Patents

Literature

60results about How to "Fully liquefied" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

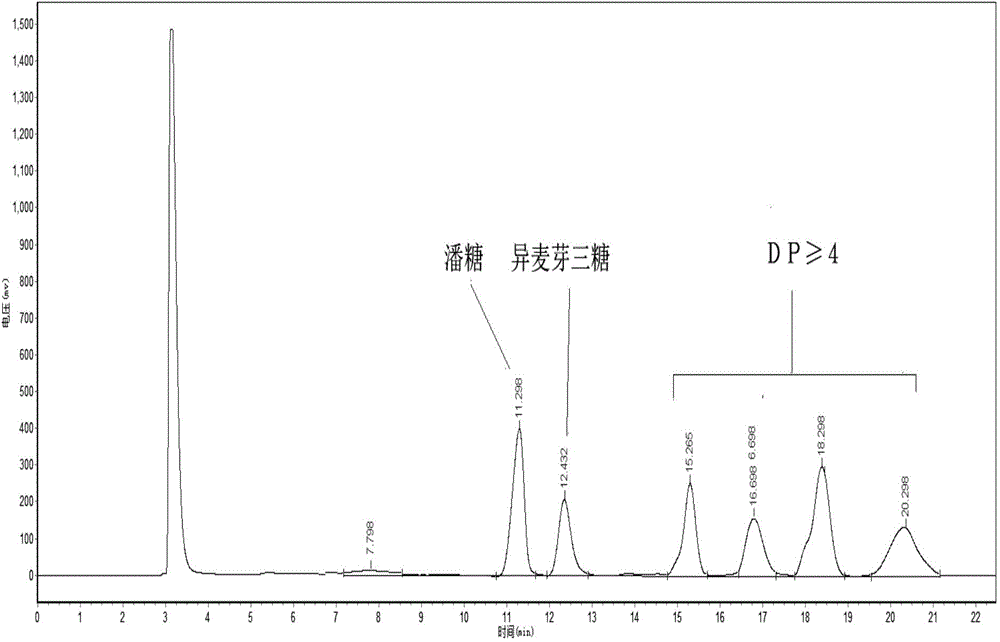

Preparation method of isomaltooligosacharide

ActiveCN104152512AIncrease contentIncrease concentrationFermentationChromatographic separationIsomaltooligosaccharide

The invention relates to a preparation method of isomaltooligosacharide. The preparation method comprises the following steps of 1, adding water into a starch raw material, adjusting a concentration and a pH value of the slurry, and adding high temperature-resistant alpha-amylase into the slurry to obtain starch slurry, 2, carrying out liquidation on the starch slurry to obtain a liquefied liquid, 3, adding maltotriose generation enzyme (AMANO AMT1.2L) and pullulanase (GENENCOR OPTIMAX L-1000) into the liquefied liquid, carrying out thermal-insulation saccharification, and carrying out enzyme denaturalixation to obtain a saccharified liquid, 4, adding alpha-glucosidetransferase into the saccharified liquid for a reaction to produce a primary trans-glucoside saccharified liquid, adding alpha-glucosidetransferase into the primary trans-glucoside saccharified liquid for a reaction, and carrying out enzyme denaturalixation to obtain a trans-glucoside saccharified liquid, and 5, carrying out decoloration on the trans-glucoside saccharified liquid, carrying out filtration, carrying out ion exchange, carrying out chromatographic separation, carrying out concentration and carrying out drying to obtain isomaltooligosacharide. The preparation method greatly improves contents of sugars such as panose, isomaltotriose and tetrasaccharide having polymerization degrees greater than or equal to 3 in the reaction product liquid.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

Preparation method of syrup special for moon cake

The invention relates to the field of starch sugar manufacturing, in particular to a preparation method of syrup special for moon cake. According to the method, corn starch is taken as the raw material, and the syrup is prepared through the steps such as size mixing, enzyme immersion, liquefaction, saccharification, glucoside conversion, decolorization, filtering, ion exchange, concentration, blending and the like. The prepared syrup comprises 20-25% of maltobiose, 12-17% of maltotriose, 15-20% of maltotetraose, 8-12% of tetrasaccharide-above, 3-5% of oligoisomaltose, 25-30% of fructose, and less than 3% of glucose. The syrup special for moon cake produced through the method is sucrose-free; the sweetness is slightly lower than that of the sucrose; the sweet taste is mild and pure, cool and refreshing; and the syrup is provided with a sweet flavor peculiar to honey, and has the advantages that the oil return property is obvious, the moisture retention property is good, the starch retrogradation is prohibited, the shelf life and the quality guarantee period of products are effectively prolonged, and the like.

Owner:BAOLINGBAO BIOLOGY

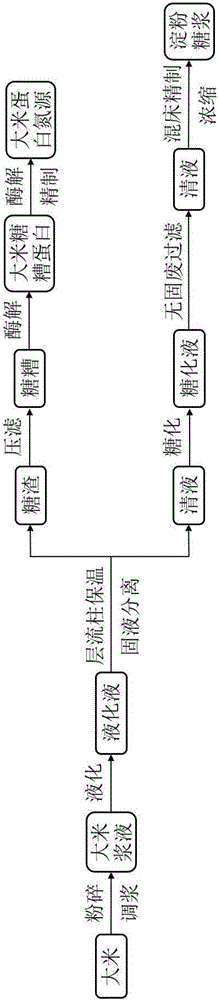

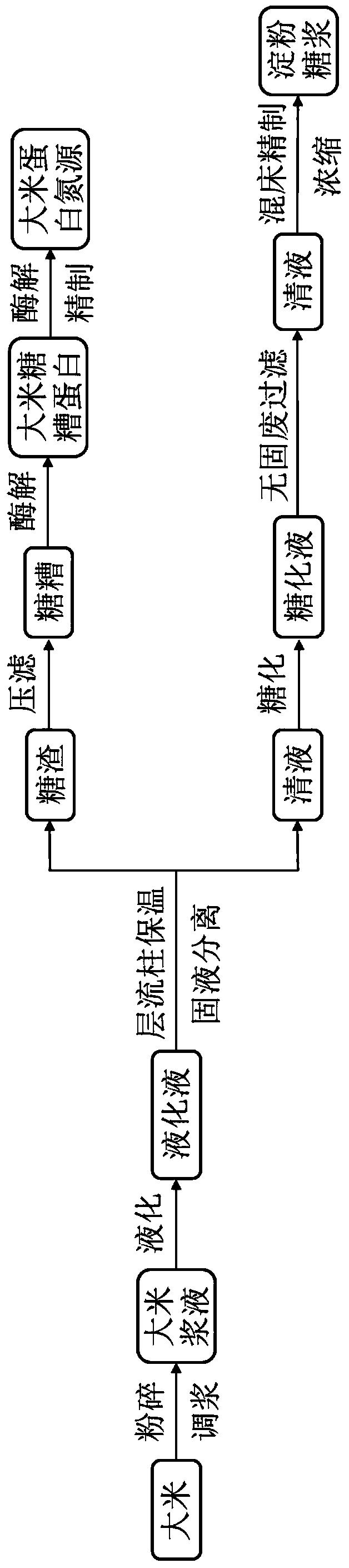

Production process for preparing starch syrup from rice

ActiveCN106191159AIncrease added valueHigh solid contentFermentationHigh concentrationAdditional values

The invention discloses a production process for preparing starch syrup from rice. The production process comprises the following steps: (1) crushing and pulping; (2) liquefying; (3) carrying out column laminar flow heat preservation and solid-liquid separation; (4) extracting a rice protein nitrogen source; (5) saccharifying; (6) carrying out solid-waste-free filtering; (7) carrying out mixed bed refining and concentrating. According to the process disclosed by the invention, in a process of preparing the starch syrup, the energy consumption is reduced through blending high-concentration starch syrup, a pulping water temperature is controlled and the liquefying time is shortened; residual sugar is recycled from sugar-free grains produced in a production process and fat in the sugar-free grains is hydrolyzed by adopting alkaline lipase; protein of the rice sugar-free grains is hydrolyzed by proteinase to prepare an organic nitrogen source, and fermentation raw materials for foods and medicines. The process disclosed by the invention is remarkably better than a traditional process for preparing the starch syrup from the rice; the production cost is low and an additional value of a product is improved; the content of produced solid wastes is extremely less and the production process is economical and environmentally friendly.

Owner:双桥(湖北)有限公司

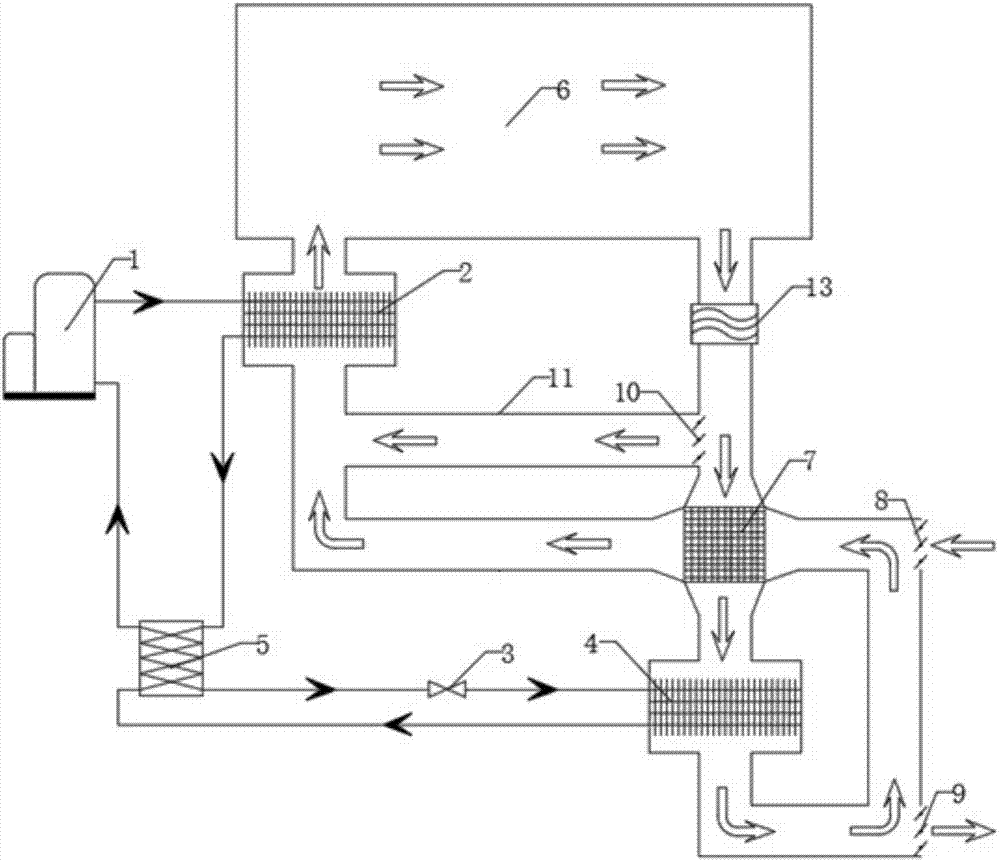

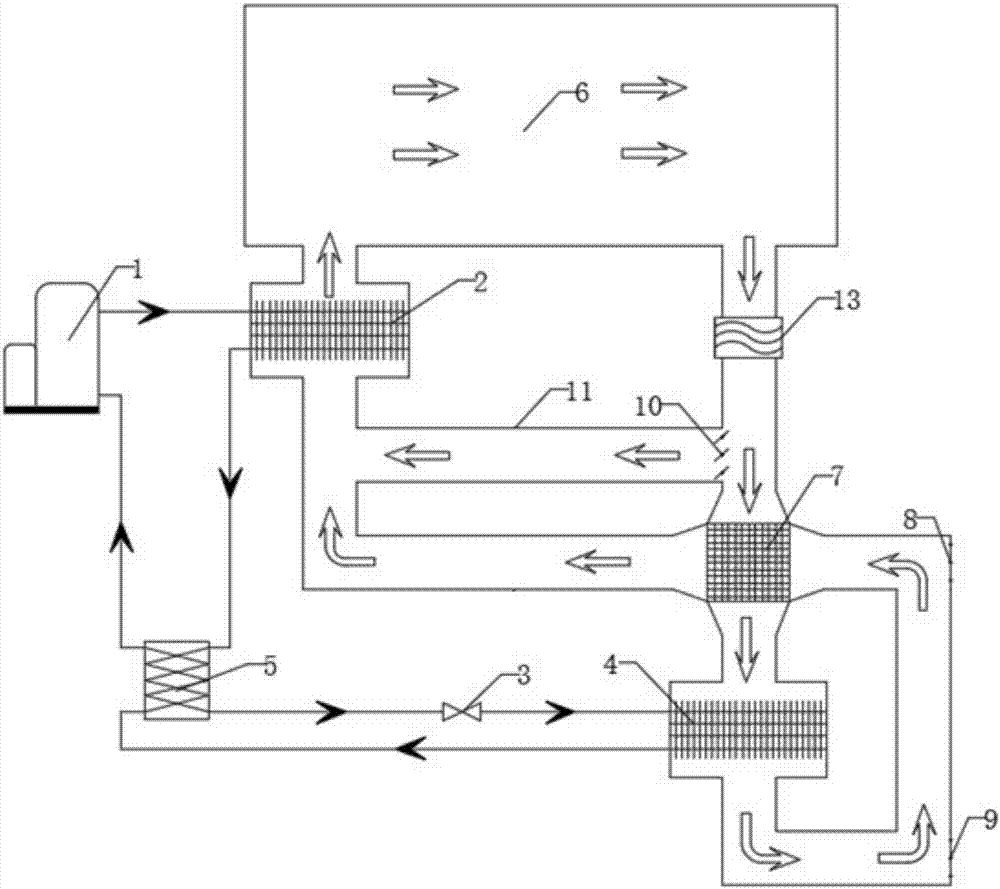

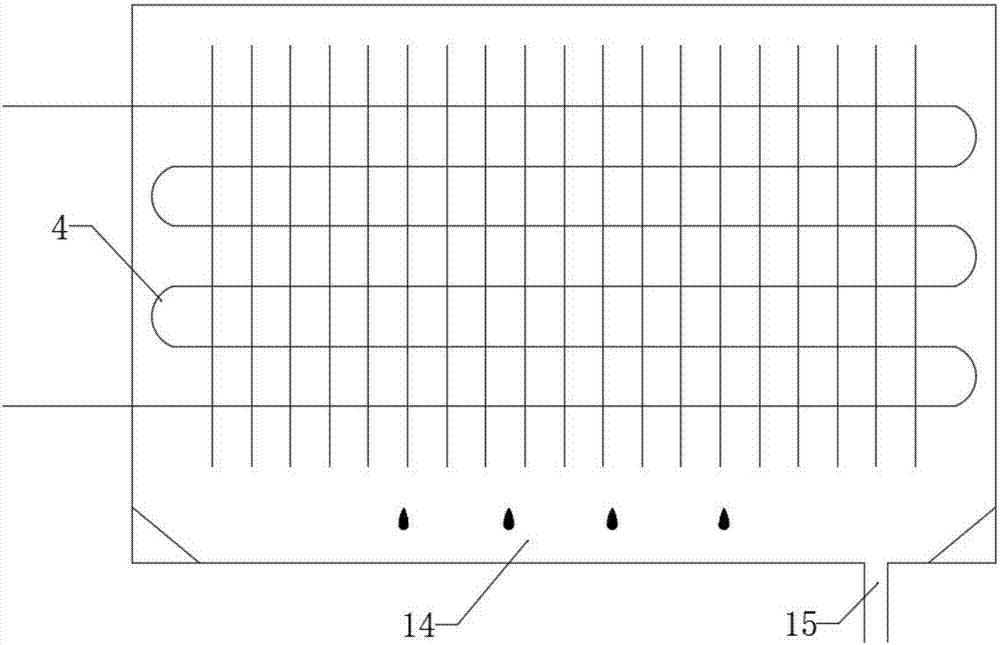

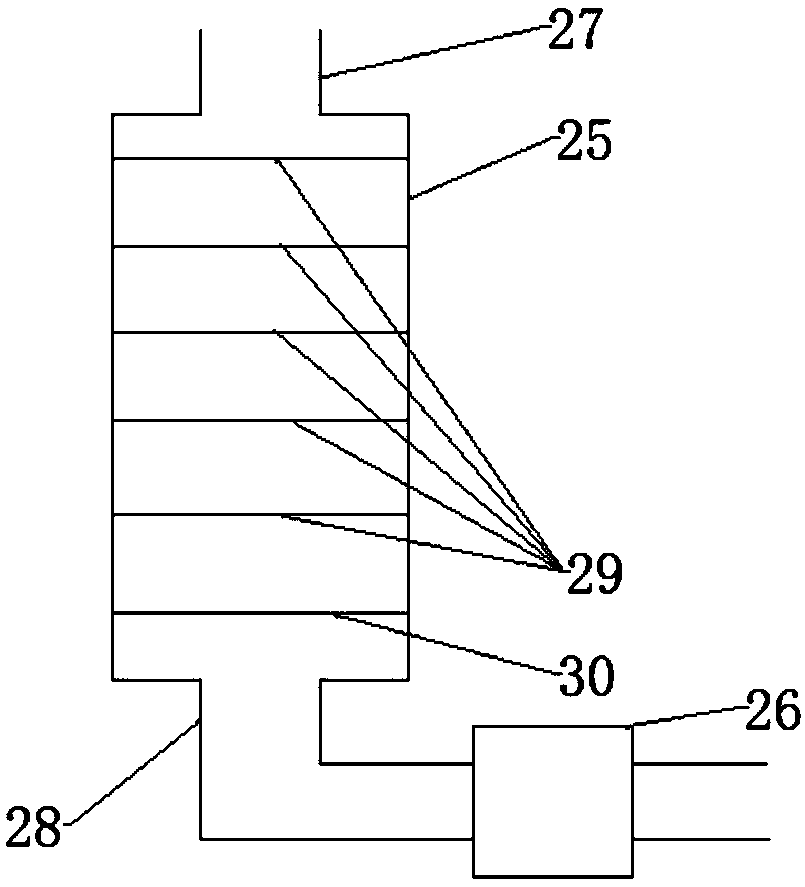

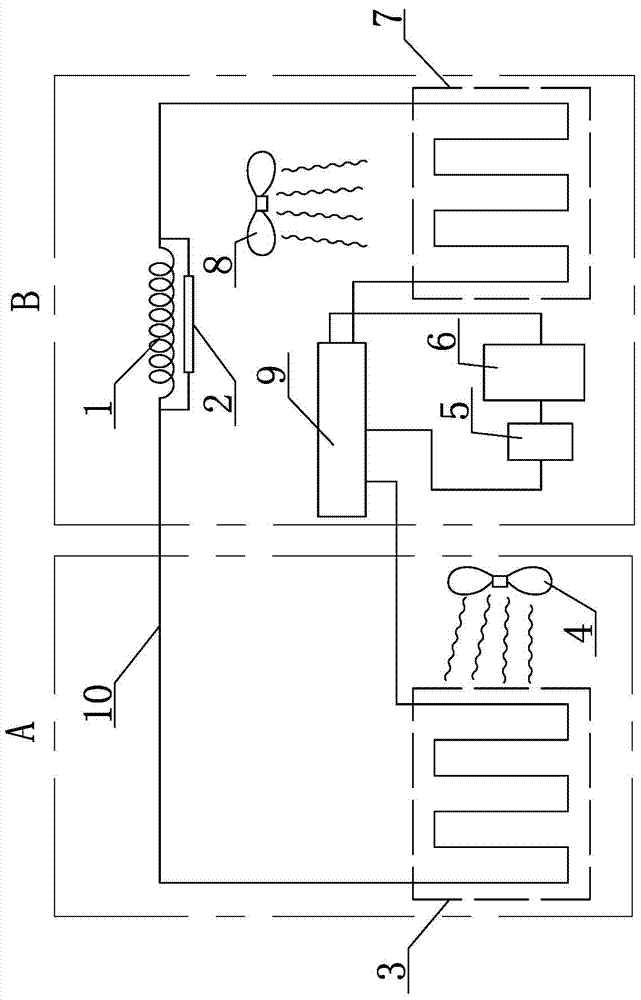

Drying system based on CO2 transcritical heat pump cycle

ActiveCN107270696AAdapt to dry conditionsImprove energy efficiencyHeat pumpsDrying gas arrangementsTranscritical cycleGas cooler

The invention relates to the technical field of heat pump drying, in particular to a drying system based on a CO2 transcritical heat pump cycle. The system comprises a drying chamber, a refrigerant loop and a drying medium loop. A compressor, a gas cooler, a regenerator, a throttling valve and an evaporator are sequentially arranged on the refrigerant loop. The gas cooler, the drying chamber, a heat exchanger and the evaporator are arranged on the drying medium loop. The heat exchanger comprises first pipelines and second pipelines which mutually exchange heat. An air outlet of the gas cooler communicates with an air inlet of the drying chamber. An air outlet of the drying chamber communicates with inlets of the first pipelines. Outlets of the first pipelines communicate with an air inlet of the evaporator. An air outlet of the evaporator communicates with inlets of the second pipelines. Outlets of the second pipelines communicate with an air inlet of the gas cooler. According to the drying system based on the CO2 transcritical heat pump cycle, the transcritical cycle is adopted, the drying system can adapt to the drying work conditions within the wider temperature range, recycling is conducted on waste heat, and the energy efficiency is improved greatly.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

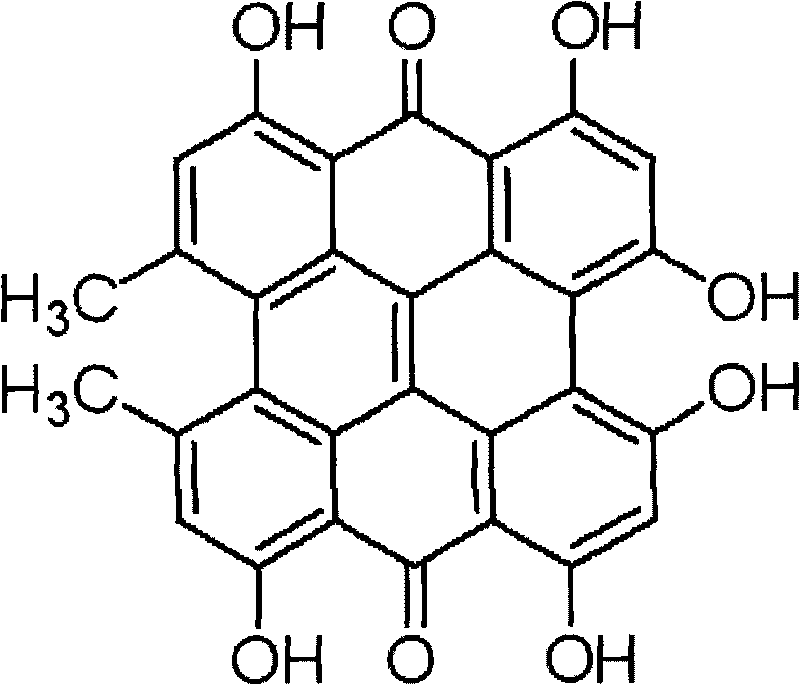

Method for preparing hypericins

InactiveCN101759549AFully extractedFully liquefiedQuinone separation/purificationHypericinHypericum perforatum

The invention relates to a method for separating and purifying hypericins by adopting a macroporous resin separation technique and an alumina chromatographic technique. The method comprises the following steps of: grinding fresh hypericum perforatum L, leaching the ground hypericum perforatum L for 1 to 2 hours in saturated lime solution, adjusting a pH value to 6 to 7 by hydrochloric acid at normal temperature, and performing resin separation, segmented elution, alumina chromatography, ethanol elution and cyclohexane to obtain the finished product. The method has the advantages of simple process, little energy consumption and high-purity hypericins.

Owner:NANJING ZELANG MEDICAL TECH

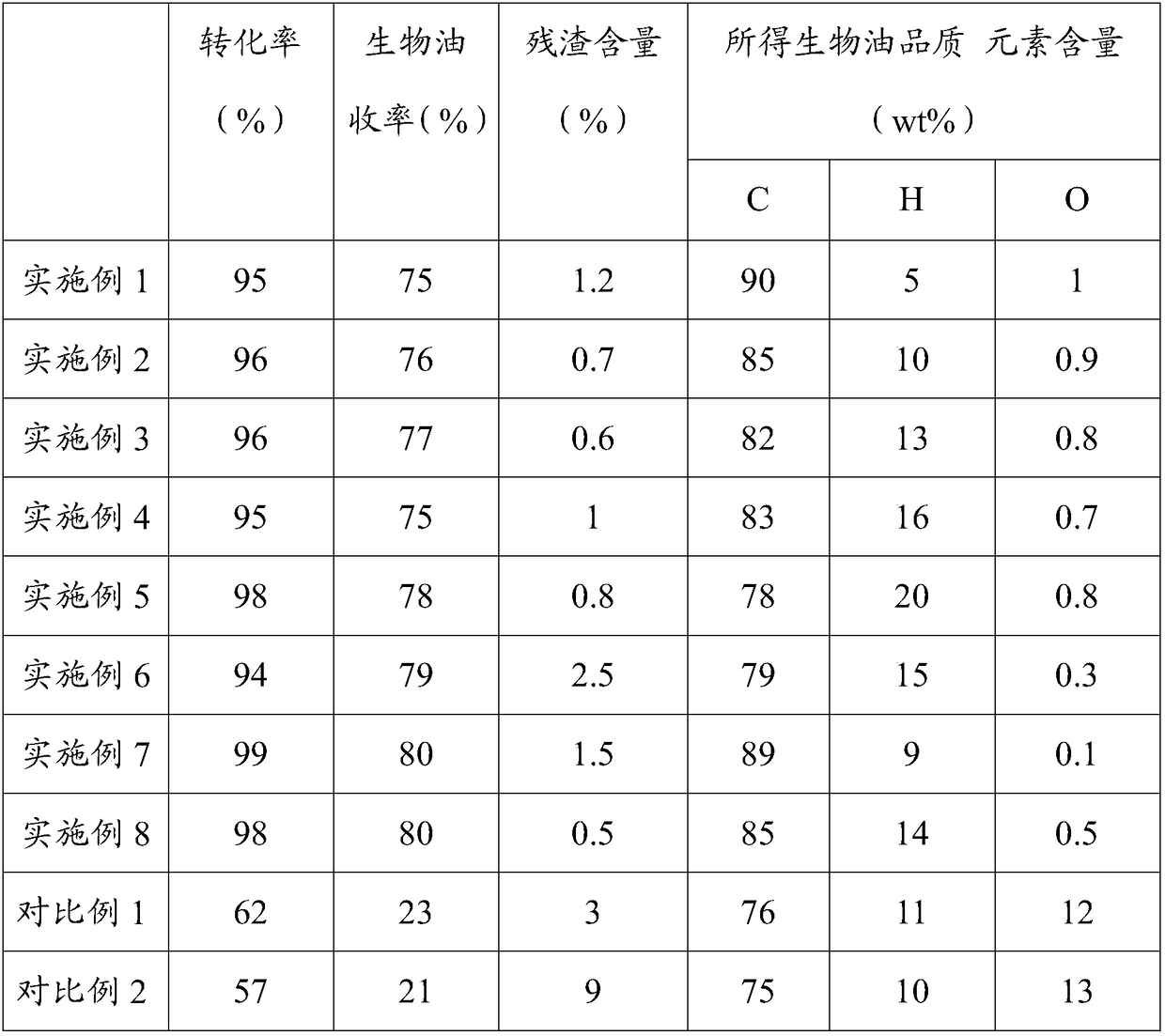

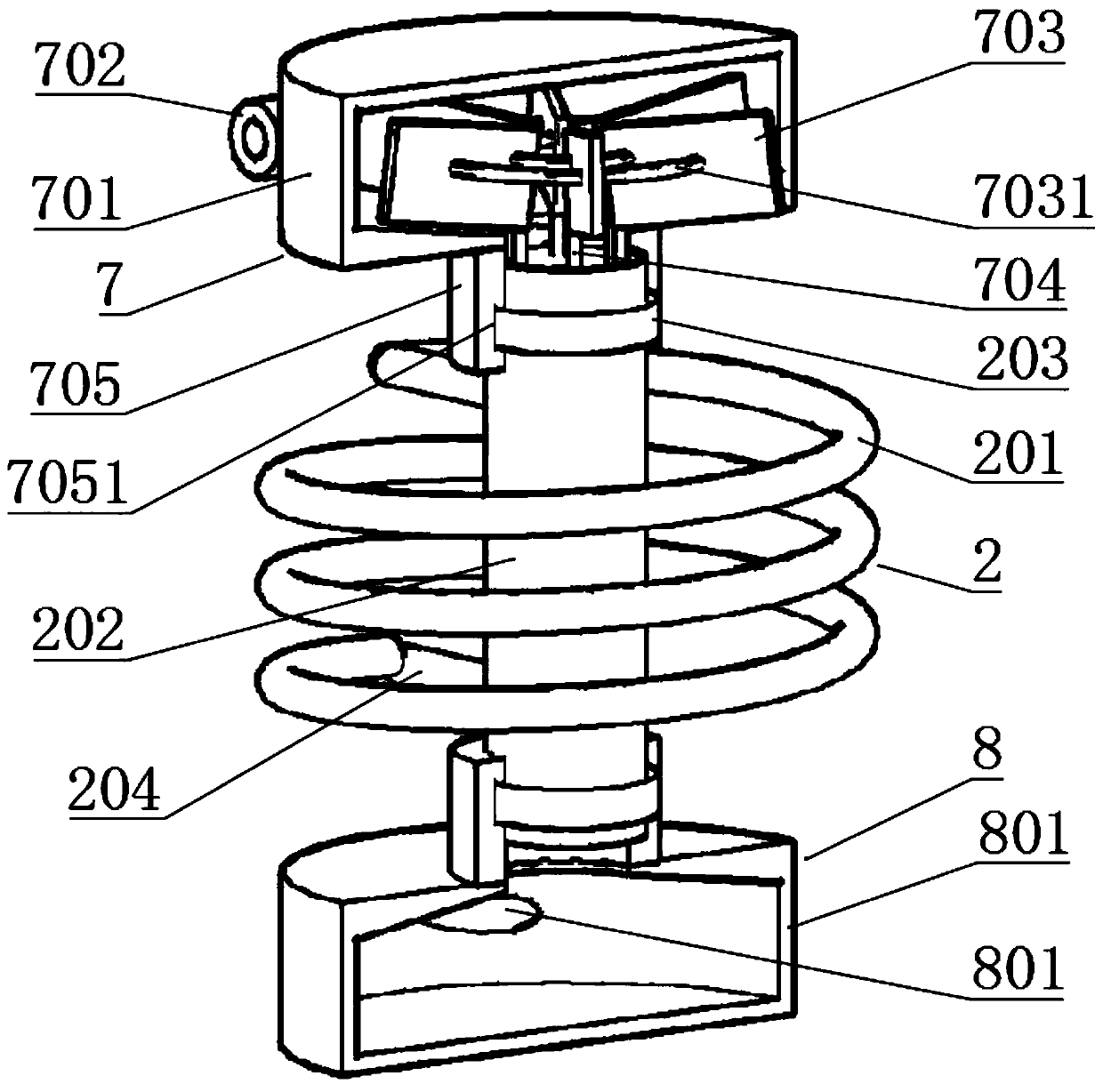

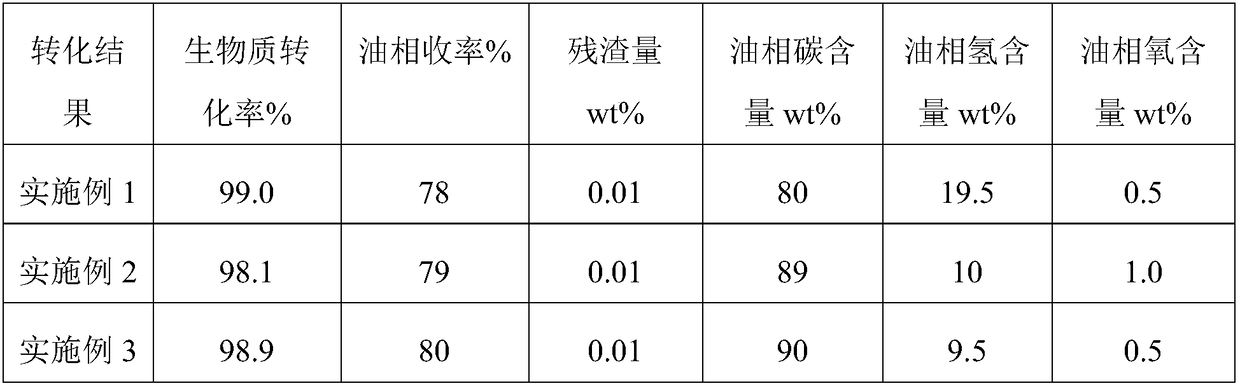

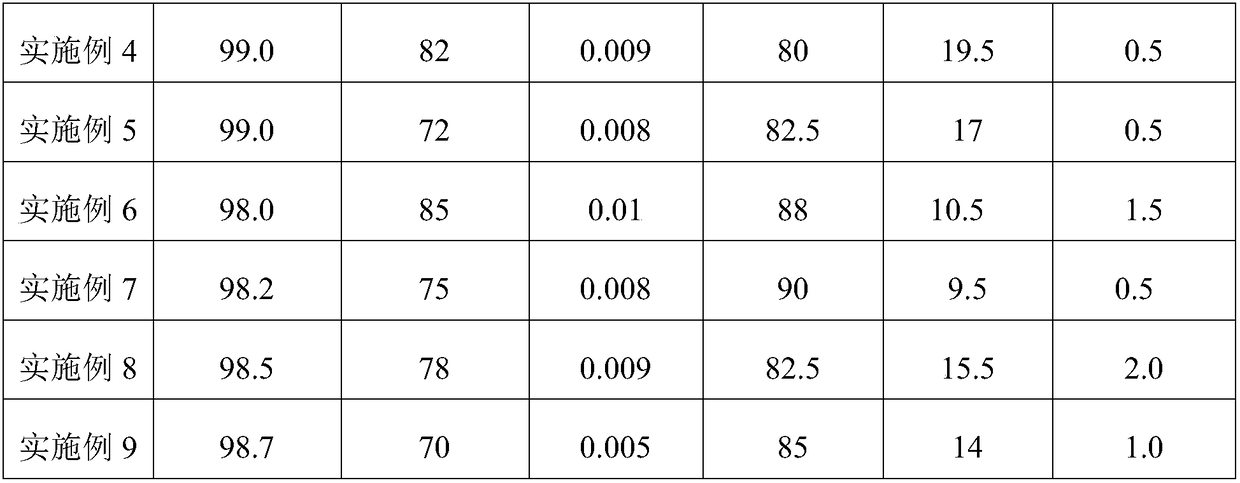

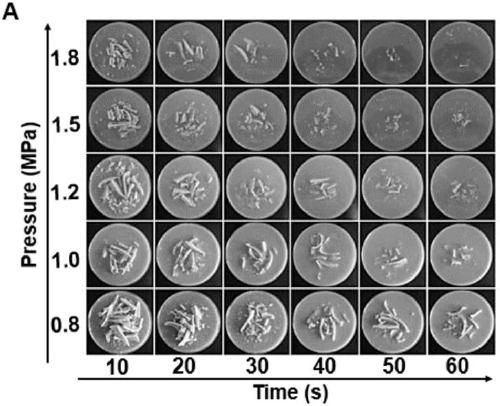

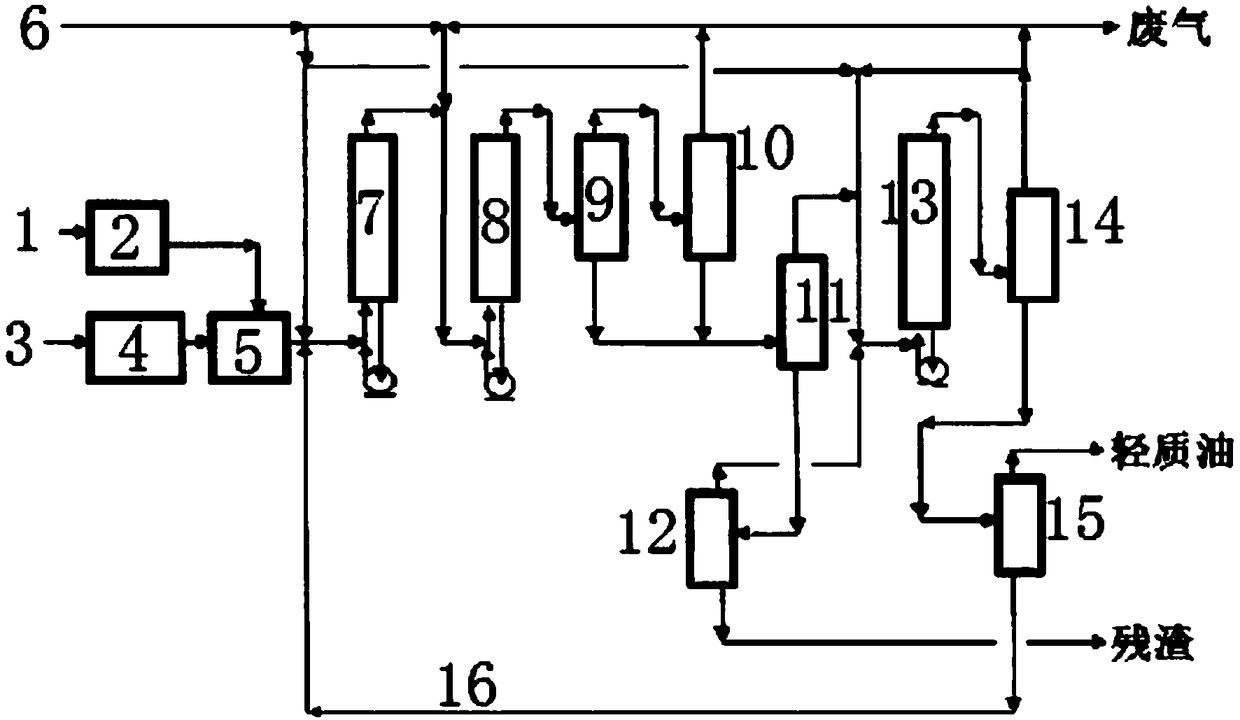

Multi-grade liquefying technology of coal and biomass

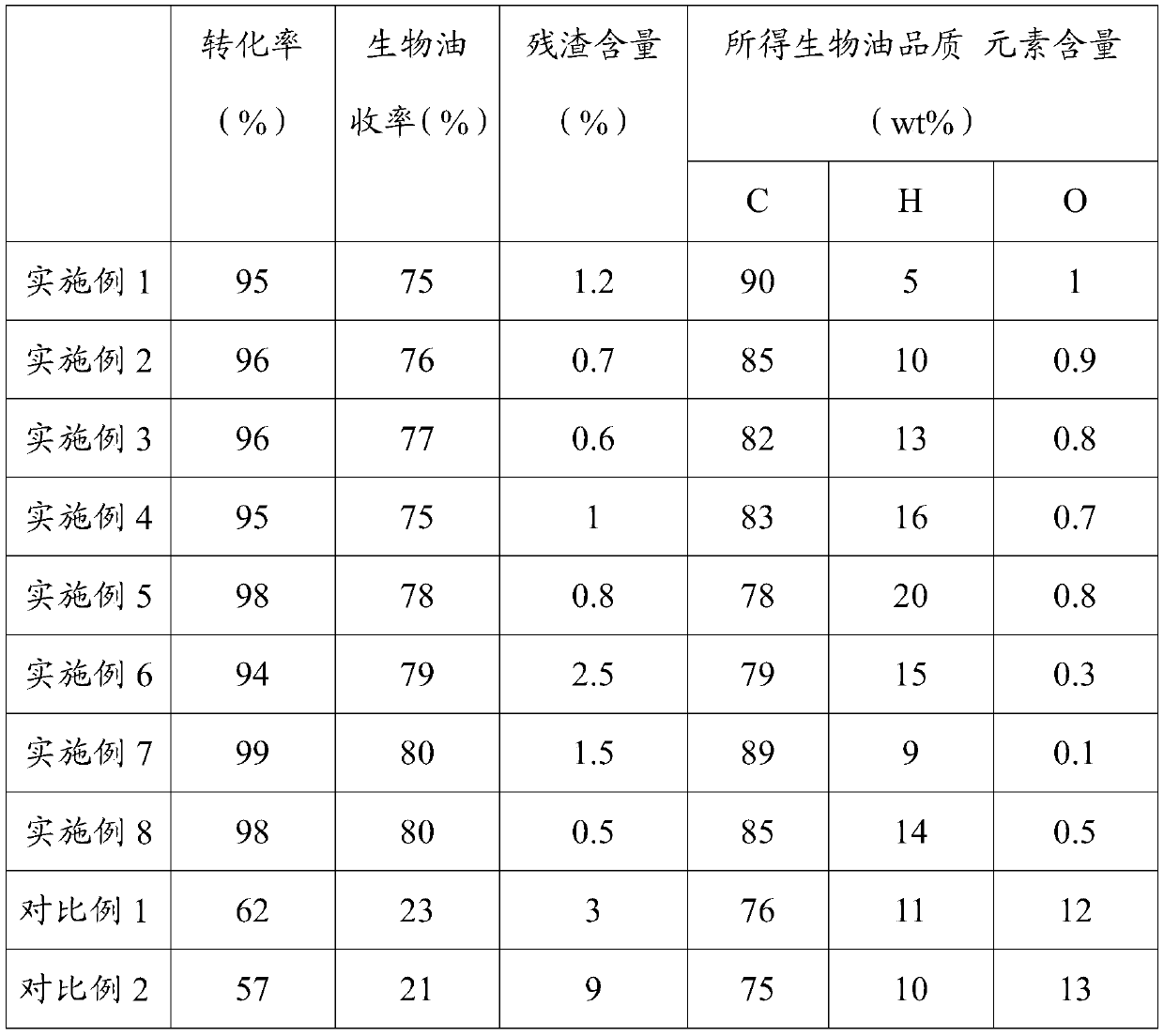

ActiveCN108285808ARealize mixing and liquefactionIncrease contactBiofuelsLiquid hydrocarbon mixture productionSolventBiomass

The invention relates to the technical field of clean energy, and specifically provides a multi-grade liquefying technology of coal and biomass. The technology is characterized in that the coal and the biomass raw materials are processed by crushing, compressing and crushing again, then the sizing is prepared, so that biomass diesel oil which is high in solid content and can be stably conveyed through a pump can be obtained; high-viscosity waste oil which cannot be used as a coal and biomass liquefying solvent in the prior art can be utilized. According to the technology, coal and biomass canbe liquefied under high pressure and high temperature in the existence of proper volume of water; the liquefying product is sequentially subjected to primary cracking, hydrogenation reaction and deepcracking and hydrogenation reaction under the effects of resisting hydrogen and a first catalyst and a second catalyst, so that the coal and the biomass can be converted into biomass oil, and the biomass oil can be refined; the conversion rate of the biomass and the coal is up to 95-99%; the yield of the biomass oil is up to 70-80%; and moreover, the residue content is less than 2.5%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

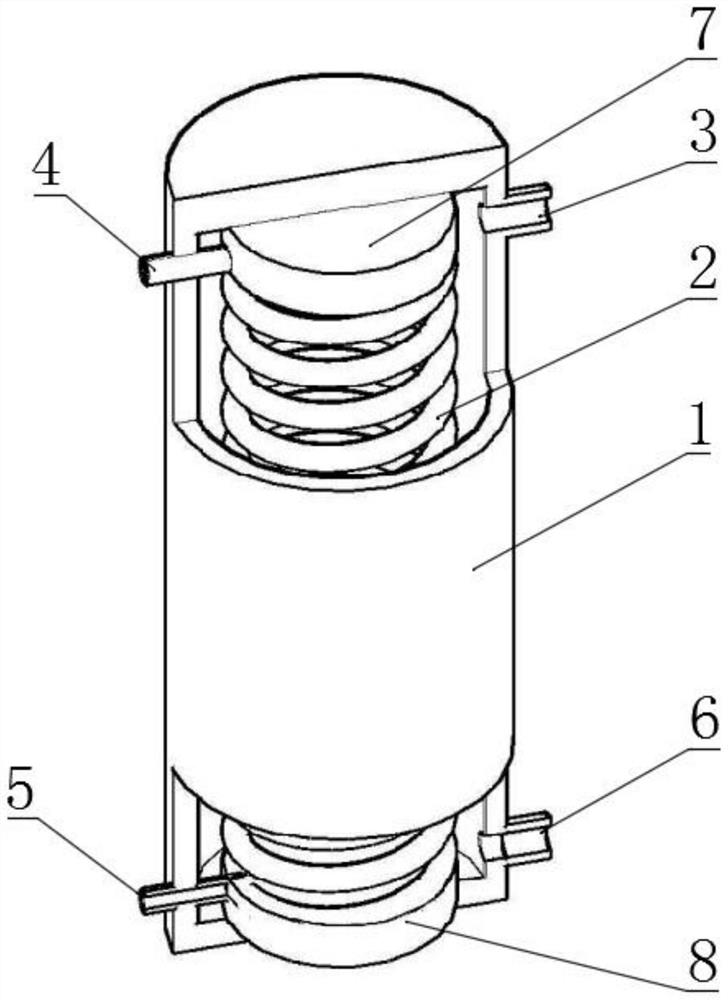

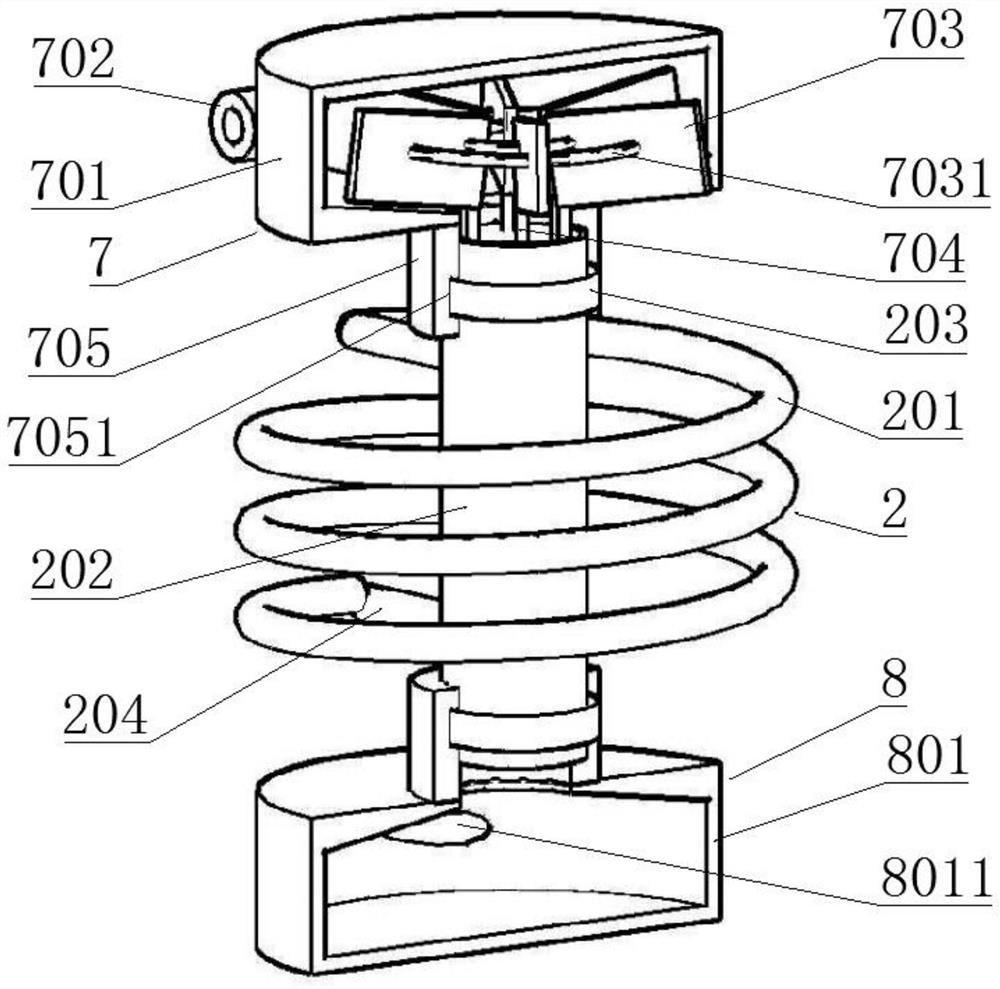

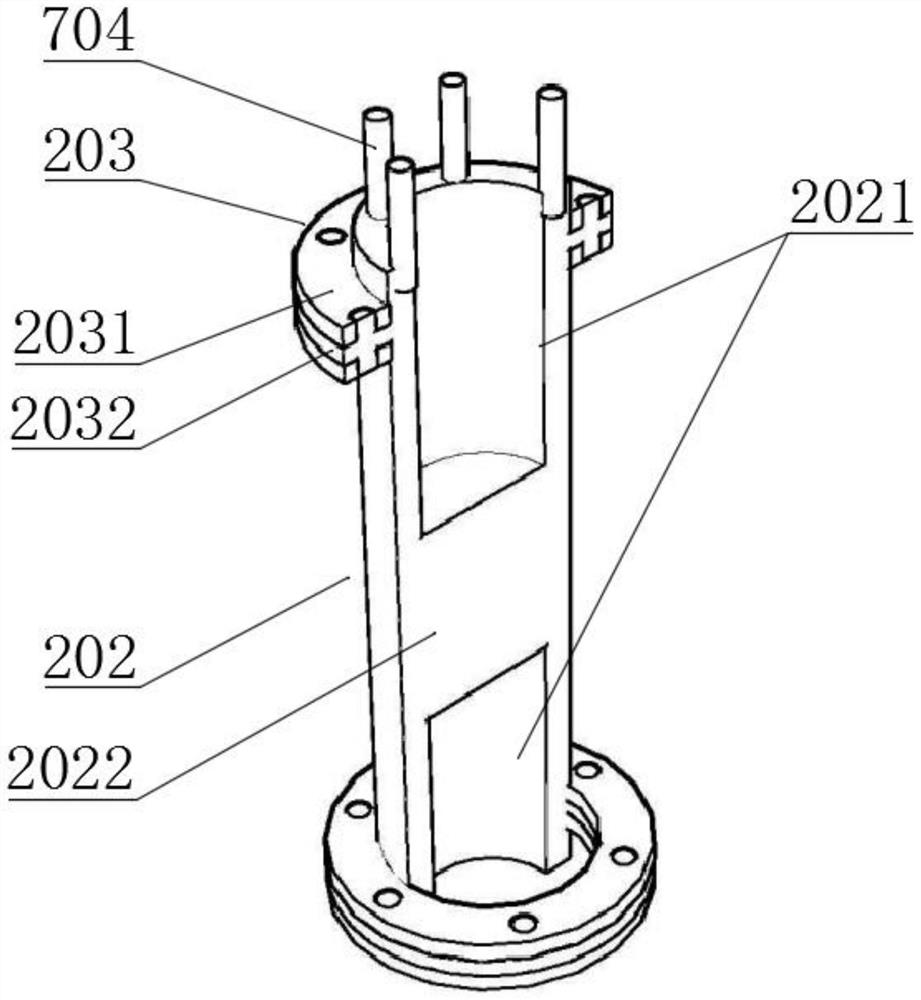

Air energy water heater

ActiveCN110793200AGuaranteed thermal conductivityReduce adhesionFluid heatersEngineeringWater heater

The invention provides an air energy water heater, and relates to the field of water heaters. The air energy water heater comprises a heat exchange box, wherein a heat exchange tube is arranged in theheat exchange box; the top end of the heat exchange tube is fixedly connected to a first rotary mechanism; the heat exchange tube communicates with the inner part of the rotary mechanism; the first rotary mechanism is fixedly arranged in the heat exchange box; the bottom end of the heat exchange tube is fixedly connected to a second rotary mechanism; and the second rotary mechanism is fixedly arranged in the heat exchange box. In the air energy water heater, the heat exchange tube rotates to generate friction with water, so that attachment of water scales is reduced, heat conduction of the heat exchange tube is guaranteed, water molecule motion speed can be increased, and therefore, heat exchange efficiency is improved, flowing time, in the heat exchange tube, of a medium is shortened, and the high-temperature medium is in sufficient contact with a heat exchanger to improve heat exchange degree; meanwhile, the medium can be sufficiently liquefied after releasing energy, so that a throttle device connected behind the heat exchanger is protected; and a connecting shaft is kept in sealing with the first rotary mechanism and the second rotary mechanism through a sealing ring.

Owner:浙江德富新能源技术有限公司

Multistage liquefaction process of biomass

ActiveCN108219817AImprove the efficiency of the liquefaction processGood suspensionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentPorositySlurry

The invention relates to the field of biological energy sources, in particular to a multistage liquefaction process of biomass. Slurry for the biological energy sources is prepared by the steps of sequentially carrying out drying, primary crushing, compressing and secondary crushing on straw, and then mixing the product with a first catalyst to obtain a mixture; adding the obtained mixture into anoil product, and grinding to prepare slurry with a straw concentration of 30-60wt%. According to the multistage liquefaction process of the biomass, a treatment process of first compressing and thensecondary crushing is carried out on the straw for the first time, and the loose straw is sequentially subjected to stages such as rearrangement, mechanical denaturation and shaping rheology by compressing the biomass, so that the volume of the straw is greatly reduced, the porosity of the straw is further reduced, the density and specific gravity of the straw are increased, the straw is more easily dispersed in the oil product, the content of the straw in the oil product is increased, and the concentration of a reaction material is increased; the multistage liquefaction process increases thebiomass conveying capacity of a pump within unit time, guarantees the smooth operation and transportation of the pump, and increases the conversion rate of the biomass.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

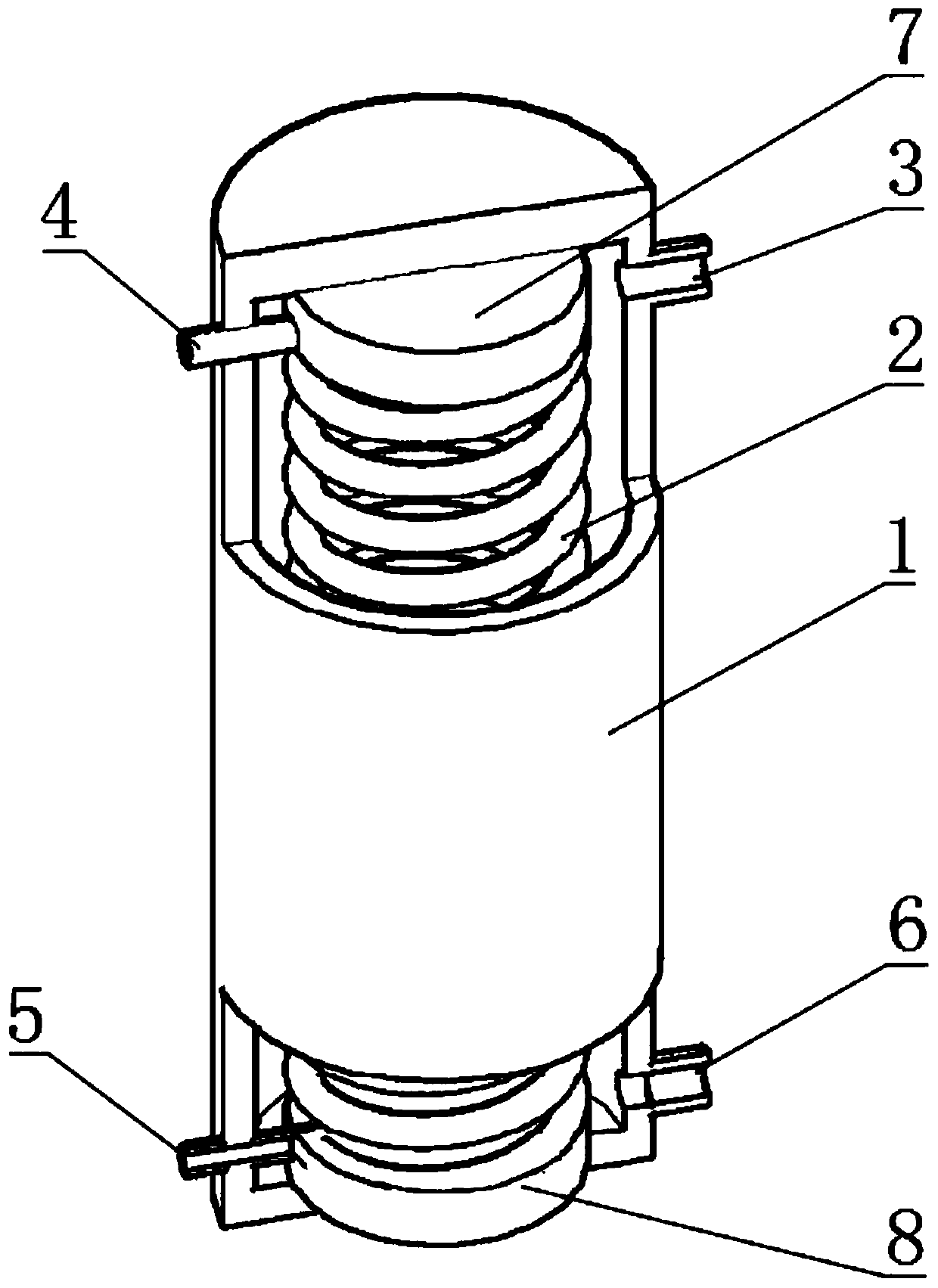

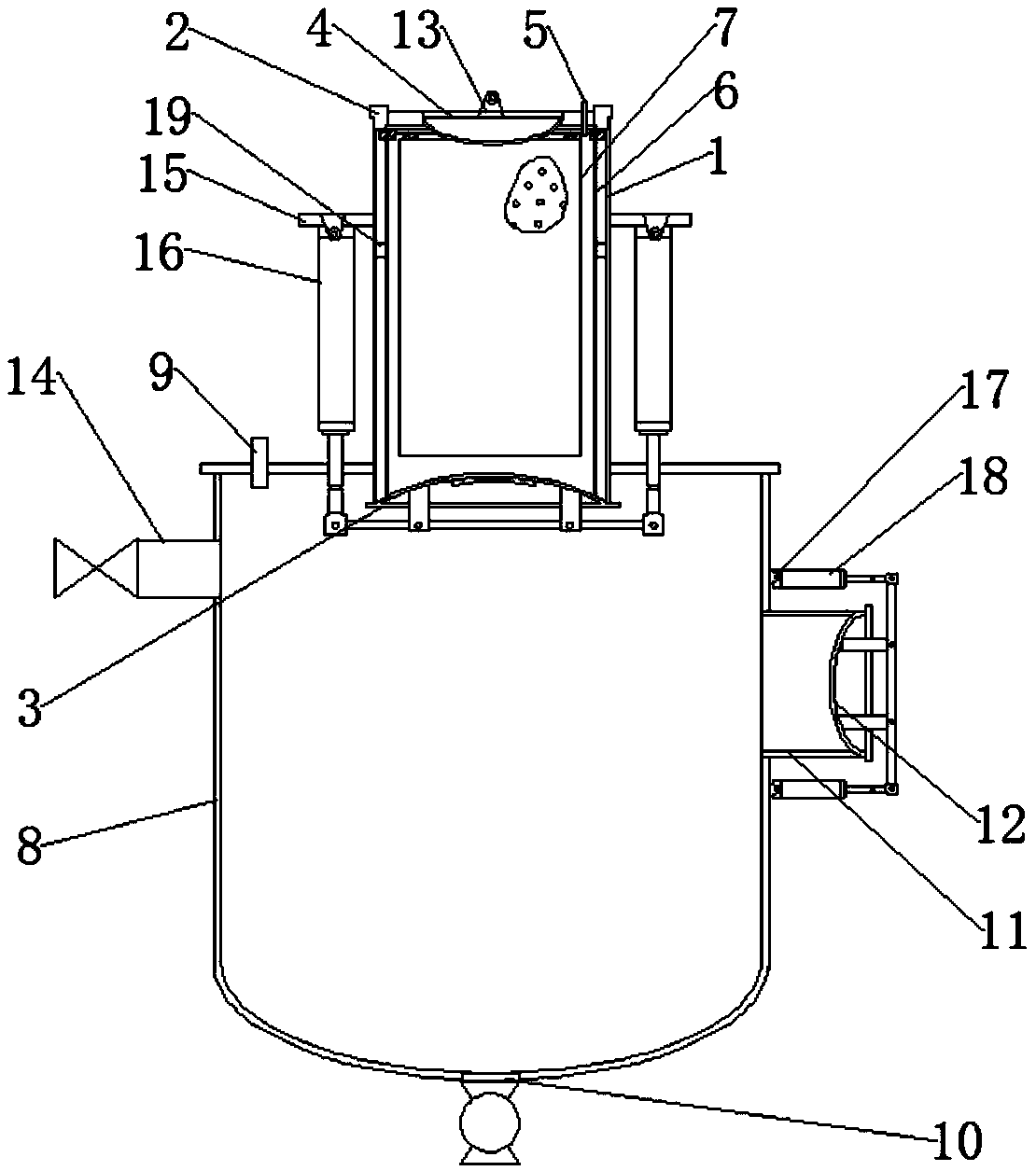

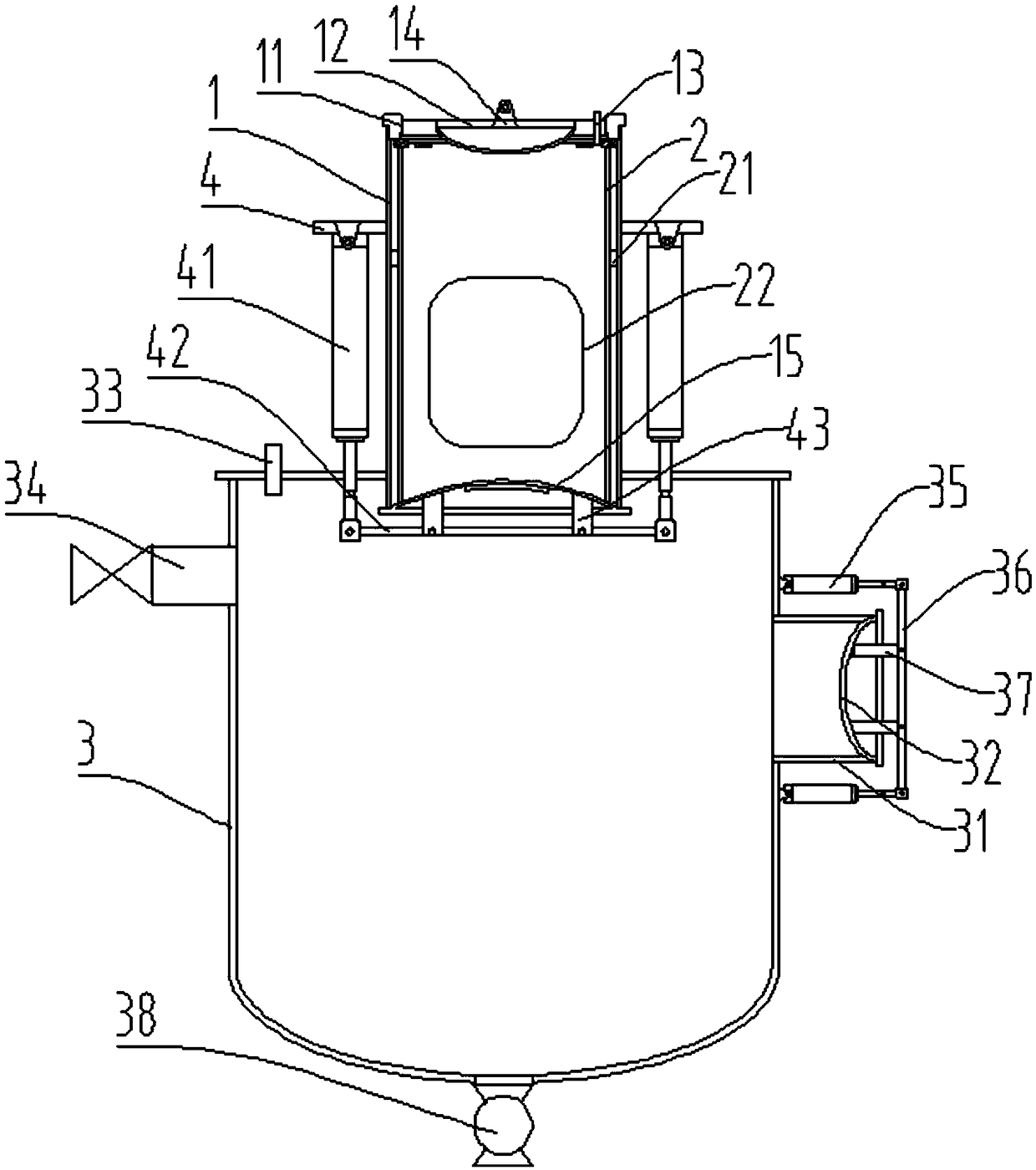

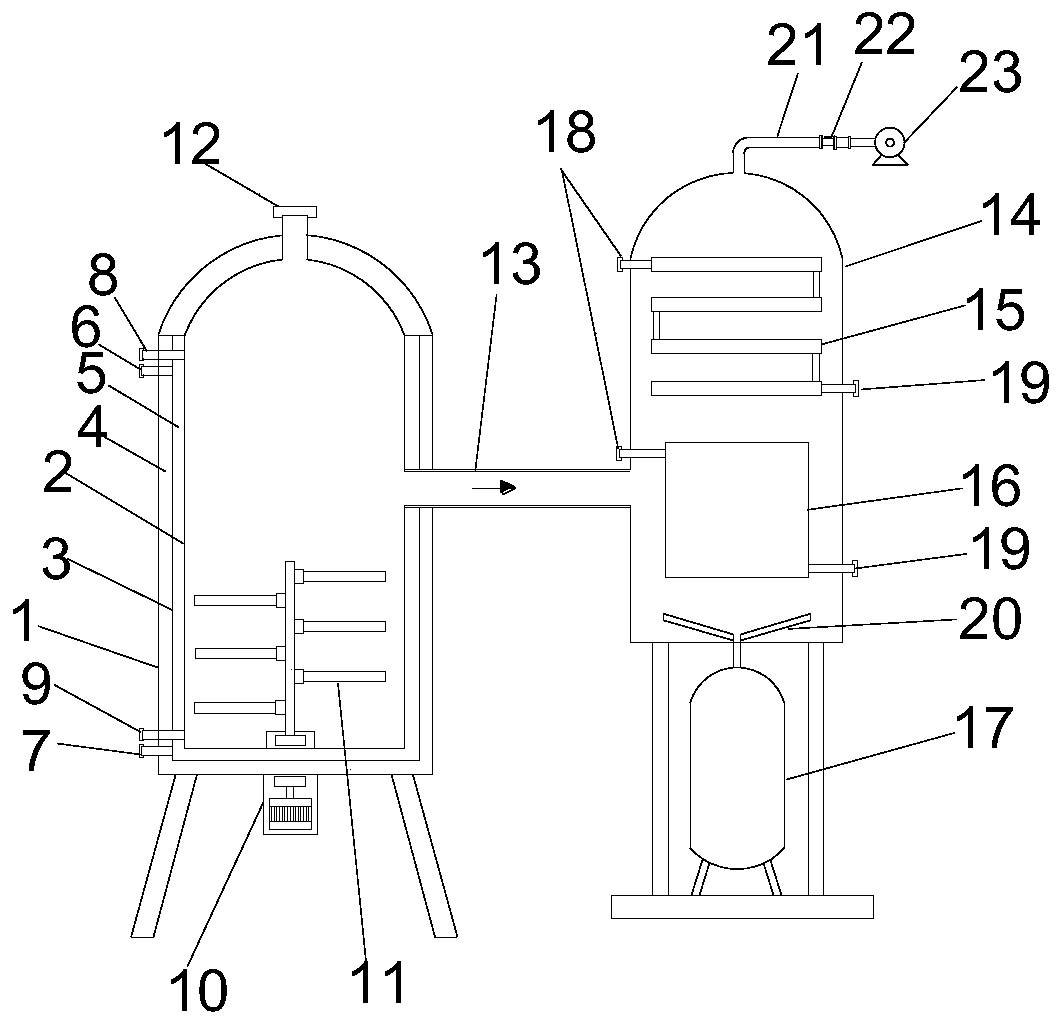

Hard bone liquefaction equipment and method for synchronously producing bone collagen polypeptides and ultrafine bone powder

ActiveCN109007235AEasy to handleImprove processing efficiencyConnective tissue peptidesTransportation and packagingEngineeringBiomedical engineering

The invention discloses hard bone liquefaction equipment. The hard bone liquefaction equipment comprises an outer chamber, a first liquefaction chamber, a stainless steel cage and a second liquefaction chamber; an upper cap is arranged at the upper end of the outer chamber in a detachable way, and a lower sealing cap which can be opened / closed so as to have the outer chamber sealed is arranged atthe lower end of the outer chamber; the first liquefaction chamber which is capable of vertically sliding is coaxially arranged in the outer chamber; the stainless steel cage is coaxially arranged infirst liquefaction chamber; and a top surface of the second liquefaction chamber is fixedly connected to an outer side wall of the outer chamber so as to have the lower end of the outer chamber positioned inside the second liquefaction chamber. The invention further provides a method for synchronously producing bone collagen polypeptides and ultrafine bone powder on basis of the hard bone liquefaction equipment. The method for synchronously producing the bone collagen polypeptides and the ultrafine bone powder comprises the following steps: selecting hard bones, and carrying out crushing; carrying out first-stage liquefaction and second-stage liquefaction so as to obtain a liquid phase and a solid phase; performing centrifuging, concentrating and drying on the liquid phase so as to obtainthe bone collagen polypeptides; and performing drying, crude crushing and ultrafine crushing on the solid phase so as to obtain the ultrafine bone powder. The method for synchronously producing the bone collagen polypeptides and the ultrafine bone powder has the beneficial effects of being simplified in processing flow, improved in production efficiency, decreased in production cost and reduced inequipment investment.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI +1

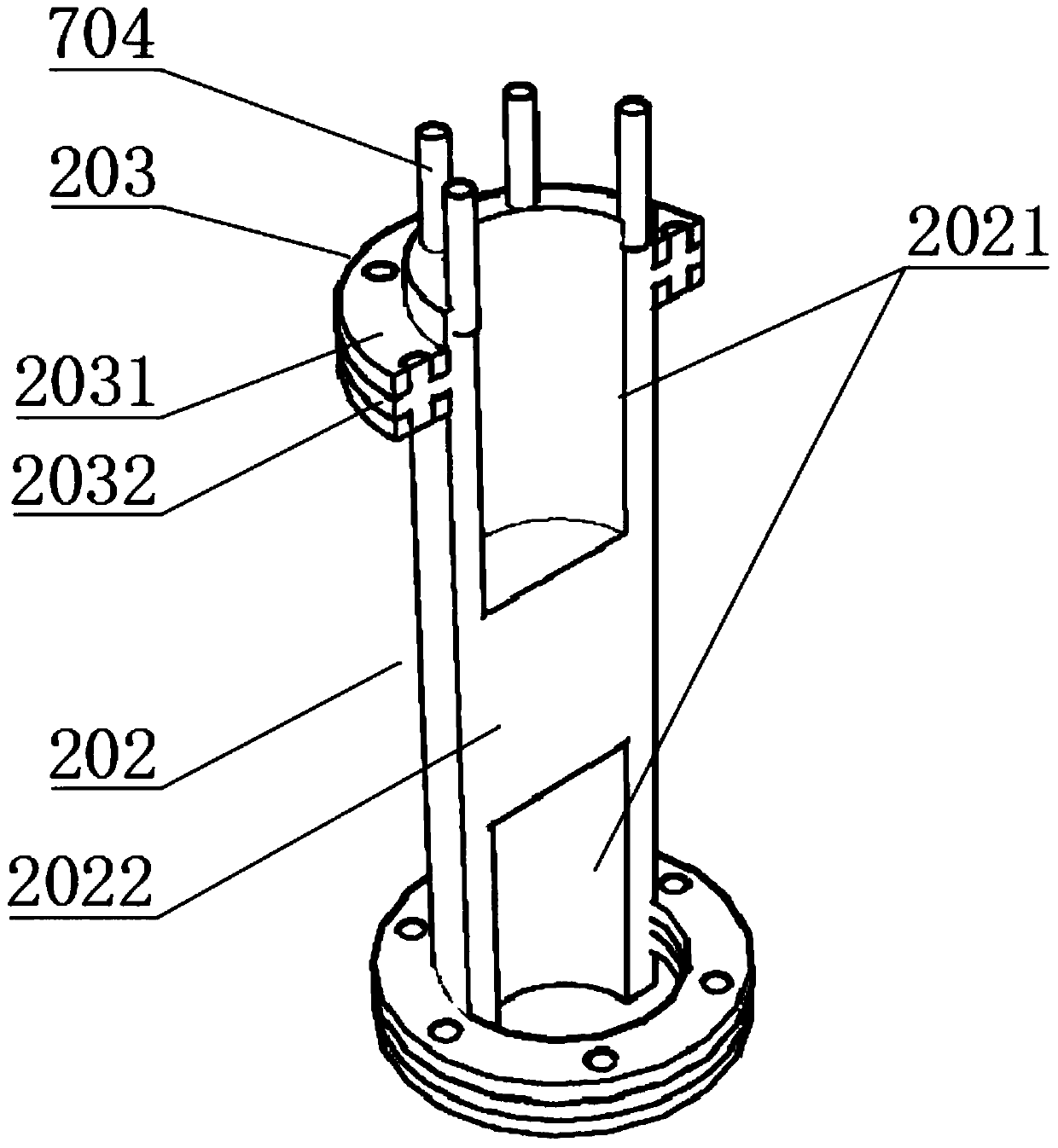

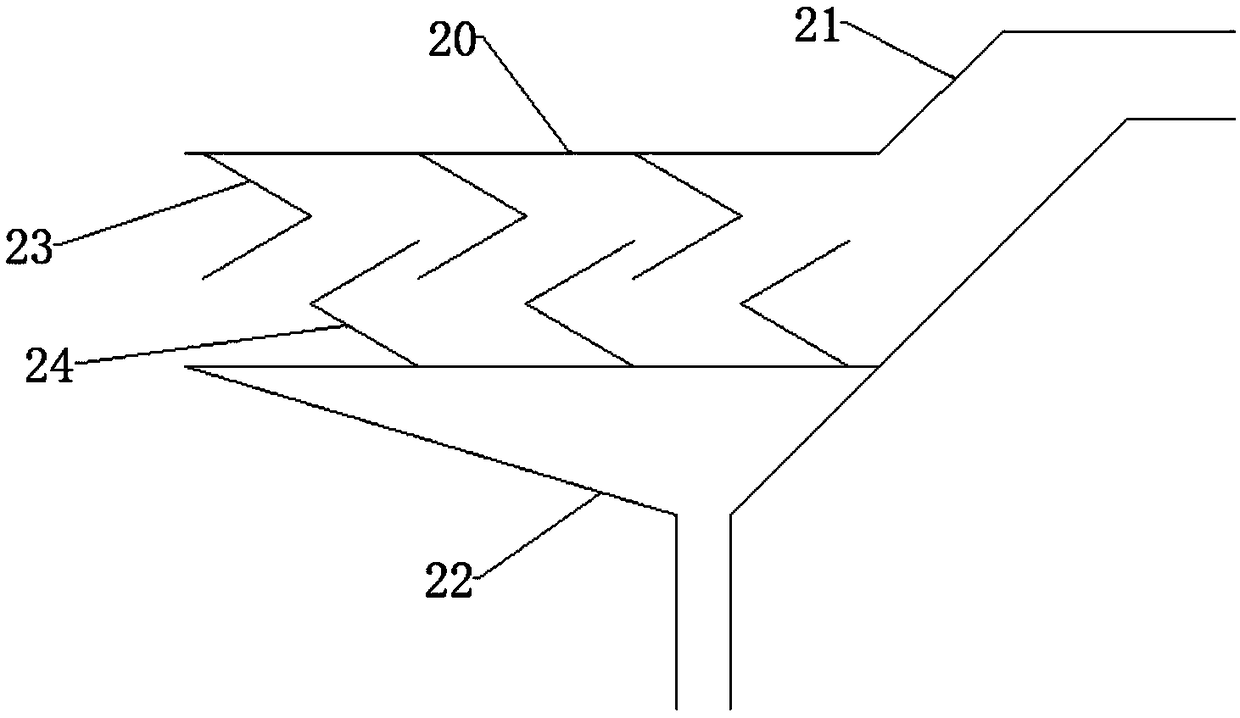

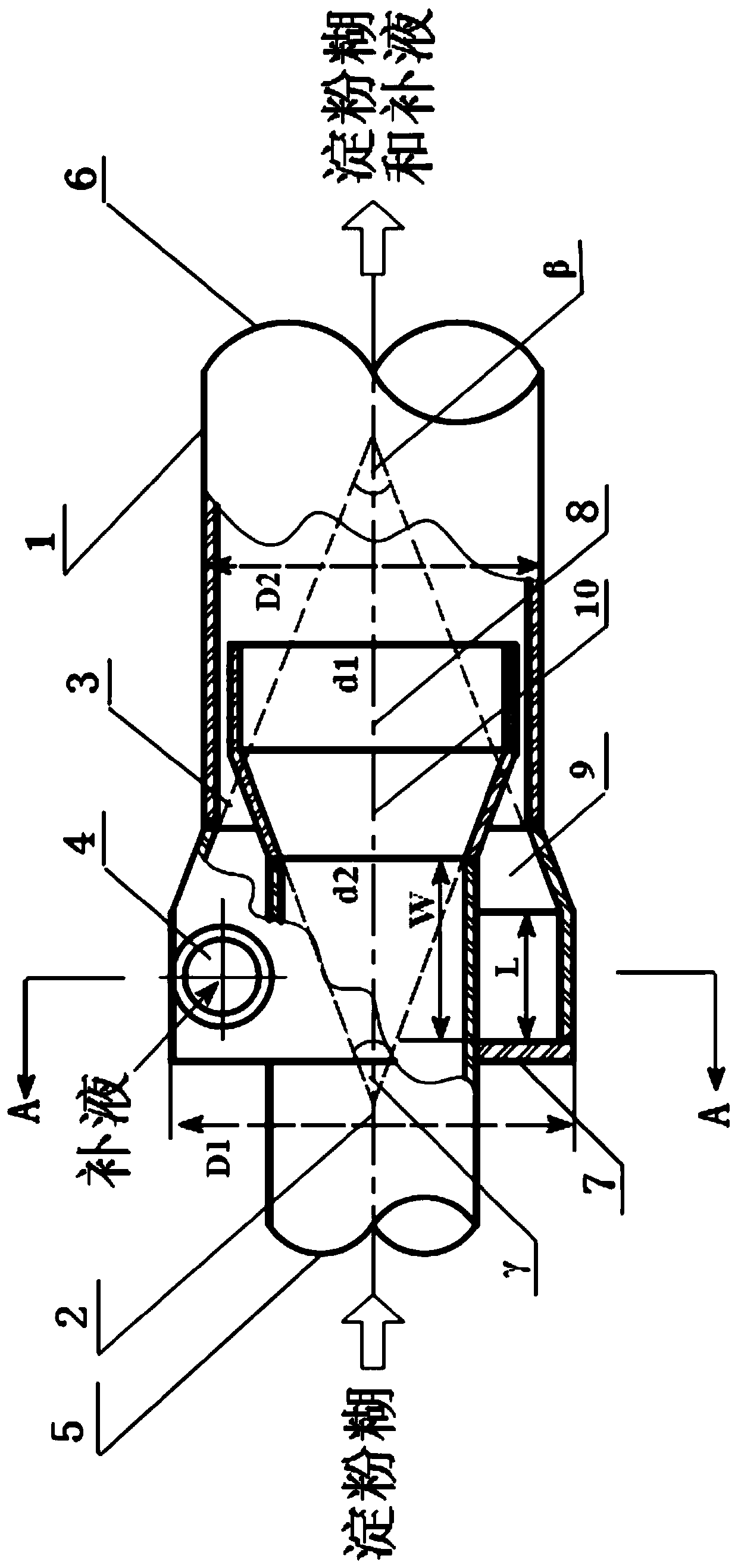

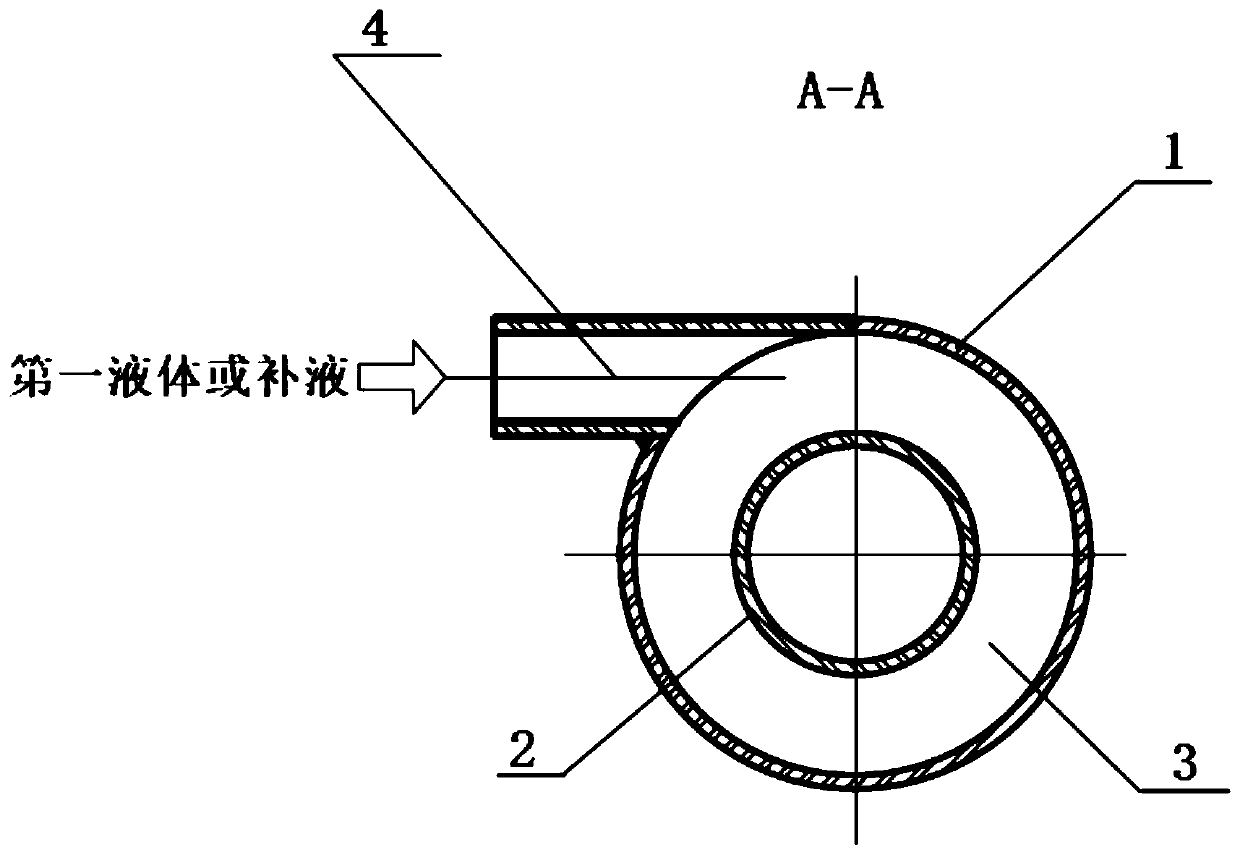

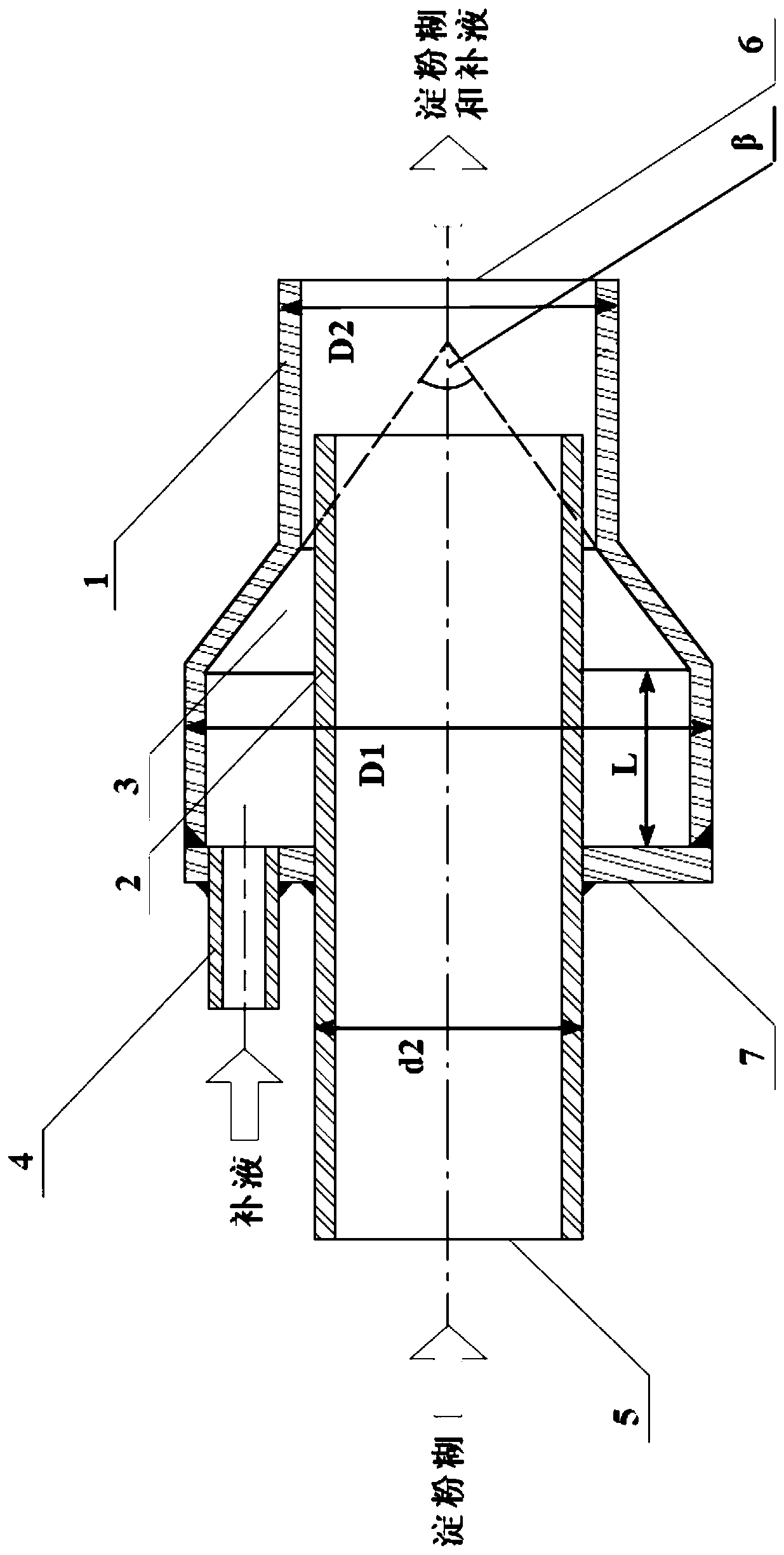

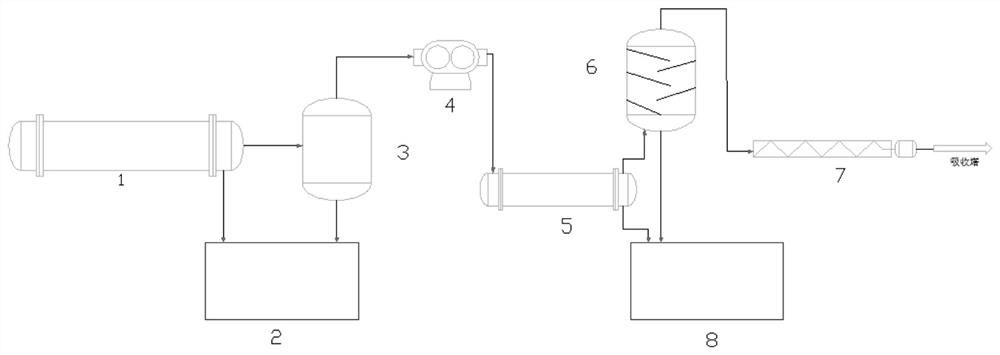

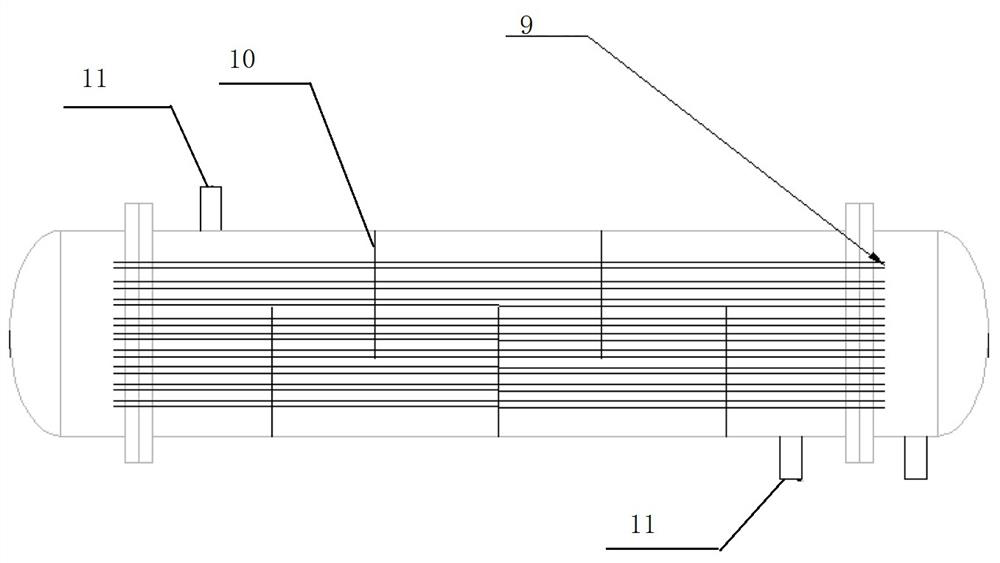

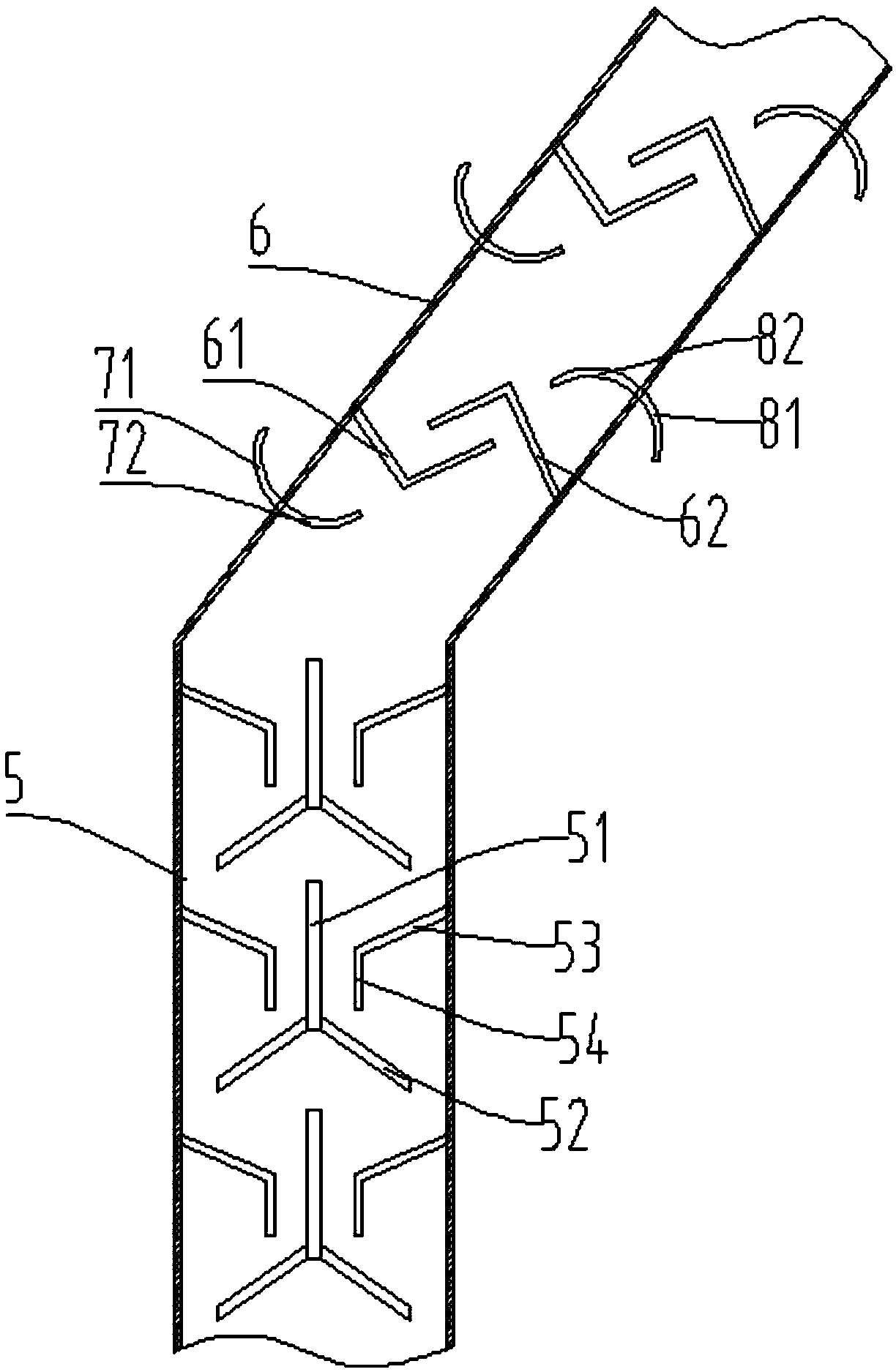

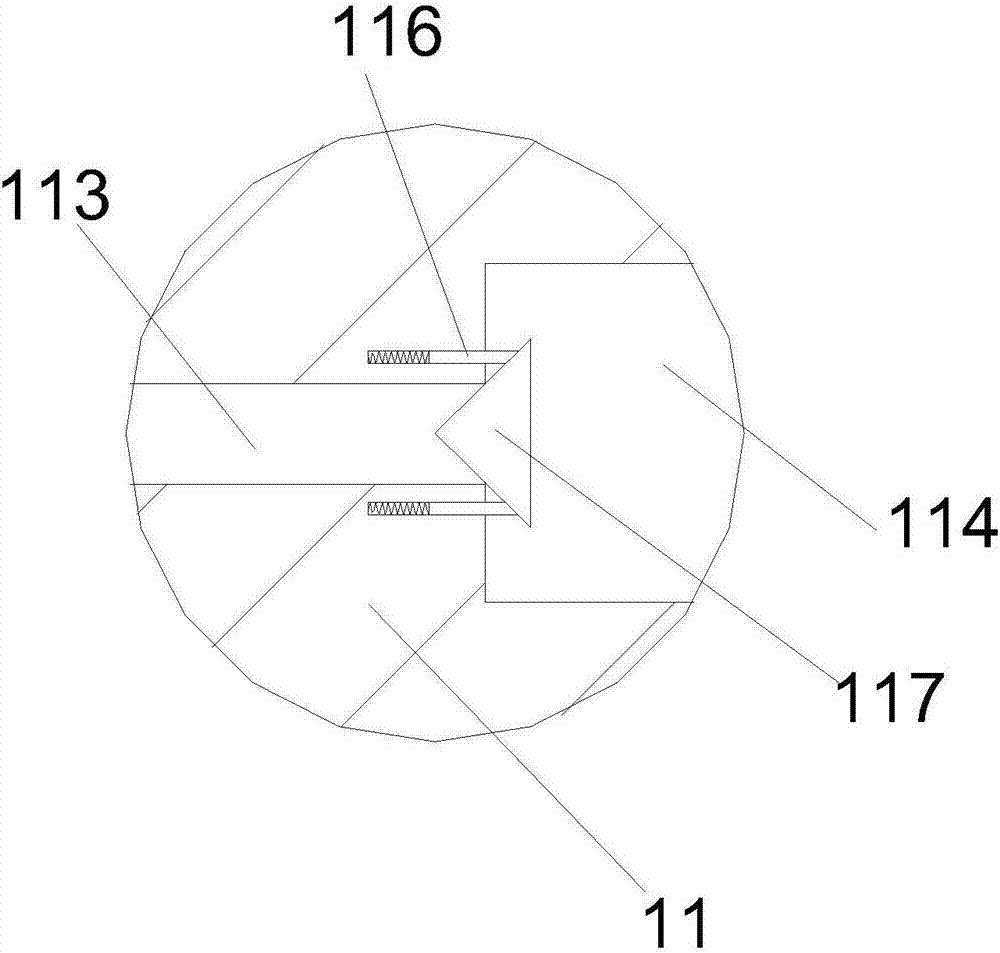

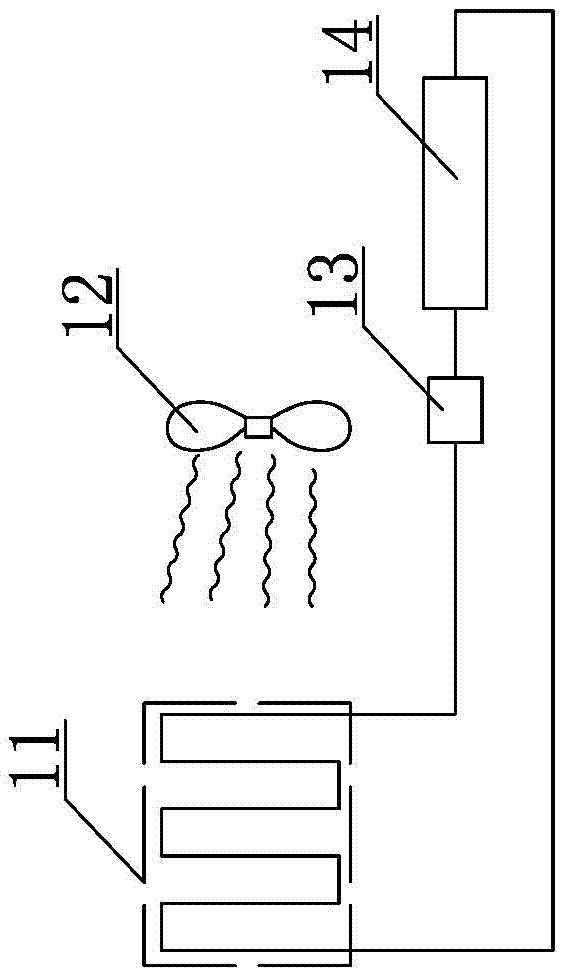

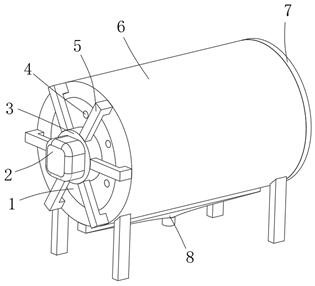

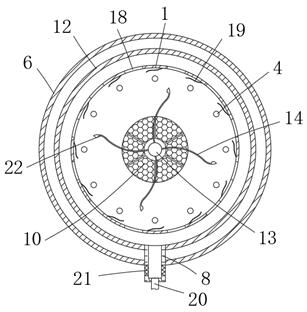

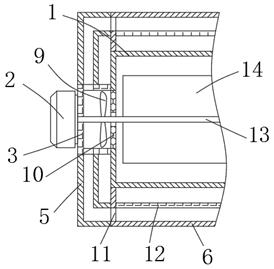

Fluid infusion machine, starch jet-cooking equipment, starch liquefaction device, and high-concentration starch milk jet-cooking and liquefying method

ActiveCN110029055AFully liquefiedLow flow resistanceBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationFluid infusion

The invention relates to the field of deep processing of starch, and discloses a fluid infusion machine, jet-cooking equipment, a starch liquefaction device, and a high-concentration starch milk jet-cooking and liquefying method. The fluid infusion machine comprises an outer pipe and an inner pipe which are in mutually sealed and sleeved connection and communication, wherein a fluid infusion machine inlet is formed in one end away from the outer pipe, of the inner pipe; a fluid infusion machine outlet is formed in one end away from the inner pipe, of the outer pipe; radial clearance is formedbetween the outer pipe and the inner pipe; and a fluid infusion pipe which communicates with the radial clearance is arranged at a joint part of the outer pipe and the inner pipe, and can inject firstfluid to the radial clearance, so that the first fluid can flow adhering the inner wall of the outer pipe. Through the adoption of the fluid infusion machine disclosed by the invention, the smooth flowing of high-concentration starch paste obtained through high-concentration starch milk gelatinization can be realized, starch liquefaction fluid is produced in a high-efficiency manner, and energy consumption is reduced.

Owner:COFCO GROUP +1

Vacuum process for cracking dimethyl dichlorosilane hydrolysate

PendingCN113603718ALow running costLow equipment maintenance and repair costsSilicon organic compoundsChemical industryOrganosiliconFluid phase

The invention provides a vacuum process suitable for cracking organic silicon hydrolysate. After vacuum gas passes through a heat exchanger A, a liquid phase enters a collecting tank, and a gas phase and a part of entrained liquid phase enter a hydrocyclone separation tank; the liquid phase separated by the hydrocyclone separation tank is returned to the collection tank again, and the gas phase enters a Roots vacuum unit; and after being primarily compressed by the Roots vacuum unit, the gas enters a screw vacuum unit to be further compressed after passing through a heat exchanger B and a buffer tank, and finally, the gas is completely discharged into an absorption tower. The vacuum gas is condensed and compressed step by step through multi-stage heat exchange, so that components with higher boiling points in the gas are ensured to be fully liquefied, the load of a vacuum unit is greatly reduced, and the high vacuum requirement of cracking dimethyl dichlorosilane hydrolysate is met; and components with higher freezing points are not crystallized, and device system faults caused by blockage of pipeline facilities of a vacuum unit due to crystallization are avoided.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

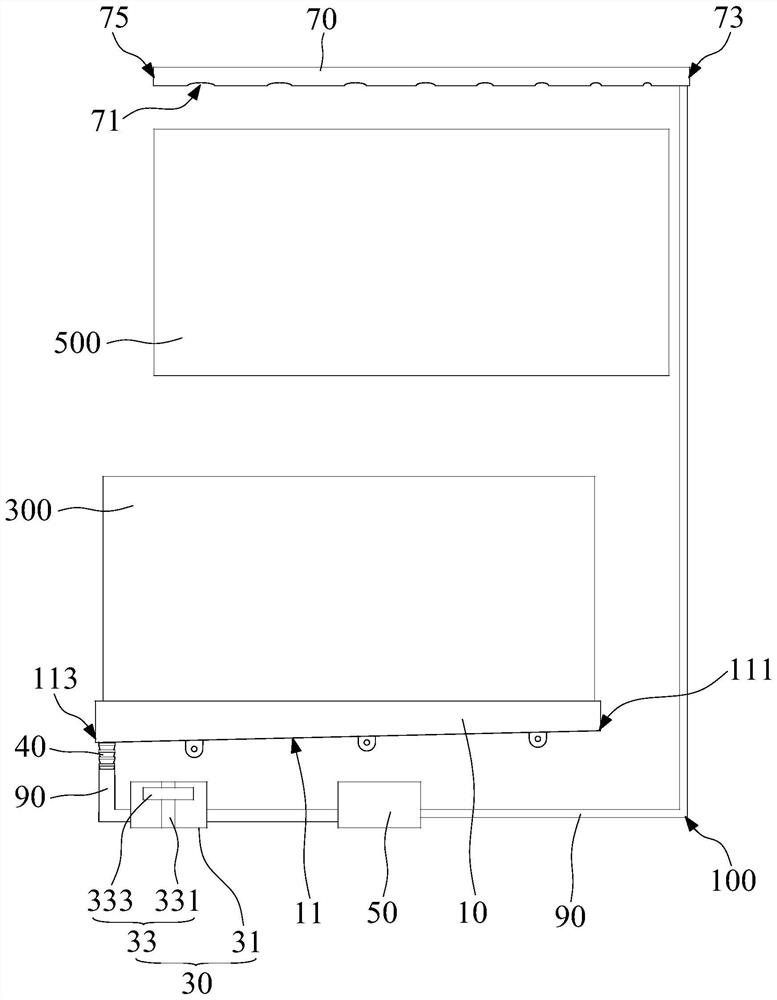

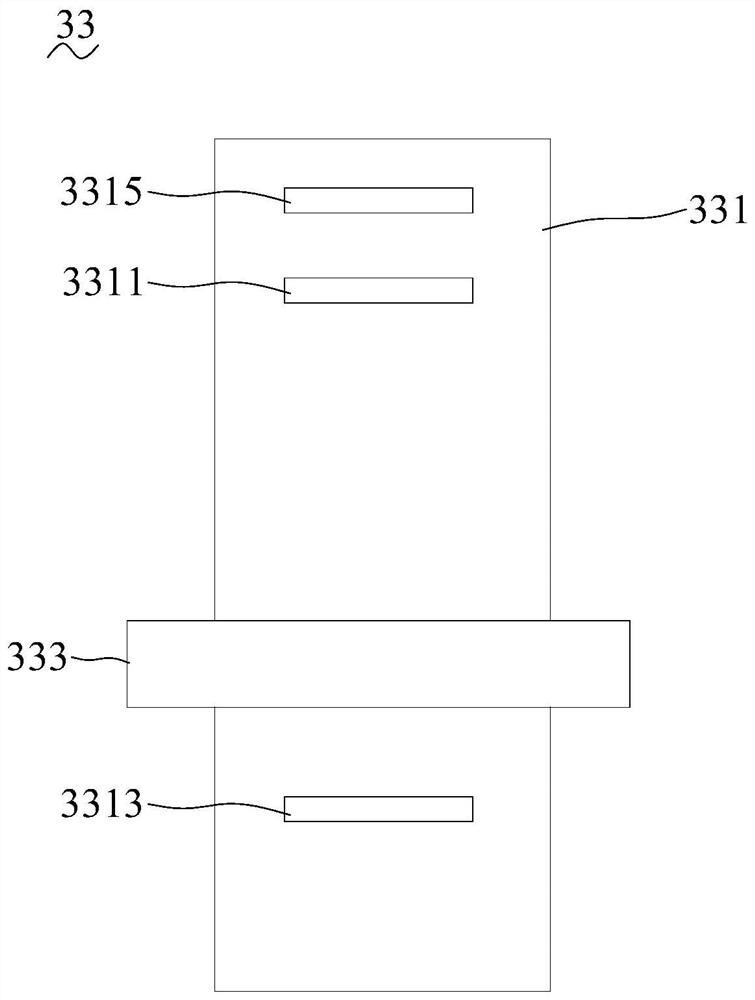

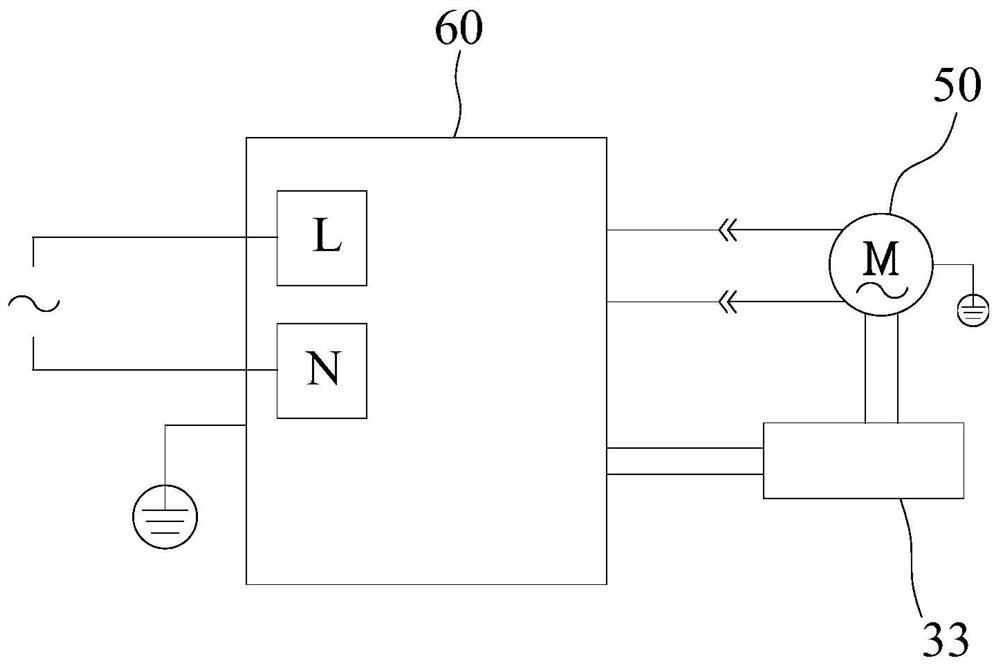

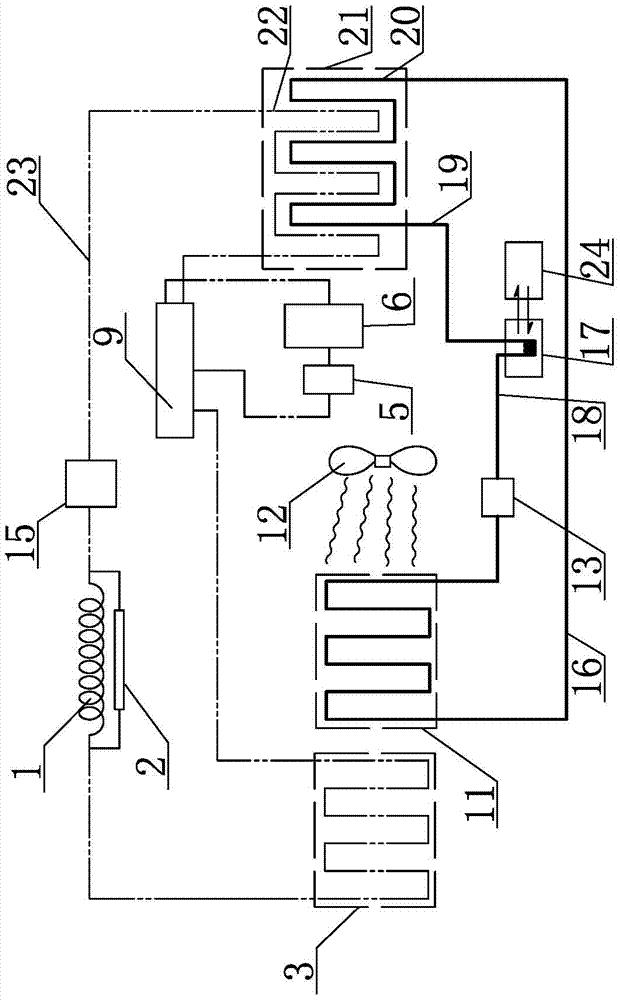

Condensation circulating device and cabinet air conditioner

PendingCN111811058AEasy to storeReduce liquefactionMechanical apparatusCondensate preventionWater storageEnvironmental engineering

The invention provides a condensation circulating device and a cabinet air conditioner. The condensation circulating device is suitable for being arranged between an evaporator and a condenser, the condensation circulating device comprises an evaporator water pan, a water storage box, a water pump, a condensed water distributor and a circulating pipeline, the evaporator water pan is suitable for being arranged below the evaporator, the water storage box comprises a water tank and a water level sensing assembly, the water tank communicates with the evaporator water pan and located below the evaporator water pan, the water level sensing assembly is installed in the water tank, the water level sensing assembly comprises a sensing part and a suspension part which are matched to output a waterlevel signal, the water pump starts or stops running according to the water level signal, the condensate water distributor is provided with a drain hole, the drain hole is suitable for facing the condenser, the circulating pipeline is connected to the evaporator water pan and the water tank, connected to the water tank and the water pump and connected to the water pump and the condensate water distributor, and after the condensation circulation device is installed on the cabinet air conditioner, energy consumption of the cabinet air conditioner can be reduced.

Owner:SHENZHEN ITEAQ NETWORK POWER TECH CO LTD

Method and equipment for coproducing chondroitin sulfate, II-type collagen oligopeptide and II-type collagen polypeptide through liquefying animal cartilages

ActiveCN108948186AImprove processing effectImprove processing efficiencyConnective tissue peptidesPeptide preparation methodsEngineeringLiquefaction

The invention discloses equipment for liquefying animal cartilages. The equipment comprises an outer cavity, a first liquefying cavity and a second liquefying cavity, wherein an upper cover is detachably arranged at the upper end of the outer cavity in a sealing manner, a lower sealing cover is openably / closeably arranged at the lower end in a sealing manner, and a feeding hole and a first gas inlet are formed in the upper cover; the first liquefying cavity is coaxially arranged in the outer cavity in an up-down sliding manner; and the top surface of the second liquefying cavity is fixedly connected to the outer side wall of the outer cavity, and then the lower end of the outer cavity stretches into the second liquefying cavity. The invention further discloses a method for coproducing chondroitin sulfate, II-type collagen oligopeptide and II-type collagen polypeptide through liquefying the animal cartilages. According to the equipment, the animal cartilages can be subjected to primaryliquefaction and secondary liquefaction so as to generate liquefied matters, so that the processing flow of the animal cartilages is simplified, and the production efficiency is improved.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

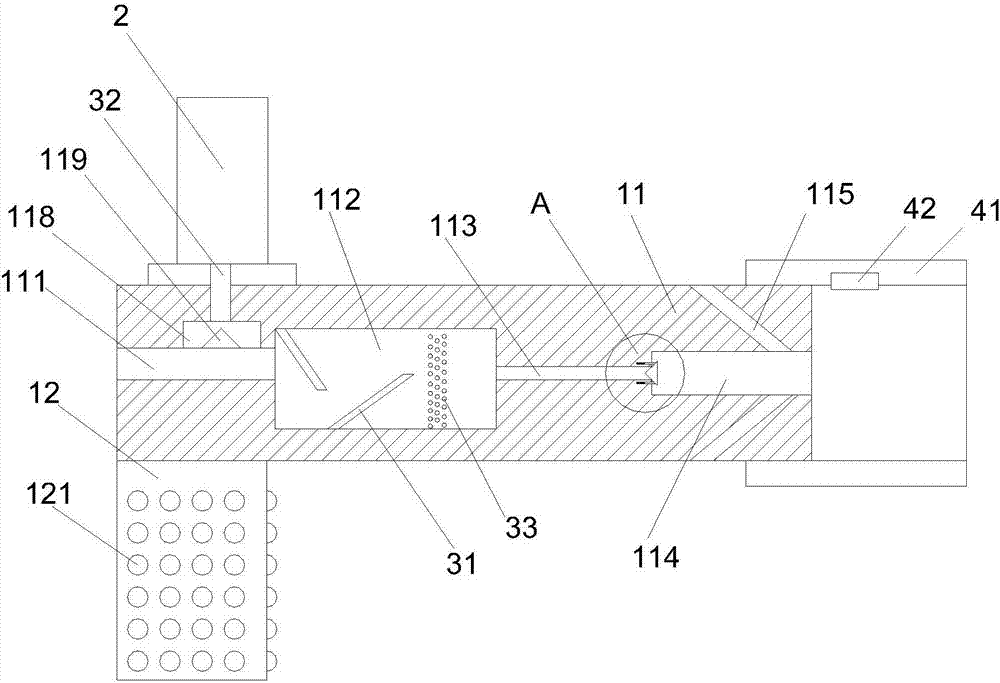

Plastic spraying gun capable of effectively reducing gasification of plastic spraying powder in plastic spraying process

ActiveCN106853418AGood for homogenization and liquefactionTo achieve a consistent effect of liquefactionLiquid spraying apparatusEngineeringOxygen

The invention discloses a plastic spraying gun capable of effectively reducing gasification of plastic spraying powder in the plastic spraying process. The plastic spraying gun comprises a plastic spraying gun body, a powder bottle, a mixing assisting device and a flame stabilizer. The plastic spraying gun body comprises a gun barrel and a gun handle, and the gun barrel is provided with a flammable gas guiding and conveying channel, a powder and gas mixing cavity, a communication channel, an exhaust channel and multiple oxygen introduction channels. The mixing assisting device comprises multiple flow guide plates and a plastic spraying powder guiding and conveying pipe, the flow guide plates are obliquely installed in the powder and gas mixing cavity and sequentially arranged along the flammable gas guiding and conveying channel and close to the communication channel, the inclination directions of any two adjacent flow guide plates are opposite, and any two adjacent flow guide plates are connected with the inner walls of the two opposite sides of the powder and gas mixing cavity; the flame stabilizer comprises a flame stabilizing frame and an ignition device, the flame stabilizing frame is detachably installed on the gun barrel and located on the exhaust channel, and the ignition device is installed on the flame stabilizing frame. The plastic spraying gun is convenient to use, plastic powder uniformity and liquefaction are benefited.

Owner:TIANCHANG JINLING ELECTRONICS

Double-medium circulating cooling and heating energy-saving air conditioner

InactiveCN107166602AThere will be no loss of adjustment abilityReach heatingMechanical apparatusSpace heating and ventilation detailsRemote controlWater source

The invention belongs to the field of indoor temperature regulation devices and particularly relates to a double-medium circulating cooling and heating energy-saving air conditioner. The double-medium circulating cooling and heating energy-saving air conditioner comprises a unit body, and an air inlet and an air outlet are formed in the unit body. The double-medium circulating cooling and heating energy-saving air conditioner is characterized in that a heat exchange fan, a water circulating system, a refrigerant circulating system and a heat exchanger are installed in the unit body; the heat exchanger comprises a water heat exchange pipe and a refrigerant heat exchange pipe, and the two sets of pipelines are mutually twined and stacked together, but do not communicate with each other; the water circulating system communicates with the water heat exchange pipe of the heat exchanger; and the refrigerant circulating system communicates with the refrigerant heat exchange pipe of the heat exchanger. According to the double-medium circulating cooling and heating energy-saving air conditioner, the advantages of a water air conditioner and a refrigerant circulating air conditioner are combined, the heat exchanger replaces an outdoor unit air cooling heat exchange part of a traditional refrigerant circulating air conditioner, heat exchange is conducted through an underground water source with the relatively-constant temperature, the dry problem of air under normal operation of the refrigerant air conditioner is improved through an independent humidifying system, temperature and humidity control and remote control can be achieved simultaneously, and the design is more humanized.

Owner:SHANDONG YICUN AIR CONDITIONING

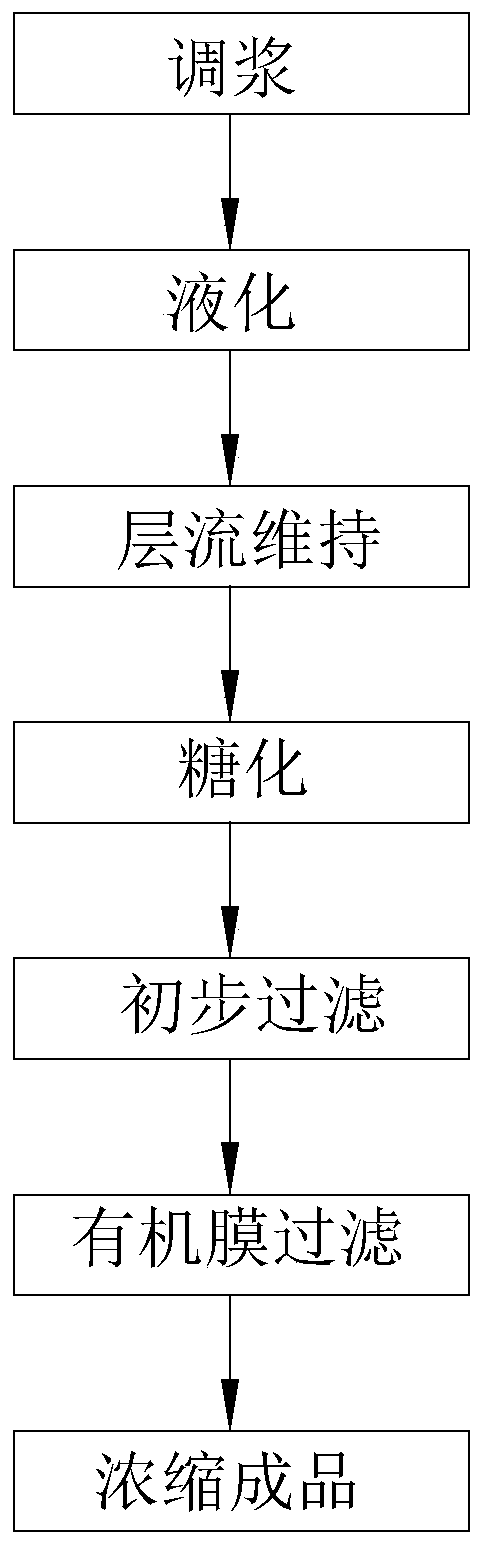

Production process of corn starch syrup

InactiveCN110885867AWill not gelatinizeImprove liquefactionEnergy inputFermentationPhysical chemistryProcess engineering

The invention relates to a production process of corn starch syrup, and relates to the technical field of syrup production. The production process comprises size mixing, liquefaction, laminar flow maintenance, saccharification, preliminary filtration, organic membrane filtration and finished product concentration so that the corn starch syrup is prepared. In the size mixing step, the temperature is raised to 60-65 DEG C by utilizing production waste heat, the temperature of the corn starch reaches the critical heat-resisting temperature of the corn starch, at the temperature, the corn starch cannot be gelatinized, the temperature is increased from 60-65 DEG C to 103-115 DEG C required by the liquefaction stage, the medium temperature difference is small, the required heating time is short,and in the process, few composite decomposition reactions are generated, few byproducts are generated and the liquefaction effect is good.

Owner:双桥(厦门)有限公司

Use method of water in glucose production

The invention discloses a use method of water in glucose production. The glucose production includes the steps of mixing by water, liquefying, saccharification,ion exchange for removing impurities, evaporation, centrifugation and affination for obtaining mother liquor and mother liquor drying; wherein the centrifugation and affination step adopts softened water obtained by reverse osmosis for affination, and the water used in mixing and the water for producing softened water by reverse osmosis are condensed water produced by the evaporation and drying steps. The invention comprehensively utilizes the condensed water, concentrated water and water for washing ion exchange column, thus being sufficient for normal production water supply; production waste water is comprehensively recycled and utilized, thus not only reducing production cost but also having good social benefit.

Owner:WEIFANG SHENGTAI PHARM CO LTD

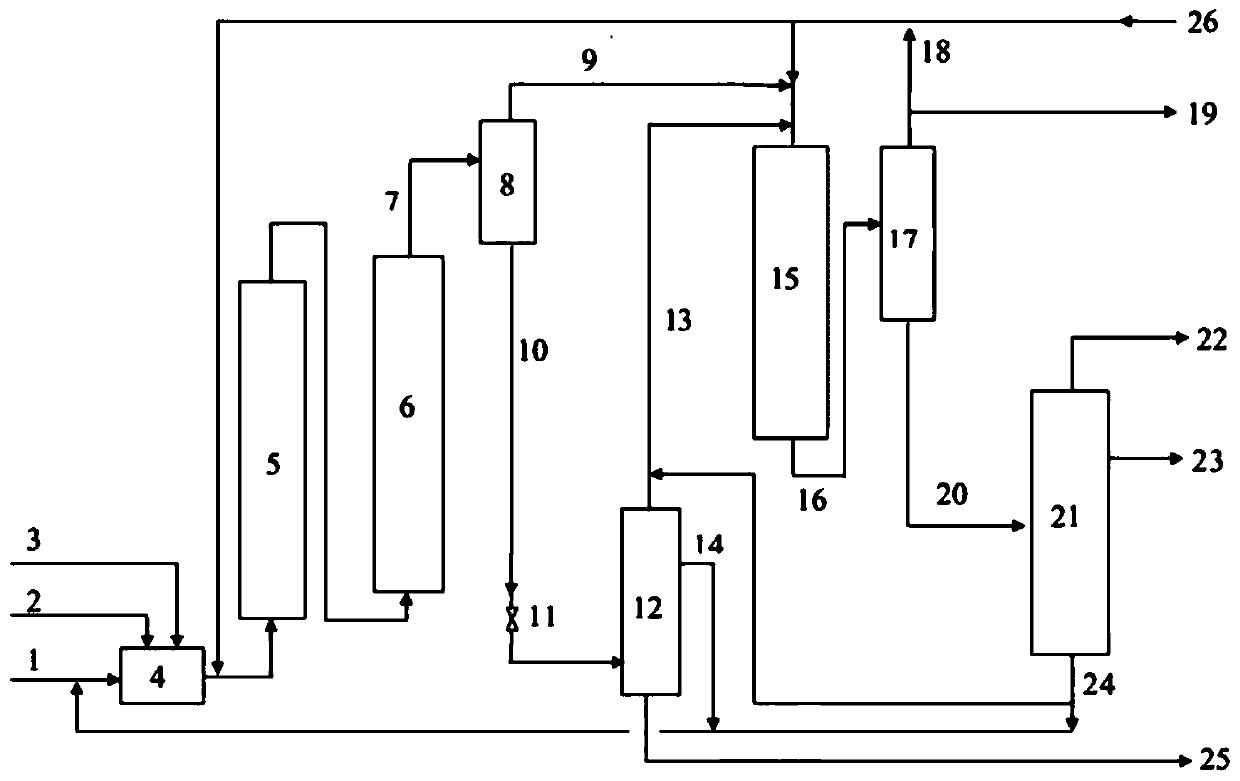

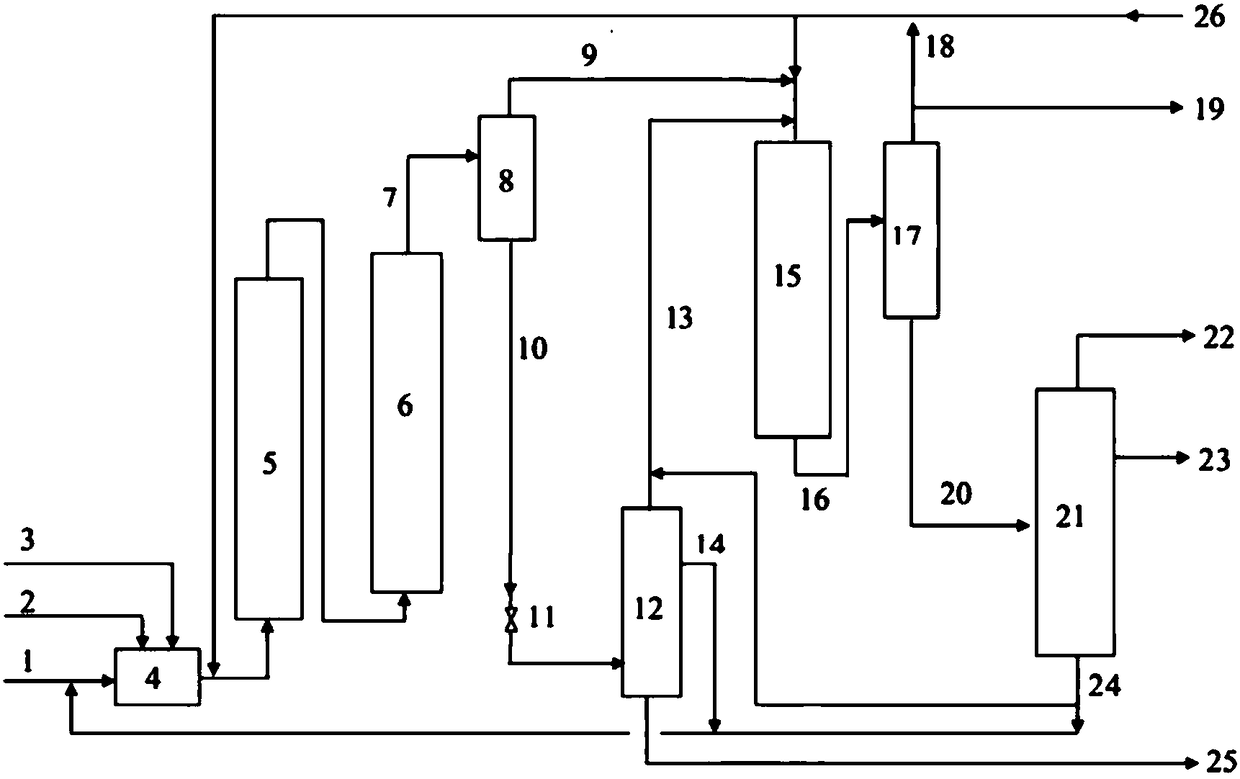

Method for direct liquefaction of biomass

The invention discloses a method for direct liquefaction of biomass. The method includes the following steps: (1) mixing the biomass, a hydrogenation catalyst and a hydrogen donor solvent to obtain abiomass slurry; (2) performing first liquefaction reaction on the biomass slurry and hydrogen to collect a first reaction product; (3) performing second liquefaction reaction on the first reaction product and hydrogen to collect a second reaction product; (4) performing first gas-liquid separation on the second reaction product at 290 to 460DEG C to collect a first liquid phase and a first gas phase; (5) performing second gas-liquid separation on the first gas phase at 30DEG C to 60DEG C to collect a second liquid phase, and mixing the first liquid phase and the second liquid phase to obtain aliquid phase; (6) performing first distillation on the liquid phase to collect a light fraction and a heavy fraction; and (7) performing second distillation on the heavy fraction to separate distillate oil and residue, wherein the light fraction and the distillate oil are liquefied liquids. The liquid yield obtained by the method is high, and the residual solid content in the liquids is low.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

Maltodextrin liquefaction process

PendingCN112301078APrecisely control the DE valueControl DE valueFermentationPhysical chemistryIon exchange

The invention relates to a maltodextrin liquefaction process. On the basis of the prior art, a maltodextrin product with better quality is obtained by improving the liquefaction process. The method comprises the specific steps of raw material preparation, size mixing, liquefaction, decolouration and filtration, ion exchange and concentration treatment and the like. In the liquefaction process, secondary enzyme addition and tertiary high-temperature injection treatment are used; parameters of each stage are accurately controlled; and thus, high-quality maltodextrin is obtained.

Owner:河南飞天生物科技股份有限公司

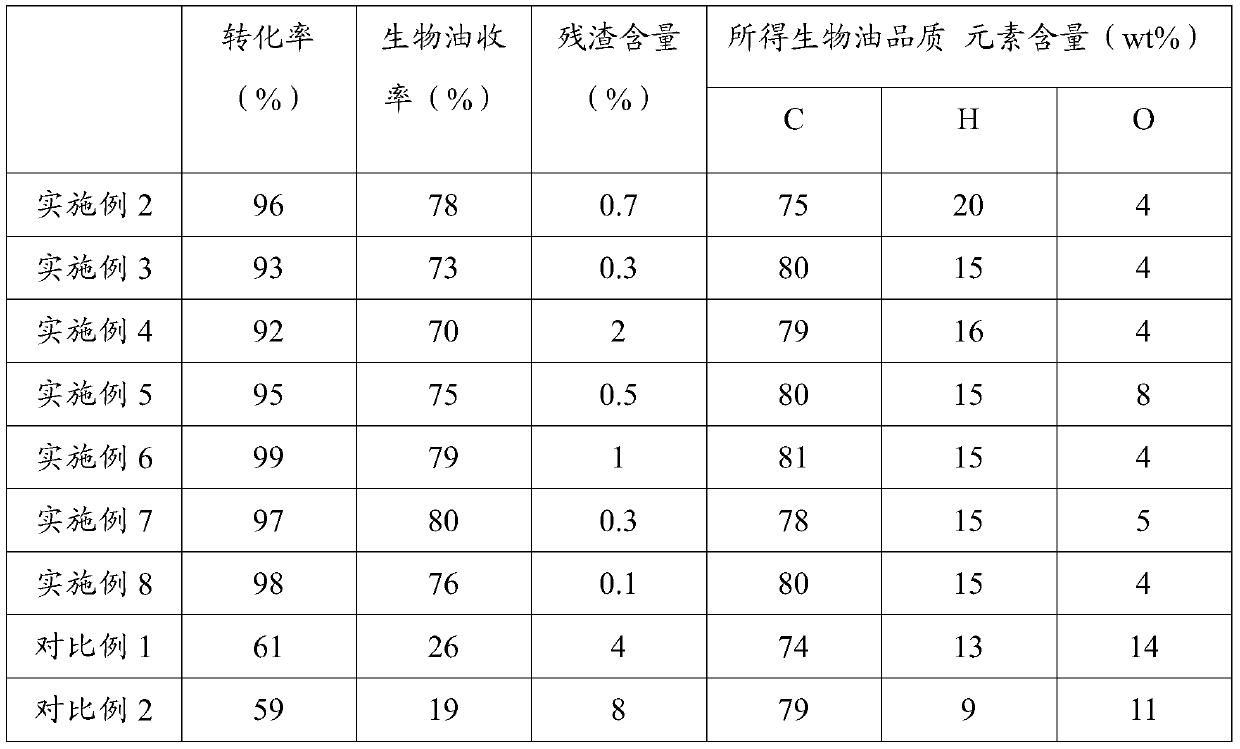

Two-stage conversion refining technology for biomass

ActiveCN109536193AHigh calorific valueRealize conversion active hydrogen hydrogenationLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesChemical industryPtru catalyst

The invention belongs to the technical fields of biomass utilization, energy and chemical industry, and concretely relates to a two-stage conversion refining technology for biomass. The conversion technology uses at least one of iron oxide, a desulfurization waste agent of the iron oxide or a regenerated material of the desulfurization waste agent of the iron oxide as a catalyst, and controls a molar ratio of the iron element to the sulfur element in a reaction system. It is found that in carbonylation can be effectively utilized to block the free radical polycondensation of the biomass in thecracking process in the presence of CO and realize active hydrogen transformation and hydrogenation of CO and water; and the biomass, especially the biomass solid, can directly undergo a conversion reaction without being hydrated in the conversion reaction, and water can be externally added to a biomass liquid or mineral oil, so the liquefaction yield is increased, the calorific value of an obtained oil product is improved, and a large amount of waste water is not generated after the conversion reaction is completed.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Purification device for volatile chemical organic compounds

InactiveCN110960879APrevent volatilizationFully airtightFractional distillationSimple Organic CompoundsThermodynamics

The invention discloses a purification device for volatile chemical organic compounds. The purification device comprises a tank body and a condensation tank, wherein the tank body comprises an outer tank and an inner tank, the outer tank is of a cylinder structure with two closed ends, the inner tank is arranged in the outer tank, a partition plate is arranged between the inner tank and the outertank, a first cavity is formed between the partition plate and the outer tank, and a second cavity is formed between the partition plate and the inner tank; a stirring mechanism is arranged at the bottom of the tank body; a connecting pipe is arranged on the side surface of the tank body, the connecting pipe is communicated with a condensation tank, and a first condensation mechanism and a secondcondensation mechanism are arranged in the condensation tank; a recovery tank is arranged at the bottom of the condensation tank; by arranging the first cavity and the second cavity, graded heating ofthe tank body is achieved, the fractionation temperature of organic matters is accurately controlled, the purification purity of the organic matters is further improved, the sealing effect is good, and volatilization of the organic matters is prevented.

Owner:郑州超之肽生物技术有限公司

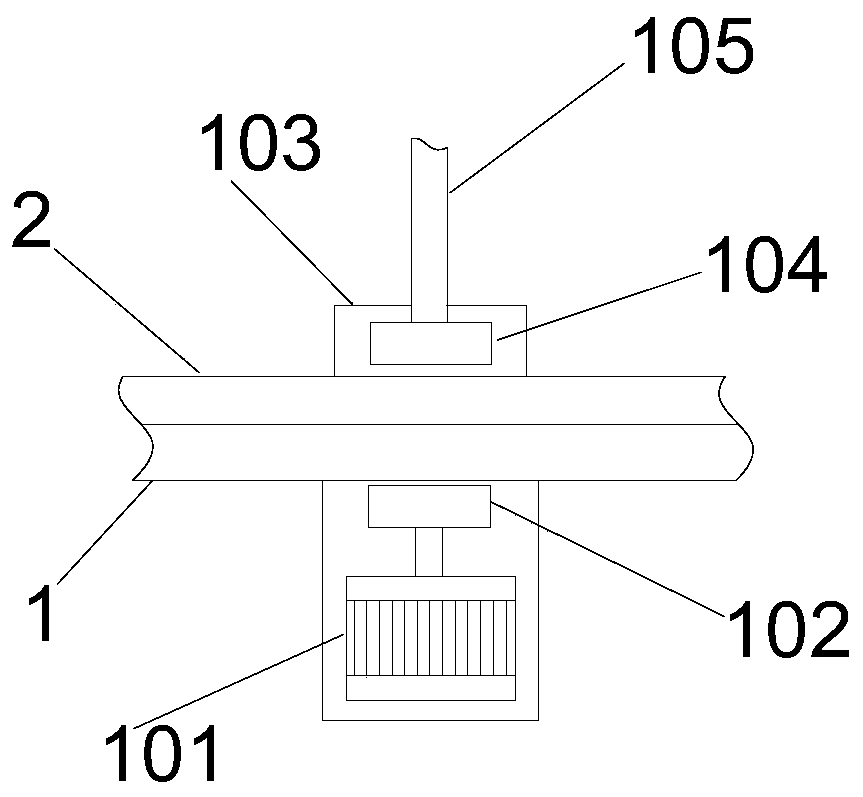

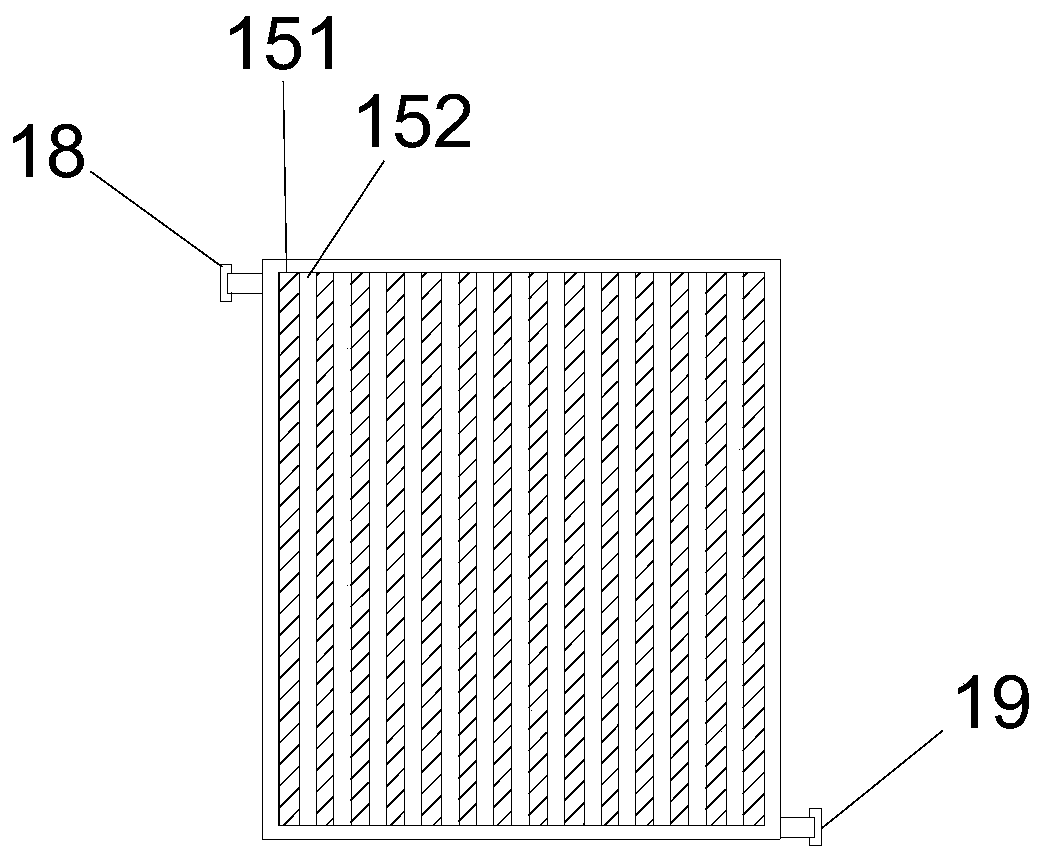

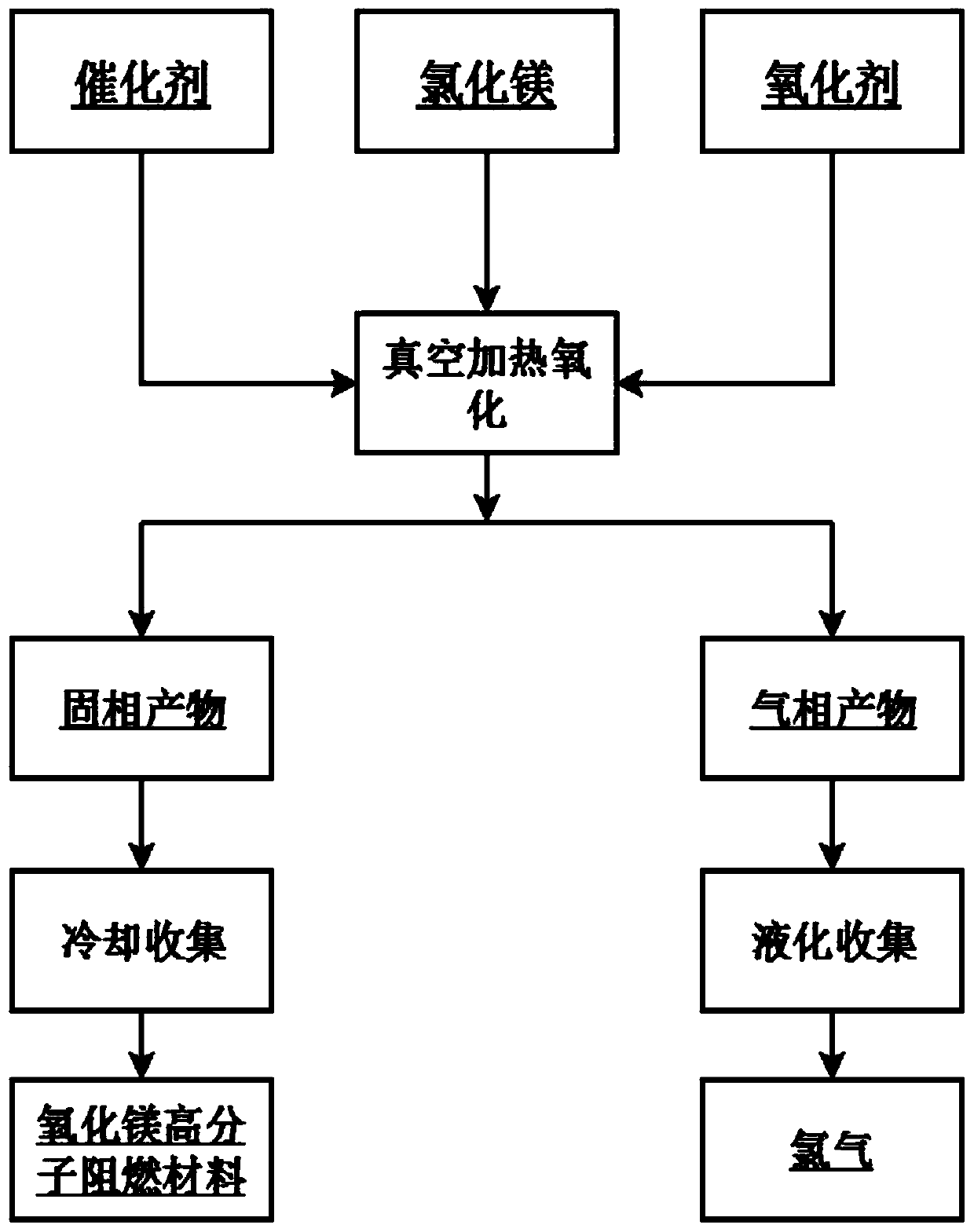

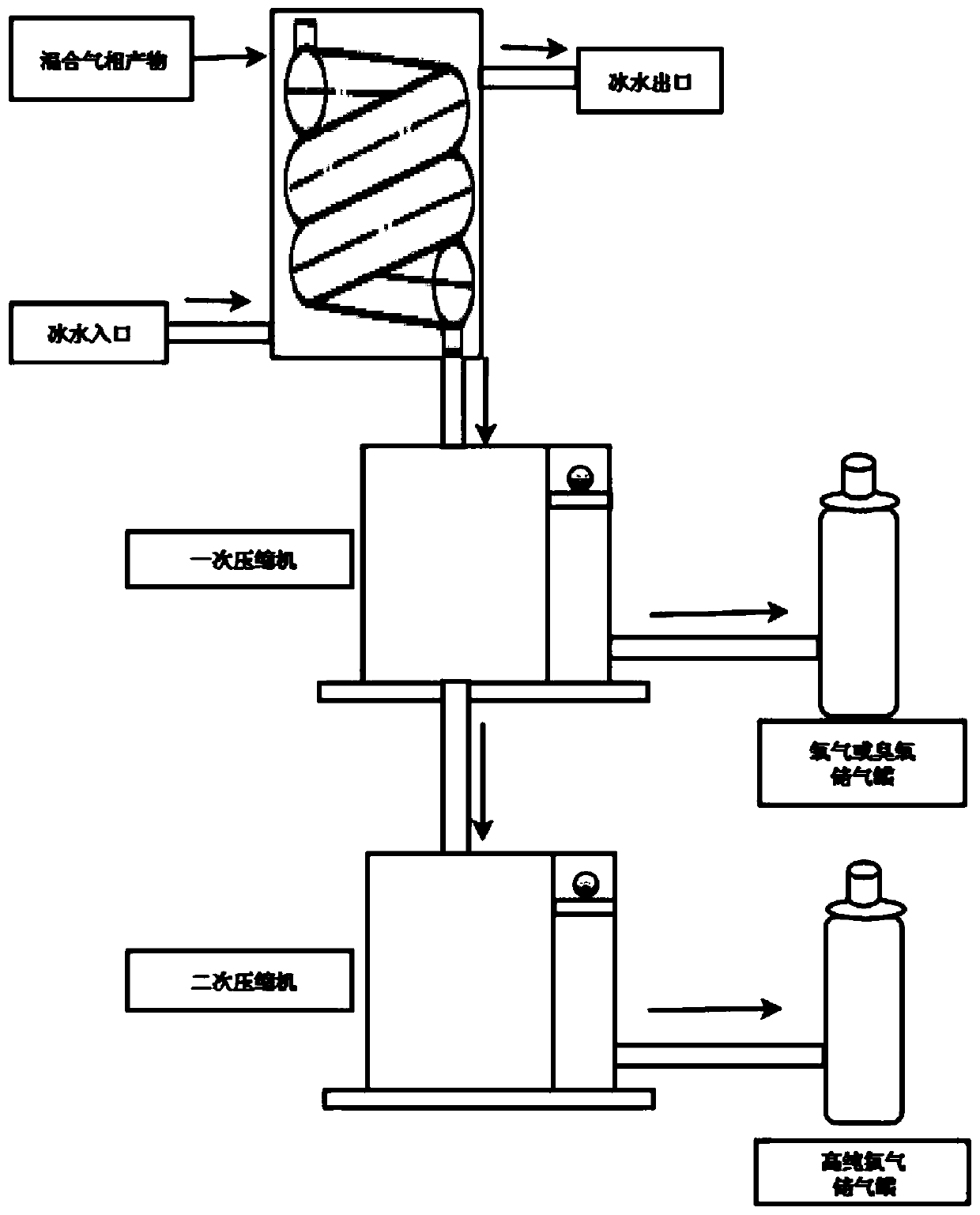

Method for obtaining high-purity chlorine by efficiently utilizing magnesium chloride residues in low-temperature vacuum system

ActiveCN110498397ALow reaction temperatureFast reaction rateChlorine/hydrogen-chloride purificationEnergy inputChemistryMagnesium

The invention relates to the technical field of waste utilization, and concretely relates to a method for obtaining high-purity chlorine by efficiently utilizing magnesium chloride residues in a low-temperature vacuum system. Molten magnesium chloride residues generated in the production process of titanium sponge are introduced into an oxidation furnace under a vacuum condition, a catalyst is added, vacuum heating oxidation is carried out to make magnesium chloride fully oxidized at a low temperature, the waste heat of the molten magnesium chloride residues is efficiently utilized to reduce the energy consumption in oxidizing calcination or spray pyrolysis of magnesium chloride, and the obtained magnesium oxide has a high purity; generated mixed gas undergoes countercurrent cooling by adopting ice water, the liquefaction temperature in a purification device is controlled to be 11-13 DEG C, and it is ensured that the first-stage liquefaction pressure in the purification device is 5-6.5MPa and the second-stage pressure is 7-10 MPa, so the chlorine is fully liquefied while other gases in the mixed gas are fully separated from the chlorine, the safe production of the chlorine is guaranteed, and the high-purity chlorine liquid with the purity of 99.7% is obtained.

Owner:GUIZHOU UNIV

Preparation method of syrup special for moon cake

The invention relates to the field of starch sugar manufacturing, in particular to a preparation method of syrup special for moon cake. According to the method, corn starch is taken as the raw material, and the syrup is prepared through the steps such as size mixing, enzyme immersion, liquefaction, saccharification, glucoside conversion, decolorization, filtering, ion exchange, concentration, blending and the like. The prepared syrup comprises 20-25% of maltobiose, 12-17% of maltotriose, 15-20% of maltotetraose, 8-12% of tetrasaccharide-above, 3-5% of oligoisomaltose, 25-30% of fructose, and less than 3% of glucose. The syrup special for moon cake produced through the method is sucrose-free; the sweetness is slightly lower than that of the sucrose; the sweet taste is mild and pure, cool and refreshing; and the syrup is provided with a sweet flavor peculiar to honey, and has the advantages that the oil return property is obvious, the moisture retention property is good, the starch retrogradation is prohibited, the shelf life and the quality guarantee period of products are effectively prolonged, and the like.

Owner:BAOLINGBAO BIOLOGY

Drying device for textile thread production

InactiveCN112414007AImprove the vocal effectImprove precipitation efficiencyDrying solid materials without heatDrying gas arrangementsTextile technologyAir compression

The invention belongs to the technical field of textile, and particularly relates to a drying device for textile thread production. The following scheme is currently provided aiming at the problems existing in the prior art. According to the scheme, the drying device comprises a drying cylinder, wherein six annularly and uniformly distributed thread guide holes corresponding to each other are formed in each of two ends of the drying cylinder, an outer cylinder is fixedly connected to the outer wall of the side surface of the drying cylinder, an inner partition cylinder is fixedly connected tothe inner wall of the side surface of the outer cylinder and comprises a shell and an inner container, a semiconductor chilling plate is fixedly connected between the shell and the inner container, and the heating surface of the semiconductor chilling plate makes contact with the shell. According to the drying device, sharp sound is generated through air compression, water in textile threads can violently vibrate through vibration generated by air driven by the sound, and turbulence holes can improve the sound production effect, so that the efficiency of water precipitation in the textile threads is improved, the drying effect is improved, the sound inside the drying cylinder can be amplified, and the efficiency of water precipitation in the textile threads can be further improved.

Owner:夏海洋

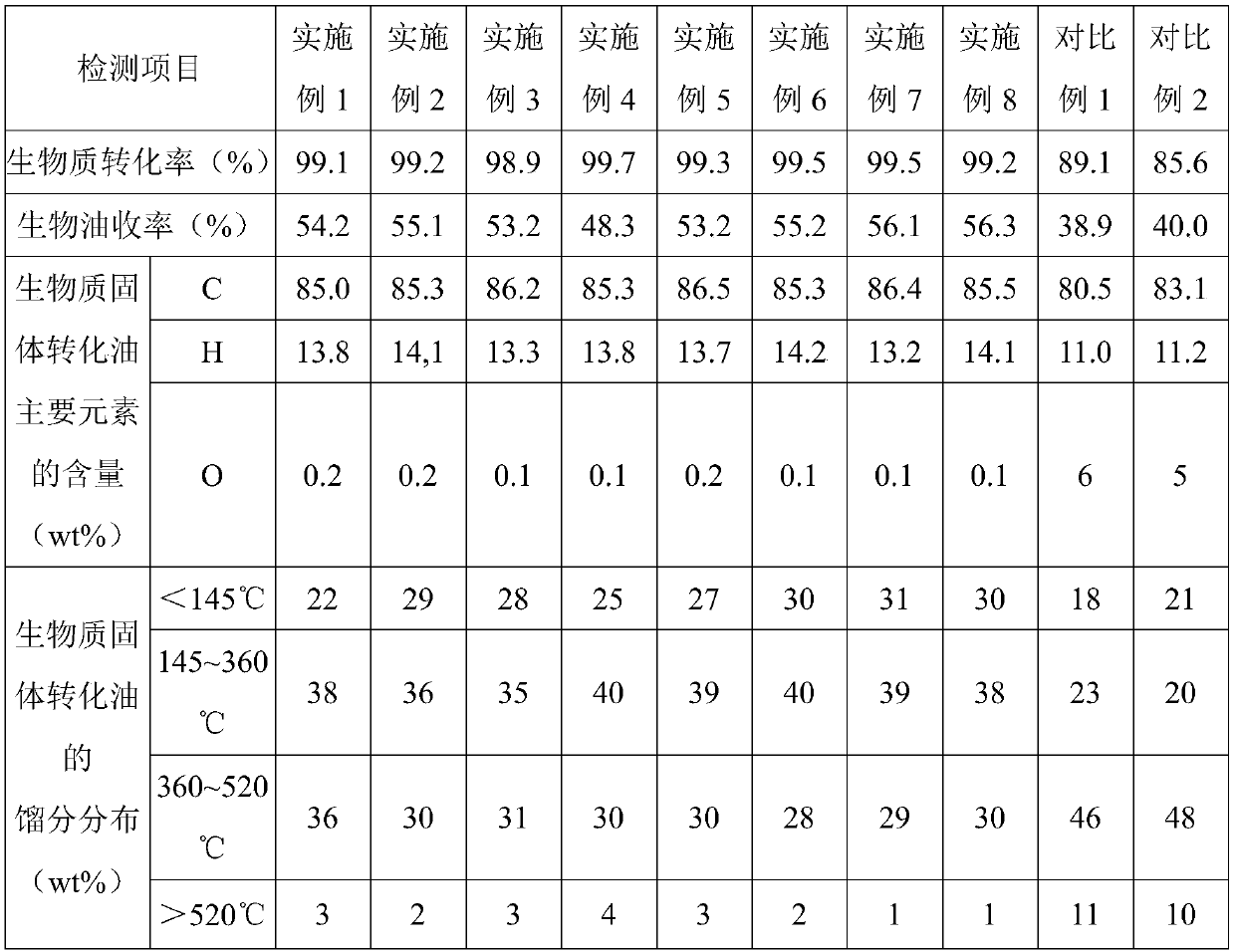

A method for producing light oil by liquefaction of biomass

ActiveCN108315039BImprove the efficiency of the liquefaction processGood suspensionLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesPtru catalystProcess engineering

The invention relates to the field of bioenergy, in particular to a method for producing light oil through liquefaction of biomass. Specific preparation steps of a biomass slurry are as follows: sequentially drying, primarily pulverizing, compressing and secondarily pulverizing straw, then mixing with a hydrogenation catalyst and a vulcanizing agent to obtain a mixture, adding the mixture into a solvent oil, grinding and slurrying to obtain the biomass slurry with the straw concentration of 30-60wt%. By an innovative technology of treating the straw through compression first and then secondarypulverization, through the compression of the biomass, the loose straw is rearranged, mechanically denaturated, shaped and fluidized and the like, so that the density and the specific gravity of thestraw are increased, dispersion of the straw in an oil product is facilitated, the content thereof in the oil product can be increased, the concentration of a reaction material is increased, the amount of the biomass delivered by a pump per unit time is increased, smooth operation and delivery of the pump are guaranteed, and the yield of the light oil is increased.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A multi-stage liquefaction process of coal and biomass

ActiveCN108285808BRealize mixing and liquefactionIncrease contactBiofuelsLiquid hydrocarbon mixture productionHigh pressureClean energy

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for producing light oil from biomass through liquefaction

ActiveCN108085041AGood suspensionGood dispersionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentSlurrySolvent

The invention relates to the field of biological energy, in particular to a method for producing light oil from biomass through liquefaction. Biomass slurry is prepared through specific steps as follows: plant oil residues are subjected to drying, primary smashing, compressing and secondary smashing in sequence and then mixed with a hydrogenation catalyst and a vulcanizing agent, a mixture is obtained and added to solvent oil to be ground into slurry, and the biomass slurry with plant oil residue concentration being 50wt%-65wt% is prepared. The plant oil residues are subjected to first compression and later secondary smashing initiatively with the treatment technology, the loose plant oil residues are subjected to re-arrangement, mechanical deformation and other stages successively by means of compression of biomass, so that density and specific gravity of the plant oil residues are increased, dispersion of the plant oil residues into the oil product is facilitated, content of the plant oil residues in the oil product can be increased, concentration of reaction materials is increased, delivery amount of the biomass in unit time by a pump is increased, and stable operation and delivery of the pump are guaranteed.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A process for producing fuel oil and chemical raw materials using coal and biomass

ActiveCN108251149BRealize mixing and liquefactionIncrease contactLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionWaste oil

The invention relates to the technical field of clean energy, and in particular relates to a co-processing process of coal and biomass. The invention creatively realizes mixing and liquefaction of thecoal, the biomass and oil for the first time. ''Crushing + compressing + re-crushing'' treatment is performed on the coal and biomass raw materials, a slurry is prepared, a biomass kerosene slurry which has a high solid content and can be conveyed smoothly by a pump is successfully obtained, and therefore waste oil with high viscosity which cannot be used as a liquefaction solvent of the coal andthe biomass in the prior art can also be utilized. According to the process provided by the invention, primary cracking is performed on the coal and the biomass, a hydrogenation reaction is performed, deep cracking is performed, and a hydrogenation reaction is performed, so that transformation from the coal and the biomass to fuel oil and chemical raw materials is realized, the conversion rate ofthe coal and the biomass can reach 90-99%, the yield of the fuel oil can reach 60-80%, and the content of residues is less than 3%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A kind of production process of preparing starch syrup from rice

ActiveCN106191159BIncrease added valueHigh solid contentFermentationHigh concentrationAdditional values

The invention discloses a production process for preparing starch syrup from rice. The production process comprises the following steps: (1) crushing and pulping; (2) liquefying; (3) carrying out column laminar flow heat preservation and solid-liquid separation; (4) extracting a rice protein nitrogen source; (5) saccharifying; (6) carrying out solid-waste-free filtering; (7) carrying out mixed bed refining and concentrating. According to the process disclosed by the invention, in a process of preparing the starch syrup, the energy consumption is reduced through blending high-concentration starch syrup, a pulping water temperature is controlled and the liquefying time is shortened; residual sugar is recycled from sugar-free grains produced in a production process and fat in the sugar-free grains is hydrolyzed by adopting alkaline lipase; protein of the rice sugar-free grains is hydrolyzed by proteinase to prepare an organic nitrogen source, and fermentation raw materials for foods and medicines. The process disclosed by the invention is remarkably better than a traditional process for preparing the starch syrup from the rice; the production cost is low and an additional value of a product is improved; the content of produced solid wastes is extremely less and the production process is economical and environmentally friendly.

Owner:双桥(湖北)有限公司

An air energy water heater

ActiveCN110793200BGuaranteed thermal conductivityReduce adhesionFluid heatersEngineeringWater heater

The invention provides an air energy water heater, and relates to the field of water heaters. The air energy water heater comprises a heat exchange box, wherein a heat exchange tube is arranged in theheat exchange box; the top end of the heat exchange tube is fixedly connected to a first rotary mechanism; the heat exchange tube communicates with the inner part of the rotary mechanism; the first rotary mechanism is fixedly arranged in the heat exchange box; the bottom end of the heat exchange tube is fixedly connected to a second rotary mechanism; and the second rotary mechanism is fixedly arranged in the heat exchange box. In the air energy water heater, the heat exchange tube rotates to generate friction with water, so that attachment of water scales is reduced, heat conduction of the heat exchange tube is guaranteed, water molecule motion speed can be increased, and therefore, heat exchange efficiency is improved, flowing time, in the heat exchange tube, of a medium is shortened, and the high-temperature medium is in sufficient contact with a heat exchanger to improve heat exchange degree; meanwhile, the medium can be sufficiently liquefied after releasing energy, so that a throttle device connected behind the heat exchanger is protected; and a connecting shaft is kept in sealing with the first rotary mechanism and the second rotary mechanism through a sealing ring.

Owner:浙江德富新能源技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com