Light brick and production method thereof

A production method and technology of lightweight bricks, applied in the field of lightweight bricks, can solve problems such as unfavorable environmental protection, energy saving, waste of related materials, environmental pollution, etc., and achieve the effects of improving the firing pass rate, saving resources, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

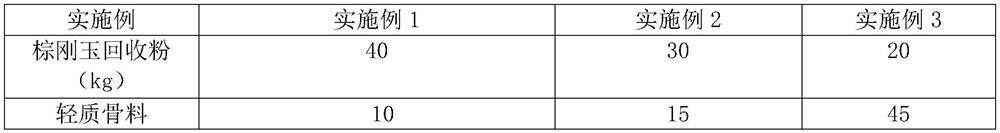

Embodiment 1

[0033] Taking embodiment 1 as an example, a kind of lightweight brick production method comprises the following steps:

[0034] A. Feeding: According to the above-mentioned raw materials, pour them into the hopper through shipment, and evenly add the materials into the pouring mixer after automatic measurement;

[0035] B. Stirring: add water to make the raw material into a slurry, fully stir evenly;

[0036] C. Pouring: pour the stirred slurry into the prepared mold in turn;

[0037] D. Demoulding: After a period of time, after the green body solidifies and reaches the cutting strength, demoulding is carried out;

[0038] E. Cutting: The green body after demoulding is sent to the cutting equipment line for vertical cutting and cross cutting, and made into corresponding product specifications;

[0039] F. Stacking: The cut products are transported to the finished product stacking area and placed neatly one by one;

[0040] G. Sintering: Put the neatly arranged products into...

Embodiment 4

[0049] In step C, during the process of pouring the slurry into the mold cavity of the mold, sometimes the material will be spilled outside the mold cavity, at this time, it is necessary to manually sweep the spilled material on the mold into the mold cavity , the operation is troublesome. Therefore, this embodiment discloses a mold. By improving the structure of the mold, the material spilled outside the mold cavity can be automatically swept into the mold cavity.

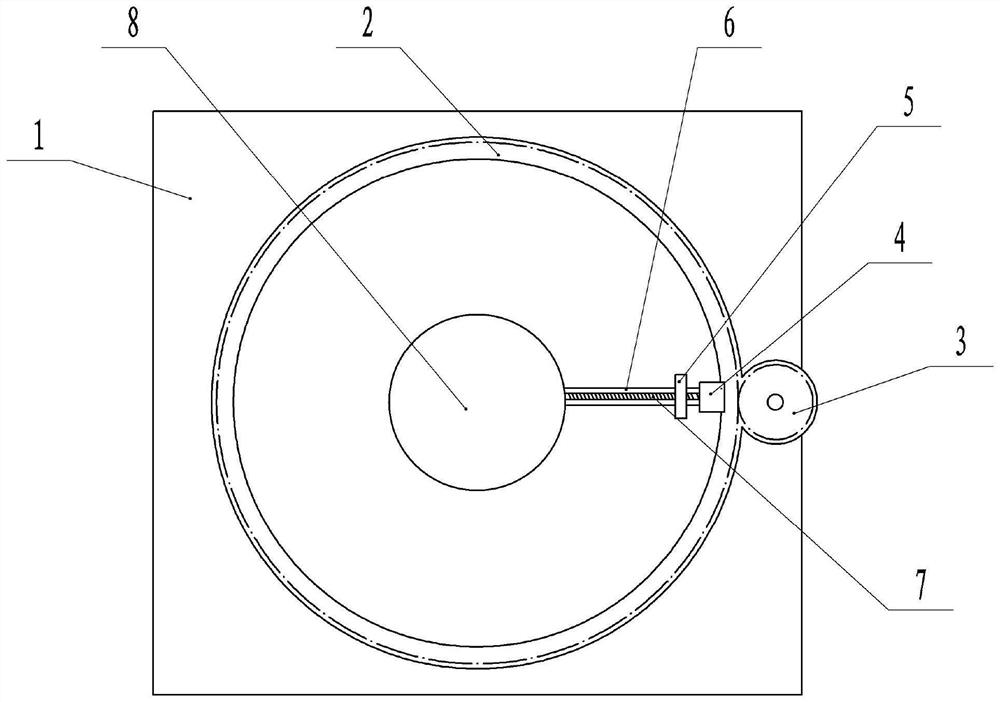

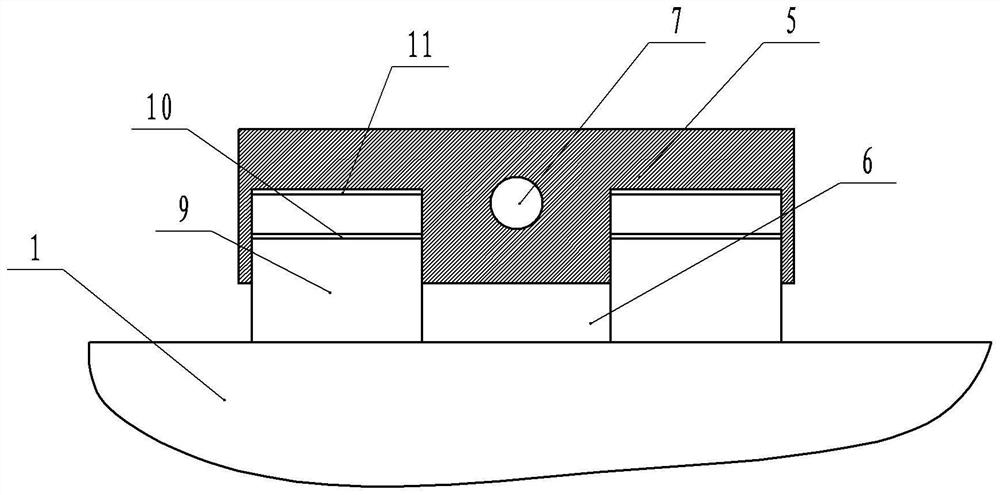

[0050] Basic as attached Figure 1-Figure 2 As shown, a mold includes a plate body 1, a mold cavity 8 is provided on the top of the plate body 1, and a ring gear 2 is rotatably connected to the top of the plate body 1. The ring gear 2 is an external gear ring, and the mold cavity 8 is located At the central part of the ring 2, the rotation mode of the ring gear 2 is as follows: the top of the plate body 1 is provided with an annular groove, and the ring gear 2 is slidably installed in the annular groove. A motor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com