Patents

Literature

106results about How to "Fully sintered" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

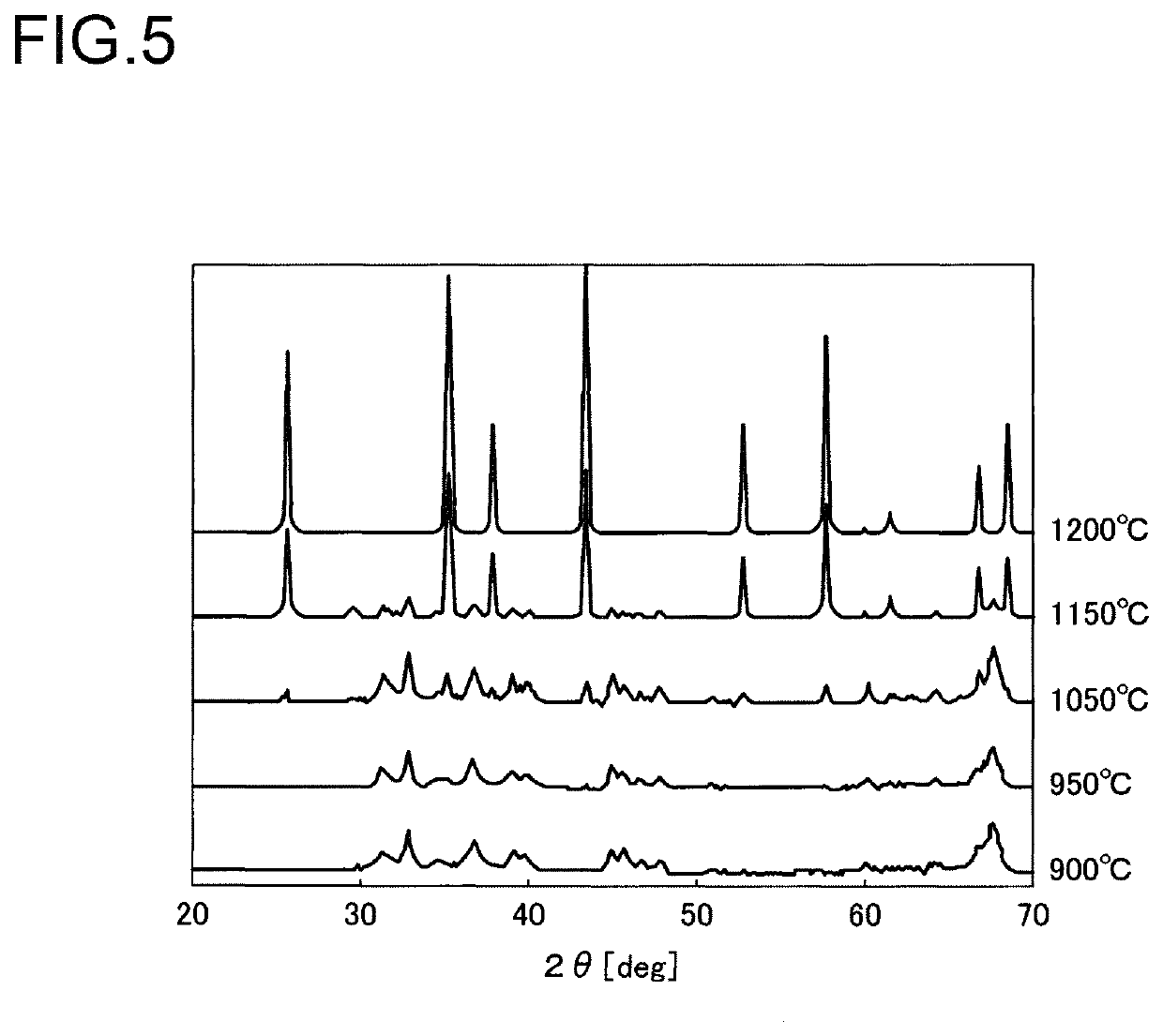

Method of manufacturing transition metal oxide having spinel structure

ActiveUS20100193104A1Fully sinteredHigh strengthFuel cells groupingFinal product manufactureOxideMetal

A novel method of manufacturing a transition metal oxide having a spinel structure is provided. A mixture of powdery metals of metal elements constituting the transition metal oxide is heated in an oxidizing atmosphere to generate the transition metal oxide.

Owner:NGK INSULATORS LTD

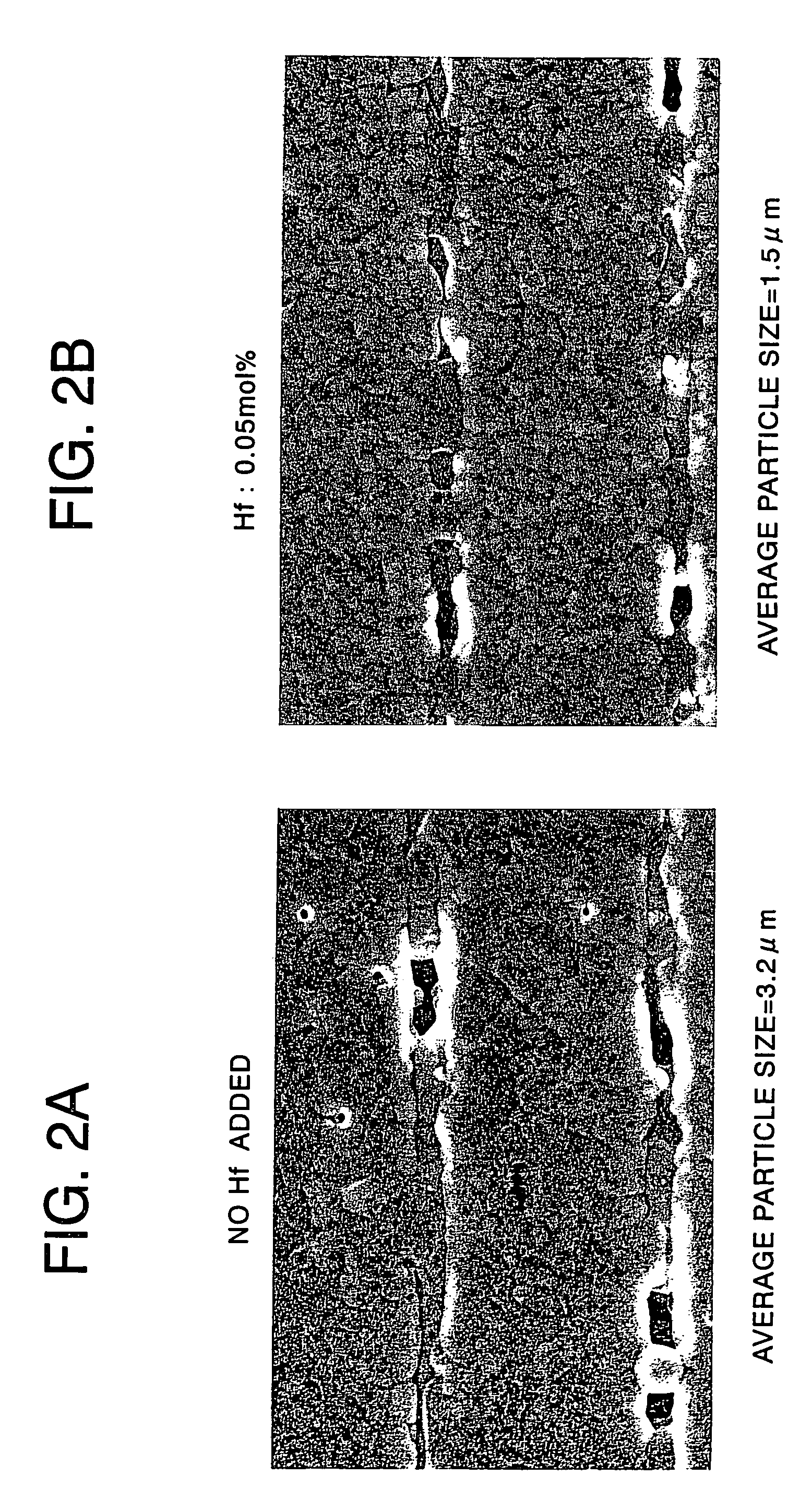

Dielectric ceramic composition, electronic device and production methods of the same

ActiveUS7312172B2Improve reliabilityReduced frequency dependenceFixed capacitor dielectricStacked capacitorsMn oxideMole ratio

A dielectric ceramic composition, comprising a main component including at least a dielectric oxide having a composition expressed by [(CaxSr1-x)O]m[(TiyZr1-y-zHfz)O2], a first subcomponent including a Mn oxide and / or an Al oxide and a glass component, wherein “m”, “x”, “y” and “z” indicating composition mole ratios in the formula included in the main component are in relationships of 0.90≦m≦1.04, preferably 1.005≦m≦1.025, 0.5≦x<1, preferably 0.6≦x≦0.9, 0.01≦y≦0.10, preferably 0.02≦y≦0.07 and 0<z≦0.20, preferably 0<z≦0.10.

Owner:TDK CORPARATION

Dielectric ceramic composition and electronic device

ActiveUS8853115B2Low dielectric constantImprove featuresFixed capacitor dielectricStacked capacitorsBronzeMaterials science

Owner:TDK CORPARATION

Microwave dielectric procelain composition and dielectric resonator

InactiveCN1476616ASufficient dielectric propertiesRaise the absolute valueCeramicsResonatorsMicrowaveDielectric resonator

The present invention relates to a microwave dielectric ceramic composition exhibiting excellent dielectric characteristics, including high Qu; and to a dielectric resonator which exhibits high Qu even when of large size. The present invention provides a microwave dielectric ceramic composition containing a primary component represented by CaTiO3-(1-x)REAlO3 (0.54 <= x <= 0.82) (wherein RE is composed only of an essential element La or composed of an essential element La and one or two optional elements selected from among Nd and Sm). The present invention also provides a microwave dielectric ceramic composition containing a primary component represented by the compositional formula: xCaTiO3-(1-x)LnAlO3 (0.54 <= x <= 0.82) (wherein Ln is at least one species selected from among Y, La, Nd, Sm, etc.); and Na in an amount as reduced to Na2O of 0.02 to 0.5 parts by mass on the basis of 100 parts by mass of the primary component. The present invention also provides a dielectric resonator produced from the aforementioned microwave dielectric ceramic composition.

Owner:MARUWA

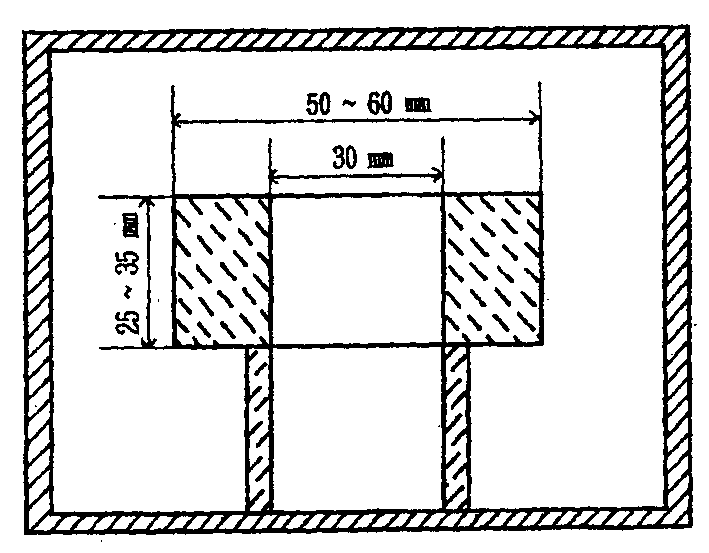

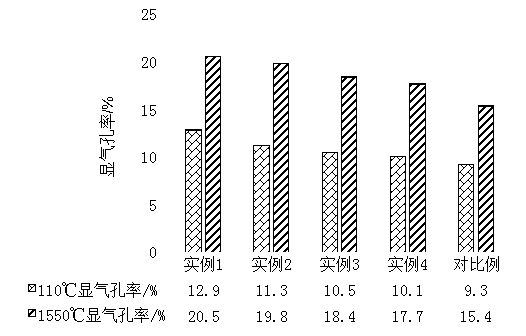

Silver clay and method for producing silver products using the silver clay

The invention discloses a sliver clay which is composed of sliver powder, bismuth powder, an adhesive, grease and water, wherein, the content of each component calculated based on weight is as follows: 70-80% of the sliver powder, 0.3-1.2% of the bismuth powder, 5-8% of the adhesive, 1-2% of the grease, and the rest of water; the sliver powder is composed of 30-40% of micro sliver powder with the average grain diameter less than or equal to 0.5Mum and the rest of micro sliver powder with the average grain diameter of 1-3Mum by weight. The sliver clay of the invention has a lower sintering temperature, and can be fully sintered at the temperature of 450-500 DEG C. The invention further discloses a method for preparing silverware with the sliver clay.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

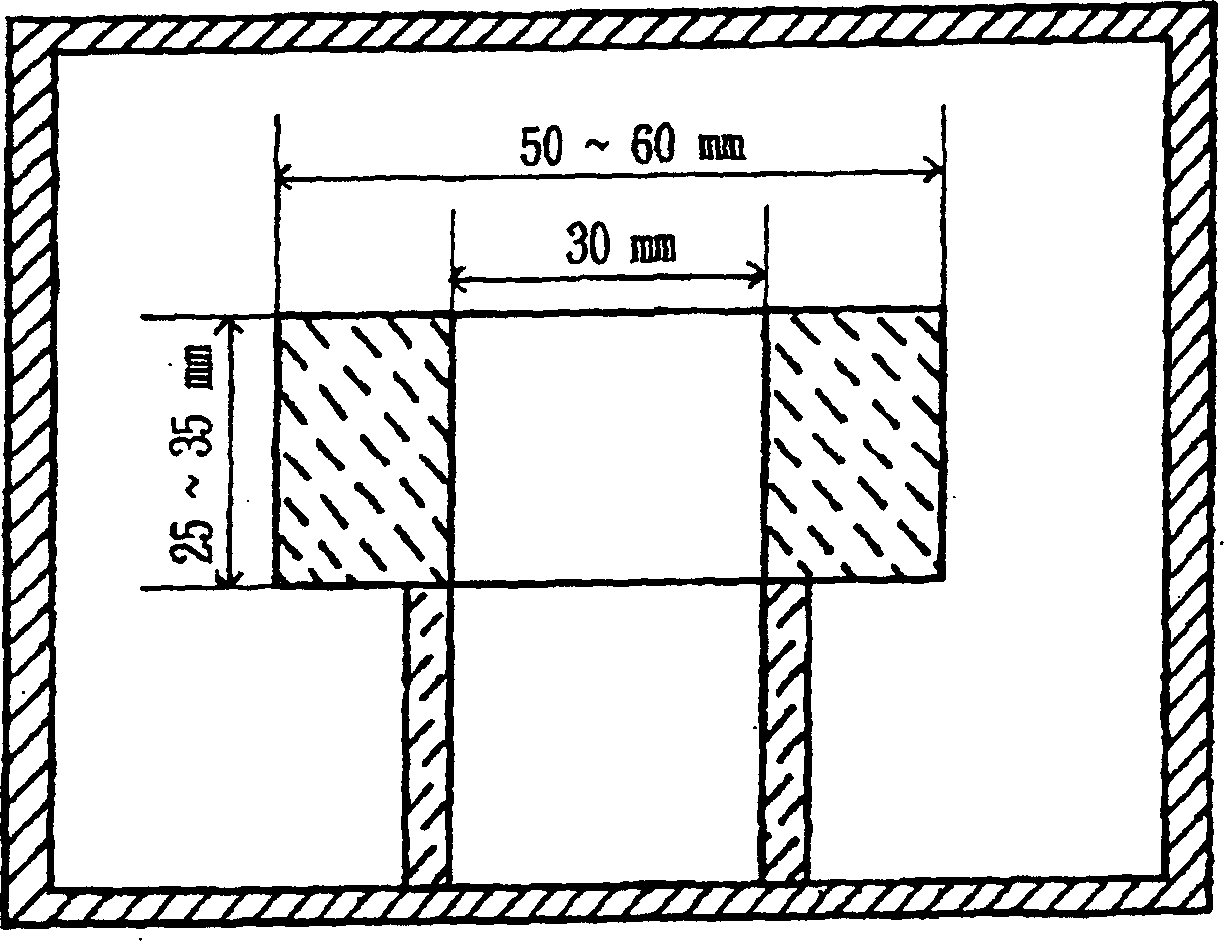

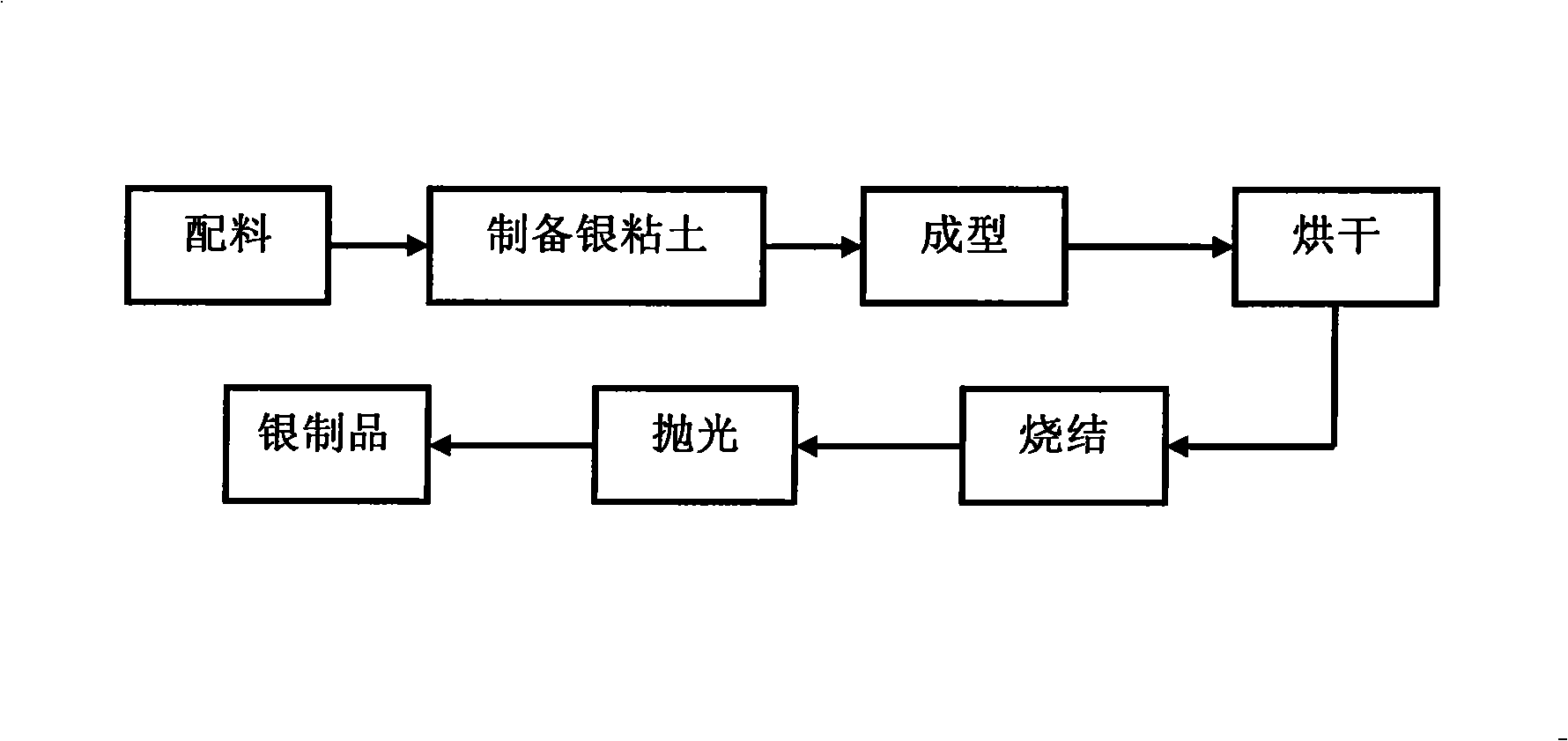

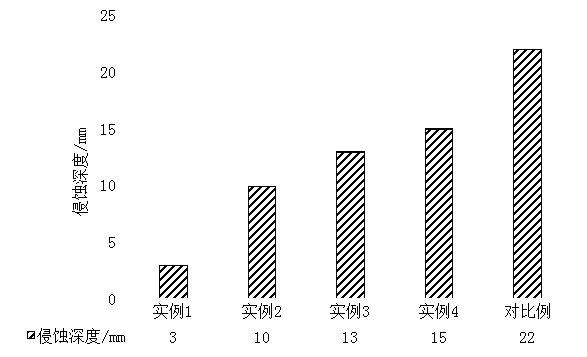

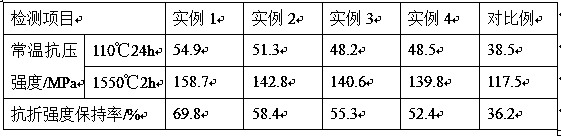

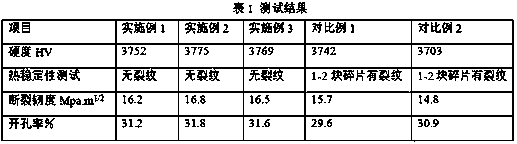

Preparation method of dispersion type gas permeable brick for ladle

The invention discloses a preparation method of a dispersion type gas permeable brick for ladle, and belongs to the technical field of refractory materials. The preparation method comprises the following steps: mixing a corundum mixture with zirconia powder, adding an additive, a dispersant, and water, stirring and mixing to obtain a mixture; transferring the mixture to a mould, carrying out vibration moulding to obtain a blank; curing the blank at a constant temperature in the absence of light, removing the mould, burning the blank in a calcining furnace, cooling the blank to a room temperature, transferring the blank to a sintering furnace, sintering the blank under the protection of argon, cooling to a room temperature, performing discharging to obtain a primarily sintered gas permeablebrick; processing the primarily sintered gas permeable brick by a processing liquid, delivering the primarily sintered gas permeable brick to a sintering furnace, carrying out low temperature carbonization under the protection of nitrogen, then performing high temperature sintering to obtain secondarily sintered gas permeable brick; mixing the secondarily sintered gas permeable brick with water,introducing carbon dioxide into water, soaking, filtering, and drying to obtain the dispersion type gas permeable brick for ladle. The prepared gas permeable brick has an excellent performance on resisting slag corrosion and thermal shock, and the breathability and mechanical properties are also very good.

Owner:常州富思通管道有限公司

Method of preparing high-temperature nickel-based alloy porous material by 3DP (three-dimensional printing) and aftertreatment process

ActiveCN109807320AMeet the needs of different purposesLow costAdditive manufacturing apparatusPore distributionPolyvinyl alcohol

The invention discloses a method of preparing a high-temperature nickel-based alloy porous material by 3DP (three-dimensional printing) and an aftertreatment process. The method comprises the following steps of: step A. mixing powder, to be specific, fully mixing a certain proportion of metal powder such as Ni, Cr, and Fe with polyvinyl alcohol powder; step B. carrying out macroscopic direct pore-forming, to be specific, designing a three-dimensional model being of a porous structure by three-dimensional design software according to the appearance feature, porosity, pore distribution law and pore shape and size design requirements of the porous material; step C. preparing the porous material by 3DP, to be specific, 3DP equipment receives a printing program, and sets printing parameters tostart printing; step D. removing residual powder, to be specific, firstly taking out a rough blank from a powder stack, and then removing the residual powder on the rough blank; step E. debonding andatmosphere sintering treatment, to be specific, sending the rough blank to a muffle surface for debonding and atmosphere sintering; step F. carrying out electrochemical corrosion, to be specific, carrying out electrochemical corrosion treatment on the sintered nickel-based porous material; step G. carrying out cryogenic treatment, to be specific, putting a workpiece in a cryogenic device for cryogenic treatment; and step H. completing the preparation and aftertreatment of the high-temperature nickel-based alloy porous material.

Owner:NANTONG INST OF TECH

Anti-sticking sand casting coating and preparation method thereof

InactiveCN108787996AHigh densityReduce voidsFoundry mouldsFoundry coresMulliteVolumetric Mass Density

The invention relates to an anti-sticking sand casting coating and a preparation method thereof, and belongs to the technical field of casting. According to the anti-sticking sand casting coating andthe preparation method thereof, a refractory aggregate is selected, an irreversible phase change is generated at a relatively low temperature and large expansion is generated, so that the surface of powder particles in a coating layer sintering shell is sintered more sufficiently, and the particles are in general adhesion due to surface fusion; the coating layer is in a glassy state, the gap of the coating layer is less, the density is higher, the shielding effects of element migration and diffusion are stronger, high-viscosity square quartz generated during high-temperature transformation canresist permeation of metal liquid, and the defect of mechanical sand sticking of castings can be prevented; and the line shrinkage coefficient differences between the glass state coating layer and the casting metal are also large after cooling, the cutting stress of the interface between the casting and the coating layer is increased, so that the coating layer and the casting are peeled off automatically, so that a casting with a smooth surface is obtained; and the thermal chemical stability of a generated mullite phase is high, the generated mullite phase is not easy to react with acid and alkaline oxides, and the prevention of the chemical sand sticking defects of castings is facilitated.

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

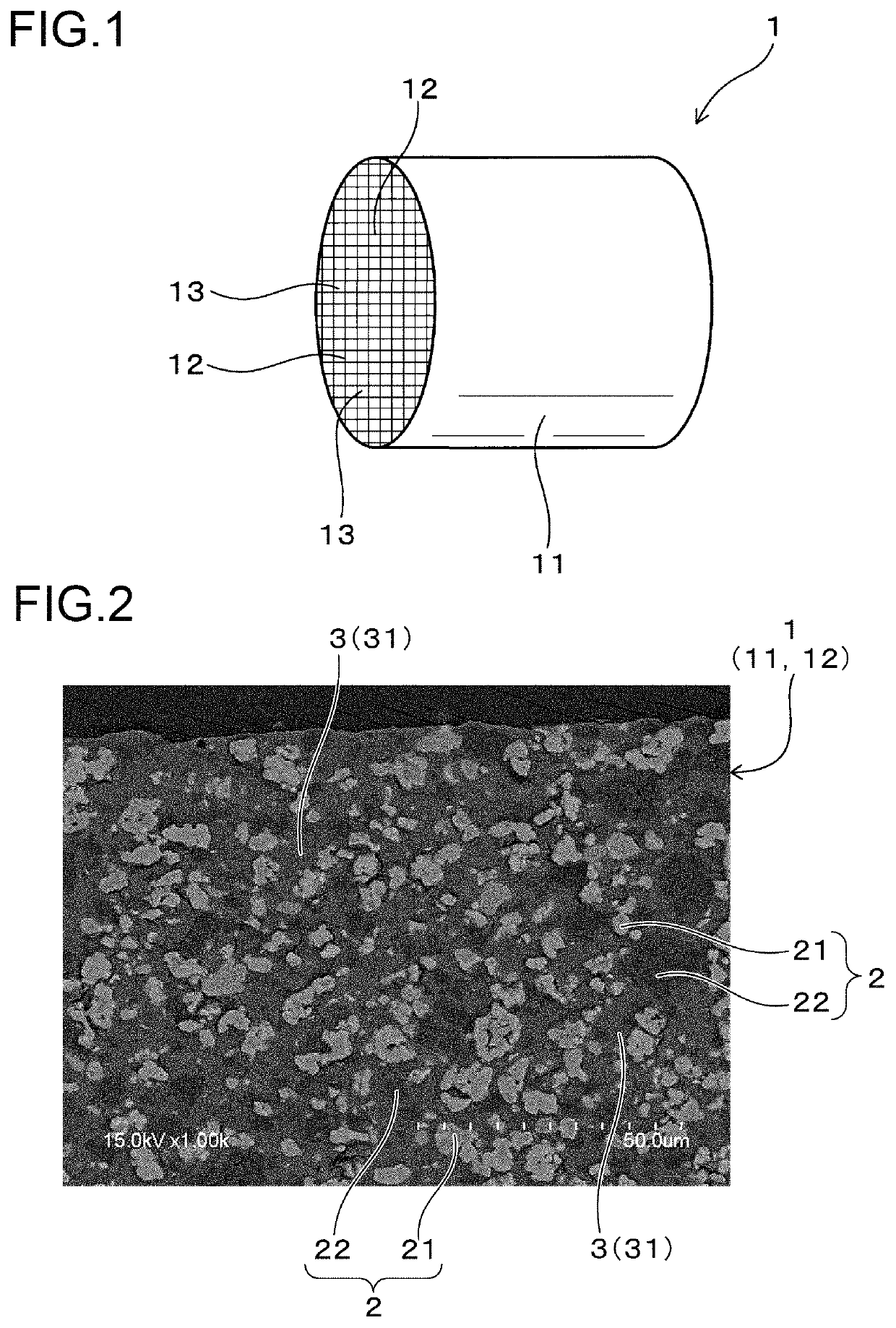

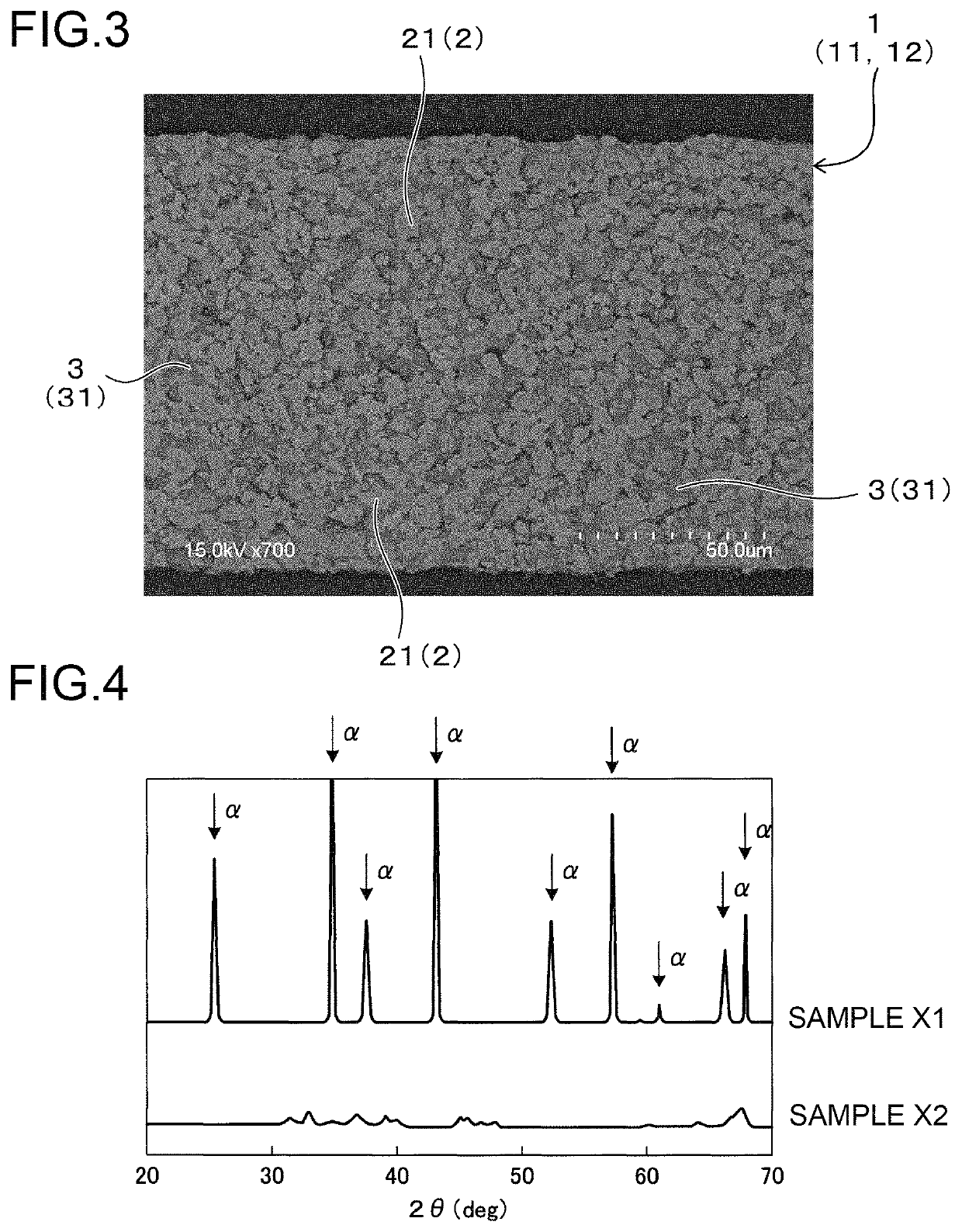

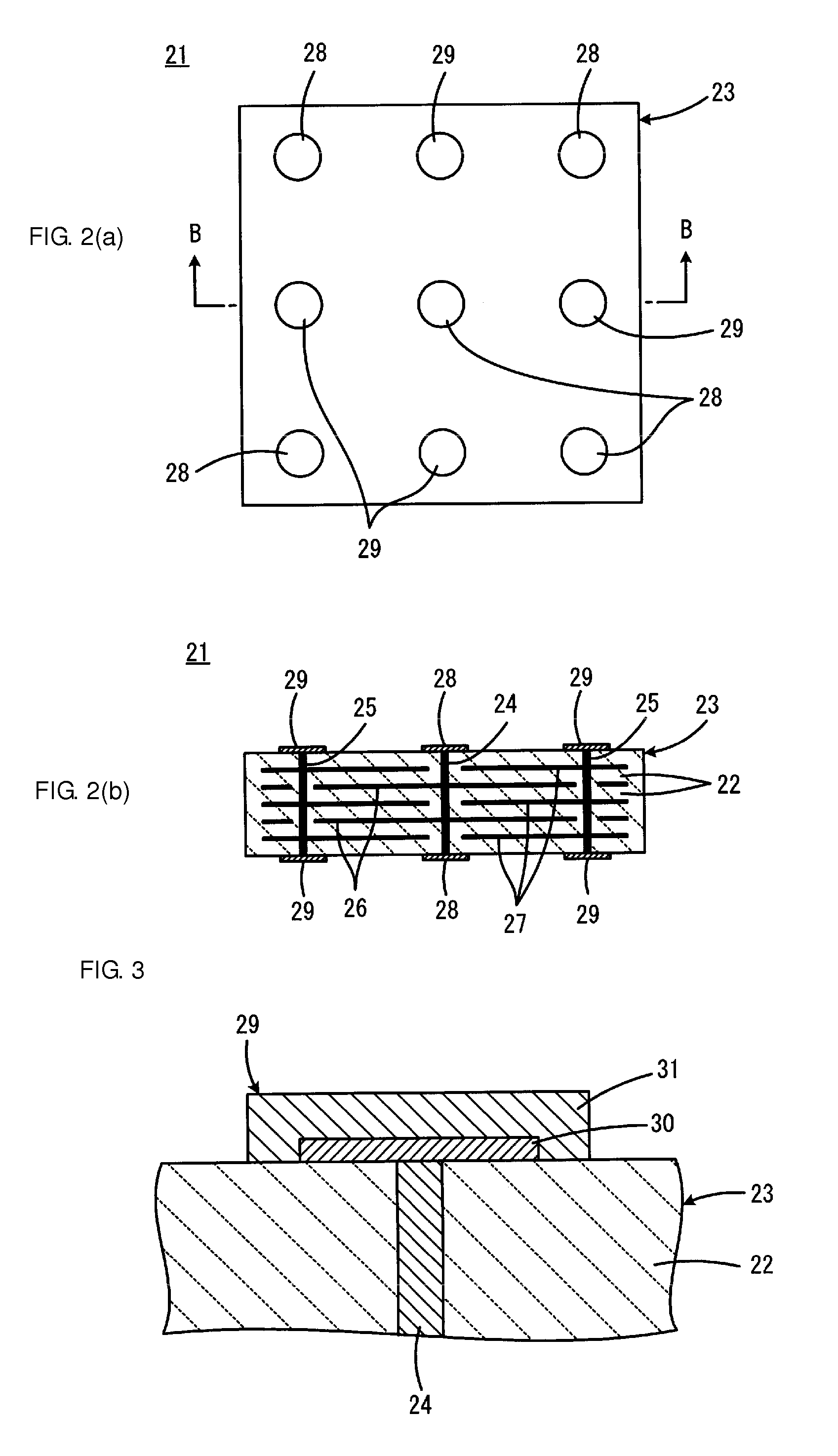

Honeycomb structure and method for manufacturing the same

ActiveUS10507457B2High strengthFully sinteredDispersed particle separationCatalyst activation/preparationSolid solutionHoneycomb like

The present invention relates to a honeycomb structure having promoter particles and a binder phase interposed between the promoter particles, and a method for manufacturing the same. The promoter particles contain at least first promoter particles made of a ceria-zirconia solid solution. The binder phase, in each of which a number of inorganic binder particles are aggregated with each other, with α-alumina being a main component, contain one or two of Fe and Cr dissolved in α-alumina. The honeycomb structure has a specific surface area at a ratio of 90% or more of after heating to before heating at a temperature of 1200° C.

Owner:DENSO CORP

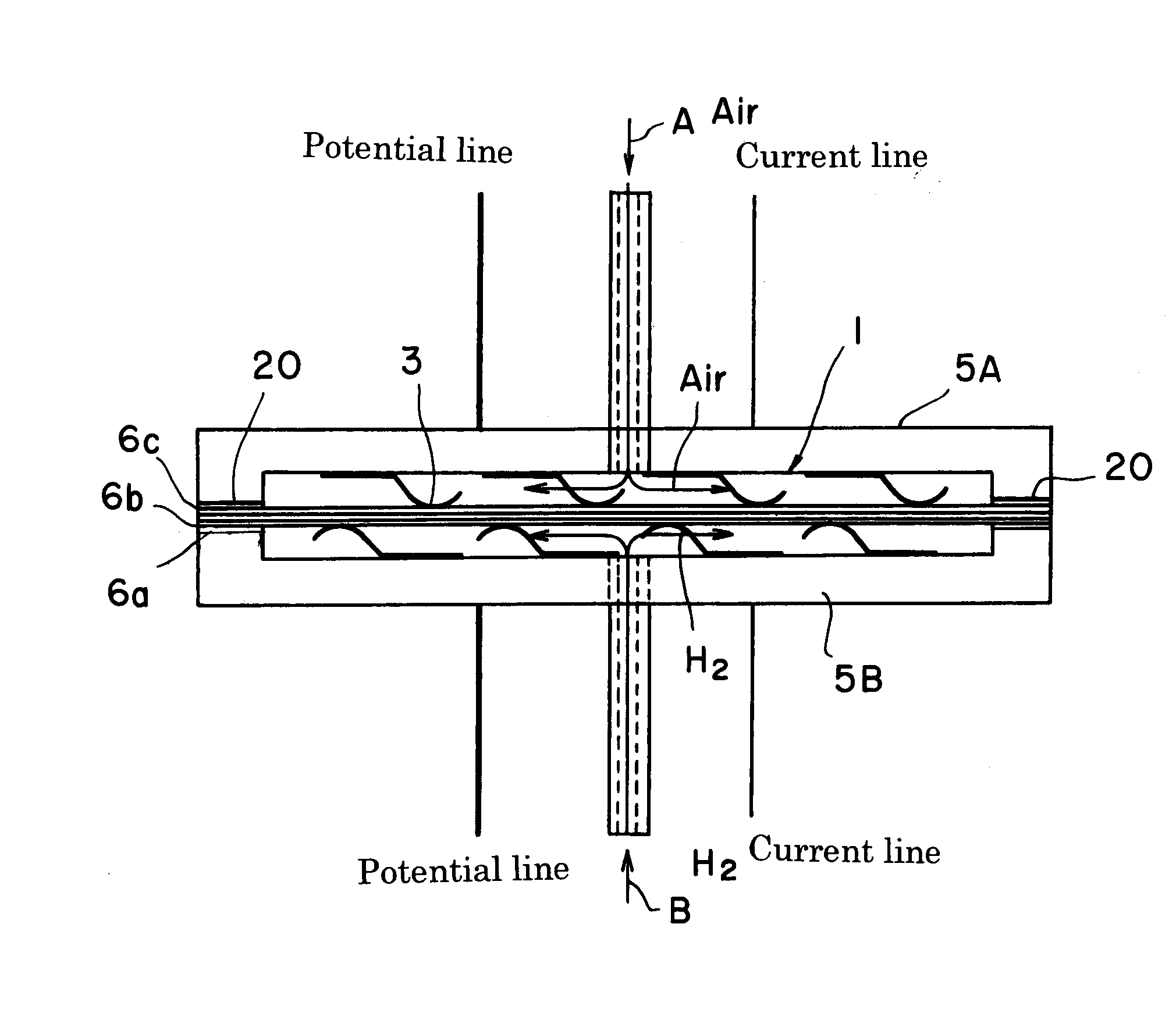

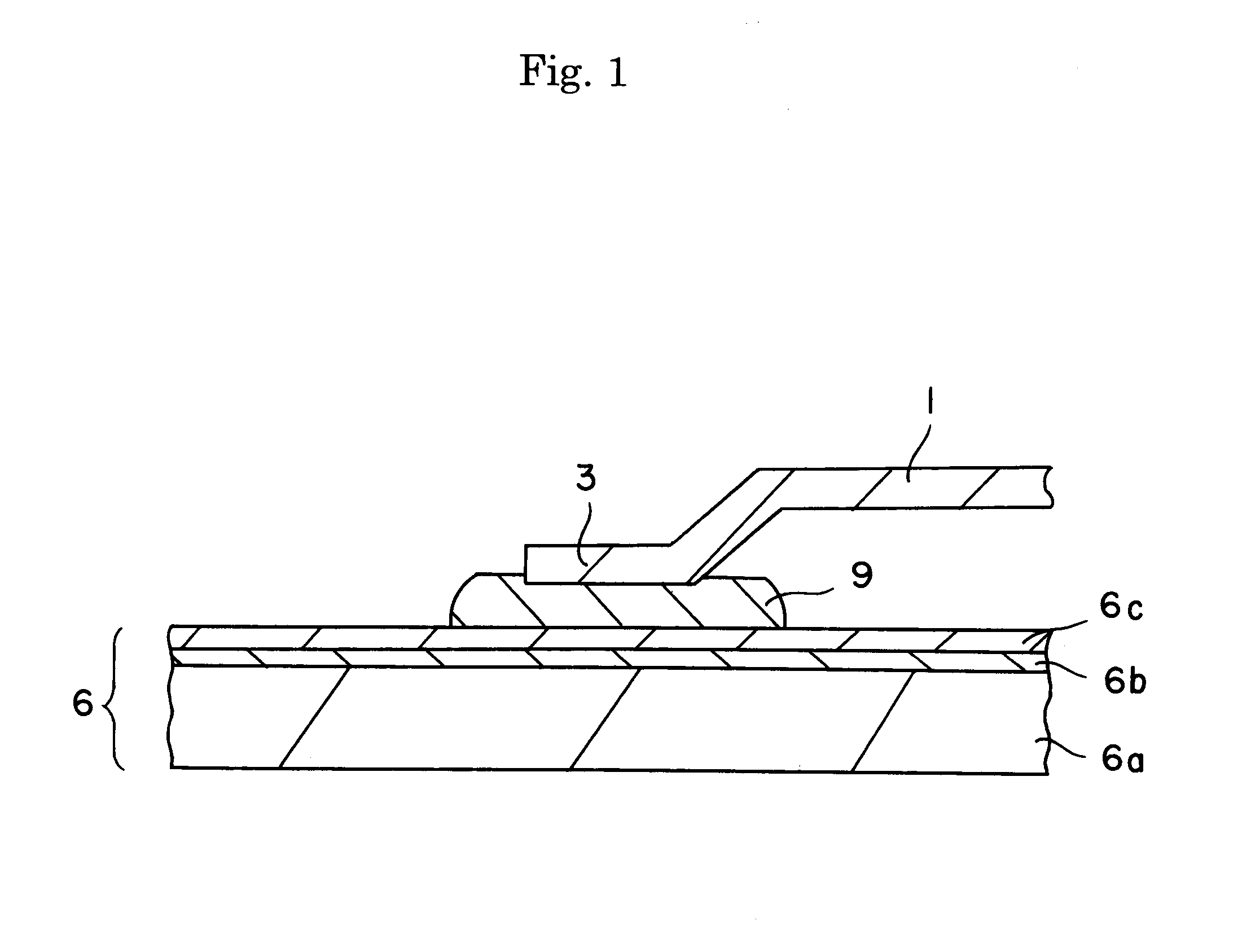

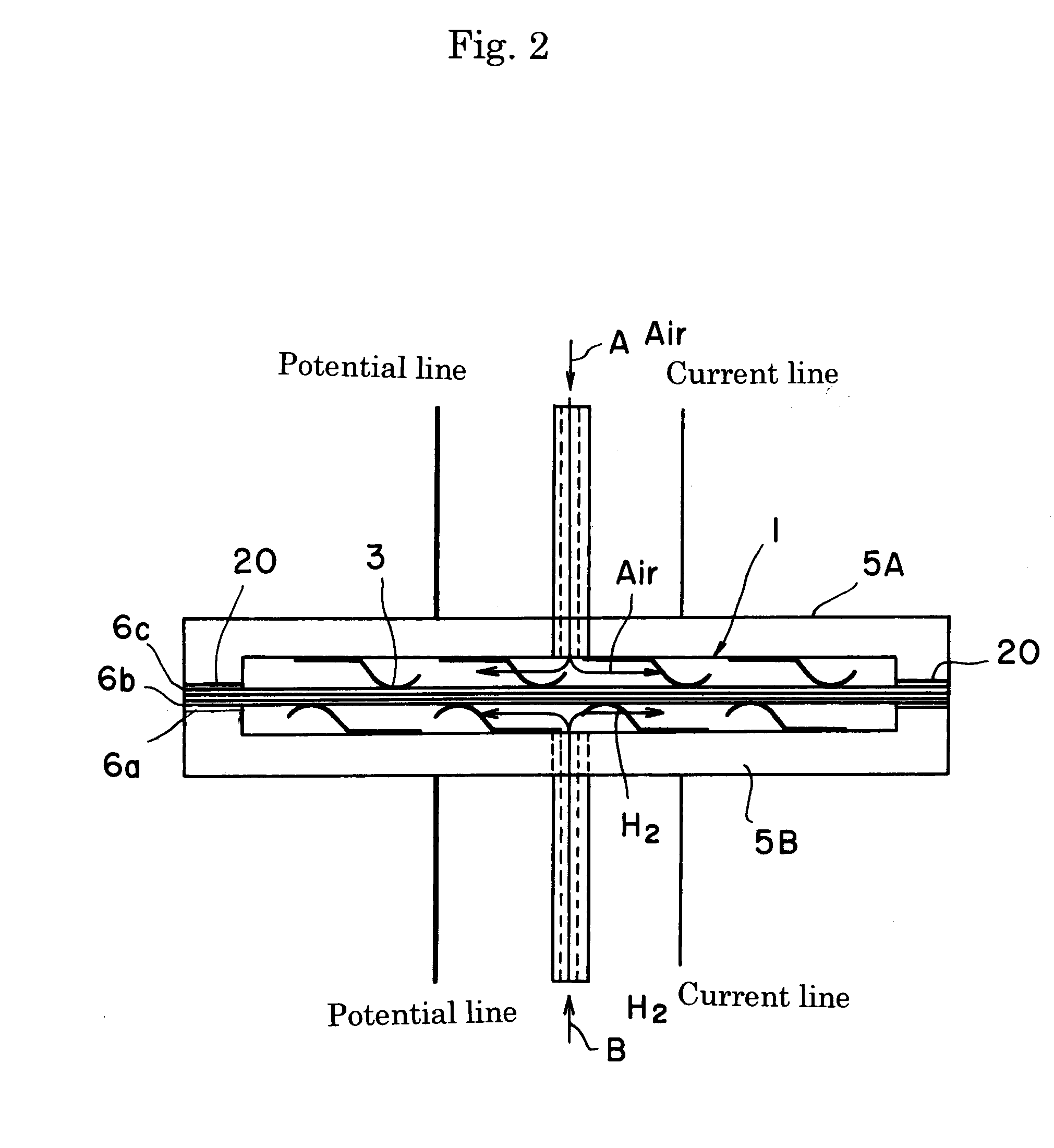

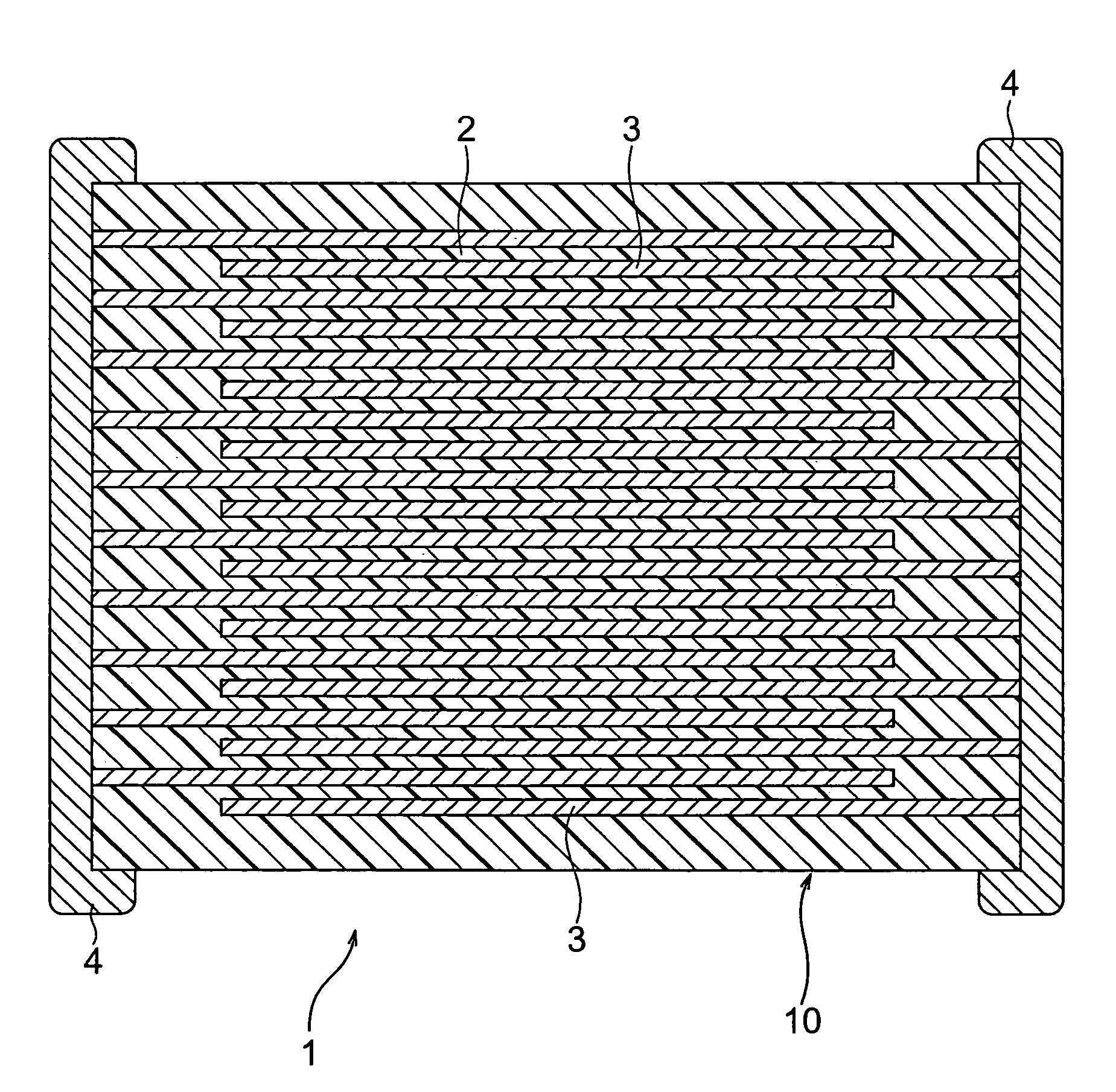

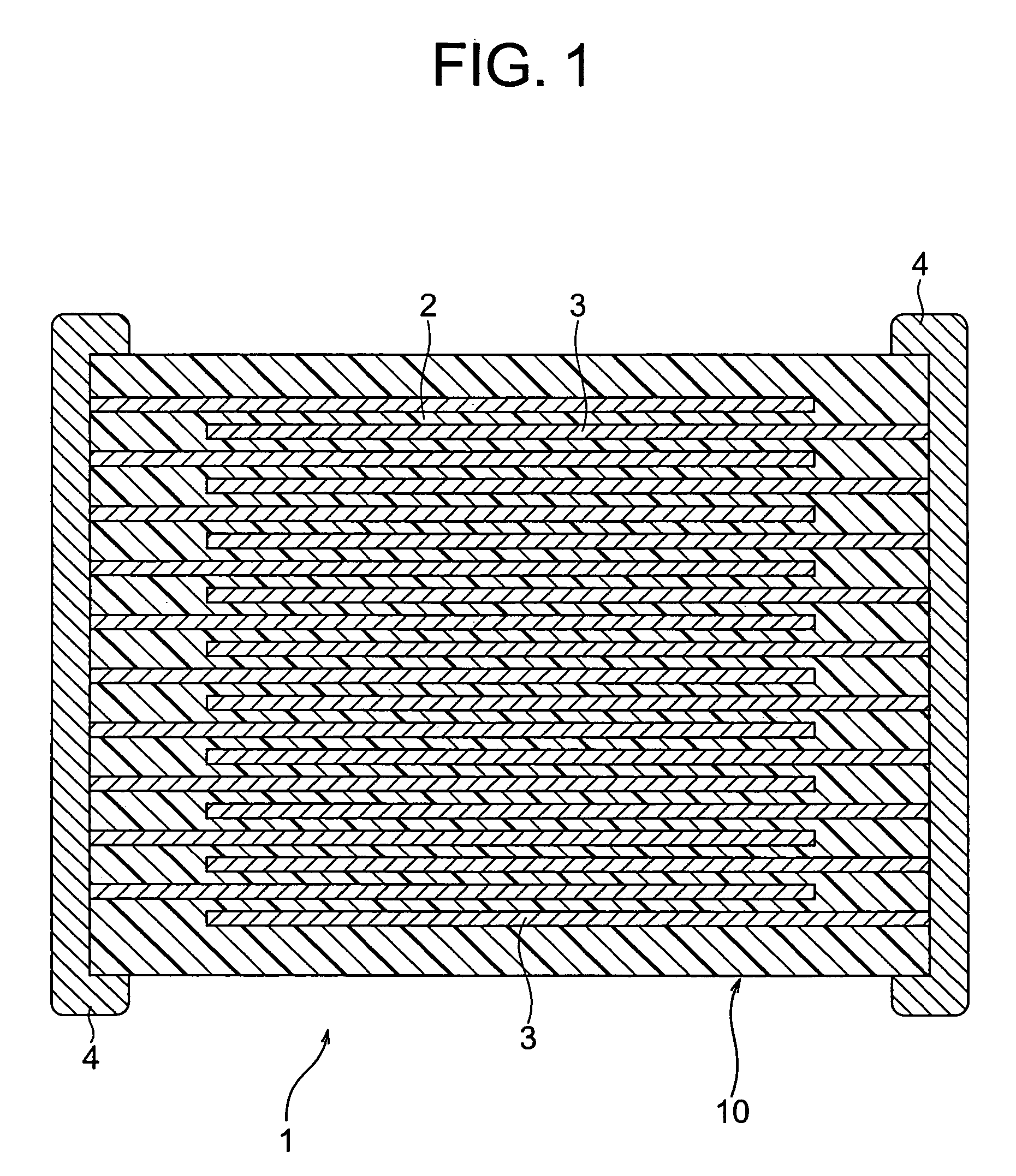

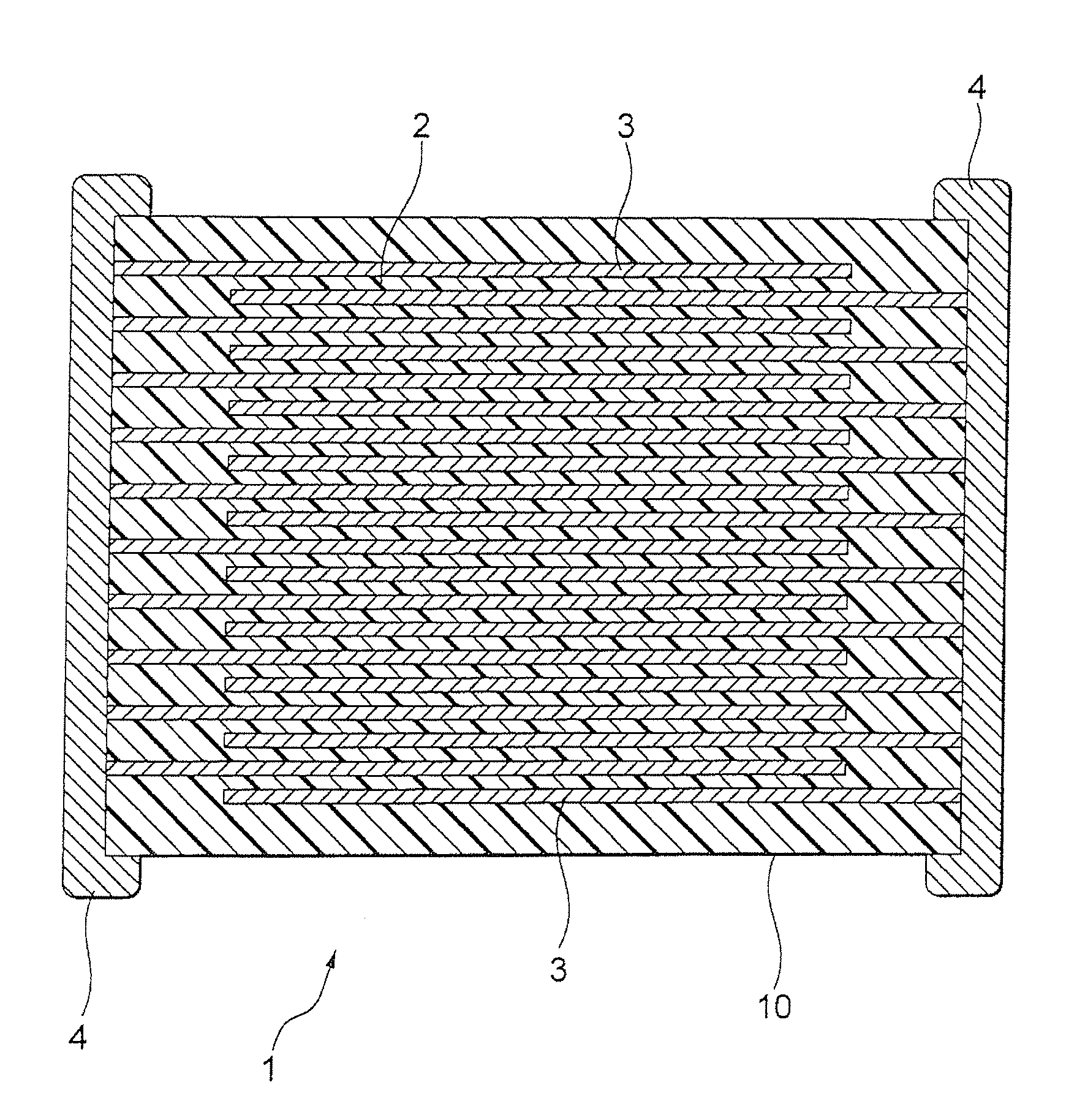

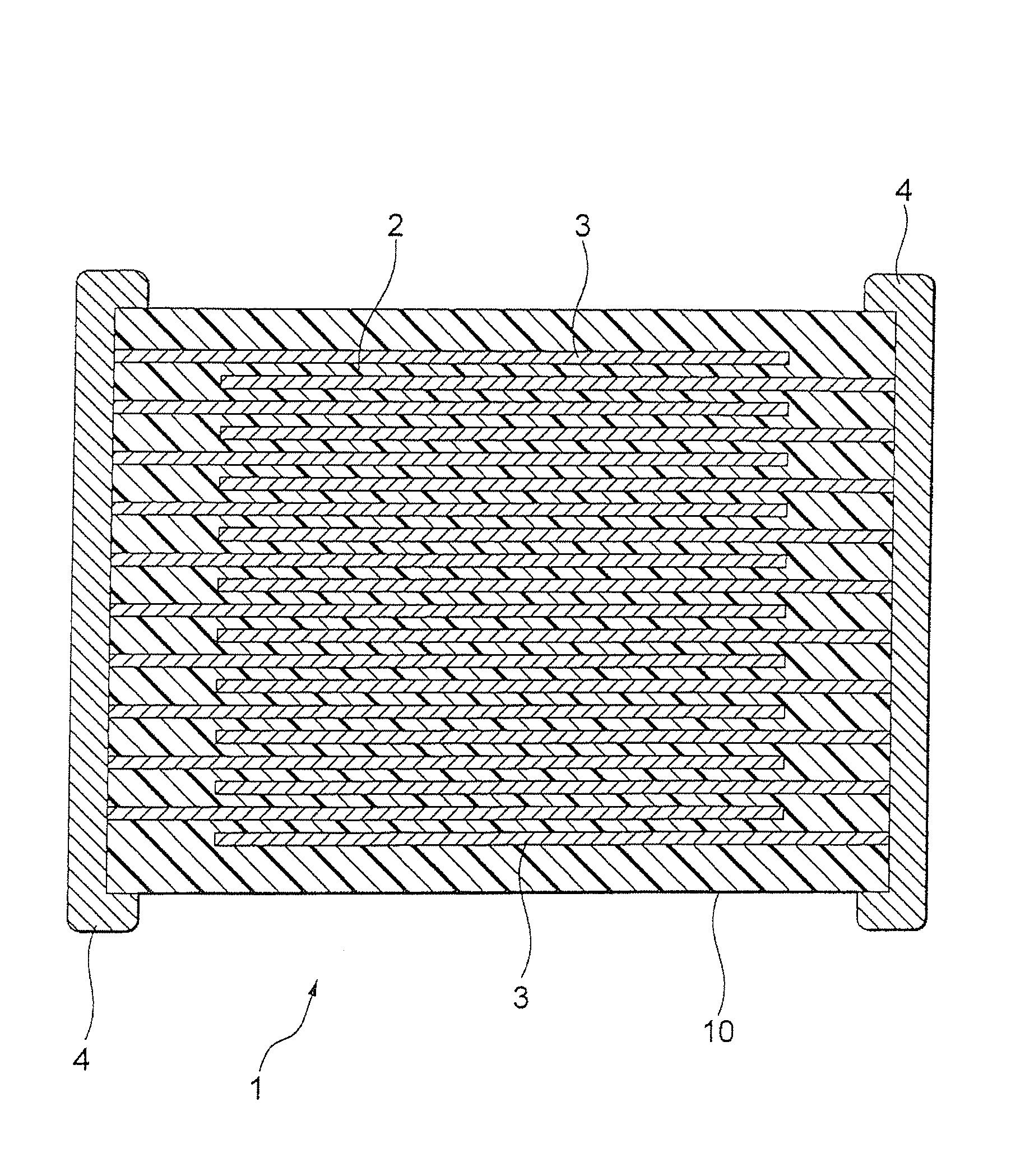

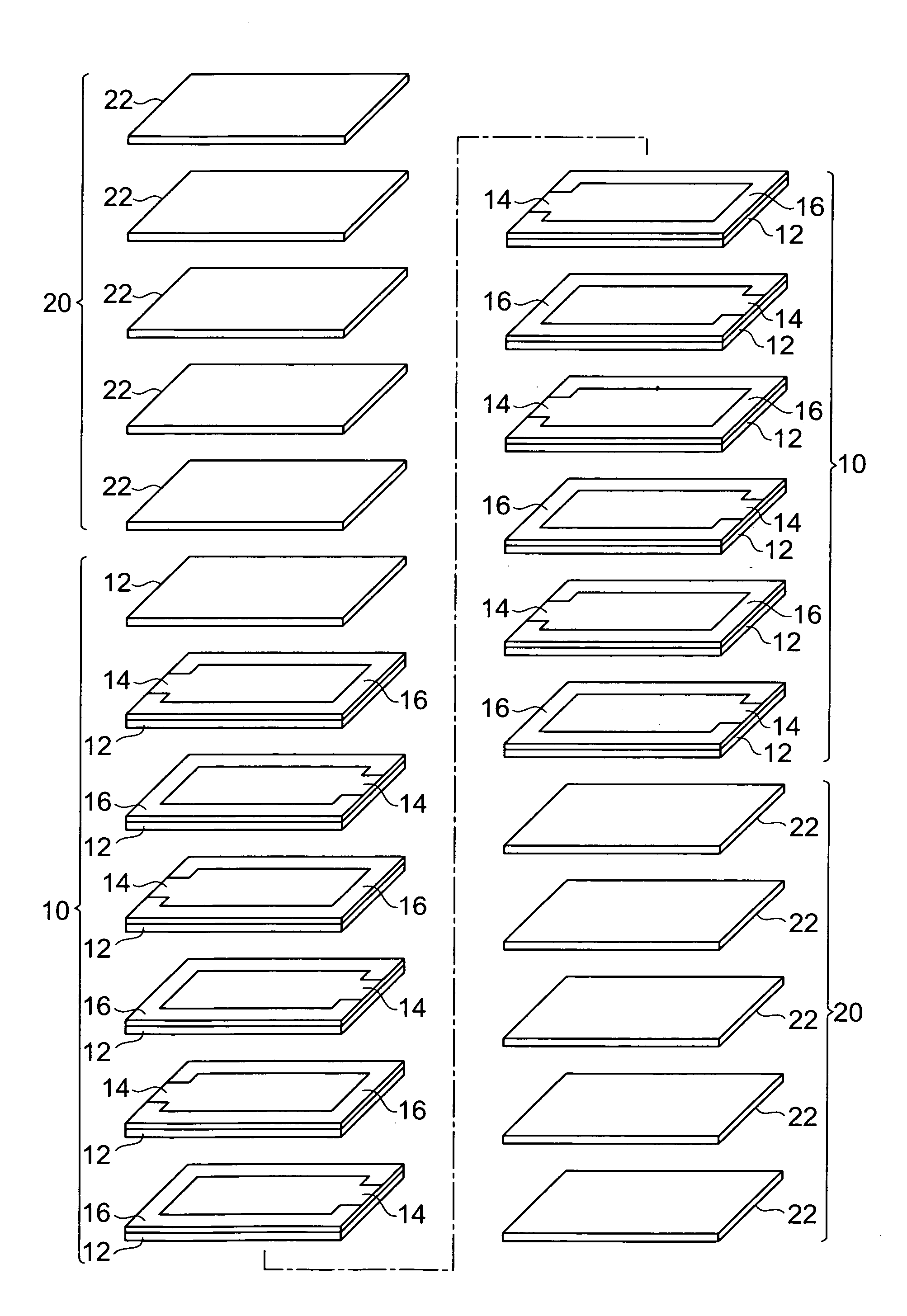

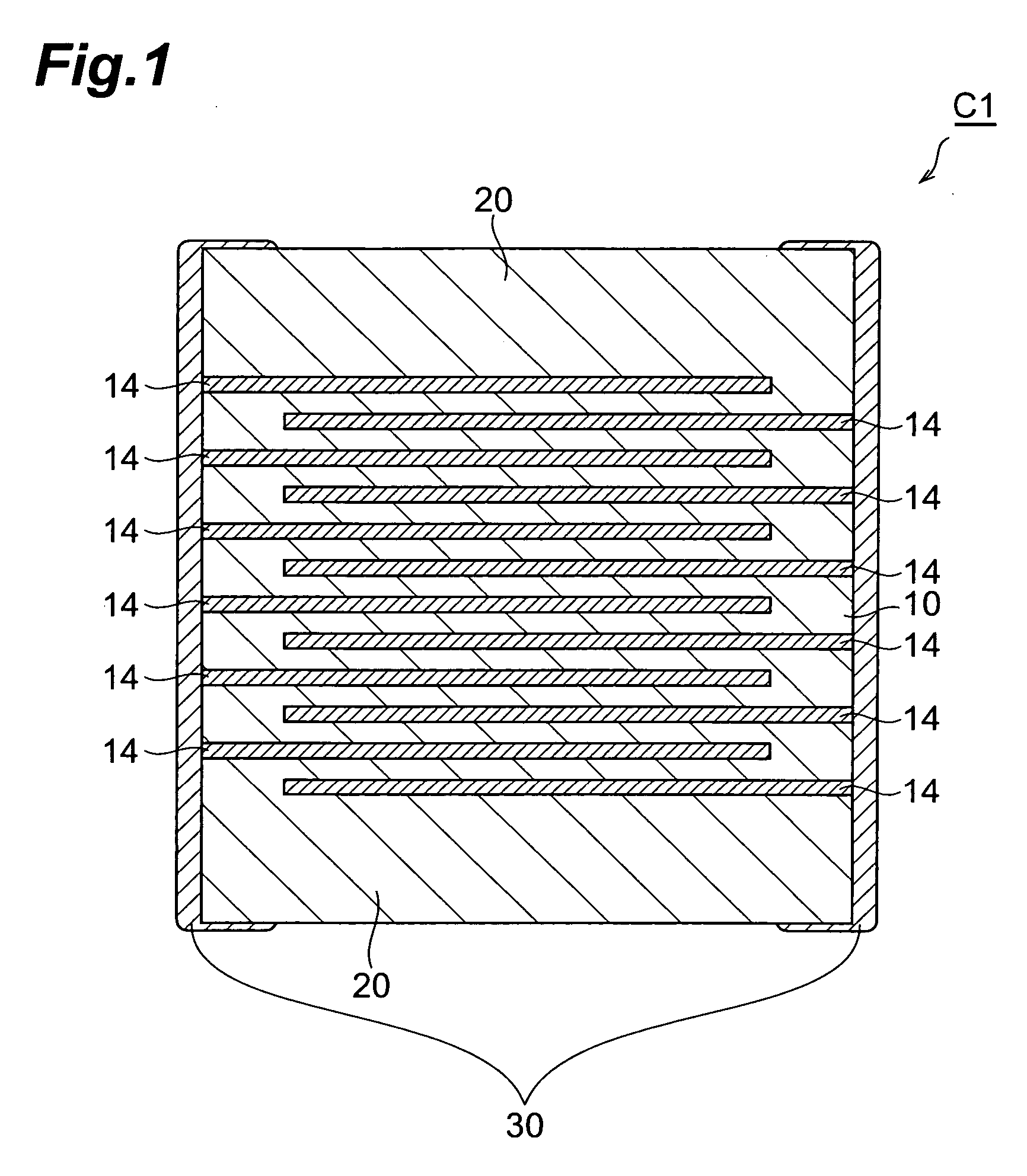

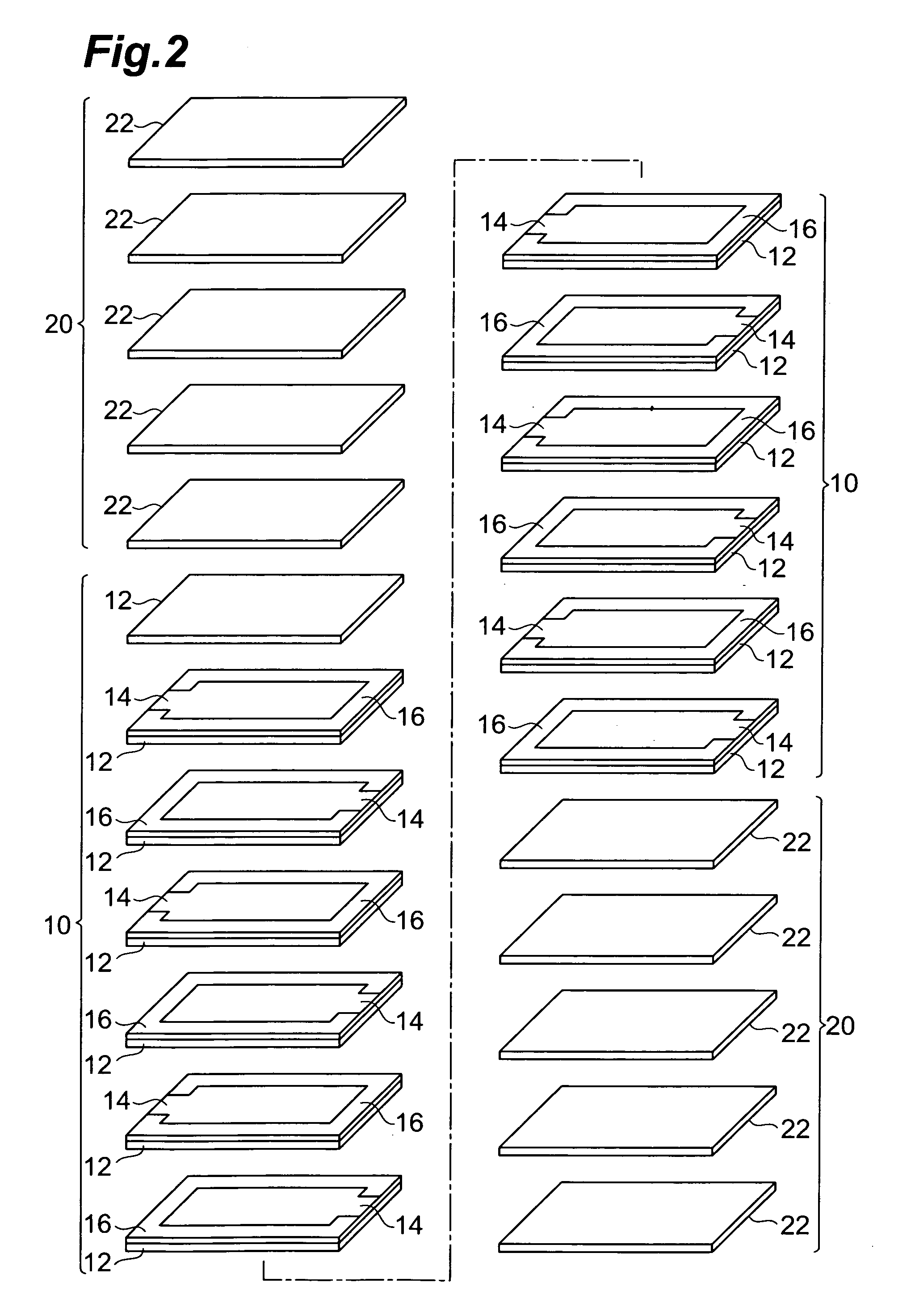

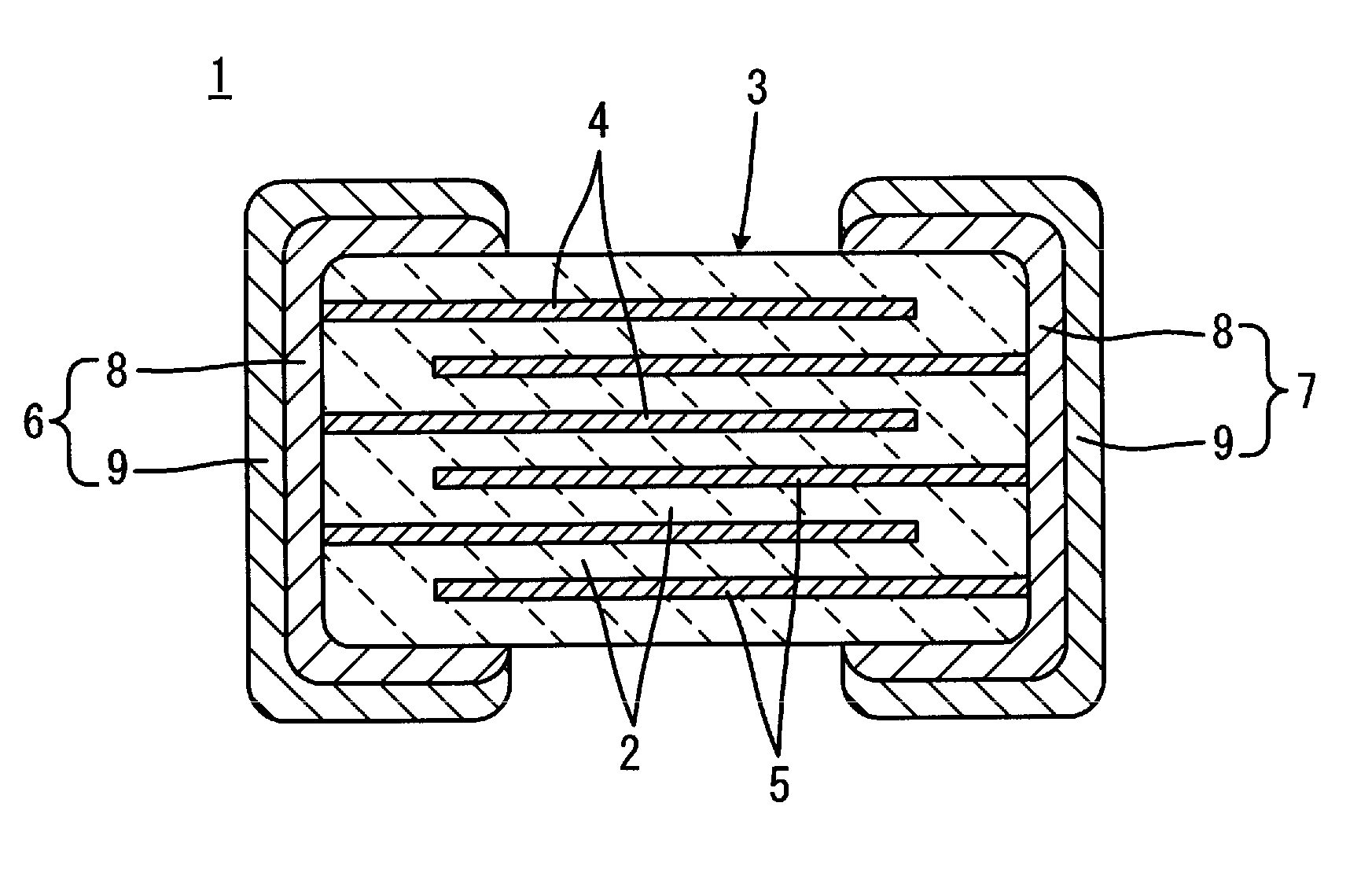

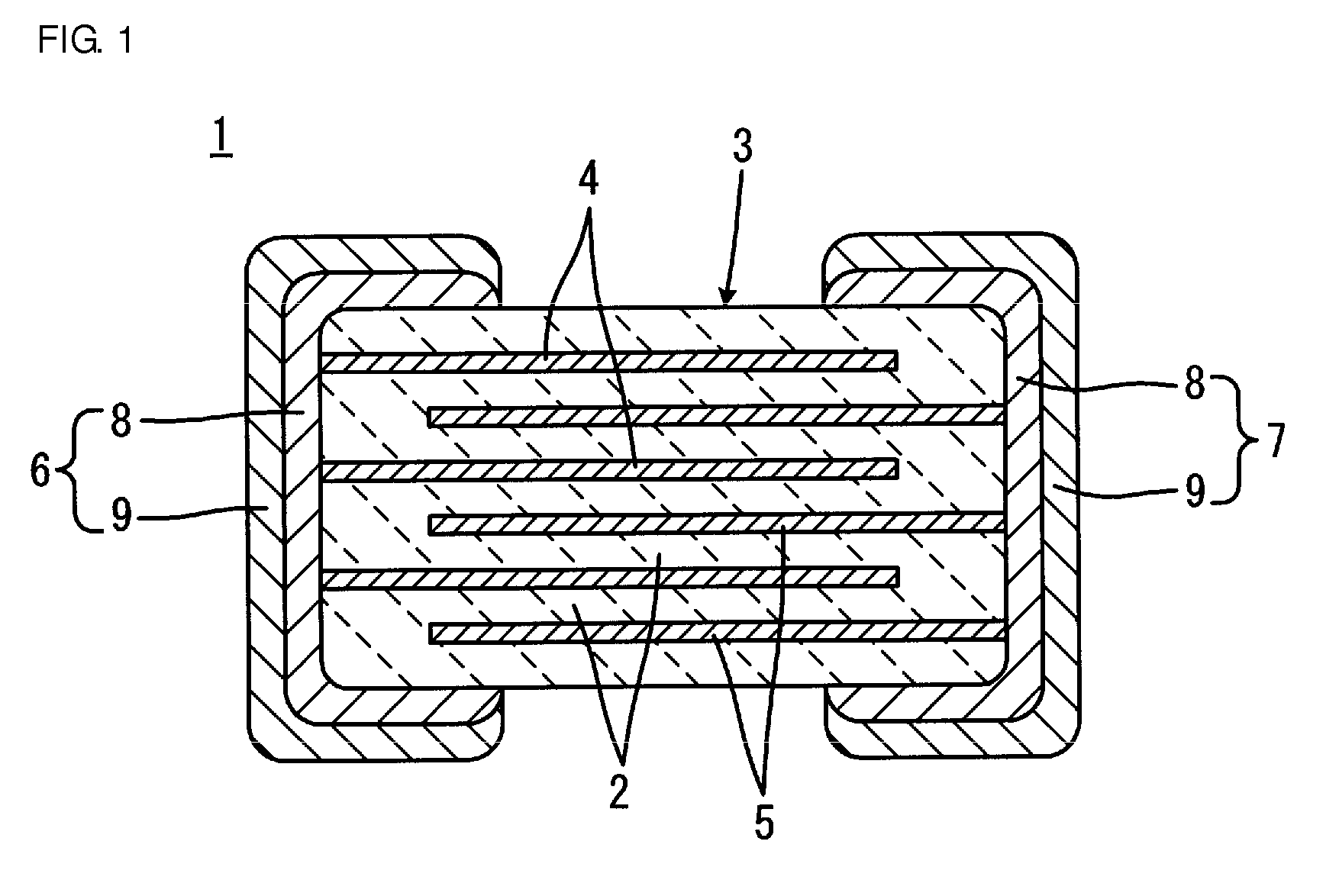

Multilayer electronic component and multilayer ceramic capacitor

InactiveUS20060285274A1Lower sintering temperatureInhibit baking unevennessFixed capacitor dielectricStacked capacitorsElectrical conductorMetallurgy

A multilayer electronic component comprises an inner multilayer portion and a pair of outer multilayer portions. The inner multilayer portion includes a plurality of first ceramic layers and a plurality of internal circuit element conductors which are alternately laminated and contain a glass component. A component amount ratio of an amount of the glass component in the second ceramic layers to an amount of a principal component of the second ceramic layers is larger than a component amount ratio of an amount of the glass component in the first ceramic layers to an amount of a principal component of the first ceramic layers.

Owner:TDK CORPARATION

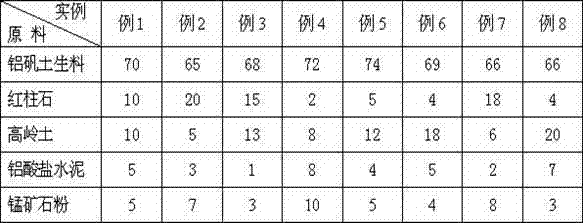

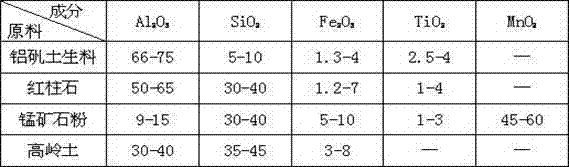

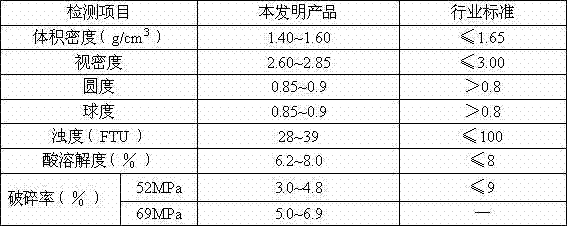

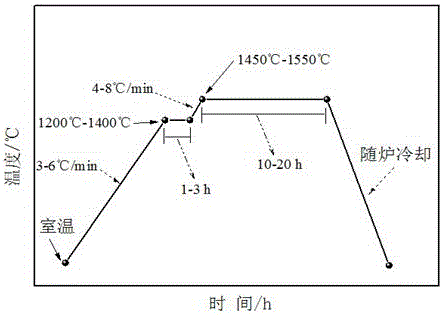

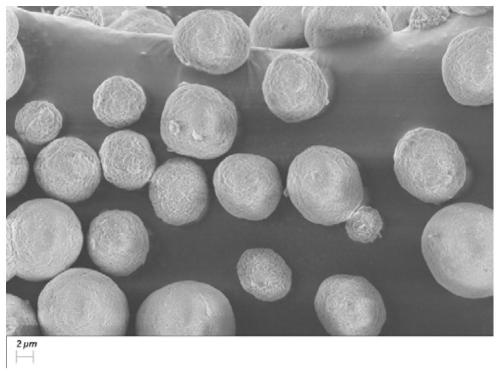

Low-density high-strength andalusite fracturing proppant and production method thereof

ActiveCN102268248ACompatibility is reasonableHigh compressive strengthFluid removalKaolin clayEngineering

The invention relates to a low-density high-strength andalusite fracturing propping agent and a production method thereof. The raw materials comprise: 65-75% of bauxite raw meal, 2-20% of andalusite, 5-20% of kaolinite, 1-8% of calcium aluminate cement, 3-10% of manganese ore powder. The production method comprises the following steps: weighing raw materials, grinding into fine powder, sieving, well mixing, adding into a rotating granulator for granulation, adding atomized aqueous vapor till the mixture becomes a spherical semifinished product, drying; sintering the semifinished product in a rotary kiln for 6-10 h with a kiln head temperature of 1300-1400 DEG C and a kiln tail temperature of 280-320 DEG C, taking the product out of the kiln to obtain a finished product. The product of theinvention has broken rates of 4.8% and 6.9% under pressures of 52 MPa and 69 MPa respectively, and has strength higher than that of other products of the same kind; the product has bulk density of 1.40-1.60 g / cm3, and apparent density of 2.60-2.85 g / cm3, and the density is lower than industrial standard; the product has high surface fineness, and can effectively reduce cost of petroleum fracturing.

Owner:郑州德赛尔陶粒有限公司

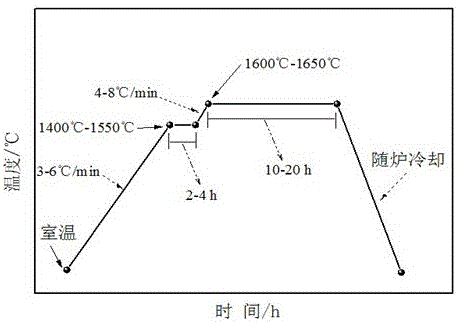

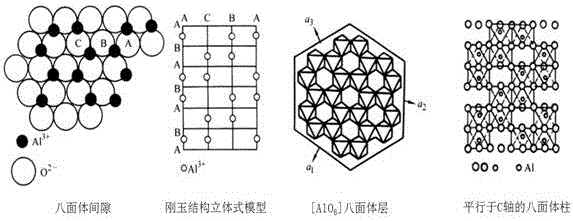

Preparation method of rare earth oxide doped alumina-based high-performance metal melt hydrogen determination probe material

ActiveCN106045482AWell mixedLarge specific surface areaMaterial impedanceMaterial electrochemical variablesChemical stabilityElectrolyte

The invention relates to a preparation method of a rare earth oxide doped alumina-based high-performance metal melt hydrogen determination probe material. Common ball milling and high-performance sand grinding are combined for preparing powder, and an optimized solid-phase synthesis method is adopted for preparing Al2-xRExO3-alpha proton conductive solid electrolyte by secondary sintering. Particularly, analytically pure Al2O3 and RE2O3 are taken as raw materials to prepare the proton conductive solid electrolyte according to a technical scheme including drying, mixing, pregrinding, performing, presintering, grinding, final grinding, final forming and final sintering. The electrolyte has a compact structure and is high in proton conductivity, high in high temperature stability and chemical stability and excellent mechanical strength and corrosion resistance, and the raw materials are low in cost relatively. By application of the electrolyte to the continuous online metal melt hydrogen determination probe material, the problem that an existing probe material which is poor in high temperature stability cannot be applied to high-melting-point melted copper and melted steel hydrogen content determination can be solved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Hydrophobic porous ceramic product and preparation technology thereof

The invention relates to the technical field of ceramic products and specifically relates to a hydrophobic porous ceramic product and a preparation technology thereof. The hydrophobic porous ceramic product comprises a green body and a glaze material; the green body comprises the following raw materials in parts by weight: 27 parts of silicon nitride, 16 parts of zirconium dioxide, 12 parts of clay, 24 parts of aluminum silicate, 16 parts of cordierite, 19 parts of silicon carbide, 14 parts of kieselguhr, 11 parts of albite, 18 parts of aluminum oxide and 13 parts of fluxing agent; the glaze material comprises the following raw materials in parts by weight: 21 parts of dolomite, 23 parts of silicon carbide, 14 parts of calcium oxide, 17 parts of potassium feldspar, 5 parts of clay and 2 parts of sodium hexametaphosphate. The preparation technology comprises the following steps: modifying raw materials of the green body; injection-molding; de-waxing and biscuit-firing; glazing; sintering. The technology provided by the invention is simple and is suitable for large-scale production. The produced ceramic product has the advantages of high mechanical strength, porous hydrophobic property and high temperature resistance.

Owner:福建省泉州市契合工贸有限公司

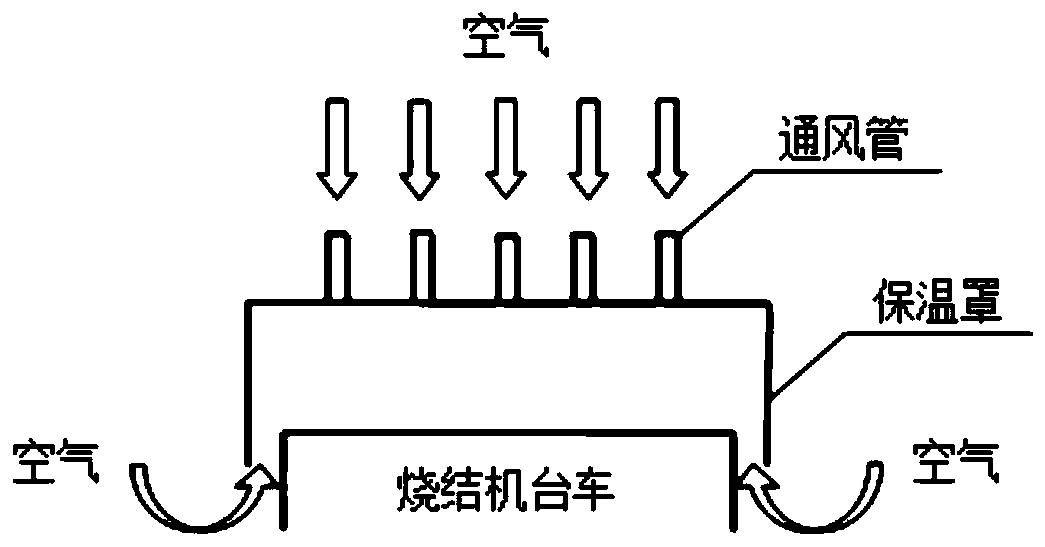

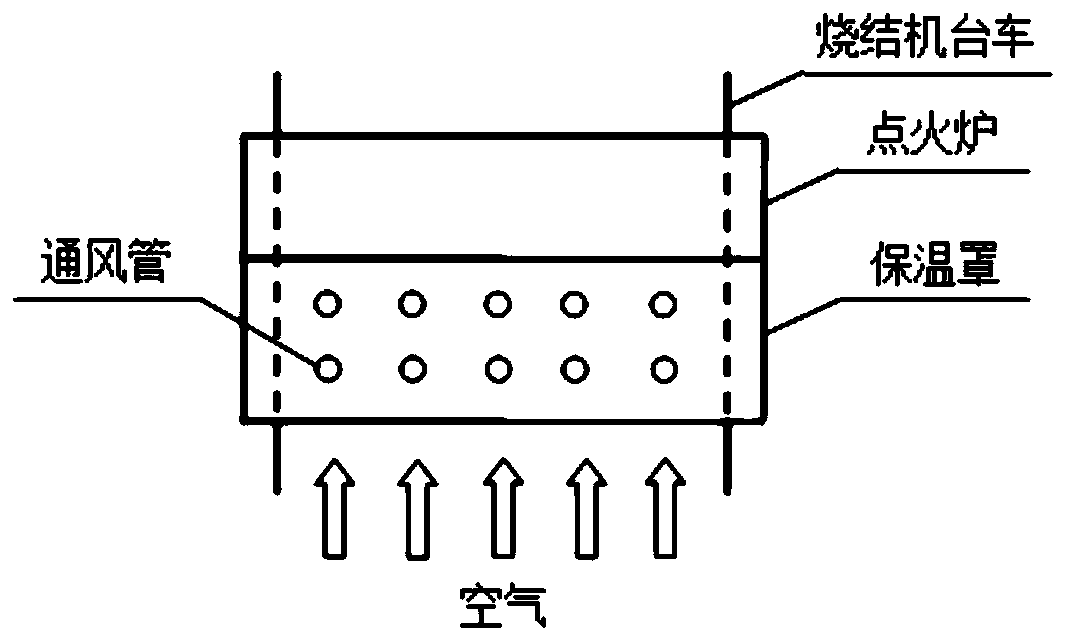

Sintering heat preservation device, sintering machine and sintering method thereof

The invention discloses a sintering heat preservation device, a sintering machine and a sintering method thereof, and belongs to the field of sintering equipment. The heat preservation device comprises a heat preservation cover with an upper opening and a lower opening, a heat exchanger is arranged in the heat preservation cover, the upper opening of the heat preservation cover is sealed, and theheat exchanger is used for preheating the outer air entering the heat preservation cover during sintering operation; and the heat preservation device can fully utilize the heat dissipated by the sintering material surface to form a gradually-reduced trapezoidal temperature field, and the oxygen supply uniformity of the cross section of a sintering trolley is improved, so that the sintering qualityof the upper part of the sintering material layer is improved, and the ore return rate is reduced. The sintering machine comprises the sintering trolley, a ignition furnace and the heat preservationdevice, the sintering machine can supply sufficient oxygen to the sintering material layer while preserving heat, and the quality of the upper part of the sintering material layer and the uniformity of the sintering cross section are improved. According to the sintering method, the above sintering machine is adopted, through setting a reasonable sintering process, the sintering material surface can be ensured to be slowly and uniformly cooled in an environment with sufficient oxygen, the sintering is uniform, and the sintering quality is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

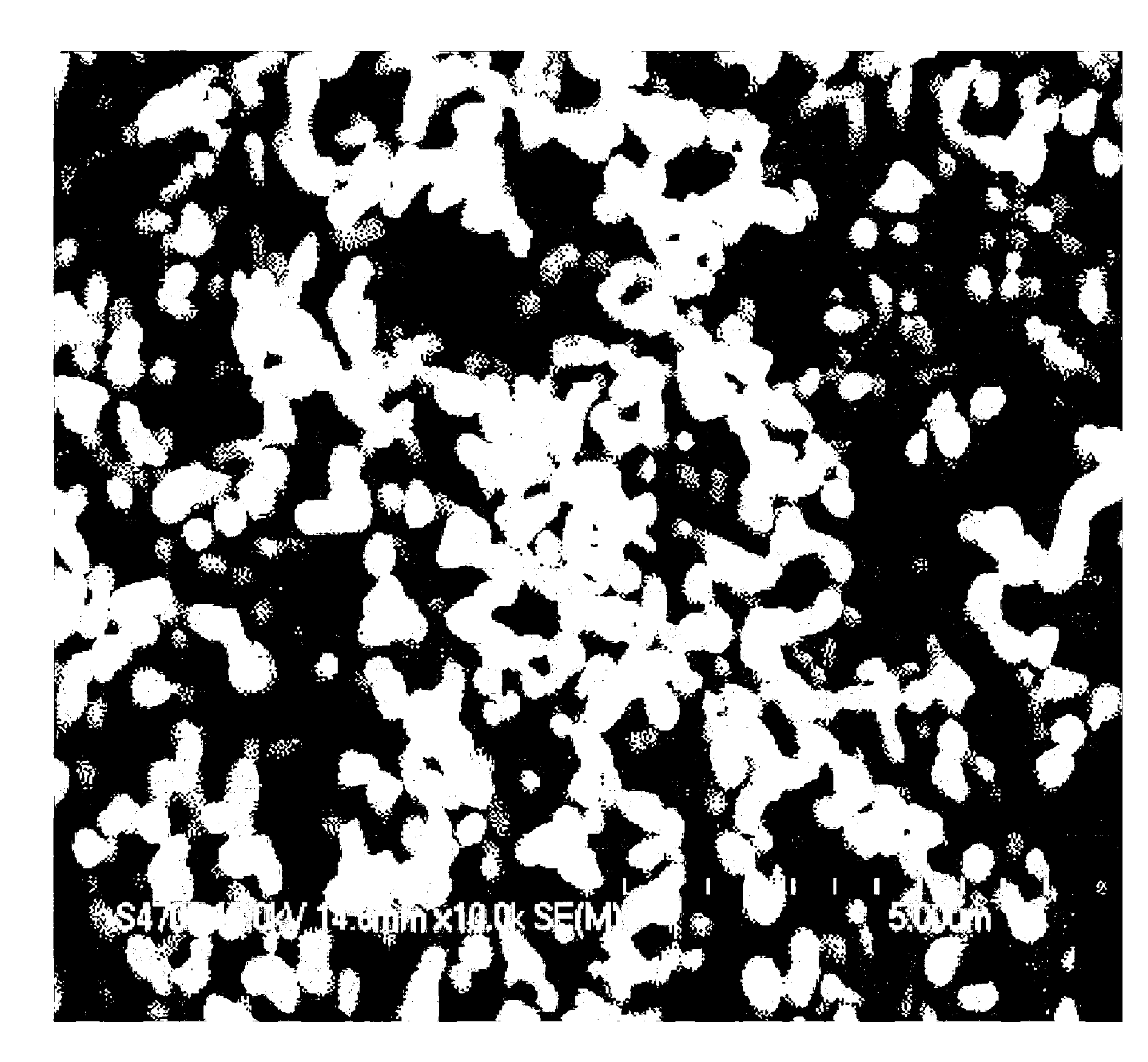

Silver particle coating composition

InactiveUS20170043396A1Improve contact efficiencyImprove conductivityPigmenting treatmentMaterial nanotechnologyAliphatic hydrocarbonMicroparticle

The present invention provides a silver particle coating composition that develops excellent conductivity by low-temperature and short-time calcining, and preferably achieves excellent adhesion between a silver coating film and a substrate. A silver particle coating composition comprising: silver nano-particles (N) whose surfaces are coated with a protective agent containing an aliphatic hydrocarbon amine; silver microparticles (M); and a dispersion solvent. The silver particle coating composition, further comprising a binder resin. The silver particle coating composition, further comprising a curable monomer and a polymerization initiator. The dispersion solvent comprises at least a glycol ester-based solvent. A silver coating composition that is suitable for intaglio offset printing.

Owner:DAICEL CHEM IND LTD

Multilayer ceramic capacitor and method for manufacturing the same

ActiveUS7751175B2Improve the immunityStable valueFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorOptoelectronics

A multilayer ceramic capacitor having external electrodes. Each of the external electrodes has a lower layer resistance electrode and an upper layer conductive electrode. A glass contained in the upper layer conductive electrode has a softening point higher than that of a glass contained in the lower layer resistance electrode by 20° C. or more.

Owner:MURATA MFG CO LTD

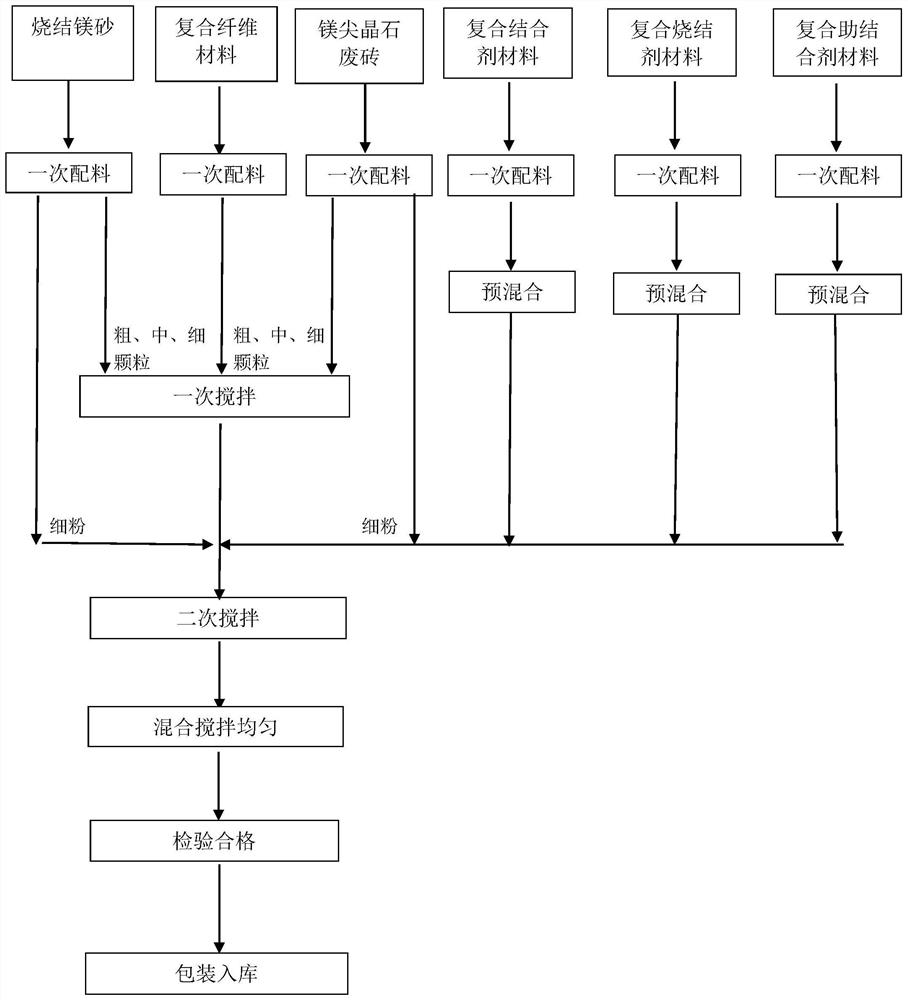

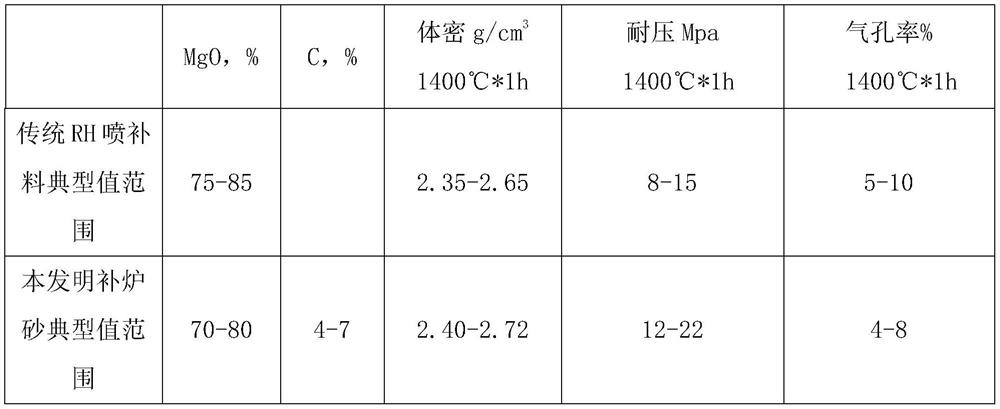

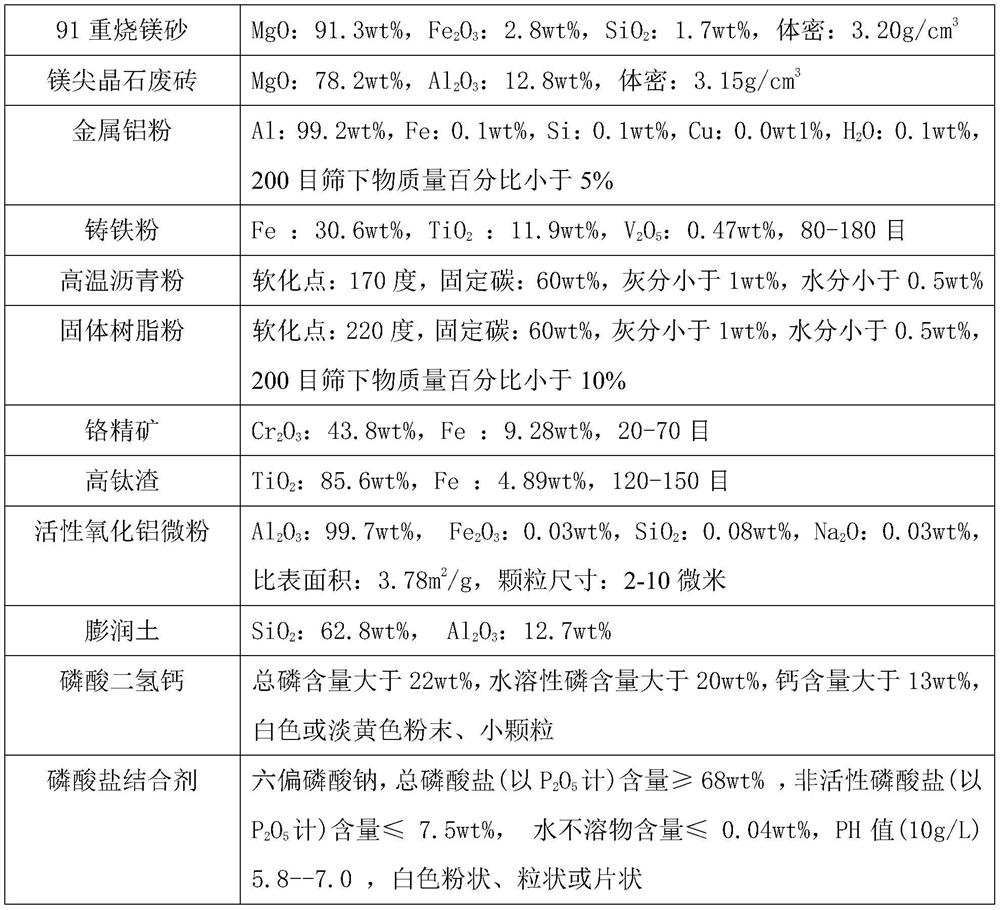

High-quality RH gunning mix added with large amount of cast iron powder and production method thereof

ActiveCN112479685AFully sinteredPromote sinteringProcess efficiency improvementCeramic materials productionFiberManufactured material

The invention relates to a high-quality RH gunning mix added with a large amount of cast iron powder and a production method thereof. The high-quality RH gunning mix is prepared from the following rawmaterials by weight: 35-60 parts of sintered magnesia, 10-30 parts of magnesia spinel waste bricks, 12-22 parts of a composite binding agent, 5-20 parts of a composite sintering agent, 3-10 parts ofa composite auxiliary binding agent and 0.1-2.0 parts of composite fibers. Compared with the prior art, the RH gunning mix has the beneficial effects that: the proportion of an existing RH gunning mixis optimally designed and improved, a large amount of cast iron powder is added for the first time in the domestic range, the sintering performance of the gunning mix is improved, so that the gunningmix meets the requirement for on-site rapid gunning maintenance of an RH dip pipe, the sintering speed is fast, the sintering strength is high, the adhesiveness is good, no resilience exists, the erosion resistance is good, meanwhile, the production method is simple and the raw material cost is lowered.

Owner:鞍山市和丰耐火材料有限公司

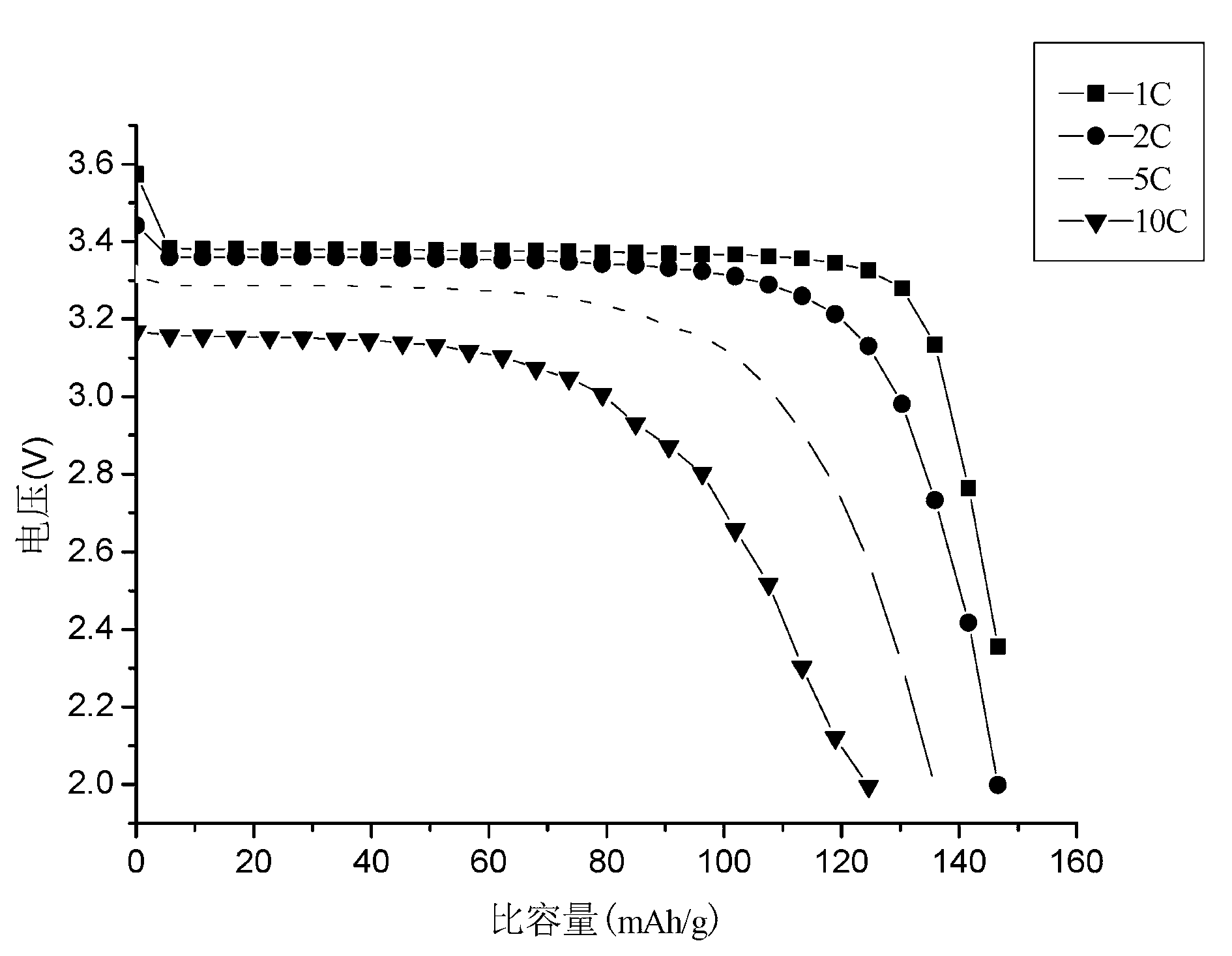

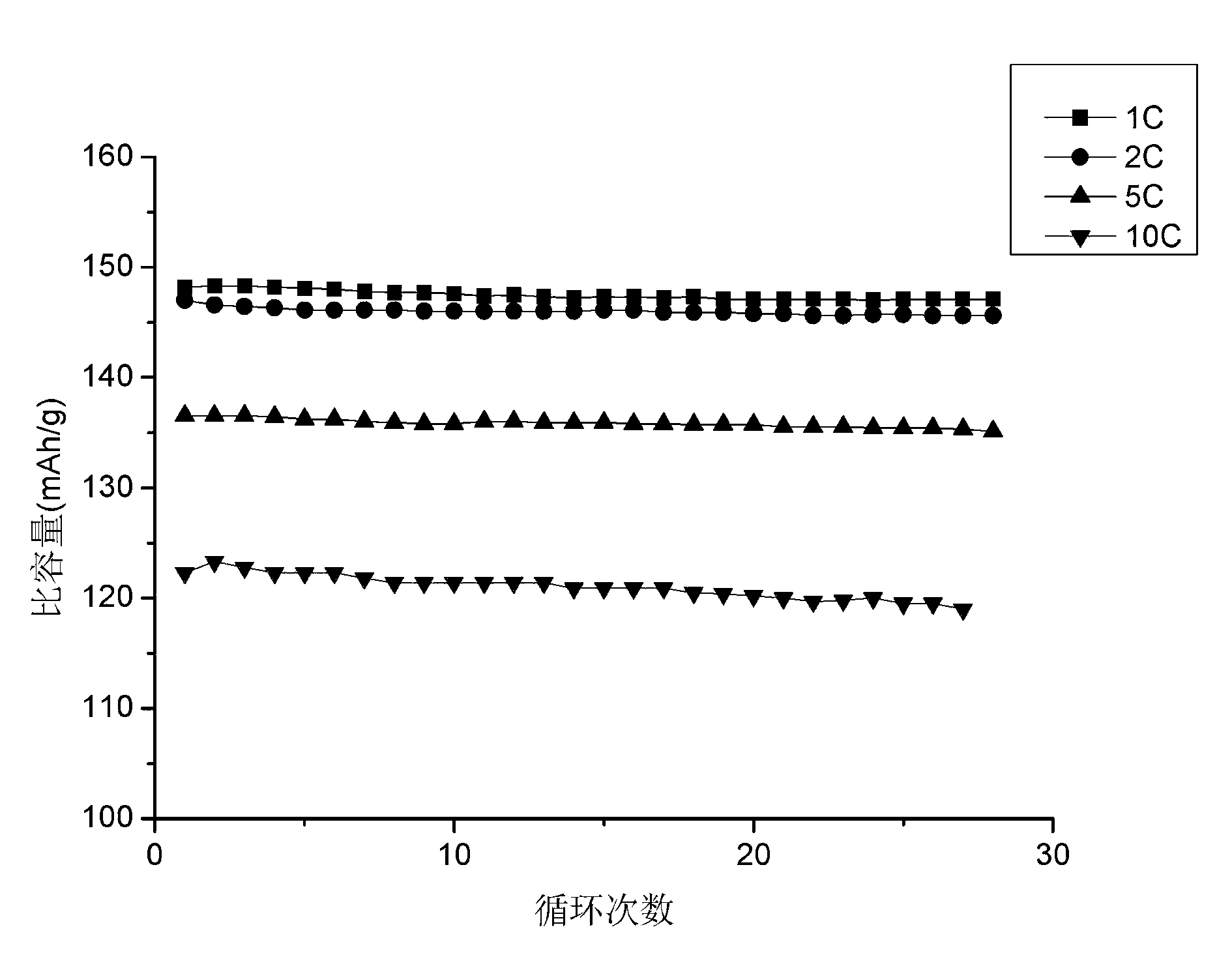

Method for preparing lithium iron phosphate in batch-type high-vacuum dynamic sintering mode

ActiveCN102856551AFully heatedShorten the sintering timeCell electrodesPhosphorus compoundsHeating timeRotary furnace

The invention discloses a method for preparing lithium iron phosphate in a batch-type high-vacuum dynamic sintering mode. The method includes: adopting a batch-type rotary furnace to heat a precursor of the lithium iron phosphate, performing sealing treatment on a furnace head and a rotary portion through a sealing pad and high-temperature-resisting vacuum fat, vacuumizing the rotary furnace during heating, and pumping oxidizing gases and steam generating in the sintering process quickly, wherein the vacuum degree is kept to be 10<2>-10<12> pa, the furnace body is rotated continuously, the heating temperature is 300-900 DEG C, the heating hour is 5-15h; stopping a vacuum pump and a pumping valve after heating is finished, leading in inert gases into the rotary furnace, and taking the product out after cooling. The prepared precursor of the lithium iron phosphate is fed into the batch-type rotary furnace for vacuum sintering, the high-vacuum state is kept by fast vacuumizing the furnace body through the multi-stage vacuum pump during the whole process, and powder materials rotate along with the furnace body to achieve the aim of dynamic sintering, so that the method for preparing lithium iron phosphate in the batch-type high-vacuum dynamic sintering mode is suitable for preparing lithium ion positive pole materials in industrial mode.

Owner:徐剑晖

Method for producing silver nano-particles and silver nano-particles

InactiveUS9776250B2Simple and safe processRelease heatMaterial nanotechnologyNon-insulated conductorsAlcoholThermal decomposition method

The present invention provides a silver nano-particle production method which is safe and simple also in terms of scaled-up industrial-level production, in a so-called thermal decomposition method in which a silver-amine complex compound is thermally decomposed to form silver nano-particles. A method for producing silver nano-particles comprising: mixing an aliphatic hydrocarbon amine and a silver compound in the presence of an alcohol solvent having 3 or more carbon atoms to form a complex compound comprising the silver compound and the amine; and thermally decomposing the complex compound by heating to form silver nano-particles.

Owner:DAICEL CHEM IND LTD

Vanadium-titanium concentrate powder thick material layer sintering technology

The invention discloses a vanadium-titanium concentrate powder thick material layer sintering technology. The vanadium-titanium concentrate powder thick material layer sintering technology comprises the following steps that sintering raw materials are mixed to be uniform, and the sintering raw materials comprise, by weight, 50-60 parts of vanadium-titanium concentrate powder, 5-8 parts of iron oreconcentrate powder, 10-20 parts of a fluxing agent and 3-5 parts of fuel; the sintering raw materials are crushed; the powder is infiltrated with water and then prepared into pellets; the pellets aredistributed on sintering equipment, and the distributing thickness is 720-740 mm; the pellets are sintered into pellet ore; and the pellet ore is cooled. By changing the component proportion of the sintering raw materials and adding the fluxing agent to improve the air flow fluidity, therefore, the large sintering material distributing thickness is achieved, and the sintered ore quality is improved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

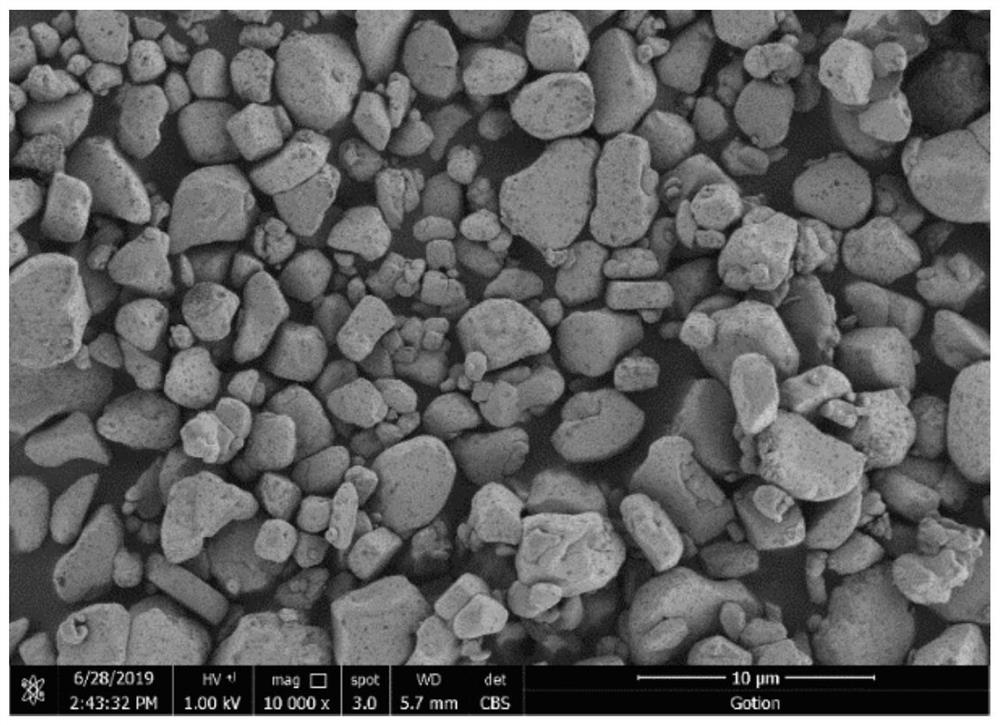

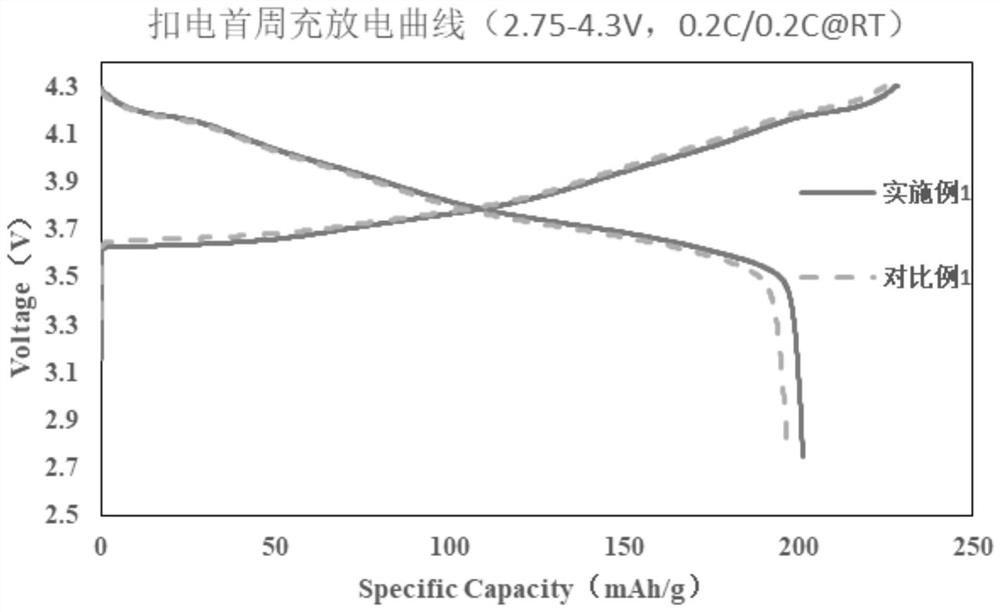

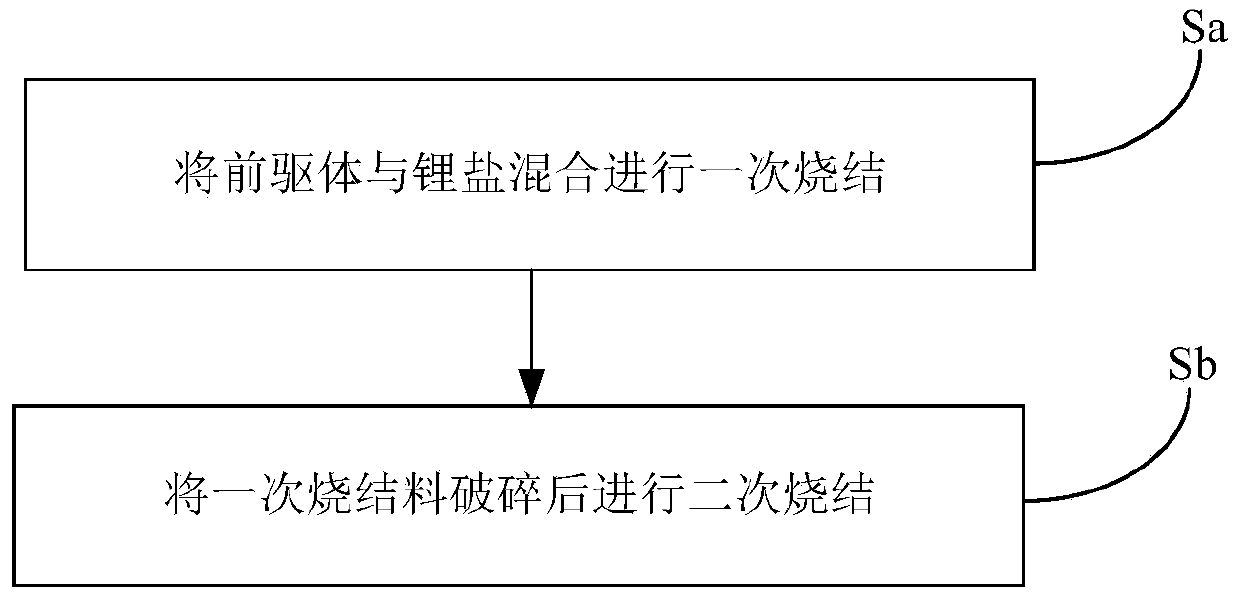

High-nickel ternary single crystal material and preparation method thereof

ActiveCN112531158ARaise oxygen partial pressureNot easy to stickCell electrodesSecondary cellsPhysical chemistrySingle crystal

The invention discloses a high-nickel ternary single crystal material and a preparation method thereof. The preparation method includes the steps that after a material precursor synthesis process is controlled and a precursor is subjected to smashing and grading treatment, the precursor and a lithium source are mixed and then subjected to low-temperature dehydration to obtain a pre-oxide, and thenthe pre-oxide is subjected to high-temperature sintering through a dynamic rotary furnace to obtain the high-nickel ternary single crystal material. Compared with a traditional synthesis method, themethod has the advantages that the internally loose and porous precursor can be rapidly synthesized, the specific surface area of the reaction of the material and the lithium source is increased through crushing and grading, the lithiation ratio of the lithium source to the precursor can be effectively reduced, and the usage amount of the lithium source is reduced; the sintering temperature can bereduced, the sintering time is shortened, the energy consumption is reduced and the production efficiency is improved; and meanwhile, sintered material particles are dispersed uniformly, agglomeration is less, and post-treatment processing is relatively easy. The high-nickel ternary single crystal material prepared by the method has the characteristics of full primary particle form, uniform dispersion, complete crystal form, stable structure, excellent electrochemical performance and the like.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

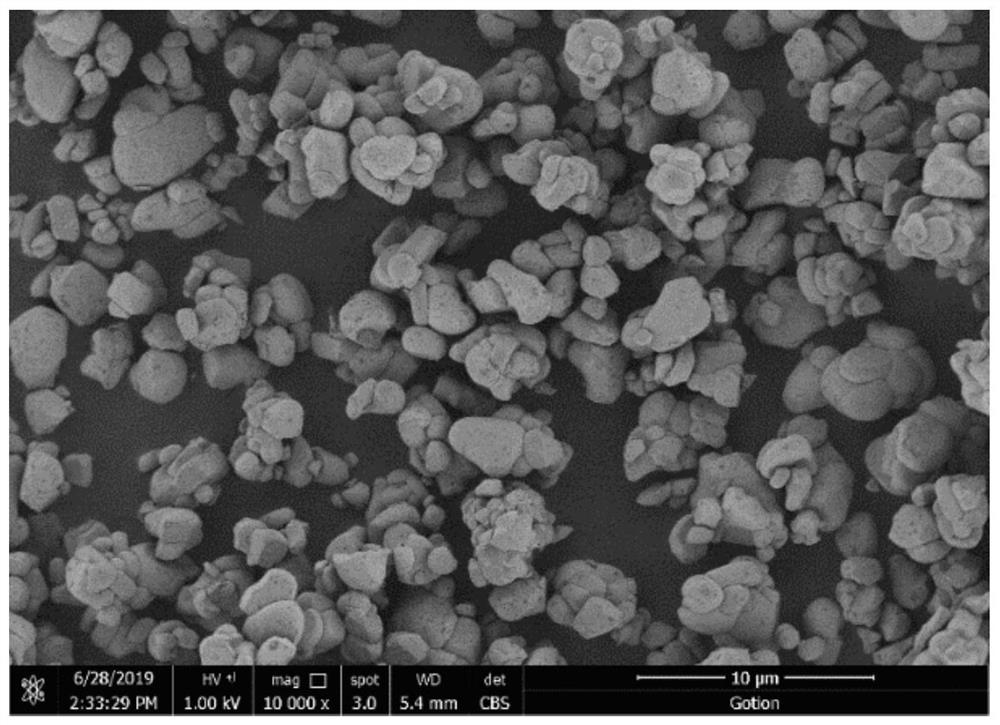

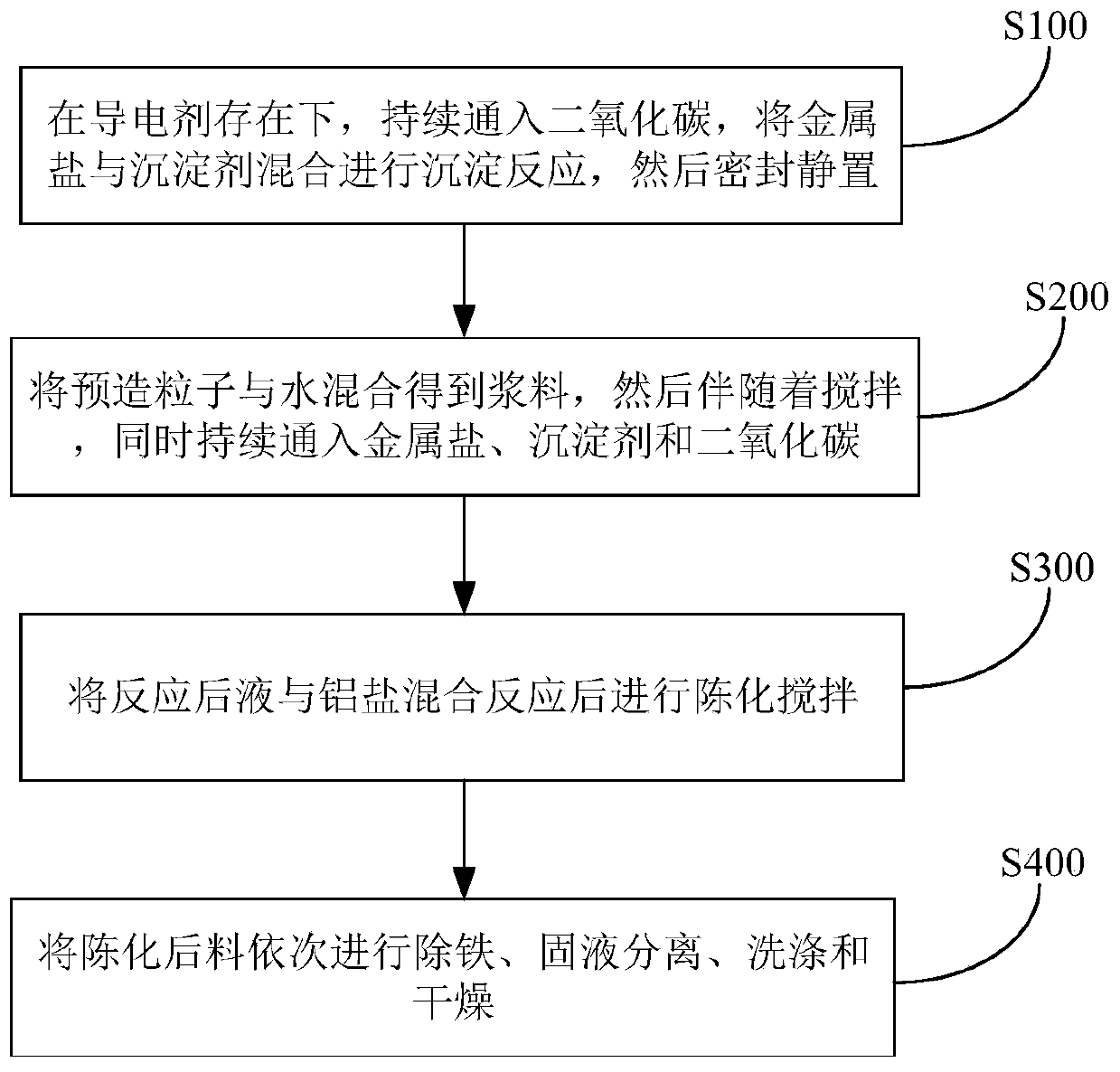

Aluminum-coated precursor as well as preparation method and application thereof

ActiveCN111434617AGranularity controllableUniform particle size distributionSecondary cellsPositive electrodesPhysical chemistryManganese

The invention discloses an aluminum-coated precursor and a preparation method thereof. The chemical formula of the aluminum-coated precursor is xMCO3(1-x)Al(OH)3, M is at least one of nickel, cobalt and manganese, and x is 0.995-0.999. The aluminum-coated precursor has the advantages of controllable particle size, uniform particle size distribution, high degree of sphericity, smooth particle surface, high tap density, low possibility of breakage and excellent electrochemical performance and energy density, and meanwhile, a positive electrode material prepared from the precursor has relativelyhigh specific capacity and excellent cycle performance and electrochemical discharge performance.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

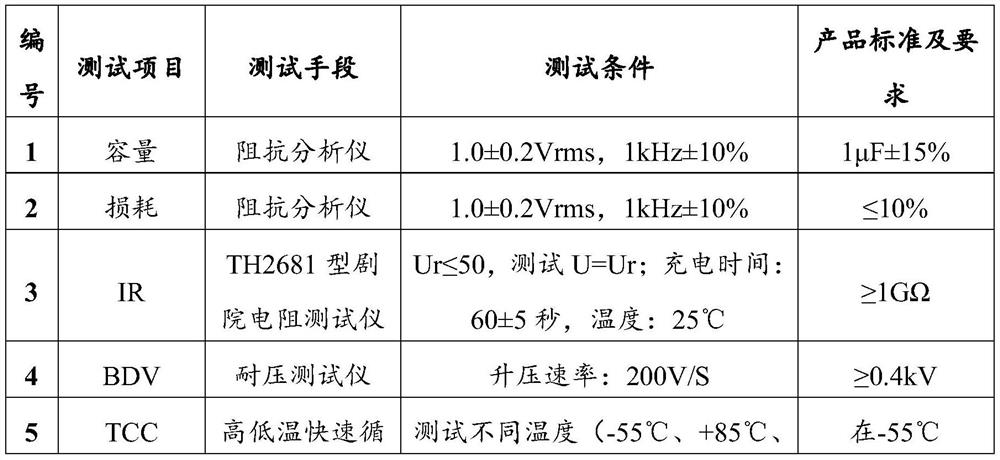

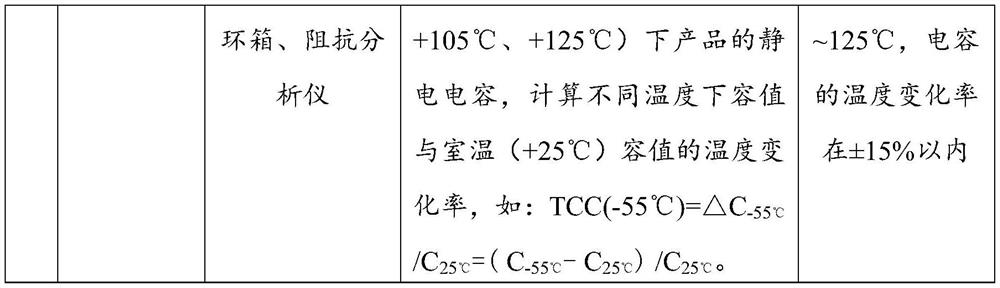

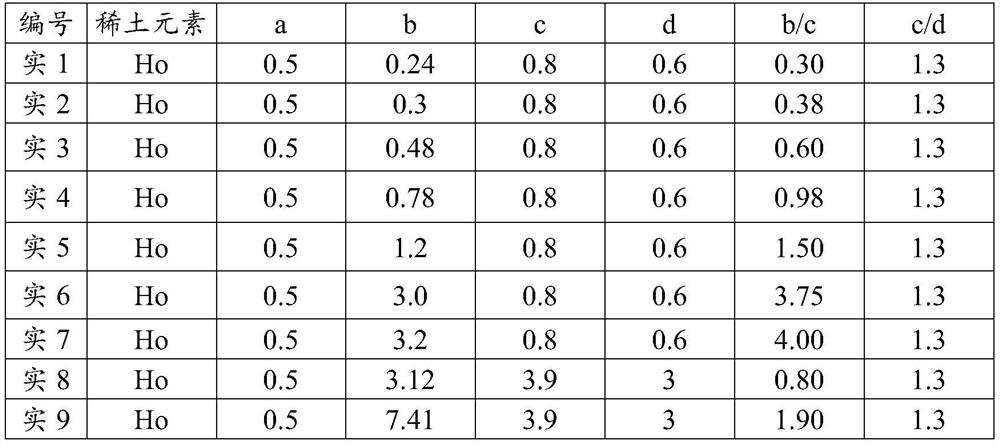

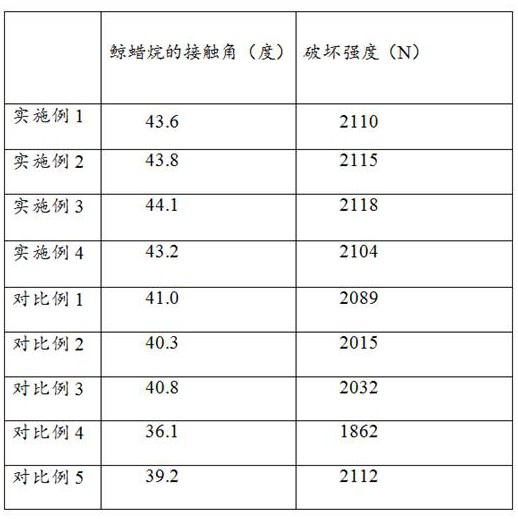

Ceramic material as well as preparation method and application thereof

ActiveCN113354410AFully sinteredPromote sinteringFixed capacitor dielectricStacked capacitorsBreaking strengthRare-earth element

The invention discloses a ceramic material as well as a preparation method and an application thereof. The ceramic material comprises a barium titanate compound, a rare earth element and a sintering aid, the content of the rare earth element and the sintering aid is not zero, and the sintering aid comprises MgO, MnO2 and SiO2; based on the molar weight of the barium titanate compound, the rare earth element accounts for 0-10%, the sintering aid accounts for 0-25%, MgO accounts for 0-10%, MnO2 accounts for 0-10%, SiO2 accounts for 0-5%, the molar ratio of MnO2 to SiO2 is 1.1-3, and the molar ratio of MgO to MnO2 is 0.3-4. By optimizing the sintering aid, the defect of weak strength of a barium titanate ceramic dielectric material is fundamentally improved, and the breaking strength and the bending strength of the multilayer ceramic capacitor are improved to be greater than or equal to 7.5 kgf and greater than or equal to 6.5 mm on the basis of ensuring that the multilayer ceramic capacitor has good electrical properties.

Owner:CHAOZHOU THREE CIRCLE GRP

Glaze capable of increasing brightness and preparation process thereof

The invention discloses glaze capable of increasing brightness and a preparation process of the glaze, and relates to the technical field of porcelain craft glaze. The glaze is prepared from, by weight, 5-10 parts of modified feldspar powder, 4-8 parts of barite powder, 10-20 parts of modified mica powder, 10-20 parts of modified quartz sand, 1-3 parts of barium oxide, 2-4 parts of zinc oxide, 0.6-1 part of sodium hexametaphosphate, 2-4 parts of zirconium silicate, 2-4 parts of manganese carbonate, 1-3 parts of modified asbestos wool, 5-10 parts of titanium dioxide, 1-3 parts of celestite, 2-6parts of lithia, 1-3 parts ofbastnasite, 1-3 parts oftantalum pentoxide, 1-3 parts of bprpm trioxide, 0.5-1 part ofhafnium oxide, 1-3 parts of modified nano calcium carbonate and 1-3 parts of modified glass fiber. The glaze has the beneficial effect that the brightness of the glaze can be improved.

Owner:江西亚航科技有限公司

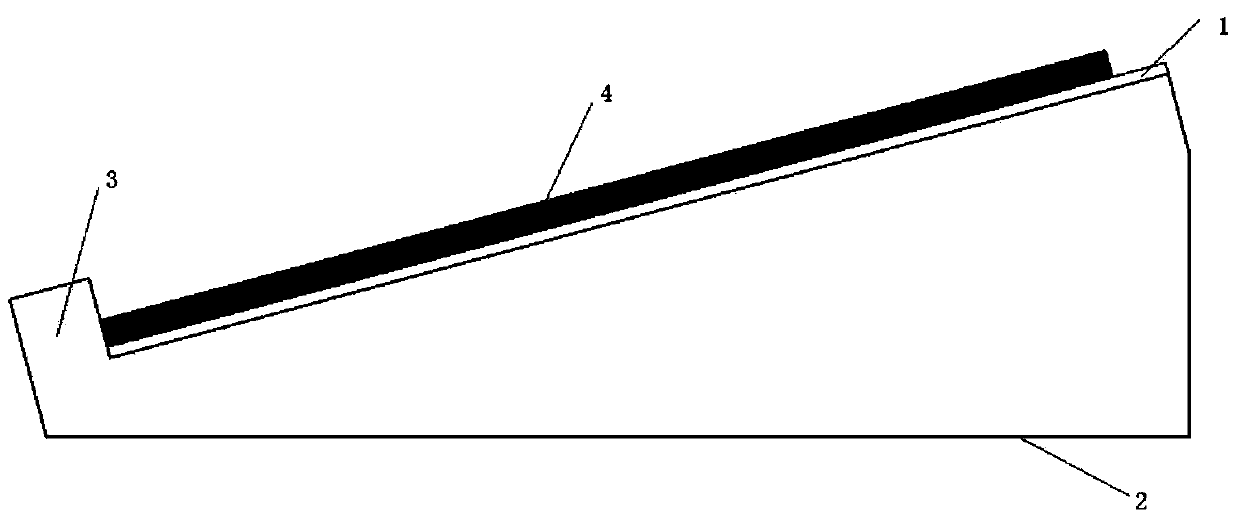

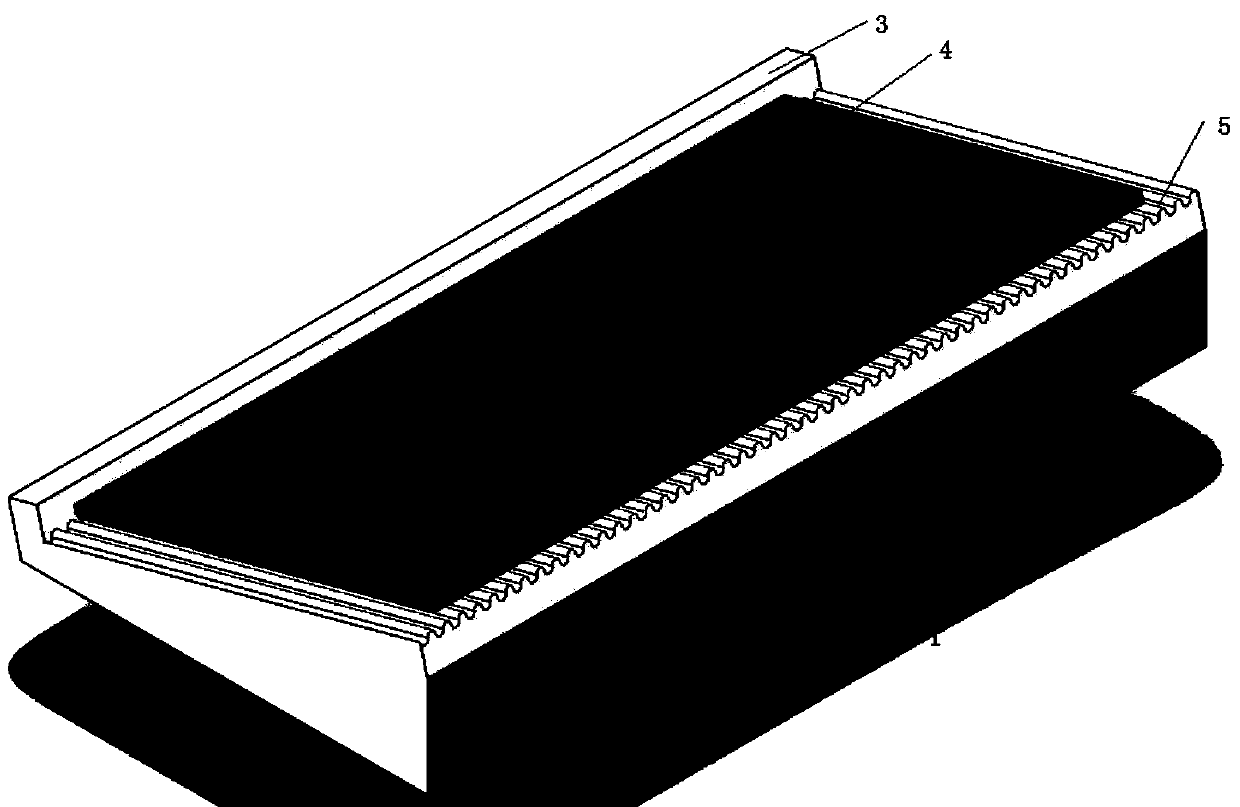

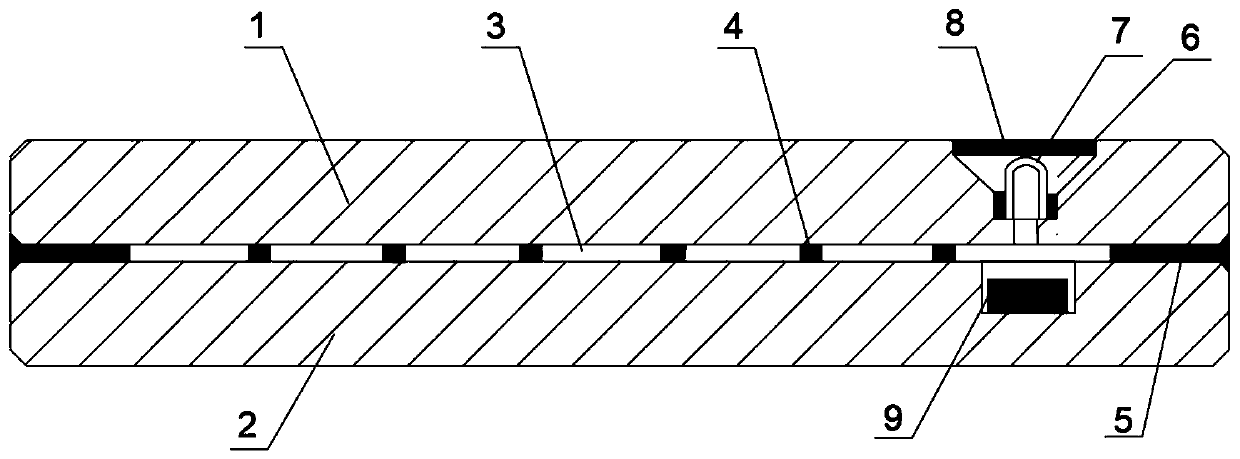

Sintering bearing plate and sintering method of planar ceramic target material

InactiveCN111006514AAvoid insufficient sinteringImprove compactnessCharge supportsFriction forceSupport surface

The invention discloses a sintering bearing plate and a sintering method of a planar ceramic target material. The burning bearing plate comprises a supporting surface and a horizontal plane, wherein the supporting surface is an inclined plane forming an inclination angle with the horizontal plane, the inclination angle of the supporting surface relative to the horizontal plane is 10-30 degrees, and the supporting surface is provided with a plurality of strip-shaped corrugated protrusions which are evenly distributed at intervals and are parallel to one another. A planar ceramic target materialgreen body is placed on the burning bearing plate with the strip-shaped corrugated bulges on the inclined surface for sintering, air permeability of a target material is improved, sufficient sintering of the target material can be promoted, the inclination angle of the supporting surface of the sintering bearing plate relative to the horizontal plane is 10-30 degrees, the friction force between atarget material green body and the sintering bearing plate due to shrinkage during sintering can be greatly reduced, target material densification is facilitated, defects of deformation, cracking andthe like of the target material are prevented, and the yield of the target material is greatly increased.

Owner:广州市尤特新材料有限公司

Oil-stain-resistant ceramic sheet and preparation method thereof

The invention discloses an oil-stain-resistant ceramic sheet, which is prepared from the following raw materials in parts by weight: 20 to 30 parts of mullite, 10 to 20 parts of cordierite, 5 to 10 parts of talcum powder, 4 to 6 parts of fiber-reinforced graphene, 2 to 6 parts of wollastonite hybrid modified alpha-aluminum oxide, 1 to 3 parts of silicon nitride composite nano powder and 1 to 5 parts of barium carbonate sintering aids. The oil-stain-resistant ceramic sheet is composed of mullite, cordierite, talcum powder and other raw materials, and the prepared product is resistant to oil stain and excellent in strength performance through the composite proportion of fiber-reinforced graphene, wollastonite hybrid modified alpha-aluminum oxide and silicon nitride composite nano powder.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

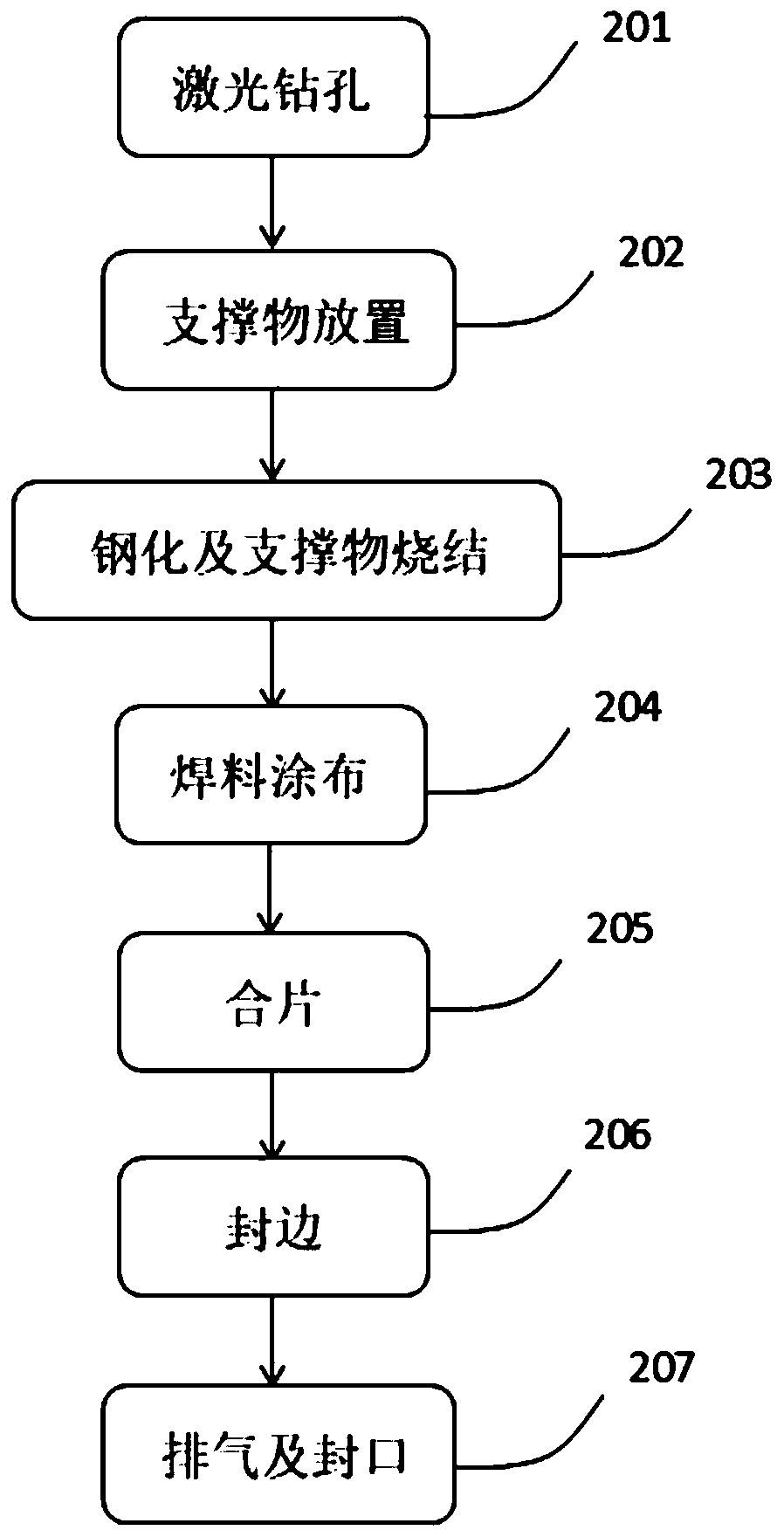

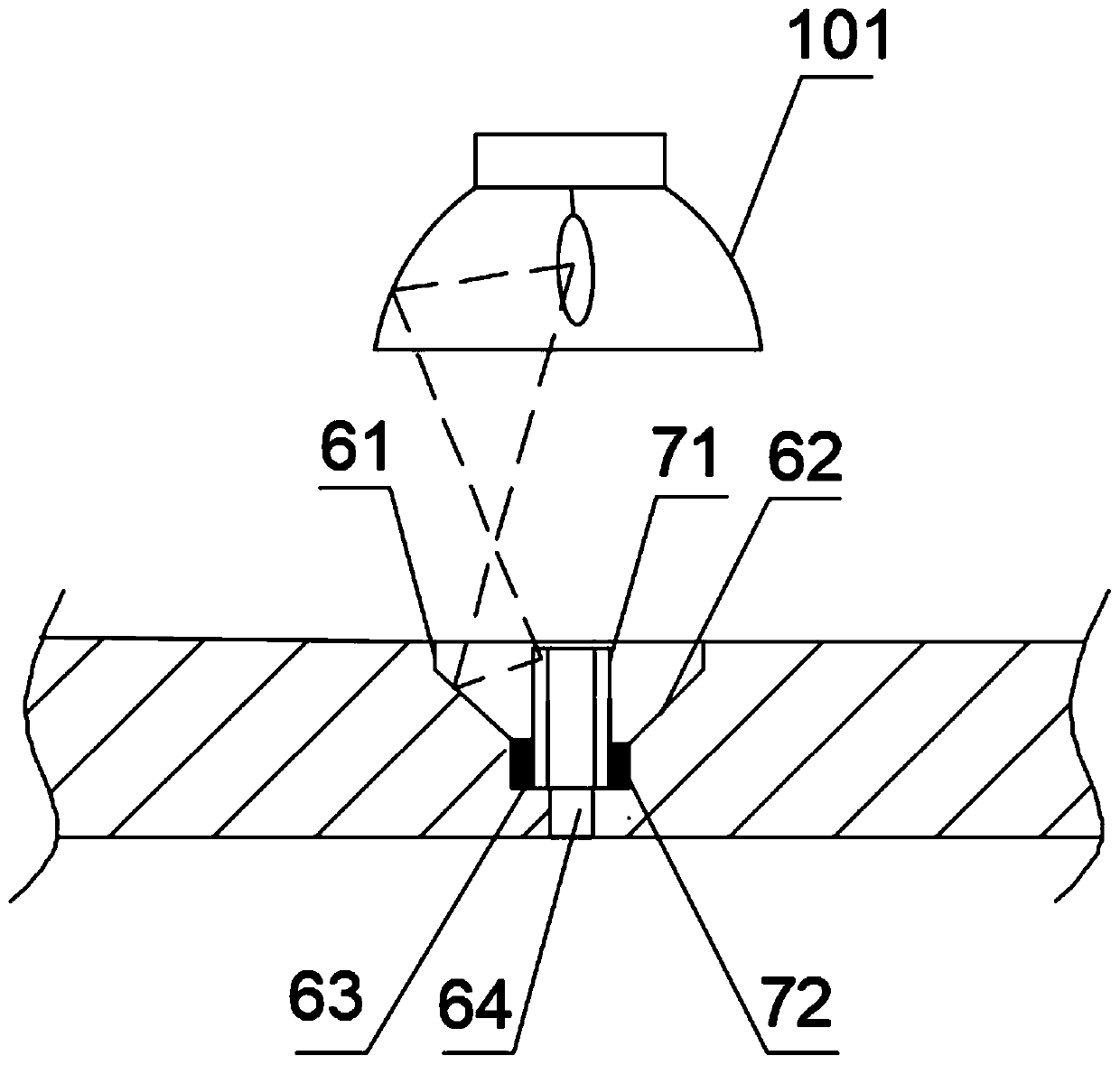

Tempered vacuum glass and manufacturing method thereof

InactiveCN111499223AFully sinteredLower sintering temperatureGlass tempering apparatusLaser beam welding apparatusToughened glassLaser drilling

The invention discloses tempered vacuum glass and a manufacturing method thereof. The tempered vacuum glass comprises upper tempered glass, lower tempered glass and a vacuum area therebetween, whereina ceramic glaze supporting object is arranged between the two pieces of glass; low-temperature welding flux used for edge sealing is arranged in gaps of the four edges, and air exhaust parts with airexhaust pipes and reflecting surfaces are arranged at the corners of the upper piece of glass. The method for manufacturing the toughened vacuum glass comprises the following steps: S1, laser drilling; S2, support arrangement; S3, toughening and support sintering; S4, solder coating; S5, glass lamination; S6, edge sealing; and S7 exhaustion and sealing. In the invention, the ceramic glaze supporthas the advantages that the ceramic glaze support and the glass are sintered together; the glass is not prone to falling off, the reflection face of the glass is beneficial to concentration of sealing heat, the air suction pipe is arranged in the glass after sealing, use is safer, low-temperature welding flux and the rapid heating and cooling technology are adopted for edge sealing in the step S6, and the glass surface stress attenuation is smaller than or equal to 5%, so that the glass surface flatness is good, and the production efficiency is high.

Owner:李长征

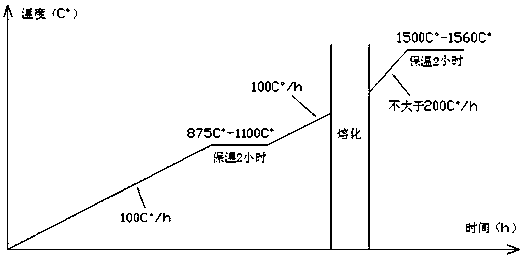

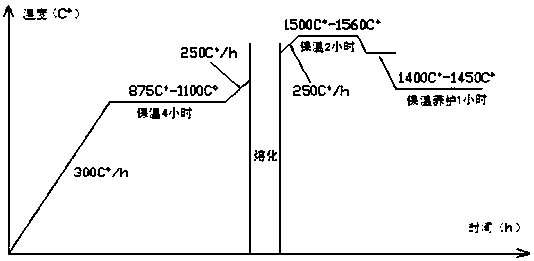

Sintering technology for quartz sand furnace lining of induction electric furnace of 1t or below

InactiveCN107860231AAdd method scienceExtended service lifeLinings repairCrucible furnacesQuartzMaterials science

The invention discloses a sintering technology for a quartz sand furnace lining of an induction electric furnace of 1t or below. The sintering technology comprises the following steps that firstly, burden is heated to 875 DEG C-1,100 DEG C at the average temperature rise speed of 300 DEG C / h, and heat preservation is conducted for 4 h; secondly, the burden is melted at the average temperature risespeed of 250 DEG C / h, the temperature of molten iron is increased to 1,500 DEG C-1,560 DEG C, and heat preservation is conducted for 2h; thirdly, the temperature of the molten iron is reduced to 1,400 DEG C to 1,450 DEG C, and heat preservation and curing are conducted for 1h; fourthly, after the furnace lining is sintered, according to the burden adding manner during daily smelting, three wastesteel press blocks are added, then a carburant is added, and the rest of waste steel press blocks are added for supplementary. The total consumed time of the sintering technology is about 12.5 h, andcompared with the previous sintering technology consuming 18 h and the burden adding manner, the sintering efficiency is improved by 31%, and the service life of the furnace lining is prolonged by 40%. The sintering technology is applied to the casting field, and a practical basis is provided for further improving and enhancing of the sintering technology for the quartz sand furnace lining of theinduction electric furnace.

Owner:HARBIN DONGAN AUTO ENGINE

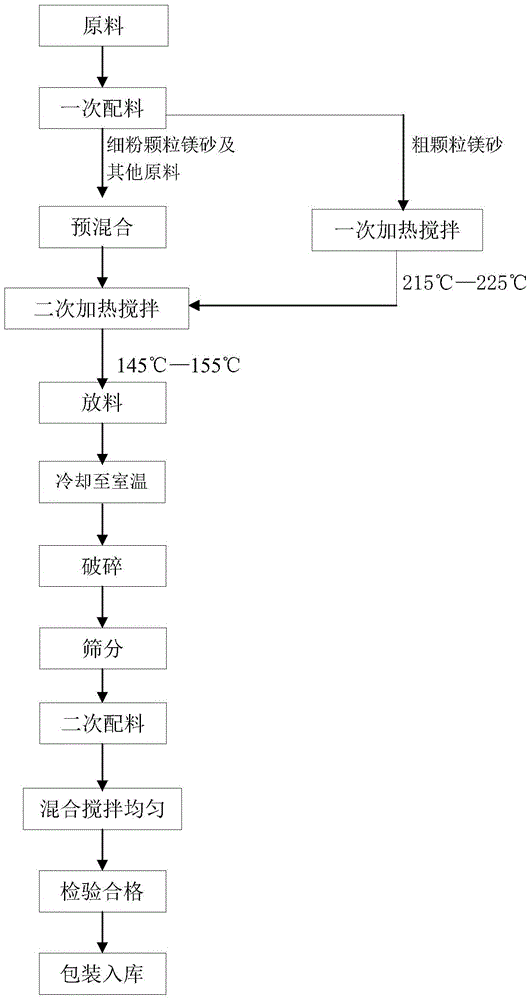

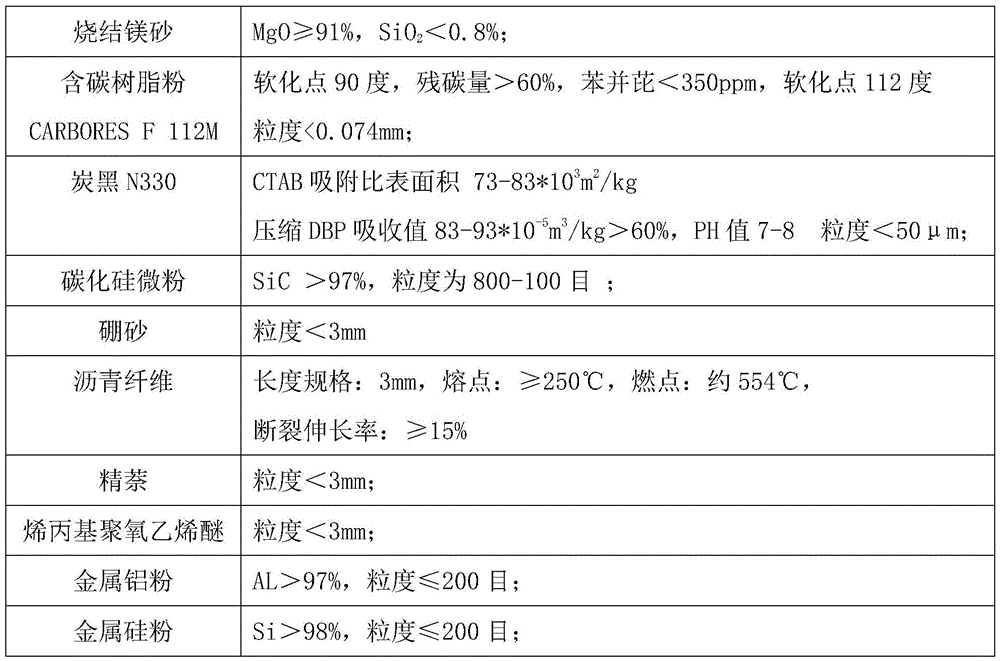

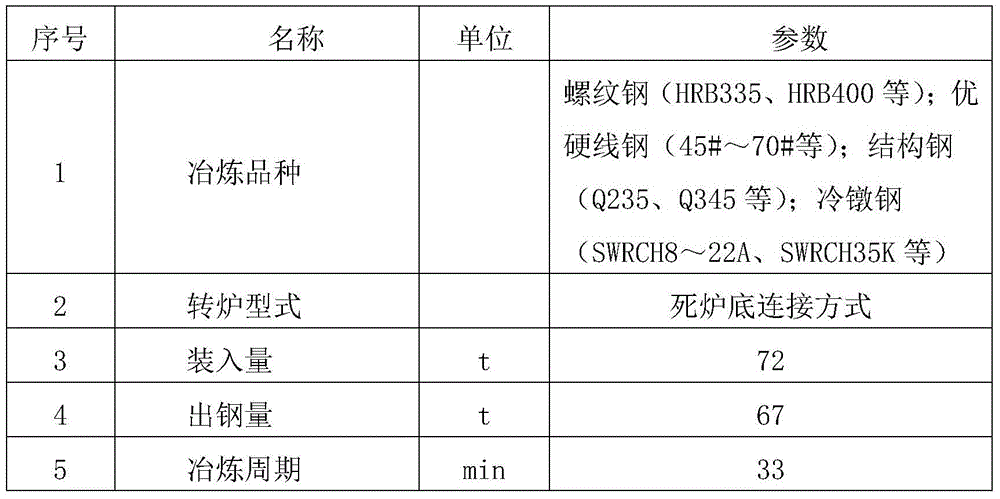

Environment-friendly type long-life fettling sand and production method thereof

The invention relates to environment-friendly type long-life fettling sand, which is prepared from the following raw materials (by weight): 65-90 parts of sintered magnesia, 12-20 parts of a composite carbon source composed of carbon-containing resin powder and carbon black, 0.01-0.20 part of pitch fiber, 2.5-4.5 parts of a composite fluidizing reagent composed of refined naphthalene and allyl polyethenoxy ether, 0.2-1.5 parts of a composite sintering agent composed of silicon carbide micro-powder and borax, and 2.0-5.5 parts of a composite antioxidant composed of metallic aluminum powder and metallic silicon powder. In comparison with the prior art, the invention has the following beneficial effects: sintering time is short; scour resistance and spalling resistance are greatly improved; especially the environmental protection effect is prominent; smoke amount is obviously reduced; there is no peculiar smell; total service life is raised by 25-32%; fettling time is reduced; labor intensity is lowered; and win-win relationship between steel mills and refractory suppliers is realized.

Owner:鞍山市和丰耐火材料有限公司

Coating material for high-temperature oxidation prevention of carbon anode

ActiveCN113563056AImprove expansion coefficient matchingHigh refractorinessBinding forceThermal shock

The invention provides a coating material for high-temperature oxidation prevention of a carbon anode. The coating material comprises the following components: 35-55 wt% of an inorganic binder, 30-60 wt% of a composite ceramic filler, 1-10 wt% of a catalyst, 0-1 wt% of a sintering agent and 1-10 wt% of a flexibilizer. The coating material disclosed by the invention has good toughness, relatively strong binding force and relatively strong thermal shock resistance, has the characteristics of convenience in construction, normal-temperature curing, low-temperature densification, no toxicity, environment friendliness, durability, effectiveness and the like, and can be used for remarkably reducing the high-temperature oxidation burning loss of a carbon anode and prolonging the service life of the anode.

Owner:河南和成无机新材料股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com