Automatic airflow control system of FDM printer

An automatic control system and printer technology, applied in the direction of 3D object support structure, manufacturing tools, processing data acquisition/processing, etc., can solve the problems of inaccurate control, manual control of compressed air, poor performance, etc., and achieve easy operation and use, The effect of simple structure and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

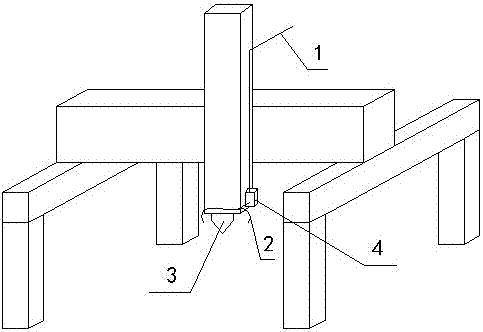

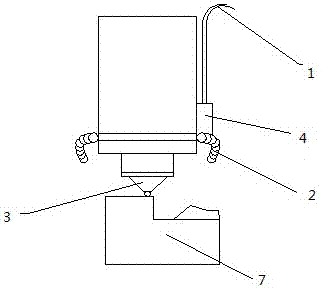

Method used

Image

Examples

Embodiment 1

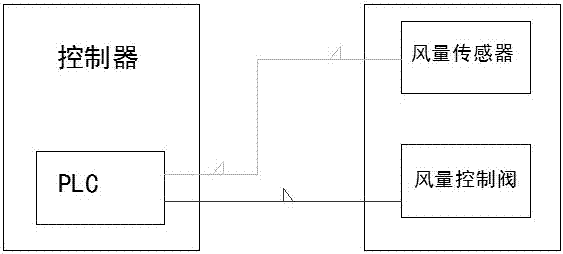

[0054] Before the printing starts, the specified air volume parameter data is input to the controller, and when the printing is running, the automatic air control system of the present invention starts to work. First, supply compressed air to the air intake compressed air pipe 1, when the compressed air passes through the air volume measuring device 5 in the automatic air control device 4, the air volume measuring device detects the air volume of the compressed air that is passed in, and the automatic air control valve 6 passes through it at the same time. The air volume is adjusted. When the measured data reaches the air volume parameter data set by the controller, the air volume measurement device 5 transmits the air volume parameter data to the PLC in the controller, and the automatic air control valve 6 is given an instruction signal to stop the adjustment through the PLC. , the automatic air control valve 6 will stop adjusting. At this time, the compressed air output from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com