Method for inductrialized separation of purified lactoferrins from cattle colostrum

A technology for separation and purification of lactoferrin, which is applied in protein food processing, animal protein processing, protein food ingredients, etc., can solve the problems that hinder the popularization and application of lactoferrin, it is difficult to realize industrialization, and the processing volume is small, so as to improve health awareness , Reduce co-precipitation, and strong dirt-holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

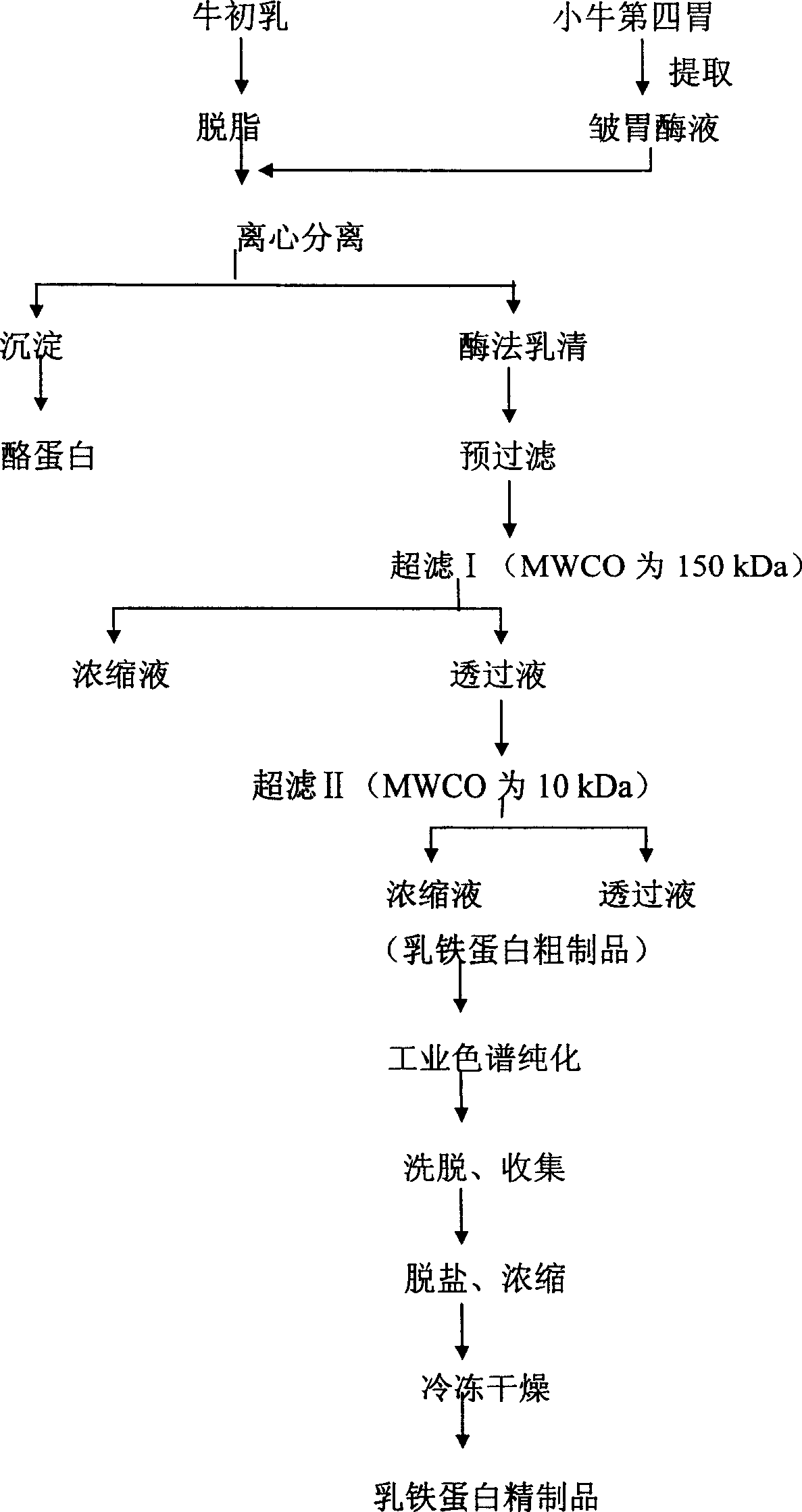

Method used

Image

Examples

Embodiment 1

[0020] Isolate and purify lactoferrin according to the above-mentioned process method in the instruction manual. Skimmed colostrum volume: 100L, lactoferrin content 1.50g / L, enzymatically remove casein to obtain 90L of enzymatic whey, two-step membrane separation to obtain concentrated solution 18L, lactoferrin concentration 6.91g / L, lactoferrin The protein recovery rate (based on the content of lactoferrin in colostrum) is 82.92%, and the purity of lactoferrin in the concentrate relative to the total protein in the concentrate is 31.40%. After chromatographic separation, desalination, concentration and freeze-drying of the concentrated solution, 113.18 g of refined lactoferrin was obtained with a purity of 94.20%. The recovery rate of lactoferrin (based on the content of lactoferrin in colostrum) was 71.08%.

Embodiment 2

[0022] The operation is the same as in Example 1, the amount of defatted colostrum: 300L, the content of lactoferrin is 1.48g / L, the enzymatic whey is obtained after removing casein by enzymatic method, 272L of enzymatic whey is obtained, and the concentrated solution is obtained after two-step membrane separation. 53L, the concentration of lactoferrin is 7.05 g / L, the recovery rate of lactoferrin (based on the content of lactoferrin in colostrum) is 84.16%, and the purity of lactoferrin in the concentrate relative to the total protein in the concentrate is 32.91%. After chromatographic separation, desalination, concentration and freeze-drying of the concentrated solution, 350.35 g of refined lactoferrin was obtained with a purity of 95.92%. The recovery rate of lactoferrin (based on the content of lactoferrin in colostrum) was 75.72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com