Patents

Literature

149 results about "Maltotriose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Maltotriose is a trisaccharide (three-part sugar) consisting of three glucose molecules linked with α-1,4 glycosidic bonds. It is most commonly produced by the digestive enzyme alpha-amylase (a common enzyme in human saliva) on amylose in starch. The creation of both maltotriose and maltose during this process is due to the random manner in which alpha amylase hydrolyses α-1,4 glycosidic bonds.

High-purity isomaltose hypgather and alcohol co-production preparation method

ActiveCN101805767AImprove qualityIncrease valueBiofuelsMicroorganism based processesGlucose highFood industry

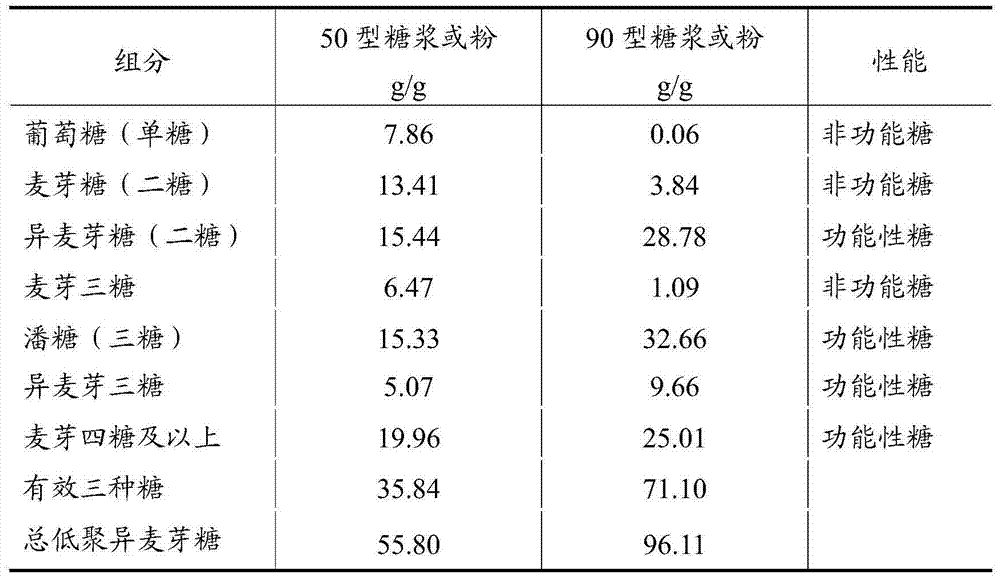

The invention belongs to the field of food industries and discloses a high-purity isomaltose hypgather and alcohol co-production preparation method. The method comprises the following steps of: preparing high-purity glucose higher than 95 percent by compounding diastatic enzymes; through diastatic enzyme conversion, fermenting by using dry activity yeast to prepare superhigh-purity isomaltose hypgather (the total content of isomaltose, panose and isomaltotriose are not less than 70 percent, and the total content of isomaltose hypgather is not less than 90 percent); and meanwhile, co-producingalcohol of 18 percent (the recovery rate is not less than 90 percent). The method can realize the organic combination of the superhigh-purity isomaltose hypgather production and the alcohol production and has novel process, excellent product quality, reduced cost, economy and practicability.

Owner:BAOLINGBAO BIOLOGY

Ink composition

An ink composition includes a first saccharide and a second saccharide. The first saccharide is a linear saccharide having 4 or more saccharide units and the second saccharide is at least one selected from the group consisting of trehalose, maltotriose, and a cyclic saccharide.

Owner:SEIKO EPSON CORP

Syrup for roasting and preparation method thereof

ActiveCN101433283ASolve the problem of component contentRich in colorPreservation by coatingFood preparationMaillard reactionIsomerization

The invention belongs to the field of food processing, in particular to special syrup for roast and a method for preparing the same. The syrup comprises the components of 34 to 36 percent of glucose, 26 to 28 percent offructose, 8 to 12 percent of maltose, and 28 to 32 percent of maltotriose and maltose with more content. The concentration of the finished product of the syrup is more than or equal to 78 percent and the pH value of the finished product of the syrup is between 4.2 and 4.8. The method takes corn flour as raw materials to prepare the syrup for roast through the steps of liquefaction, saccharification, ultrafiltration, ion exchange, six-effect evaporation and concentration, isomerization of immobilized enzyme, ultrafiltration, ion exchange and six-effect evaporation and concentration. The syrup for roast can improve quality of roasted products, keep Maillard reaction at a certain degree, improve the color and luster of the products, maintain the humidity of the products, prevent the product form aging and provide a new type of starch sugar.

Owner:BAOLINGBAO BIOLOGY

Method for improving extraction ratio of trehalose

InactiveCN101230407ATotal production cost reductionAchieving a green circular economySaccharides productionChromatographic separationSimulated moving bed

The invention discloses a method of increasing the extraction yield of trehalose, which belongs to sugar industry technical field. Adopting the techniques of hydrogenation and chromatographic resolution, the microorganism or enzyme are used for transforming the starch and the trehalose obtained undergoes the hydrogenation reaction with the mixing solution of the maltose, glucose and maltotriose; therefore the impurity in the mixing solution produces the maltitol, sorbierite and maltotriitol; the trehalose has no reducibility, and is stable in the hydrogenation reaction; and the trehalose is separated from the maltitol, sorbierite and maltotriitol in the mixing solution by the chromatographic resolution technique simulating the moving bed; and the purity and extraction yield of the trehalose are largely increased; the trehalose is crystallized by cooling, and the trehalose product is finally obtained. Compared with the technique of producing the trehalose by adopting the original microorganism or enzyme method, the technique of the invention increases the extraction yield over 80 percent, the sub product maltitol has a comparatively high utilization value; and therefore the production cost for producing the trehalose and the market price are reduced, which makes sense for increasing the market competition of trehalose.

Owner:FUTASTE PHARM CO LTD

Method for producing high purity malt sugar product

The production process of high purity malt sugar products, including malt sugar syrup, malt sugar alcohol and solid malt sugar, includes the following steps: adding high temperature alpha-amylase into starch milk, spray liquefication, cooling, adding beta-amylase, pullulan enzyme and maltotriose hydrolase for synergetic hydrolysis, and adding medium temperature amylase to saccharify to obtain malt sugar syrup, which may be further processed to obtain other products. The present invention has simple technological process and low production cost, and expands the use of malt sugar syrup.

Owner:SOUTH CHINA UNIV OF TECH

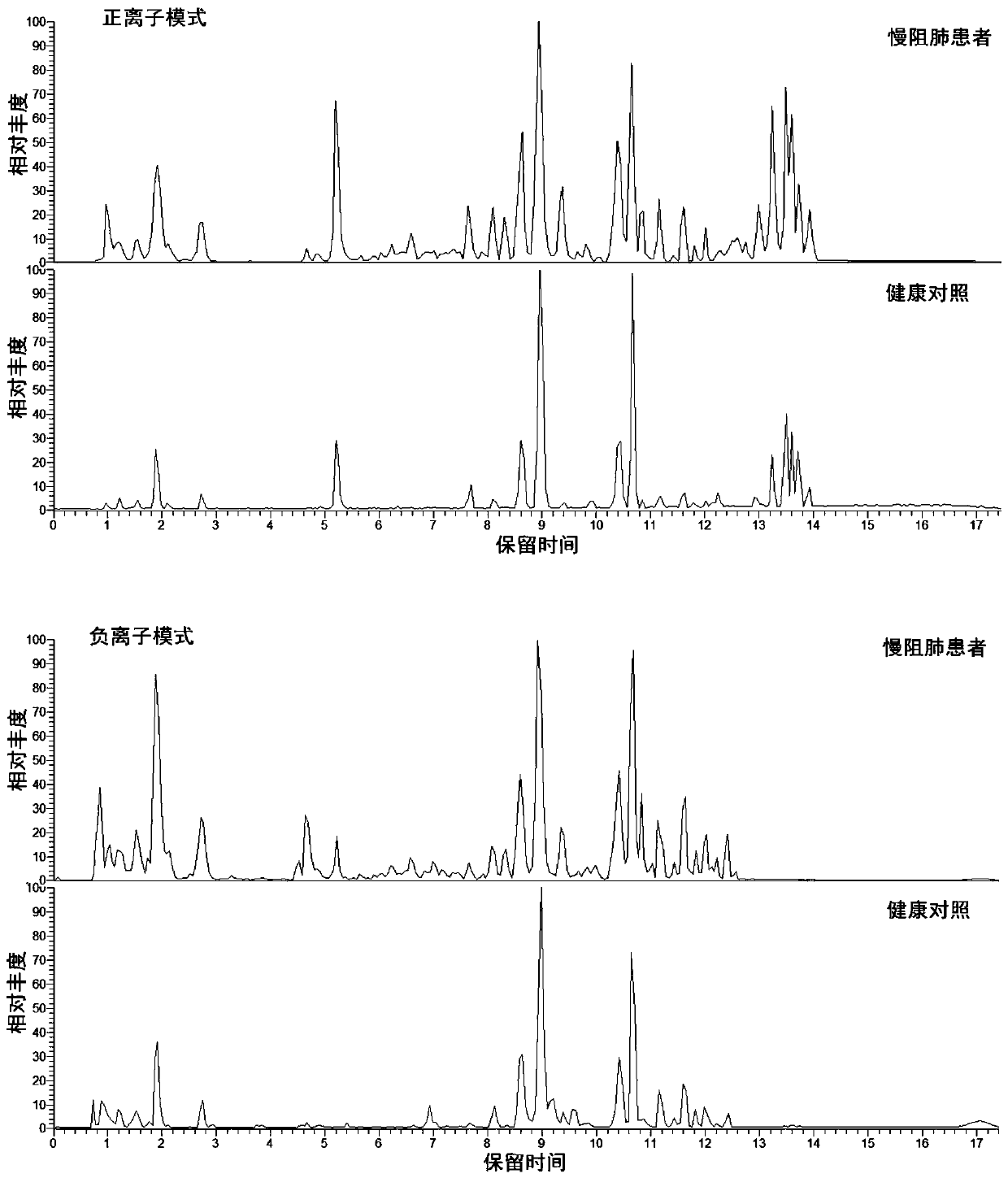

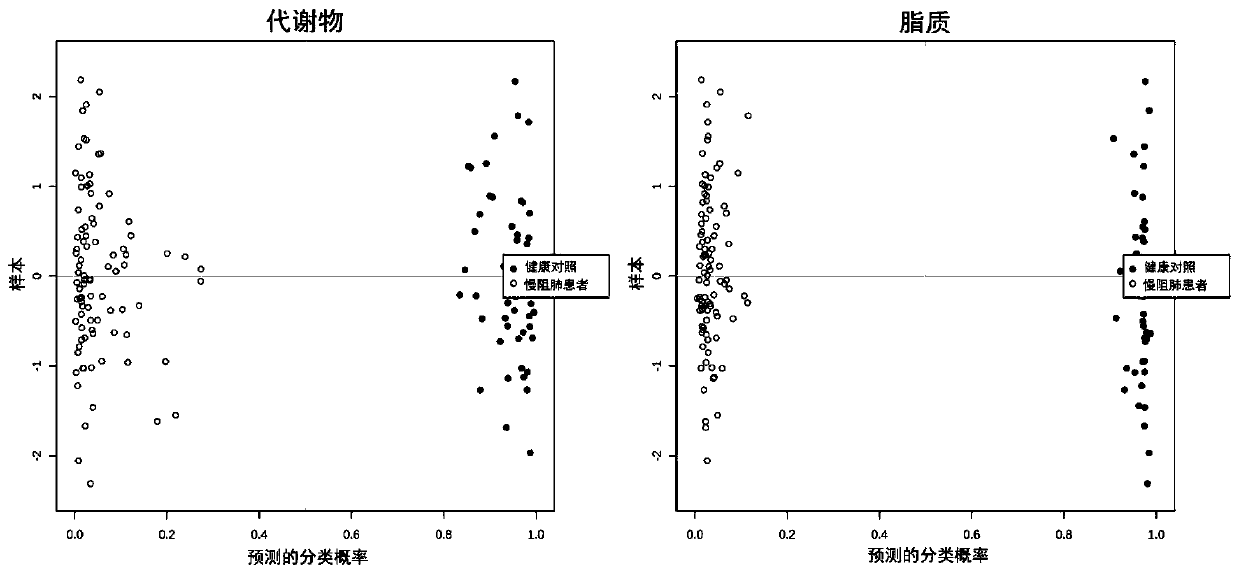

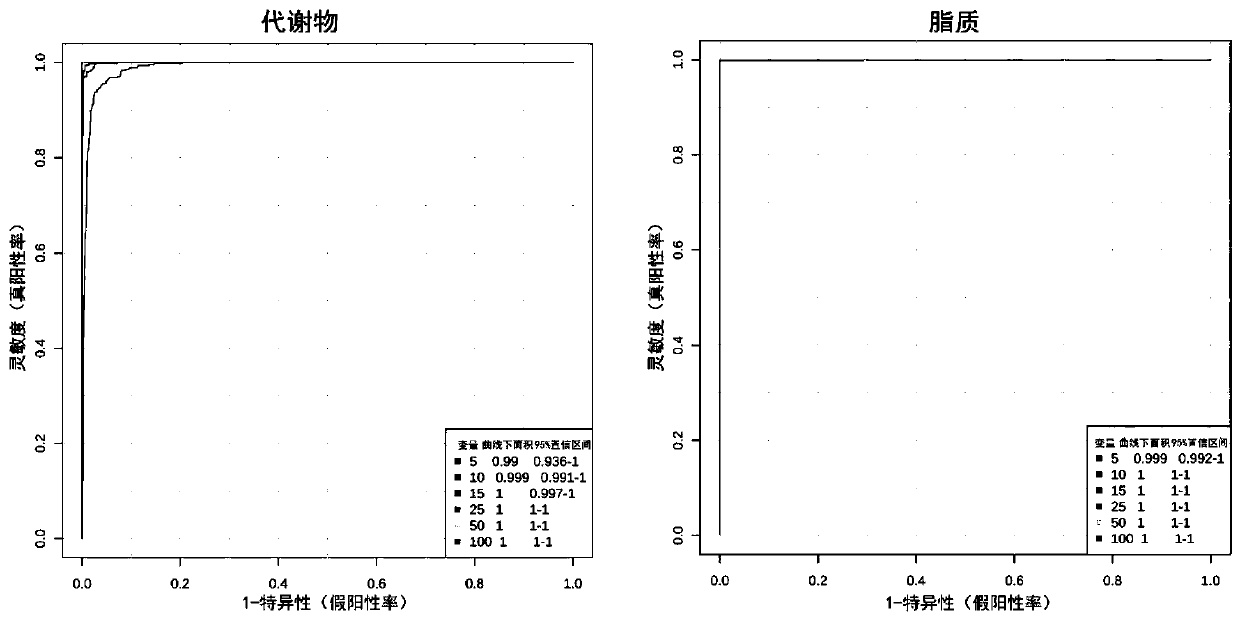

Metabonomics-based early diagnosis marker for chronic obstructive pulmonary disease and application thereof

InactiveCN111289736AExpand clinical applicationHigh promotional valueComponent separationDisease diagnosisDihydrouracilDimethylaniline N-oxide

The invention discloses a metabonomics-based diagnosis marker for chronic obstructive pulmonary disease and application thereof. The diagnosis marker comprises the following 28 blood plasma metabolismmarkers: phosphatidylcholine PC 16:1-36:3, phosphatidylcholine PC 26:0-22:4, phosphatidylcholine PC 26:0-22:3, phosphatidylcholine PC 47:5e, phosphatidylcholine PC 44:11e, phosphatidylcholine PC 16:0-24:5, phosphatidylcholine PC 20:2-20:3, phosphatidylcholine PC 40:10, phosphatidylcholine PC 38:9e, phosphatidylcholine PC 18:1-20:4, phosphatidylcholine PC 16:0-20:3, phenylacetaldehyde, dihydrouracil, nicotinamide, 4-methoxycinnamic acid, ketovaline, threonine, DL-3-aminoisobutyric acid, pyruvic acid, stachyose, caffeic acid, N, N-dimethylaniline, maltotriose, D(-)-gulonate-gamma-lactone, and L-asparaginase. The marker provided by the invention has good classification on metabolome data of patients suffering chronic obstructive pulmonary disease and healthy people, and can accurately distinguish the patients suffering chronic obstructive pulmonary disease from the healthy people.

Owner:PEKING UNIV +1

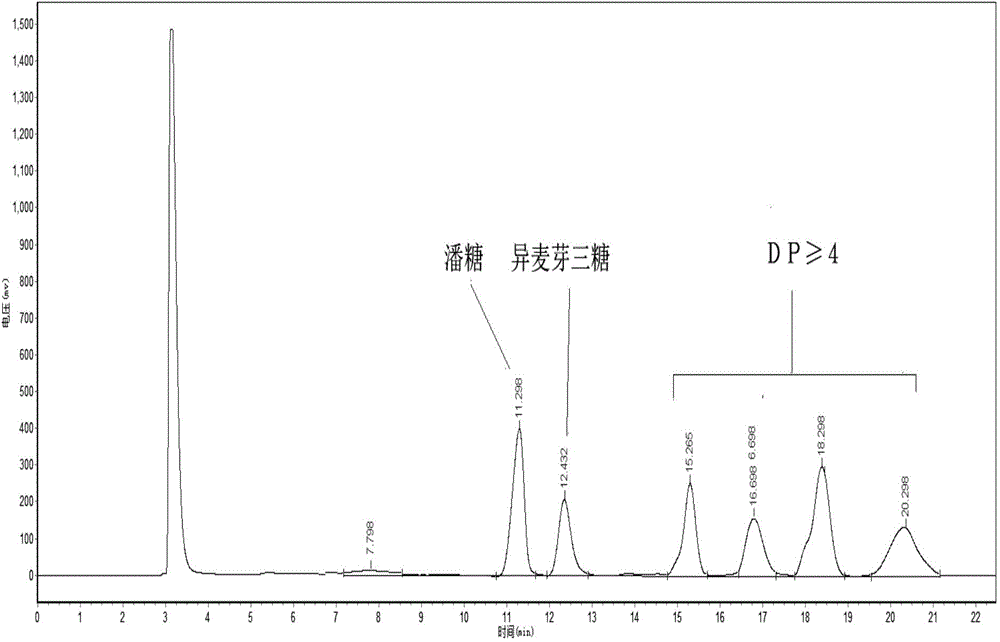

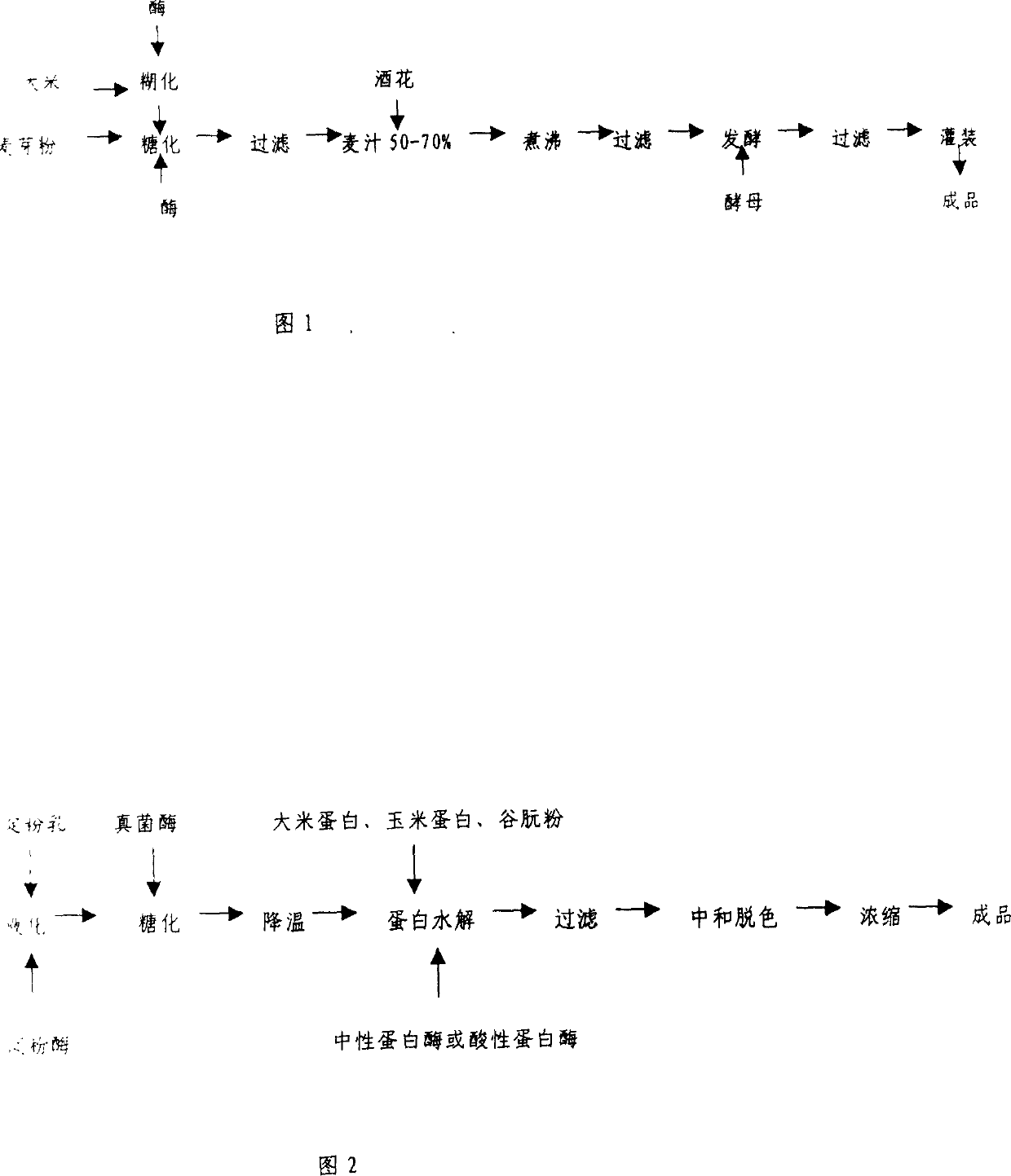

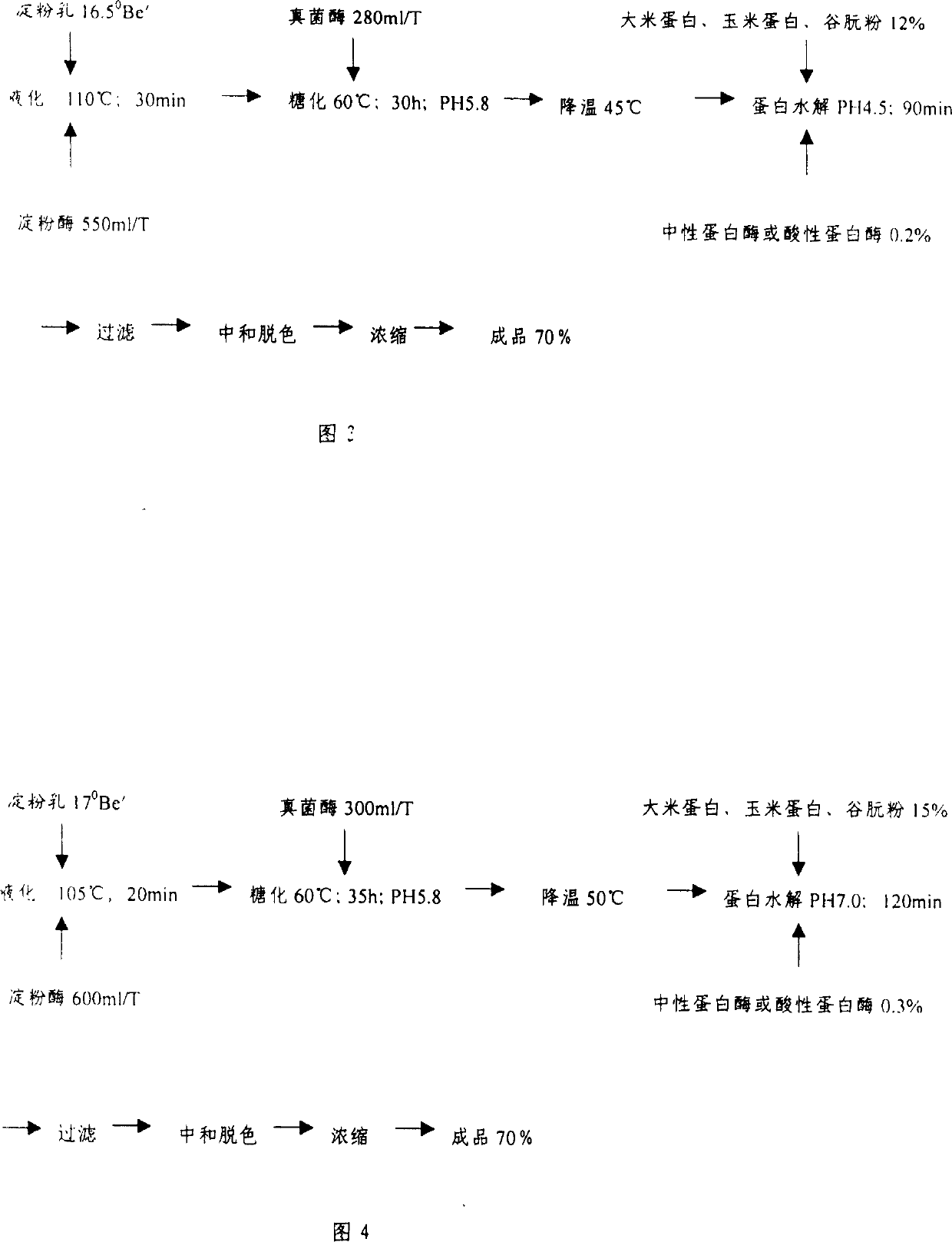

Preparation method of isomaltooligosacharide

ActiveCN104152512AIncrease contentIncrease concentrationFermentationChromatographic separationIsomaltooligosaccharide

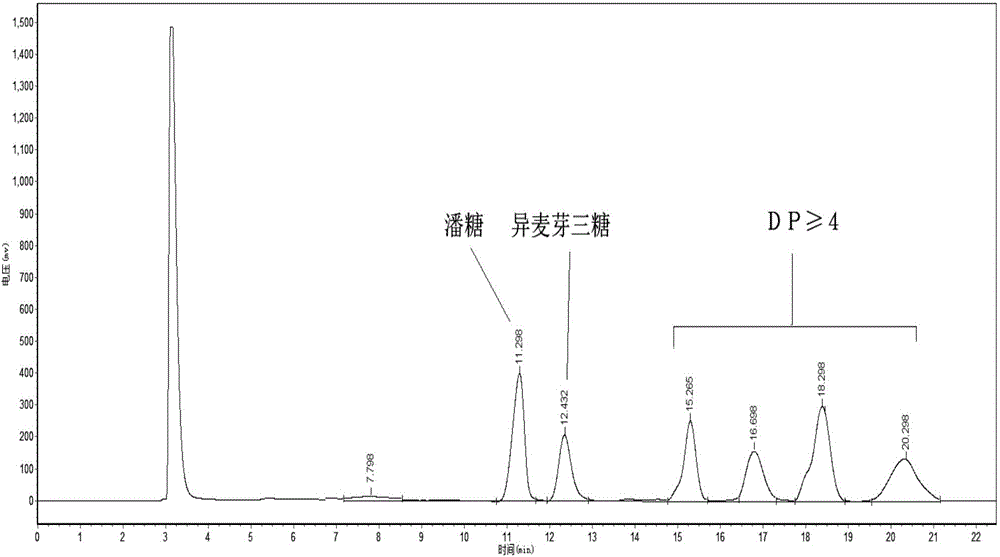

The invention relates to a preparation method of isomaltooligosacharide. The preparation method comprises the following steps of 1, adding water into a starch raw material, adjusting a concentration and a pH value of the slurry, and adding high temperature-resistant alpha-amylase into the slurry to obtain starch slurry, 2, carrying out liquidation on the starch slurry to obtain a liquefied liquid, 3, adding maltotriose generation enzyme (AMANO AMT1.2L) and pullulanase (GENENCOR OPTIMAX L-1000) into the liquefied liquid, carrying out thermal-insulation saccharification, and carrying out enzyme denaturalixation to obtain a saccharified liquid, 4, adding alpha-glucosidetransferase into the saccharified liquid for a reaction to produce a primary trans-glucoside saccharified liquid, adding alpha-glucosidetransferase into the primary trans-glucoside saccharified liquid for a reaction, and carrying out enzyme denaturalixation to obtain a trans-glucoside saccharified liquid, and 5, carrying out decoloration on the trans-glucoside saccharified liquid, carrying out filtration, carrying out ion exchange, carrying out chromatographic separation, carrying out concentration and carrying out drying to obtain isomaltooligosacharide. The preparation method greatly improves contents of sugars such as panose, isomaltotriose and tetrasaccharide having polymerization degrees greater than or equal to 3 in the reaction product liquid.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

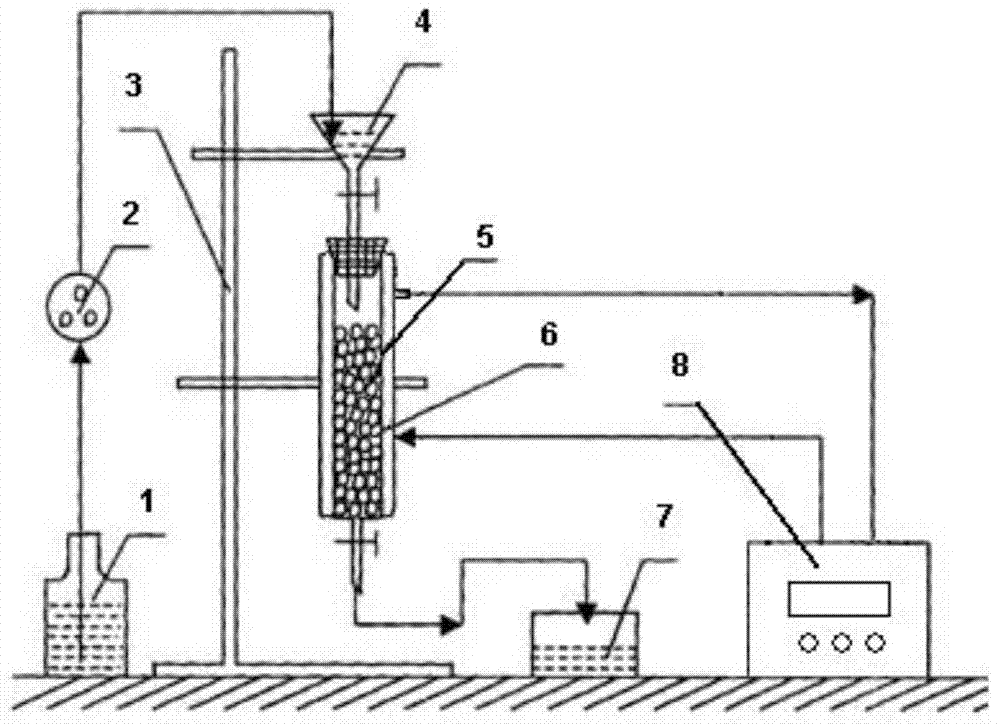

Method of using alpha-glucosidase for preparing isomaltooligosaccharide

ActiveCN103497983AHigh yieldImprove stabilityOn/in organic carrierFermentationAlgluceraseIsomaltooligosaccharide

The invention relates to a method of using alpha-glucosidase for preparing isomaltooligosaccharide. The method includes alpha-glucosidase immobilization, continuous reaction and isomaltooligosaccharide preparation. The alpha-glucosidase is immobilized through alginate, carrageenan and chitosan to implement continuous reaction, converting rate of raw material is 75%, and production cost is reduced by 1 / 3. By the aid of the method, isomaltooligosaccharide 50 or total isomaltooligosaccharide content of the isomaltooligosaccharide 50 is 55%, and the total content of isomalt, panose and isomaltotriose is 35%; isomaltooligosaccharide 90 or total isomaltooligosaccharide content of the isomaltooligosaccharide 90 is 95%, and the the total content of isomalt, panose and isomaltotriose is 70%.

Owner:WUXI JIANTE PHARM CO LTD

Preparation method of syrup special for moon cake

The invention relates to the field of starch sugar manufacturing, in particular to a preparation method of syrup special for moon cake. According to the method, corn starch is taken as the raw material, and the syrup is prepared through the steps such as size mixing, enzyme immersion, liquefaction, saccharification, glucoside conversion, decolorization, filtering, ion exchange, concentration, blending and the like. The prepared syrup comprises 20-25% of maltobiose, 12-17% of maltotriose, 15-20% of maltotetraose, 8-12% of tetrasaccharide-above, 3-5% of oligoisomaltose, 25-30% of fructose, and less than 3% of glucose. The syrup special for moon cake produced through the method is sucrose-free; the sweetness is slightly lower than that of the sucrose; the sweet taste is mild and pure, cool and refreshing; and the syrup is provided with a sweet flavor peculiar to honey, and has the advantages that the oil return property is obvious, the moisture retention property is good, the starch retrogradation is prohibited, the shelf life and the quality guarantee period of products are effectively prolonged, and the like.

Owner:BAOLINGBAO BIOLOGY

Preparation method of high-purity 95 isomaltose hypgather

ActiveCN103667392AHigh purityLow viscosityFermentationChromatographic separationIsomaltooligosaccharide

The invention provides a preparation method of high-purity 95 isomaltose hypgather. The preparation method comprises the following steps: performing jet liquefying on starch or starch milk used as a raw material; performing saccharification transglycosidation through maltase (fungus alpha-amylase or beta-amylase) and alpha-galctosyl-hydroxylysyl glucosyl transferase to obtain 50 type coarse isomaltose hypgather liquor; decomposing non-trisaccharide (isomaltose, panose and isomaltotriose hereinafter referred to as 'trisaccharide') ingredients by use of efficient liquid saccharifying enzyme to obtain glucose; separating by use of a chromatographic separation purification technology to remove glucose; decolorizing, desalting and refining to obtain 95 isomaltose hypgather (the 'trisaccharide' content is not less than 95%). The high-purity 95 isomaltose hypgather has the advantages that the effective ingredients 'trisaccharide' are high in purity reaching more than 95%, low in syrup viscosity and high in sweetness; the physiology functions are high; the bifidobacterium cultivation effect is three times higher than that of the common 90 type isomaltose hypgather.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

Preparation method of isomaltooligosaccharide

ActiveCN104131051AExtend the liquefaction timeIncrease productivityFermentationChromatographic separationIsomaltooligosaccharide

The invention relates to a preparation method of isomaltooligosaccharide. The preparation method comprises the following steps: (1) adding water into a starch raw material so as to regulate slurry, regulating pH and then adding high-temperature-resistant alpha-amylase, to obtain starch slurry; (2) insulating the starch slurry, and conducting secondary spray liquefaction to obtain liquefied liquor; (3) adding alpha-transglucosidase, reacting and then deactivating enzymes to obtain trans-glycosylation liquor; and (4) conducting decoloring, filtering, hybridization, chromatographic separation, concentration and drying to obtain the isomaltooligosaccharide. According to the preparation method, polysaccharides with glucoamylase degradation polymerization degree of more than or equal to 3 can be reduced, the reacted liquor mainly comprises constituents: polysaccharides such as panose, isomaltotriose, isomaltotetrose and the like with polymerization degree of more than or equal to 3, furthermore, the saccharification process can be omitted, the reaction time can be shortened by 20-30h, the production efficiency can be greatly improved, and the cost can be comprehensively saved by 10%.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

Special starch syrup for QQ sugar and preparation method thereof

InactiveCN103710410AHigh in polysaccharidesSpecial physiological functionFermentationLiquid glucoseFlocculation

The invention discloses a preparation method of special starch syrup for QQ sugar, which comprises the following steps: (1) pulping, and liquefying; (2) performing high-temperature filtration; (3) performing low-temperature filtration; (4) saccharifying; (5) decoloring; (6) performing ion exchange desalination; and (7) concentrating. The special starch syrup for QQ sugar, prepared according to the method, comprises the following sugar components: 0.8-1.2% of glucose, 44-48% of maltobiose, 17-19% of maltotriose and 38-42% of maltotetrose. The invention has the following advantages: (1) fine control is performed on the liquefied liquid glucose components through a special injection and liquefying process, thus obtaining low liquefaction liquid having high DE value; (2) high-temperature deslagging filtration and low-temperature protein flocculation are performed, thereby being more beneficial to impurity removal; (3) a mixed enzyme preparation is added in the saccharifying process, thus regulating and controlling the content of the sugar contents more effectively; and (4) the finished product is high in polysaccharide content, and the content of the sugar components presents a discontinuous ascending ratio, thus having a special physiological function.

Owner:河南飞天生物科技股份有限公司

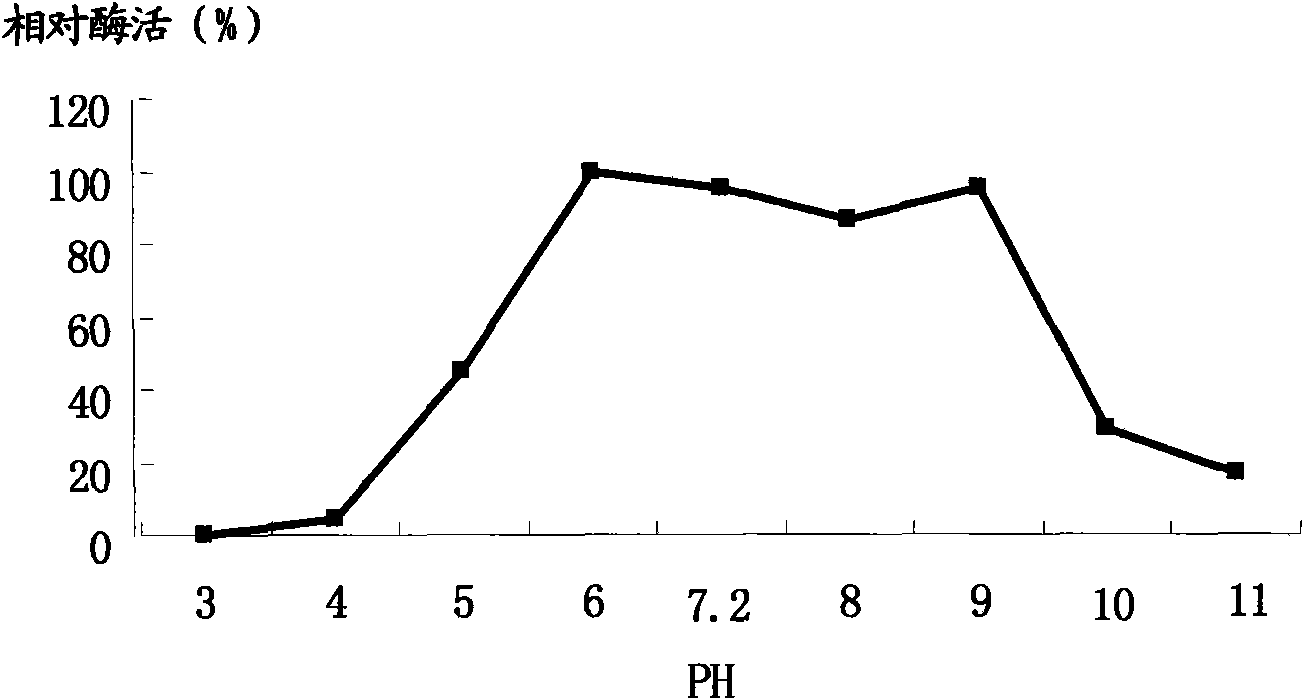

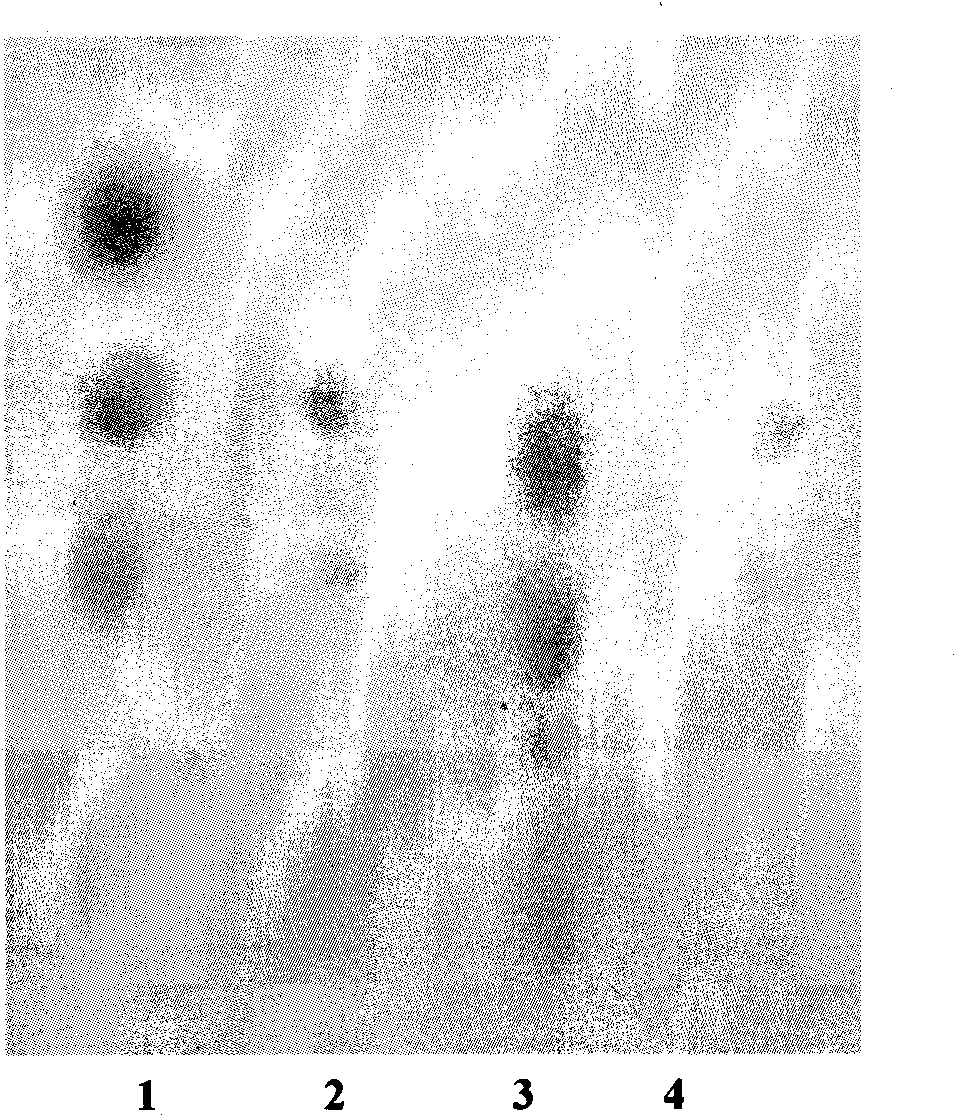

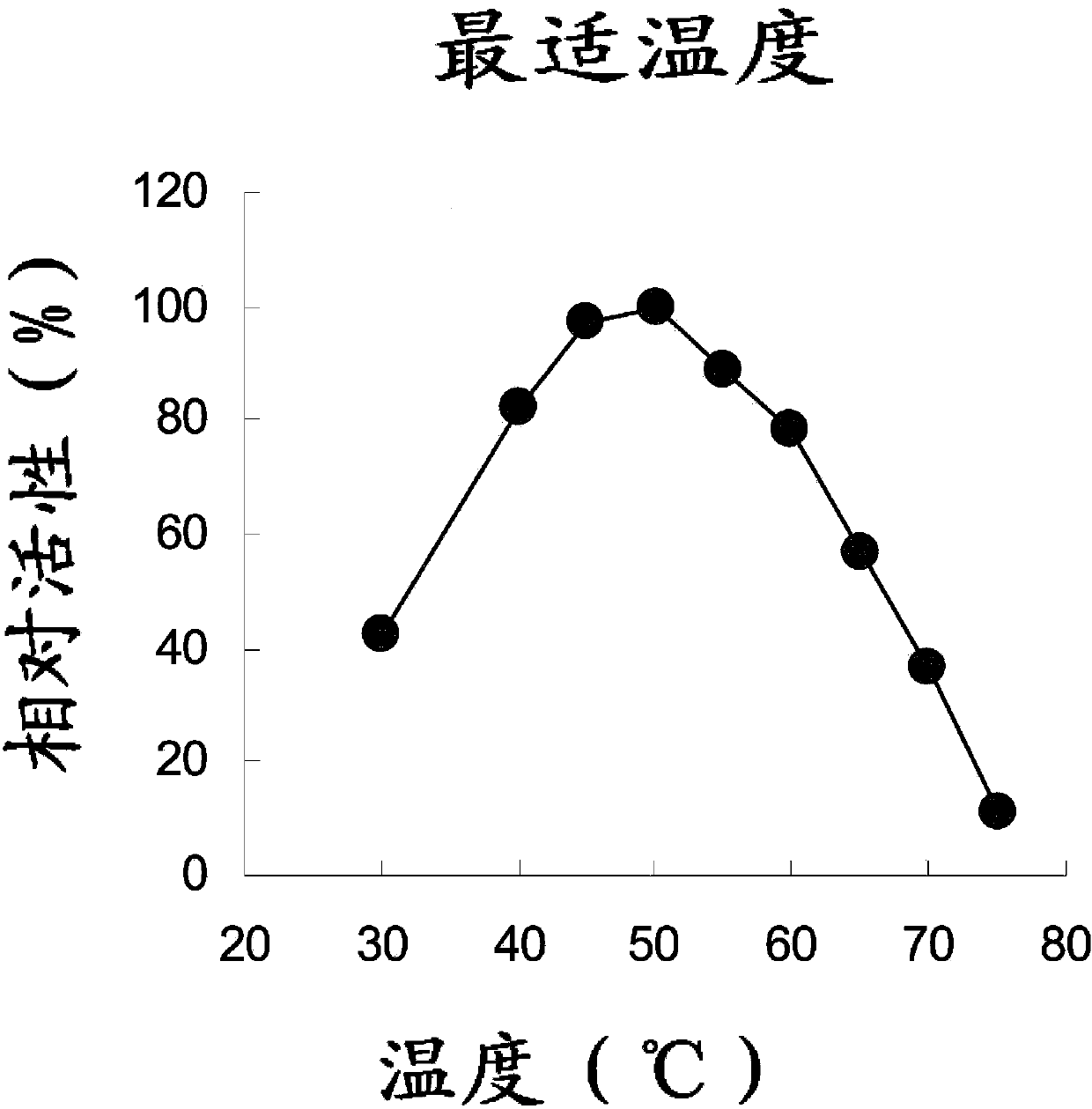

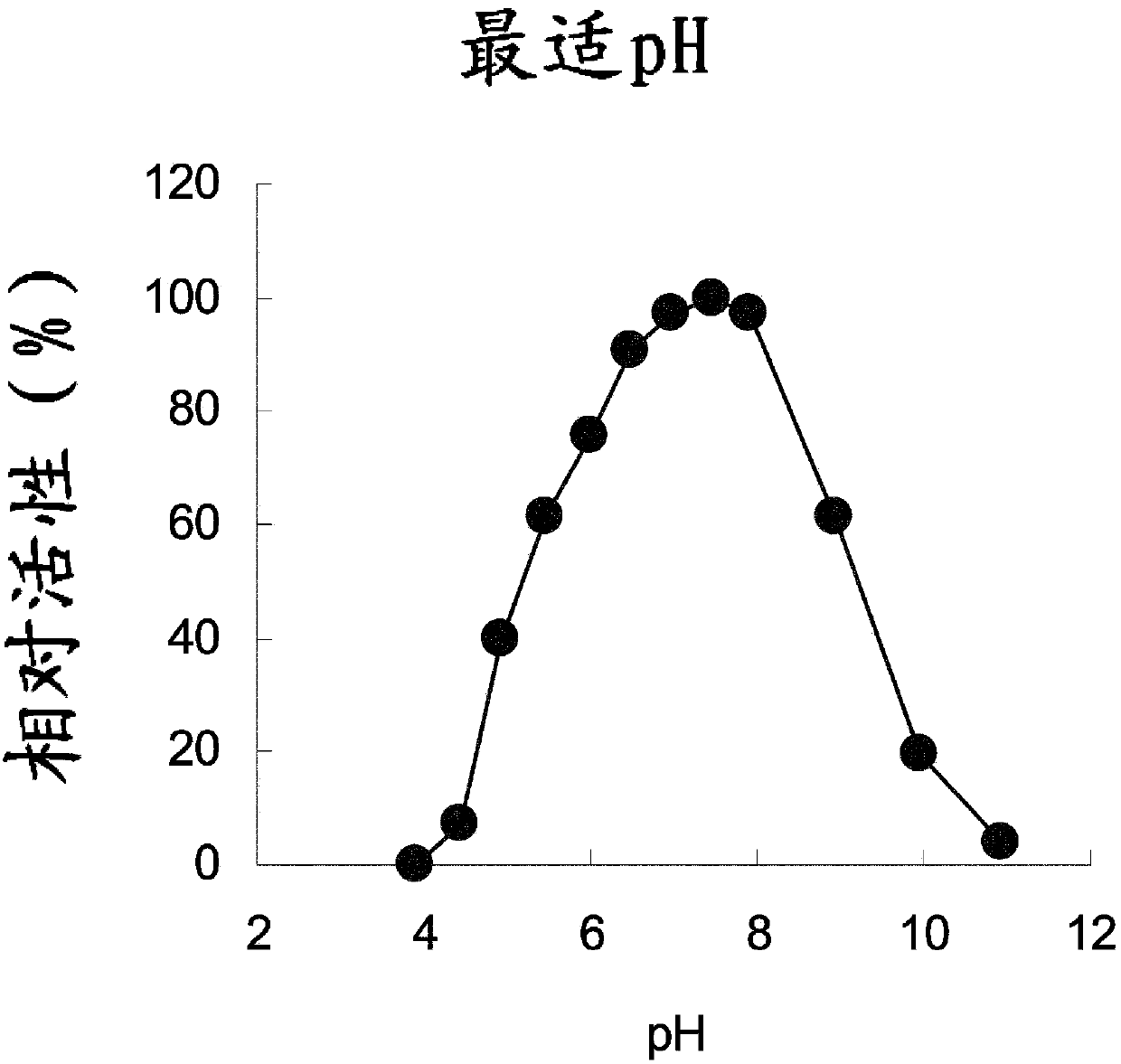

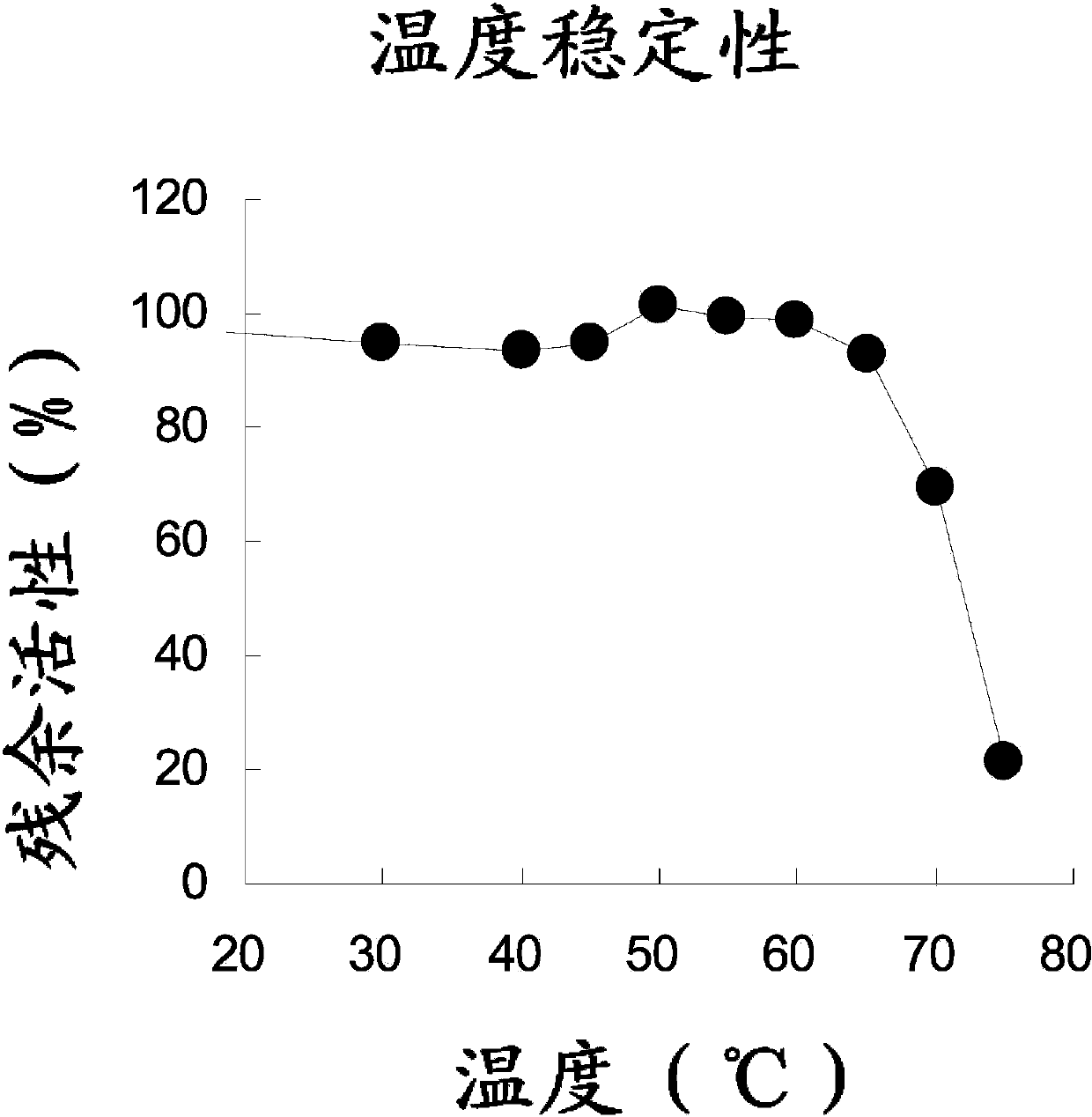

Pullulanase XWPu2 and gene thereof

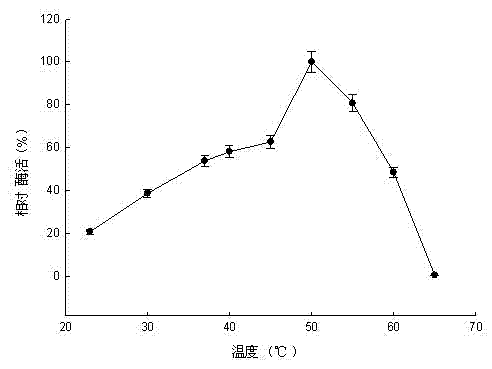

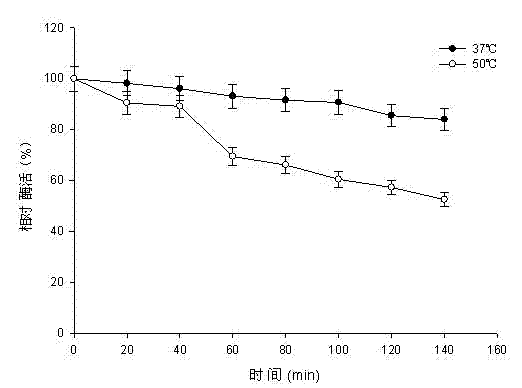

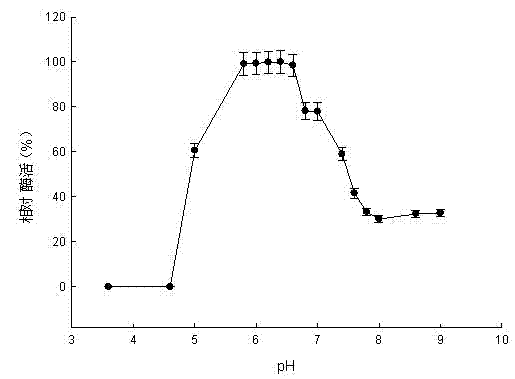

ActiveCN102965361AStrong activationEnhanced inhibitory effectFungiBacteriaChemical industryNucleotide

The invention discloses pullulanase XWPu2 and the gene thereof. The amino acid sequence of the pullulanase XWPu2 is shown in SEQID No. 1, and the nucleotide sequence of the pullulanase XWPu2 is shown in SEQID No. 2; and the recombinant vector and the recombinant strain of the pullulanase XWPu2 are provided. The pullulanase XWPu2 taking pullulanase as a substrate has the following properties that the optimum temperature is 50 DEG C; the optimum pH is 5.8-6.8; beta-mercaptoethanol having a final concentration of 1 mM, and metal ions Ca<2+>, Mn<2+>, Fe<2+> and K<+1> having a final concentration of 1 mM have a strong activation effect on enzyme; the residual enzyme activities after heat preservation for 140 minutes at 37 DEG C and at 50 DEG C are greater than 84% and greater than 52% in sequence; the residual enzyme activities after treatment for 90 minutes in a buffering solution having a pH of 5.0 and in a buffering solution having a pH of 8.6 are greater than 74% and greater than 57% in sequence; and the specific activity is 383.5 U / mg. Additionally, a qualitative analysis adopting thin-layer chromatography indicates that the pullulanase XWPu2 can be used for thoroughly hydrolyzing pullulanase to generate single maltotriose, hydrolyzing corn amylopectin to generate dextrin, and hydrolyzing cyclodextrin to generate glucose. The researches indicate that the pullulanase XWPu2 has a potential application prospect in the industries such as food, chemical industry, pharmacy and energy.

Owner:KUNMING QACTIVE BIOLOGICAL TECH CO LTD

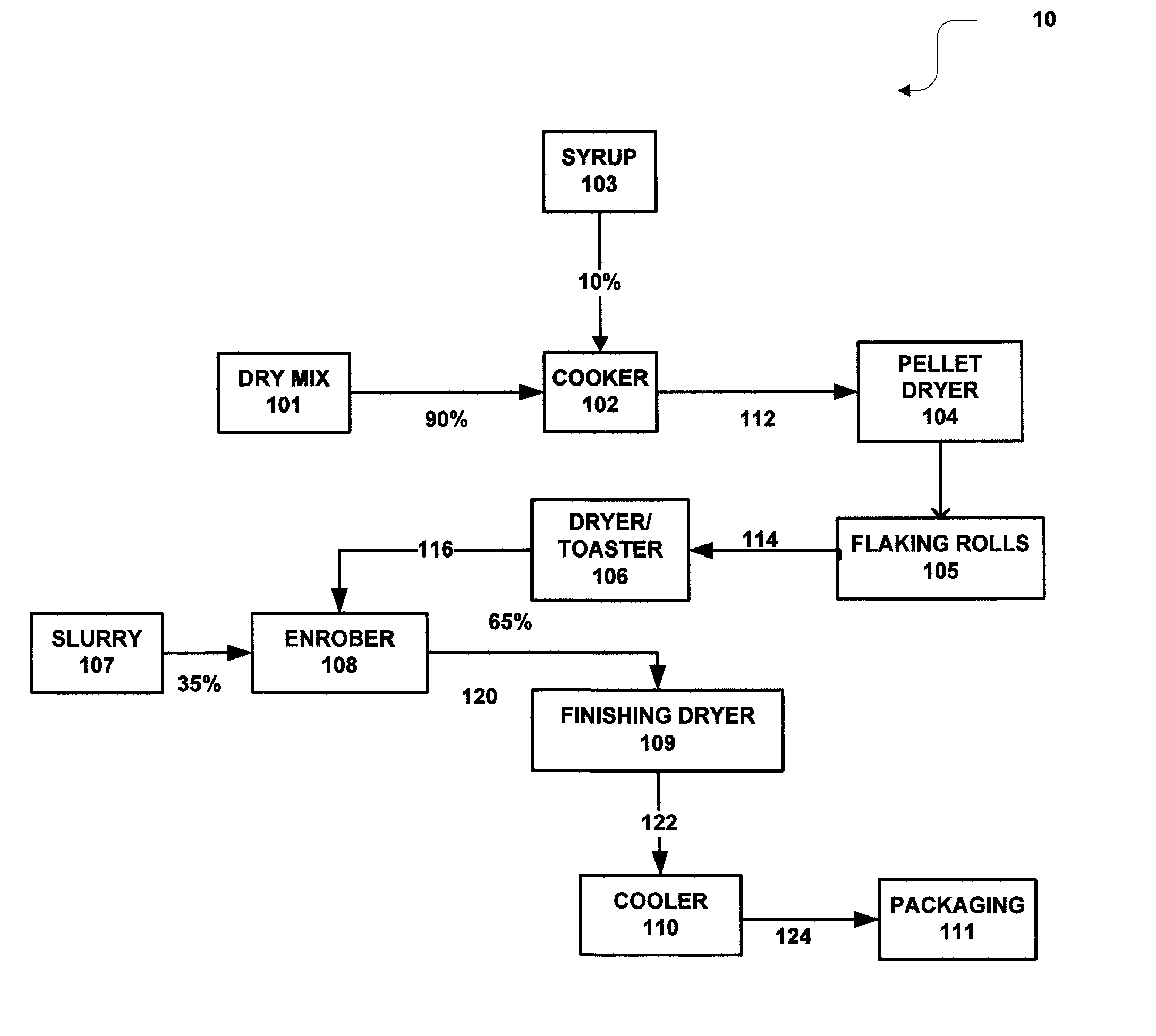

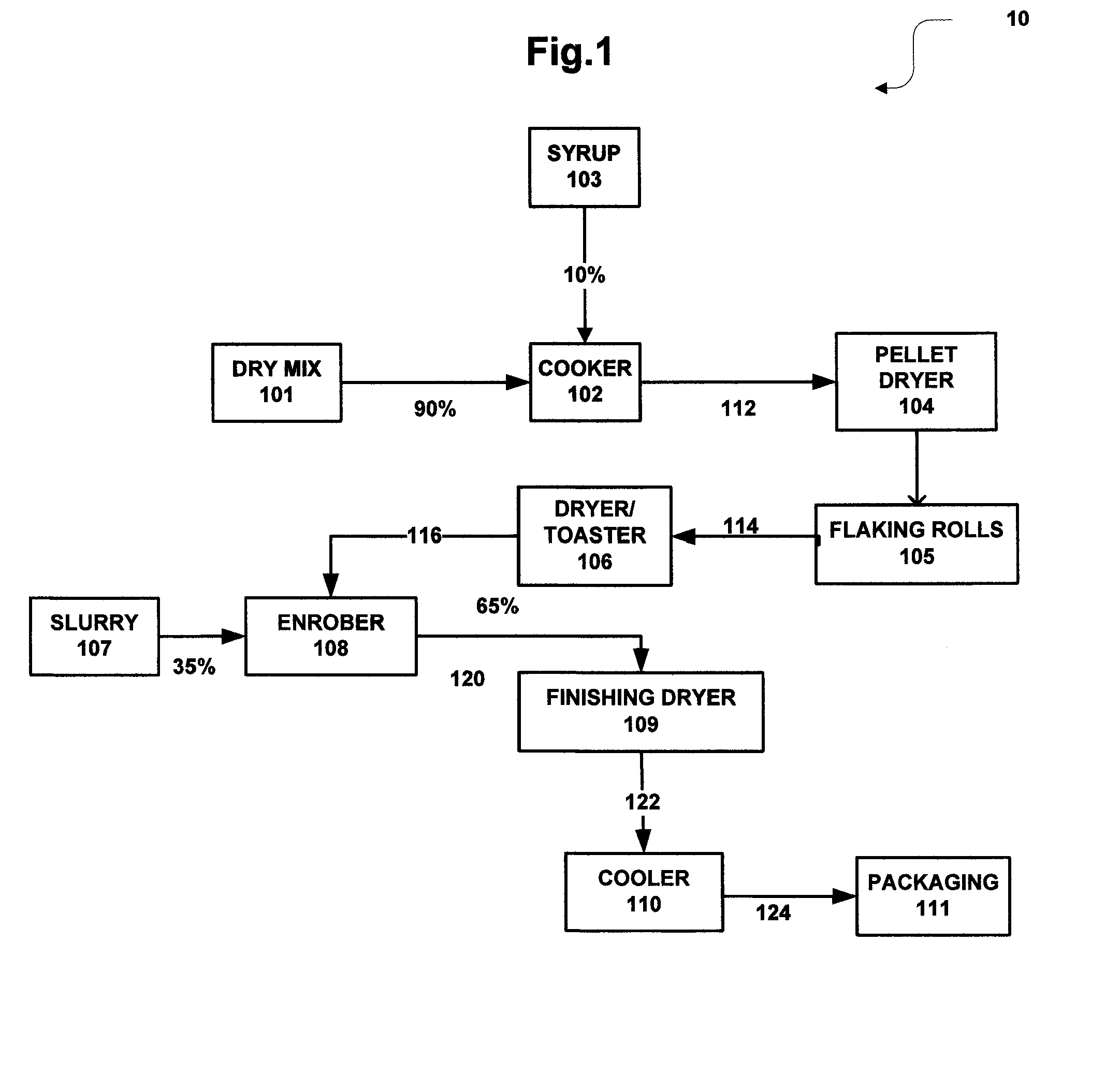

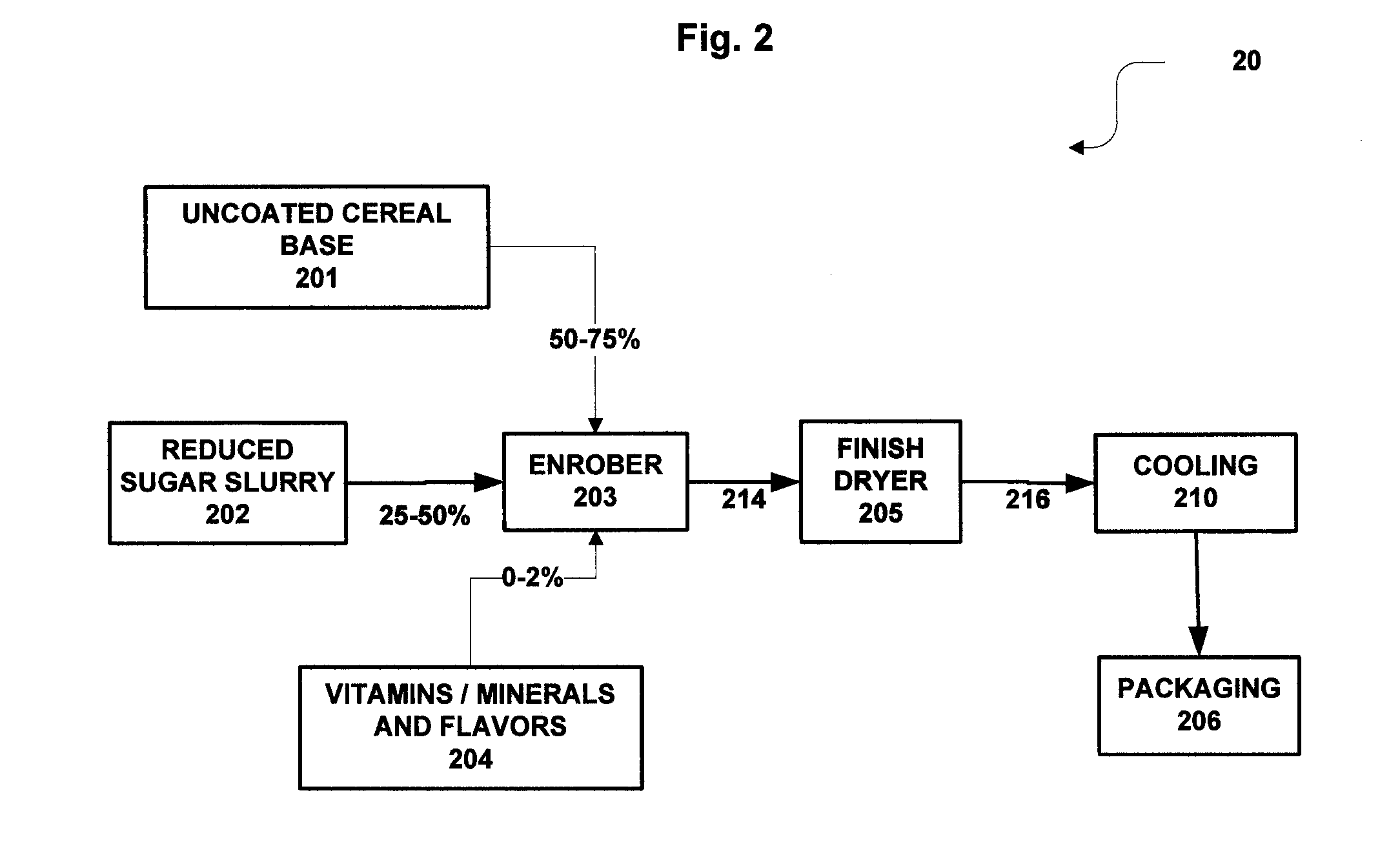

Reduced sugar pre-sweetened breakfast cereals comprising tri- and tetra saccharides and methods of preparation

InactiveUS20100173051A1Improve performanceReduced sugar coatingSugar food ingredientsConfectioneryReady to eatTrisaccharide

A reduced sugar presweetened ready to eat breakfast cereal is prepared by coating dried cereal base pieces or food pieces with a reduced-sugar composition comprising maltotriose, maltotetrose in full or partial substitution for sucrose, and a high potency sweetener. The reduced-sugar coating can have a sucrose content of less than 70%, yet provides taste, texture, appearance, and bowl life that mimics presweetened R-T-E cereals having a coating with more sucrose.

Owner:GENERAL MILLS INC

Method for glycosylation of flavonoid compounds

ActiveUS20100256345A1Effective glycosylationGood water solubilityCosmetic preparationsNervous disorderSolubilityΓ cyclodextrin

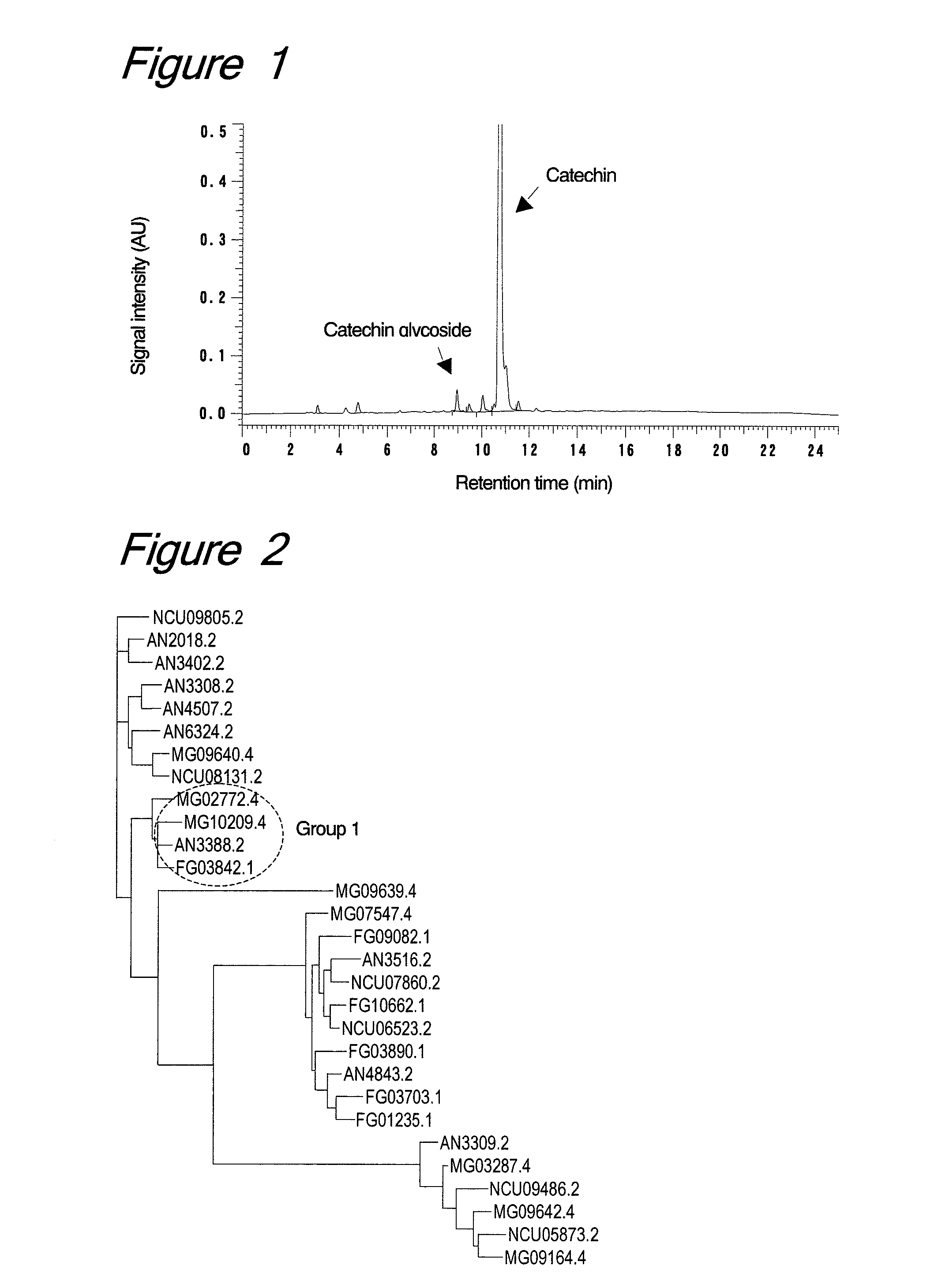

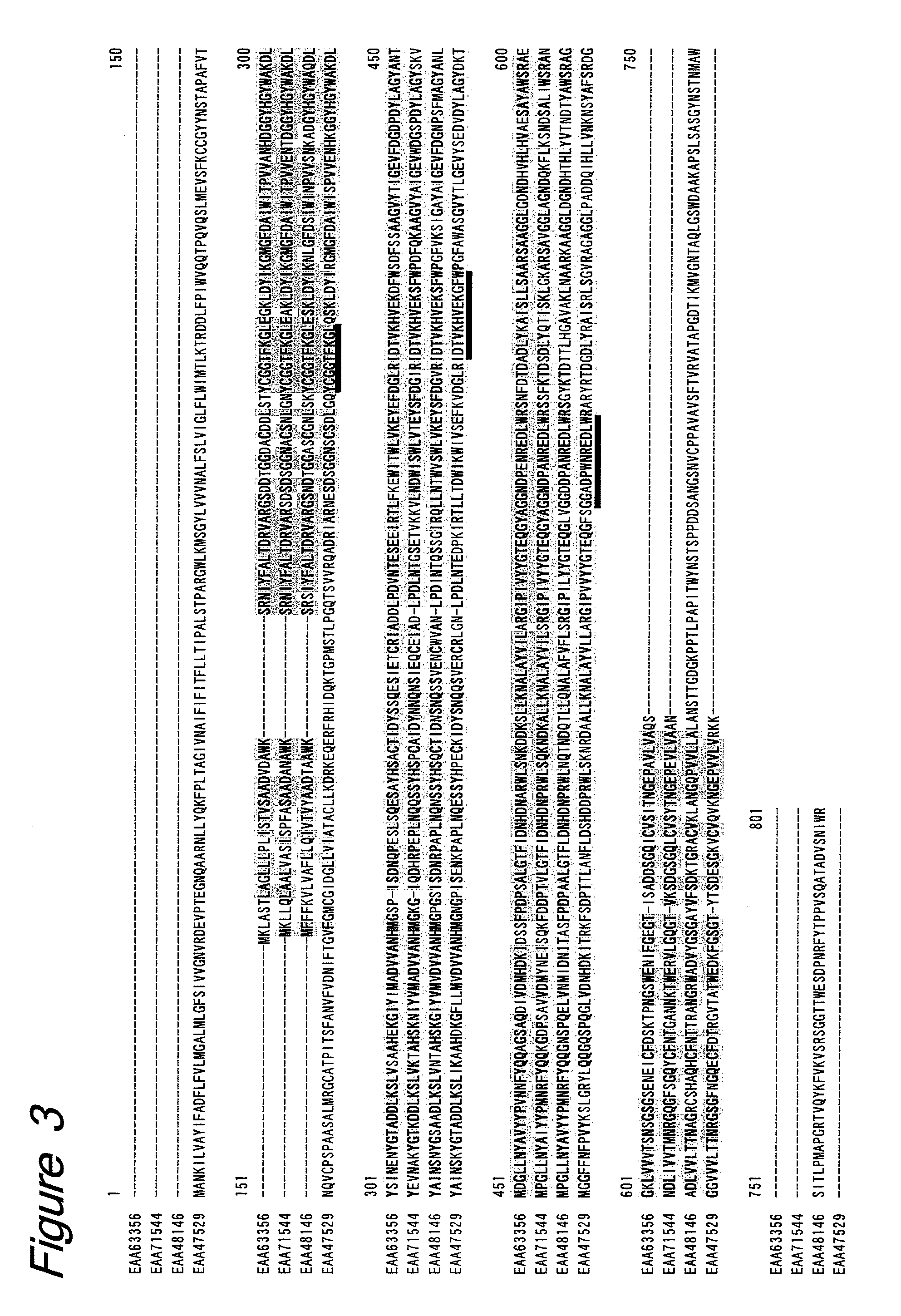

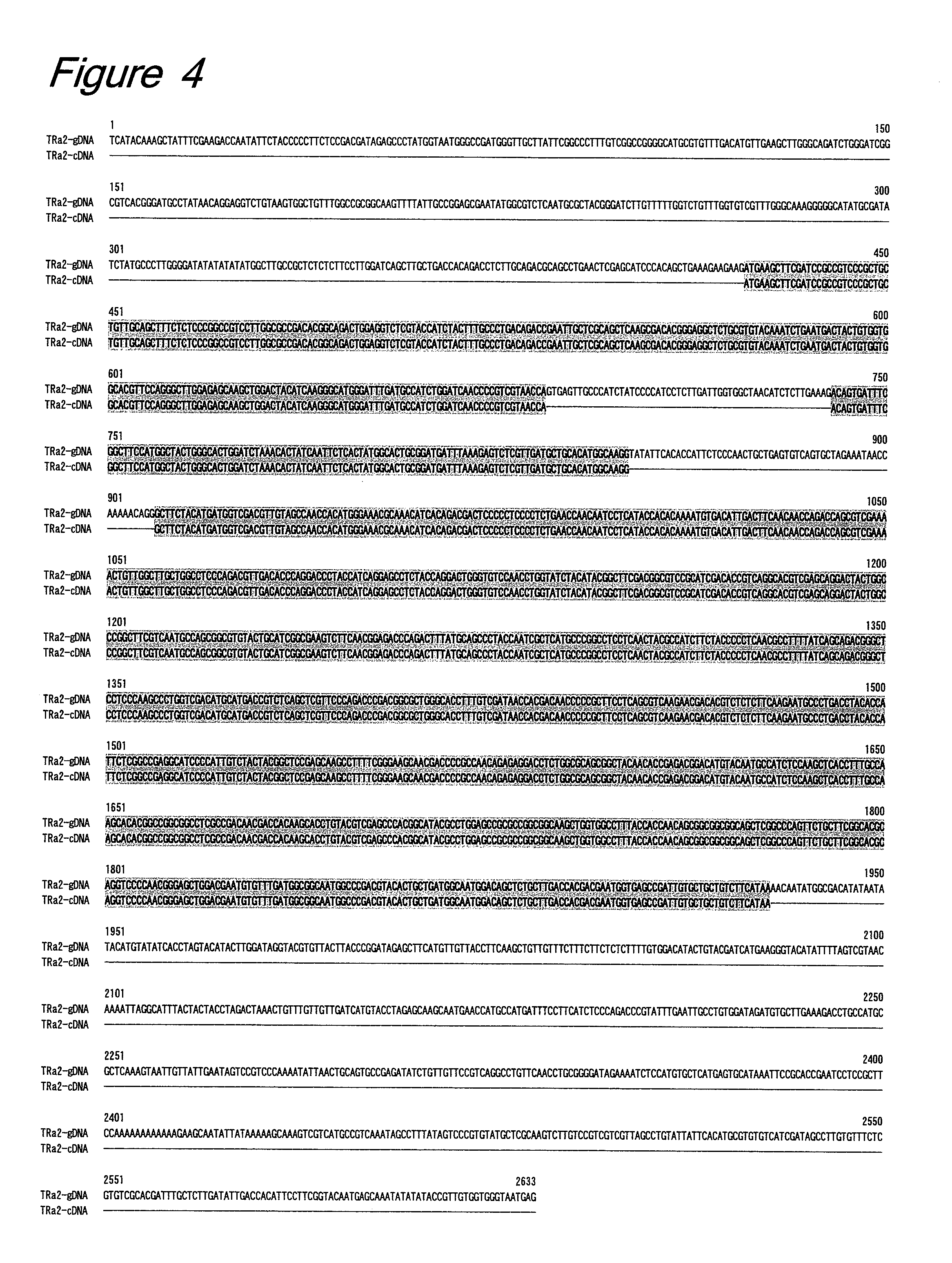

The present invention provides a method for preparing a glycoside of a flavonoid compound, which comprises the step of treating flavonoid and a glycosyl donor with an enzymatic agent having glycosylation activity and being derived from the genus Trichoderma (preferably Trichoderma viride or Trichoderma reesei). Such a flavonoid compound includes a catechin compound or a methylated derivative thereof, and the glycosyl donor includes a carbohydrate containing a maltotriose residue (preferably maltotriose, maltotetraose, maltopentaose, maltohexaose, maltoheptaose, dextrin, γ-cyclodextrin or soluble starch). Glycosides obtained by the present invention have higher water solubility, improved taste, and increased stability. The present invention also provides novel glycosides of catechin compounds, which are obtained by the method of the present invention.

Owner:SUNTORY HLDG LTD

Moisture-keeping syrup and preparation method thereof

ActiveCN101438782AEasy to evaporateNot easy to evaporateFood processingPreservation by coatingFiltrationIon exchange

A preparation method of moisturizing syrup belongs to the moisturizing technical field. The preparation method takes starch or starch milk as raw materials and adopts Amano AMT1.2L and Genencor OPTIMAX L-1000 for saccharification and production of the moisturizing syrup after liquefaction, the maltose content in the syrup is 13-20 percent, maltotriose is more than 60 percent, oligosaccharides more than tetraose are lower than 18 percent (as the preparation process detects that the triose content is 68 percent, the invention turns to emphasize the contents of two components of the triose and the tetraose), and the glucose is lower than 5 percent. The preparation method adopts pulp conditioning liquefaction, Amano AMT1.2L and the Genencor OPTIMAX L-1000 saccharification, membrane filtration and decolorization, continuous counter-current ion exchange, multi-effect plate-typed vacuum evaporation and concentration and other and advanced production technologies for simplifying process, saving energy and reducing consumption during the implementation process, thereby realizing the environmental friendly and high-efficient production of the special syrup for moisturizing.

Owner:BAOLINGBAO BIOLOGY

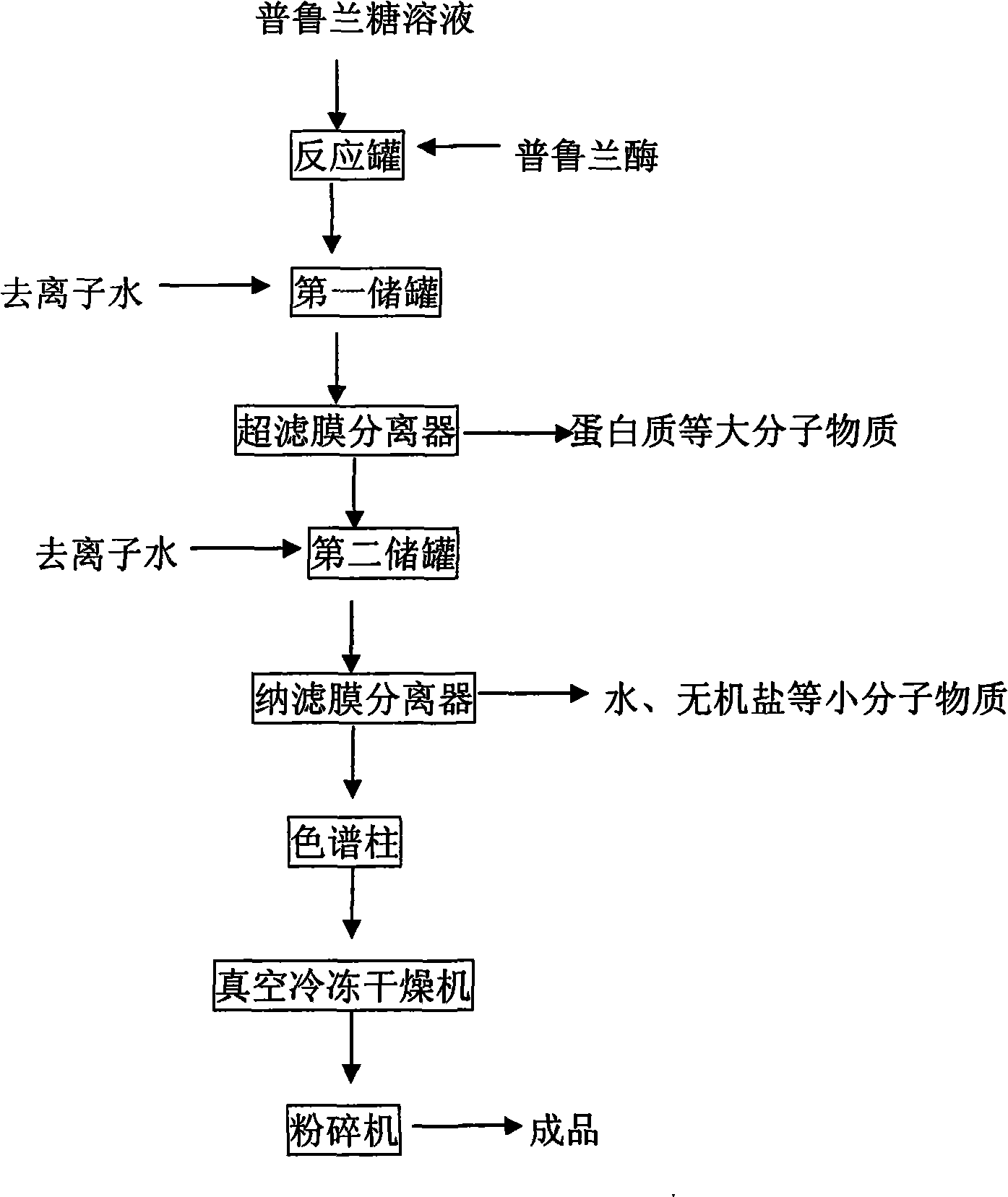

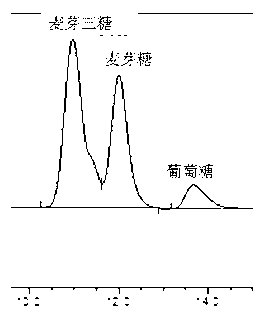

Method for using pulullan to prepare high-purity maltotriose

InactiveCN101555507ASimple manufacturing processHigh puritySugar derivativesOligosaccharidesUltrafiltrationPancreas diseases

The invention discloses a method for using pulullan to prepare high-purity maltotriose. The technical proposal is as below: (1) using pullulanase to carry out zymohydrolysis on the pulullan; (2) using an ultrafiltration membrane to remove macromolecular protein type substances in reaction liquid; (3) using a nanofiltration membrane to remove micromolecular salt type substances and condense the reaction liquid; and (4) using chromatographic column separation to collect the pure product of the maltotriose, and obtaining the finished product of the maltotriose through vacuum drying. The method adopts an enzyme process to produce the maltotriose and realizes over 99 percent of product purity and low cost; the production process can realize continuity and automation; a great amount of pharmaceutical-grade maltotriose can be prepared; and the method is of great significance in producing a fast diagnosis reagent for curing acute pancreas diseases and developing saccharides with medicinal use.

Owner:杨凌壹之农微生物工程技术研究院有限公司

Preparation method of superhigh malt syrup

ActiveCN103409484AMild reaction conditionsEasy to operateSugar derivativesDisaccharidesChromatographic separationMalt Grain

The invention provides a preparation method of superhigh malt syrup of which the maltose content is higher than 98%. The preparation method mainly comprises the following steps: preparing malt syrup, carrying out chromatographic separation, carrying out yeast fermentation to remove glucose, and separating yeast cells with a ceramic membrane to obtain the superhigh malt syrup in which the maltose content on dry basis is higher than 98%. The invention adopts the conventional chromatographic separation resin, thereby avoiding the steps of resin pretreatment, transformation and the like, and being efficient and quick; the yeast rapid fermentation is adopted to remove glucose, and thus, the method has the advantages of fewer byproducts and mild reaction conditions and is convenient to operate; the maltose content in the obtained product is higher than 98%; and meanwhile, maltotriose, maltotetrose, glucan tetrasaccharide above, and other miscellaneous glucoses are removed.

Owner:SHANDONG FUTASTE

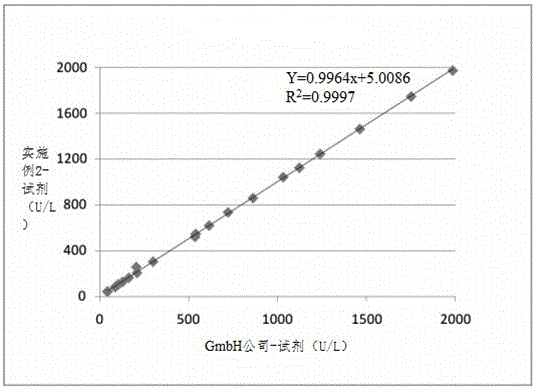

Alpha-amylase detection reagent and application thereof

ActiveCN105021543AThe measurement result is accurateReduce mistakesColor/spectral properties measurementsLaboratory orderMedical laboratory

The present invention belongs to the field of medical laboratory technology, and in particular relates to an alpha-amylase detection reagent and application thereof. The reagent comprises a reagent R1 and a reagent R2; the reagent R1 is mainly composed of an MES buffer, NH4Cl, CaCl2, a surfactant and a preservative; the R2 reagent consists of an MES buffer, a 2-chloro-4-nitrobenzene-maltotriose and a preservative. The alpha-amylase detection reagent provided by the invention does not contain NaN3, does not lead to alpha-amylase allosterism in the determination process, and can reduce the error in measurement results; at the same time, the test does not need additional tool enzyme, and has short delay time; the test results have good repeatability and stability. Therefore, the invention is conducive to the clinical application of alpha-amylase detection reagent.

Owner:郑州金域临床检验中心有限公司

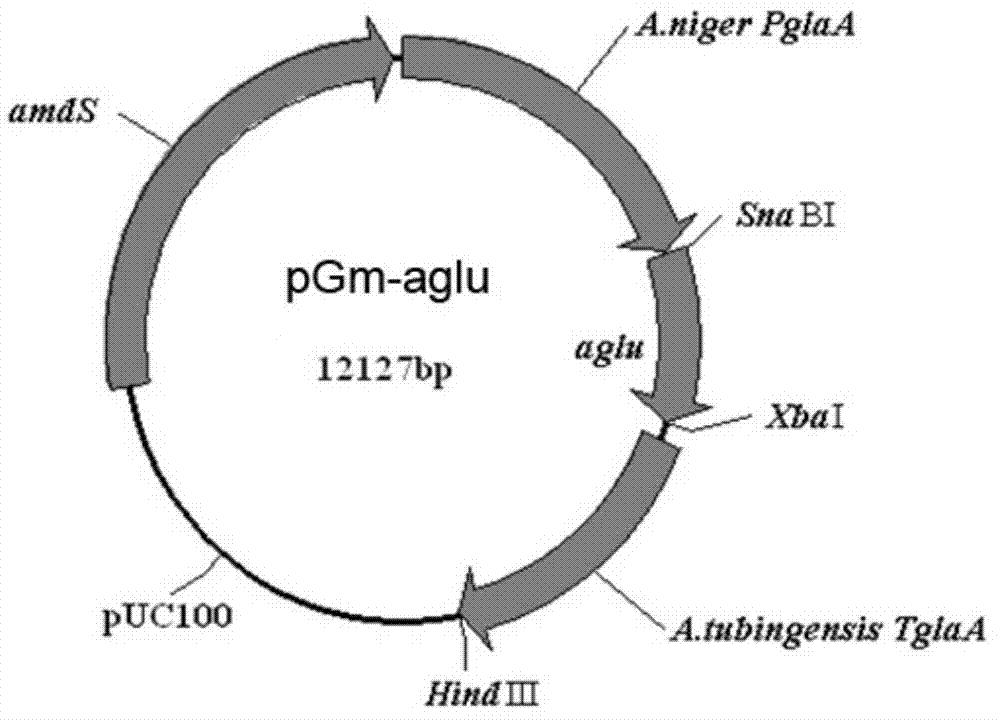

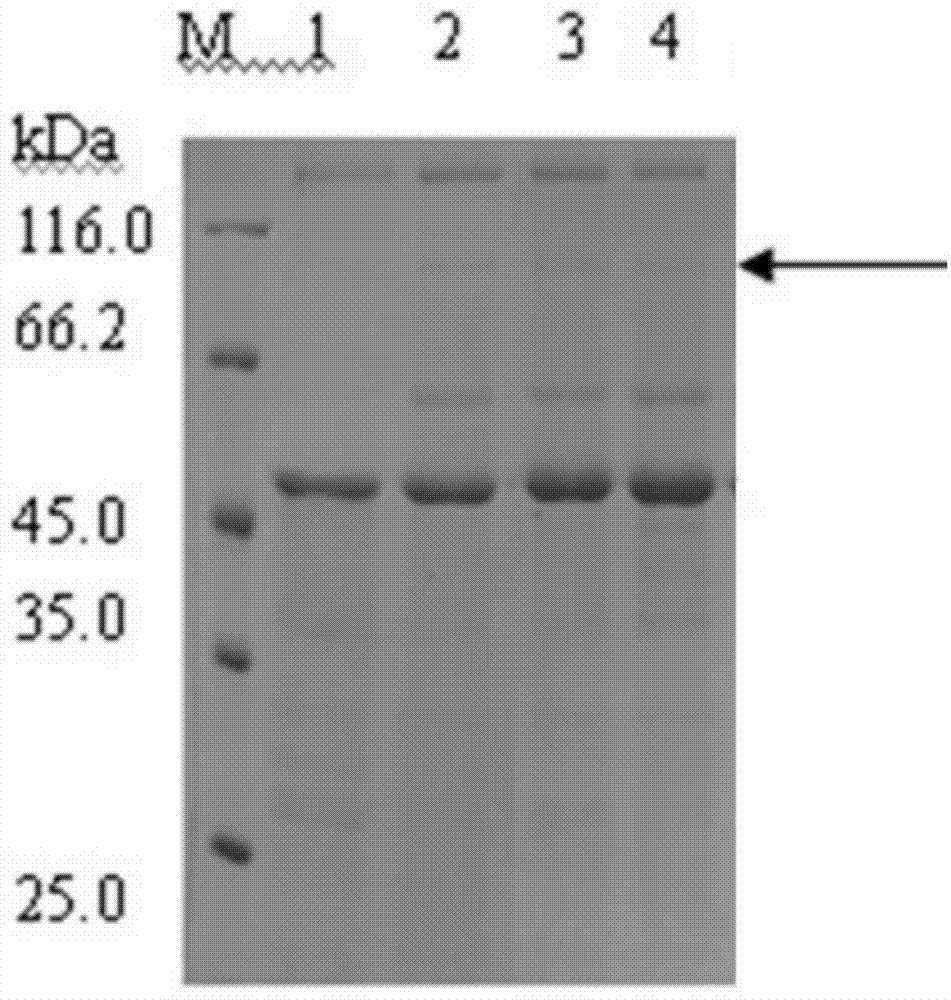

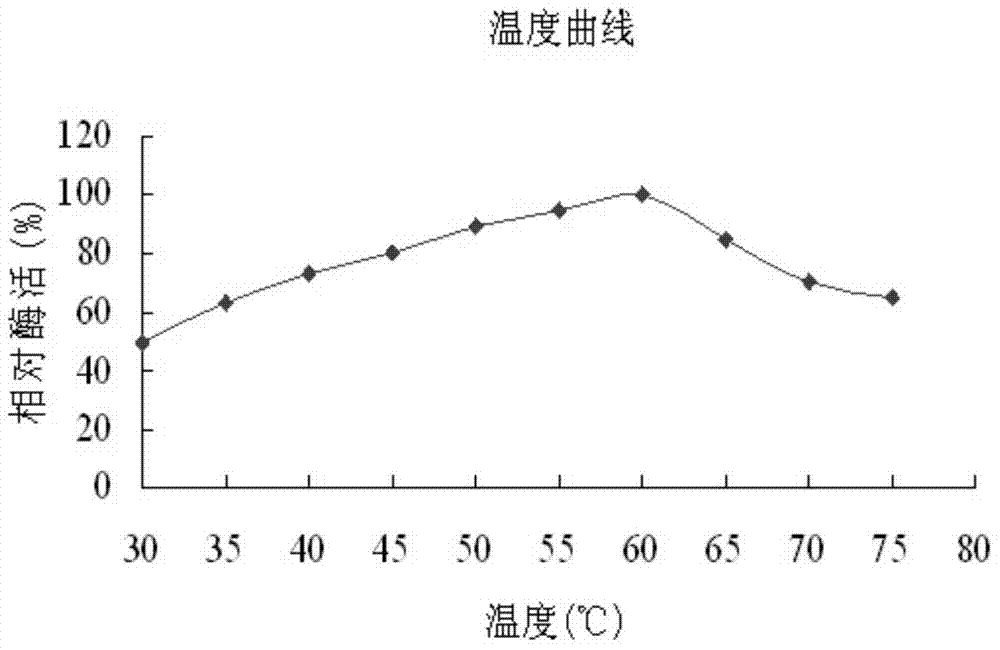

Alpha-glucosidase and application of alpha-glucosidase

ActiveCN104328096AIncrease contentEfficient conversionFungiMicroorganism based processesAlgluceraseIsomaltooligosaccharide

The invention provides alpha-glucosidase. The amino acid sequence of the alpha-glucosidase is SEQ ID NO:1. The optimum action temperature of the alpha-glucosidase is 60 DEG C; over 80% of enzyme activity can be retained in a range of 50-65 DEG C; the optimum action pH value is 4.5; over 80% of enzyme activity can be retained in a pH range of 3.0-6.0. The alpha-glucosidase is capable of efficiently converting maltose; the content of isomaltose, the content of panose and the content of isomaltotriose in a conversion product are the highest and respectively reach 44.1%, 23.0% and 21.2%; the total content of the isomaltose, the panose and the isomaltotriose is 88.3%. Therefore, the alpha-glucosidase can be widely applied to production of isomalto oligosaccharides and has a wide market prospect.

Owner:QINGDAO VLAND BIOTECH GRP

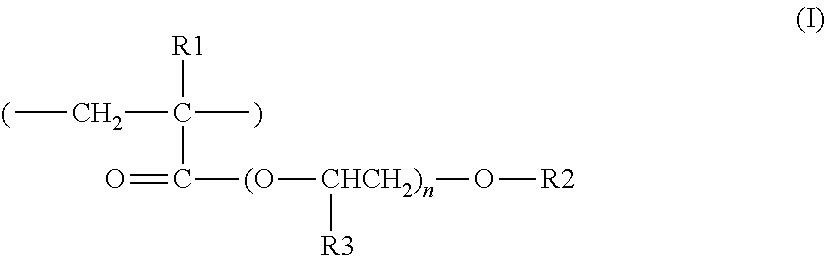

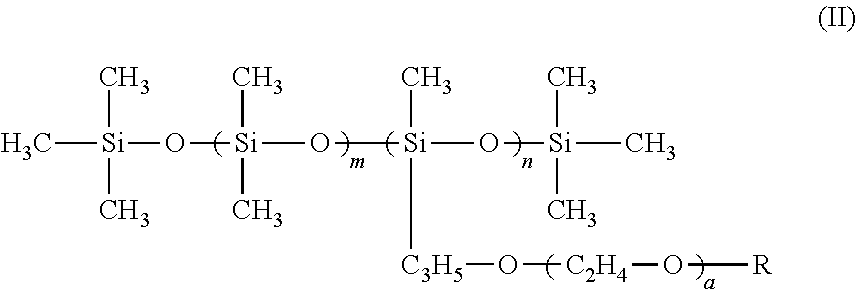

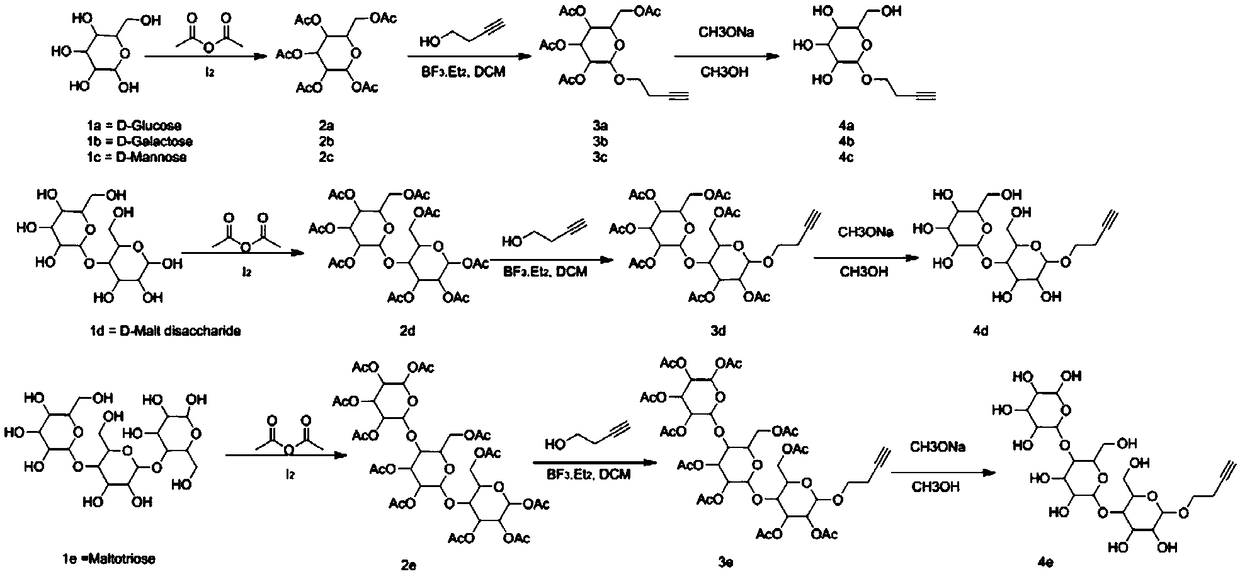

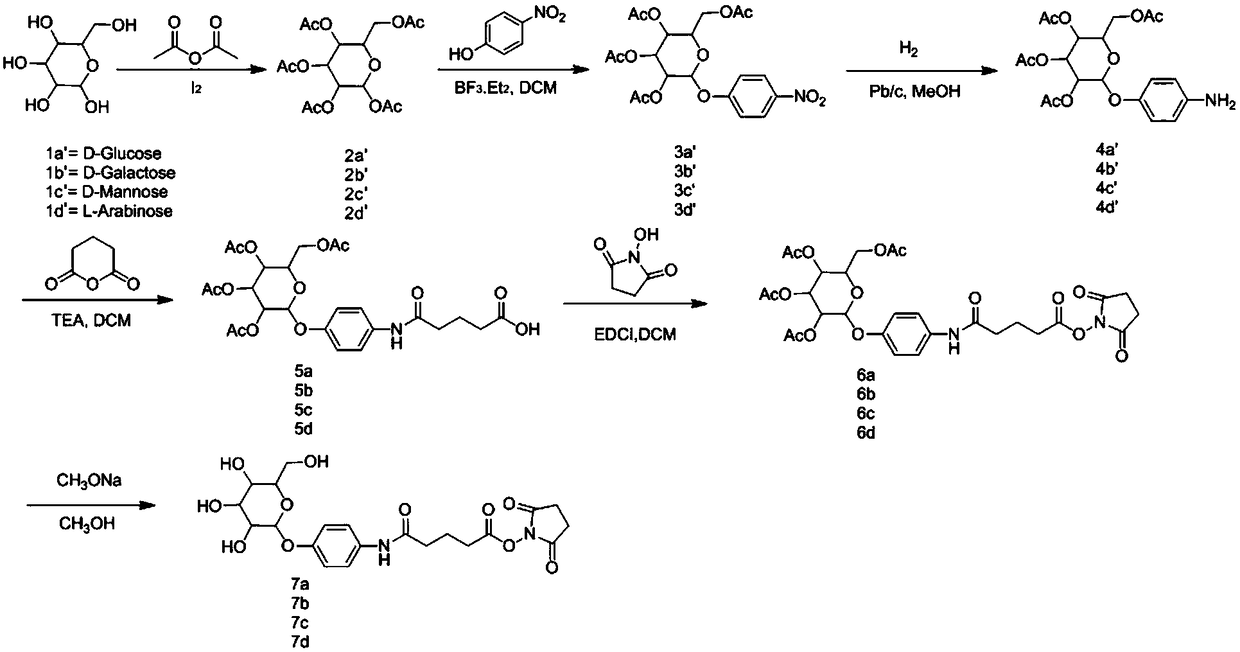

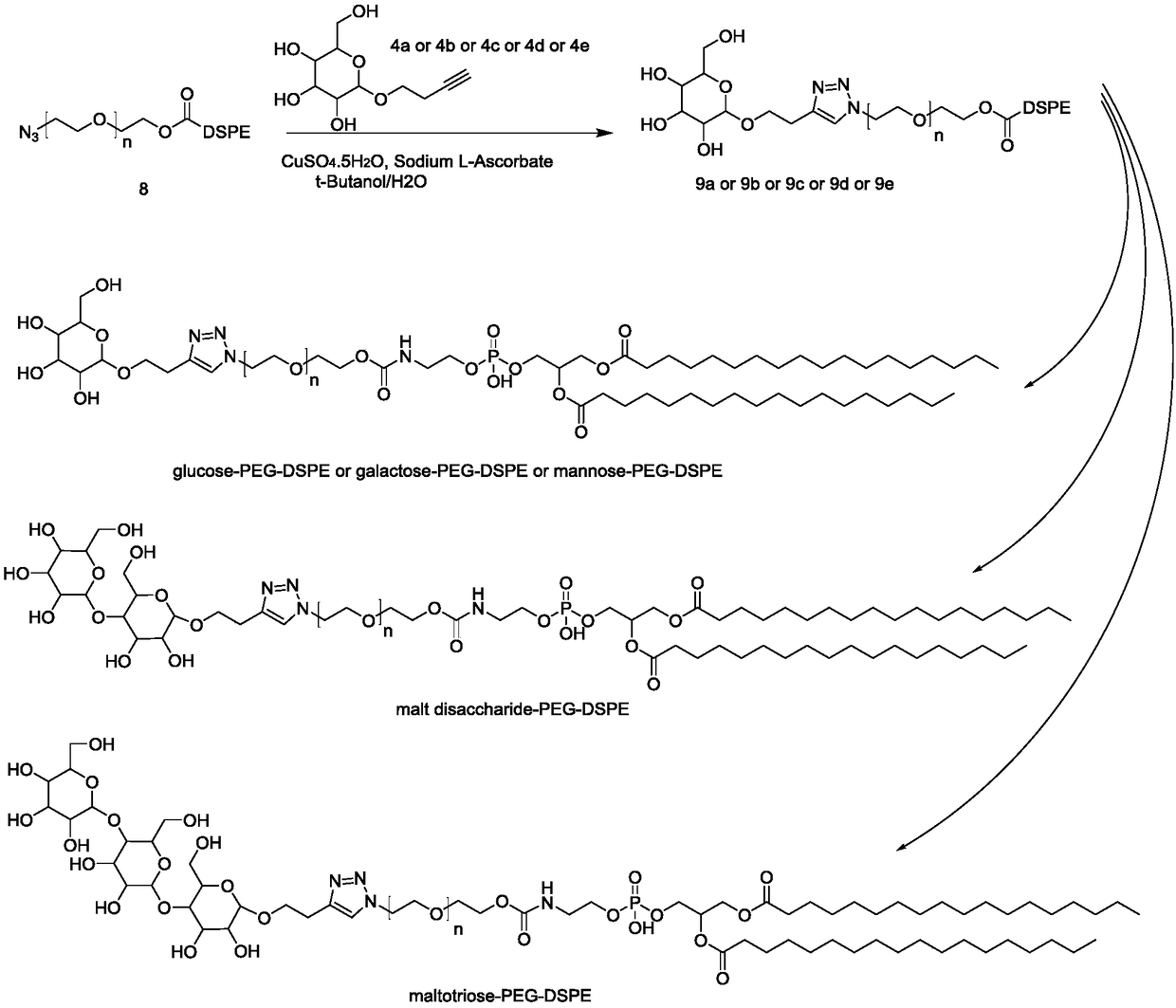

Sugar-polyethylene glycol-DSPE (1,2-distearoyl-sn-glycero-3-phosphoethanolamine) conjugated compound and preparation method and application thereof

ActiveCN109350598AEasy to purifyRaw materials are easy to getAerosol deliveryPharmaceutical non-active ingredientsPolyethylene glycolDspe peg

The invention discloses sugar-polyethylene glycol-DSPE (1,2-distearoyl-sn-glycero-3-phosphoethanolamine) conjugated compound and a preparation method and application thereof, wherein the sugar-polyethylene glycol-DSPE conjugated compound is prepared by conjugating sugar to DSPE-PEG (polyethylene glycol). The sugar is one of a monosaccharide, a disaccharide, a polysaccharide and the sugar acetylated, wherein the monosaccharide includes mannose, galactose, arabinose and glucose; the disaccharide includes maltose; the polysaccharide is maltotriose. DPSE is artificial phospholipid, having lipotropism; PEG is a hydrophilic substance; a sugar ligand is a target of a targeting material. The compound herein is applicable to the design of targeting carriers, especially liposomes and micelles, and is also applicable as a surfactant. In addition, the invention also provides the preparation method of the compound herein; materials for the preparation method are easy to attain, reaction conditionsare mild and easy to control, the preparation method is simple to perform, the product is easy to purify, and the yield is high. The product is applicable to biological researches and is important tothe preparation of drug carriers and the disease treatment.

Owner:HARBIN MEDICAL UNIVERSITY

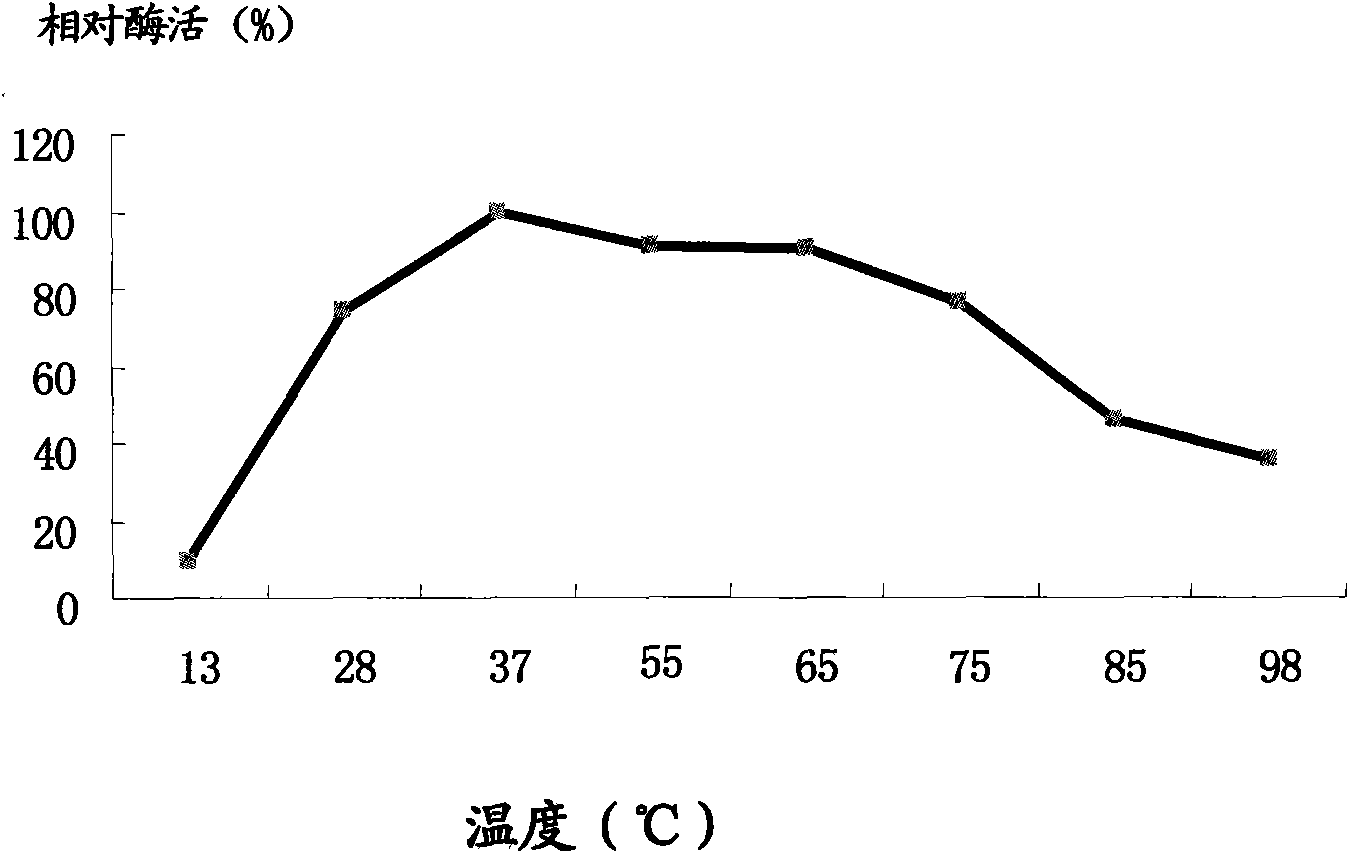

Method for preparing alpha-amylase by high-temperature laceyella sacchari RHA1 virus strain and purification method thereof

The invention discloses a method for preparing high-temperature alpha-amylase by a heat resistant high-temperature laceyella sacchari RHA1 virus strain and a purification method thereof. The high-temperature laceyella sacchari RHA1 virus strain is white and transparent, has corrugations, dry surfaces, different positive colors and negative colors, ball shapes, laceyella sacchari gram-positive bacterium, no flagella or no pilus; and a large number of mycelium is produced when culturing liquid. The method for preparing the amylase by the high-temperature laceyella sacchari RHA1 comprises the following steps: carrying out ultrafilter concentration and ammonium sulfate precipitation on a fermentation supernatant through an ultrafilter envelope of 1KD to obtain crude enzyme liquid, and filtering by Superdex 75 10 / 300 gelatin to obtain pure heat resistant alpha-amylase. The molecular weight of the alpha-amylase obtained in the invention is only 11.9 KDa, and the alpha-amylase is a monomer protein and is an amylase with the minimal molecular weight reported recently. The alpha-amylase hydrolyzes amylose and soluble starch to obtain maltose and maltotriose, can resist high temperature and has wide action temperature range and application values in food processing, medicines, detergents and the like.

Owner:KUNMING UNIV OF SCI & TECH

Enzymatic-process preparation method for maltotriose glycosyl-beta-cyclodextrin

The invention provides an enzymatic-process preparation method for maltotriose glycosyl-beta-cyclodextrin, which belongs to the technical field of cyclodextrin. The method comprises the steps: taking pulullan polysaccharide and beta-cyclodextrin as substrates, utilizing the hydrolysis property of pullulanase to transform the pulullan polysaccharide into high-purity maltotriose, ensuring that the maltotriose and the beta-cyclodextrin are appropriately proportioned, utilizing the reverse synthesis capability of the pullulanase to connect the maltotriose with the beta-cyclodextrin through alpha-(1,6) glycosidic bonds and obtaining a maltotriose glycosyl-beta-cyclodextrin product. The method has the advantages of simplifying the preparation process of the maltotriose glycosyl-beta-cyclodextrin, along with mild controllable reaction conditions, high production security and low cost. The obtained product has the characteristics of high solubility and high security, and is applicable in food, medicaments, cosmetics, additives, flavors and fragrances, environmental protection, analytical detection and other fields.

Owner:JIANGNAN UNIV

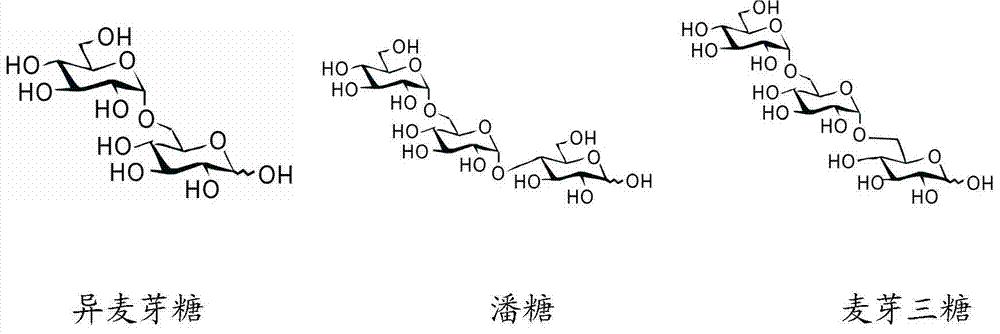

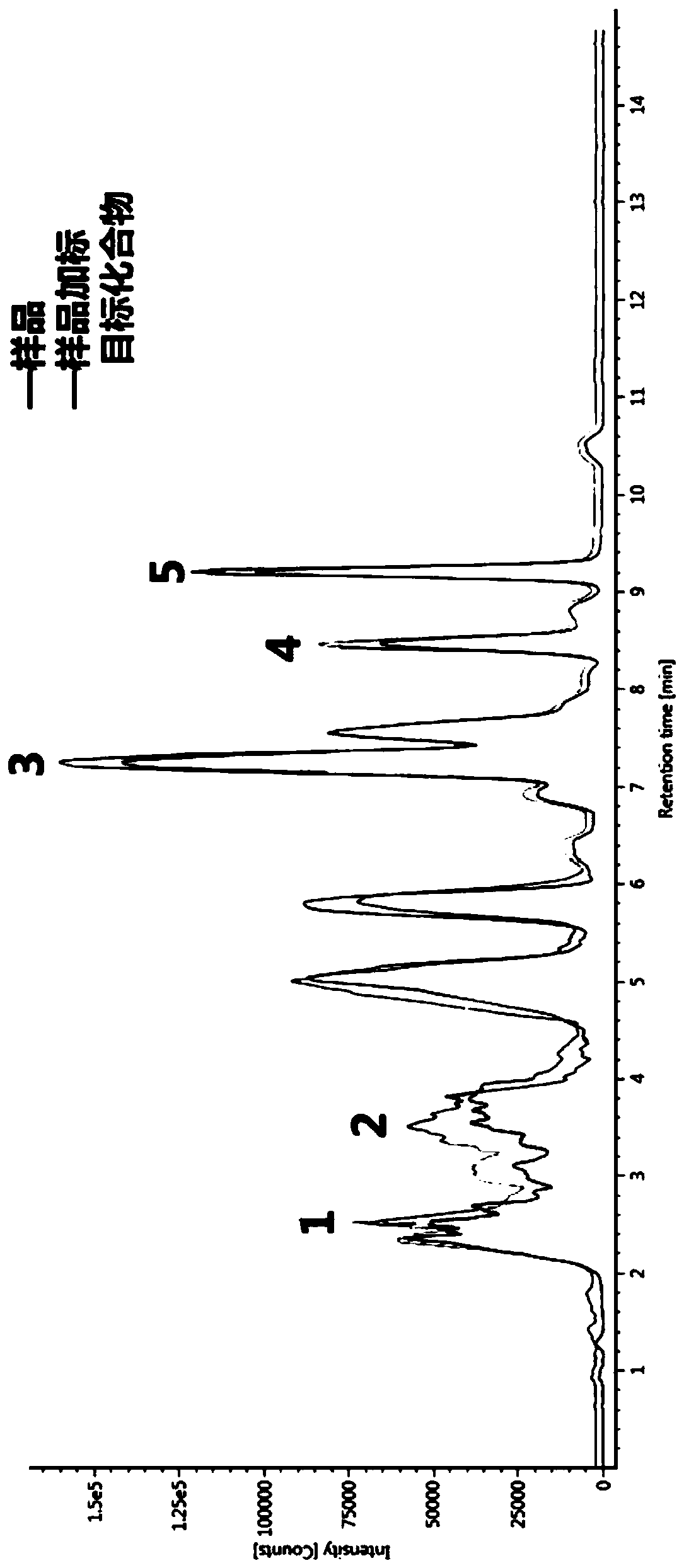

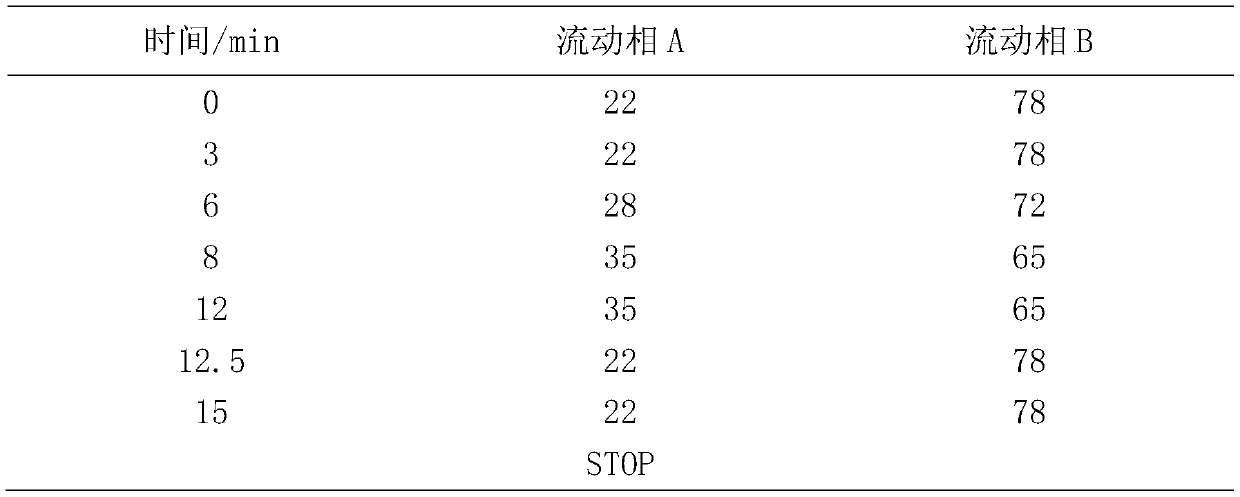

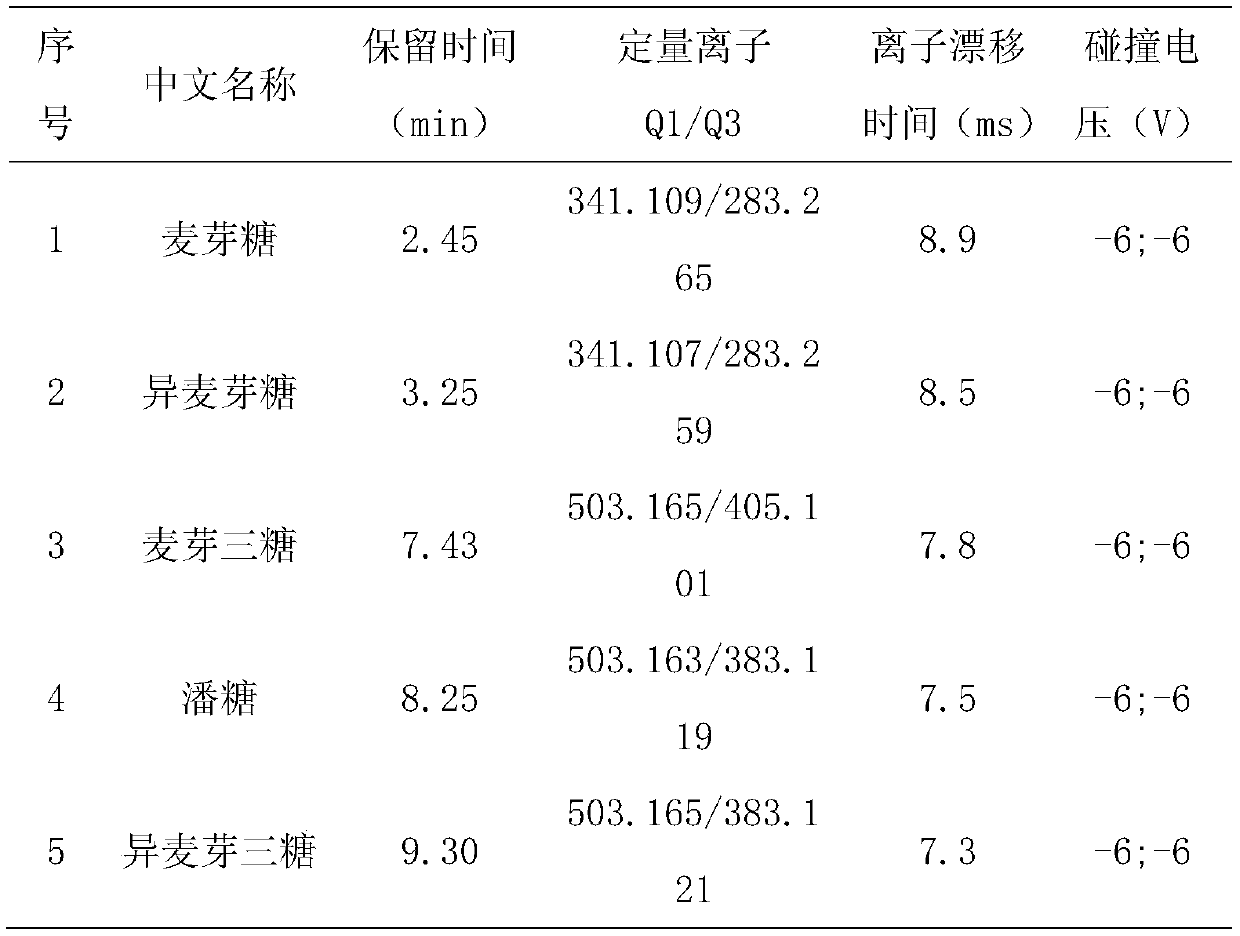

Method for analyzing isomalto-oligosaccharide and isomeride thereof in yoghourt

ActiveCN110554114ASolve problems that are difficult to distinguish accuratelyHigh sensitivityComponent separationIsomaltooligosaccharideRetention time

The invention relates to a method for analyzing isomalto-oligosaccharide and isomeride thereof in yoghourt. The method comprises the following steps: applying an ultra-high performance liquid chromatography-ion mobility-triple quadrupole mass spectrometry tandem time-of-flight mass spectrometry technology; using an HMSE mode for collecting a sample; using primary and secondary ion fragments for quantification; determining the nature by using the retention time and the ion drift time; accurately analyzing maltose, maltotriose, isomaltose, panose and isomaltotriose in the yoghourt from multipledimensions; establishing the UPLC-IMS-QTof method for isomalto-oligosaccharide in yoghourt, the blank in the field is filled, a more efficient and accurate analysis method is provided for workers in the industry, and technical support is provided for detecting the oligosaccharide content of yoghourt on the market.

Owner:广东省科学院生物与医学工程研究所

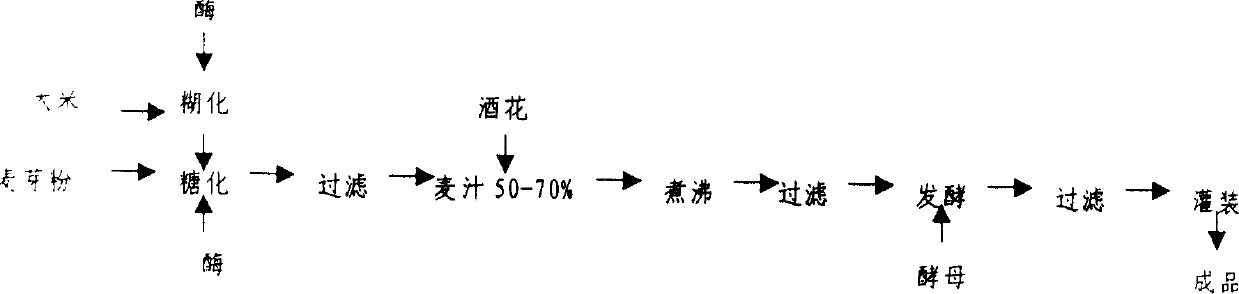

Syrup specially for beer and its prepn

InactiveCN1526808AQuality improvementReduce manufacturing costFermentationBeer brewingGlucose polymersD-Glucose

The syrup specially for beer consists of glucose 5-15 wt%, maltose 45-70 wt%, maltotriose 10-20 wt%, maltotertrose and higher maltose 10-20 wt%; contains amino nitrogen of 120-180 mg / L; and has saccharide to non-saccharide ratio of 1 to 0.15-0.35. The present invention is prepared by means of advanced bioengineering technology, has stable quality and low production cost, and may be used in replace rice and malt partially or completely in beer production. The syrup may be used in the amount over 50 % through direct addition to boiling pot to lower beer producing cost and raise beer quality.

Owner:鲁洲生物科技(山东)有限公司

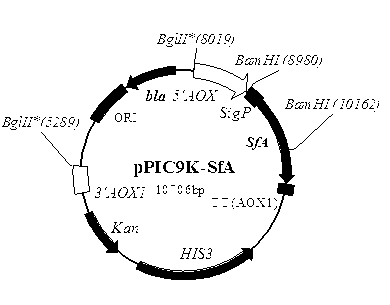

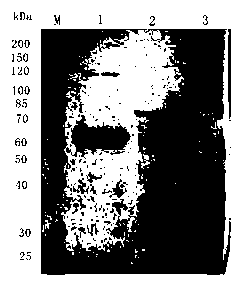

Maltotriose preparation method with starch as raw material and special fungal alpha-amylase thereof

InactiveCN103014097ASimple processReduce manufacturing costFungiMicroorganism based processesBiotechnologyActivated carbon

The invention discloses a maltotriose preparation method with starch as a raw material and a special fungal alpha-amylase thereof and belongs to the technical field of starch sugar manufacturing and enzyme engineering. The preparation method disclosed by the invention comprises the following steps: based on a variety of plant starches as raw materials, carrying out liquefaction and saccharification by utilizing fungal alpha-amylase SfA to obtain the syrup in which maltotriose accounts for 46% to 55% of the total sugar; and carrying out activated carbon adsorption and alcohol elution to obtain the syrup in which maltotriose accounts for not less than 90% of the total sugar. The invention further provides an efficient preparation method of fungal alpha-amylase SfA. The fungal alpha-amylase SfA gene is derived from sacchromycopsis fibuligera CICIMY2037, recombinant Pichia pastoris is obtained by a genetic recombination method, and the SfA efficient preparation is carried out through the recombinant strain. In comparison with the prior method, the preparation method of maltotriose with fungal alpha-amylase SfA has the advantages of low cost of raw materials, independence on starch liquefied enzyme and starch debranching enzyme, simple process and easiness in enlargement.

Owner:绿爱控股股份有限公司

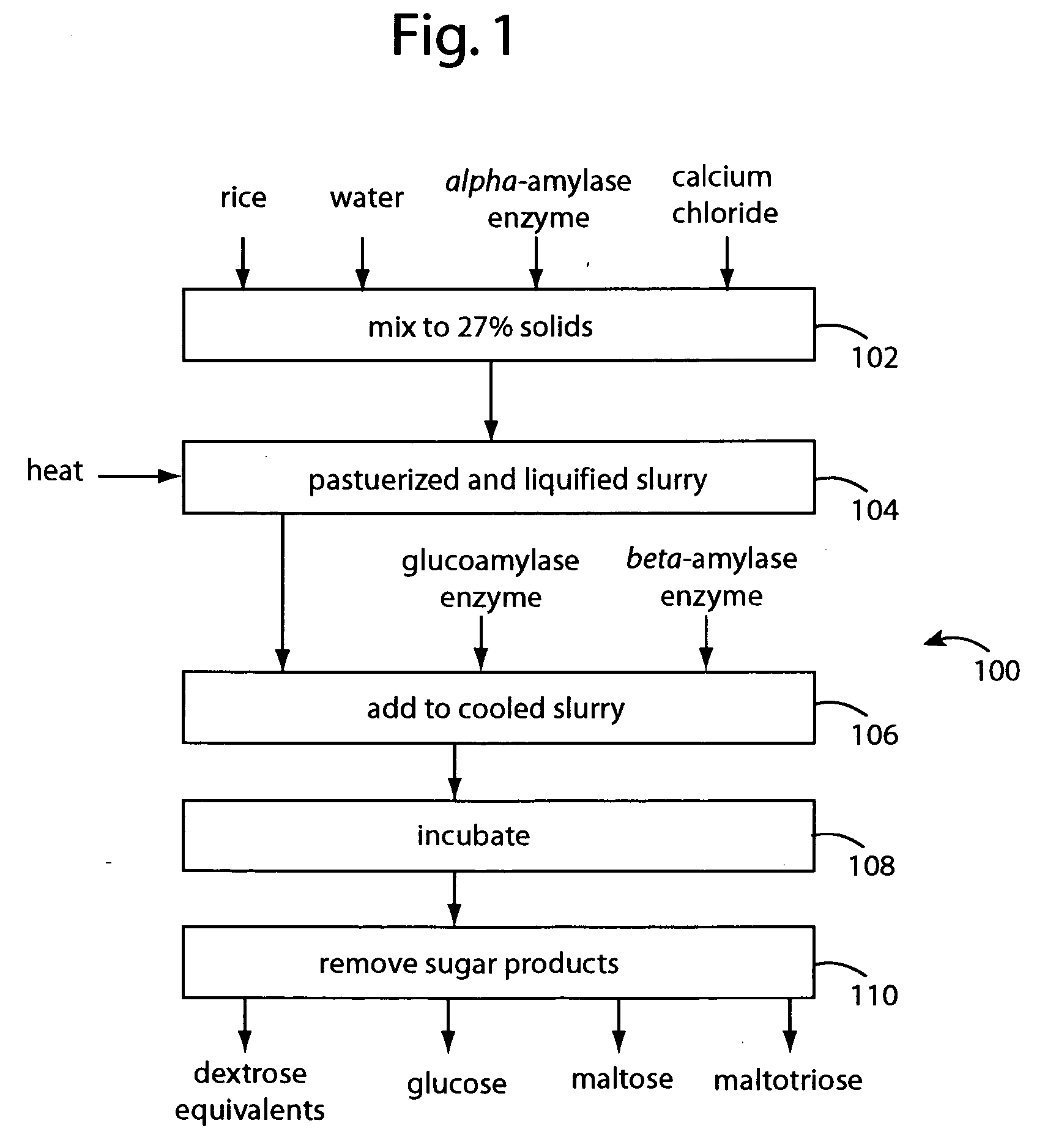

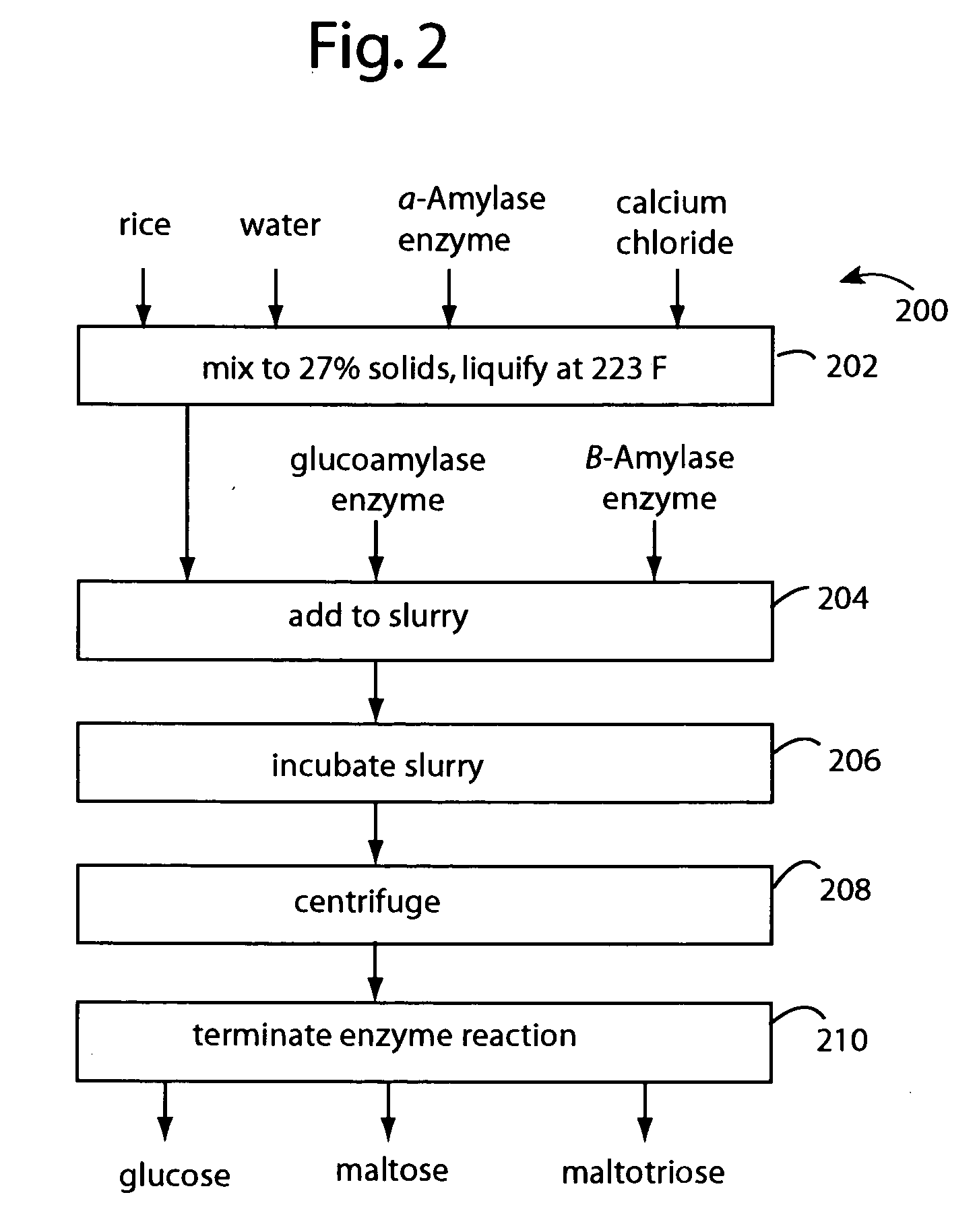

High-temperature enzyme starch-to-sugar conversion

A starch-to-sugars conversion method comprises mixing rice flour with water, alpha-amylase enzyme, and calcium chloride into a slurry with 27% solids. The slurry is liquefied at about 223° F. Glucoamylase and beta-amylase enzymes are added and the slurry is incubated. The action of the three enzymes is terminated. The slurry is centrifuged to produce dextrose equivalents, glucose, maltose, and maltotriose. The whole processing time is under two hours.

Owner:CALIFORNIA NATURAL PRODS

Novel use of maltotriosyl transferase

The purpose of the present invention is to provide a novel use of maltotriose transferase. Provided is a method for producing rice cakes or noodles, said method being characterized by comprising using a dough containing maltotriosyl transferase and carrying out a heat treatment step whereby starch in the dough is gelatinized. Also provided is a method or the like for producing an indigestible saccharide, said method being characterized by comprising carrying out a step for treating a saccharide with maltotriosyl transferase.

Owner:AMANO ENZYME INC

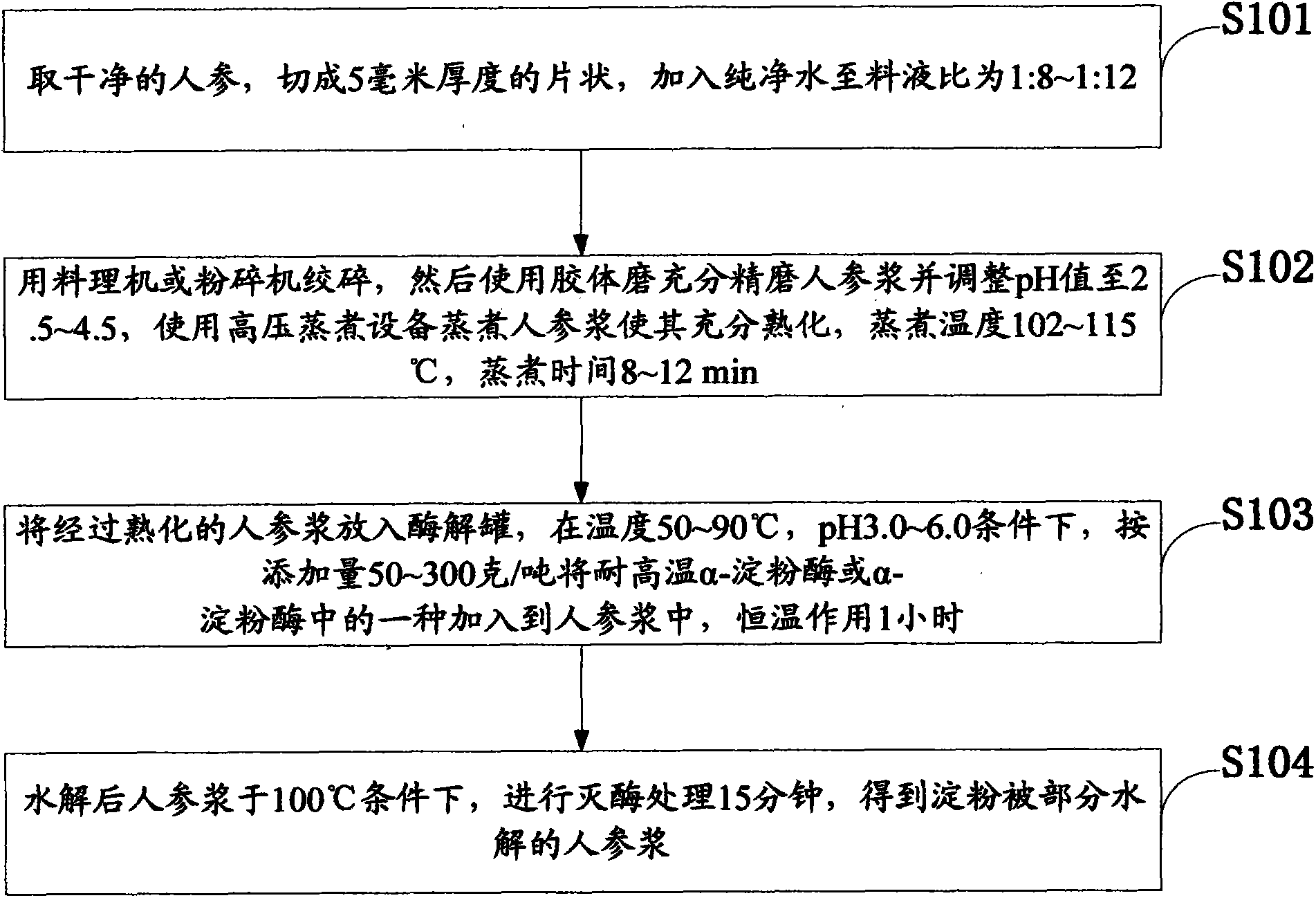

Alpha-amylase-based method for preparing ginseng slurry

ActiveCN103446209AIncrease productionReduce use costFood preparationPlant ingredientsChemical productsSlurry

The invention discloses an alpha-amylase-based method for preparing ginseng slurry. The method comprises the following steps: taking clean ginseng, cutting into sheets with the thickness of 5mm, and adding pure water till the material-liquid ratio is (1:8)-(1:12); grinding by a food processor or a grinder, then using a colloid mill to perform full fine grinding of the ginseng slurry, adjusting the pH value, and using a high-pressure stewing device to stew the ginseng slurry to fully cook the ginseng slurry, wherein the stewing temperature is 102-115 DEG C and the stewing time is 8-12min; placing the ginseng slurry after cooking into an enzymolysis tank, placing alpha-amylase into the ginseng slurry, and performing constant-temperature action for 1h; and performing enzyme inactivation treatment on the ginseng slurry after hydrolysis under the condition of 100 DEG C for 15min so as to obtain the ginseng slurry with partially hydrolyzed starch. After high temperature-resistant alpha-amylase or alpha-amylase treatment is performed on the ginseng slurry prepared by the method disclosed by the invention, macromolecular starch is degraded into maltose, maltotriose and alpha-dextrin, the yield of glucose during the later-stage saccharification treatment process is increased, the using cost of chemical products, namely acids and bases is reduced, and the emission quantity of waste liquid is reduced.

Owner:白山市弘源现代农业发展有限公司

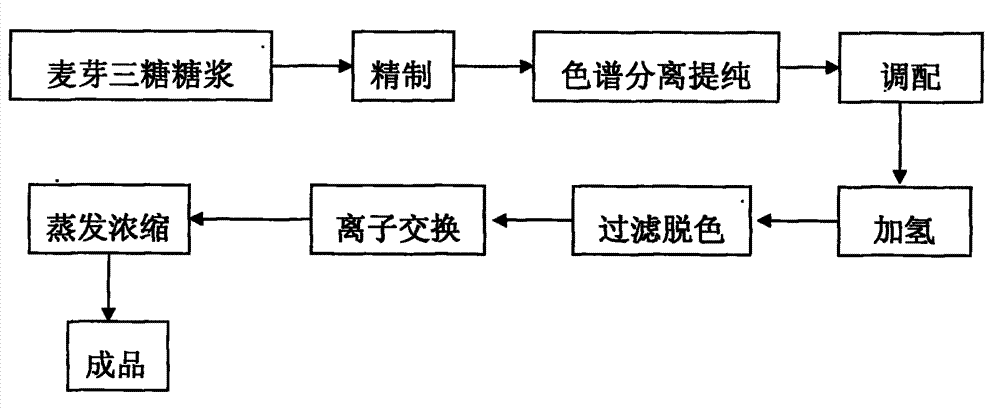

Preparation method of high-purity maltotriose alcohol

InactiveCN103204886AHigh purityLow in miscellaneous sugarsSugar derivativesSugar derivatives preparationChromatographic separationAlcohol sugars

The invention provides a preparation method of high-purity maltotriose alcohol. The preparation method comprises the following steps of: (a) chromatographing and purifying: separating maltotriose from maltotriose and maltose by utilizing the chromatography technology to obtain maltotriose liquid with the component being more than 90%; (b) hydrogenating: carrying out hydrogenating reaction on the purified maltotriose to prepare the high-purity maltotriose alcohol by taking skeletal nickel as a catalyst under the conditions of the temperature being 80-130 DEG C and the pressure being 8-12Mpa; and (c) refining: carrying out activated carbon decoloration filtering, ion exchange desalination and vacuum concentration on the obtained high-purity maltotriose alcohol liquid to obtain a high-purity maltotriose alcohol product. Compared with the common sugar alcohol, the high-purity maltotriose alcohol prepared by the invention has the characteristics of high-purity single sugar alcohol, less micromolecule sugar alcohol, good hygroscopicity and moisturizing properties, low sweetness, good heat resistance and acid resistance, and the like.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com