Method for using pulullan to prepare high-purity maltotriose

A technology of pullulan and maltotriose, which is applied in the preparation of sugar derivatives, chemical instruments and methods, oligosaccharides, etc., can solve the problems of not being able to be used as diagnostic reagents, difficulty in separation and extraction, and difficulty in extraction, etc. Low, high product purity, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

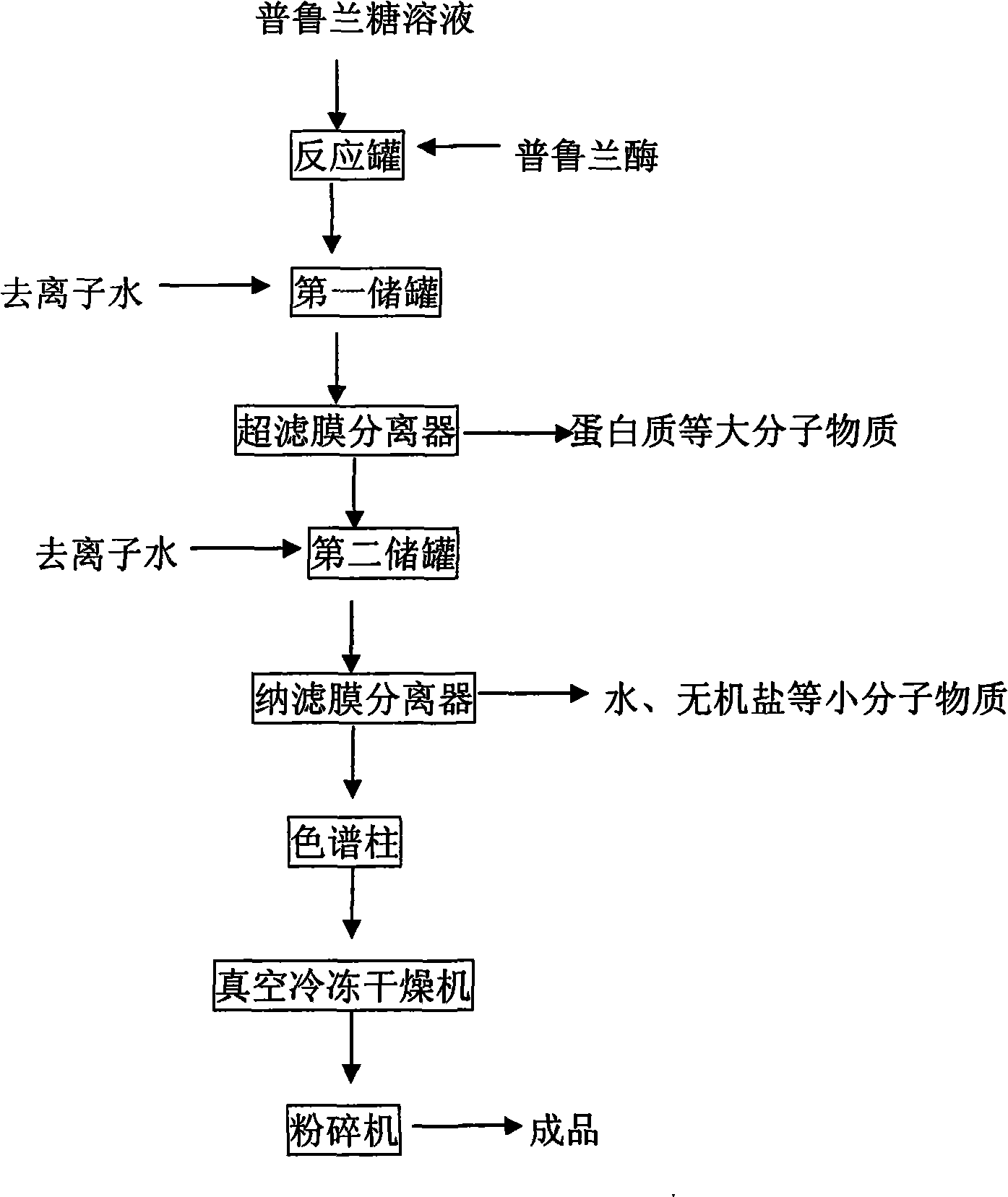

Method used

Image

Examples

Embodiment 1

[0018] (1) Dissolve 8kg of pullulan in 92kg of 0.2M pH5.7 phosphate buffer (dissolution and reaction are carried out in the same tank, the tank volume is 150L, with stirring), and it is prepared to have a mass percent concentration of 8 % pullulan polysaccharide solution, then add 250g pullulanase, keep the temperature between 45~48°C, stir constantly, and the reaction time is 8 hours;

[0019] (2) After the reaction is over, the reaction liquid is pumped into the first storage tank, and then pumped into the ultrafiltration membrane separator by the first storage tank. The molecular weight cut-off of the membrane is 5000D, and the retained liquid is returned to the tank. Molecular salts and water permeate the membrane, and the permeate is collected in the second storage tank. During this process, deionized water is continuously added to the first storage tank. The amount of deionized water added is 50% of the liquid volume, when the residual amount of maltotriose in the rete...

Embodiment 2

[0023] (1) Dissolve 6.4kg of pullulan in 73.6kg of 0.2M pH5.7 phosphate buffer (dissolution and reaction are carried out in the same tank, the tank volume is 150L, with stirring), and it is prepared as a mass percent concentration 8% pullulan polysaccharide solution, then add 200g pullulanase, keep the temperature between 45-48°C, keep stirring gently, and the reaction time is 8 hours;

[0024] (2) After the reaction is over, the reaction liquid is pumped into the first storage tank, and then pumped into the ultrafiltration membrane separator by the first storage tank. The molecular weight cut-off of the membrane is 7000D, and the retained liquid is returned to the tank. Molecular salts and water permeate the membrane, and the permeate is collected in the second storage tank. During this process, deionized water is continuously added to the first storage tank. The amount of deionized water added is 50% of the liquid volume, when the residual amount of maltotriose in the rete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com