Reduced sugar pre-sweetened breakfast cereals comprising tri- and tetra saccharides and methods of preparation

a technology of triand tetrasaccharides and breakfast cereals, which is applied in the field of food products and has a reduced sugar coating composition and a triand tetrasaccharide technology, can solve the problems of high sugar content of finished products, lack of bite or crispness of finished products containing such substitutes, and lack of bowl life of milk products, etc., to achieve the effect of reducing the sugar coating and high potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

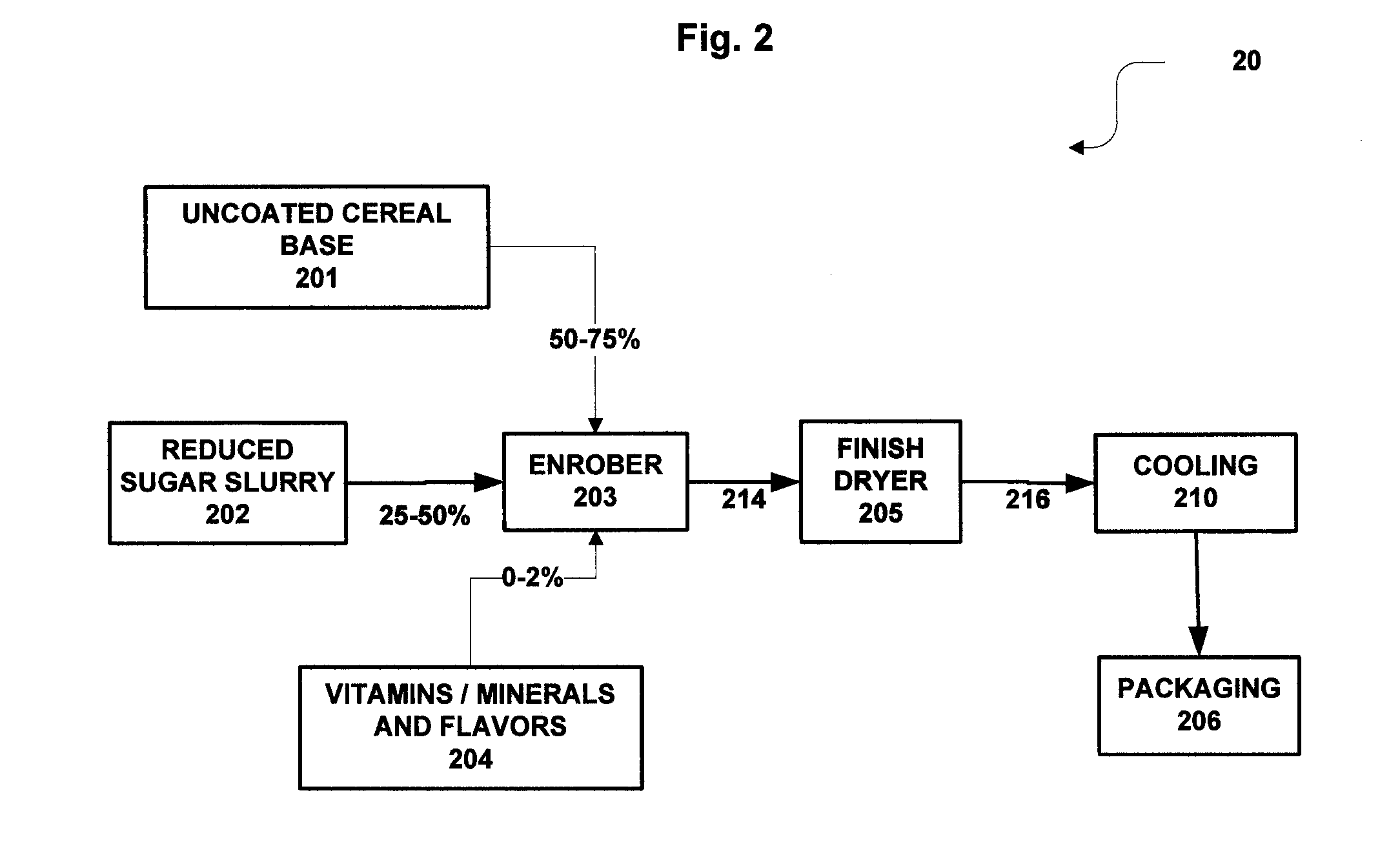

[0022]The present invention relates to a reduced-sugar coating or binder prepared from a slurry that includes a reduced-sugar composition comprising sucrose sugar as its principal ingredient, and further including a DP3 and / or a DP4 carbohydrate such as maltotriose, maltotetrose in full or partial substitution for the sucrose, and at least one high-potency sweetener. Other ingredients such as such as other carbohydrates, triglycerides, vitamins, minerals, and flavors can be added to the coating composition to provide the coating composition and / or mixed with the cereal base or other product components to enhance the finished product's organoleptic properties or nutritional value.

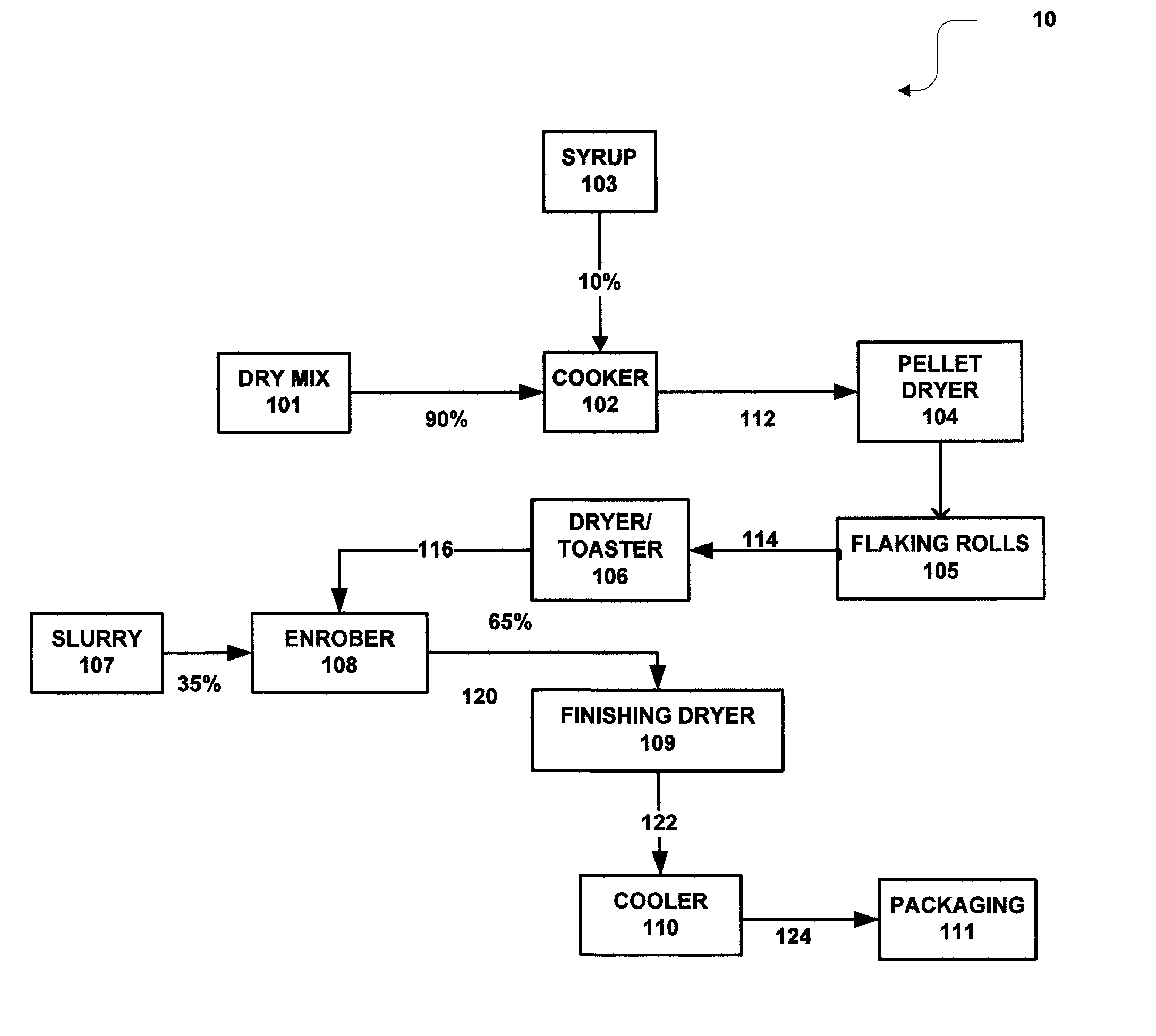

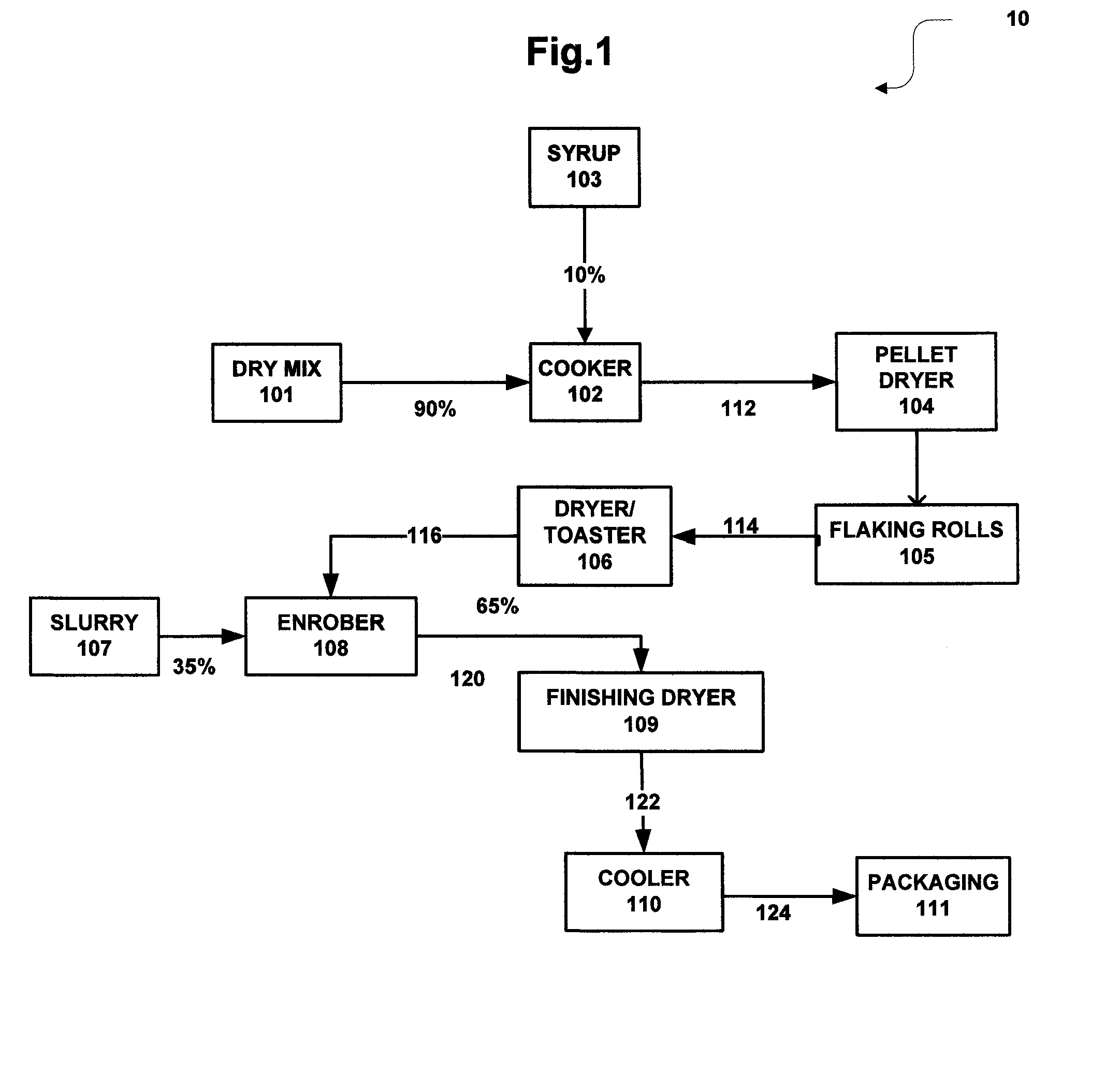

[0023]In the following detailed description, reference is made to the accompanying drawings that form a part hereof, and in which are shown by way of illustration specific embodiments or examples. These embodiments can be combined, other embodiments can be utilized, and structural, logical, and procedural ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com