Preparation method of high-purity maltotriose alcohol

A maltotriitol and maltotriose technology, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problem of low maltotriitol content, inability to fully exert physical and chemical properties, and failure to market and other problems, to achieve the effect of low sweetness, low miscellaneous sugar content, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

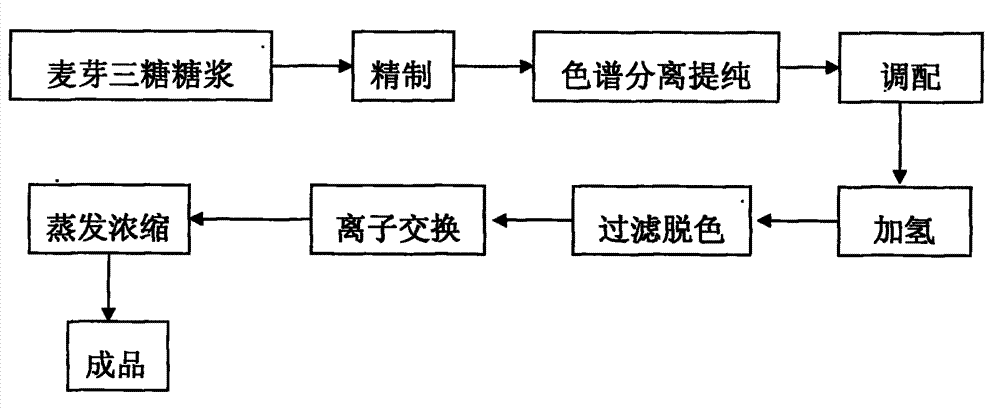

Image

Examples

Embodiment 1

[0017] Ordinary maltotriose crude liquid, the content of each component is about 70% maltotriose, about 22% for glucose and maltose, DP 4 -DP 8 about 8%.

[0018] Take the refined maltotriose, adjust the mass percentage of the syrup to 56% with secondary reverse osmosis water, heat up to 60°C, use calcium-type cationic resin as the separation resin, and secondary reverse osmosis water as the eluent, pass through the column, Purified maltotriose was obtained. The purified maltotriose, detected by high performance liquid chromatography, its composition is glucose 0%, maltose 0.2%, maltotriose 91.8%, DP 4 -DP 8 8%.

[0019] Adjust the mass percentage of the purified maltotriose to 40% with two-stage reverse osmosis water, adjust the pH to 8.0 with reagent grade sodium hydroxide, inject 2 / 3 volume of sugar solution into the reaction kettle, and use nitrogen to remove the air 3 times, and then use hydrogen to exclude nitrogen, so that the hydrogen concentration can reach more...

Embodiment 2

[0025] Ordinary maltotriose crude liquid, the content of each component is about 70% maltotriose, about 22% for glucose and maltose, DP 4 -DP 8 about 8%.

[0026] Take the refined maltotriose, adjust the mass percentage of the syrup to 55% with secondary reverse osmosis water, heat up to 59°C, use calcium-type cationic resin as the separation resin, and secondary reverse osmosis water as the eluent, pass through the column, Purified maltotriose was obtained. The purified maltotriose, detected by high performance liquid chromatography, its composition is glucose 0%, maltose 0.1%, maltotriose 92.2%, DP 4 -DP 8 7.7%.

[0027] Adjust the mass percentage of the purified maltotriose to 40% with two-stage reverse osmosis water, adjust the pH to 7.9 with reagent grade sodium hydroxide, inject 2 / 3 volume of sugar solution into the reaction kettle, and use nitrogen to remove the air 3 times, and then use hydrogen to exclude nitrogen, so that the hydrogen concentration can reach mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com