Preparation of low DE value malt amylin by spraying alpha-amylase process

A technology of maltodextrin and spray liquefaction, applied in food preparation, food science, application, etc., can solve the problems of not meeting market demand, lack of low DE value, unstable product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of maltodextrin with DE value of 5-6.

[0038] Sizing: 500Kg corn starch, concentration 30% (W / W), pH 6.5, enzyme 0.3L / t starch.

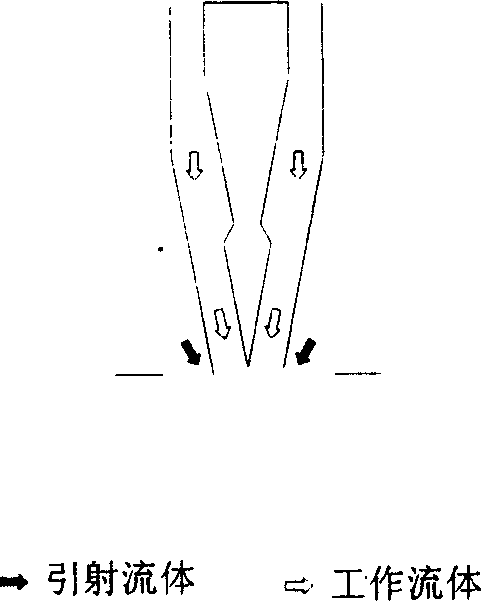

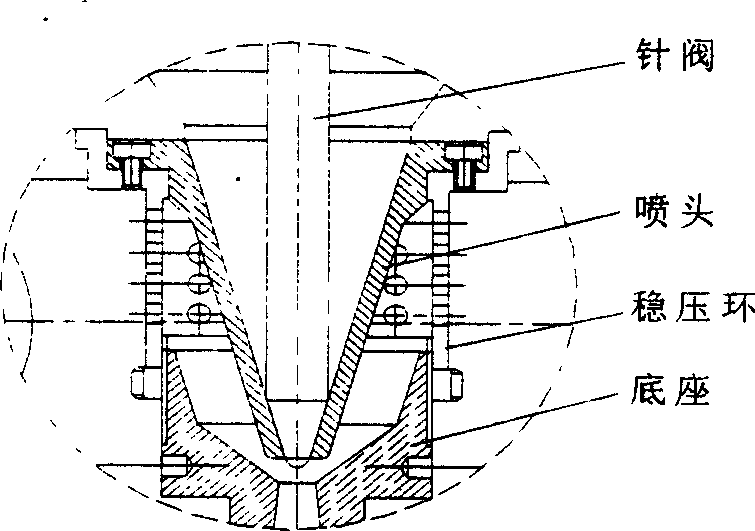

[0039] Injection: The height of the needle valve is 1 circle, the material pressure is 0.4Mpa, the steam pressure is 0.13Mpa, the back pressure is 0.03Mpa, and the injection temperature is 105-107°C.

[0040] Insulation liquefaction: temperature 90°C, time 1.5 hours.

[0041] Enzyme inactivation: The height of the needle valve is 1.5 circles, the material pressure is 0.4Mpa, the steam pressure is 0.3Mpa, the back pressure is 0.2Mpa, and the injection temperature is 130°C.

[0042] The product is obtained by decolorization, plate and frame filtration, concentration and spray drying.

Embodiment 2

[0044] Preparation of maltodextrin with DE value of 2-3.

[0045] Blending: 55Kg indica rice flour, concentration 25% (W / W), pH 6.1, enzyme 0.3L / t starch.

[0046] Injection: The injection temperature is 105-107°C.

[0047] Insulation liquefaction: the temperature is 95°C, and the time is 15 minutes.

[0048] Enzyme inactivation: spraying temperature 130°C

[0049] It is obtained by concentration and spray drying.

Embodiment 3

[0051] Application of maltodextrin with DE value of 5-6.

[0052] Chrysanthemum extract %

[0053] Maltodextrin with a DE value of 5-6 has the characteristics of low sweetness, good solubility and stability, and can be used in clear solid chrysanthemum essence beverages. When maltodextrin replaces about 66% of powdered sugar, the sweetness of the product is acceptable. The addition of maltodextrin can reduce the amount of chrysanthemum extract and reduce product cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com