Magnet assembly and preparing method thereof

A technology of magnet components and magnetic sheets, which is applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of difficult control of glue output, low viscosity of glue, long time, etc., and achieve favorable glue output The effect of controlling, ensuring insulation and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

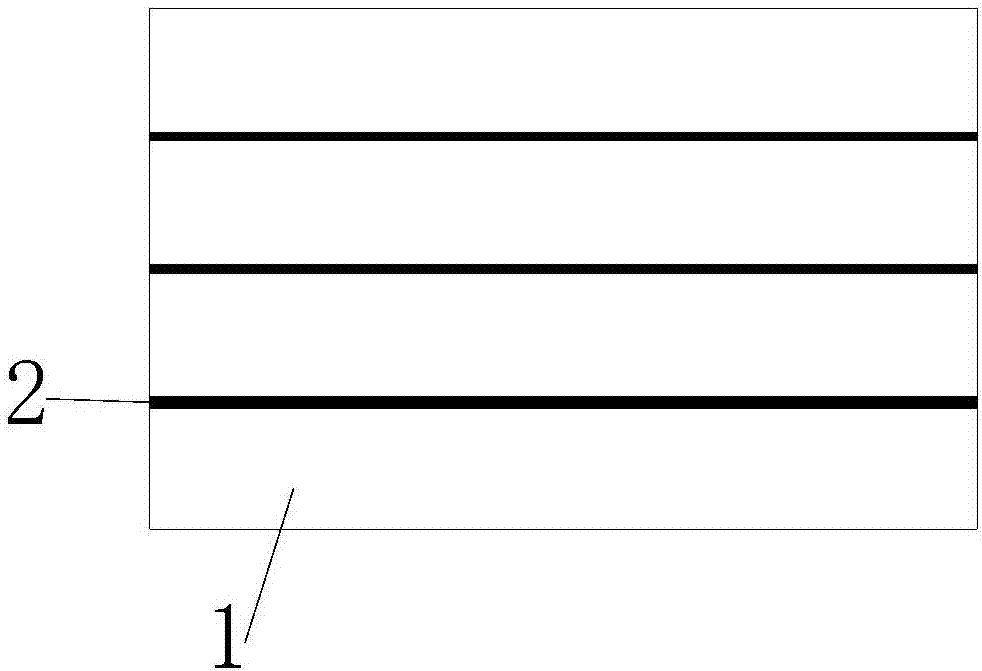

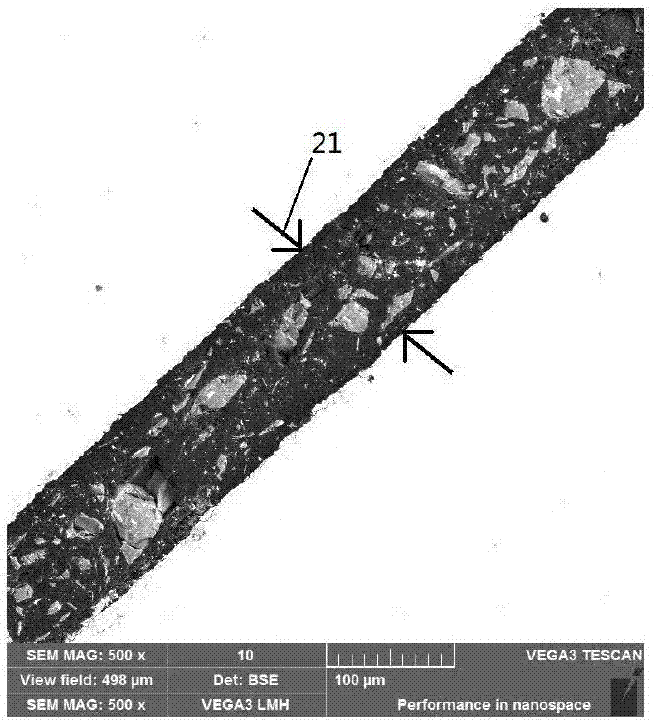

[0046] The magnet assembly prepared in this embodiment includes 4 magnet pieces, and the magnet piece to be glued is a phosphating surface-treated product with a size of 30×24.5×2mm, wherein the 2mm length direction is the orientation direction of the magnet piece. The magnet assembly preparation process is as follows:

[0047] 1. Mix epoxy resin glue and irregularly shaped quartz sand particles evenly to obtain adhesive glue. The particle size D50 of the irregularly shaped quartz sand particles is controlled to be 10 μm, and its mass is 8 wt% of the mass of the epoxy resin glue. Vacuumize and stir in a closed container at a stirring speed of 200 rpm for 1 h.

[0048] 2. Pour the glue into the rubber cylinder of the automatic glue dispenser, and spray it onto the upper surface of the magnetic sheet through the glue dispenser.

[0049] 3. Superimpose the glued magnetic pieces in sequence. The fourth magnetic piece is not glued, but placed directly on the glued surface of the t...

Embodiment 2

[0069] The magnet assembly prepared in this embodiment includes 4 magnet pieces, and the magnet piece to be glued is a phosphating surface-treated product with a size of 30×24.5×2mm, wherein the 2mm length direction is the orientation direction of the magnet piece. The preparation process is as follows:

[0070] 1. Mix epoxy resin glue and irregularly shaped quartz sand particles evenly to obtain adhesive glue. The particle size D50 of the irregularly shaped quartz sand particles is controlled to be 20 μm, and its mass is 3 wt % of the mass of the epoxy resin glue. Vacuumize and stir in a closed container at a stirring speed of 200 rpm for 1 h.

[0071] 2. Pour adhesive glue into the rubber cartridge of the glue dispenser, and spray it onto the upper surface of the magnetic sheet through the glue dispenser.

[0072] 3. Superimpose the glued magnetic pieces in sequence. The fourth magnetic piece is not glued, but placed directly on the glued surface of the third magnetic piece...

Embodiment 3

[0078] The magnet assembly prepared in this embodiment includes 4 magnet pieces, and the magnet piece to be glued is a phosphating surface-treated product with a size of 30×24.5×2mm, wherein the 2mm length direction is the orientation direction of the magnet piece. The preparation process is as follows:

[0079] 1. Mix epoxy resin glue and irregularly shaped quartz sand particles evenly to obtain adhesive glue. The particle size D50 of the irregularly shaped quartz sand particles is controlled to be 14 μm, and its mass is 10 wt% of the mass of the epoxy resin glue. Vacuumize and stir in a closed container at a stirring speed of 200 rpm for 1 hour.

[0080] 2. Pour adhesive glue into the rubber cartridge of the glue dispenser, and spray it onto the upper surface of the magnetic sheet through the glue dispenser.

[0081] 3. Superimpose the glued magnetic pieces in sequence. The fourth magnetic piece is not glued, but placed directly on the glued surface of the third magnetic pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com