Novel micro binder gun

InactiveCN101780448AIncrease or decrease stroke sizePrevent leakageLiquid surface applicatorsCoatingsMicrometerEngineering

The invention discloses a micro binder gun, which comprises a gun body. A material cavity and an air cavity are arranged in the gun body; the lower end of the gun body is connected with a glue-spreading head; the upper end of the cavity and a cover body are connected to seal the air cavity; the material cavity is communicated with a glue-feeding head; a piston is arranged in the air cavity; the air cavity is divided into an upper air cavity and a lower air cavity by the piston; the upper cavity is communicated with a normally-ventilating pipe joint; the lower air cavity is communicated with an air inlet pipe joint; the piston is also connected with a thimble which downwards extends to the material cavity; the thimble at passing part is sealed with the material cavity; the thimble at passing part is sealed with the air cavity; the cover body is provided with a micrometer; a threaded insert of the micrometer is axially arranged on the cover body; and a screw of the micrometer extends into the air cavity and aligns with the plug. The invention can accurately control the glue spreading amount through the micrometer, thereby ensuring the glue-dispersing precision.

Owner:王燕

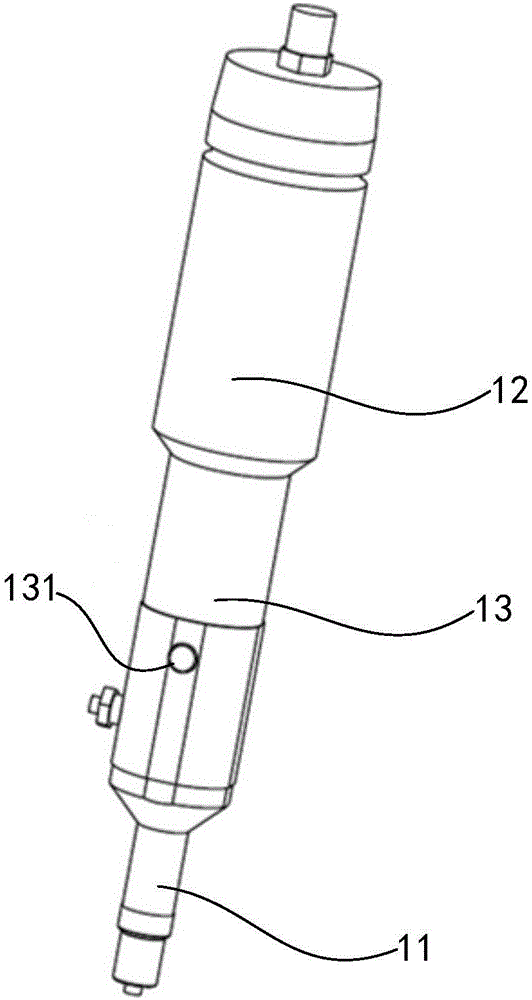

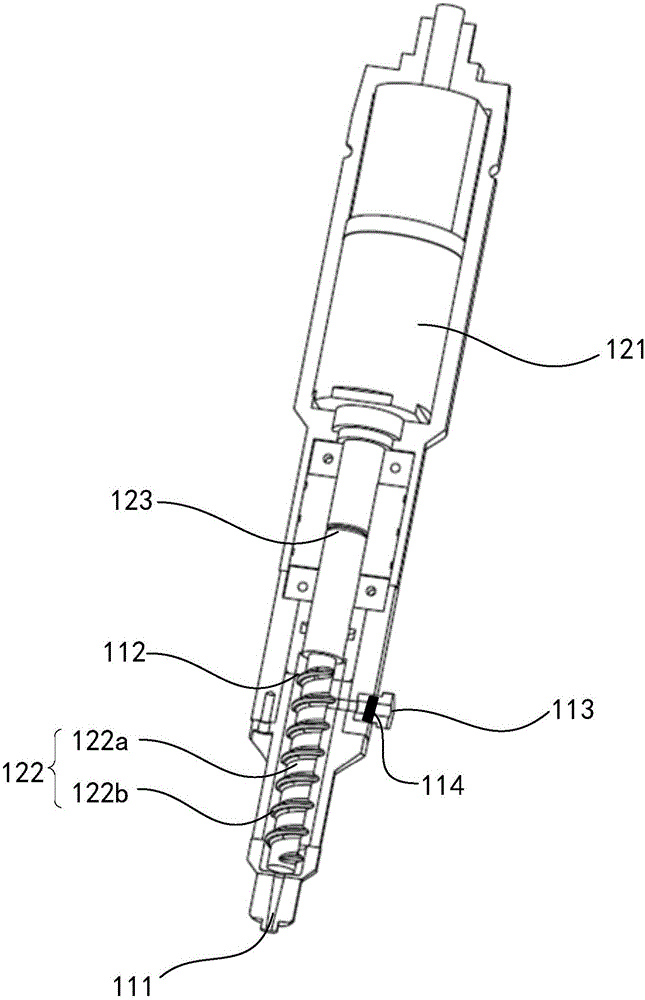

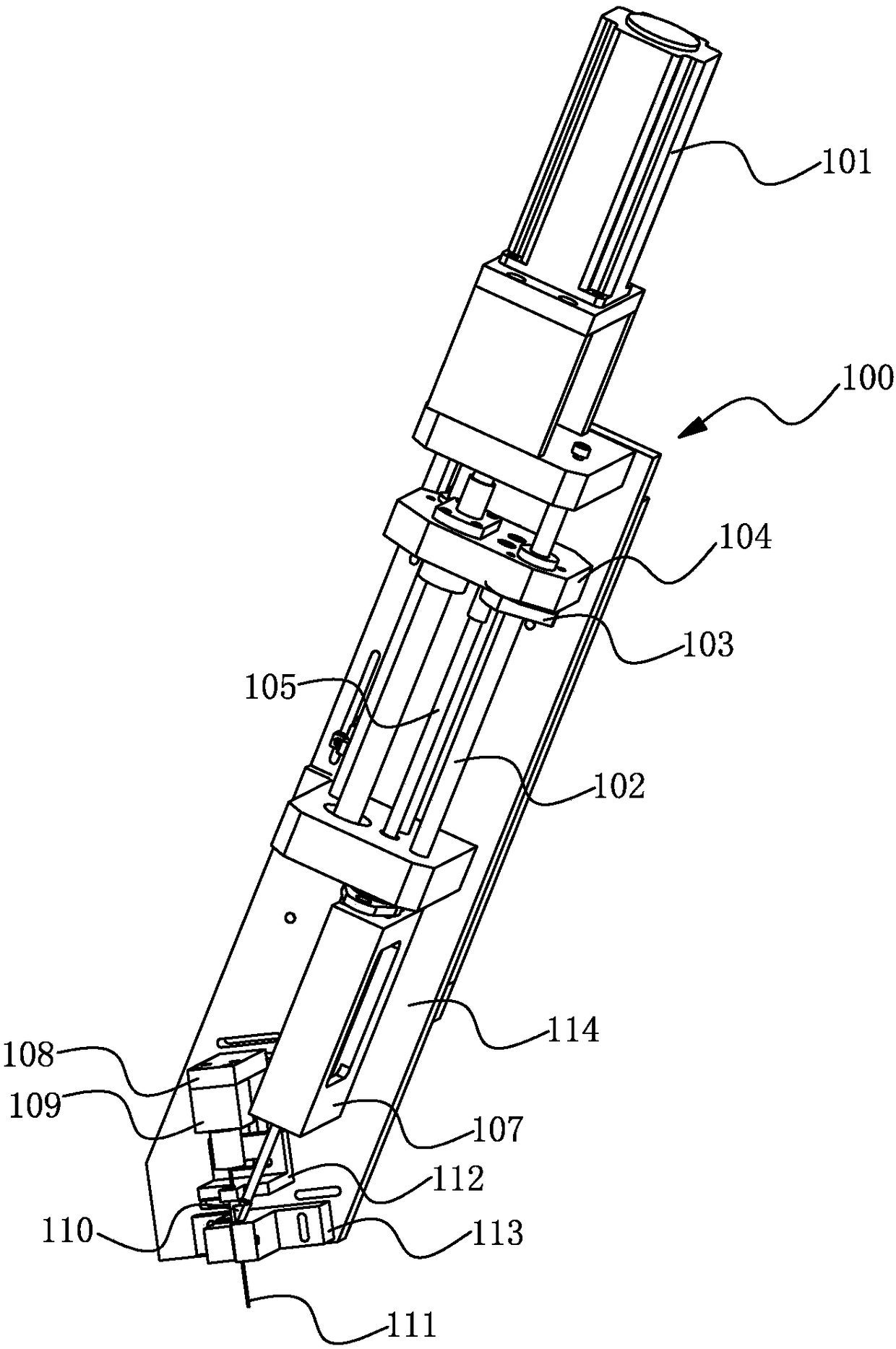

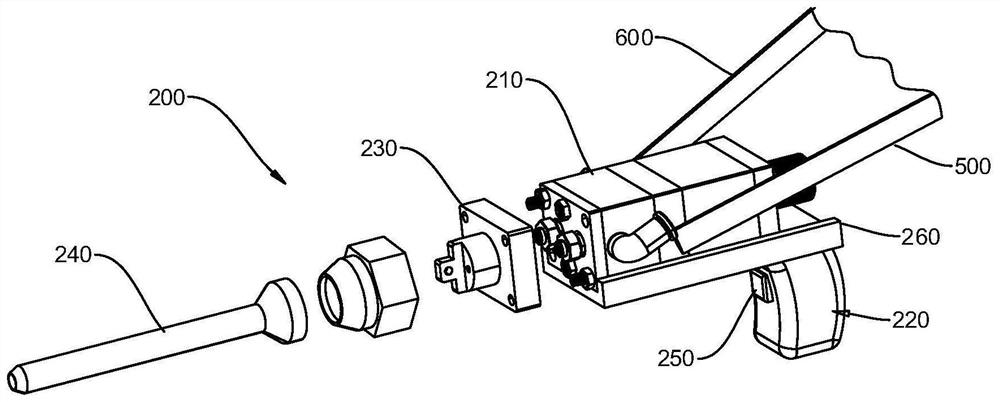

Electrical handheld dispenser and electrical handheld dispensing equipment

PendingCN106694327ASimple structureLow manufacturing costLiquid surface applicatorsCoatingsElectrical and Electronics engineeringEngineering

The embodiment of the invention relates to the technical field of dispensing and particularly discloses an electrical handheld dispenser and electrical handheld dispensing equipment. The electrical handheld dispenser comprises a glue discharging mechanism for accommodating glue and an electrical valve body; a glue outlet is formed in one end of the glue discharging mechanism; the other end of the glue discharging mechanism serves as a connecting end; a through hole is formed in the connecting end; a glue inlet is formed in the side wall of the glue discharging mechanism; the electrical valve body comprises a driving device and a screw; the driving device is in transmission connection with the screw; the screw penetrates through the through hole and is arranged in the glue discharging mechanism; the driving device is fixedly connected with the connecting end of the glue discharging mechanism; the screw is matched with the through hole in diameter. The electrical handheld dispenser and the electrical handheld dispensing equipment provided by the embodiment of the invention are simple in structure and low in manufacturing cost; in addition, the glue outlet amount can be accurately controlled.

Owner:SHENZHEN BELLSING ACOUSTIC TECH CO LTD

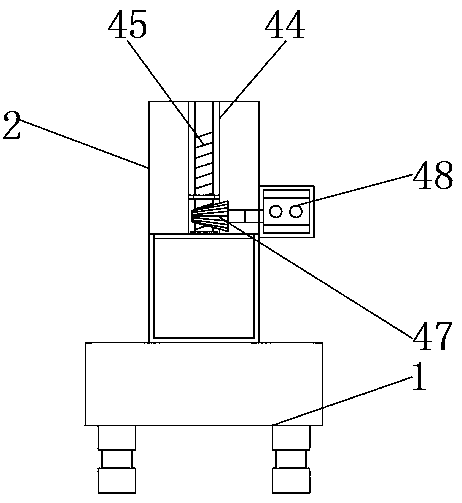

Glue dispensing device

InactiveCN109382263AGlue is fastControl the amount of glueLiquid surface applicatorsCoatingsCouplingEngineering

The invention relates to a glue dispensing facility, and especially relates to a servo motor controlled glue dispensing device that can carry out precise glue dispensing and is used to perform automatic glue dispensing. The provided glue dispensing device comprises servo motor, which is connected to a screw set through a coupler; when the servo motor rotates, the rotation is transmitted to the screw set, and a screw nut moves downwards to drive a push rod to press a glue cylinder to extrude glue out. Moreover, the glue dispensing device is also provided with a cylinder to control a glue dispensing switch. The servo motor provides a driving force, the glue discharging speed is accelerated, and the amount of discharged glue can be precisely controlled. The glue dispensing device can be connected to a mechanical arm through signals, the whole glue dispensing process is automatic, the efficiency is improved, and at the same time, labor is saved.

Owner:KUNSHAN HANDING PRECISION METAL CO LTD

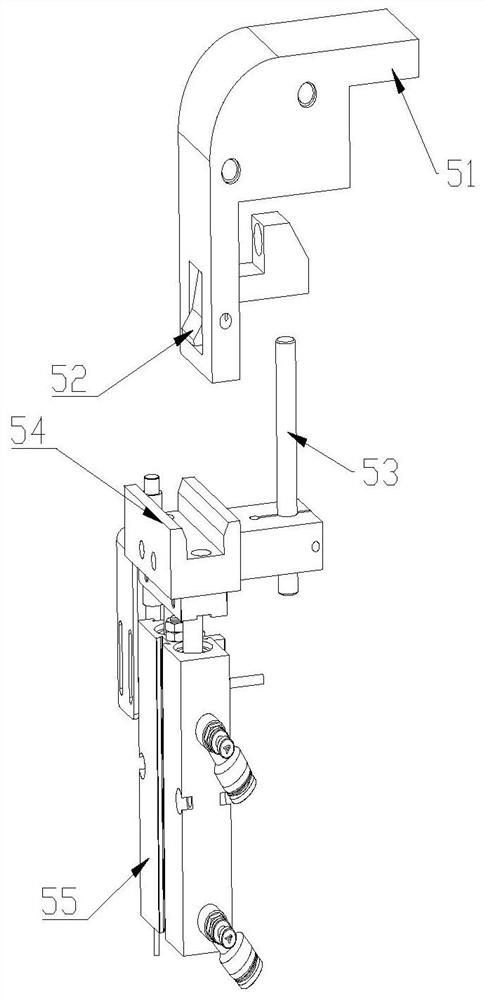

Gluing device for mask processing

InactiveCN111229547AControl the amount of glueNo need to change path of travelLiquid surface applicatorsCoatingsGear wheelEngineering

The invention relates to a gluing device for mask processing. The device comprises a base, a stand rod, an upper cross beam, a glue extruding mechanism, a positioning mechanism and a conveying mechanism; the upper cross beam is fixedly connected to the upper end side surface of the stand rod; the positioning mechanism is arranged under the upper cross beam; and the conveying mechanism is arrangedon the upper surface of the base. A lead screw and bevel gear are arranged in the glue extruding mechanism; the bevel gear rotates to drive the lead screw to rotatably lower or ascend; the glue outletamount can be controlled through threaded rotation of the lead screw and the bevel gear, so that the glue outlet amount can be preferably controlled; and a buffer structure is formed by a hollow rodof a fixing mechanism of the gluing device, a buffer spring and a connecting rod, the moving distance of the connecting rod is the same as the deformation of the buffer spring, and the size of a lowerpressing plate is the same as that of an upper pressing plate, so that a mask can be preferably positioned and glued, and the position of the mask is changed during gluing.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

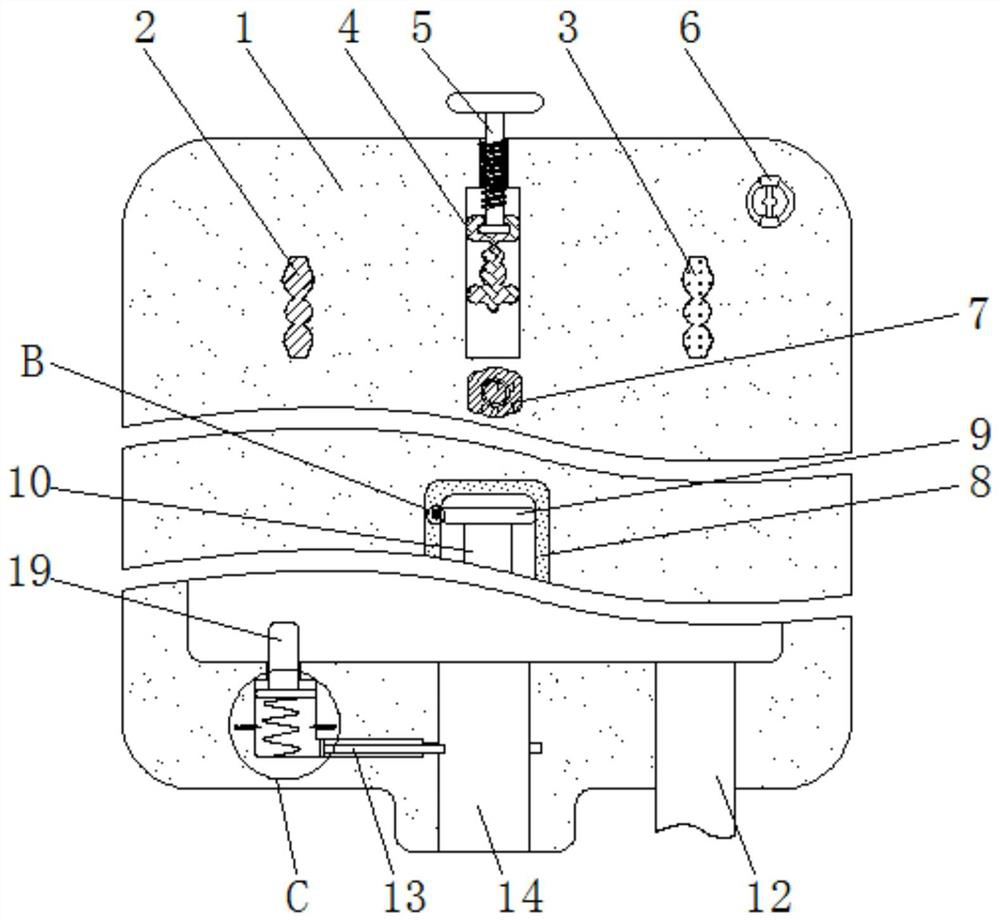

Glue outlet amount control device and method

InactiveCN107774525AControl the amount of glueIncrease usageLiquid surface applicatorsCoatingsEngineeringControl valves

The invention discloses a glue outlet amount control device. The glue outlet amount control device comprises a workbench used for containing a product, a dispensing head arranged on one side of the workbench and provided with a glue storage barrel and a glue outlet, an inflation air cylinder arranged on one side of the dispensing head, a control valve arranged on the inflation air cylinder and used for controlling start and shutdown of the inflation air cylinder, a timer arranged on one side of the inflation air cylinder and connected with the control valve, and a touch foot pad arranged on one side of the timer and connected with the timer, wherein an air outlet of the inflation air cylinder is connected to the glue storage barrel of the dispensing head. By means of the glue outlet amountcontrol device, opening and closing of an electromagnetic valve are controlled through the timer, the glue outlet amount of glue is effectively controlled, the glue utilization rate is greatly increased, and the production cost is saved.

Owner:SHENXUN COMP KUNSHAN

Purging sealing gun for seam of color plate

The invention discloses a purging sealing gun for a seam of a color plate. The purging sealing gun comprises a gun barrel body, a muzzle arranged at one end of the gun barrel body, a driving mechanism arranged in the other end in the gun barrel body, and a rubber pipe used in cooperation with the gun barrel body. The gun barrel body comprises a pipe body with an opening formed in the side wall, and an air pipe arranged in the axial direction of the pipe body. The muzzle of the purging sealing gun is in a wedged L shape, the front end of the muzzle is used for stretching into a narrow space, the front portion of the muzzle stretches forwards towards the side portion, the section of the front portion of the muzzle is in a wedge shape, one side of the front end of the wedge shape is slightly inserted into the seam of the color plate, the muzzle is used for being inserted into the seam, then purging airflow is generated through a high-pressure air source in the forward direction of the muzzle, impurities and dust in the seam are blown out through the airflow, and a glue outlet in the rear side of the muzzle extrudes glue into the seam soon afterwards; and construction is completed through one action and two processes together, the rotating speed of a pneumatic motor is controlled through a multidirectional air valve, and therefore the forward speed of a screw rod is adjusted, the glue outlet speed can be controlled, and the glue outlet amount can be controlled.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

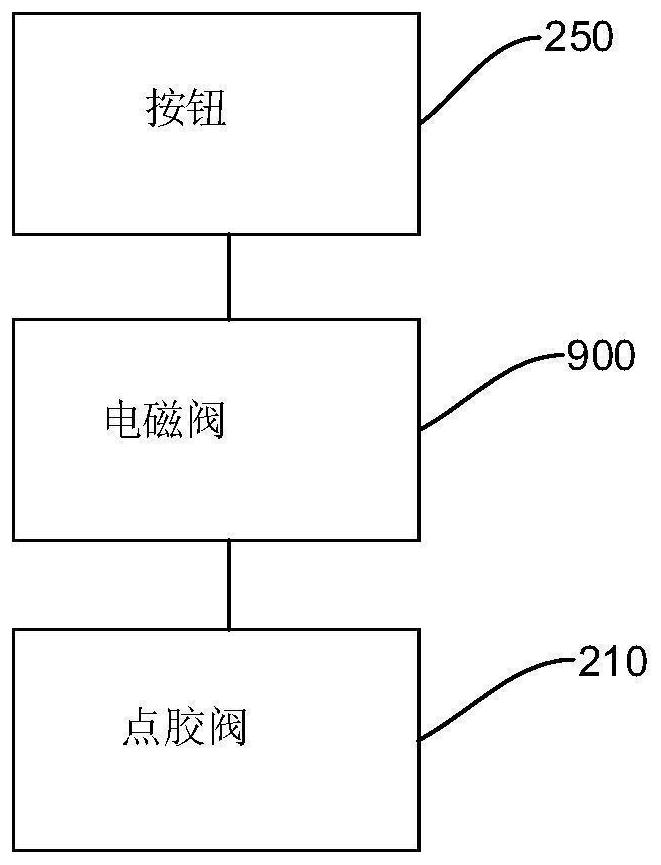

Glue supplementing device and glue supplementing equipment

InactiveCN113731757AAvoid wastingPrecise control of glue outputLiquid surface applicatorsCoatingsAdhesive glueEngineering

The embodiment of the invention provides a glue supplementing device and glue supplementing equipment, and relates to the field of equipment glue supplementing. The glue supplementing device comprises a glue supplementing head and an electromagnetic valve; the glue supplementing head comprises a shell, a glue dispensing valve and a button; the glue dispensing valve and the button are arranged on the shell; the electromagnetic valve is electrically connected with the button and the glue dispensing valve at the same time; and the electromagnetic valve is used for controlling the glue dispensing valve according to the working condition of the button. In the process of using the glue supplementing device, the electromagnetic valve can be powered on or powered off through the button, so that the electromagnetic valve drives the glue dispensing valve to discharge or collect glue. According to the glue supplementing device, the glue dispensing valve can be accurately controlled through the electromagnetic valve, so that the glue discharging amount is accurately controlled, and the problem of glue waste is avoided.

Owner:江淮华霆(安庆)电池系统有限公司

Foil plating device for producing copper foil adhesive tape

InactiveCN112812700APress tightlySmooth rotationLiquid surface applicatorsFilm/foil adhesivesAdhesive beltMetallurgy

The invention discloses a foil plating device for producing a copper foil tape. The foil plating device comprises a foil plating device body and a motor, the motor is mounted at the top end of the foil plating device body, the output end of the motor is fixedly connected with a connecting shaft, and the end, away from the motor, of the connecting shaft is fixedly connected with a first bevel gear; and the surface of the first bevel gear is meshed with the surface of a second bevel gear, the inner wall of the second bevel gear is fixedly connected with a first rotating shaft, and the surface of the first rotating shaft is fixedly connected with the inner wall of the first rotating gear. An adhesive smearing rod and a rotating disc are arranged, adhesive can be evenly smeared on the surface of a copper foil through rotation of the adhesive smearing rod, the adhesive amount on the surface of the adhesive smearing rod can be effectively controlled through rotation of the rotating disc, rotation of an extrusion shaft is facilitated through a third rotating gear and a fourth rotating gear, and copper foil adhesive tape pressing is more compact through rotation.

Owner:张永宏

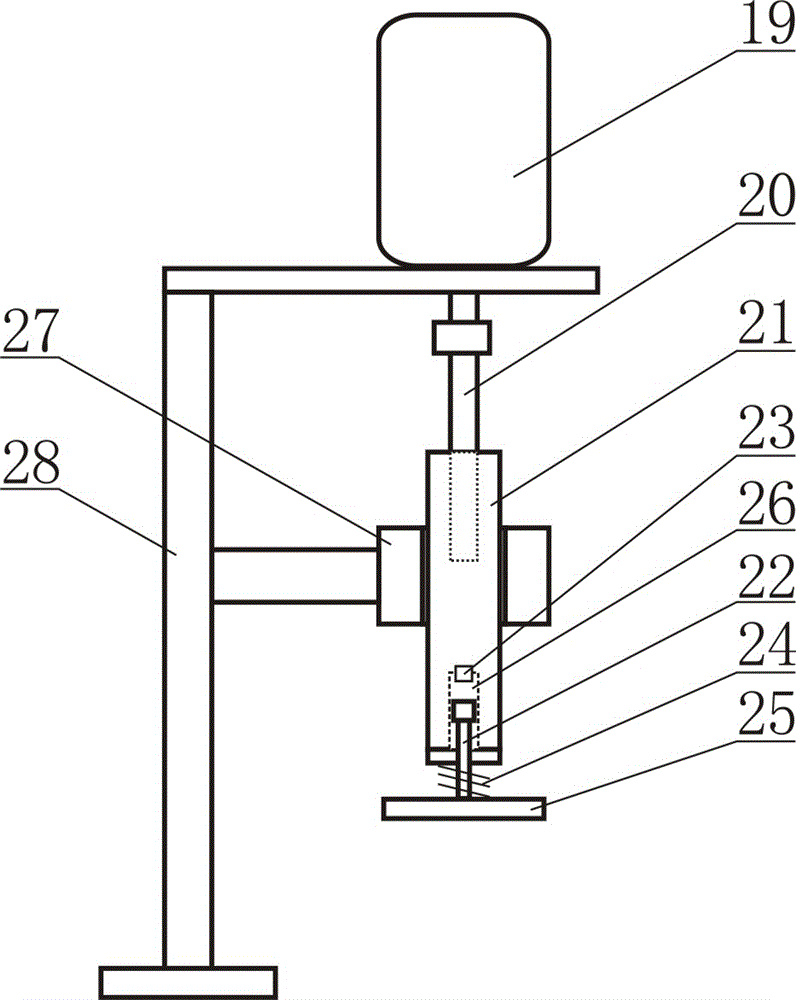

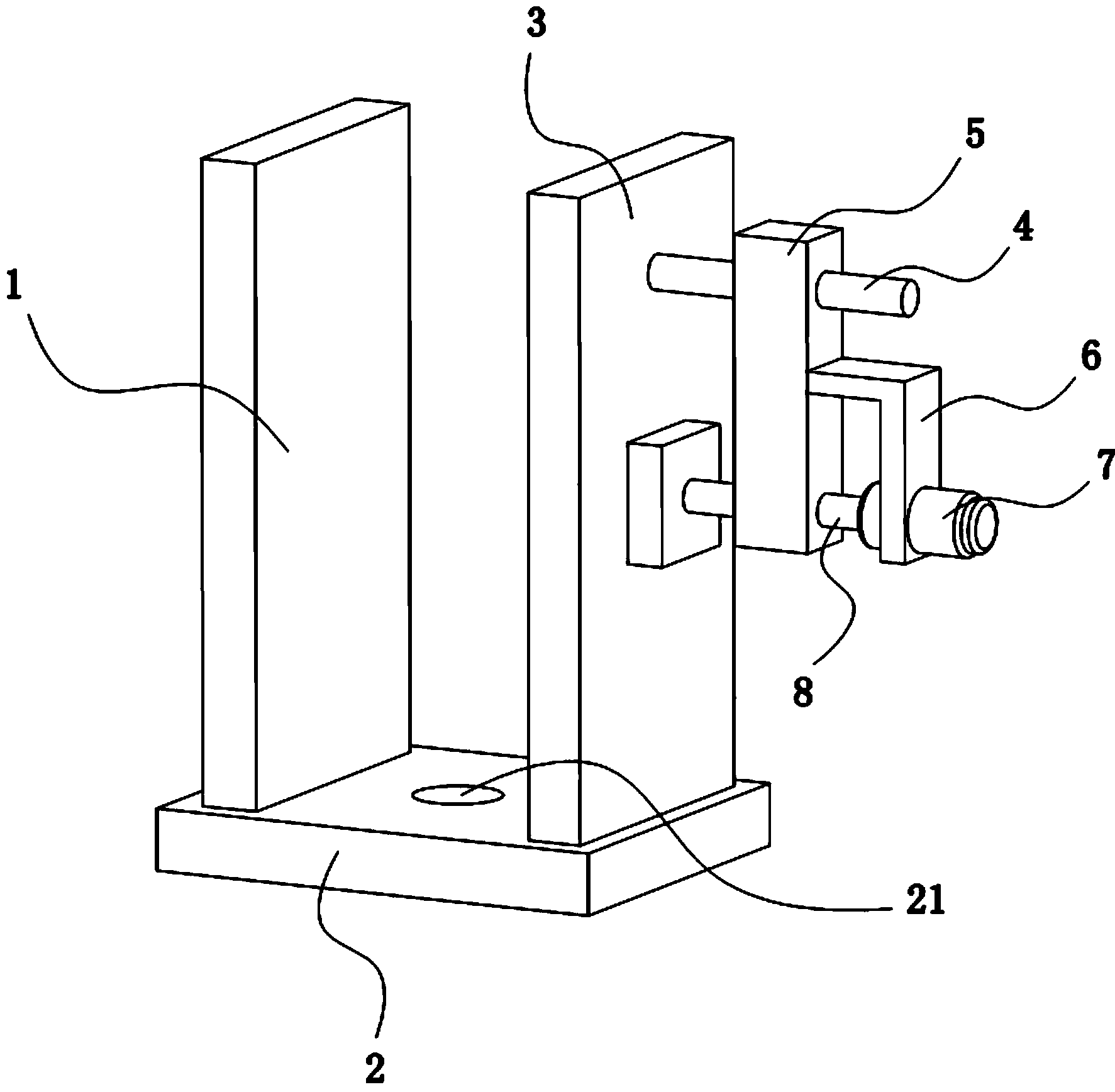

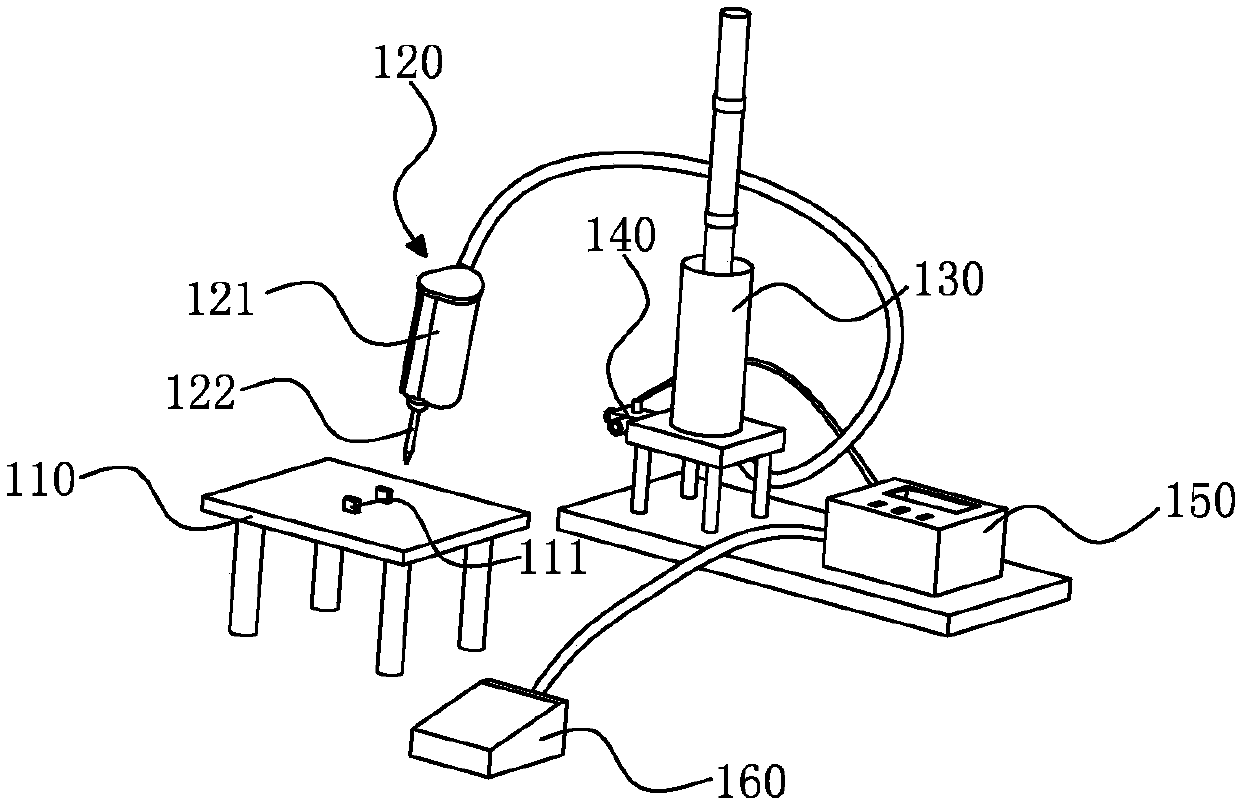

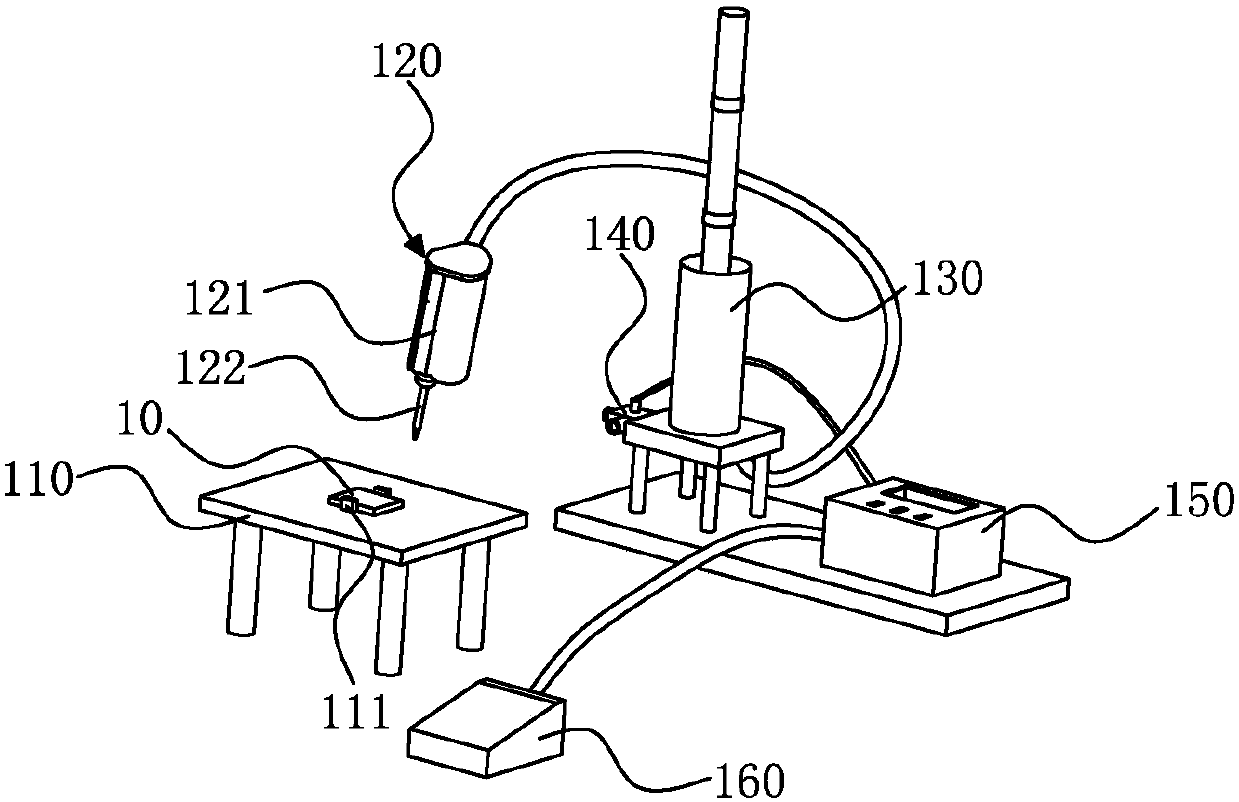

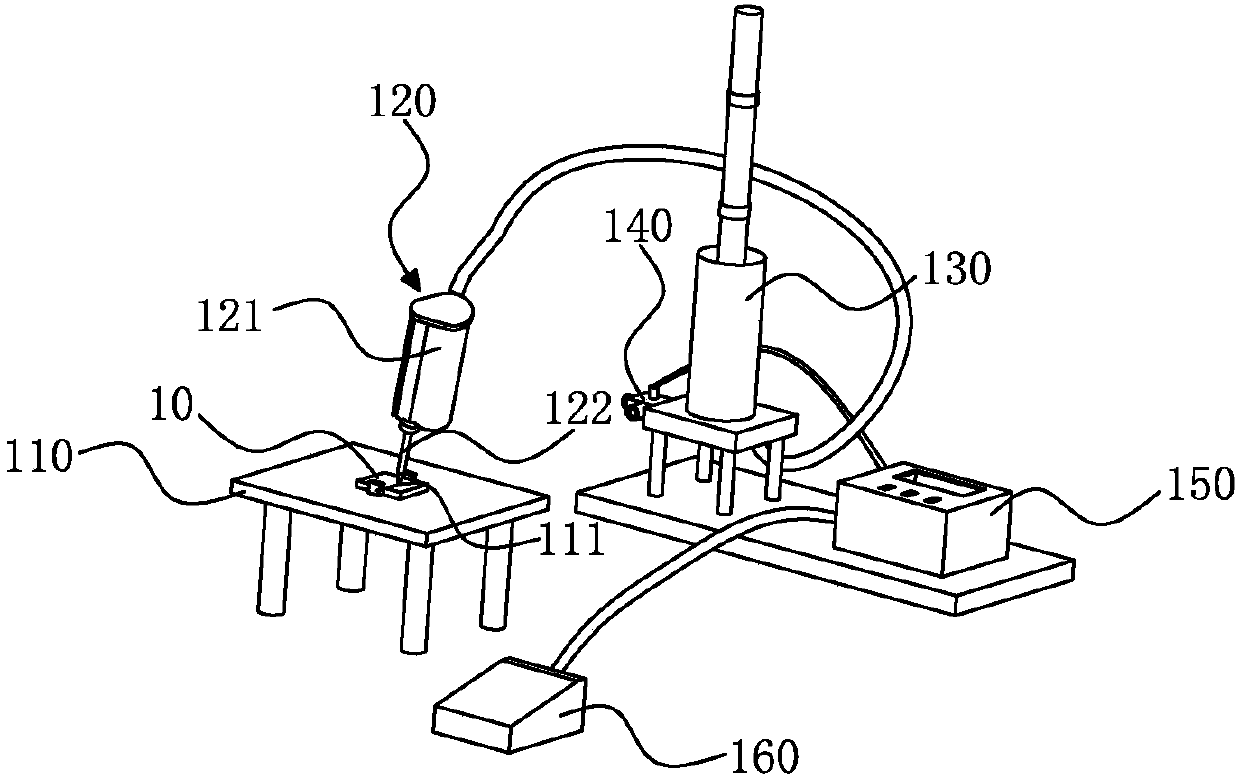

Pump pipe gluing device in blood pipeline

PendingCN107876339AGuaranteed lengthControl lengthLiquid surface applicatorsCoatingsRotary pumpInsertion depth

Disclosed is a pump pipe gluing device in a blood pipeline. The pump pipe gluing device in the blood pipeline is provided with a gluing mechanism used for gluing mucilage glue liquid on the outside wall of the pimp pipe, a liquid storage mechanism used for storing the mucilage glue liquid, and a supporting mechanism. The supporting mechanism is fixed above the gluing mechanism, and the liquid storage mechanism is arranged on the supporting mechanism. The mucilage glue liquid in the liquid storage mechanism enters into the gluing mechanism by a guiding pipe. The pump pipe gluing device in the blood pipeline has the following beneficial effects that the mucilage glue liquid in the gluing mechanism is always in a flow condition to ensure that the mucilage glue liquid in an absorber is alwaysin a saturation condition, so that the quantity of the gluing can be controlled effectively; the insertion depth of the pimp pipe can be fixed by the gluing mechanism, and the gluing length of the side surface of the pump pipe is controlled; a plurality of absorbers are embedded into a gluing portion so as to ensure that gluing in the side surface of the pump pipe can be complete when the pump pipe rotates, and the problems of incomplete gluing and white seal are solved; the end portion of the pump pipe can not straightly be inserted into the liquid level of the glue mucilage to prevent the glue of the inside wall of the pump pipe splashing.

Owner:贝恩医疗设备(广州)有限公司

Multifunctional dispensing equipment for solar battery pieces

ActiveCN111701800APrecise closureClosed tightlyLiquid surface applicatorsCoatingsEngineeringSolar battery

The invention discloses multifunctional dispensing equipment for solar battery pieces. The multifunctional dispensing equipment comprises a conveying platform, racks, a working frame, a dispensing device and a transmission structure. The dispensing device comprises a movable block capable of moving back and forth on the working frame, a first air cylinder arranged below the movable block, a fixeddisc arranged at the top end of the first air cylinder, a connecting block rotatably arranged below the fixed disc, a glue gun rotatably arranged below the connecting block, a telescopic structure arranged in the connecting block and used for squeezing the glue gun, a transmission gear arranged on the outer wall of the connecting block and an adjustable power assembly arranged at one side of the glue gun. According to the multifunctional dispensing equipment, the length of the telescopic structure is controlled through the arrangement of the transmission gear, the glue discharging amount within the unit time is effectively controlled, and is unlikely to get affected by external factors, the stability of discharging is greatly improved, and the uniformity of glue discharging is guaranteed;and meanwhile, through the arrangement of the adjustable power assembly, a variety of dispensing modes are provided, and thus the working adaptability of the apparatus is improved.

Owner:广东淘家建筑装饰工程有限公司

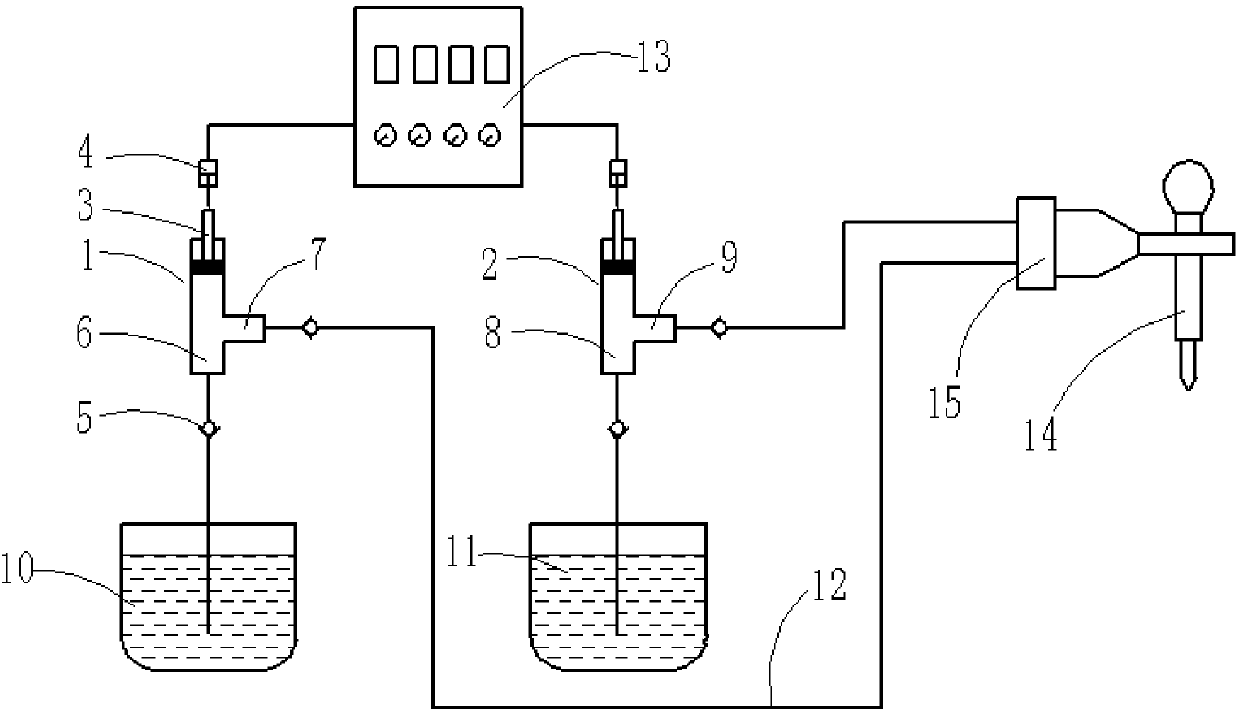

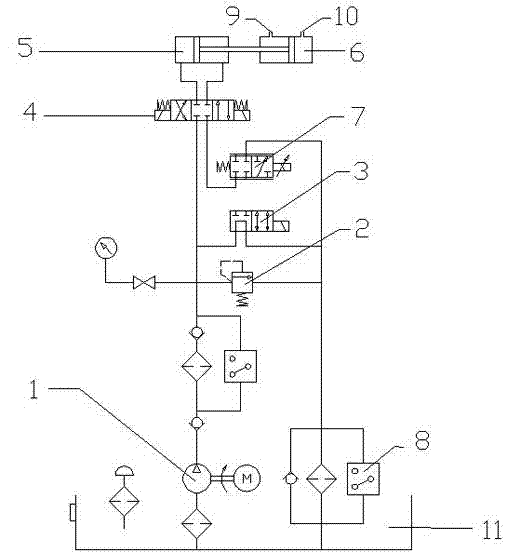

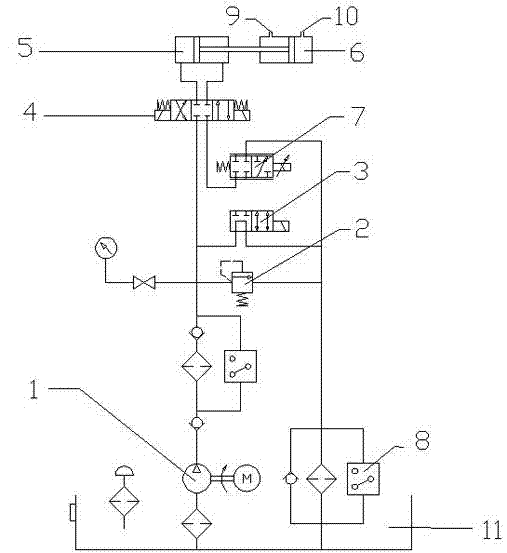

Automatic control system for sealant amount of automatic seal line for hollow glass

InactiveCN101972734BControl movement speedControl the amount of glueLiquid surface applicatorsCoatingsHydraulic cylinderAutomatic control

The invention discloses an automatic control system for the sealant amount of an automatic seal line for hollow glass, which is easy to operate and works reliably. The automatic control system for the sealant amount of the automatic seal line for the hollow glass comprises a hydraulic system, a hydraulic cylinder and a sealant extruding cylinder connected in turn, wherein the hydraulic system is respectively connected with a cavity with a piston rod and a cavity without piston rod of the hydraulic cylinder; and a piston of the sealant extruding cylinder and a piston of the hydraulic cylinder are connected through a piston rod. For further improvement, the hydraulic system comprises an oil pump, a first solenoid valve, a second solenoid valve and a flow regulating device, wherein two openings at one end of the first solenoid valve are respectively communicated with an oil inlet and an oil outlet of the oil pump, while two openings at the other end are respectively communicated with thecavity with the piston rod and the cavity without piston rod of the hydraulic cylinder; openings of the second solenoid valve are respectively connected with the oil outlet and the oil inlet of the oil pump; and an opening of the flow regulating device is respectively communicated with the oil inlet of the oil pump and an oil return opening of the first solenoid valve.

Owner:JINAN DECA GLASS MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com