Method for preparing oxide dispersion strengthened cobalt-based super alloy

A technology of cobalt-based superalloy and dispersion strengthening, which is applied in the field of metal matrix composite materials, to achieve the effect of improving medium temperature strength and uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

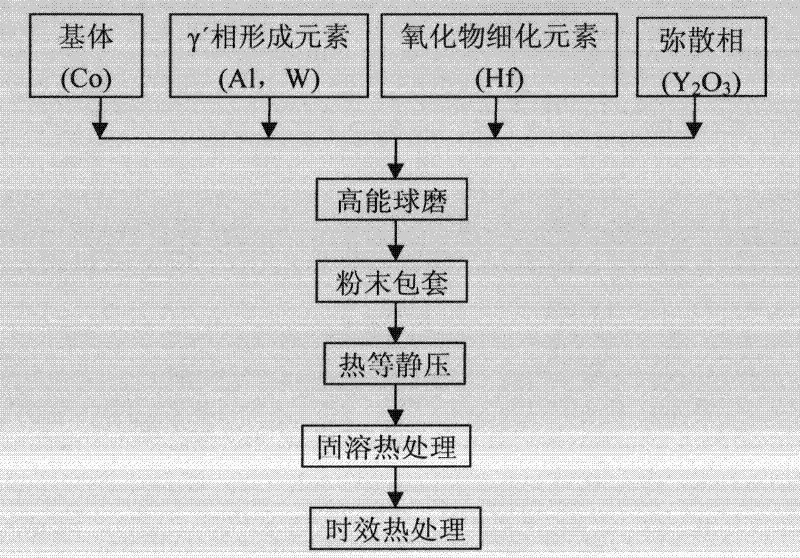

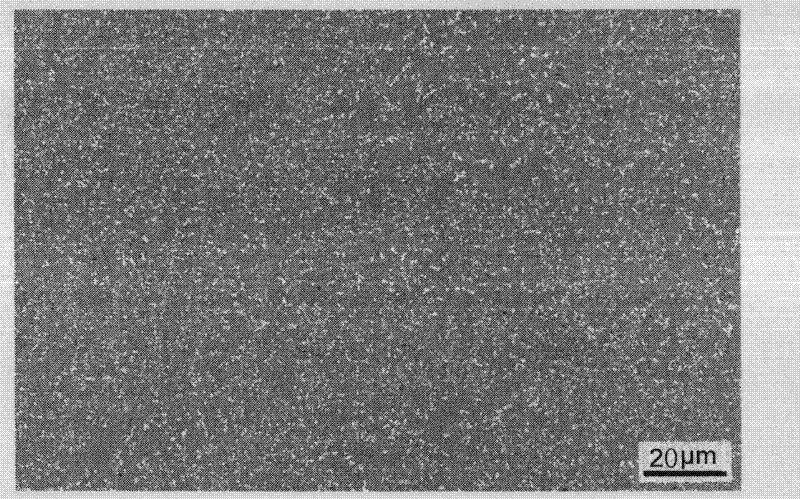

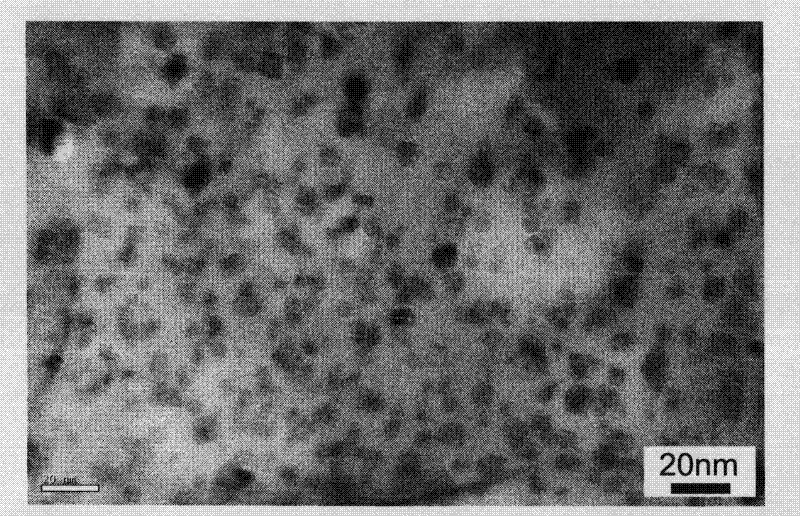

[0014] Example 1: A novel cobalt-based ODS alloy with a γ′ phase volume fraction of 37% was prepared.

[0015] Use Y with a particle size of 20-30nm 2 o 3 Powder and high-purity Co powder, Al powder, W powder as raw materials. The composition of a new cobalt-based ODS alloy is designed to be 3.7 wt% Al, 21.1 wt% W, 1 wt% Y 2 o 3 , 1.5% by weight Hf and the balance Co. Firstly, Co powder, γ′ phase forming elements (Al, W), oxide refining elements (Hf) and oxide disperse phase (Y 2 o 3 ) premixed evenly, and then Y 2 o 3 The particles are evenly dispersed in the Co matrix, the speed of the ball mill is 480 rpm, and the ball milling time is 48 hours; then the alloy powder after high-energy ball milling is covered with a low-carbon steel ladle and hot isostatically pressed at 1150 ° C for 3 hours. The samples after hot isostatic pressing are subjected to solution heat treatment (1300°C×2h) and aging heat treatment (700°C×24h) to obtain the final nanophase-reinforced compos...

Embodiment 2

[0016] Example 2: Preparation of a novel cobalt-based ODS alloy with a γ′ phase volume fraction of 45%.

[0017] Use Y with a particle size of 20-30nm 2 o 3 Powder and high-purity Co powder, Al powder, W powder as raw materials. The composition of the new cobalt-based ODS alloy is designed to be 3.6 wt% Al, 26.8 wt% W, 1 wt% Y 2 o 3 , 2% by weight Hf and the balance Co. Firstly, Co powder, γ′ phase forming elements (Al, W), oxide refining elements (Hf) and oxide disperse phase (Y2 o 3 ) premixed evenly, and then Y 2 o 3 The particles were uniformly dispersed in the Co matrix, the speed of the ball mill was 480 rpm, and the ball milling time was 60 hours; then the alloy powder after high-energy ball milling was covered with a low-carbon steel ladle and hot isostatic pressed at 1150°C for 1 hour. The samples after hot isostatic pressing are subjected to solution heat treatment (1300°C×2h) and aging heat treatment (900°C×24h) to obtain the final nanophase-reinforced compos...

Embodiment 3

[0018] Embodiment 3: Preparation Y 2 o 3 A novel cobalt-based ODS alloy with a content of 0.8% by weight.

[0019] Use Y with a particle size of 20-30nm 2 o 3 Powder and high-purity Co powder, Al powder, W powder as raw materials. The composition of the new cobalt-based ODS alloy is designed to be 3.6 wt% Al, 26.8 wt% W, 0.8 wt% Y 2 o 3 , 1.5% by weight Hf and the balance Co. Firstly, Co powder, γ′ phase forming elements (Al, W), oxide refining elements (Hf) and oxide disperse phase (Y 2 o 3 ) premixed evenly, and then Y 2 o 3 The particles were evenly dispersed in the Co matrix, the speed of the ball mill was 480 rpm, and the ball milling time was 72 hours; then the alloy powder after high-energy ball milling was covered with a low-carbon steel ladle and hot isostatically pressed at 1200°C for 2 hours. The samples after hot isostatic pressing are subjected to solution heat treatment (1300°C×2h) and aging heat treatment (900°C×24h) to obtain the final nanophase-reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com