Syrup specially for beer and its prepn

A technology for syrup and beer, which is applied in the field of malt syrup containing α-amino nitrogen and its preparation, which can solve the problems that the production cost cannot be reduced, the comparison cost is not obvious, and the application and promotion are limited, so as to improve the utilization rate of equipment and omit wort Effect of filtering process and cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

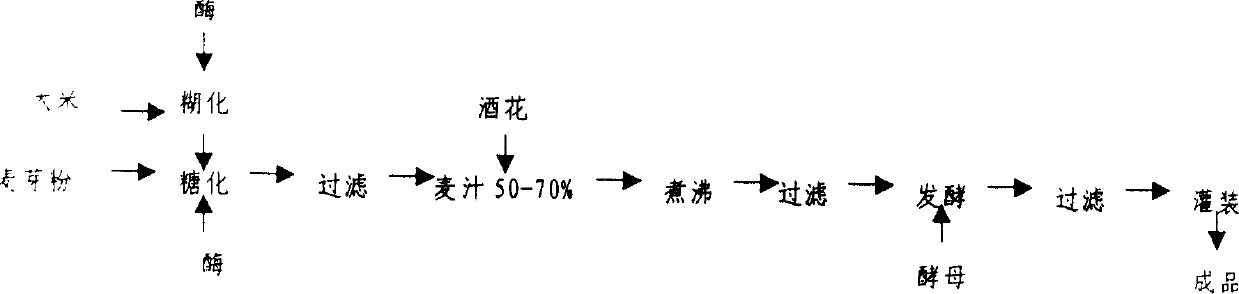

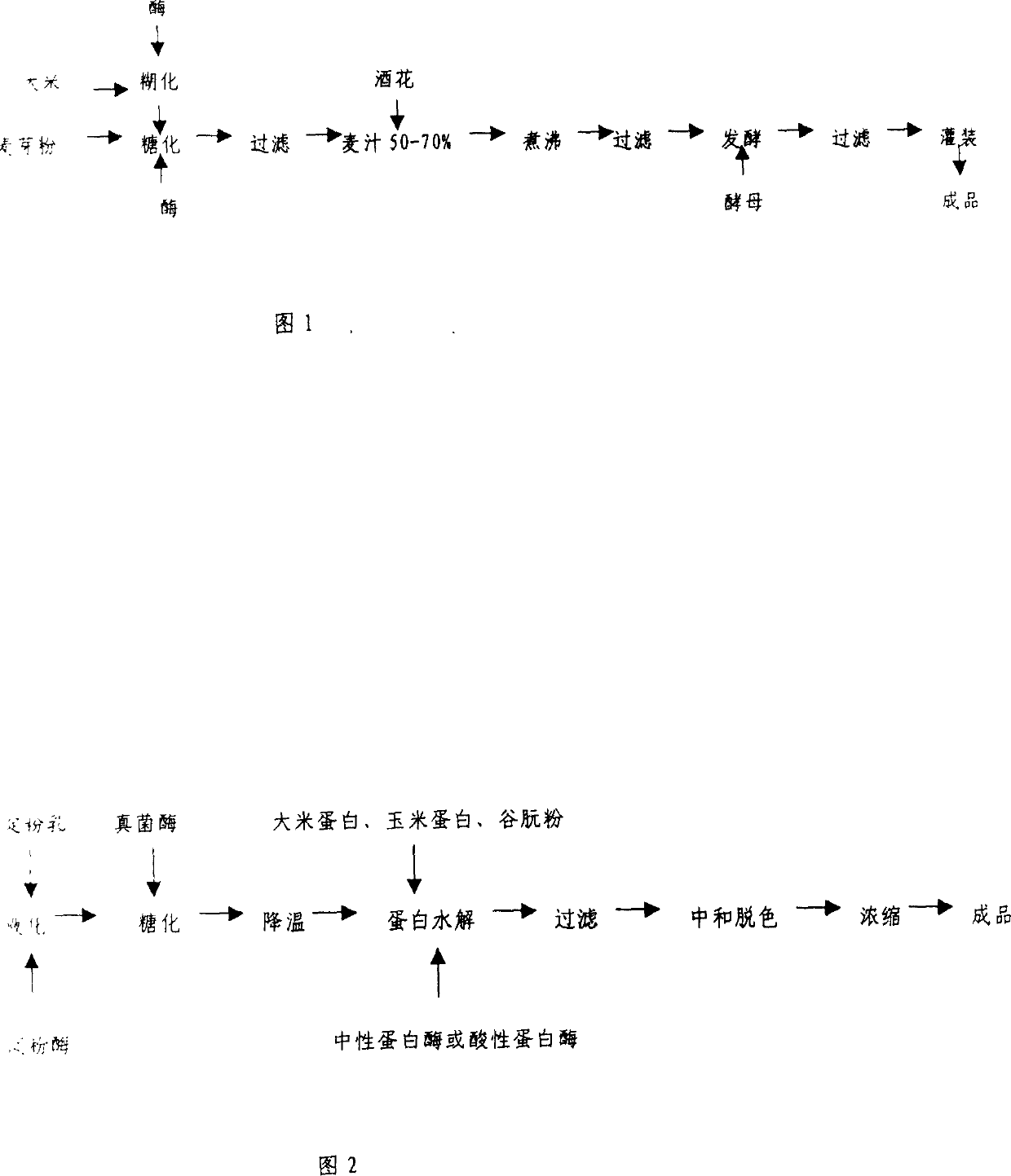

[0026] As shown in Figure 2, the present invention is a special syrup for beer, and its components are: 5-15% of glucose; 45-70% of maltose; 10-20% of maltotriose; Nitrogen 120~180mg / L (10% solids); sugar: non-sugar 1: 0.15~0.35.

[0027] A preparation method of special syrup for beer, characterized in that:

[0028] A. The concentration of starch milk is 16-20°Be', add α-amylase 400-800ml / T (dry base starch) for continuous jet liquefaction, the temperature is 70-110°C, and the time is 20-120 minutes;

[0029] B. Add fungal enzyme 200-500ml / T (dry sugar) for saccharification, the saccharification time is 12-48 hours, the saccharification temperature is 40-80°C, and the pH value is 4.5-7.0;

[0030] C, saccharification is finished, add zein, rice protein, gluten (weight ratio 6: 2: 2) that account for 5% to 30% of dry base sugar in the saccharification tank, then add acid or neutral protease, and its amount is mixed 0.2-1% of the protein, hydrolyzed at 35-70°C, and the hydrol...

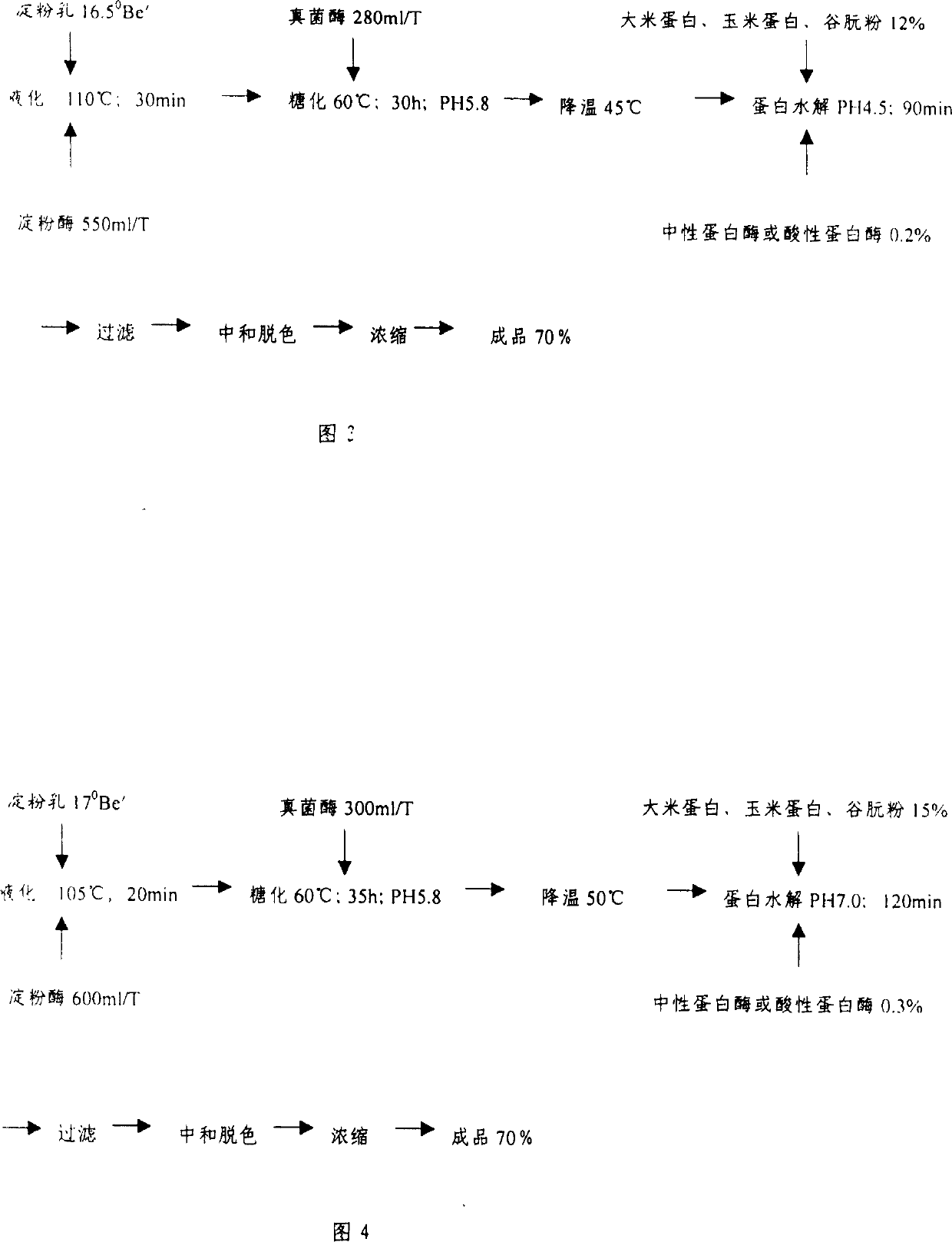

Embodiment 2

[0034] Its quality index of special syrup for beer of the present invention is: glucose 5~15%; Maltose 45~70%; Maltotriose 10~20%; Tetrasaccharide above 10~20%; solid matter); sugar: non-sugar 1: 0.15~0.35.

[0035] As shown in Figure 4, as the production of α-amino nitrogen 150mg / L (10% solids), beer special syrup with 70% dry matter, the following preparation method is required: A, starch milk concentration 17 ° Be ', add α - Amylase 600ml / T (starch on a dry basis) for continuous jet liquefaction at a temperature of 105°C for 20 minutes. B. Add fungal enzyme 300ml / T (dry sugar) for saccharification, saccharification time 35h, saccharification temperature 60°C, pH 5.8. C. After the saccharification is complete, add corn protein, rice protein, and gluten (weight ratio 6:2:2) that account for 15% of the dry sugar in the saccharification tank, adjust the pH to 7.0 and then add neutral protease in an amount of mixed protein 0.3% of the hydrolysis at 50 ° C, hydrolysis time 120m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com