Patents

Literature

238results about How to "Promote deep processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Runtime adaptable search processor

ActiveUS20060136570A1Reduce stacking processImproving host CPU performanceWeb data indexingMultiple digital computer combinationsData packInternal memory

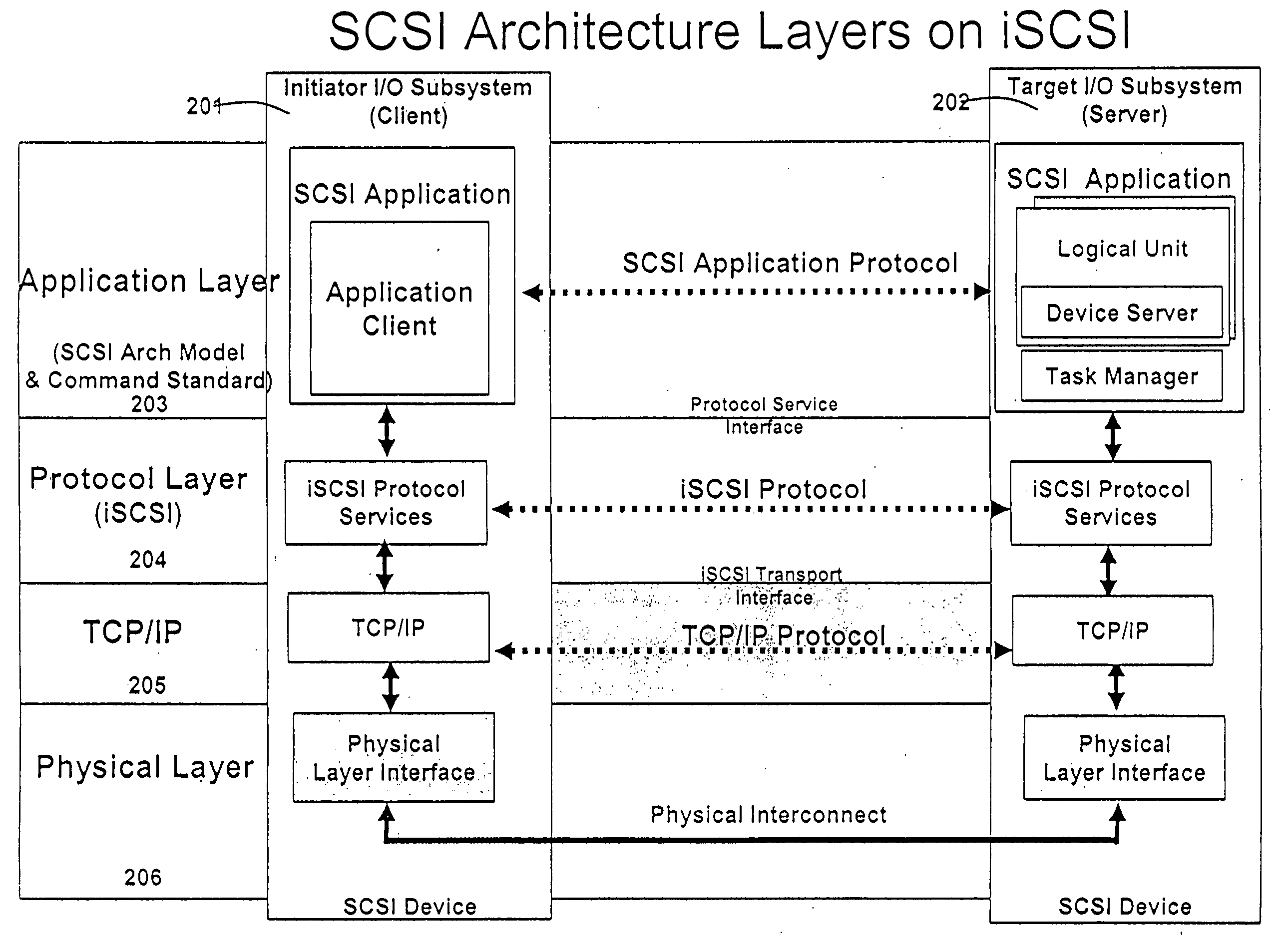

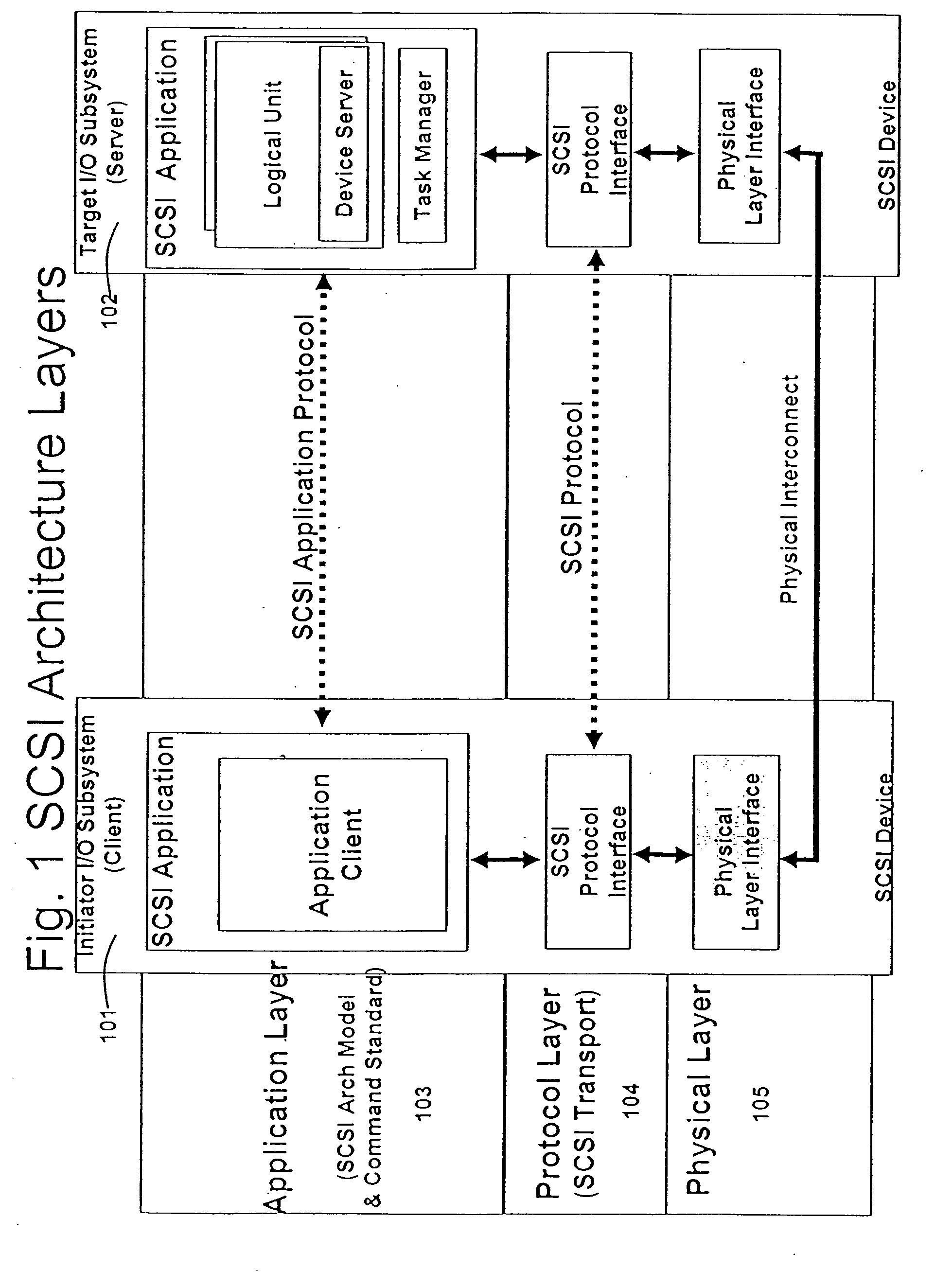

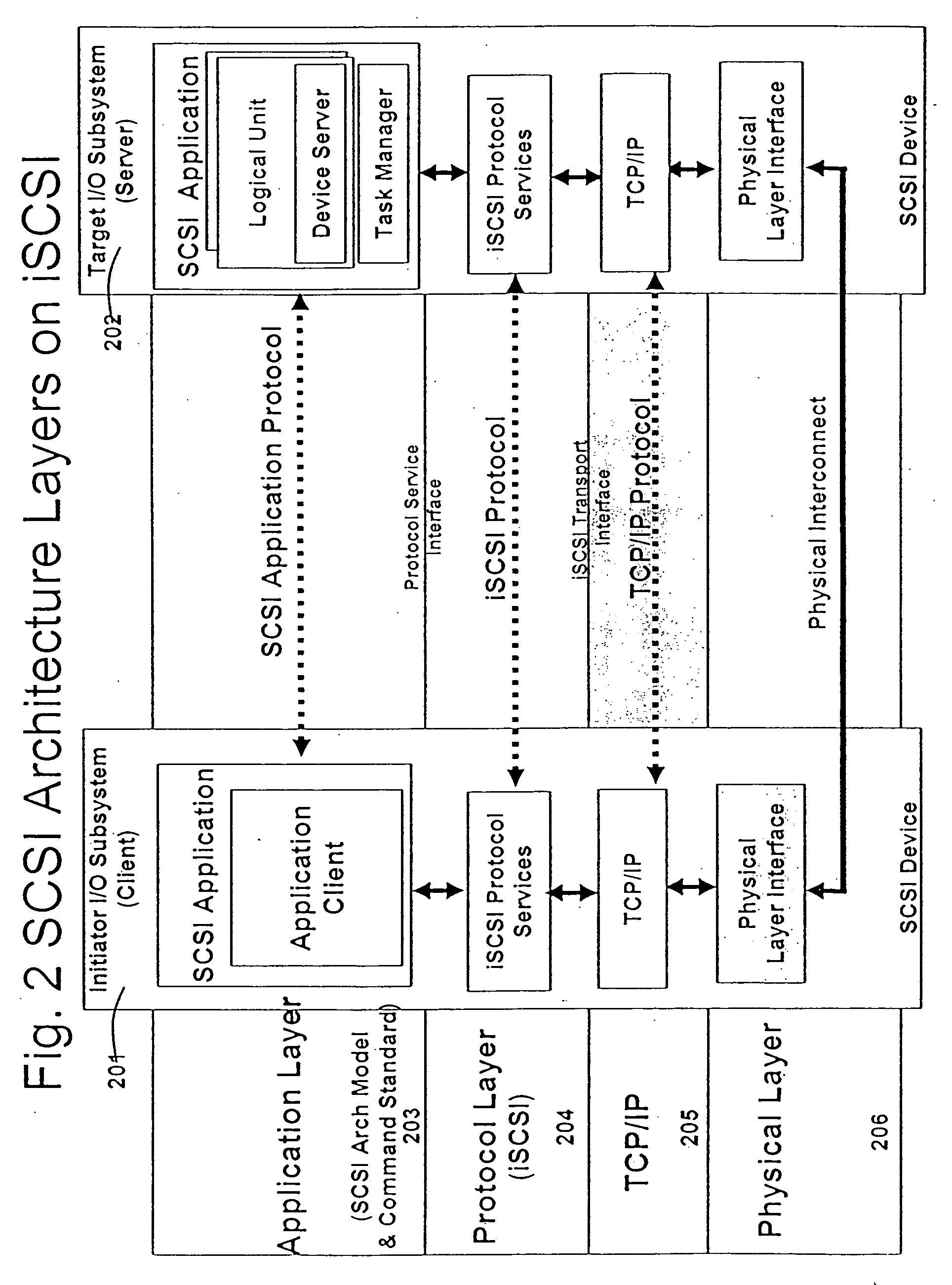

A runtime adaptable search processor is disclosed. The search processor provides high speed content search capability to meet the performance need of network line rates growing to 1 Gbps, 10 Gbps and higher. he search processor provides a unique combination of NFA and DFA based search engines that can process incoming data in parallel to perform the search against the specific rules programmed in the search engines. The processor architecture also provides capabilities to transport and process Internet Protocol (IP) packets from Layer 2 through transport protocol layer and may also provide packet inspection through Layer 7. Further, a runtime adaptable processor is coupled to the protocol processing hardware and may be dynamically adapted to perform hardware tasks as per the needs of the network traffic being sent or received and / or the policies programmed or services or applications being supported. A set of engines may perform pass-through packet classification, policy processing and / or security processing enabling packet streaming through the architecture at nearly the full line rate. A high performance content search and rules processing security processor is disclosed which may be used for application layer and network layer security. scheduler schedules packets to packet processors for processing. An internal memory or local session database cache stores a session information database for a certain number of active sessions. The session information that is not in the internal memory is stored and retrieved to / from an additional memory. An application running on an initiator or target can in certain instantiations register a region of memory, which is made available to its peer(s) for access directly without substantial host intervention through RDMA data transfer. A security system is also disclosed that enables a new way of implementing security capabilities inside enterprise networks in a distributed manner using a protocol processing hardware with appropriate security features.

Owner:MEMORY ACCESS TECH LLC

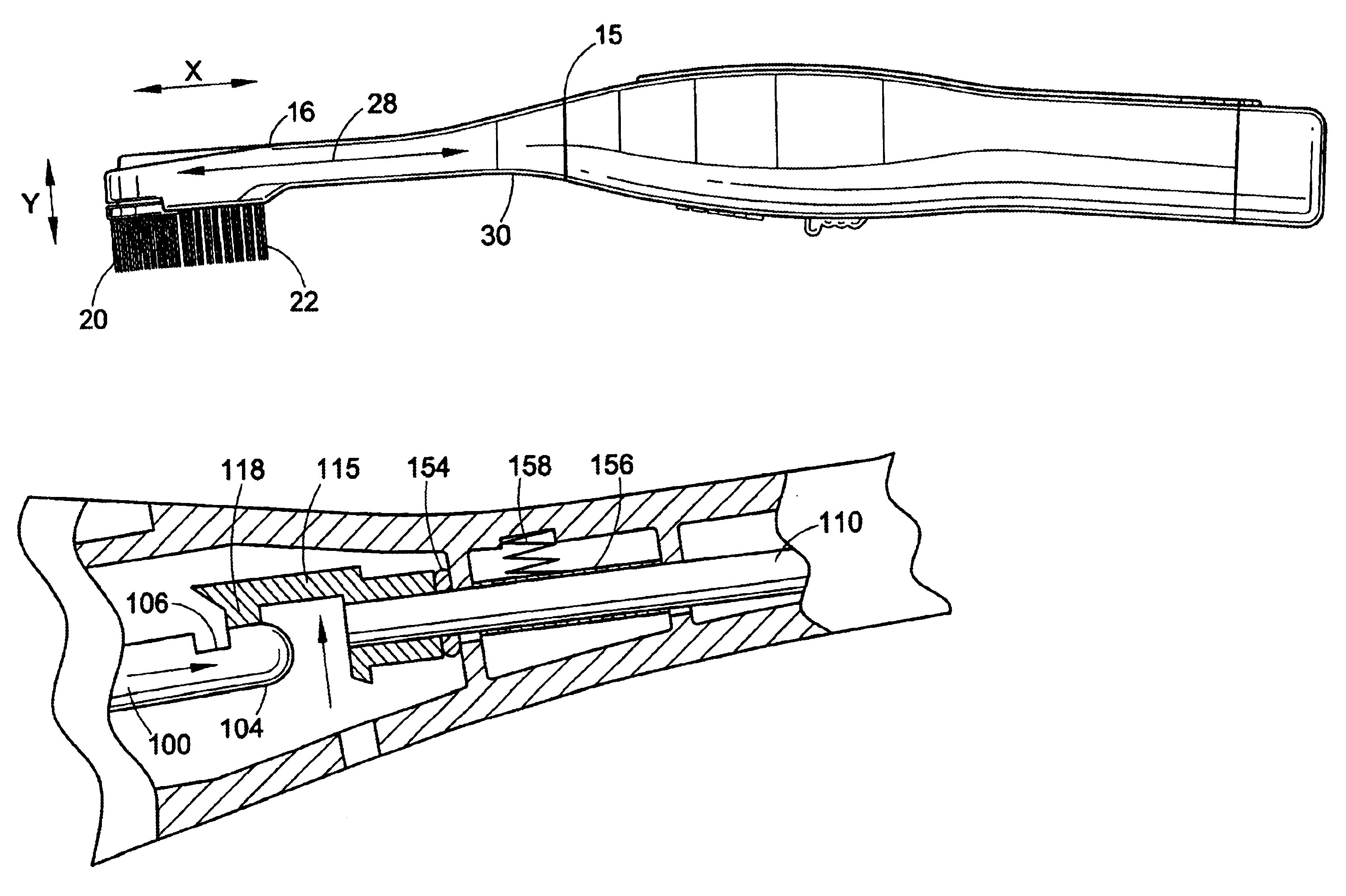

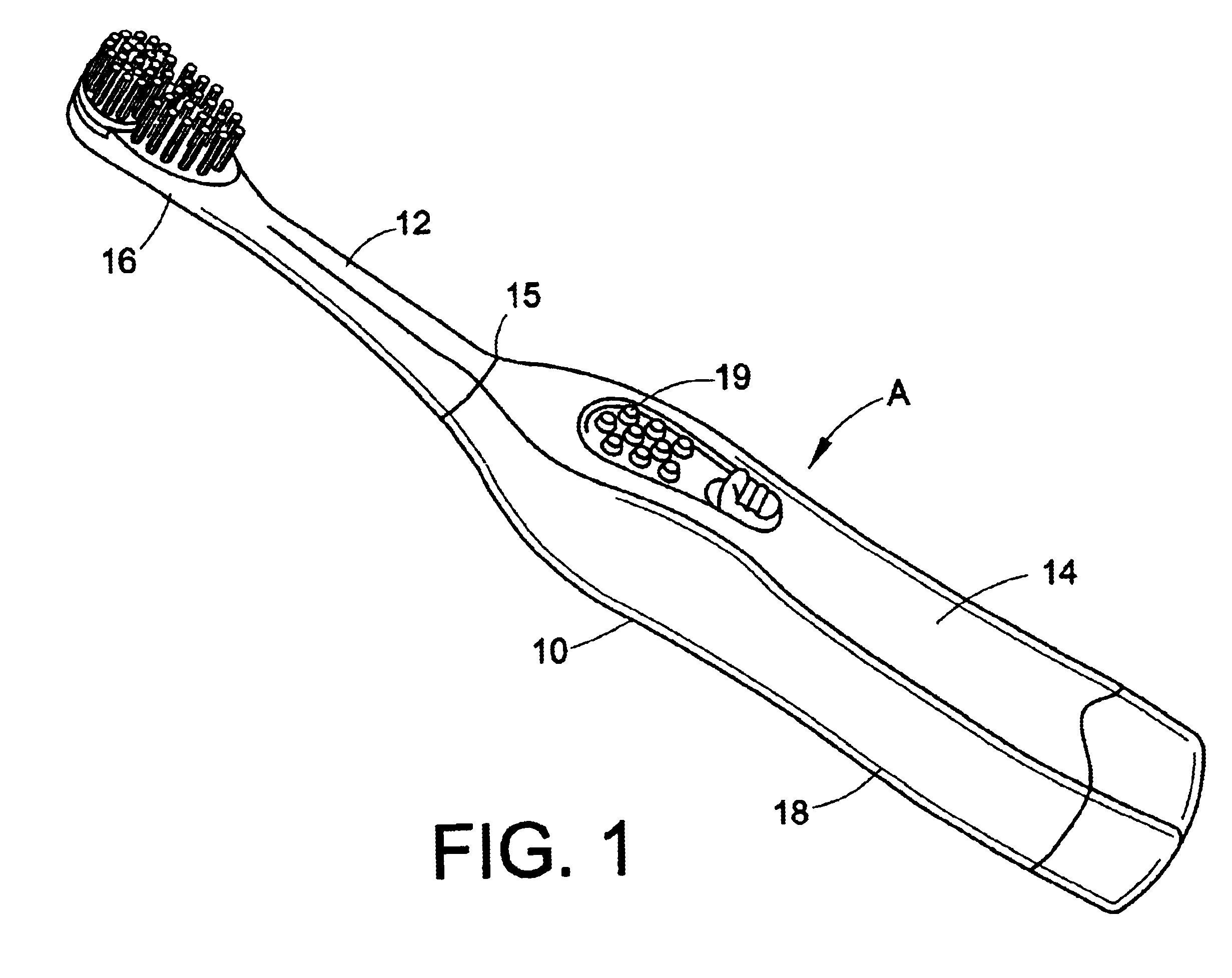

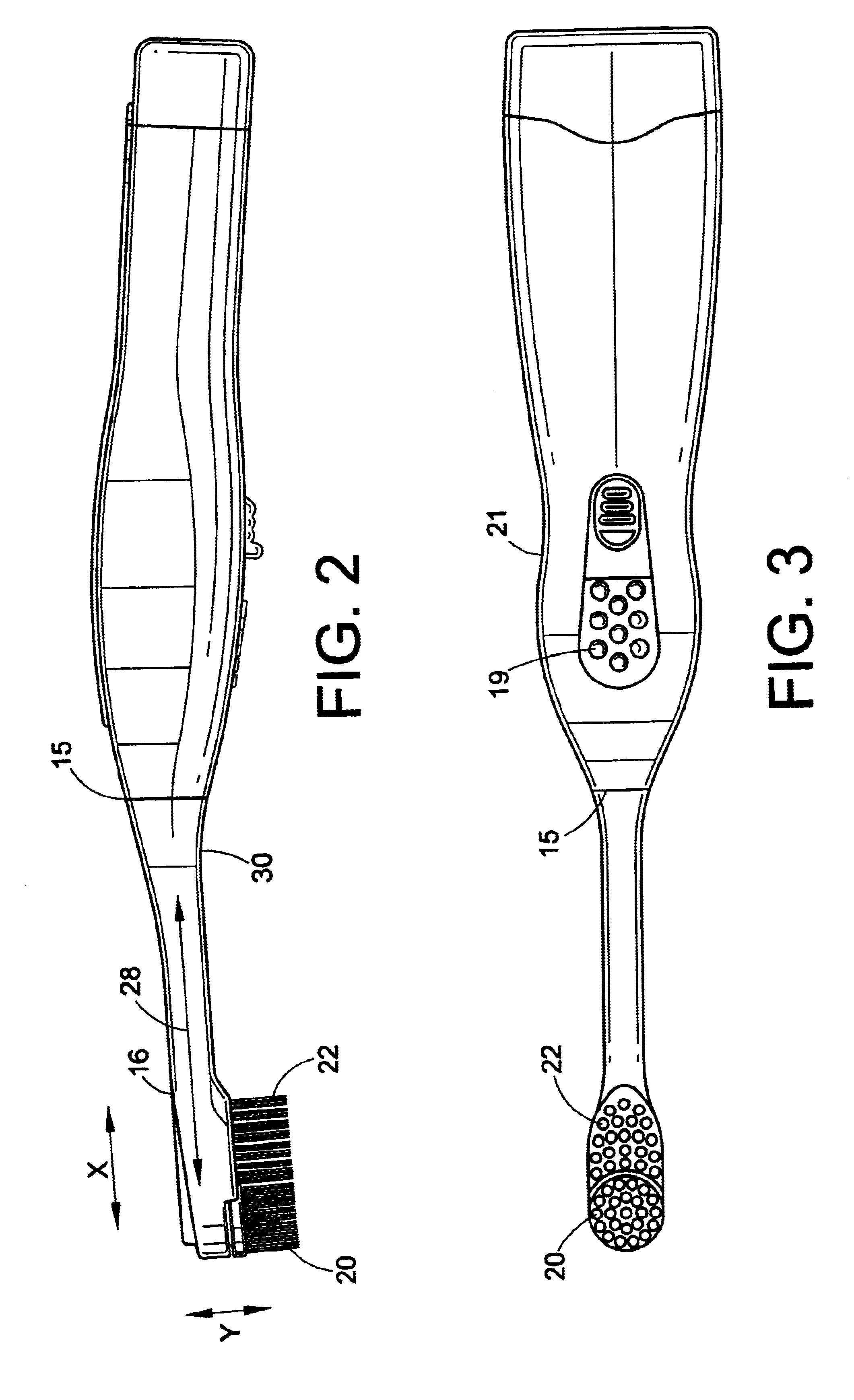

Replaceable head electric toothbrush and connection structure therefor

InactiveUS6836917B2Easy to replaceNot to damageCarpet cleanersKitchenware cleanersEngineeringHair shaft

An electric toothbrush comprising an elongated body portion and a head including a static portion and a moving portion, a handle, and an angled shaft between the head and the handle. The portion of the toothbrush containing the head is detachably connected to the portion of the toothbrush containing the handle. A shaft within the head is selectively connectable to a mating shaft within the handle by a cooperating notch and peg assembly biased into a locking position by a spring member disposed to bias the head shaft into the desired position.

Owner:CHURCH & DWIGHT CO INC

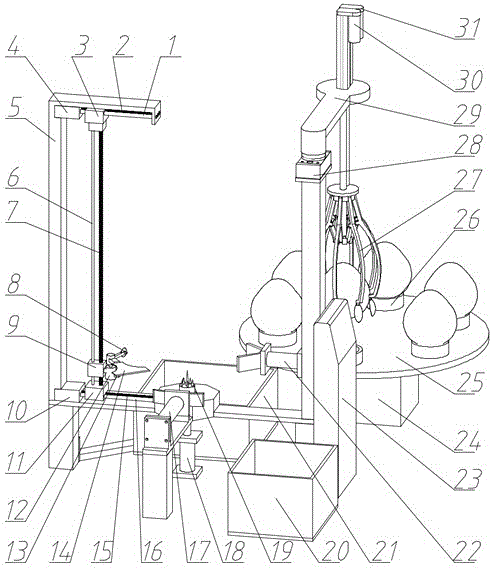

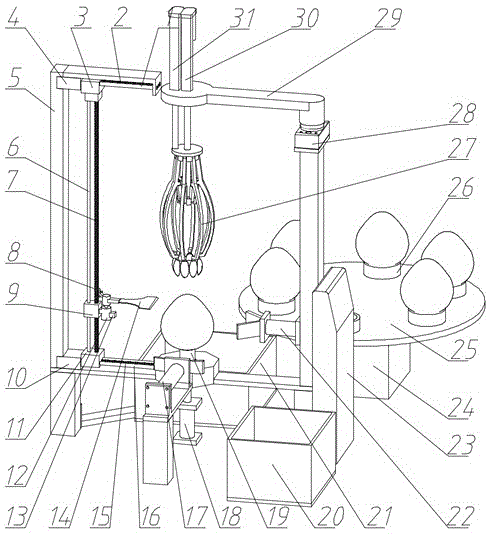

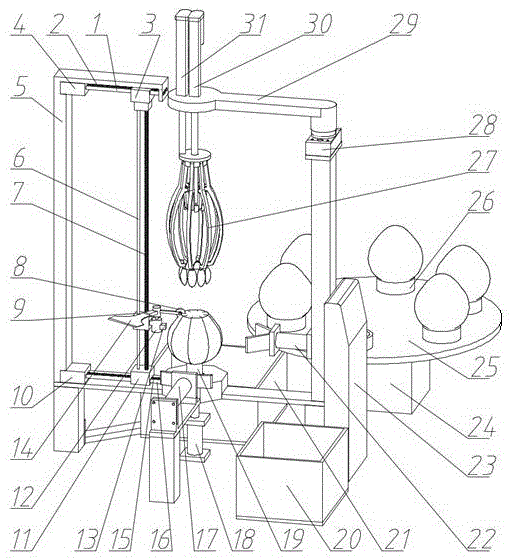

Automatic pomelo peel-flesh separating device and method

The invention discloses an automatic pomelo peel-flesh separating device and an automatic pomelo peel-flesh separating method. The method comprises the following steps: first, clamping and placing a pomelo on a fixing needle which is in the center of a working bench by cooperatively controlling a vertical electric push rod and an unfolding electric push rod, and operating a peeling mechanical claw; then, measuring the size of the profile of the pomelo by utilizing a laser distance sensor, performing data analysis processing on the data of the profile size of the pomelo and determining subsequent actions by a power supply and a control cabinet, and respectively cutting off the top cover of the pomelo and dividing the peel of the pomelo into eight pieces equally by cooperatively controlling the actions of an upper horizontal stepping motor, a lower horizontal stepping motor and a vertical stepping motor, and utilizing a top removal cutting knife and a peel scratching hobbing knife; finally, cooperatively controlling the vertical electric push rod and the unfolding electric push rod to move, and enabling the peeling mechanical claw to move along the trajectory in the peel of the pomelo to peel the peel of the pomelo, clamp the flesh of the pomelo and separate the flesh from the peel. According to the device and the method, the pomelo can be charged and discharged automatically; after the top of the pomelo is removed and the peel is scratched, all pieces of the peel are peeled precisely simultaneously without hurting the flesh.

Owner:JIANGSU UNIV

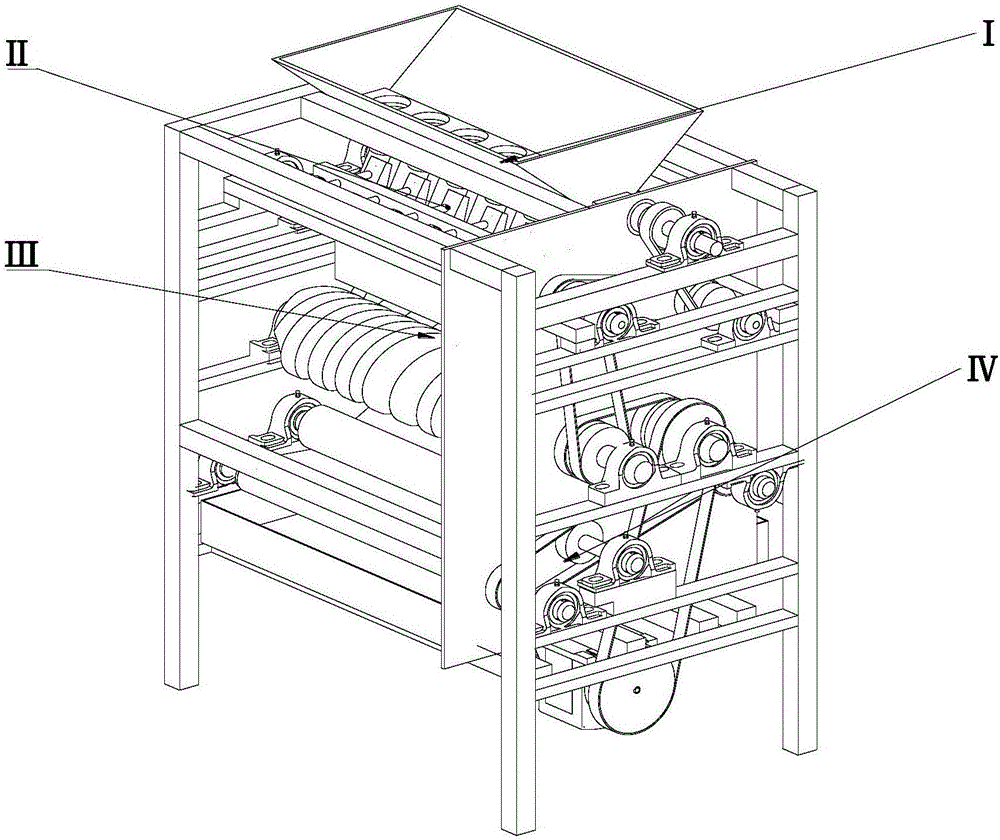

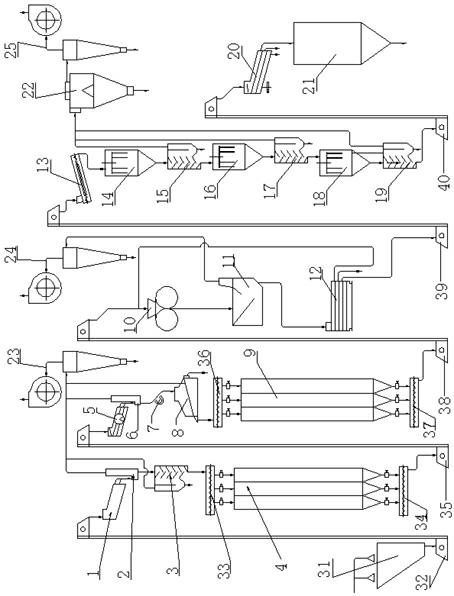

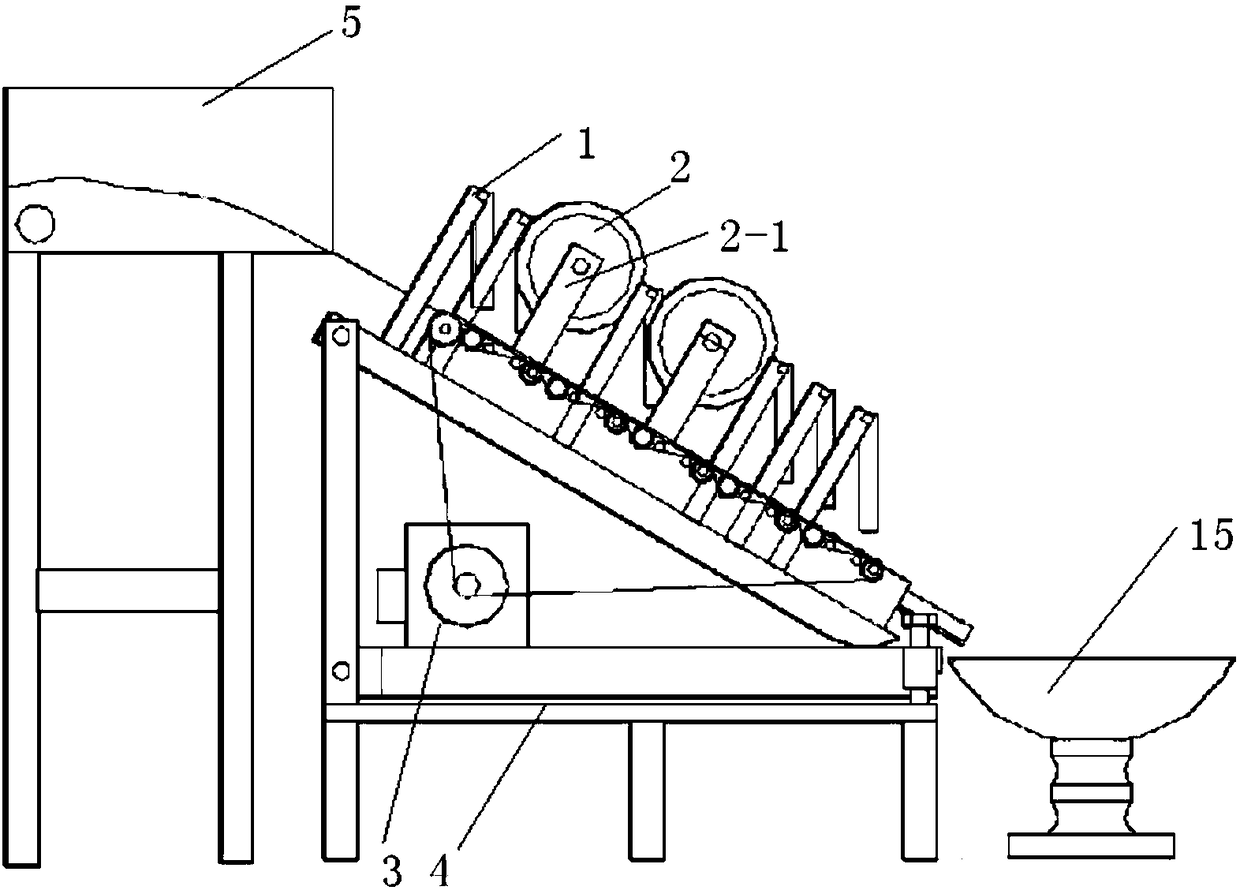

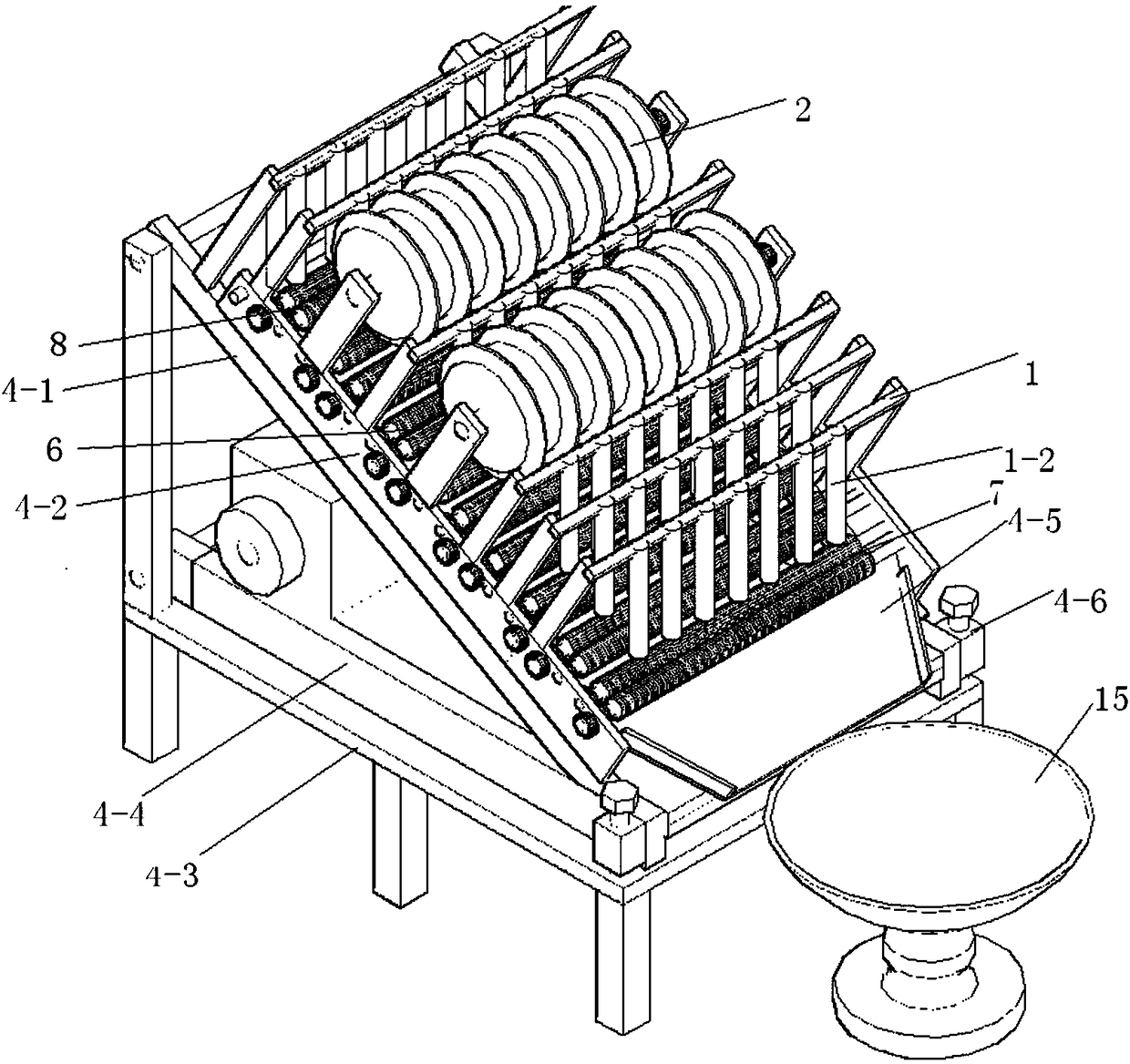

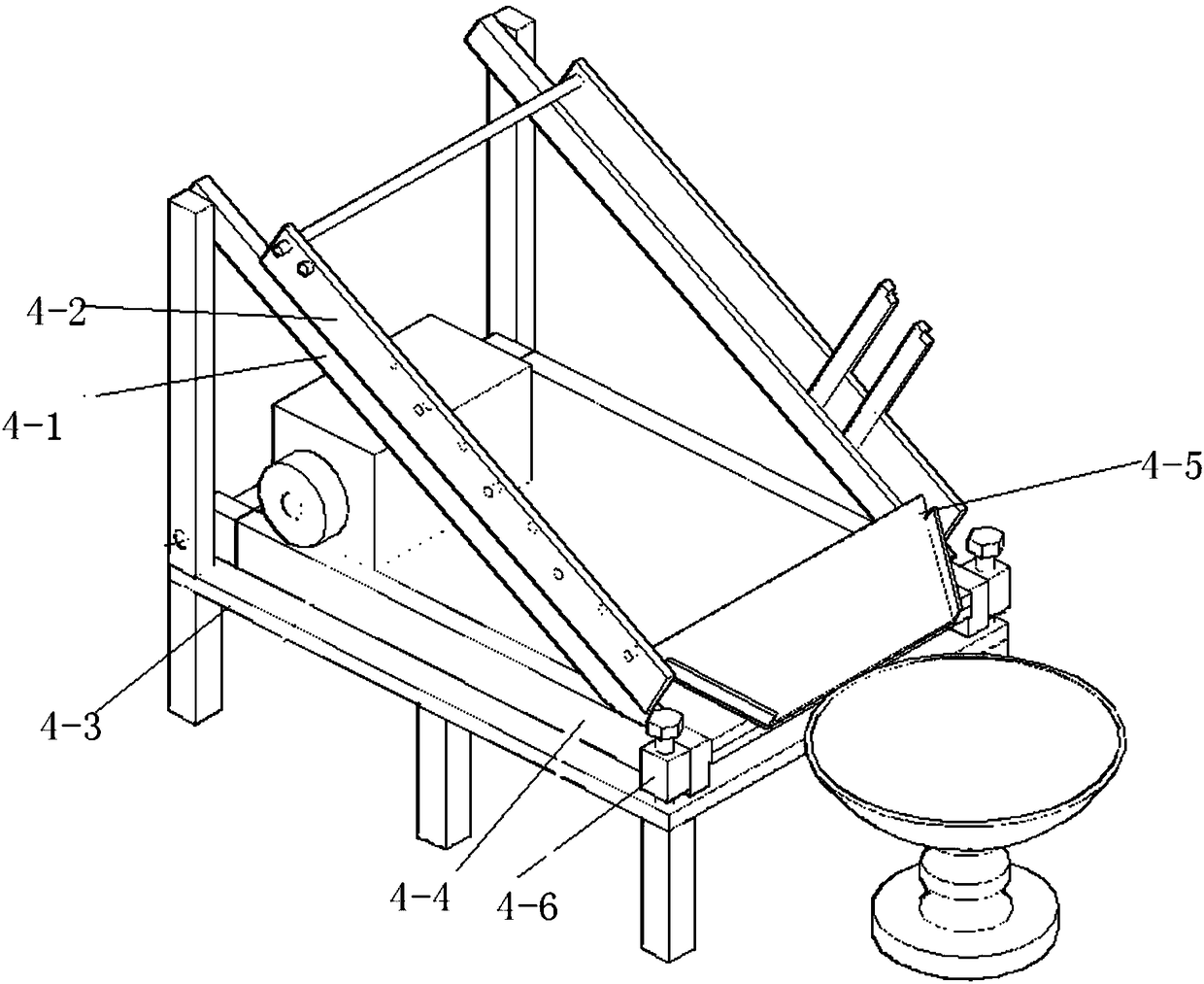

Device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion

ActiveCN106473167AReduce grading processPrecise pre-crackingHuskingHullingWalnut NutReciprocating motion

The invention discloses a device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion. The device comprises an intermittent feeding device, the a shell pre-breaking device, a flexible shell breaking device and a separating device, which are fixed on a machine frame, wherein the intermittent feeding device is used for performing intermittent batch feeding for the shell pre-breaking device; the shell pre-breaking device comprises an extruding part and a blanking part which are mutually matched; the extruding part is in reciprocating movement, and is matched with the blanking part for extruding walnuts, so that cracks are generated in the walnuts; the blanking part is in reciprocating movement, so that the extruded walnuts fall off to the flexible shell breaking device; the flexible shell breaking device is used for breaking walnut shells; and shells and kernels of the walnuts after shell breaking are separated for storage through the separating device. The device disclosed by the invention integrates a plurality of systems, and is compact in structure, the manufacturing cost of a machine is reduced, the occupied space for the operation of the machine is also reduced, and the miniaturization and the high efficiency of the machine are facilitated; in structure design, multiple connections including splicing, combining and the like for cooperating work can be realized; and the requirements of various production scales and the requirements of various production sites can be met, and the device is also suitable for families, and is widely applied.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +2

Soluble egg powder and preparation method thereof

The invention provides a preparation method of soluble powder, which consists of the following procedures: making the egg liquid material into emulsification one by practicing mechanical dispersion and emulsification; putting the emulsification egg liquid at 38-48 DEG C for heat preservation and stirring 0.5-4.5 hr; making the referred egg liquid into the soluble powder by spraying and drying. The method in the invention damages the particle structure of the egg liquid through mechanical dispersion and forms the O / W type emulsification, so as to get the O / W type powder particles easily after spraying and drying; makes the protein moderate hydrolysis by activating the protease in the egg liquid and lowers the molecular weight and the viscosity of the protein which will help improve the solubility of the egg powder after spraying and drying. Therefore, the egg powder of the method will dissolve in the normal temperature water and hot water and form uniform emulsification which will not form egg-water-like-gel after heating.

Owner:FOODSTUFF INST BEIJING +1

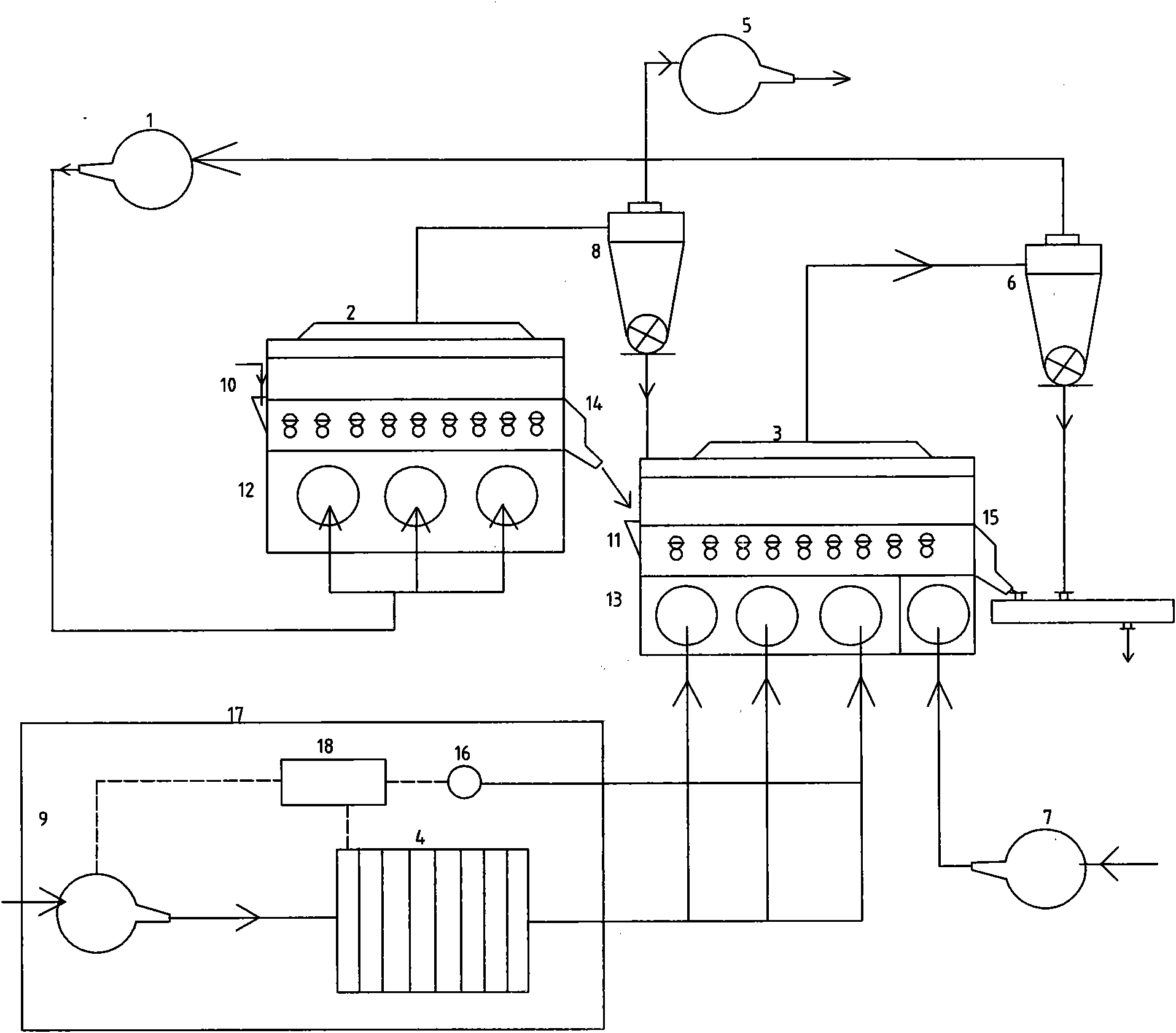

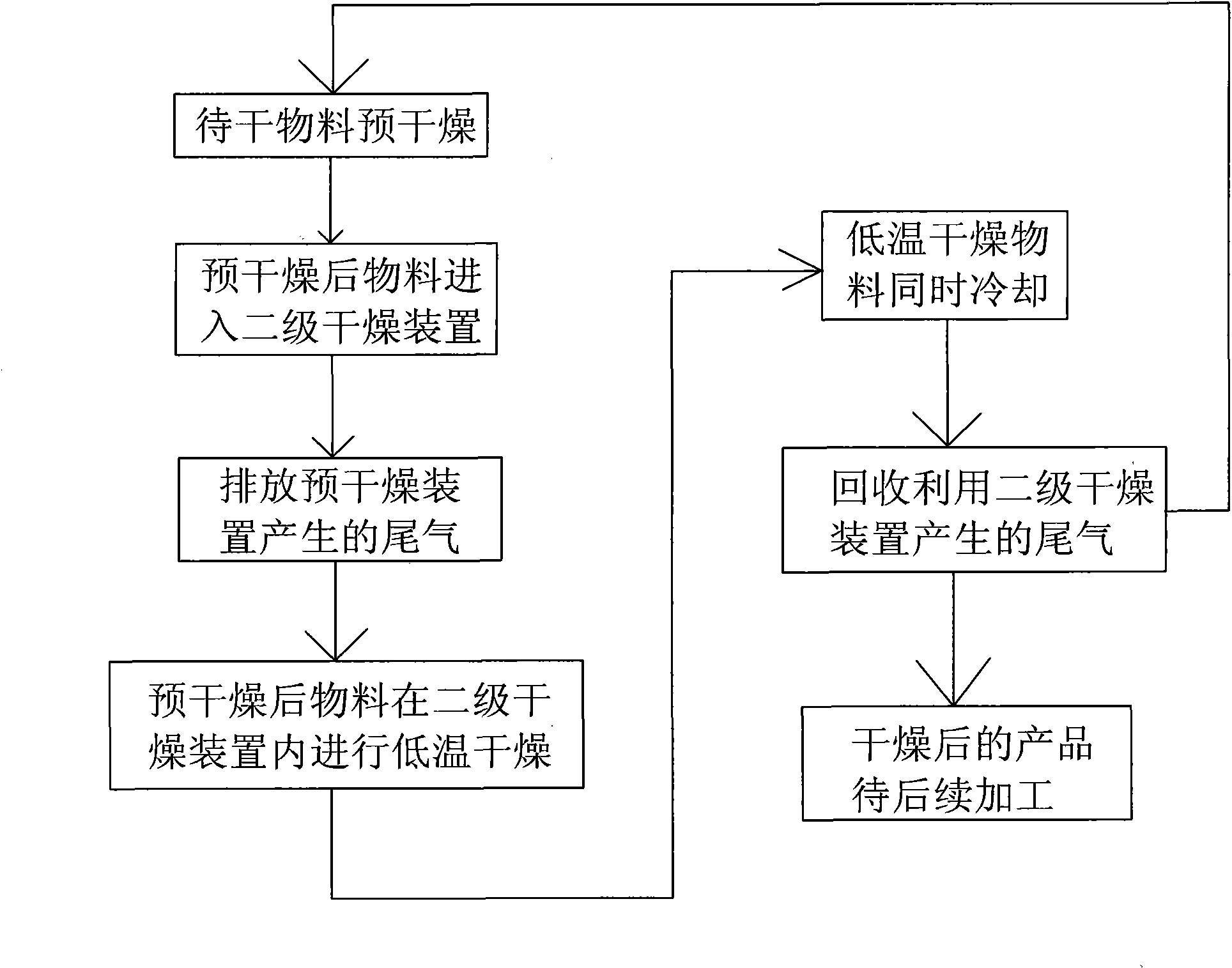

Low-temperature high-efficiency fluidization combined drying process and equipment thereof

InactiveCN101881550AQuality improvementReduce heat consumptionDrying solid materials with heatDrying machine combinationsProcess systemsProcess engineering

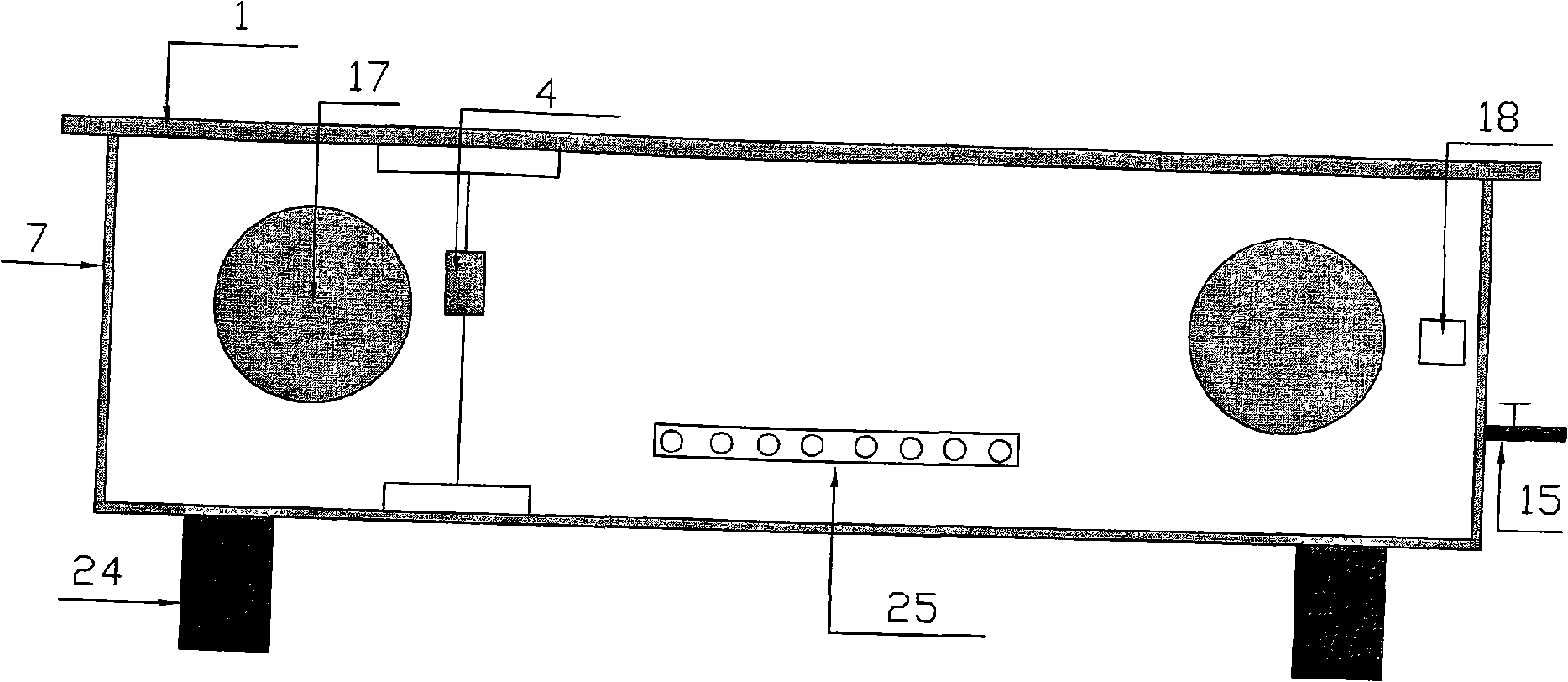

The invention discloses a low-temperature high-efficiency fluidization combined drying process and equipment thereof; the drying equipment comprises an afterheat utilization primary pre-heating device, a secondary drying device, cyclone separators, blowers and a temperature control device; the afterheat utilization primary pre-drying device or the secondary drying device comprises a feed opening, a discharge port, a vent and a drying chamber; the discharge port of the afterheat utilization primary pre-drying device is connected with the feed opening of the secondary drying device; the vent of the afterheat utilization primary pre-drying device is sequentially connected with a cyclone separator A, the secondary drying device, a cyclone separator B, a blower A and the drying chamber of the afterheat utilization primary pre-drying device; the vent of the cyclone separator A is connected with the blower B; and the drying chamber of the secondary drying device is respectively connected with a blower C and the temperature control device. The invention quickly and homogeneously dries material to be dried under the premise of meeting the original quality of raw grain, leavening and other products, has the advantages of energy-saving, environment production, low temperature and high efficiency, meets the requirements of continuous and scale production, and has good process system maintenance performance.

Owner:ACAD OF STATE GRAIN ADMINISTRATION

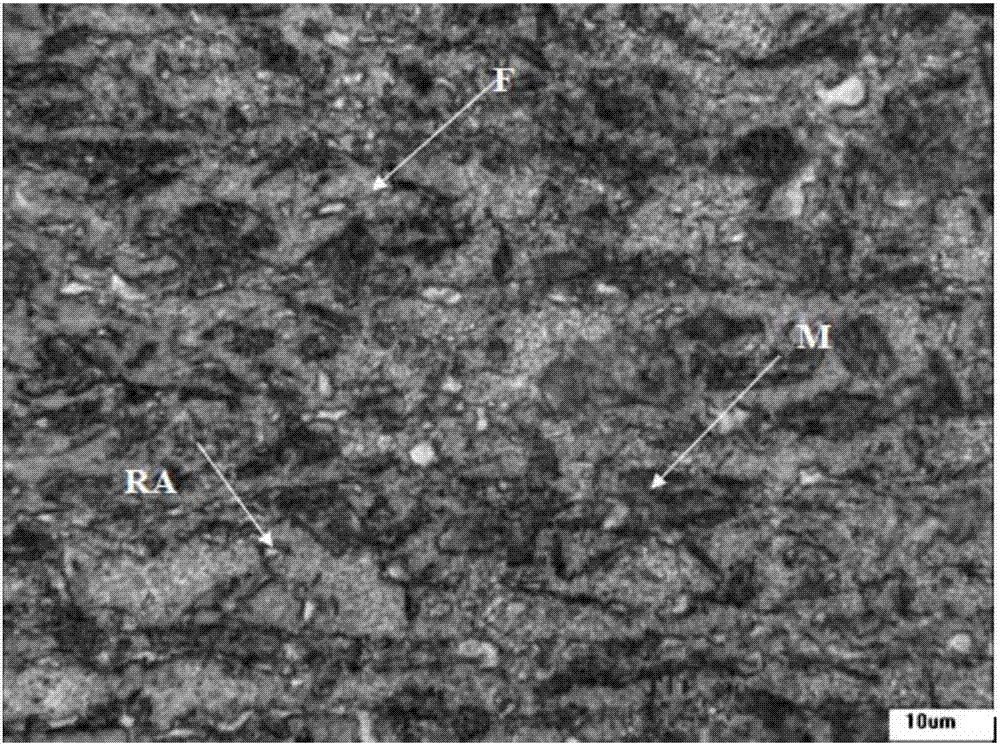

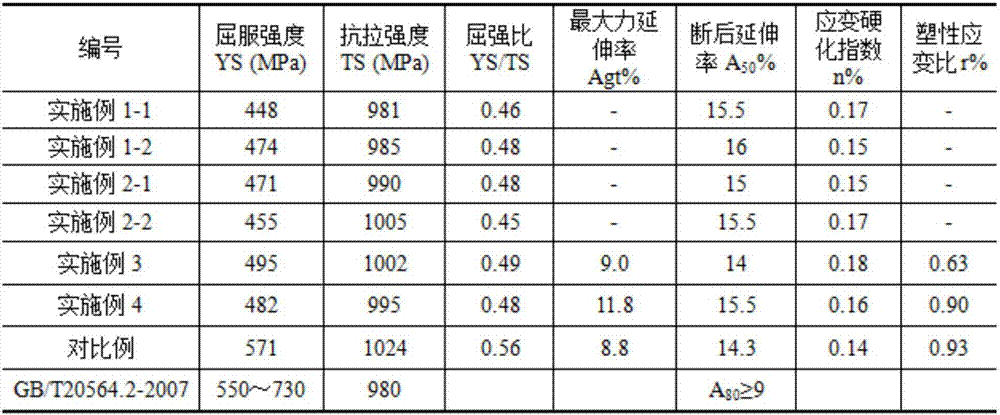

Ultralow yield ratio 980 MPa-grade cold rolling two-phase steel and manufacturing method thereof

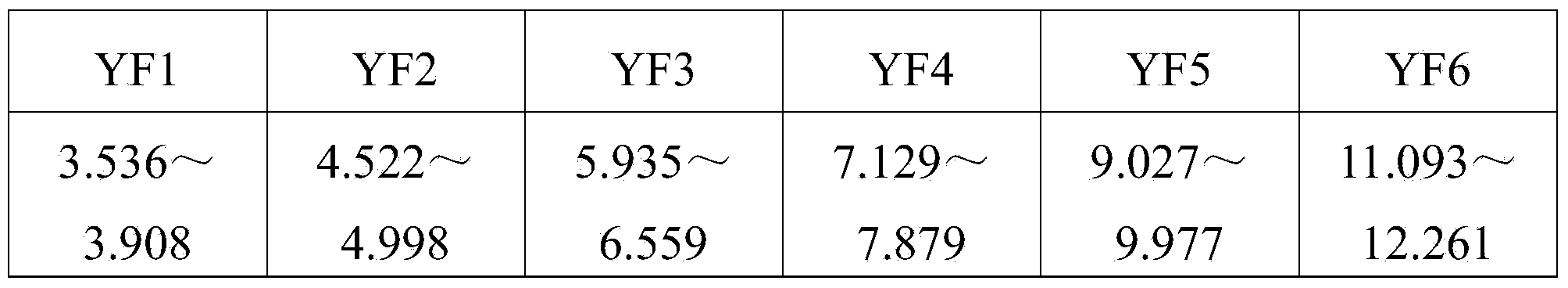

The invention discloses ultralow yield ratio 980 MPa-grade cold rolling two-phase steel and a manufacturing method of the ultralow yield ratio 980 MPa-grade cold rolling two-phase steel, and belongs to the technical field of two-phase steel. Chemical components of the steel comprise, by weight, 0.13-0.18% of C, 0.3-0.6% of Si, 1.7-2.4% of Mn, 0.03-0.06% of Als, 0-0.05% of Nb, 0.3-0.5% of Cr and the balance Fe and inevitable impurities. In composition design, the composite strengthening way mainly comprising phase transformation strengthening and combining solid solution strengthening, refined crystalline strengthening, phase change strengthening and precipitation strengthening is adopted, the cold rolling two-phase steel plate can be used as an automobile anti-collision part, a structural part and an inner plate material. The steel has the advantages that DP980 has the ultralow yield ratio YS / TS which is smaller than 0.50, good ductility A50 which is larger than or equal to 14%, the high n value, the small mechanical property fluctuation range, the low process sensitivity and other property characteristics, can reduce springback after stamping and is beneficial to follow-up deep processing of the automobile industry.

Owner:CENT IRON & STEEL RES INST

Method, device and use of a device for producing fuel from moist biomass

ActiveUS20110089271A1Good disintegrationAccelerates the removal of moistureBiocideDrying using combination processesComminutionBiomass

The invention relates to a method and to devices, and to the use of the same, for producing fuel pellets from moist biomass of all kinds, wherein the biomass is comminuted, mechanically dehydrated, dried, and then processed into pellets, wherein the comminution is a fine comminution and / or the biomass is washed before or after the comminution—optionally with the water developing during the mechanical dehydration—and is optionally pre-dehydrated and / or heated before the mechanical dehydration step, and is optionally comminuted again after the mechanical dehydration for easier drying.

Owner:WERNER HANS

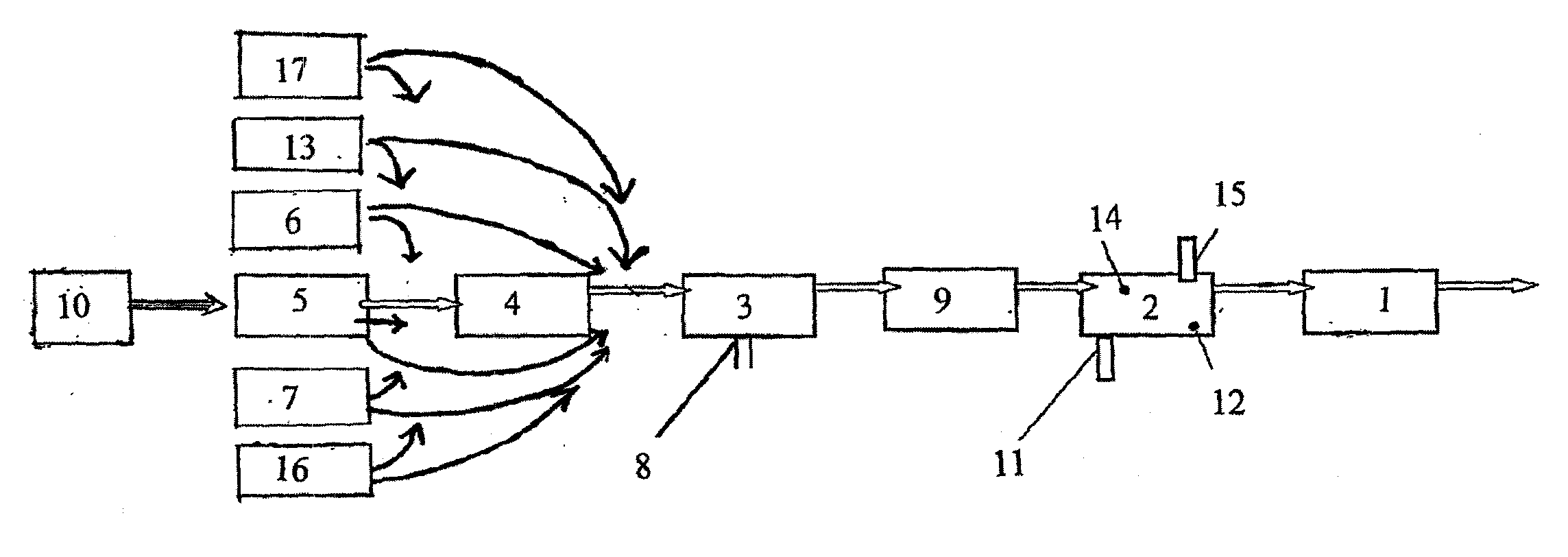

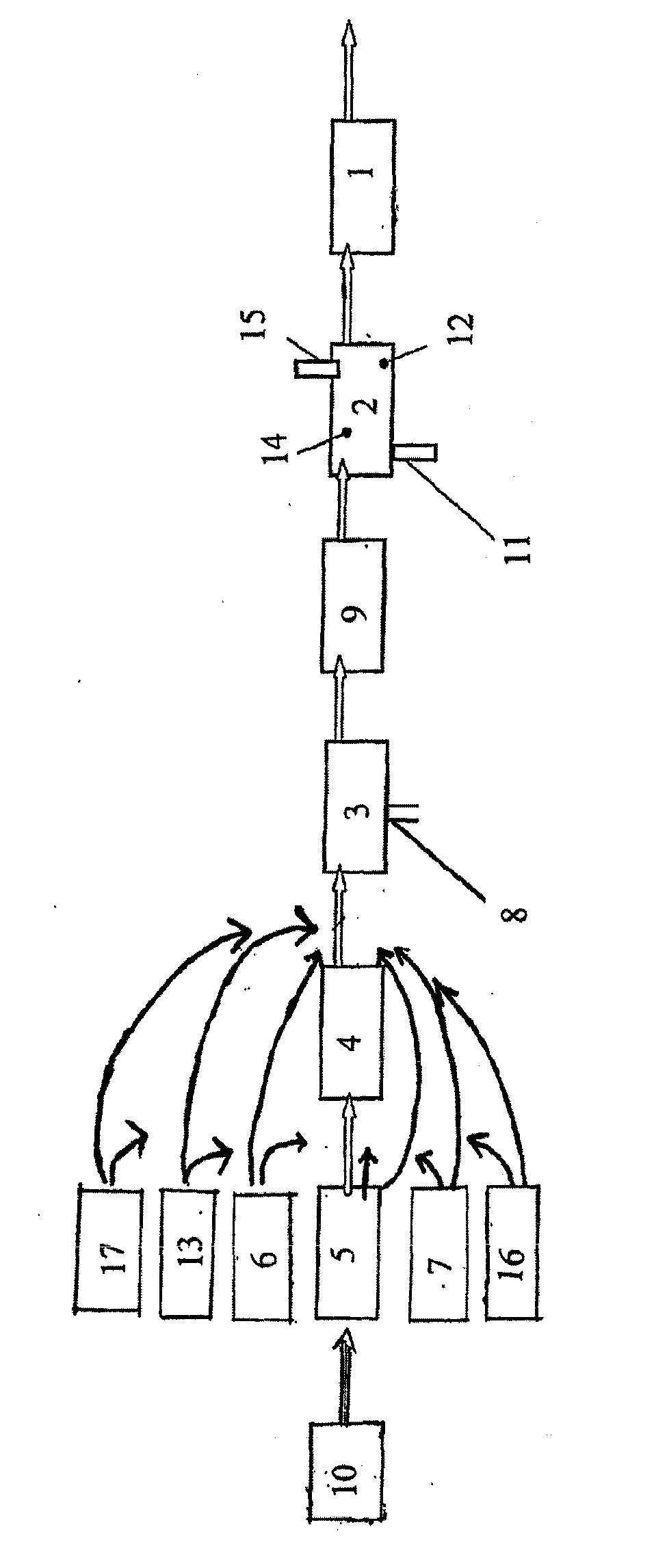

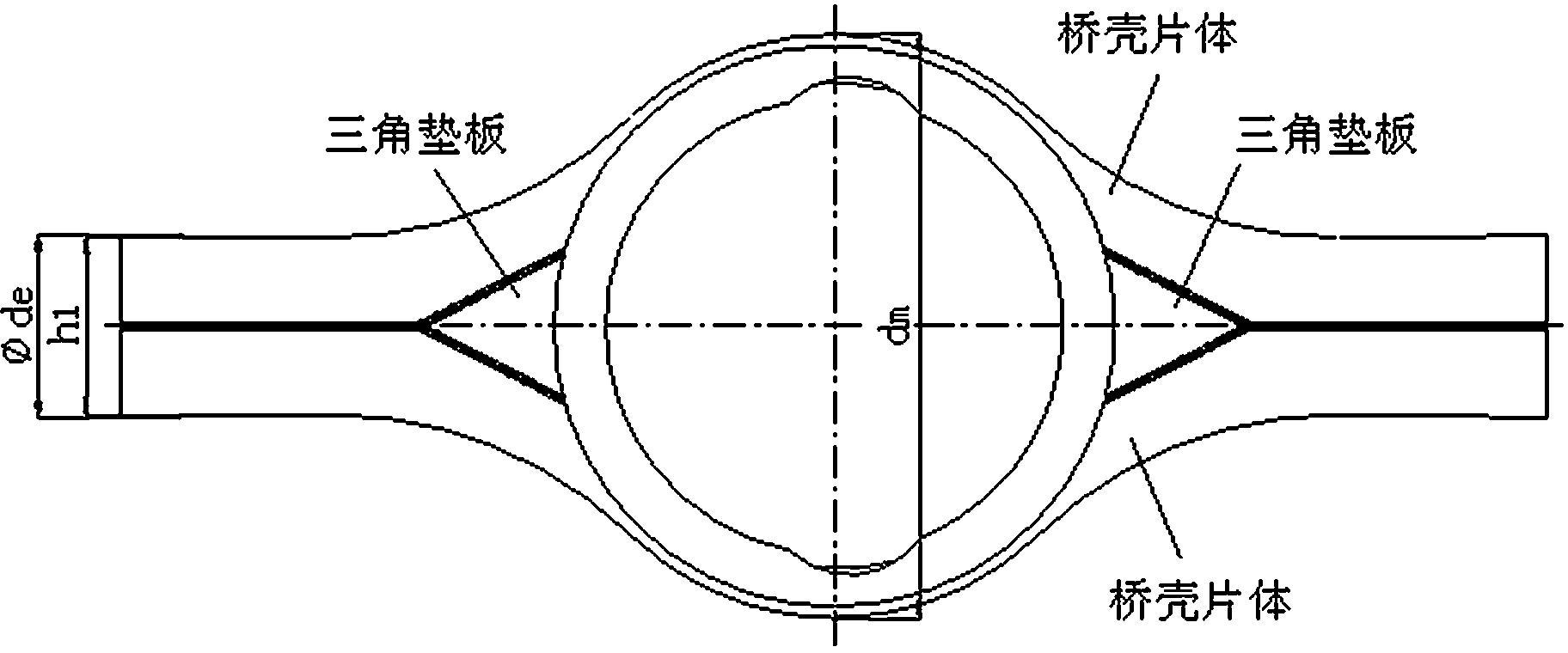

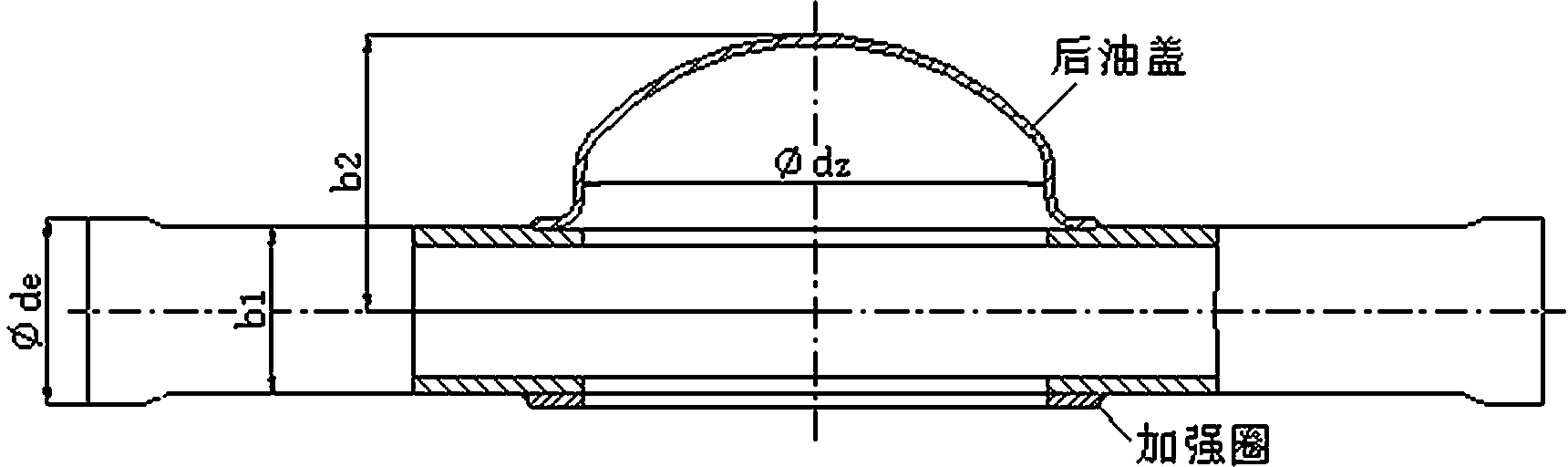

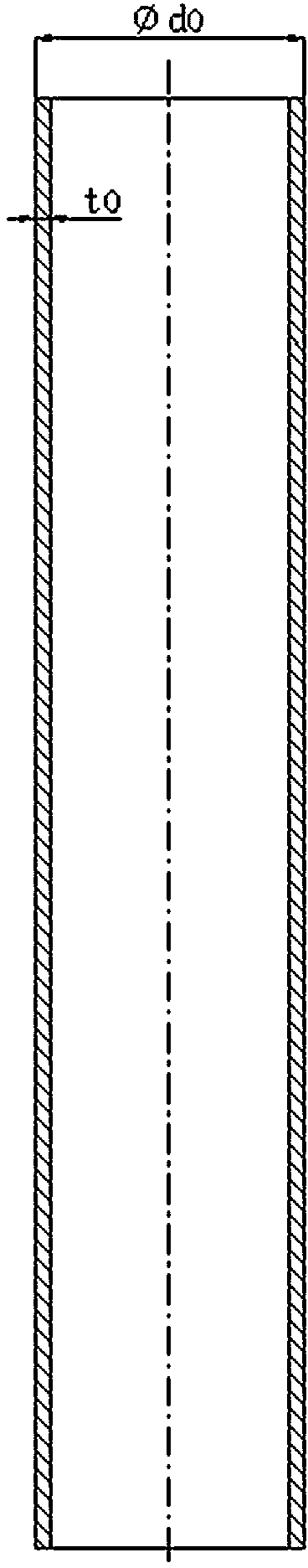

Integral forming method of weldless axle housing of heavy truck

ActiveCN103252404AReasonable distribution of wall thicknessIncreased strength and rigidityHousing FirstTruck

The invention discloses an integral forming method of a weldless axle housing of a heavy truck. According to the method, reversed central spindle necking is carried out on two sides of the axle housing first, then hydro-bugling is carried out on the middle of the axle housing to obtain a bulging tube blank with sizes of two sides of the axis different, and then necking is carried out on two ends of the axle housing to obtain a preformed tube blank; ends of the preformed tube blank are sealed by a left pressure head and a right pressure head of a die and liquid is filled in the axle housing on a four-way hydraulic machine, integral press-forming is carried out on the preformed tube blank from the upper side, the lower side, the front side and the back side through an upper module, a lower module, a front module and a back module to obtain an axle housing tube fitting, a hemispherical rear oil cap is arranged on the rear side of an axle package part, and the front side of the axle package part is a plane; a round hole is punched in the front side of the axle package, the rear oil cap is reshaped with a stamping die, and then an axle housing workpiece is obtained. The heavy truck axle housing manufactured with the method is weldless, high in strength and rigidity, high in shape accuracy, good in wall thickness distribution, and low in manufacturing cost. Compared with a traditional hydro-bugling technique, the method has the advantages that liquid pressure needed in a manufacturing process is reduced by more than 60% and the tonnage of forming equipment is reduced by more than 50%.

Owner:QINHUANGDAO TONGQIAO TECH CO LTD

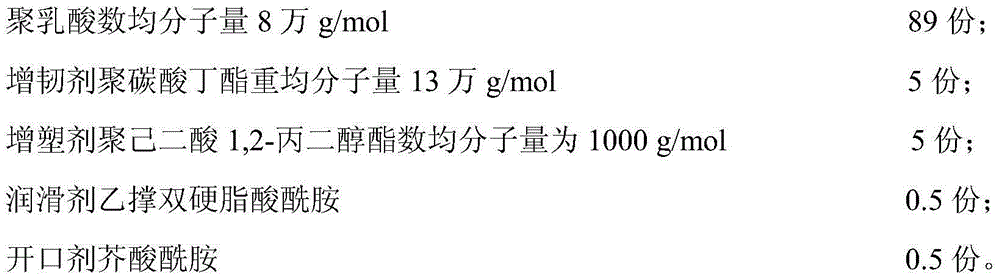

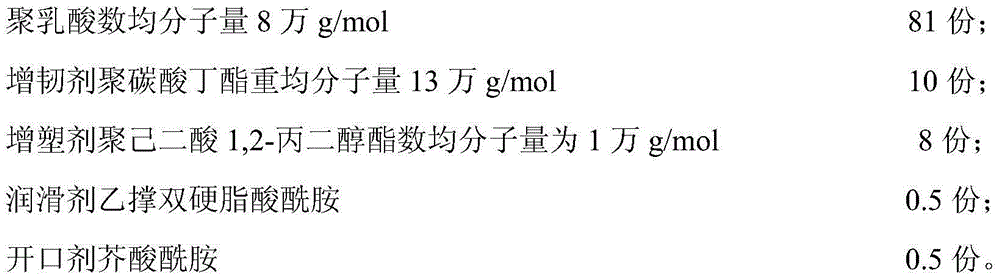

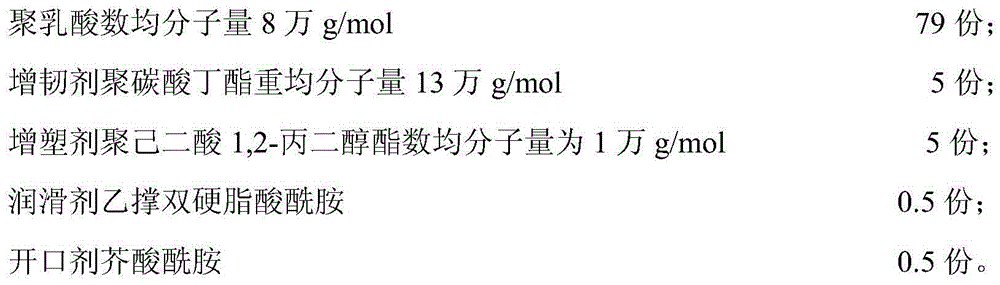

Transparent, tear-resistant and biodegradable polylactic acid thin film and preparation method thereof

InactiveCN104387732AIncreased tensile elongation at breakHigh tear strengthPolymer sciencePlasticizer

The invention provides a transparent, tear-resistant and biodegradable polylactic acid thin film and a preparation method thereof, belonging to the field of high molecular material and solving the technical problem of high brittleness, poor tear resistance and poor flexibility of the polylactic acid thin film in the prior art. The transparent, tear-resistant and biodegradable polylactic acid thin film comprises a mixture of polylactic acid, a toughening agent, a plasticizer, a lubricant and a plastic lubricant. The preparation method comprises the following steps: mechanically mixing polylactic acid, the toughening agent, the plasticizer, the lubricant and the plastic lubricant to obtain a premix at first; feeding the premix from the feeding opening of a twin-screw extruder; metering the plasticizer and adding the metered plasticizer from the liquid feeding opening of the twin-screw extruder; and pelleting by melt extrusion to finally obtain the transparent, tear-resistant and biodegradable polylactic acid thin film. The elongation at break and tearing strength of the polylactic acid thin film provided by the invention are improved obviously, the transparency of polylactic acid is retained, the brittleness defect of the polylactic acid thin film is solved, the rheological behavior of the material is improved obviously, the tensile strength is 43.2MPa at most, the elongation at break is 48%, and the right angle tear strength is 127KN / m.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Transparent and toughening polylactic acid resin and method for preparing the same

The invention provides a transparent and toughening polylactic acid resin and method for preparing the same. The polylactic acid resin consists of polylactic acid, methyl methacrylate-butyl acrylate copolymer as the flexibilizer, citrate plasticizer, pentaerythritol toltetranitrate (Benzenepropanoic acid, 3,5-bis(1,1-dimethylethyl)-4-hydroxy-) as the antioxidant and tris (2,4-ditert-butylphenyl) phosphate. First, premix is prepared by mixing polylactic acid, flexibilizer, plasticizer and antioxidant mechanically. Then the premix is subject to melt extrusion and granulation by utilizing double-screw extruder. The above method has the advantages of increasing the anti-impact strength, tensile strength and elongation at break of polylactic acid and maintaining the transparency thereof. In addition, the viscosity of the blends is decreased, thereby remedying the defects of brittleness of polylactic acid and improving the rheological behavior of materials obviously. The impact strength is up to 60.1KJ / M2.The light transmittance and the haze of the products are 89% and 8.5% respectively when the thickness thereof is 0.04mm.The above polylactic acid resin, instead of PE and PVC, is applicable to the preparation of films, plates, sheet materials, foamings and injection moulding plastics.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

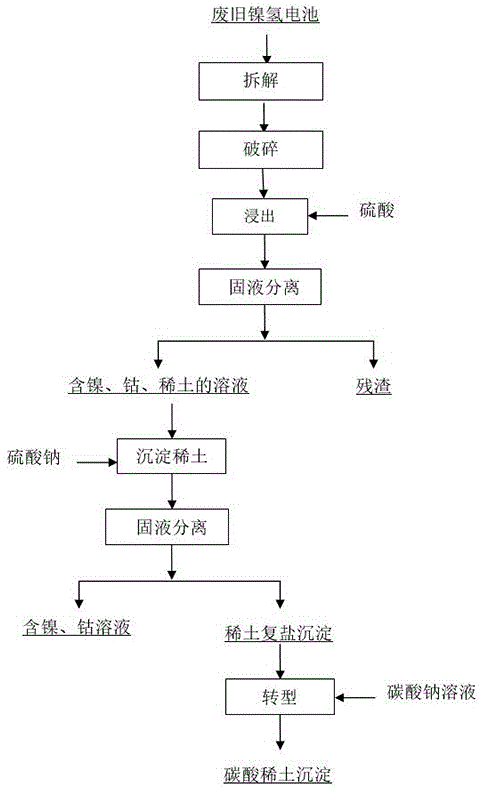

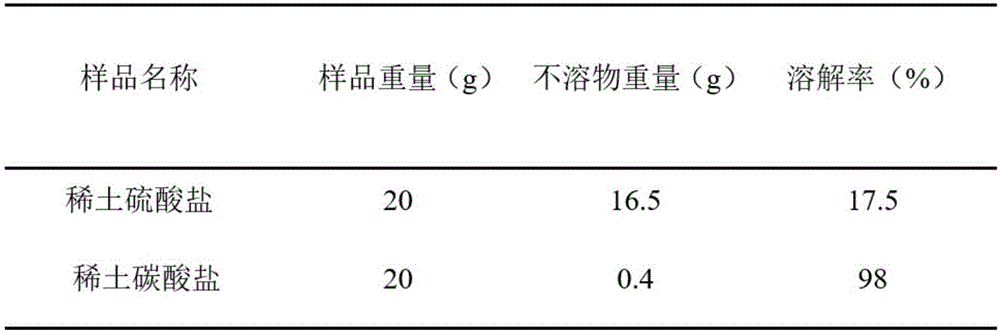

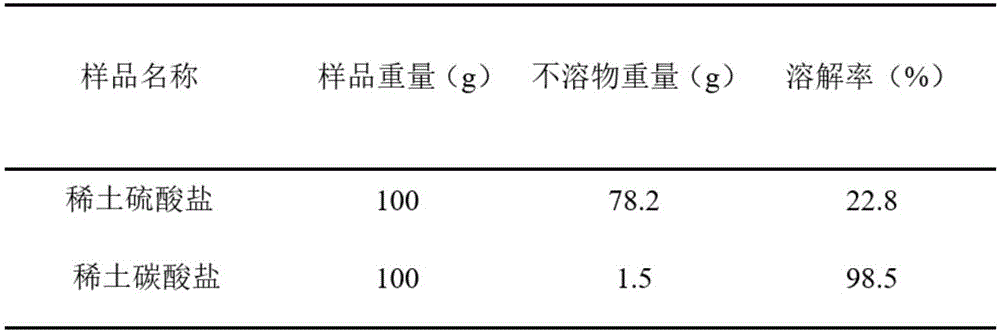

Method for recycling rare earth from waste nickel-hydride battery and conducting transformation

ActiveCN106222456AEasy to recycleImprove solubilityWaste accumulators reclaimingProcess efficiency improvementReaction temperatureRare earth

The invention discloses a method for recycling rare earth from a waste nickel-hydride battery and conducting transformation. The method comprises seven steps including the first step of crushing treatment, the second step of acid leaching treatment, the third step of primary solid-liquid separation, the fourth step of primary sedimentation treatment, the fifth step of secondary solid-liquid separation, the sixth step of sulfuric acid rare earth double salt transformation treatment and the seventh step of rare earth sedimentation extraction. Compared with rare earth sulfate, carbonic acid rare earth sediment is easy to dissolve, the carbonic acid rare earth sediment can be better conducted to further deep processing and can be well separated from nickel and cobalt in the waste nickel-hydride battery, recycling of the rare earth is facilitated, and other valuable metal can be recycled. The reaction is conducted under the normal pressure, the reaction temperature is low, and therefore energy consumption is low. The waste nickel-hydride battery is crushed under the temperature condition of 15 DEG C, volatilization of harmful substances of the waste nickel-hydride battery can be reduced, and the waste nickel-hydride battery can be easier to crush; and to prevent temperature rise of the waste nickel-hydride battery due to collisions in the crushing process, it is most proper to crush the waste nickel-hydride battery in winter.

Owner:JINCHUAN GROUP LIMITED

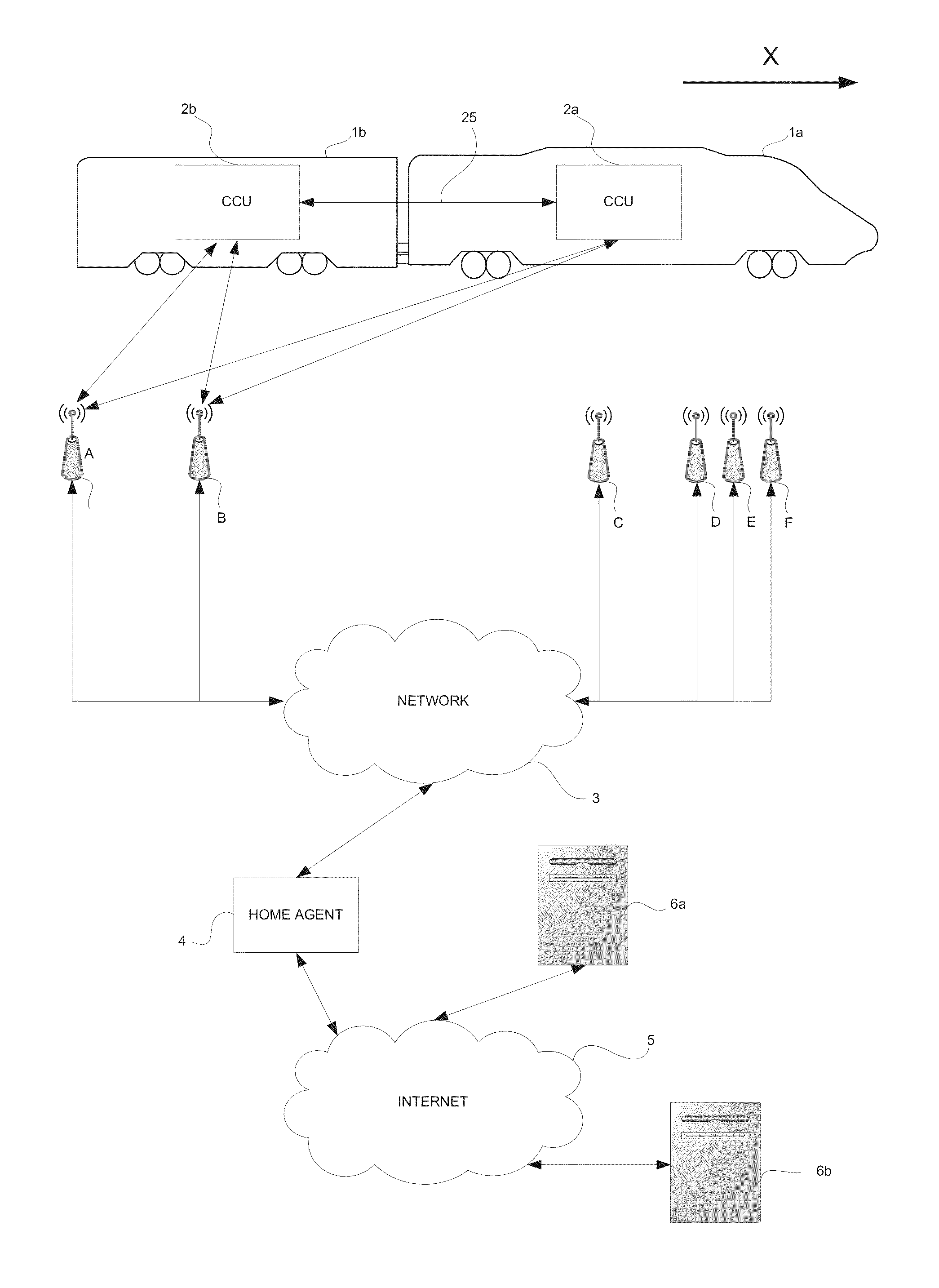

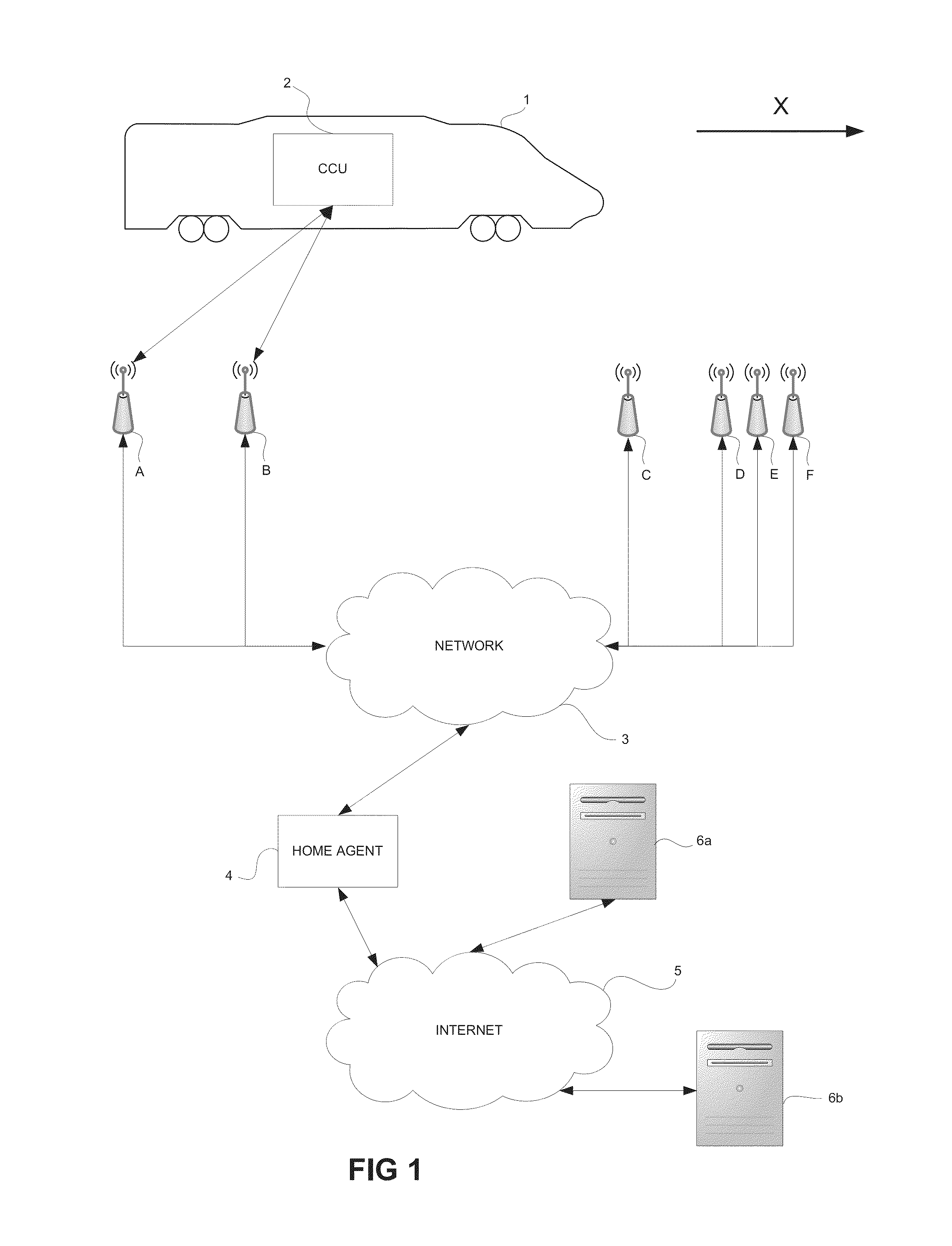

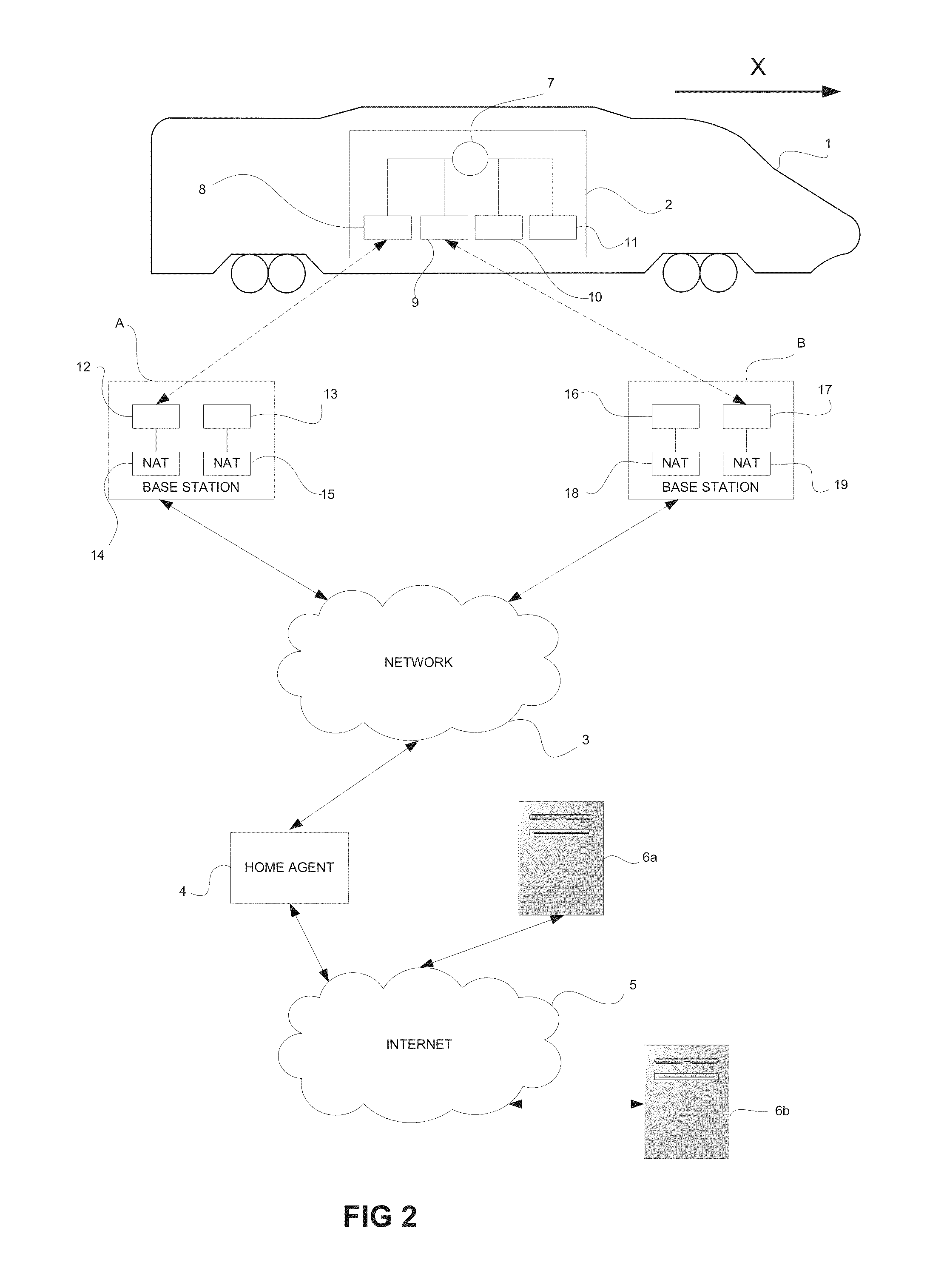

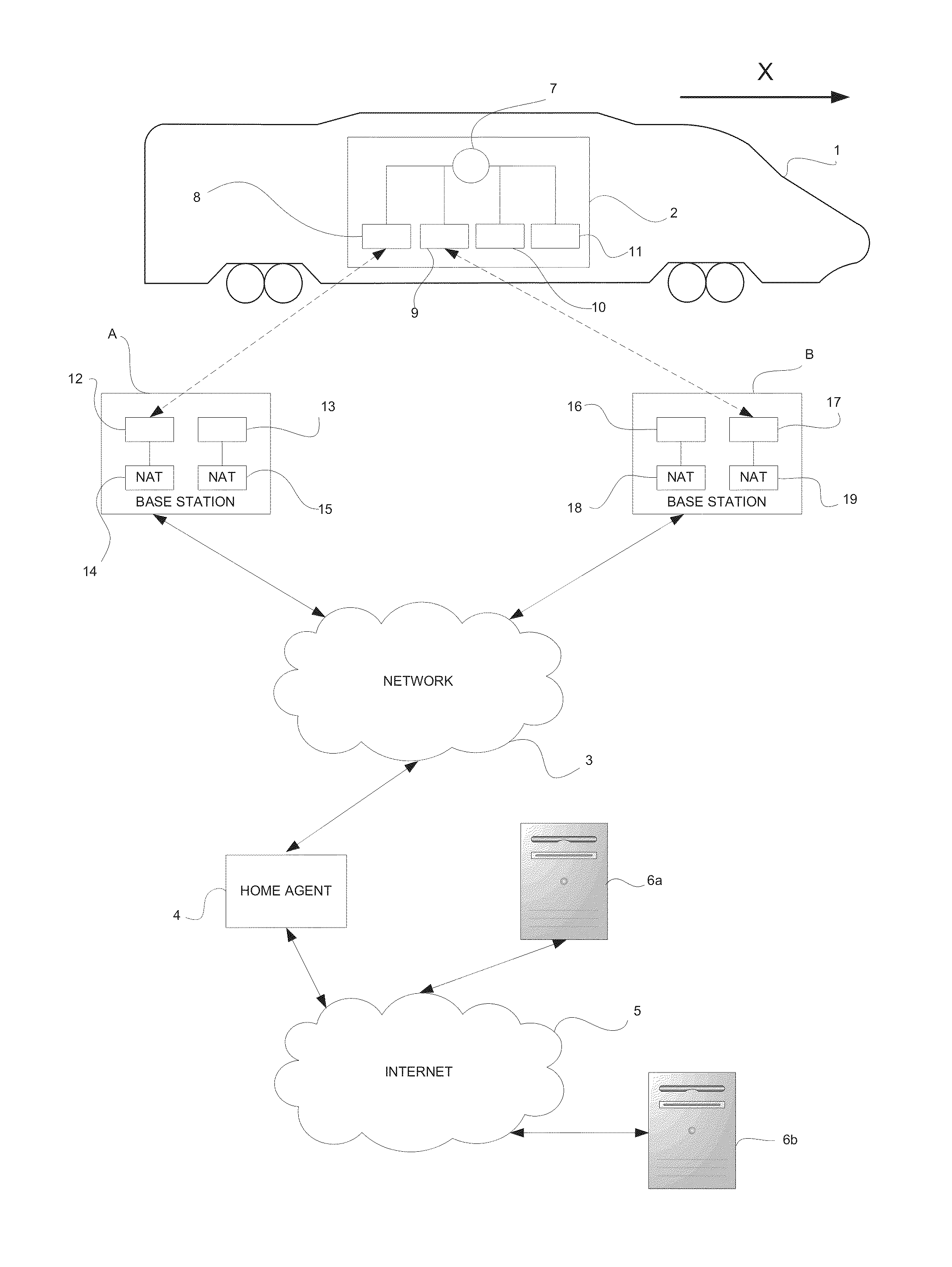

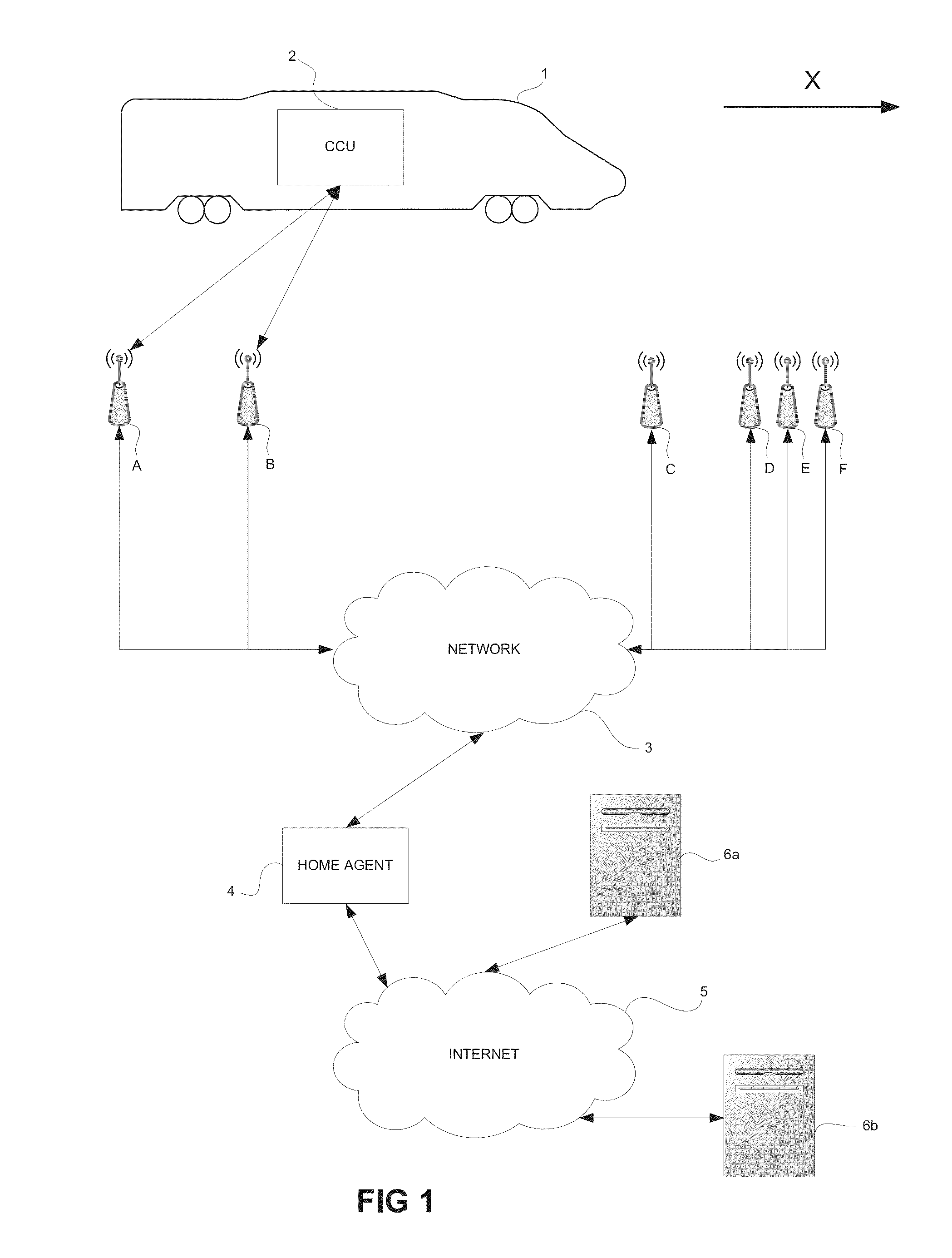

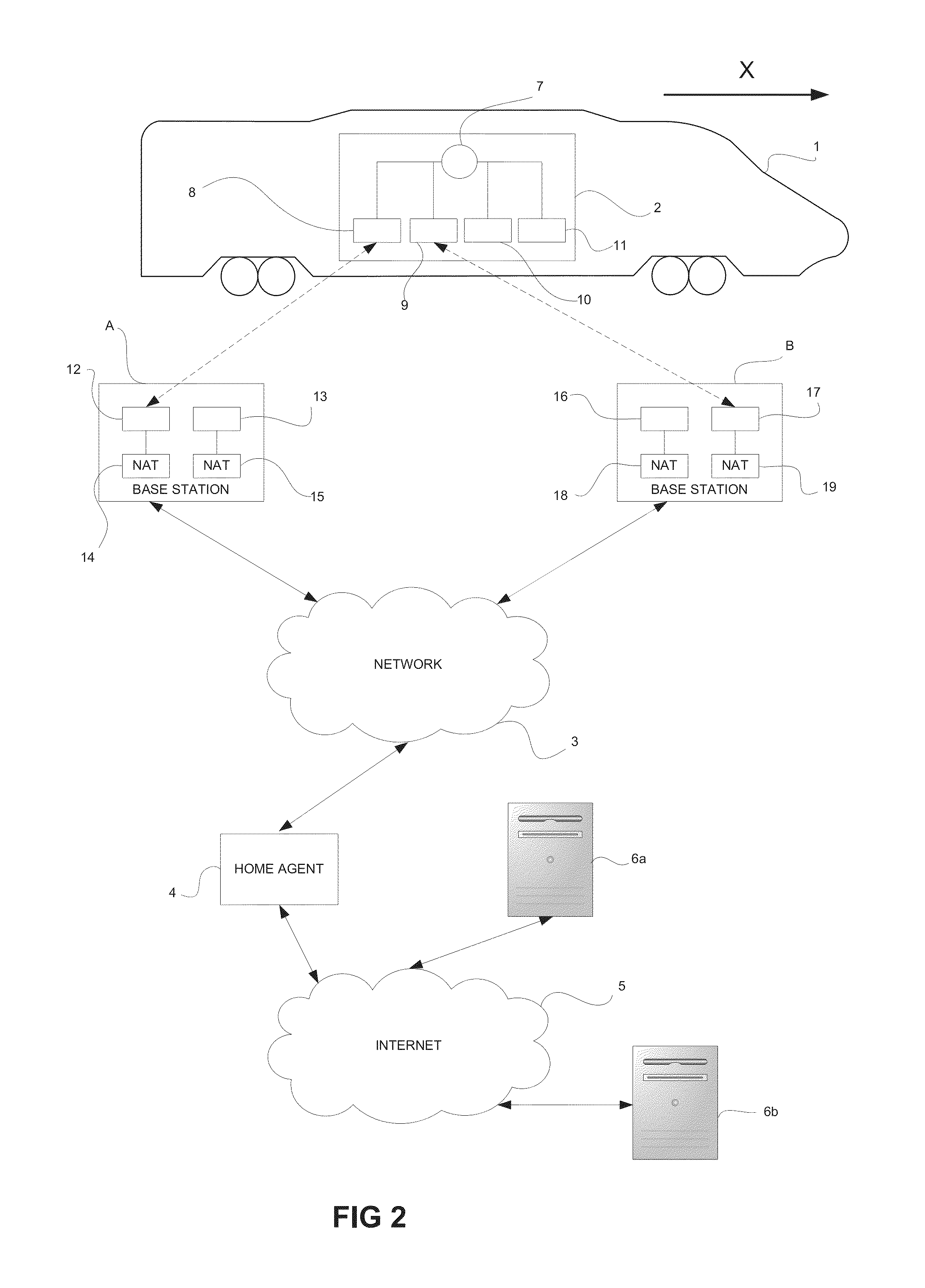

Communication Method

ActiveUS20140146749A1Promote deep processingWireless commuication servicesTransmissionComputer science

Owner:NOMAD DIGITAL LTD

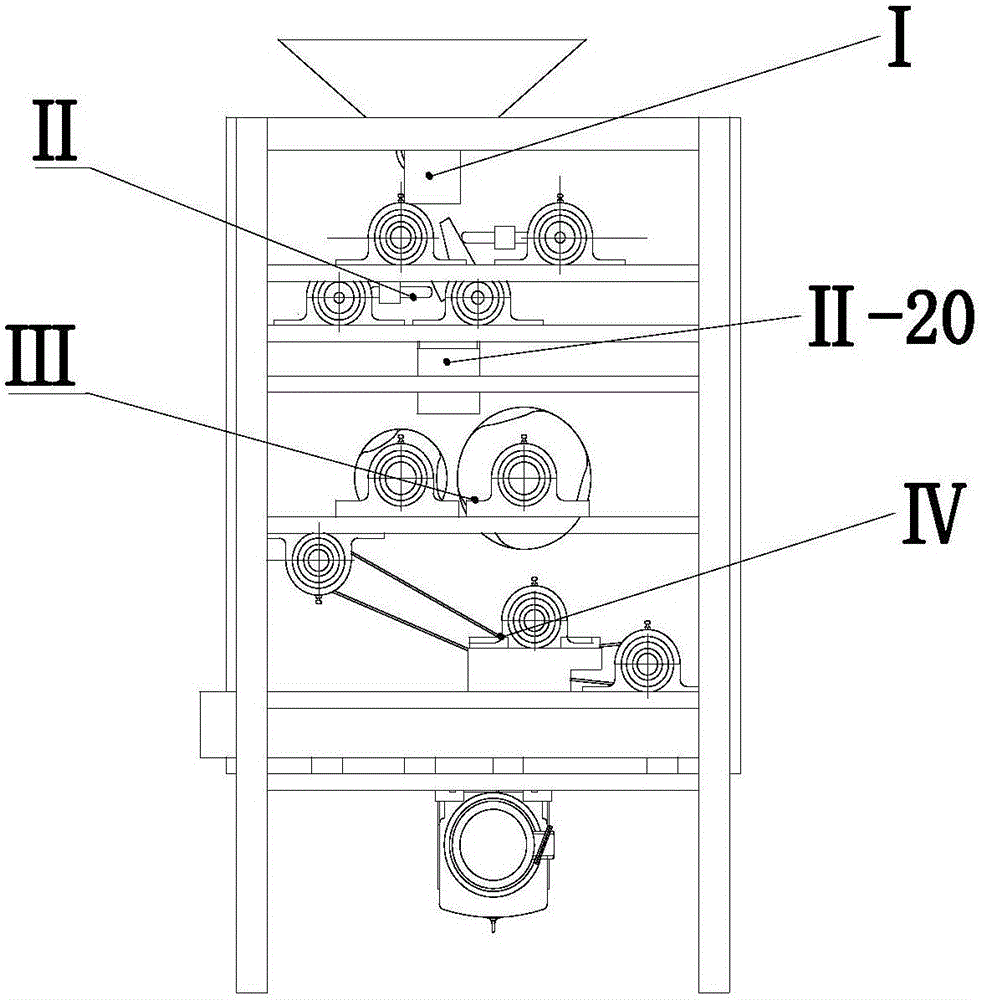

Rice making process and device

InactiveCN102441453AReduce outputReduce energy consumptionGrain huskingGrain polishingAgricultural engineeringBroken rice

The invention relates to rice making process, which comprises a coarse rice peeling procedure. The coarse rice peeling procedure consists of a wetting procedure and a stirring peeling procedure. The wetting procedure includes steps that water with the weight of 0.5%-2.5% of that of coarse rice is added in the coarse rice by a wetting machine, the temperature of the water ranges from 10 DEG C to 60 DEG C, after being wetted, the coarse rice is conveyed to the stirring peeling procedure to be processed within 10 minutes, the height of the coarse rice is controlled within 0.3m to 2m in the stirring peeling procedure, a stirring machine is used during stirring, and the linear speed of a stirring bar of the stirring machine is controlled within 1-6m / S. The rice making process is used for peeling the coarse rice by a stirring peeling method, action force to the coarse rice is low, soft and balanced, removal rate of a coarse rice skin layer is high, yield of broken rice is low, and economical benefit is remarkable.

Owner:王洪福

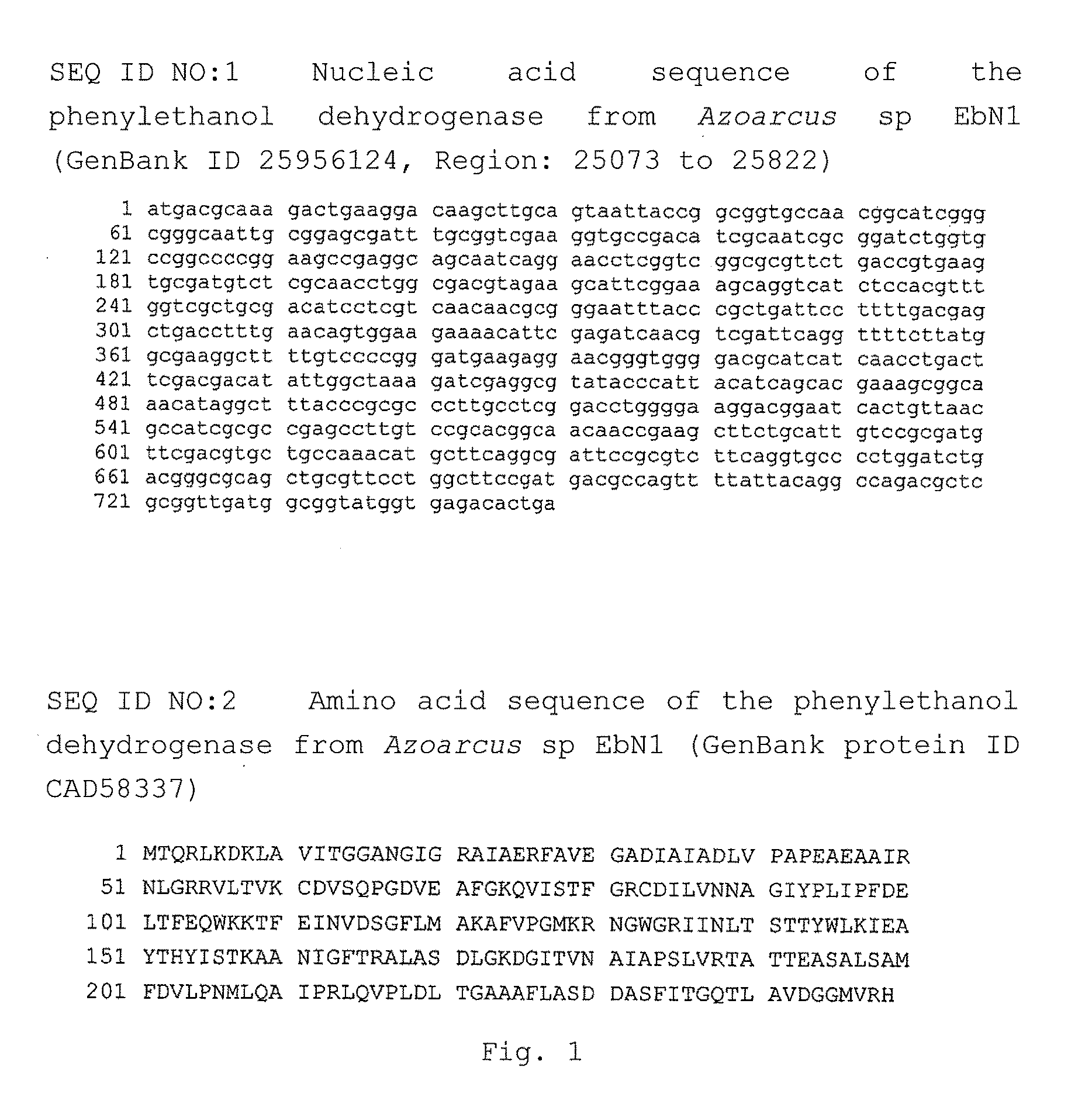

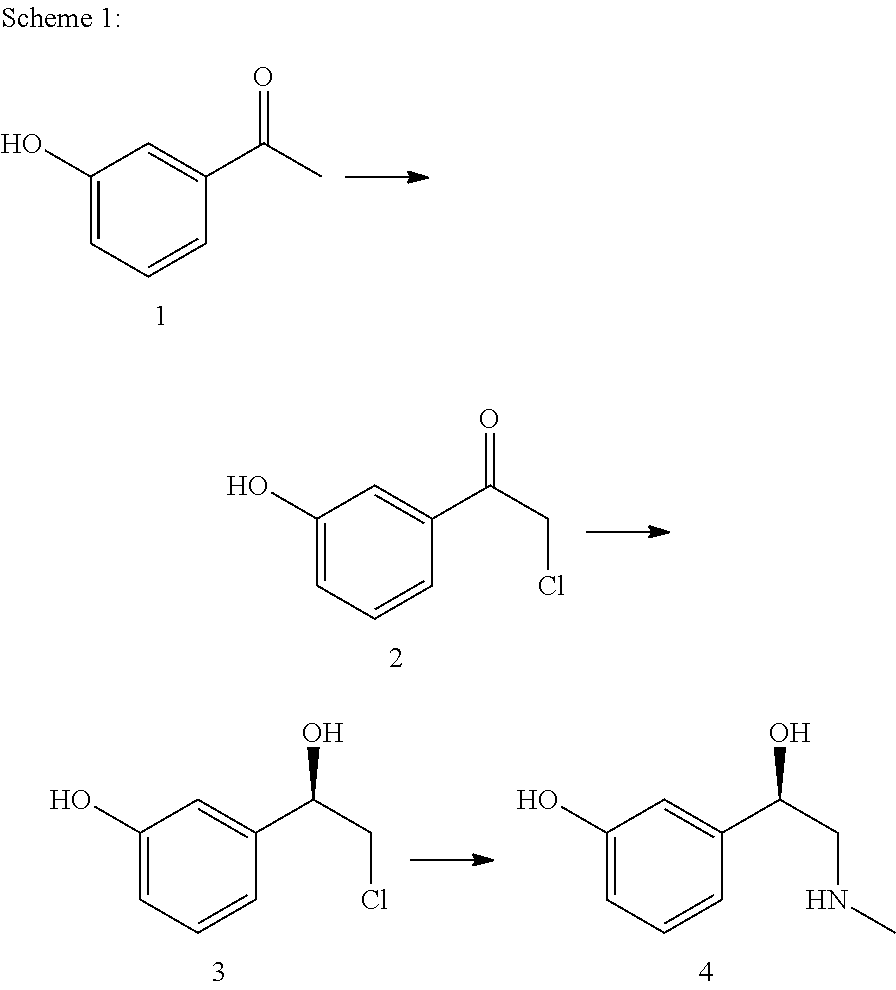

Method for producing l-phenylephrine using an alcohol dehydrogenase of aromatoleum aromaticum ebn1 (azoarcus sp. ebn1)

ActiveUS20110171700A1High stereoselectivityMoreOrganic compound preparationCarbonyl compound preparationAlcoholAzoarcus sp.

The present invention relates to a multi-stage process for producing substituted, optically active alcohols, comprising an enzyme-catalyzed synthesis step, in particular a synthesis step which is catalyzed by an alcohol dehydrogenase. The inventive method is particularly suitable for producing phenylephrine, i.e. 3-[(1R)-1-hydroxy-2-methylamino-ethyl]-phenol.

Owner:BASF AG

Gastrodia tuber noodle and making method thereof

InactiveCN1669464AMany beneficial ingredientsAvoid destructionPre-baking dough treatmentFood preparationGastrodiaSlurry

The invention discloses a gastrodia tuber noodle and making method, which comprises flour and fresh rhizoma Gastrodiae slurry by the proportion of 1 : 0.03-0.15, and the preparing process comprises the steps of feed preparation (including washing, scraping, slacking, beating) and enzyme eradicating at 80-90 deg. C, material mixing, forming and packaging.

Owner:符晶

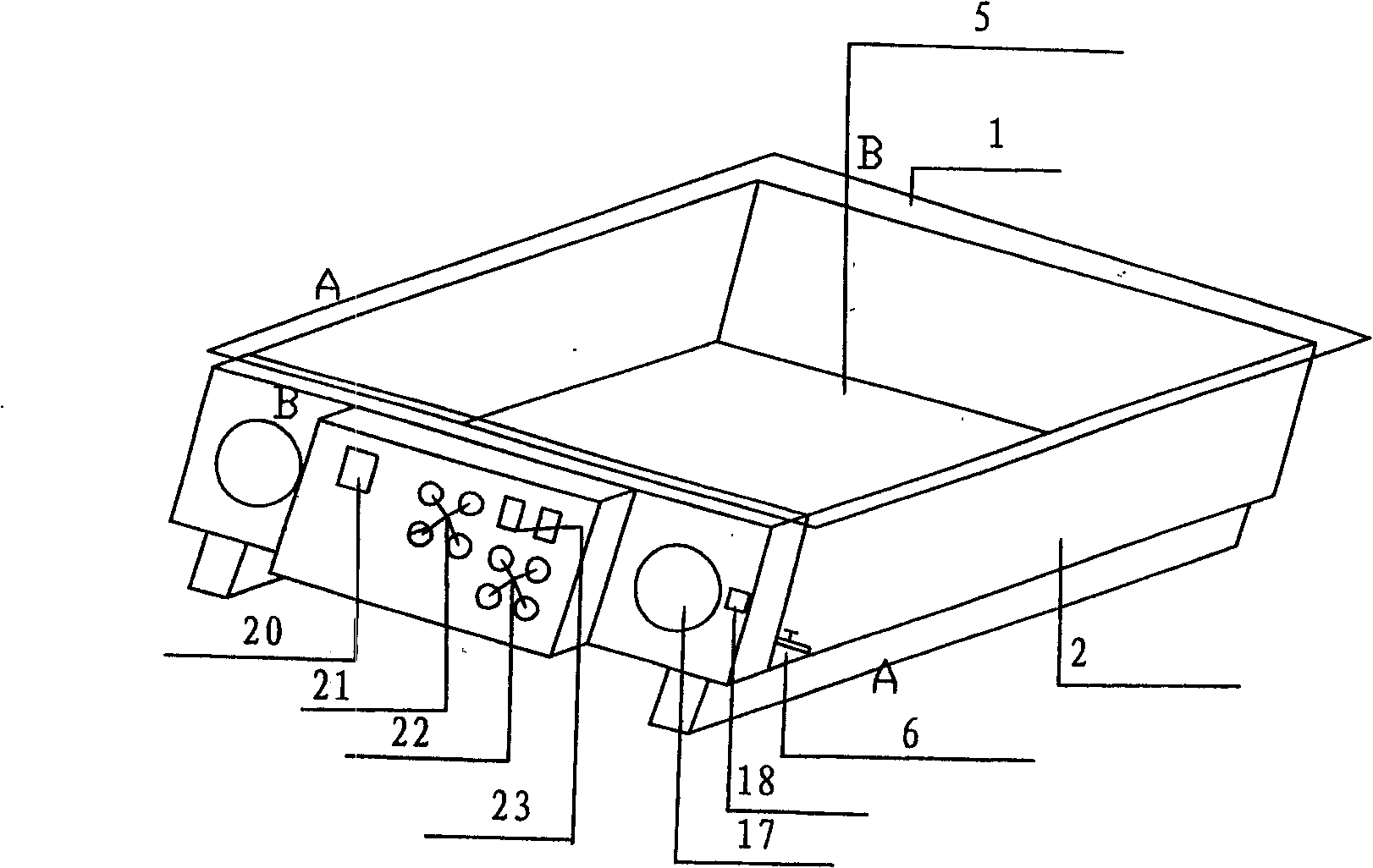

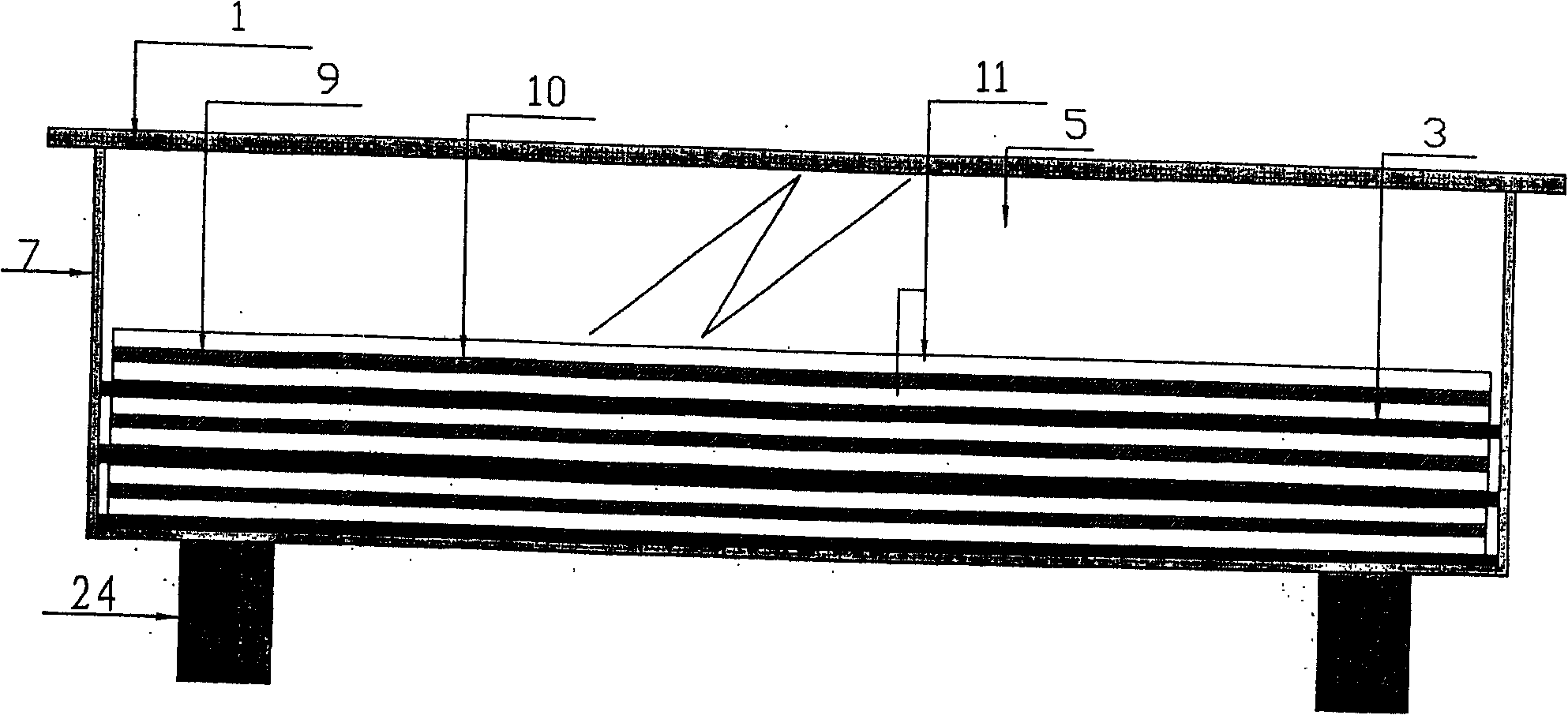

Method for making low-temperature adhesive plate vacuum glass and apparatus thereof

InactiveCN101298370AThe appearance of the product is beautifulProduct quality and long lifeSmooth surfaceGlass production

The invention relates to a method for producing vacuum slab glass that has a smooth surface and has no vertebrate tail and sealing plug and an equipment thereof. One piece of glass is cut into two pieces, then a support is arranged between the two pieces of glass, a bonding agent is coated on the four sides of the glass and one notch is left without coating the bonding agent and is used as vacuum passage of later step, the two pieces of glass are placed into a vacuum box after the bonding process is finished; the inside of the vacuum box is provided with a heating device and a glue-filling machine; also a vacuum pipe is arranged on the vacuum box, then the heating device is started to heat the glass, and a vacuum valve is started to vacuumize, then the glue-filling machine is started to seal the passage, finally the vacuum box is cooled and the pressure is relived to obttain the finished vacuum glass. Compared with the other vacuum glass which has vertebrate tail protuberance on the surface and is sealed by rubber plugs, the vacuum glass production process reduces the production procedure; also the product is more beautiful as the product has no projection or sealing rubber plug; the production line is short, which needs less investment, consumes less energy and reduces the manufacturing cost.

Owner:胡屹博 +2

High-efficiency extraction method of effective ingredients in golden camellia tea and application thereof in cigarette preparation

ActiveCN101607003AImprove qualityPromote deep processingTobacco treatmentAntinoxious agentsCelluloseAlcohol

The invention discloses a high-efficiency extraction method of effective ingredients in golden camellia tea and the application thereof in cigarette preparation. The extraction method comprises the steps of crushing, enzymolysis, alcohol extraction, separation and concentration, wherein the enzymolysis is carried out by using cellulose and prolease. The application of the extraction method in cigarette preparation comprises the following steps: adding extracted effective-ingredient concentrated solution of golden camellia tea into a cigarette group according to a mass ratio of 0.1 per thousand to 10 per thousand to prepare cigarettes. By adopting the extraction method, the effective ingredients in the golden camellia tea are extracted with high efficiency and low cost. The extracted effective-ingredient concentrated solution of the golden camellia tea is applied to the cigarette preparation and changes smoke gas to be soft, delicate and clear, the irritation is reduced, residues reduced in the oral cavity are reduced, the sweet backing sense is obviously strengthened, and the cigarette quality is obviously improved.

Owner:CHINA TOBACCO GUANGDONG IND

Method for inductrialized separation of purified lactoferrins from cattle colostrum

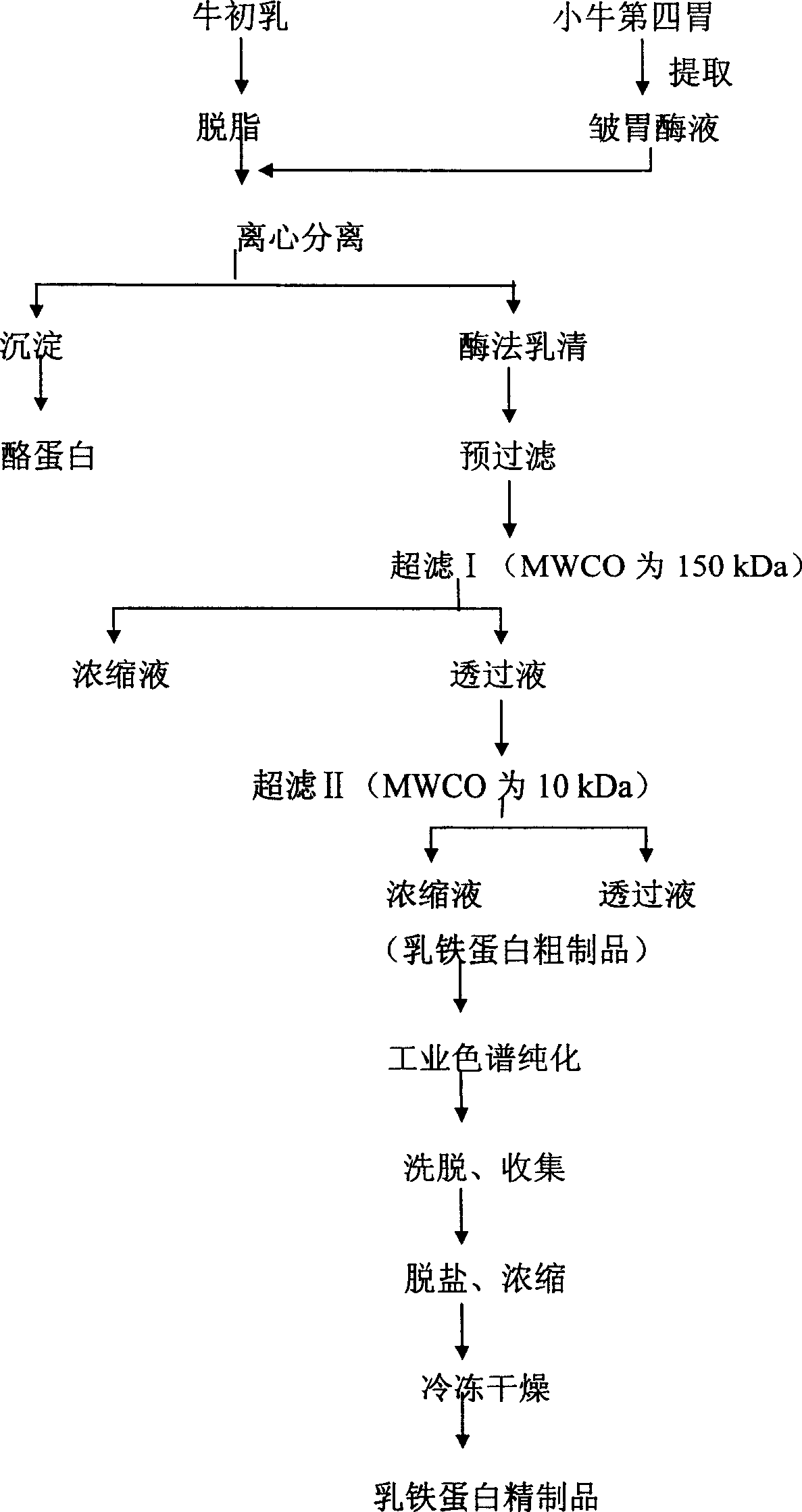

InactiveCN1849903AHigh clarityReduce co-precipitationAnimal proteins working-upLactoferrinMilk products

The present invention relates to a method for industrial separation and purification of lactoferrin from beestings. It is characterized by that it uses beestings defatted serum as raw material, adopts enzyme method to remove casein and utilizes combination of membrane separation technique and industrial chromatographic technique to separate out lactoferrin whose purity is above 90% from beestings.

Owner:JIANGNAN UNIV

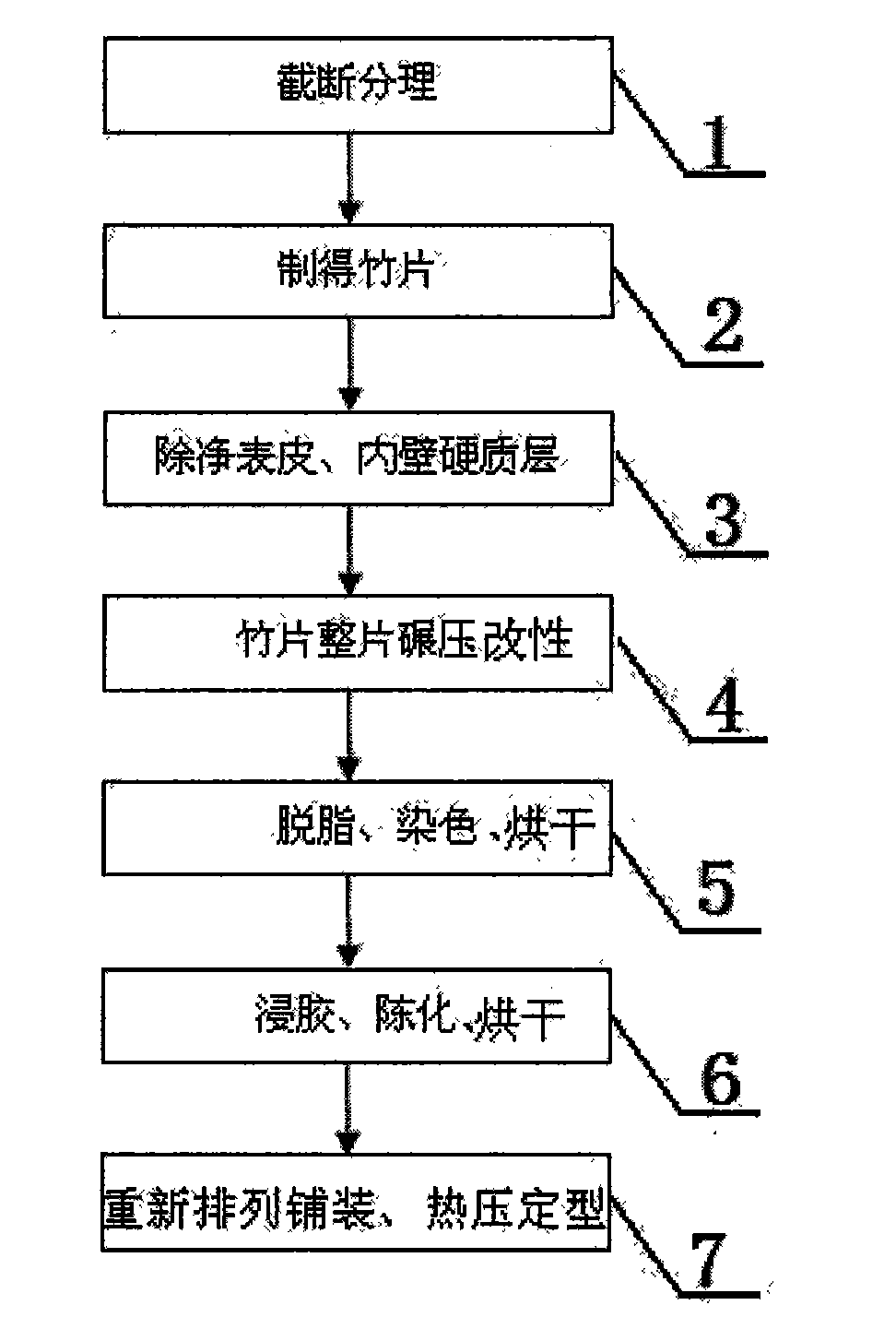

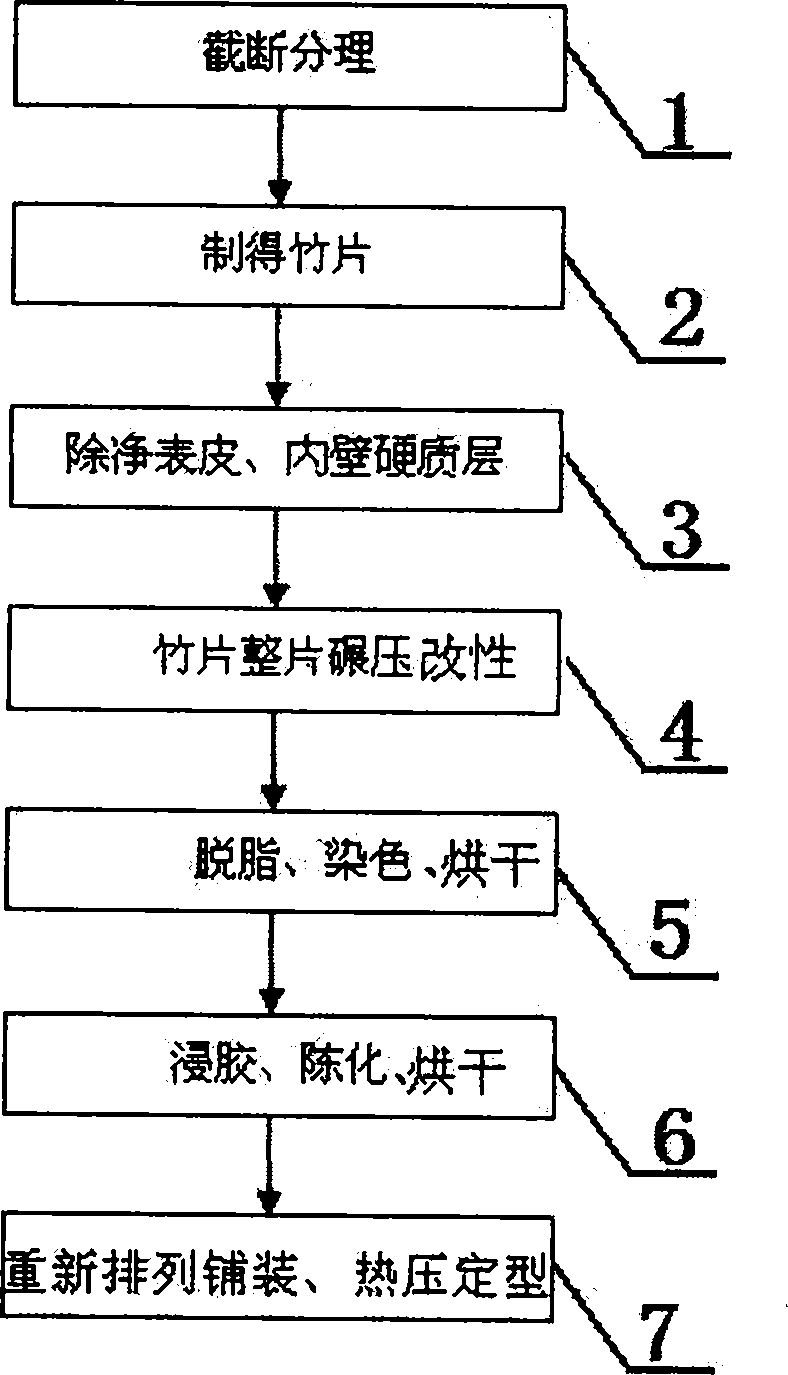

Process for manufacturing large-breadth plates by using all-bamboo modified material

The invention discloses a process for manufacturing large-breadth plates by using an all-bamboo modified material, which comprises the following steps of: (1), fully clearing way a surface wax layer and an inner hard layer; (2), modifying and laminating bamboo sheets into sheet bamboo materials which are in strips, filaments and fibres and are cracked but not fragile; (3), degreasing, dying and drying the bamboo material; (4), impregnating, ageing and drying the bamboo material; and (5), rearranging and laying the bamboo material to form blanks, and performing hot pressing on the blanks to mold the blanks into the large-breadth plates of the all-bamboo modified material. The large-breadth plates of the all-bamboo modified material are fine and smooth in vein and compact in structure and are applied to the application field of manufacturing all-bamboo furniture, floors, decoration materials and engineering, construction and military materials, and can effectively and greatly save raw materials, energy, labour cost, production field and storage field. At the same time, because the bamboo material is modified, 10 kinds of bamboos can be selected as processing raw materials.

Owner:上海缘竹实业有限公司 +2

Snow lotus fruit vinegar beverage

InactiveCN102334706AMild sourUnique flavorVinegar preparationFood preparationFlavorEconomic benefits

The invention relates to a beverage, in particular to a snow lotus fruit vinegar beverage, belonging to the technical field of food processing. The snow lotus fruit vinegar beverage is brewed through pure liquid state fermentation by taking snow lotus fresh fruits as raw materials, and the blended snow lotus fruit vinegar beverage has gentle sour, unique flavor and intense combined flavor of the snow lotus fruits and table vinegar. The snow lotus fruit vinegar beverage integrates nutrition and functions of the snow lotus fruits and the table vinegar, has a wide market prospect, greatly increases the economic benefits of planting the snow lotus fruits and provides a new approach for enriching the variety of vinegar beverages and promoting the fine and further processing of the snow lotus fruits.

Owner:曹洪

Soluble egg powder and preparation method thereof

The invention provides a method for producing soluble egg powder, which comprises the following steps: implementing mechanical dispersion and emulsion treatment to the egg liquid material; adding at least an auxiliary agent which is selected from a complexing agent, a precipitator and an emulsifier; and implementing spray drying to the egg liquid undergoing dispersion and emulsion treatment. In the method of the invention, mechanical dispersion is used for breaking the particle structures in the egg liquid to form O / W type emulsion, and O / W type egg powder particles can be easily obtained after spray drying; the addition of the complexing agent or the precipitator can reduce the concentration of divalent metal ions in the egg liquid and improve the solubility of the egg powder; and the addition of the emulsifier is beneficial to improving the hydrophilicity of the surface of the egg powder particles. The egg powder produced by the invention can be soluble to normal temperature water and hot water to form uniform emulsion; and when the emulsion is heated, no egg-flower-shaped gel is formed.

Owner:FOODSTUFF INST BEIJING +1

Nanguo pear brandy and preparation technique thereof

InactiveCN104560504ASolve the single varietyLow degree of resolutionMicroorganism based processesAlcoholic beverage preparationBiotechnologyLees

The invention aims to provide a brandy prepared from Nanguo pear and a brewage technique thereof. The technique comprises the following steps: cleaning, pulping, juicing, adding white granulated sugar and yeast into the peel pomace juice raw material, carrying out primary low-temperature temperature-control fermentation, filtering to separate the peel pomace and juice, leaching the peel pomace, carrying out secondary low-temperature temperature-control fermentation on the peel pomace, distilling, aging, and blending to obtain Nanguo pear distilled liquor mainly composed of peel pomace brandy; and filtering the juice, carrying out secondary low-temperature temperature-control aging fermentation on the juice, separating, removing crude lees, distilling, storing, blending and aging to obtain the Nanguo pear brandy.

Owner:刘思言

Process for preparing perfluorosulfonyl resin

A process for preparing perfluorosulfonyl resin includes copolymerization of perfluorosulfonyl vinylether with tetrafluoroethene in the presence of perfluoroalkane / perfluorocycloether mixture and initiator, and adding haloalkane for precipitation or adding deionized water for distilling. Its advantages are high content (more than 20%), and low equivalent weight.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

Communication Method

ActiveUS20140149547A1Promote deep processingAssess restrictionNetwork topologiesData transmissionHuman–computer interaction

Owner:NOMAD DIGITAL LTD

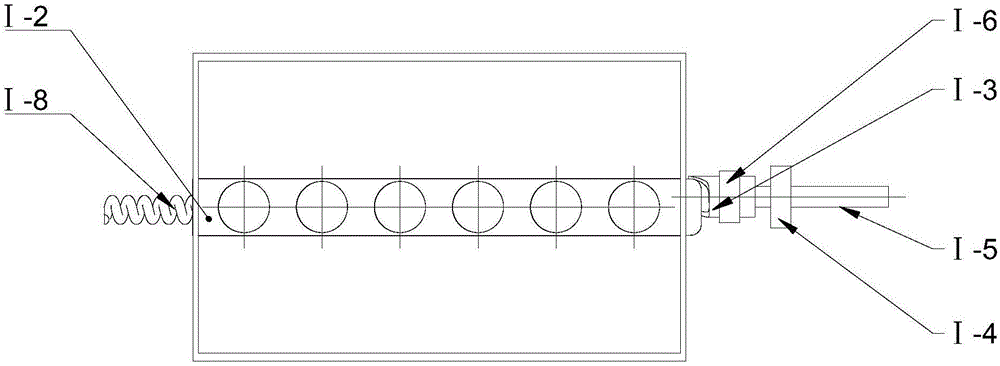

Roller-type mandarin orange peeling system and control method thereof

ActiveCN108464515AImprove peeling efficiencyKeep it originalVegetable peelingEngineeringCitrus nobilis

The invention discloses a roller-type mandarin orange peeling system and a control method thereof. The roller-type mandarin orange peeling system comprises a material feeding and receiving apparatus,and a peeling apparatus; the material feeding and receiving apparatus comprises a material box, a material receiving disc, and a second motor; the peeling apparatus comprises a first motor, a machineframe, and a peel cutting mechanism used for cutting open mandarin orange peel and a peeling mechanism used for separating the mandarin orange peel which are orderly arranged on the machine frame; thematerial box is connected with the peel cutting mechanism; the material receiving disc is connected with the peeling mechanism; and the second motor is respectively connected with the peel cutting mechanism and the peeling mechanism. A single-chip is used as a control device of the roller-type mandarin orange peeling system; and thus, fully automated manual-operation-free processing way is realized. Peeling is achieved by the peel cutting mechanism, the peeling mechanism and a tangerine pith separating mechanism instead of the processes of performing heating, steaming and peeling of the priorart; and thus, the effects of high degree of integrity is achieved without causing damage on mandarin orange flesh. The roller-type mandarin orange peeling system effectively solves the problems of the prior art, namely oversize equipment, excessive low efficiency, excessive low final-product utilization rate, unavailable direct eating and requirement for re-processing treatment.

Owner:YULIN UNIV

Raw material and grog composite fragrant distiller's yeast

The composite fragrance type distiller's yeast consists of saccarifying enzyme, yeast, cellulase, rhizopus and aroma-forming yeast, and is produced through compounding material, sieving material, mixing and packing. The composite fragrance type distiller's yeast consists of enzyme preparations completely, and has low production cost and capacity of maintaining the characteristics of traditional white liquor. It is suitable for use in producing clear, mellow and delicious grain white liquor through a liquid process or a solid process. It has high activity and high white liquor yield. It may be also applied in fermenting stalks, and producing fermented glutinous rice food and rice wine.

Owner:翟国军

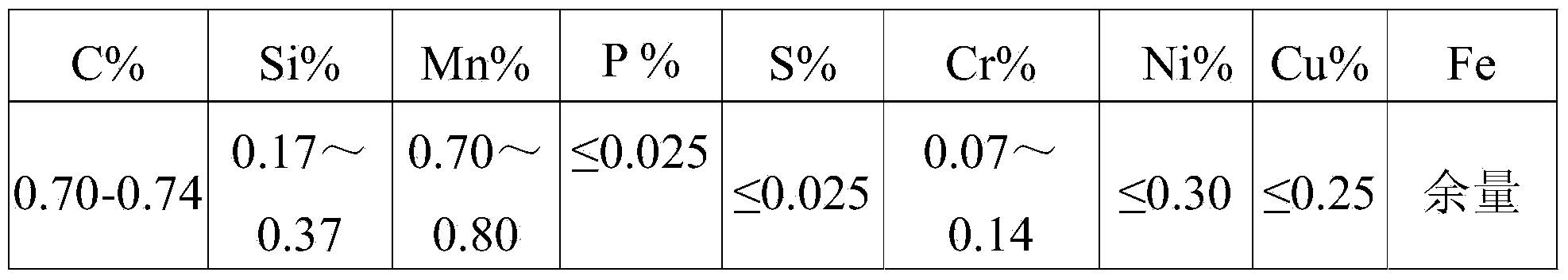

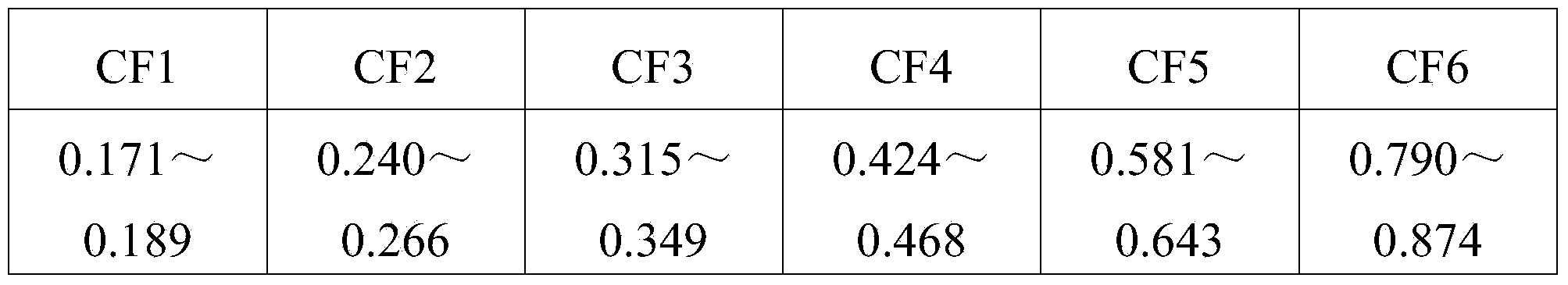

Hot-rolled wire rod for manufacturing high-strength steel strand of strong and smart grid and production method of hot-rolled wire rod

ActiveCN104233097ACompact configurationReasonable configurationMetal rolling arrangementsWire rodChemical composition

The invention discloses a hot-rolled wire rod for manufacturing a high-strength steel strand of a strong and smart grid and a production method of the hot-rolled wire rod, and relates to a hot-rolled wire rod for manufacturing a high-strength steel strand of a grid. Chemical composition of the hot-rolled wire rod is composed of the following substances in percentage by weight (%): 0.70-0.74% of C, 0.17-0.37% of Si, 0.70-0.80% of Mn, 0.07-0.14% of Cr, less than or equal to 0.025% of P, less than or equal to 0.025% of S, less than or equal to 0.30% of Ni, less than or equal to 0.25% of Cu and the balance of Fe. According to the phi6.5mm hot-rolled wire rod produced by the method disclosed by the invention, tensile strength is 1120-1200Mpa, area reduction is 40-50% and percentage of elongation is more than or equal to 18%. The hot-rolled wire rod disclosed by the invention has the advantages that process equipment and parameter setting are reasonable, longstanding problems are solved and product quality is improved; the wire rod is drawn into a steel wire to enhance strength, and a loading bearing capacity of a steel strand processed from the steel wire is greatly improved; and the hot-rolled wire rod is easy to draw, and capable of avoiding an intermediate heat treatment process and saving energy.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

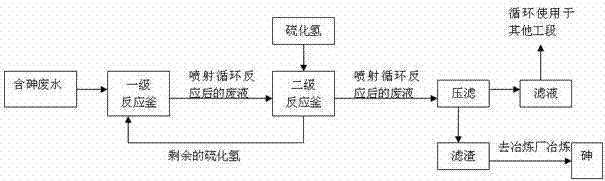

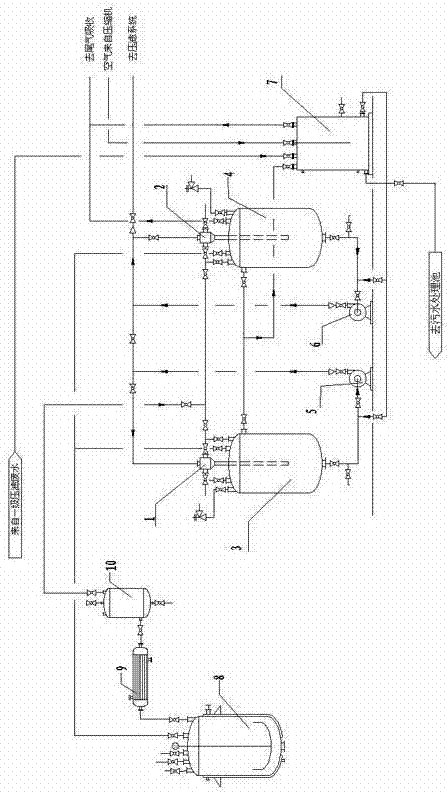

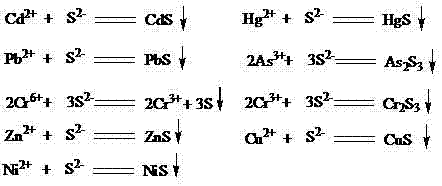

Double-circulation spraying type arsenic removal method and equipment for sulfuric acid industry

InactiveCN102897885AControl the amount added at any timeThe amount added is notWater/sewage treatment by flocculation/precipitationLiquid wasteSlag

The invention provides a double-circulation spraying type arsenic removal method and equipment for sulfuric acid plants. Vulcanizing agents are placed in a hydrogen sulfide generator, generated hydrogen sulfide enters a reaction kettle (3) through a pipeline, and a circulation pump (5) is opened so that materials in the reaction kettle (3) carry out internal circulation; and meanwhile, the rest hydrogen sulfide of the reaction kettle (3) enters a reaction kettle (4), and a circulation pump (6) is opened so that the materials in the reaction kettle (4) carry out internal circulation. After the reaction is carried out for 60 to 90 minutes, liquid after reaction in the reaction kettle (3) is placed in a storage tank through a pipeline, the still standing is carried out for 30 to 60 minutes, the liquid is subjected to filter pressing, the obtained filter slag can be conveyed to a smelting plant for heavy metal recovery, the filter liquid is directly discharged, and waste liquid of the reaction kettle (4) is left to be used as the subsequent reaction liquid of the reaction kettle (3). The method and the equipment have the advantages that the arsenic removal rate can reach higher than 99 percent, the arsenic content of the filter slag is high, and the deep processing is favorably realized.

Owner:GUANGXI NANNING DHXY ENTECH

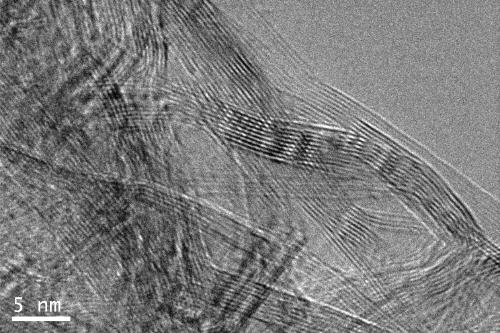

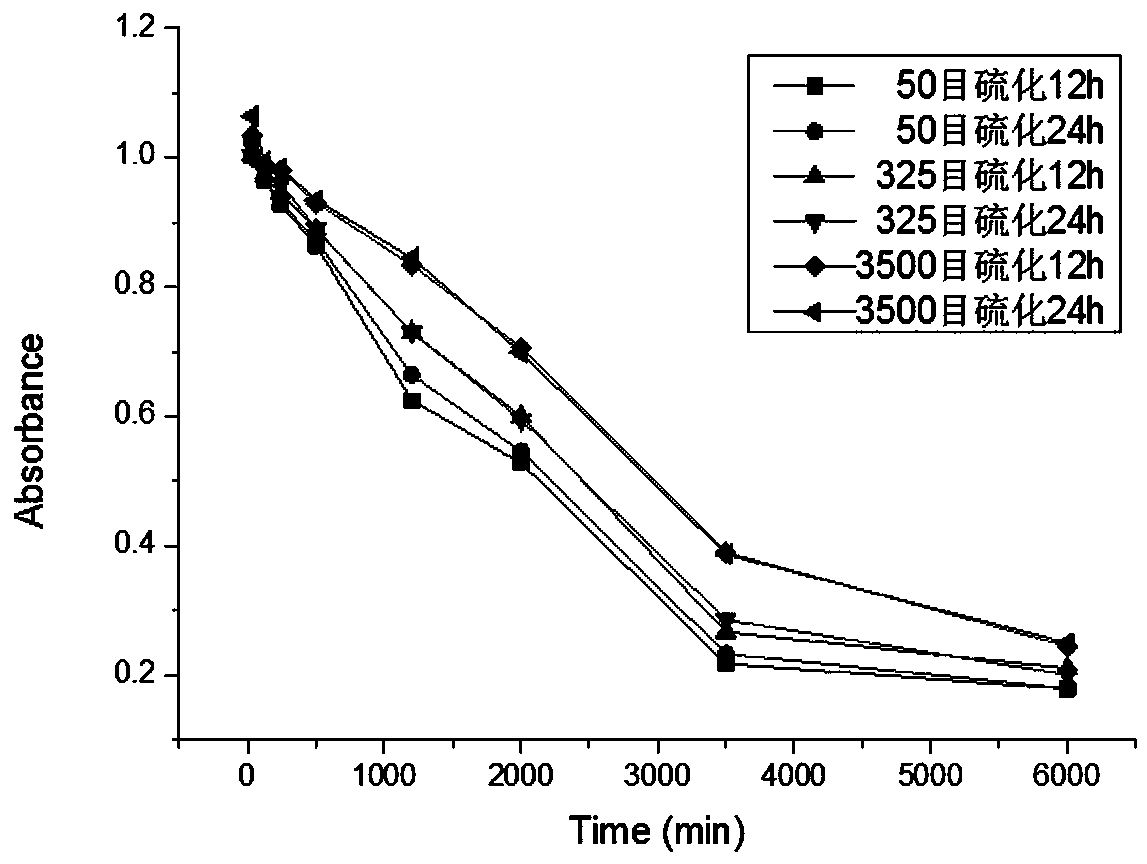

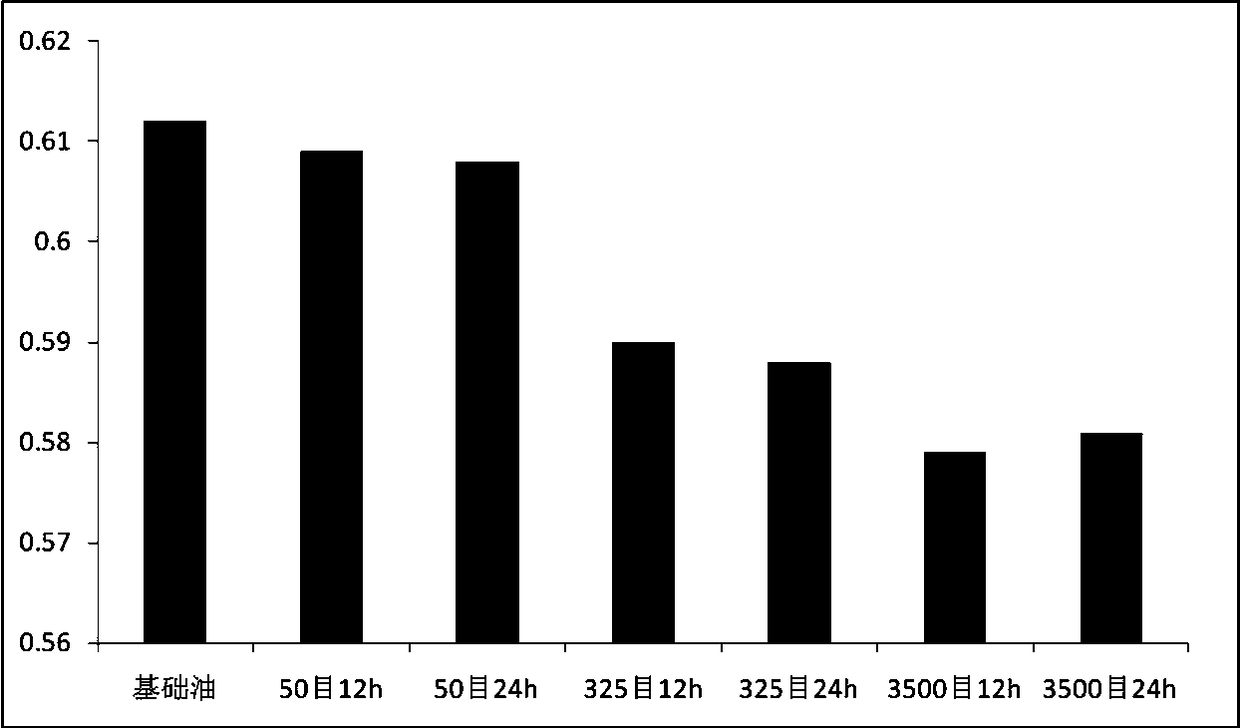

Preparation method of graphene sulfide

ActiveCN109486547AExcellent anti-wear and anti-friction propertiesImprove anti-friction and anti-wear effectCarbon compoundsAdditivesCvd grapheneChemistry

The invention relates to graphene sulfide as well as a preparation method and application thereof. The preparation method comprises the following steps: oxidizing graphene by using potassium permanganate and concentrated sulfuric acid, and then vulcanizing the oxidized graphene by using P4S10, thereby preparing the graphene sulfide. In addition, the dispersion performance and absorption performance of the graphene sulfide in lubricating oil basic oil are also researched, the tribological performance of a graphene reaction lubricating membrane is tested, and the lubricating mechanism is researched. The result shows that the dispersion performance of the graphene can be improved by virtue of vulcanization, and the wear-resisting and friction reducing effect of the graphene can be improved.

Owner:中国人民解放军空军勤务学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com