Process for manufacturing large-breadth plates by using all-bamboo modified material

A modified material and manufacturing process technology, which is applied in the direction of manufacturing tools, pretreatment of molding materials, wood processing appliances, etc., can solve the needs of deep processing of middle and high-end furniture that cannot be fully applied, and the fineness, compactness, and format cannot meet the requirements and other problems, to achieve the effect of stable overall quality, small expansion coefficient, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

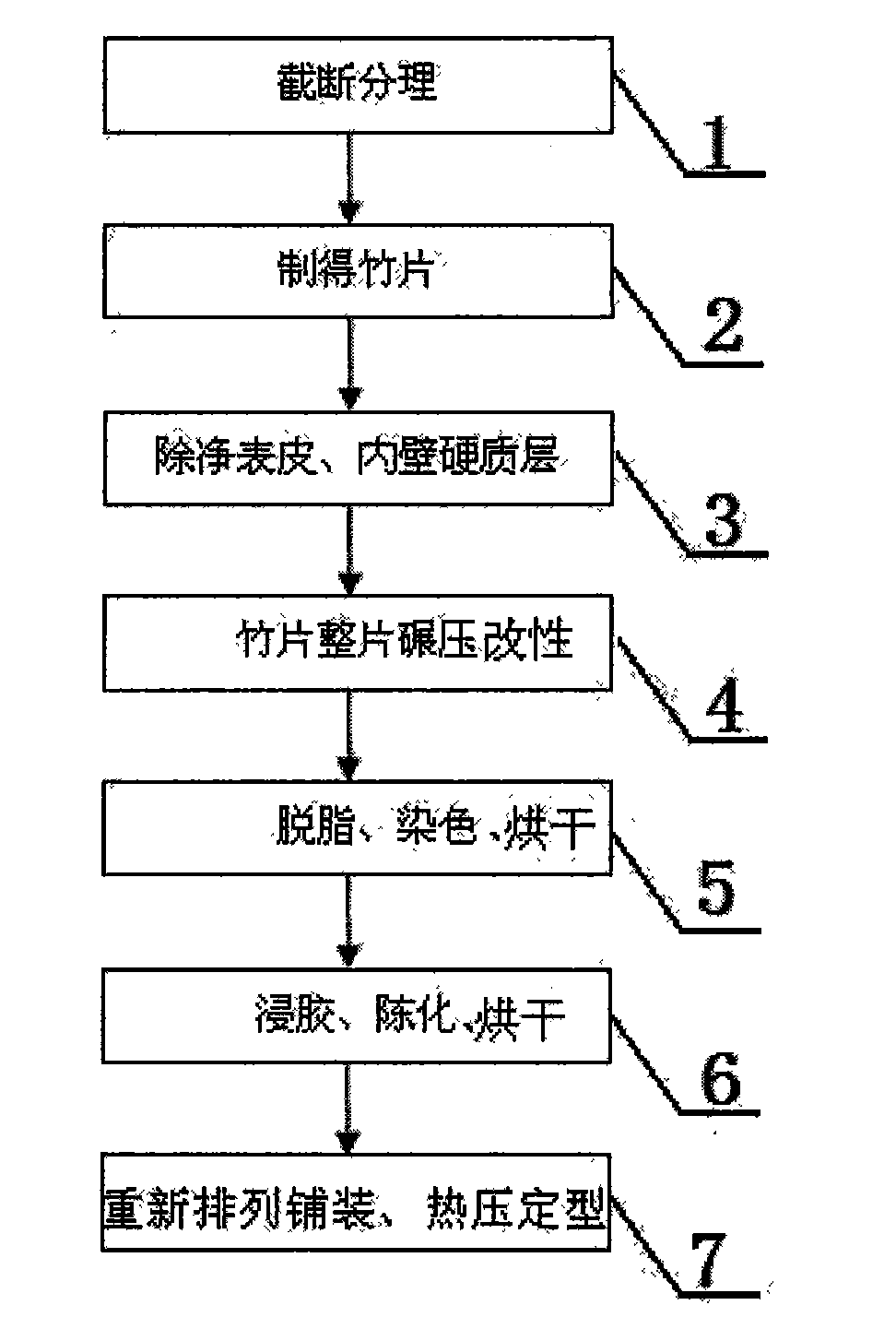

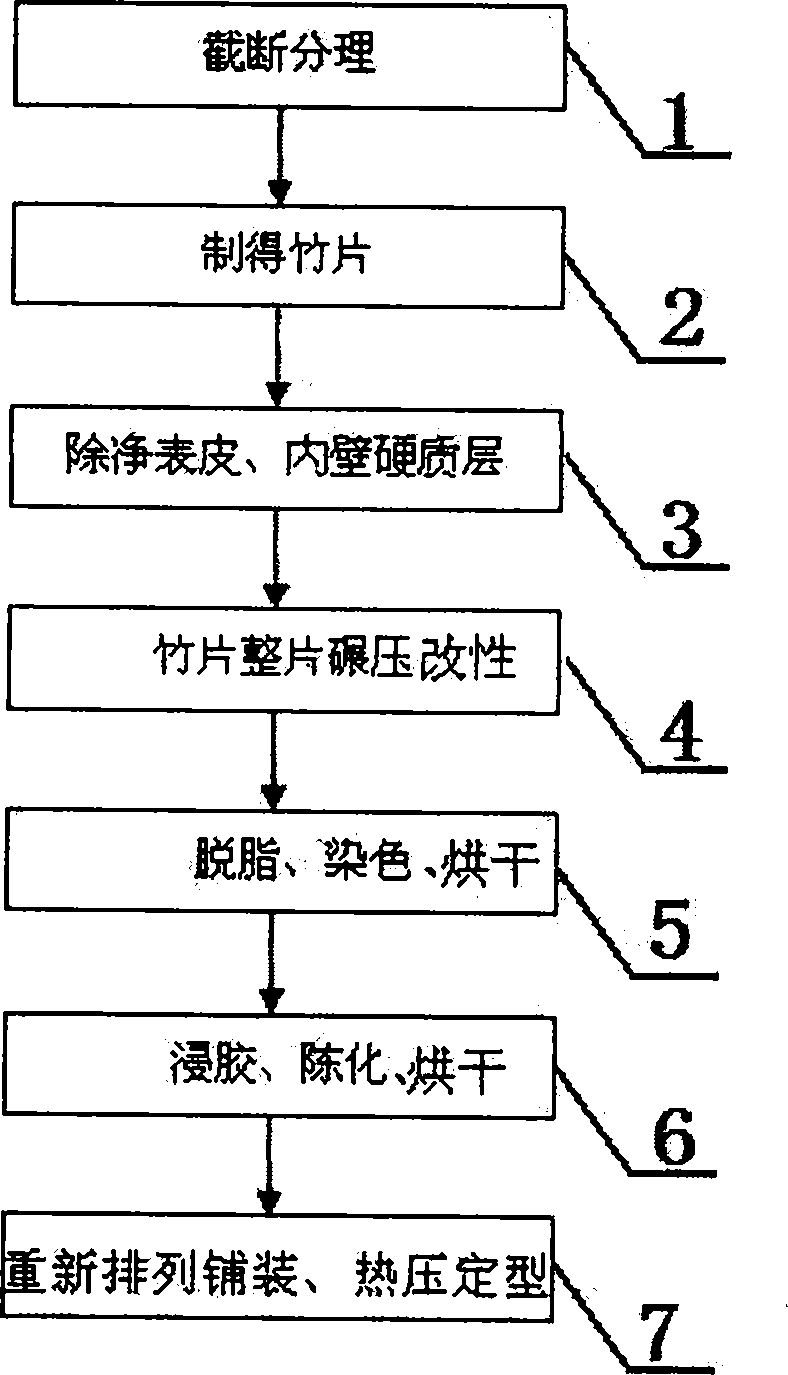

[0032] The present invention aims to solve the existing problems that most of the existing main furniture, floors, decoration materials and engineering, construction, and military fields are solid wood materials, forestry products, chemical materials, and metal materials, as well as the existing bamboo materials. Insufficient; And provide a kind of manufacture method of whole bamboo modified material, this method can manufacture the large-scale plate board of whole bamboo high strength, high density, multifunctional modified material. Such as figure 1 Shown:

[0033] The method includes the following steps:

[0034] (1) First cut off the bamboo used, according to the rod, tip, thickness and fineness, reserve 1-2cm allowance for the bamboo acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com