Alpha-amylase-based method for preparing ginseng slurry

An amylase and ginseng technology, which is applied in the field of preparing ginseng pulp based on alpha-amylase, can solve the problems that the functional components of ginseng cannot be fully utilized, the production cycle is long, the consumption of raw materials is large, etc. The effect of environmental protection pressure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

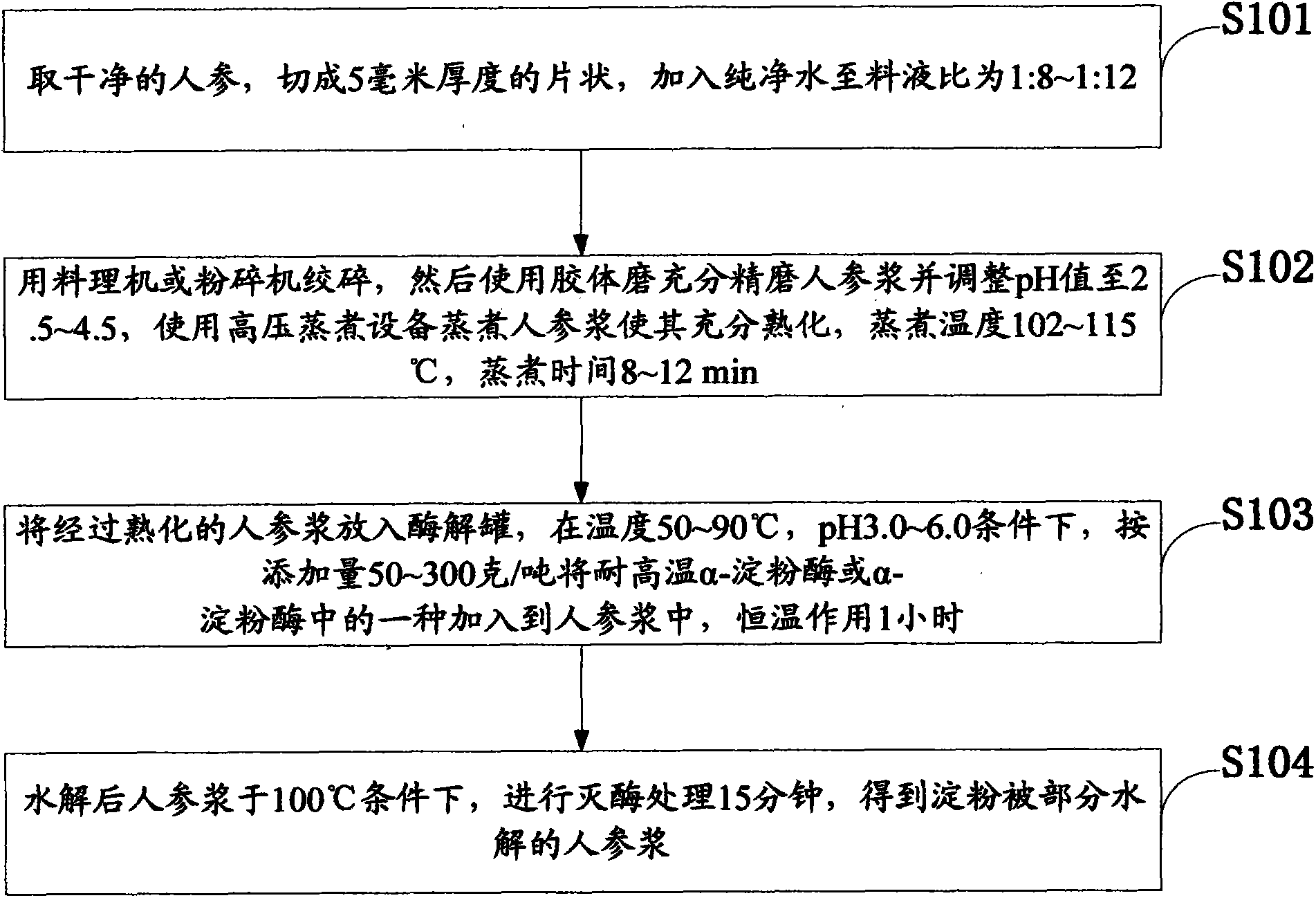

Method used

Image

Examples

Embodiment 1

[0040] Take 1 kg of fresh Northeastern ginseng, cut it into slices about 5 mm thick, add 10 liters of pure water, grind it with a cooking machine or a grinder, then use a colloid mill to fully finely grind the ginseng pulp, and use 10% edible citric acid solution Adjust the pH value to 3.5, use high-pressure cooking equipment to cook the ginseng pulp, the cooking temperature is 110°C, and the cooking time is 10 minutes, adjust the pH of the matured ginseng pulp to 6.0 with sodium bicarbonate solution, and at a temperature of 75°C, add 3 grams of Add high-temperature-resistant α-amylase to ginseng pulp, and keep the temperature constant for 1 hour. After hydrolysis, the ginseng pulp is treated at 100° C. for 15 minutes to inactivate the enzyme to obtain 10,200 ml of ginseng pulp with partially hydrolyzed starch.

Embodiment 2

[0042] Take 300 grams of American ginseng and white dry ginseng, cut into flakes with a thickness of about 5 mm, add 10 liters of purified water, use a food processor to fully pulverize the material to a uniform slurry, use 10% edible citric acid, 15% lactic acid compound solution to adjust pH value to 3.5, use high-pressure cooking equipment to cook ginseng pulp, cooking temperature 108 ° C, cooking time 12 minutes, adjust the pH of the mature ginseng slurry to 6.0 with sodium bicarbonate solution, and α-starch under the condition of temperature 52 ° C Enzymes were added to the ginseng pulp and kept at a constant temperature for 1 hour. The hydrolyzed ginseng pulp was treated at 100° C. for 15 minutes to inactivate the enzyme to obtain 10,400 ml of starch partially hydrolyzed ginseng pulp.

Embodiment 3

[0044] Take 1 kg of fresh Korean ginseng, cut it into slices with a thickness of about 5 mm, add 10 liters of purified water, use a food processor to fully pulverize the material to a uniform slurry, use 10% edible citric acid solution, and adjust the pH value to 3.5, Use high-pressure cooking equipment to cook ginseng pulp, cooking temperature 103 ° C, cooking time 10 minutes, adjust the pH of the mature ginseng pulp to 6.0 with sodium bicarbonate solution, and add 1.0 g of α-amylase to the mixture at a temperature of 55 ° C. The ginseng slurry was subjected to constant temperature for 1 hour, and the hydrolyzed ginseng slurry was subjected to an enzyme-inactivating treatment at 100°C for 15 minutes to obtain 10,300 ml of starch partially hydrolyzed ginseng slurry.

[0045]The positive effect of the present invention is that after the ginseng slurry is treated with high-temperature-resistant α-amylase or α-amylase, the macromolecular starch is degraded into maltose, maltotrios...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com