Recycling device of organic solvent in high-concentration organic waste gas

A technology of organic waste gas and organic solvents, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of heat loss, explosion, carbon bed ignition, etc., and achieve the effect of low price and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

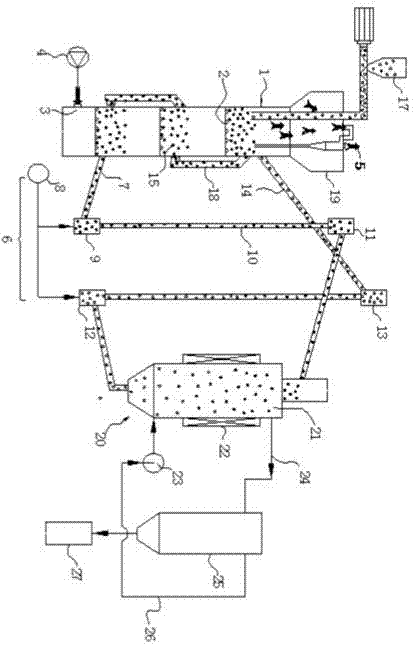

Image

Examples

Embodiment 1

[0025] (1) Acetone organic waste gas in the waste gas, the treatment capacity is 300m3 / h, and the acetone content is 10g / m3;

[0026] (2) There are multi-layer gas distribution plates inside the multi-layer fluidized bed adsorption tower, a gas flow inlet is set at the bottom and connected to an exhaust gas fan, and a cyclone dust collector with a purified gas outlet is set at the top, through which the 40-mesh coconut shell activated carbon adsorbent The exhaust gas is flowed and adsorbed inside; the external circulation is adopted between the layers of the adsorption tower;

[0027] (3) Use a multi-layer fluidized bed adsorption tower with 3 layers, and the layer height: 1200mm;

[0028] (4) The organic waste gas is in contact with the adsorbent, the residence time of the gas in the bed is 5s, and the residence time of the solid in the bed is 6min;

[0029] (5) The desorption gas in the desorption tower is nitrogen, which is recycled, and the optimum temperature is 190°C; ...

Embodiment 2

[0034] (1) Isopropanol organic waste gas in the exhaust gas, the treatment capacity is 300m3 / h, and the isopropanol content is 15g / m3;

[0035] (2) There are multi-layer gas distribution plates inside the multi-layer fluidized bed adsorption tower, a gas flow inlet is set at the bottom and an exhaust gas fan is connected, and a cyclone dust collector with a purified gas outlet is set at the top, and the 50-mesh coconut shell activated carbon adsorbent is passed through The exhaust gas is flowed and adsorbed inside; the external circulation is adopted between the layers of the adsorption tower;

[0036] (3) Use multi-layer fluidized bed adsorption tower with 10 layers, layer height: 800mm;

[0037] (4) The organic waste gas is in contact with the adsorbent, the residence time of the gas in the bed is 40s, and the residence time of the solid in the bed is 60min;

[0038] (5) The desorption gas in the desorption tower is nitrogen, which is recycled, and the optimum temperature i...

Embodiment 3

[0042] (1) Toluene organic waste gas in the waste gas, the treatment capacity is 300m3 / h, and the toluene content is 15g / m3;

[0043] (2) There are multi-layer gas distribution plates inside the multi-layer fluidized bed adsorption tower, a gas flow inlet is set at the bottom and an exhaust gas fan is connected, a cyclone dust collector with a purified gas outlet is set at the top, and the 70-mesh coconut shell activated carbon adsorbent is passed through The exhaust gas is flowed and adsorbed inside; the external circulation is adopted between the layers of the adsorption tower;

[0044] (3) Use a multi-layer fluidized bed adsorption tower with 15 layers, layer height: 600mm;

[0045] (4) The organic waste gas is in contact with the adsorbent, the residence time of the gas in the bed is 60s, and the residence time of the solid in the bed is 80min;

[0046] (5) The desorption gas in the desorption tower is nitrogen, which is recycled, and the optimum temperature is 165°C;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com