Method for extraction-oxidation ultra-deep desulfurization of diesel in microreactor system

A micro-reactor, deep desulfurization technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc. The problem of poor mixing effect of phase materials can shorten the mixing time of materials, improve the efficiency of single-pass desulfurization, and increase energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

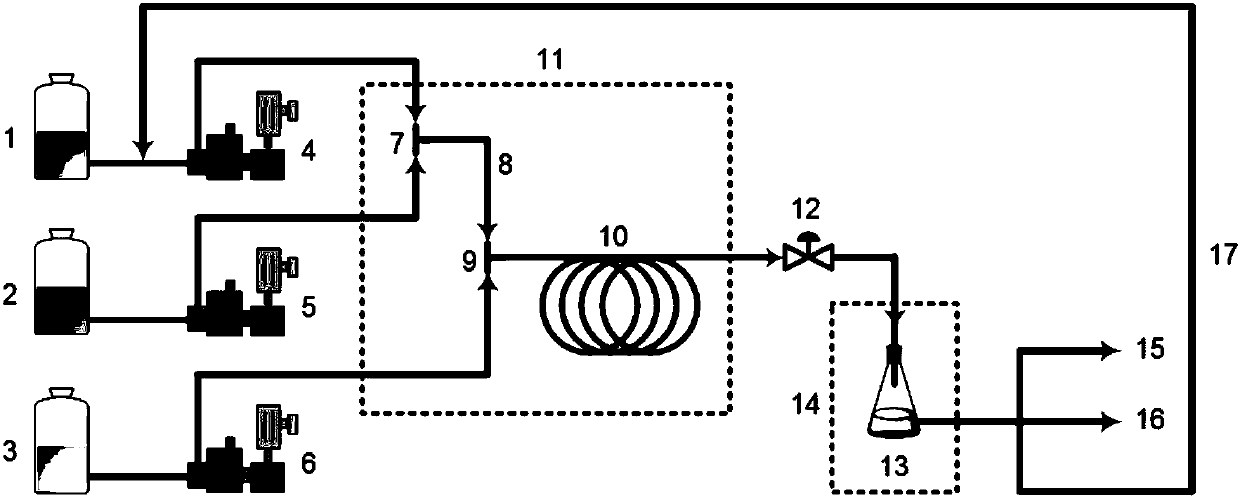

[0024] For verifying the effect of the present invention, be the model diesel oil (the mixture of dibenzothiophene and n-octane) of 500ppm with sulfur content as research object, adopt ionic liquid BmimPF 6 as extractant, containing 30wt% hydrogen peroxide (H 2 o 2 ) of hydrogen peroxide as oxidant, ammonium heptamolybdate [(NH 4 ) 6 Mo 7 o 24 4H 2 O] as a catalyst, using figure 1 As shown in the process flow, the desulfurization experiment is carried out on the model diesel. Among them, the two micro-mixers adopt the T-shaped mixing method, the diameter of the micro-mixing channel is 0.5 mm, and the length is 100 mm; the diameter of the micro-reaction channel is 0.5 mm, and the length is 5000 mm.

[0025] Before carrying out the desulfurization experiment, first prepare [(NH 4 ) 6 Mo 7 o 24 4H 2 O] BmimPF at a concentration of 4 g / L 6 -[(NH 4 ) 6 Mo 7 o 24 4H 2 O] mixture, and vibrated with ultrasonic waves, to get dispersed with [(NH 4 ) 6 Mo 7 o 24 4H ...

Embodiment 2

[0052] The reaction process is described with reference to Example 1. Set the reaction temperature to 60°C, the outlet pressure of the microchannel reactor to 275kPa, and BmimPF 6 The molar ratio to sulfur is 100, H 2 o 2 The molar ratio to sulfur is 18, the diesel flow rate is adjusted to 13.83μL / min, BmimPF 6 The flow rate of the suspension is 2.77 μL / min, and the flow rate of hydrogen peroxide is 0.28 μL / min, so that the diesel-BmimPF 6-The residence time of the hydrogen peroxide three-phase material in the micro-reaction channel is 60min, and the model diesel oil is desulfurized in the same micro-reactor system as in Example 1. The results show that the sulfur content of desulfurized diesel oil is 3.8ppm, and the desulfurization rate is 99.24%, which meets the requirements of ultra-deep desulfurization of diesel oil; the pressure drop of the microchannel reactor is 0.7kPa, which meets the process design requirements.

Embodiment 3

[0060] The reaction process is described with reference to Example 1. Set the reaction temperature to 60°C, the outlet pressure of the microchannel reactor to 275kPa, and BmimPF 6 The molar ratio to sulfur is 250, H 2 o 2 The molar ratio to sulfur is 45, the diesel flow rate is adjusted to 21.78μL / min, BmimPF 6 The flow rate of the suspension is 10.89 μL / min, and the flow rate of hydrogen peroxide is 1.09 μL / min, so that the diesel-BmimPF 6 -The residence time of the hydrogen peroxide three-phase material in the micro-reaction channel is 30min, and the desulfurization experiment is carried out on the model diesel in the same micro-reactor system as in Example 1. The results show that the sulfur content of desulfurized diesel oil is 6.2ppm, and the desulfurization rate is 98.76%, meeting the requirements of ultra-deep desulfurization of diesel oil; the pressure drop of the microchannel reactor is 0.7kPa, which meets the process design requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com