Patents

Literature

64results about How to "Fast reaction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adsorbent sheet material for parallel passage contactors

ActiveUS7077891B2Maximize capacityImprove efficiencyMaterial nanotechnologyOther chemical processesParticulatesSorbent

An adsorbent material fabricated into a reinforcement-free, self-supported coherent thin sheet and configured for use as a parallel passage contactor element in adsorption / separation applications with gases and liquids is disclosed. The adsorbent sheet material is obtained by enmeshing fine adsorbent particulates in a polymer binder. Particulates include but are not limited to carbon particles, inorganic oxides particles, or ceramic particles, or synthetic polymer resin particles. The adsorbent sheet advantageously contains a large volume percentage of active adsorbent particles. The parallel passage contactor device fabricated from the adsorbent sheet material is characterized by minimal mass transfer resistance and better separation efficiency expressed as height equivalent to a theoretical plate, while it maintains most of the adsorptive properties of the starting particulates, and can be used in gas separation applications with short adsorption cycles, such as rapid pressure swing adsorption, rotary concentrators, rapid electric swing adsorption.

Owner:AIR PROD & CHEM INC

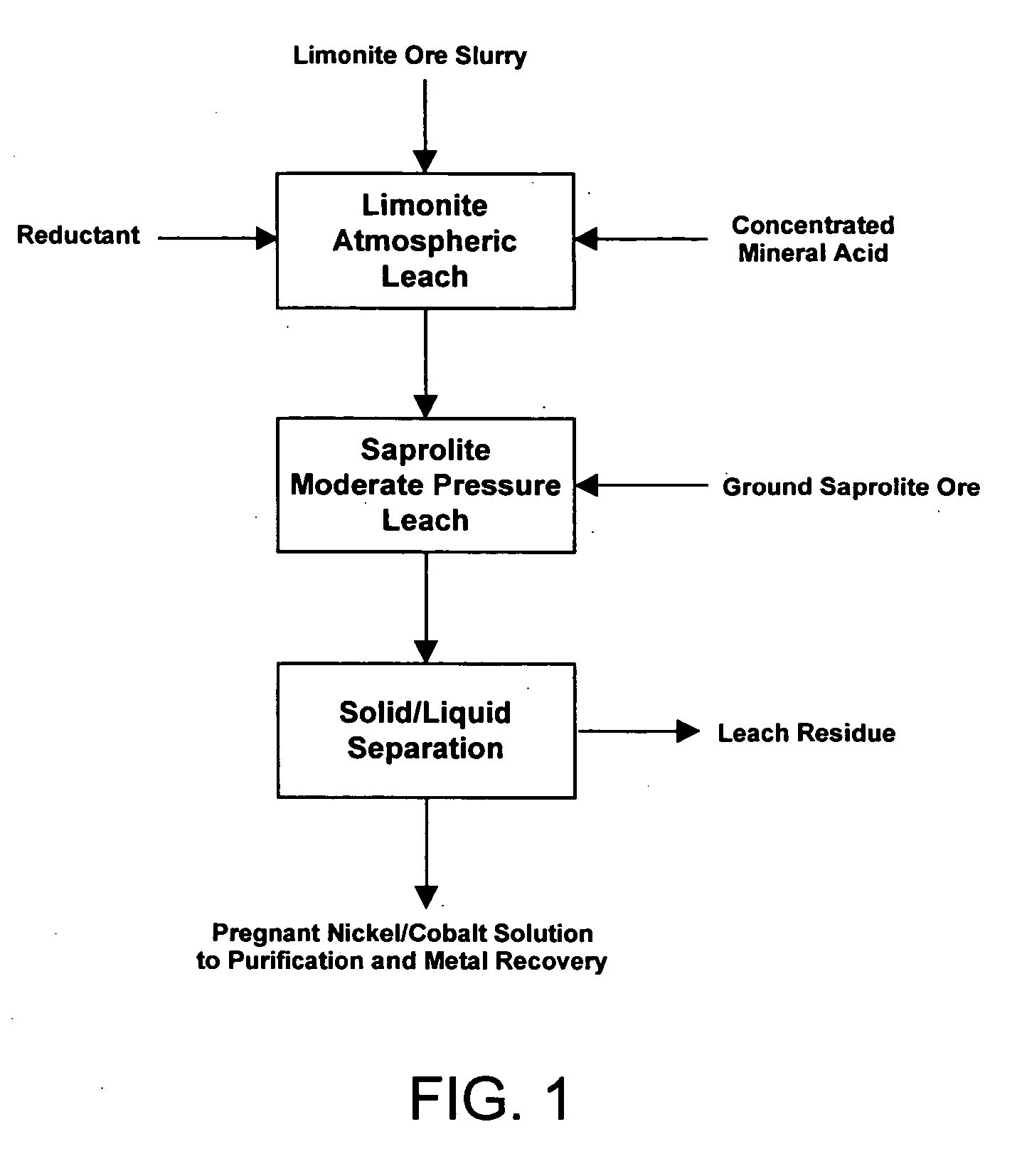

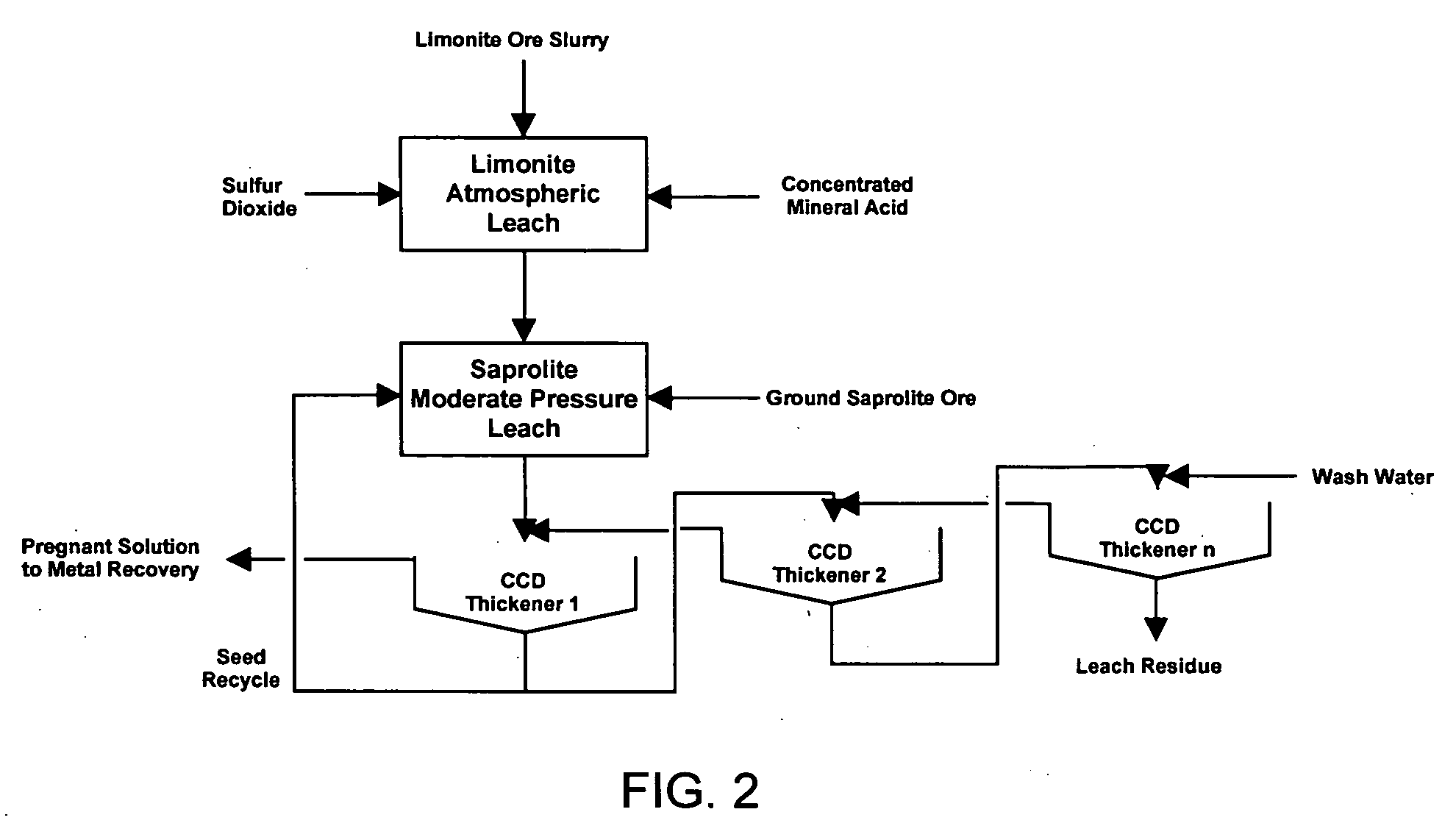

Method for nickel and cobalt recovery from laterite ores by combination of atmospheric and moderate pressure leaching

InactiveUS20060024224A1Efficient leachingEfficient separationIron compoundsCobalt compoundsRecovery methodIon exchange

A process for leaching laterite ores containing limonite and saprolite. Sufficient mineral acid is added to a slurry of limonite which is leached at atmospheric pressure to dissolve most of the soluble non-ferrous metals and soluble iron. After adding saprolite the slurry is further leached at a temperature above the normal boiling point and at a pressure above atmospheric pressure for a time sufficient to leach most of the contained nickel in the saprolite and to precipitate most of the iron in solution. The pressure of the slurry is then reduced, and nickel and / or cobalt is subsequently recovered from the leach solution by solvent extraction, resin-in-pulp or other ion exchange, sulfide or hydroxide precipitation, or other recovery method.

Owner:SKYE RESOURCES

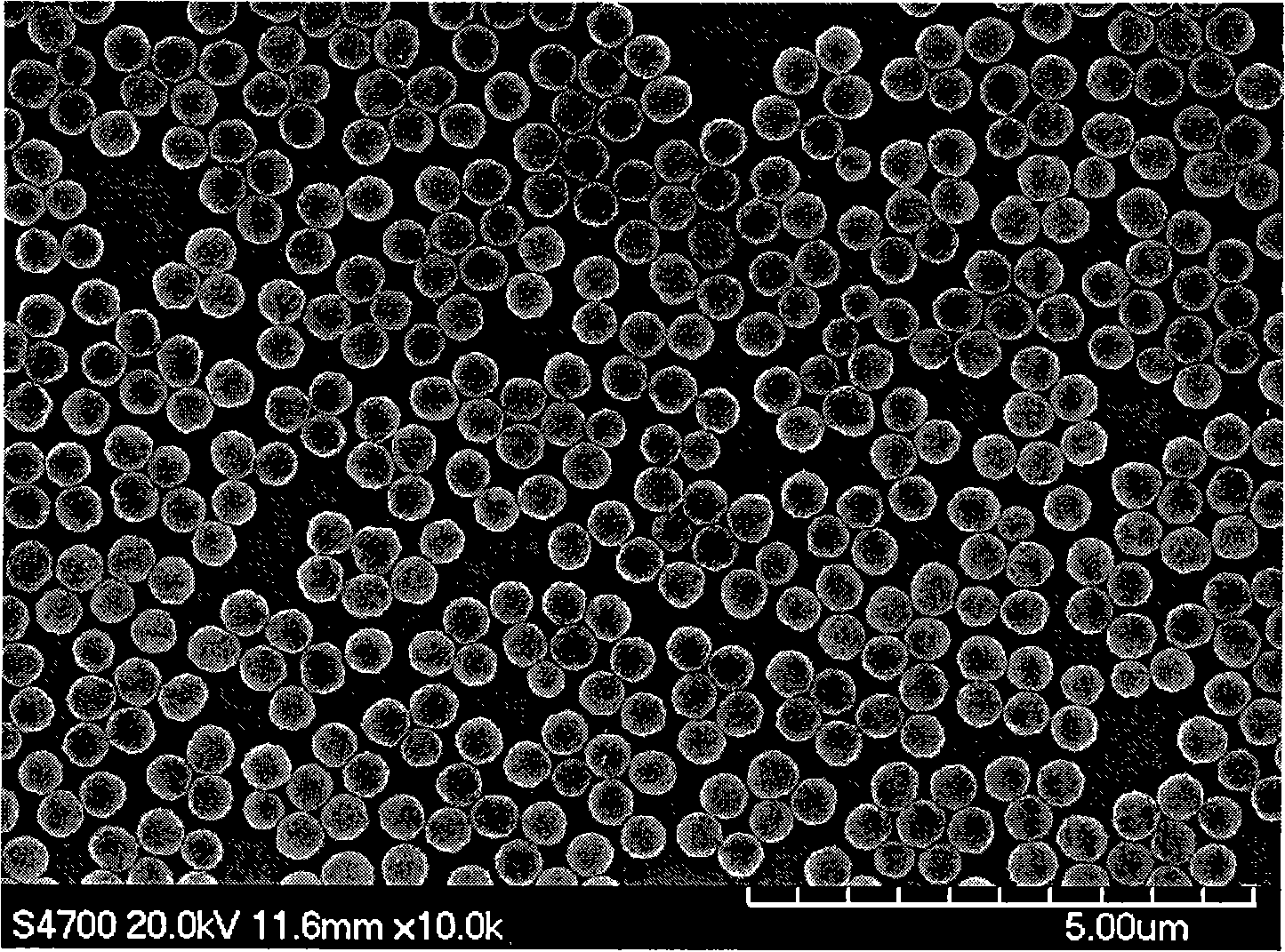

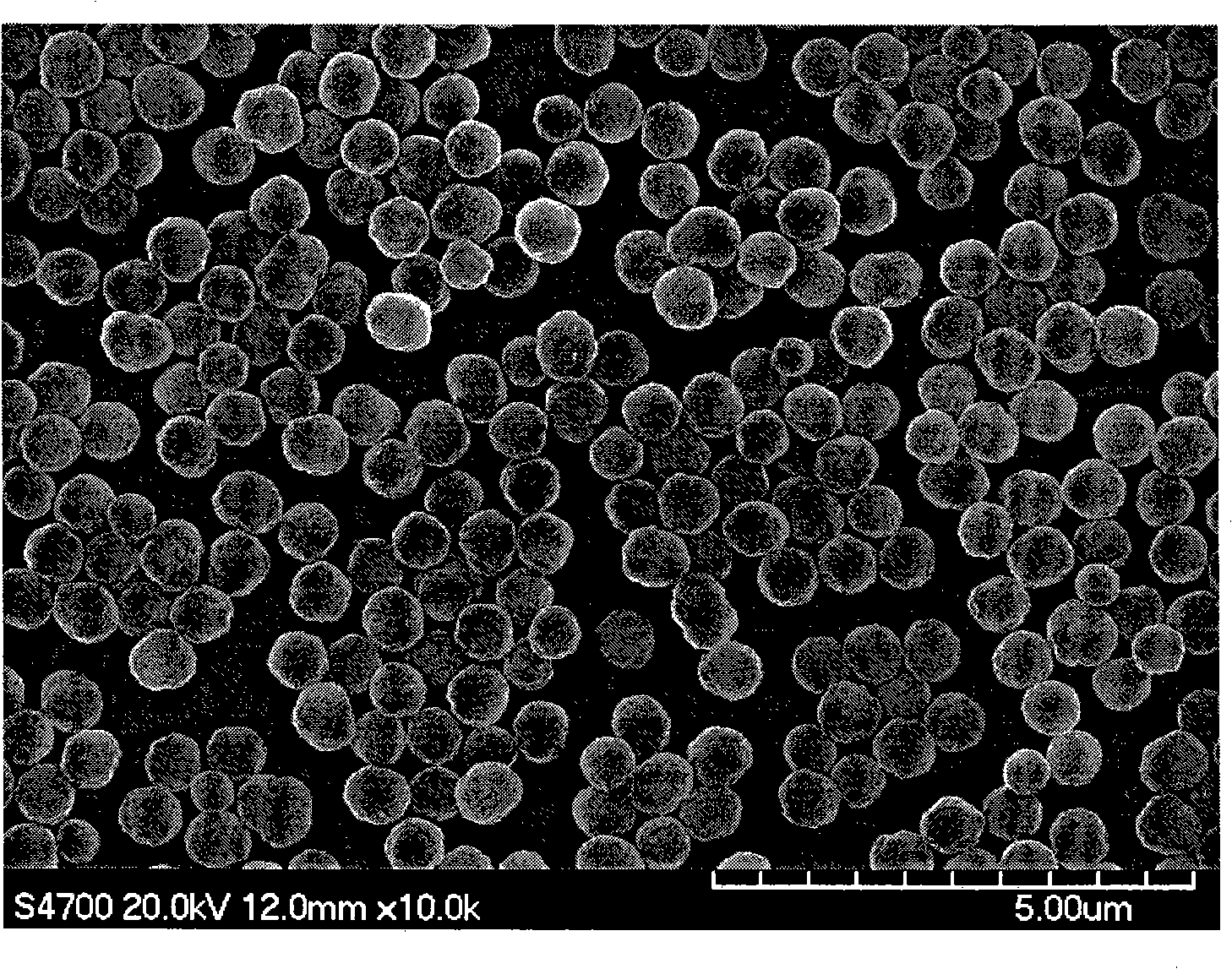

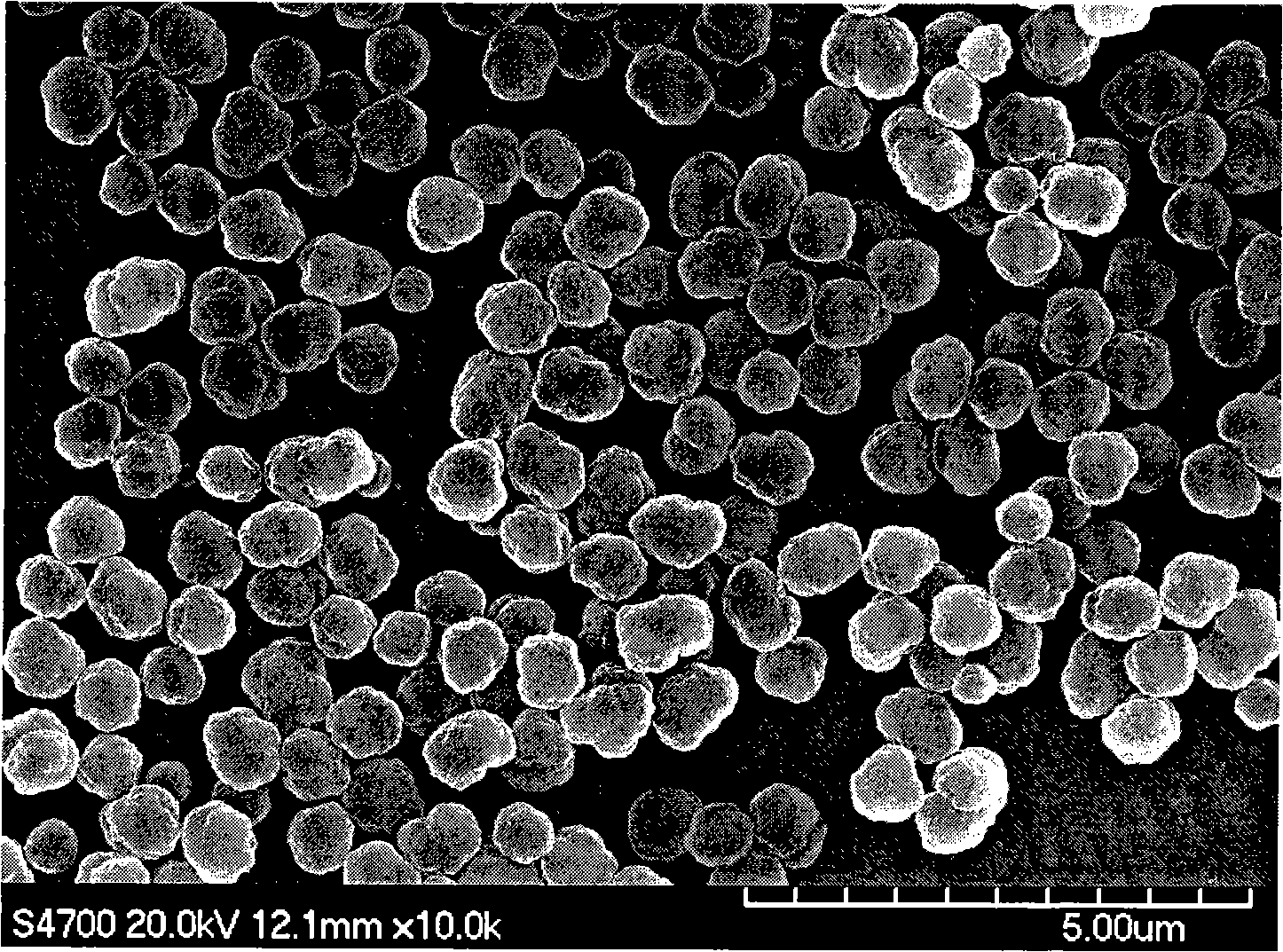

Process for preparing cross-linking maleic anhydride-vinyl acetate copolymer

A cross linking maleic anhydride-vinyl acetate copolymer preparation method belongs to the field of copolymers. The invention is characterized in that a polymerization reaction system comprises a reactive monomer, cross linking agents, initiators and medium; the reactive monomer is maleic anhydride and acetate vinyl, and the mol ratio is from 1:9 to 9:1; the mass concentration of the monomer in the polymerization system is from 0.45 percent to 45 percent; the cross linking agents being used are polyfunctionality organic molecules; the initiators being used are organic peroxides or azo compounds; the mass of the initiator is 0.02 percent to 1 percent of the total monomers; the rest is the medium; the copolymerization lasts 4 to 24 hours. The invention does not use stabilizers, does not introduce impurities such as surface active agents, etc. into the surfaces of particles to affect the surface properties of the particles; the preparation process is simple and is easy to control, and the invention can save the cost and is environment-friendly.

Owner:BEIJING UNIV OF CHEM TECH

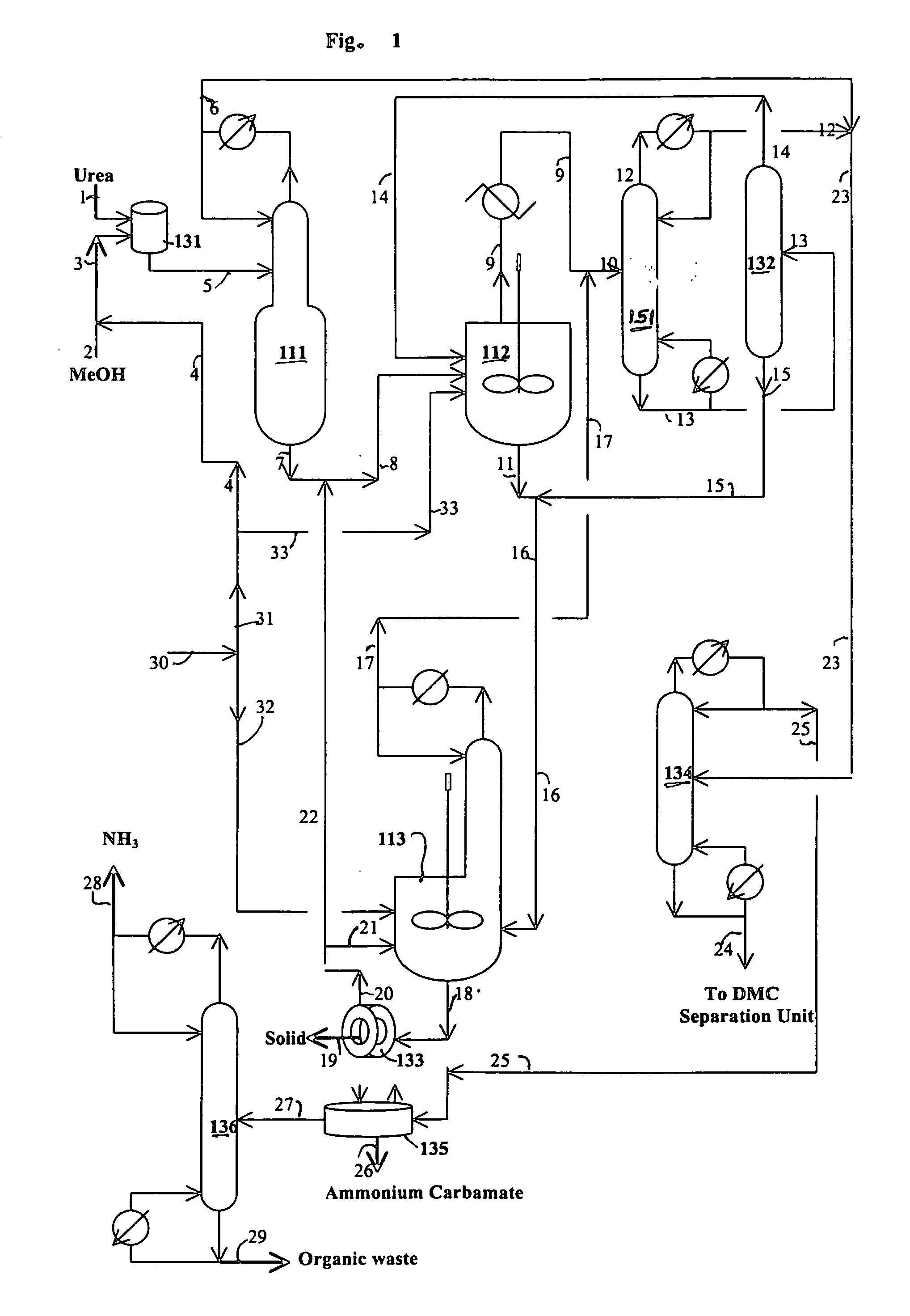

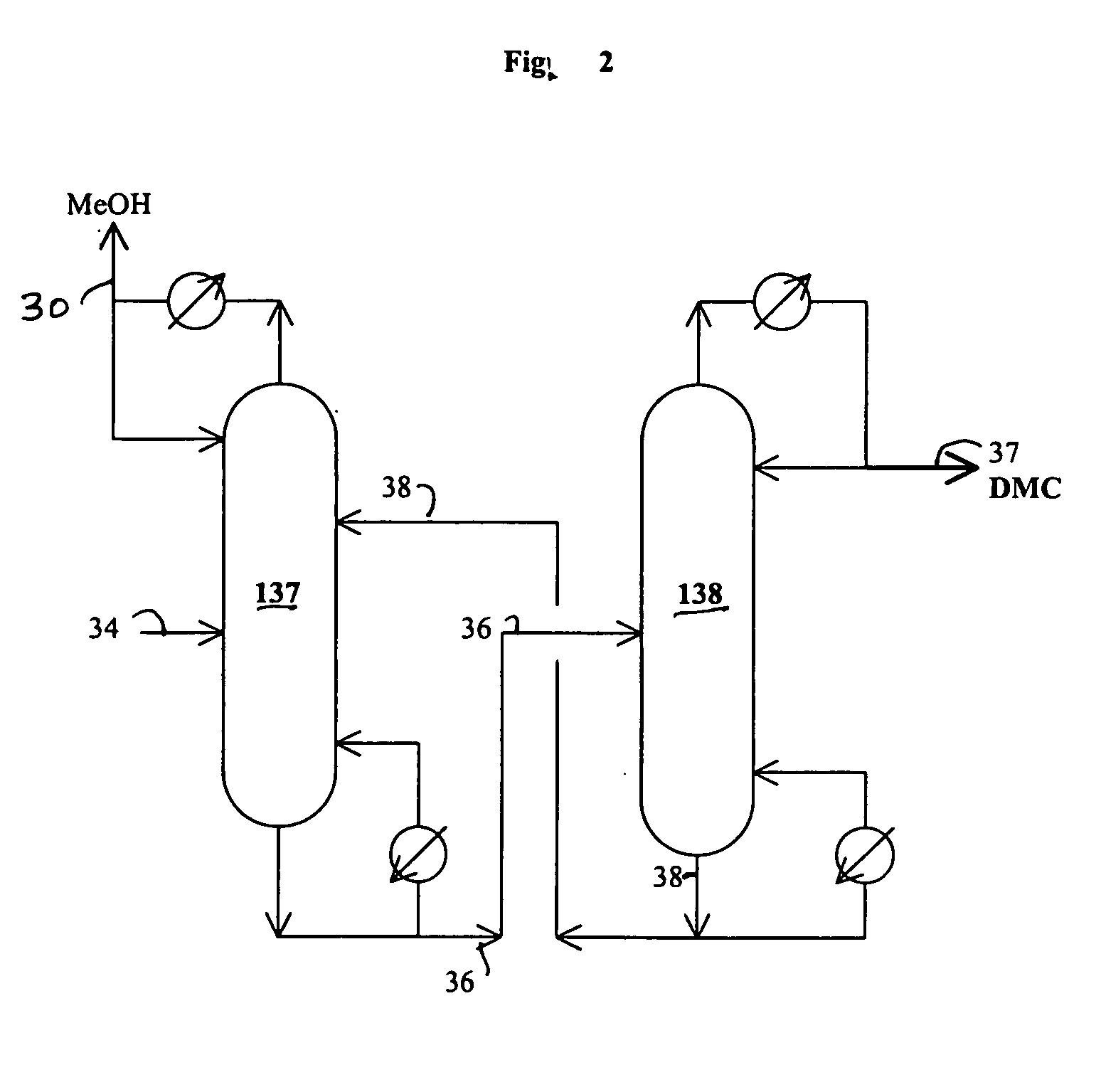

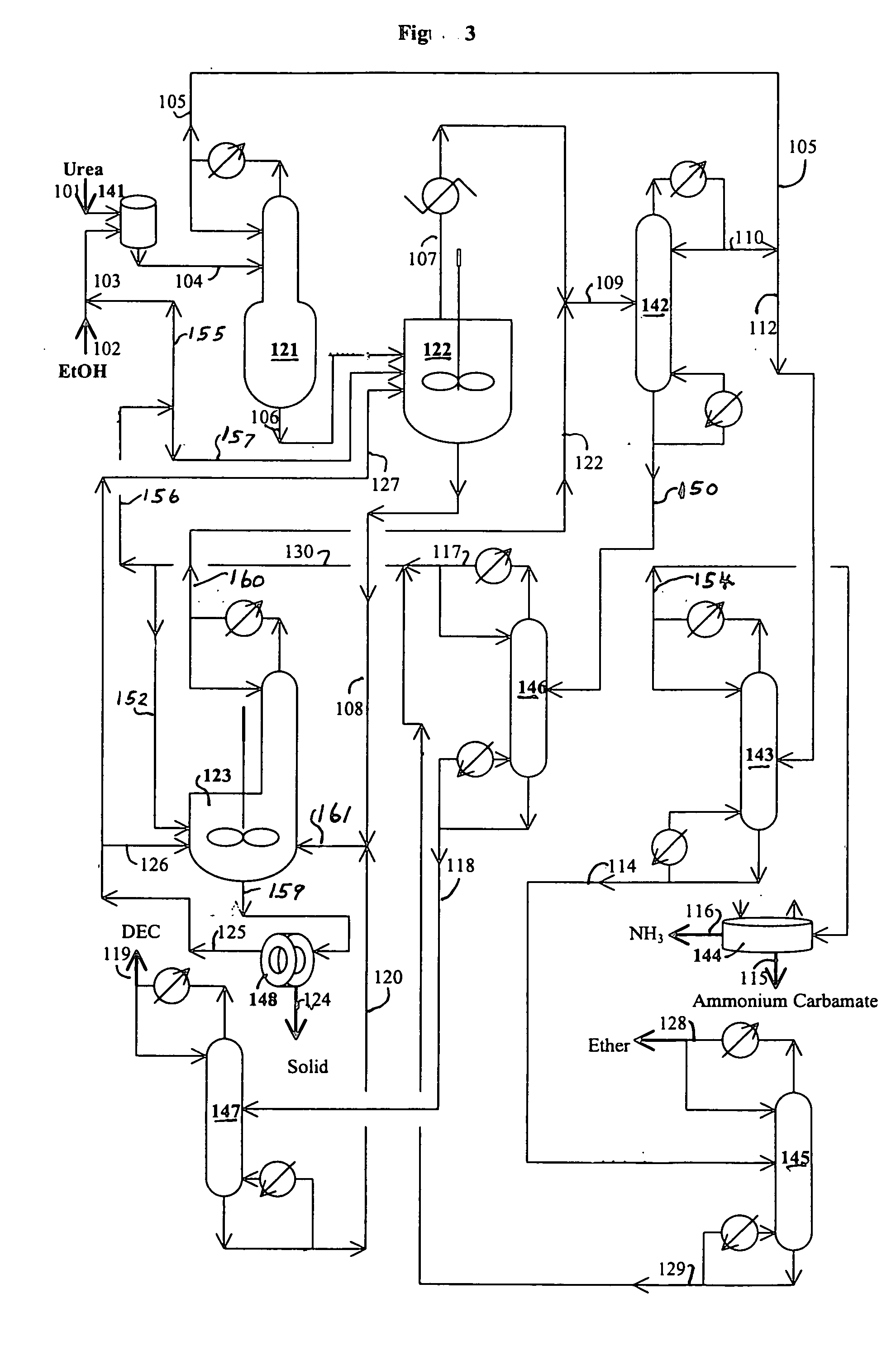

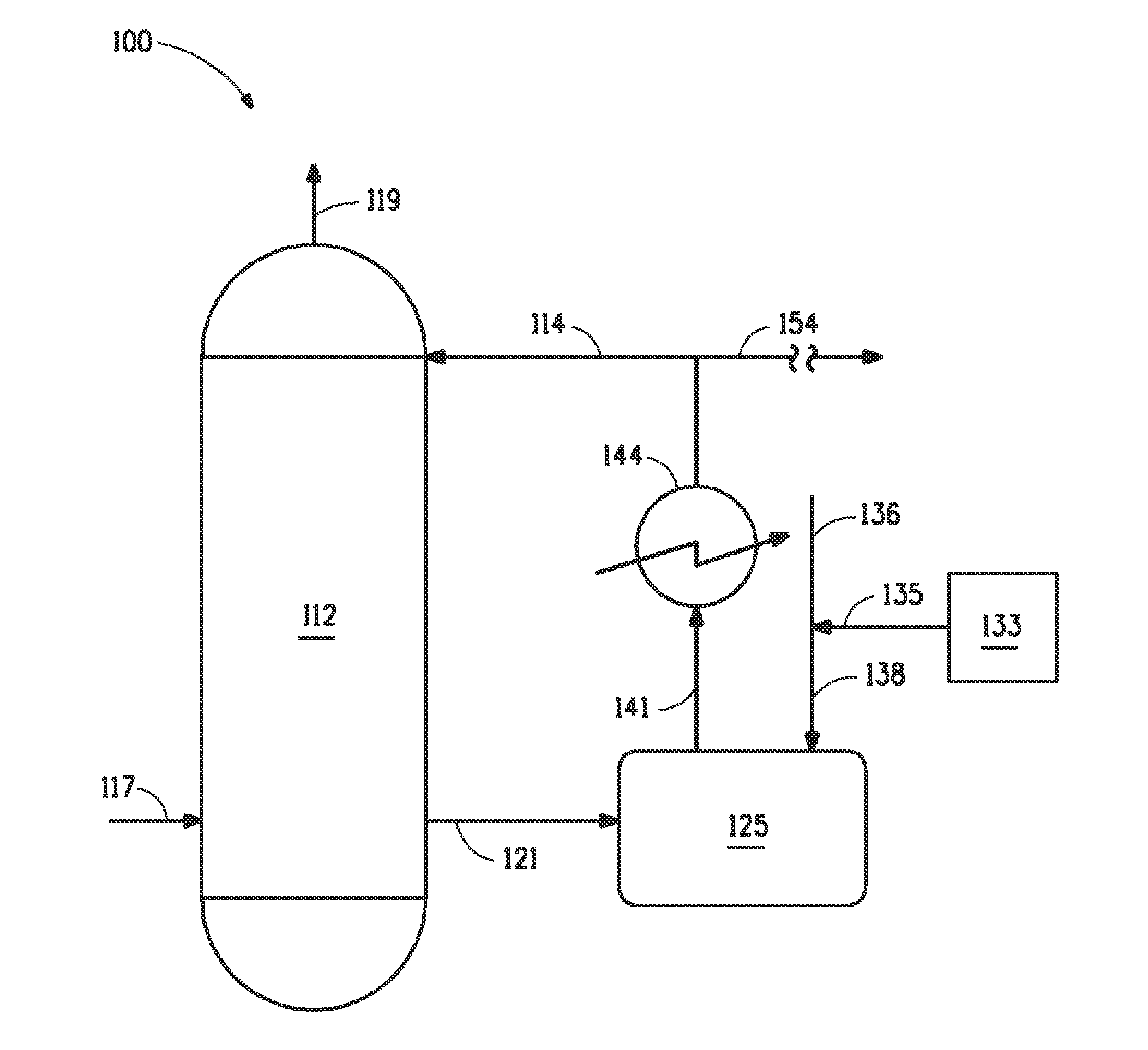

Process for making dialkyl carbonates

ActiveUS20050203307A1Fast reaction rateReduce separation costsOrganic compound preparationCarbonic/haloformic acid esters preparationNH3 compoundBy-product

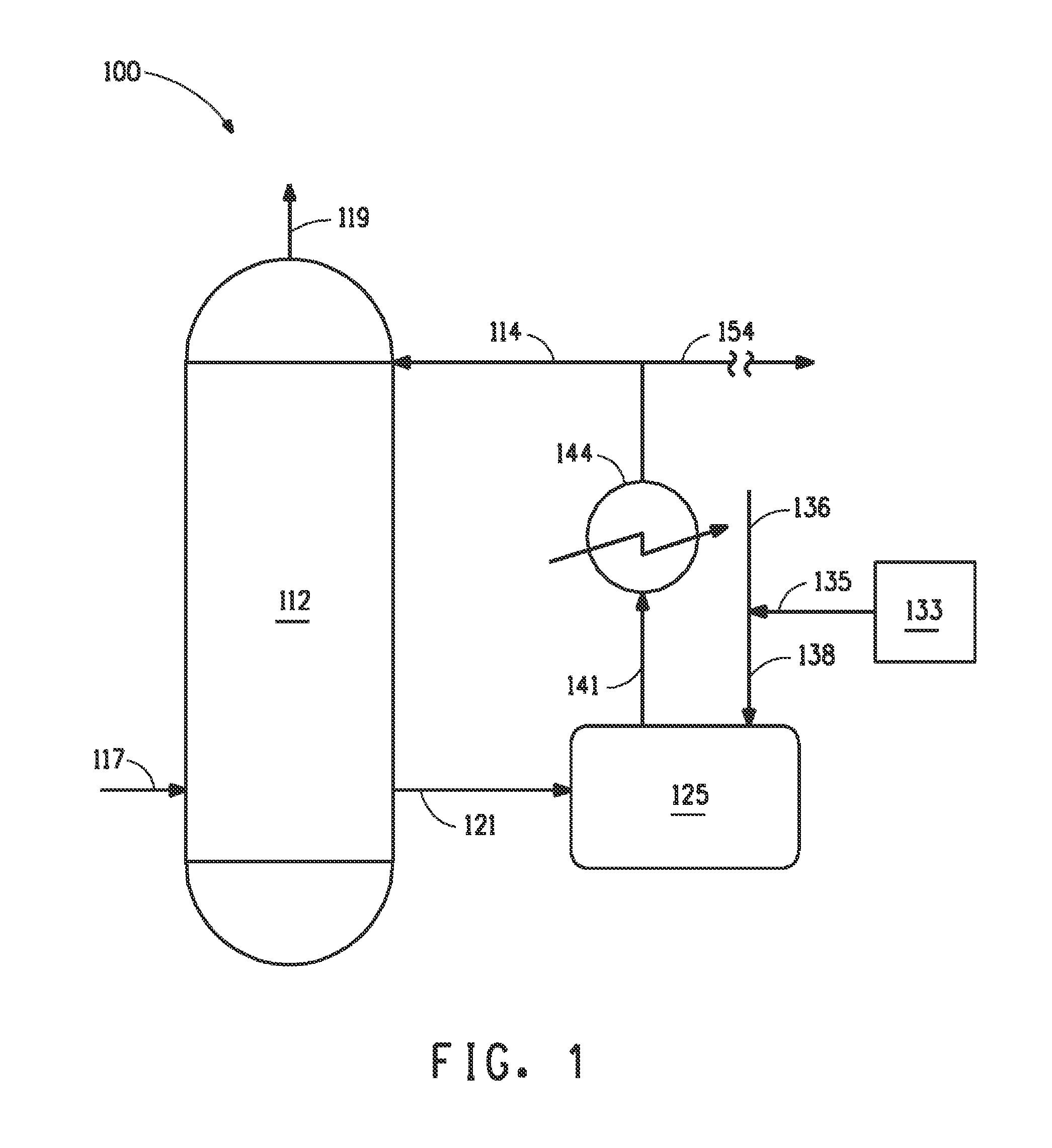

A process for the production of dialkyl carbonates from the reaction of alcohol, for example C1-C3 alcohols, with urea is disclosed wherein the water and ammonium carbamates impurities in the feed are removed in a prereactor. The water is reacted with urea in the feed to produce ammonium carbamate which is decomposed along with the ammonium carbamates originally in the feed to ammonia and carbon dioxide. In addition some of the urea is reacted with the alcohol in the first reactor to produce alkyl carbamate which is a precursor to dialkyl carbonate. Dialkyl carbonates are produced in the second reaction zone. The undesired by-product N-alkyl alkyl carbamates are continuously distilled off from the second reaction zone along with ammonia, alcohol and dialkyl carbonates under the steady state reactor operation. N-alkyl alkyl carbamates can be converted to heterocyclic compounds in a third reaction zone to remove as solids from the system.

Owner:CHEM RES & LICENSING CO

Method for synthesizing short-chain hydroxyl silicone oil

The invention relates to a synthetic method for short-chain hydroxyl silicone oil. Firstly, the materials are proportionally measured according to raw materials components, then adding acid clay, water, and cyclotetrasiloxanes to a three-mouth flask with a reflux device, adding concentrated sulfuric acid in agitation condition, and reacting by controlling the reaction temperature, when the reaction is completed, adding magnesia and agitating about 10 minutes, then processing pumping filtration, distilling and recovering acetone using a rotary evaporimeter used for filtrating under the temperature of 45 DEG C, then adding sodium carbonate solution for neutralization under controllable temperature for stratification; then watering and washing the organic layer on the upper layer once or twice, then discharging water through stratification, and then feeding the organic layer into the rotary evaporimeter for warming up to 95 DEG C, depressing and detracting low-boiling residues, obtaining micromolecule hydroxyl silicone oil. The synthetic method for short-chain hydroxyl silicone oil has the advantages of simple technological process, easy controllable reaction condition, low cost and easily available raw materials, fast reaction generating speed, good product quality and high reactivity, and wide application range.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

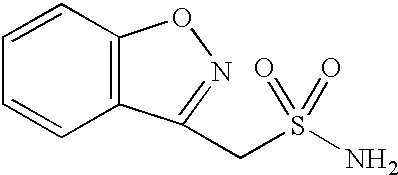

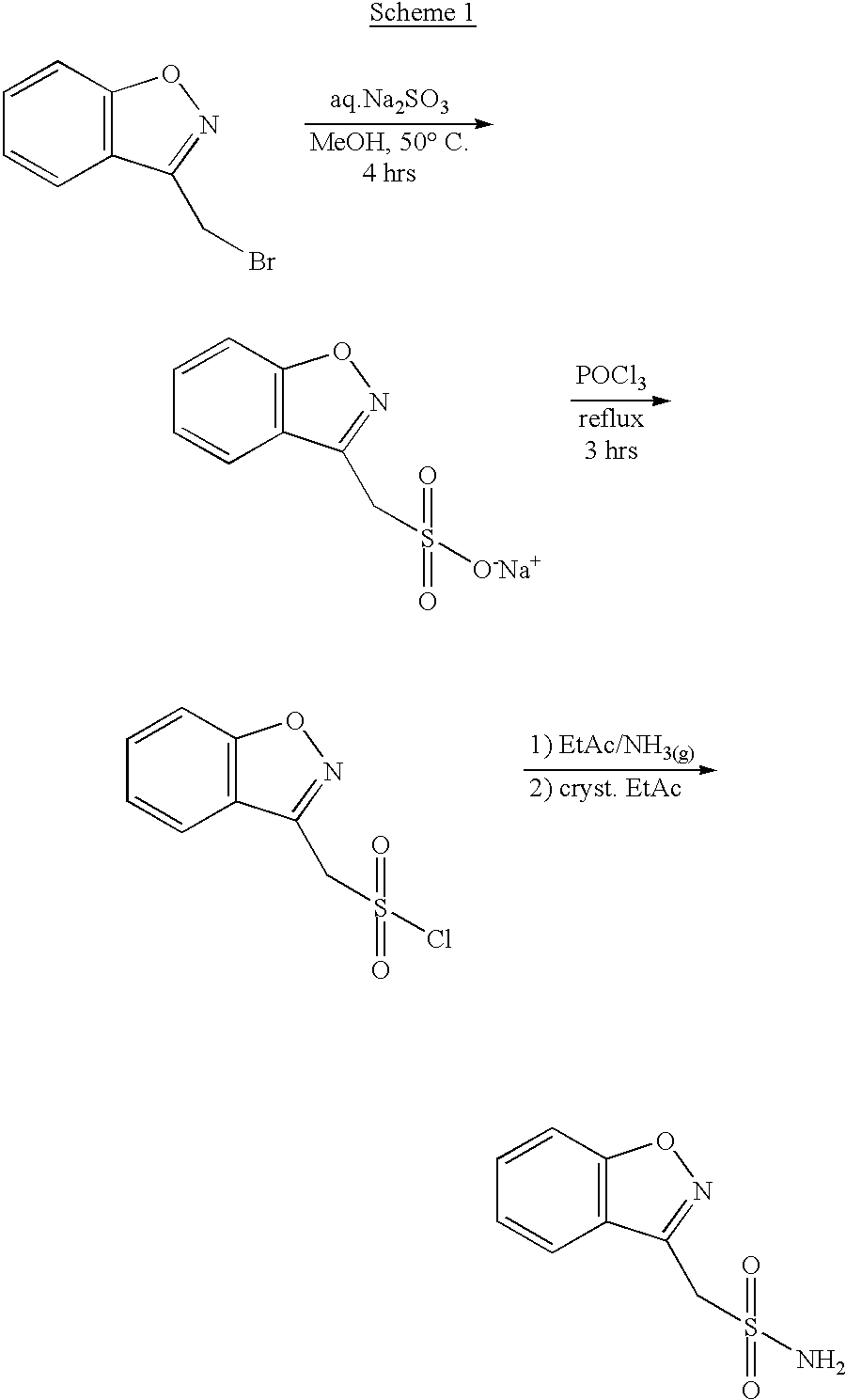

Process for the preparation of 1,2-benzisoxazole-3-acetic acid

InactiveUS20020183525A1High puritySpeed up the processOrganic chemistryAcetic acidMethane sulfonic acid

The present invention provides a process for preparing 1,2-benzisoxazole-3-acetic acid, comprising the step of reacting 4-hydroxy-coumarin with hydroxyl-amine in the presence of a base. The present invention further provides a process for preparing a salt of benzisoxazole methane sulfonic acid, comprising the steps of 1) sulfonating 1,2-benzisoxazole-3-acetic acid using chlorosulfonic acid in a solvent mixture comprising methylene chloride and sodium hydroxide; and 2) isolating the salt of benzisoxazole methane sulfonic acid.

Owner:TEVA PHARM USA INC

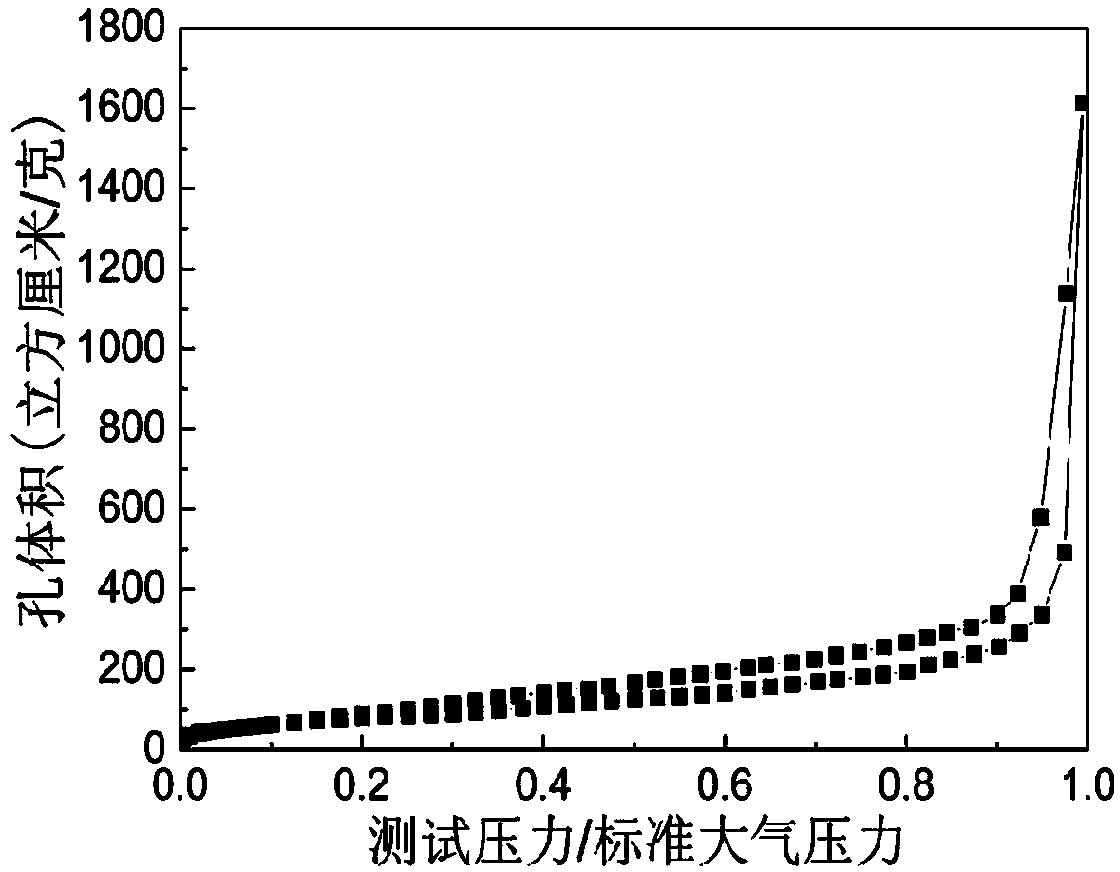

Method for preparing resorcinol-formaldehyde aerogel

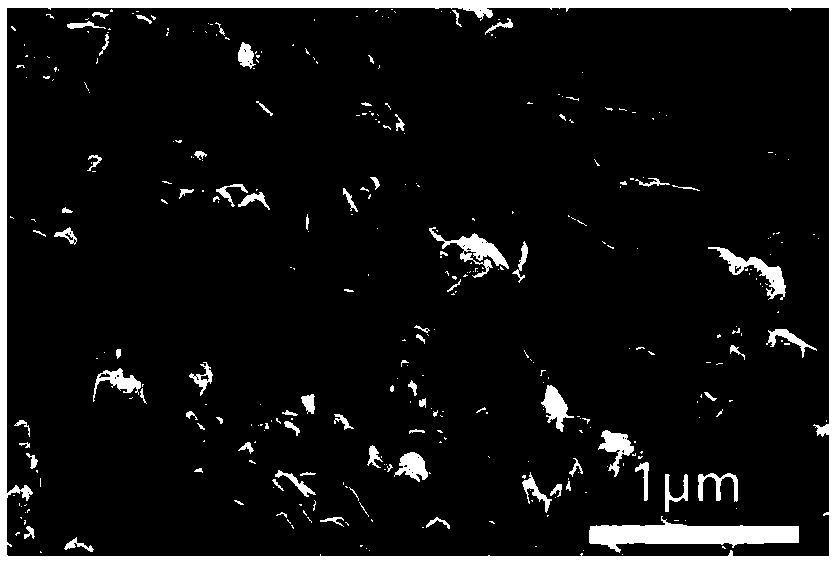

InactiveCN103933900AFast reaction rateShort reaction timeColloidal chemistry detailsPhotoinitiatorWater soluble

The invention provides a method for preparing resorcinol-formaldehyde aerogel. The preparation method comprises the following steps: adding a certain amount of water-soluble and neutral light initiator to a reaction of base catalysis of resorcinol-formaldehyde aerogel, and synthesizing organic aerogel under ultraviolet light irradiation. The method has the characteristics that by virtue of the selected water-soluble and neutral light initiator, the structure of the organic aerogel is not greatly changed due to introduction of the light initiator besides that the gelation time of a resorcinol-formaldehyde solution can be greatly shortened. The resorcinol-formaldehyde aerogel and a derivative, carbon aerogel, thereof prepared by the method disclosed by the invention can be applied to related fields of a laser inertial confinement fusion target material, a supercapacitor electrode material, a lithium battery electrode material, a hydrogen storage material, a thermal insulation material, other composite nano materials and the like.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

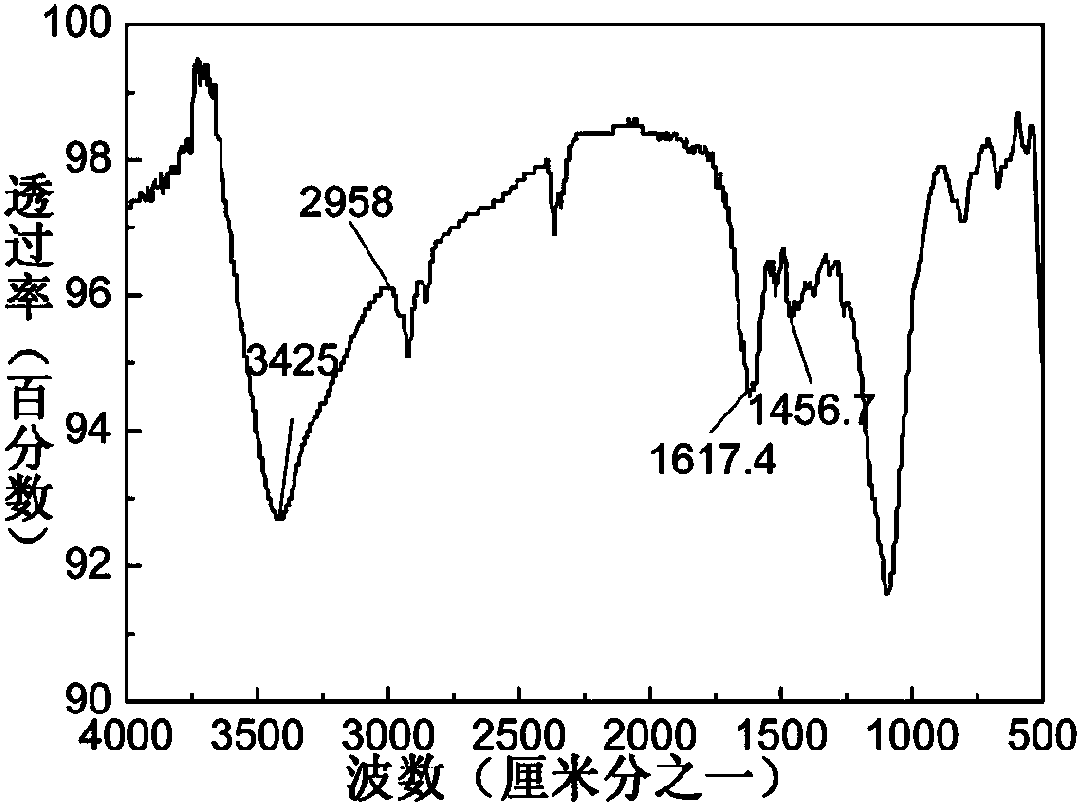

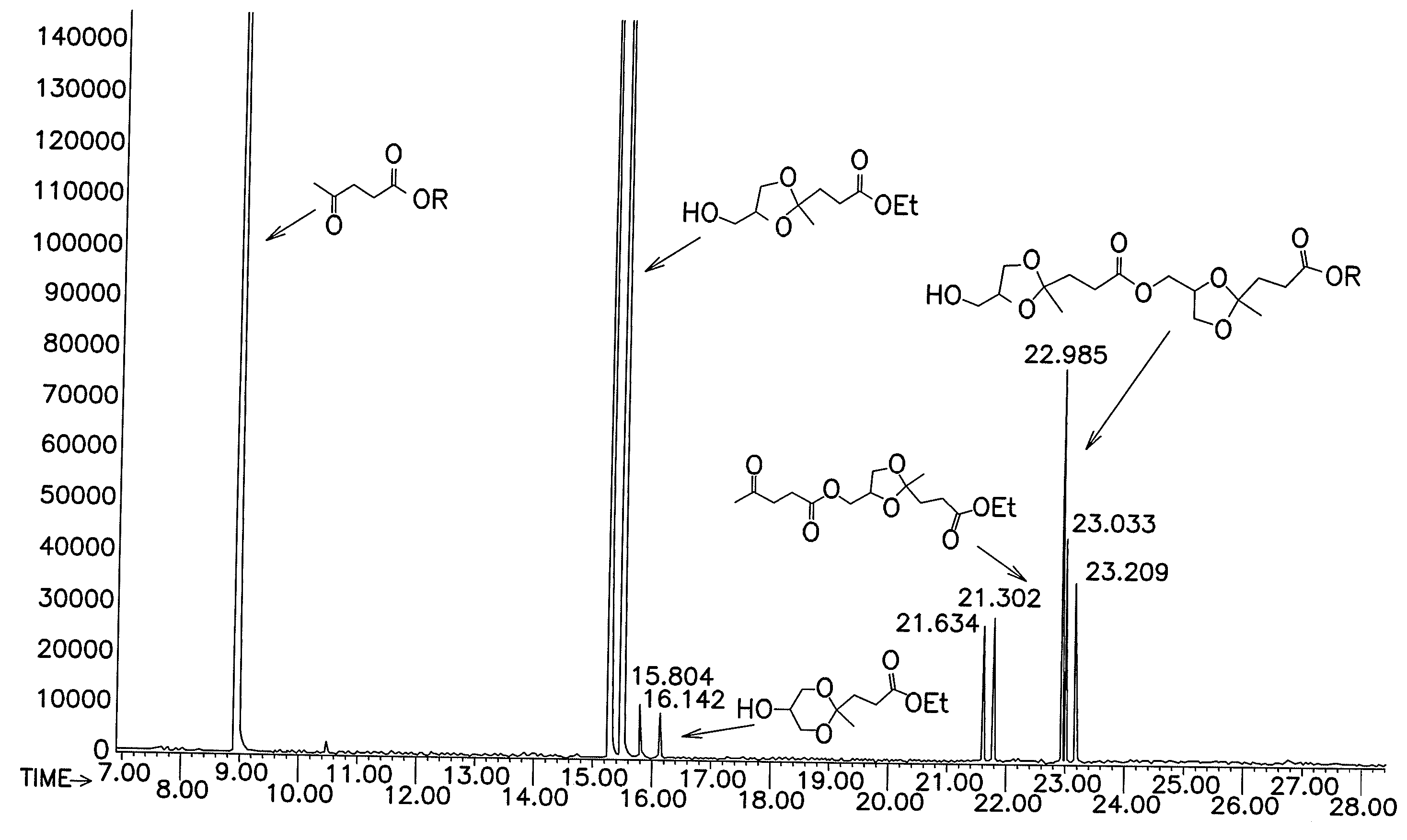

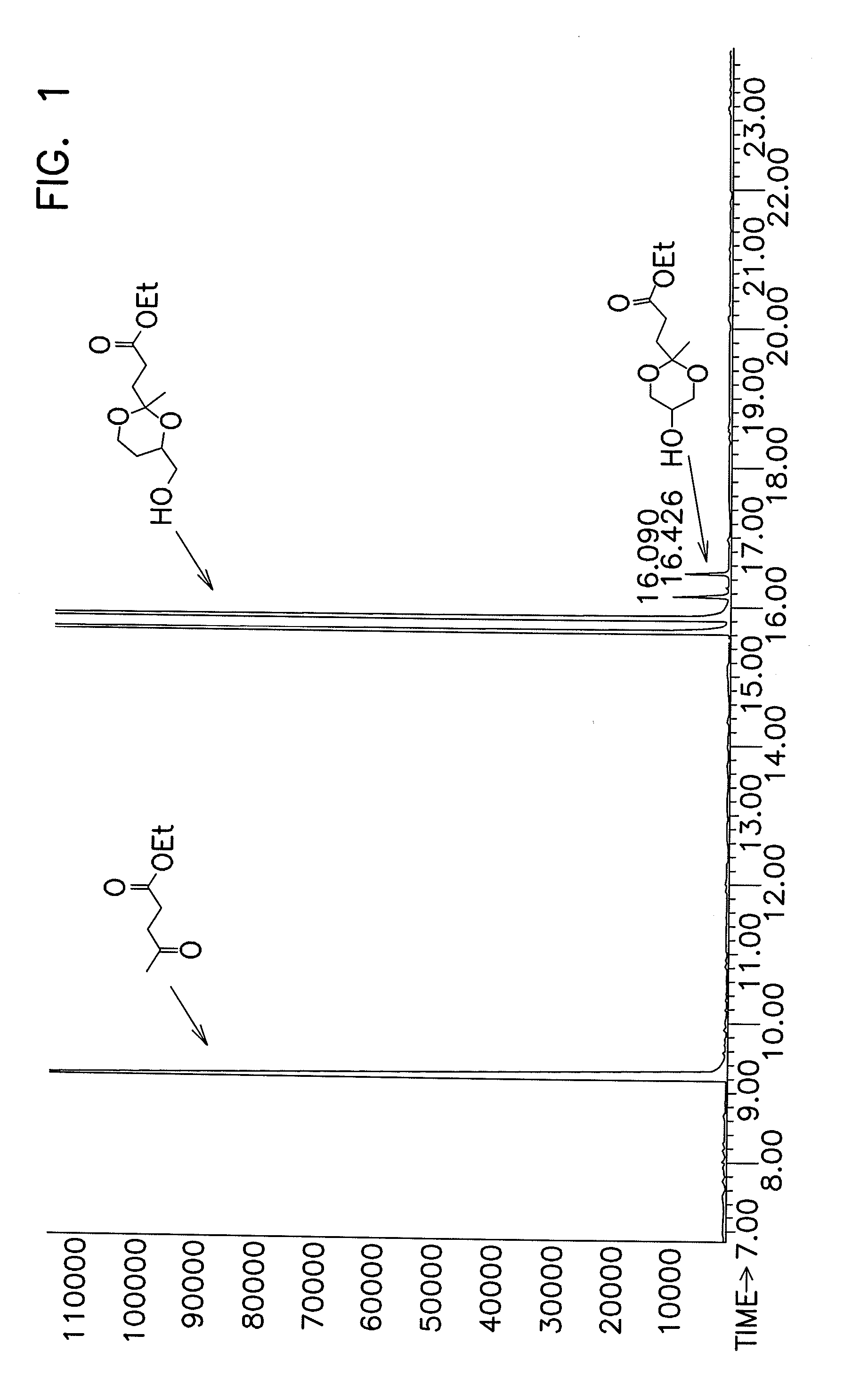

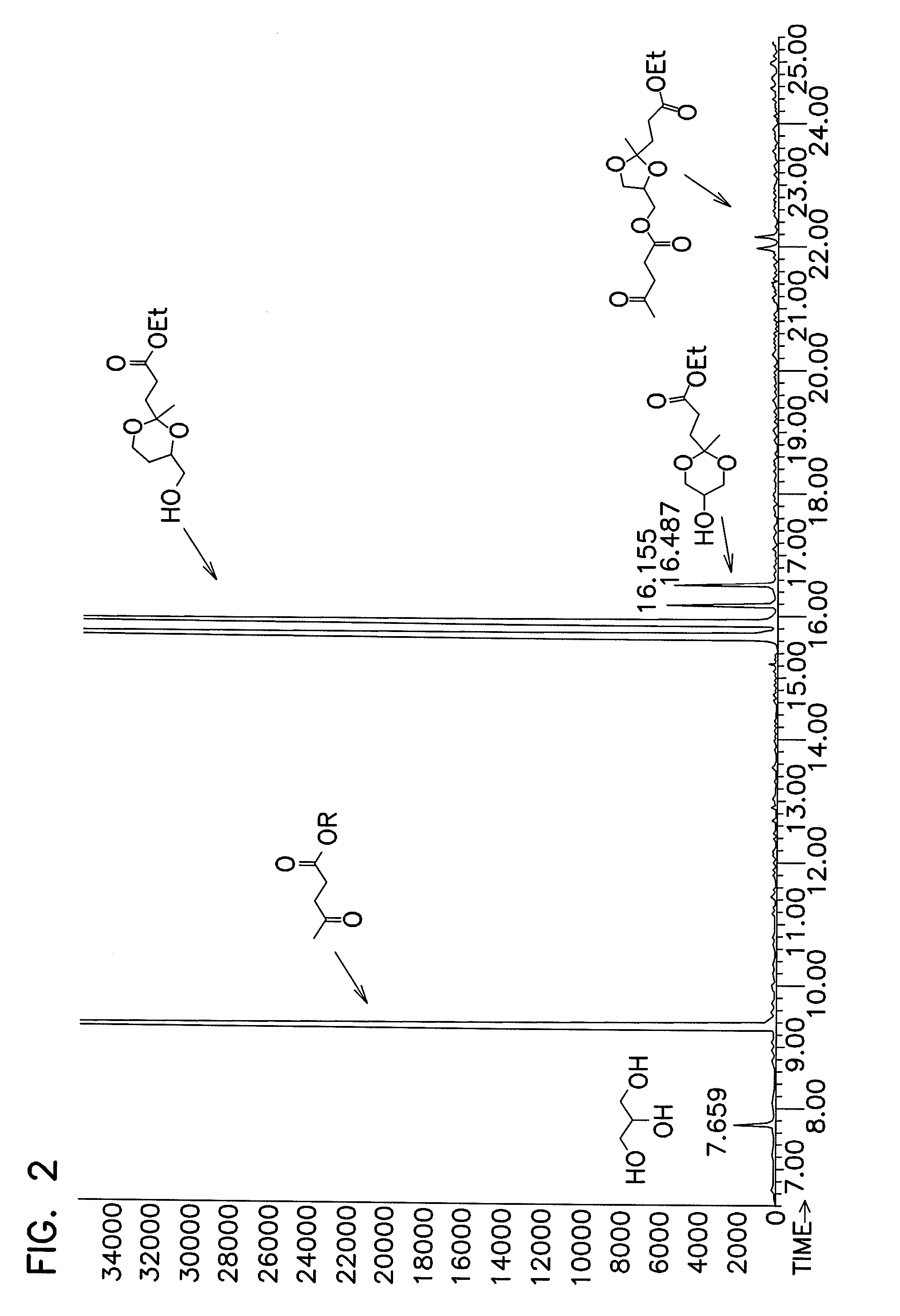

Method of Making Ketals and Acetals

ActiveUS20100292491A1Less side-product formationQuick responseOrganic chemistryAlcoholCarboxylic acid

The reaction of alcohols with oxocarboxylates to form acetals or ketals is catalyzed by unexpectedly low levels of protic acids. By employing low acid catalyst levels compared to amounts conventionally used, rapid formation of acetal or ketal is facilitated while the formation of oxocarboxylate esters is minimized. Further employing a significant molar excess of oxocarboxylate in conjunction with low acid catalyst level gives rise to the rapid and clean formation of acetals and ketals from oxocarboxylates and alcohols.

Owner:GFBIOCHEM

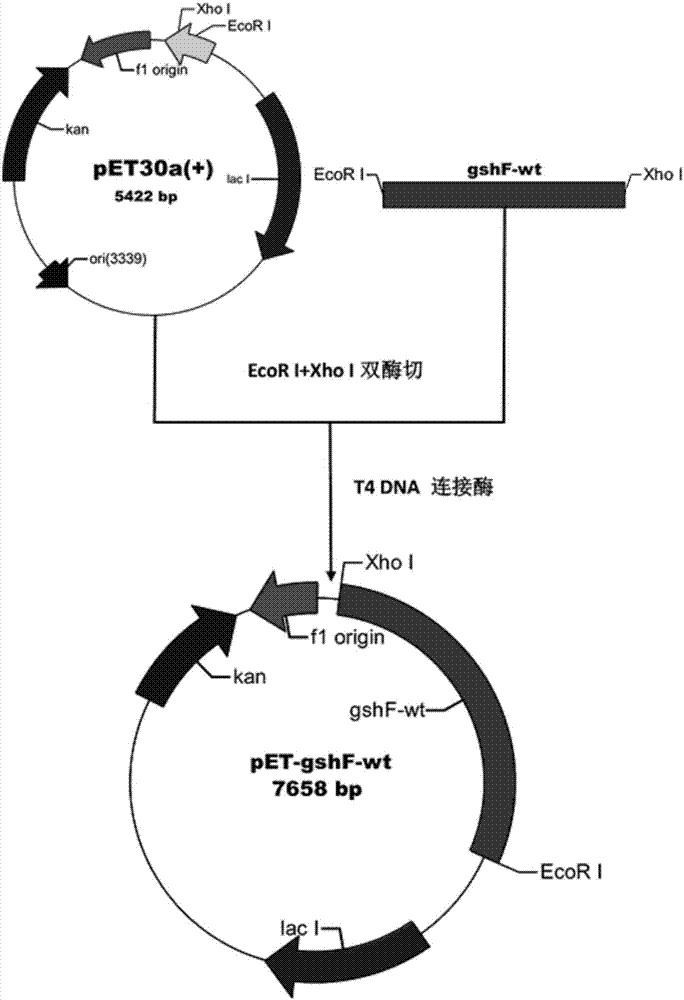

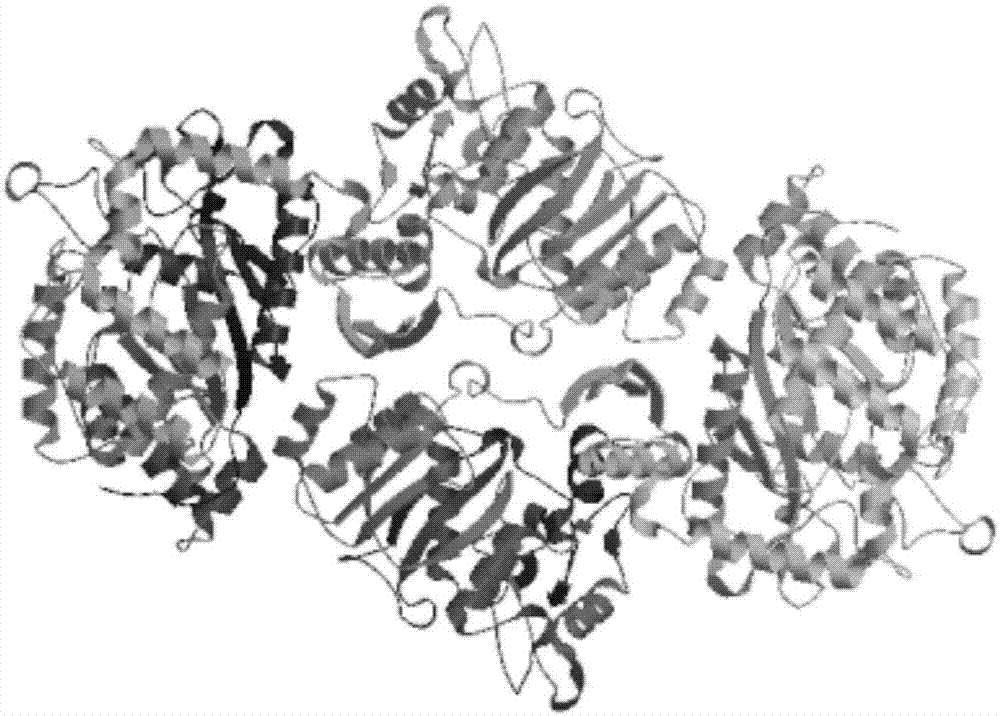

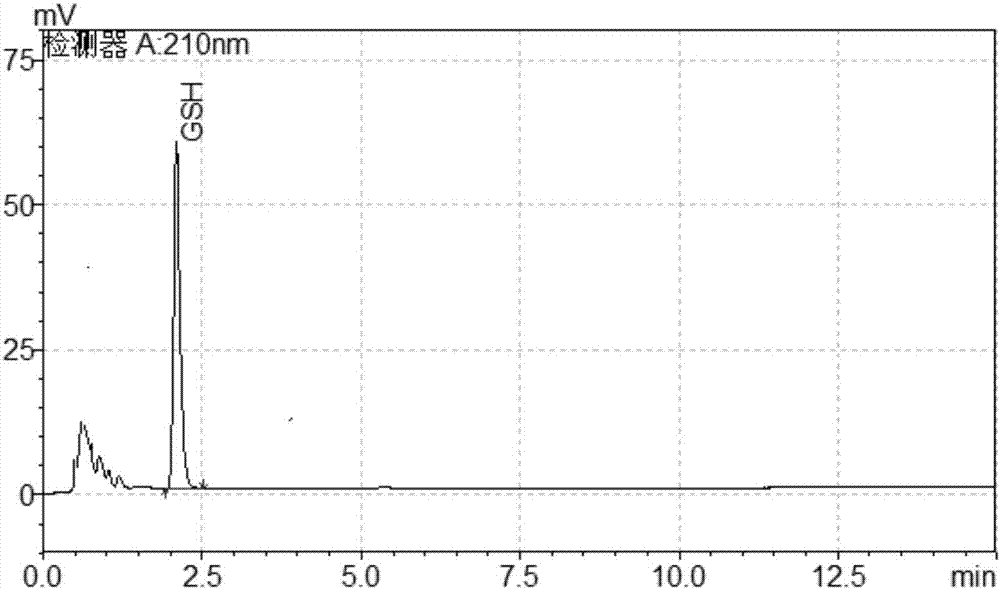

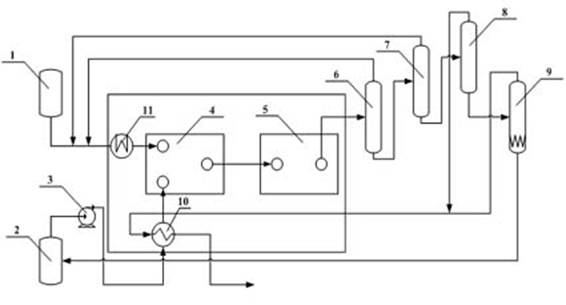

Bifunctional glutathione synthetase mutant, and nucleotide sequence, preparation method and application thereof

ActiveCN107267471AHigh synthetic activityFast reaction rateLigasesFermentationAmino acidImmobilized enzyme

The invention discloses a bifunctional glutathione synthetase mutant, and a nucleotide sequence, a preparation method and an application thereof. At least one of sites in the third position, the 123rd position, the 161st position, the 194th position, 382nd position and 390th position of the amino acid sequence of a GshF mutant is different from the corresponding sites of the wild GshF amino acid sequence of Streptococcus salivarius in amino acids in order to obtain the GshF mutant having a high synthesis activity, a fast reaction rate and a good conversion efficiency. The synthesis vitality of a GshF-4 mutant is improved 12.8 times, the specific vitality is improved 11 times, the optimum temperature is increased by 20 DEG C, the vitality keeps at 91.3% after standing at 55 DEG C for 60 min, an immobilized enzyme of the GshF-4 mutant allows the concentration of GSH to reach 21 g / L when participating in the catalytic synthesis of the GSH at 50 DEG C under a pH value of 8.0 for 60 min, can be continuously used for 300 times or more, and has very good operating stability.

Owner:HUNAN FLAG BIOTECHNOLOGY CO LTD

Method for recovering copper through copper anode mud supersonic pretreatment

InactiveCN103320616AFast reaction rateImprove leaching rateProcess efficiency improvementSupersonic wavesLeaching rate

The invention belongs to the field of wet metallurgy, and specifically relates to a method for recovering copper through a copper anode mud supersonic pretreatment. According to the invention, sulfuric acid with concentration of 50-400g / L is added to copper anode mud, such that slurry is prepared; the copper anode mud slurry is placed in a supersonic wave generator; an oxidant is added into the copper anode mud slurry; supersonic frequency is regulated to 20-40kHz, a power is 500-4000w, and leaching is carried out for 30-90min under normal pressure and a temperature of 20-90 DEG C. With the method, a problem of long leaching time and generally low leaching rate of prior art are overcome. Compared with the leaching rate with no supersonic treatment, the leaching rate is improved by more than 10-30%, and a copper leaching rate reaches 93-99%.

Owner:NORTHEASTERN UNIV

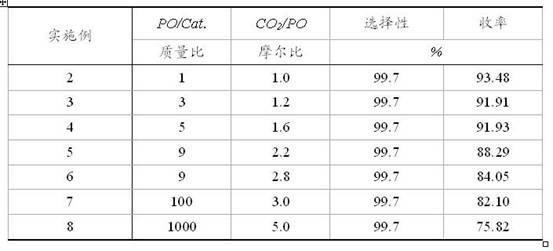

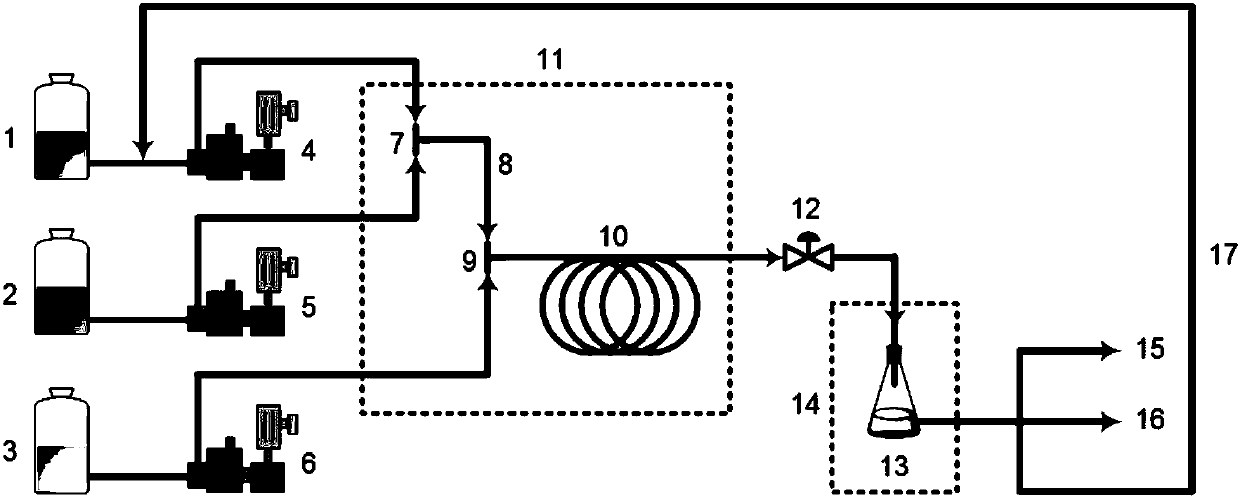

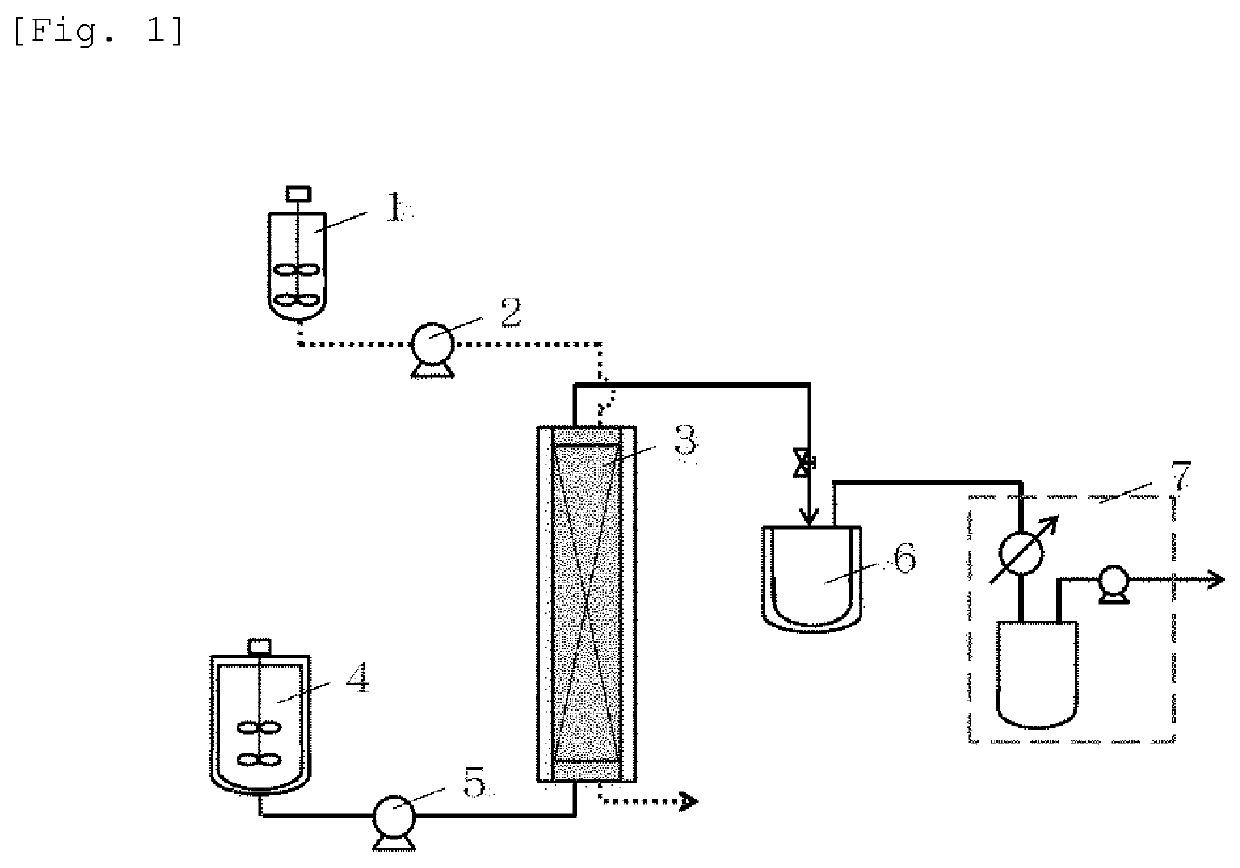

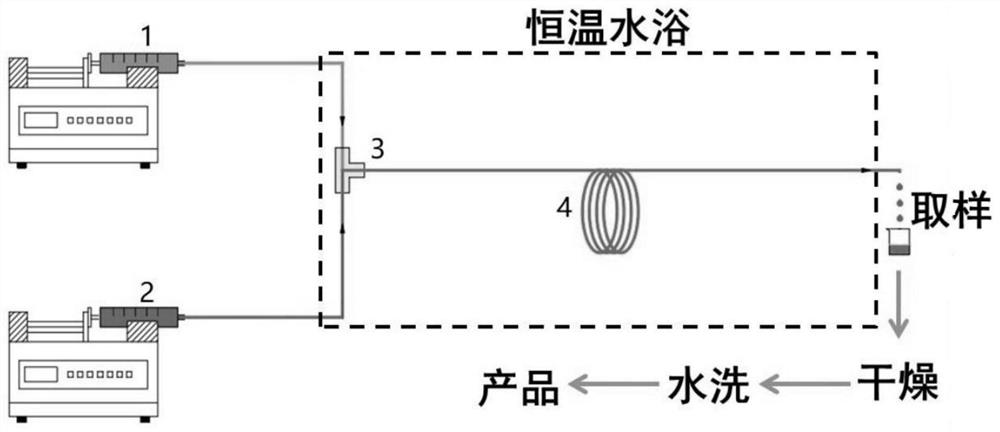

Method for synthesizing cyclic carbonate ester in micro reactor system

ActiveCN102464521AImprove energy efficiencyFast reaction rateChemical industryChemical/physical/physico-chemical processesEpoxideCarbon dioxide

The invention relates to a method for synthesizing cyclic carbonate ester in a micro reactor system, which comprises the following steps of: firstly mixing a liquid material containing an epoxy compound and a catalyst with a gas material containing carbon dioxide in a micro mixer, and then synthesizing cyclic carbonate ester in a micro channel reactor through a cyclization reaction. For the method, the reaction temperature is 100-220 DEG C, the pressure is 1.0-7.0 MPa, the molar ratio of carbon dioxide to epoxy compound in the gas-liquid two-phase material is 1.0-5:1, the mass ratio of the epoxy compound to the catalyst is 1.0-1000:1, and the retention time of the gas-liquid two-phase material in the micro channel reactor is 1.0-300 s. The reaction system has quick mass transfer and heat transfer rates, continuous process, easiness in control, high process safety and high energy utilization ratio, and the space-time yield and the selectivity of the target product can be greatly increased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

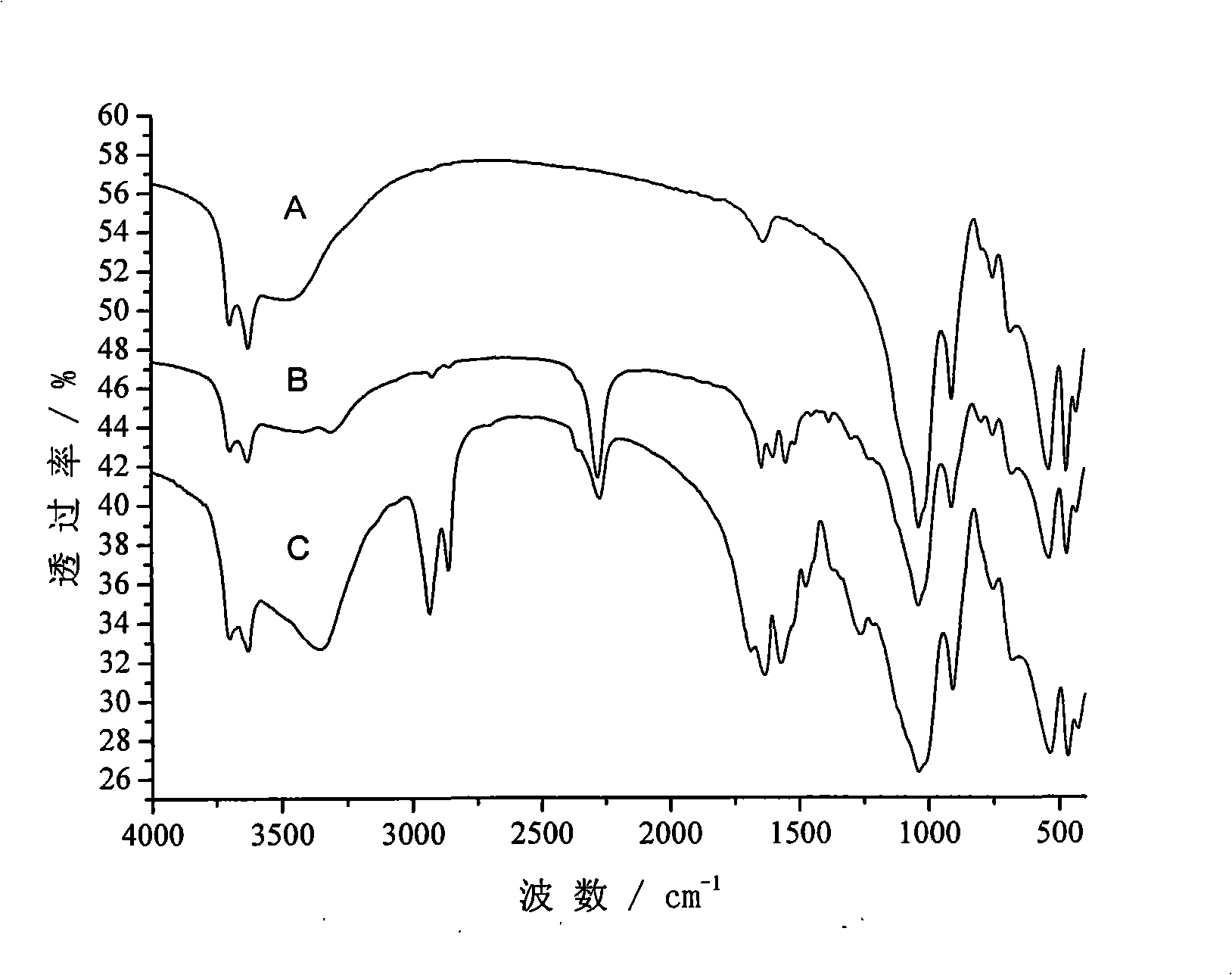

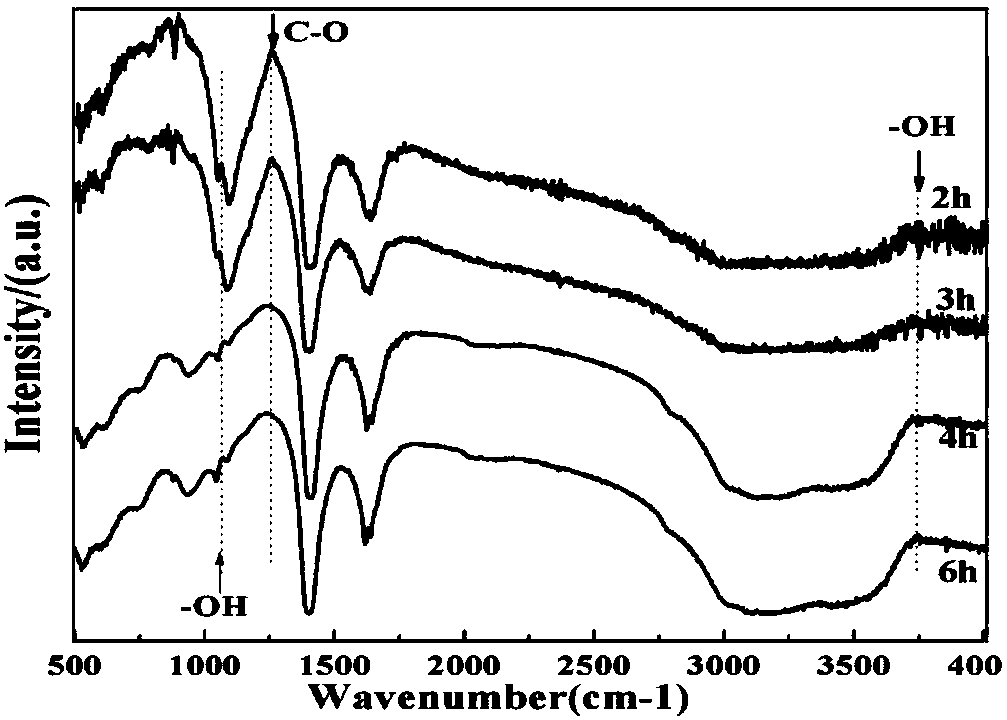

Organic surface modification halloysite nano-tube and method for making same

InactiveCN101284670AExpand the scope of applicationFast reaction rateSilicon compoundsSurface functionPolymer

The invention relates to a surface functional organified nerchinskite nanotube and a preparation method thereof. The method takes the nerchinskite nanotube as the raw material, and obtains the nerchinskite nanotube with-NCO radicals key-jointed on the surface by certain physical and chemical methods. The preparation method comprises the steps of refining the nerchinskite nanotute; vacuum drying and ultrasonic dispersing the nerchinskite nanotube into acetone; adding a certain amount of vulcabond and dibutyl tin laurate; subjecting the nerchinskite nanotube to ultrasonic irradiation reaction for 1 to 5 hours; filtering, washing, vacuum drying to obtain the function-organized nerchinskite nanotube with the-NCO radicals on the surface. The function-organized nerchinskite nanotube has the -NCO radicals on the surface and good reactivity, thereby providing diverse options for preparing polymer base nanocomposites.

Owner:NORTHWEST NORMAL UNIVERSITY

Hydraulic cavitated cell wall disruption device

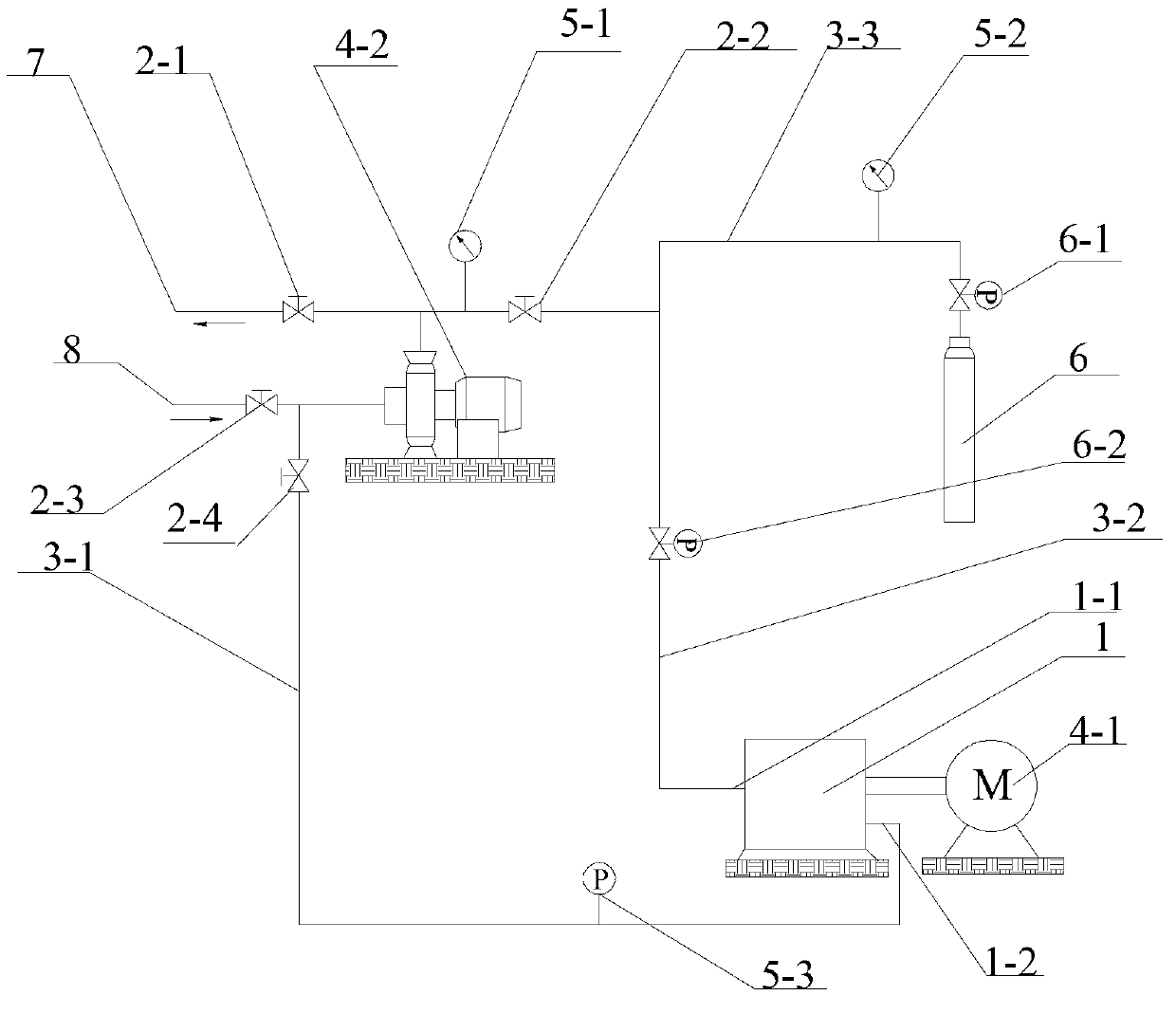

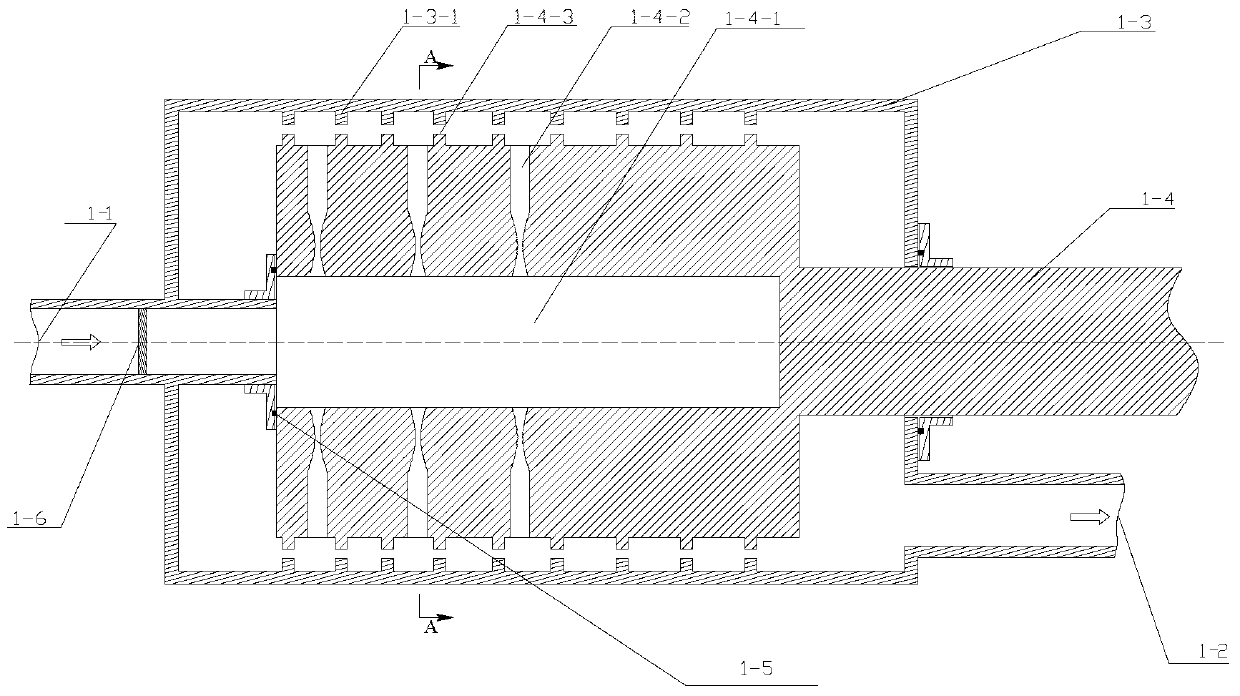

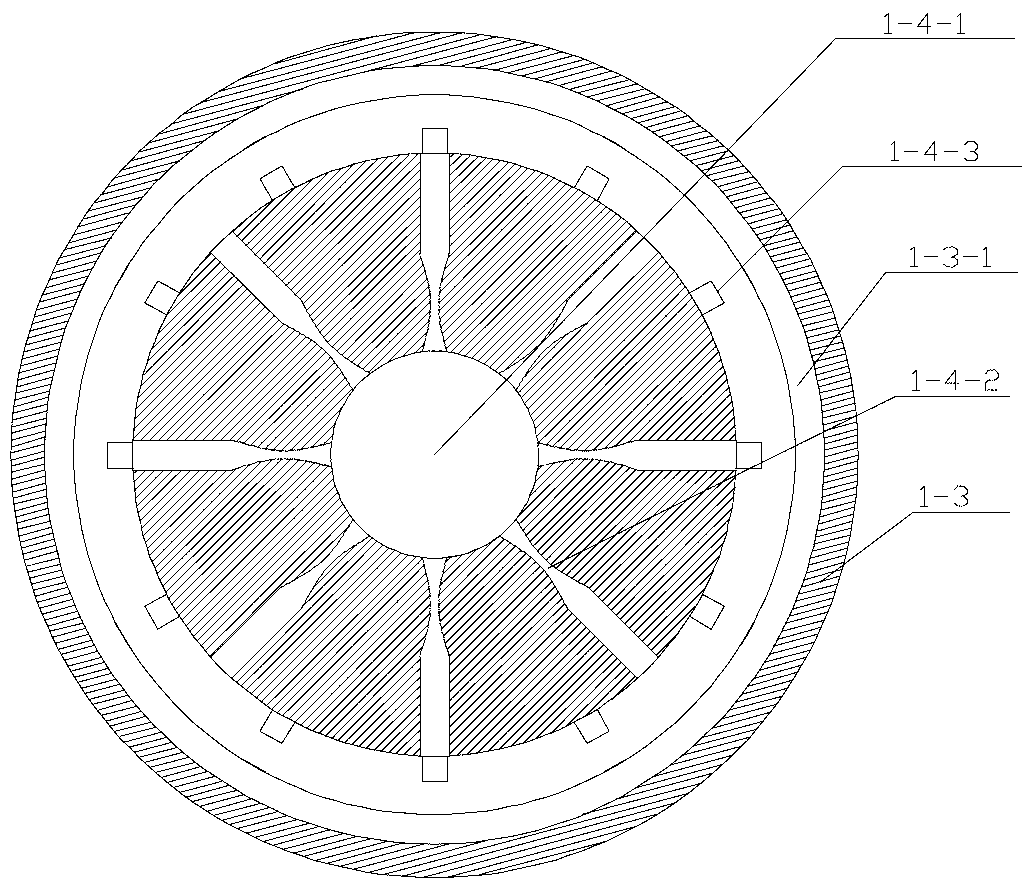

ActiveCN103343089AFast reaction rateLow machining accuracy requirementsBioreactor/fermenter combinationsBiological substance pretreatmentsJet flowEngineering

The invention provides a hydraulic cavitated cell wall disruption device which comprises a cavitation device, an air supply device and a circulation line connected with the cavitation device. The hydraulic cavitated cell wall disruption device is provided with three different hydraulic mechanical conditions to disrupt the cell wall in a multi-stage way. According to a circulation system, the cavitation bubbles and the cells wholly move to generate the hydraulic change one after another, and the local high temperature and high pressure and the jet flow are generated nearby the cavitation bubbles when the cavitation bubbles are ruptured, so that the cell surfaces can be broken, and the cell walls nearby the cavitation bubbles can be broken. According to the air supply device, the initial air content of the fluid can be increased, and the wall disruption effect can be enhanced. The cavitation bubbles are fine and are evenly distributed in the fluid, so that the cell walls can be sufficiently disrupted by the means that the material fluid passes through for 5-15min. The cell wall disruption device provided by the invention is free from environment pollution, quick in reaction speed, not high in structural machining precision requirement, easy to implement, and low in cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

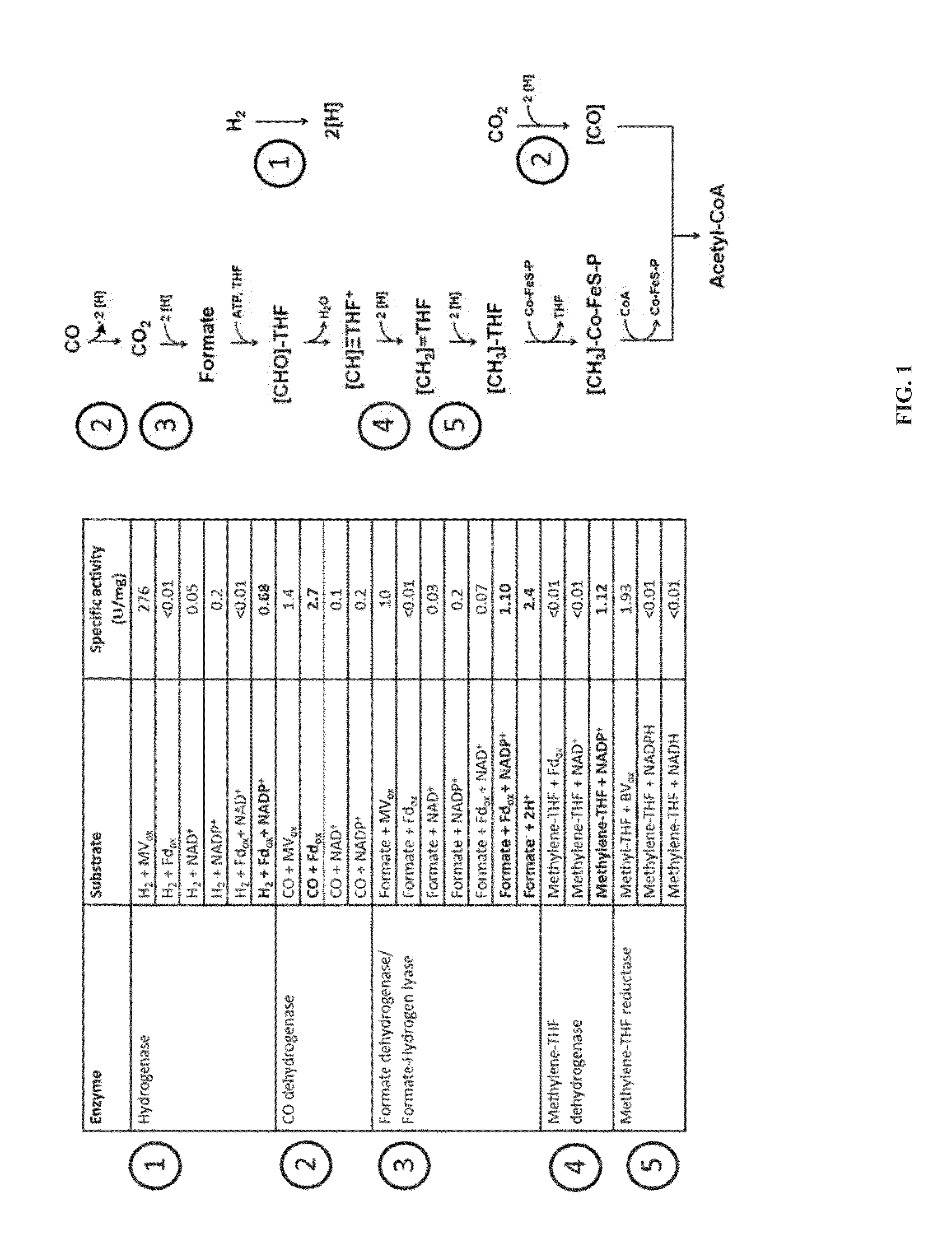

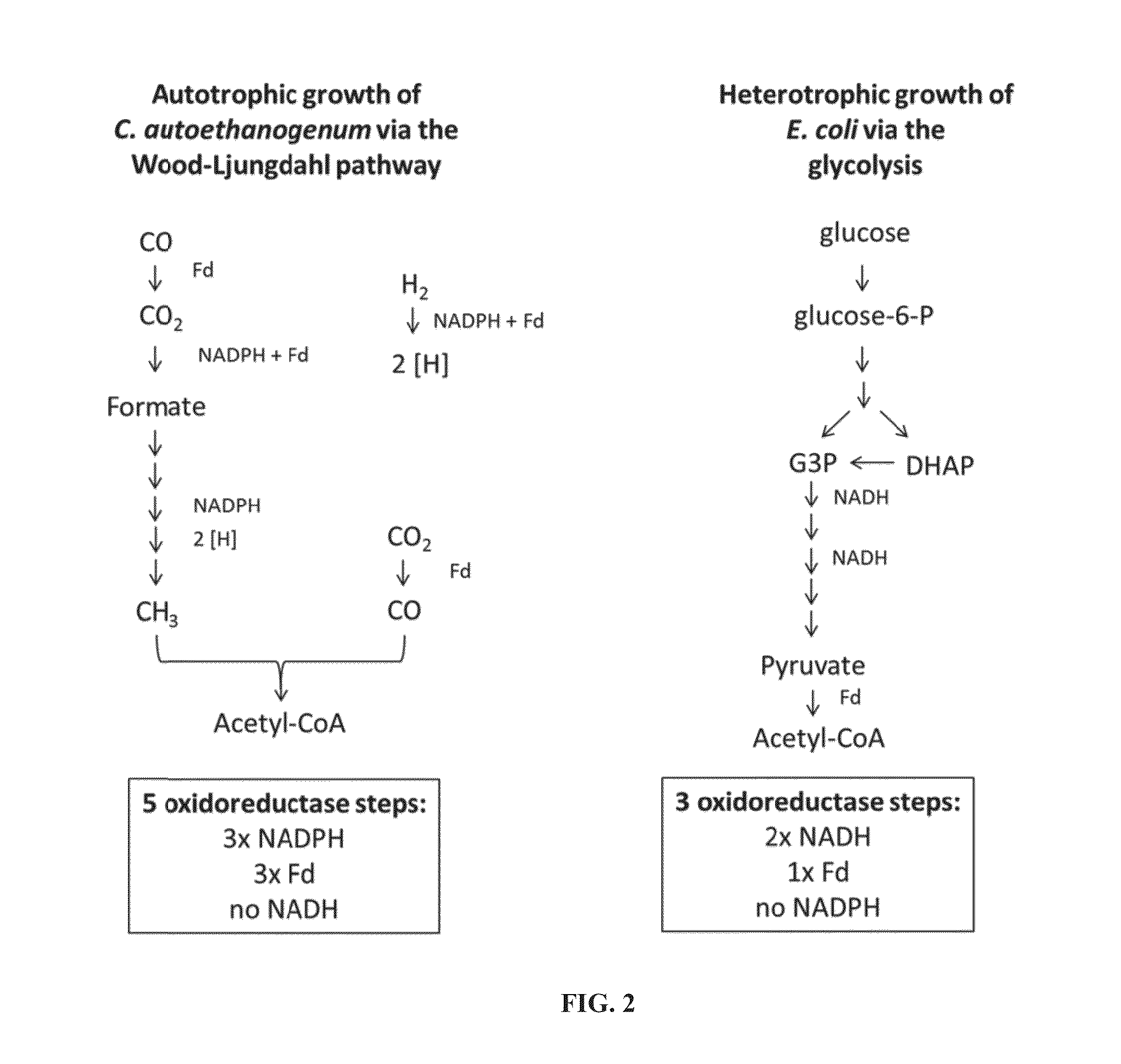

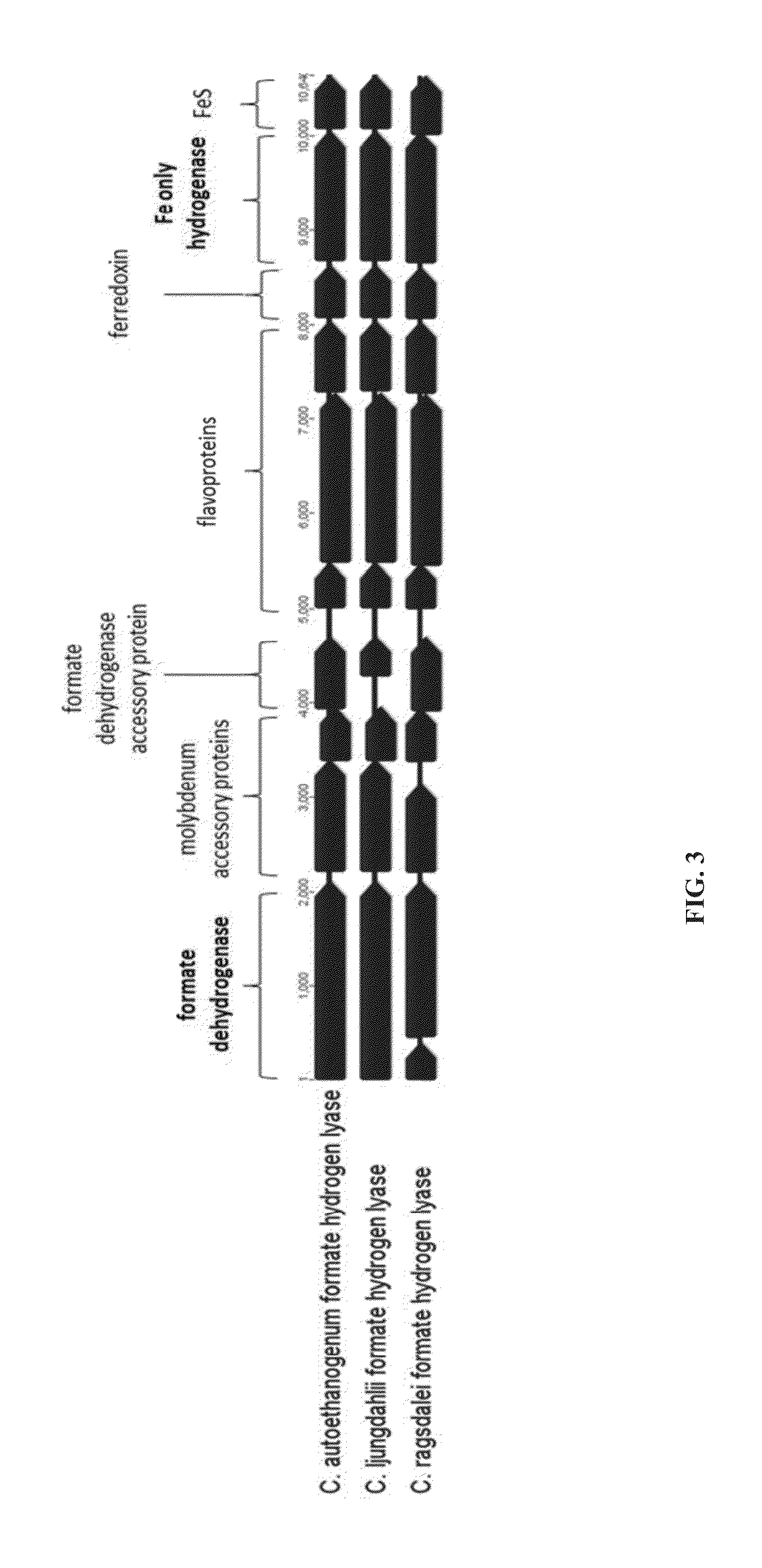

Recombinant microorganisms comprising NADPH dependent enzymes and methods of production therefor

The invention provides a recombinant carboxydotrophic Clostridia microorganism with increased overall utilization of NADPH relative to a parent microorganism. Further, the invention provides a method of producing a recombinant carboxydotrophic Clostridia microorganism which exhibits increased NADPH utilization relative to a parental microorganism. In particular, the invention relates to increasing the overall utilization of NADPH in a recombinant carboxydotrophic Clostridia microorganism in order to increase the production of at least one fermentation product by the microorganism.

Owner:LANZATECH NZ INC

Method for preparing high-quality titanium white from titanium-containing solution

The invention discloses a method for preparing high-quality titanium white from titanium-containing solution. The method comprises the following steps of: adding kali salt, zinc salt and aluminum salt into the titanium-containing solution to atomize the titanium-containing solution; adding the atomized titanium-containing solution into a reactor dropwise; introducing hot air into the reactor and hydrolyzing the titanium-containing solution at the temperature of between 150 and 350 DEG C so as to generate solid-phase hydrated titanium dioxide; and calcining the hydrated titanium dioxide at the temperature of between 300 and 1,000 DEG C for 1 to 5 hours so as to obtain the high-quality titanium white. In the method, continuous spray hydrolysis is used instead of the conventional intermittent liquid-phase hydrolysis, so that reaction speed is high, yield is high, problems encountered in the conventional titanium white producing process by a sulfuric acid method can be solved effectively, product quality is enhanced, damage to the environment is avoided and the production cost of the titanium white can be lowered simultaneously.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

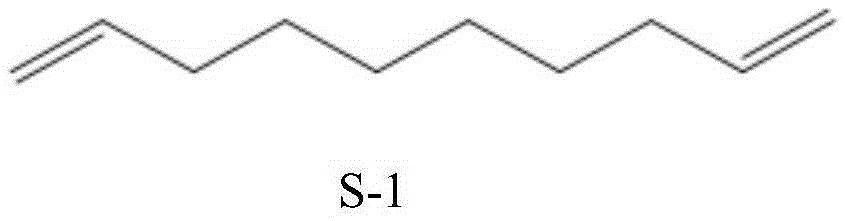

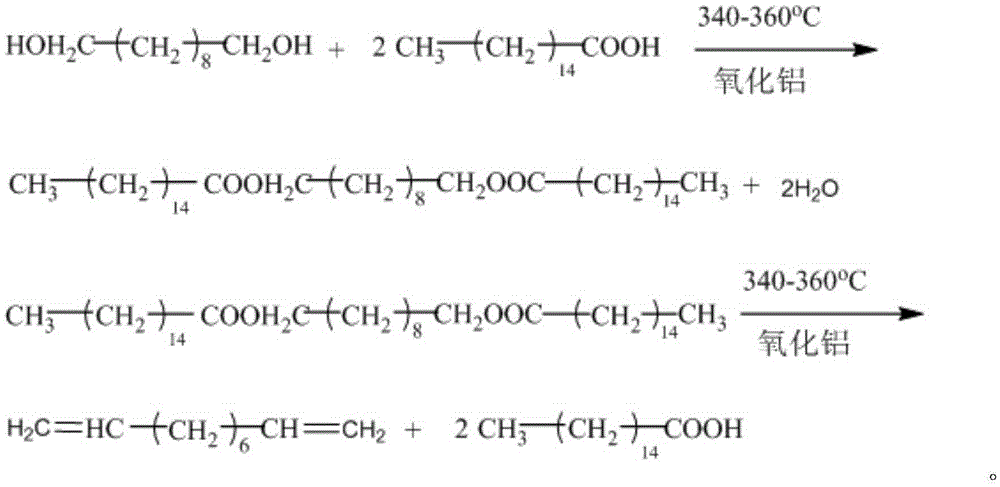

Synthetic method of 1,9-decadiene

InactiveCN105254464ALow priceFast reaction rateHydrocarbon from oxygen organic compoundsHydrocarbonsMixed solutionReaction rate

The invention discloses a synthetic method of 1,9-decadiene. The synthetic method comprises steps as follows: 1), higher aliphatic acid and a catalyst are uniformly stirred and mixed and then are heated to 340-360 DEG C, 1,10-decanediol is continuously dropwise fed, and continuous discharge is realized in a rectification mode; 2), a discharged material obtained in the step 1) is subjected to normal-pressure rectification, and 1,9-decadiene is obtained. The synthetic method further comprises a circular reaction in the step 3) as follows: bottom residues produced through normal-pressure rectification in the step 2) are mixed with 1,10-decanediol, a mixture replaces 1,10-decanediol in the step 1), a residual mixed solution formed after the reaction of the step 1) replaces a mixed bottom material in the step 1), and the circular reaction is performed according to the step 1). The method is adopted to synthesize 1,9-decadiene and has the characteristics of simple process, mild reaction conditions, low production cost, high reaction rate, high yield and the like.

Owner:ZHEJIANG UNIV

Method for extraction-oxidation ultra-deep desulfurization of diesel in microreactor system

ActiveCN107557060AWell mixedDecentralized precise controlTreatment with plural serial refining stagesChemical/physical/physico-chemical processesMicroreactorRetention time

The invention provides a method for extraction-oxidation ultra-deep desulfurization of diesel in a microreactor system. The method is characterized by improving an existing extraction-oxidation ultra-deep desulfurization technology based on ionic liquid by utilizing the microreactor system. The method comprises the following steps: enabling the diesel and an extracting agent-ionic liquid to be subjected to contact and mixing in a first micromixer; extracting most of sulfide from the diesel to the ionic liquid in a micromixing channel; then enabling a diesel-ionic liquid two-phase mixed material and an oxidant to be subjected to contact and mixing in a second micromixer, and completing oxidation and removing of the sulfide in a microchannel reactor connected with an outlet of the second micromixer, thus realizing ultra-deep desulfurization of the diesel, wherein the retention time of reaction materials in the microchannel reactor is 10 to 90 minutes. Compared with the prior art, the method has the advantage that efficient desulfurization and equipment miniaturization are realized through intensification on a desulfurization process; the technology is simple, continuous production can be realized, and a wide practical industrial application prospect is obtained.

Owner:YANTAI UNIV

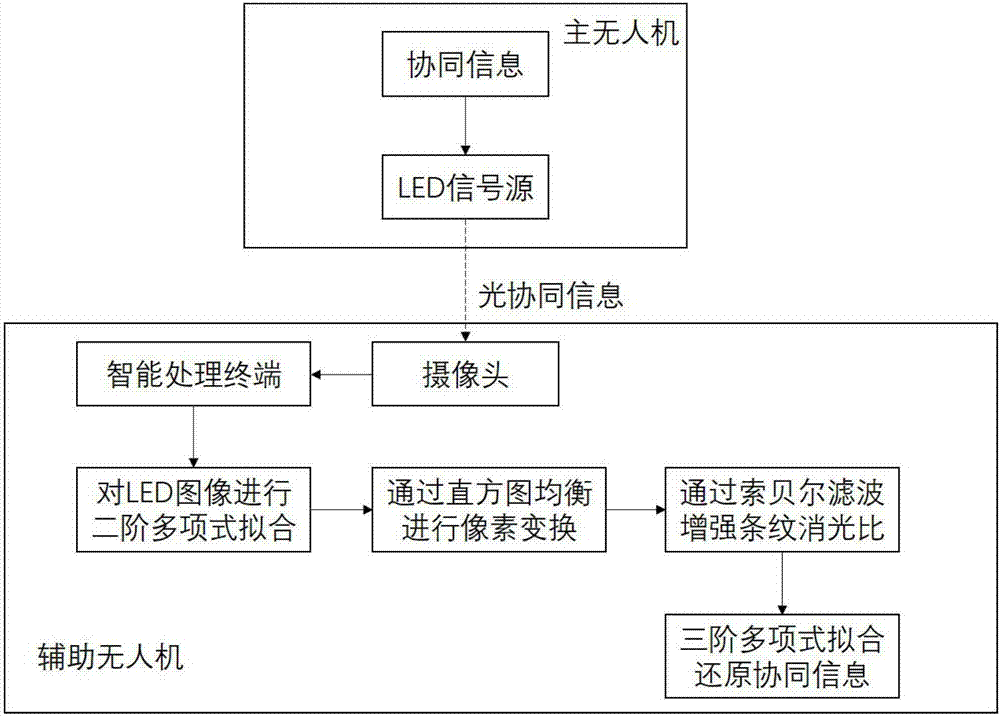

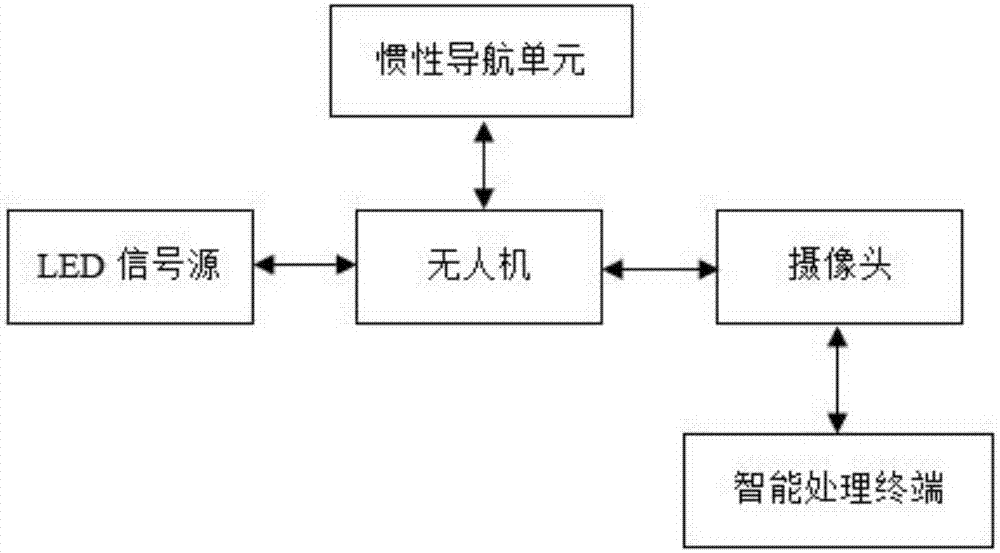

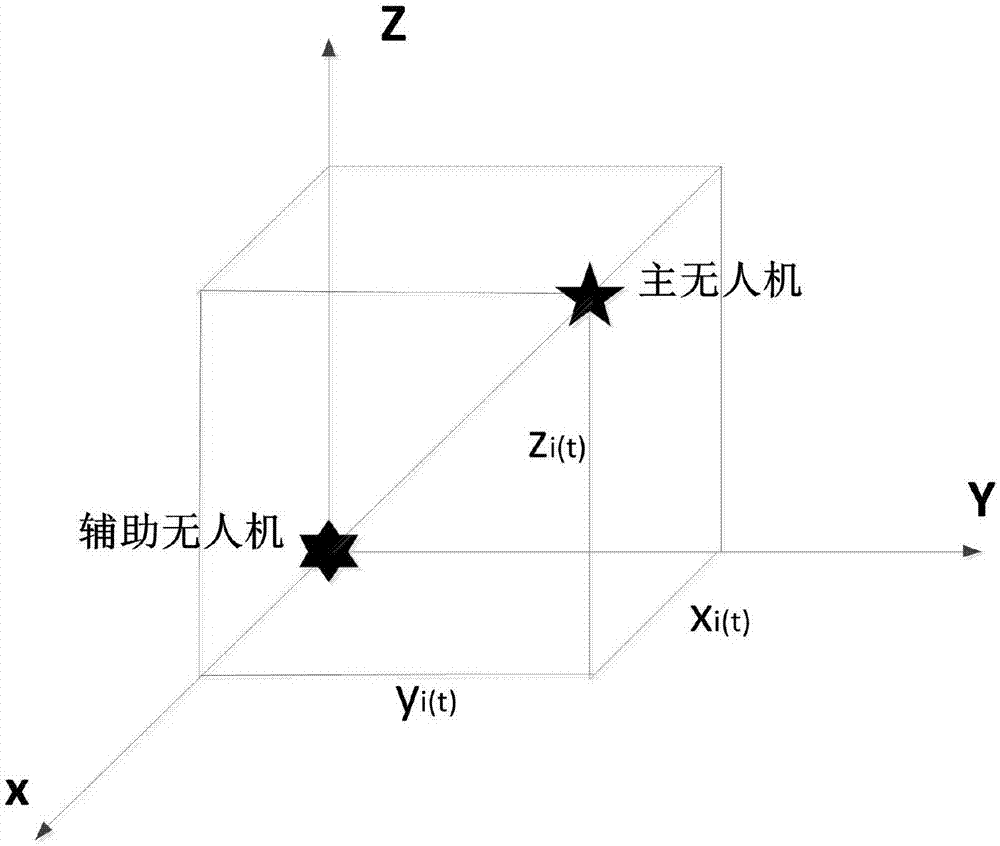

UAV collaboration SLAM method based on visible light visual communication

ActiveCN107453811AImprove accuracyElimination of indistinguishable defectsClose-range type systemsElectromagnetic receiversSignal lightVisual perception

The invention provides a UAV collaboration SLAM method based on visible light visual communication. The method comprises collecting a LED signal light source twinkling at a high frequency on a master UAV by using a CMOS camera on an auxiliary UAV, and converting an optical signal into a digital signal, eliminating a defect that it is possible to unclearly differentiate between dark stripes and bright stripes because of the saturation overflow of pixel electrons in a high-frequency flicker imaging process so as to ensure information coordination of the master UAV and the auxiliary UAV, to achieve the lighting and the communication simultaneously, and to improve the communication rate and the reaction rate between the master UAV and the auxiliary UAV, thereby enhancing a coordination effect between the master UAV and the auxiliary UAV. Furthermore, the visible range of visibility communication mode of visible light can ensure information confidentiality, prevent the information from being monitored, cannot generate electromagnetic interference, and is suitable for confidential or electromagnetically sensitive applications.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Preparation method of phosphite ester by using dividing wall tower reaction rectification technique

InactiveCN101775033AFast reaction rateLess by-productsGroup 5/15 element organic compoundsPhosphite esterBy-product

The present invention discloses a preparation method of phosphite ester by using a dividing wall tower reaction rectification technique, comprising the following steps: selecting phosphorous acid, a reactant alcohol and a water carrying agent as raw materials, the dosage of the reactant alcohol is 2 to 9 times the demand of the reaction; adding the raw materials into a reactor which is additionally provided with a dividing wall-typed rectifying tower for reaction, the reaction temperature is between 80 to 160 DEG C, leading cooling water into the overhead condenser timely, distilling off the lowest binary azeotrope formed by the water of the reaction and the reactant alcohol or the lowest ternary azeotrope formed by the water of the reaction, the reactant alcohol and the water carrying agent from the tower top, leading the distillate into a stratifying device after condensation, leading the oil phase into the side communicated with the reactor and leading the aqueous phase into the other side; stopping the backflow when the amount of the water in the aqueous phase reaches the preconcerted amount, distilling off the excessive reactant alcohol; stopping the heat when no distillate appears on the tower top, and the product let out from the tower bottom is phosphite ester. The invention has fast reaction speed, high product purity and fewer by-products.

Owner:QINGDAO UNIV +1

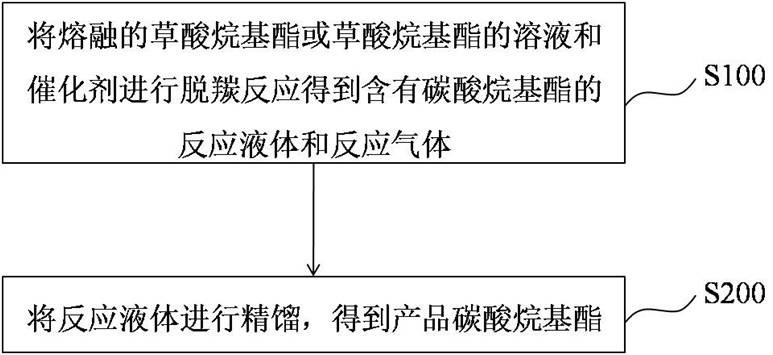

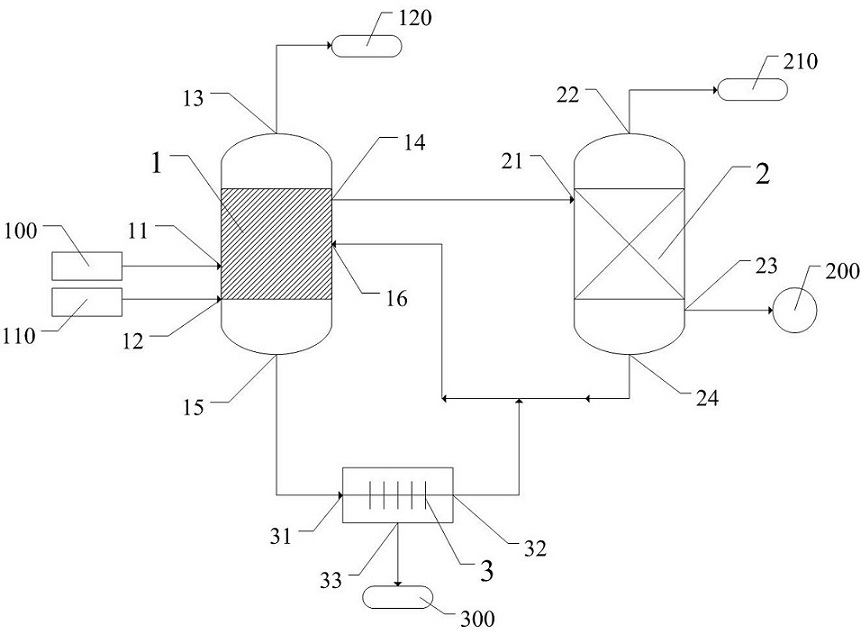

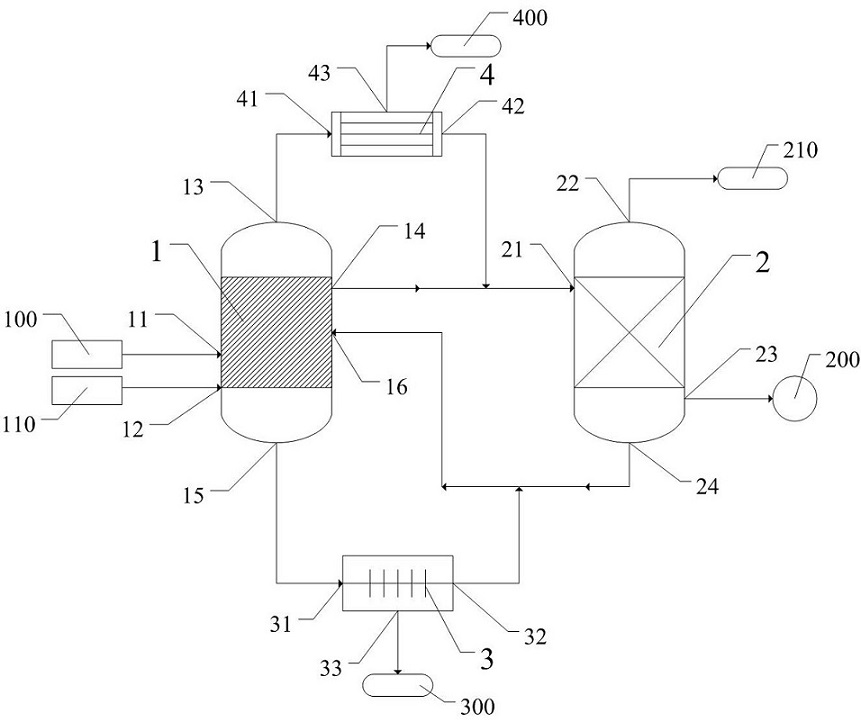

Preparation method and preparation system of alkyl carbonate

PendingCN112028771AEasy to manufactureCost-effective manufacturingOrganic compound preparationChemical industryOxalatePtru catalyst

The invention discloses a preparation method and a preparation system of alkyl carbonate. The preparation method comprises the following steps: a decarbonylation reaction step: carrying out a decarbonylation reaction on molten alkyl oxalate or a solution of alkyl oxalate and a catalyst under the conditions that the temperature is 50-160 DEG C and the pressure is 0.5-5 bar; carrying out the decarbonylation reaction to obtain reaction gas and reaction liquid containing alkyl carbonate; and a rectification treatment step: rectifying the reaction liquid to obtain the product alkyl carbonate. The preparation method disclosed by the invention is short in process flow, simple in required reaction device, high in reaction process speed, high in product yield and capable of realizing continuous production, the reaction raw material alkyl oxalate is easy to prepare and low in price, and the alkyl carbonate can be economically and efficiently prepared by virtue of the preparation method and the preparation system for the alkyl carbonate disclosed by the invention; the method is suitable for industrial large-scale production, and has huge industrial practical and economic values.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

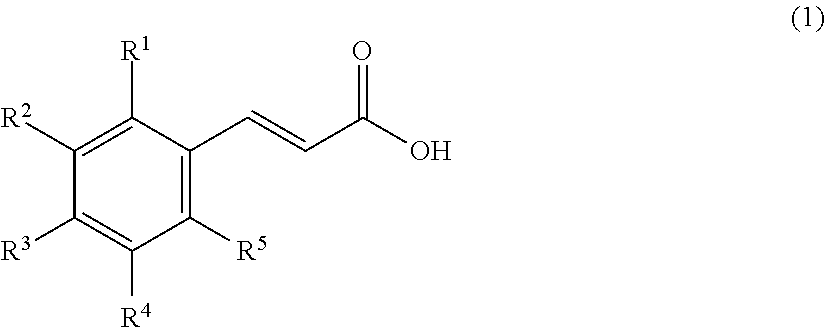

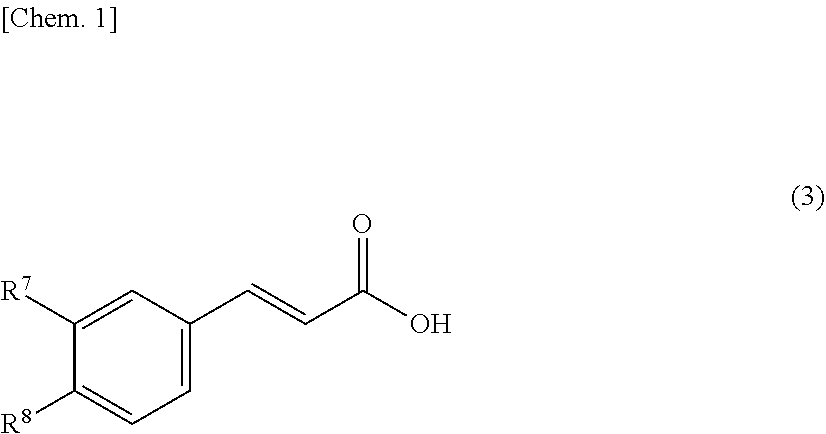

Method for producing cinnamic acid ester compound

ActiveUS20200123094A1Increased toxicityReduced activityOrganic compound preparationOrganic chemistry methodsPhenethyl alcoholCaffeic acid

A method for producing a cinnamic acid ester derivative includes reacting a cinnamic acid derivative compound represented by the formula (1), wherein the symbols are as defined in the description, with an alcohol compound represented by the formula: R6OH, wherein the symbol is as defined in the description, in the presence of a strong acid resin catalyst without using a solvent. As the cinnamic acid derivative compound, cinnamic acid, ferulic acid, and caffeic acid are preferred, and as the alcohol compound, methanol, ethanol, propanol, butanol, pentanol, hexanol, ethylene glycol, glycerol, phenethyl alcohol, and a monosaccharide are preferred.

Owner:TOHOKU UNIV

Process for producing sulfuric acid with low levels of nitrogen oxides

A process for producing sulfuric acid with reduced levels of nitrogen oxides (NOx) within a typical sulfuric acid production line. A hydrazine source material can be mixed with a sulfuric acid effluent at a temperature of at least about 90° C. for a period of at least 1 minute to reduce the level of NOx is the sulfuric acid effluent.

Owner:VEOLIA NORTH AMERICA REGENERATION SERVICES LLC

Efficient terminalization preparation method for hydroxyl terminal nano diamond for biological application

ActiveCN107840332AAvoid bringing outThe method is safer and simplerDiamondALUMINUM HYDRIDERates reactions

The invention discloses an efficient terminalization preparation method for hydroxyl terminal nano diamond for biological application and belongs to the field of biological and medicinal functionalized basic material preparation. The method comprises the following process steps: a, performing mixed acid pickling, and washing a nano diamond powder turbid liquid to be neutral with deionized water; b, dissolving nano diamond powder and lithium aluminum hydride into a tetrahydrofuran solution, and putting into a high-temperature reaction kettle container till the volume of 60-90%; c, sealing an outer high-temperature reaction kettle steel sleeve, putting into a constant-temperature heating tank, and keeping a constant temperature; d, after a heat preservation time is met, cooling, taking out areaction after solution, and adding hydrochloric acid which does not react with diamond or tetrahydrofuran, but is used for dissolving metal ions instead; e, performing centrifugal separation, and washing the nano diamond powder with deionized water for multiple times till neutral without acid residue; and f, washing with acetone, and performing ethanol ultrasonic washing so as to obtain a hydroxyl terminal nano diamond turbid liquid, and performing dispersion purification, thereby obtaining high-quality hydroxyl terminal nano diamond. The method disclosed by the invention is convenient and simple and rapid in reaction velocity, and terminalization of a relatively large amount of nano diamond powder is achieved with solutions of same ratios and volumes.

Owner:UNIV OF SCI & TECH BEIJING

Method for nitration synthesis of acifluorfen in microreactor

PendingCN112358400AIncrease contact areaMass transfer rate and reaction rate are fastChemical industryChemical/physical/physico-chemical microreactorsTrifluoromethylHeat transfer efficiency

The invention relates to a method for nitration synthesis of acifluorfen in a microreactor. The method for nitration synthesis of acifluorfen in the microreactor comprises the following steps: proportionally pumping a nitrating agent composed of a solution containing raw materials 3 (2chlorine 4trifluoromethyl phenoxy) benzoic acid, fuming sulfuric acid and fuming nitric acid into the micro-channel reactor in parallel through a metering pump; and reacting to synthesize the 5 (2chlorine 4trifluoromethyl phenoxy) 2nitrobenzoic acid (acifluorfen). The acifluorfen is synthesized by nitration of the micro-channel reactor, the phase contact area is increased, and the mass transfer rate and the reaction rate are high; The heat transfer efficiency is increased, reaction heat is transferred quickly, and safety is improved; The continuous operation is achieved, product quality is stable, operation is flexible, and amplification is easy; under optimized conditions, the reaction conversion rate can reach 99.19%, and the reaction selectivity is 81.08%.

Owner:YANTAI UNIV

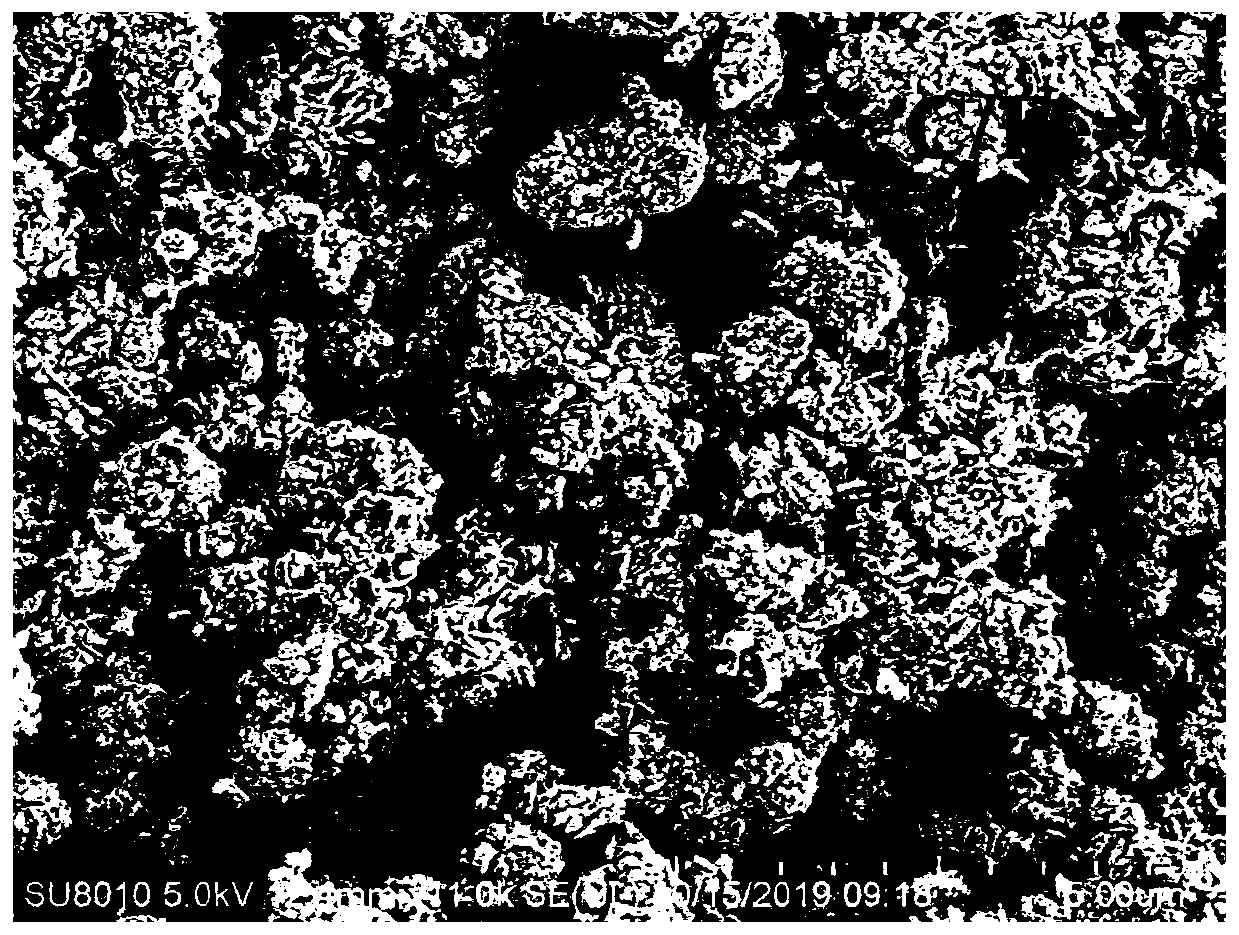

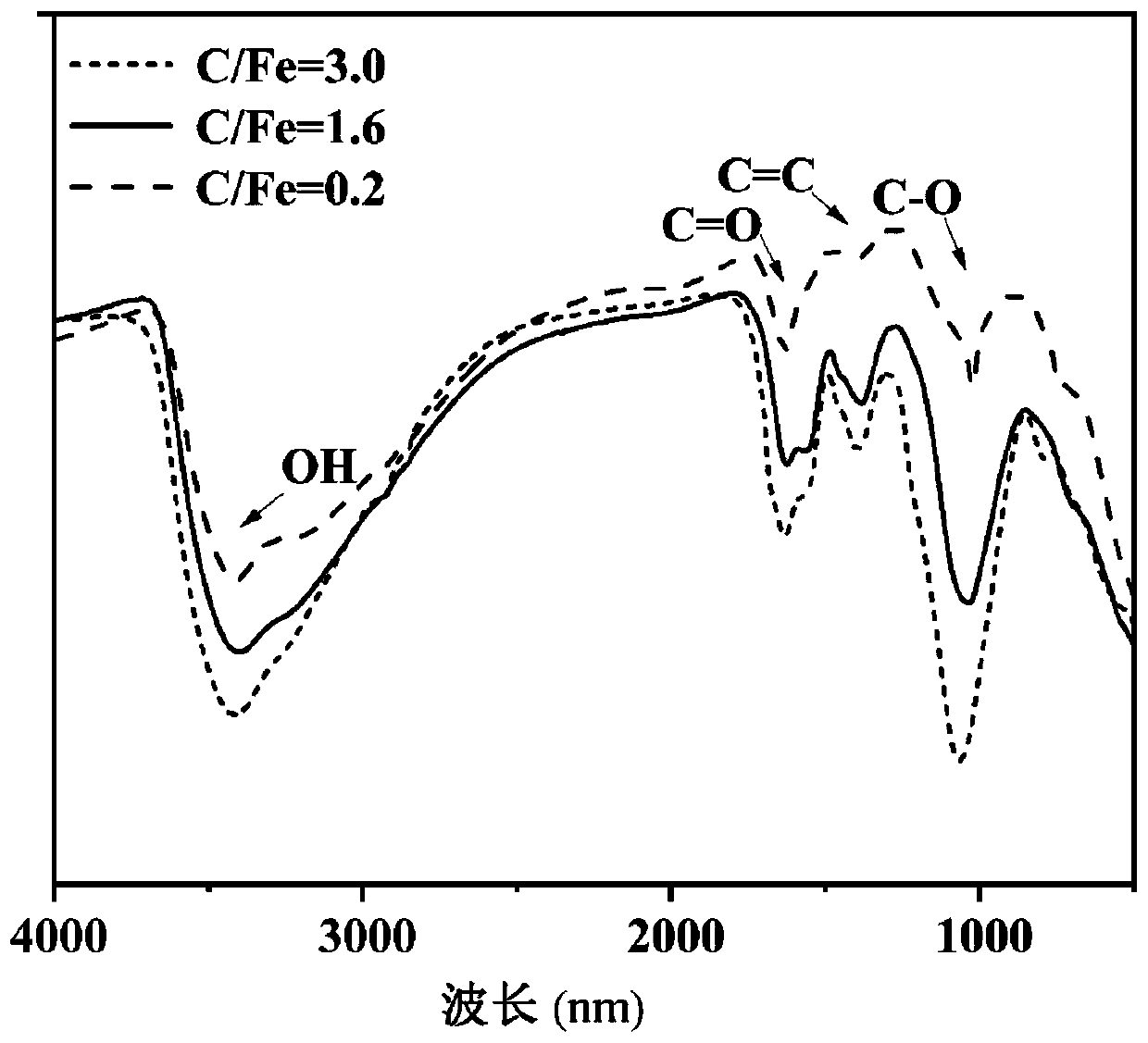

Preparation method of soluble black carbon-iron oxide coprecipitation Fenton-like catalyst, and application of catalyst in catalytic degradation of norfloxacin

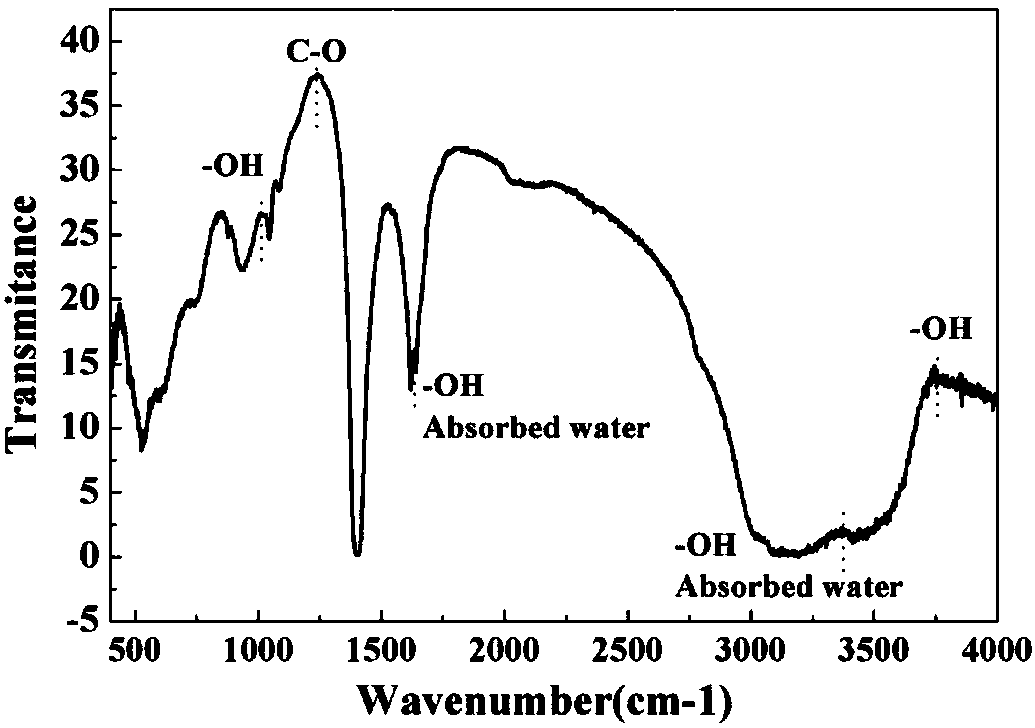

ActiveCN110721688AEasy to synthesizeMild reaction conditionsWater treatment compoundsWater contaminantsEthanesulfonic acidPtru catalyst

The invention provides a preparation method of a soluble black carbon-iron oxide coprecipitation Fenton-like catalyst, and an application of the catalyst in catalytic degradation of norfloxacin. The synthesis method comprises the following steps: 1, preparing black carbon; 2, extracting soluble black carbon; 3, carrying out coprecipitation preparation of the soluble black carbon-iron oxide: taking2-(N-morpholine)ethanesulfonic acid as a buffer solution, adding the soluble black carbon according to a final carbon-iron molar ratio of 0.2-3, adjusting the pH value to 6, putting the obtained system into a shaking table until Fe<2+> in the system is completely oxidized into Fe<3+>, centrifugally collecting the obtained solid-phase product, and washing and freeze-drying the solid-phase productto obtain the soluble black carbon-iron oxide coprecipitation material with different carbon-iron ratios. The prepared soluble black carbon-iron oxide coprecipitation Fenton-like catalyst is applied to treatment of norfloxacin-containing wastewater, and has the advantages of high reaction rate, high degradation efficiency and high reusability. The preparation method has the advantages of wide material sources, simple material preparation process, and facilitation of promotion and application in the actual wastewater treatment process.

Owner:DALIAN UNIV OF TECH

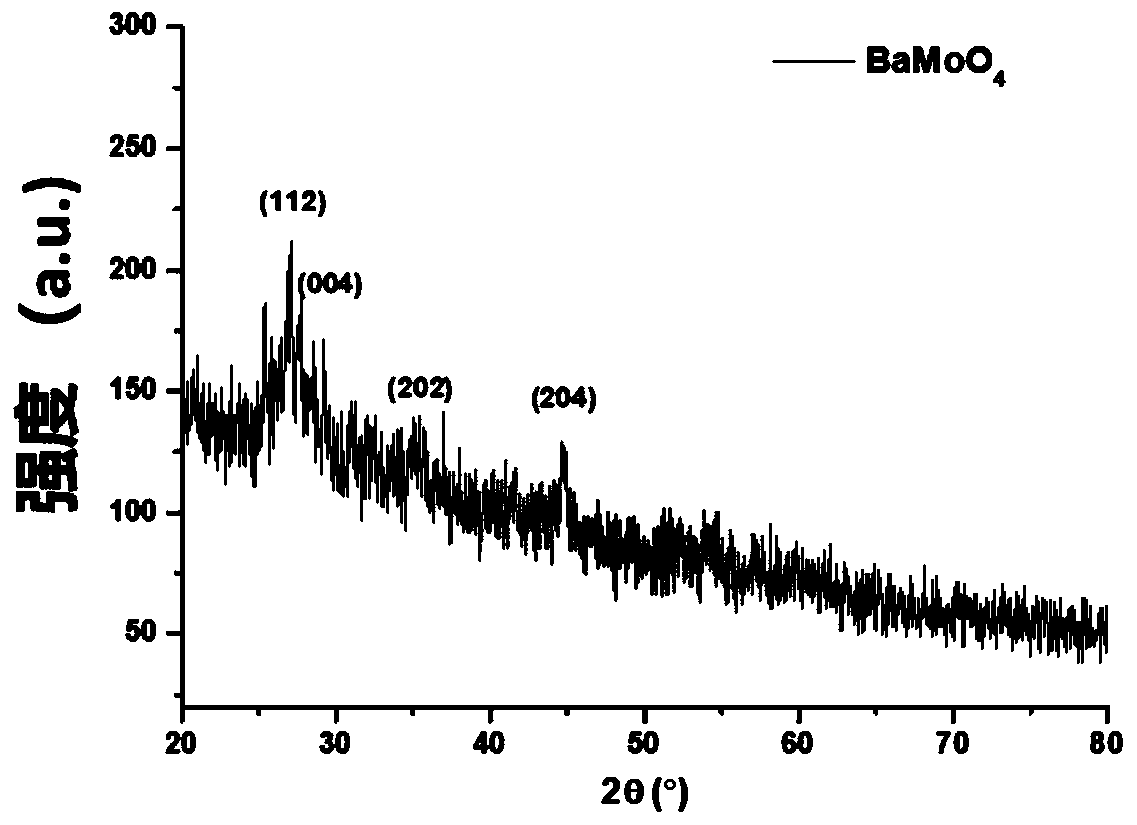

Method for preparing two-dimensional BaMoO4 by fast precipitation

The invention relates to the technical field of nanomaterial preparation and discloses a method for preparing two-dimensional BaMoO4 by fast precipitation. The method comprises the following steps: 1)0.18M of Ba(NO3)2 and 0.14M of (NH4)6Mo7O24.4H2O are dissolved in 15 ml of water respectively at room temperature, and a mixed solution is prepared for standby application; 2) the mixed solution is stirred uniformly by a mixer at the rated speed of 300 rpm until a large quantity of visible white precipitates are separated from the mixed solution for standby application; 3) the white precipitatesin step 2) are washed with water and ethanol and dried in a drying oven at 60 DEG C, and the high-purity two-dimensional nanomaterial BaMoO4 is obtained. The method for preparing two-dimensional BaMoO4 by fast precipitation is used for preparing the material with a liquid-phase room-temperature precipitation method, compared with the traditional sol-gel method and reverse micelle method, the method is low in cost, high in reaction rate, simple to operate, mild, easy to control, energy-saving and environmentally friendly, and the product has high purity and novel morphology.

Owner:LIAONING STARRY SKY SODIUM BATTERY CO LTD

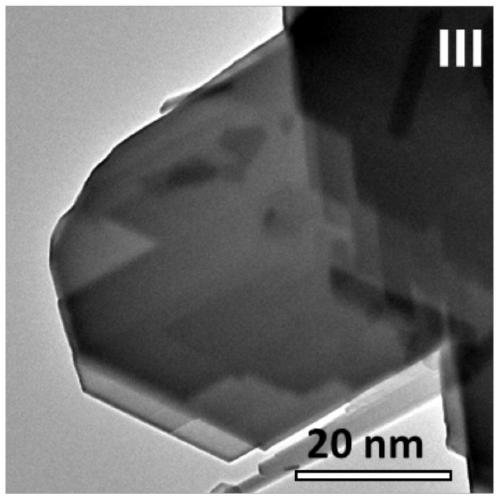

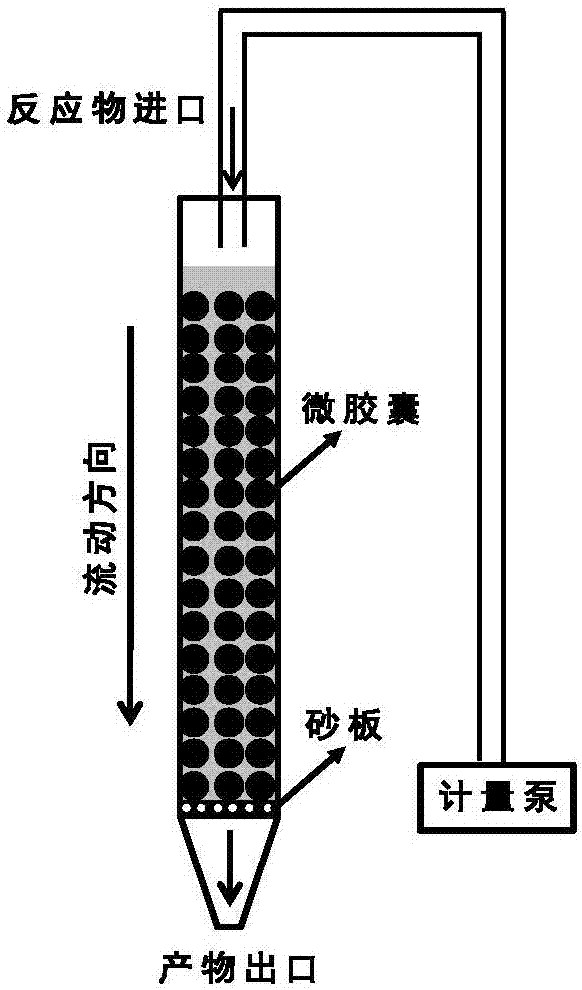

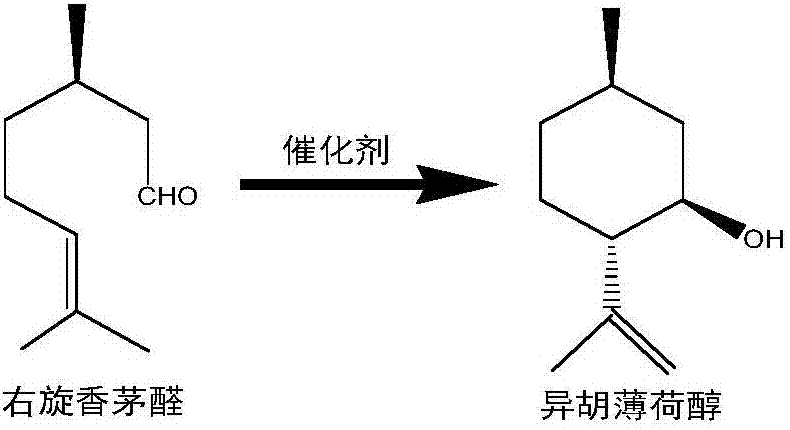

Method of preparing isopulegol by cyclization reaction of citronellal

InactiveCN106946652AHigh mechanical strengthUnbreakablePhysical/chemical process catalystsPreparation by oxygen reductionOil phaseOxide

The invention provides a method of preparing isopulegol by a cyclization reaction of citronellal. The method comprises the following steps: with nano silicon oxide with interfacial activity as an emulsion stabilizer, phosphotungstic acid as an aqueous phase and an organic solvent as an oil phase, stirring to form a Pickering emulsion of water in oil; then with the Pickering emulsion as a template, performing surface chemical crosslinking to prepare microcapsules packaging a phosphotungstic acid catalyst inside; and filling a continuous flowing reaction column with the microcapsules as a fixed phase, inputting dextrocitronellal as a moving phase from the upper end of a reactor, wherein a product flows out from the bottom of the reactor. The reaction system can provide a relatively large reaction interface, and can repeatedly use the catalyst while keeping excellent catalytic performance of phosphotungstic acid. After continuous reaction for 1000 hours, the conversation ratio still can be kept at 90% and above, and the selectivity on isopulegol can reach 60%-75%.

Owner:SHANXI UNIV

Preparation method of polymethyl methacrylate with narrow molecular weight distribution

InactiveCN104497182AEasy to prepareFast reaction rateBulk chemical productionMethyl methacrylateSolvent

The invention provides a preparation method of polymethyl methacrylate with narrow molecular weight distribution, and belongs to the field of preparation methods of high polymer material. The problems that the existing preparation method of polymethyl methacrylate with narrow molecular weight distribution is complex in process, rigor in polymerization condition and long in polymerization period are overcome. The method includes that: methyl methacrylate, solvent and initiator are put into a reaction vessel for reacting for 60-180min at the temperature of 90DEG C-180 DEG C, and thereby the polymethyl methacrylate with narrow molecular weight distribution is obtained; the solvent is dialkyl imidazole ionic liquid. According to the preparation method, the dialkyl imidazole ionic liquid is used as the solvent, so that the polymethyl methacrylate with narrow molecular weight distribution is obtained by high temperature polymerization; furthermore, the preparation method is simple and quick in reaction speed; the materials can be directly used without pretreatment, and the molecular weight distribution index of the prepared polymethyl methacrylate is 1.0-1.3.

Owner:CHANGCHUN UNIV OF TECH

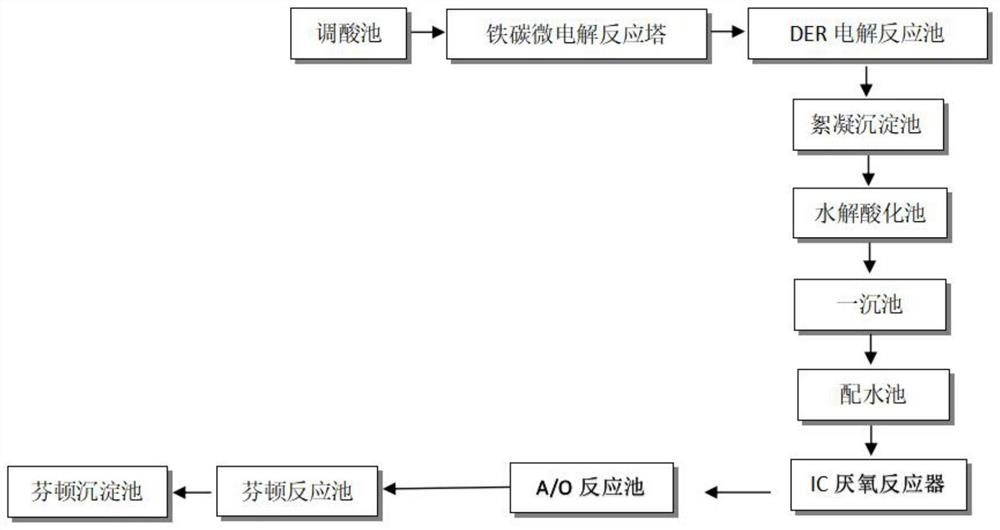

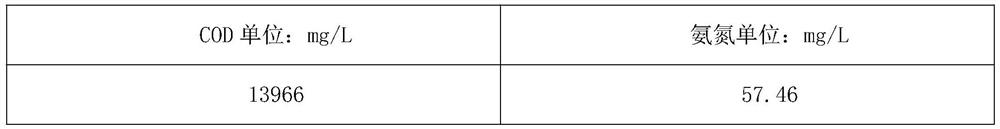

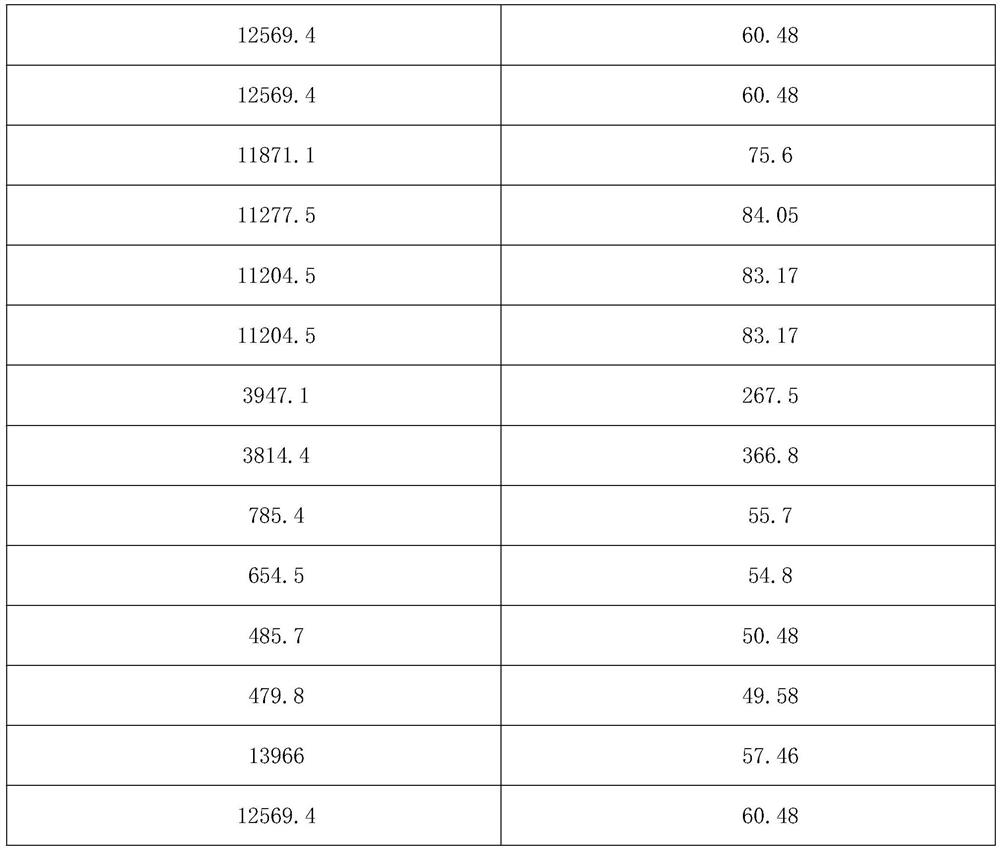

Wastewater treatment process

InactiveCN112591982AFast reaction rateWide rangeWater treatment parameter controlWater treatment compoundsWater treatmentMembrane reactor

The invention discloses a wastewater treatment process which comprises the following steps of: pumping wastewater into an acid regulator, carrying out air aeration treatment on the wastewater in a neutralization tank by using an aeration device, carrying out air aeration treatment on the wastewater in a tower by using the aeration device, enabling the wastewater to flow into the neutralization tank automatically, carrying out air aeration treatment on the wastewater in the tower by using the aeration device, meanwhile, adding alkali into the tank, enabling the wastewater to automatically flowinto a DER electrolytic reaction tank, performing air aeration on the electrolytic reaction tank by using the aeration device, enabling the wastewater to enter a flocculation sedimentation tank, enabling effluent to enter a hydrolysis acidification tank, stirring the wastewater in the tank by using a submersible stirrer, enabling the effluent to enter a primary sedimentation tank, enabling the effluent to enter a water distribution tank, pumping the effluent into an IC anaerobic reactor by using a pump, enabling the effluent to automatically flow into an anaerobic sedimentation tank, enablingthe effluent to enter A / O, enabling the effluent to enter an MBR membrane reactor, enabling the effluent to enter a Fenton reaction tank, adding PAM to enable small particles to form large particles for rapid sedimentation, and enabling the effluent to enter the flocculation sedimentation tank to realize mud-water separation and supernatant discharge. The problem of wastewater treatment is fundamentally solved.

Owner:山东晟旭达环保工程有限公司

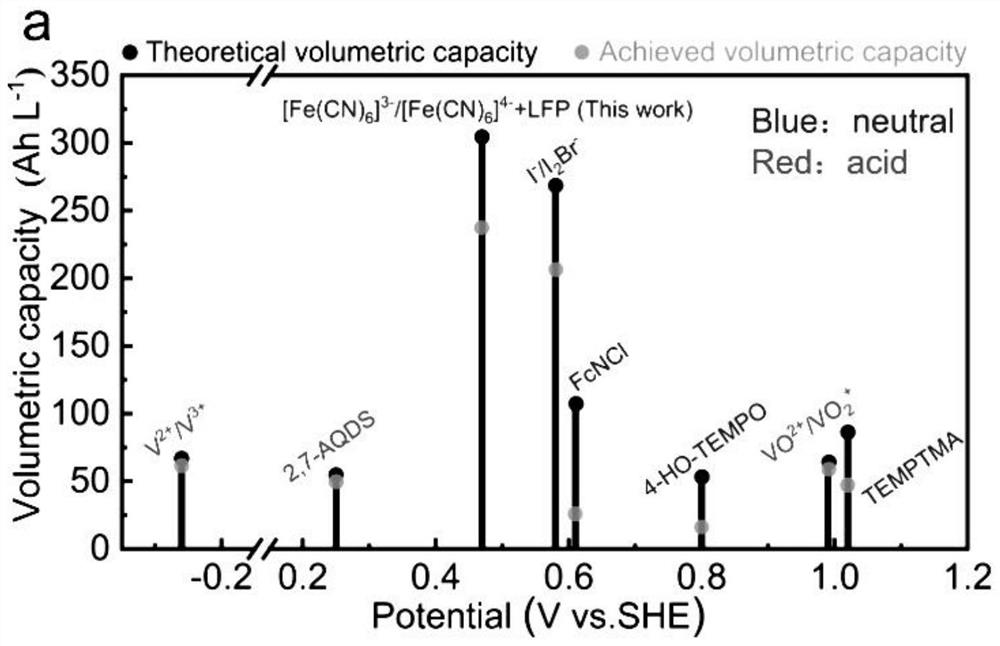

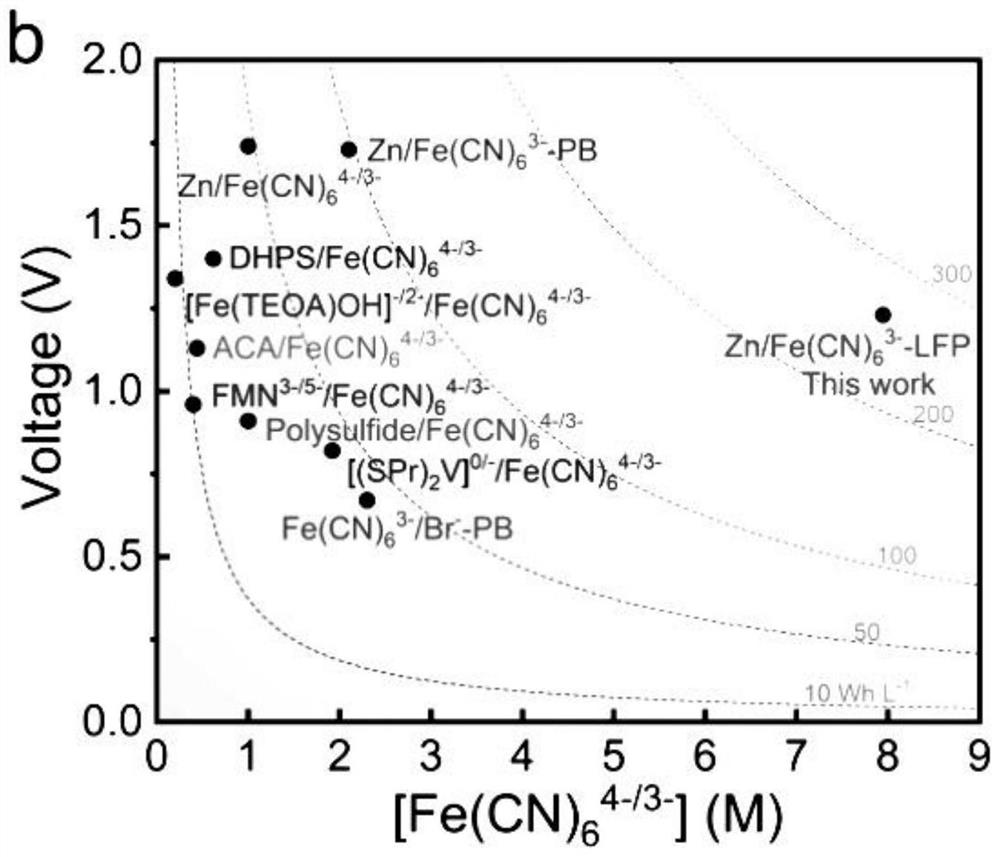

Stable and high-capacity neutral aqueous liquid flow lithium battery based on redox targeting reaction

ActiveCN113258114AExcellent volume specific capacityImprove stabilityRegenerative fuel cellsAqueous electrolytesBattery cellEnergy storage

The invention discloses a stable and high-capacity neutral aqueous liquid flow lithium battery based on redox targeting reaction, which belongs to the technical field of liquid flow lithium batteries. The technical problem that an existing liquid flow battery can only work at low current density is solved. The liquid flow lithium battery comprises a positive electrode storage tank and a negative electrode storage tank, the positive electrode storage tank is filled with a positive electrode electrolyte, the negative electrode storage tank is filled with a negative electrode electrolyte, and the liquid flow lithium battery is characterized in that the positive electrode electrolyte of the liquid flow lithium battery comprises a salt containing [Fe(CN)6]<4-> and / or [Fe(CN)6]<3->, and the positive electrode storage tank is also filled with LFP particles and / or FP particles. The battery has a wide application prospect in the field of large-scale energy storage.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com