A laser tuning method and tuning system for tuning fork gyro based on nano-silver paste

A technology of tuning fork gyroscope and nano-silver paste, which is applied in the direction of speed measurement by gyro effect, gyroscope/steering sensing equipment, measuring device, etc. It can solve problems such as mechanical coupling error, improve accuracy, shorten process time, and be easy to volatilize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

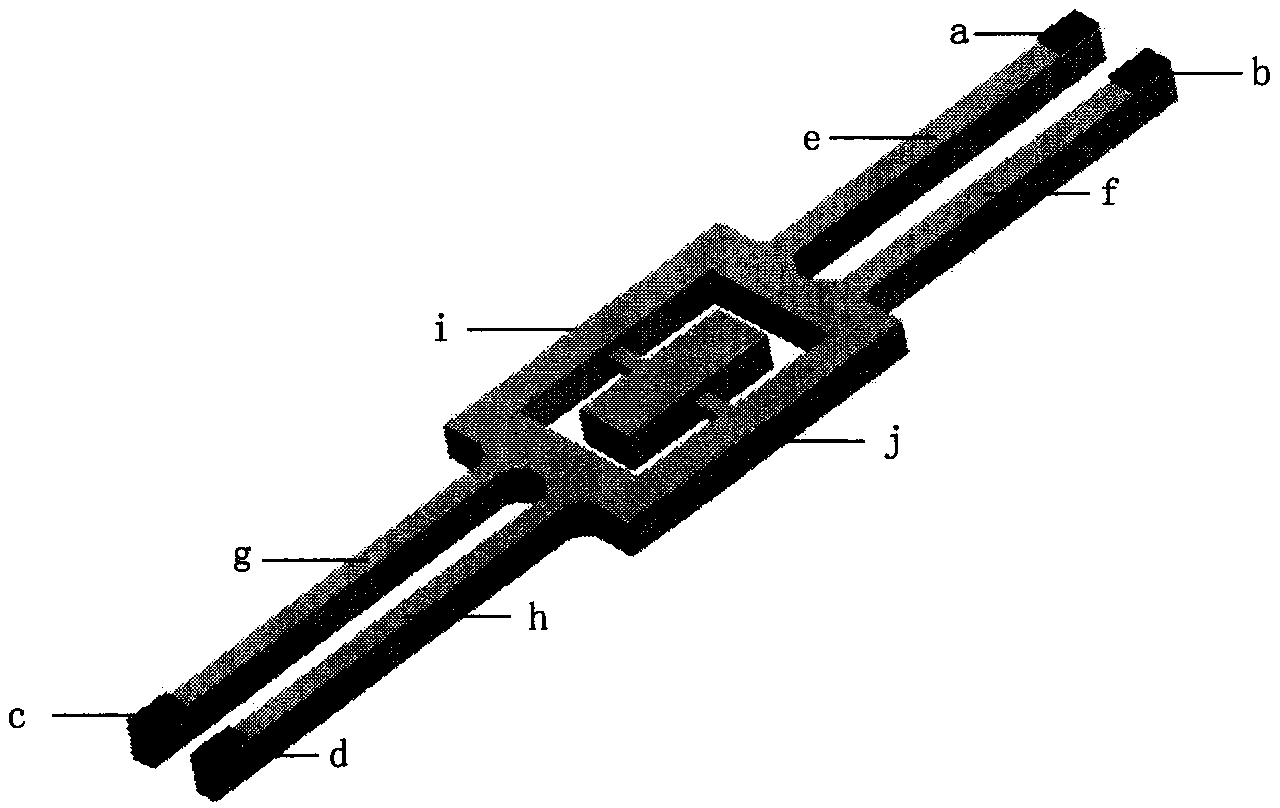

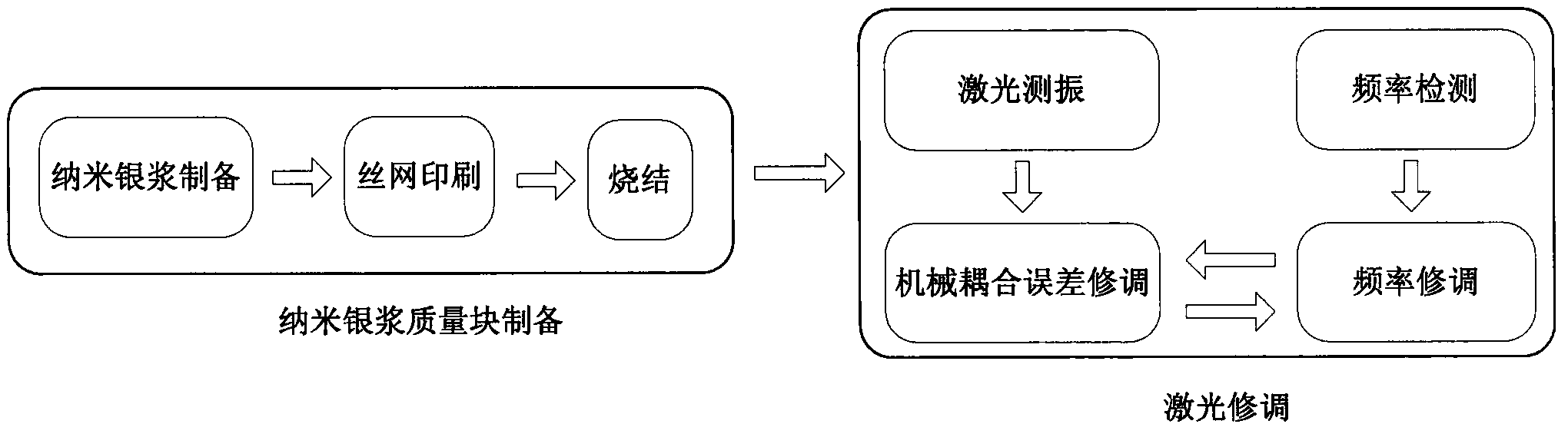

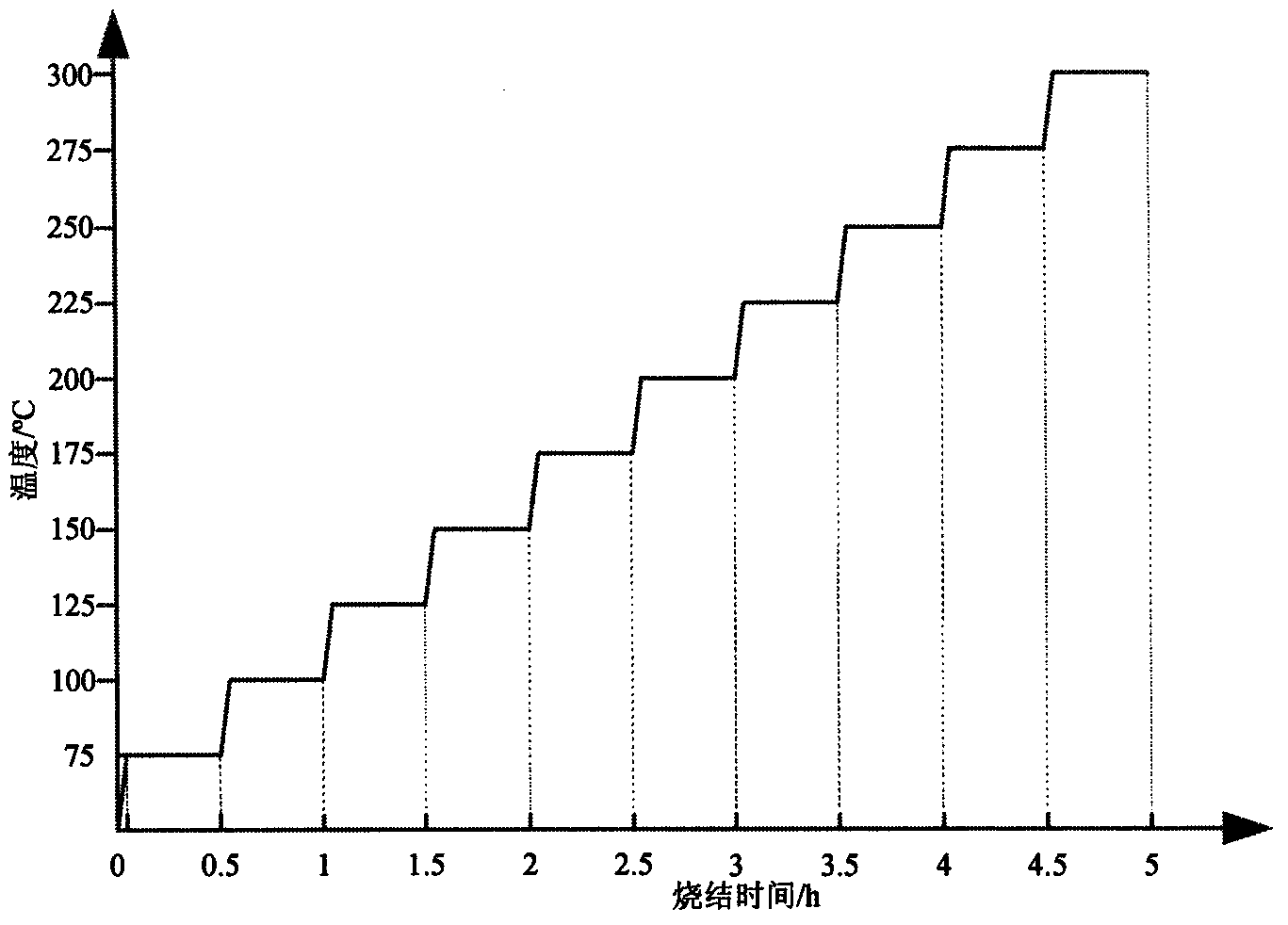

[0040] The present invention designs excellent nano-silver paste suitable for tuning fork gyroscope characteristics, utilizes screen printing thick film production technology, deposits nano-silver paste quality blocks at the end of the fork arm of the tuning fork in advance, adopts laser trimming technology, Selectively remove the sintered nano-silver paste to realize the adjustment of the mechanical coupling error and frequency interval of the tuning fork gyroscope. The laser vibrometer is used to detect the vibration pattern of the tuning fork base on-line to realize the mechanical coupling error of the tuning fork gyroscope. Precise control, through the frequency detection circuit, the frequency interval between the driving frequency of the tuning fork gyro and the frequency of picking up is detected online, so as to realize the precise control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com