Casting process of ultralow-temperature valve casting

A casting process and ultra-low temperature technology, which is applied in the field of casting technology of ultra-low temperature valve castings, can solve the problems of material stress deformation and metamorphosis, and achieve the effect of improving ductility and toughness, improving purity and avoiding differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A casting process for ultra-low temperature valve castings, comprising the following steps:

[0032] S1: Casting design: including modeling design of valve castings, calculation of shrinkage rate of valve castings, and selection of parting surfaces, etc., to ensure the dimensional accuracy and quality of valve castings.

[0033] S2: Production preparation: Combining with the casting design in step S1, the preparation includes material preparation and production machinery equipment for producing valve castings, and core making work is performed at the same time.

[0034]S3: Smelting: According to the design, material and production requirements of the valve castings in steps S1 and S2, carry out the proportioning of furnace charges, select a suitable melting method, set a reasonable melting temperature and time, and control the material composition content of the valve castings; The charge ratio is mainly to use 90-95% of the high-alloy steel return material of this stee...

Embodiment 2

[0041] Performance inspection of ultra-low temperature valve castings in low temperature environment:

[0042] The castings produced by the casting process of Example 1 were placed in an environment of minus 196°C to carry out the impact test. The number of samples was 5, and the experiment was repeated. The test results are shown in Table 1:

[0043] Table 1. Impact test report of ultra-low temperature castings at -196°C

[0044]

Embodiment 3

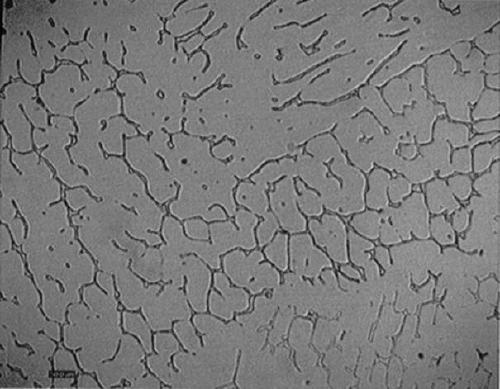

[0046] The casting sample Z3 described in Example 2 will be used for gold sample analysis, the test method is GB / T13298-2015 metal microstructure inspection method, and the detection equipment is a metallographic microscope MS03, and the test results are as follows: figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com