Pre-oxidation device for carbon fiber production

A pre-oxidation and carbon fiber technology, applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of poor sealing of the furnace body and uneven isothermal zone, etc., and achieve the effect of uniform temperature, reasonable distribution of temperature zone and temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the following detailed description is not considered to limit the present invention.

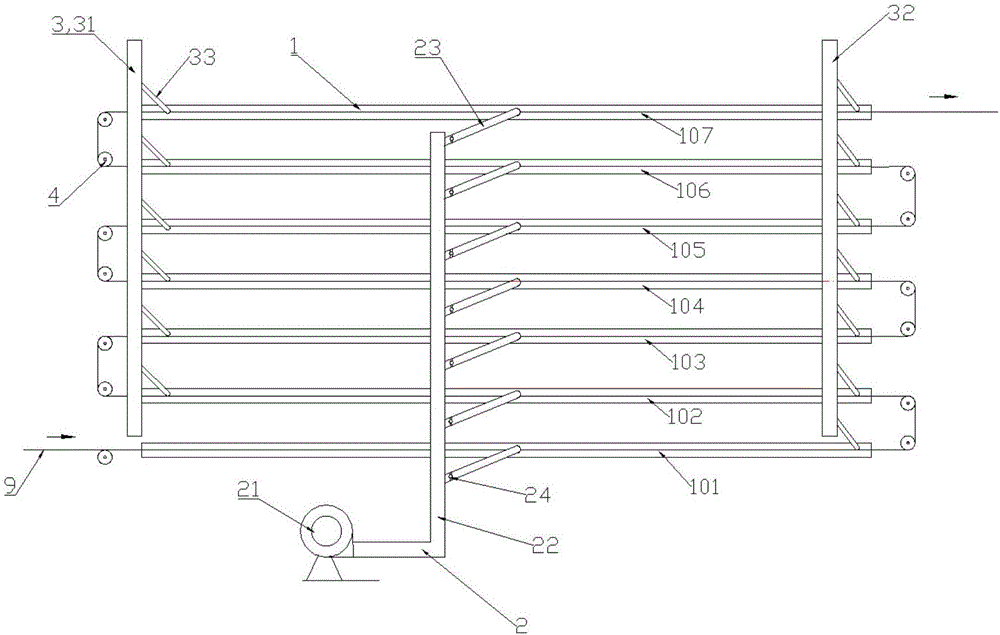

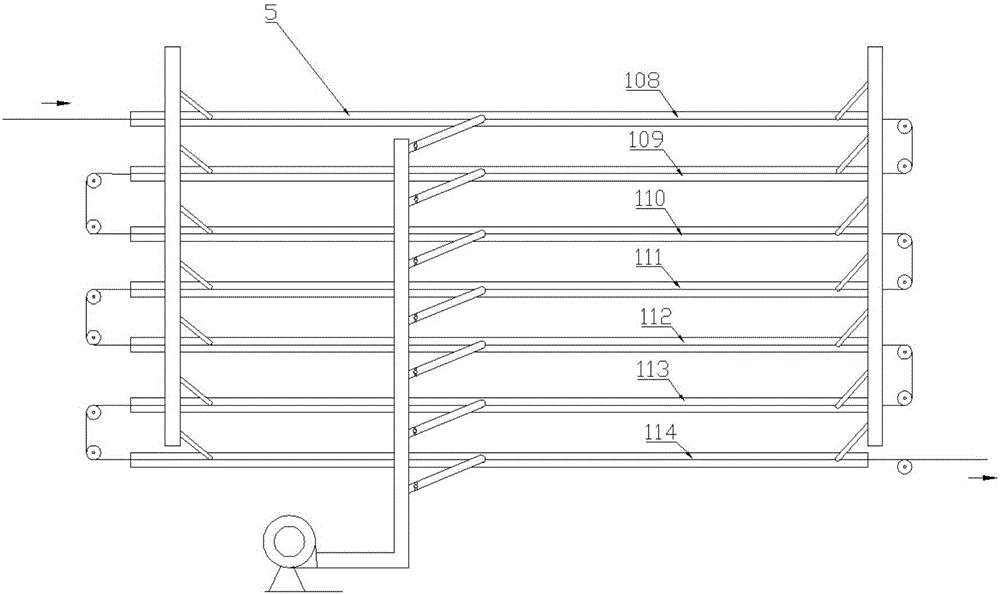

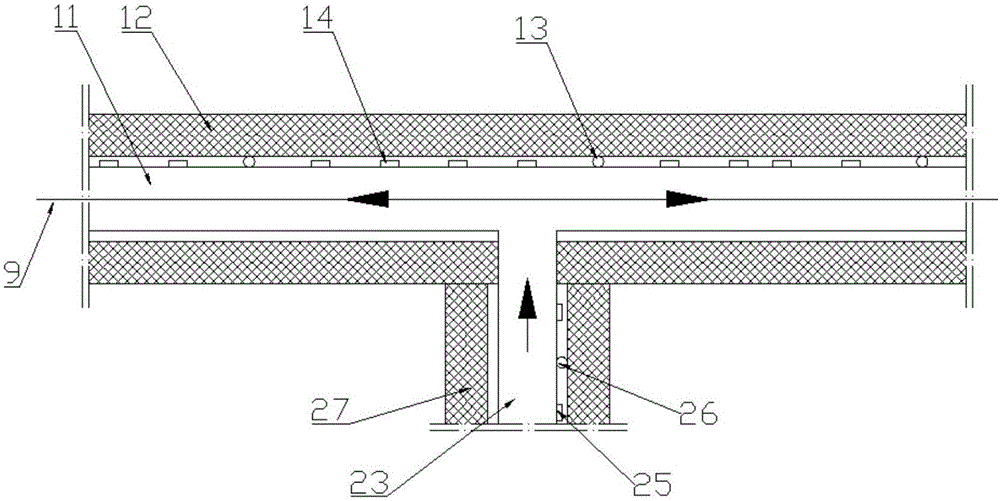

[0021] in, figure 1 It is a schematic diagram of the structure of the first pre-oxidation furnace body of the present invention. figure 2 It is a schematic diagram of the structure of the second pre-oxidation furnace body of the present invention. figure 1 and figure 2 The direction of the middle arrow is the advancing direction of the fiber tow. image 3 It is a structural schematic diagram of the joint between the ventilation pipe and the furnace of the present invention. image 3 The direction of the middle arrow is the flow direction of the hot air provided by the air supply system.

[0022] From Figure 1-Figure 3 It can be seen that the pre-oxidation device comprises two pre-oxidation furnaces connected in series, i.e. the first pre-oxidation furnace 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com