Patents

Literature

2181results about How to "Improve production safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

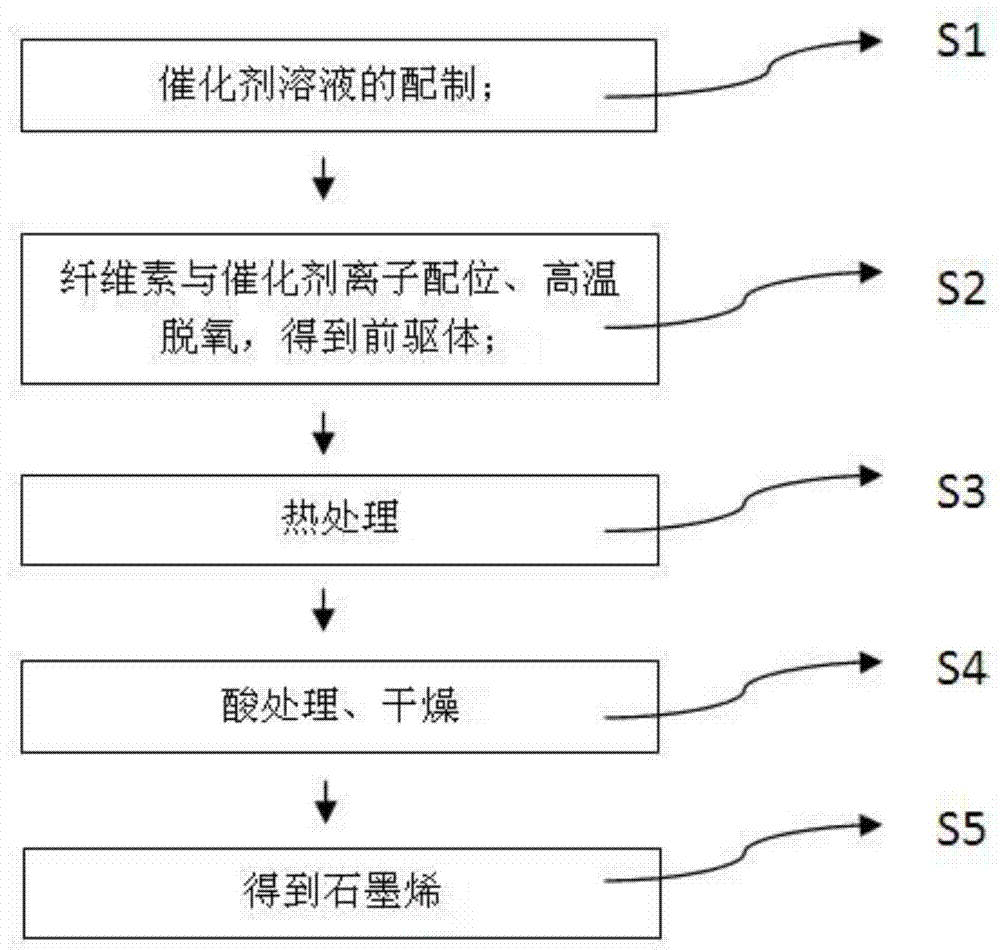

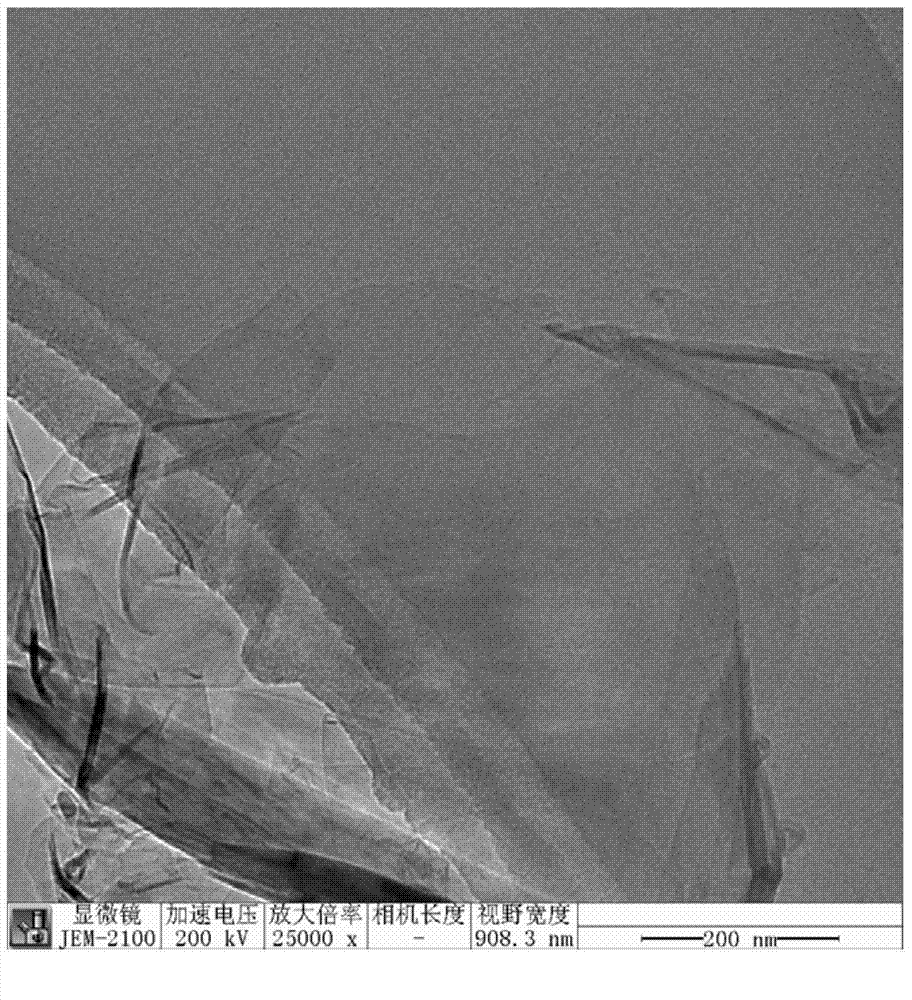

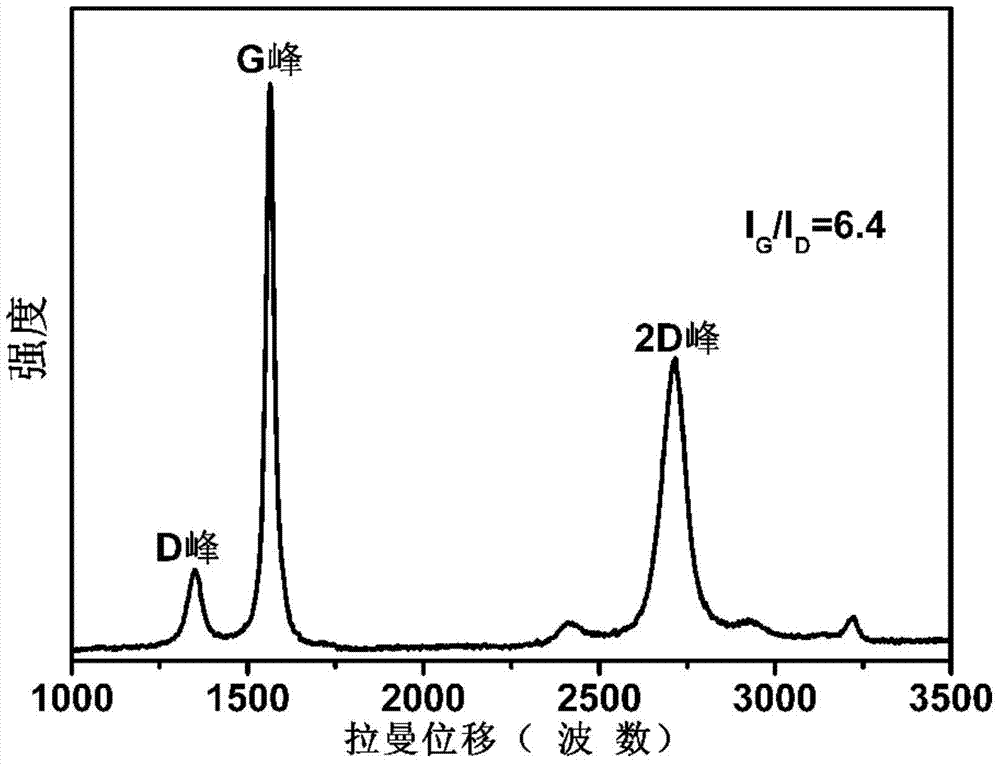

Method for preparing biomass graphene employing cellulose as raw material

ActiveCN104724699AUniform sizeIncrease productionPhysical/chemical process catalystsGrapheneCellulosePolymer science

The invention provides a preparation method of graphene, and particularly relates to a method for preparing biomass graphene employing cellulose as a raw material. The specific preparation method comprises the following steps: 1, preparing a catalyst solution; 2, carrying out ionic coordination and high-temperature deoxidization on cellulose and a catalyst, so as to obtain a precursor; 3, carrying out thermal treatment; 4, carrying out acid treatment, and drying to obtain the graphene, wherein the prepared graphene is uniform in morphology, has a single-layer or multi-layer two-dimensional layered structure; the dimension is 0.5-2 microns; and the electrical conductivity is 25,000-45,000S / m. The preparation method is simple in preparation technology, low in cost, high in yield, high in production safety, and controllable in product dimension and physical property; industrialized production can be realized; the graphene prepared by the method can be applied to electrode materials of super capacitors and lithium ion batteries, and can also be added to resin and rubber as an additive; and the physical property of the material can be improved.

Owner:HEILONGJIANG UNIV +1

Quick preparation method for pickled vegetable containing biodiasmin

InactiveCN103120294AImprove production efficiencyIncrease productivityFood preparationVegetable processingSalt content

The invention provides a quick preparation method for a pickled vegetable containing biodiasmin. The quick preparation method comprises the following steps of: preparing biodiasmin liquor, preparing pickled vegetable fermentation liquor, preparing a seasoning fermentation liquor, pre-treating and preparing a finished pickled vegetable containing biodiasmin. According to the quick preparation method disclosed by the invention, the pickled vegetable fermentation liquor is independently prepared according to the conventional pickled vegetable production way, and the pickled vegetable fermentation liquor is treated by seasoning to form seasoning fermentation liquor; osmotic dehydration and the brittleness-keeping treatment are carried out on the fresh vegetable to obtain a semi-finished product; and the semi-finished product is pickled by the seasoning fermentation liquor, and the seasoning fermentation liquor is quickened up to permeate into the vegetable through the vacuum treatment to obtain the delicious finished pickled vegetable. The pickled vegetable is prepared by the preparation method disclosed by the invention is low in salt content, short in production time, high in calcium content and biodiasmin content and beneficial to the body health of a user; and moreover, the automation degree of the pickled vegetable processing is improved.

Owner:HEFEI UNIV

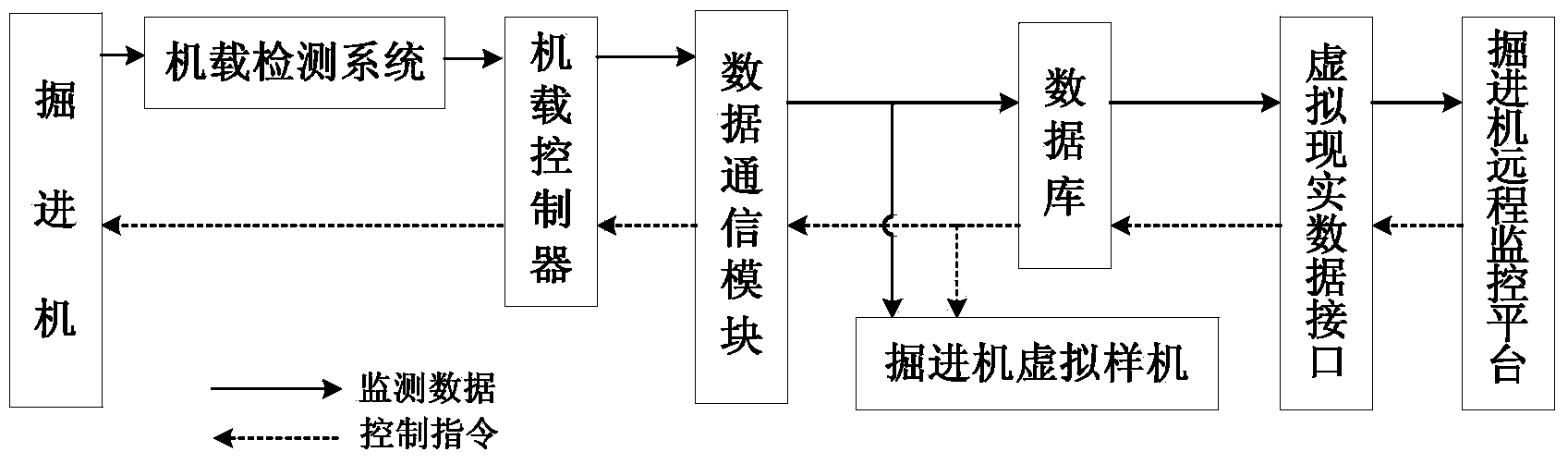

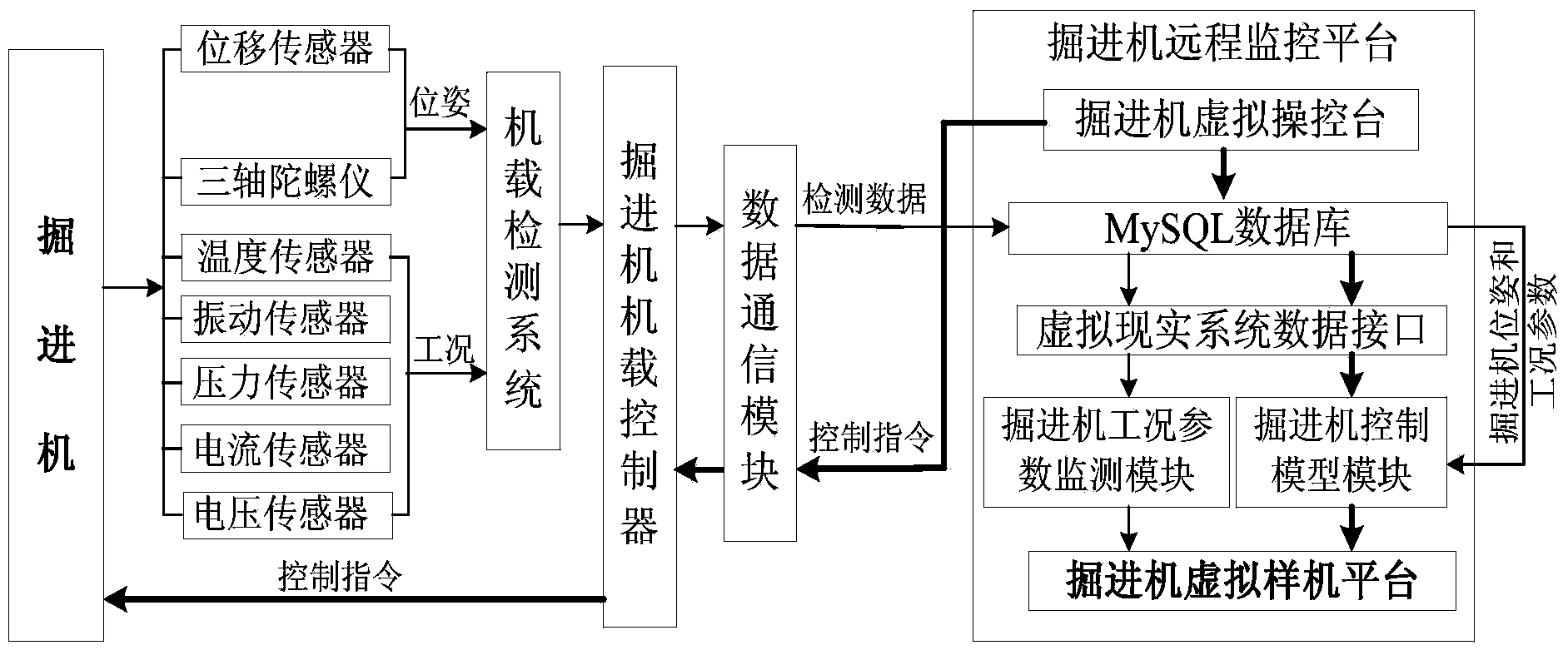

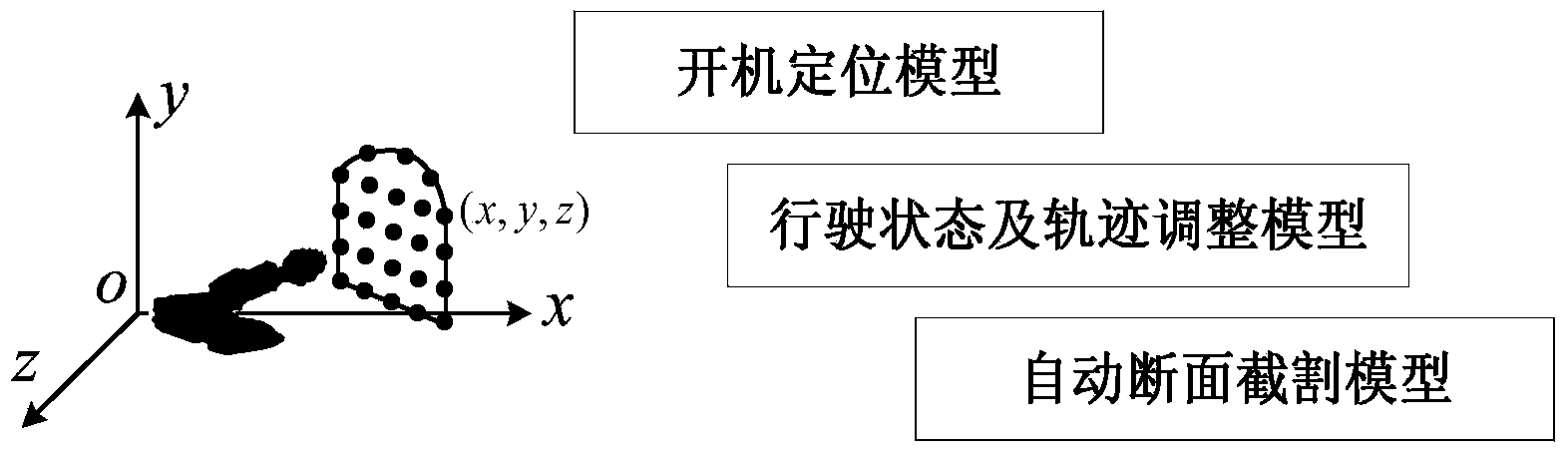

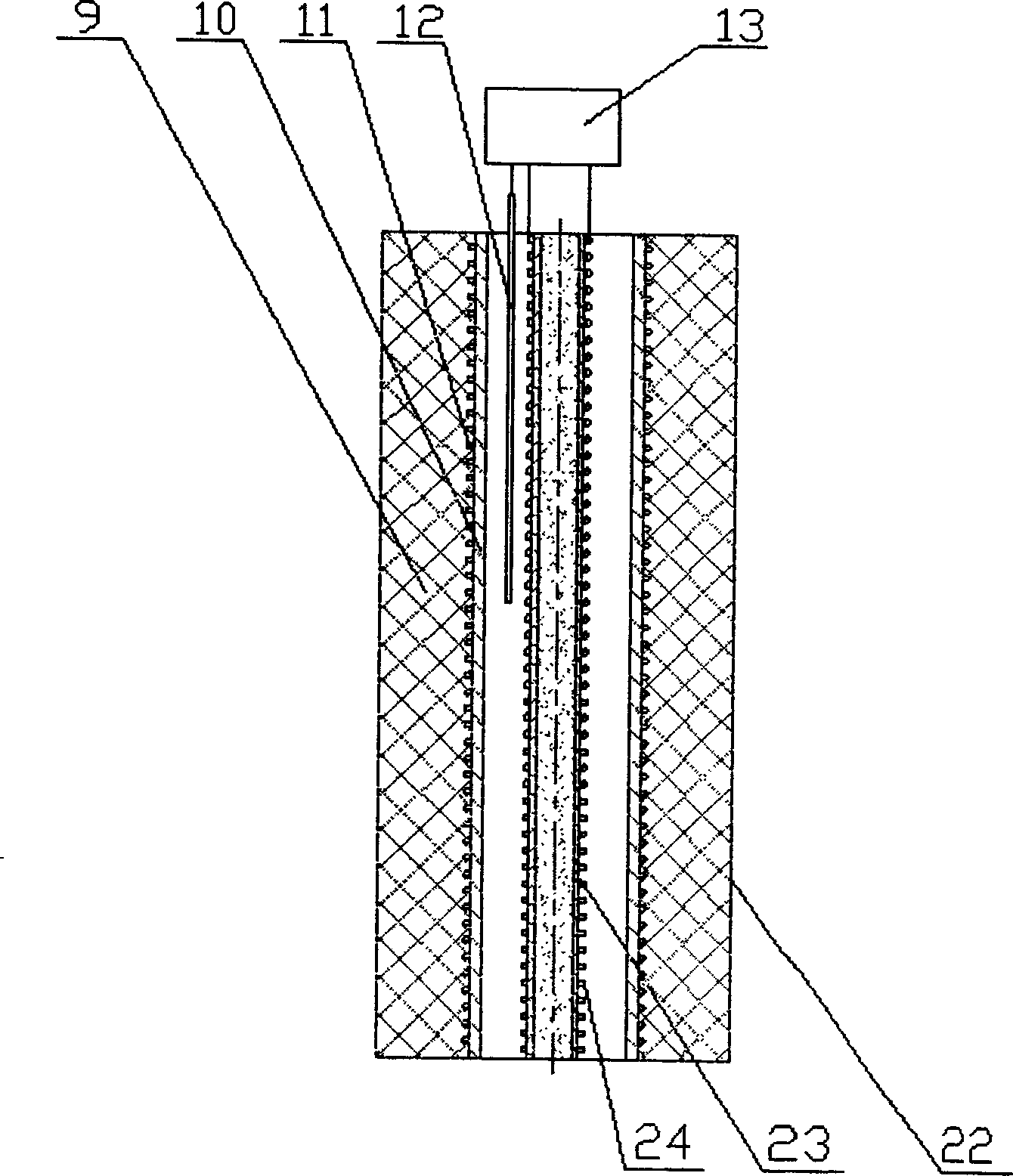

Remote control system and remote control method of heading machine

ActiveCN103867205AImplement the binding actionEnsure consistencySlitting machinesMachine controlRemote control

The invention discloses a remote control system and a remote control method of a heading machine. The remote control system comprises a sensor arranged on the heading machine, an onboard detection system, an onboard controller, a data communication module and a heading machine remote monitoring platform, wherein the heading machine remote monitoring platform comprises a heading machine virtual control table, a database, a virtual reality system data interface, a heading machine control model module, a heading machine working condition parameter monitoring module and a heading machine virtual prototype platform. The system and the method solve the problems that the working environment of the heading machine in underground coal mine has abundant dust and high noise, an operator has difficulty in mastering the specific situation of the heading cross section, and controls blindly due to lacking of working condition data and pose information of the heading machine, thereby promoting the roadway drifting quality and the drifting safety. The remote control system has good interaction, good reality sense, reasonable design, strong practicability and high popularization and application values.

Owner:XIAN UNIV OF SCI & TECH

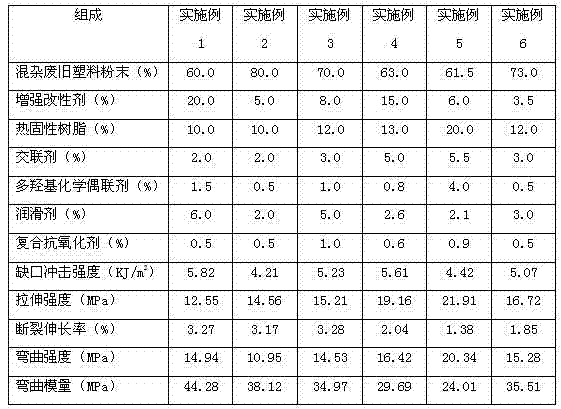

Composite board based on mixed waste polymers and preparation method thereof

The present invention discloses a composite board based on mixed waste polymers and a preparation method thereof. The preparation method of the composite board based on the mixed waste polymers is characterized by comprising the following steps of: (1) weighing the raw materials according to a certain proportion, adding the raw materials to a high-speed mixer, mixing at the temperature of 40-60 DEG C and the rotation speed of 800-2000 rpm for 20-30 minutes, cooling to room temperature and discharging; and (2) adding the mixed material to a mold, vulcanizing at the temperature of 150-180 DEG C and the pressure of 10-15 MPa for 10-20 minutes, cooling and relieving pressure. The composite board based on the mixed waste polymers provided by the invention does not need to consider the complex compatibility and plasticizing problems of multiple polymers, effectively solves the problems that the existing mixed waste polymers can not be classified and are discarded, and can be used as the substitute for wood to be applied in the tray manufacturing field and other fields. The production process provided by the invention is simple, uses existing equipment and is suitable for mass production.

Owner:佛山市南海承骏科技有限公司 +1

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

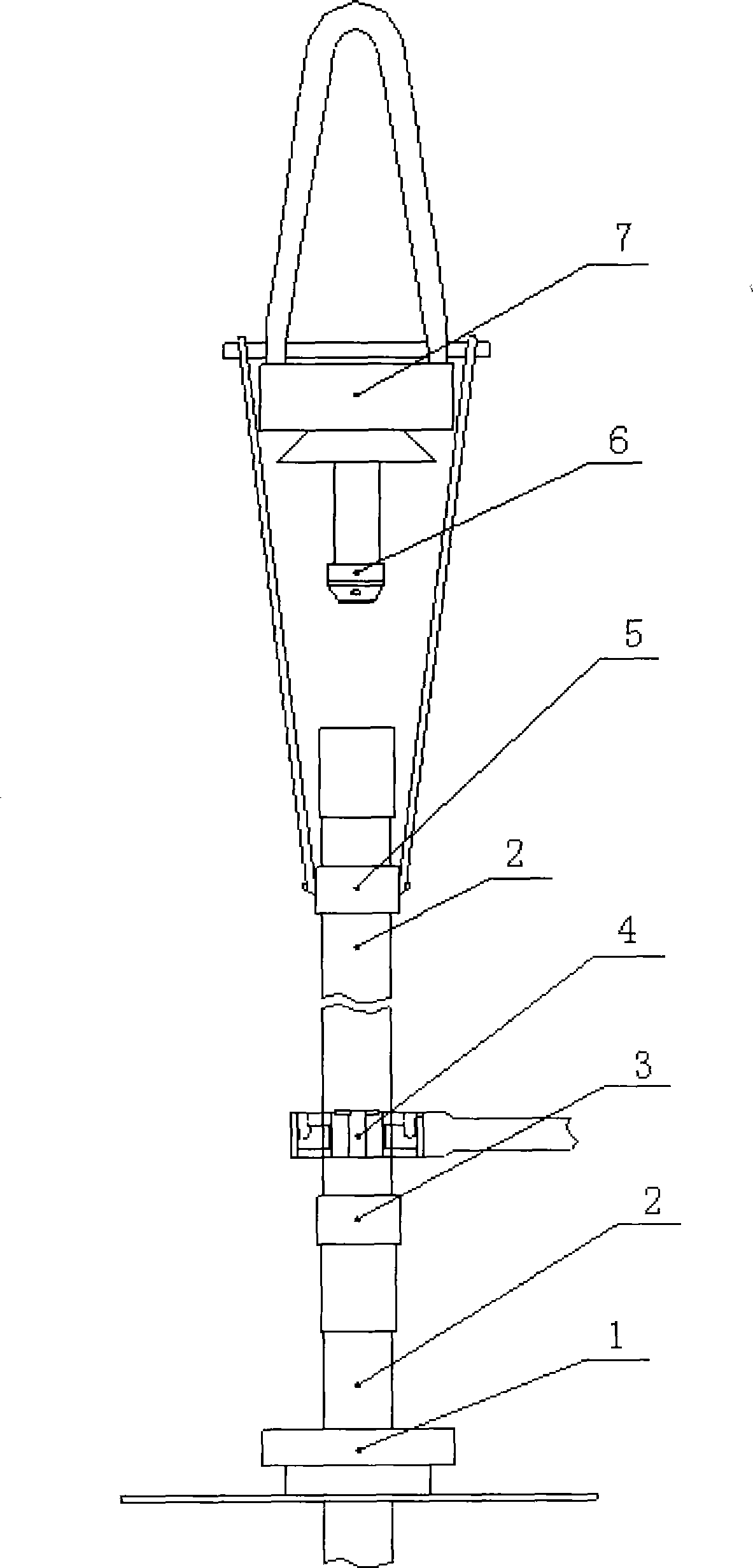

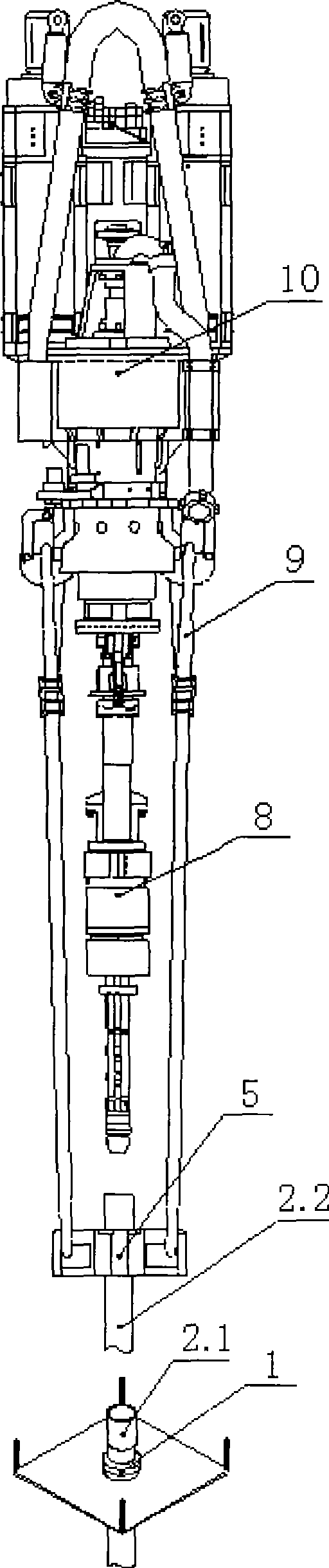

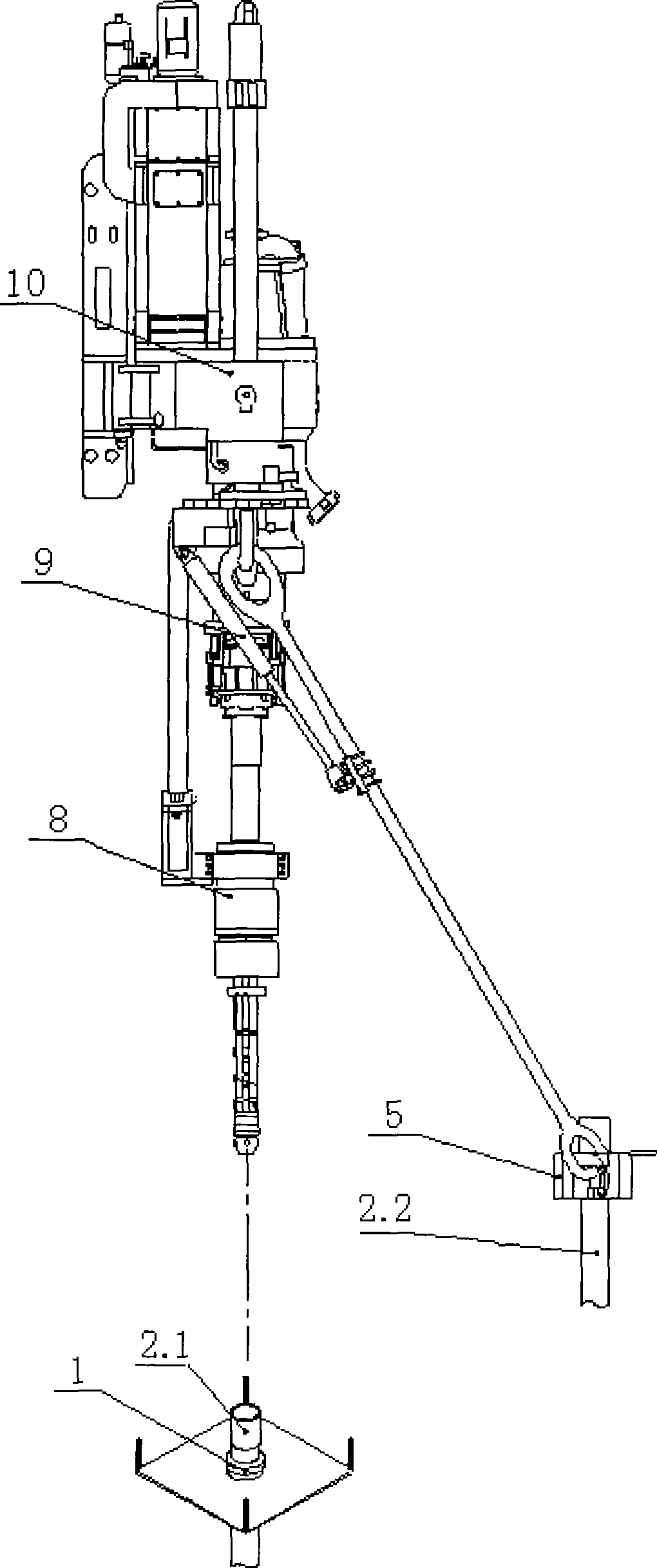

Method for top-driving casing job of drilling apparatus

ActiveCN101487377AHigh degree of automationSimplify the work processDrilling machines and methodsTop driveWell drilling

A method for casing job by using a top drive drilling unit is applied to the petrol cementing technique field, and is characterized in that a casing elevator is used for lifting a single casing which is buckled with a casing string oppositely; a top-driven casing device is driven to tightly clamp the single casing; the top drive drilling unit is driven to revolve, which allows the single casing to be connected with the casing string; an air slips of a drill stand is loosed, which allows a top-driven flying ring and the casing elevator to support the single casing and the casing string; the single casing and the casing string are lowered; the air slips of the drill stand is used for fixing the single casing; slurry is poured to the interior cavities of the single casing and the casing string through a chief axis hydrophthalmia of the top drive drilling unit and a central spindle hydrophthalmia of the top-driven casing device; and finally, all the casing strings are lowered to the well bottom. The method has the advantages of reducing working equipments, simplifying working process, being capable of revolving casing string and cycling slurry timely according to the actual needs, increasing the automatic degree of the casing job, and improving the production efficiency and safety.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

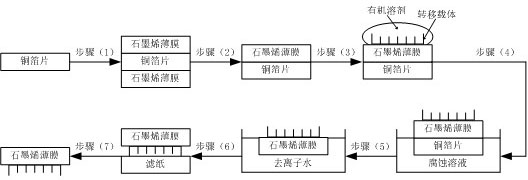

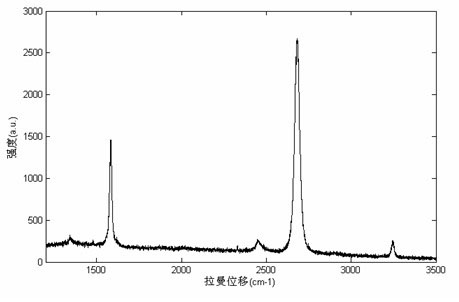

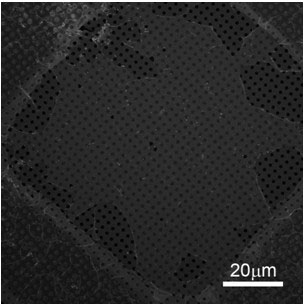

Direct graphene film transfer method

The invention relates to a direct graphene film transfer method. Currently, transferring graphene films from metal surfaces is quite inconvenient. The method includes: using the chemical vapor deposition method to grow a graphene film on a copper foil; using oxygen plasma cleaner to clear graphene on one side of the copper foil to obtain a combination of the single-layer graphene film with the copper foil; flatly attaching a transfer carrier onto the surface of the graphene film and drip adding an organic solvent of a proper quality to increase the interaction between the transfer carrier andthe graphene film; using etchant solution to clear the copper foil to obtain a combination of the single-layer graphene film with the transfer carrier; using deionized water to clean the graphene film for multiple times; and using a filter paper to clear the deionized water on the surface of the graphene film. Using the direct graphene film transfer method avoids the graphene films from being damaged by transfer media such as organic colloid and the like, single-layer graphene films of 100 micrometers or more can be obtained, simple equipment is required, product dimension is controllable, production safety is high, and industrial application is easy to implement.

Owner:ZHEJIANG UNIV

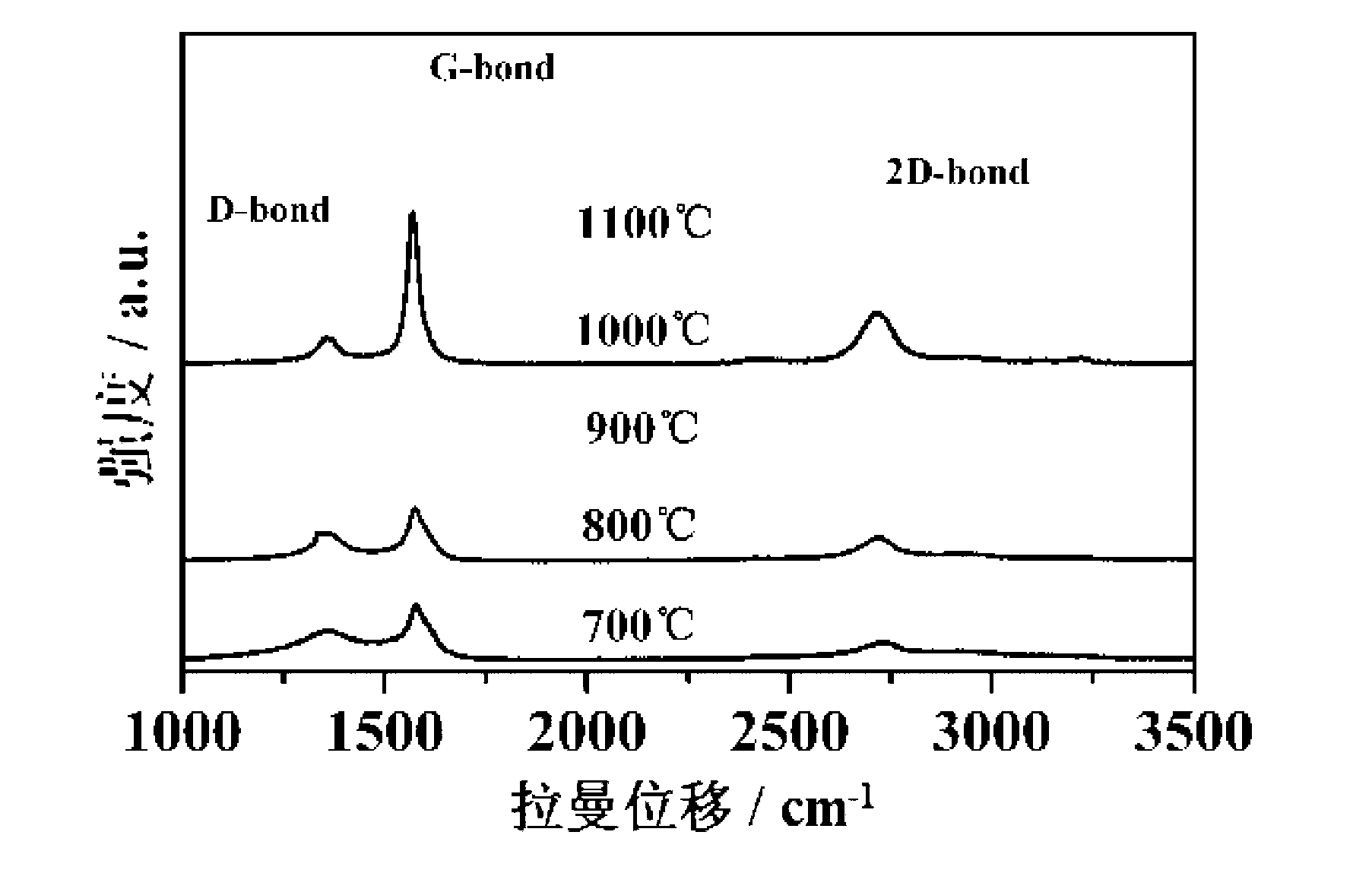

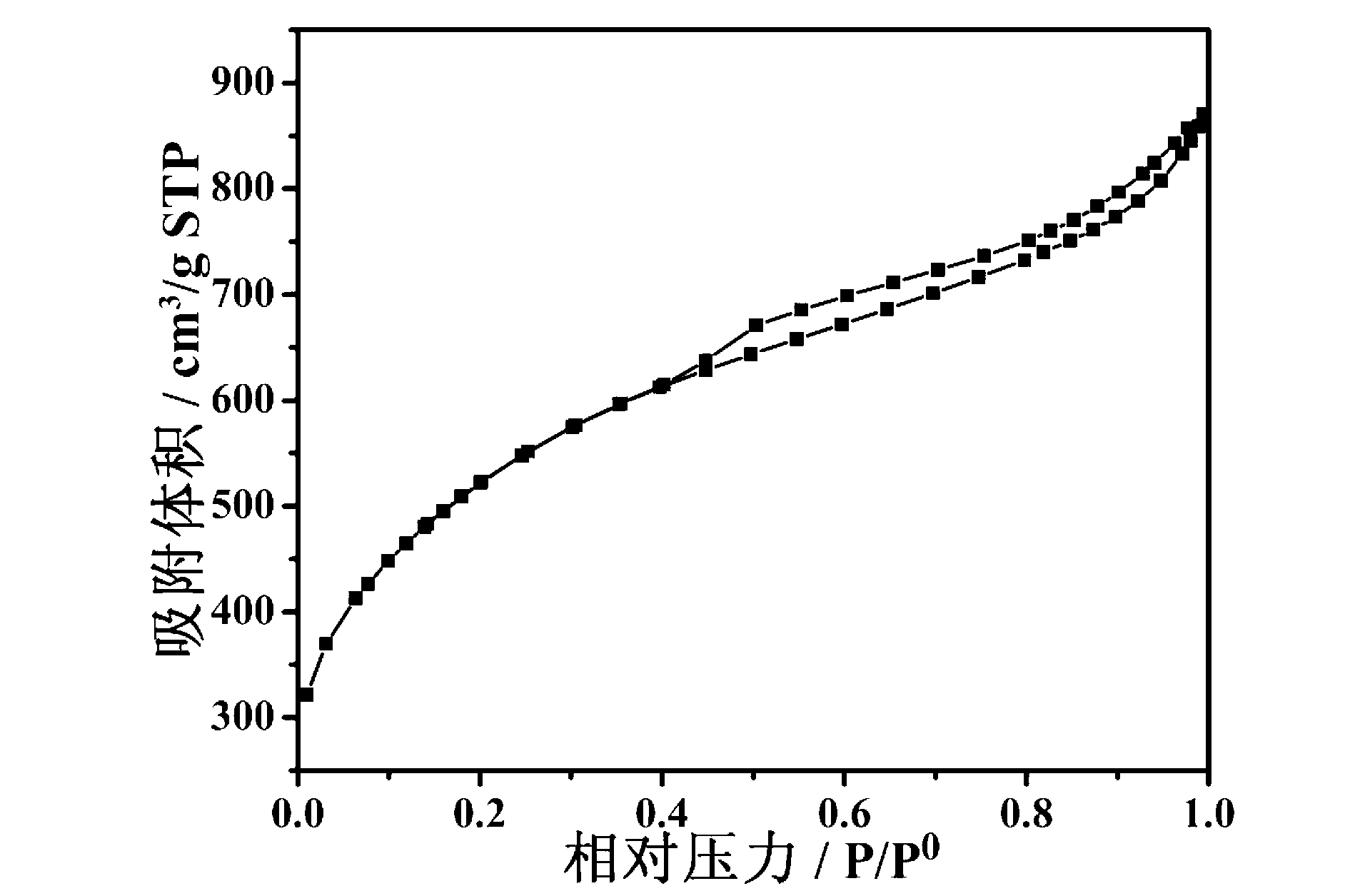

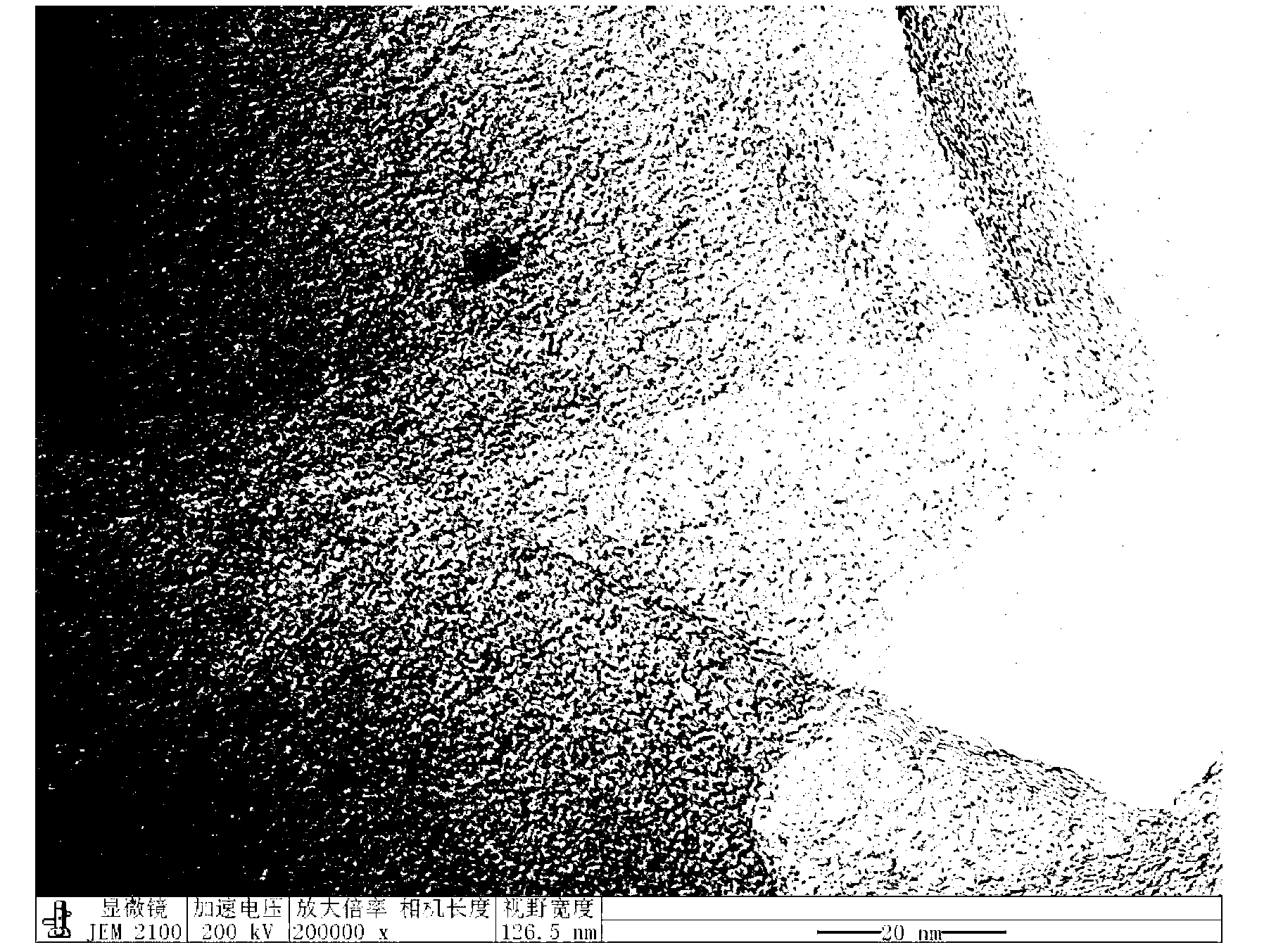

Method for preparing high-specific-surface-area porous graphitic nanocarbon plate with coconut shells serving as raw materials

InactiveCN103011129ASolve pollutionSimple equipmentMaterial nanotechnologyNano-carbonResource utilizationDistilled water

The invention provides a method for preparing a high-specific-surface-area porous graphitic nanocarbon plate with coconut shells serving as raw materials, and relates to a preparation method of a graphitic nanocarbon material, and the method is used for solving the problems of conventional preparation method of the graphitic nanocarbon material that the production cost is high, the process is complex, the safety is poor, the output is low, the industrialization is hard to realize, and the prepared graphitic nanocarbon material is low in specific surface area and poor in graphitic degree. The preparation method comprises the following steps: 1, preprocessing the raw materials; 2, coordinating the raw materials with catalysts and activating agents; 3, curing the coordination compound; 4, thermally treating under an inert gas condition; and 5, carrying out acid leaching, washing by distilled water, and drying, so as to obtain the high-specific-surface-area porous graphitic nanocarbon plate. The porous graphitic nanocarbon plate prepared by the method provided by the invention is high in specific surface area, high in graphitic degree and excellent in electrochemical performance; the method is simple, low in energy consumption, high in safety, and suitable for industrial production; and a scientific way is provided for realizing the resource utilization of biological wastes like the coconut shells.

Owner:HEILONGJIANG UNIV

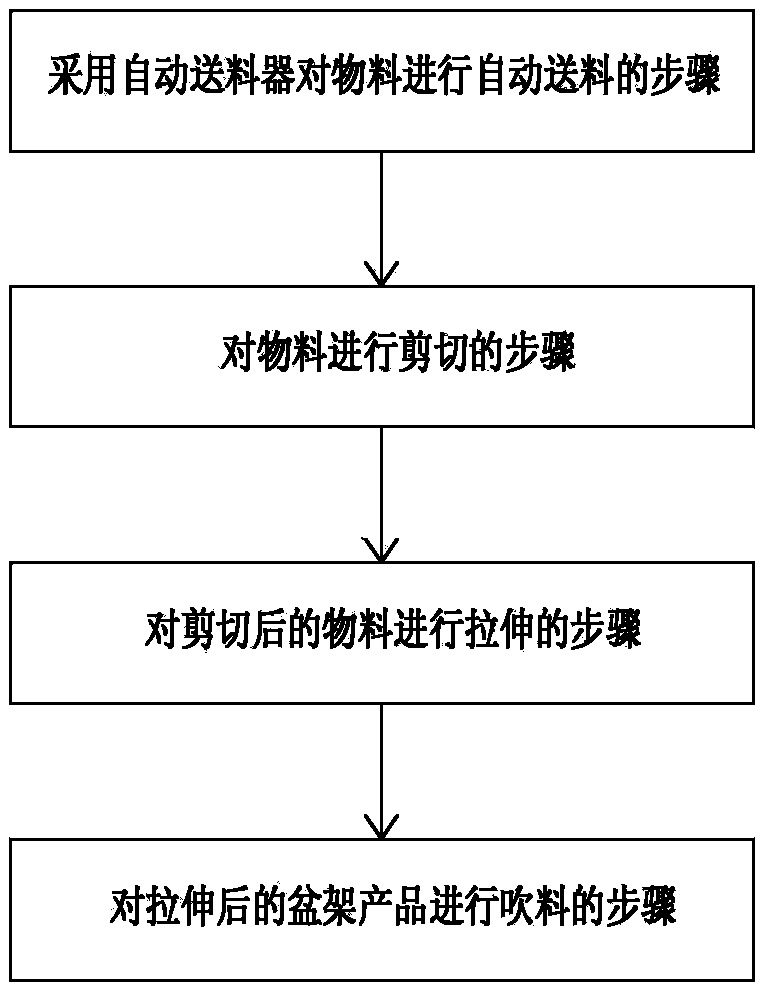

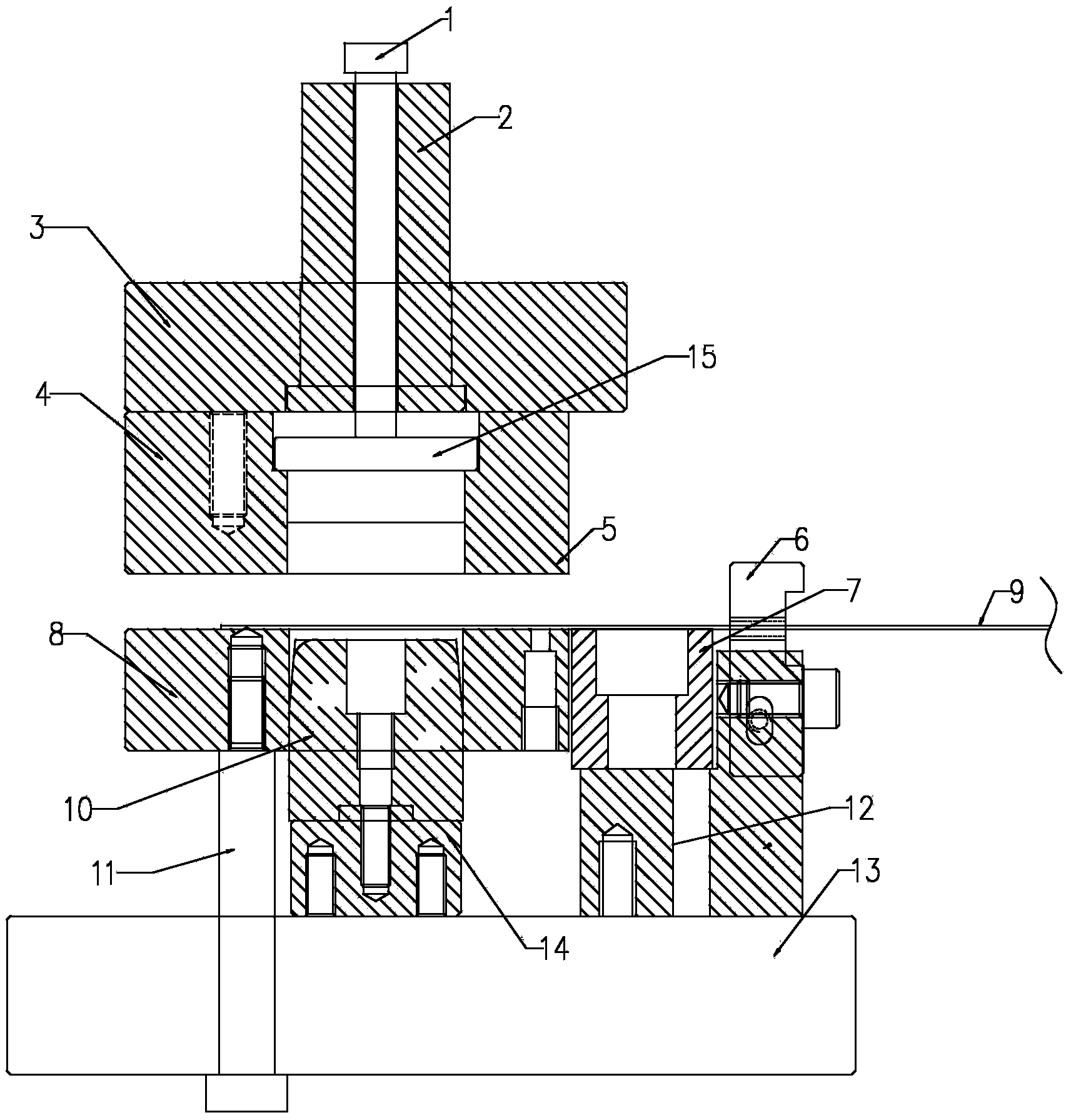

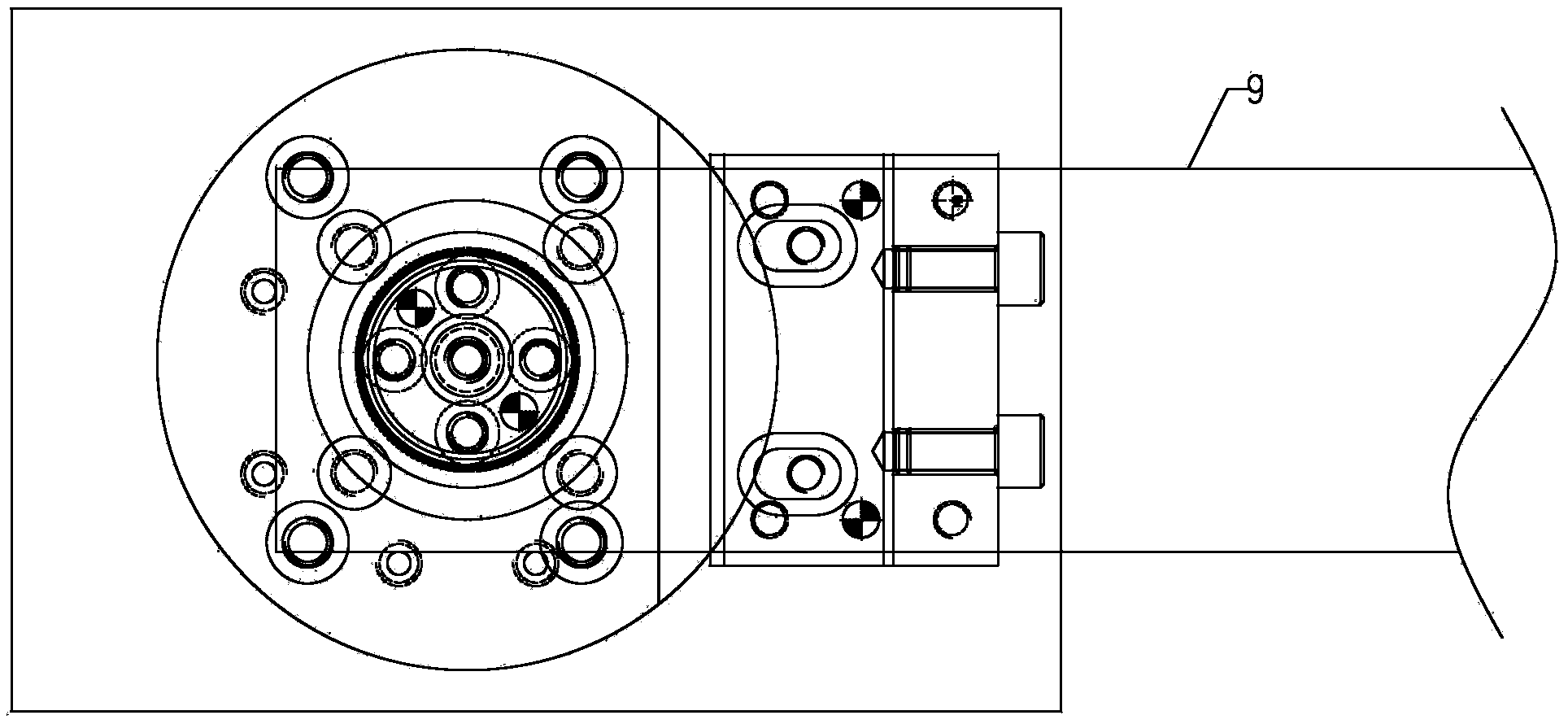

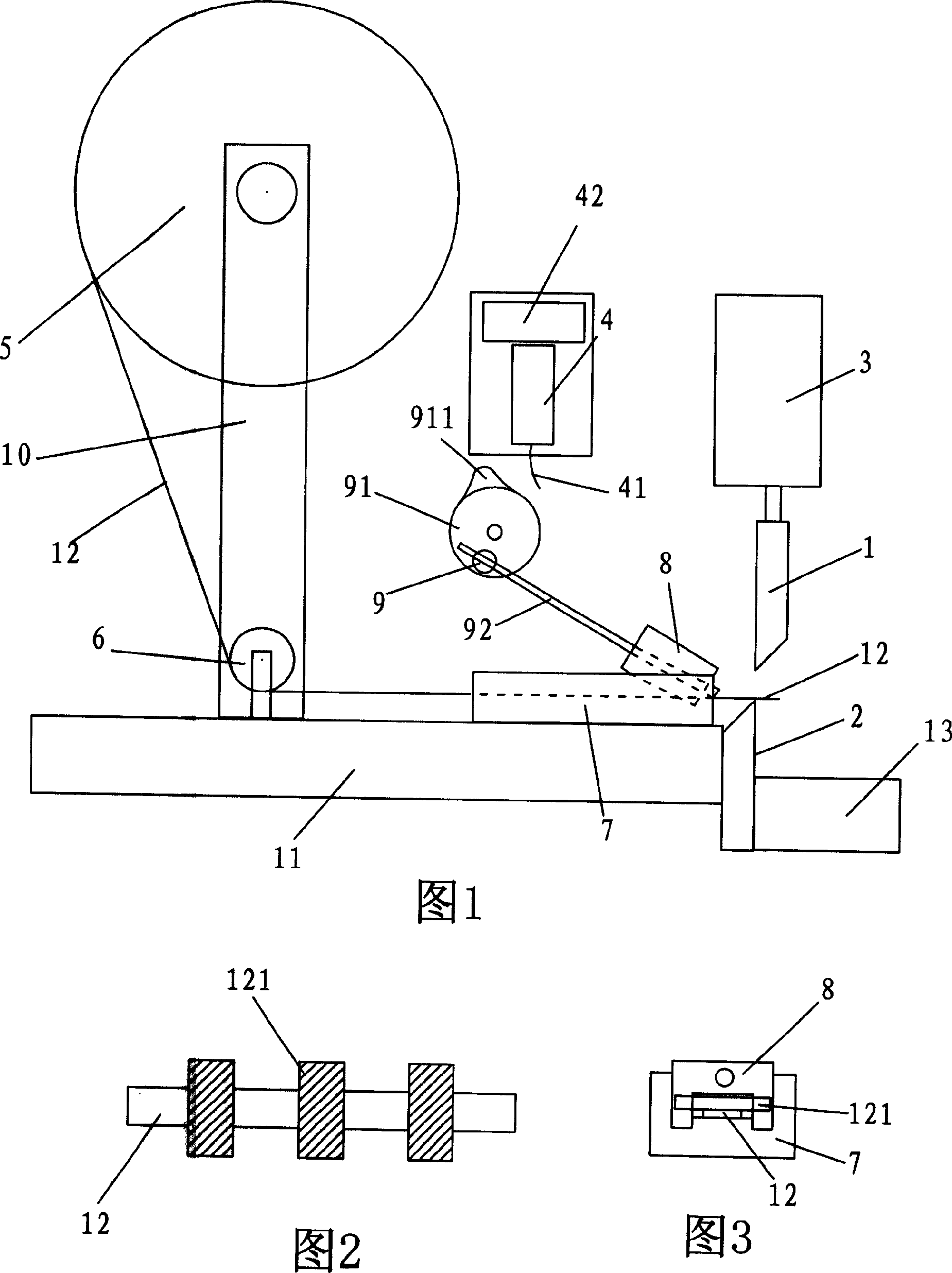

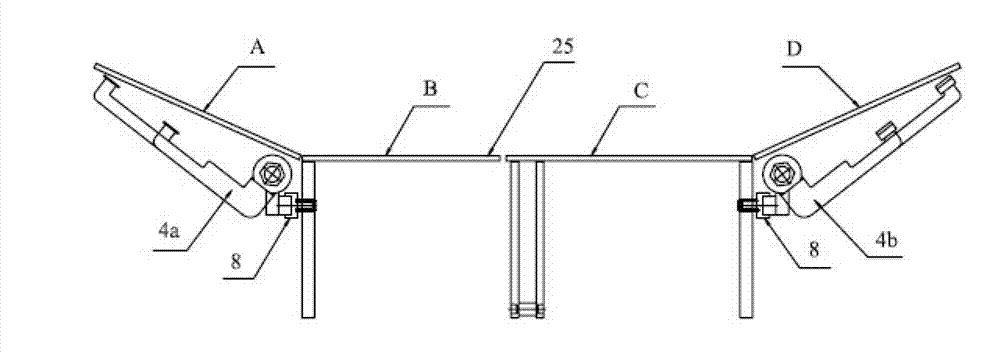

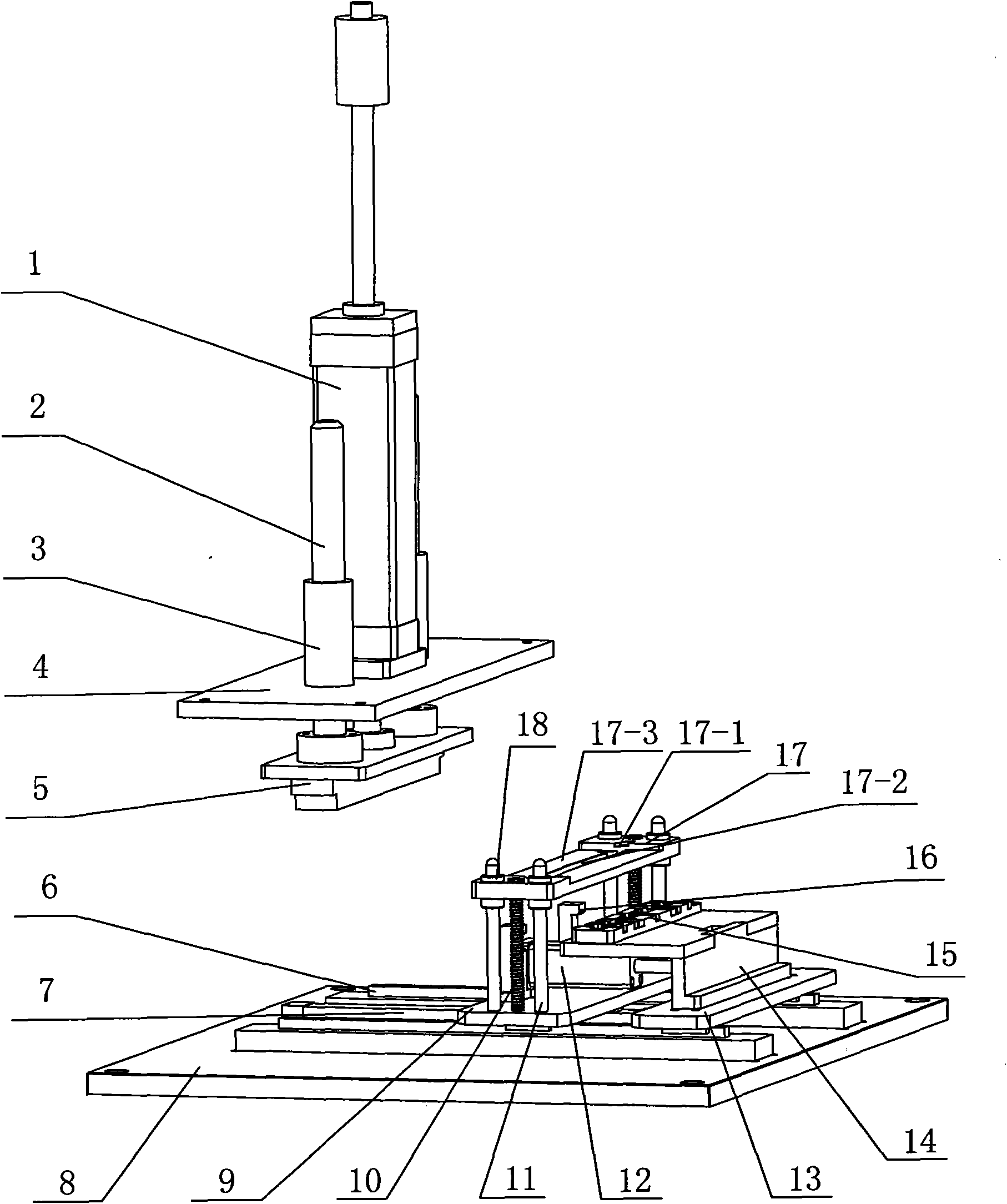

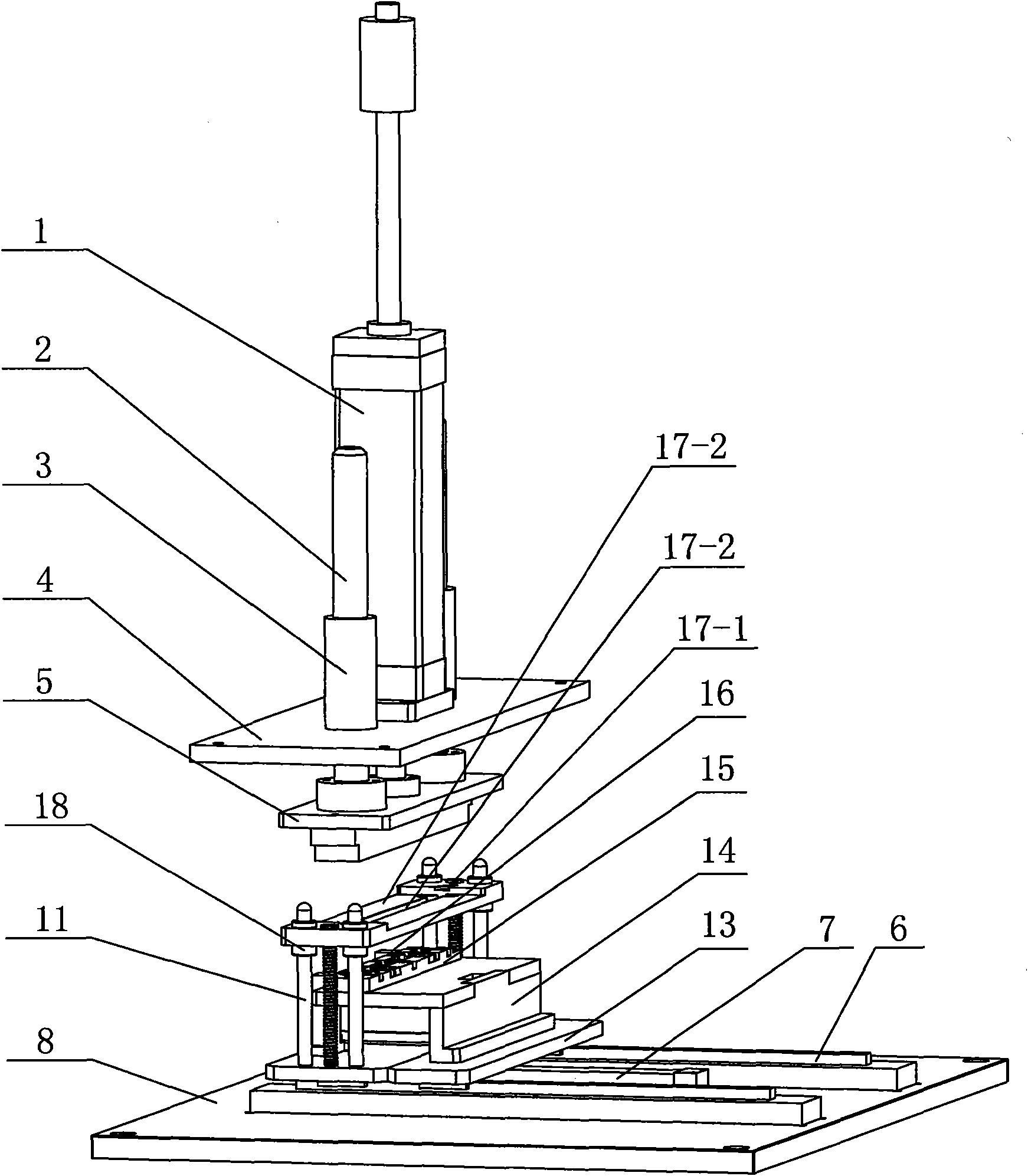

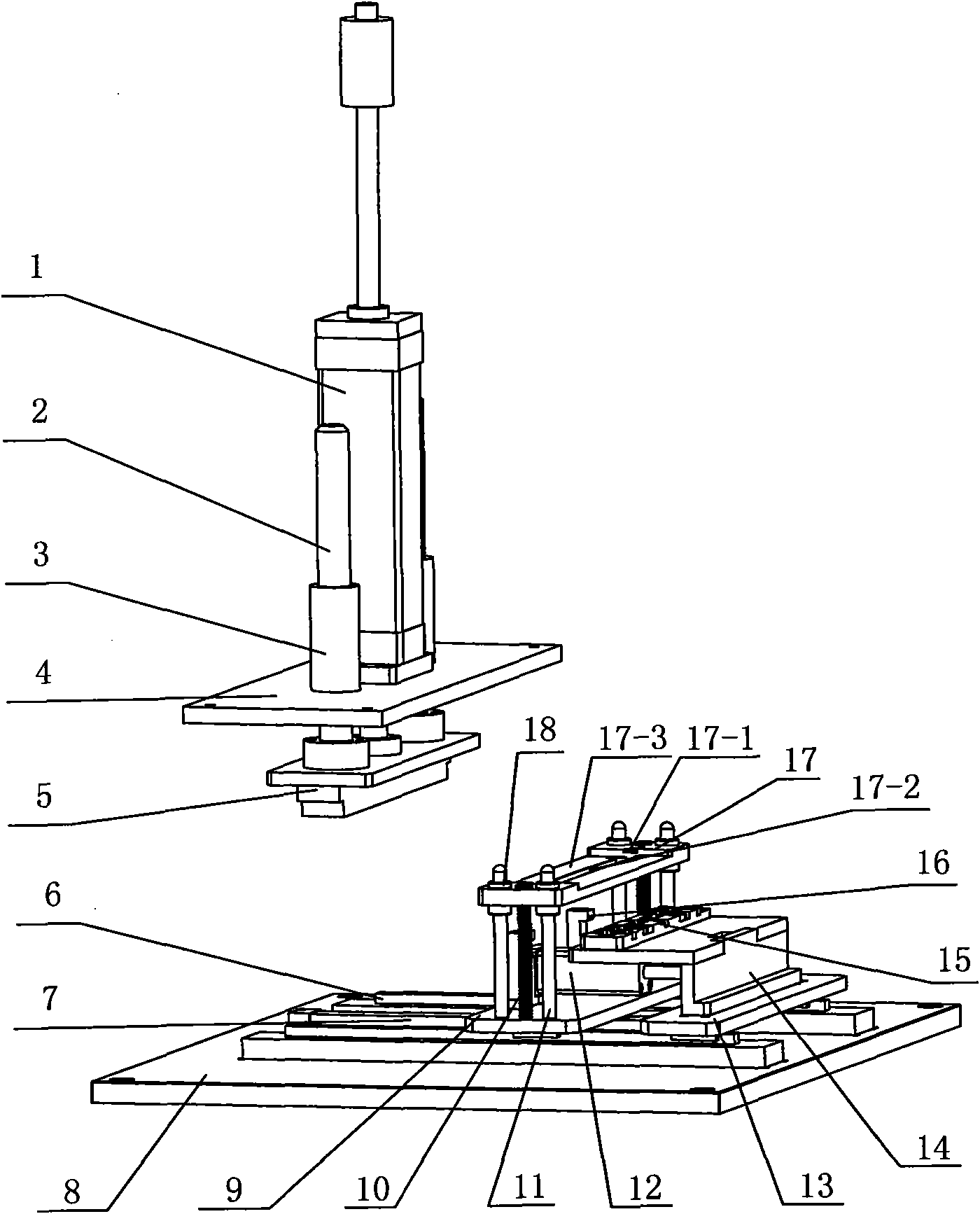

Cutting and drawing process of basin frame

InactiveCN103639282AImprove productivity and safetyReduce labor intensityShaping toolsEjection devicesEngineeringMachining

The invention relates to the technical field of dies and discloses the cutting and drawing process of a basin frame. The cutting and drawing process comprises the material cutting step and the material drawing step. The material drawing step is performed after the material cutting step. Automatic feeding is performed on materials through an automatic feeder before the material cutting step. The blowing step which comprises performing material blowing on the basin frame product after drawing forming is performed after the material drawing step. The machining of the cutting step, the drawing step and the blowing step is performed through the same die. A cutting mechanism, a drawing mechanism and a blowing mechanism are arranged in the die in turn. The cutting mechanism is used for cutting the materials, the drawing mechanism is used for performing the drawing forming on the cut materials, and the blowing mechanism is used for performing the material blowing on the basin frame product after the drawing forming. According to the cutting and drawing process of the basin frame, the cutting mechanism, the drawing mechanism and the blowing mechanism are arranged in the same die in turn for the cutting, drawing and blowing machining and accordingly the automatic process of the cutting, drawing and discharging is achieved, the production efficiency and the safety are improved, and the labor intensity of workers is reduced.

Owner:WUZHOU HENGSHENG ELECTRONICS

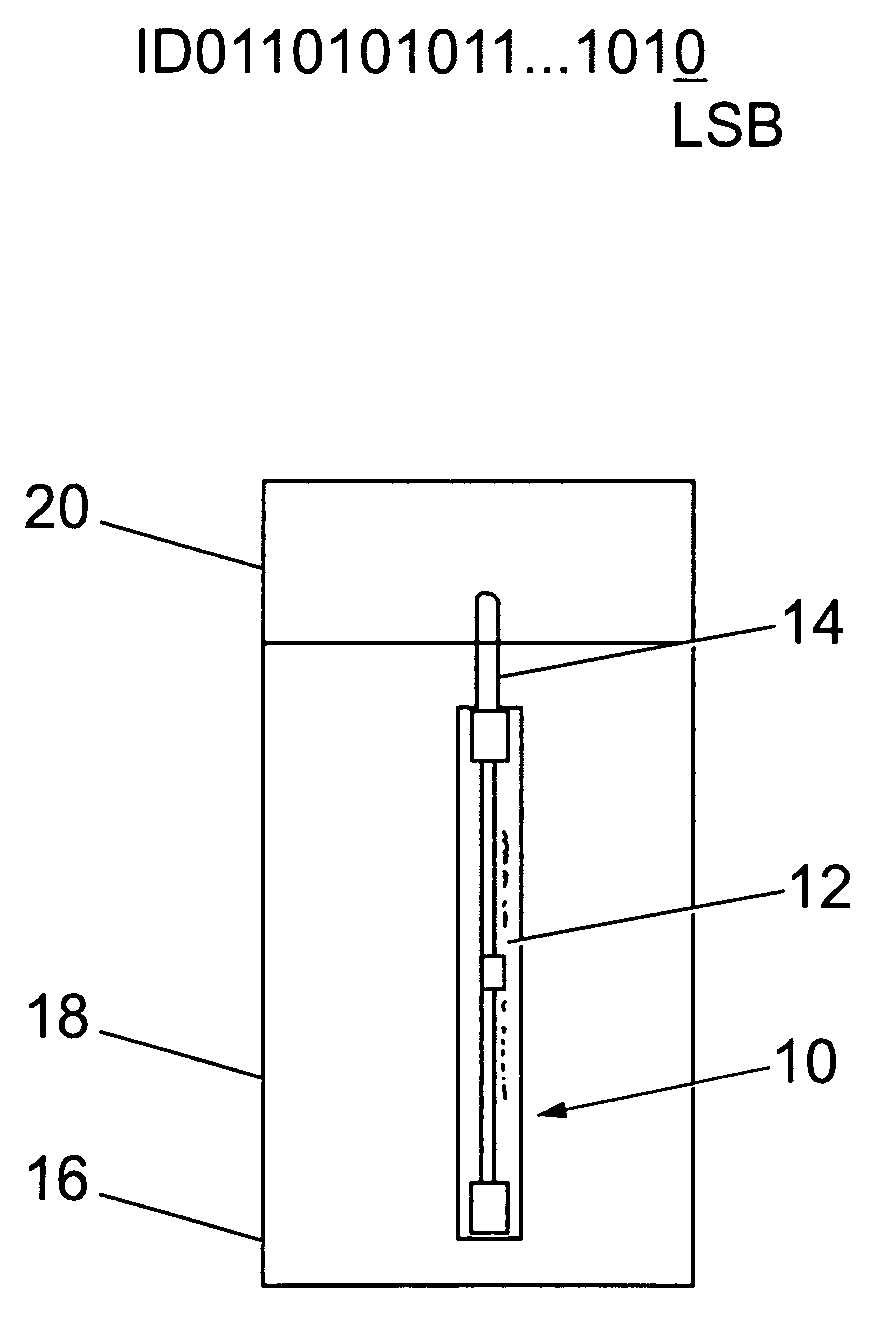

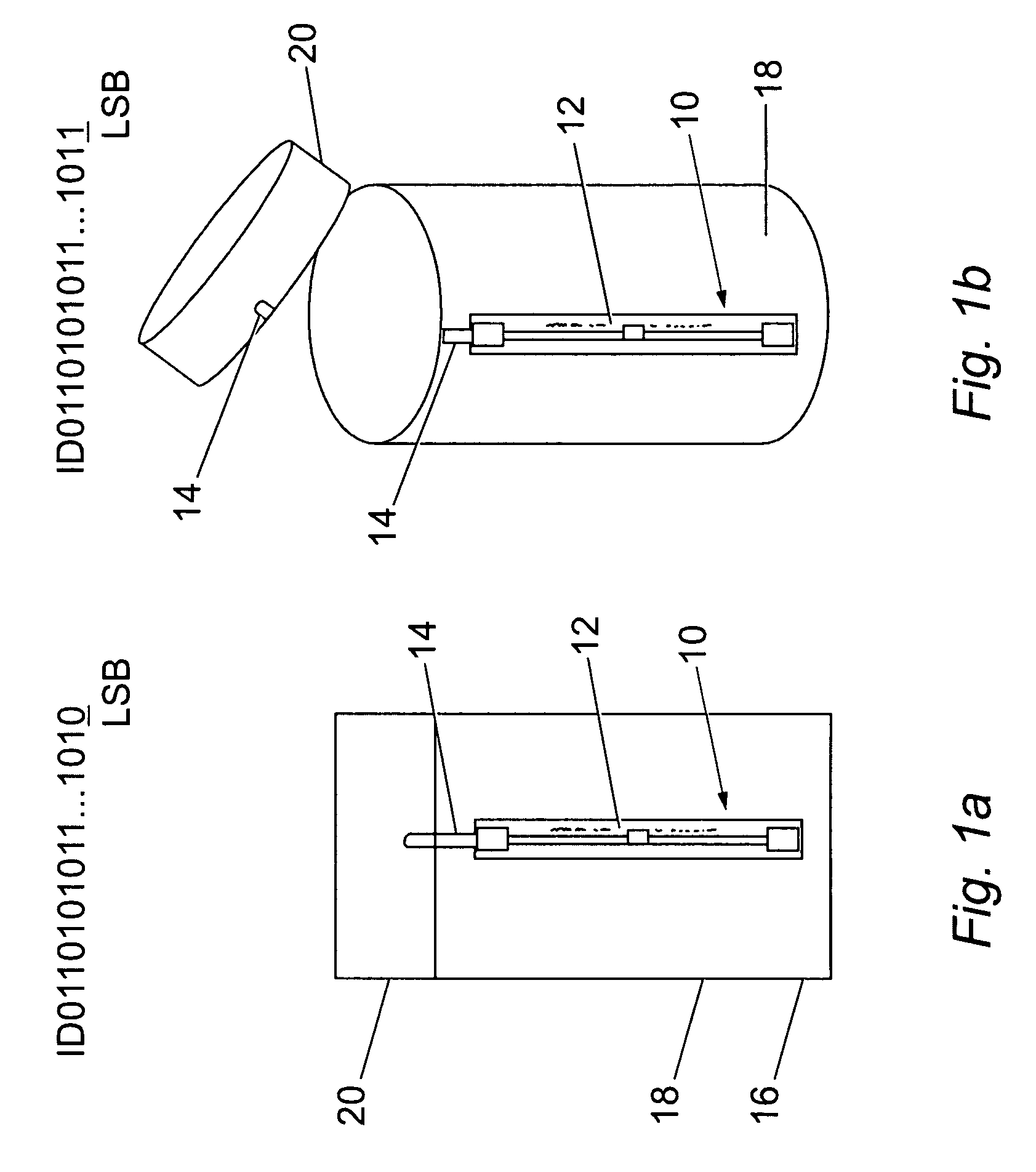

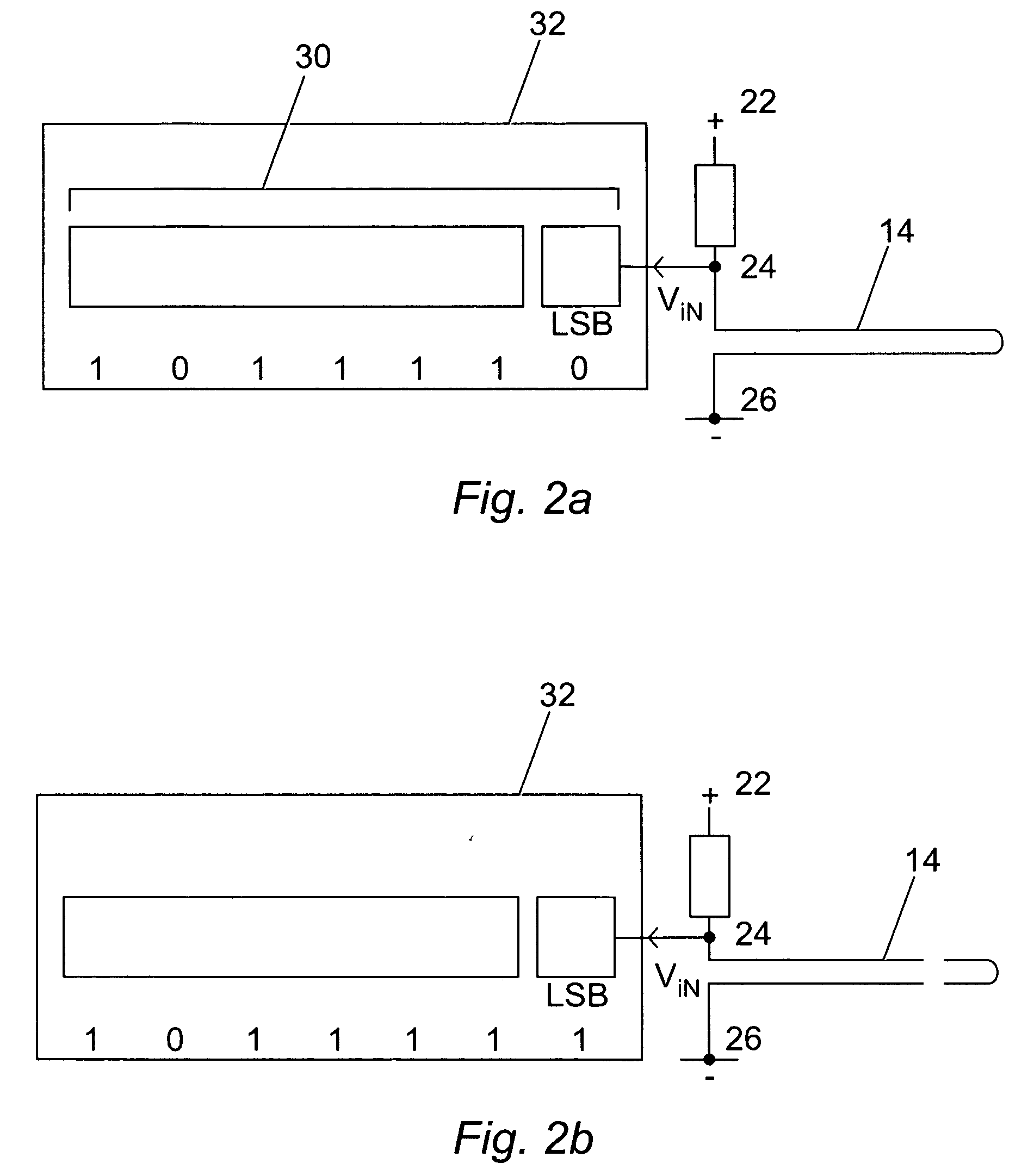

System and method of tamper detection

ActiveUS20060238341A1Easy to controlFacilitates rapid container integrity checkingBurglar alarm by hand-portable articles removalLocking devicesElectrical connectionHemt circuits

The present invention relates to a system and method of tamper detection. A tamper detection system in accordance with an embodiment of the present invention includes: a passive electronic sensor including a circuit having first, second, and third nodes; a load connected between the first and second nodes of the circuit; a friable electrical connection element connected between the second and third nodes of the circuit; and a storage unit, connected to the second node of the circuit, for storing an identification code of the sensor; wherein in use a voltage is applied across the first and third nodes of the circuit, and when the friable electrical connection element is intact, the second node of the circuit is at a first voltage, and when the friable electrical connection element is broken, the second node of the circuit is at a second voltage.

Owner:IBM CORP

Beta-carotene microcapsule production method

ActiveCN103976353AIncrease productivityFacilitate large-scale industrial productionFood shapingFood ingredient functionsBeta-CaroteneOil phase

Owner:武汉星辰现代生物工程有限公司

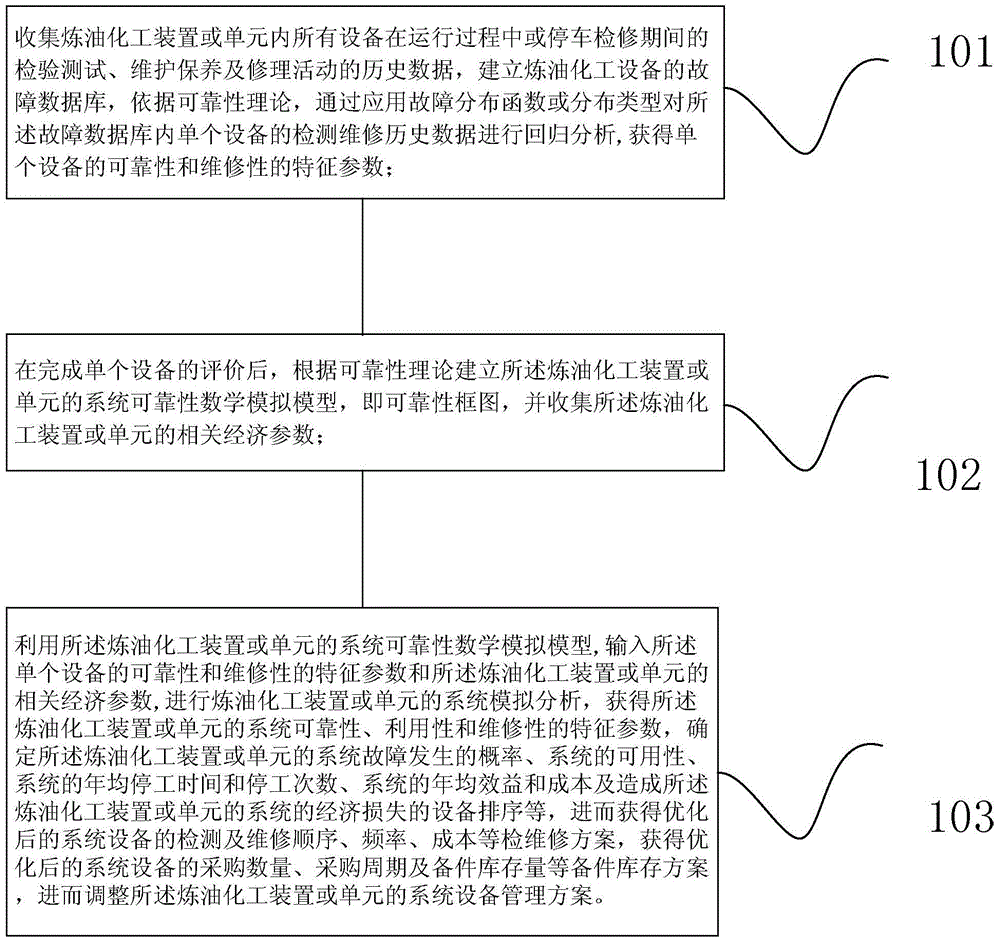

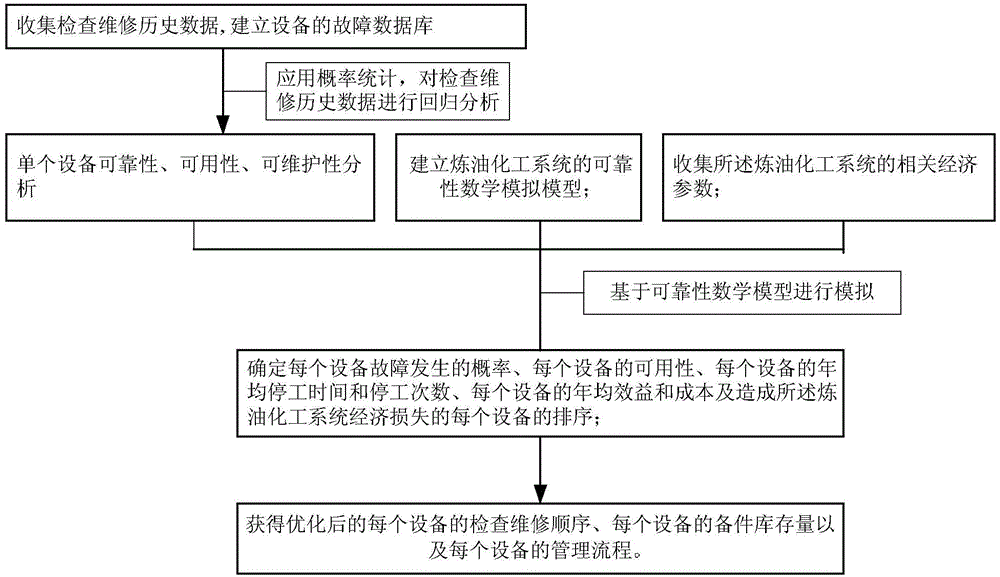

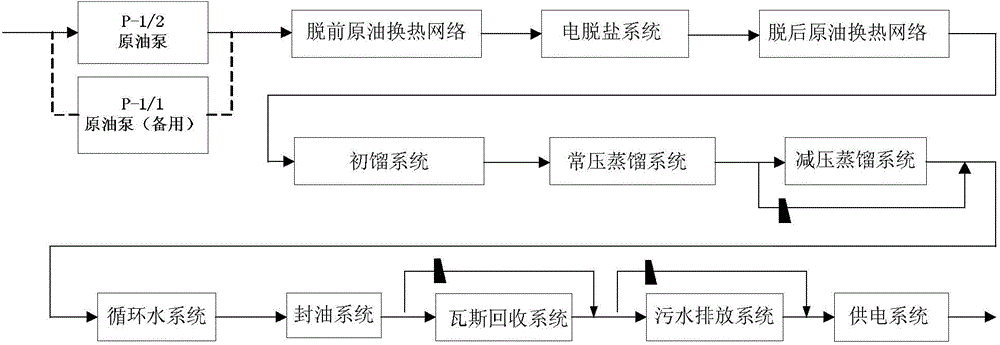

Method for optimizing reliability and maintenance strategy of chemical refining equipment

InactiveCN104636826AImprove reliabilityReduce lossesForecastingRegression analysisMathematical simulation

The invention discloses a method for optimizing reliability and maintenance strategy of a piece of chemical refining equipment. The method comprises the following steps of collecting the historical testing and maintaining data of equipment inside a chemical refining device; carrying out the regression analysis by a failure distribution function for the historical data to obtain the characteristic parameters of the reliability and maintenance of single equipment; establishing a mathematical simulation model of system reliability of the chemical refining device, and collecting the relevant economic parameters of the device; carrying out the system simulation analysis for the chemical refining device by using the mathematical simulation model of system reliability, then obtaining the characteristics parameters of system reliability, usability and maintenance of the device, and then further obtaining the testing and maintaining scheme of the optimized system equipment, such as inspecting and maintaining order, frequency and cost; and obtaining the spare part stock scheme of the optimized system equipment, such as purchasing quantity, purchasing cycle and spare part stock, thus adjusting the equipment managing strategy of the device. The method for optimizing the reliability and maintenance strategy of the chemical refining equipment reduces the unplanned fault rate of the chemical refining equipment, and provides guarantee for long-period safety operation of the chemical refining equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recycling device of organic solvent in high-concentration organic waste gas

InactiveCN104740973ALost in timeLow priceDispersed particle separationHigh concentrationOrganic solvent

The invention provides a recycling device of an organic solvent in a high-concentration organic waste gas. The recycling device comprises a multi-layer fluidized bed adsorption column, an adsorbent conveying system, a desorption column and a condensing column, wherein the middle section in the fluidized bed adsorption column is separated into 3-15 layers via gas distribution plates, and the layer height is 600mm-1200mm; the bottom of the fluidized bed adsorption column is provided with an air stream inlet and is connected with a waste gas fan; the top of the fluidized bed adsorption column is provided with a cyclone separator with a purified gas outlet and a spiral feeding device; irregular hard nut shell active carbon with the particle size of 40 meshes-70 meshes acts as an adsorbent and flows inside to adsorb waste gas, and the adsorbent flows from the upper layer to the lower layer via an external overflow pipe; nitrogen at 165 DEG C-190 DEG C in the desorption column acts as a desorption gas, and can be recycled. The device not only can solve the difficulty that a bed layer is fired and exploded since reaction heat cannot dissipate due to ultrahigh concentration of a high-concentration organic waste gas at present, and also can reduce the solvent recycling cost.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

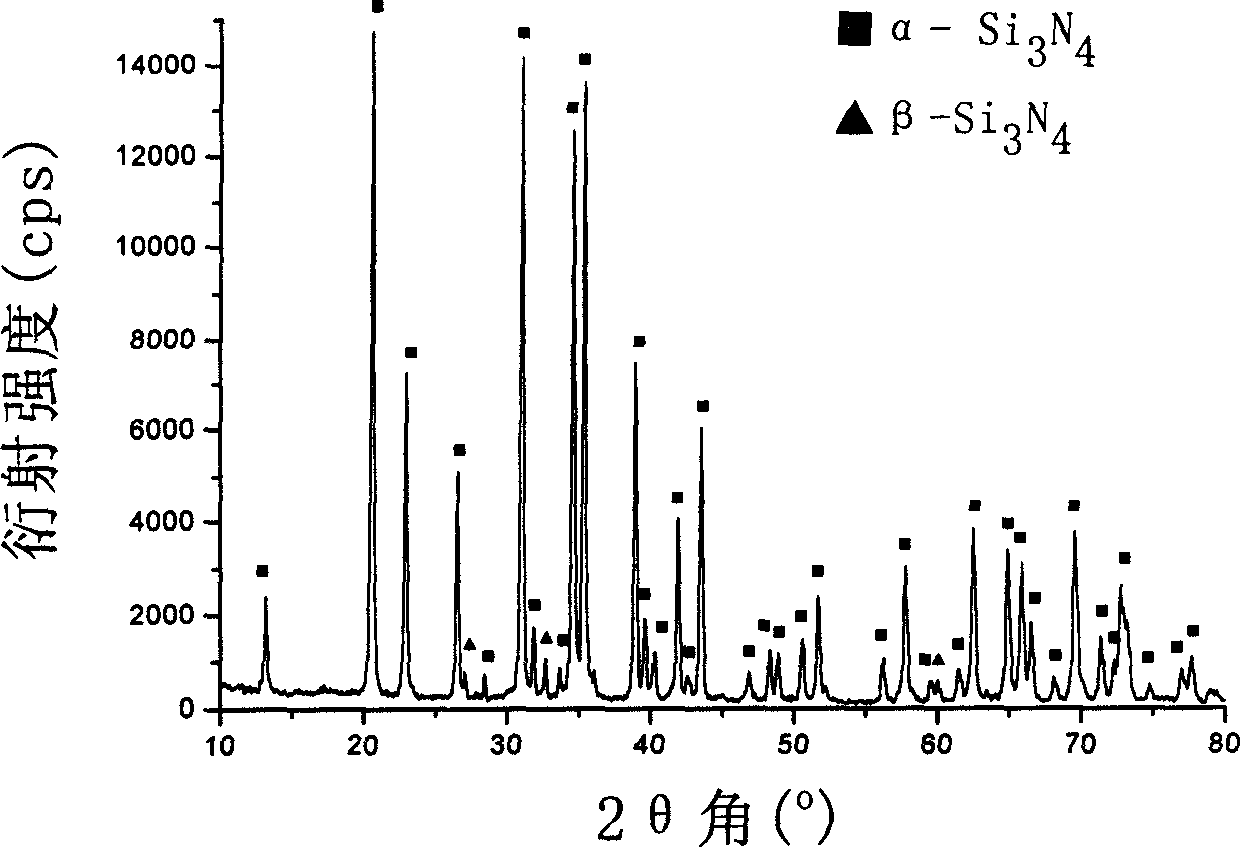

Method for synthesizing silicon nitride powder by atmospheric pressure combustion

A process for synthesizing silicon nitride powder by atmospheric pressure combustion includes such steps as proportionally mixing Si powder with catalyst, adding silicon nitride for activating and combustion reaction. Its main product is Si3N4.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

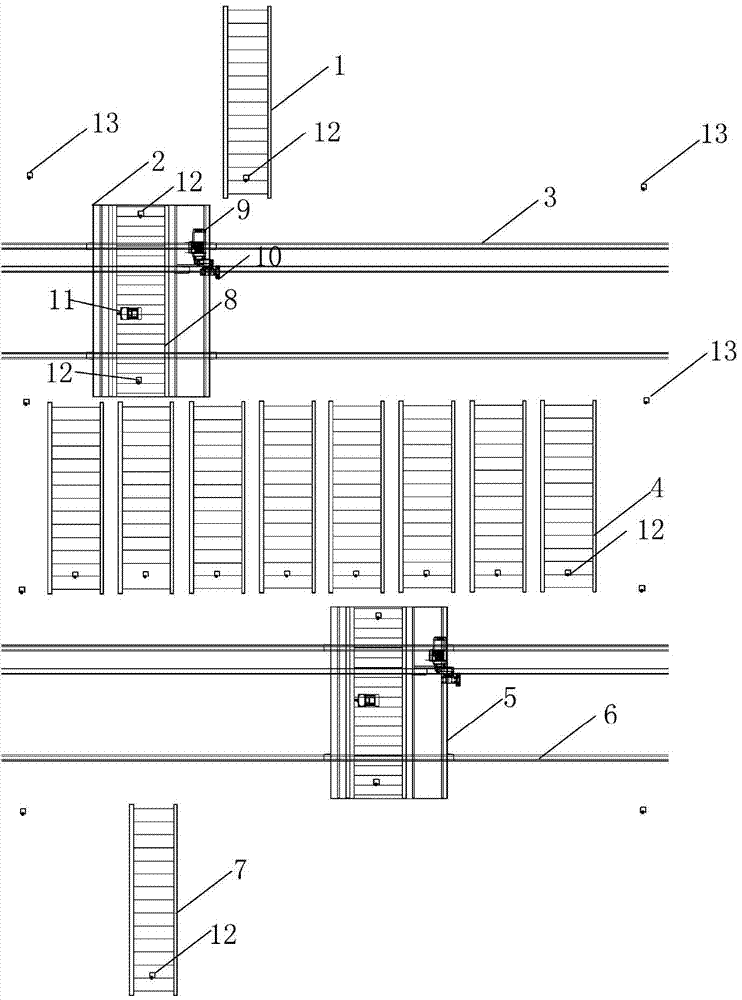

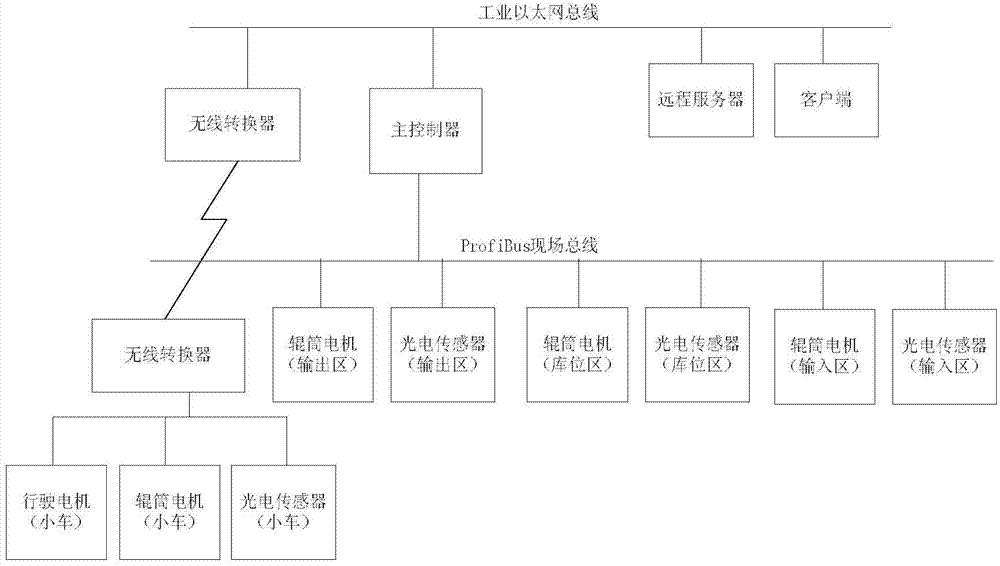

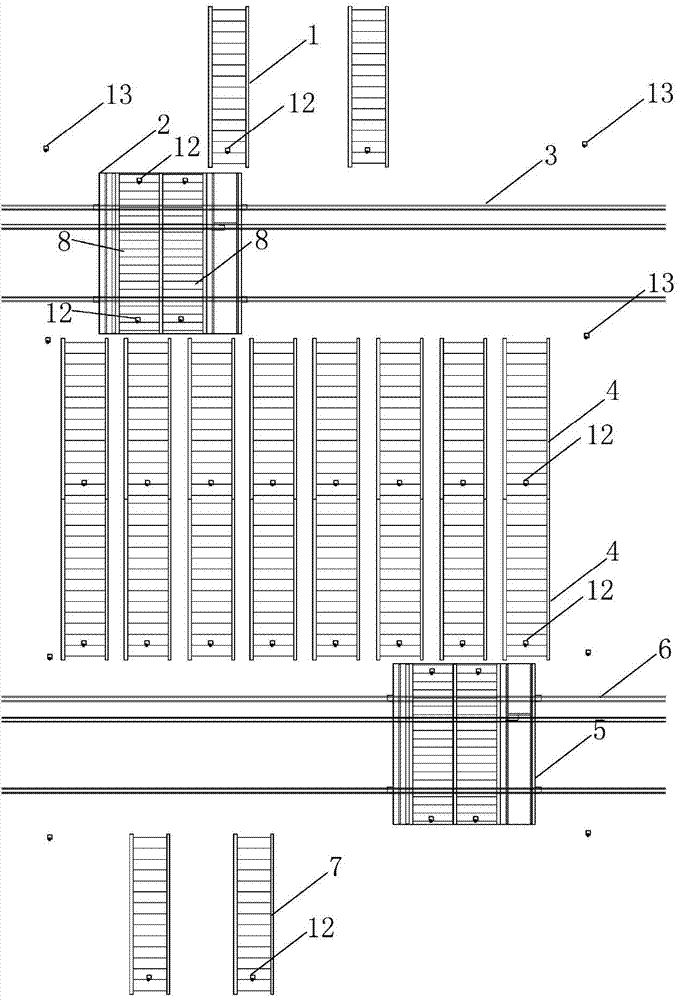

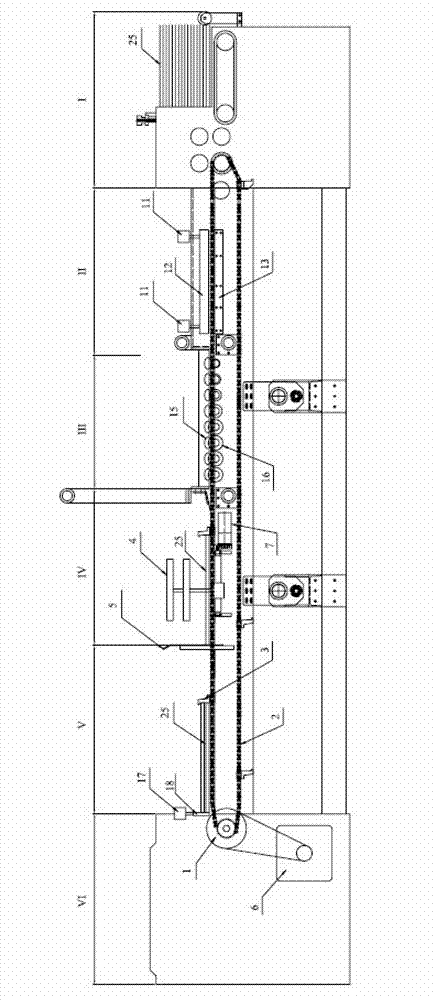

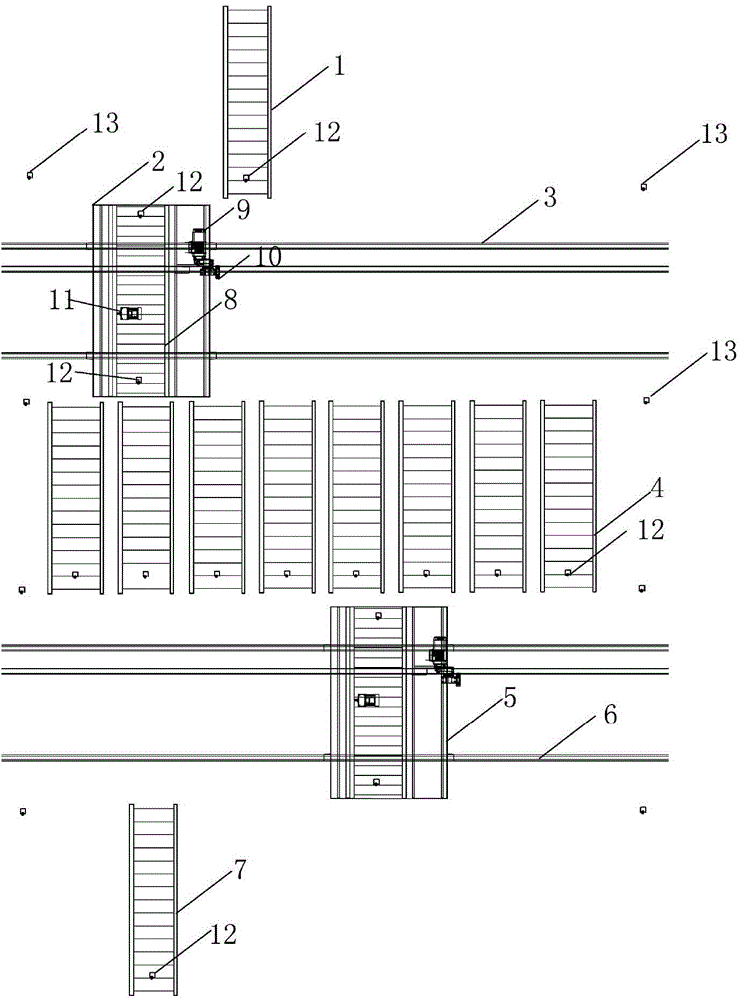

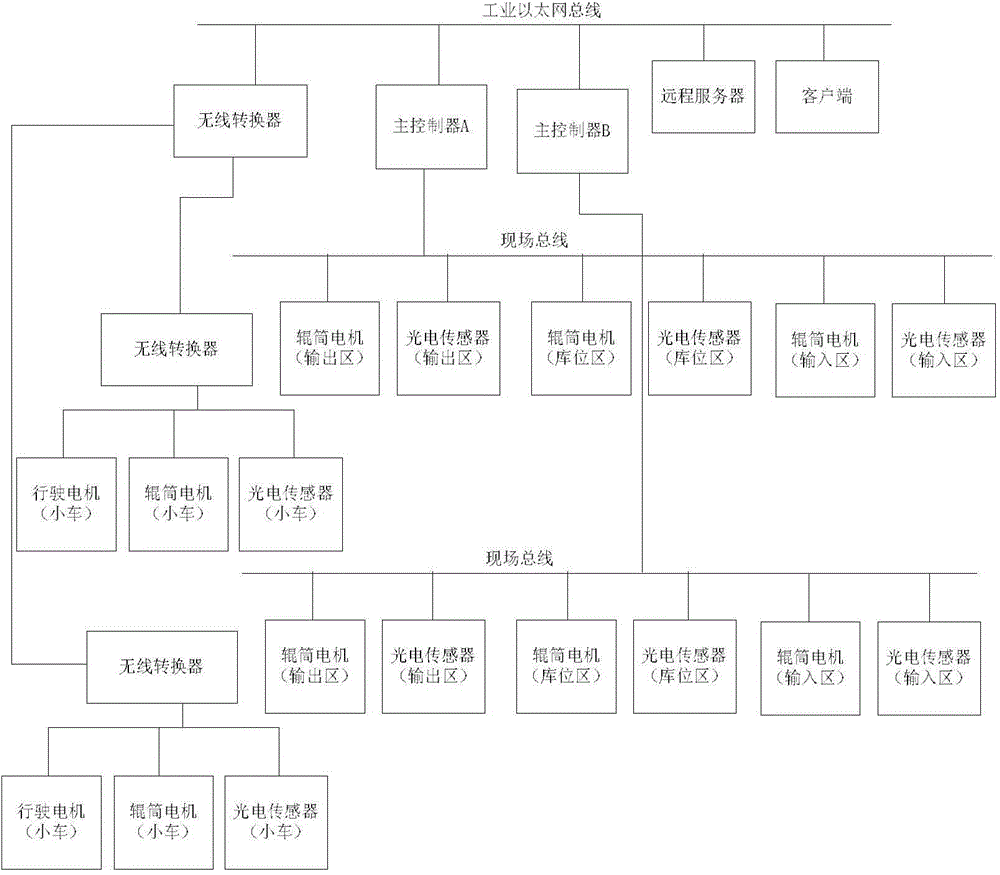

Automatic warehouse output and input device and method of plate production line

The invention discloses an automatic warehouse output and input device and an automatic warehouse output and input method of a plate production line. The device comprises a plate output area, a warehouse input guide rail, a warehouse position area, a warehouse output guide rail, a plate input area and a main controller, wherein the plate output area, the warehouse input guide rail, the warehouse position area, the warehouse output guide rail and the plate input area are arranged along a plate conveying direction; roller conveyors are arranged in the plate output area and the plate input area; a plurality of roller conveyors are arranged in the warehouse position area and are arranged in at least one row; two conveying trolleys are respectively arranged on the warehouse input guide rail and the warehouse output guide rail, and each conveying trolley is provided with a driving motor, a rotary encoder and one or two roller conveyors; each roller conveyor is provided with a roller motor, and a photoelectric sensor which is used for in-place detection of plates is arranged on the output end of each roller conveyor; the main controller is electrically connected with the roller motors, the photoelectric sensors, the driving motors and the rotary encoders. The automatic warehouse output and input device has the advantage of reasonable design, automatic handling of the plates among different equipment on the production line can be realized, the manpower is released, and the working efficiency, the accuracy and the production safety are increased.

Owner:NANJING OLO HOUSEHOLD CO LTD

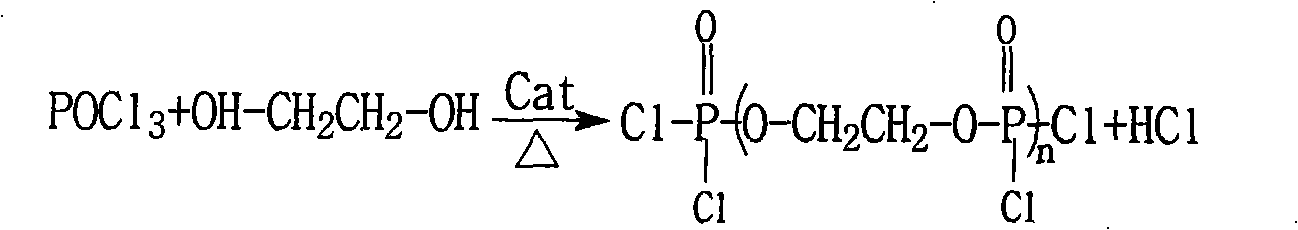

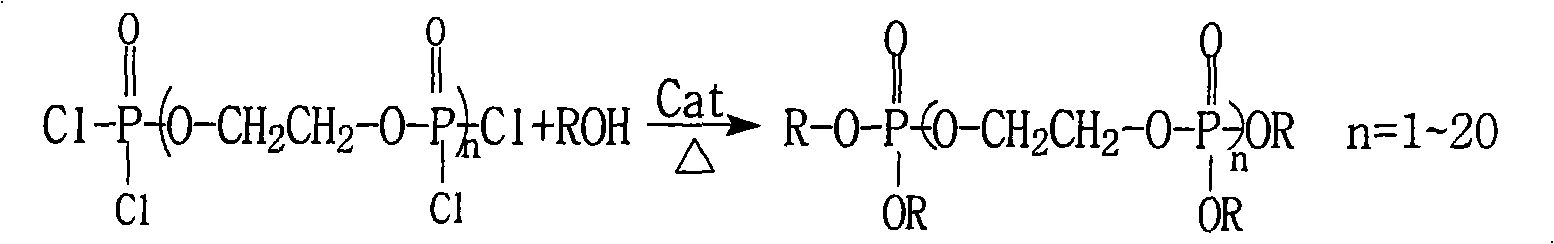

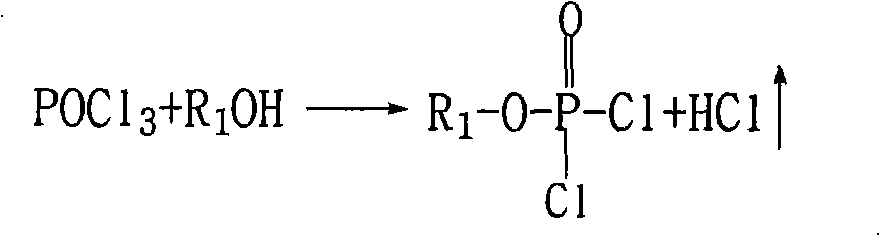

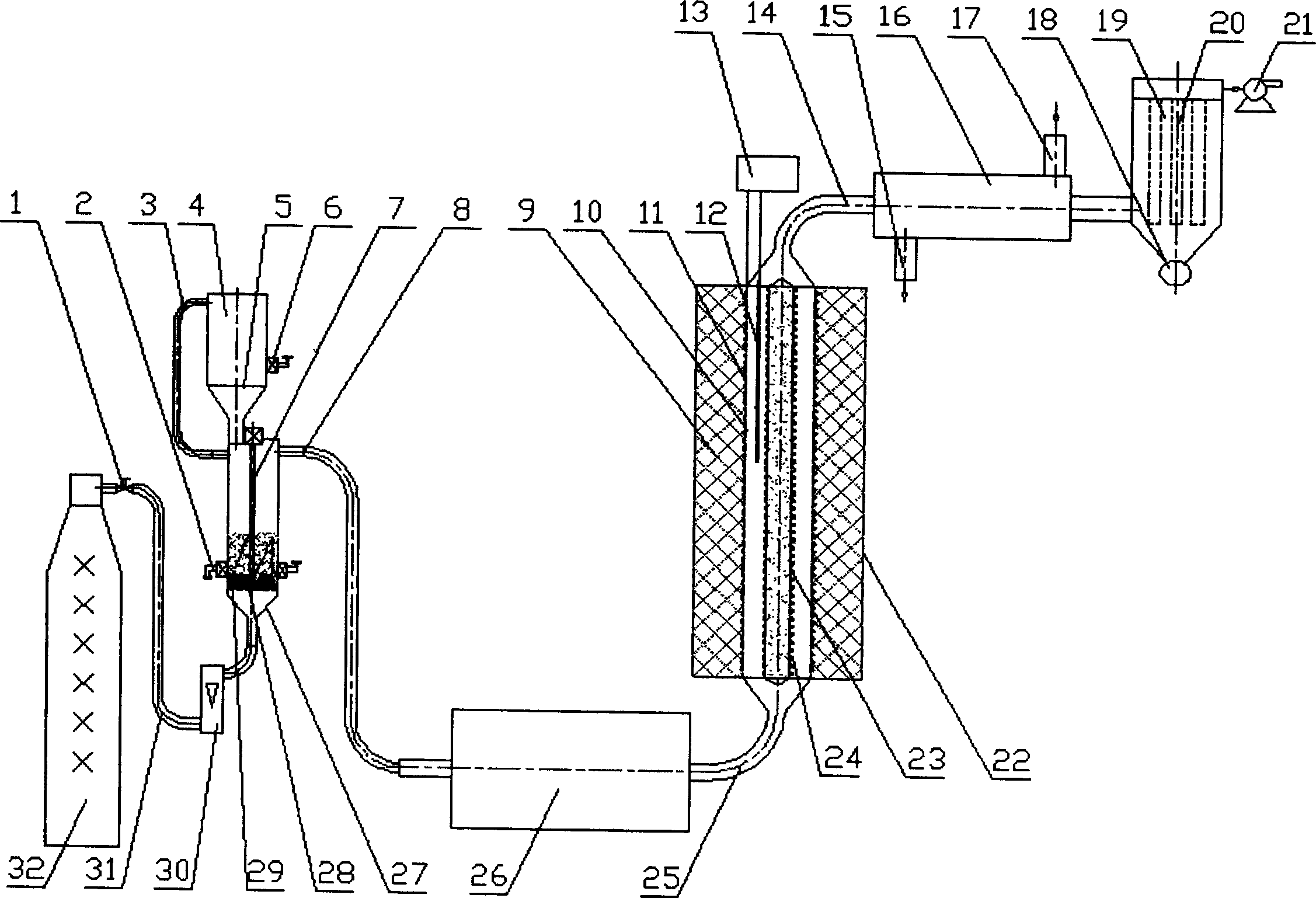

Preparation of low polyphosphate

InactiveCN101293896ALow priceRaw materials are easy to getGroup 5/15 element organic compoundsAlcoholAluminium chlorohydrate

The invention relates to an improved preparation method of an oligomeric phosphate ester, and is characterized in that the method comprises the steps of: obtaining dichloro-monoalkyl phosphate ester monomer through the reaction of phosphorus oxychloride and a monohydric alcohol performing the polymerization of the dichloro-monoalkyl phosphate ester monomer with a dihydric alcohol, and blocking end with a monohydric alcohol. Compared with the prior art, the inventive preparation method has the advantages of easily accessible raw materials, low corrosiveness, low cost (reducing cost by about 50%), no dangerous chemicals as raw materials, good safety, synthesis under relatively low temperature and low pressure, simple process, high production safety factor, simple equipment and operation, and no pollution in production process. The produced hydrogen chloride during reaction can be directly used in production of polyaluminum chloride.

Owner:JIANGSU YOKE TECH

Preparation method of superfine crystal lead-free delay element for detonator

The invention discloses a preparation method of a superfine crystal lead-free delay element for a detonator. The preparation method comprises the following steps: firstly, preparing a superfine crystal Zn-Al alloy blank pipe by adopting casting, extrusion, rolling and machining; then drawing or rolling the superfine crystal Zn-Al alloy blank pipe with delay powder to form a Zn-Al alloy pipe; and finally, cutting and packaging the prepared Zn-Al alloy pipe so as to obtain the Zn-Al alloy delay element. Through using the technical scheme of the invention, lead pollution is avoided, use occasionis not limited, and production process is safer.

Owner:NANJING UNIV OF SCI & TECH

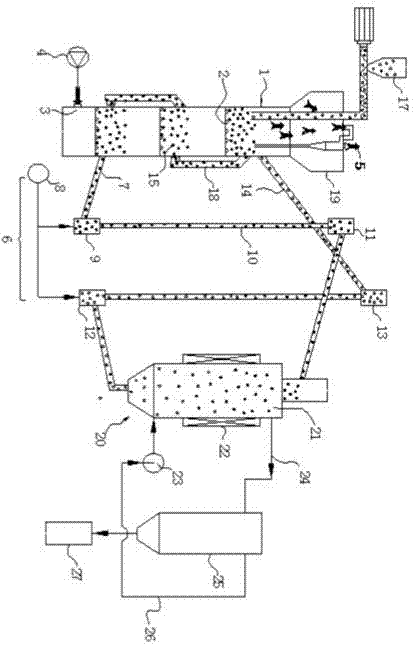

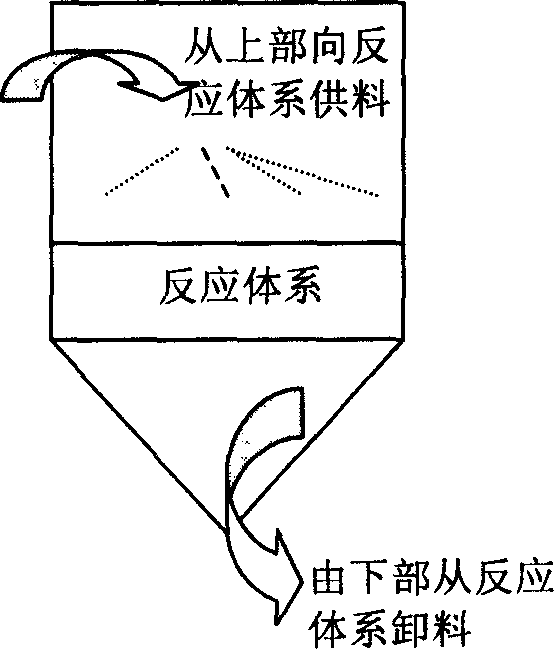

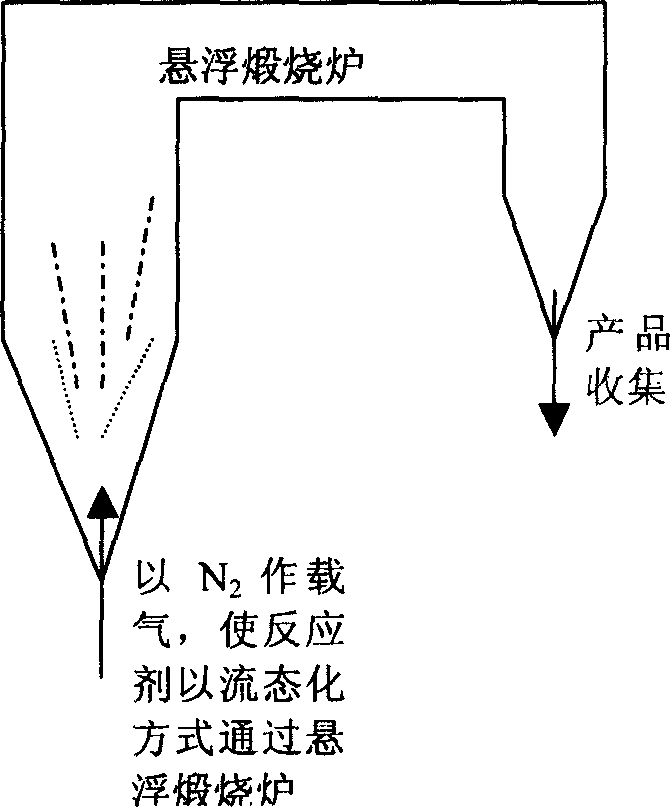

Process for ordinary pressure continuous synthesizing silicon nitride powder by fluidized bed tech.

ActiveCN1792774ALarge specific surface areaAvoid dependencyNitrogen compoundsCombustionFluidized bed

A process for continuously synthesizing silicon nitride powder under ordinary pressure by fluidized bed includes such steps as using N2 to carry the Si powder or the mixture of Si powder and silicon nitride in high-speed fluidized bed, fluidizing, fast leaving from the high-speed fluidized bed, coming in high-temp nitrifying furnace, combustion for synthetic reaction, cooling by heat exchanger, and collecting the product by bag capture.

Owner:UNIV OF SCI & TECH BEIJING

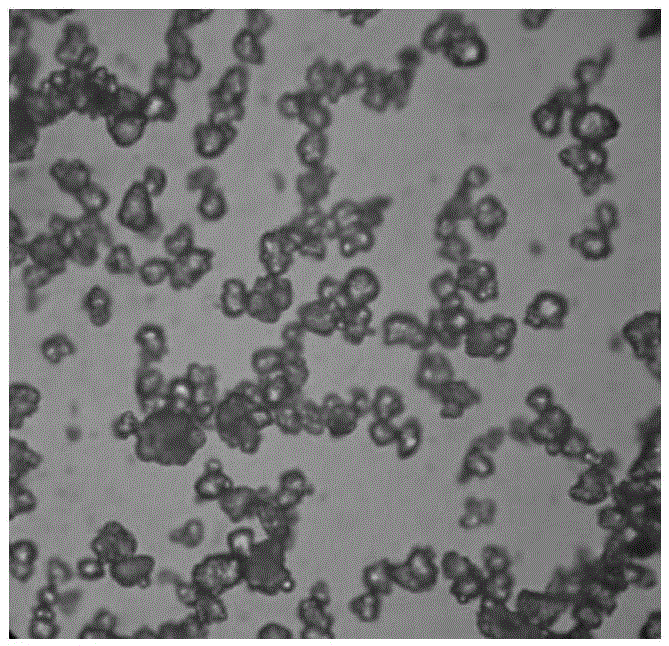

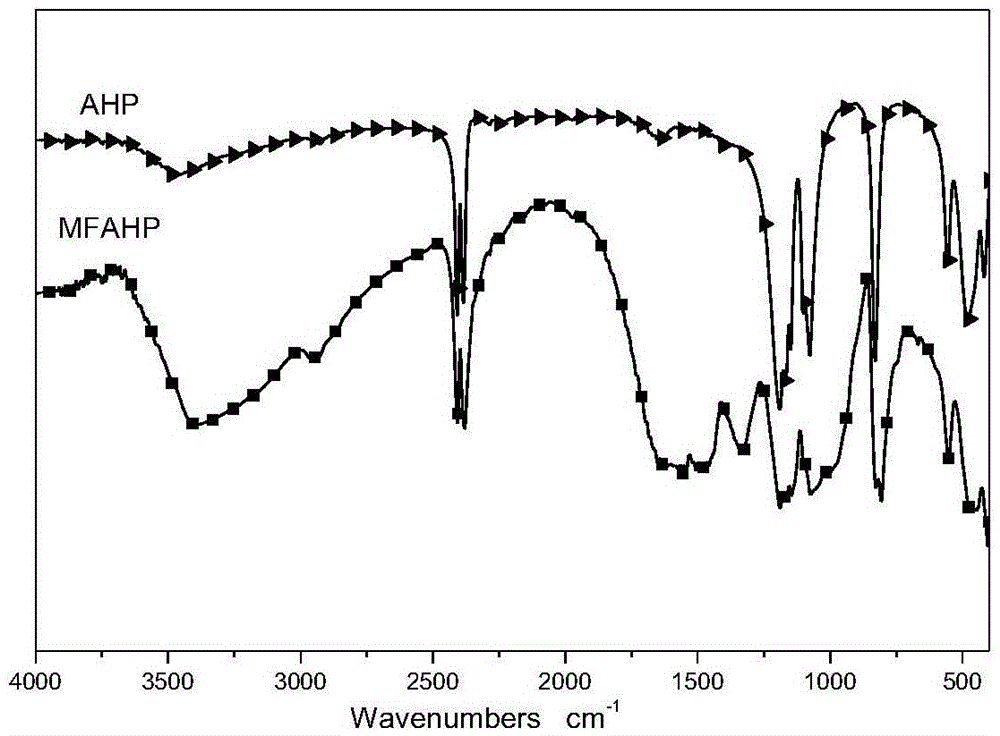

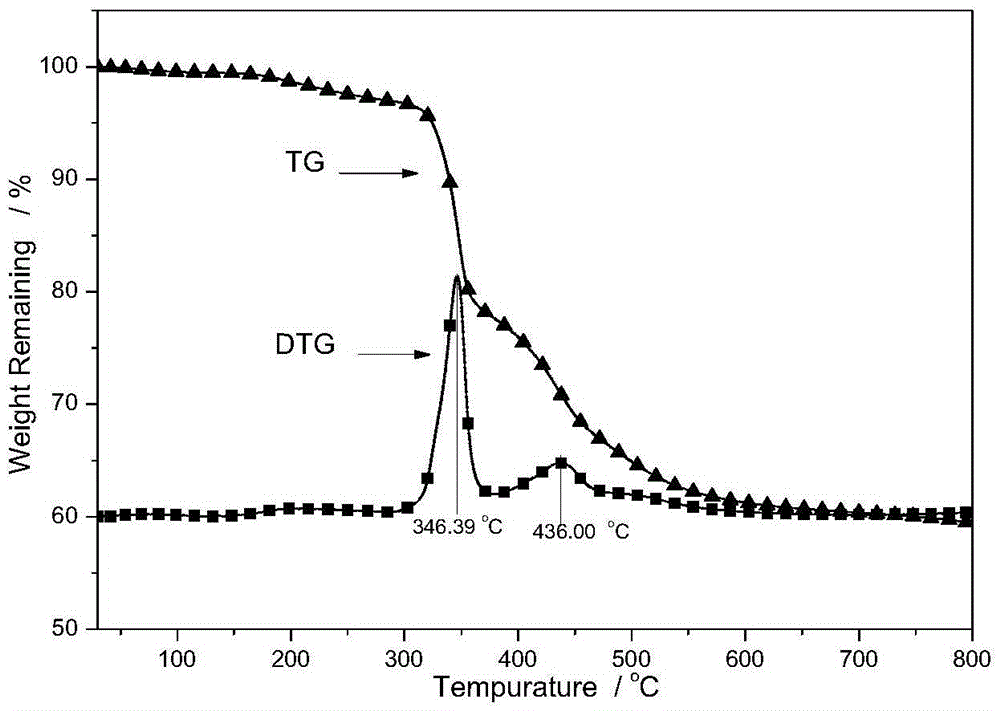

Preparation method of microcapsule aluminum hypophosphite flame retardant

ActiveCN105457574AOvercome water solubleOvercome the disadvantage of being flammableMicroballoon preparationMicrocapsule preparationPhosphoric acidALUMINUM PHOSPHATE

The present invention relates to a preparation method of a microcapsule aluminum hypophosphite flame retardant. The method comprises the steps of: first reacting melamine, a formaldehyde solution and a resin modifier under reaction conditions of pH of 8-10 and a temperature of 50-80 DEG C for 0.5-2 h to prepare a melamine resin prepolymer; then slowly adding the prepolymer to water with aluminum phosphate dispersed therein, reacting at 65-95 DEG C for 1-5 h, and treating to obtain the microcapsule coated inorganic aluminum phosphate flame retardant. The obtained microcapsule inorganic aluminum hypophosphite flame retardant has greatly improved water resistance, boiling residual rate of 92% to 97% and average particle diameter of 10-35 mum, solves the disadvantage of flammability of inorganic aluminum hypophosphite, and greatly improves the safety of the production and application process.

Owner:JINAN TAIXING FINE CHEM

Waterless stemming for blast furnace

InactiveCN1523120AImprove workabilityEasy to squeeze outBlast furnace componentsBlast furnace detailsAnthraceneContraction rate

The present invention provides an anhydrous stemming for blast furnace. Its composition includes (wt%) coarse brown corundun 1-4%, fine brown corundum 2-5%, coarse mullite 7-15%, fine mullite 9-20%, coke powder 15-20%, clay 10-19%, silicon carbide 7-11%, sericite 5-8%, bitumen 2-4% and anthracene oil 15-25%. It has good working property, stable high temperature resistance, excellent caking property, quick agglutinating property, low ton-iron stemming consumption, low contraction rate and high strength, it can raise tap up-to-standard rate to 100% from original 61.5%, can raise production safety of blast furnace, and can raise smelting strength.

Owner:WUKUN STEEL

Full-automatic lug cutting machine

ActiveCN101015867ASimple structureLow costElectrode manufacturing processesMetal-working feeding devicesElectrical batteryEngineering

The invention relates to a cutter of polar ear of lithium battery, which comprises an aerated blade, a fixed blade, a cylinder, a metering controlling switch and a feeder, wherein the fixed blade and the cylinder are mounted on a workbench, the aerated blade is mounted on the cylinder connected with the metering controlling switch, the feeder triggers the metering controlling switch when feeds the polar ear base band to on site to start the cylinder to cut polar ear. The feeder comprises a frame, a release support, a guide wheel, a feeding block, a crank connecting rod and a motor, wherein the release support is mounted on the frame, the guide wheel and the guide groove are mounted on the workbench, the polar ear base band is mounted on the release support and movably connected with the guide wheel and the guide groove, the feeding block, polar ear base band and the guide groove are engaged with each other, the crank connecting rod is connected with the motor and arranged with a cam, and the connecting rod is connected with the feeding block. The invention has low cost, accurate positioning, automatic metering, and high efficiency or the like.

Owner:HANGZHOU SKYRICH POWER CO LTD

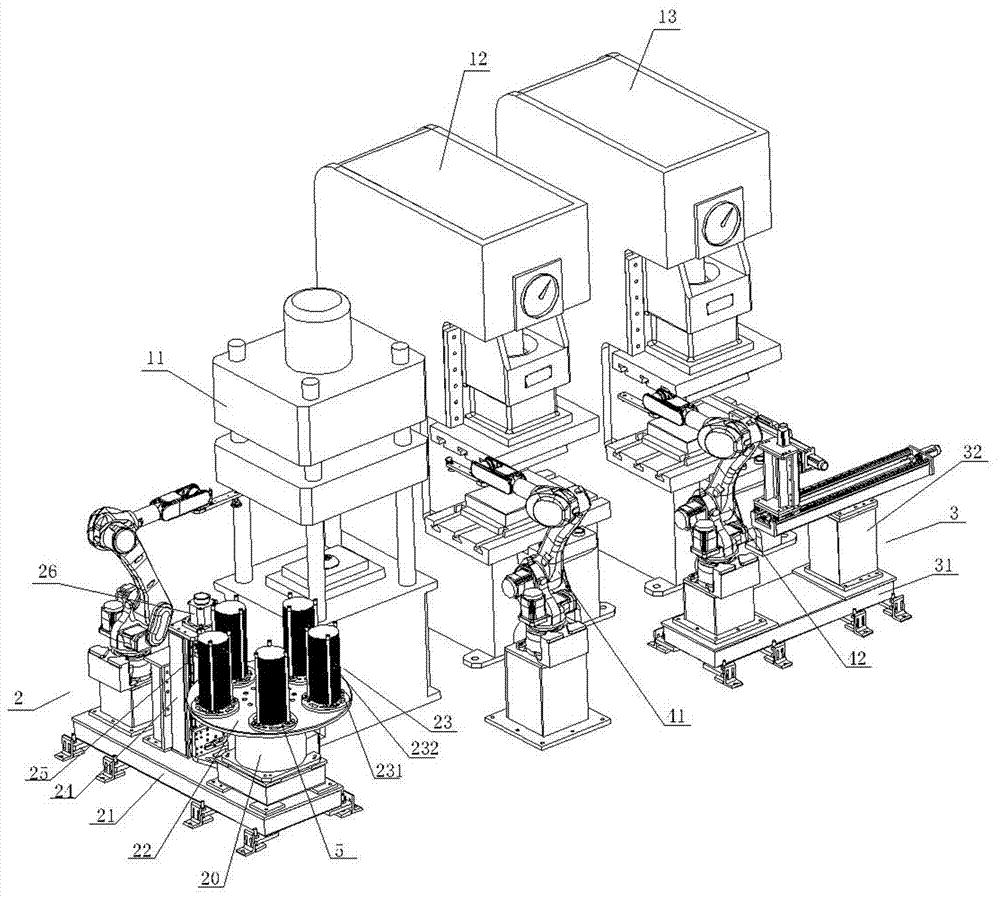

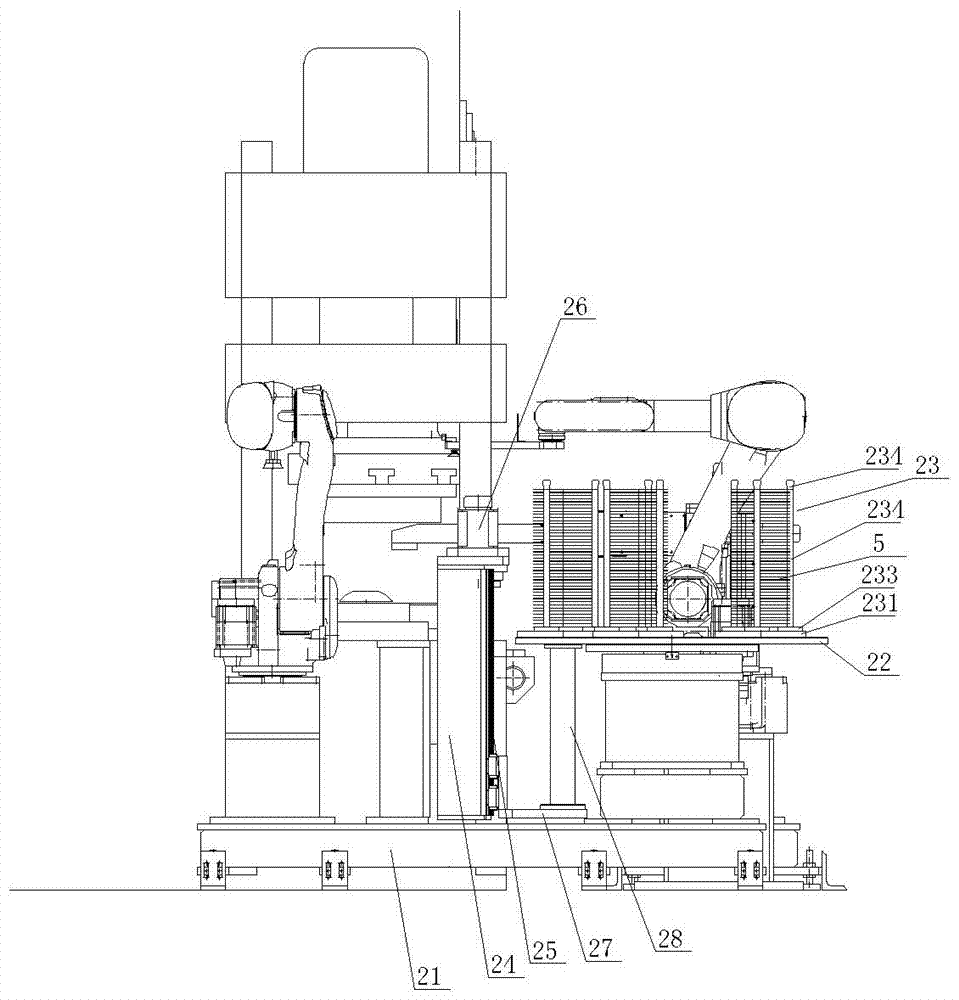

Automatic feed and discharge system of press robot

InactiveCN107159803AConvenient continuous feedingImprove feeding efficiencyMetal-working feeding devicesPositioning devicesNumerical controlAutomatic control

The invention relates to an automatic feed and discharge system of a press robot. The automatic feed and discharge system comprises at least one punch press, an automatic feed device, an automatic discharge device and a computer automatic-control system. The automatic feed device comprises a rotary feeding mechanism and a feed manipulator device, and the computer automatic-control system comprises an integrated chip, a numerical control circuit, a display screen and a control panel; automatic feed, stamping forming and automatic discharge of the punch press, the rotary feeding mechanism, the feed manipulator device and the automatic discharge device are achieved through the computer automatic-control system. By adopting the above structure, the automatic feed and discharge system has the advantages that the machining is quick and accurate, and the machining accuracy is even; the production efficiency is improved, and the manpower cost is reduced; and manual feed and discharge are avoided, and the production safety is improved.

Owner:GUANGZHOU ZHENGBAO PRECISION MACHINERY +1

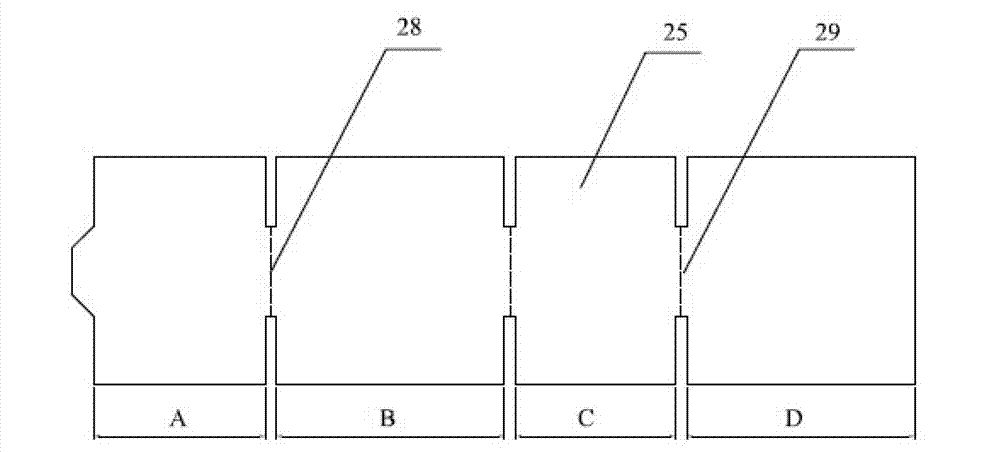

Carton manufacturing device

ActiveCN103029323APrevent crashPrevent overrunningBox making operationsPaper-makingProduction lineCardboard

The invention relates to a carton manufacturing device. A chain driving shaft and a manipulator are respectively controlled by different servo motors, and a line pressing part and an extrusion part are added to carry out secondary line pressing and extrusion processing on cardboards; and meanwhile, a gap adjusting part is added and comprises a carton aligning device for carrying out alignment processing on the cardboards, and a nail wire conveying mechanism is added in a box nailing and sticking part. According to the device, the cost of the whole production line is greatly reduced, so that the device is suitable for being installed and used by small-and-medium-sized enterprises; and the control accuracy is high, so that the pass rate of the manufactured carton is greatly increased, and the quality of the carton is strictly ensured.

Owner:无锡唐诚机械有限公司

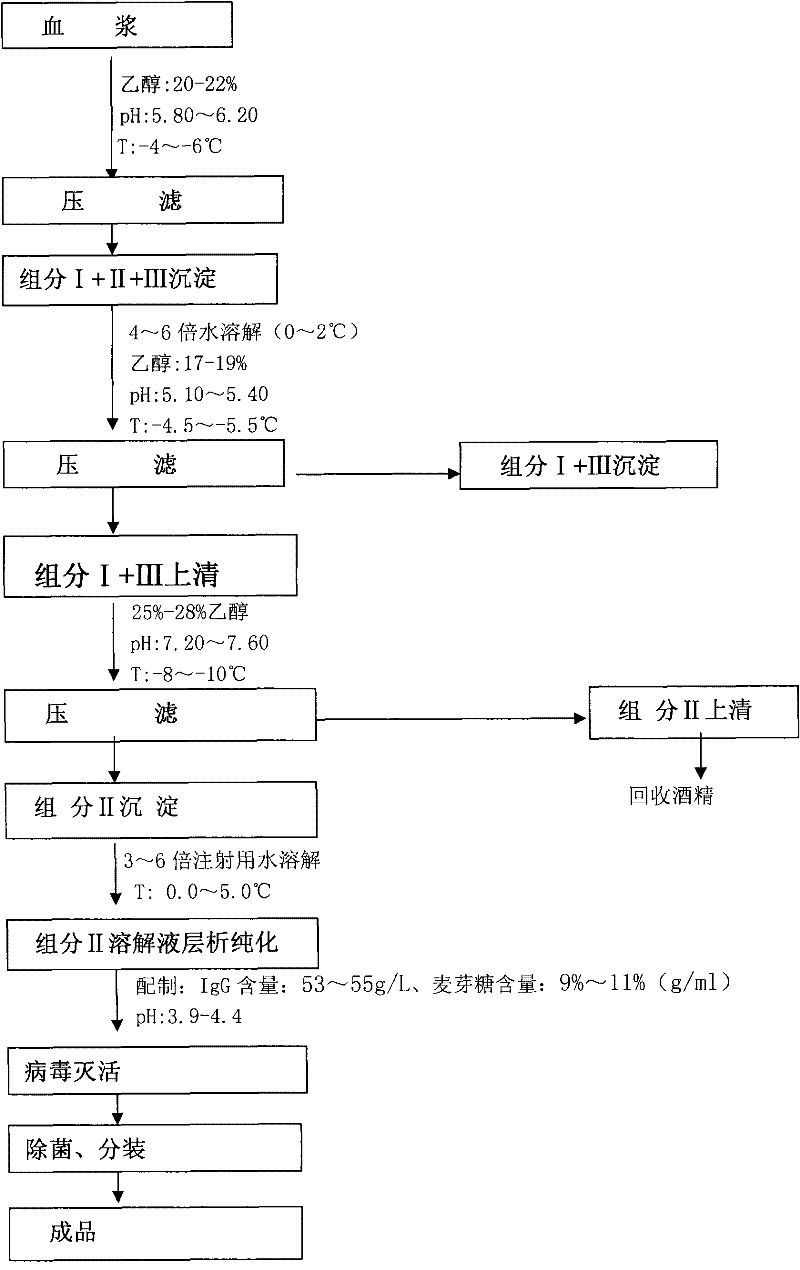

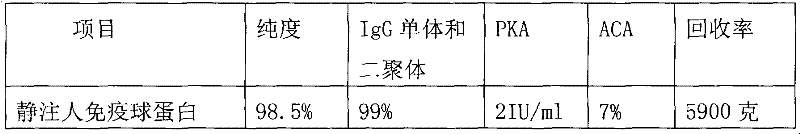

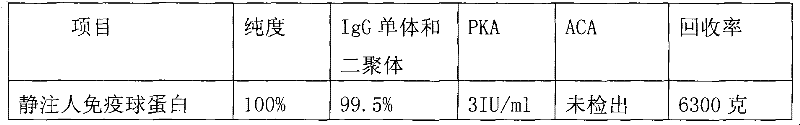

Method for producing intravenous injection human immune globulin

ActiveCN102178951AEasy temperature controlFast separationSerum immunoglobulinsAntibody ingredientsIon exchangeEngineering

The invention relates to a preparation method of human plasma protein, in particular a method for producing intravenous injection human immune globulin by using filter press technique for separation in combination with chromatograph for purification. The method is characterized in that a filter press is adopted as a main separation device to replace a centrifugal machine for producing intravenous injection human immune globulin, so that the temperature and other conditions for separation are easy to control, the separation speed is quick, and the safety is high without a high-speed operating device. Meanwhile, ion-exchange column chromatography is adopted to further purify the product and acquire the intravenous injection human immune globulin with the purity as high as 98.5-100%. The sum of monomer and dipolymer reaches 99-99.5%. PKA (proteinkinase A) is no more than 3IU / ml and ACA (Anti Cardiolipin Antibodies) is no more than 9%. Besides, the process is high in recovery rate, and for each ton of blood plasma, 5600-6300g of intravenous injection human immune globulin can be harvested.

Owner:哈尔滨派斯菲科生物制药有限公司

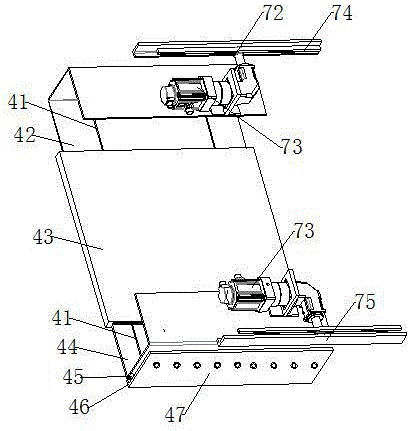

Lamp crimping and assembling mechanism

The invention relates to a lamp crimping and assembling mechanism, which comprises an upper crimping assembly and a lower crimping assembly, wherein a lower connecting base of the lower crimping assembly is provided with two linear guide tracks and a first cylinder in the transverse direction; a first sliding plate and a second sliding plate are arranged on the two linear guide tracks and are movable; the piston of the first cylinder is connected with the first sliding plate; at least two springs arranged on the first sliding plate are supported to a first limiting plate; the first limiting plate is provided with a mounting surface for mounting parts, a positioning groove and an H-shaped discharge notch arranged on the mounting surface; a second cylinder arranged on the first sliding plate is connected with a supporting plate arranged on the second sliding plate; a second limiting plate is arranged on the supporting plate; the second limiting plate is provided with a mounting surface for mounting parts and more than two spacing grooves; and the first sliding plate is provided with a positioning block for height positioning of the second limiting plate, and the positioning block is provided with a side positioning notch. The lamp crimping and assembling mechanism ensures that two parts can be placed in a staggered mode, can improve the assembly efficiency, and has accurate positioning, and safe and convenient operation.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST

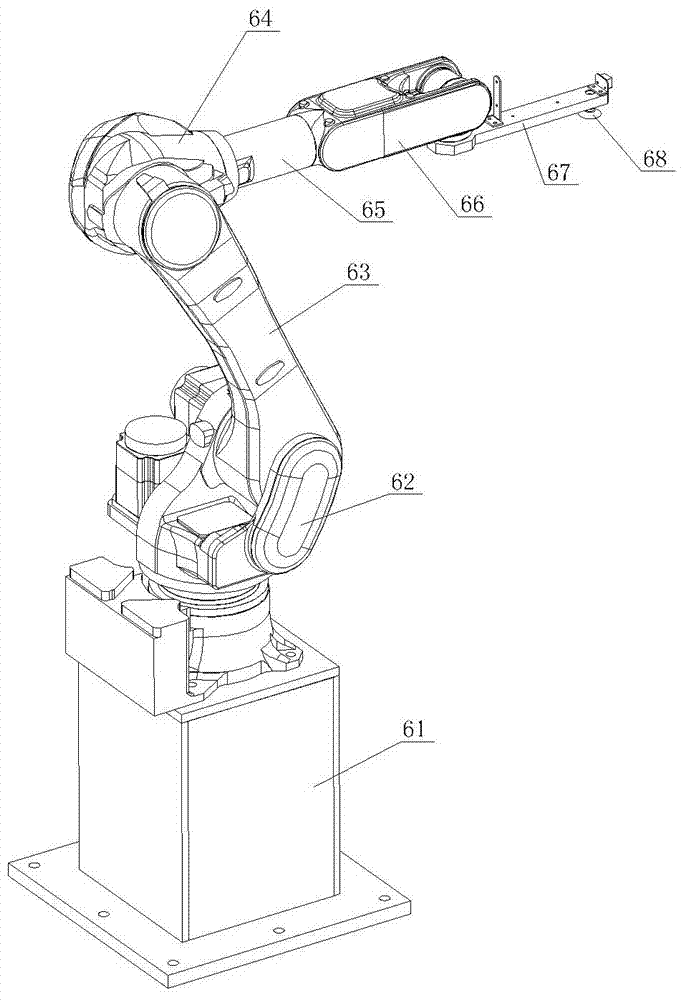

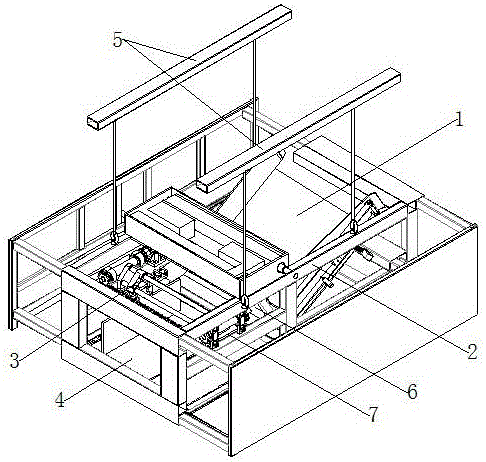

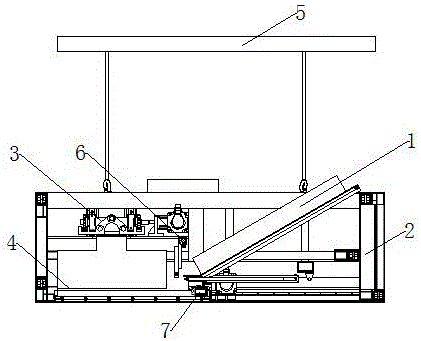

Intelligent loading robot for bagged packing materials and operating method thereof

ActiveCN105923418AReduce exposure timeReduce respiratory diseaseLoading/unloadingEngineeringDepth direction

The invention discloses an intelligent loading robot for bagged packing materials. The robot comprises a main body frame which can be flexibly adjusted according to the width of a wagon box, and a pushing manipulator, a stacking tongue, a stopping manipulator and an unloading and stretching manipulator which are mounted in the main body frame; the pushing manipulator pushing a material bag on the stacking tongue along the width direction of the wagon box and the stopping manipulator blocking the material bag on the stacking tongue along the depth direction of the wagon box to isolate the material bag from the stacking tongue are arranged above a stacking table of the stacking tongue; the unloading and stretching manipulator driving the stacking tongue along the depth direction of the wagon box is connected to the stacking tongue. The invention further discloses an operating method of the intelligent loading robot for bagged packing materials. According to the invention, the width of the main body of the loading robot can be adjusted, so that the robot can fit different wagon box widths and quickly finish automatic loading without blind areas, and the robot is high in efficiency and good in safety.

Owner:MIANYANG LANAO HEAVY MACHINERY MFG

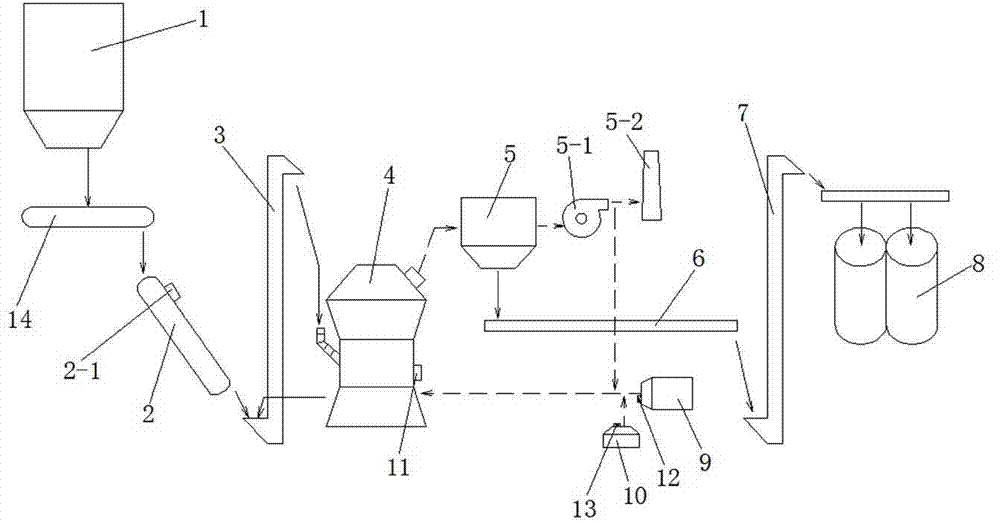

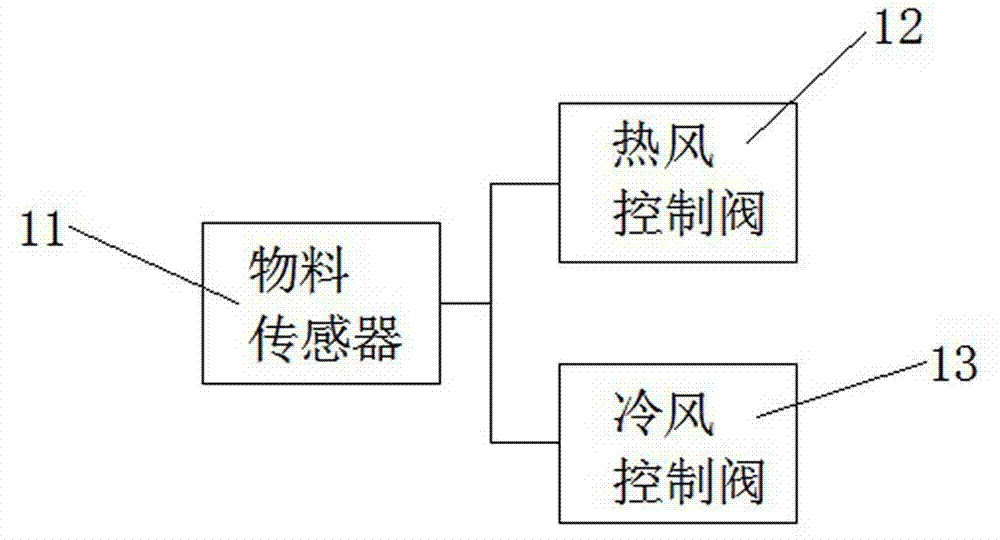

Novel mineral slag grinding system

The invention relates to the technical field of a mineral slag grinding system, and in particular relates to a novel mineral slag grinding system, wherein a discharge hole of a feeding bin is connected with a feeding hole of a first bucket elevator by a belt conveyor; a discharge hole of the first bucket elevator is connected with a feeding hole of a vertical mill machine; a discharge hole of the vertical mill machine is connected with a feeding hole of a bag type dust collector; a discharge hole of the bag type dust collector is connected with a feeding hole of a second bucket elevator by an air chute. According to the system, a raw material discharged from the feeding bin is conveyed into the first bucket elevator by the belt conveyor and is conveyed into the vertical mill machine by the first bucket elevator so as to be ground; a ground material is collected by the bag type dust collector, and is conveyed into a finished product storage sequentially by the air chute and the second bucket elevator; in the grinding process, the ground material is blown by high-speed airflow by a gas hot air furnace and an air cooler, thus being conveniently collected; the novel mineral slag grinding system is reasonable in design, high in productivity and high in production safety.

Owner:NANTONG LIYUANHENG MACHINERY

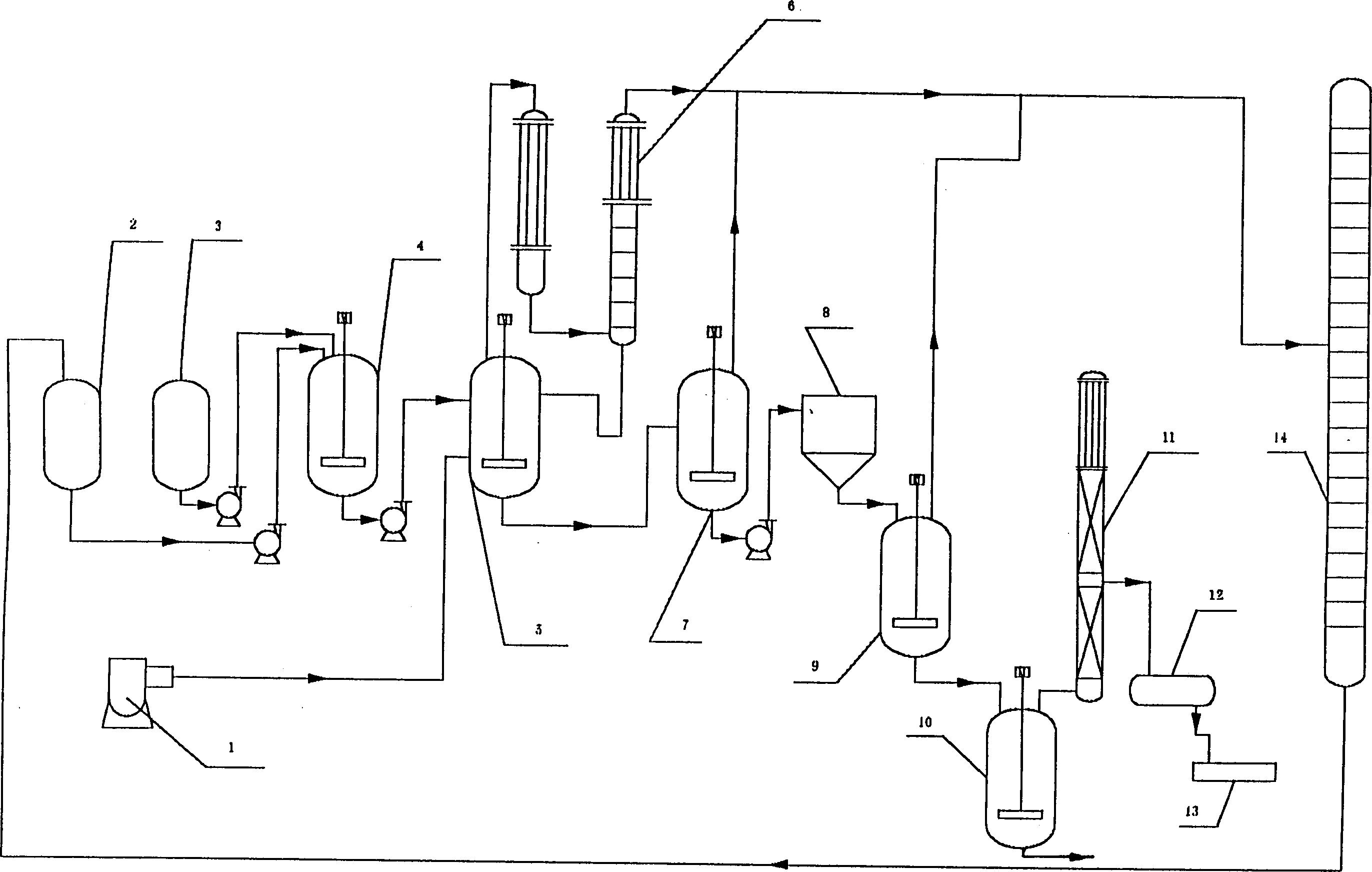

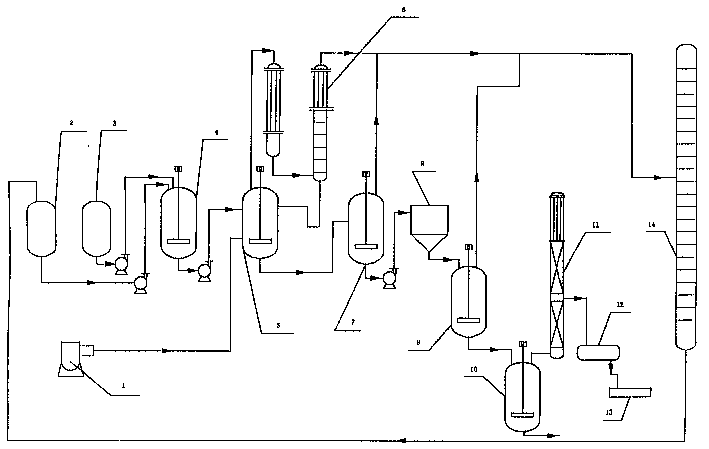

Process for production of trimellitic anhydride by continuous oxidizing process

A process for preparing trimellitic anhydride from metatritoluene, acetic acid as solvent, and catalyst (cobalt acetate, manganess acetate, tetrebromoethane, or hydrogen bromide) by continuous oxidization method includes continuous oxidizing reaction, anhydridization, refining, slicing or granulating and recovering solvent. Its advantages are high yield (up to 120%), high safety, high quality of product, and long service life of equipment.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

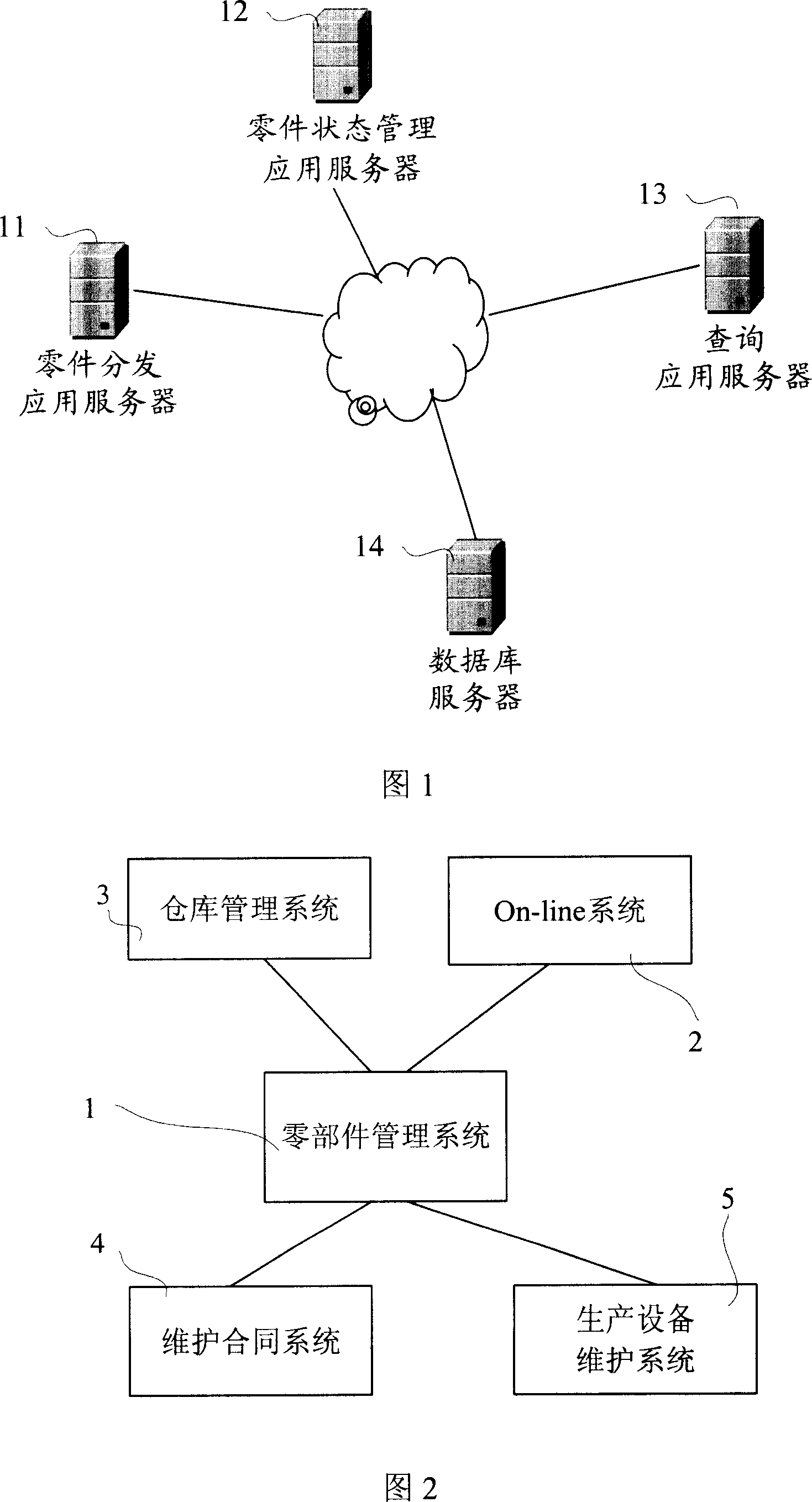

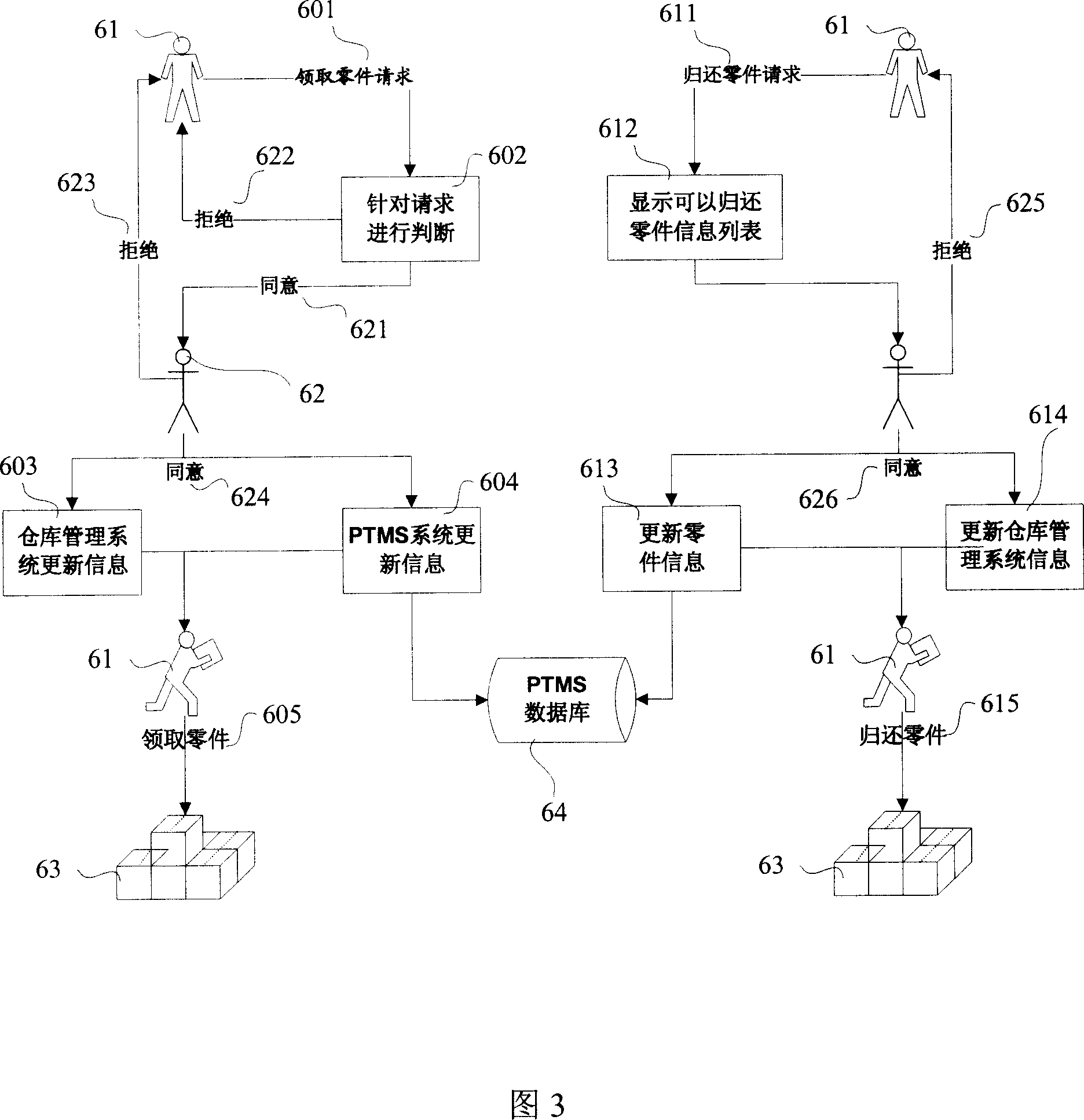

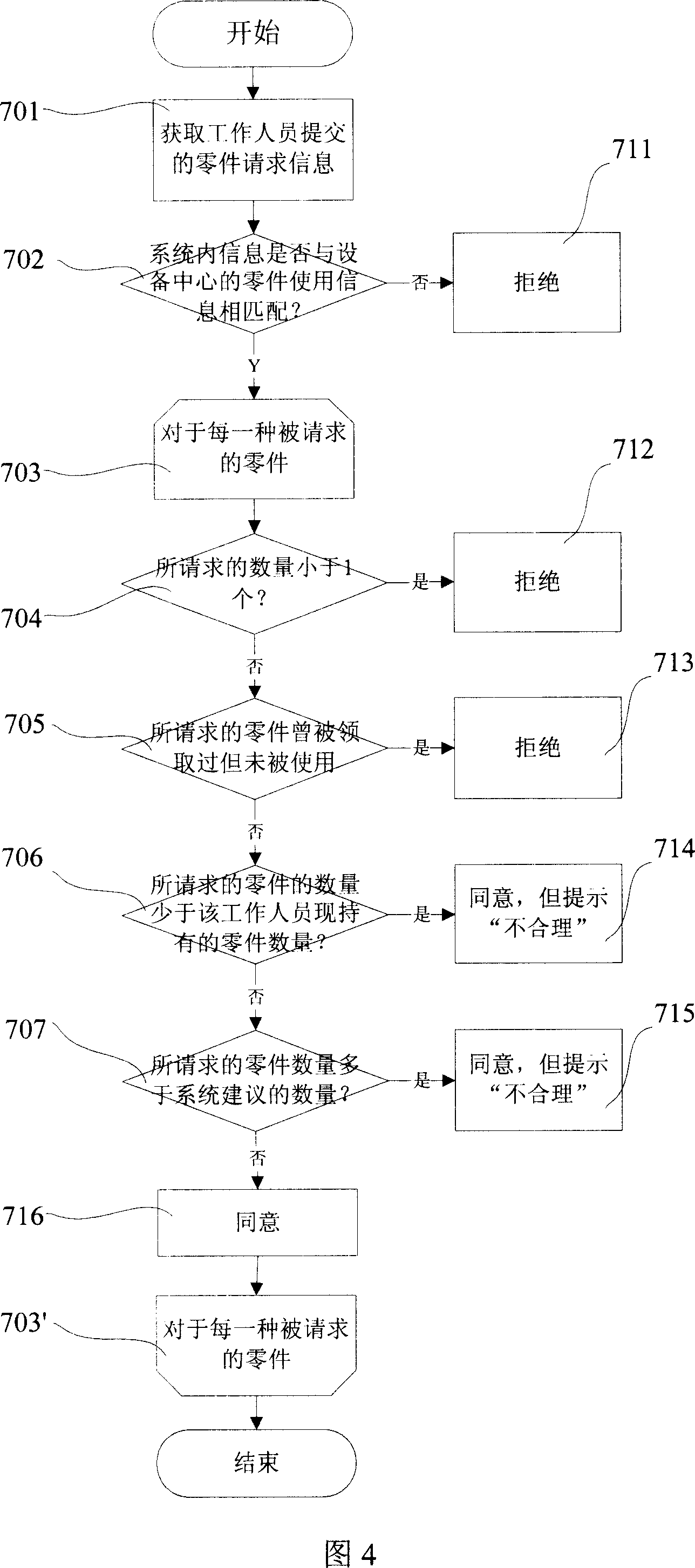

Part management system

This invention provides one new part management system, which combines with current production device maintain system, bare management system, online system integration, associate work part use status and real use time information to give detail advice on work human part for rapid and accurate judgment on device plan sustaining time and to recycle the parts and spare parts by alarming the device dangers.

Owner:SEMICON MFG INT (SHANGHAI) CORP

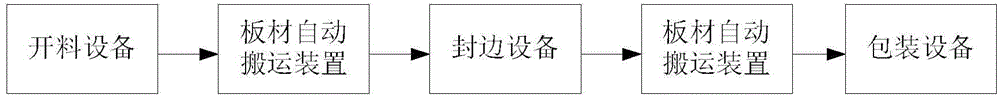

Automatic panel production line

ActiveCN104787569AEasy to expand and upgradeReasonable design layoutControl devices for conveyorsElectricityProduction line

The invention discloses an automatic panel production line. The automatic panel production line comprises a cutting device, an edge sealing device and a packaging device which are arranged in the panel machining direction, an automatic panel carrying device is arranged between each upstream machining device and the corresponding downstream machining device and comprises a panel conveyed-out area, a storage guide rail, a storage location area, a stock removal guide rail and a panel conveyed-in area; roller conveying machines are arranged in the panel conveyed-out areas and the panel conveyed-in areas respectively; a plurality of roller conveying machines are arranged in the storage location areas and are arranged to be in at least one row; two conveying trolleys are arranged on the storage guide rails and the stock removal guide rails respectively and are each provided with a traveling motor, a rotary encoder and a roller conveying machine; each roller conveying machine is provided with a drum motor, and a photoelectric sensor used for panel in-place detection is arranged at the output end of each roller conveying machine. The device further comprises a master controller which is electrically connected with drum motors, the photoelectric sensors, the traveling motors and the rotary encoders. The automatic panel production line is reasonable in design; the automatic panel carrying devices are introduced, so that the manpower is released, and the yield and the production safety performance are improved.

Owner:NANJING OLO HOUSEHOLD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com