Painting and repairing material in use for wall of casting ladle

A technology for repairing materials and ladles, used in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of slurry adhesion, less than 90%, materials will rebound, etc., to accelerate sintering and bonding, promote Medium temperature strength, the effect of promoting firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] First, mix the weighed corundum fine powder, magnesia fine powder, magnesia micropowder, silicon micropowder, organic fiber and water reducer for about 10 minutes, then add high-aluminum raw materials and mix for 3 minutes, and the present invention provides Applicable repair material for pouring ladle walls.

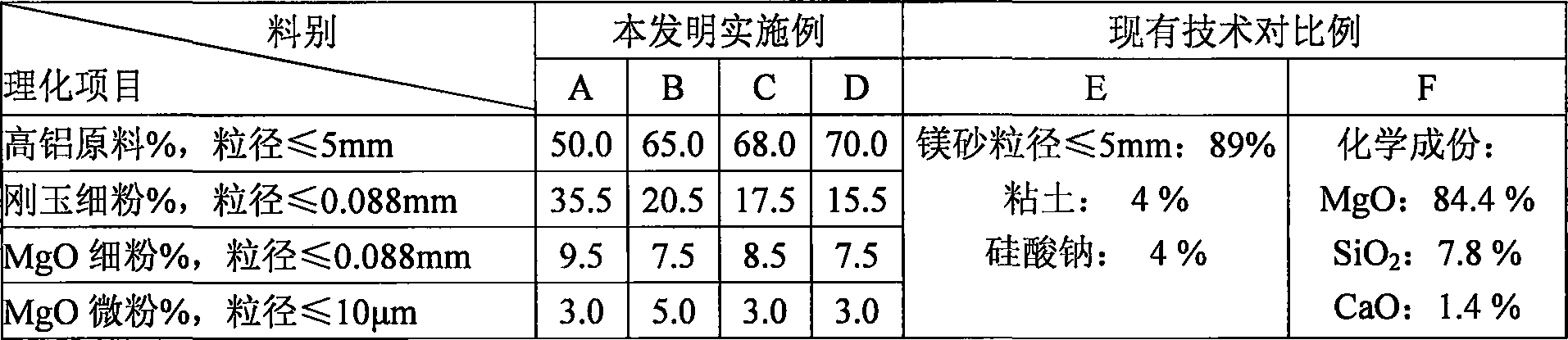

[0025] The following table 1 compares the examples of the present invention with the comparative examples of the prior art, so as to better illustrate the good application effect of the smearing repair material for pouring ladle walls provided by the present invention. In Table 1, A, B, C and D are 4 embodiments of the present invention, E is an existing domestic typical basic ladle gunning material, and F is an existing imported Japanese ladle gunning material.

[0026]

[0027] Silica powder%, particle size ≤ 1μm

2.0

2.0

3.0

4.0

3.0%

Al 2 o 3 : 1.8%

Na 2 O: 0.83%

Organic Fiber %

0.15

0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com