Patents

Literature

194results about How to "Extended hold time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

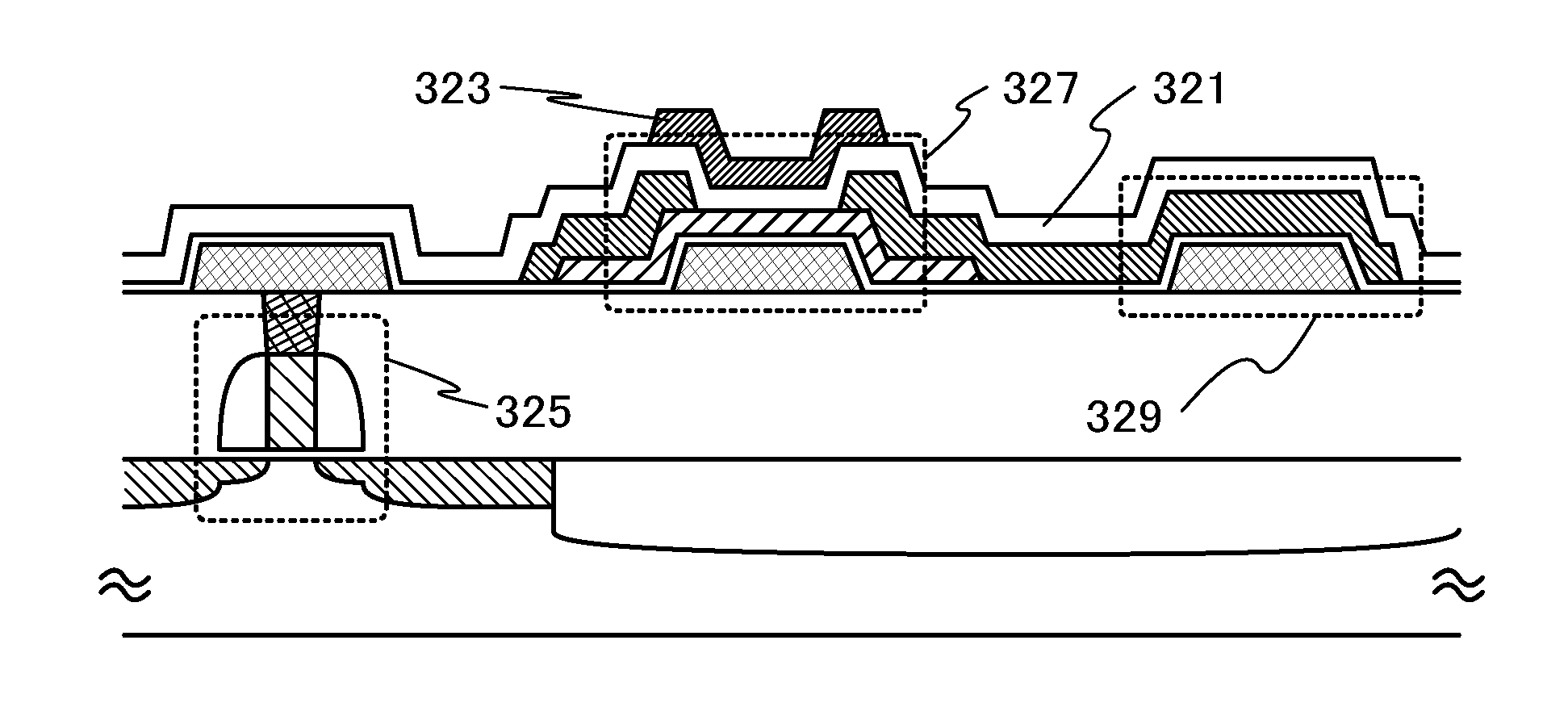

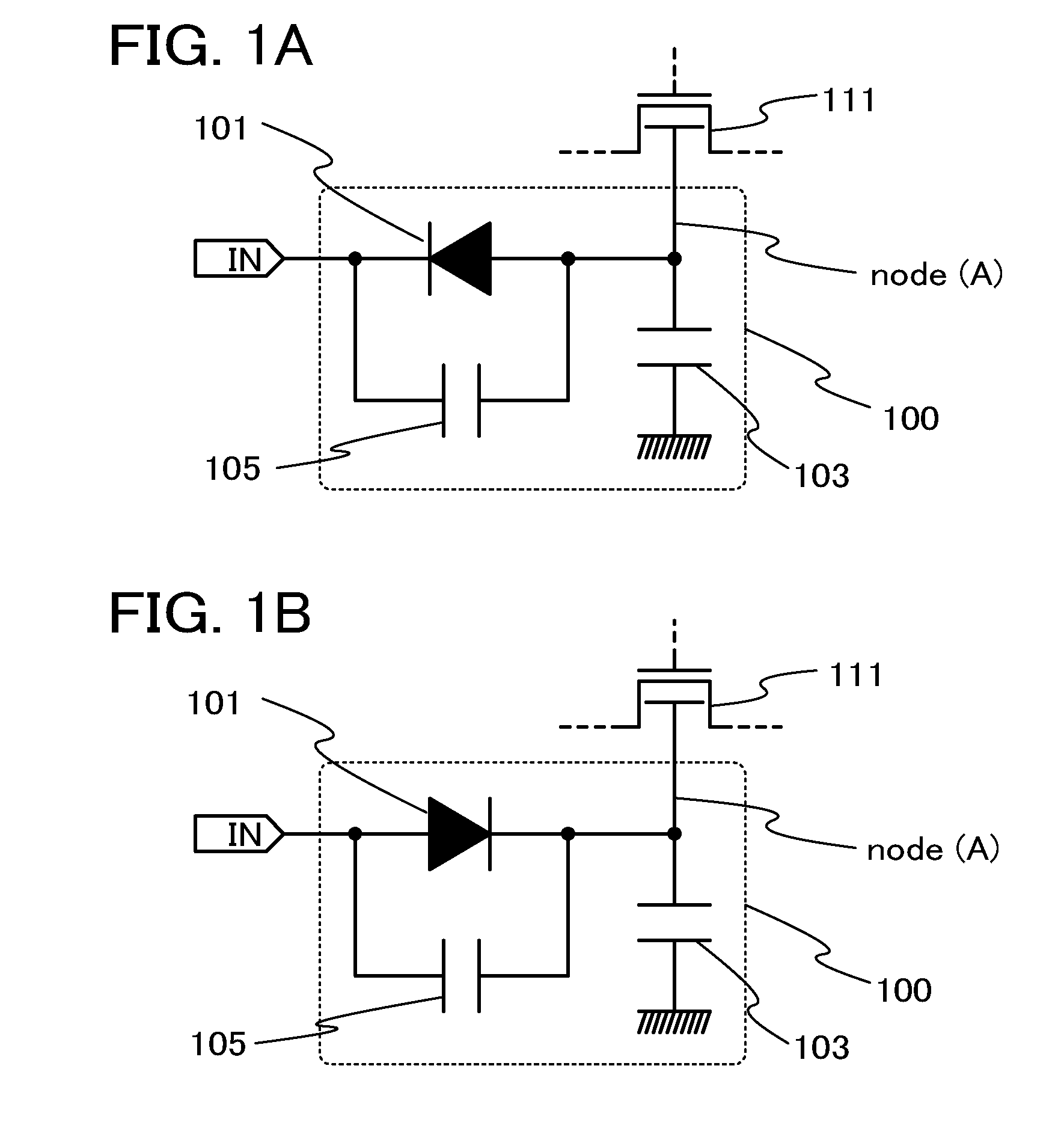

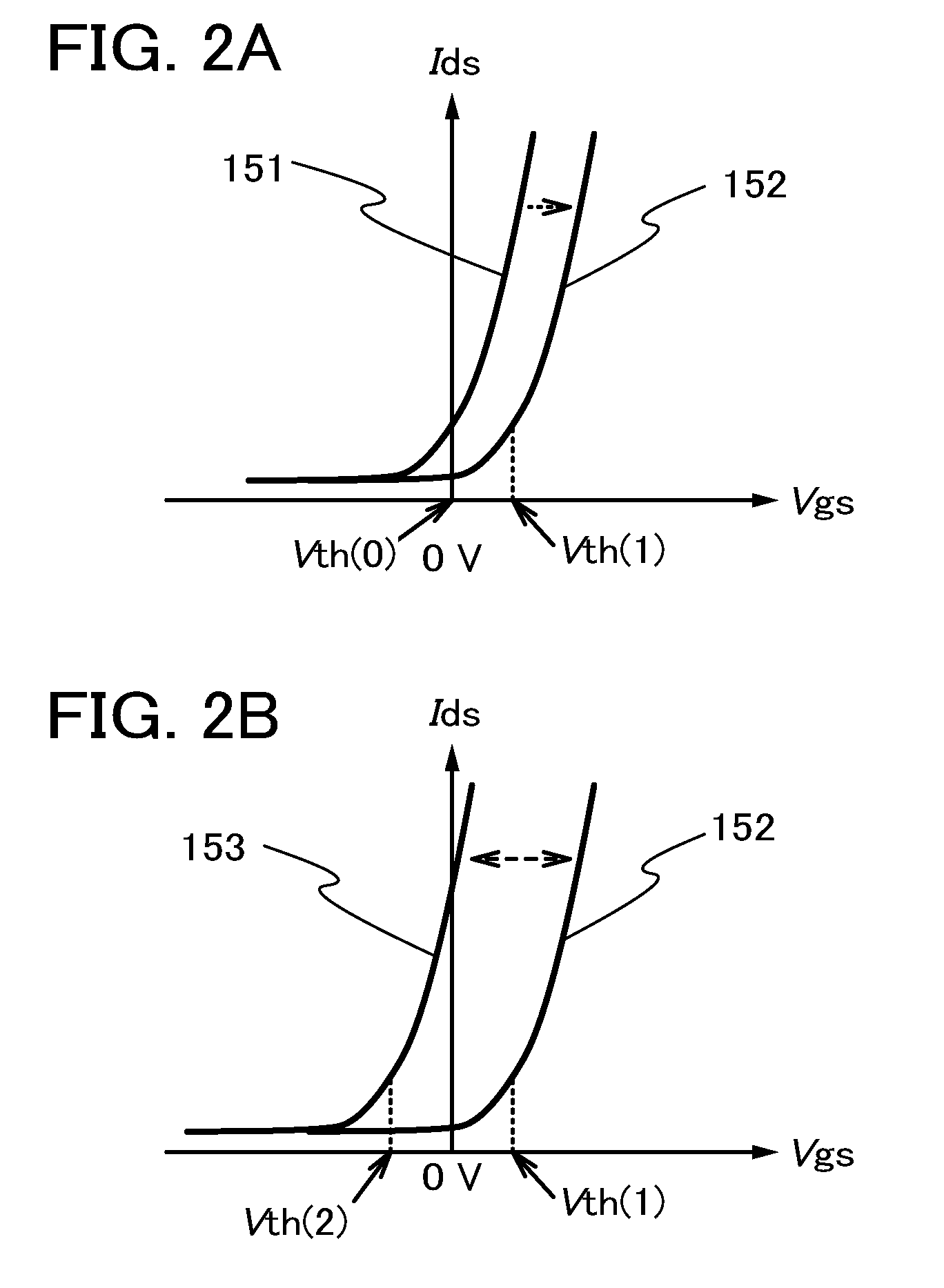

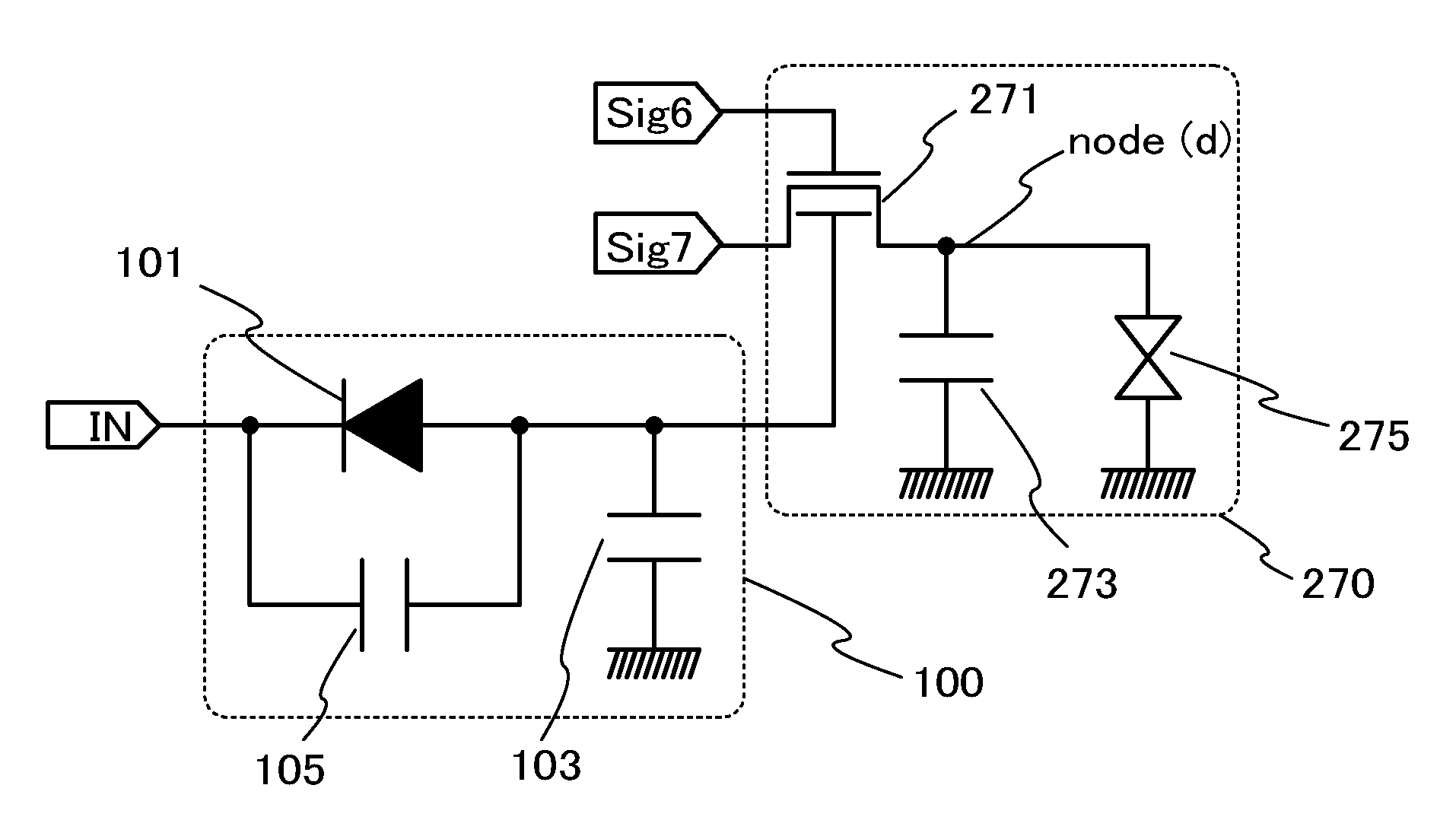

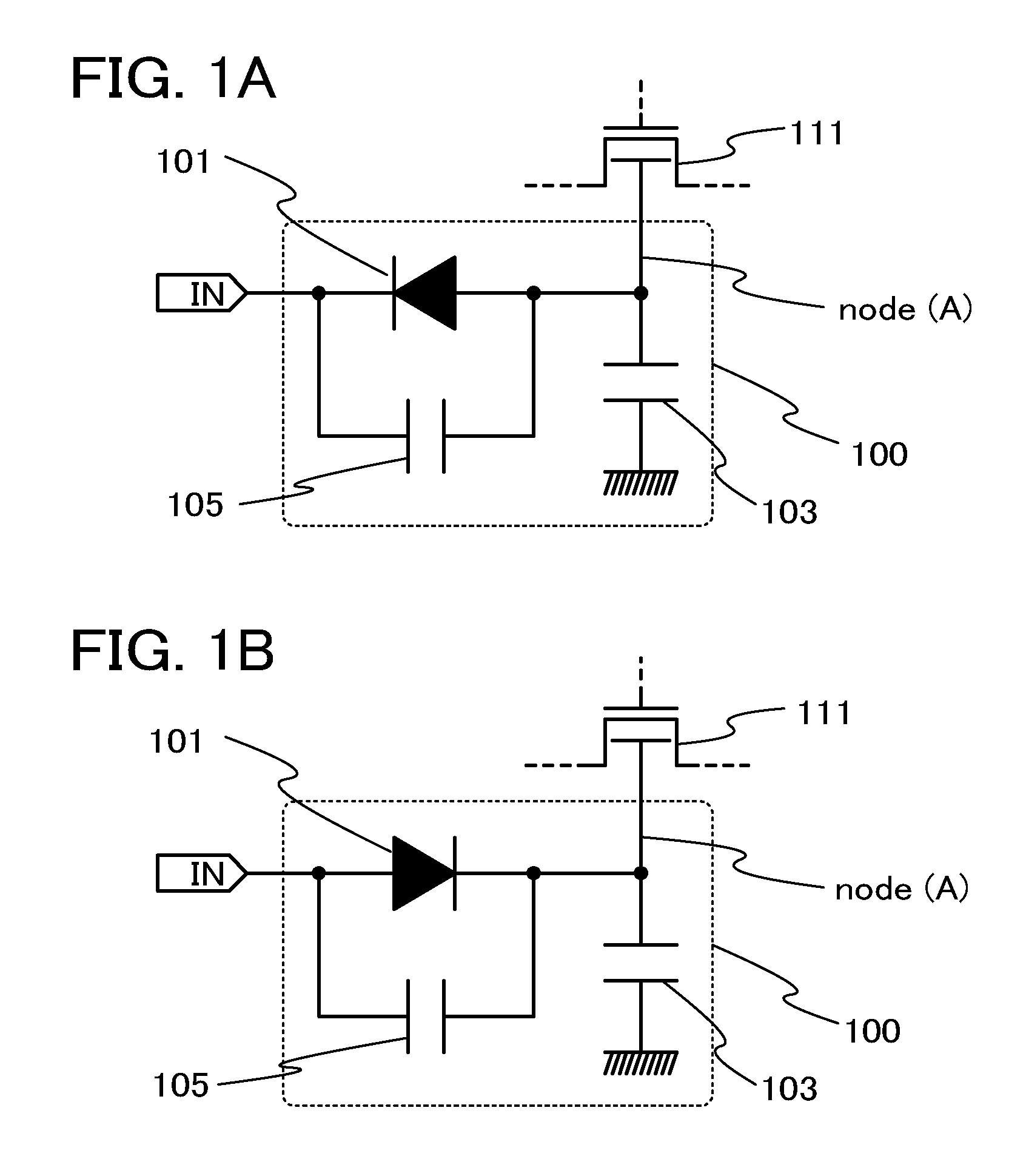

Semiconductor circuit, method for driving the same, storage device, register circuit, display device, and electronic device

ActiveUS20120161139A1Reduce power consumptionLow power consumptionTransistorStatic indicating devicesEngineeringSemiconductor

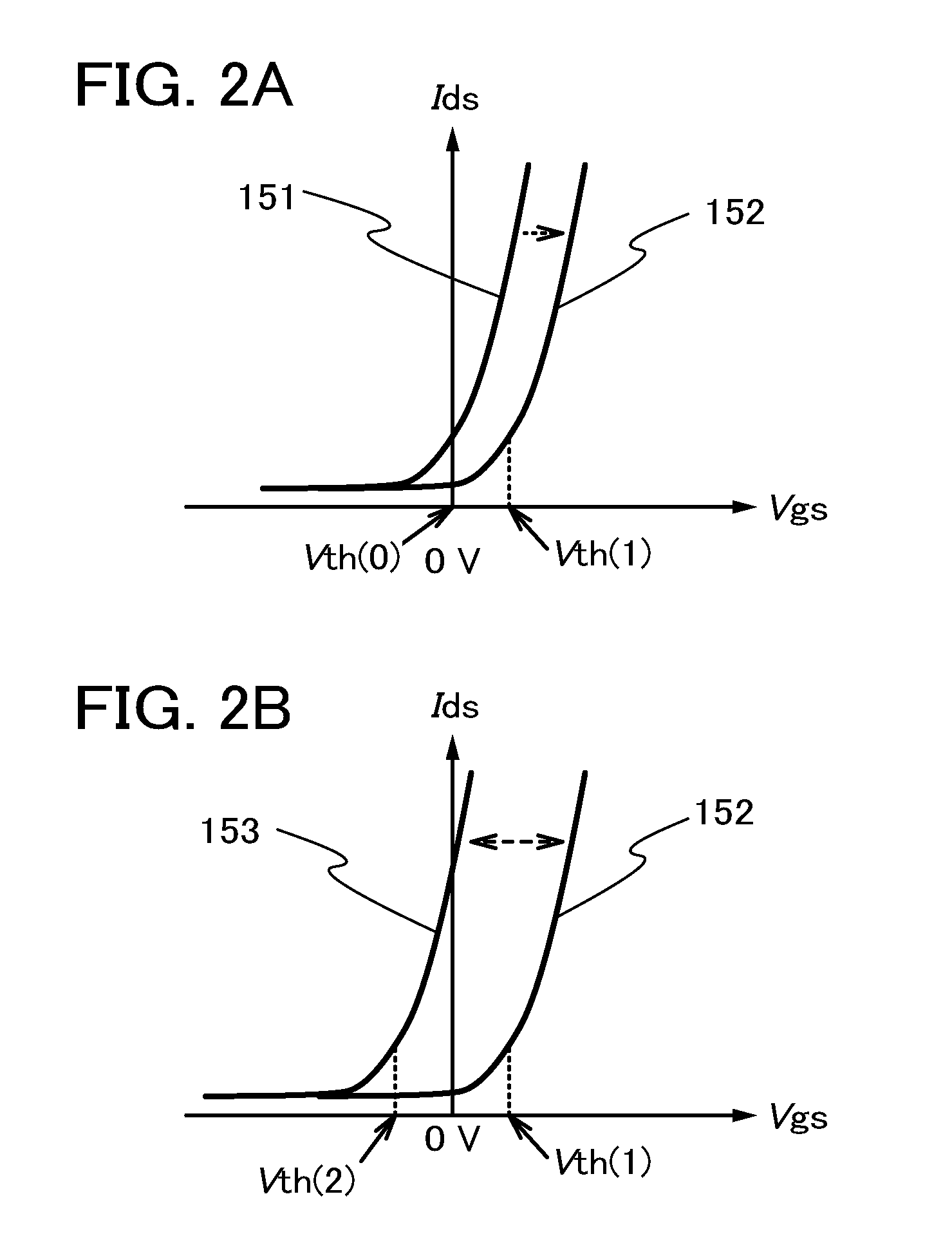

A semiconductor circuit capable of controlling and holding the threshold voltage of a transistor at an optimal level and a driving method thereof are disclosed. A storage device, a display device, or an electronic device including the semiconductor circuit is also provided. The semiconductor circuit comprises a diode and a first capacitor provided in a node to which a transistor to be controlled is connected through its back gate. This structure allows the application of desired voltage to the back gate so that the threshold voltage of the transistor is controlled at an optimal level and can be held for a long time. A second capacitor connected in parallel with the diode is optionally provided so that the voltage of the node can be changed temporarily.

Owner:SEMICON ENERGY LAB CO LTD

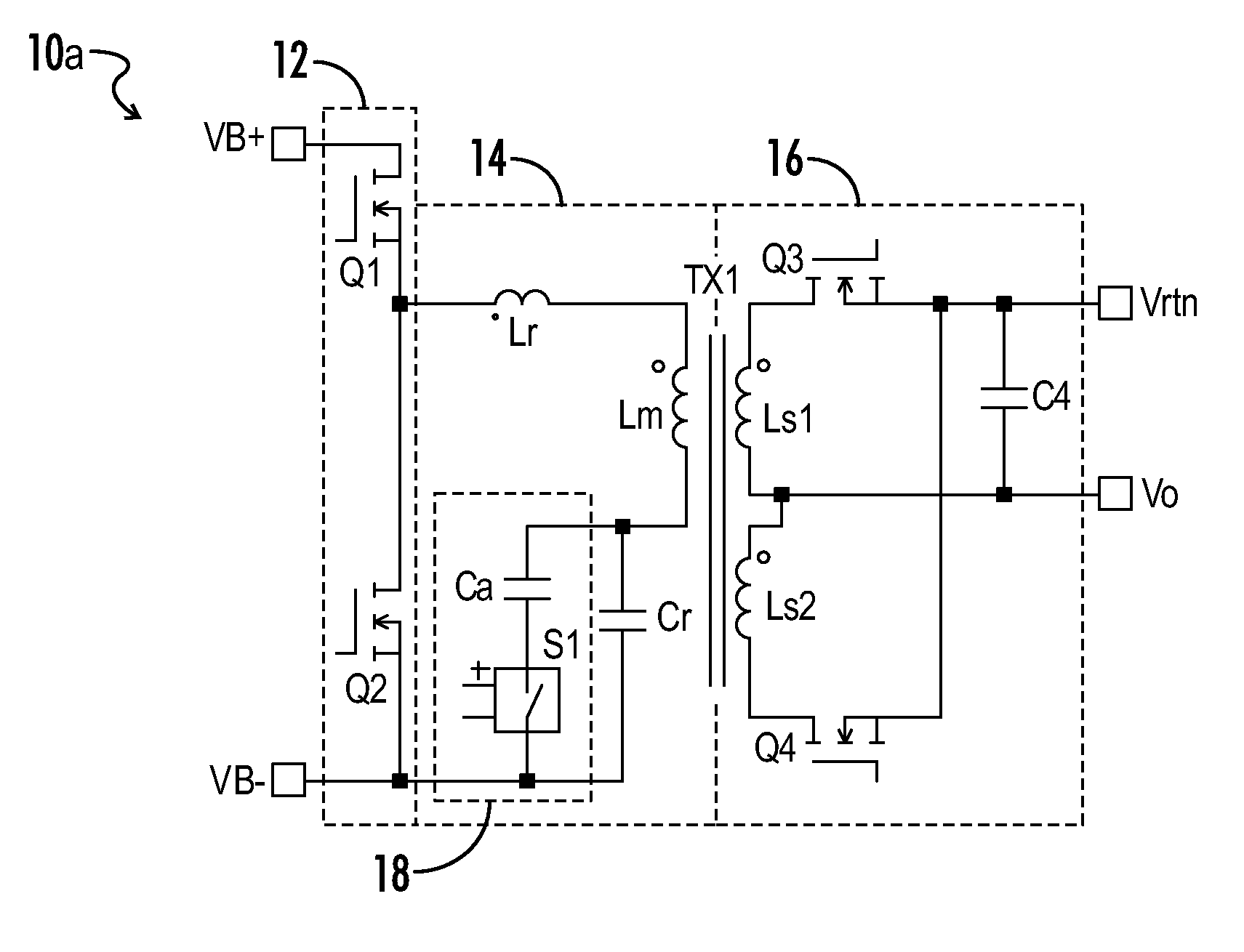

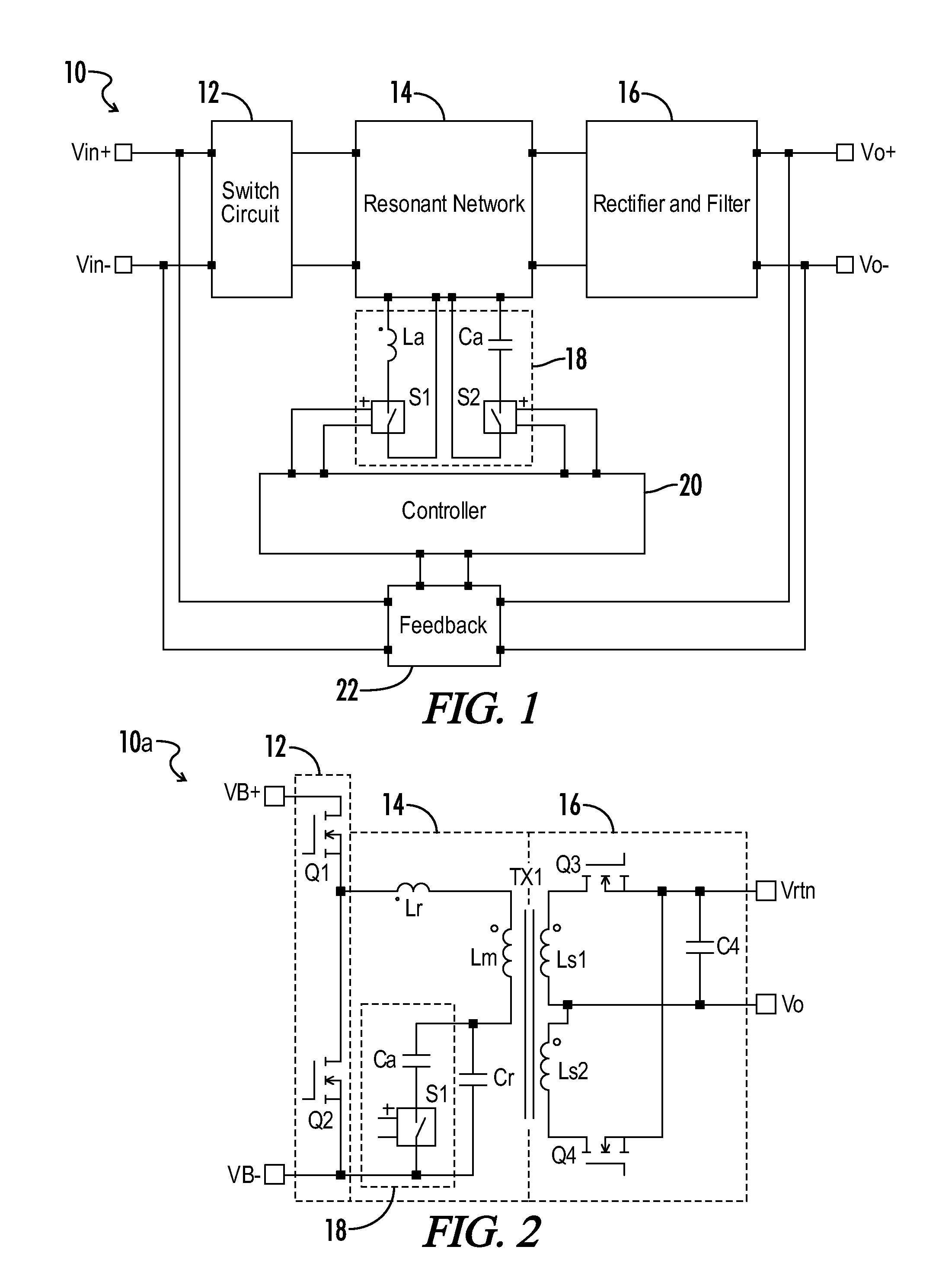

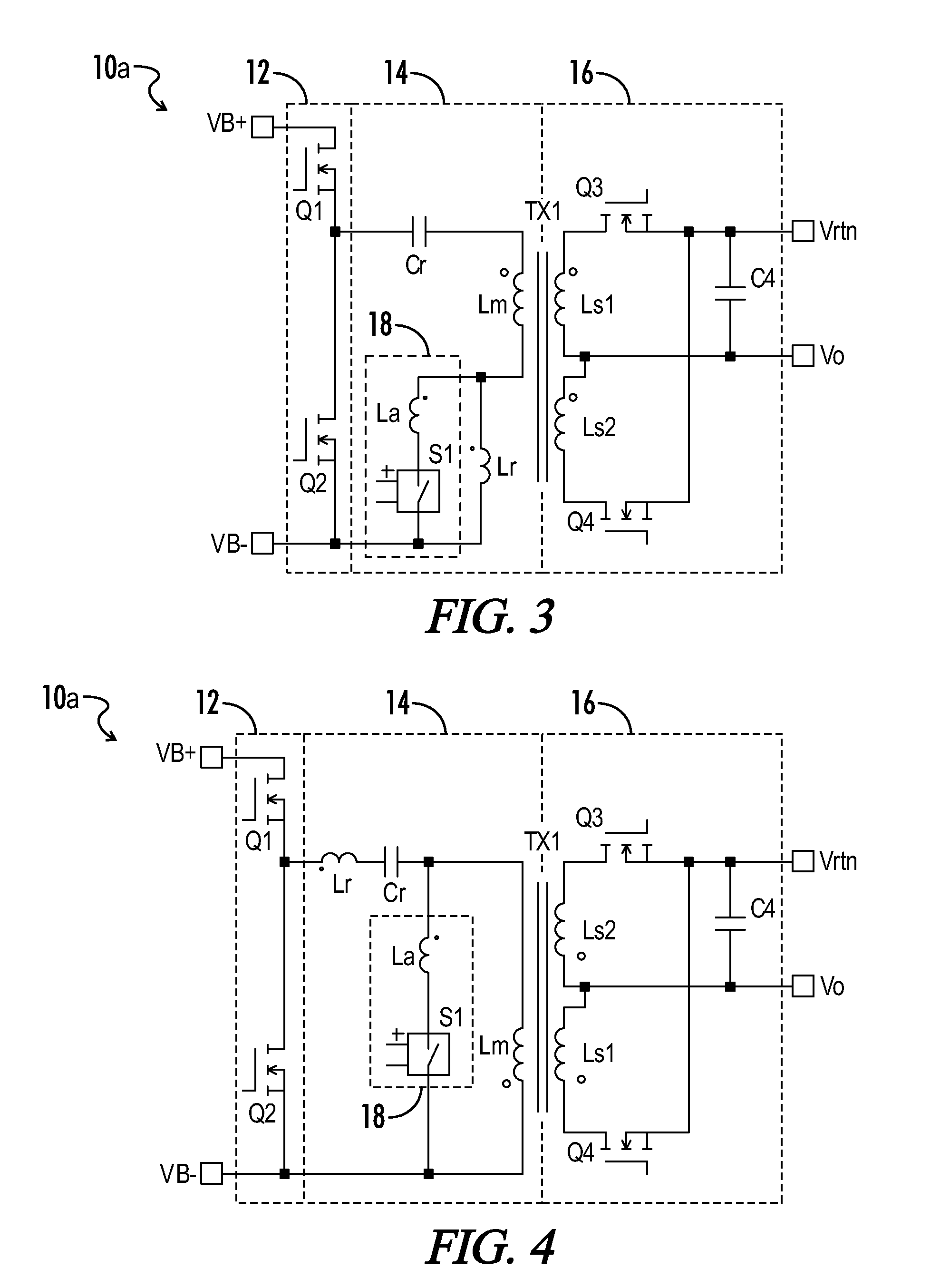

Resonant converter with auxiliary resonant components and holdup time control circuitry

InactiveUS20130194831A1Improve efficiencyLow efficiencyEfficient power electronics conversionDc-dc conversionResonant inverterCapacitance

A resonant power converter is provided with auxiliary circuit branches and control circuitry for switchably coupling the auxiliary branches to resonant circuit components during holdup times. Auxiliary branches are coupled in parallel with any one or more of a resonant inductor, a resonant capacitor, and a magnetizing inductive winding via respective switches. When a holdup time condition is detected in accordance with, for example, a drop in the mains line voltage, the switches are controlled to adjust the corresponding inductance or capacitance for the duration of the holdup time condition or otherwise for a predetermined duration. The power converter in normal operation is configured for high efficiency and in a holdup time operation is configured to produce sufficient holdup time.

Owner:BEL POWER SOLUTIONS INC

Semiconductor circuit, method for driving the same, storage device, register circuit, display device, and electronic device

ActiveUS9024317B2Reduce power consumptionTotal current dropTransistorStatic indicating devicesDisplay deviceSemiconductor

A semiconductor circuit capable of controlling and holding the threshold voltage of a transistor at an optimal level and a driving method thereof are disclosed. A storage device, a display device, or an electronic device including the semiconductor circuit is also provided. The semiconductor circuit comprises a diode and a first capacitor provided in a node to which a transistor to be controlled is connected through its back gate. This structure allows the application of desired voltage to the back gate so that the threshold voltage of the transistor is controlled at an optimal level and can be held for a long time. A second capacitor connected in parallel with the diode is optionally provided so that the voltage of the node can be changed temporarily.

Owner:SEMICON ENERGY LAB CO LTD

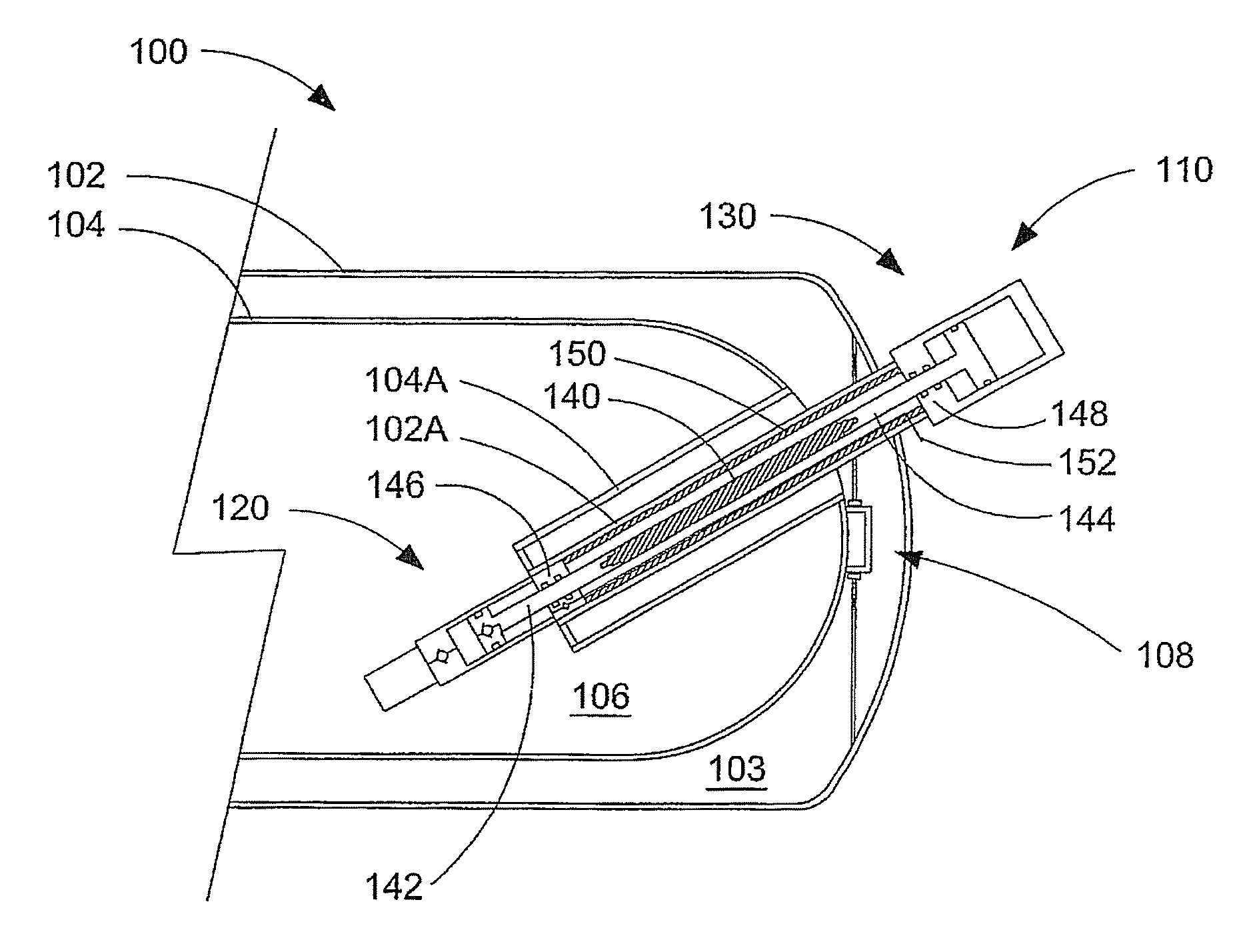

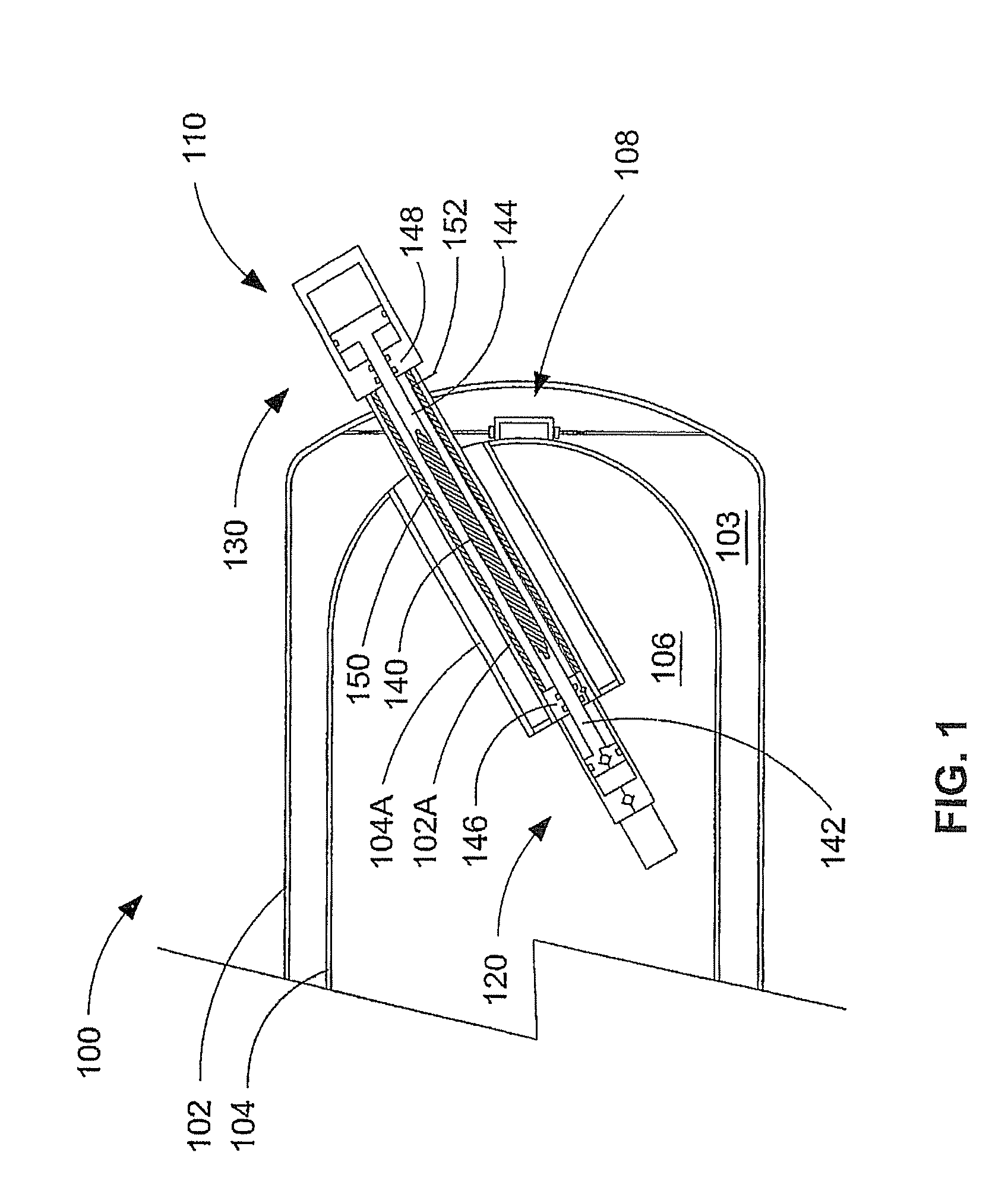

Apparatus And Method For Holding A Cryogenic Fluid And Removing Cryogenic Fluid Therefrom With Reduced Heat Leak

ActiveUS20070000259A1Reduce heat leakageExtended hold timeInternal combustion piston enginesFuel supply apparatusDrive shaftHeat leak

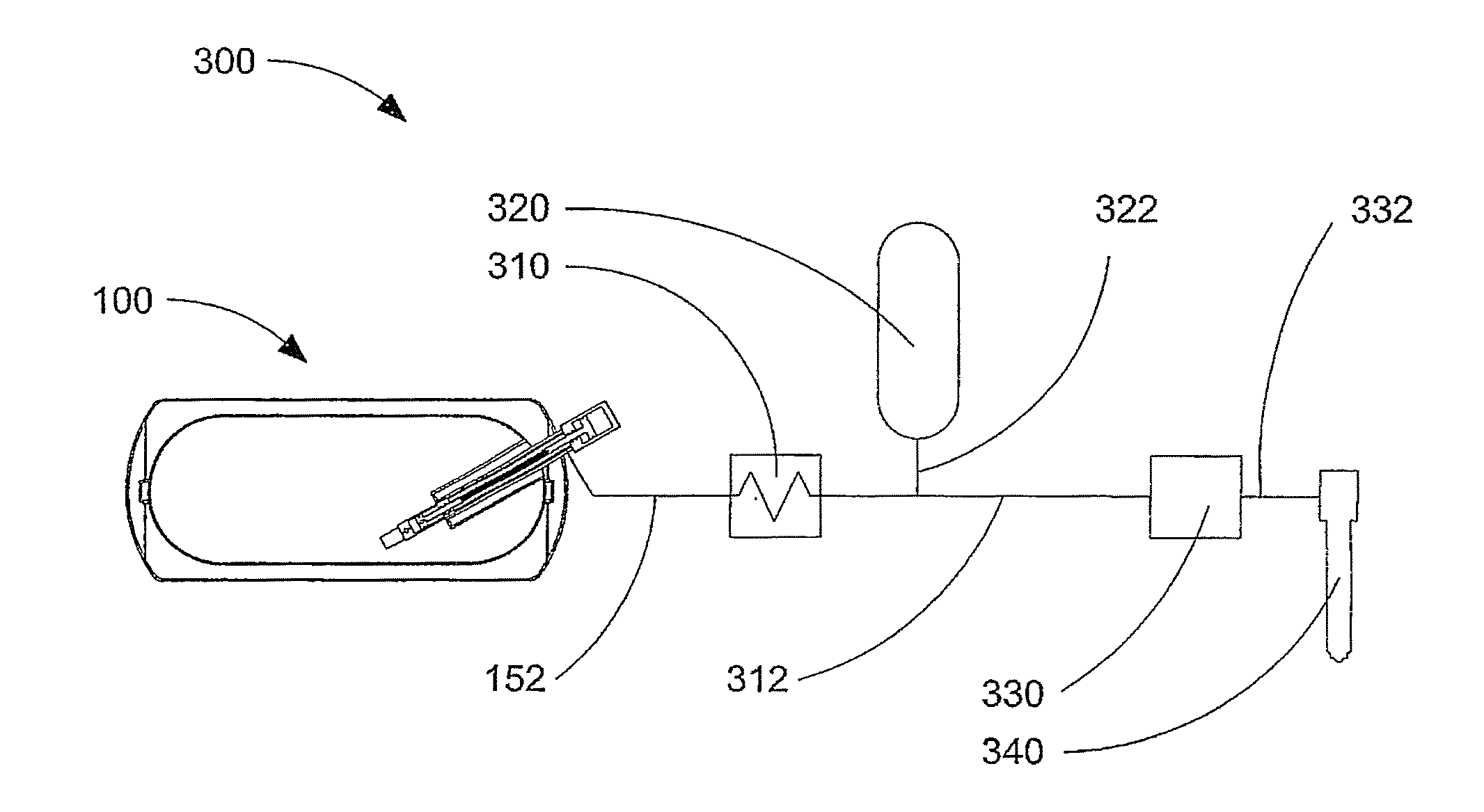

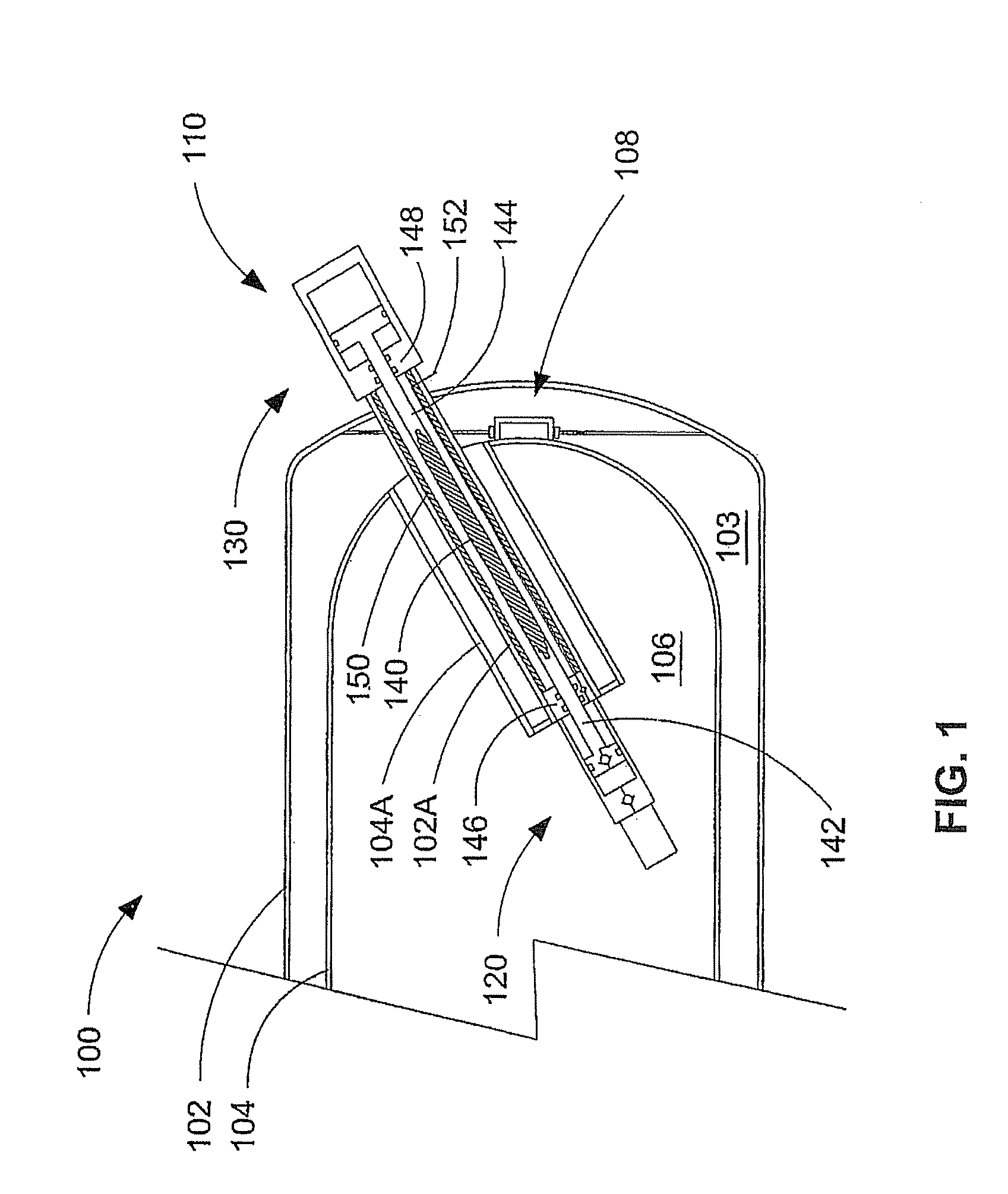

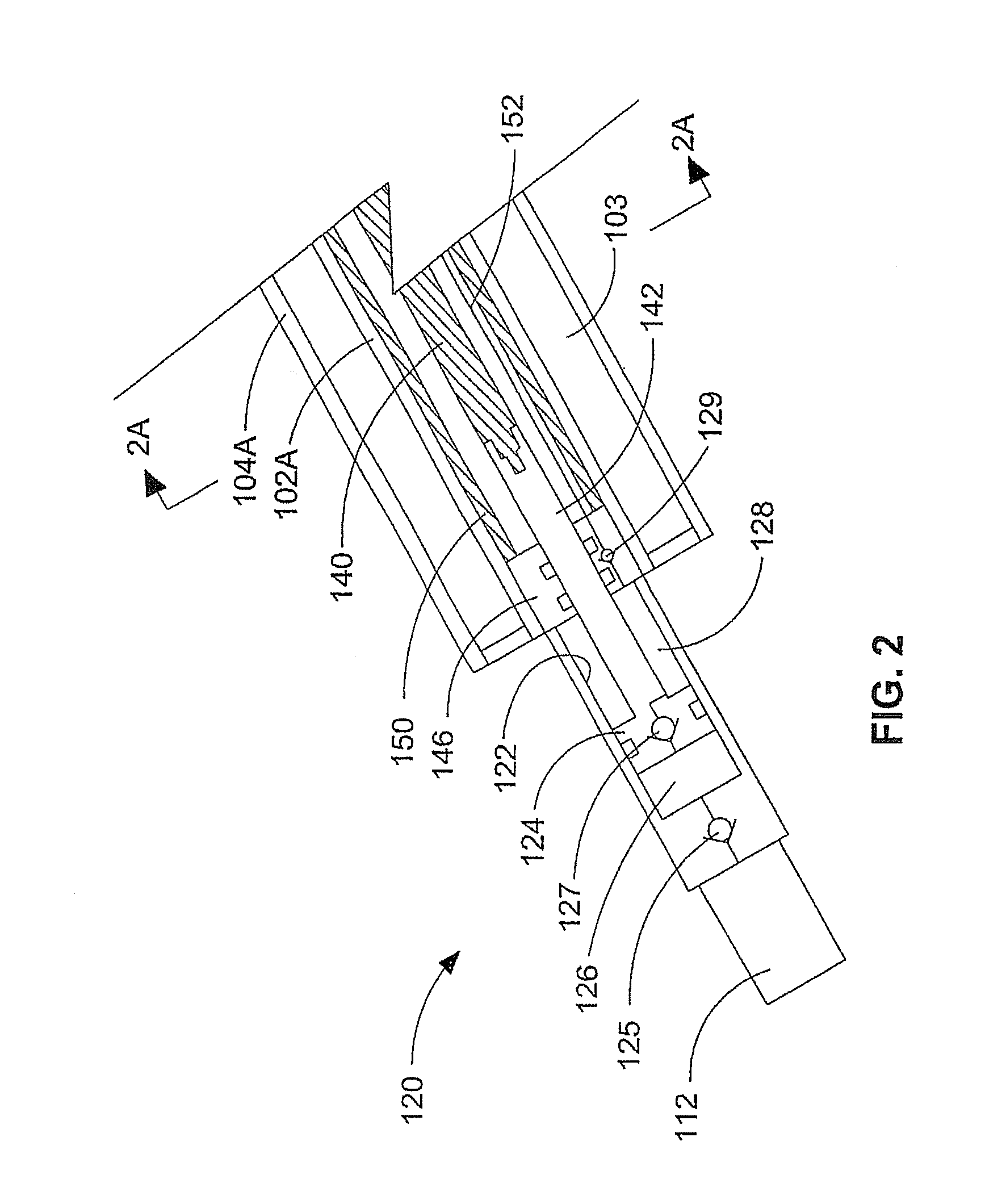

The apparatus comprises a double walled vacuum insulated vessel defining a cryogen space for holding a cryogenic fluid, a pump assembly comprising a pump with a suction inlet disposed within the cryogen space, and at least one elongated member extending from the pump to a drive unit disposed outside the cryogen space. The elongated member comprises an elongated non-metallic section that has a thermal conductivity that is less than that of a structurally equivalent elongated stainless steel member of the same length. In preferred embodiments, the elongated member can be one or both of a drive shaft or a rigid structural member for supporting the pump and holding it in a fixed relationship to the drive unit. The method employs the apparatus to increase hold times for holding cryogenic fluids by reducing heat leak into the cryogen space.

Owner:WESTPORT FUEL SYST CANADA INC

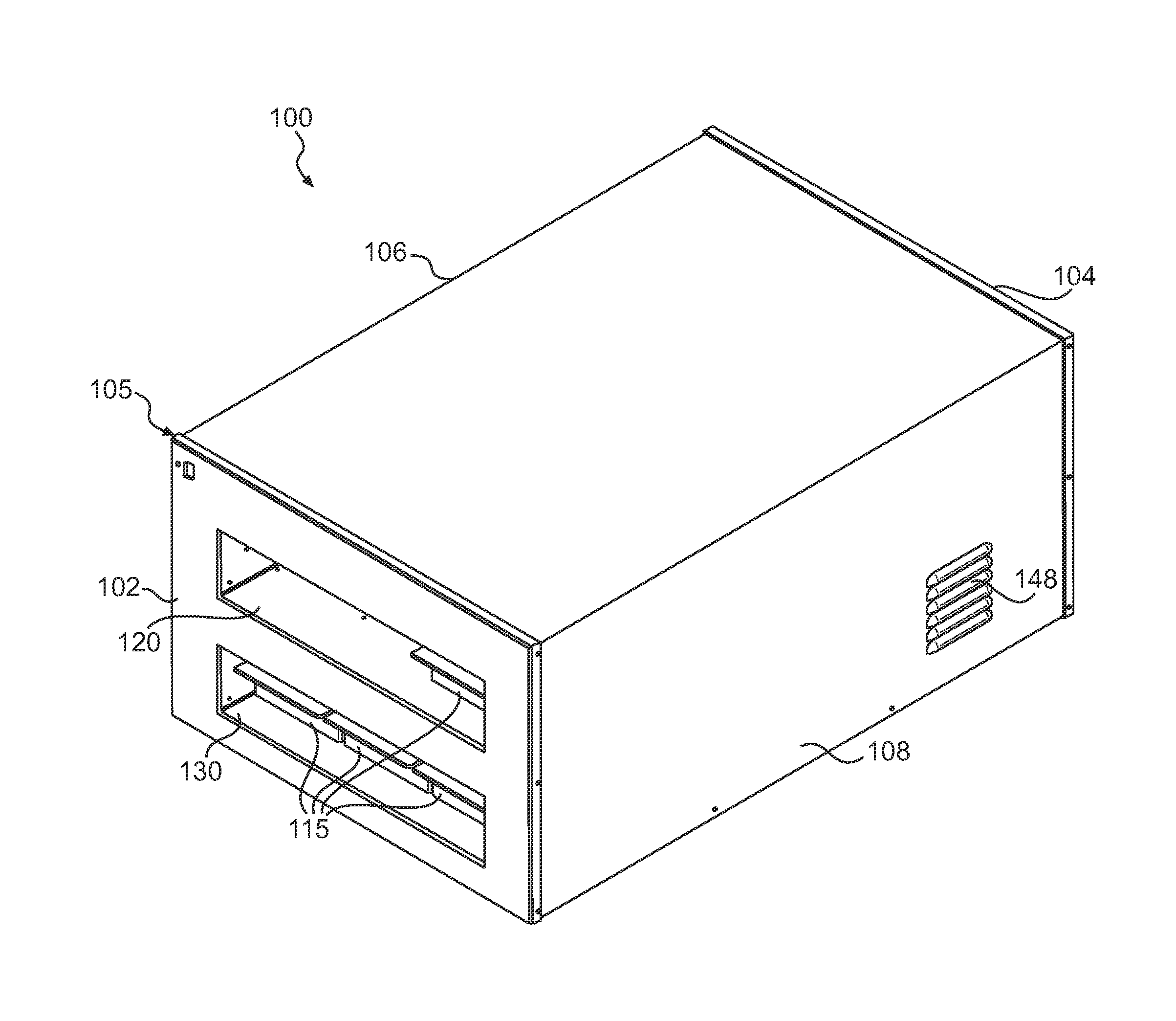

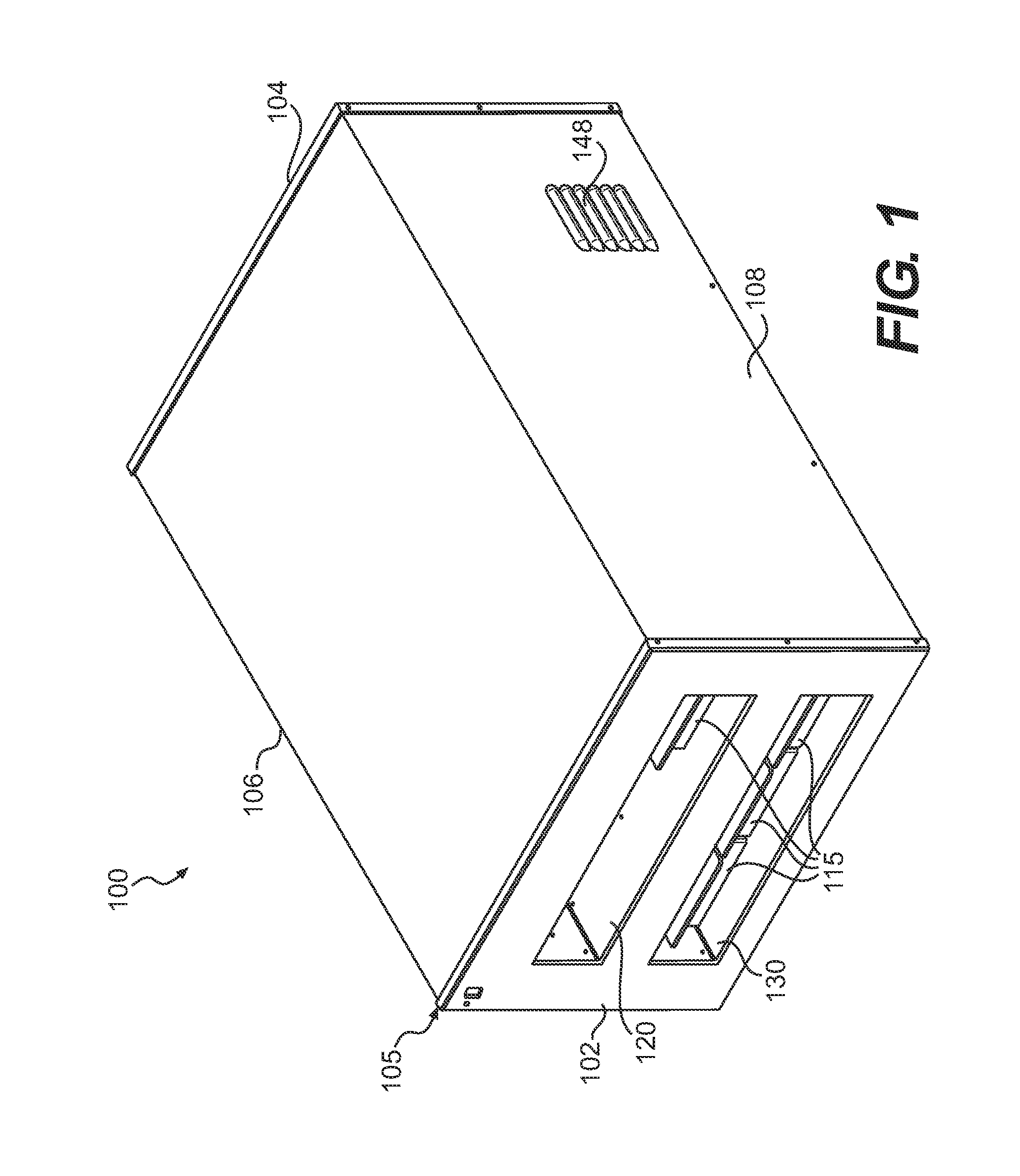

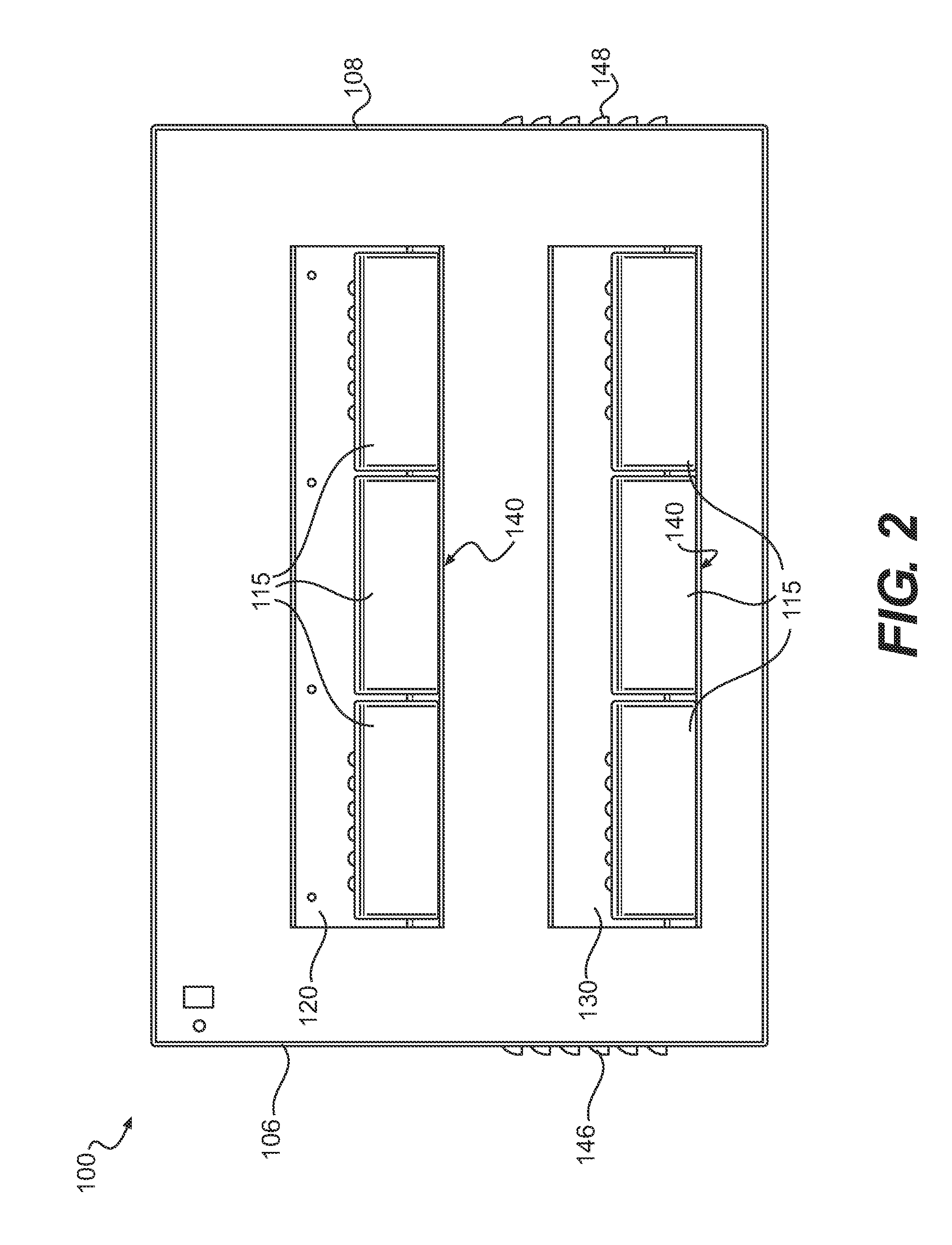

Holding cabinets, methods for controlling environmental conditions in holding cabinets, and computer-readable media storing instructions for implementing such methods

A holding cabinet includes a body defining a holding space and a holding compartment disposed within the holding space for holding a product therein. The holding cabinet further includes a heating source, a steam generator, a temperature sensor, a humidity sensor, a product detector, and a controller. The controller is configured to regulate environmental conditions of the holding compartment according to a determined setpoint, which corresponds to a predetermined temperature and relative humidity. The controller regulates such environmental conditions by acquiring the sensed air temperature, relative humidity, and the detected type of product, and activating and deactivating the heating source and the steam generator in accordance with the acquired air temperature, relative humidity, and the determined setpoint corresponding to the type of product detected and a holding time of the product, to maintain the air temperature and the relative humidity within a predetermined range based on the determined setpoint.

Owner:HENNY PENNY CORP

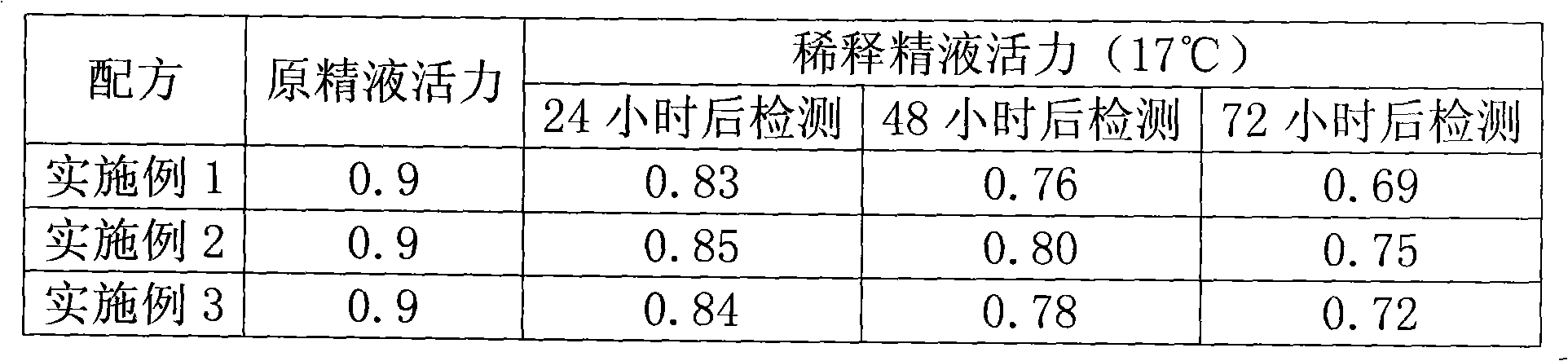

Diluent for storing the sperm of pig under normal temperature and preparation and dilution method thereof

The invention relates to a diluent for storing the sperm of a pig under normal temperature, which is characterized by comprises the following components by weight ratio: 9-11 of glucose, 0.2-0.3 of ethylene diamine tetraacetic acid, 0.5-0.6 of trisodium citrate, 0.08-0.12 of 1570U / mg penicillin and 0.2-0.25 of 720U / mg streptomycin. The diluent is completely dissolved in distilled water with distilled water according to the dilution ratio that diluent of 1g is diluted with distilled water of 20ml, and dilution liquid with the pH of being 6.5-6.8 and the osmotic pressure of being 290-310mOsmo / L is obtained; the diluent of the sperm of the pig, produced by the formulation, can effectively prolong the holding time, has convenient use and low cost, is suitable for being used by an artificial insemination station of the pig and a large-scale pig farm, has good application effect in the long-term production, has wider application range than the imported sperm, and can lead the conception rate of a sow in the oestrous period when being applied to a foreign pig to enable conception rate of a sow to be up to 86.8 percent with the litter size of 11.2 heads.

Owner:SICHUAN ANIMAL SCI ACAD

High tensile cold-rolled steel sheet excellent in ductility and in strain aging hardening properties, and method for producing the same

InactiveUS6692584B2Improve ductilityImprove stamping effectFurnace typesHeat treatment furnacesSheet steelHigh intensity

The present invention provides a high tensile cold-rolled steel sheet having superior ductility, strain age-hardening characteristics, and crash resistance properties, and also provides a manufacturing method therefor. As a particular means, a thin cold-rolled steel sheet containing 0.05% to 0.30% of C, 0.4% to 2.0% of Si, 0.7% to 3.0% of Mn, 0.08% or less of P, 0.02% or less of Al, and 0.0050% to 0.0250% of N on a mass % basis is manufactured in which N / Al is 0.3 or more. This thin cold-rolled steel sheet is heated to a temperature between (an Ac1 transformation point) and (an Ac3 transformation point+50° C.), is cooled at a cooling rate of 5 to 150° C. / second in the range of at least 600 to 500° C., and is held in the temperature range of 350 to 500° C. This steel sheet has superior ductility, strain age-hardening characteristics having a DeltaTS of 50 MPa or more, and crash resistance properties.

Owner:JFE STEEL CORP

Production method for non-annealed medium carbon cold heading steel hot-rolled wire rod

ActiveCN104759469AIncrease weightRefine the grain sizeTemperature control deviceMetal rolling arrangementsTemperature controlWire rod

The invention discloses a production method for a non-annealed medium carbon cold heading steel hot-rolled wire rod. The production method includes steps that (1) smelting molten steel, and continuously casting to form a billet; (2) slowly cooling the billet to release stress; (3) heating the slowly cooled hot-rolled billet to 1150 to 1190 degrees centigrade, preserving the heat for 110 to 140 minutes, and dephosphorizing through high pressure water; (4) carrying out rough intermediate rolling, pre-precision rolling and finish rolling on the dephosphorized hot-rolled billet, wherein the finish rolling temperature is 965 to 995 degrees centigrade, the coiling temperature is controlled at 960 to 980 degrees centigrade after finishing finish rolling, and the dimensional precision is performed with negative common difference; (5) feeding a hot-rolled steel wire rod to a cooling line, closing a fan and a heat holding cover, and keeping the steel wire rod in the heat holding cover for at least 40 minutes to obtain the hot-rolled wire rod. The production method for the non-annealed medium carbon cold heading steel hot-rolled wire rod enables the drawing amount to be reduced, avoids the hardness increase due to large drawing amount, meets the non-annealing production demand of the downstream user, enables the cost to be reduced, avoids the environment pollution due to annealing, and is featured with energy saving, environment friendliness and low cost.

Owner:XINGTAI IRON & STEEL

Hardening and tempering technology of alloy-steel tube

ActiveCN102676780AStress reliefUniform internal organizationFurnace typesHeat treatment furnacesHydraulic cylinderFree cooling

The invention discloses a hardening and tempering technology of an alloy-steel tube, and through the technology, the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The technology comprises the following steps of: (1) annealing treatment: warming to 870-880 DEG C at the speed of 20-25 DEG C / minute, keeping the temperature for 35-40 minutes, and then cooling to 500 DEG C below; (2) quenching treatment: warming to 930-935 DEG C at the speed of 5-10 DEG C / minute, keeping the temperature for 50-60 minutes, then cooling rapidly at the speed of 190-200 DEG C / second to 320-325 DEG C, and cooling naturally to 30-40 DEG C; and (3) tempering treatment: warming to 500-510 DEG C at the speed of 5-10 DEG C / minute, then keeping the temperature for 230-240 minutes, and then cooling naturally to room temperature, thus the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The hardening and tempering technology of the alloy-steel tube provided by the invention is mainly applied to the hardening and tempering of the alloy-steel tube for a hydraulic cylinder barrel.

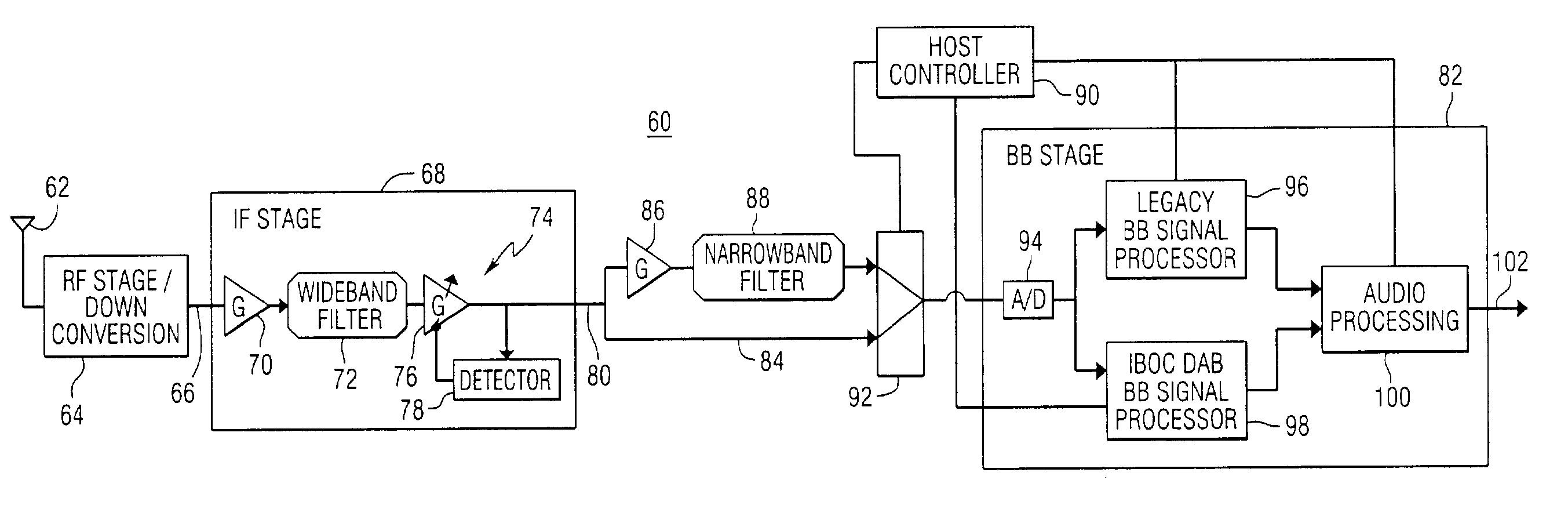

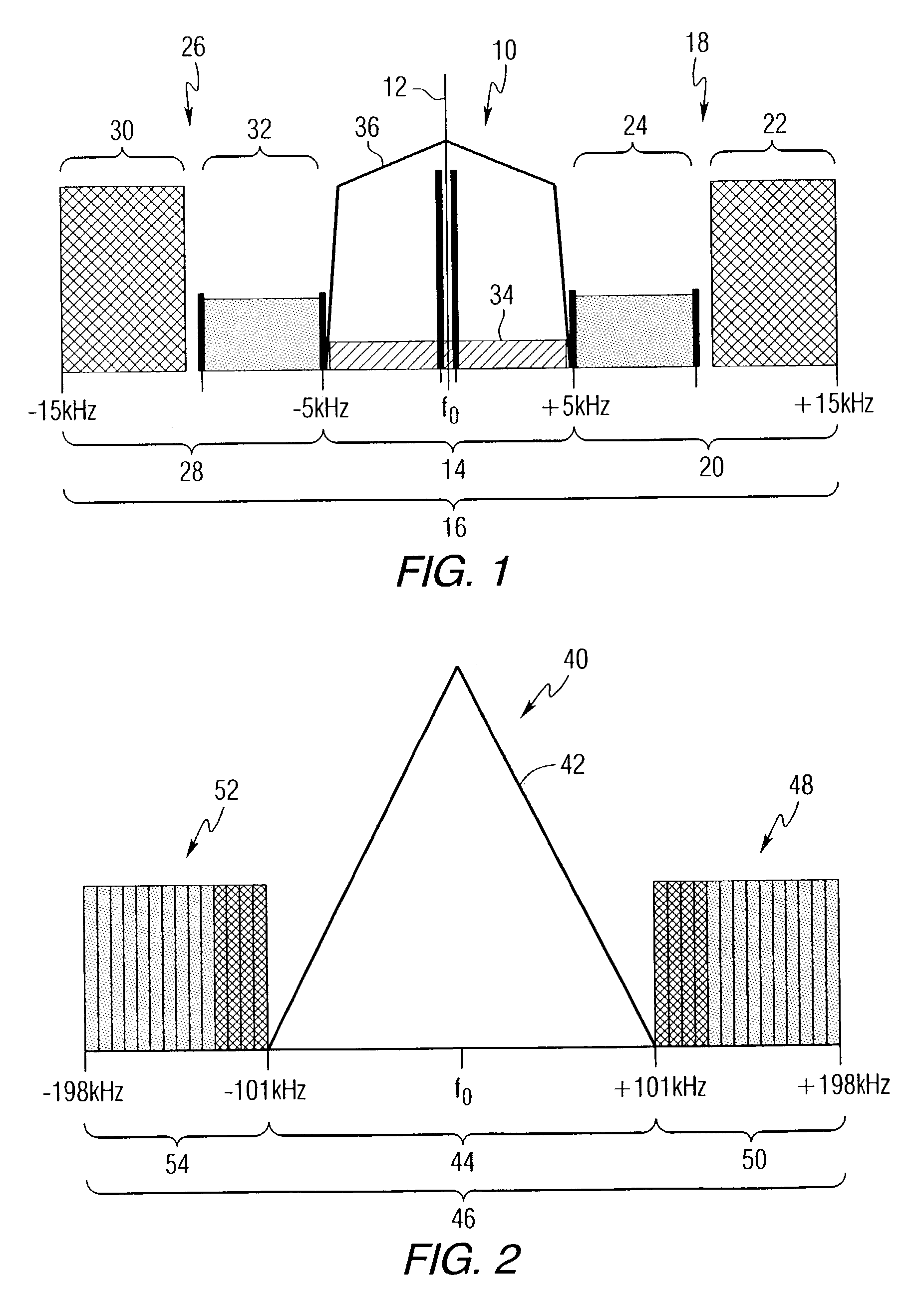

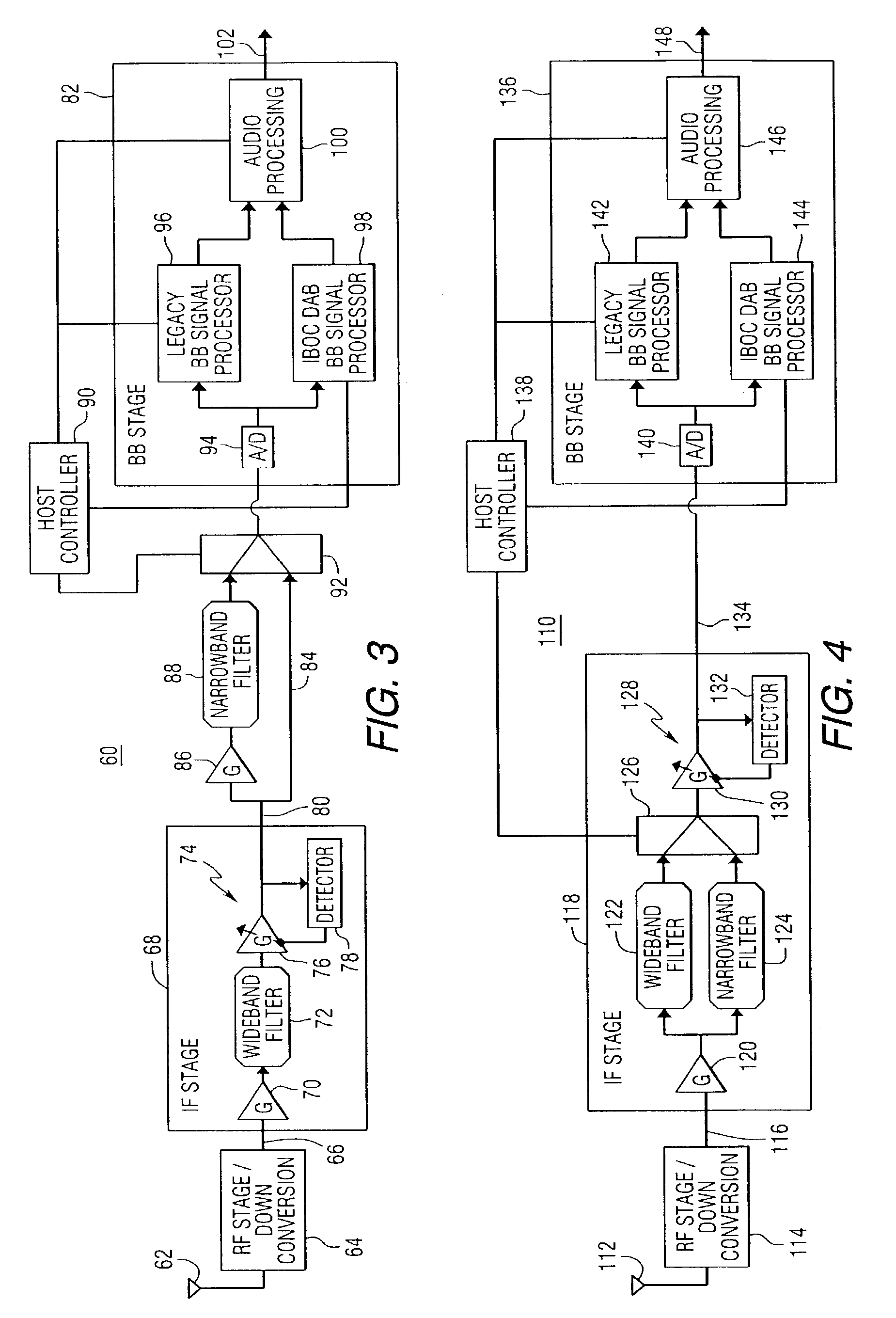

Method and apparatus for dynamic filter selection in radio receivers

ActiveUS6970685B2Shorten holding timeExtended hold timePlural information simultaneous broadcastRadio transmissionRadio receiver designRadio receiver

A method for processing a radio signal which may include a narrowband signal or a wideband signal or both, comprises the steps of receiving the radio signal, initially processing the radio signal using a narrowband filter, switching to a wideband filter for further processing of the radio signal, determining if the wideband signal is acquired, and if the wideband signal is not acquired, alternating between narrowband filter processing for a narrowband filter hold time and wideband filter processing for a wideband filter hold time, where the narrowband filter hold time is gradually increased until a predetermined maximum time limit is reached. If the wideband signal is acquired, the narrowband filter hold time can be set to a predetermined minimum time limit. Receivers which implement the method are also provided.

Owner:IBIQUITY DIGITAL CORP

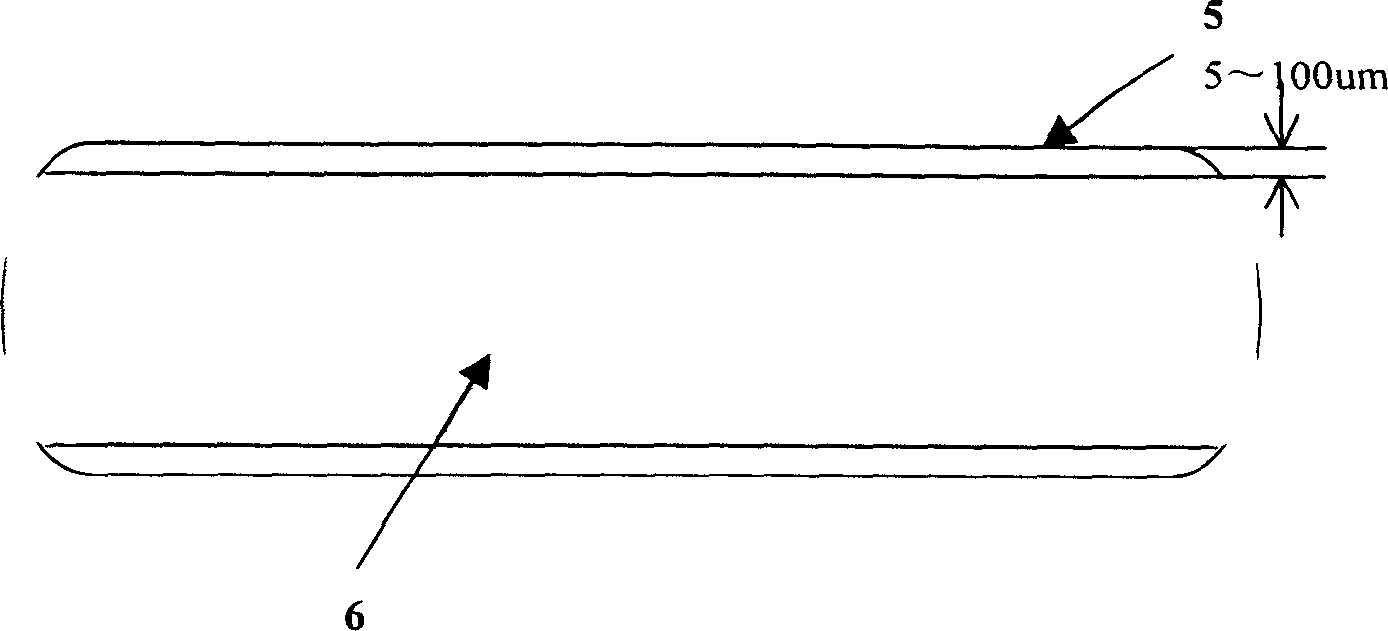

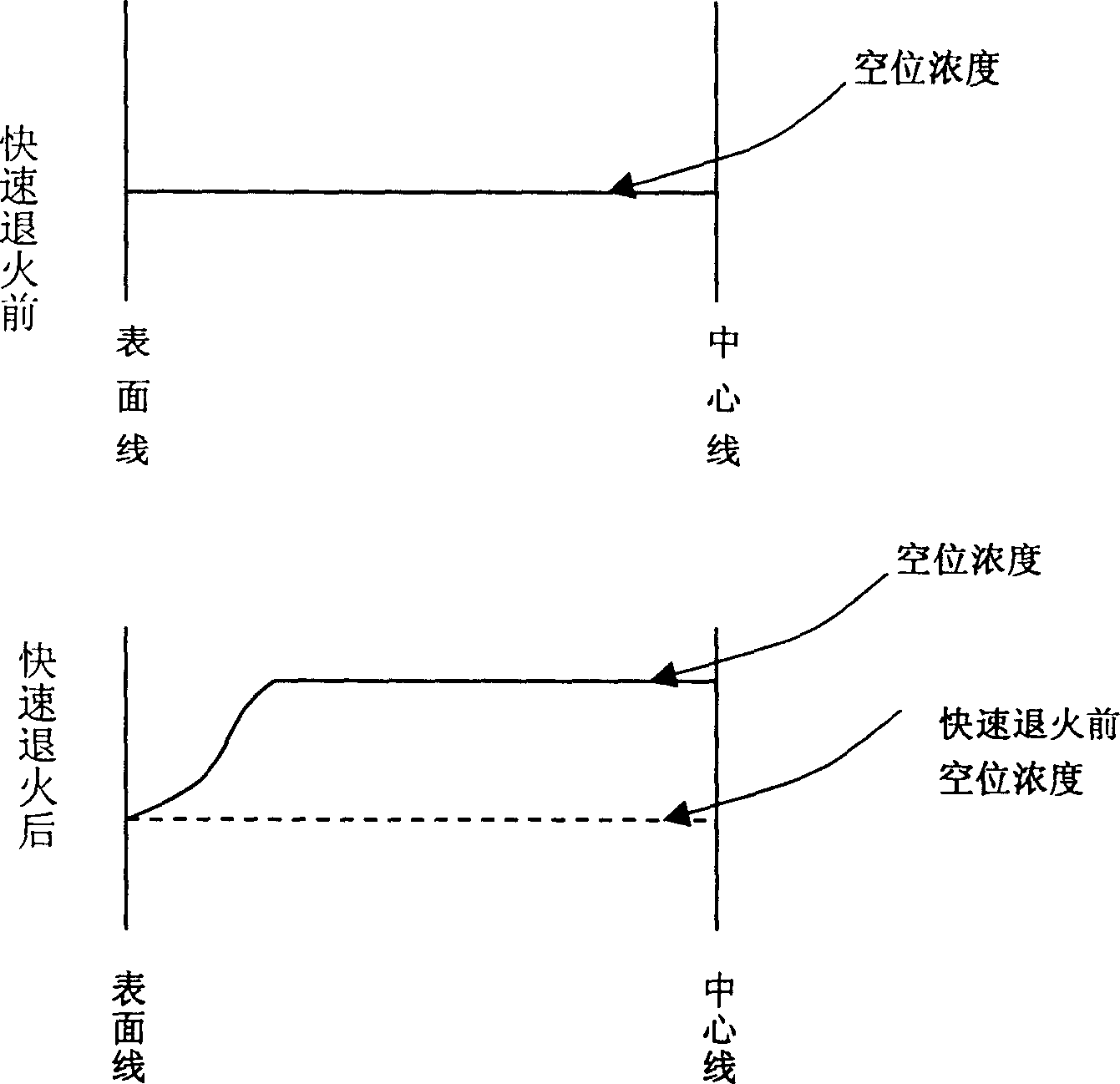

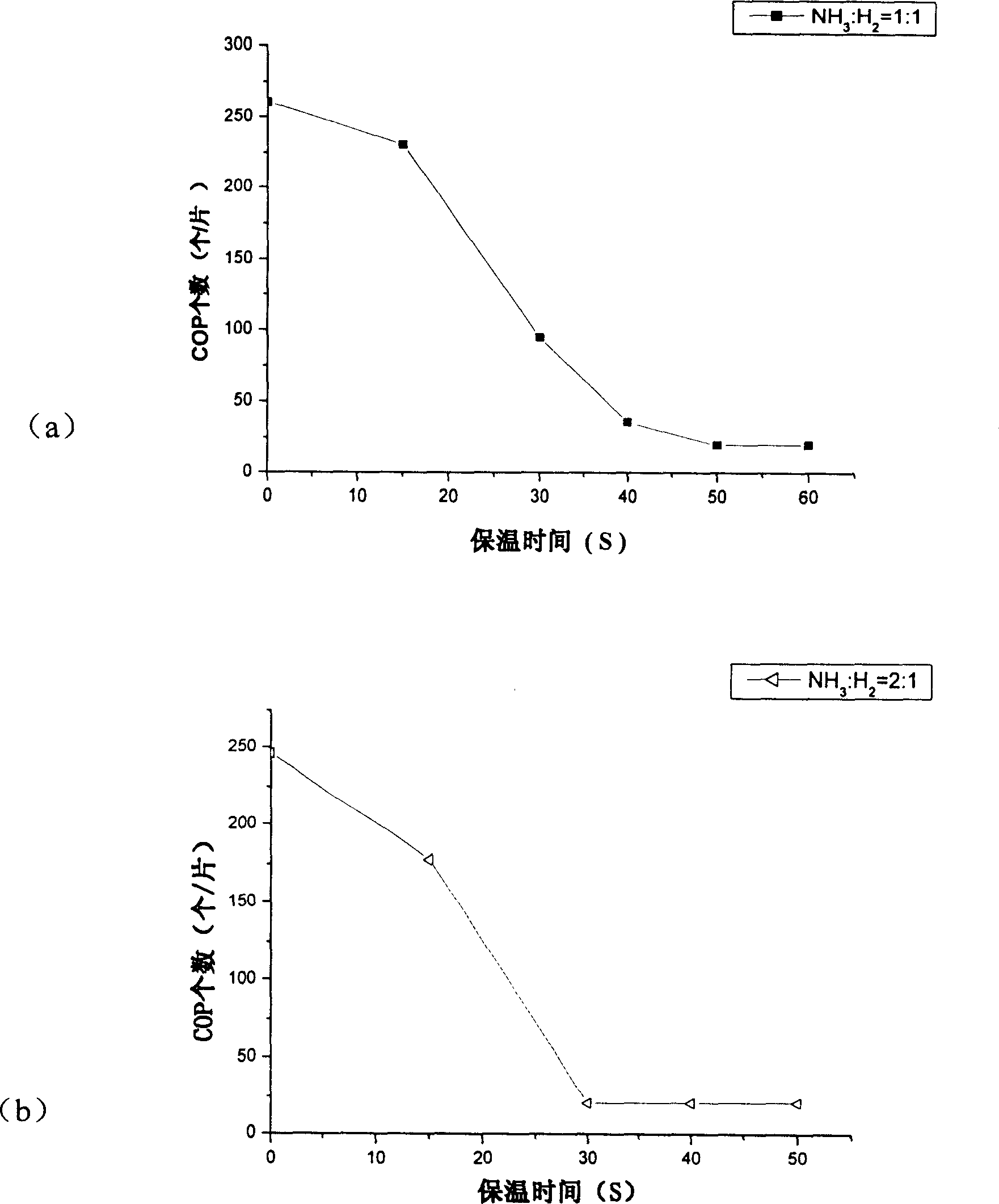

Rapid thermal process for silicon sheet capable of obtaining denuded zone and product thereof

ActiveCN1838388AImprove eliminationMeet the requirements of getteringSemiconductor/solid-state device manufacturingHeat treatedOxygen

This invention relates to a silicon fast heat process technology for obtaining clear area and its product. The method includes: (1) in Ar / NH3 / H2 or N2 / NH3 / H2, heating silicon sheet up to 1150- 1250DEG.,then keeping the temperature of the silicon sheet under 1150-1250DEG., then lowering temperature by 20-100DEG. / S speed to normal temperature; (2)anneal by regular method ; (3) heat processing by regular method to obtain the silicon sheet with clear area. This technology can control the thickness of the clear area between 5-40 mum, under which the technology can improve the oxygen deposition density of the impurity absorbing area and lower COP density of the surface.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

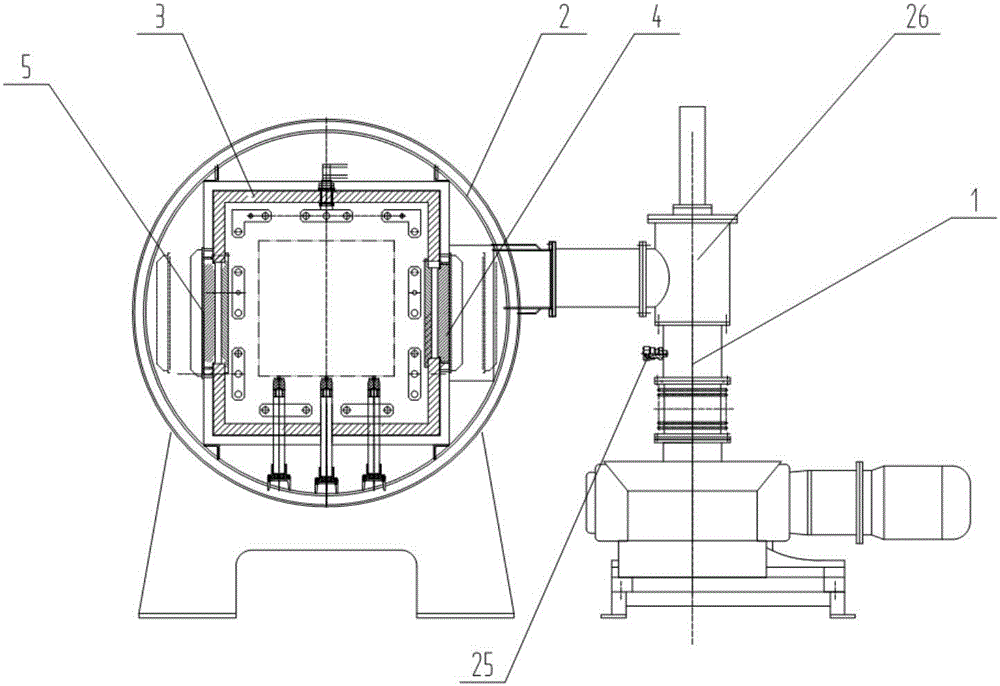

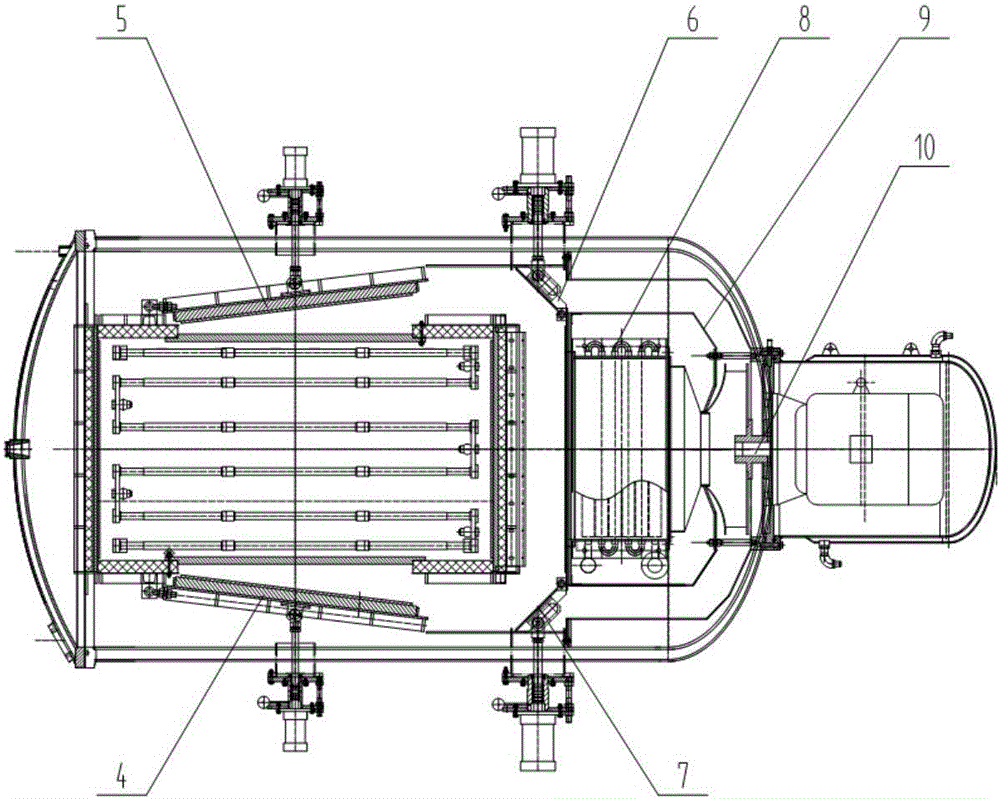

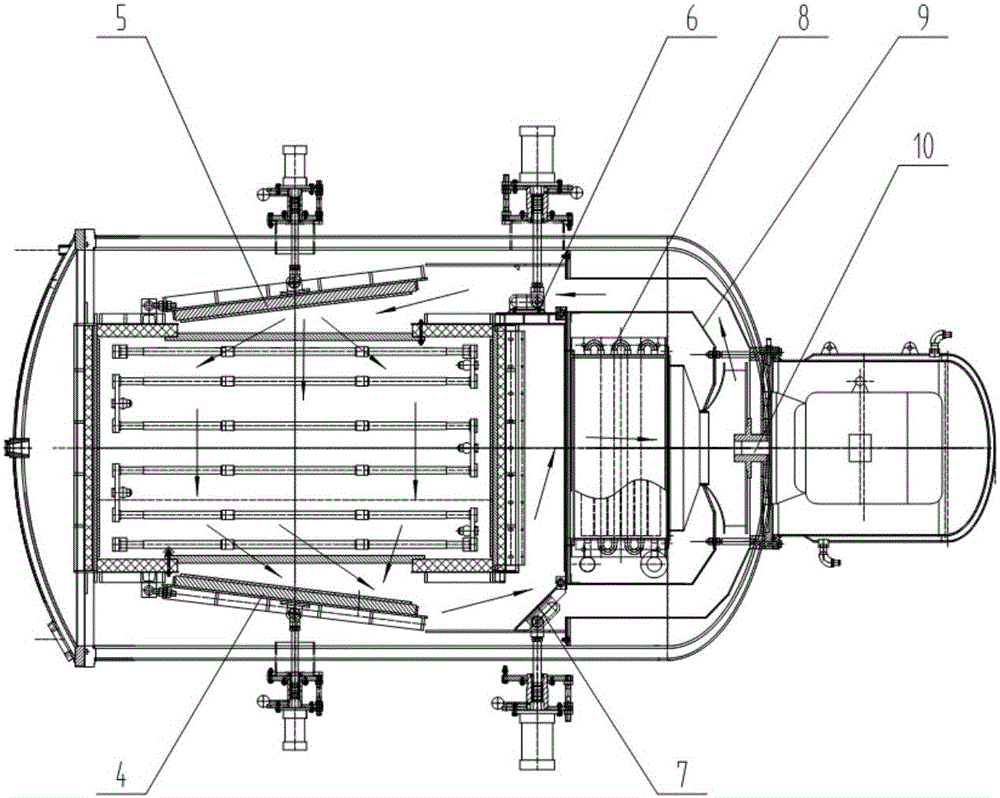

Multifunctional vacuum furnace

InactiveCN106500503AAvoid energy lossHeating evenlyMuffle furnacesRetort furnacesVacuum furnaceReverse mode

Disclosed is a multifunctional vacuum furnace. The multifunctional vacuum furnace is characterized in that the front portion of the body of a heating chamber is provided with a movable front left air door and a movable front right air door, a rear left reversing air door and a rear right reversing air door are symmetrically installed at the air flue end outside the heating chamber, air door air cylinders are installed outside a furnace shell, and air cylinder piston rods penetrate through the furnace shell to be connected with air door pin shafts through sealing structures. The multifunctional vacuum furnace has the advantages that in the heating process, the front left air door and the front right air door are closed, no air through hole is formed, energy loss in the heating process is avoided, energy is saved, and it is ensured that heating is more uniform; and in the cooling process, the opening degree of the front left air door and that of the front right air door are large, meanwhile, the rear left air door and the rear right air door can achieve reversing, in other words, airflow alternately flows in a reversing mode inside the heating chamber, outside the heating chamber, on the left of the heating chamber and on the right of the heating chamber, reversing time can be set, accordingly, workpieces are uniformly cooled, the cooling speed is increased, and the furnace discharge time is shortened. The problem that production efficiency is affected is solved, energy consumption is lowered to minimum, product performance is higher, and production efficiency is improved.

Owner:SHENYANG HENGJIN VACUUM TECH

100-260 mm-thick tempering-state prehardened plastic mold steel plate and manufacturing method thereof

ActiveCN107177796AImprove organizationImprove the quality of flaw detectionSheet steelChemical composition

The invention relates to a 100-260 mm-thick tempering-state prehardened plastic mold steel plate. The steel plate has the following chemical components in percentage by mass: 0.35-0.45 of C, 0.20-0.50 of Si, 0.60-1.00 of Mn, 1.00-2.50 of Cr, 0.20-0.50 of Mo, 0.04-0.15 of V+Ti, 0.01-0.04 of Als, 0.015 or less of P, 0.005 or less of S, and the balance of Fe and inevitable impurities; the steel plate is uniform in performance; the overall hardness difference is not more than 2.0 HRC; and the steel plate reaches NB / T47013.3 plate part I grade requirements by ultrasonic detection. The overall hardness difference is not more than 2.0 HRC; the steel plate reaches NB / T47013.3 plate part I grade requirements by ultrasonic detection; and the total inclusion grade is not higher than 2.5. The chemical components of the mold steel plate are simplified; the improvement is performed from the production process angle; the difference of the steel plate in the thickness direction is reduced; and in particular, the section hardness uniformity is improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

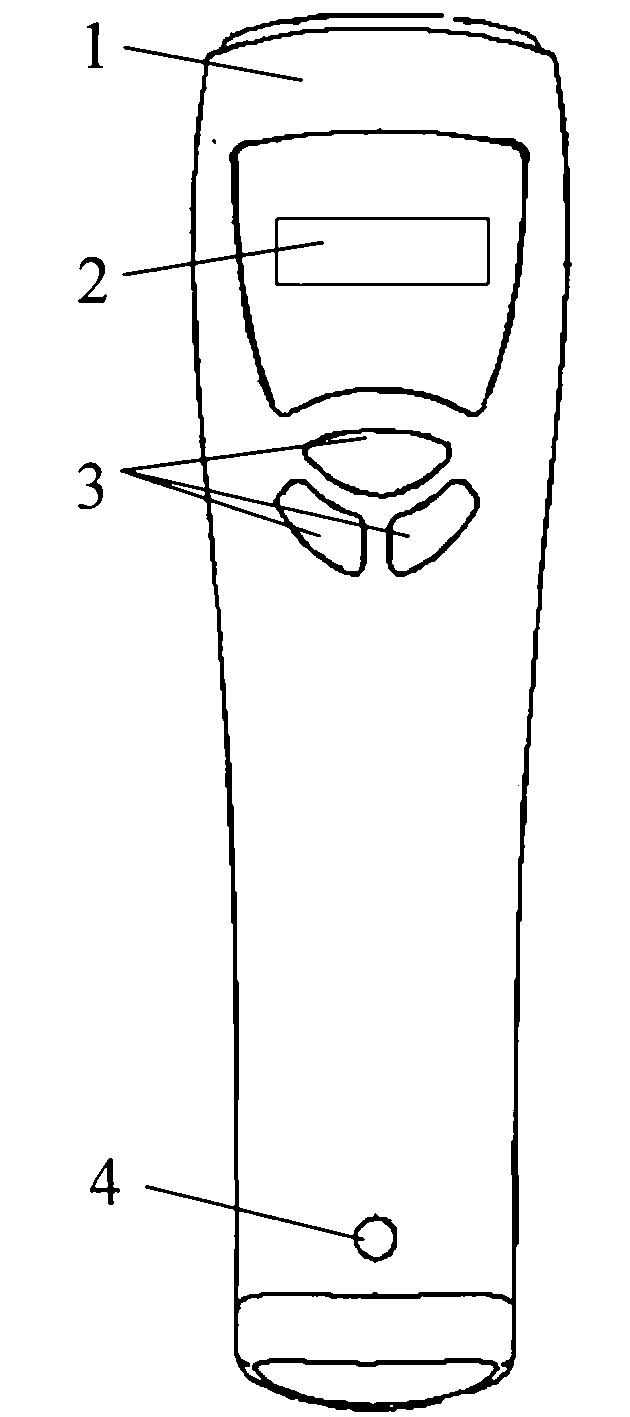

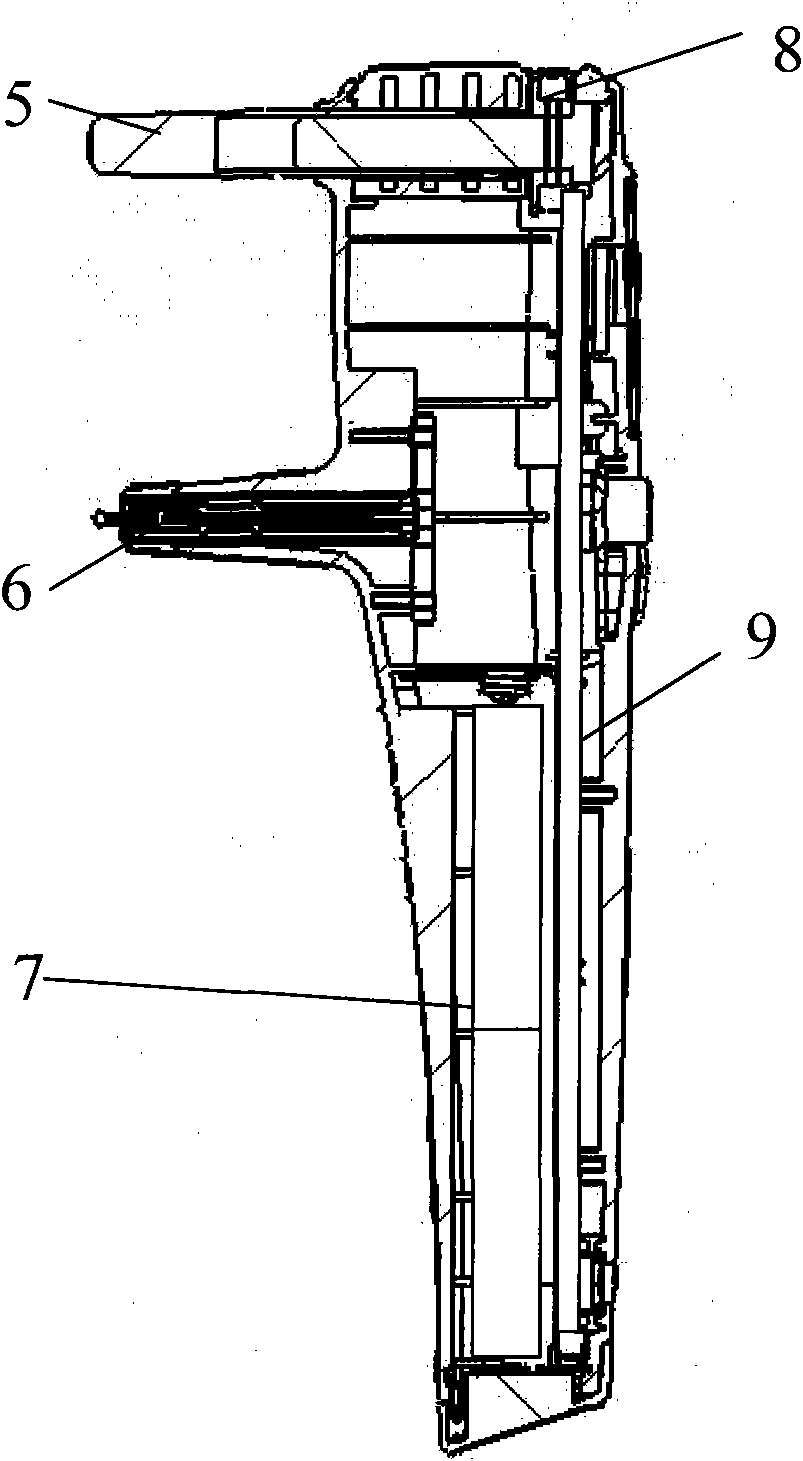

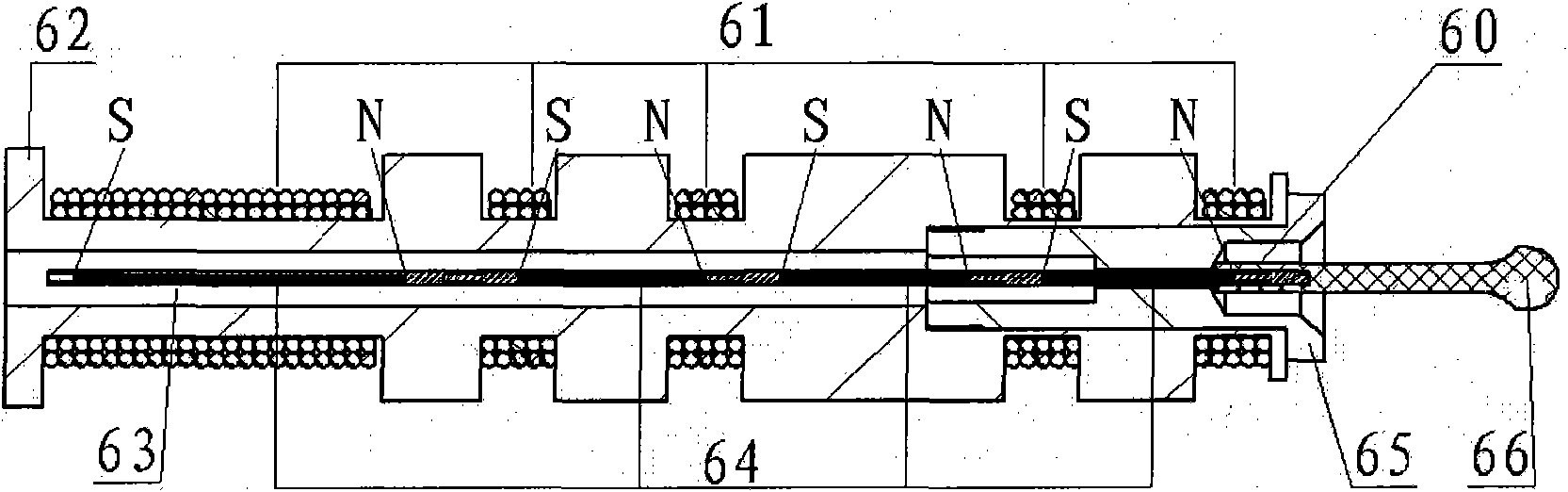

Equipment for measuring intra-ocular pressure and method for measuring intra-ocular pressure using same

The invention relates to equipment for measuring intra-ocular pressure, which is mainly characterized by comprising a probe supported in a probe shoulder, a plurality of coils wound on a framework, and a circuit board for collecting and processing voltage signals of the coils. The probe consists of a plastic probe head and a magnetic probe tail, and the probe tail consists of one or several joints of magnetic needles. The equipment for measuring the intra-ocular pressure is mainly characterized in that the coils are electrified with different directions to drive the magnetic needles at the probe tail to ensure part of the probe head to move toward or far away from a cornea at a high speed, and the intra-ocular pressure is figured out by the time interval between the probe closing to the cornea and the probe just leaving the cornea. By adopting the technical scheme of the invention, the speed-up time of the probe is shortened, the retention time of high speed motion is long, and the system efficiency is high, thereby fully ensuring that the probe can hit against the surface of the cornea at a speed high enough, greatly reducing the complexity and cost of the system, and simultaneously improving the reliability of the system.

Owner:TIANJIN SUOWEI ELECTRONICS TECH

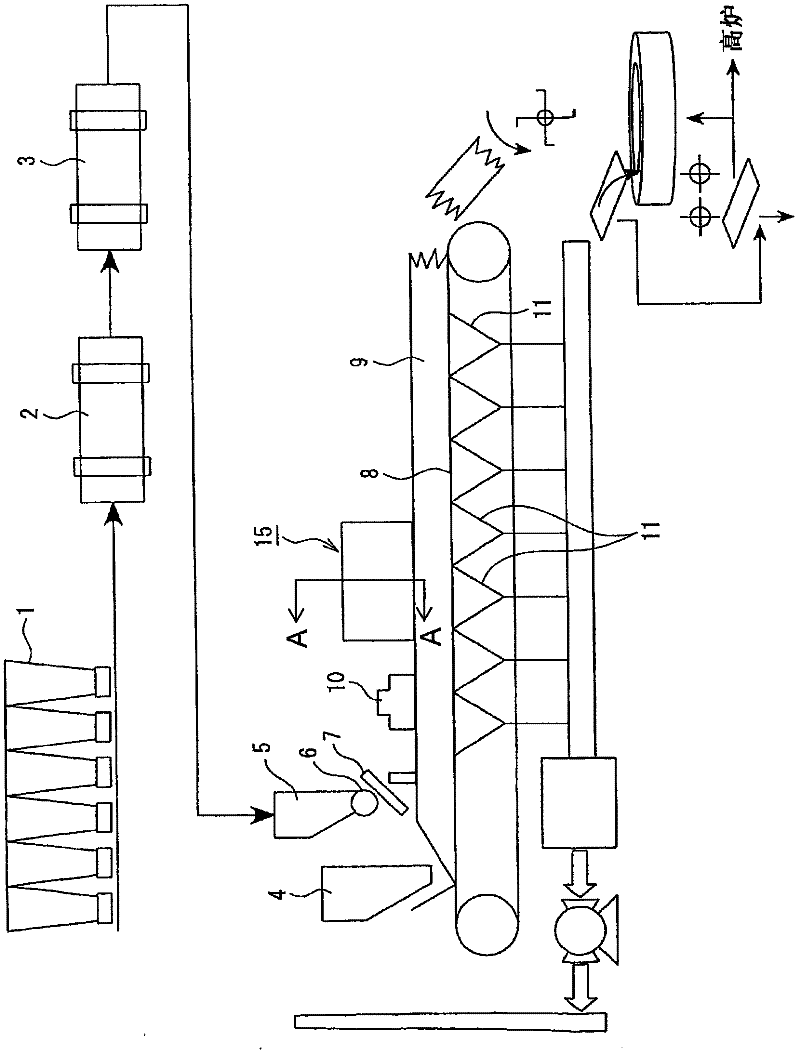

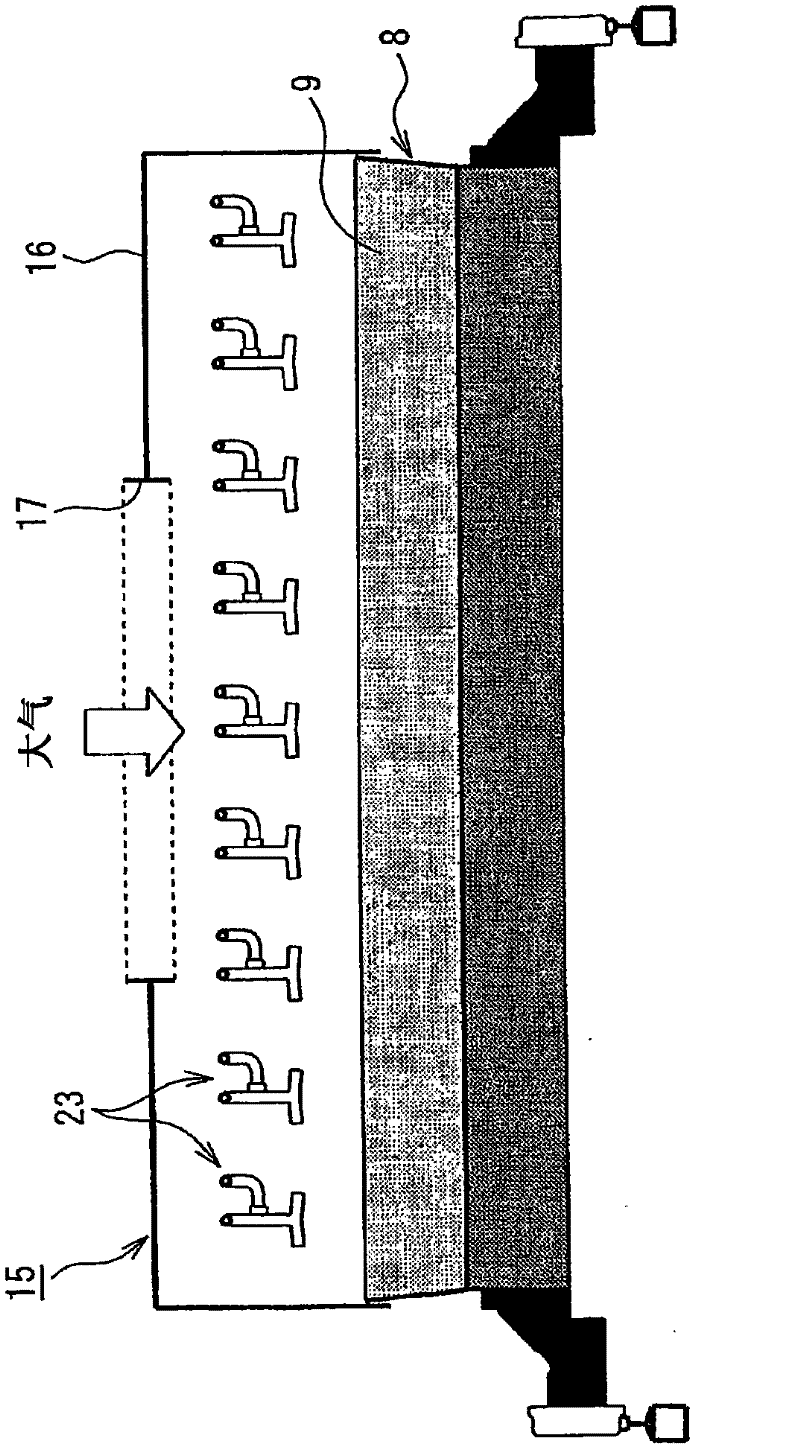

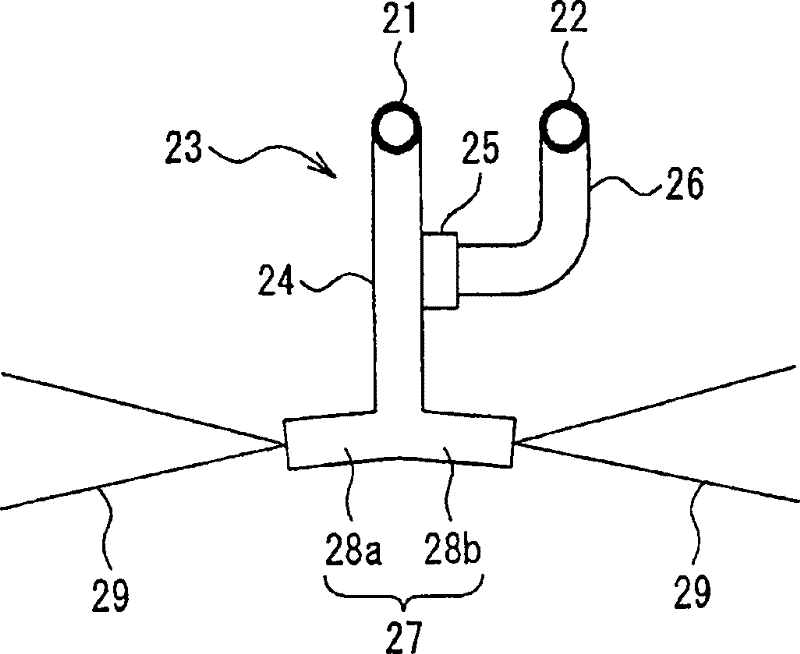

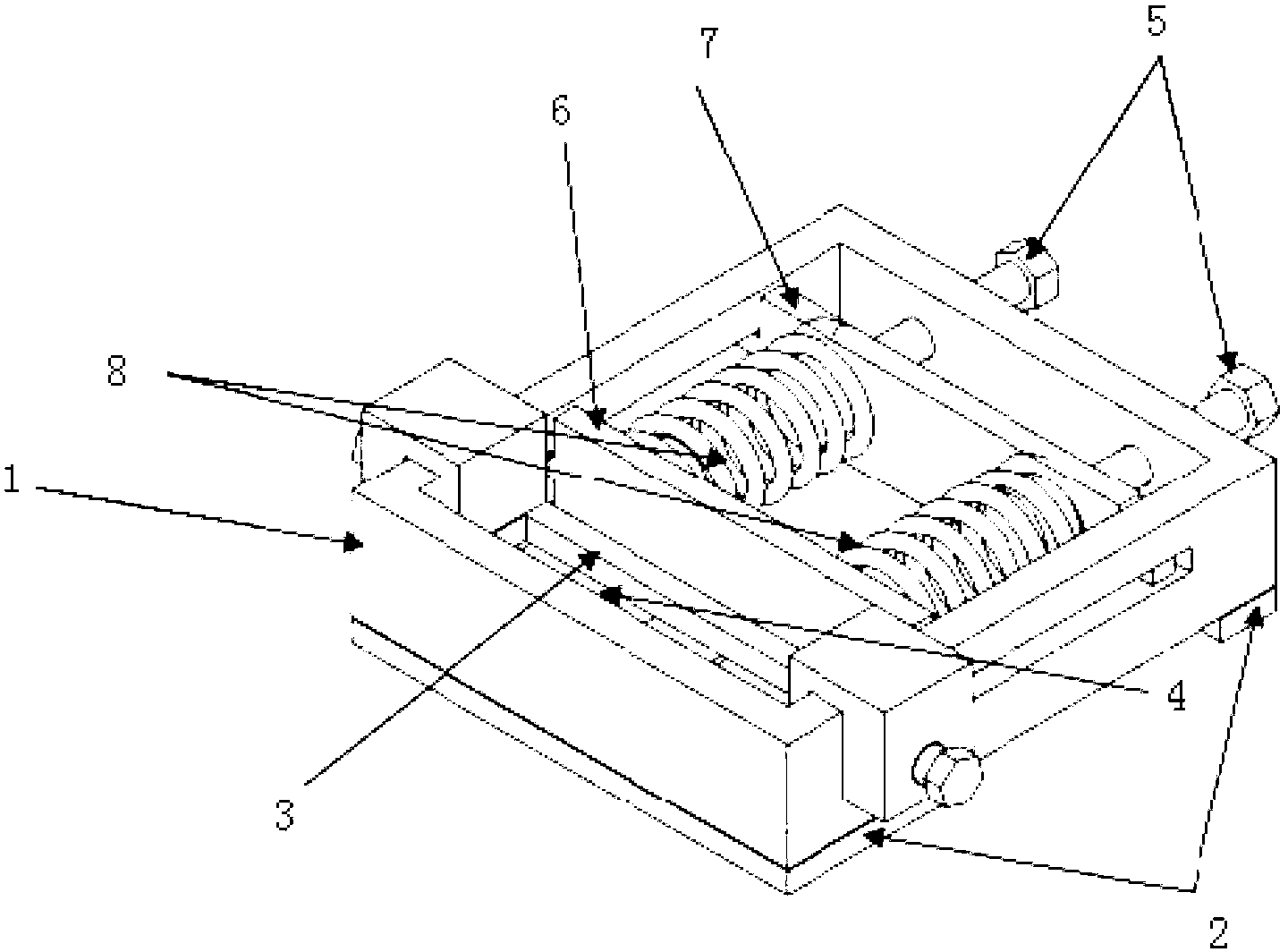

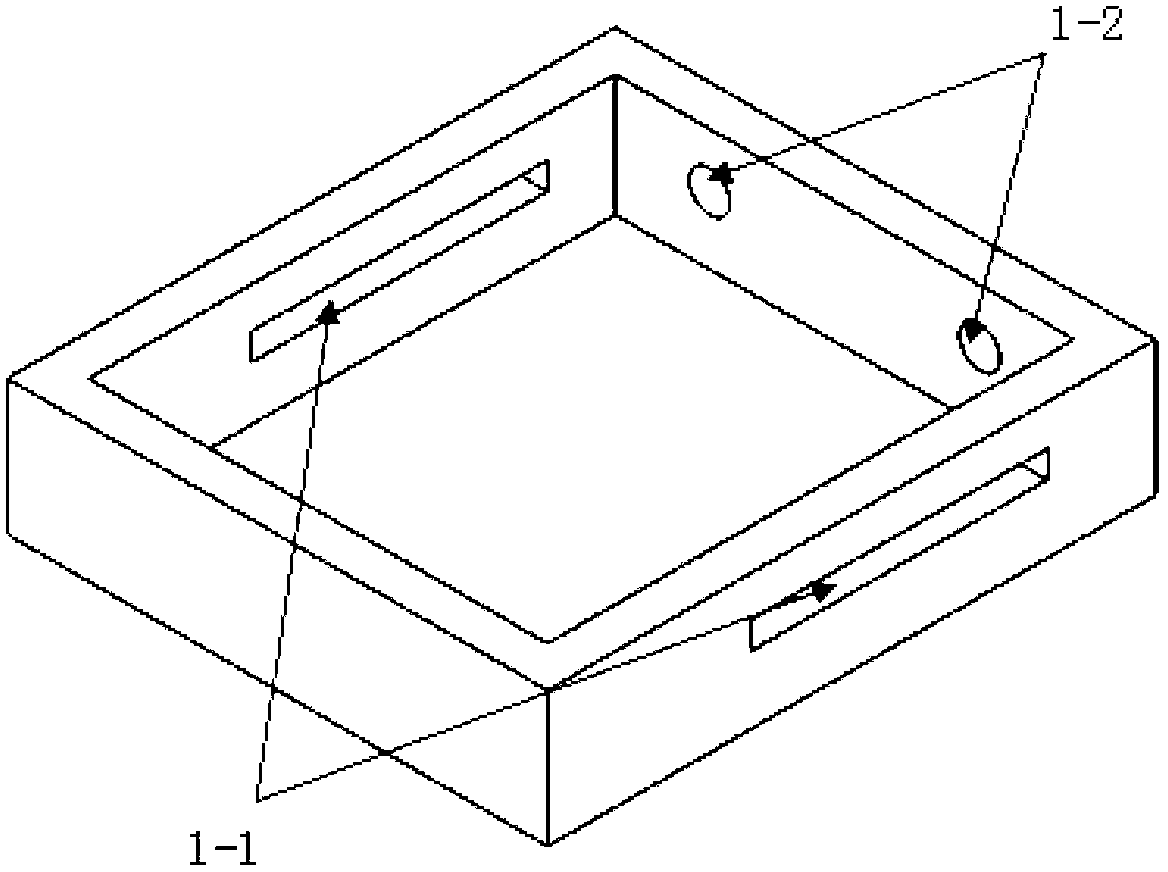

Process for producing sintered ore and sintering apparatus

A process for sintered-ore production in which high-quality sintered ore having high strength can be safely produced in a high yield with a sintering apparatus of a downward suction type; and the sintering apparatus. The process for sintered-ore production comprises: placing a raw material to be sintered comprising fine ore and a carbon material, on a circulating pallet (8) to form a raw-material layer (9); igniting the carbon material of the raw-material layer in an ignition furnace; and sucking air with a wind box disposed under the pallet to thereby produce sintered ore. After the raw-material layer (9) has been ignited in the ignition furnace, a liquid fuel is atomized to a particle size of 100 [mu]m or smaller and supplied to over the raw-material layer (9), and the atomized liquid fuel is supplied from over the raw-material layer (9) into the raw-material layer (9) after having been diluted at least to the lower limit of ordinary-temperature combustion concentrations. The sintering apparatus has, disposed downstream from the ignition furnace, a liquid-fuel injector which injects the liquid fuel over the raw-material layer.

Owner:JFE STEEL CORP

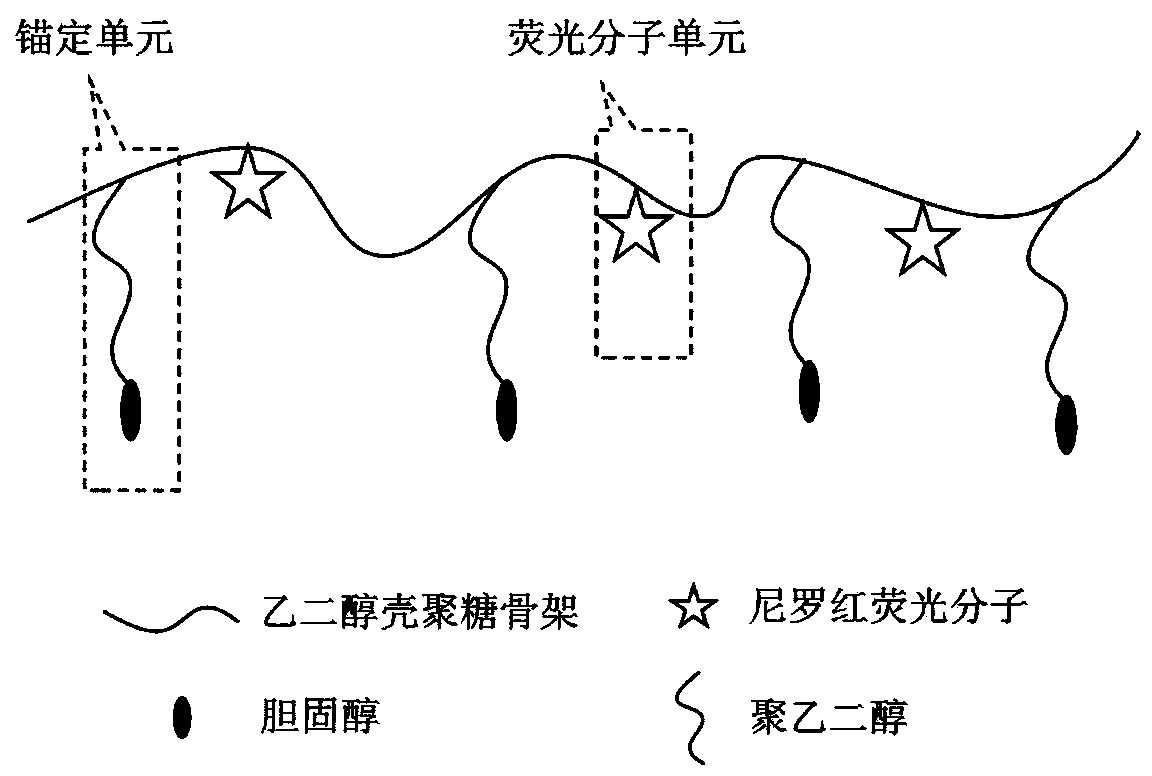

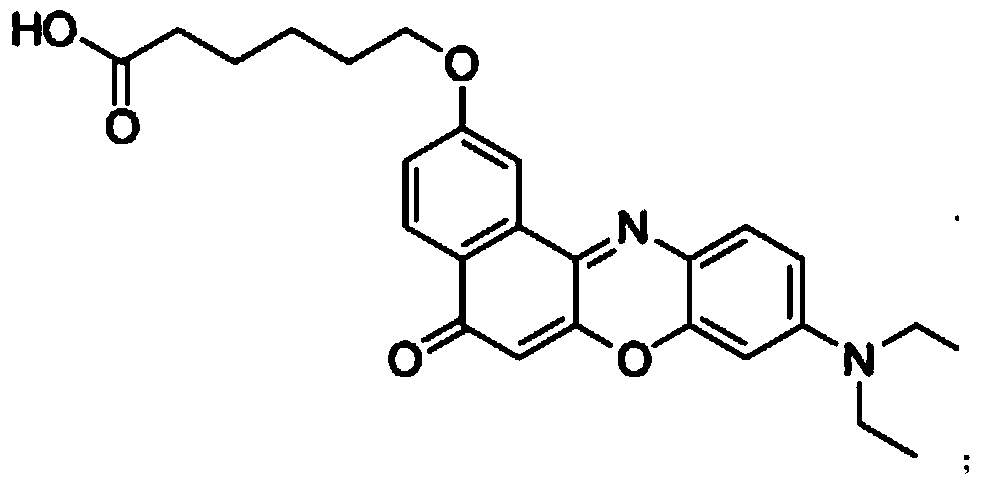

Washing-free long-time cell membrane fluorescence imaging reagent and preparation method thereof

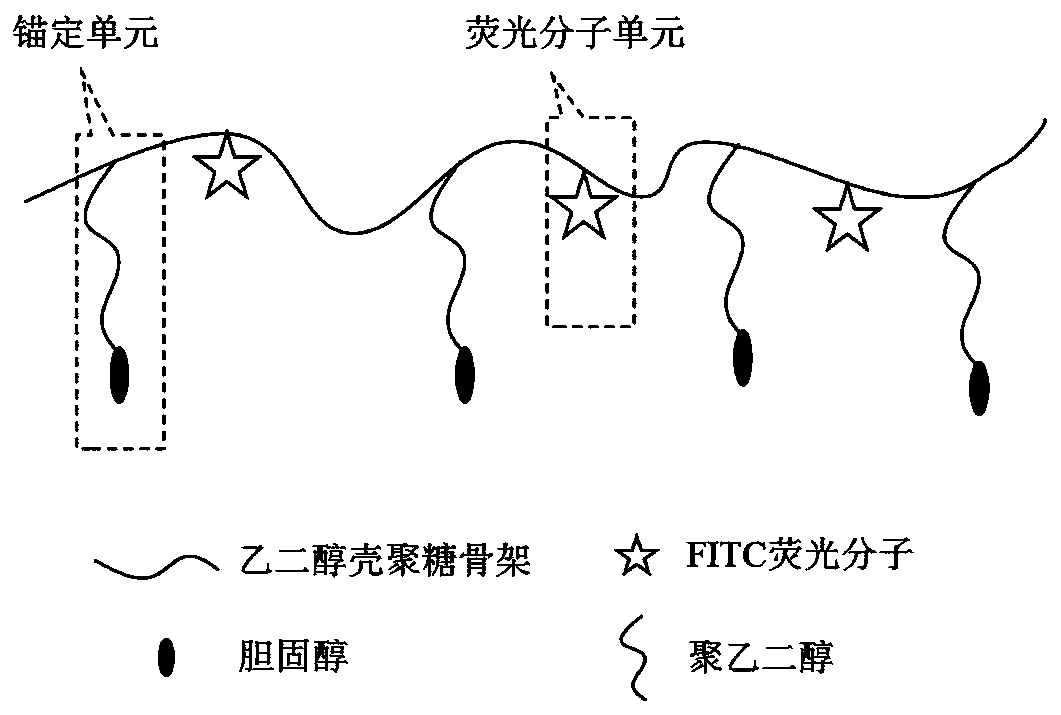

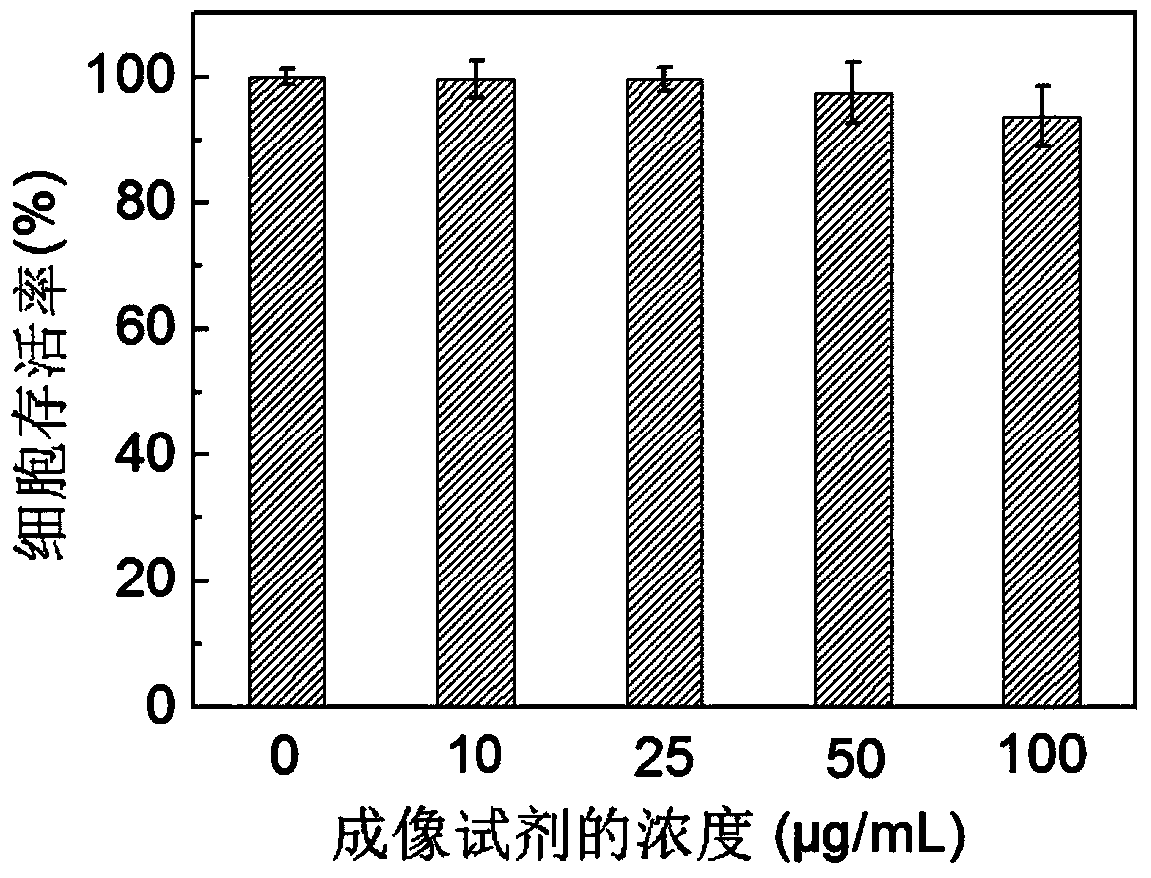

InactiveCN104288787AGood biocompatibilityEasy to synthesizeIn-vivo testing preparationsMulti siteStaining

The invention provides a washing-free long-time cell membrane fluorescence imaging reagent. The side chain of the reagent is an ethylene glycol chitosan macromolecule containing a hydrophobic unit and a low-efficiency fluorescence unit. Based on multi-site anchoring, the reagent has the advantages of good biocompatibility, simple synthesis, low cost and convenience in staining, does not need washing, cannot be easily endocytosed by cells, and can be used as a long-time cell membrane specificity tracing labelling probe.

Owner:SOUTHEAST UNIV

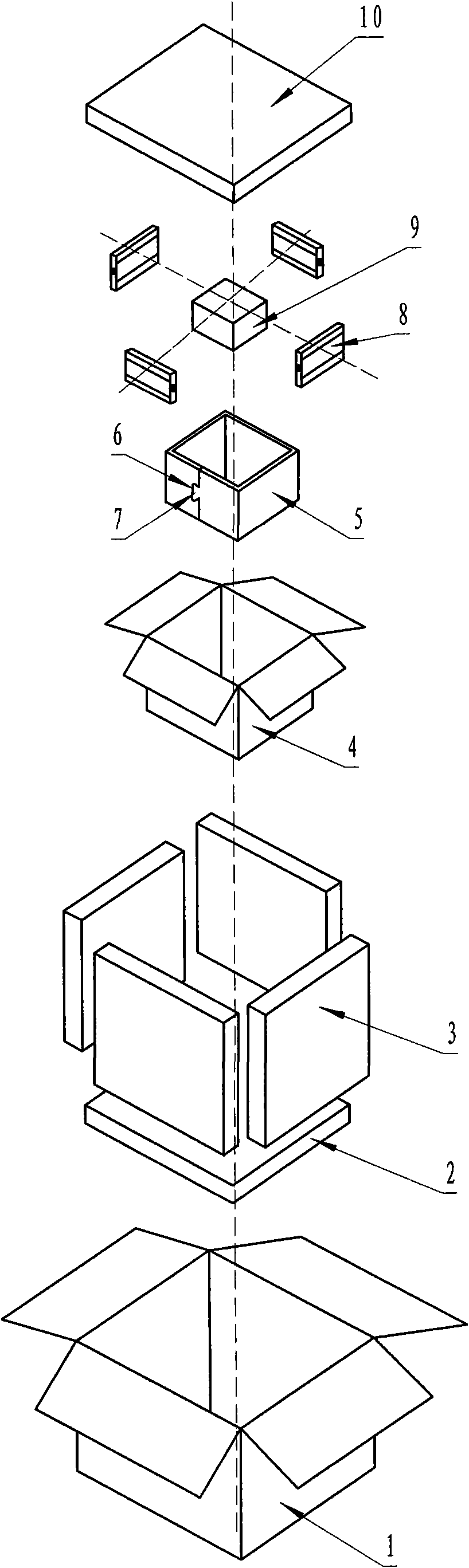

Foldable phase-change energy-storing cold chain refrigerator

InactiveCN101638162ALow costEasy to transportDomestic cooling apparatusLighting and heating apparatusCold chainTransport time

The invention relates to a foldable phase-change energy-storing cold chain refrigerator, comprising a foldable packing outer box and a foldable insulating inner box, wherein the foldable insulating inner box is made by an insulating plate which is internally and externally attached with aluminium films; in order to improve the time of refrigerating and insulating, a foam insulating side plate block, a foam insulating bottom plate block and a foam insulating top plate block are respectively arranged between the foldable packing outer box and the foldable insulating inner box; and the foldable insulating inner box is internally provided with a foldable insulating ring sleeve which is made by the insulating plate which is internally and externally attached with aluminium films. The foldable insulating ring sleeve is internally provided with a phase-change energy-storing bag or a phase-change energy-storing box meeting the requirements of phase-change temperature and refrigerating temperature. The foldable phase-change energy-storing cold chain refrigerator has low cost, compressible folding, and convenient transportation and recovery, and can meet the requirements of different cold chain refrigerating transportation time and refrigerating and insulating due to the arrangement of the foam insulating side plate block, the foam insulating bottom plate block, the foam insulating top plate block, the foldable insulating ring sleeve, the phase-change energy-storing bag and the phase-change energy-storing box.

Owner:商立军

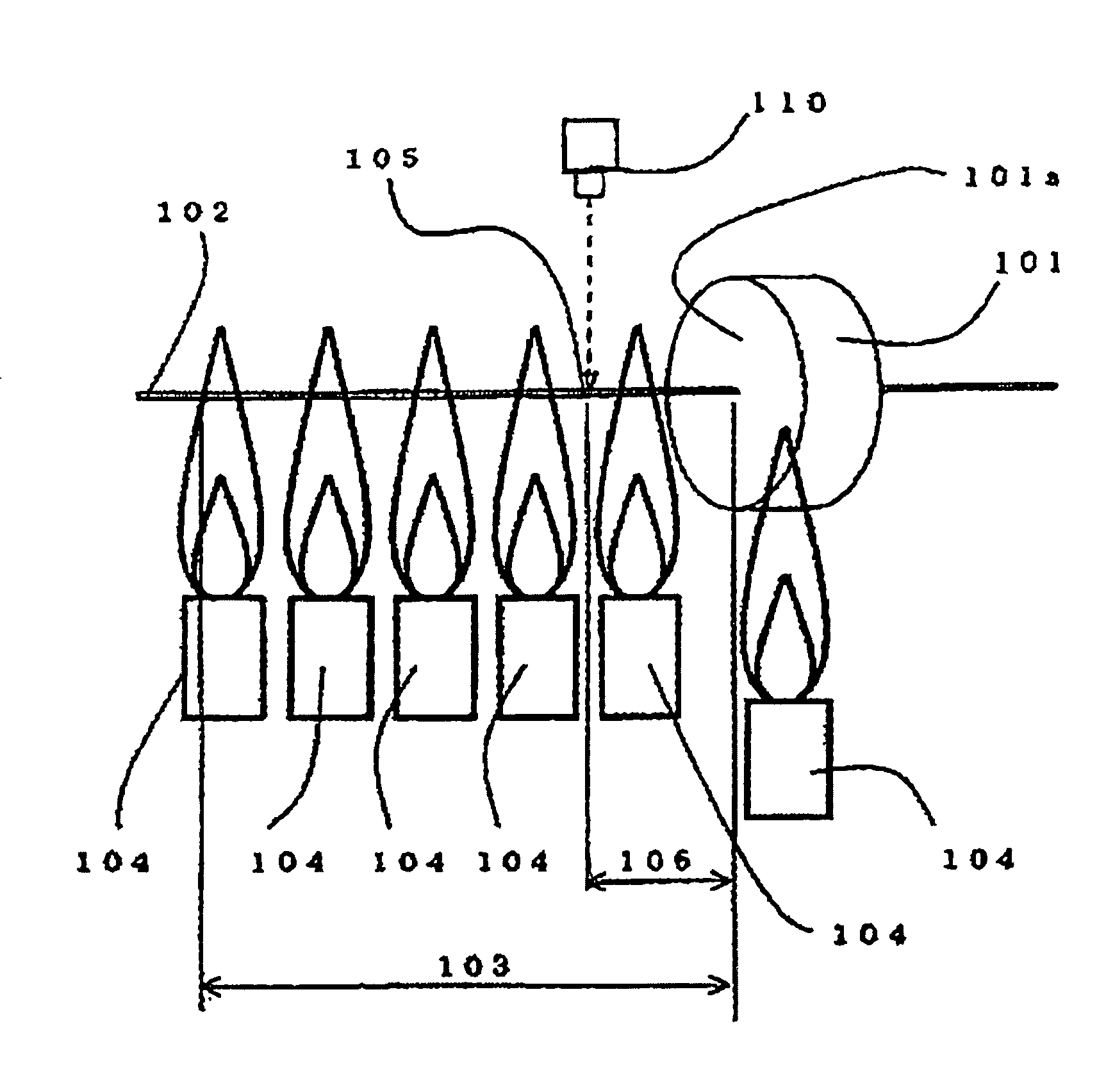

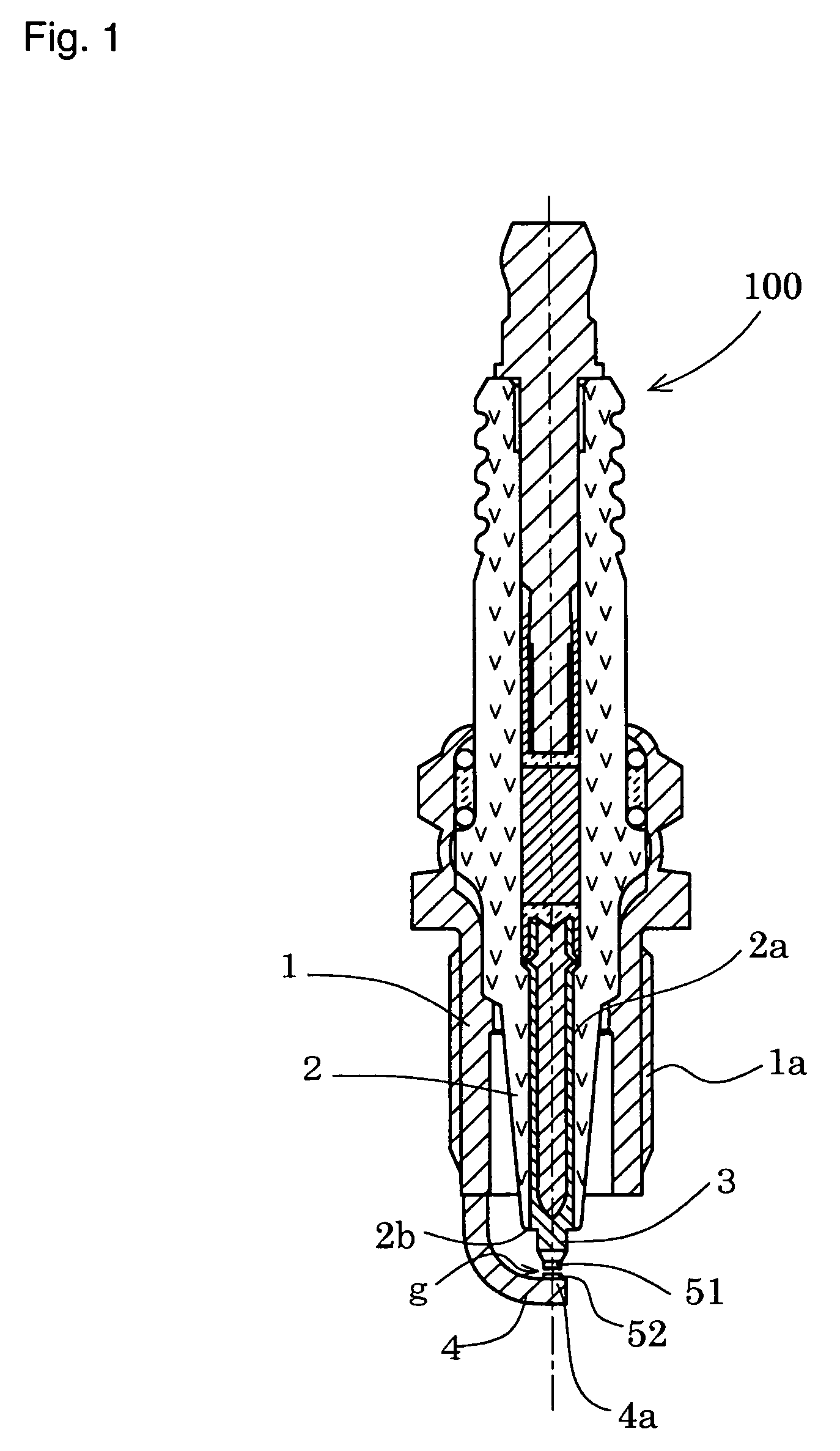

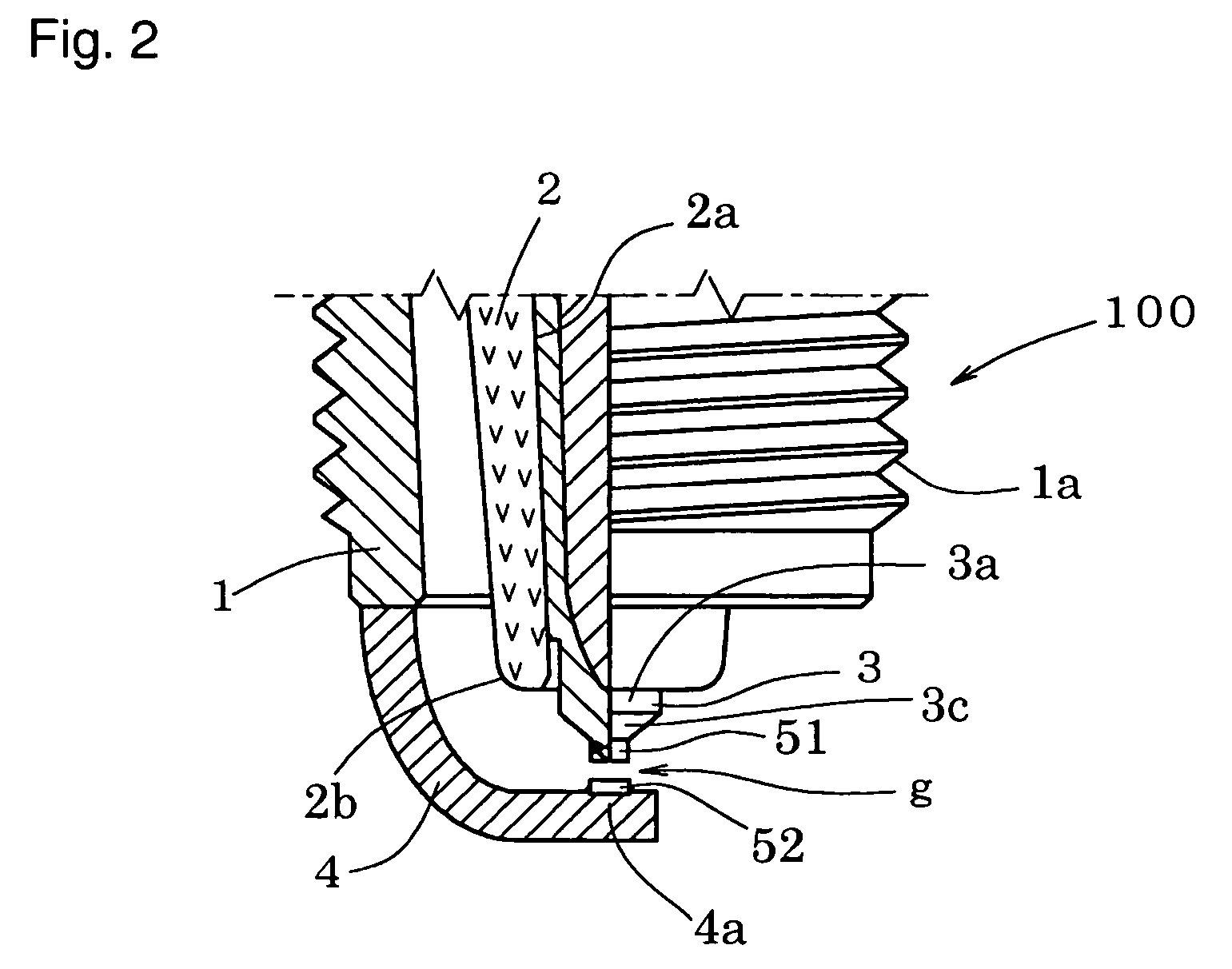

Method for manufacturing noble metal electric discharge chips for spark plugs

ActiveUS7131191B2Suppress oxidation volatilityRemarkable effectContact member manufacturingSpark gapsIridiumPlatinum

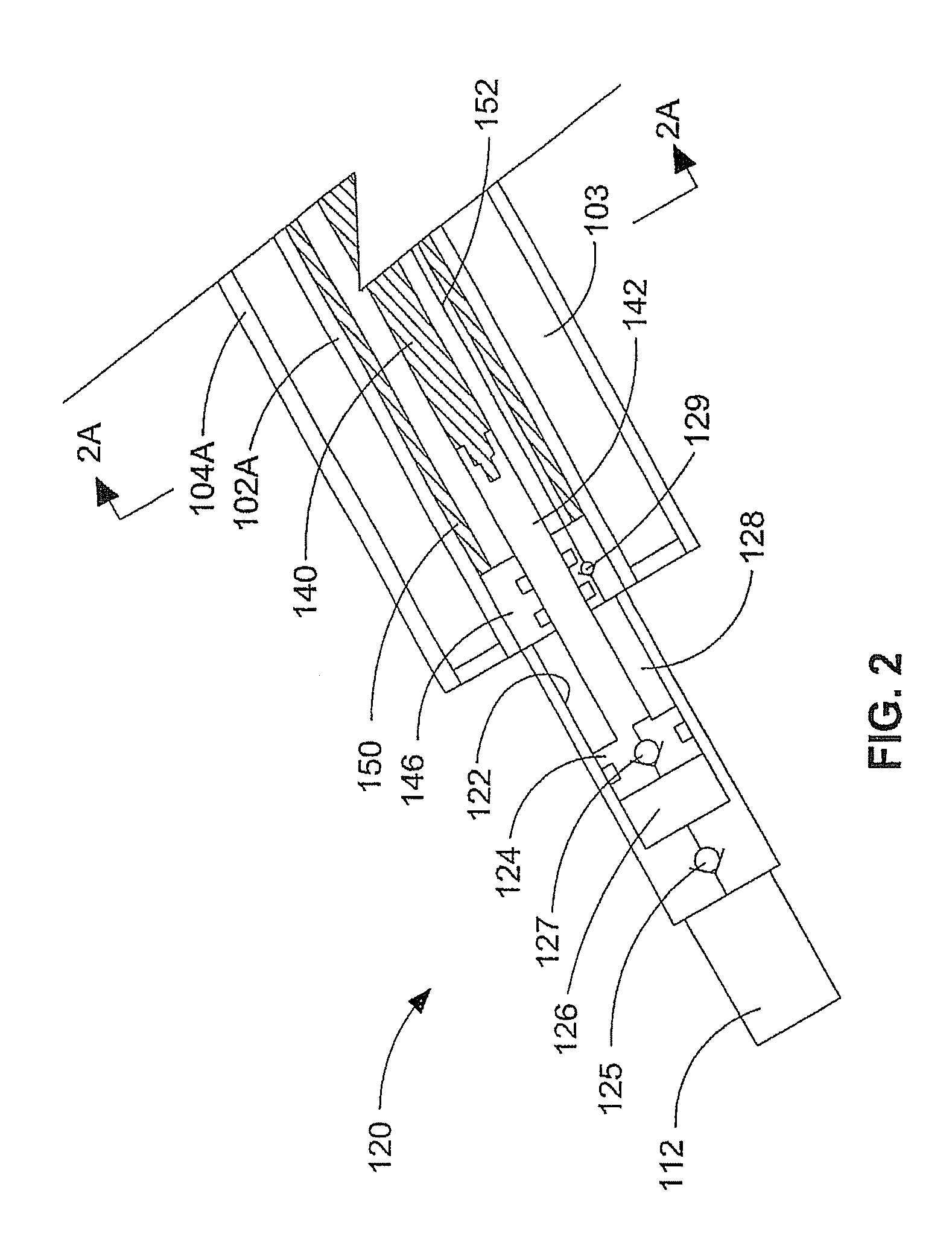

In a wire drawing process for forming a wire rod containing iridium as a main component and which further contains nickel and at least one of platinum, rhodium and ruthenium, and having a cross-sectional area of not smaller than 0.05 mm2 and not larger than 1.2 mm2. The worked material is continuously heated red hot and / or white hot in a heating region 103 extending up to 60 mm from the work inserting surface 101a of a die 101 in a direction opposite that in which the work 102 moves, the work being heated to a temperature of 1000 to 1150° C. at a temperature measuring position 105 which is removed from the work inserting surface 101a by 20 mm. Furthermore, the temperature in the region 106 extending from the temperature measuring position 105 to the work inserting surface 101a is set to not lower than 1000° C., and the wire drawing rate is set to 300 to 1600 mm / min.

Owner:NGK SPARK PLUG CO LTD

Fired mold low-pressure casting process of integral type compressor impeller

InactiveCN103658536AReduce labor intensityIncrease pressureFoundry mouldsFoundry coresImpellerStaining

The invention provides a fired mold low-pressure casting process of an integral type compressor impeller. The process comprises the following steps of preparing coating with silica sol binder for fired mold casting, wherein a fireproofing surface layer and a second layer are made of fused alumina powder and sand, and a reinforced layer is made of mullite powder and sand special for fired mold casting; when coating the coating on the reinforced layer, adopting a two-time slurry staining method, i.e. firstly staining thin coating and secondly staining thick coating; and after dewaxing a shell, roasting at the low temperature of 500 DEG C, storing, and roasting at high temperature before pouring, wherein the temperature of high-temperature roasting is 1000 DEG C, the heat preservation time is 4h, and the temperature of the shell during pouring is 100-150 DEG C. The prepared shell is high in strength, low-pressure pouring can be carried out by utilizing a single shell, the pouring temperature of molten aluminum is 670-680 DEG C, the mold-filling pressure is 0.03 MPa, the mold-filling time is 10s, the solidification holding pressure is 0.35 MPa, and the holding pressure time is 5min. The integral type compressor impeller produced by adopting the fired mold low-pressure casting process is good in mold-filling and feeding effect, compact in casting tissue, good in product mechanical property and inner quality, high in production efficiency, and low in labor intensity, and has no need to be modeled through binning.

Owner:SHANDONG JIANZHU UNIV

Apparatus and method for holding a cryogenic fluid and removing cryogenic fluid therefrom with reduced heat leak

ActiveUS7356996B2Extended hold timeReduce heat leakageInternal combustion piston enginesFuel supply apparatusDrive shaftHeat leak

Owner:WESTPORT FUEL SYST CANADA INC

Casting process of ultralow-temperature valve casting

ActiveCN109877274AImprove purityReduce inclusionsFoundry mouldsFurnace typesRare-earth elementAustenitic stainless steel

The invention discloses a casting process of an ultralow-temperature valve casting. The casting process comprises the steps of production preparation, smelting, casting, sand removing, finishing and the like. The content of ferrite in austenite is reduced by reducing the chromium / nickel equivalent ratio so as to avoid or reduce the ferrite embrittlement and martensite transformation of austeniticstainless steel. The element nitrogen is introduced to reduce the content of harmful elements sulfur and phosphorus. Silicon-calcium alloy and rare earth elements are introduced during molten steel deoxidation, so that the oxygen content and the impurity ratio are reduced. Measures such as the outage of a slagging process are adopted to improve the low-temperature impact resistance of the casting. In addition, more improvements have been made in the wall thickness difference of the casting, molten steel purification, a casting system, casting dead head cutting, shot blasting operation, heat treatment and the like since the start of the design of the casting process. Check results indicate that the valve casting produced by the casting process is stable in size stability and sealing performance after being subjected to treatment at the temperature of -196 DEG C, has the plasticity and toughness in a low-temperature environment, and is better in comprehensive usability.

Owner:JIANGSU EVALVE GRP

Preparation method of wolfram filament for halogen tungsten lamp

InactiveCN101157997AHigh dispersion is beneficialPromote deep processingLamp incadescent bodiesAmmonium paratungstatePotassium

The invention provides a preparation method for high yield rate, good high temperature and anti-deforming performance tungsten filament used by a tungsten lamp. The recrystallization of the invention can form good coattail joint structure, the aspect ratio is greater than 12, the high temperature intension is high in a high temperature ignition status, the high temperature anti-sag performance and anti-deforming performance is good; normal temperature intension in a normal status and ductility is good, which extends the durability of the halogen tungsten lamp; the invention levels up the high temperature anti-sag performance and enwinding performance of the tungsten used by the halogen tungsten lamp. The invention has the key technique of thinning and even dispersion of tungsten wire potassium bubble, taking A3 type ammonium paratungstate as raw material, tungsten powder preparation plan adopting tungsten powder C is different from the existing tungsten powder preparation technique, design vertical melt sintering and middle-high temperature annealing according to the height dispersion and homogenization of apotassium bubble. The invention adopts the novel production techniques such as using corundum tube oven to a first recrystallization annealing.

Owner:GANZHOU HONGFEI TUNGSTEN & MOLYBDENUM MATERIALS

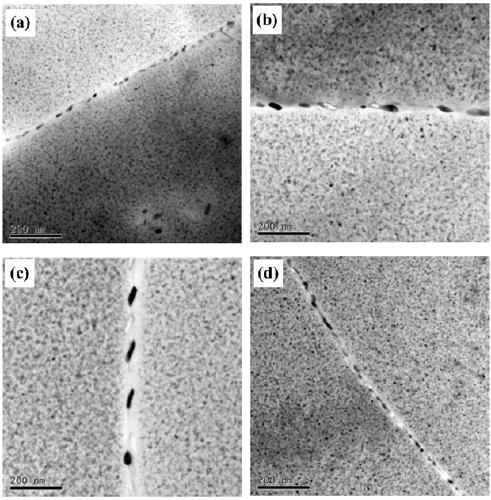

Electron beam pressurizing connection method for aluminum alloy and particle-reinforced aluminum matrix composite material

InactiveCN103008869AIncrease soldering temperature and holding timeWell formed weldWelding/cutting auxillary devicesAuxillary welding devicesAluminum matrix compositesVacuum cooling

The invention provides an electron beam pressurizing connection method for aluminum alloy and a particle-reinforced aluminum matrix composite material, and relates to an electron beam assisted heat source diffusion welding method for the aluminum alloy and the particle-reinforced aluminum matrix composite material, aiming at solving the problems of serious metal burning loss, interface reaction, air pores and the like existing in the traditional fusion welding technique of the particle-reinforced aluminum matrix composite material. The electron beam pressurizing connection method for the aluminum alloy and the particle-reinforced aluminum matrix composite material comprises the following steps of: 1) conducting pretreatment to two base metal blocks to be welded; 2) putting the two base metal blocks into a welding fixture and applying pressure to squeeze the base metal blocks; 3) conducting vacuum pumping treatment; 4) conducting welding for the first time by adopting an upward defocusing mode; 5) conducting welding for the second time; and 6) conducting vacuum cooling to complete the electron beam pressurizing connection of the aluminum alloy and the particle-reinforced aluminum matrix composite material. The electron beam pressurizing connection method for the aluminum alloy and the particle-reinforced aluminum matrix composite material belongs to the field of pressurizing assisted welding.

Owner:HARBIN INST OF TECH

Smelting method of ultralow-oxygen and medium-high-carbon steel

ActiveCN106435084AReduce desulfurization pressureReduce processing timeManufacturing convertersProcess efficiency improvementHigh carbonSlag

The invention provides a smelting method of ultralow-oxygen and medium-high-carbon steel. Molten iron is pretreated until [S] is smaller than or equal to 0.003%, and special low-sulfur waste steel is matched. [C] at the end point of a converter is controlled between 0.1% and 0.2%, the [S] at the end point is smaller than or equal to 0.01%, carbon powder is adopted before tapping and in a tapping process for primary deoxidization, the carbon powder added before tapping accounts for 50-65% of the total quantity, and the carbon powder accounting for 35-50% of the total quantity is added after tapping is started for 2-4 minutes. The molten iron which is treated by primary deoxidization is lifted into a ladle furnace and is heated, and at the same time, part of refining slags is added. The total slag quantity is controlled at 12-15kg per ton of steel. Then, after the molten iron is lifted into a RH furnace and kept at the condition that the vacuum degree is smaller than or equal to 70pa for 6-7 minutes, aluminum pellets are added according to 0.6-0.8kg per ton of steel, and vacuum is kept for another 3 to 5 minutes; and finally, vacuum alloying is carried out, vacuum is kept for another 5-6 minutes. The molten iron treated by the RH furnace is lifted into the ladle furnace again, and at the same time, deoxidization is carried out by using aluminum pellets for making white slags. Finally, after pure calcium lines are fed according to 1.0-1.2m per ton of steel to carry out inclusion denaturating treatment, and soft blowing is carried out for 20-25 minutes, tapping and continuous casting pouring are sequentially carried out.

Owner:YANGCHUN NEW STEEL CO LTD

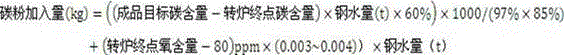

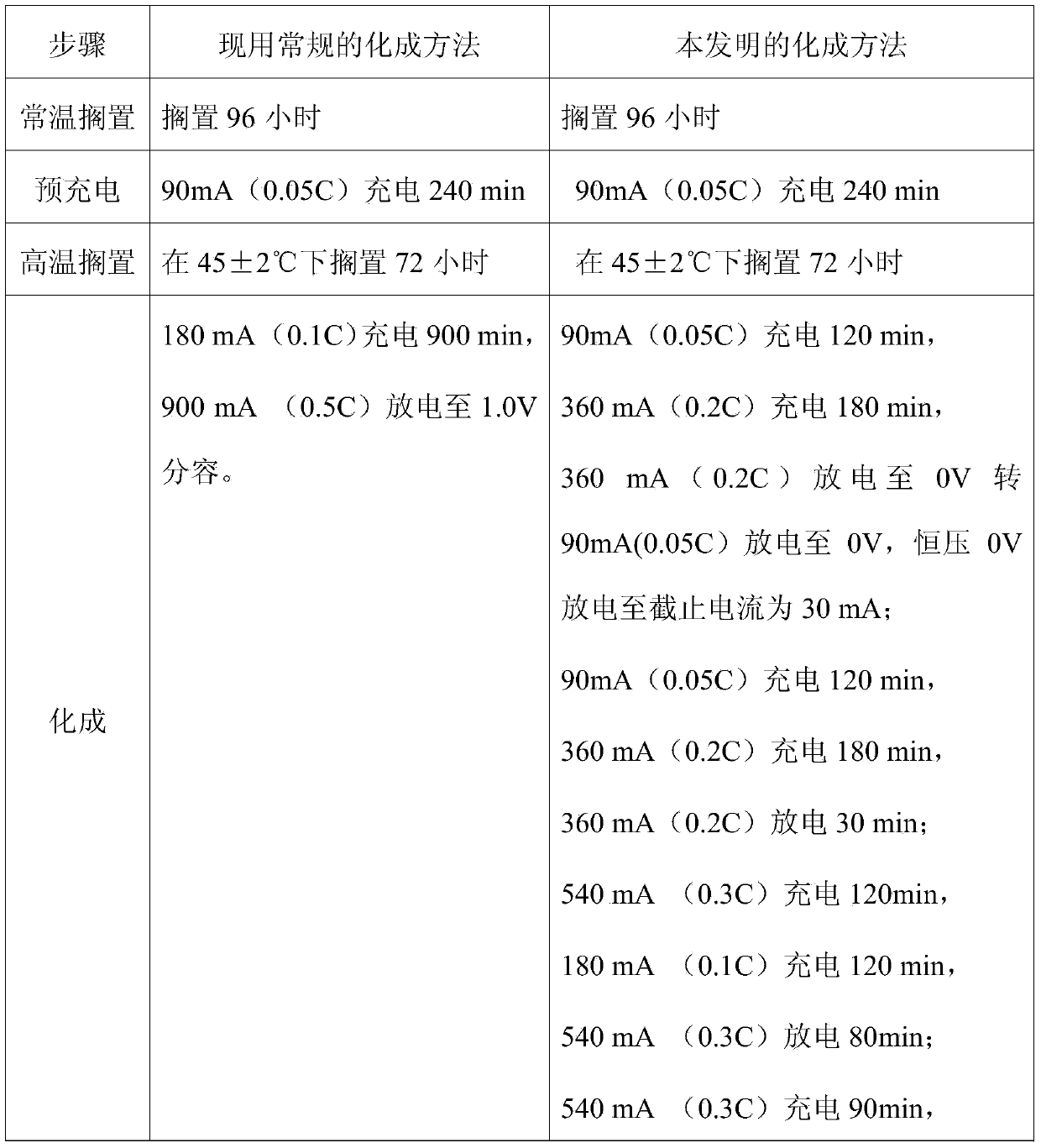

Forming method of nickel-metal hydride battery

ActiveCN104218265AImprove retentionSmall self-dischargeFinal product manufactureAlkaline accumulators manufactureCharge retentionPower flow

The invention provides a forming method of a nickel-metal hydride battery. The method comprises laying an assembled battery at room temperature for a certain time; precharging the battery with a current of 0.01-0.1 C until reaching 10%-40% of the rated capacity; laying the battery at a high-temperature environment of 30-70 DEG C for 60-144 hours; performing formation and grading on the battery, wherein the grading comprises multiple charging and discharging steps, and the first charging and discharging step includes charging the battery with a current of 0.005-0.1 C and a current of 0.1-0.3 C sequentially, deeply discharging the battery with a current of 0.05-0.5 C to be 0.8 V lower than a cut-off voltage for at least once, and discharging the battery in a constant voltage mode to be 0.05 C lower than a cut-off current, and the others forming charging and discharging steps perform constant-current charging and constant-current timed discharging through a current lower than 0.5 C. The forming method of the nickel-metal hydride battery can effectively reduce self-charging and self-discharging of the battery, improve the charge retention ratio of the battery by 3%-6%, improve OCV (open circuit voltage) maintenance of the battery and increase the voltage maintaining time.

Owner:YIYANG CORUN BATTERY

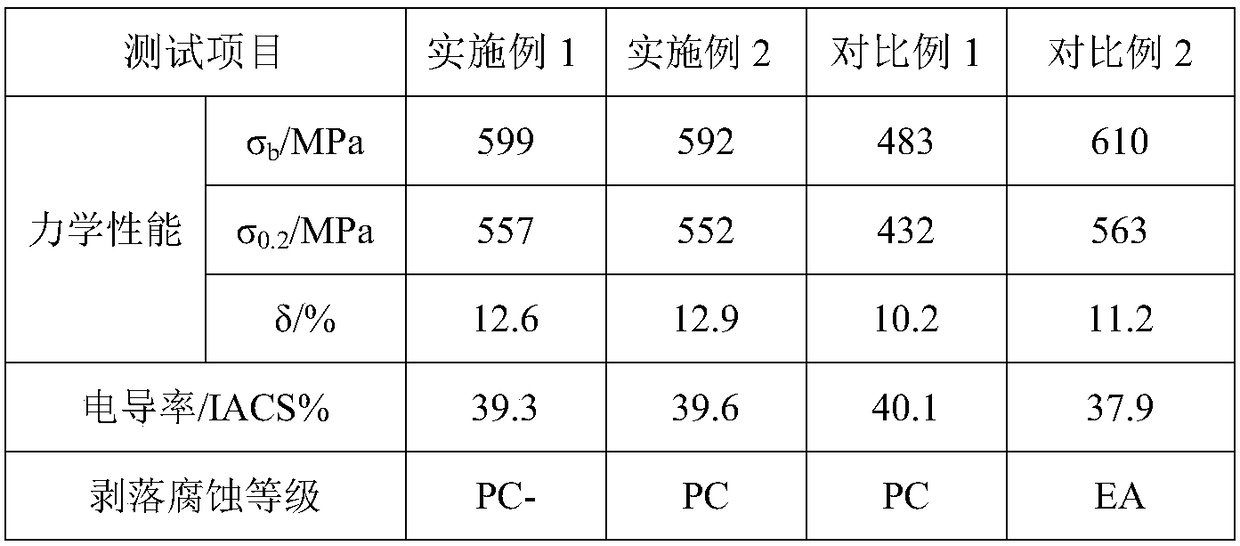

In-situ preparation method for micrometer scale T1 phase based on Al-Cu-Li alloy

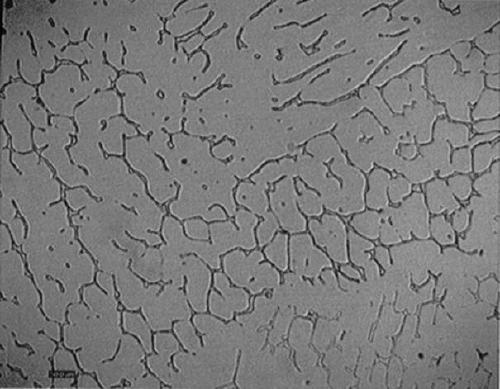

ActiveCN107858614AEliminate elemental segregationInhibition formationSolution treatmentMicrometer scale

The invention discloses an in-situ preparation method for a micrometer scale T1 phase based on Al-Cu-Li alloy. The method includes the following steps that first, an Al-Cu-Li alloy sample to be treated is put into a heat treatment furnace for solution treatment; second, the Al-Cu-Li alloy sample with solution treatment being completed is subjected to quenching treatment, the quenching medium refers to water of 0-5 DEG C, and the quenching transfer time is no longer than 10s; and third, the quenched Al-Cu-Li alloy sample is put into the heat treatment furnace for classified heat treatment, thenfurnace cooling is performed to an indoor temperature, and the T1 phase with the longitudinal dimensions being 5-10 microns is prepared in the Al-Cu-Li alloy in an in-situ mode. The micrometer scaleT1 phase can be prepared in the in-situ mode, and the corrosion and electrochemical behaviors of the single T1 phase can be better studied.

Owner:CHONGQING UNIV OF TECH

Intelligent temperature control early warning food security insulation box

ActiveCN104787484AHigh strengthReduce weightDomestic cooling apparatusLighting and heating apparatusTemperature controlThermal insulation

The invention discloses an intelligent temperature control early warning food security insulation box. The intelligent temperature control early warning food security insulation box comprises a box body, an upper cover and an insulation inner cavity formed by the box body and the upper cover; the box body and the upper cover are each sequentially provided with a shell, a vacuum thermal insulation layer and a cavity wall from exterior to interior; the inner side of the upper cover is provided with a pressing sheet, and the pressing sheet is connected with the upper cover through a spring; the longitudinal direction and the transverse direction of the inner wall of the box body are each provided with an elastic fixing belt, and therefore objects can be fixed in a cross traction mode after the object is well put into the box body. The intelligent temperature control early warning food security insulation box is used for solving the defects in the prior art, a detachable support air channel is arranged in the shell of the box body, the maintenance is facilitated, the air flow in the thermal insulation inner cavity is enhanced, and the thermal insulation effect of the objects is improved.

Owner:CHINA RAILWAYS CORPORATION

Fluorescence imaging reagent for cell membrane based on multi-site anchoring and preparation method thereof

ActiveCN104231114AGood biocompatibilityEasy to synthesizeFluorescence/phosphorescenceLuminescent compositionsMulti siteFluorescence

The invention provides a fluorescence imaging reagent for a cell membrane based on multi-site anchoring. The fluorescence imaging reagent is an ethylene glycol chitosan polymer of which a side chain contains a hydrophobic unit and a fluorescent unit. The fluorescence imaging reagent for the cell membrane is based on a multi-site anchoring technology and has the advantages of good biocompatibility, simplicity for synthesis, low cost and short dyeing time; besides, the fluorescence imaging reagent is not easily intemalized by cells and can be used as a specific tracer labeling probe of the cell membrane.

Owner:SOUTHEAST UNIV

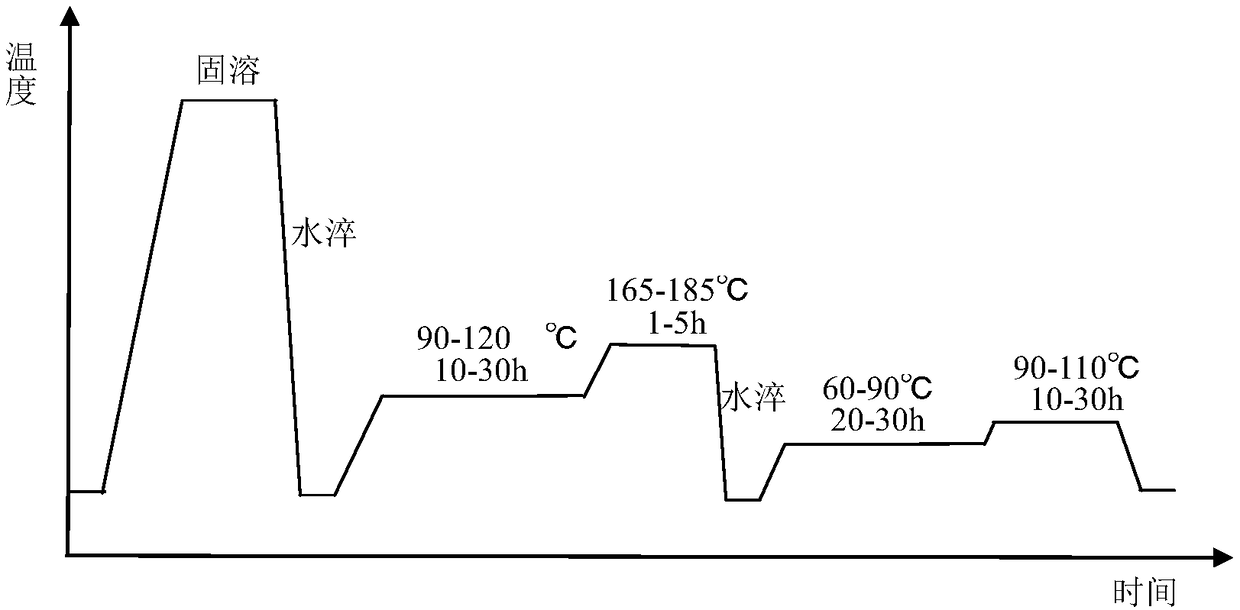

Aging heat treatment method for 7-series aluminum alloy

The invention discloses an aging heat treatment method for a 7-series aluminum alloy, and belongs to the field of non-ferrous metal materials and heat treatment thereof. The aging heat treatment method is used for the 7-series aluminum alloy after solid solution treatment, and comprises the following steps that (1) first-stage aging is performed, specifically, a 7-series aluminum alloy workpiece is placed in a heating furnace of 90-120 DEG C for heat preservation for 10-30h; (2) second-stage aging is performed, specifically, the temperature is raised to a second-stage predetermined aging temperature of 165 DEG C-185 DEG C along with the furnace, and after the heat preservation is performed for 1-5h, the 7-series aluminum alloy workpiece is subjected to water cooling to the room temperature; (3) third-stage aging is performed, specifically, the 7-series aluminum alloy workpiece is then placed at a third-stage predetermined aging temperature of 60-90 DEG C for heat preservation for 20-30h; and (4) fourth-stage aging is performed, specifically, the temperature is raised to a fourth-stage predetermined aging temperature of 90-110 DEG C along with the furnace, and after the heat preservation is performed for 10-30h, the 7-series aluminum alloy workpiece is subjected to air cooling to the room temperature. In the second-stage high-temperature aging process, a method of lowering the temperature than the RRA temperature and increasing the heat preservation time is adopted, and the problem of uneven structure and performance caused by the temperature gradient due to rapid heating and cooling of large components is solved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

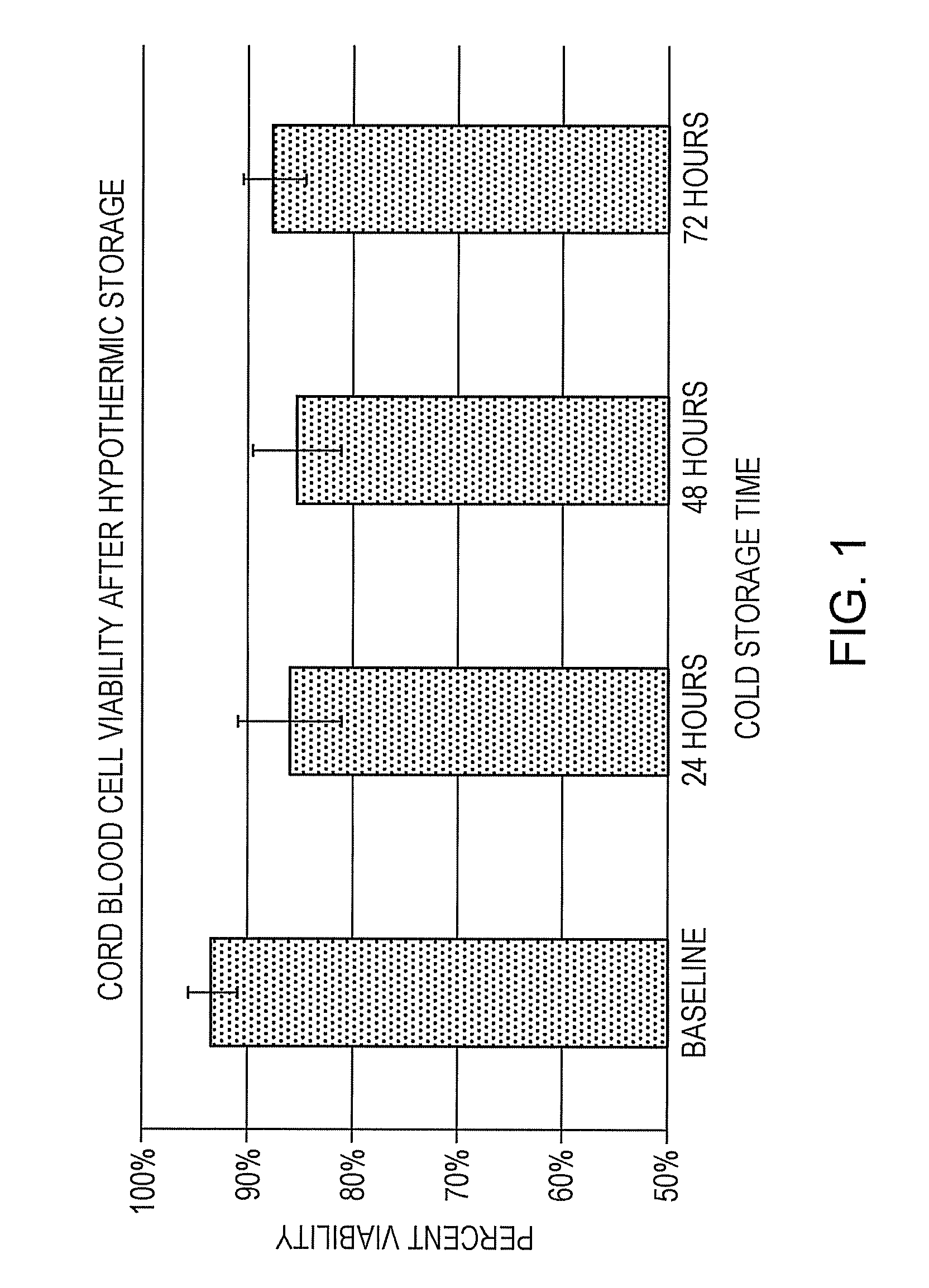

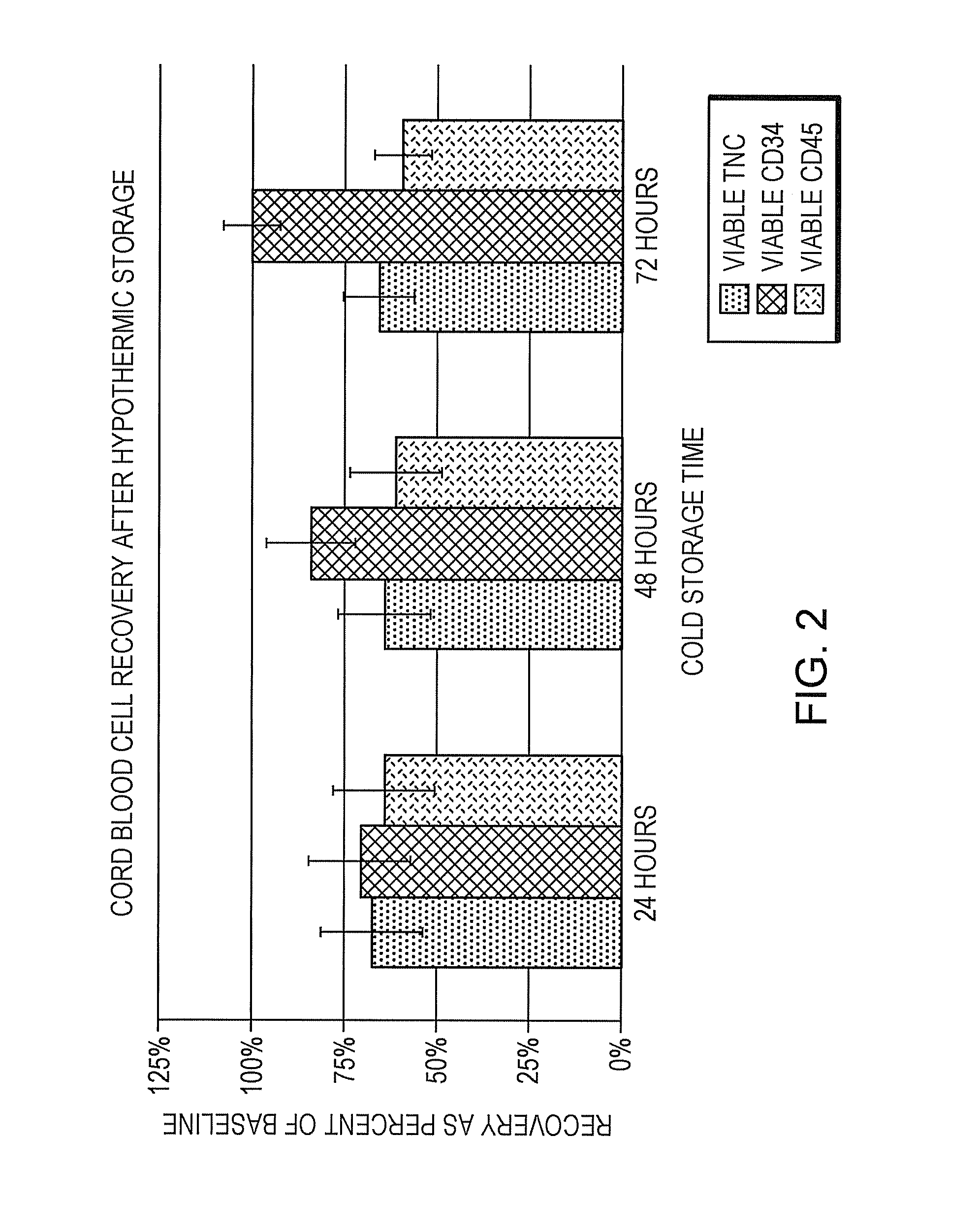

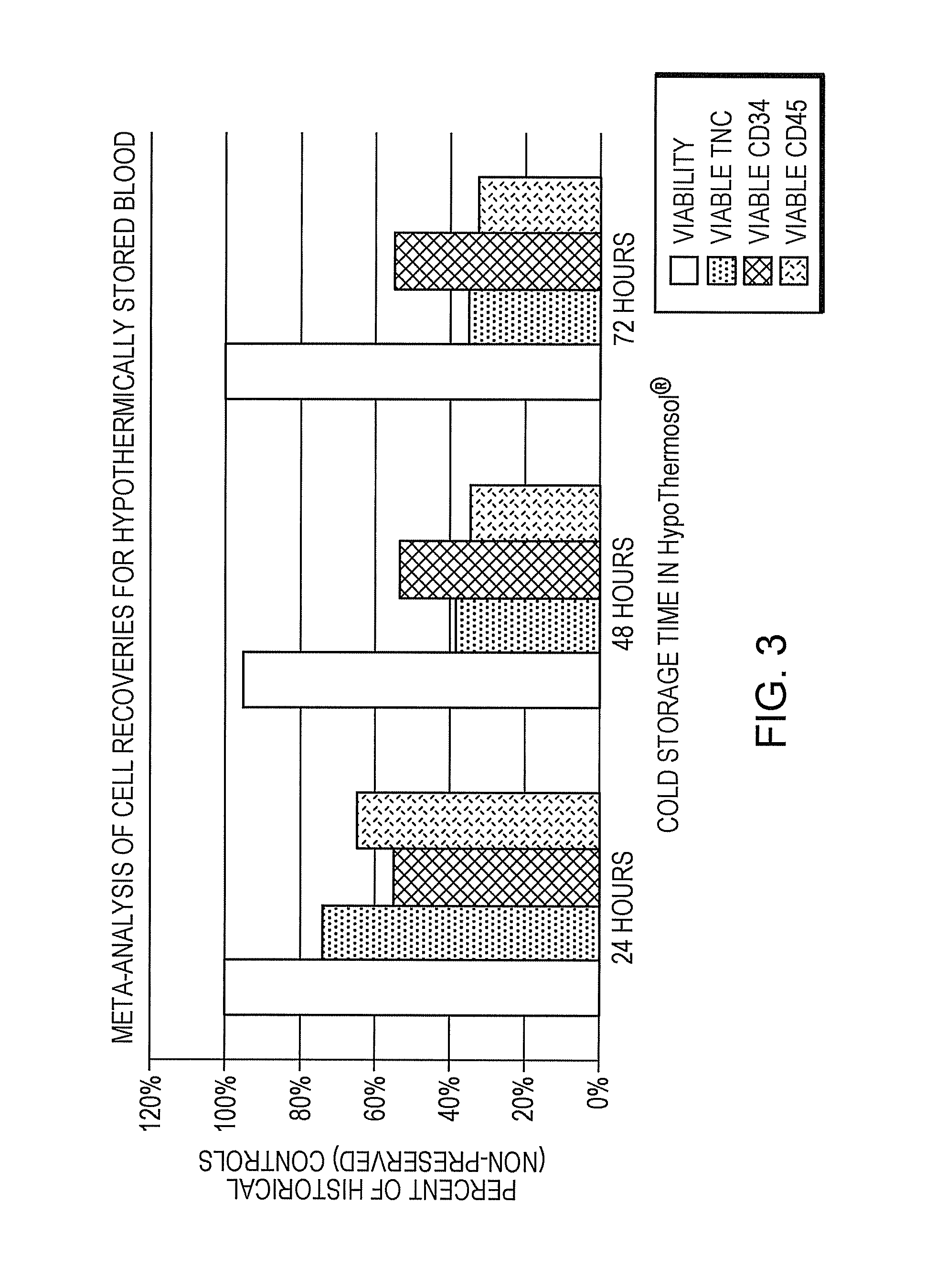

Materials and methods for hypothermic collection of whole blood

ActiveUS8642255B2Quality improvementExtended hold timeMammal material medical ingredientsDead animal preservationNutritionApoptosis

The present invention relates to materials and methods for hypothermic collection of whole blood, and components thereof, which can extend the holding time of blood beyond the current useable limit. Additionally, blood can be drawn directly into a hypothermic preservation solution without the addition of standard anticoagulants. This is enabled by providing sustained cellular viability under hypothermic conditions using a nutrient matrix devoid of animal proteins and containing energy substrates, free-radical scavengers, and impermeants that is ionically balanced for storage of biologic materials at low temperatures to prevent cellular stress-induced apoptosis.

Owner:BIOLIFE SOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com