Method for preparing magnesium oxide through spray pyrolysis and spray pyrolysis furnace used therein

A technology of spray pyrolysis and magnesium oxide, applied in magnesium oxide and other directions, can solve the problems of unsatisfactory efficiency, high cost and large operating load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

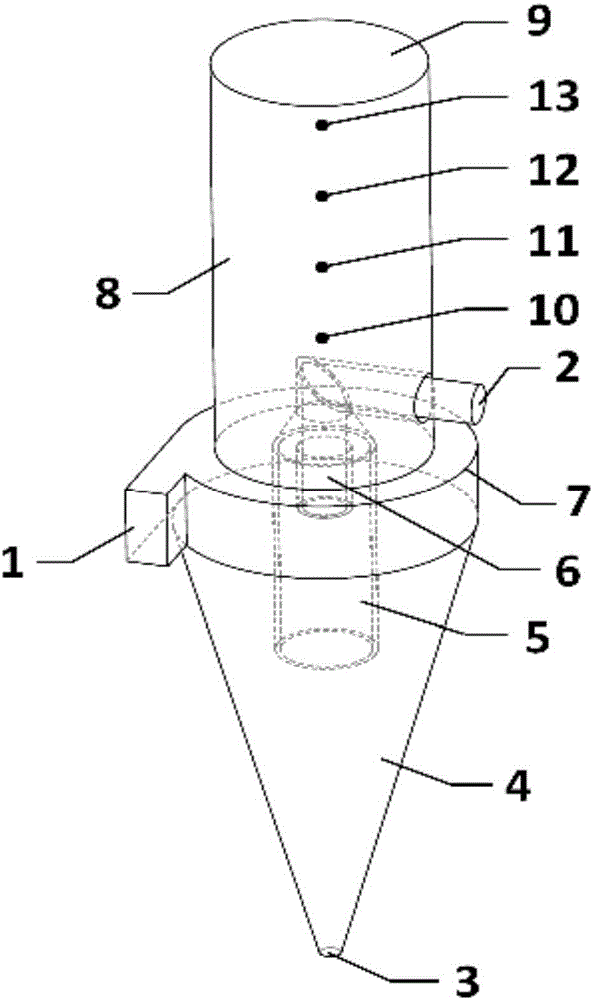

[0101] This embodiment includes a furnace body and an insulating layer made of refractory materials installed around the furnace body. The insulation layer is made of common asbestos material and stainless steel shell. figure 1 It is the structural representation of the furnace body in embodiment 1, comprising: rectangular tangential inlet (1), cylindrical rotating chamber (7), conical cyclone structure (4), conical bottom outlet (3), tail gas outlet pipe ( 2), a primary cylinder (5) and a secondary cylinder (6) coaxial with the cylindrical rotating chamber (7) connected to the tail gas outlet pipe (2), a cylindrical furnace chamber (8), Close furnace top (9), the liquid nozzle (optional position such as 10-12 etc. positions) and nozzle connecting pipe arranged on the axis of described cylindrical furnace chamber (8) and nozzle connecting pipe are formed by described cylindrical furnace chamber The side wall of (8) stretches in and is fixed by flange sealing.

[0102] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com