A detachable independently sealed fuel battery

A fuel cell, separate technology, used in fuel cells, fuel cell parts, solid electrolyte fuel cells, etc., can solve problems such as cost reduction, assembly leakage, complex manufacturing process, etc., to avoid wrinkles and torn, Easy to make and assemble, simple to make and assemble effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The fuel cell of the present invention will be further described below with reference to the accompanying drawings and specific examples, so as to facilitate understanding of the content of the present invention.

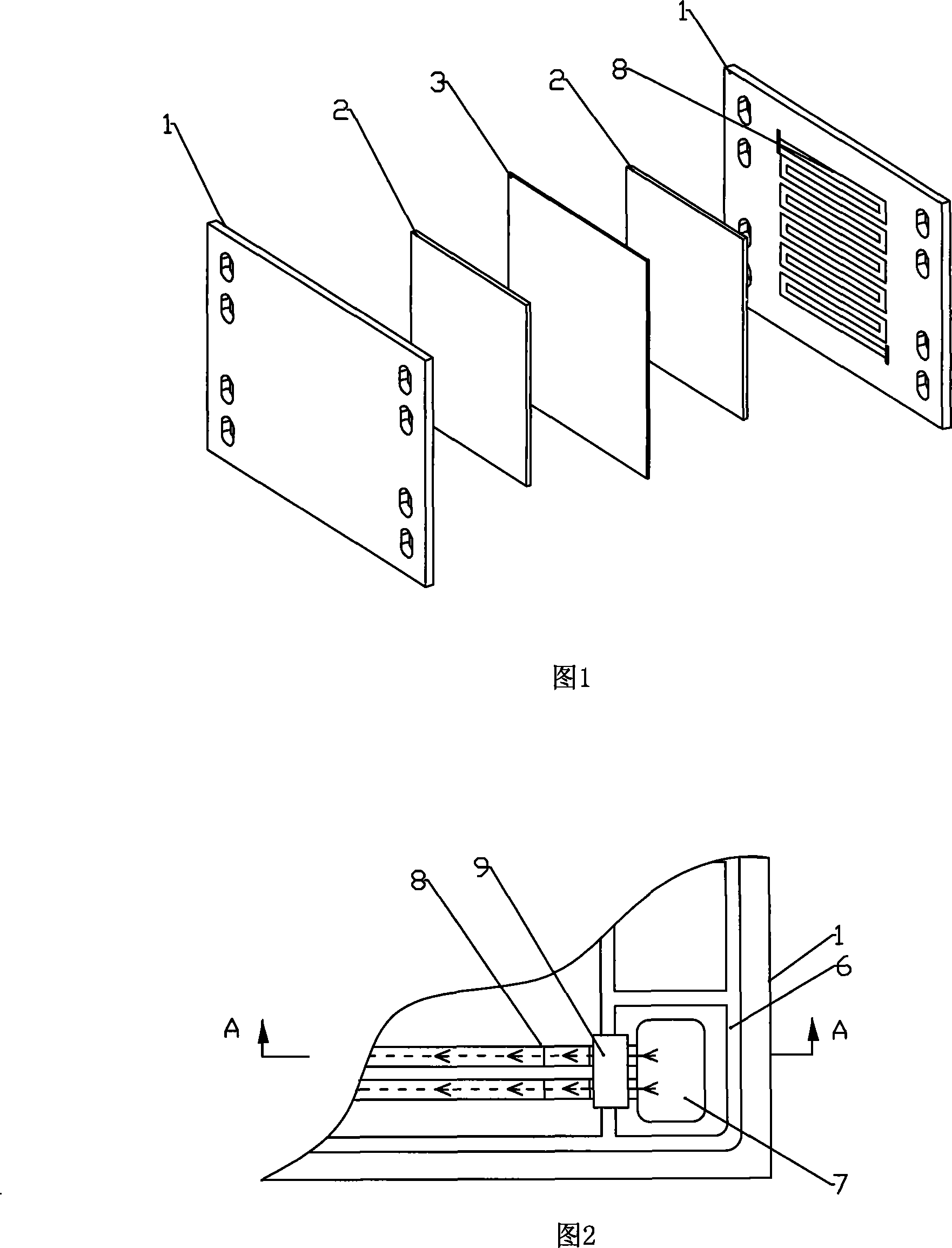

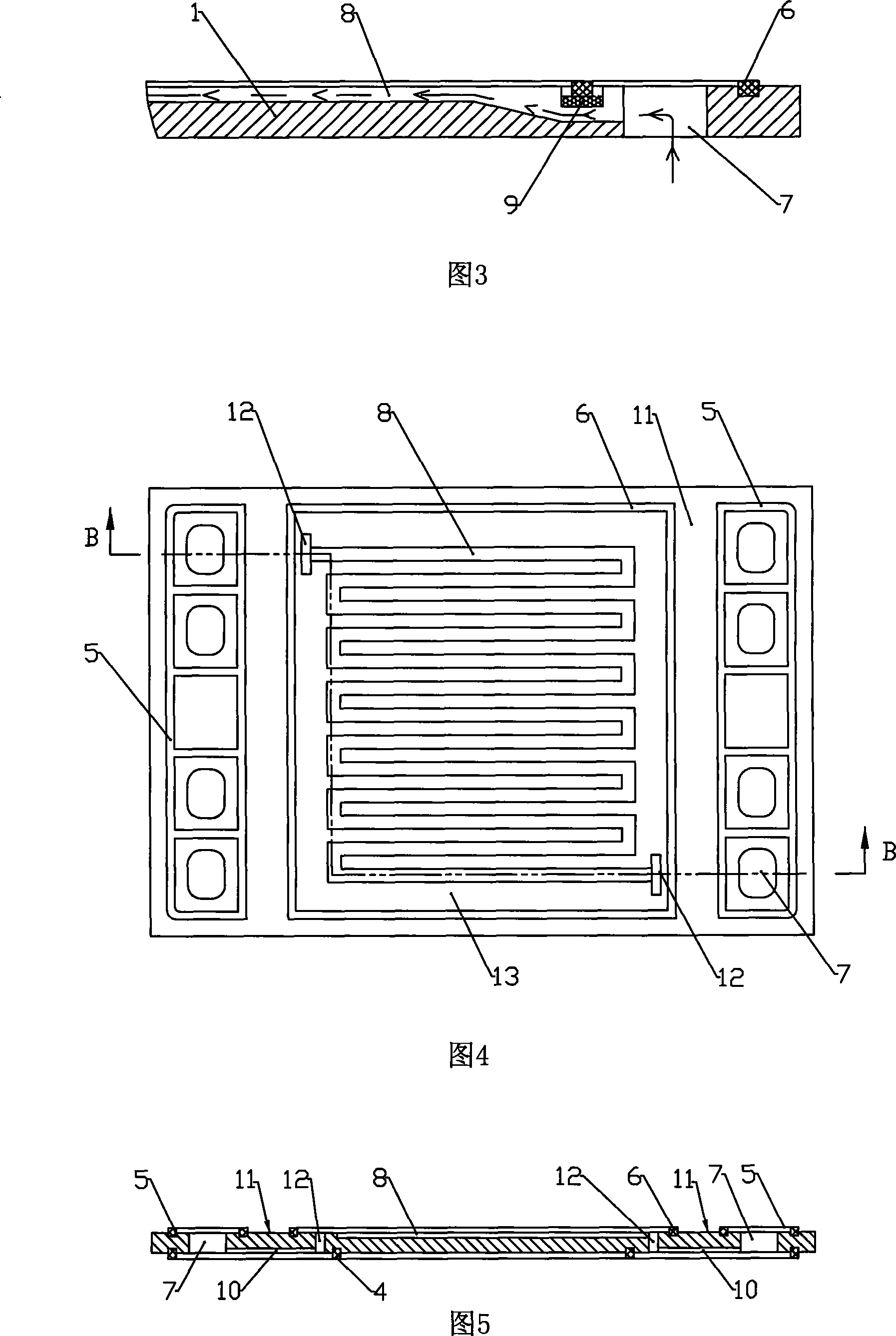

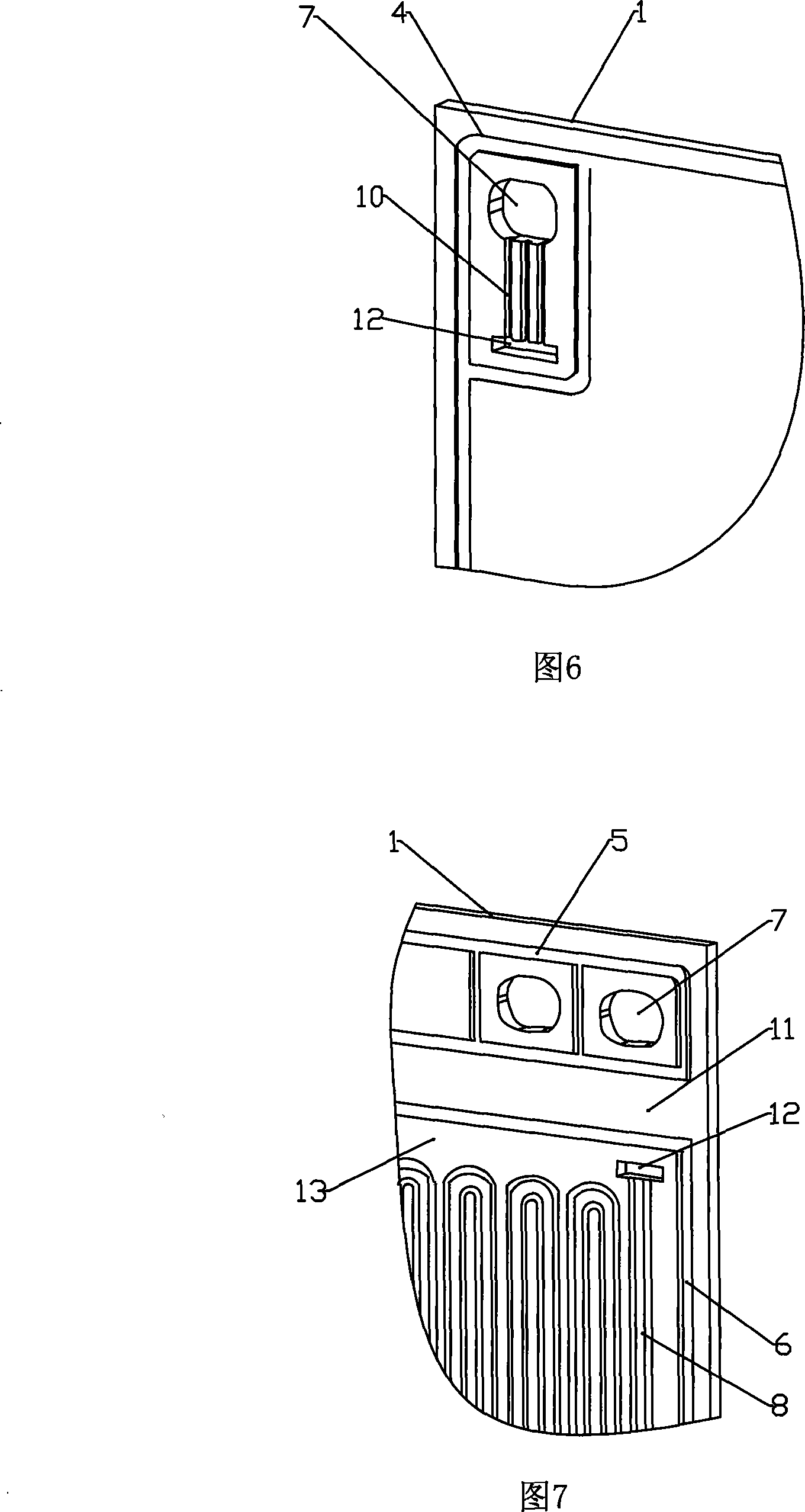

[0029] The fuel cell of the present invention is also composed of at least one basic battery unit, and each basic battery unit is also composed of two parallel gas guide plates and a membrane electrode assembly sandwiched between them. The membrane electrode assembly is divided into two parts, the electrochemical active area and the sealing area. In the electrochemical active area, the membrane electrode assembly is synthesized by hot pressing of the proton exchange membrane, the catalyst layer and the carbon paper layer on both sides. The area part is formed by the expansion of the proton exchange membrane; the gas deflector also includes two parts, the active area and the inactive area, and the size and shape of the active area on the front of the gas deflec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com