Method for preparing alpha-amylase by high-temperature laceyella sacchari RHA1 virus strain and purification method thereof

A kind of technology of Saccharomyces saccharomyces and purification method, which is applied in the field of applied microorganisms, and can solve the problems of no high-temperature actinomycetes and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Isolation, screening and identification of Saccharomyces saccharomyces hyperthermia strain RHA1:

[0035] Thermoactinomycetes RHA1 strain, isolated from Tengchong Hot Spring. Strain selection medium is (g / L): (NH 4 ) 2 SO 4 , 1.3; peptone, 1; soluble starch, 4; KH 2 PO 4 , 0.276; MgSO 4 ·7H 2 O, 0.25; yeast extract, 1; Na 2 MoO 4 2H 2 O, 0.000025; CuSO 4 , 0.000016; MnSO 4 ·H 2 O, 0.0022; H 3 BO 3 , 0.0005; ZnSO 4 ·7H 2 O, 0.0005; CoCl 2 ·6H 2 O, 0.000046; CaSO 4 ·H 2 O, 0.06; FeSO 4 , 0.099; pH7.5. The culture conditions are temperature 50° C., shaking culture at 150 rpm, and the culture time is about 18 hours.

[0036] The bacterial system identification method was used to identify the RHA1 strain of Saccharomyces thermoactinoides. The morphological characteristics of the bacteria are as follows: the white cloth is transparent, wrinkled, dry on the surface, and the front and back colors are different, Gram-positive bacteria. Observed by electro...

Embodiment 2

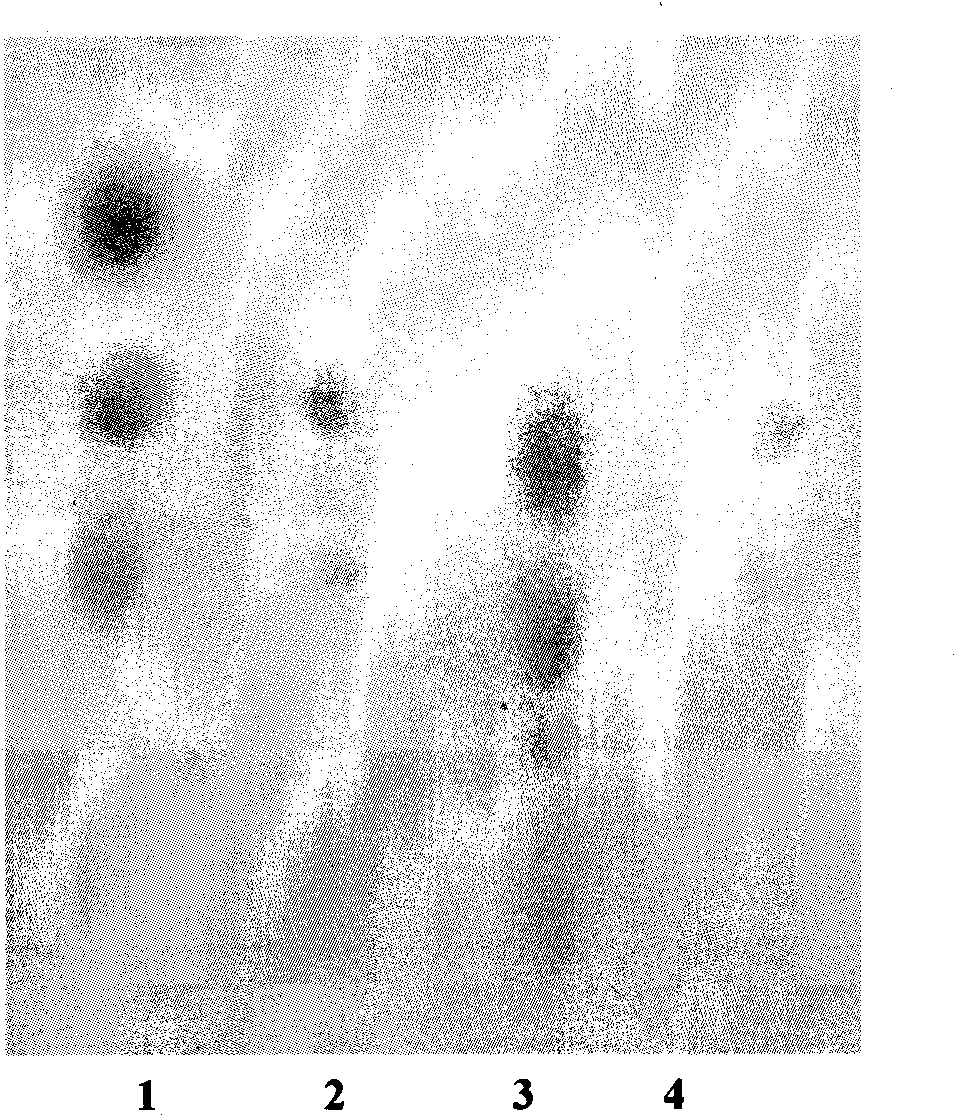

[0038] Purification of α-amylase:

[0039] (1) Concentration by ultrafiltration: the fermentation and culture conditions of the hyperthermic actinomycetes RHA1 strain are temperature 50° C., pH 7.5, and the culture time is about 18 hours. Centrifuge the fermentation broth, take the supernatant, and use a 10KDa ultrafiltration membrane bag for ultrafiltration and concentration.

[0040] (2) Ammonium sulfate precipitation: Add ammonium sulfate to the concentrated liquid to 40% saturation, centrifuge to take the supernatant, continue to add ammonium sulfate to 60% saturation, centrifuge to discard the supernatant, and finally use pH7.0 phosphate buffer for precipitation The solution was dissolved to make a crude enzyme solution.

[0041] (3) Superdex 7510 / 300 gel filtration chromatography: centrifuge the obtained crude enzyme solution, concentrate the supernatant, and load it on a Superdex 7510 / 300 gel pre-equilibrated with 50mM, pH7.0 phosphate buffer Filter the chromatographi...

Embodiment 3

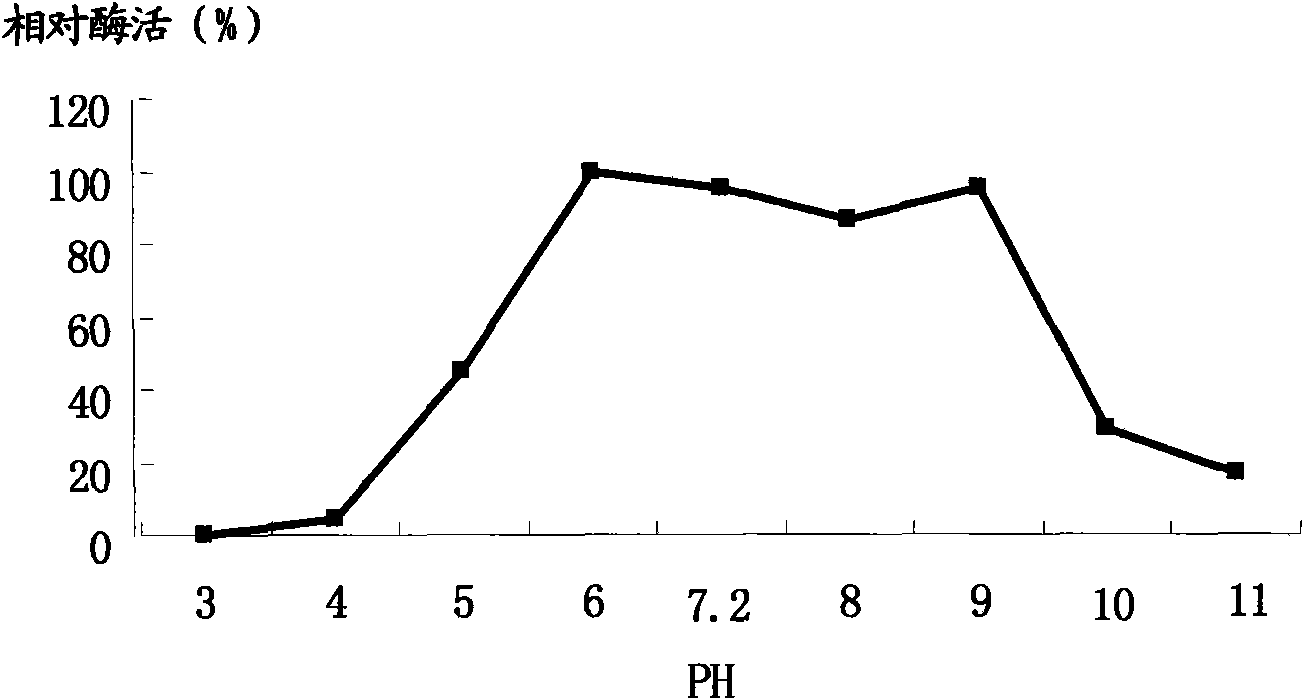

[0045] Characteristics of α-amylase:

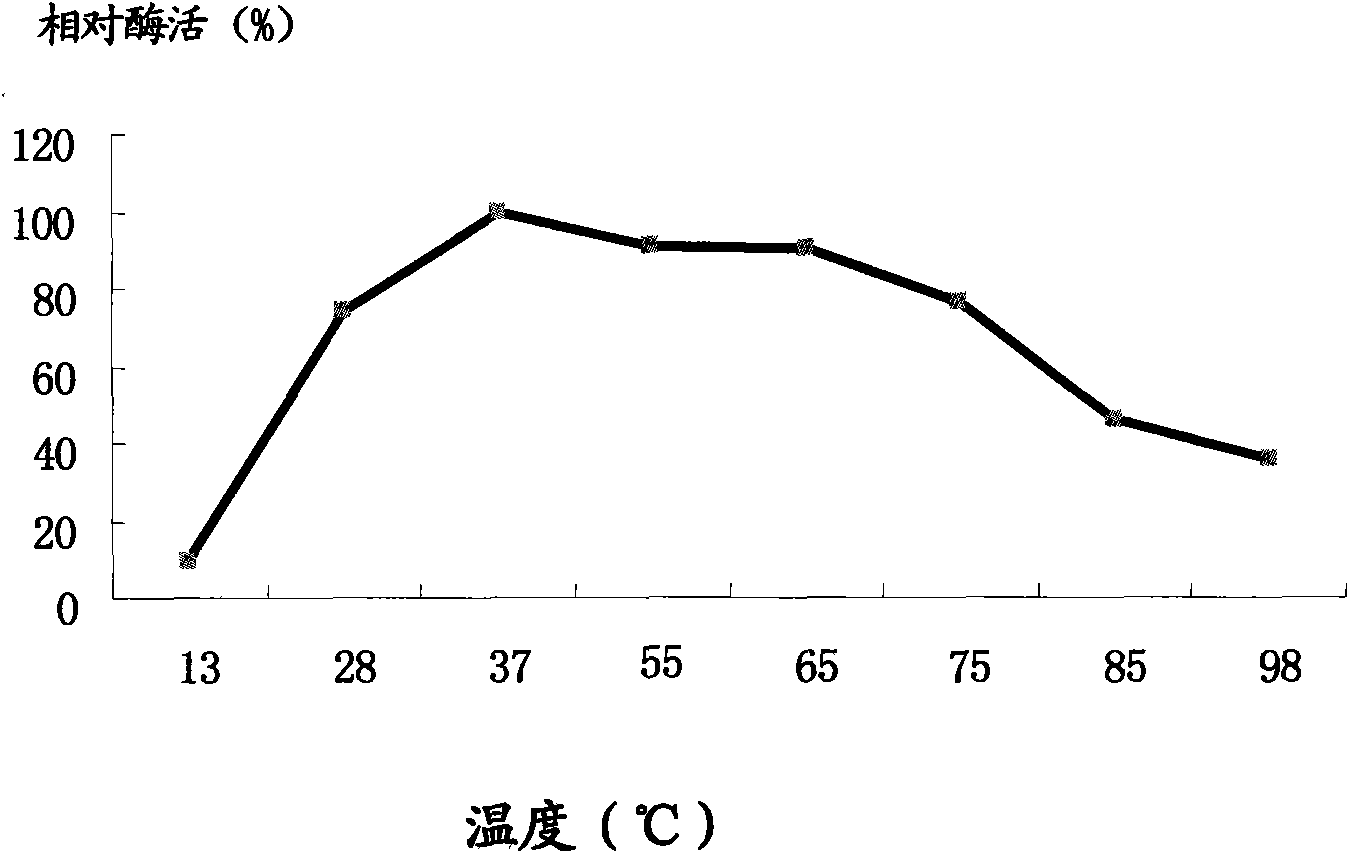

[0046] ①Optimum enzyme activity temperature

[0047] Add enzyme liquid to phosphate buffer (50mM phosphate buffer, pH 7.0), use soluble starch as substrate, under the condition that the substrate concentration is 1%, measure the amylase produced by RHA1 strain at 28-98 Enzyme activity at different temperatures in the °C range. The result is as figure 1 As shown, it shows that the optimum enzyme activity temperature of the α-amylase is 37°C.

[0048] ②Thermal stability

[0049] Add the enzyme solution to phosphate buffer (50mM phosphate buffer, pH 7.0), keep it warm in constant temperature water baths at different temperatures, take samples at different times (0-90min, sampling interval is 15min), and then follow the standard Enzyme activity assay method to measure enzyme activity. The effect of temperature on enzyme stability is expressed as the percentage of remaining enzyme activity in the original enzyme activity after a certain p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com