Sintering technology for quartz sand furnace lining of induction electric furnace of 1t or below

A technology of induction electric furnace and process, which is applied in the sintering process of quartz sand furnace lining and the field of sintering process of quartz sand furnace lining of induction electric furnace below 1t, which can solve the problems of poor operability, short service life of furnace lining, and long sintering process time, etc. , improve the sintering quality, add scientific effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

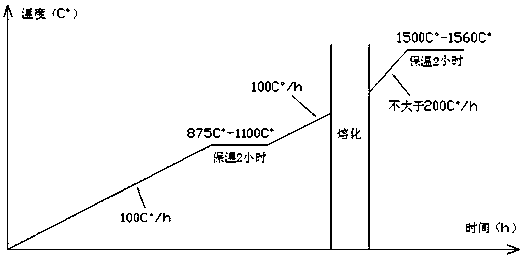

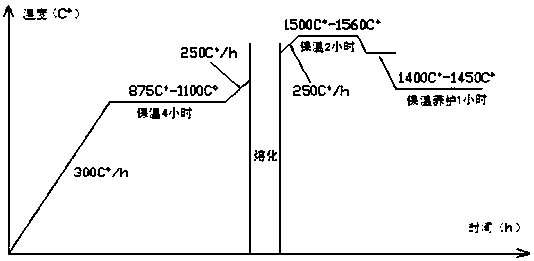

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the protection scope of the present invention middle.

[0029] 1. Select the quartz sand of United Minerals Co., Ltd. for the test.

[0030] 2. Build the furnace according to the furnace building process provided by United Minerals Co., Ltd. of the United States.

[0031] 3. Formulate 9 test methods, carry out the test step by step, and give the test results.

[0032] 3.1 Experiment 1 Improvement of charging charging method in daily smelting

[0033] The furnace lining sintering process remains unchanged, and the test is carried out by improving the way of adding furnace materials during daily smelting.

[0034] Before improvement: add recarburizer fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com