Preparation method of large solid quartz ceramic material

A quartz ceramic, solid technology, applied in the field of preparation of large-scale solid quartz ceramic materials, can solve the problems of undiscovered large-scale solid quartz ceramic material preparation methods, affecting the performance of fused silica materials, and poor microstructure uniformity, etc., to achieve microscopic Good structural uniformity, conducive to popularization and application, scientific and reasonable preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

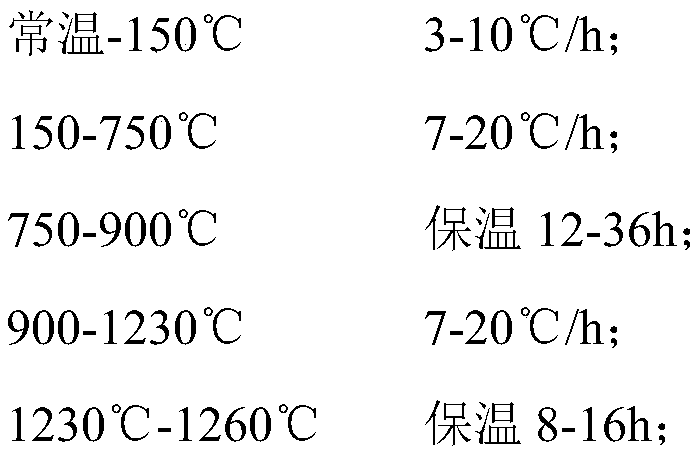

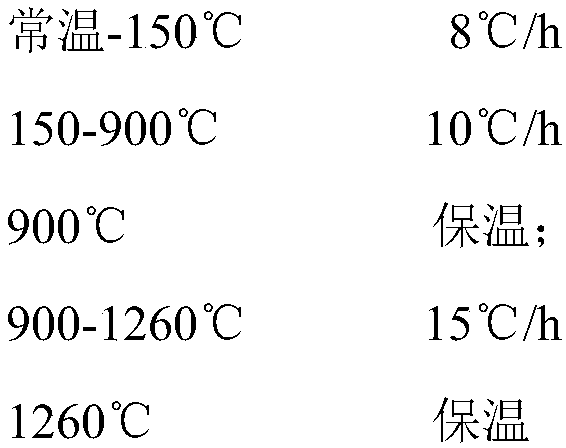

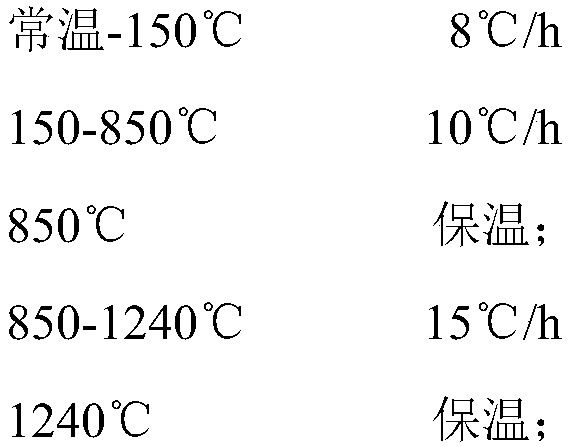

Method used

Image

Examples

Embodiment 1

[0033] 1) Preparation of mixture: quartz material adopts commercially available SiO in terms of mass percentage 2 For fused silica particles, quartz fine powder, quartz micropowder and spherical quartz micropowder with a content greater than 99.9%, weigh 35% of quartz coarse particles, 30% of quartz fine particles, and the particle size of quartz coarse particles is 1-3mm. The particle size of fine particles is 0.1-1mm, add 2% PVA solution to the mixer, stir for 15 minutes, then add 17% of quartz fine powder with a particle size greater than 0 and less than or equal to 44 μm, and quartz powder with a particle size greater than 0 and less than or equal to 5 μm 8%, 8% of spherical quartz powder greater than 0 and less than 2 μm, stirred for 15 minutes to form a mixture;

[0034] 2) The rubber mold is lined with a 3mm thick cardboard, which is tightly attached to the rubber mold, and the mixture is loaded, and after 40 minutes of vacuuming, it is isostatically pressed at 120MPa; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com