Patents

Literature

107results about How to "Adjustable air volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Granular crop grain drying device and method

InactiveCN105605906AImprove efficiencyGood high temperature resistanceDrying gas arrangementsDrying solid materialsEngineeringMoisture

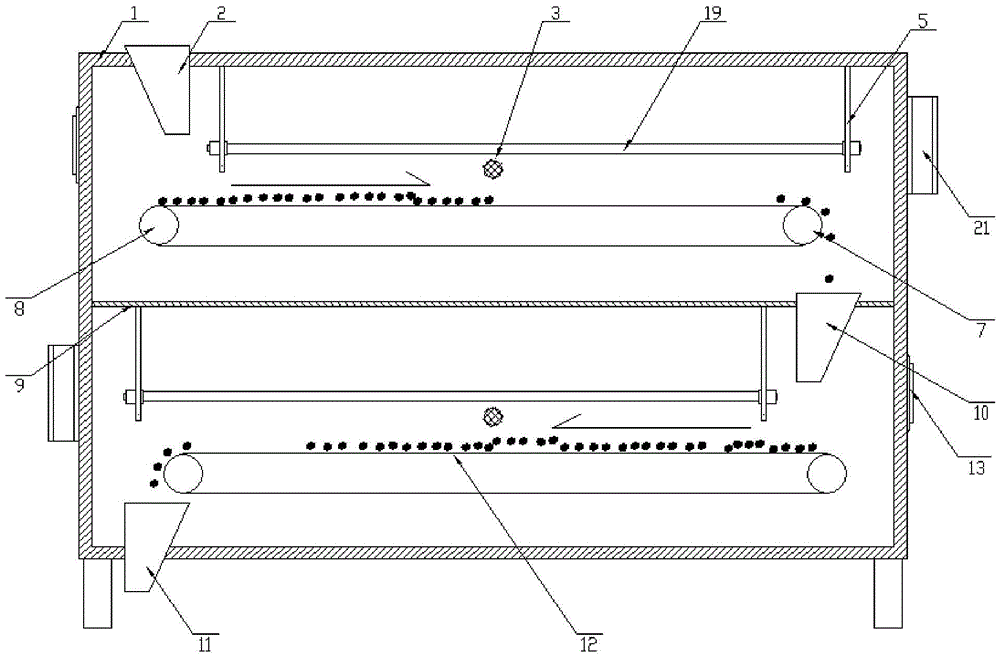

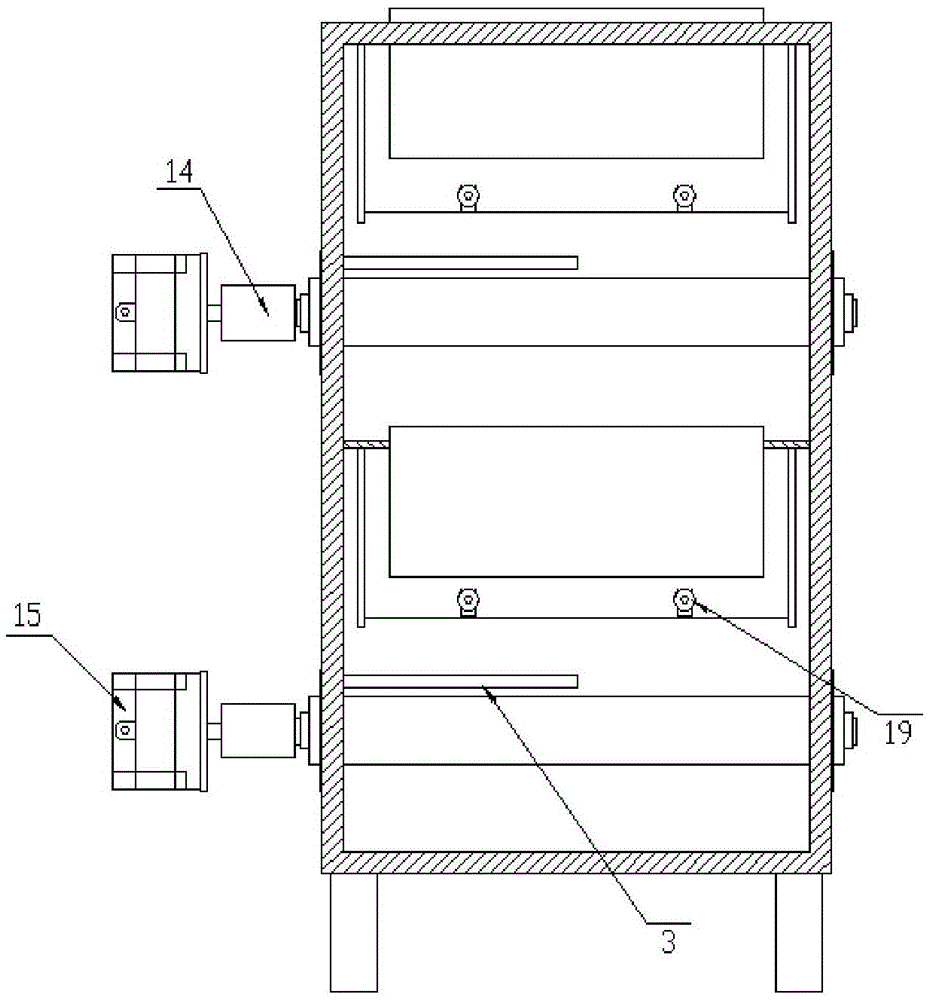

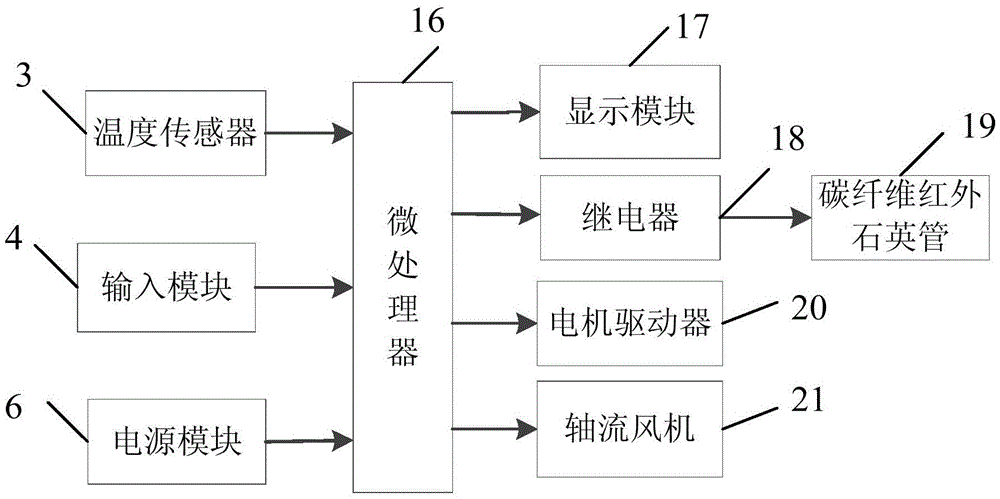

The invention discloses a granular crop grain drying device and method. The drying device comprises a drying box, a conveying mechanism, a drying mechanism, a moisture removal mechanism, a temperature sensor, an input module and a microprocessor, wherein the top of the drying box is provided with a feed port; the bottom of the drying box is provided with a discharge port; the conveying mechanism is used for supporting and conveying crop grains, a feed end of the conveying mechanism is positioned below the feed port, and a discharge end of the conveying mechanism is positioned above the discharge port; the drying mechanism is horizontally arranged above or below the conveying mechanism, and used for emitting infrared rays and irradiating the infrared rays onto the crop grains; the moisture removal mechanism comprises a vent hole arranged in the drying box, and an axial fan installed on the drying box; the temperature sensor is used for detecting the temperature in the drying box; the input module is used for inputting a command by a user; and the microprocessor is respectively connected with the input module, drying mechanism, moisture removal mechanism and temperature sensor. The drying device has the advantages of high stability, high drying efficiency, high drying quality, high automation degree and low energy consumption.

Owner:SOUTHWEST UNIVERSITY

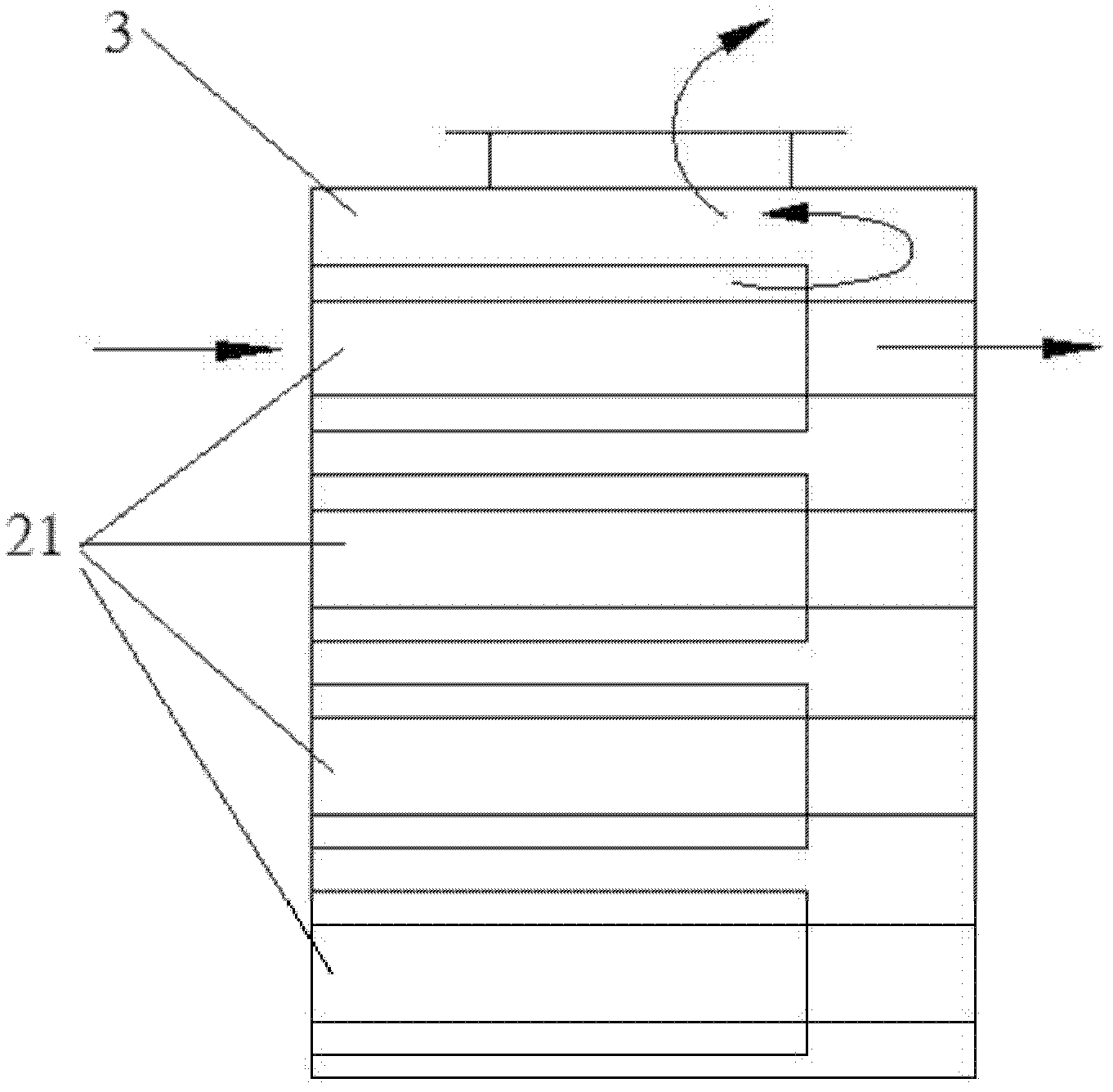

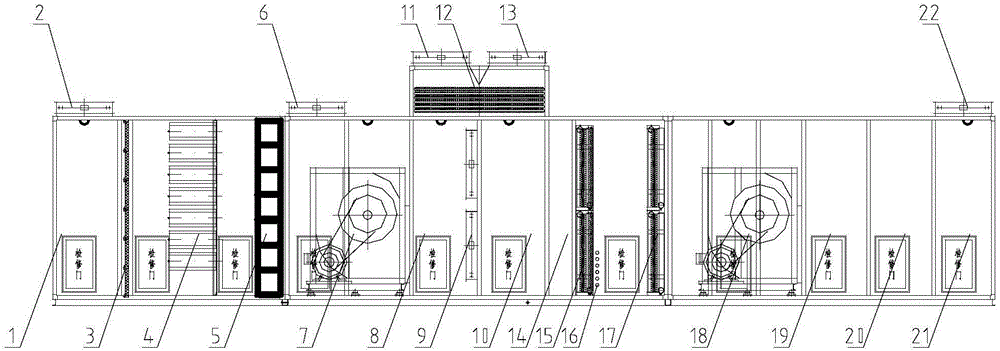

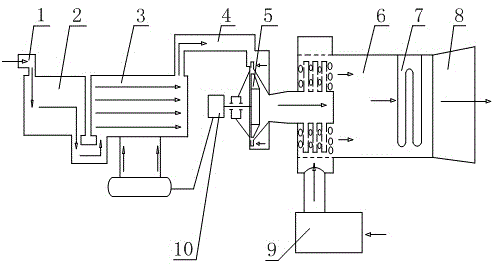

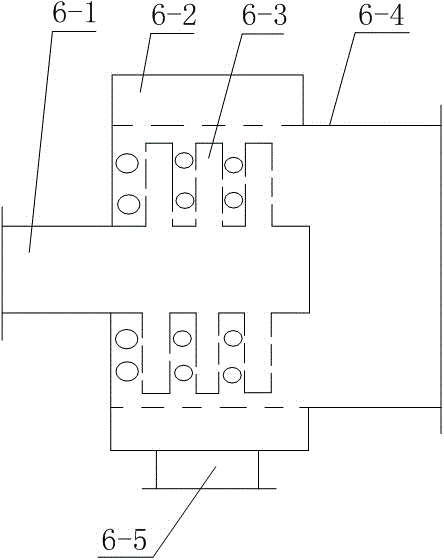

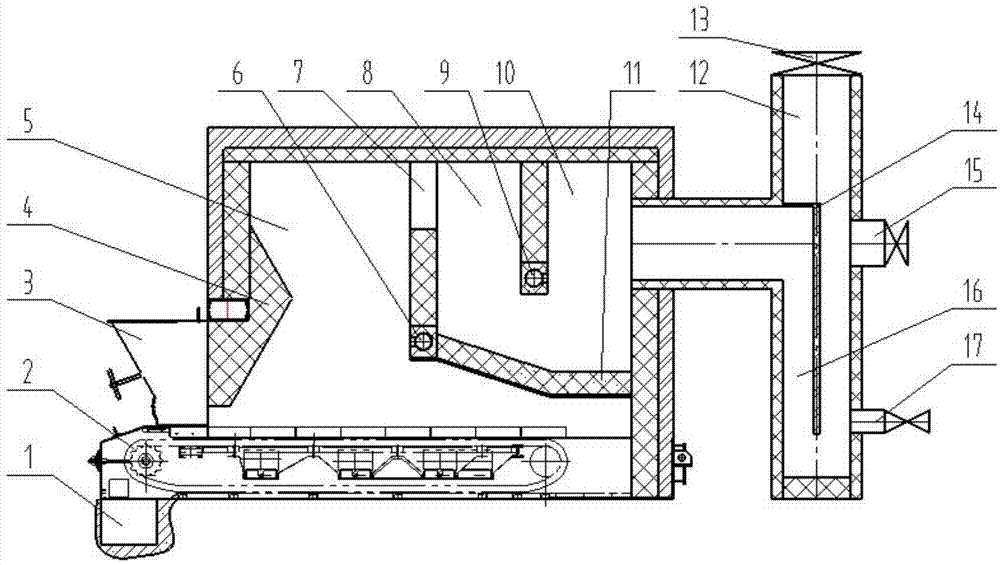

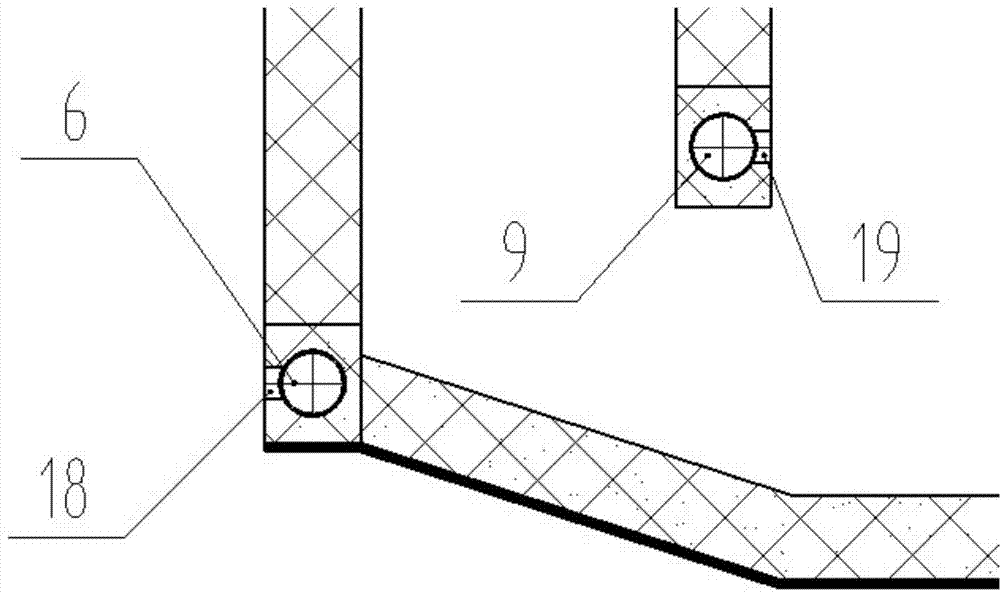

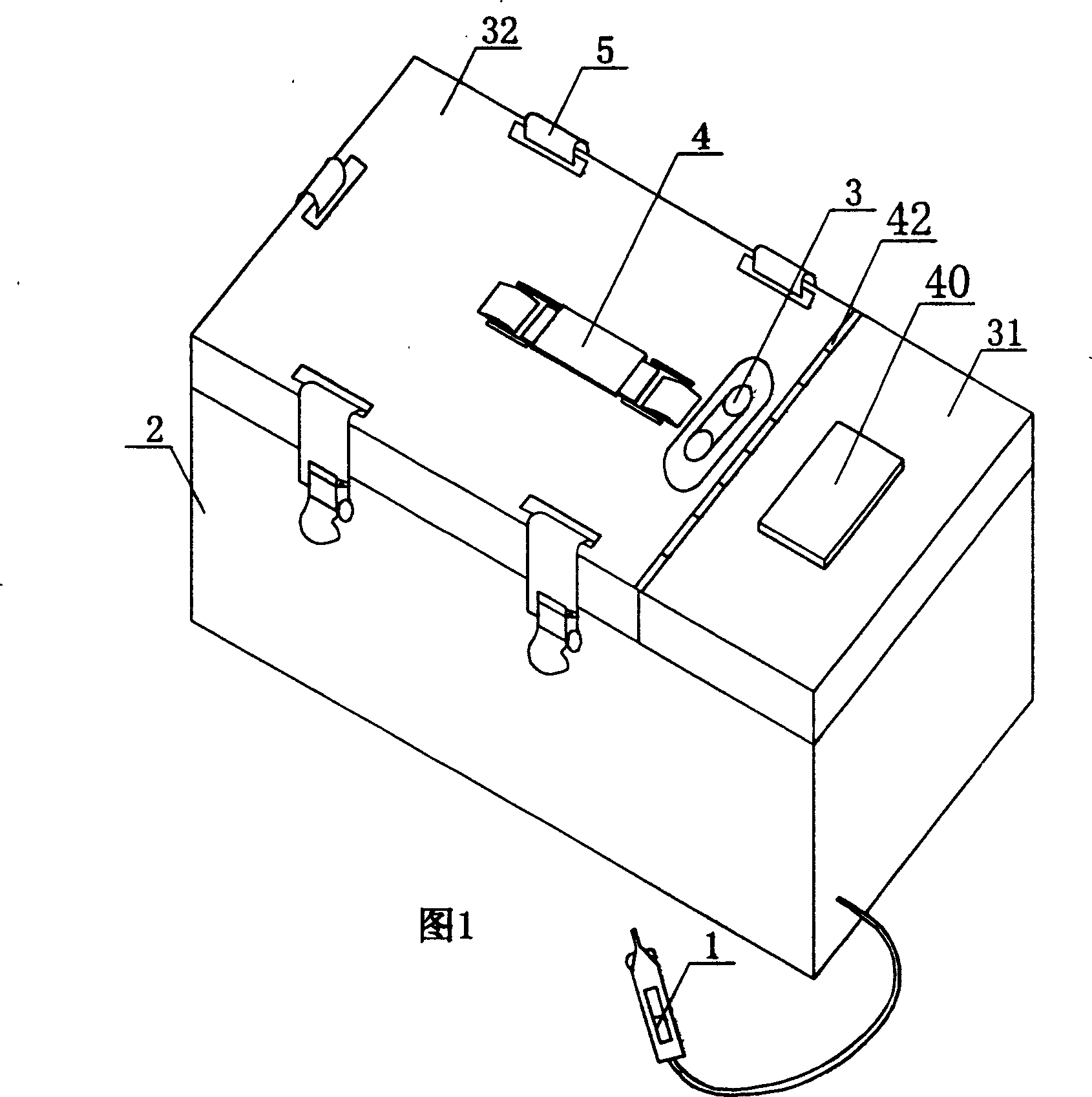

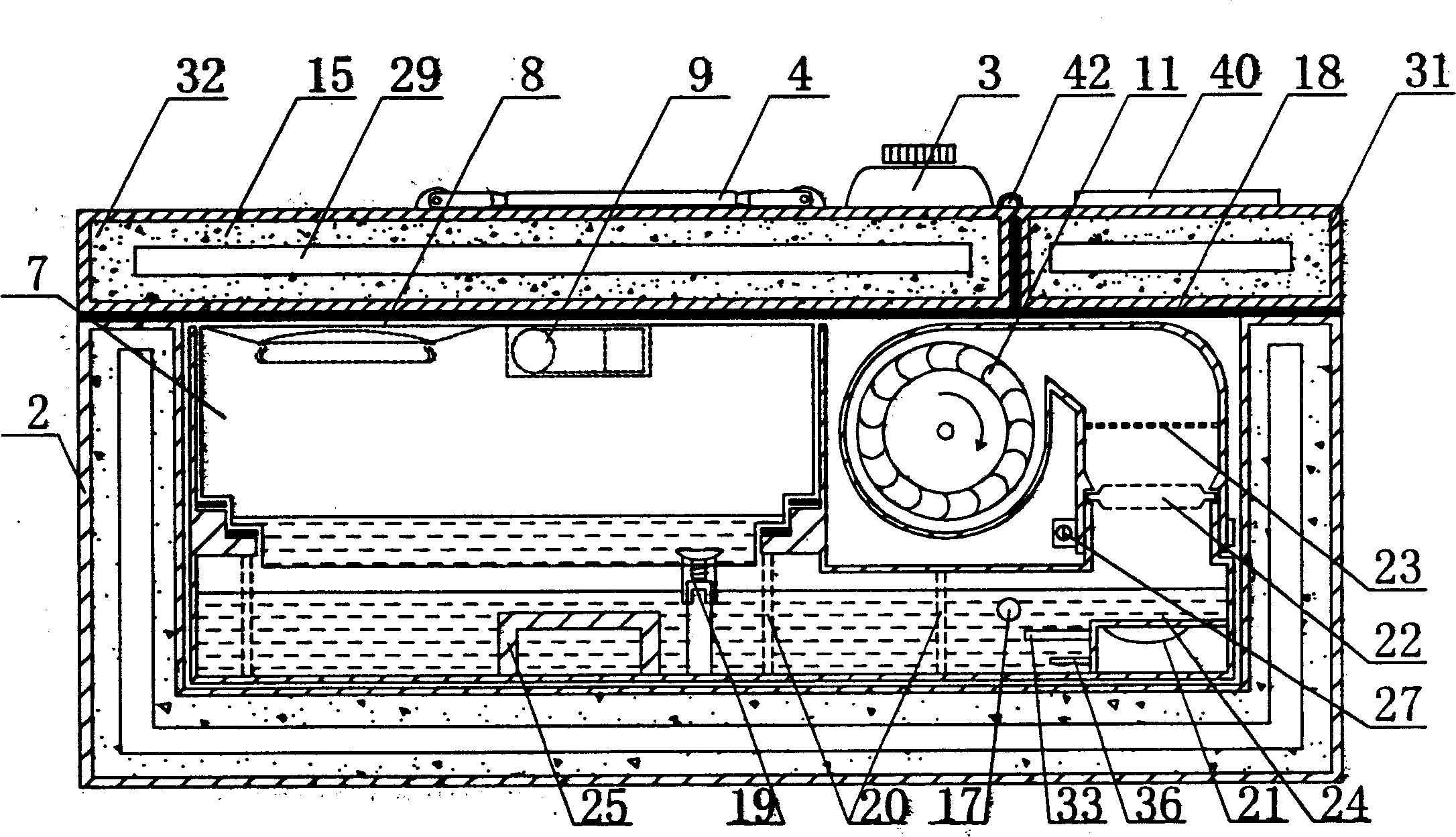

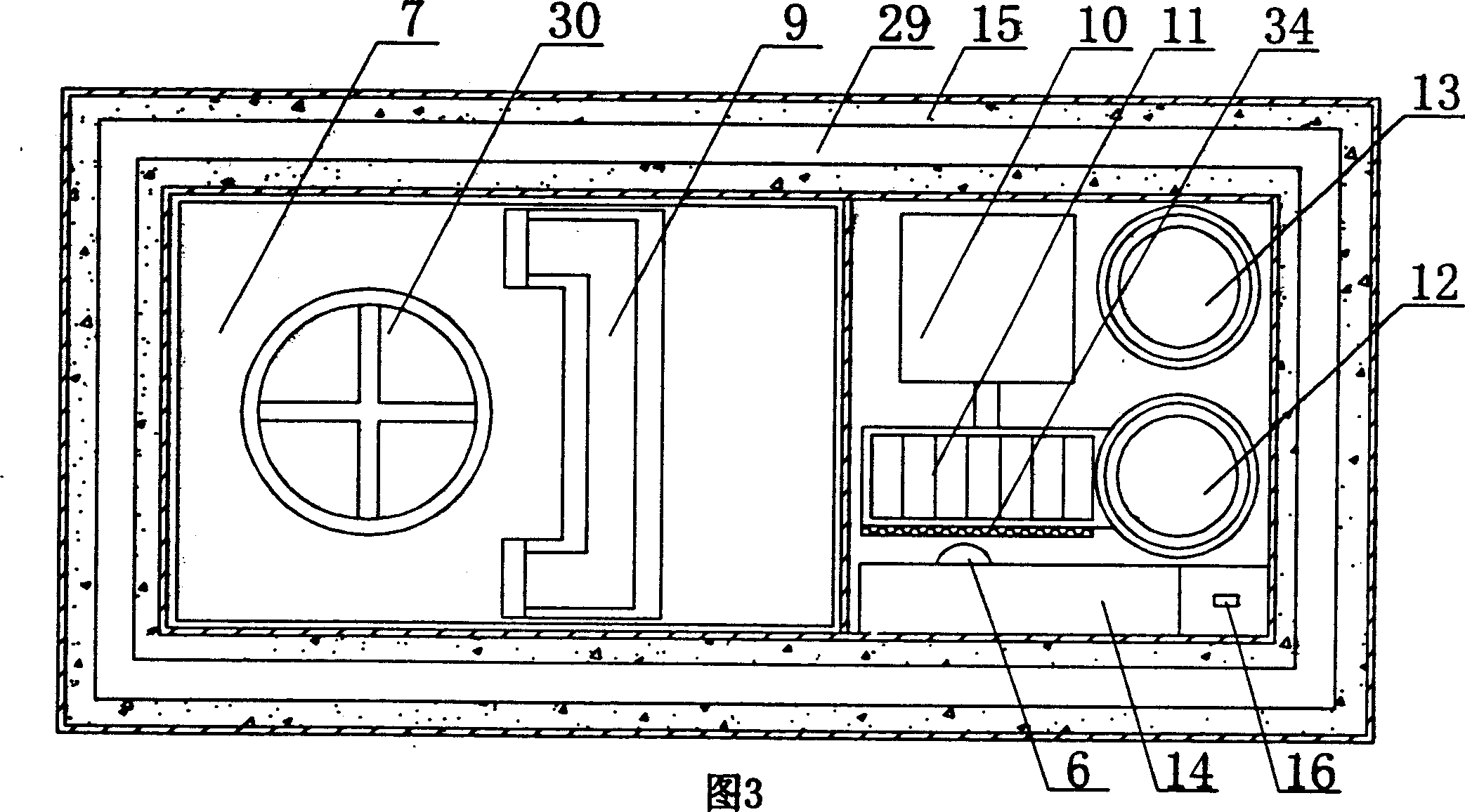

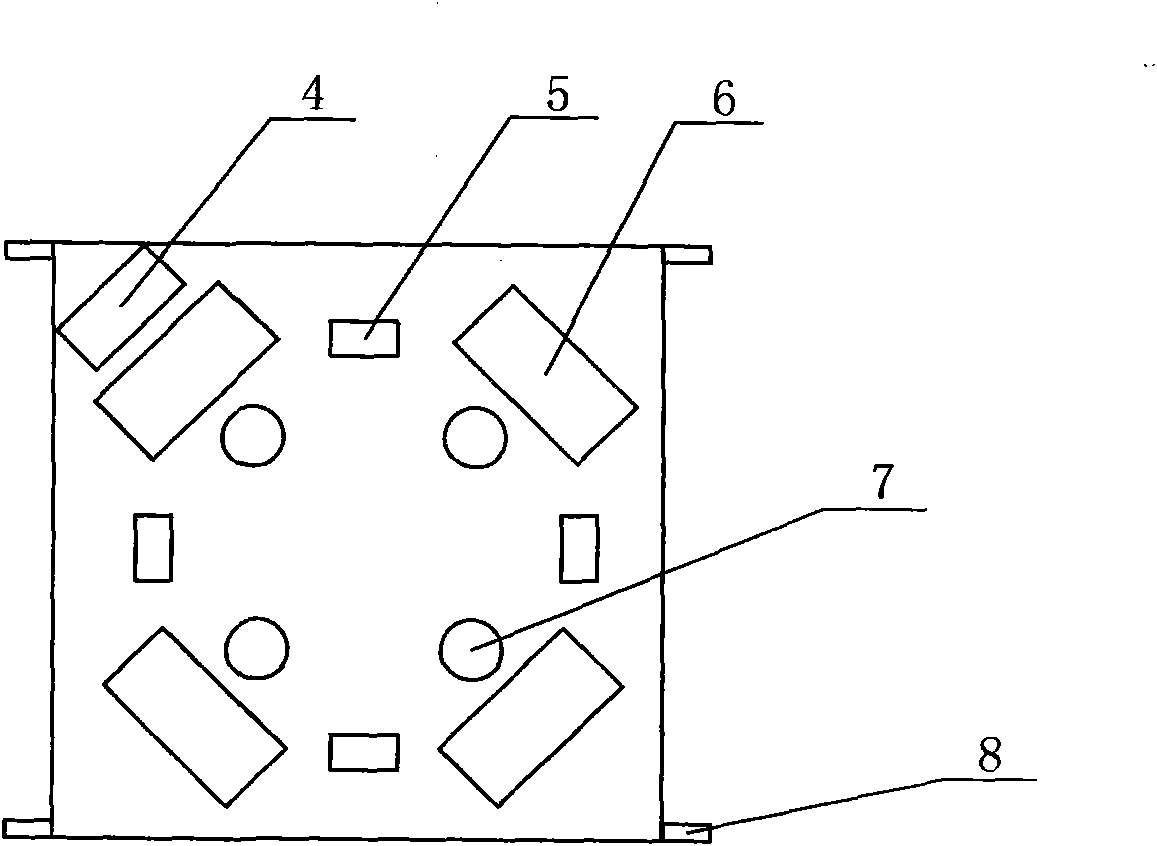

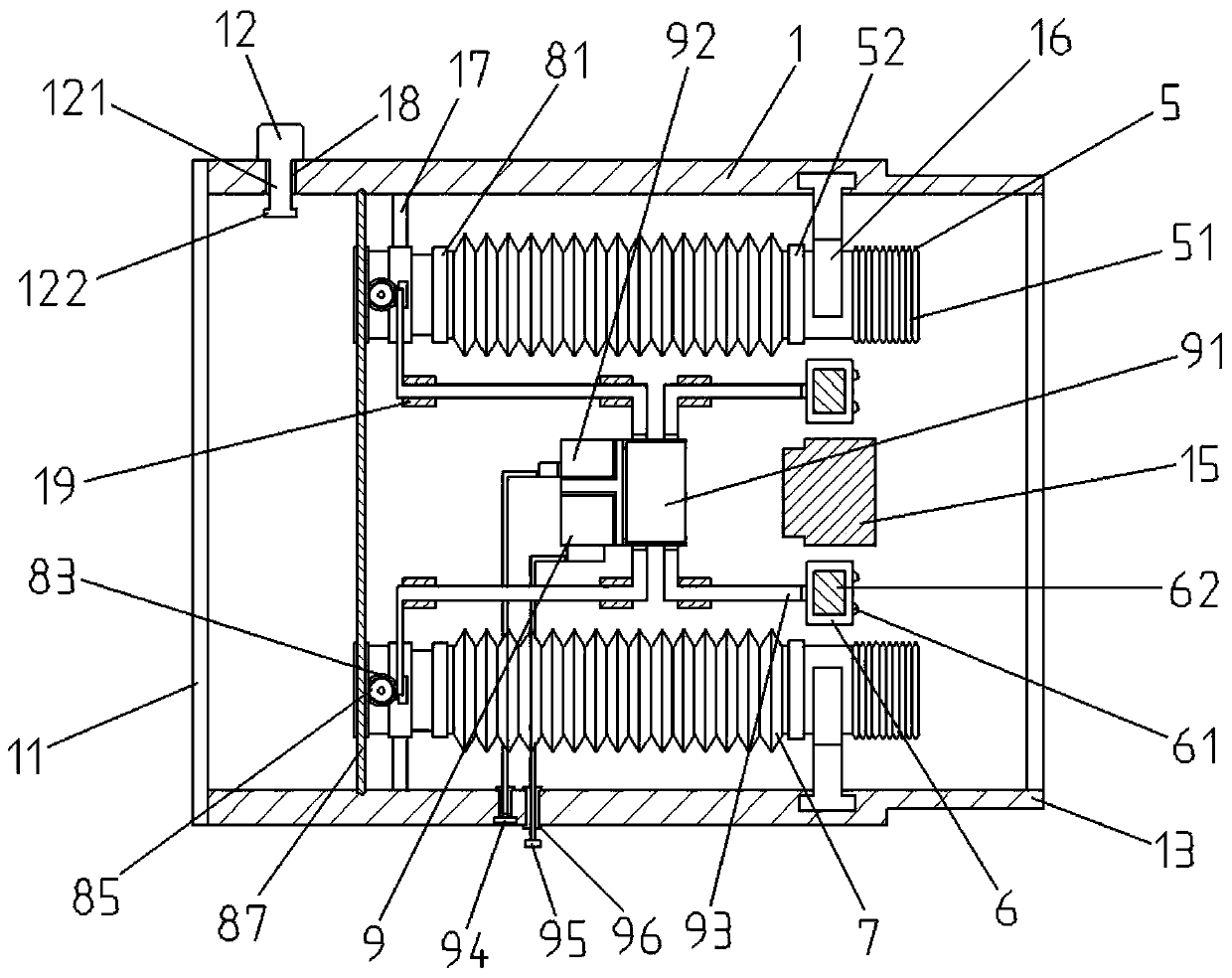

Evaporative cooling air conditioning unit provided with inertia filter and suitable for northwest districts

InactiveCN102635909AImprove filtering effectAdjustable air volumeEvaporators/condensersSpace heating and ventilation detailsEvaporative coolerEngineering

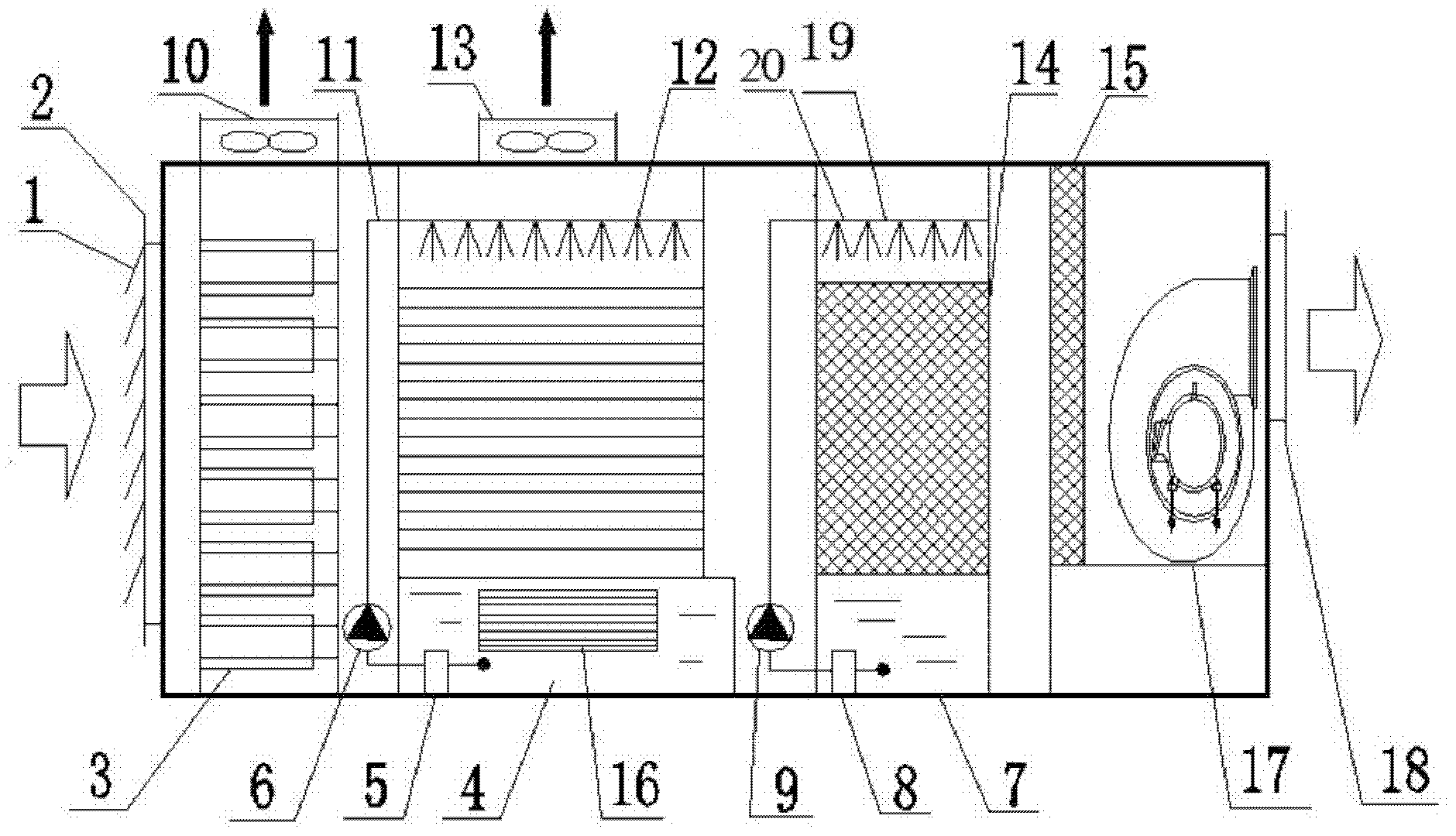

The invention discloses an evaporative cooling air conditioning unit provided with an inertia filter and suitable for northwest districts, and the evaporative cooling air conditioning unit comprises an air inlet and an air supply outlet, a shutter, an inertial filter, a tubular indirect evaporative cooler, a direct evaporative cooler, a filler b and an air supply fan, wherein the air inlet and the air supply outlet are respectively arranged on the opposite lateral walls of a unit shell; the shutter is arranged on the outer side of the air inlet; the inertial filter, the tubular indirect evaporative cooler, the direct evaporative cooler, the filler b and the air supply fan are sequentially arranged in the unit shell according to the air intake direction; the shell wall, corresponding to the upper part of the inertial filter, of the unit shell is provided with a filter air exhaust port; the wall, corresponding to the upper part of the tubular indirect evaporative cooler, of the unit shell is provided with a secondary air outlet; and the wall, corresponding to the lower part of the tubular indirect evaporative cooler, of the unit shell is provided with a secondary air return port. According to the evaporative cooling air conditioning unit provided by the invention, through the optimization design of a filtering section, a tubular indirect evaporative cooling section and a direct evaporative cooling section by utilizing an evaporative cooling technology, the purification and heat transfer and mass transfer effects of the evaporative cooler are improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

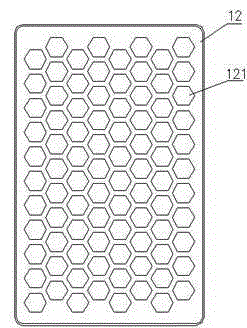

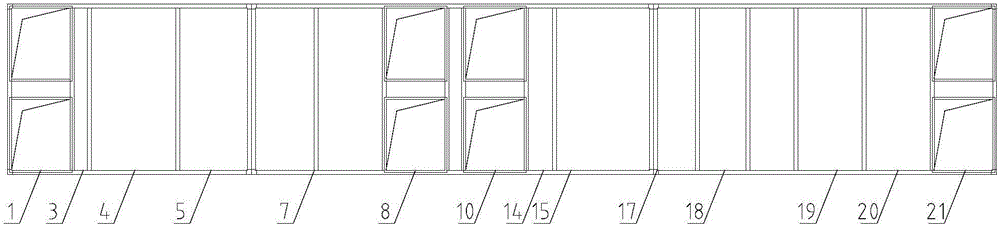

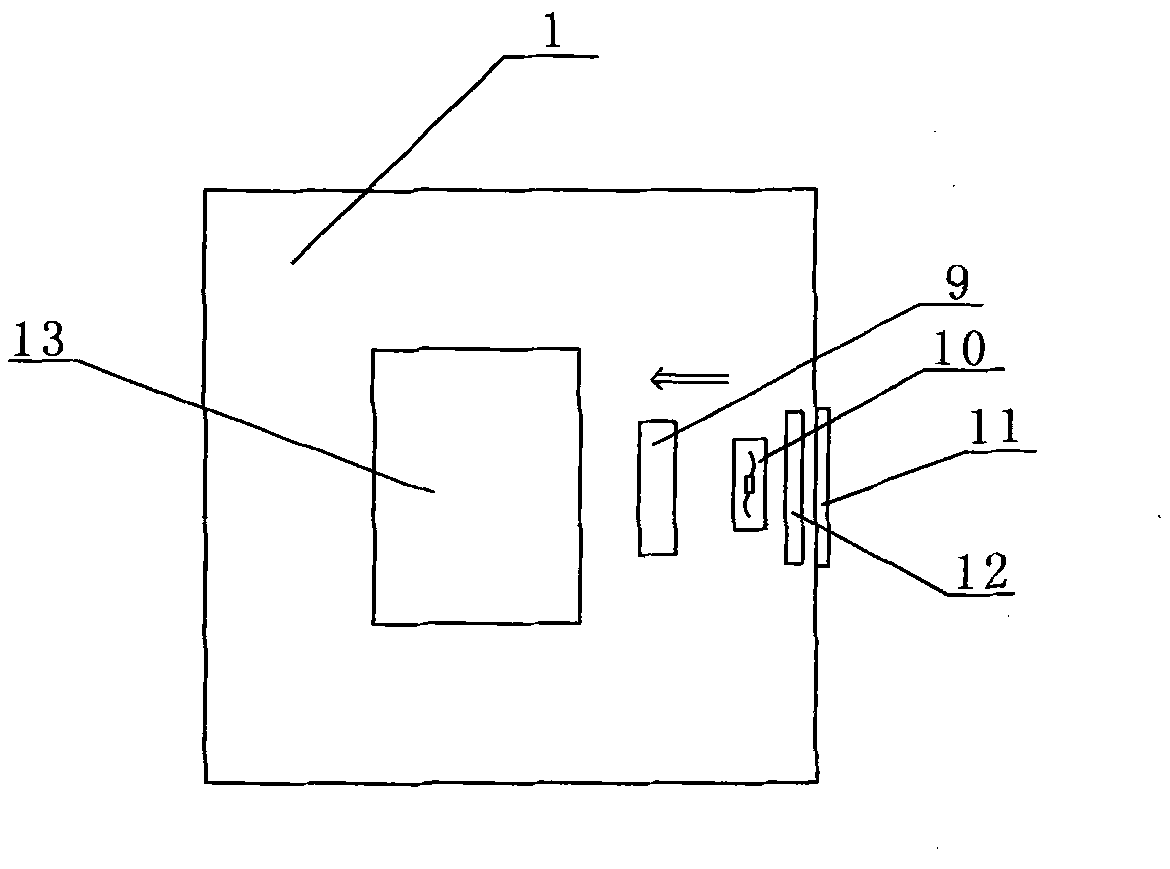

Air purifier

InactiveCN105169826AThere will be no phenomenon that is not filteredImprove filtration efficiencyDispersed particle filtrationFire rescueAir purifiersEnvironmental engineering

The invention relates to an air purifier, which comprises a purifying main body, one side of the purifying main body is provided with an air inlet, a filter and a fan are arranged sequentially along an air flow path in the purifying main body, and the entire purifying main body is covered by the filter; the purifying main body is provided with an air passage at a position corresponding to the fan; the air passage is communicated with an air outlet formed in one side of the purifying main body; a flow guide plate for air flow is arranged at one side of the fan, the flow guide plate is divided by ribs, and the ribs are in contact with the filter. The air purifier is small in size and lightweight, and therefore is convenient to carry, the air supply and filtering power is high, active air supply is adopted, breathing resistance is low, and the air purifier is comfortable.

Owner:BROAD A Q TECH

Combined oil mist purifying unit of air conditioner

InactiveCN105698297ARealize cooling and dehumidificationRealize isohumidity heatingEnergy recovery in ventilation and heatingMechanical apparatusExhaust valveAir volume

The invention discloses a combined oil mist purifying unit of an air conditioner. The combined oil mist purifying unit comprises an air return filtering part and a fresh air conveying part, wherein the oil return filtering part is used for performing suction filtering on air in a workshop and filtering oil mist particles and comprises an air return section, an oil mist filtering section, a peculiar smell purifying section, an air return fan section and an exhaust regulating section which communicate in sequence; the fresh air conveying part is used for feeding clean fresh air into the workshop and regulating the temperature of the air, and comprises a fresh air regulating section, an air filtering section, a temperature adjusting section, an air feeder section and an air feeding section which communicate in sequence; the exhaust regulating section and the fresh air regulating section communicate by an air mixing valve; and an exhaust valve and a fresh air valve are jointly arranged on a thermal recovery section. According to the combined oil mist purifying unit disclosed by the invention, by organically combining oil mist purification and the air conditioner, exhausting and thermal recovery can be realized; in addition, no cross contamination exists in the fresh air and the exhausted air; and the temperature and the air volume can be adjusted according to the technological requirements. The combined oil mist purifying unit has the functions of utilizing waste heat of the unit and purifying waste gases, and has the advantages of safety, reliability, reduction of pollution, convenience in technological operation and high degree of automation.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

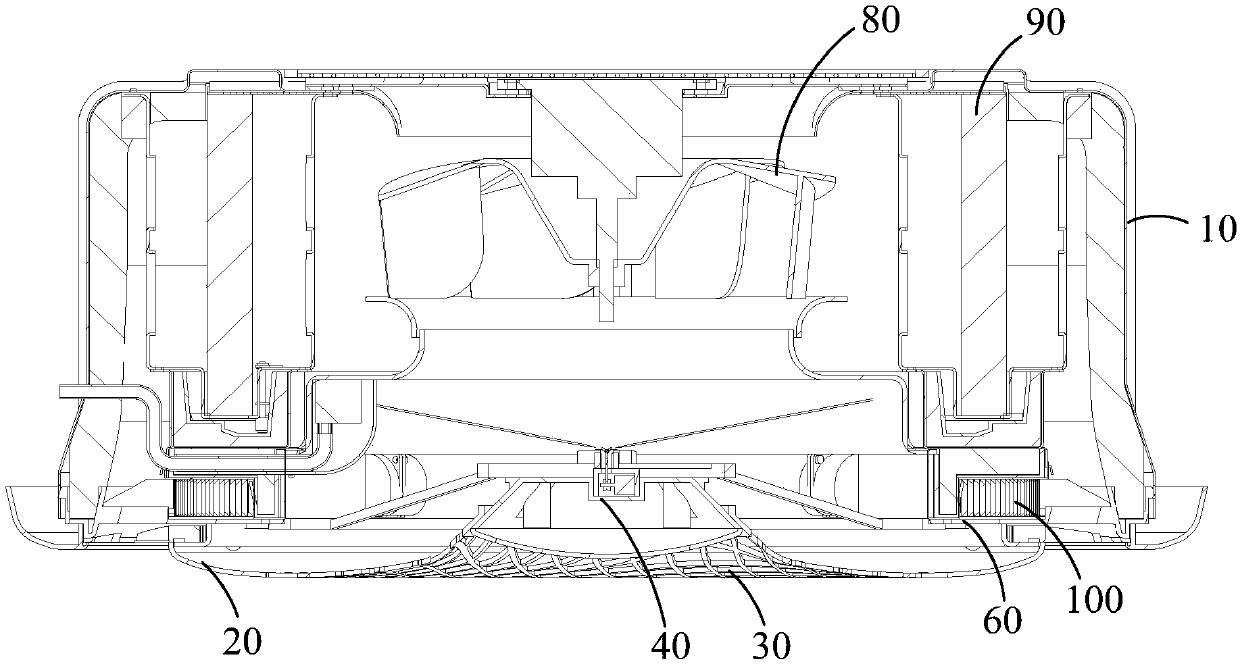

Ceiling-mounted air conditioner

PendingCN107366978AReduce air volumeIncrease air volumeLighting and heating apparatusAir conditioning systemsAir volumeEngineering

The invention discloses a ceiling-mounted air conditioner. The ceiling-mounted air conditioner comprises a shell, a flexible air guide ring, and drivers; the shell comprises a panel assembly, and the panel assembly is provided with an air inlet with a downward opening and an air outlet annually arranged around the air inlet; the flexible air guide ring is annularly arranged, and the flexible air guide ring is slidably mounted on the panel assembly so as to be expanded or contracted along a radial direction to adjust the opening degree of the air outlet; and the drivers are mounted on the shell, and are connected to the flexible air guide ring to drive the flexible air guide ring to be expanded or contracted along the radial direction. The ceiling-mounted air conditioner disclosed by the invention can realize the adjustability of the air volume of the ceiling-mounted air conditioner.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Central air conditioner fresh air handling unit structure and operating method thereof

ActiveCN104676780AHigh precisionLow powerMechanical apparatusSpace heating and ventilation safety systemsUnit structureEvaporator

The invention discloses a central air conditioner fresh air handling unit structure and an operating method thereof. An air conveying device is connected with an expansion machine, the expansion machine is connected with a mixer, the mixer is connected with a heater, the air is inputted to an evaporator after being compressed by an air compressor, and mainstream air is cooled in the evaporator; the low-temperature mainstream air is dried by virtue of a dryer; the low-temperature mainstream air passing by the dryer enters the expansion machine to be expanded and re-cooled, and then the cooled mainstream air can be mixed with secondary stream air which is supplied by a secondary air supply unit in the mixer. The fresh air machine is pollution-free, the fresh air does not contact returned air of an indoor exhaust system, so that the indoor returned air pollution can be avoided; the energy is saved, and the energy consumption is reduced; the exhaust air rate of the fresh air machine is multiplied compared with that of the air compressor, the equipment scale of the fresh air machine is reduced, the exhaust air rate, the humidity content and the exhaust air temperature of the fresh air machine are adjustable, and the user application system equipment is simplified; the electric heater rapidly responds to the cold-heat load variation of a target user.

Owner:殷洪生

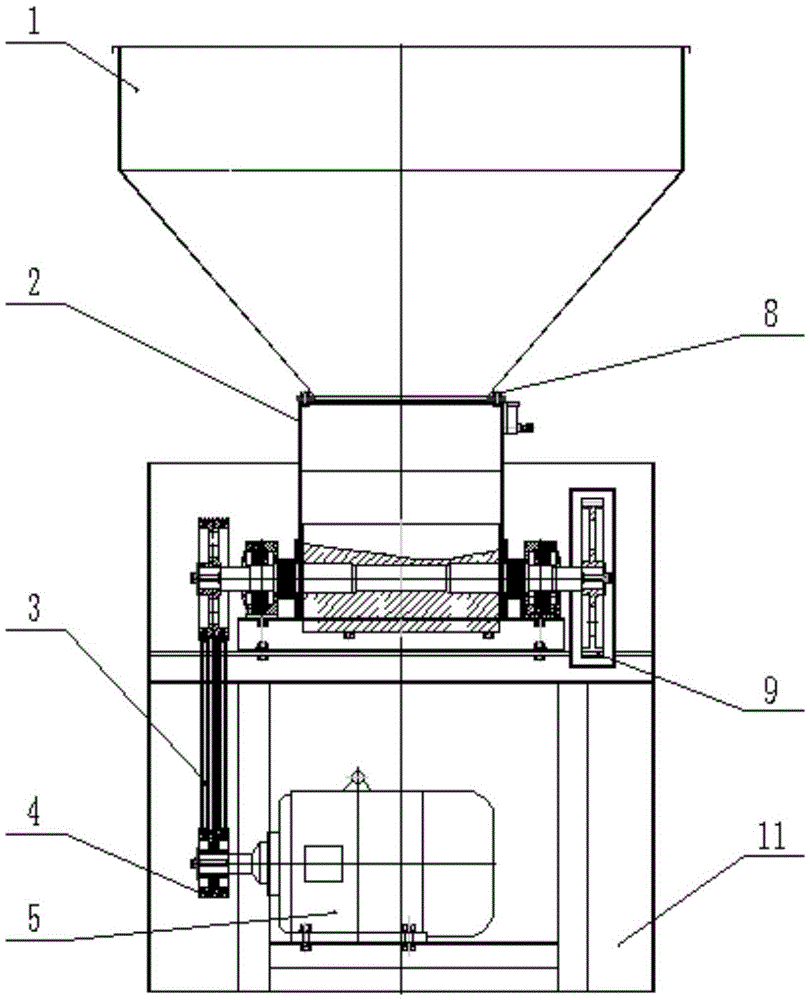

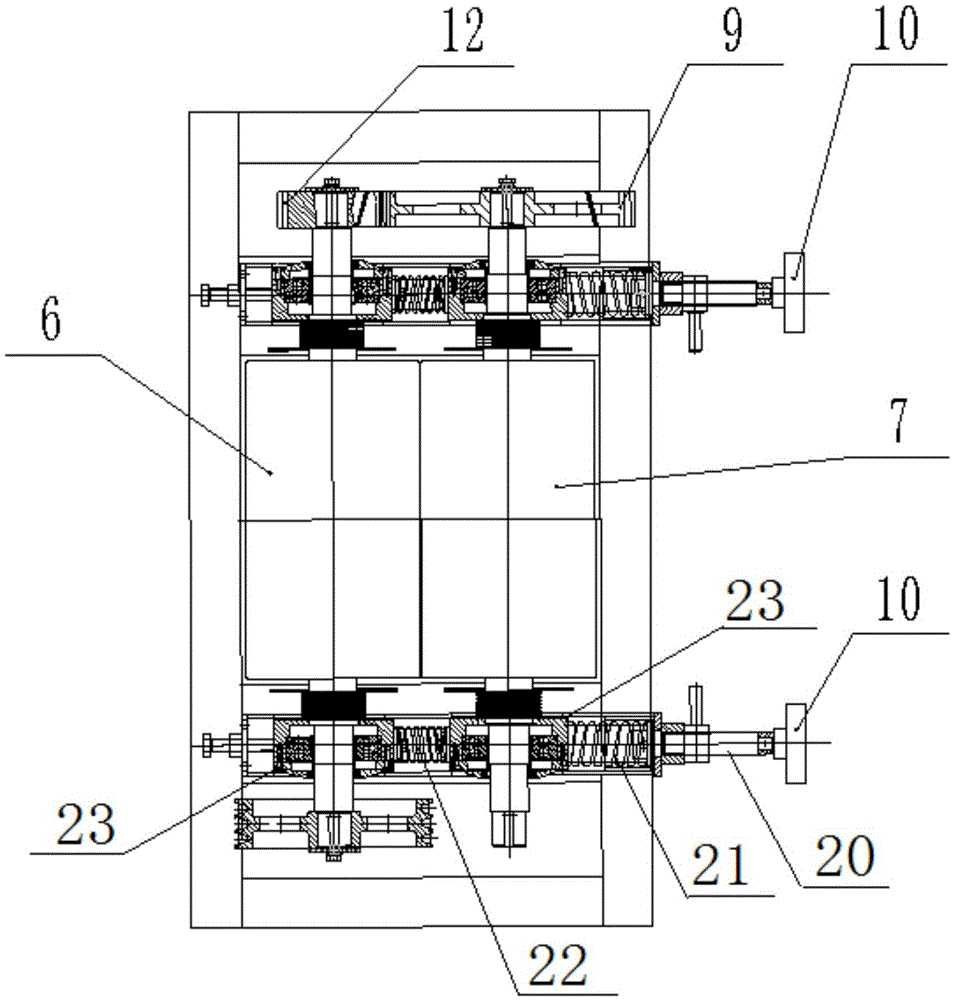

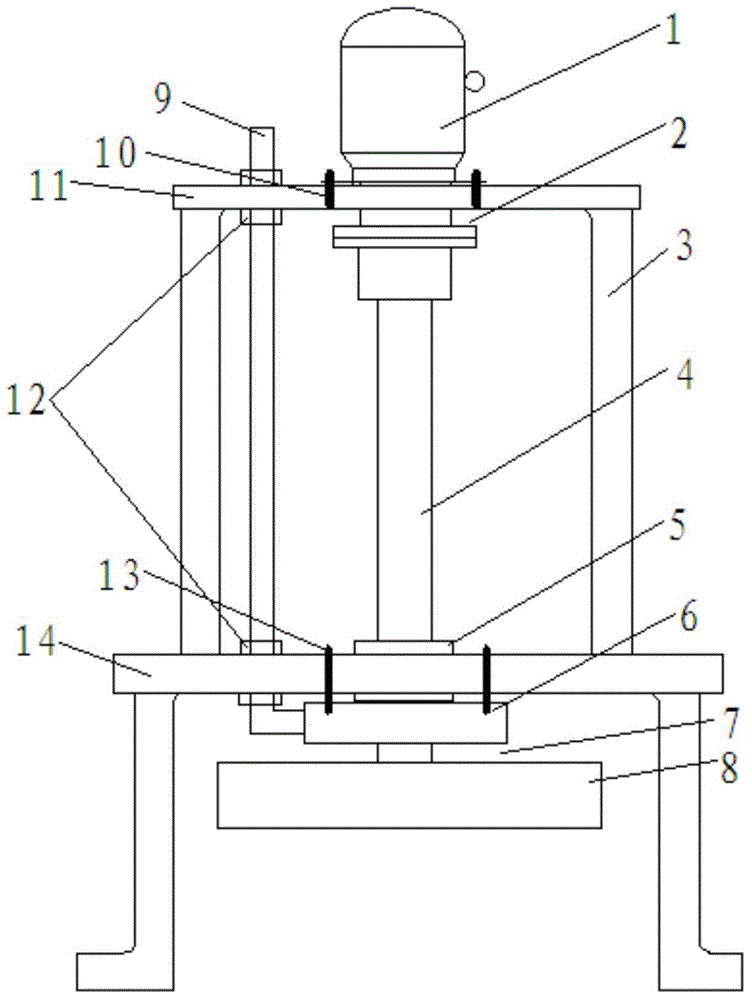

Dense-medium dry separation equipment

ActiveCN102974543AImprove stabilityMaintain stabilityGas current separationFluidized bedProcess engineering

The invention discloses a dense-medium dry separation equipment, which comprises a fluidized bed, a tank body, a material guiding and propelling device, an air distribution device, a scraper conveying device and a material taking and screening device, wherein the fluidized bed is used for separating materials; the tank body is used for providing a space and installation equipment for forming of the fluidized bed; the material guiding and propelling device is used for guiding the materials into the fluidized bed along the side end of the fluidized bed to be loosened and layered and propelling the materials to move forwards; according to the air distribution device, compressed air passes through an air distribution plate to acquire pressure difference and is then conveyed into the fluidized bed to be sufficiently, evenly and stably fluidized, and clean coal, middings coal and gangue are separated in an optimal manner; the scraper conveying device is a large-scale scraper conveying device for the dry separation equipment, an anti-deformation measure is adopted by scrapers in order to prevent wider scraper components from deforming, and the separated gangue and middings coal are discharged from the scrapers; and after the materials pass through the separating fluidized bed, the clean coal is taken out from the material taking and screening device at the fluidized bed side, and dense media are screened out and return to the fluidized bed in the material taking process. The dense-medium dry separation equipment disclosed by the invention can overcome the defect of incapability of fluidizing and separating caused by blockage of an air outlet.

Owner:孙刚 +3

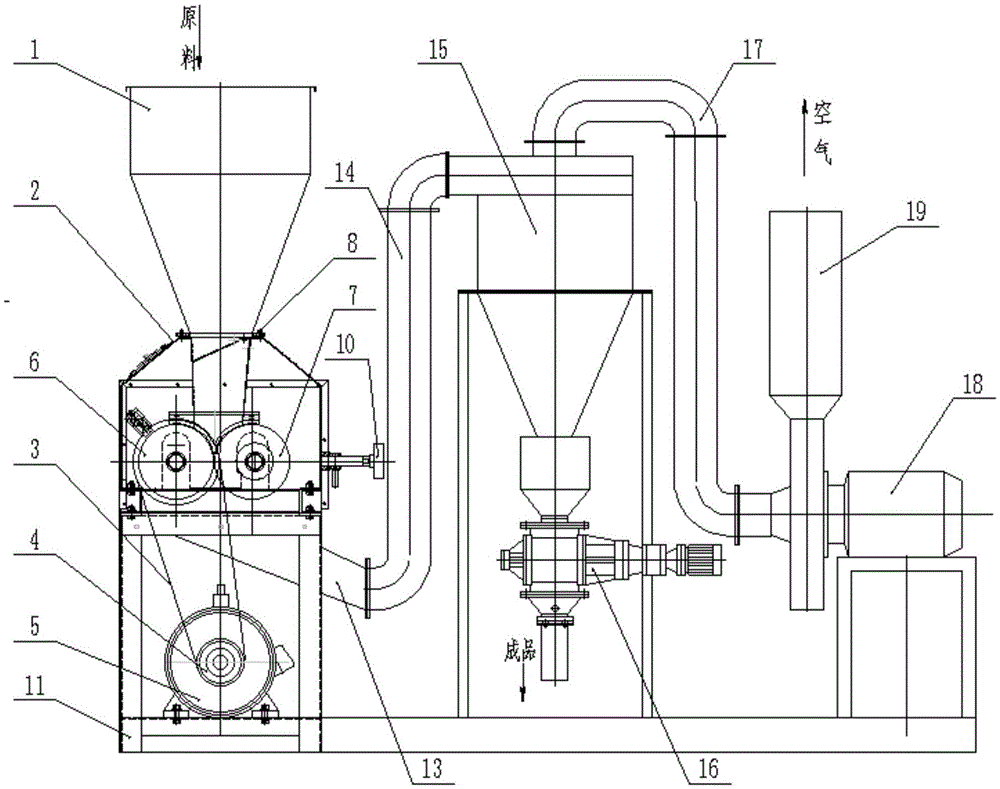

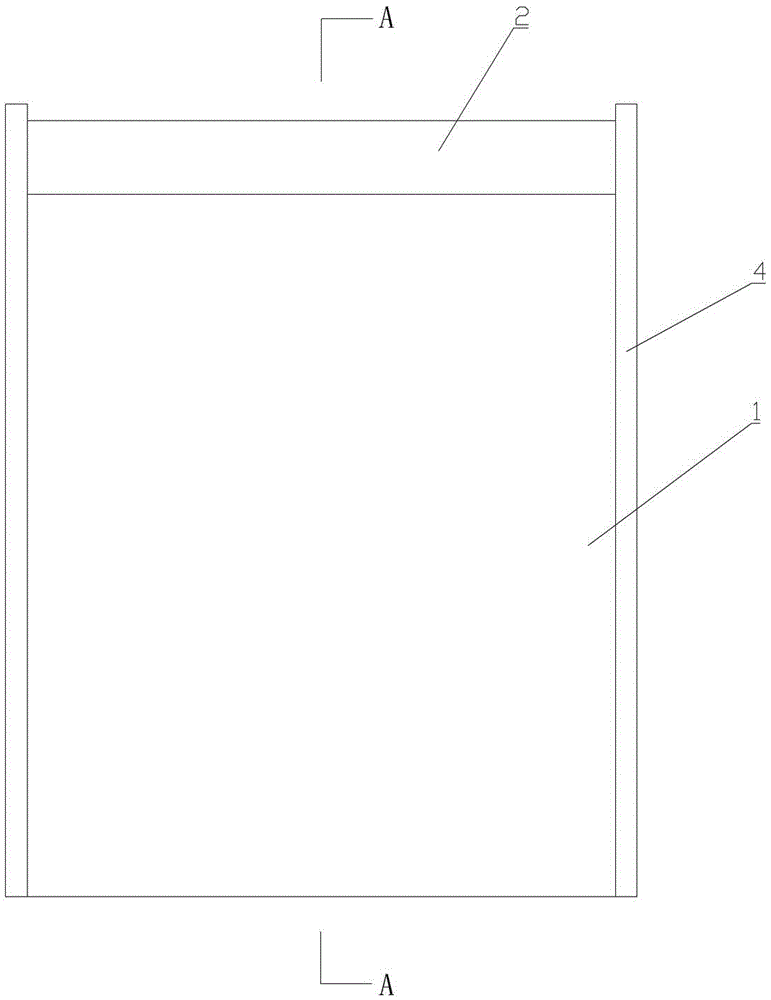

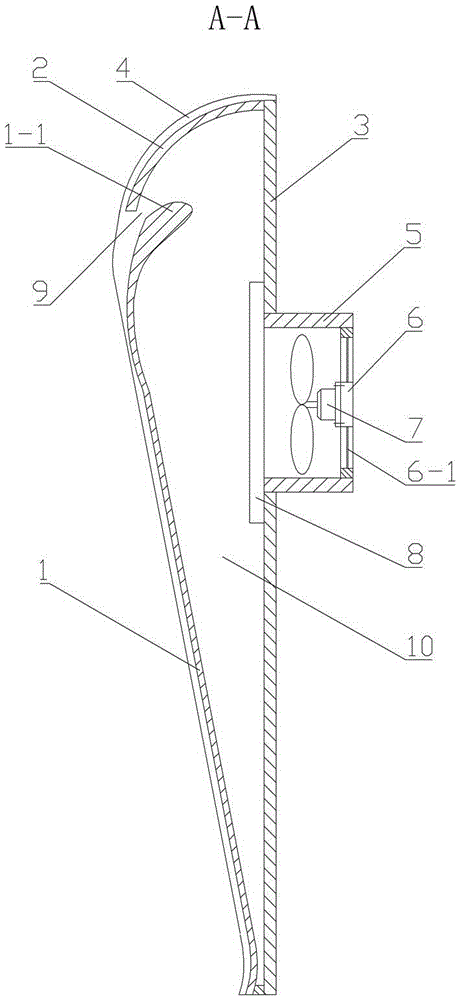

Roll pulverizer with dust suction function

InactiveCN105562186AAdjustable air volumeWon't overflowReversed direction vortexGrain treatmentsEngineeringMechanical engineering

The invention discloses a roll pulverizer with a dust suction function. The roll pulverizer comprises a rack. A smashing chamber is fixed to the rack, and an opening in the top of the smashing chamber is matched with a feeding hopper. The smashing chamber communicates with a collecting device through a collecting pipeline, the top of the collecting device is connected with one end of an air outlet pipeline, and the other end of the air outlet pipeline is connected with an induced draft fan. A driving roll and a driven roll which are different in rotating speed and opposite in rotating direction are mounted in the smashing chamber, materials are smashed between the driving roll and the driven roll, and finished products and dust are collected through the collecting device through the action of the induced draft fan. Material smashing and finished product collecting are connected together through a pipeline, the whole process from material smashing to finished product collecting is sealed, and no dust overflows. Power is provided by the induced draft fan for finished product collecting, the dust generated in the smashing process is collected by a cyclone collector and discharged out of the roll pulverizer together with the finished products, and clean air is exhausted out of an exhaust opening of the induced draft fan.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Indoor air ventilation device based on Coanda Effect

InactiveCN105352101AMeet fresh air requirementsAdjustable air volumeLighting and heating apparatusNoise suppressionEngineeringIndoor air

The invention discloses an indoor air ventilation device based on the Coanda Effect. The indoor air ventilation device comprises a Coanda airfoil-shaped panel, an arc-shaped shield plate, a bottom plate, side plates, an air inlet barrel, an annular frame and a variable frequency fan, wherein the Coanda airfoil-shaped panel, the arc-shaped shield plate and the side plates are arranged on the bottom plate; the arc-shaped shield plate is arranged on the upper end, on which a flow guidance head provided with a smooth curve surface is arranged, of the Coanda airfoil-shaped panel; the two side plates are separately arranged on the two sides of the Coanda airfoil-shaped panel and the arc-shaped shield plate; an air inlet cavity is formed by the Coanda airfoil-shaped panel, the arc-shaped shield plate, the side plates and the bottom plate; a strip-shaped air outlet is formed between the arc-shaped flow guidance head of the Coanda airfoil-shaped panel and the arc-shaped shield plate; the air inlet barrel is arranged on the bottom plate, and is communicated with the air inlet cavity; the assembly height of the air inlet barrel is lower than that of the strip-shaped air outlet, so that noise which is generated when air flow flows out of the air inlet cavity is reduced; the annular frame is arranged in a barrel hole at one end of the air inlet barrel; and the variable frequency fan is arranged in the barrel hole of the air inlet barrel, and is fixed on the annular frame through screws.

Owner:NANHUA UNIV

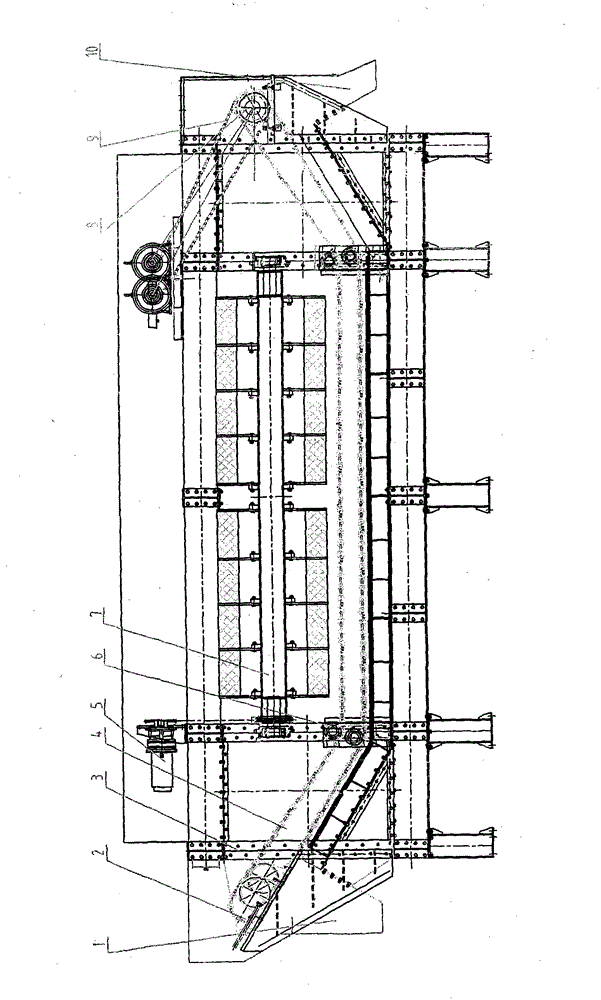

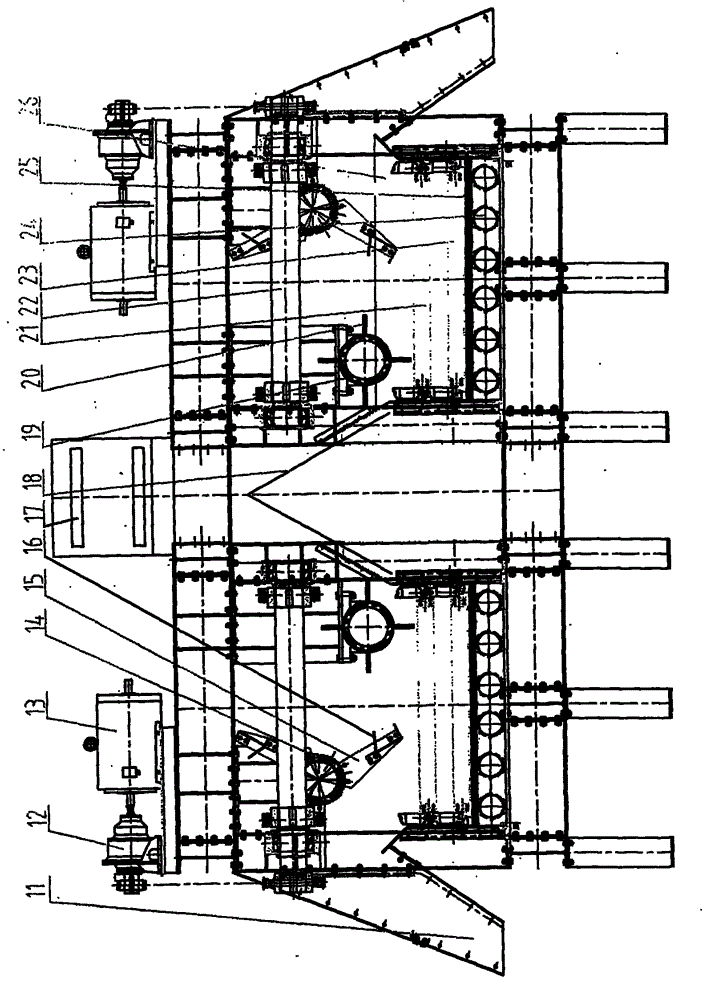

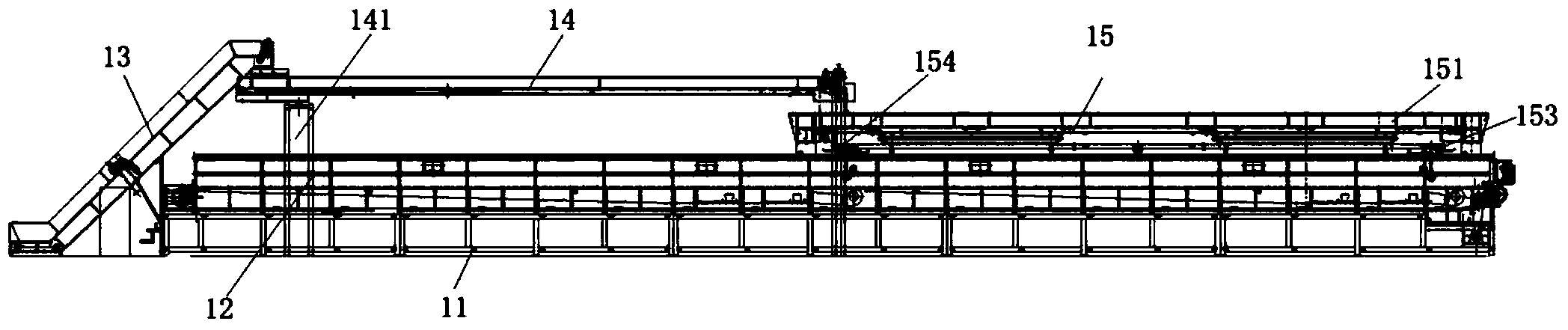

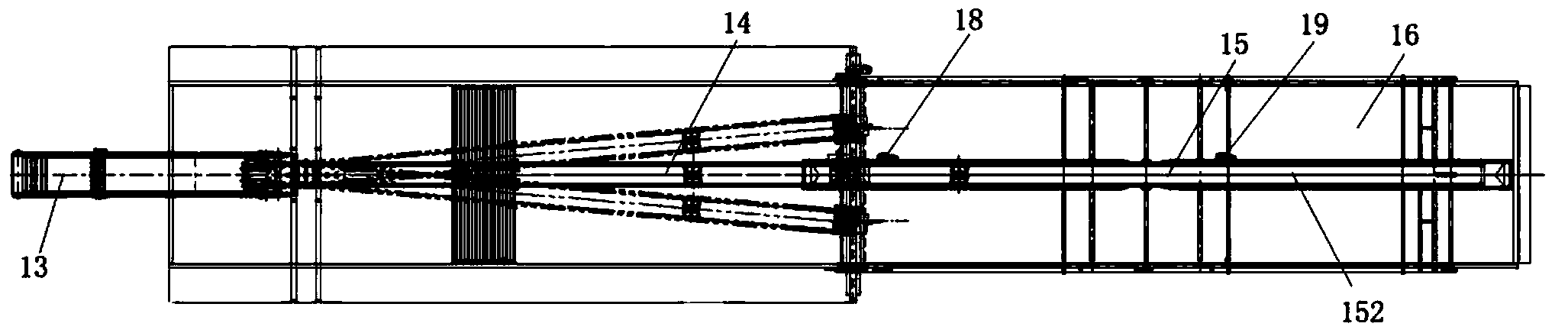

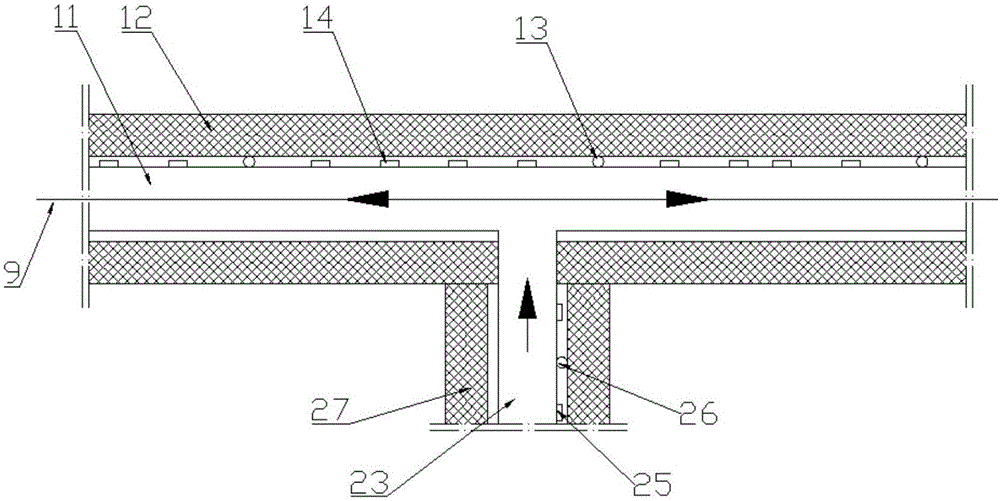

Band-type roasting machine cooling and hot wind returning system and band-type roasting machine cooling and hot wind returning method

PendingCN107120963AImprove cooling effectLow calorific valueFurnace typesFurnace coolingWind systemProcess engineering

The invention relates to a band-type roasting machine cooling and hot wind returning system and a band-type roasting machine cooling and hot wind returning method. The band-type roasting machine cooling and returning hot wind system comprises a forced air drying section, a down-draft drying section, a preheating section, a roasting section and a cooling section. The band-type roasting machine cooling and returning hot wind system is characterized in that the cooling section is divided into three cooling sections, a cooling fan is arranged at the lower part of a cooling section 1, a shared fan is arranged at the lower parts of a cooling section 2 and a cooling section 3; a hot waste air induced wind cover I is arranged at the upper part position of the cooling section 1, the hot waste air produced from the three cooling section is correspondingly connected to a sintering section, the preheating section and the forced air drying section correspondingly through three induced wind covers, a hot wind returning pipeline and a branch pipeline group. The band-type roasting machine cooling and hot wind returning system and the band-type roasting machine cooling and hot wind returning method have the advantages that the blast capacity and the wind temperature of each section are adjustable, the hot wind returning system is recycled and utilized efficiently, the flexible and convenient operation is achieved, and the thermal regulation in the roasting machine is more reasonable.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Vibration air separation device

PendingCN109454001AAvoid flyingAvoid enteringSievingGas current separationLeft directionPositive pressure

The invention relates to a vibration air separation device. The vibration air separation device comprises a material inlet, a powdery particle separation segment and a light and heavy material layering segment, materials enter the powdery particle separation segment from the material inlet, small particles are discharged from a powdery particle outlet after vibration screening, large particles enter the light and heavy material layering segment which is in stepped arrangement, light materials are made to be located at the upper portion of a material layer through falling head and positive pressure airflow, then a separation stage is performed, under guiding of the positive pressure airflow and negative pressure airflow, the light materials move towards the upper left direction, this moment, an adsorbing roller will generate strong negative pressure airflow to make the light materials be adsorbed on the adsorbing roller and rotate towards a light material outlet along with the adsorbingroller, when the light materials move to an air blocking ring, the negative pressure airflow disappears, the light materials fall down and are discharged from the light material outlet, because heavymaterials are large in bulk density and less affected by the airflow, the heavy materials fall directly to be discharged from a heavy material outlet, so that separation of the powdery particles, thelight materials and the heavy materials is achieved.

Owner:HENAN WINNER VIBRATING EQUIP

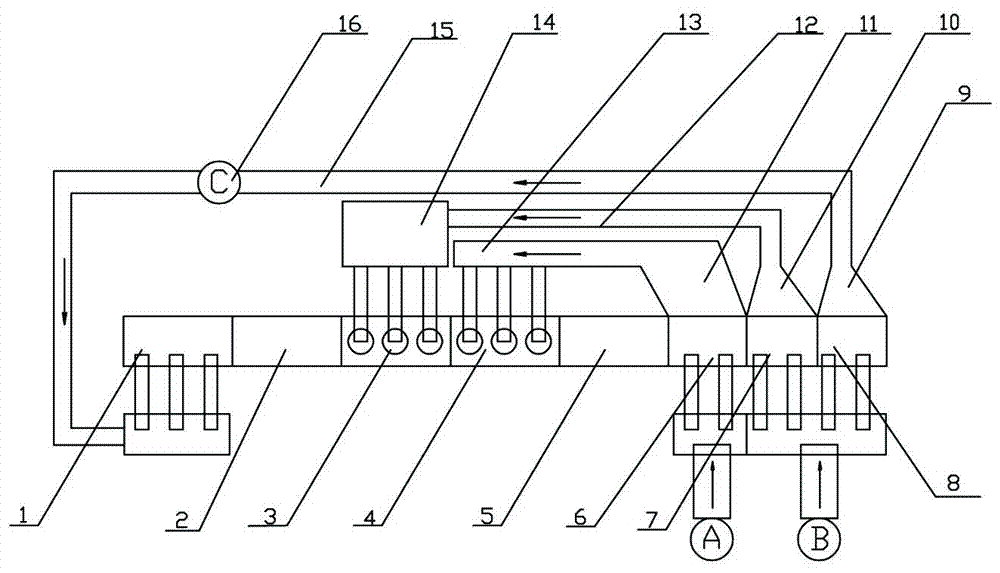

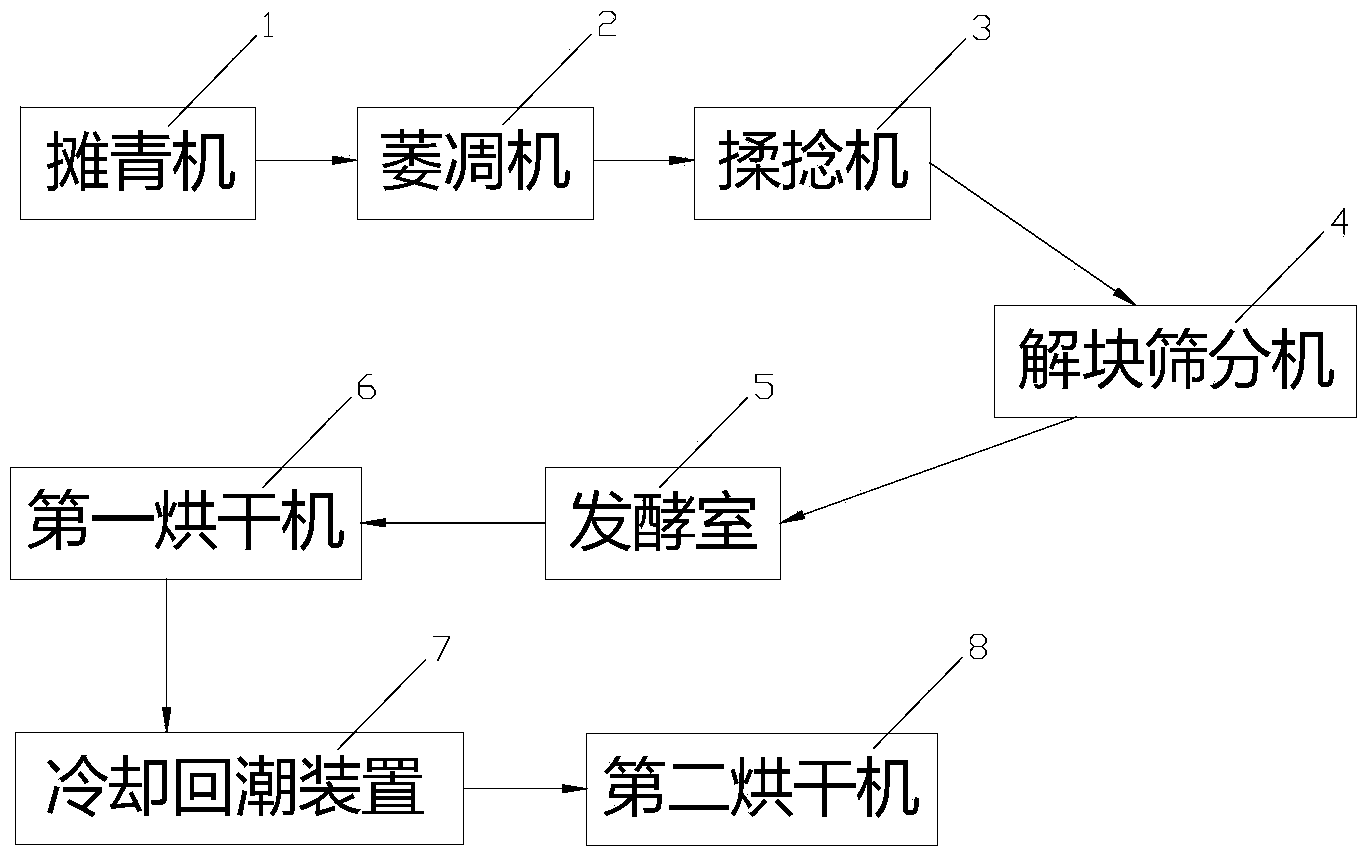

Automatic black tea primary manufacturing system

ActiveCN104304527AEasy to control temperatureControllable leaf thicknessPre-extraction tea treatmentAutomatic controlAir volume

The invention discloses an automatic black tea primary manufacturing system. The system comprises a tedding machine, a withering machine, a twisting machine, a deblocking screening machine, a fermentation chamber, a first drying machine and a second drying machine, which are connected with one another in sequence; a cooling and dampening device is also arranged between the first drying machine and the second drying machine. The system further comprises an automatic control unit used for controlling temperature, humidity and air volume of the manufacturing system. The automatic black tea primary manufacturing system disclosed by the invention is invented according to the traditional Congou black tea making requirements as well as performance and characteristics of modern tea making machinery; in the withering procedure, the temperature is controllable, the air volume is adjustable, the time is controllable and the spreading thickness is adjustable; in the twisting procedure, tea leaves are automatically fed, electronically weighed, automatically put, automatically twisted and automatically discharged; in the fermenting procedure, the temperature is controllable, the humidity is detected, the time is automatically controlled and the spreading thickness is adjustable; the whole manufacturing system has the production characteristics of continuity, automation and cleanness; the manufacturing capacity can reach 500 kg / h.

Owner:谢裕大茶叶股份有限公司

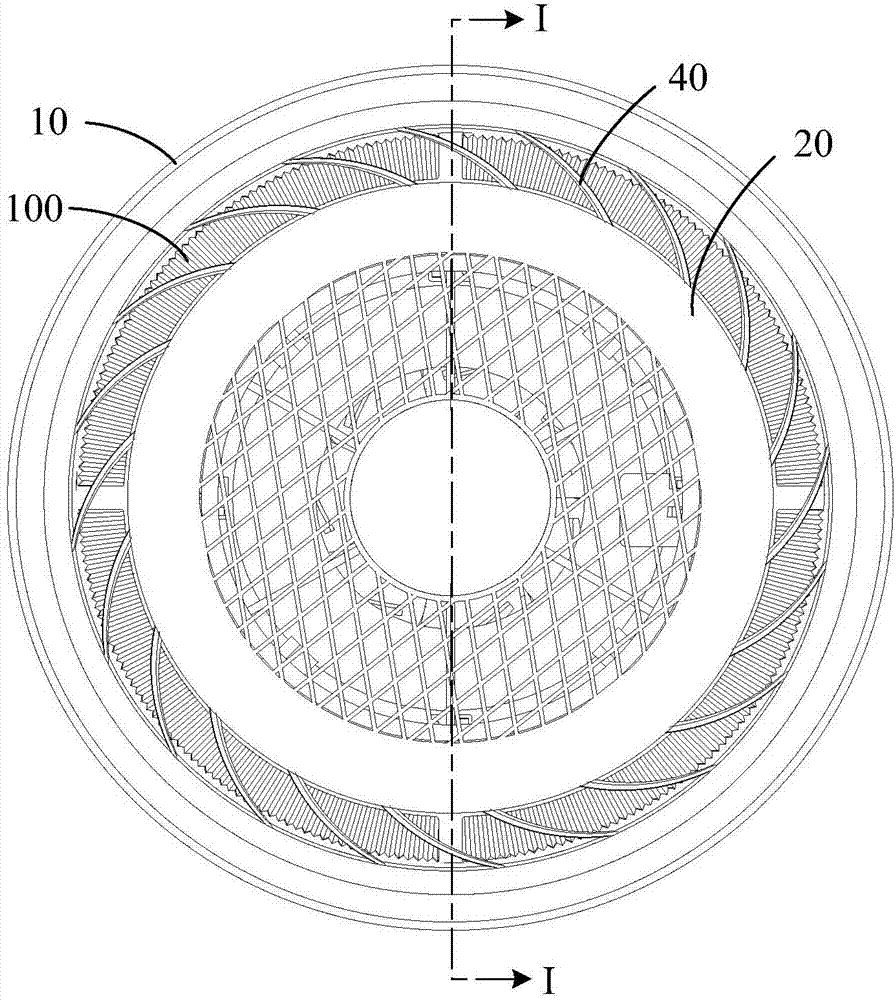

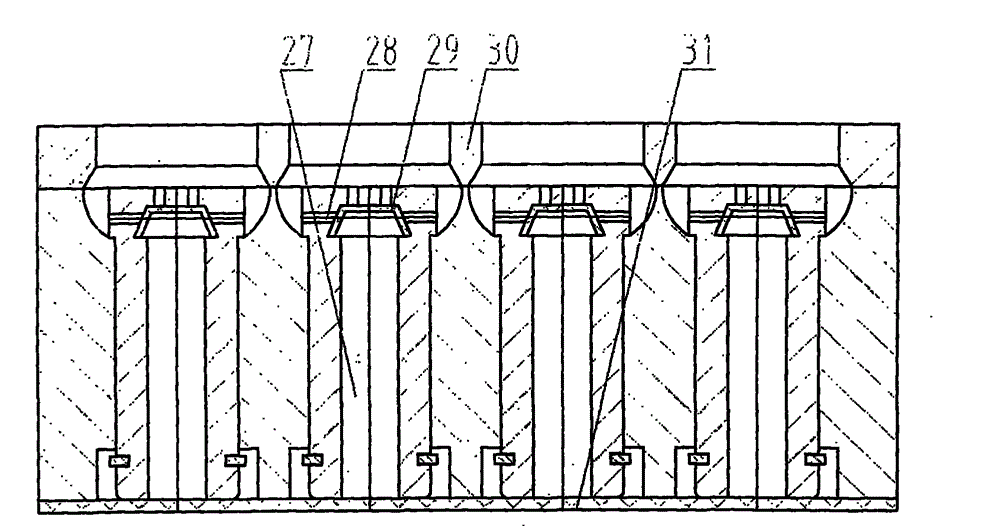

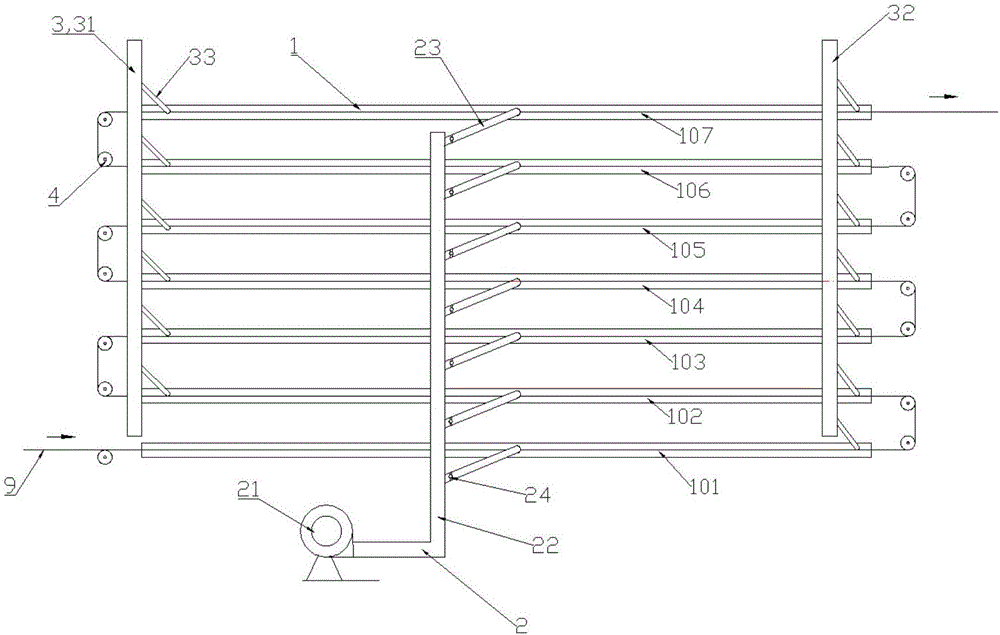

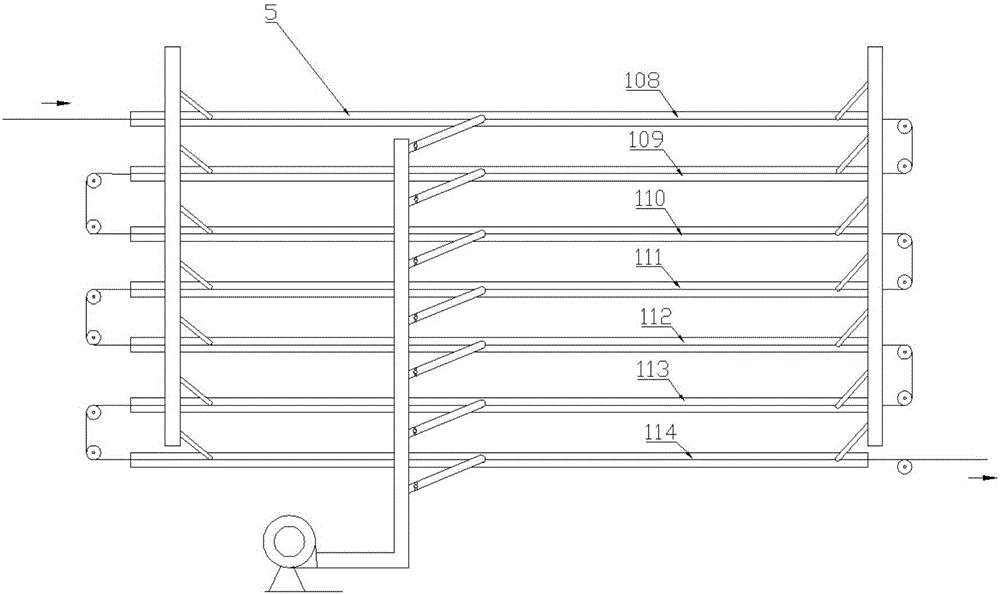

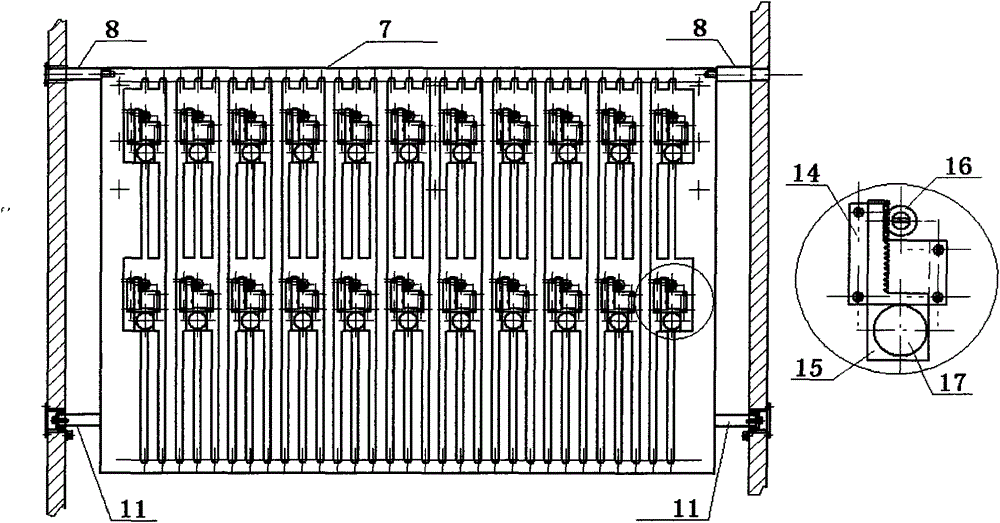

Pre-oxidation device for carbon fiber production

ActiveCN106480553AReasonable temperature zoneReasonable temperatureFibre chemical featuresFiberTemperature control

The invention discloses a pre-oxidation device for carbon fiber production and belongs to the technical field of carbon fiber production and processing. The pre-oxidation device comprises a pre-oxidation furnace, an air supply system, an exhaust system, driving devices and a temperature detection control system; the pre-oxidation furnace is serially composed of a first pre-oxidation furnace body and a second pre-oxidation furnace body, each of the first pre-oxidation furnace body and the second pre-oxidation furnace body is provided with a plurality of hearths arrayed up and down in parallel, temperature of the hearths in the first pre-oxidation furnace body is gradually increased from bottom to top, and temperature in the second pre-oxidation furnace body 5 is gradually increased from top to bottom; the air supply system and the exhaust system are connected with the hearths of the first pre-oxidation furnace body and the second pre-oxidation furnace body through pipelines, and the driving devices are mounted at two ends of the hearths. The pre-oxidation device has the advantages of reasonable distribution of temperature regions and temperature gradient, temperature uniformity of a heating system and the like, the temperature in the hearths can be precisely controlled to be gradually varied within 100DEG C and 300DEG C, and temperature control precision is ensured not to be lower than + / -0.5DEG C.

Owner:HARBIN TIANSHUN CHEM TECH DEV CO LTD

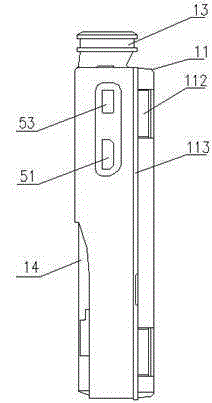

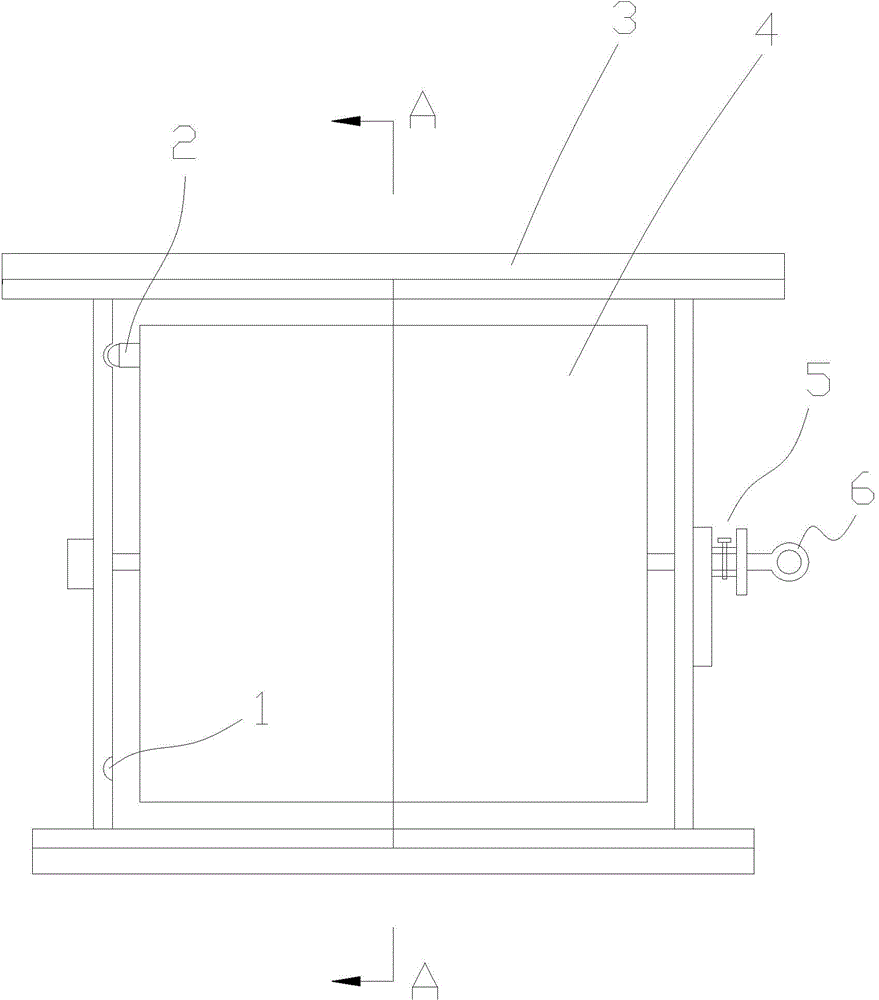

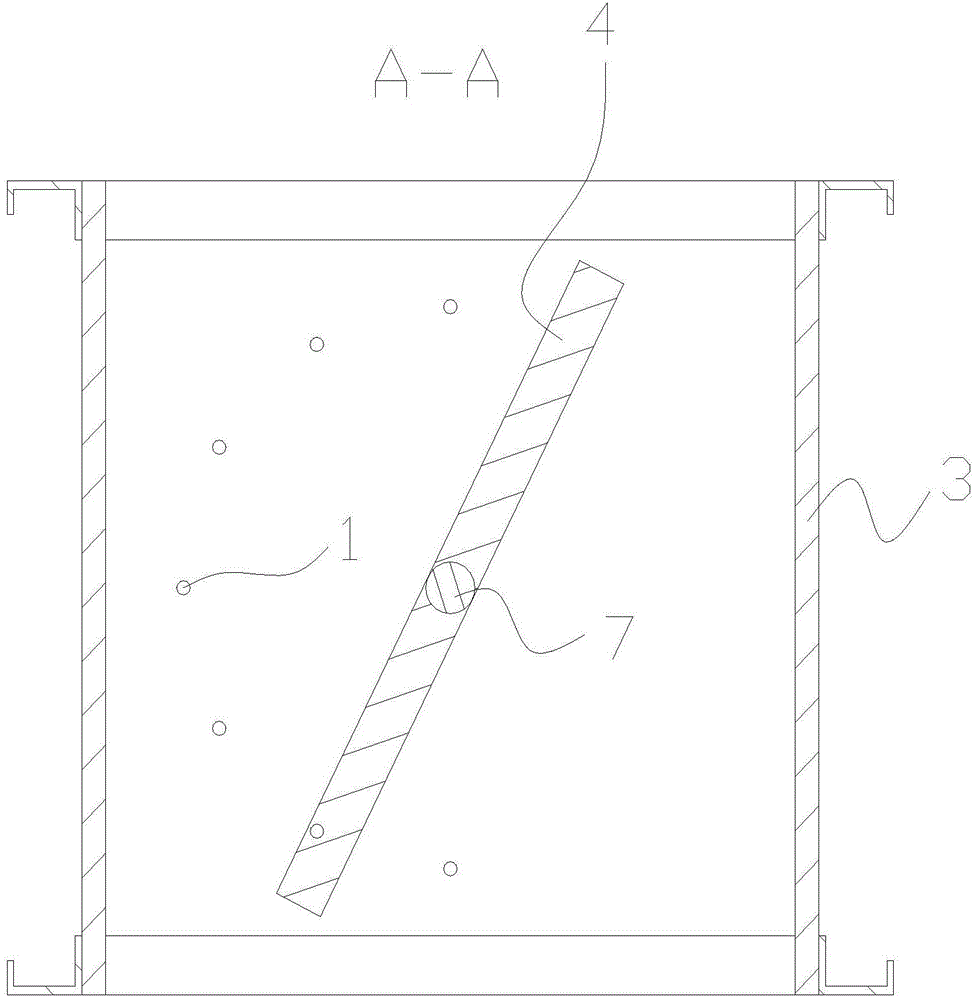

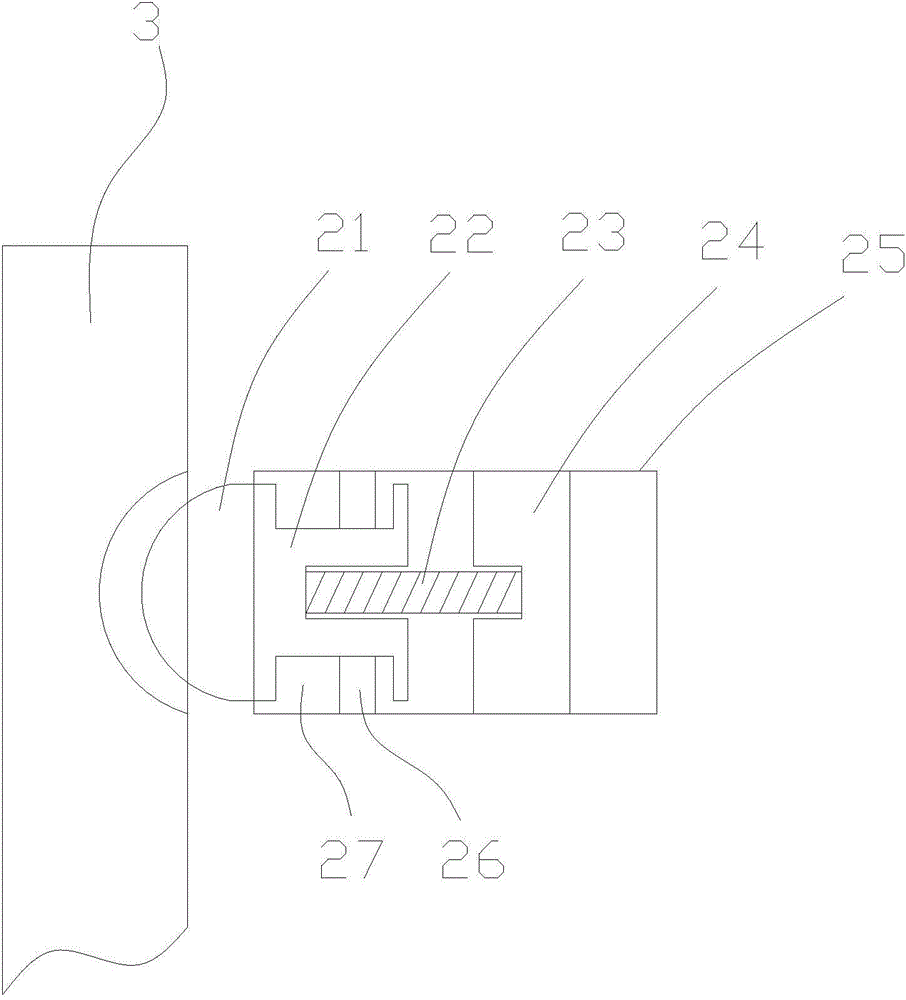

Hot-blast stove heat supply regulator locking device

The invention provides a hot-blast stove heat supply regulator locking device, and relates to the technical field of hot-blast stoves. The hot-blast stove heat supply regulator locking device comprises a segment of rectangular air channel which is internally provided with an air shielding plate. The two sides of the air shielding plate are installed on the side wall of the rectangular air channel via rotating shafts. The rotating shaft of one side of the air shielding plate penetrates through the side wall of the rectangular air channel to be connected with a revolving handle. The internal side of the revolving handle is provided with a locking device. One side wall provided with the rotating shaft is provided with multiple positioning grooves which are evenly distributed on the semicircular tracks with the rotating shaft acting as the center. The side surface of the air shielding plate is provided with elastic limiting devices matched with the positioning grooves. Quantity of hot-blast air can be regulated. Hot-blast air regulation possesses multiple gears. Each gear is accurately positioned by the positioning grooves. The air shielding plate can be accurately regulated. After the air shielding plate is well regulated, the air shielding plate can be locked by the locking device so that rotation of the air shielding plate caused by the effect of air flow can be avoided.

Owner:怀远县巨龙机械制造有限公司

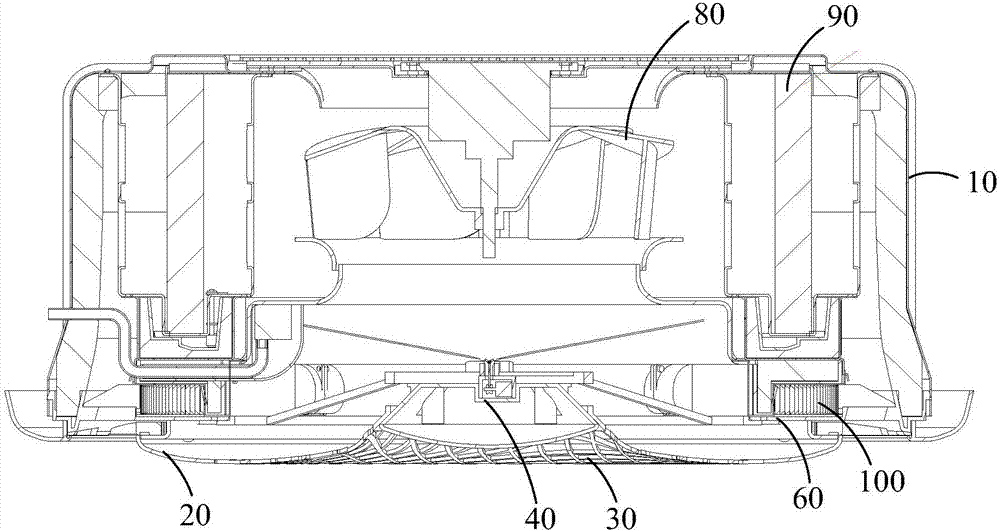

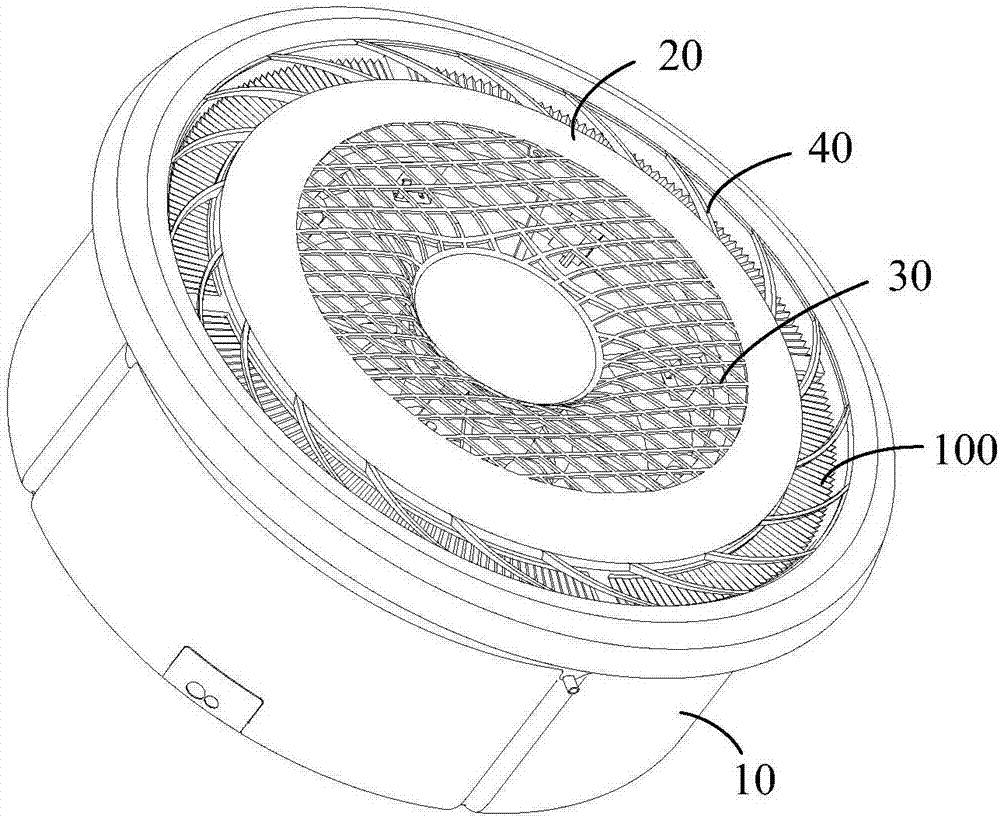

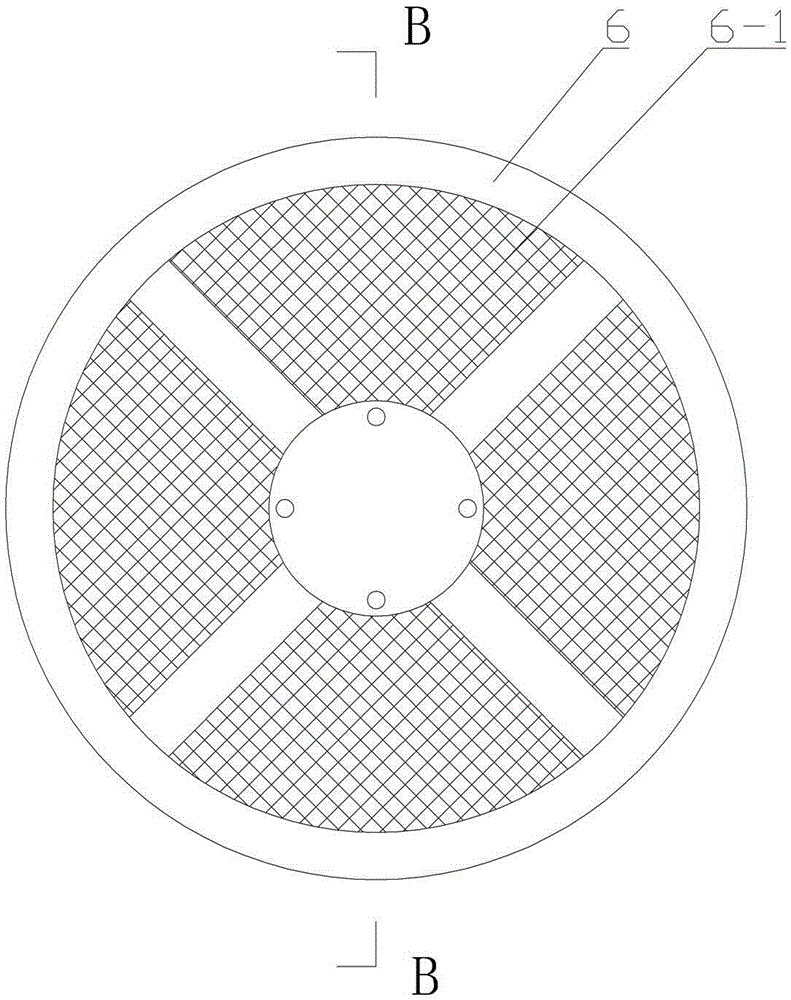

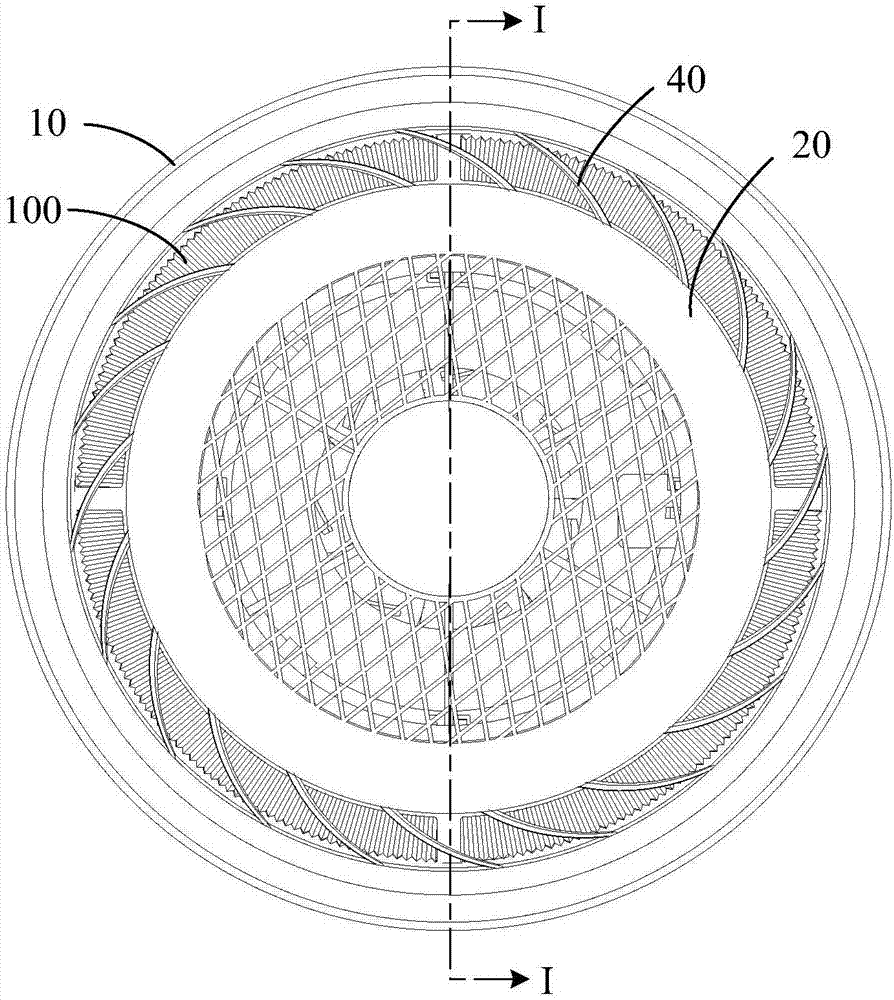

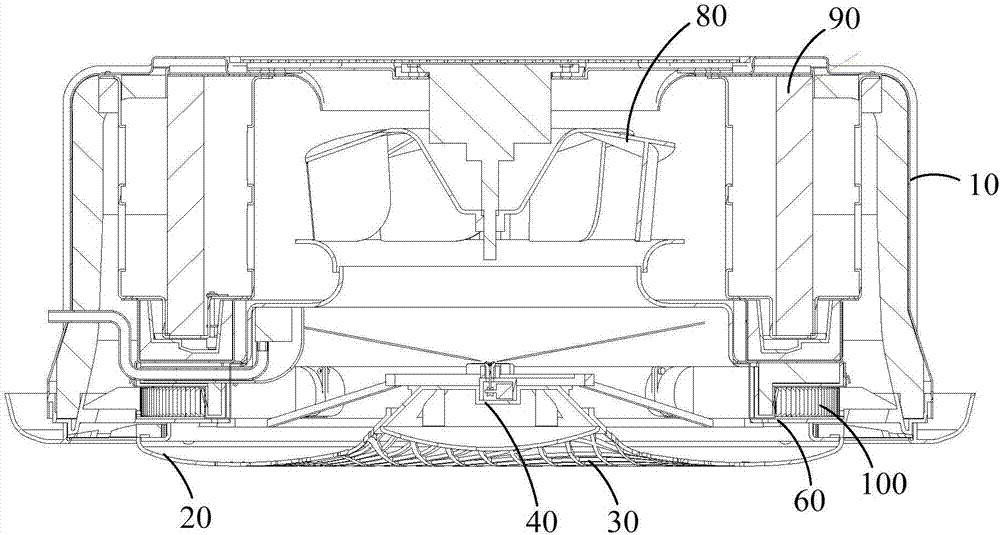

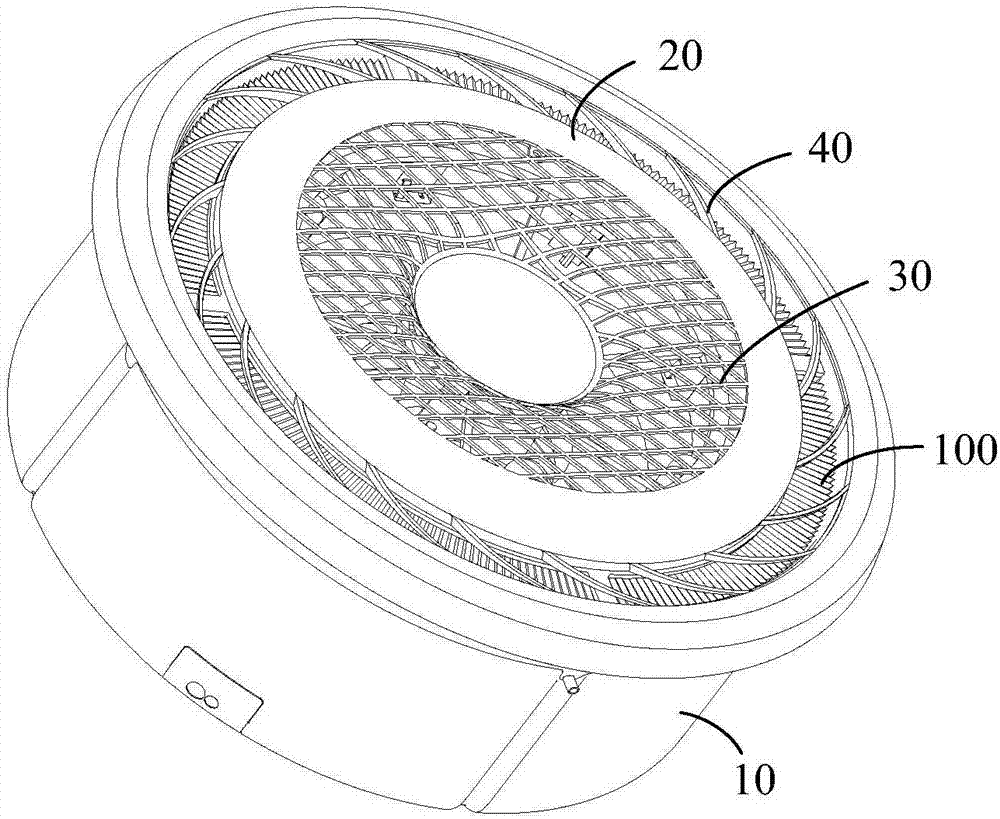

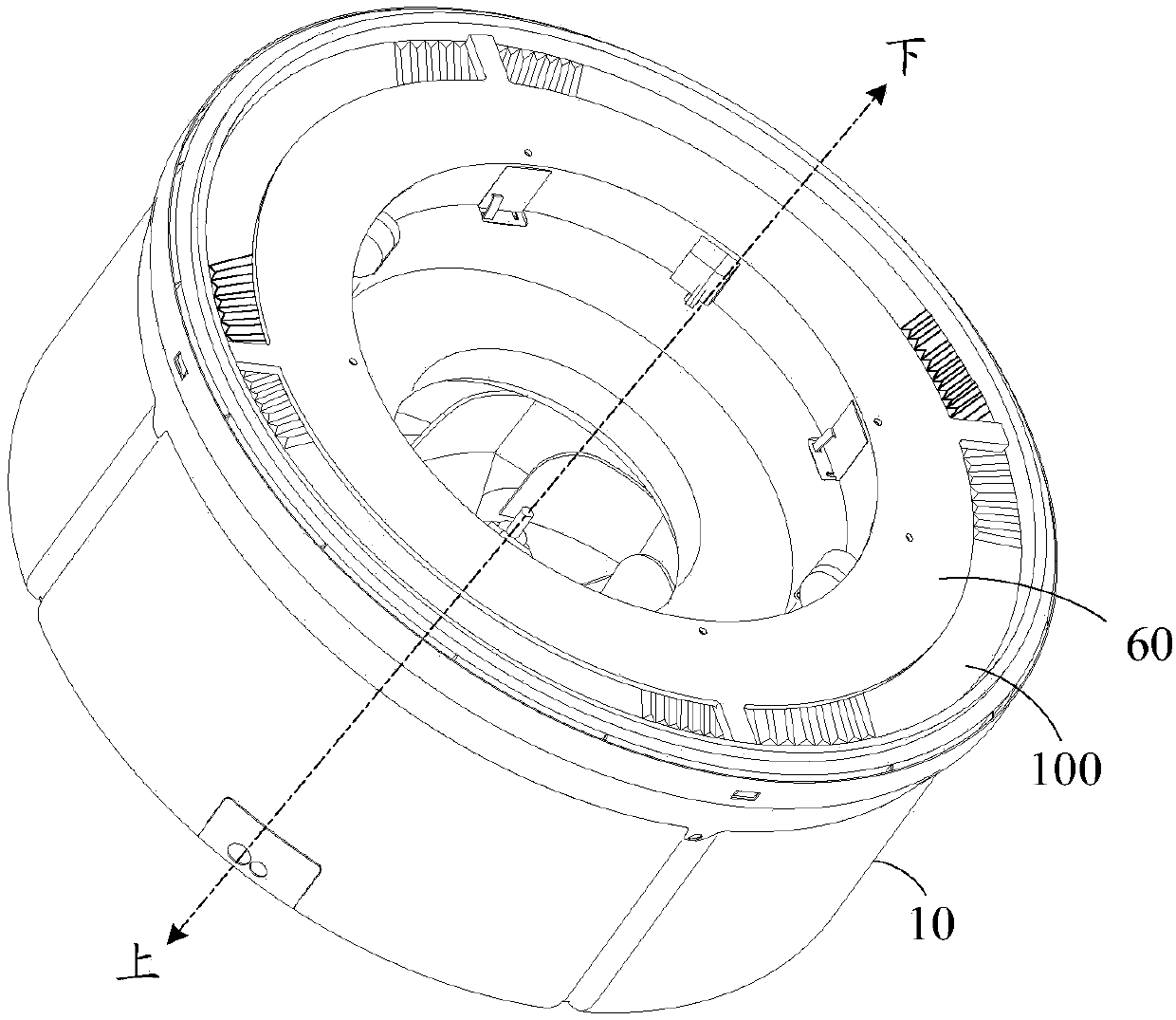

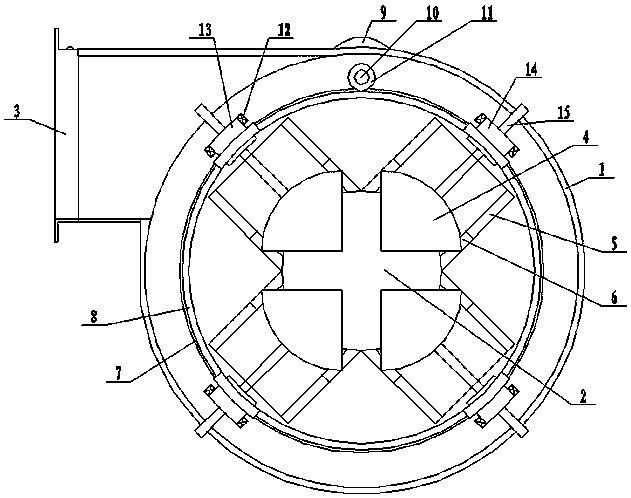

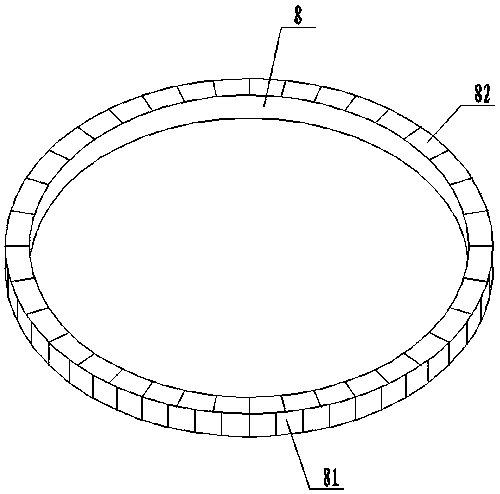

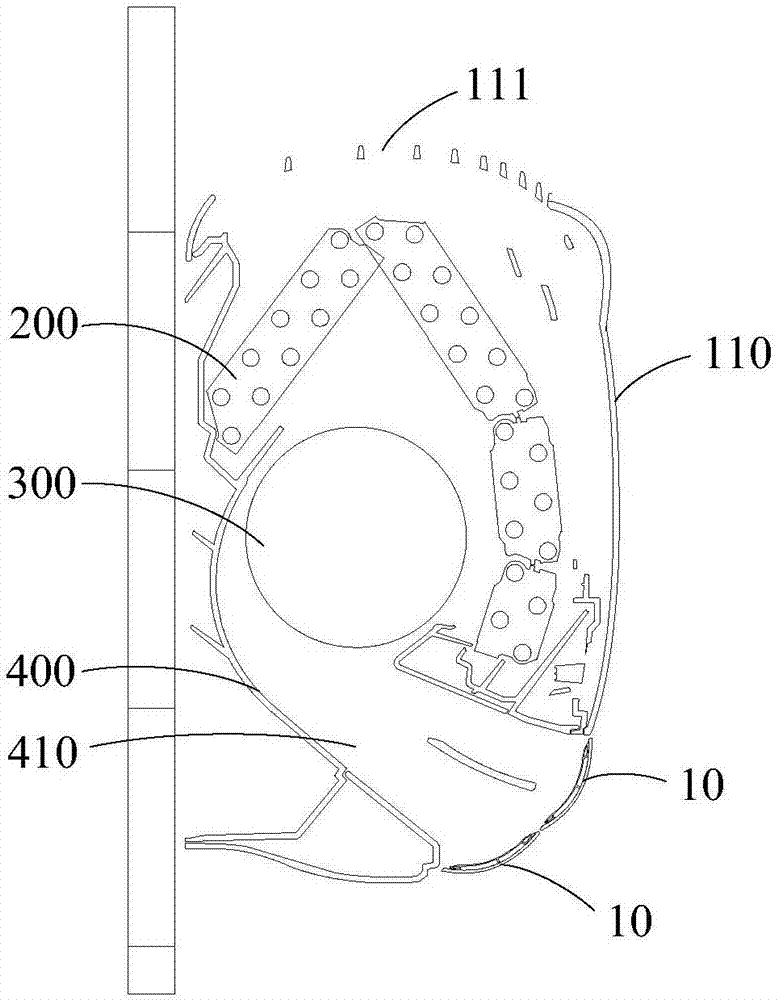

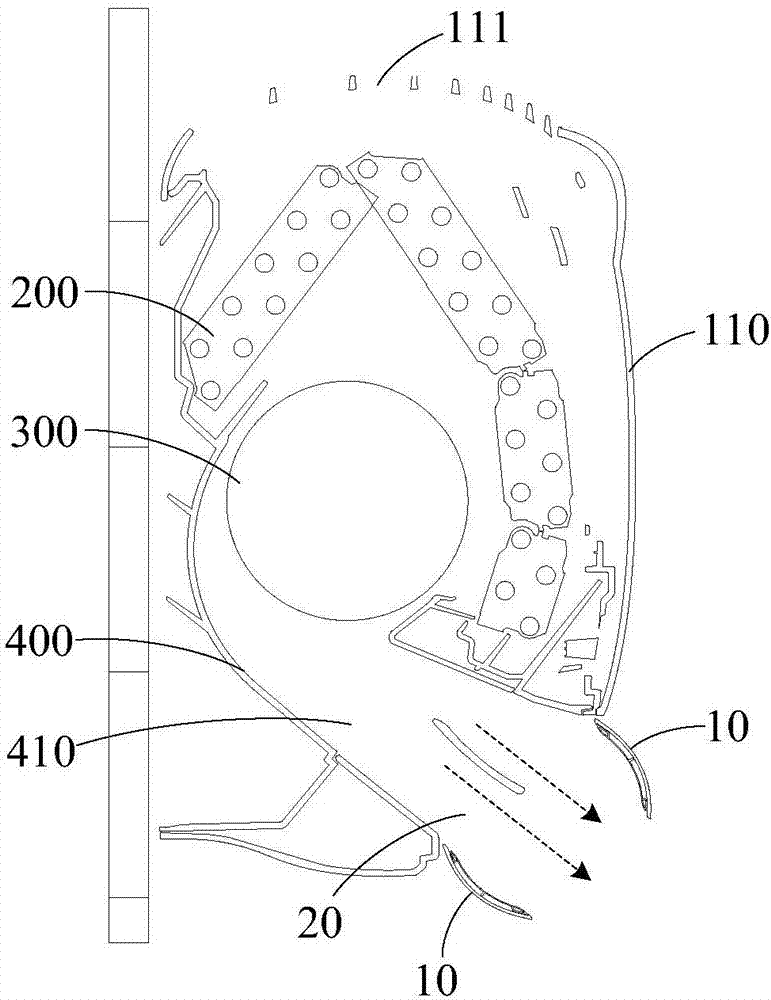

Ceiling machine

ActiveCN107388391AAdjustable air volumeExpand the wind rangeLighting and heating apparatusAir conditioning systemsAir volumeEngineering

The invention discloses a ceiling machine which comprises a shell, an air guide ring and a driving device. The shell comprises a panel component which is provided with a downwards-open air inlet and an air outlet surrounding on the periphery of the air inlet, at least part of arc sections of the air guide ring is made of a flexible material, and the air guide ring is slidably mounted on the upper surface of the panel component to enable the air guide ring to expand or contract along the radial direction of the air outlet; the driving device is mounted in the shell, connected with the air guide ring and used for driving the air guide ring to expand or contract along the radial direction of the air outlet. The ceiling machine can realize adjusting of air outgoing quantity.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Gas heat blower

The invention relates to a gas heat blower, belonging to the technical field of industrial hot-blast air. The gas heat blower has the main technical characteristics that a gas distributor is installed at the front end of the cavity in the case and is sheathed on the outer diameter of the front end of the gas distributor; a casing pipe with a flange is installed on one side of a wind outlet tube; the wind outlet tube, the air distributor flange and the case are fixedly connected and fixed; the upper end of the case is provided with an air inlet; and the lower end of the case is provided with a gas inlet. The invention mixes and burns gas and air to generate gas hot-blast air with large flow and high calorific value; compared with the method that air is only heated to generate hot-blast air, the device utilizes the advantages of large flow and high calorific value of the hot-blast air generated by chemical reaction so as to effectively reduce fan volume; because the air inlet and the gas outlet are respectively connected with the control pipeline of an electric control valve, the air inflow and supply air rate of the gas distributor and the air distributor can be independent and adjustable and can satisfy different working condition requirements.

Owner:SHANXI ALEX ENVIRONMENTAL PROTECTION TECH

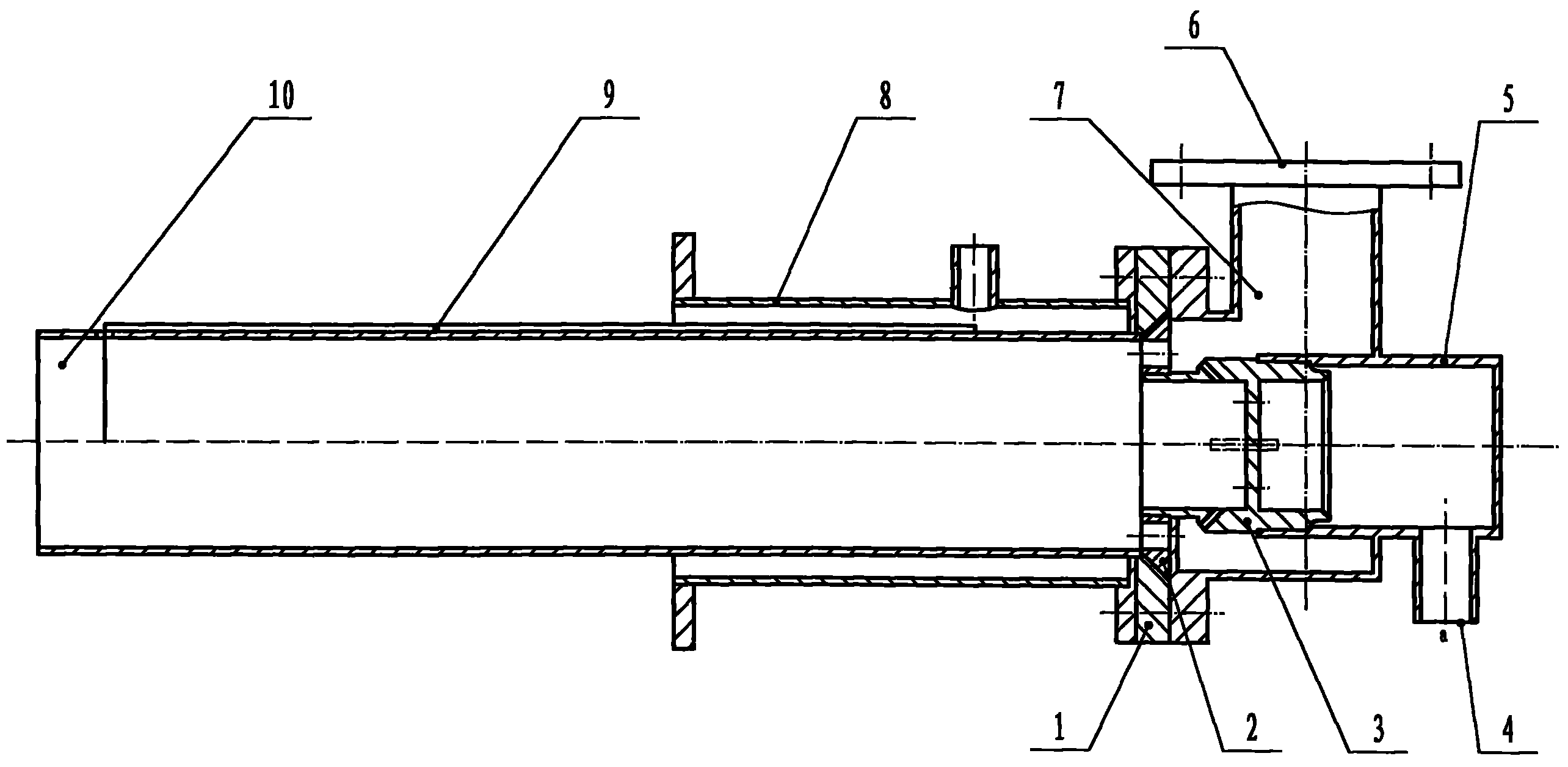

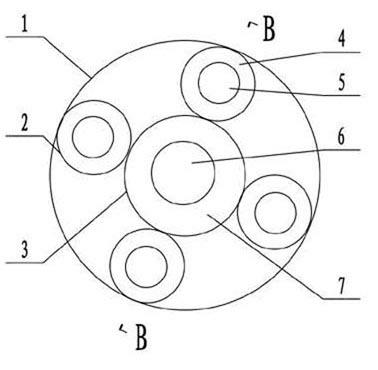

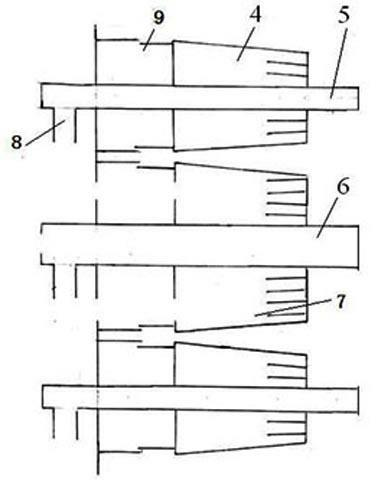

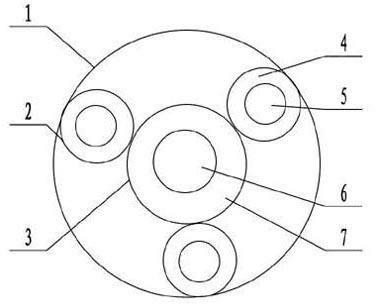

Combustor for high/low-calorific-value gas

InactiveCN102679344AImprove combustion effectImprove combustion intensityIndirect carbon-dioxide mitigationGaseous fuel burnerAir volumeCombustor

The invention relates to a combustor for high / low-calorific-value gas, which comprises a central burner and 3-8 peripheral burners, wherein the central burner is provided with a central fuel nozzle and a central air nozzle, and each peripheral burner is provided with a peripheral fuel nozzle and a peripheral air nozzle; the central fuel nozzle and the peripheral fuel nozzles are respectively provided with an air inlet pipe, the central air nozzle and the peripheral air nozzles are respectively provided with an air inlet, and the air inlet is provided with an air-quantity regulating mechanism; the air inlet is selectively connected with an oxygen-enriched preparation device, and the oxygen-enriched preparation device is an oxygen-enriched film or a PSA (pressure swing adsorption) oxygenerator; and each burner is provided with an independent fuel nozzle and an independent air nozzle, thereby ensuring the fully mixing of fuel gas and combustion-supporting gas, improving the combustion effect of the combustor, and improving the operation flexibility. The combustor provided by the invention has the advantages that: (1) an effect of combustion is performed through a plurality of nozzles, so that the fuel flows of the nozzles are fine, and fuels are fully mixed with air; (2) the air quantity is regulated by using a regulating mechanism, so that fuels with different calorific values can be combusted; and (3) different type of gas can be combusted simultaneously, thereby facilitating the reasonable application of gas resources.

Owner:中科为宇(北京)科技发展有限公司

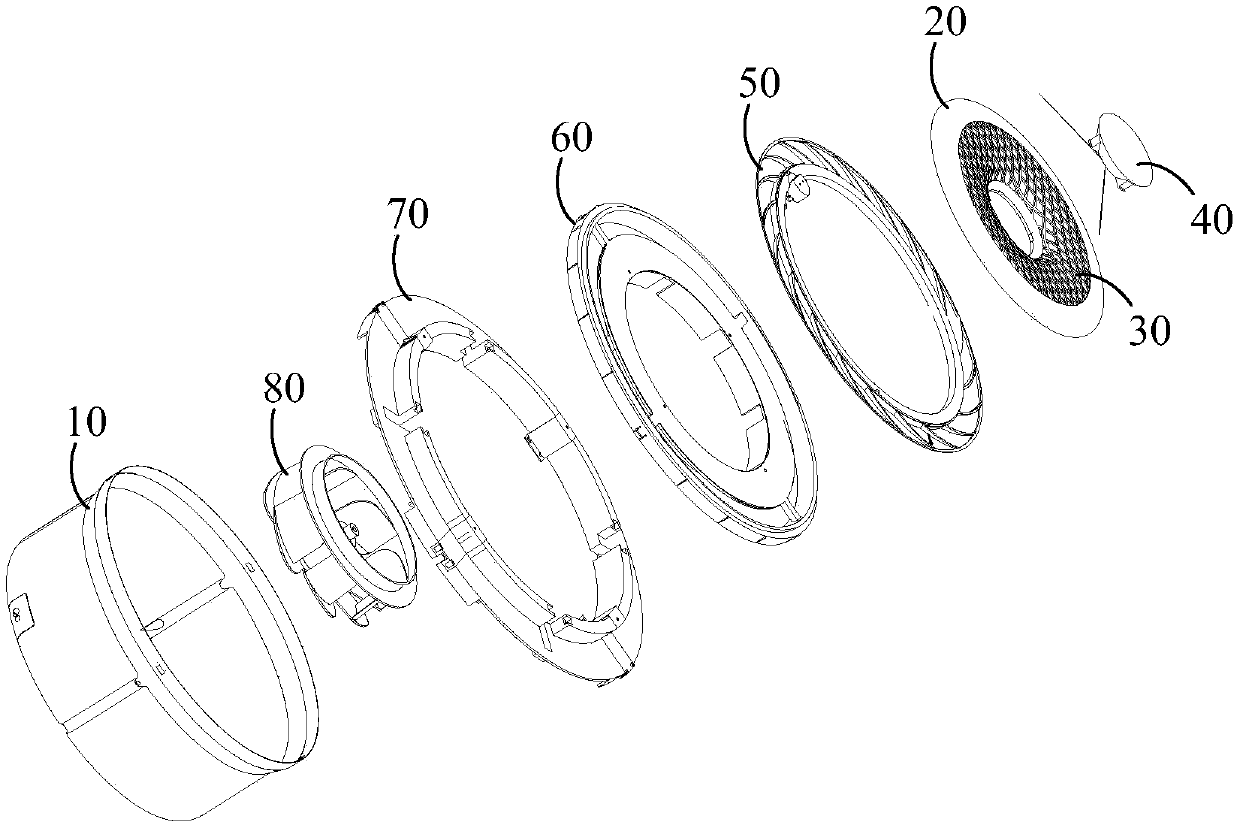

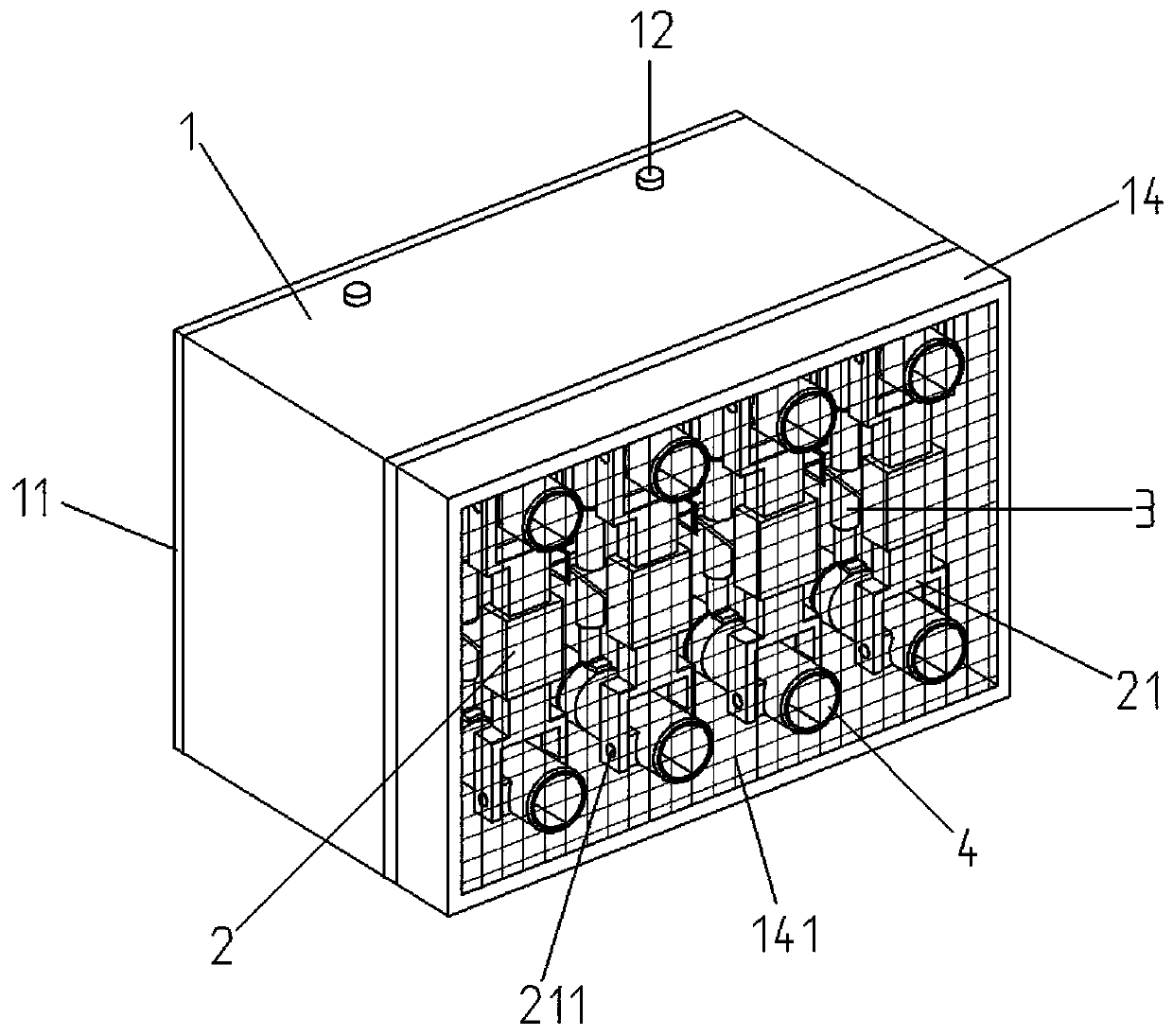

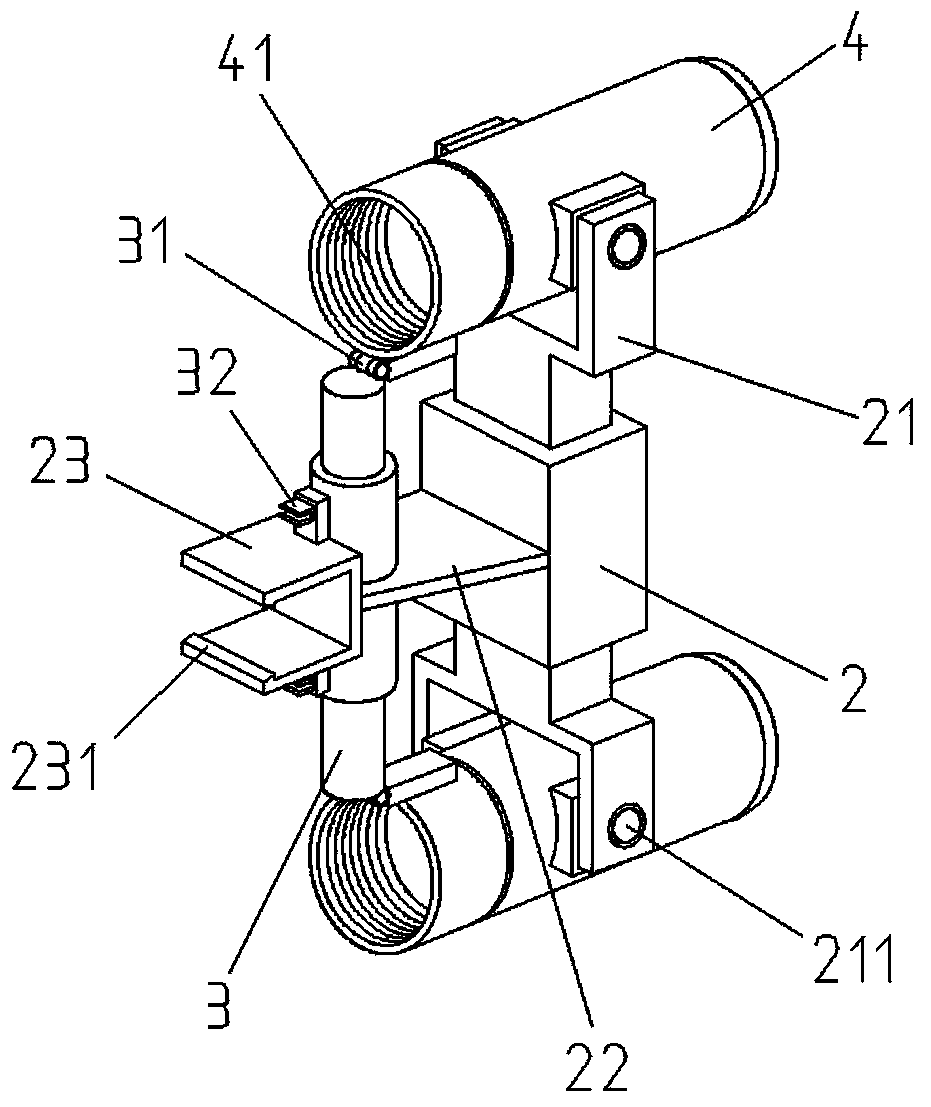

Ceiling-mounted cassette type indoor unit

PendingCN107559961AChange the openingAdjustable air volumeLighting and heating apparatusAir conditioning systemsAir volumeEngineering

The invention discloses a ceiling-mounted cassette type indoor unit. The ceiling-mounted cassette type indoor unit comprises a shell, an air guide ring and a plurality of driving devices. The shell comprises a panel assembly. The panel assembly is provided with an air inlet which is opened downwards and an air outlet which is annularly formed in the periphery of the air inlet. The air guide ring comprises a plurality of arc-shaped air guide sections which are sequentially spliced. Each arc-shaped air guide section comprises an air guide body and flexible joints arranged at the two ends of theair guide body. The air guide ring is installed on the panel assembly in a sliding mode so that the air guide ring can be expanded or contracted in the radial direction of the air outlet to adjust theopening degree of the air outlet. The driving devices are installed inside the shell and further connected with the air guide body to drive the air guide ring to be expanded or contracted in the radial direction of the air outlet. By means of the ceiling-mounted cassette type indoor unit, the air outlet amount of the ceiling-mounted cassette type indoor unit can be adjusted.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

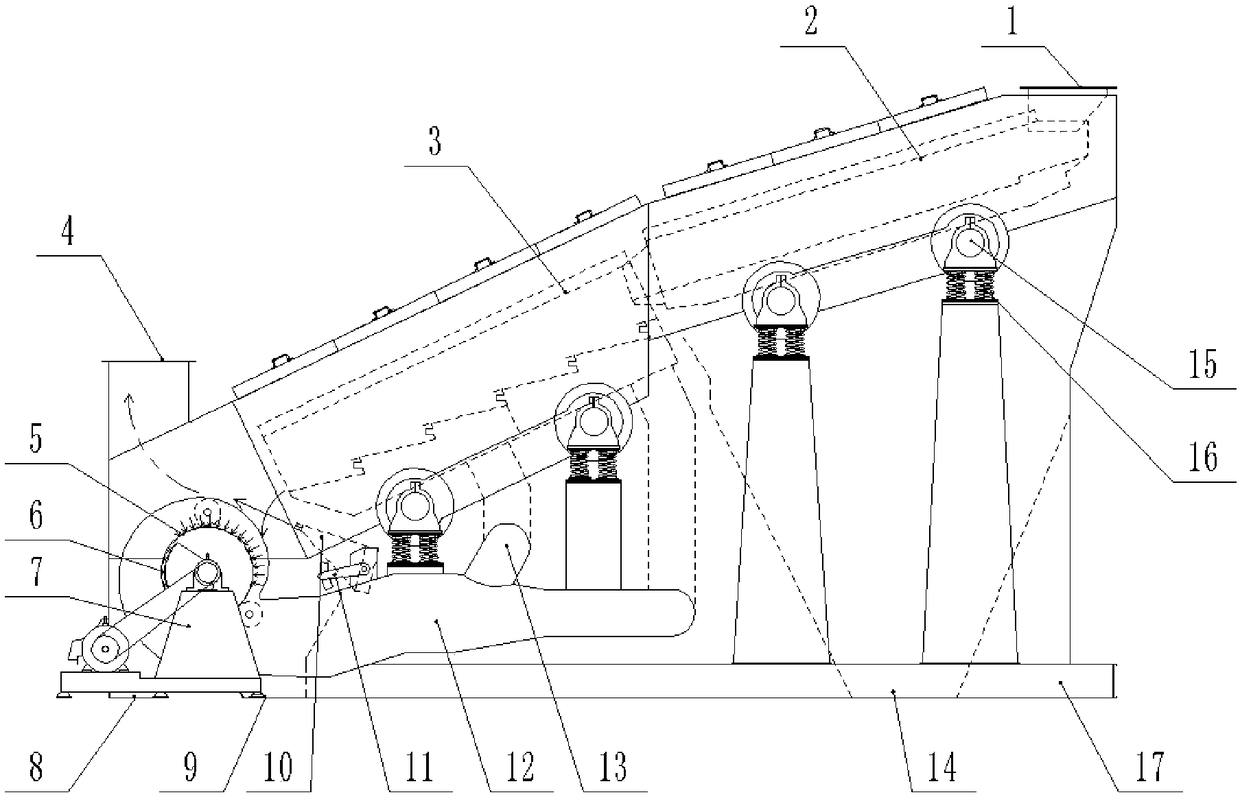

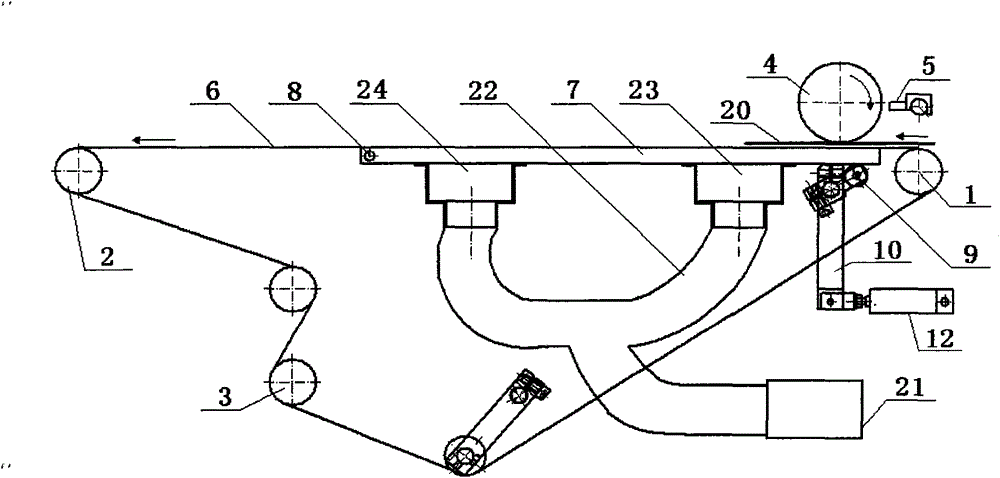

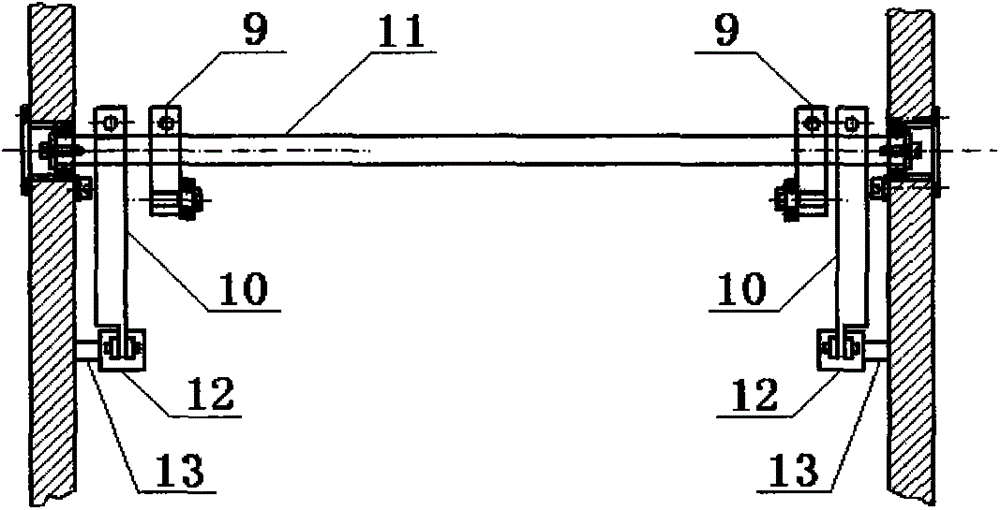

Adjustable air-suction paper-feeding mechanism

ActiveCN105314424AUniform suction distributionGuaranteed not to slipArticle feedersAir volumeEngineering

The invention discloses an adjustable air-suction paper-feeding mechanism. The adjustable air-suction paper-feeding mechanism comprises a front belt roller, a rear belt roller, a driving roller, a photoelectric switch, a printing rubber roller, an air-suction belt, an air chamber plate, air bellows, a hinge pin, top frames, swing arms, a swing arm shaft, cylinders and air hole switch assemblies. The two ends of the front belt roller, the two ends of the rear belt roller and the two sides of the driving roller are arranged on wall boards of the two sides respectively, the photoelectric switch is arranged in front of the printing rubber roller, the front belt roller, the rear belt roller and the driving rollers are wrapped with the air-suction belt, the air bellows of a front row and a rear row are installed below the air chamber plate, one end of the air chamber plate is positioned on the wall boards of the two sides, and the other end of the air chamber plate is arranged on the top frames; the top frames and the swing arms are fixed on the same swing arm shaft, the swing arm shaft is arranged on the wall boards of the two sides, the other end of the each swing arm is hinged to the corresponding cylinder, the cylinders are fixed on the wall boards of the two sides through fixing shafts, and the air hole switch assemblies are installed on the air chamber plate. According to adjustable air-suction paper-feeding mechanism, air suction is even, the air suction area and the air volume are adjustable, and rapid and stable conveying can be achieved whether paper is big or small.

Owner:YUTIAN DINGYU PRINTING MACHINERY MFG

Centrifugal fan capable of adjusting air volume of air inlet

InactiveCN109209944AAdjustable air volumeCompact structurePump componentsPump controlAir volumeEngineering

The invention discloses a centrifugal fan capable of adjusting the air volume of an air inlet. The centrifugal fan comprises a shell, the air inlet formed in the side face of the shell and an air outlet formed in the end surface of the shell; the side, close to the air inlet, of the shell is evenly provided with a plurality of fan-shaped baffles matched with the air inlet, the multiple fan-shapedbaffles form a circular structure, slide rails corresponding to the fan-shaped baffles in a one-to-one manner are arranged on the shell, the fan-shaped baffles are slidably arranged on the slide railsthrough sliders, toothed discs are rotationally arranged on the portions, on the outer sides of the sliding rails, of the shell through large bearing blocks, and a servo gear motor is arranged at theupper end of the shell, a first gear is arranged on a motor shaft of the servo gear motor, the first gear is engaged with first gear teeth on the outer sides of the toothed discs, and a swivel nut isrotationally arranged on the portion, on the outer sides of the sliding rails, of the shell through a small bearing block.

Owner:JIANGSU SHUANGJU FANS

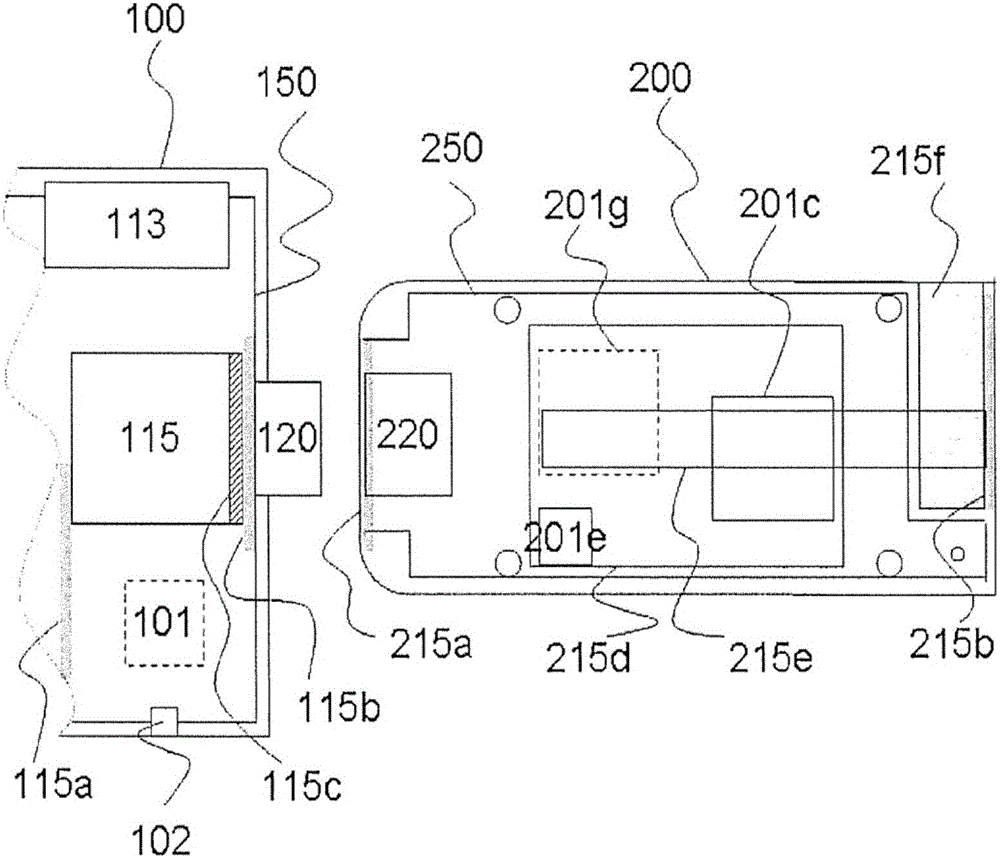

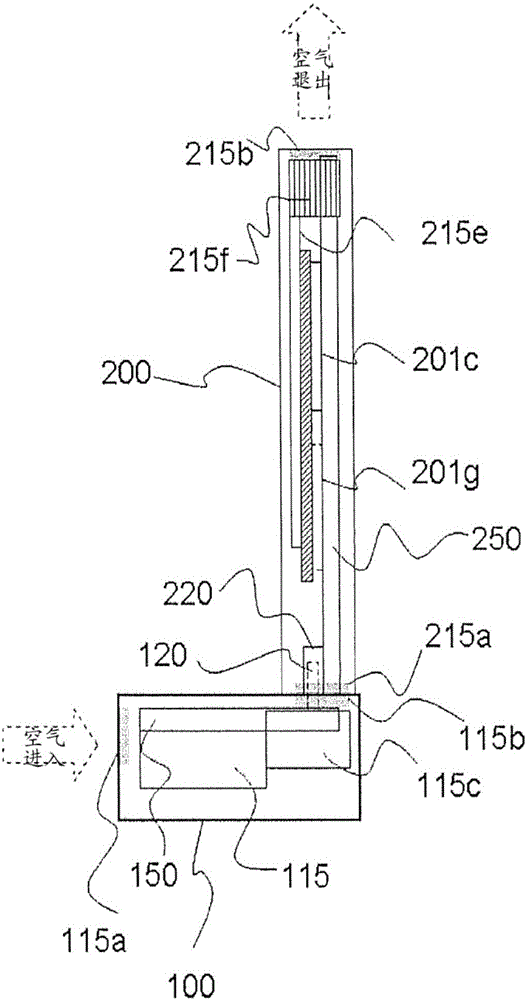

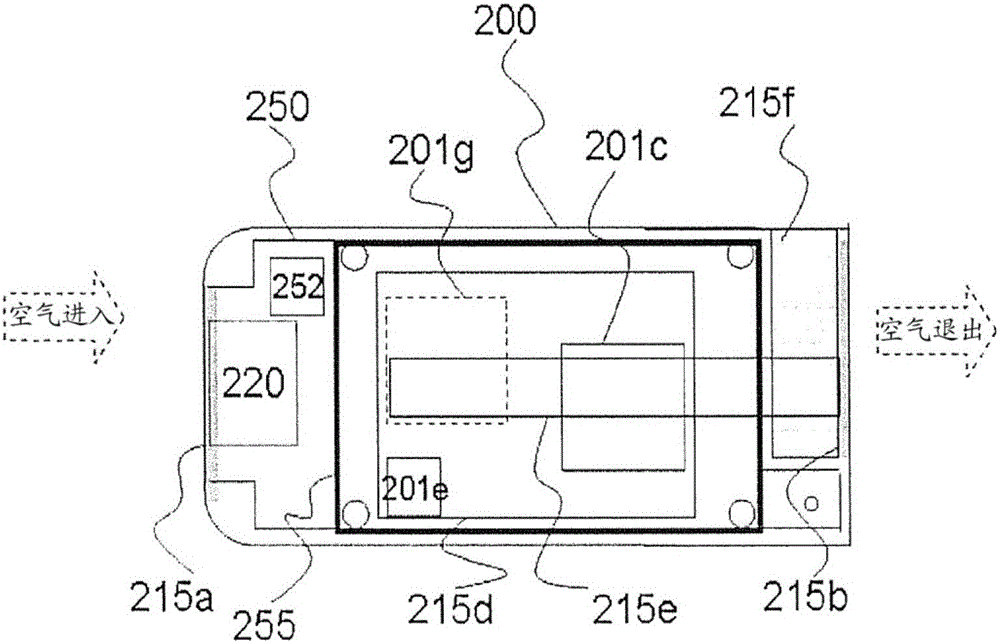

Modular computer and thermal management

InactiveCN105122173AAdjustable air volumeAvailable flowDigital data processing detailsEnergy efficient computingModularityComputer engineering

An enclosure design facilitates heat dissipation from a space-limited computer core device. An external computer platform is provided to connect the computer core device, the external computer platform including a fan that provides an air flow to the connected computer core device. The computer core device and the computing platform may be tightly connected by connectors located on their respective enclosure walls. Both the computer core device and the external computing platform are provided air inlets and outlets on their respective enclosures. When connected, an air inlet of the computer core device faces an air outlet of the external computing platform such that a single cooling air flow flows through the external computing platform and the computer core device. The external computing platform may include a built-in fan to blow air into or draw air from the matching air inlets and outlets.

Owner:ICE COMP

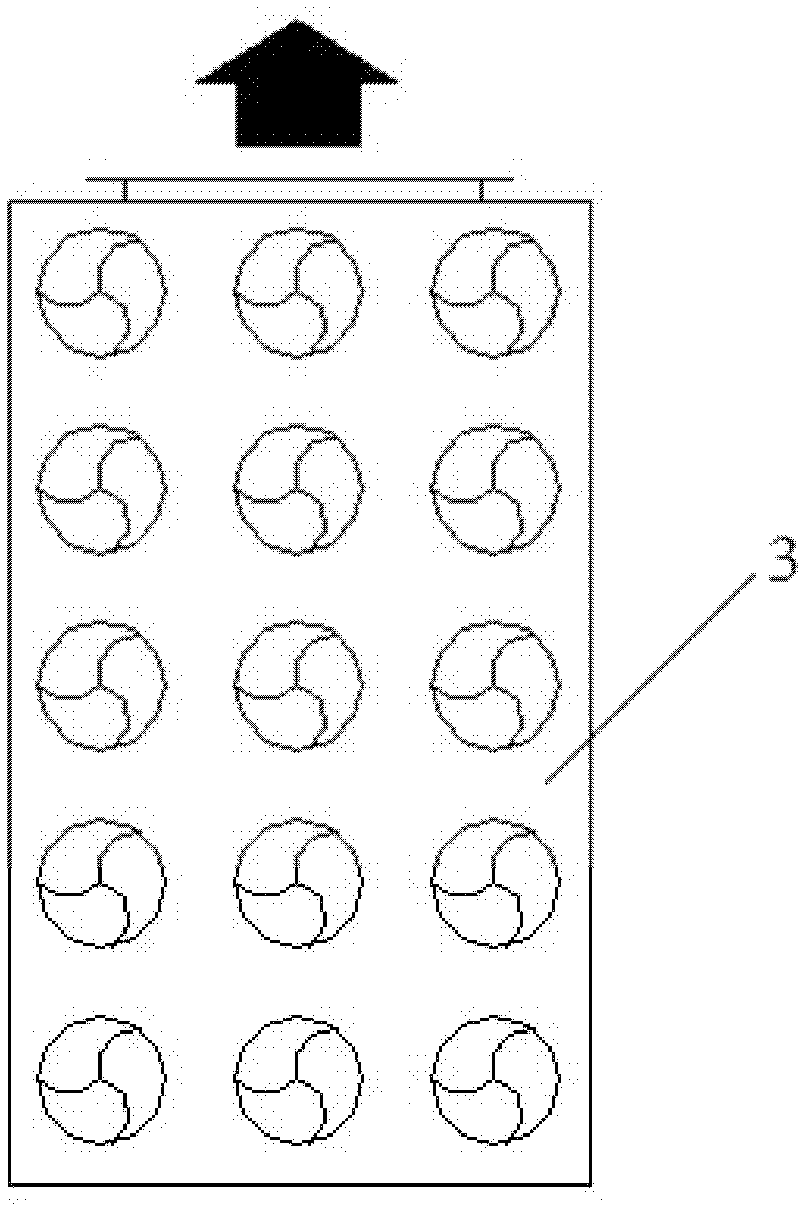

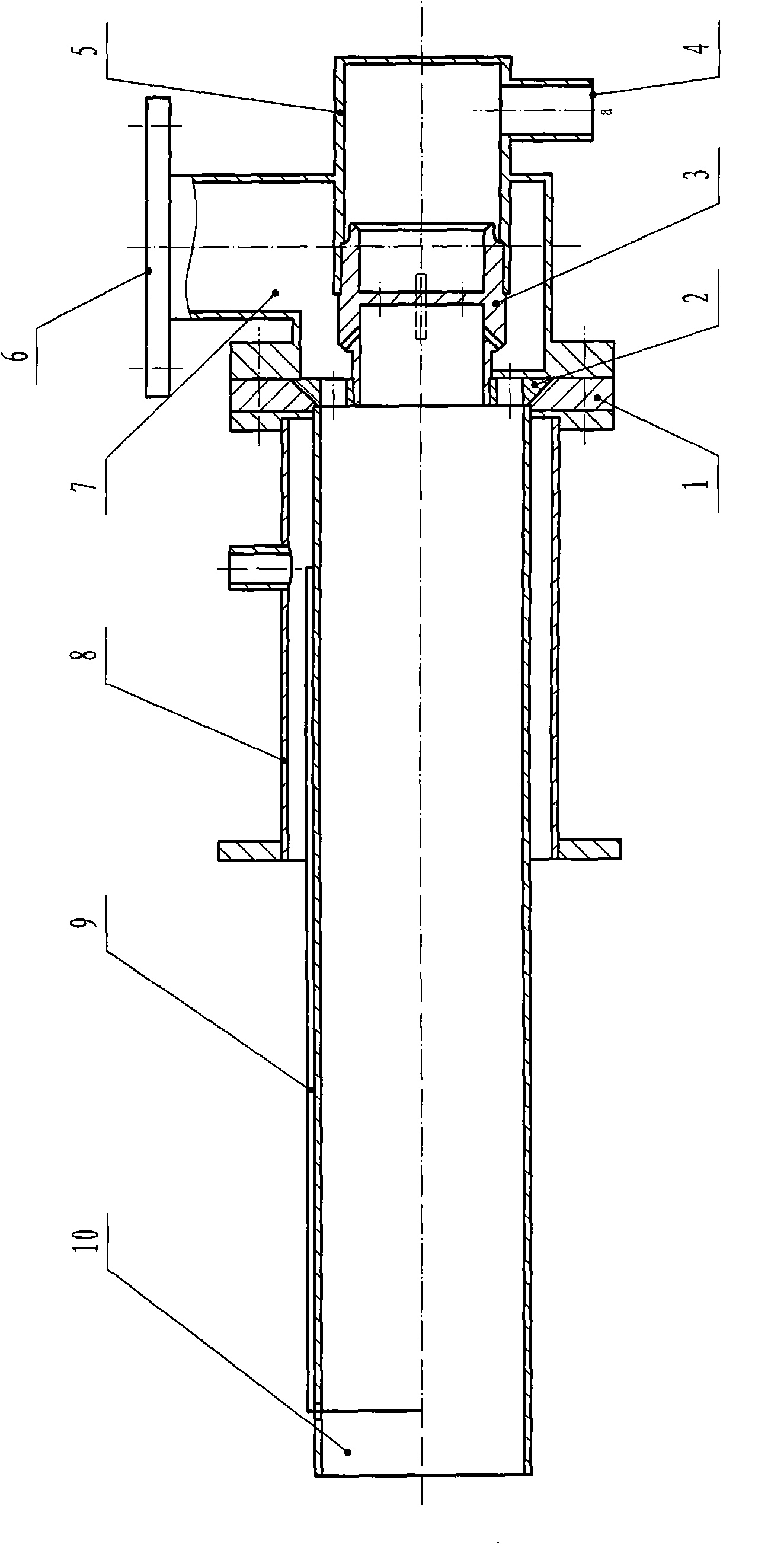

Underwater closed pump type impeller inspiration and aeration machine

InactiveCN104355397ANo cloggingSize noiseTreatment using aerobic processesSustainable biological treatmentImpellerUnderwater

The invention belongs to the technical field of sewage aerobic treatment equipment, and relates to an underwater closed pump type impeller inspiration and aeration machine which is characterized in that a first flat plate and a second flat plate are respectively fixedly arranged on the upper end and in the middle of a bracket with a framework structure, a motor is arranged on the first flat plate through a fixing bolt, the lower end of the motor is in transmission connection with a stirring shaft through a coupling, an air inlet disc is arranged below the second flat plate through a regulating bolt, one side of the air inlet disc is communicated with an air inlet pipe in a butted manner, the air inlet pipe is arranged through a guide bracket in a penetration manner, and the guide bracket is embedded on the first flat plate and the second flat plate; a bearing is embedded at the center of the second flat plate in a penetration manner, the lower end of the stirring shaft is in transmission connection with a closed type impeller after penetrating through the air inlet disc, and a water inlet gap with adjustable size is formed between the closed type impeller and the air inlet disc. The equipment is simple in structure, reasonable in design, reliable in principle, convenient to maintain and install, adjustable in air quantity, small in noise, low in power consumption, strong in aeration capability, good in aeration effect, wide in application range, and friendly to use environment.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

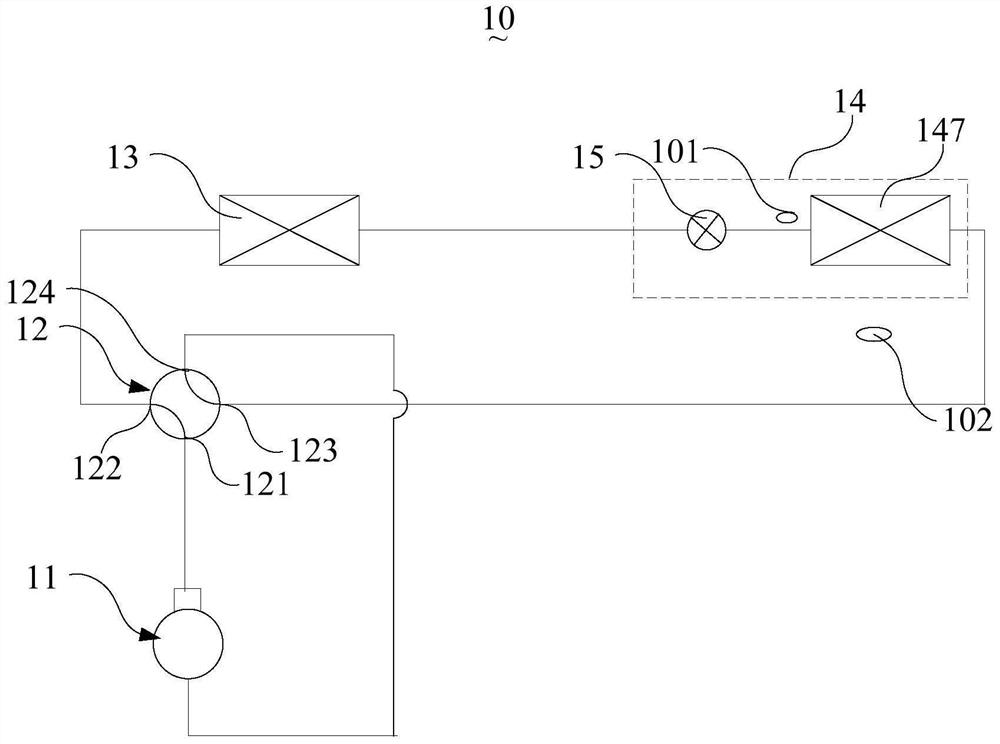

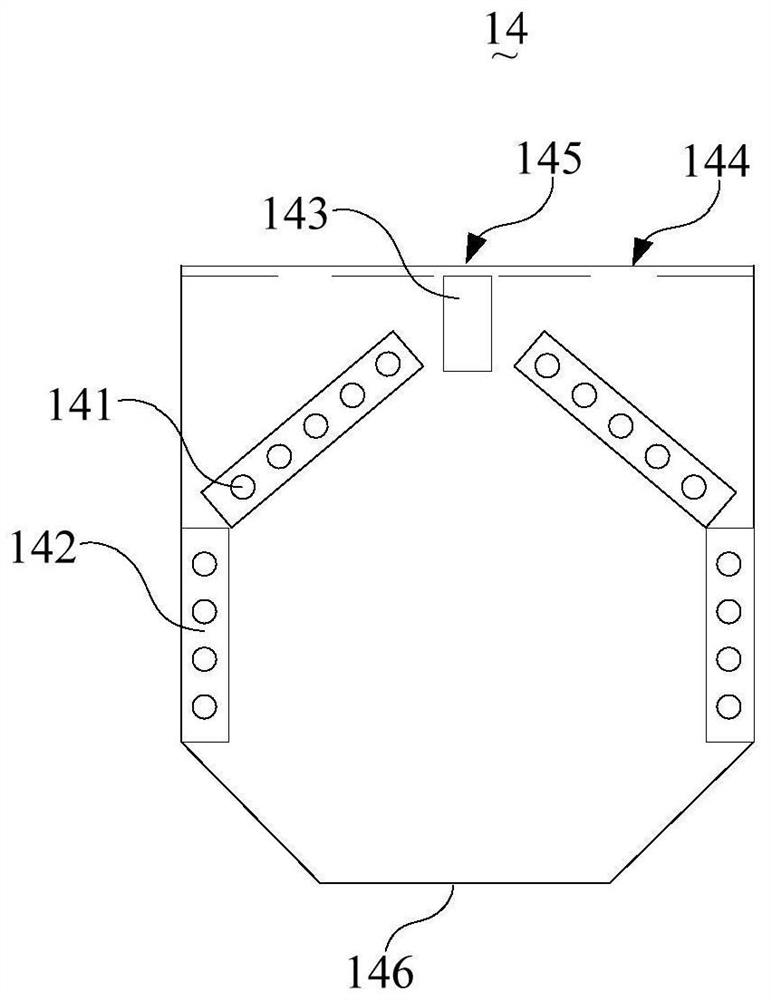

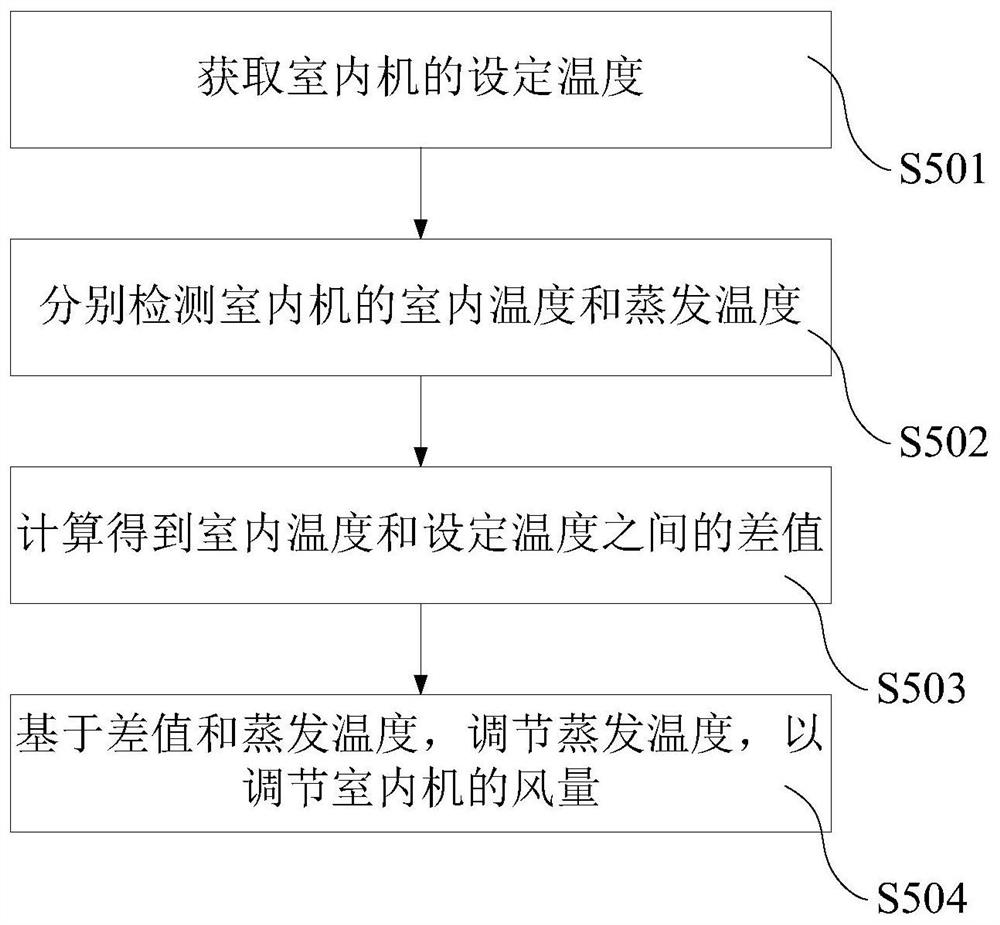

Control method, air conditioning system and computer storage medium

InactiveCN112503715AAdjustable air volumeMechanical apparatusSpace heating and ventilation safety systemsAir volumeNatural convection

The invention discloses a control method, an air conditioning system and a computer storage medium. The control method is applied to the air conditioning system and comprises the steps that the set temperature of an indoor unit is obtained; the indoor temperature and the evaporation temperature of the indoor unit are detected respectively; calculating is conducted to obtain a difference value between the indoor temperature and the set temperature; and based on the difference value and the evaporation temperature, the evaporation temperature is adjusted so as to adjust the air volume of the indoor unit. In this way, the air volume of the indoor unit can be adjusted by adjusting the evaporation temperature of the indoor unit, and then the air volume of the natural convection type indoor unitcan be adjusted.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Biomass hot blast stove

ActiveCN103884009AAchieve secondary combustionBurn fullyAir heatersSolid fuel combustionCombustion chamberCombustor

The invention discloses a biomass hot blast stove. The biomass hot blast stove comprises a hot blast stove body and an emergency vent chimney (12). The hot blast stove body comprises a charging port (3), a fire grate (2), an ash pit (1), a front combustor (5), a rear combustor (10), a primary settling chamber (8), a primary air-cooled beam (6), a secondary air-cooled beam (9) and a smoke window (7). The emergency vent chimney (12) comprises a flame retarding plate (14), a tertiary settling chamber (16), a tertiary air-cooled port (17), an emergency vent chimney outlet (15) and an emergency vent smoke outlet (13). The upper portion of the front combustor (5) is communicated with the upper portion of the primary settling chamber (8) through the smoke window (7). The lower portion of the rear combustor (10) is communicated with the lower portion of the primary settling chamber (8). The emergency vent chimney (12) is connected with the rear combustor (10). High-temperature smoke produced by the front combustor (5) in the burning process flows in the hot blast stove body circuitously. Through the biomass hot blast stove, secondary combustion is achieved, fuel can be fully combusted, the thermal efficiency is high, and the pollution is little.

Owner:包钢重菱锅炉制造有限公司 +1

Air humidifier of vehicle

InactiveCN1853969AGuaranteed not to freezeAvoid damageAir-treating devicesUltrasonic sensorWaste management

An air moistener for car is composed of an thermal insulating case and such unit arranged in said thermal insulating case as water tank, the main body of moistener with ultrasonic transducer and communicated via valve to said water tank, fan, air inlet tube, and air outlet tube.

Owner:栾丕军

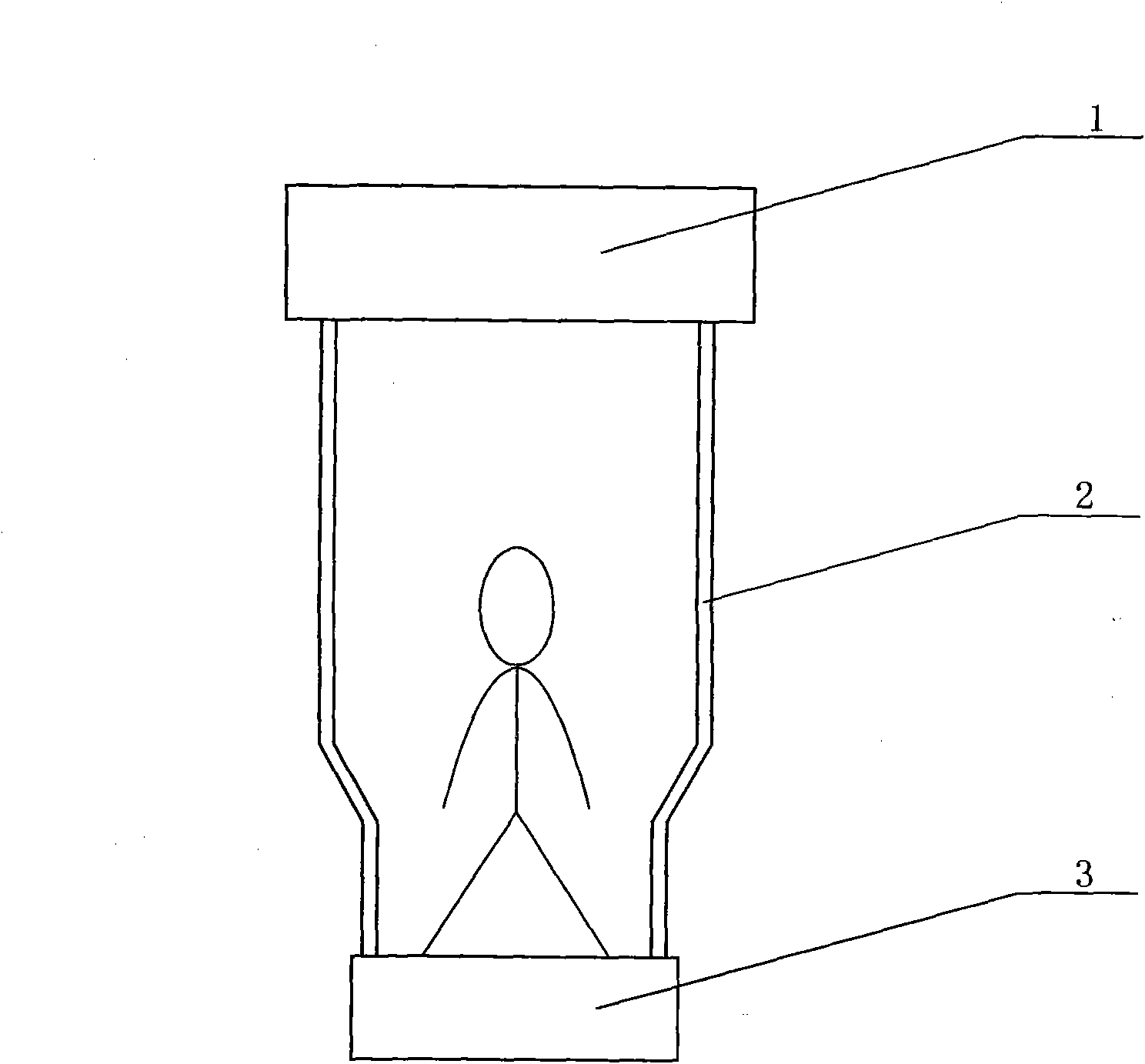

Multipurpose duty-performing platform

InactiveCN101914997AVersatileSimple structureLighting and heating apparatusElectric heating systemRound functionRefrigerant

The invention discloses a multipurpose duty-performing platform. The multipurpose duty-performing platform comprises a platform main body, a heating system, a refrigerating system, a lighting system, a sound compensating system and a control system which controls the work of the systems, wherein the platform main body consists of a main frame and a base which are connected through an upright column; the heating system comprises a plurality of infrared heating devices arranged in the main frame and a heating device arranged in the base; the refrigerating system comprises a refrigerant circulation system and an air flow system which is arranged in the main frame; the lighting system comprises a plurality of LED illumination lamps and LED outline marker lamps arranged on the main frame; and the sound compensating system comprises a pickup device, a modulator-demodulator and a playback device. The invention has the advantages of simple structure, all-round functions, safe and reliable use and convenient and fast operation and can improve the working conditions of personnel on duty, enhance the duty-performing efficiency and increase the safety coefficient of the duty-performing platform.

Owner:ELECTRIC POWER OF HENAN LUOYANG POWER SUPPLY +1

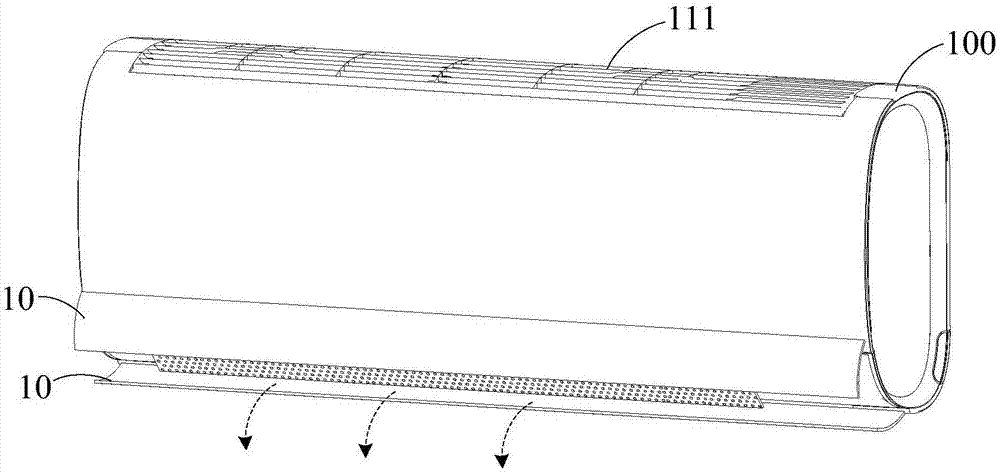

Wall hanging type indoor unit and air conditioner

PendingCN107477691AThe effect of extending the air supply distanceAdjustable air volumeLighting and heating apparatusAir conditioning systemsAir volumeStructural engineering

The invention discloses a wall hanging type indoor unit and an air conditioner. The air conditioner comprises the wall hanging type indoor unit. The wall hanging type indoor unit comprises a shell, two wind shields and two drive devices, the shell is provided with an air outlet, the two wind shields are vertically arranged on the air outlet, one wind shield is in pivot joint with the upper edge of the air outlet, the other wind shield is in pivot joint with the lower edge of the air outlet, the two drive devices are arranged in the shell, and are sequentially and correspondingly connected with the two wind shields, and therefore the wind shields are driven to turn over. According to the wall hanging type indoor unit, the size of the air outlet of the wall hanging type indoor unit can be changed, and the adjustment of the air outlet amount can be achieved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Air outlet guide device of central air conditioner

ActiveCN109827313AIncrease flexibilityImprove practicalityDucting arrangementsMechanical apparatusElectricityAssistive device/technology

The invention discloses an air outlet guide device of a central air conditioner, and belongs to the technical field of indoor air conditioner auxiliary equipment. The air outlet guide device comprisesa protective shell, an air adjusting pipeline is arranged on one side inside the protective shell, a wind baffle is arranged between the outer side of the air adjusting pipeline and the protective shell, connecting pipelines are arranged on the other side of the protective shell, gas guide folding pipes are arranged between the connecting pipelines and air adjusting pipelines, a positioning sliding rod is arranged in the protective shell, an installing block is arranged on the positioning sliding rod in a sliding mode, the upper side and the lower side of the installing block are provided with air guide pipelines corresponding to the connecting pipelines correspondingly, and the inlet sides of the air guide pipelines are provided with bidirectional electric telescopic rods, a single-chipmicrocomputer control module is arranged inside the protective shell, the single-chip microcomputer control module is electrically connected with a relay module, and the output end of the relay moduleis electrically connected with the bidirectional electric telescopic rods. The problem that the direction of the air outlet of an existing central air conditioner is not flexible is solved, the windpower of the air outlet can be effectively dispersed, the air blowing direction can be adjusted correspondingly, and the flexibility of the air supply direction of the central air conditioner is improved.

Owner:TAIZHOU YUANCHUANG NEW MATERIAL TECH

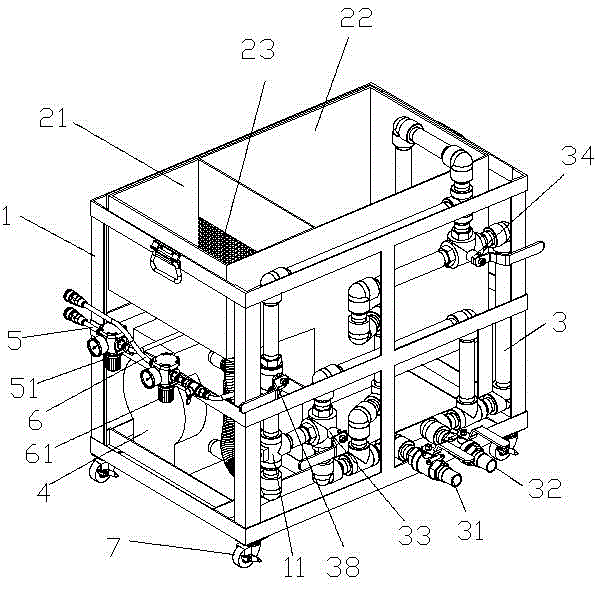

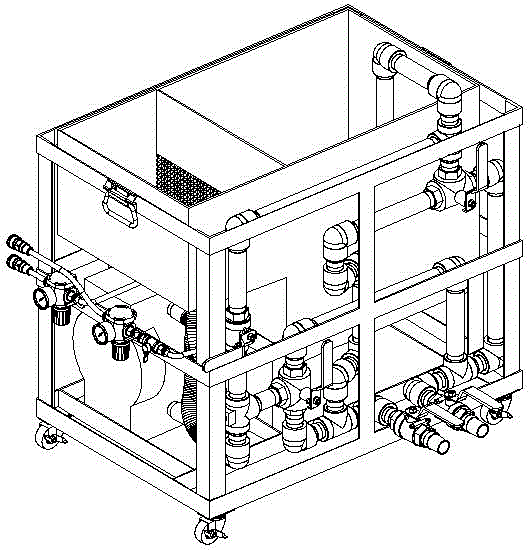

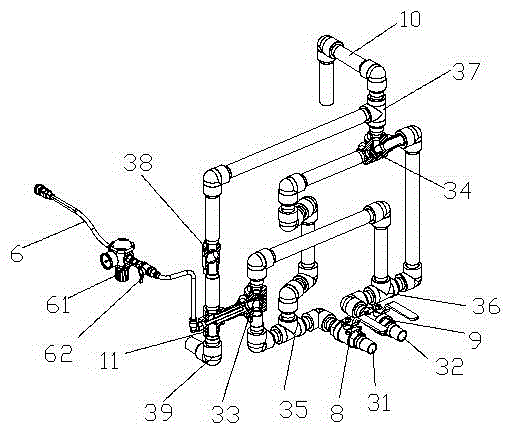

Self-service multifunctional circulation waterway cleaning machine

The invention discloses a self-service multifunctional circulation waterway cleaning machine. The self-service multifunctional circulation waterway cleaning machine comprises a machine frame. A water tank is arranged at the upper end of the machine frame. A cleaning pipeline connected with the water tank is arranged below the water tank and comprises a first water hole, a second water hole, a first three-way valve and a second three-way valve. The first water hole communicates with the first three-way valve through a first three-way pipe connector. The second water hole communicates with the second three-way valve through a second three-way pipe connector. The first three-way valve communicates with the second three-way pipe connector. The second three-way valve communicates with the first three-way pipe connector. The first three-way valve further communicates with a water inlet pipe. The second three-way valve further communicates with a water outlet pipe. The water inlet pipe communicates with the water tank. Diluted pipeline cleaning agents are added into water troughs of the cleaning machine, an air pump of the cleaning machine provides circulation power, the cleaning agents are made to circularly flow in the pipeline, and forward and reverse switching can be realized rapidly, so that the purposes of cleaning up waste and impurities inside the pipeline and enabling equipment to recover original functions and effects are realized.

Owner:KUNSHAN MINAMAX PRECISION IND

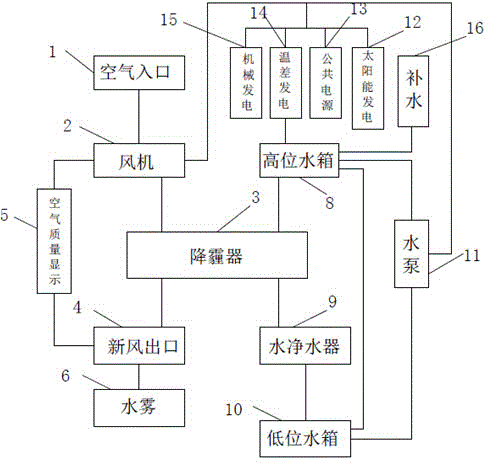

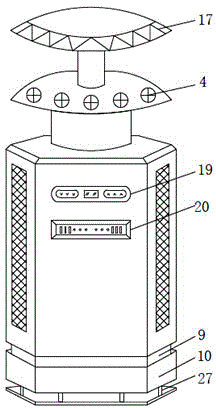

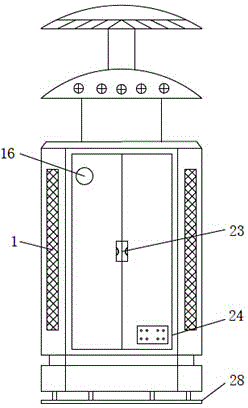

Multidimensional power-strengthening washing-to-reduce-haze fresh air generator

ActiveCN104676785ALow costThe power source is clean and environmentally friendlyMechanical apparatusSpace heating and ventilation safety systemsPower gridFresh air

The invention relates to a multidimensional power-strengthening washing-to-reduce-haze fresh air generator. Air is filtered via an air filter under the action of a fan prior to being controlled to enter a haze reducer, low-haze 'fresh air' is generated via an air-water separation barrier after the air is subjected to washing, coagulating, conglomerating and settling in the haze reducer, spraying water in the haze reduce comes from a head water tank equipped with a temperature difference power generation device, sprayed water flows to a lower water tank after treatment of a water purification system, the water is delivered back to the head water tank through a circulation water pump, water mist is arranged at the upper end of the outlet of the low-haze 'fresh air' to have air humidity controlled, power sources of the fan and the circulating water pump come from thermoelectric power generation, solar energy, wind energy, public power, mechanical power, potential energy difference and a siphon principle, stable operation is achieved, dependence on power grids is avoided, and an independent device with multidimensional power is formed; the spraying water is in closed circulation, and water resources are efficiently utilized; the device can be flexibly arranged according to application places; energy conservation and emission reduction effect is obvious.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com