Patents

Literature

246results about How to "Fully pyrolyzed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

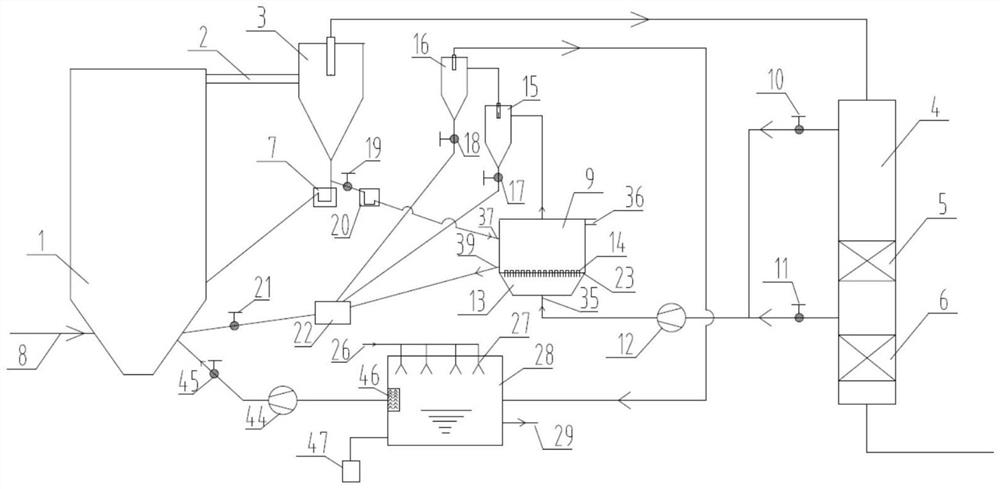

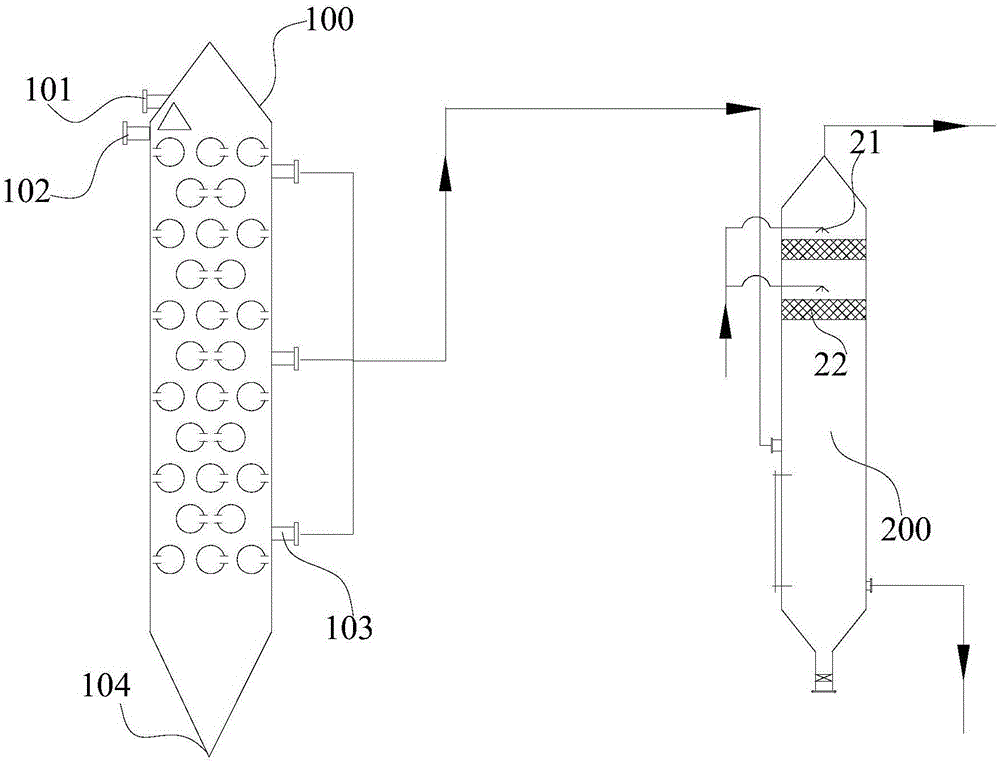

Two-stage gasification method and gasification device for fuels with wide size distribution

ActiveCN102703131AExtensive sources of raw materialsWide particle size distributionCombined combustion mitigationGranular/pulverulent flues gasificationTarProcess engineering

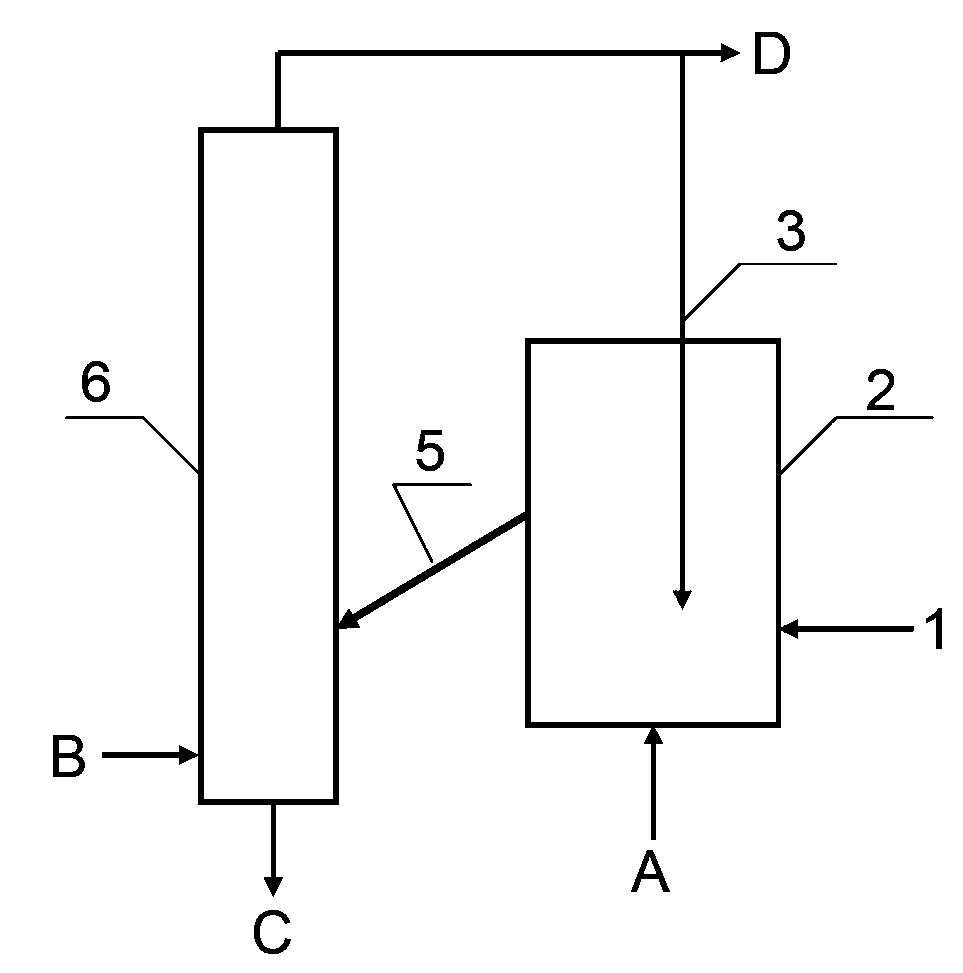

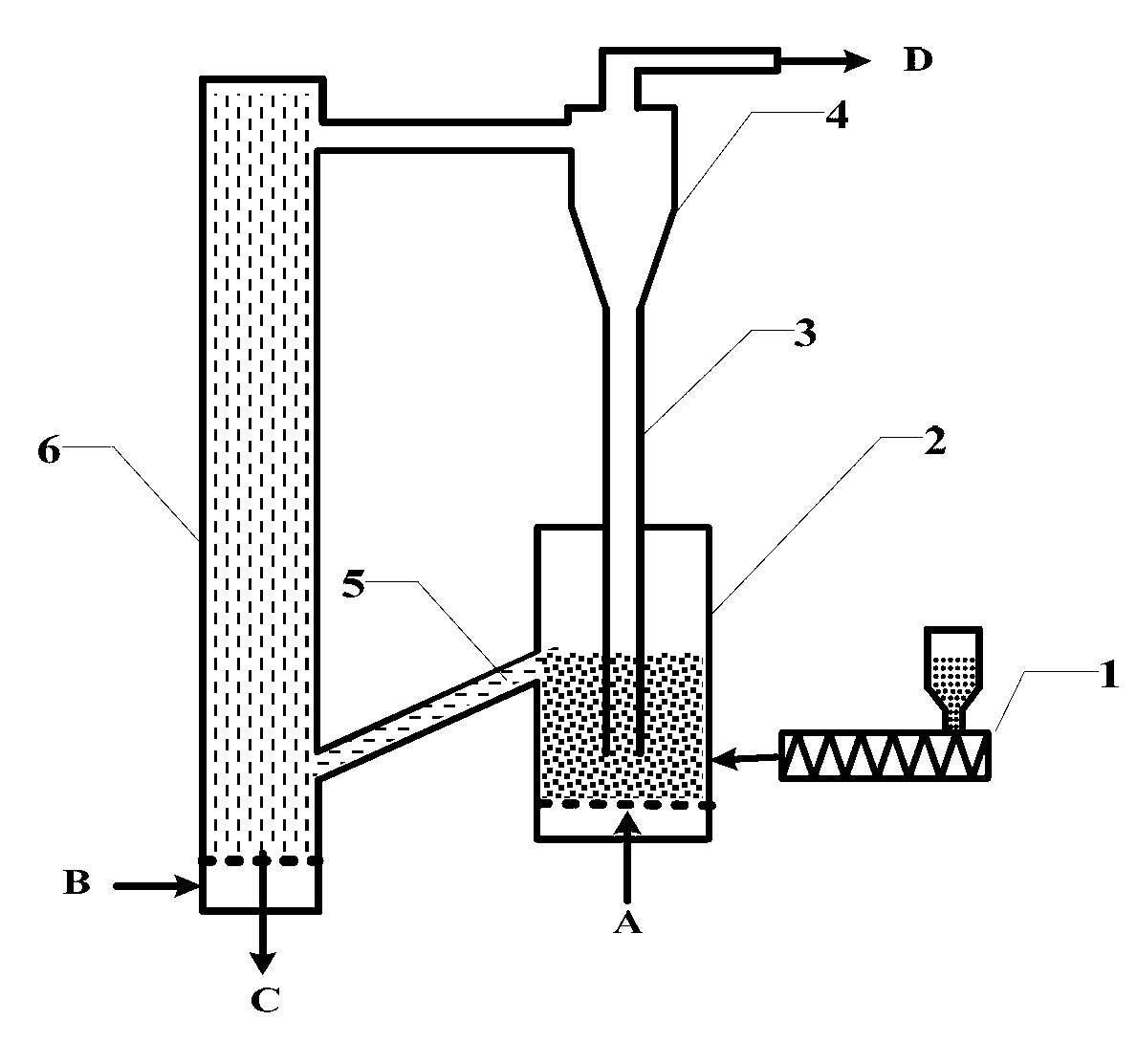

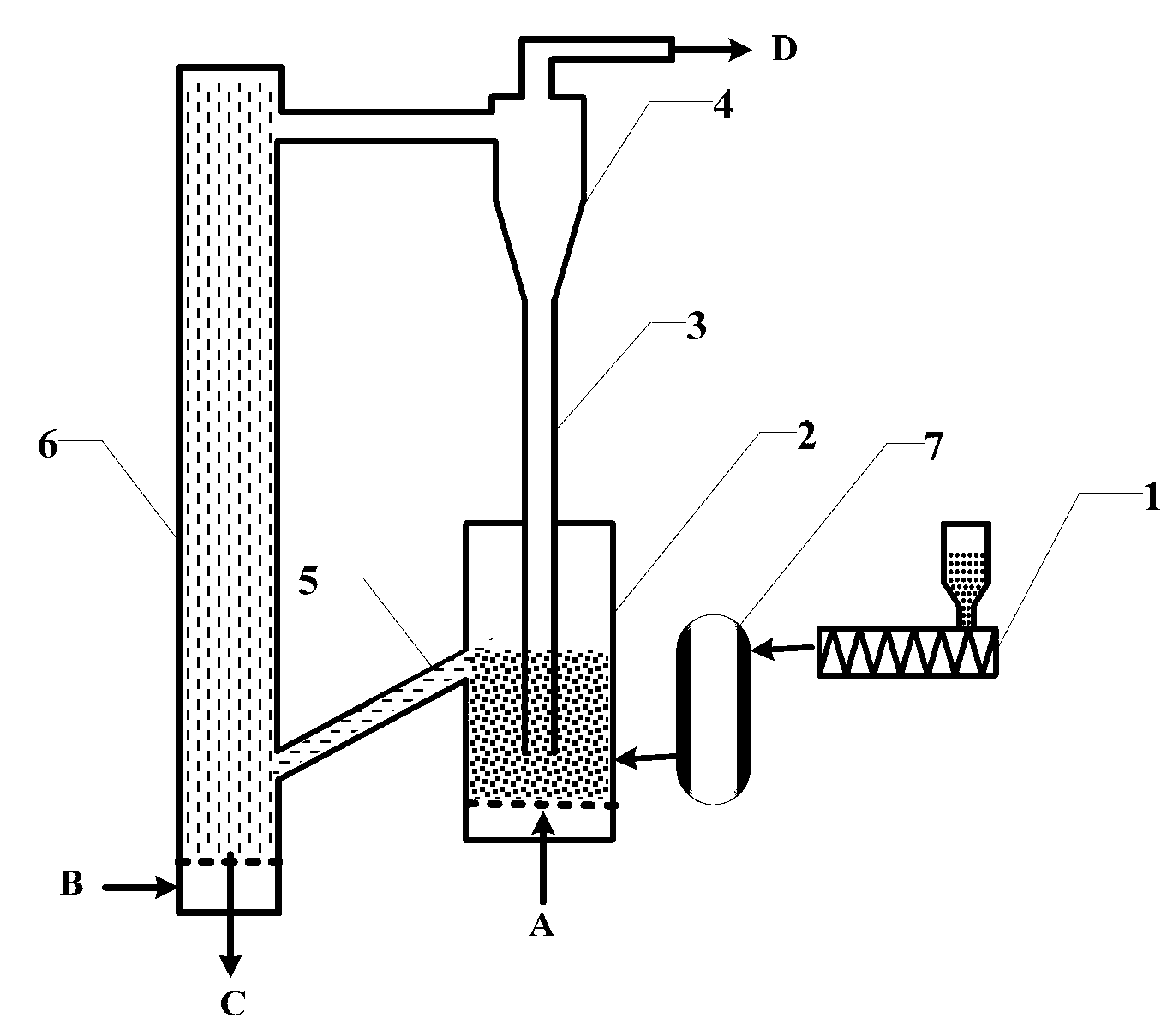

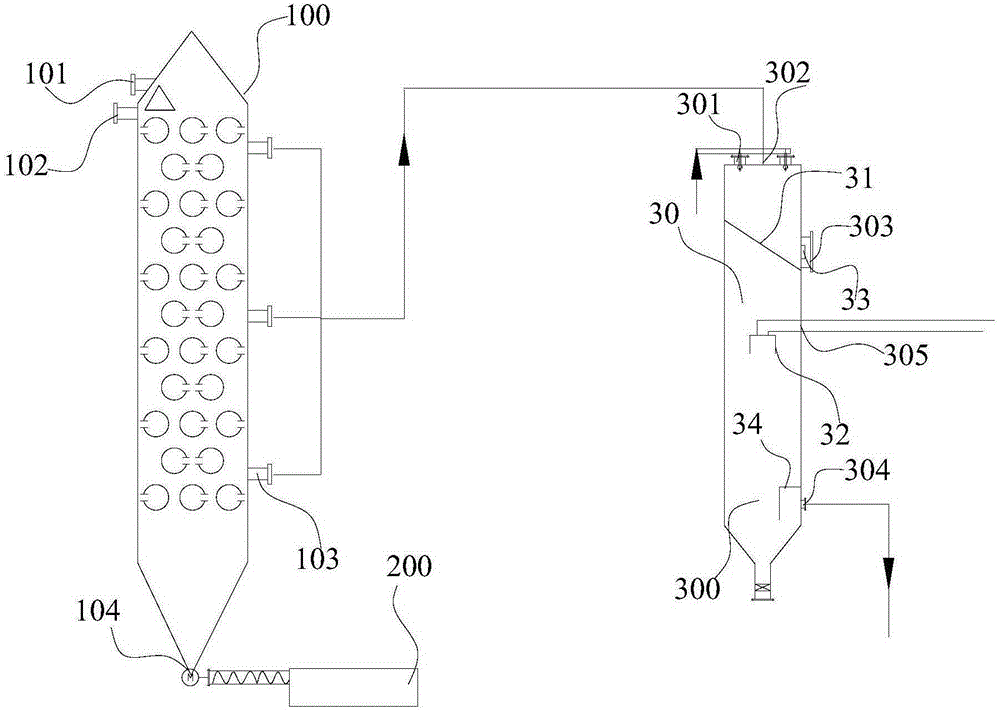

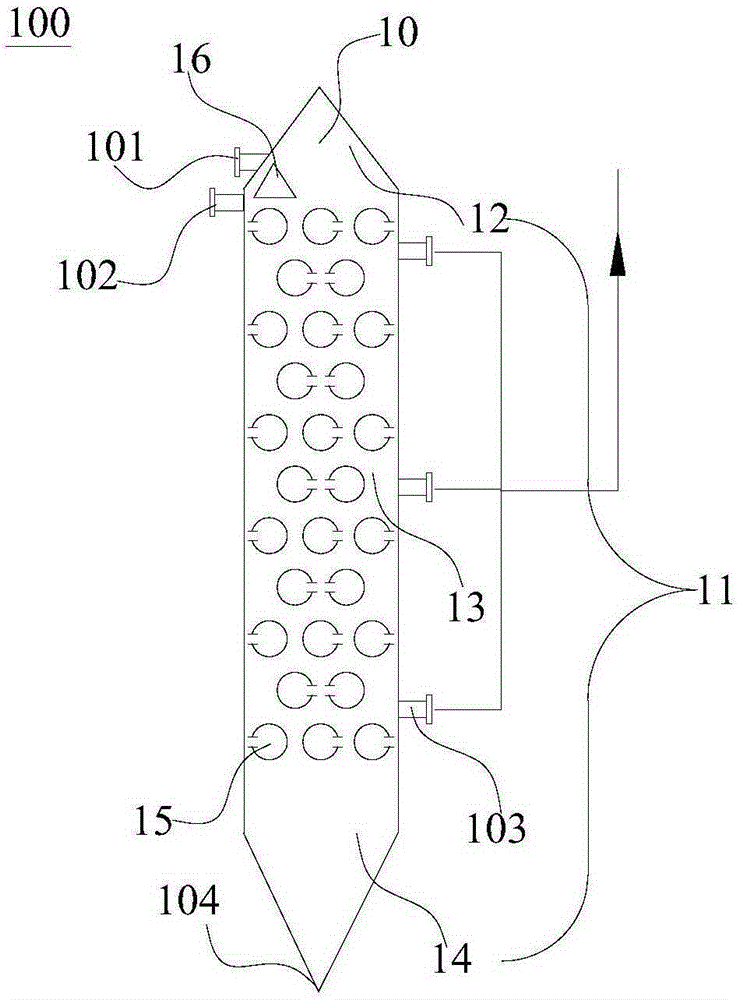

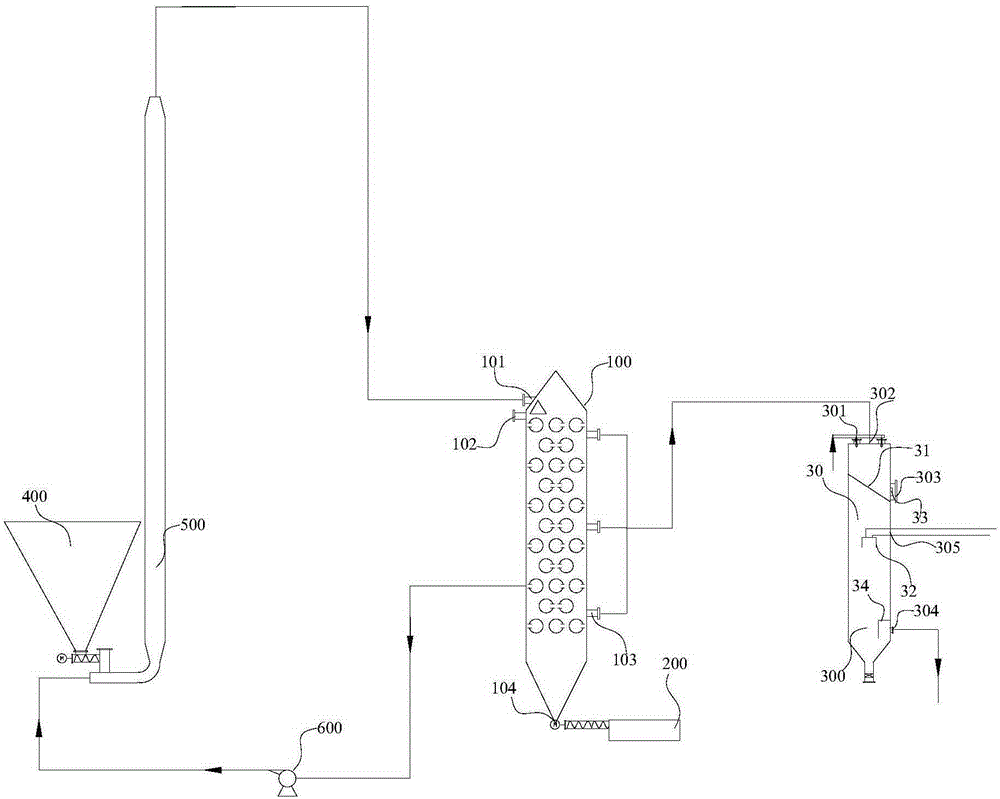

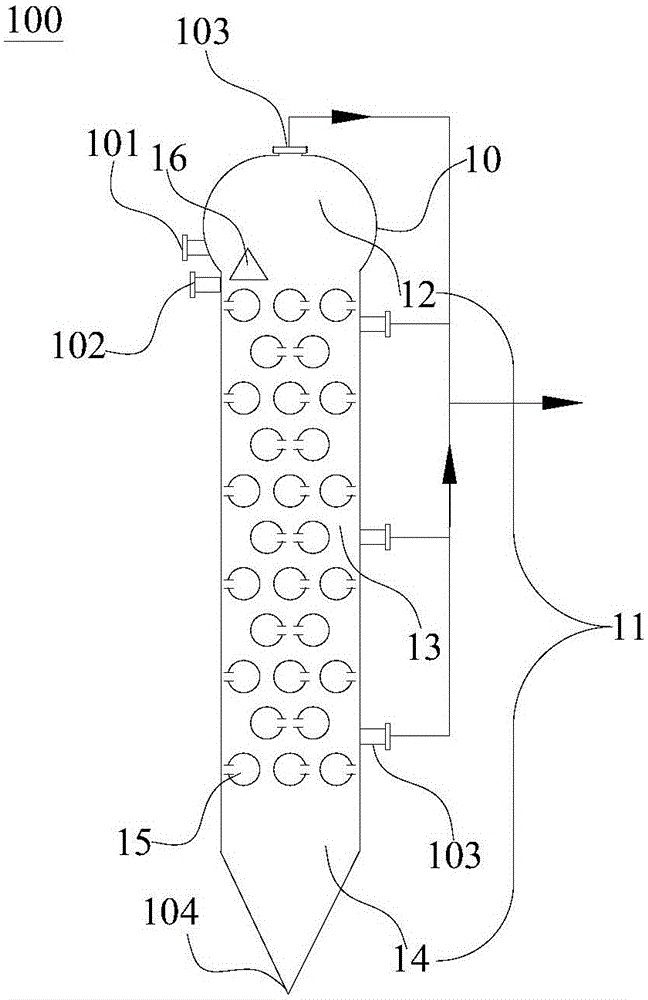

The invention relates to a two-stage gasification method and a gasification device for a fuel with wide size distribution. The two-stage gasification method for the fuel with wide size distribution comprises the steps of 1) adding the fuel to a fluidized bed pyrolyzer by a feeding device; adding a gasifying agent to the fluidized bed pyrolyzer; drying / pyrolyzing or partly gasifying the fuel under semicoking of the pyrolyzer and heating of the gasifying agent; and 2) sending the solid and gas generated in the step 1) to a fluidized bed gasification furnace, adding the gasifying agent to the fluidized bed gasification furnace, finishing complete gasification of semicoke; removing tar by high-temperature pyrolysis, part oxidization and semicoke catalytic reforming in the fluidized bed so as to produce clean gas. With the adoption of the method, the traditional fuel gasification process is divided into a material pyrolysis stage and a semicoke gasification stage, which are performed in an upper fluidized bed pyrolyzer and a lower fluidized bed gasification furnace.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

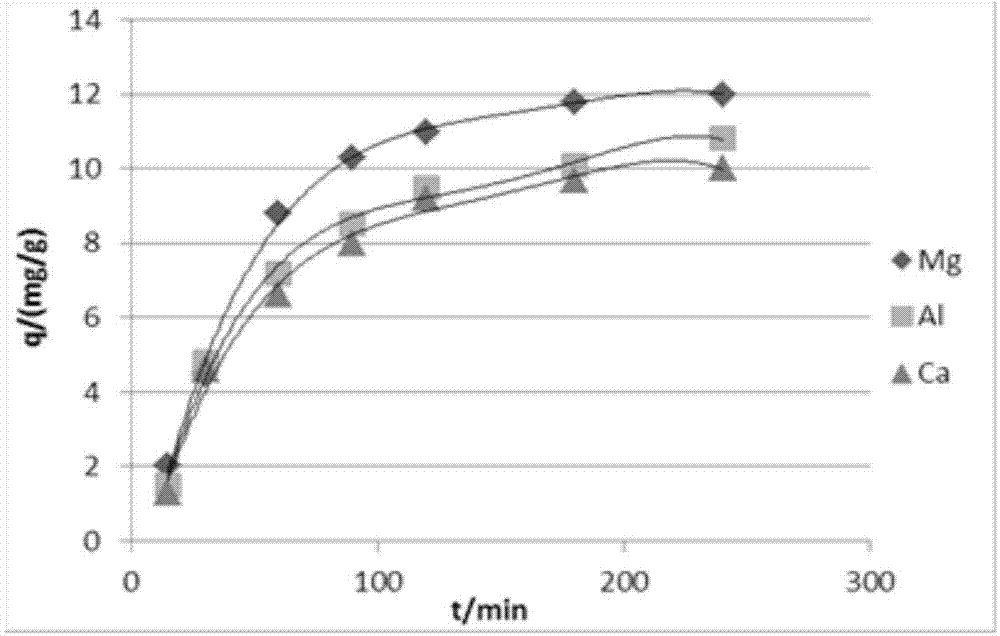

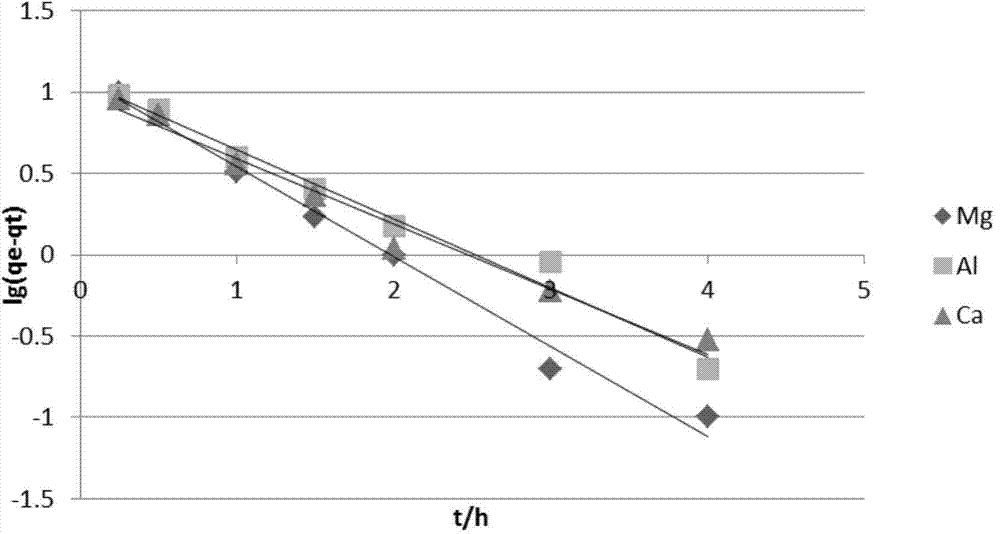

Metal element improved biochar-based nitrate radical adsorbent and preparation method thereof

InactiveCN104258812AEfficient removalReduce pollutionOther chemical processesWater contaminantsAdsorption equilibriumSorbent

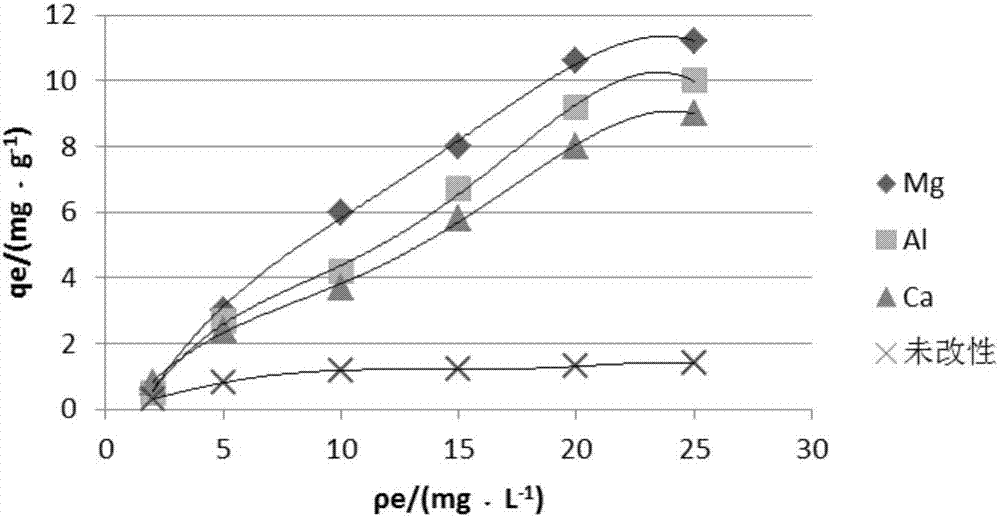

The invention discloses a metal element improved biochar-based nitrate radical adsorbent and a preparation method thereof. Straws are used as raw materials, and metal ions are impregnated, pyrolyzed and washed under certain conditions, so a metal ion improved cbiochar is prepared. According to the metal element improved biochar-based nitrate radical adsorbent and the preparation method thereof disclosed by the invention, by using adsorption research on nitrate radical waste water and comparing the adsorption effect of the biochar before and after improvement, the improved biochar prepared by the preparation method disclosed by the invention has good adsorption effect for potassium nitrate, wherein Mg<2+> improved wheat straw biochar has optimal adsorption effect for nitrate nitrogen; compared with the unmodified biochar, the Mg<2+> improved biochar prepared under the optimizing conditions has the advantages that the adsorption performance is improved by 10 times, and the adsorption equilibrium can be realized in a shorter time. The modified biochar adsorbent is a green adsorbent with application potential and can be used for effectively removing the nitrate nitrogen in a water body; besides, the effects of fixing carbon, reducing discharge and relieving the non-point source pollution are achieved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

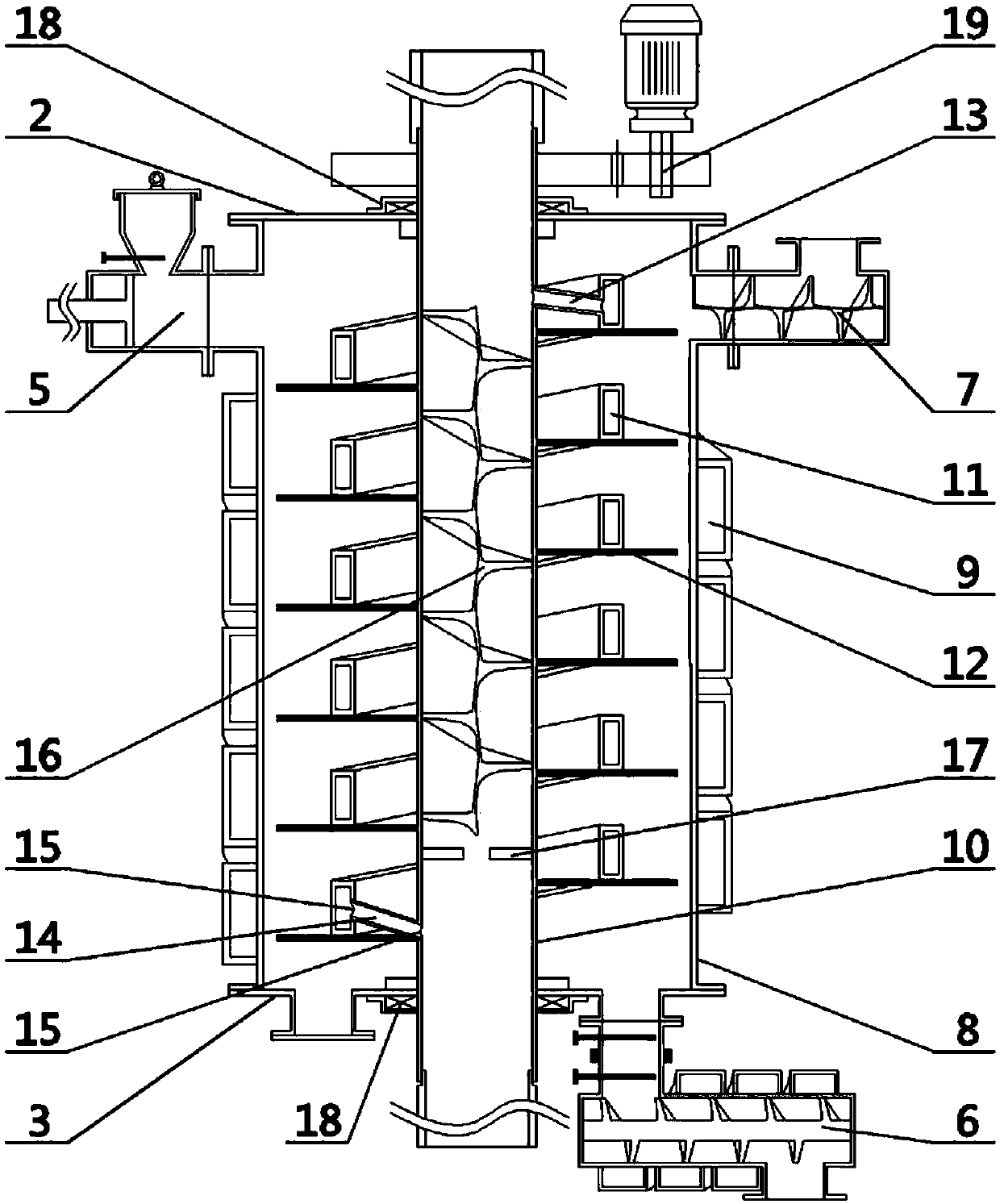

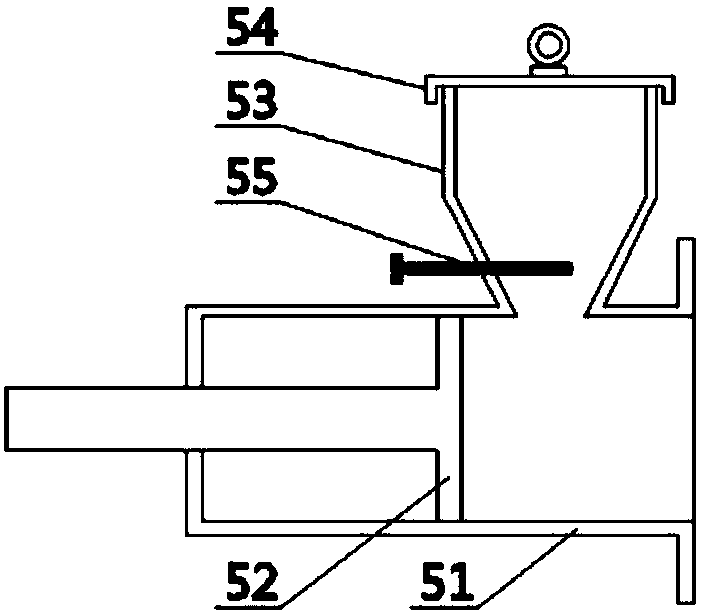

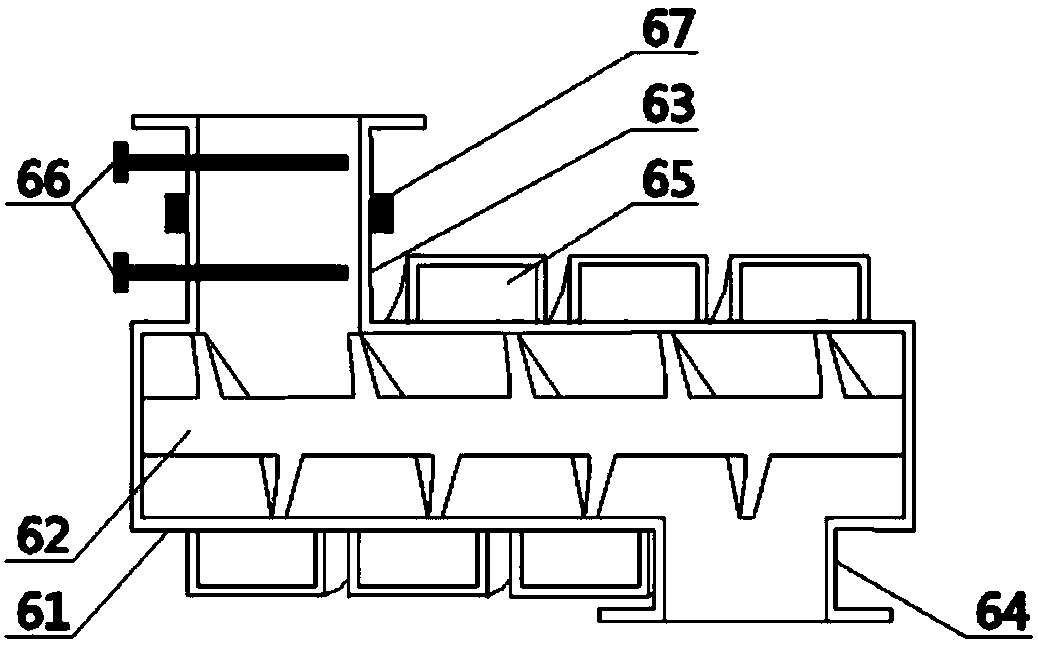

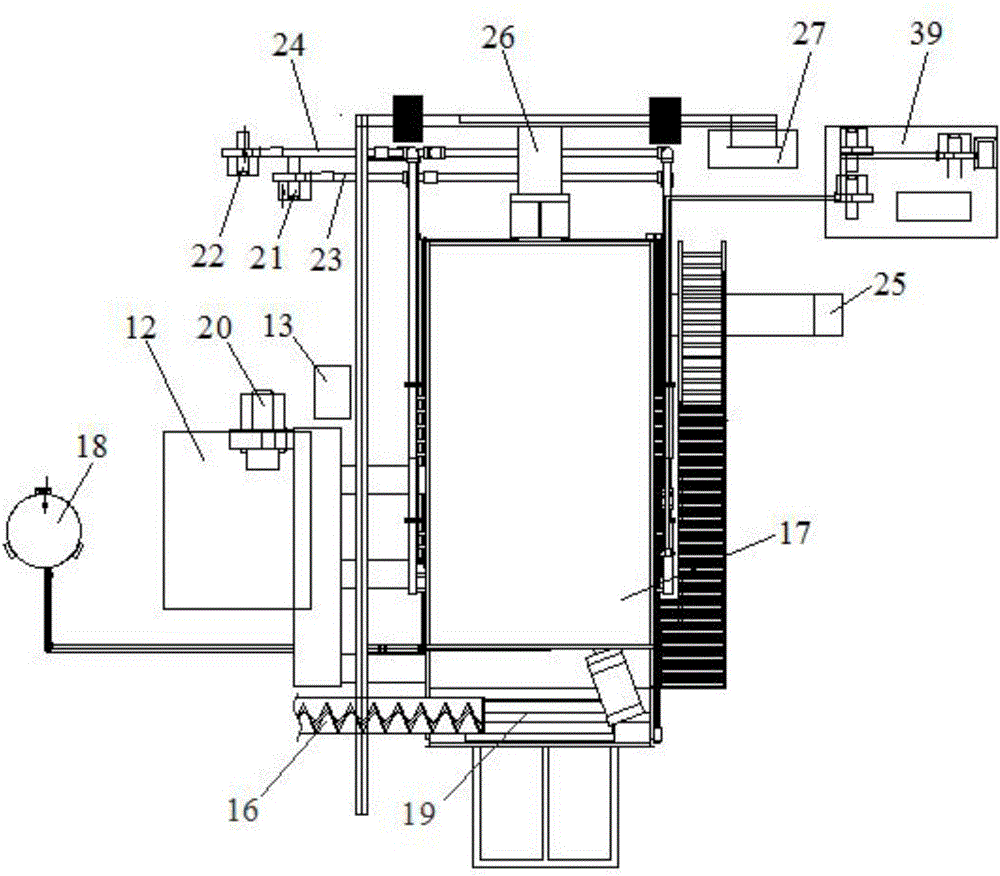

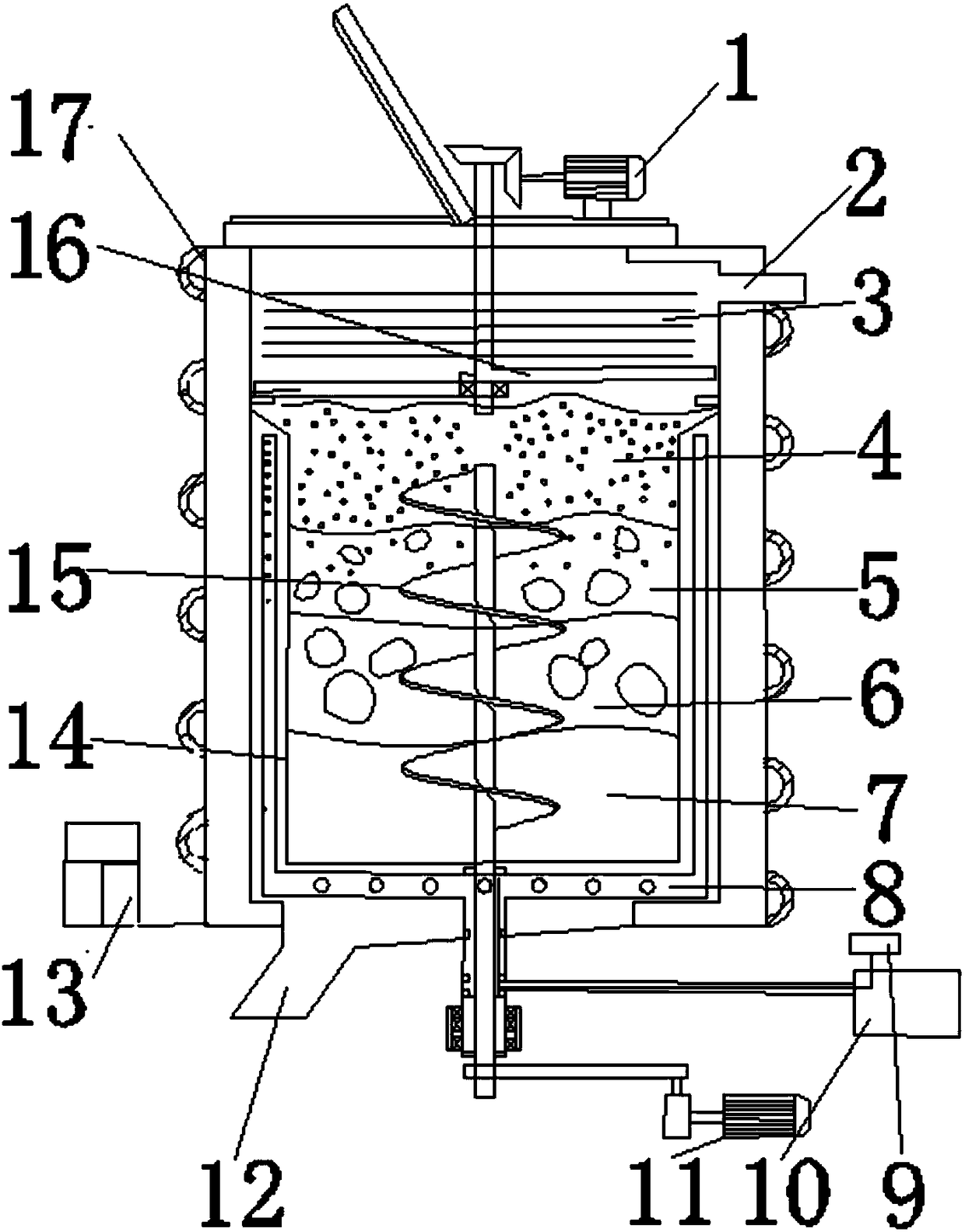

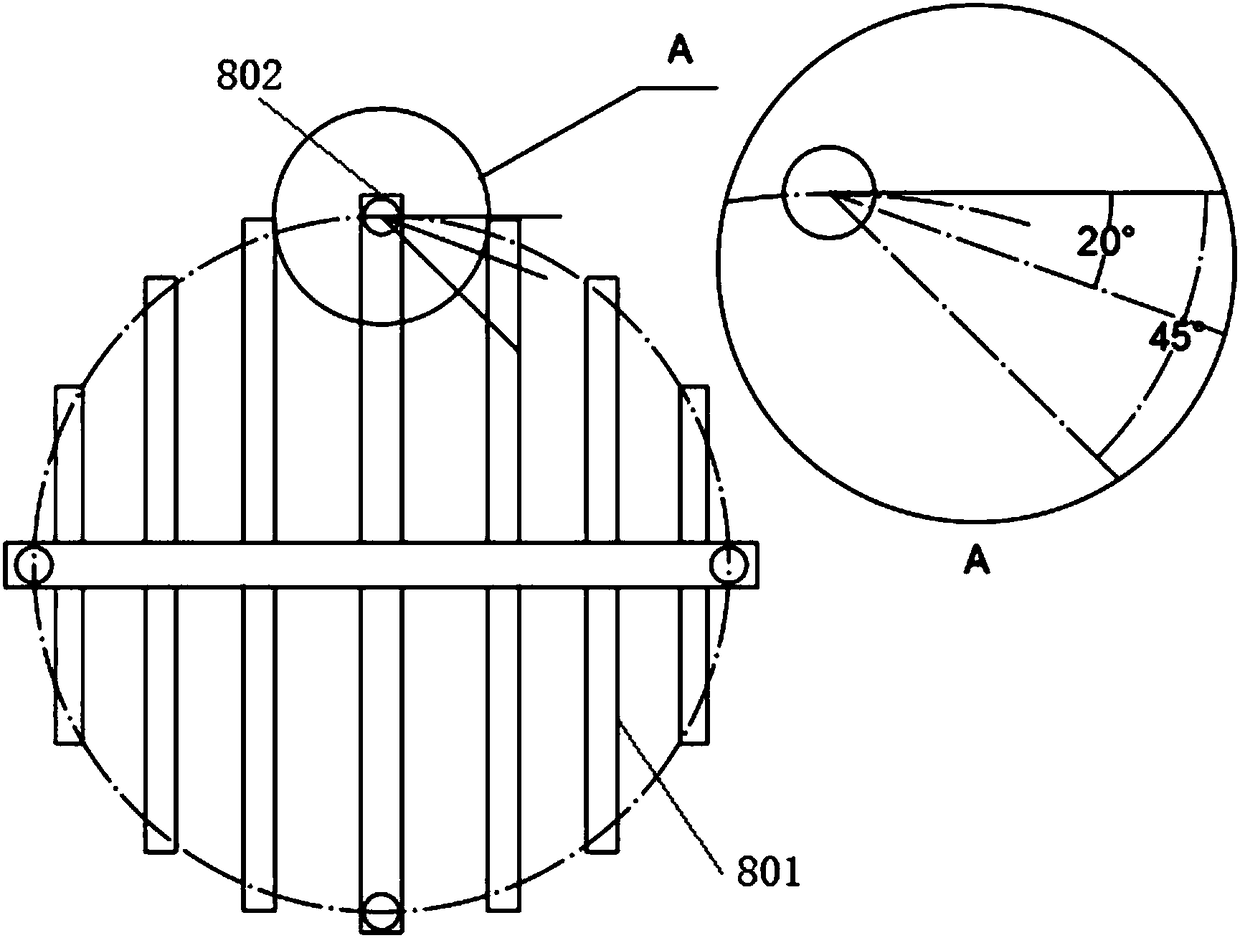

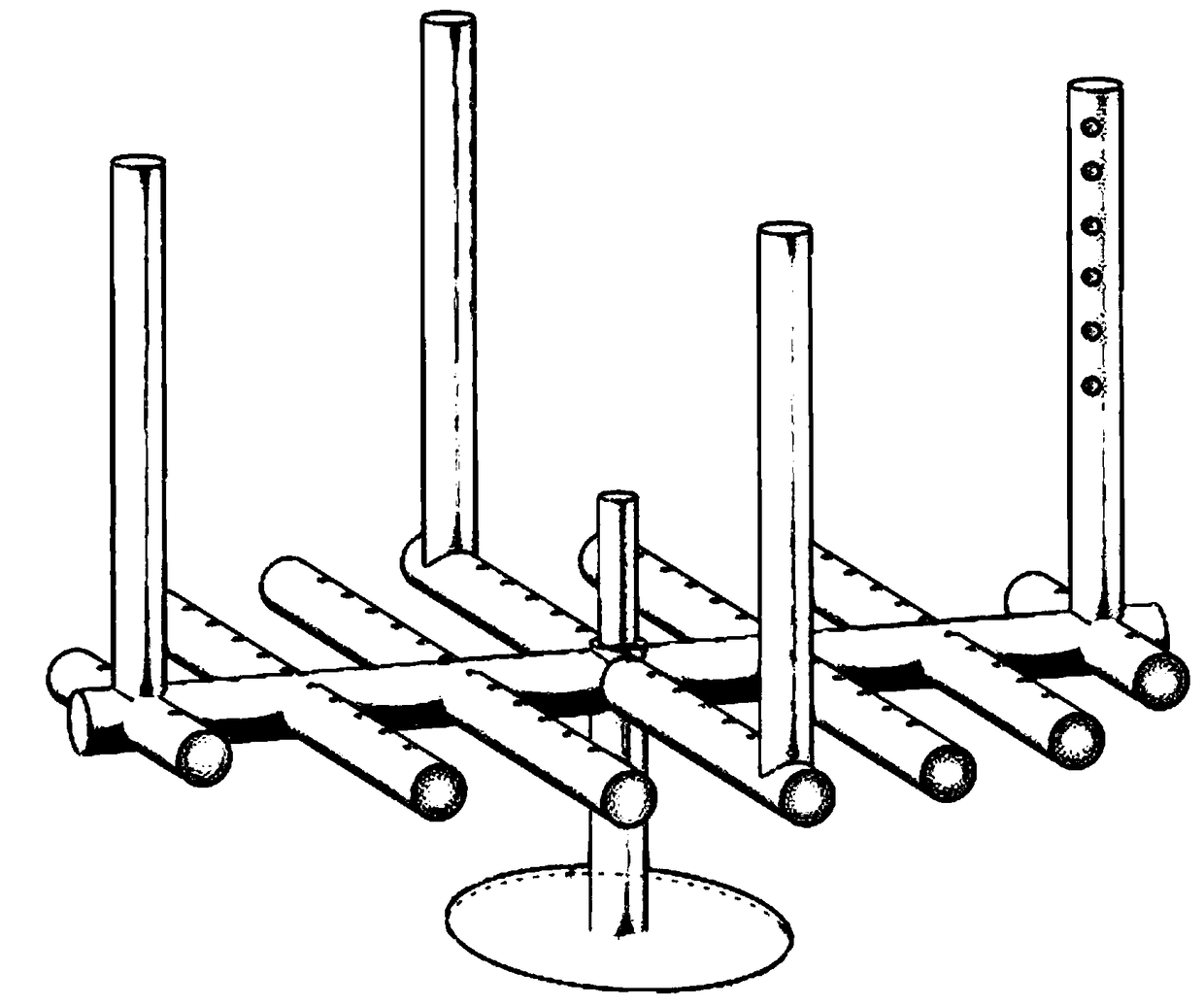

Vertical multidirectional heating organic solid waste pyrolysis device

ActiveCN107649491AExtended stayRelease fullyTransportation and packagingSolid waste disposalSlagEngineering

The invention discloses a vertical multidirectional heating organic solid waste pyrolysis device. Closed pyrolysis space is formed among an outer barrel body, an inner barrel body, an upper end coverand a lower end cover of the device. A spiral coiled pipe serving as an outer heating channel is coiled on the outer wall of an outer barrel of the device, and a feeding opening connected with a feeding device and a gas outlet connected with a pyrolysis gas guide-out device are formed in the outer side face of the upper portion of the outer barrel. A spiral pipe barrel is coiled on the periphery of a center barrel of the device, the spiral pipe barrel is fixed through blades on the outer side of the center barrel, the two ends of the spiral pipe barrel communicate with the center barrel, a spiral plate is arranged in the center barrel, and therefore a heating gas spiral channel is formed in the center barrel, and a flow limiting hole plate is arranged below the spiral plate. The center barrel is driven by a variable frequency motor, and the lower sealing cover is provided with a slag outlet connected with a slag outlet device. The vertical multidirectional heating organic solid waste pyrolysis device is provided with an inner heating heat source and an inner heating heat source, the inner heat source is divided into a center heat source and a middle heat source, and the pyrolysis device guarantees material anaerote continuity. By means of the spiral channel, the heating area and the heating gas retention time are greatly increased, heat can be fully released, and the productioncapacity can be improved.

Owner:青岛伊诺威能源化工新技术有限公司

Simple method for synchronous preparation of water glass and activated carbon with rice husk pyrolyzed ash

ActiveCN102515156AHigh yieldModulus controllableCarbon compoundsAlkali metal silicatesSilicon dioxideHydrolysis

The invention relates to a simple method for synchronous preparation of water glass and activated carbon with rice husk pyrolyzed ash, and especially relates to a simple method, which takes rice husks as raw materials that are first pyrolyzed so as to obtain pyrolyzed ash with a high C / SiO2 ratio, and then performs synchronous preparation of activated carbon during increasing the modulus of a water glass product. In the method, the main raw material sodium hydroxide is employed for hydrolysis of the pyrolyzed ash under heating and pressurization conditions so as to obtain a high modulus water glass solution, and simultaneously the surface of carbon is activated so as to obtain activated carbon. The pyrolysis method adopted in the invention ensures no secondary pyrolysis in pyrolysis, and also ensures that the volatile matter of the pyrolyzed ash can be fully pyrolyzed and contains no tar component, thus ensuring the whiteness of a silica product prepared in subsequent operations. Compared with other pyrolysis methods, the C / SiO2 ratio obtained in the invention is high, and is beneficial to improve the yield of activated carbon. Also, the produced water glass product has controllable modulus, and the produced activated carbon has good application performance. With simple process and low energy consumption, the method of the invention is easy to realize easy industrialized production and has broad application prospects.

Owner:JILIN UNIV

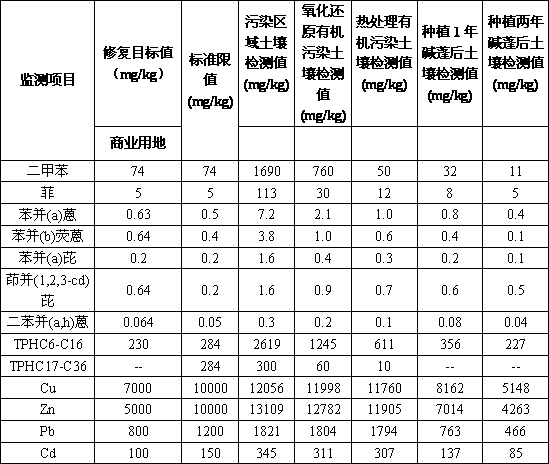

Harmless remediation method of organic polluted soil

InactiveCN108723081ASimple fixReach repair levelContaminated soil reclamationGreenhousePollution soil

The invention relates to a harmless remediation method of organic polluted soil. The method comprises the steps of (1) excavating a foundation pit in an organic polluted field; carrying the excavatedorganic polluted soil into a closed greenhouse; adding an oxidant and a catalyst to the organic polluted soil, and fully stirring and uniformly mixing; and accumulating for 24-28h to obtain oxidized and reduced organic polluted soil; (2) thermally treating the oxidized and reduced organic polluted soil for 30-50min under the temperature of 150-200 DEG C to obtain thermally-treated organic pollutedsoil; (3) adding an organic substance to the thermally-treated organic polluted soil, and uniformly mixing to obtain planting soil; and (4) backfilling the planting soil to the foundation pit excavated in a field area, and planting common seepweed herb by a common method. The remediation method is simple; the remediation effect is good; and soil subjected to various pollutions can be remediated.

Owner:HEBEI YUHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

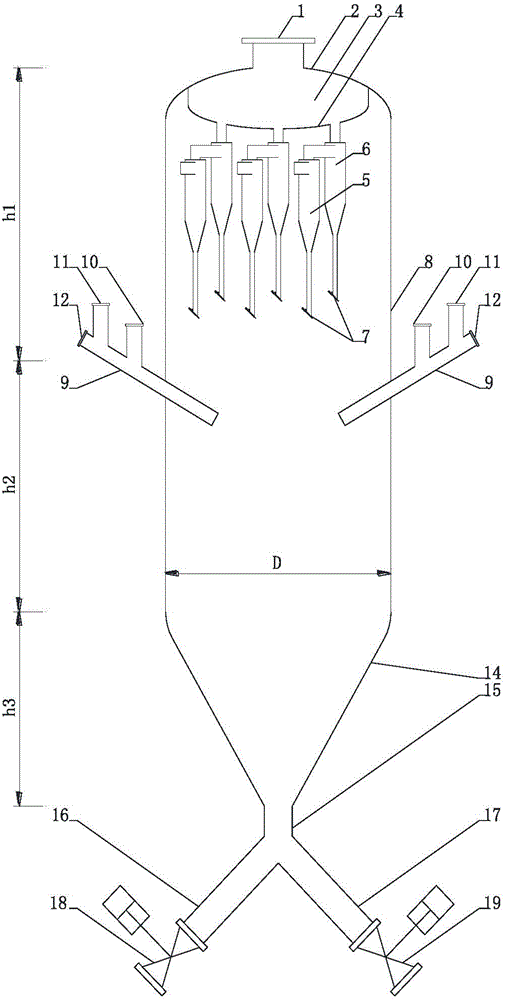

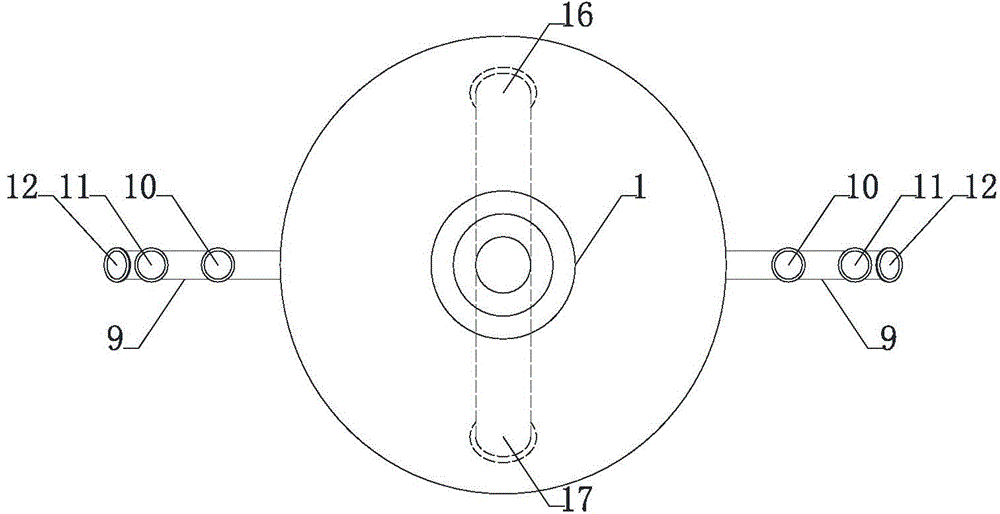

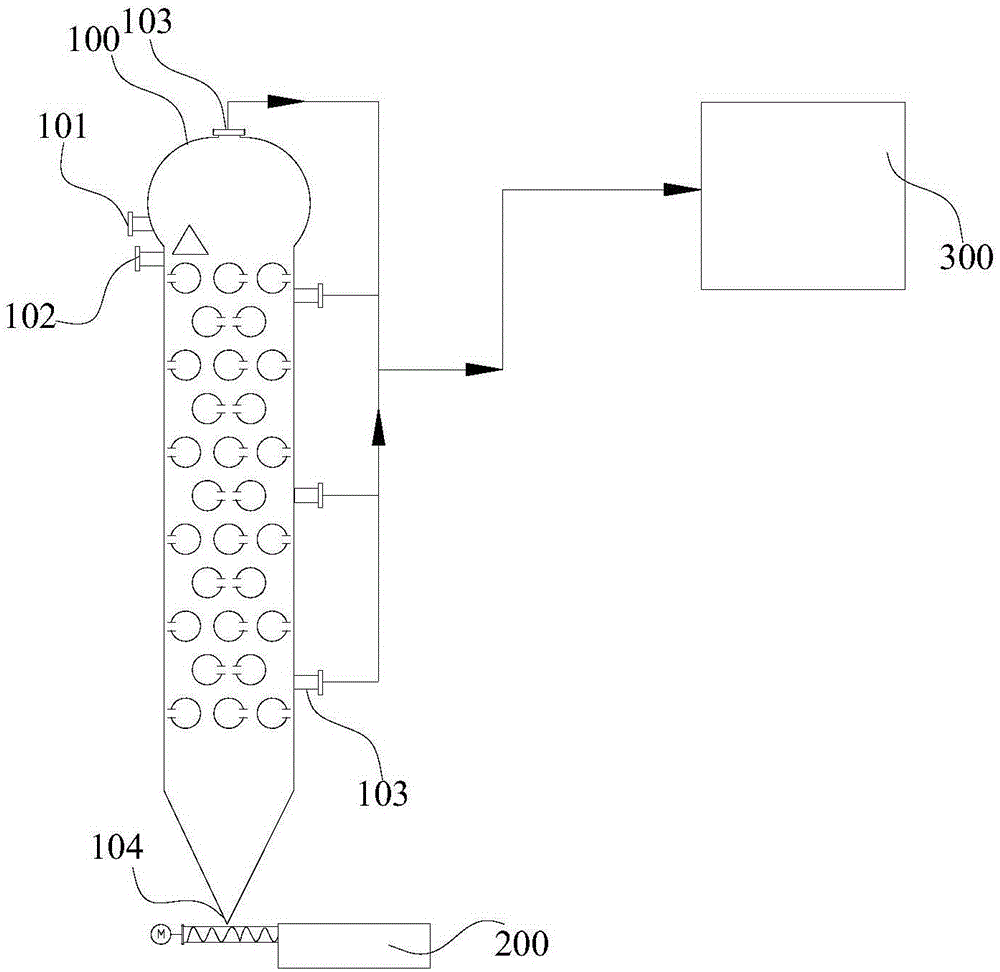

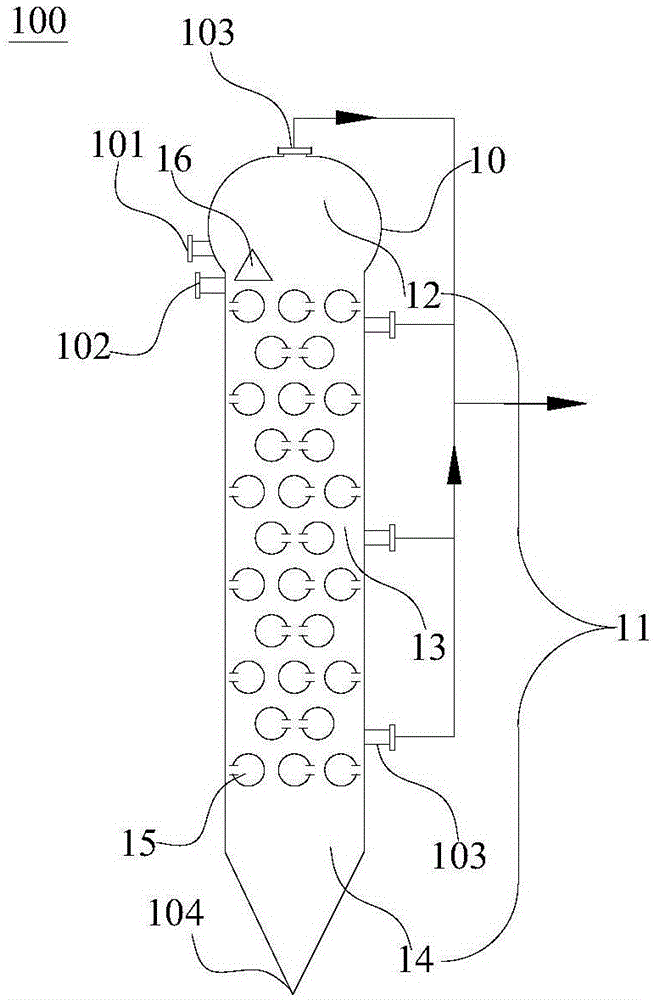

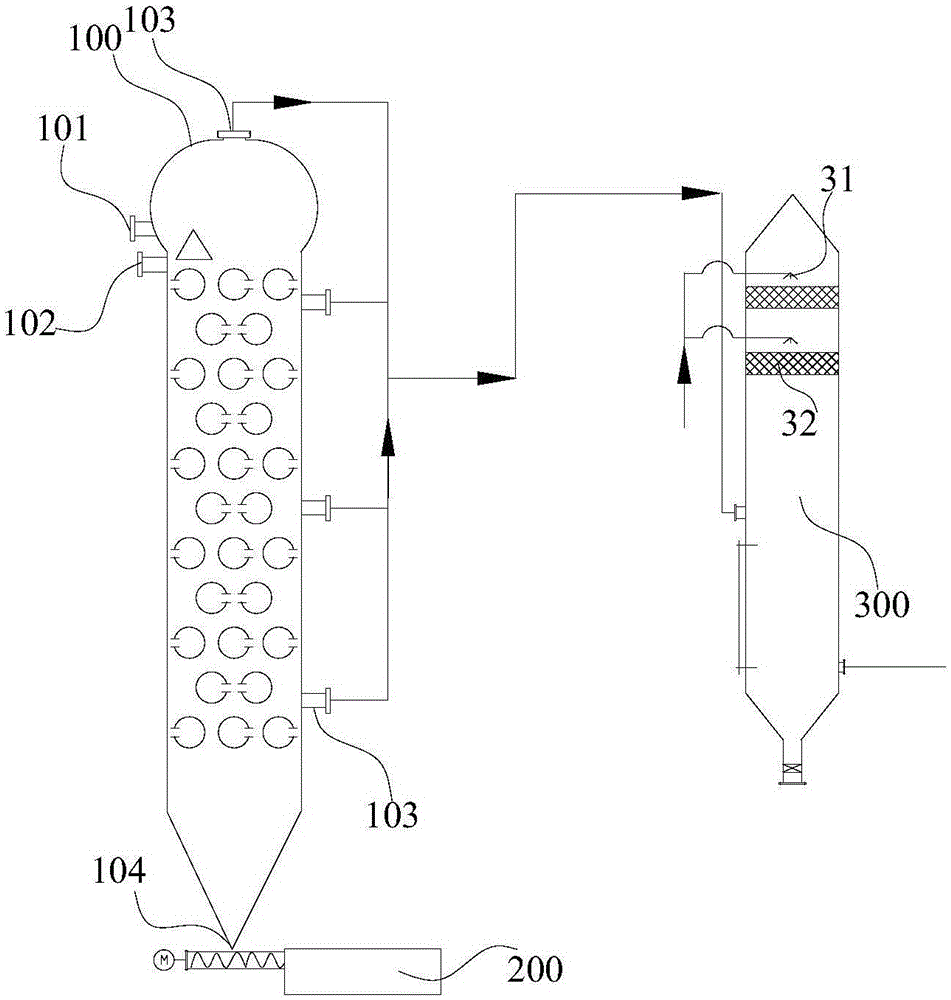

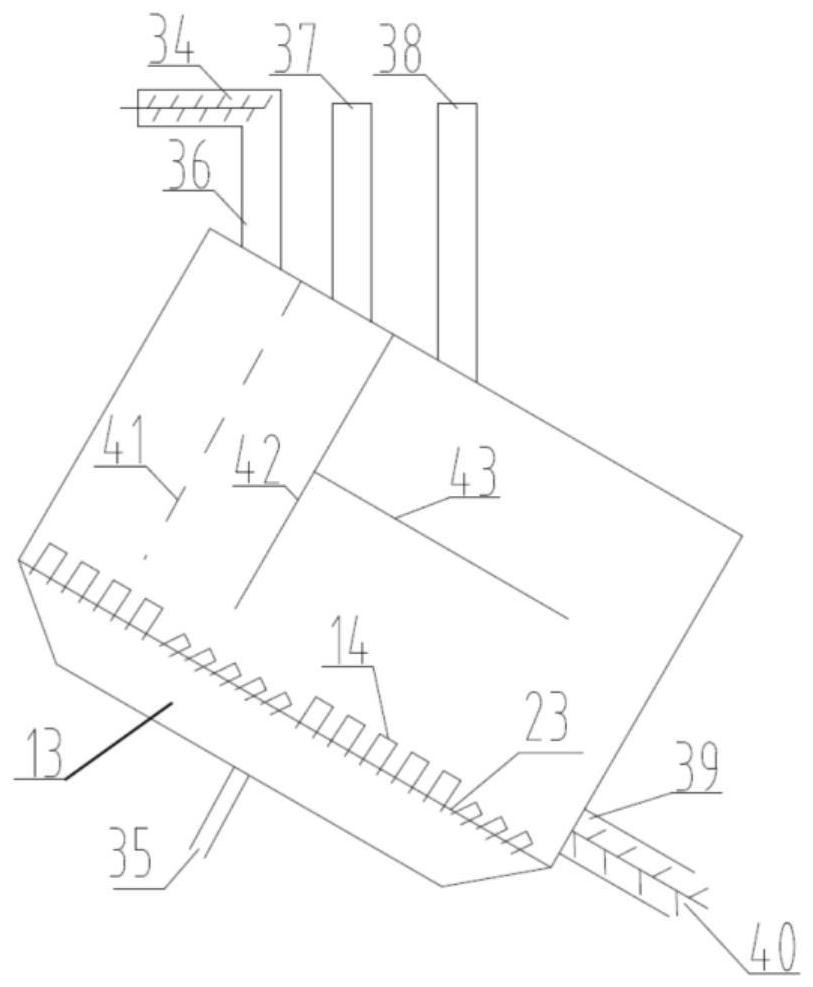

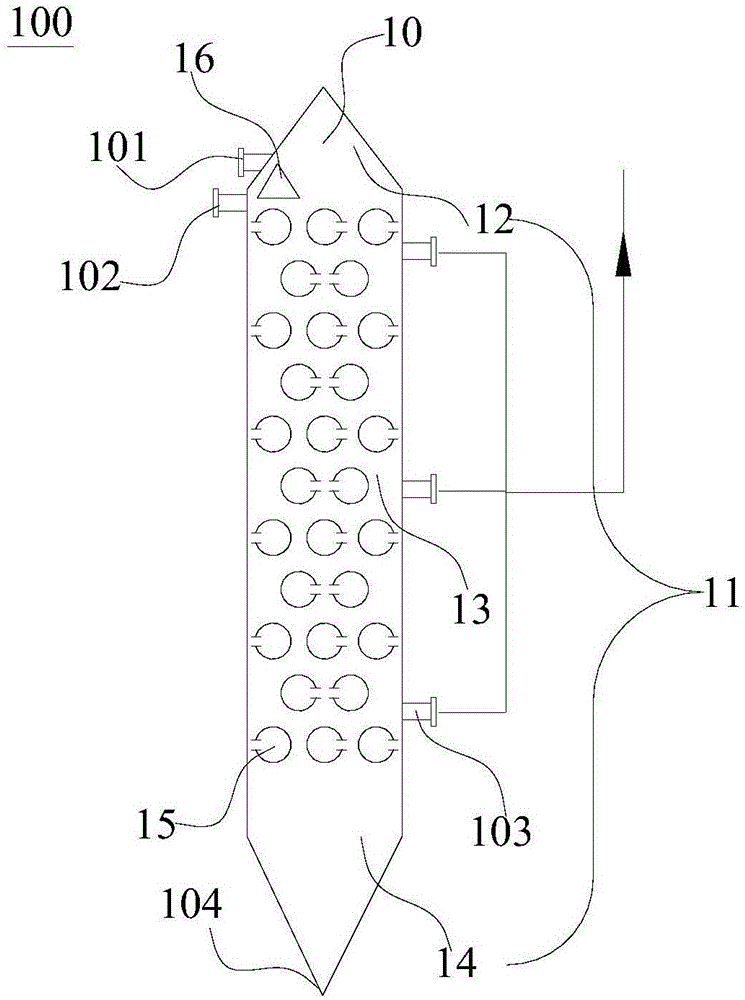

Internally rotary dedusting type solid heat carrier and moving bed pulverized coal pyrolysis method and device

InactiveCN104893747APyrolysis gas contains less dustImprove pyrolysis effectSpecial form destructive distillationHeat carrierEngineering

The invention discloses an internally rotary dedusting type solid heat carrier and moving bed pulverized coal pyrolysis method and device. The internally rotary dedusting type solid heat carrier and moving bed pulverized coal pyrolysis device comprises a cylinder body, wherein an upper sealing head is arranged at the top of the cylinder body; a pyrolysis gas outlet is formed in the middle of the upper sealing head; a collecting pipe box is defined between the upper sealing head and a collecting pipe box sealing head connected with the upper sealing head; a plurality of cyclone separator sets communicated with the collecting pipe box are arranged at the lower part of the collecting pipe box sealing head; a plurality of mixing pipes are symmetrically arranged on the two sides of the cylinder body; a coal gas inlet, a pulverized coal inlet and a heat carrier inlet are formed in each mixing pipe; a tapered lower sealing head is arranged at the lower part of the cylinder body; a discharge pipe is arranged at the bottom of the lower sealing head; a circulating semicoke blanking pipe and a product semicoke blanking pipe are symmetrically connected to the discharge pipe, and the discharge pipe and the blanking pipes form an inverted Y-shaped pipe branch; a valve is arranged on each of the circulating semicoke blanking pipe and the product semicoke blanking pipe. The pulverized coal used as the raw material is adequate in source, cheap, and easy to obtain; the device and the method have the characteristics of being wide in application range, simple in technological process, relatively low in investment, easy to operate, safe, stable and the like.

Owner:神木市锦丰源洁净煤科技有限公司

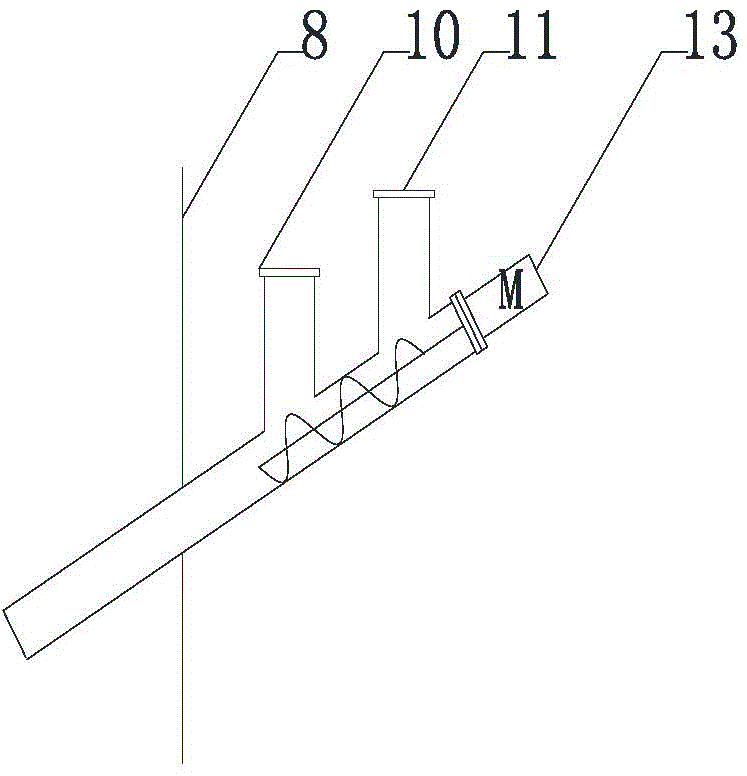

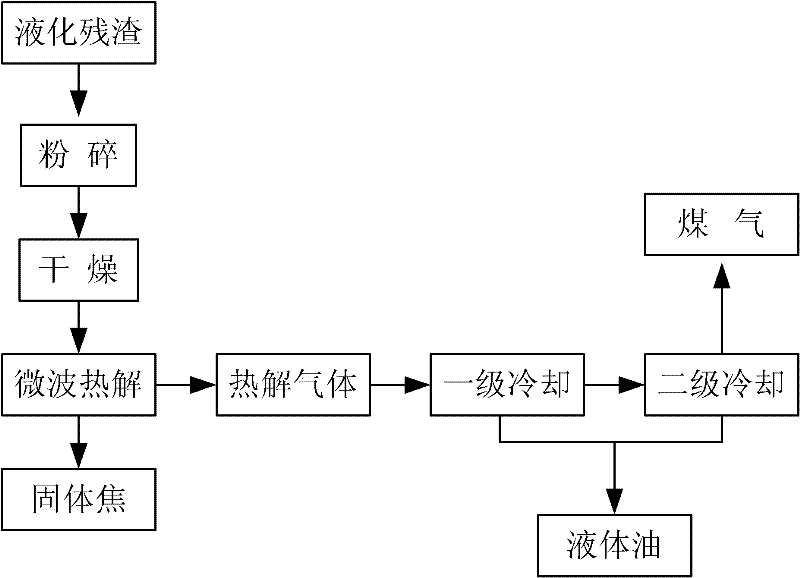

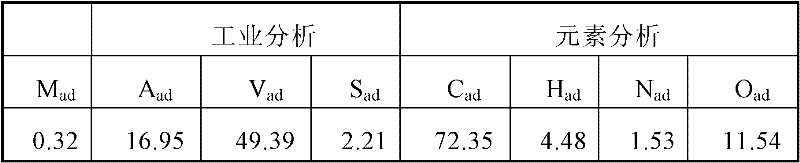

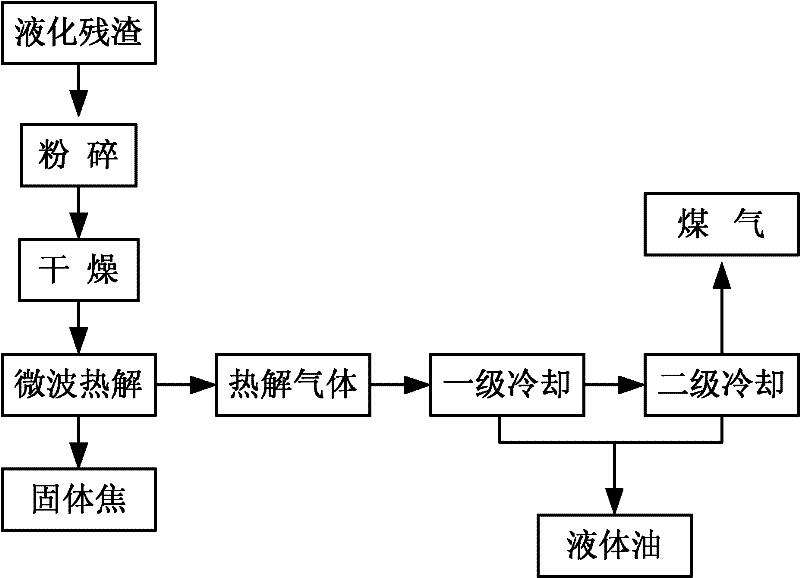

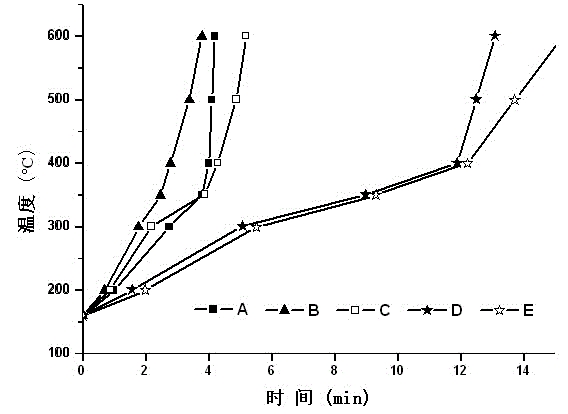

Method for quick pyrolysis of coal direct liquefaction residues by utilizing microwaves

InactiveCN102199434AFast heating rateGood choiceLiquid hydrocarbon mixture productionSpecial form destructive distillationProcess engineeringCoal liquefaction

The invention relates to a method for the quick pyrolysis of coal direct liquefaction residues by utilizing microwaves, which comprises the following steps of: heating the coal direct liquefaction residues to the temperature of between 500 and 900 DEG C by utilizing the microwaves as a heating heat source; crushing the coal direct liquefaction residues to less than 30 millimeters, and putting into drying equipment for drying; and putting the dried coal direct liquefaction residues into a microwave pyrolysis reactor, heating to the temperature of between 500 and 900 DEG C to obtain solid coke and pyrolysis gas, and cooling to separate liquid oil from gas. The method is mainly used for recycling the coal direct liquefaction residues comprehensively, and hydrogen-rich gas is obtained while the liquid oil is separated quickly and efficiently, so the method has characteristics of high pyrolysis speed, production efficiency, yield of the liquid oil and hydrogen content in the gas.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Coal flash pyrolysis system and method

ActiveCN105154120AEvenly dispersedImprove running stabilityIndirect heating destructive distillationSpecial form destructive distillationSlagTar

The invention discloses a coal flash pyrolysis system and method. The coal flash pyrolysis system comprises a flash pyrolysis reactor, a slag cooler and a cooling device. The flash pyrolysis reactor comprises a reactor body, multiple layers of heat storage type radiant tubes, a coal inlet, a distributor, a distribution gas inlet, multiple pyrolysis gas outlets and a semicoke outlet. The slag cooler is connected with the semicoke outlet and is suitable for cooling semicoke. The cooling device is connected with the pyrolysis gas outlets and is suitable for cooling pyrolysis gas so that tar and fuel gas can be obtained. The system can significantly increase the tar yield and greatly simplify the flash pyrolysis reaction technological process.

Owner:SHENWU TECH GRP CO LTD

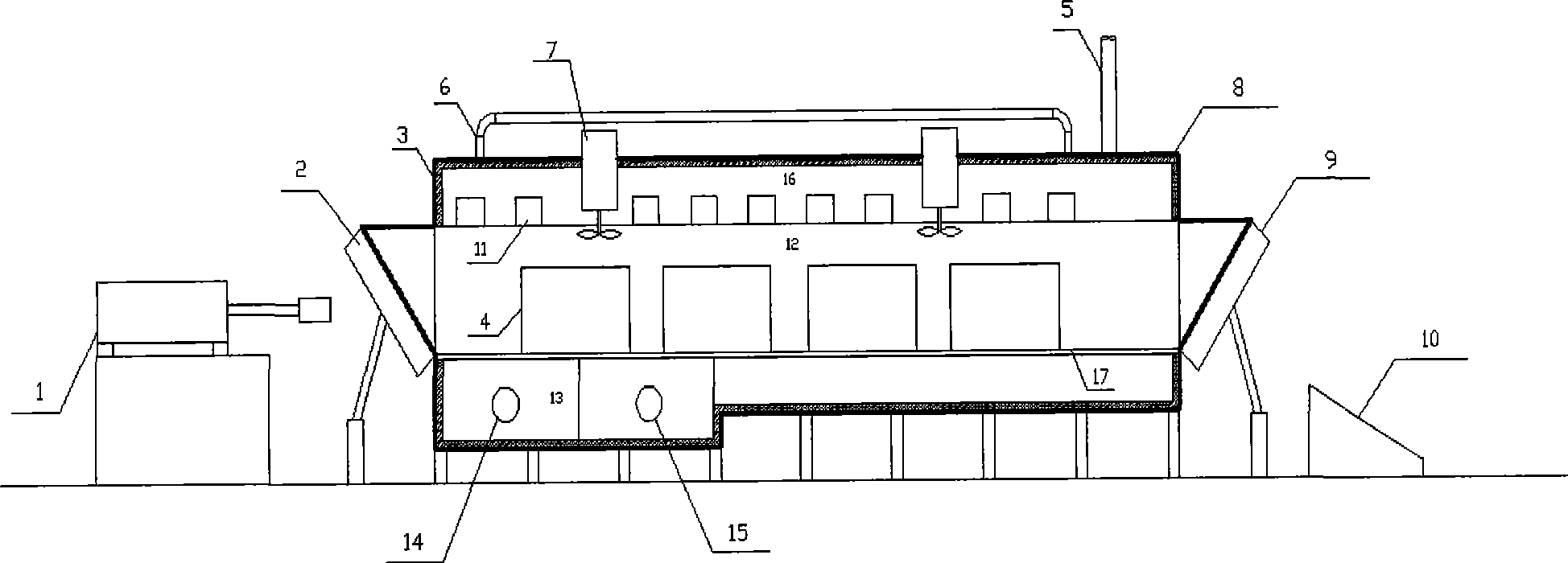

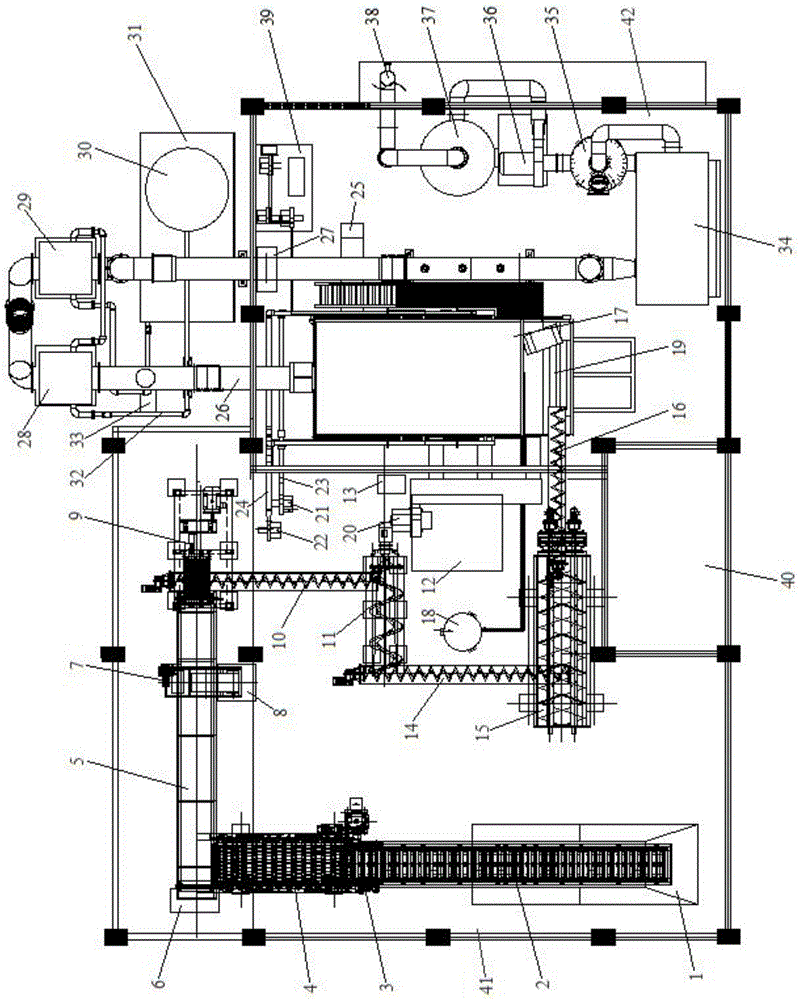

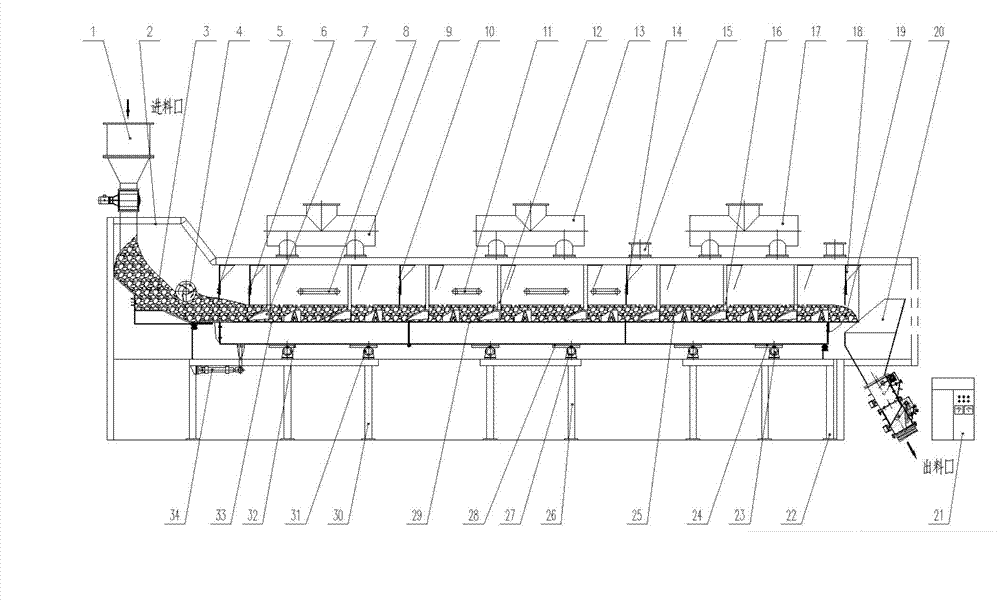

Tunnel type pyrolysis gasifying device and pyrolysis gasification method

InactiveCN101463257AHigh recovery rateFully pyrolyzedSpecial form destructive distillationProduction rateCombustion chamber

The invention provides a tunnel-type pyrolysis gasification device and a pyrolysis gasification method. The tunnel-type pyrolysis gasification device is provided in sequence with a feeding table, a pyrolysis furnace body and a discharging table from a feeding end; both sides of the pyrolysis furnace body are provided with sealing furnace doors, the furnace body is internally provided with a pyrolysis chamber, a combustion chamber and a flue between the pyrolysis chamber and the inner wall of the furnace body, the upper part of the furnace body is provided with an exhaust port and a pyrolysis gas pipeline, the lower part of the furnace body is provided with a pyrolysis gas combustion nozzle and a fuel combustion nozzle, wherein, the tunnel-type pyrolysis gasification device also comprises an electric push rod, a feed frame and a slide rail, the feed frame filled with the feeds is pushed by the electric push rod to get into and out of the furnace body, the slide rail is arranged on the lower part of the furnace body so that the feed frame can slide forwards thereon. By employing the tunnel-type pyrolysis gasification device of the invention, in accordance with the pyrolysis gasification method of the invention, not only the semi-automatic feeding and discharging can be realized to improve the productivity on the basis of the favorable sealing effect, but also the materials can be pyrolyzed completely with simple operations, high metal recovery ratio, good energy-saving effect and little environmental pollution.

Owner:TIANJIN UNIV

Rapid biomass pyrogenation system and method

ActiveCN105176563AEvenly dispersedImprove running stabilityBiofuelsLiquid hydrocarbon mixture productionSpray towerProcess engineering

The invention discloses a rapid biomass pyrogenation system and method. The system comprises a rapid pyrogenation reactor, a residue cooling machine and a spraying tower. The rapid pyrogenation reactor comprises a reactor body, a multi-layer heat storage type radiation pipe, a biomass inlet, a material distributor, a distribution gas inlet, a plurality of pyrogenation gas outlets and a semicoke outlet. The residue cooling machine is connected with the semicoke outlet and suitable for cooling semicoke. The spraying tower is connected with the pyrogenation gas outlet and suitable for spraying pyrogenation gas through cooling liquid so that bio-oil and fuel gas can be obtained. The system can convert biomass into bio-oil with high value-added, and therefore efficient and clean utilization of biomass is achieved, and the rapid pyrogenation reaction technological process is greatly simplified.

Owner:SHENWU TECH GRP CO LTD

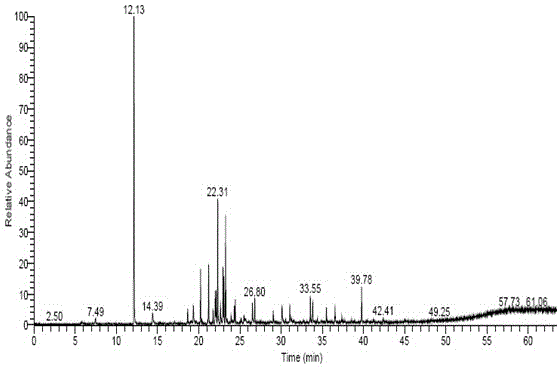

Preparation method for light-aromatic-rich bio-oil

ActiveCN104560091AAlleviate the phenomenon of secondary crackingMitigate or even avoid the phenomenon of secondary crackingLiquid hydrocarbon mixture productionMicrowave pyrolysisOil water

The invention discloses a preparation method for light-aromatic-rich bio-oil. The preparation method comprises the following steps: uniformly mixing a biomass raw material and a microwave additive, performing microwave preheating treatment, then performing microwave pyrolysis, condensing generated pyrolyzed volatile components, and performing oil-water separation to obtain the light-aromatic-rich bio-oil. The target product prepared by the preparation method disclosed by the invention is high in yield, high in component content and low in moisture content; furthermore, the process is simple, a catalyst is not required to be added, and the product can be easily separated; the preparation method is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flash pyrolysis reaction device

ActiveCN105154119AEvenly dispersedImprove running stabilityIndirect heating destructive distillationSpecial form destructive distillationDistributorStorage type

The invention discloses a flash pyrolysis reaction device. The flash pyrolysis reaction device comprises a reactor, multiple layers of heat storage type radiant tubes, a distributor, a material inlet, a distribution gas inlet, multiple pyrolysis gas outlets and a semicoke outlet. The reactor comprises a reactor body, and a reaction space is defined in the reactor body and forms a dispersion zone, a pyrolysis zone and a discharge zone from top to bottom. The multiple layers of heat storage type radiant tubes are distributed at intervals in the pyrolysis zone in the height direction of the reactor body, and each layer of heat storage type radiant tubes comprises multiple heat storage type radiant tubes distributed at intervals in the horizontal direction. The material inlet is located in the position, above the distributor, in the dispersion area. The distribution gas inlet is located in the dispersion zone and communicated with the distributor so that materials in the distributor can be conveniently blown out through distribution gas to enter the dispersion zone and then evenly fall into the pyrolysis zone. The multiple pyrolysis gas outlets are formed in the dispersion zone and / or the pyrolysis zone. The semicoke outlet is formed in the discharge zone. The device can significantly increase the tar yield and greatly simplify the flash pyrolysis reaction technological process.

Owner:SHENWU TECH GRP CO LTD

Garbage disposal combustion furnace and garbage disposal system

PendingCN107525082AReduce moisture contentTo achieve the goal of zero emissionsCombustion technology mitigationAir/fuel supply for combustionCombustion chamberFlue gas

The invention discloses a garbage disposal combustion furnace and a garbage disposal system. The combustion furnace comprises a furnace body, a blower is arranged on one side of the furnace body to ventilate a fire grate, a first combustion chamber and a second combustion chamber are sequentially arranged above the fire grate, a first secondary blower and a second secondary blower are arranged on the outside of the furnace body to ventilate the first combustion chamber and the second combustion chamber respectively, and full combustion of garbage and flue gas is facilitated. When temperature of the first combustion chamber reaches a preset value, an extraction pump extracts a garbage leachate from a leachate filter tank to spray to the first combustion chamber for gasification disposal, and the purpose of zero discharge of the garbage leachate is achieved; after the garbage is combusted in the first combustion chamber, flue gas enters the second combustion chamber for secondary high-temperature combustion, harmful substances in the flue gas are fully pyrolyzed, the flue gas combusted is disposed through a flue gas disposal part, generation of dioxin can be greatly reduced, and the flue gas finally discharged is allowed to meet the national discharge standard.

Owner:珠海市云筒环保设备有限公司

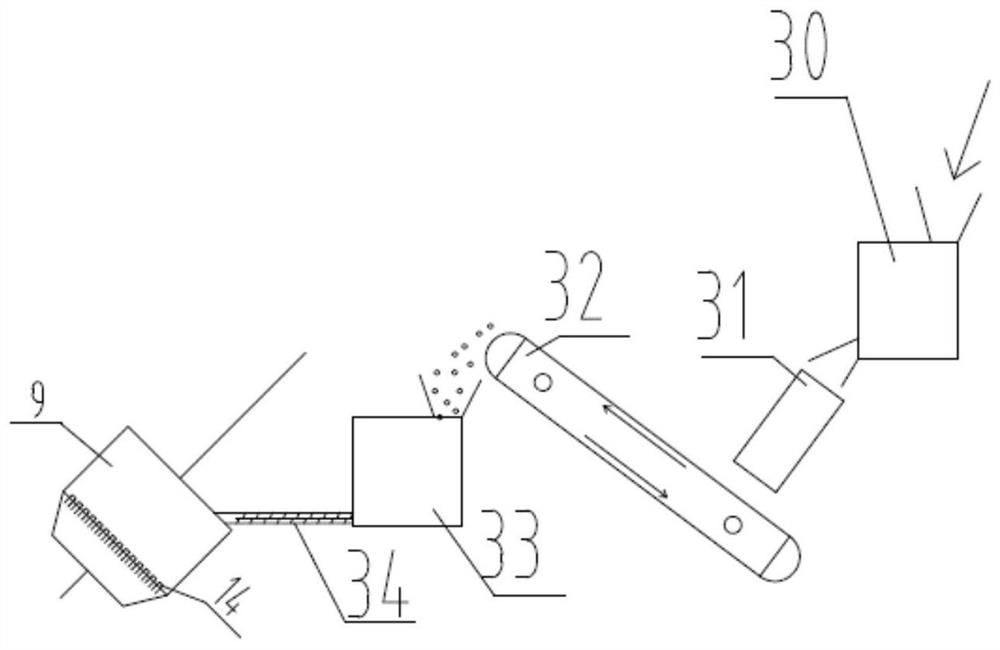

Waste fan blade pyrolysis recovery system and working method thereof

ActiveCN113046107AIndependent and flexible structureHarmlessProductsReagentsFan bladeCirculating fluidized bed boiler

The invention discloses a waste fan blade pyrolysis recovery system and a working method thereof, and belongs to the technical field of resource recovery. The waste fan blade pyrolysis recovery system comprises a crushing system, a circulating fluidized bed boiler system, a pyrolysis reactor, a material collecting and conveying device, a pyrolysis gas-solid separation system and a cracking oil separation system. According to the invention, composite materials in waste blades can be effectively cracked, cracking oil generated by cracking can be recovering, cracking gas is pumped to a hearth to be effectively incinerated, heat value contained in the cracking gas is effectively utilized, pollutants generated in the combustion process can be discharged in a standard reaching mode by means of an environment-friendly device arranged in an original boiler system, and a pyrolysis reaction in a pyrolysis reactor under an anoxic atmosphere effectively avoids the potential problems of dioxin generation and emission, and the like caused by direct incineration of the waste leaves, so that harmless and resourceful treatment of the waste leaves is completely achieved; and before the comprehensive recycling technology of the blade material is mature and utilized on a large scale, the influence of the waste blade on the environment and the like can be effectively solved, and good environmental protection benefits and economic benefits are generated.

Owner:HUANENG CLEAN ENERGY RES INST

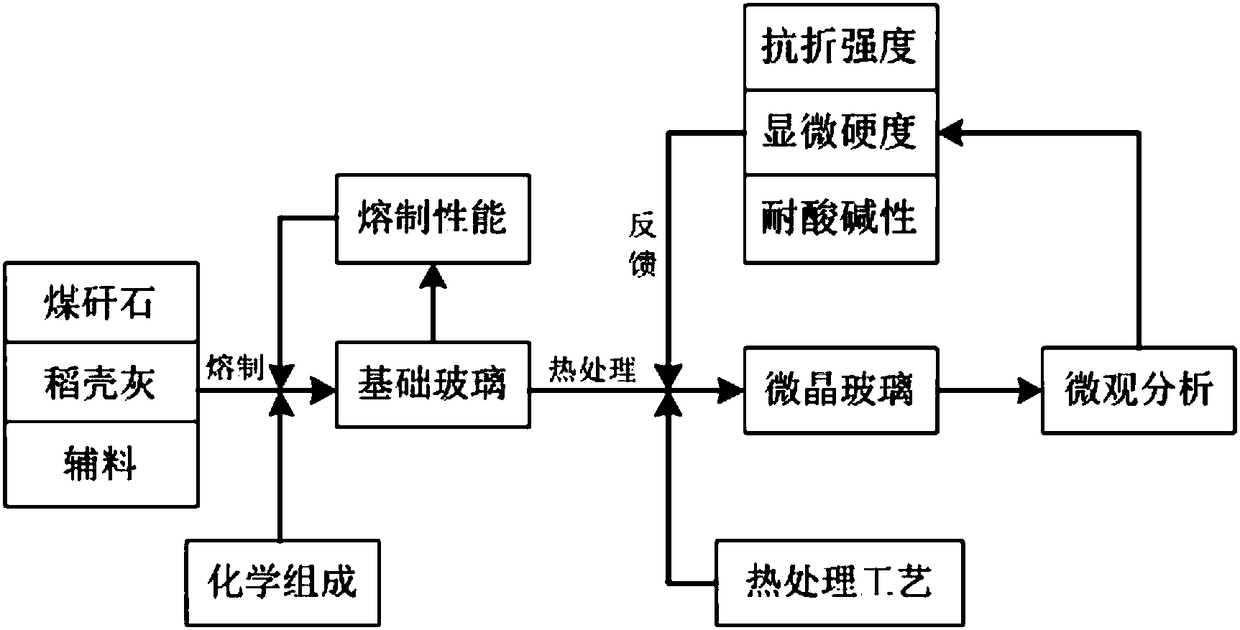

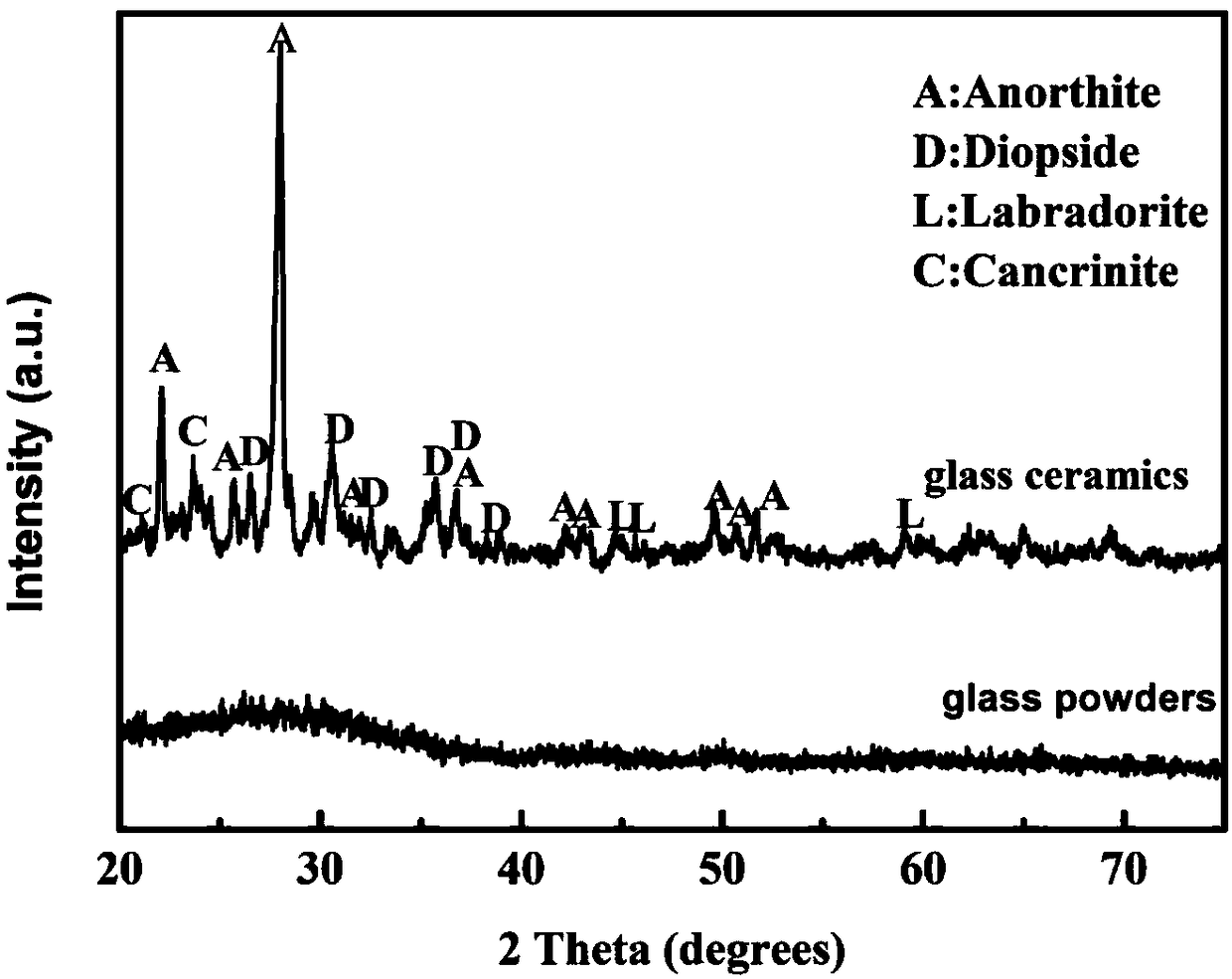

Glass ceramic mainly prepared from coal gangue and rice husk ash and preparation method thereof

ActiveCN108503224ALow costPromote healthy ecological developmentGlass shaping apparatusQuenchingMaterials science

The invention discloses a method for preparing glass ceramic by sintering bulk of solid waste coal gangue and rice husk ash serving as main raw materials. The glass ceramic provided by the invention is prepared from the following raw materials in parts by weight: 28.1 to 32.5 parts of coal gangue, 4.0 to 6.5 parts of rice husk ash, 3.5 to 5.0 parts of sodium carbonate, 7.0 to 8.5 parts of calciumcarbonate, 2 to 3 parts of magnesium oxide and 2 to 3 parts of titanium dioxide. The method comprises the following steps: mixing the ingredients evenly, and heating to a melting temperature of 1,400to 1,450 DEG C; performing quenching, ball milling and tableting on the obtained glass melt, preserving heat at 740 to 790 DEG C and 820 to 870 DEG C for 1 to 1.5 hours, and performing heat treatmentto obtain glass ceramic which takes calciclase as a principal crystalline phase and takes diopside as a secondary crystalline phase. A large amount of SiO2 in the rice husk ash serving as a raw material reduces the high aluminum characteristic of the coal gangue, adjusts the ratio of Si to Al in the formula, and improves the utilization ratio of the solid waste coal gangue and rice husk; moreover,the method has the advantages of simple formula composition, low melting temperature and relatively low heat treatment temperature; the prepared glass ceramic has high compactness, corrosion resistance and wear resistance, and the added value of two solid wastes of coal gangue and rice husk is greatly increased.

Owner:ANHUI UNIV OF SCI & TECH

Wind power blade waste pyrolysis incinerator and control method thereof

The invention discloses a wind power blade waste pyrolysis incinerator and a control method thereof. The wind power blade waste pyrolysis incinerator comprises an incinerator body; a cooling pipe is arranged at the exterior of the incinerator body; an opening is formed in the top of the incinerator body; a smoke vent communicating with the outside is formed in the upper end of the incinerator body; an ash discharge chute furnace is arranged at the bottom of the incinerator body; a working cavity is formed in the incinerator body; an electric control feed door, a spiral agitator, a gas supply and distributing device and an isolation hood are arranged in the incinerator body; the electric control feed door and the spiral agitator are driven by motors correspondingly; the electric control feed door is arranged between a drying zone and a pyrolysis zone; a plurality of through holes are formed in the electric control feed door; the spiral agitator is located in the pyrolysis zone and the combustion zone; the gas supply and distributing device is arranged at the bottom of a combustion zone, is connected with a spiral bearing and can rotate in the incinerator body; and the isolation hoodis arranged on the inner side of the gas supply device and is used for isolating the gas supply device and a wind power blade material. Wind power blade waste can be pyrolyzed and burnt fully, and pollution is reduced.

Owner:上海博士高环保成套工程有限公司

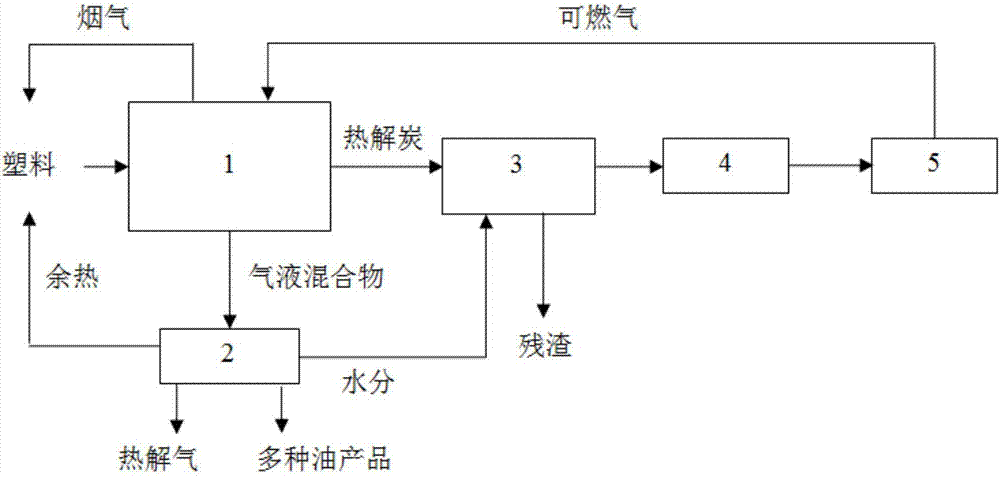

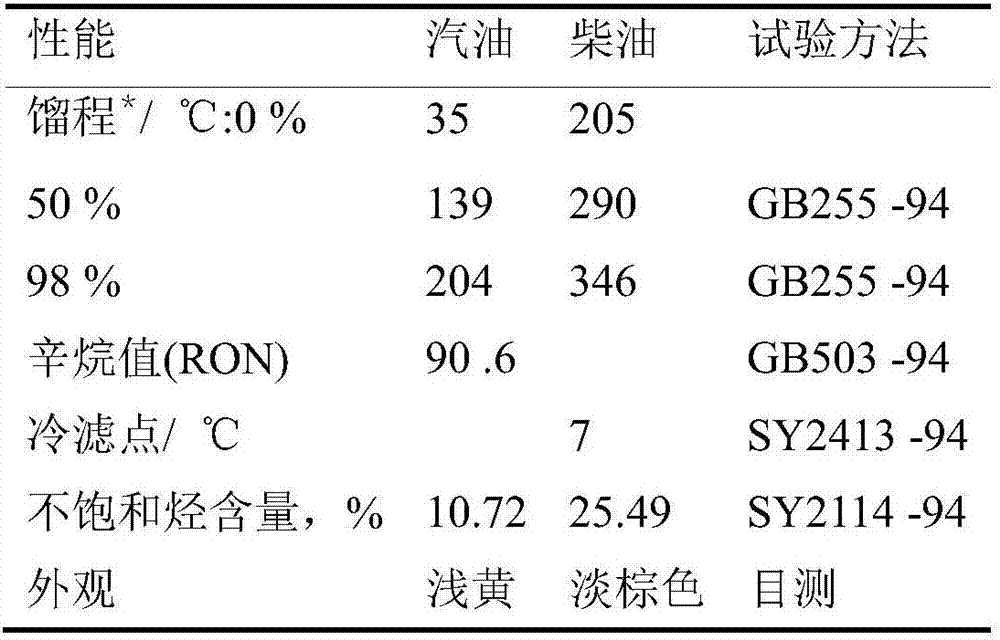

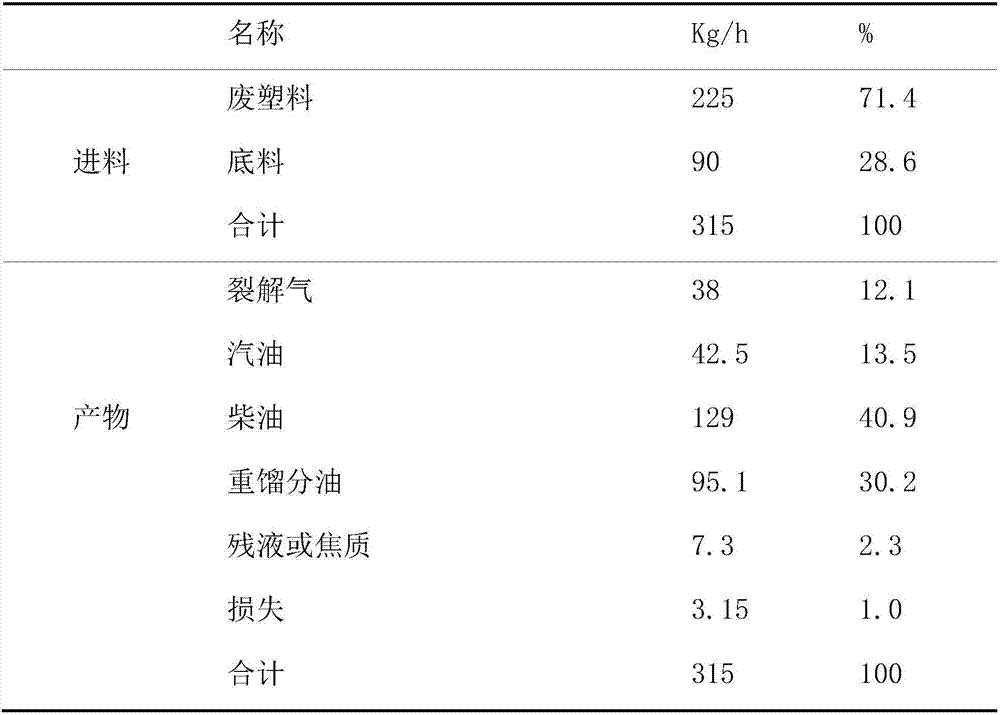

System and method for preparing oil product through pyrolysis and gasification of plastics

The invention relates to a system and a method for preparing an oil product through pyrolysis and gasification of plastics. The system comprises a heatless carrier heat accumulation type rotating bed and a fractionating tower, the heatless carrier heat accumulation type rotating bed comprises a rotating bed pyrolysis furnace, a heat accumulation type gas radiation tube burner, the shell of the rotating bed pyrolysis furnace is provided with a material inlet, a gas and liquid mixture outlet, a material outlet, a combustible gas inlet and a flue gas outlet, the gas and liquid mixture outlet is arranged on the sidewall of the shell, and the bottom furnace of the rotating bed pyrolysis furnace is a rotatable annular furnace bottom; and the heat accumulation type gas radiation tube burner is arranged on the annular furnace wall of the rotating bed pyrolysis furnace, the heat accumulation type gas radiation tube burner comprises an upper heat accumulation type gas radiation tube and a lower heat accumulation type gas radiation tube which are respectively positioned at the upper side and the lower side of the rotatable annular furnace bottom. The heatless carrier heat accumulation type rotating bed adopts radiation tube heating, so air is effectively isolated, generation of dioxins and other harmful gases is reduced, and the stability and the controllability of the oil and gas product are increased.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

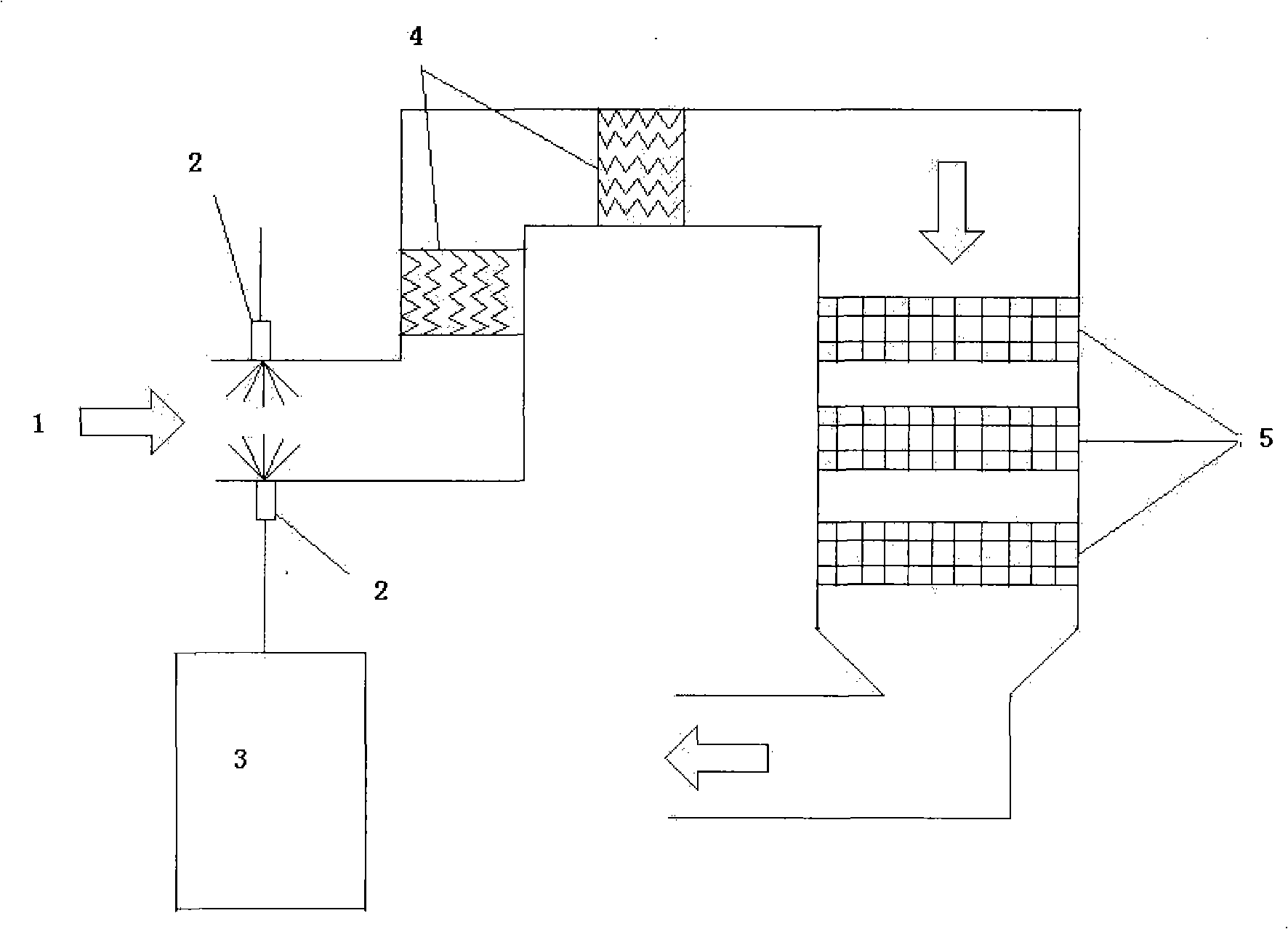

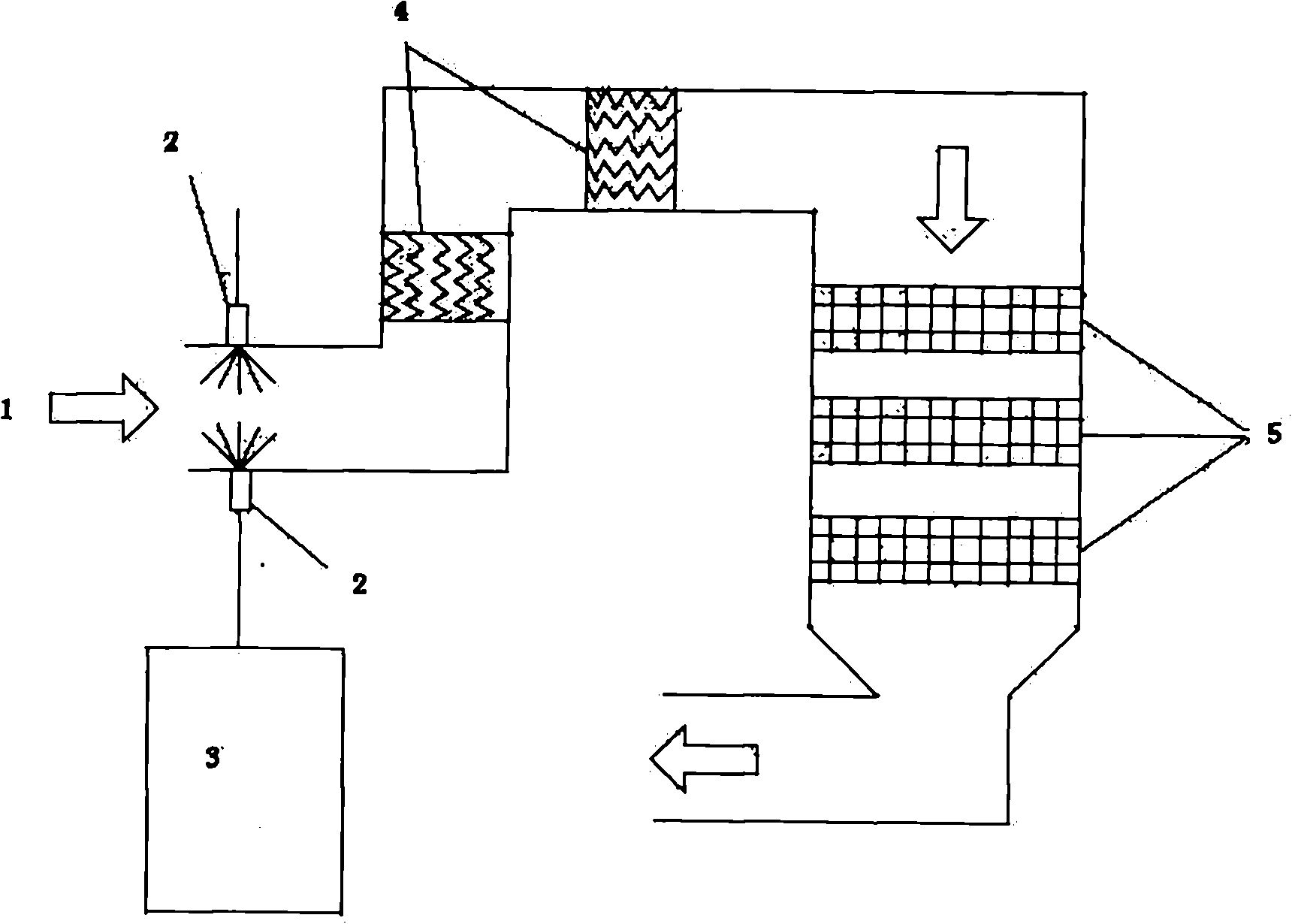

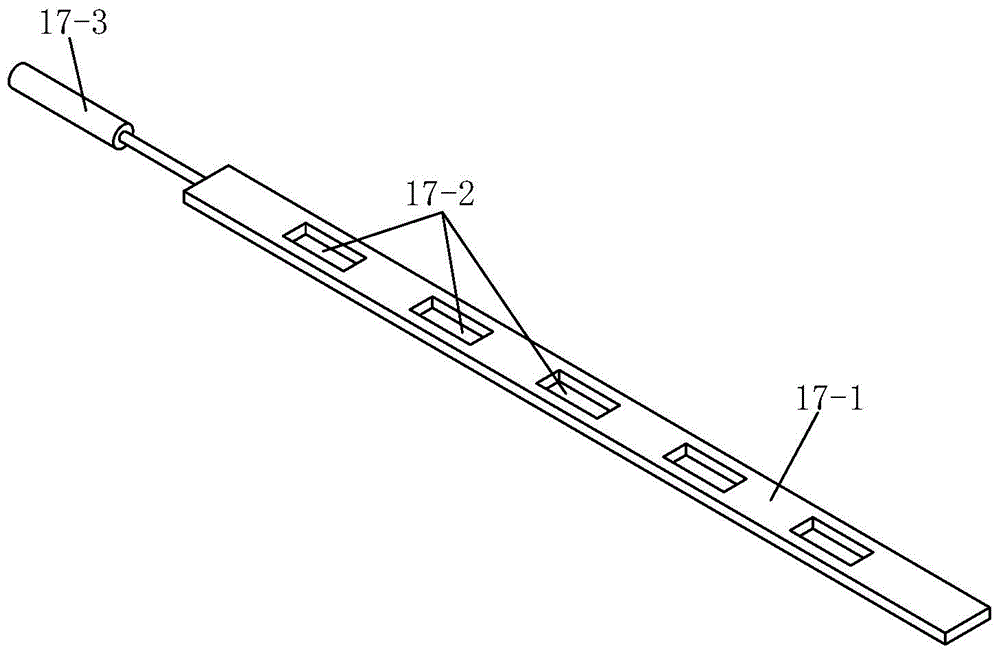

Selective catalytic reduction device by directly spraying urea solution and method thereof

InactiveCN102210974ALow investment and operating costsSave equipment spaceDispersed particle separationAmmonia preparation/separationFlueChemistry

The invention discloses a selective catalytic reduction device by directly spraying a urea solution and a method thereof, and relates to the technical field of environmental protection. The device comprises a plurality of groups of spray guns for spraying the urea solution, which are arranged at an inlet flue before a selective catalytic reduction (SCR) reactor, and a mixer and a catalyst which are arranged along the flowing direction of flue gas in turn, wherein each spray gun is connected with a urea solution tank through a metering distributor. Compared with the prior art, the invention has the advantages that: the urea solution is directly sprayed into the flue to thermally decompose the supplied ammonia, the operating cost and equipment investment are reduced, the space is saved, and the device is safe and reliable to use.

Owner:TONGFANG ENVIRONMENT

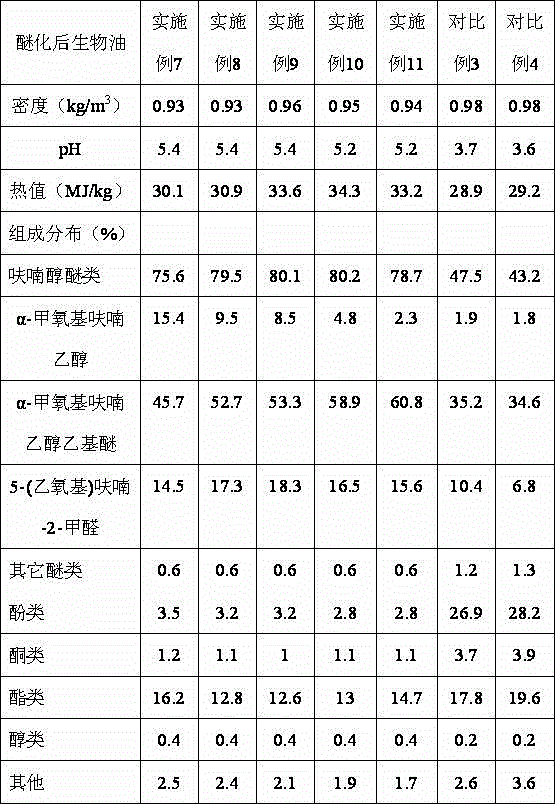

Method for preparing high-quality fuel oil from biomass

ActiveCN104560225AAlleviate the phenomenon of secondary crackingMitigate or even avoid the phenomenon of secondary crackingLiquid carbonaceous fuelsAlcoholMicrowave pyrolysis

The invention discloses a method for preparing high-quality fuel oil from biomass. The method comprises the following steps: uniformly mixing a biomass raw material and a microwave additive with an acidic solution; performing microwave hydrolysis treatment; performing microwave dehydration treatment; performing microwave pyrolysis on the dehydrated biomass; recovering generated pyrolysis volatile components by multistage condensation; performing solid-liquid separation to obtain the biological oil; producing an etherification reaction of the biological oil to obtain the furyl alcohol ether-rich fuel oil. The fuel oil obtained by the method is high in yield, simple in component, high in heat value, good in storage stability and suitable for being used as gasoline and diesel oil or an additive component of the gasoline and diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

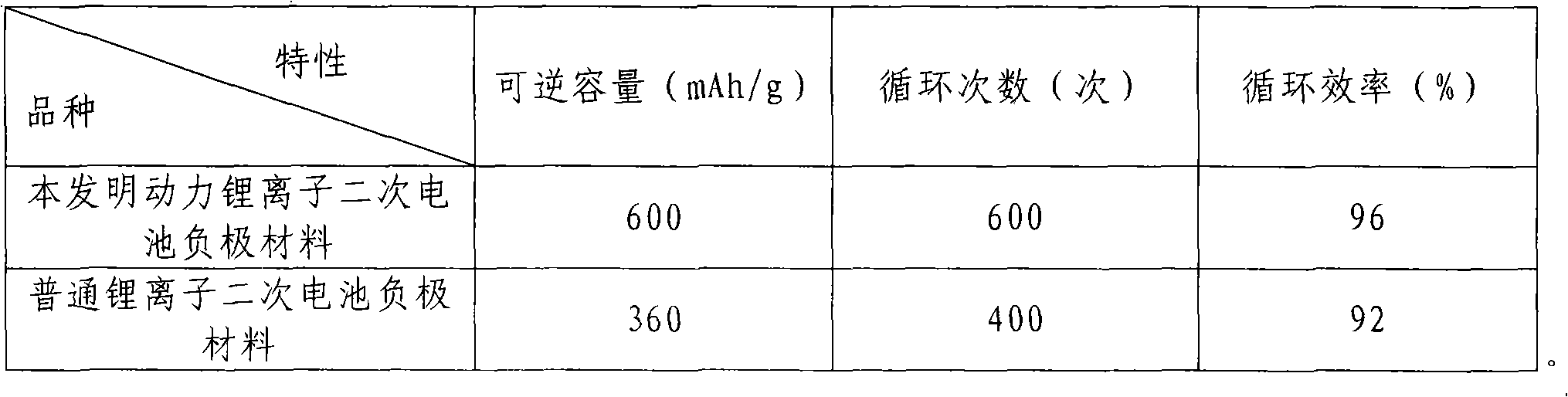

Method for preparing cathode materials of power lithium ion secondary batteries

InactiveCN101572302AFully pyrolyzedUniform state of fusionElectrode manufacturing processesElectrical batteryCarbonization

The invention relates to a method for preparing cathode materials of power lithium ion secondary batteries, which is mainly used for preparing the cathode materials of the power lithium ion secondary batteries. The preparation method mainly comprises the following steps: adopting phenol-formaldehyde resin as a raw material, adding a certain proportion of additive, placing the mixture into a carbonization furnace for carbonization in the vacuum state at the temperature of between 600 and 800 DEG C, using a crushing and classifying machine to crush and classify the obtained pyrolytic carbon after carbonization, using a certain proportion of coating agent to coat the obtained materials with the particle diameter of between 5 and 30 mu m, crosslinking the coating agent on the surface of the pyrolytic carbon at the temperature of 300 DEG C to form a coated shell, and preparing the cathode materials of the power lithium ion secondary batteries after performing carbonization on the coated materials at the temperature of 700 DEG C and high-temperature graphitization on the coated materials at the temperature of 2,800 DEG C, wherein the reversible capacity of the cathode materials of the power lithium ion secondary batteries reaches 600 mAh / g, the cycle index reaches 600 times, and the cycle efficiency reaches 96 percent.

Owner:KENLI SANHE NEW MATERIAL TECH

System and method of fast pyrolysis of oil shale

ActiveCN105131992AEvenly dispersedImprove running stabilityIndirect heating destructive distillationSpecial form destructive distillationSpray towerShale oil and gas

The invention discloses a system and a method of fast pyrolysis of oil shale. The system comprises a fast pyrolysis reactor and a spray tower, wherein the fast pyrolysis reactor comprises a reactor body, a multilayer regenerative radiant tube, an oil shale inlet, a distributing device, a distributing gas inlet, a plurality of pyrolysis gas outlets and a carbocoal outlet, the fast pyrolysis reactor is suitable for performing fast pyrolysis treatment on the oil shale by adopting the regenerative radiant tube, so as to obtain carbocoal and pyrolysis gas, and the spray tower is connected with the plurality of pyrolysis gas outlets and is suitable for performing spray treatment on the pyrolysis gas by adopting cooling liquid, so as to obtain shale oil and gas. According to the system, fast pyrolysis of the oil shale can be realized, and the yield of the obtained shale oil is high.

Owner:SHENWU TECH GRP CO LTD

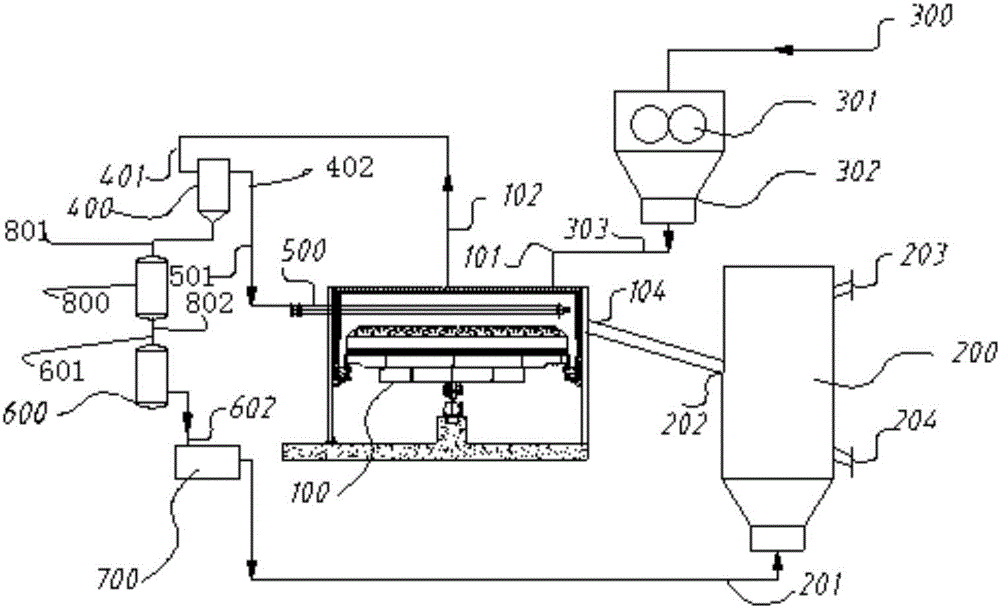

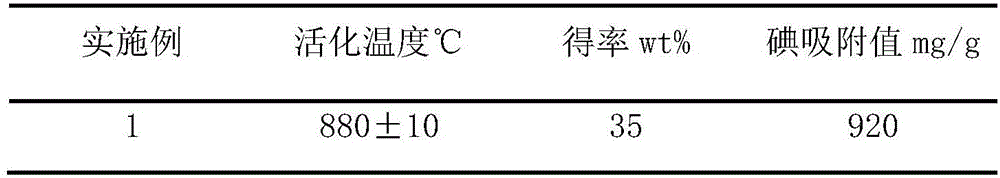

Coal pyrolysis and activated carbon production integrated device

The invention discloses a coal pyrolysis and activated carbon production integrated device. The integrated device comprises a thermal insulation jacket, a preheating furnace, a pyrolysis furnace used for performing pyrolysis on preheated coal, an activating furnace used for activating semi-coke generated after pyrolysis, and an activating agent conveying pipe used for inputting gas activating agents into the activating furnace. The preheating furnace, the pyrolysis furnace and the activating furnace are sequentially communicated from top to bottom. An activating furnace heating cavity is formed between the activating furnace and the thermal insulation jacket. A gas conveying channel is formed between the thermal insulation jacket and the pyrolysis furnace. The activating furnace is provided with an associated gas outlet for associated gas produced through activation of the semi-coke to enter the gas conveying channel. A gas heat carrier inlet for the associated gas to enter the pyrolysis furnace from the gas conveying channel is formed in the side wall of the pyrolysis furnace. The integrated device can effectively improve the pyrolysis and activation efficiency, the tar yield is effectively increased, high-quality coal gas, tar and activated carbon can be produced at the same time, and the additional value for quality-divided processing and utilizing of the coal is improved.

Owner:XIAN UNIV OF SCI & TECH

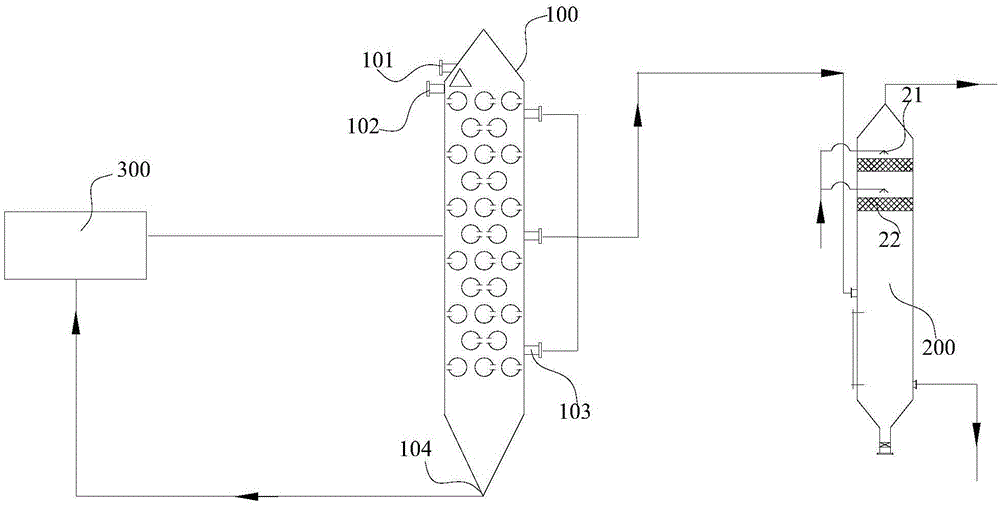

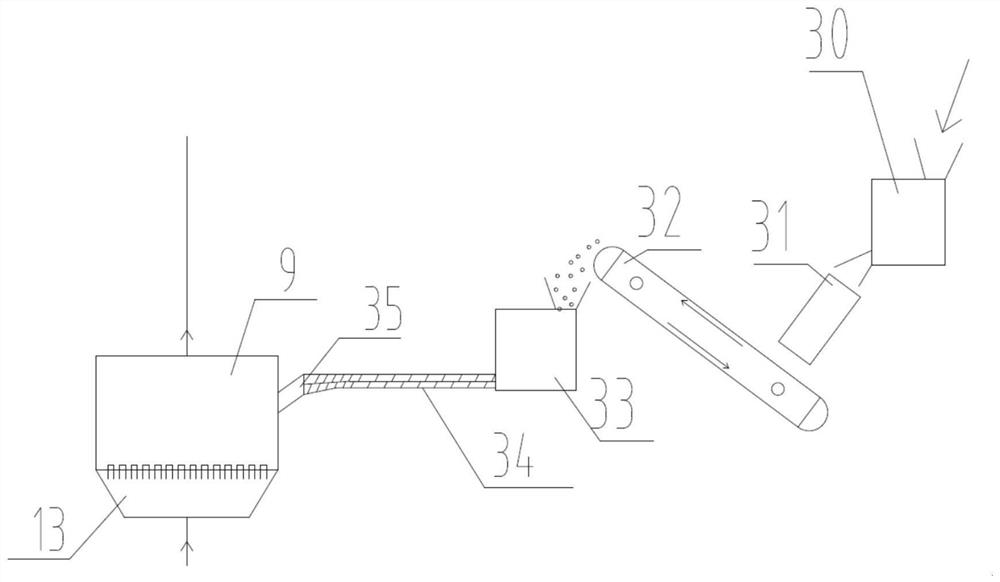

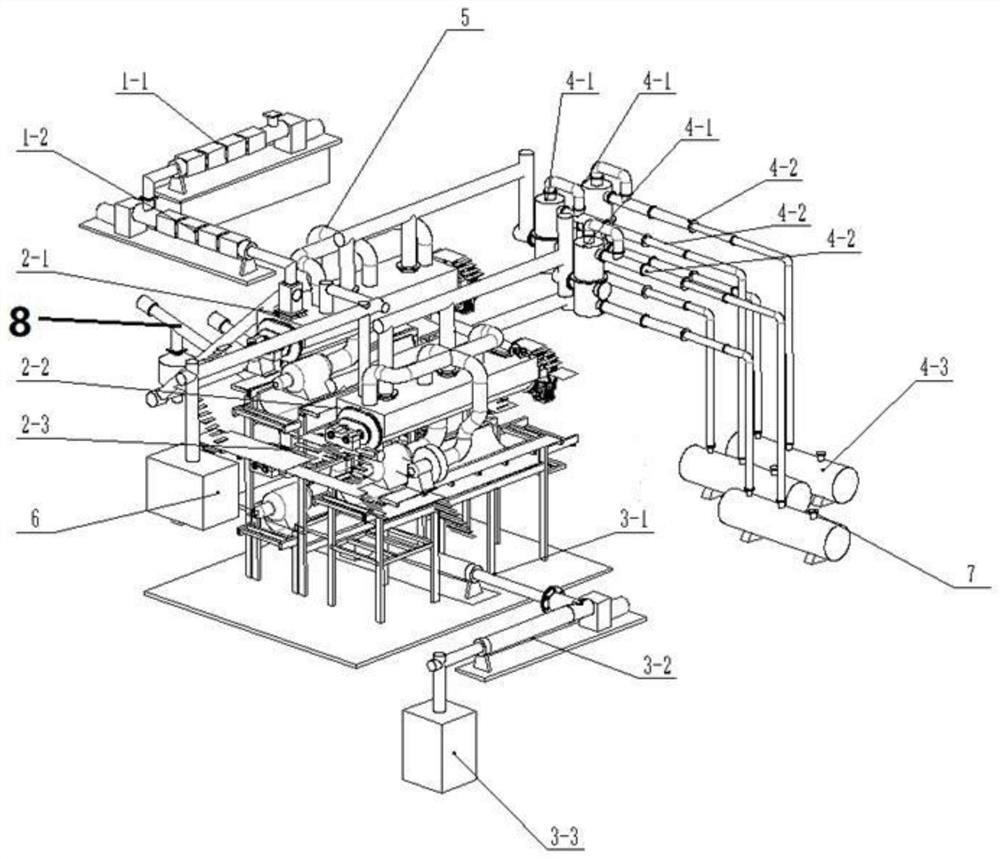

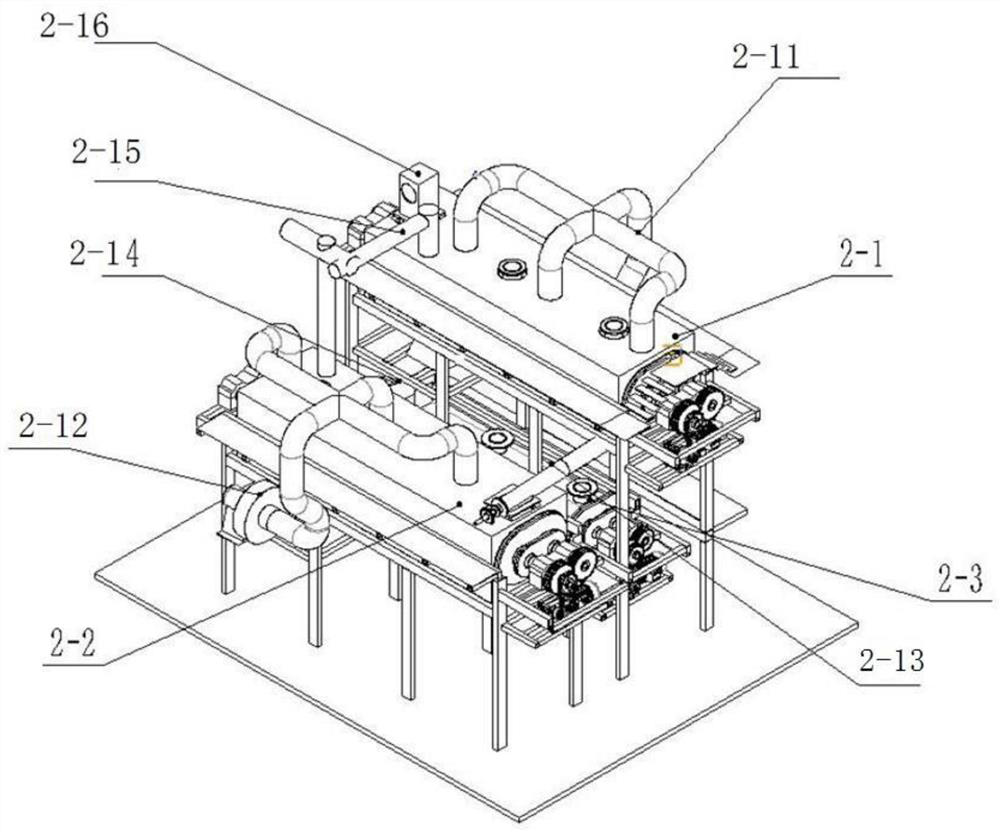

System for extracting glass fiber and pyrolysis oil from fan blade and working method of thereof

ActiveCN113020215AHarmlessAchieving processing powerTransportation and packagingSolid waste disposalGlass fiberResource recovery

The invention discloses a system for extracting glass fiber and pyrolysis oil from a fan blade and a working method thereof, and belongs to the technical field of resource recovery. The system for extracting the glass fiber and the pyrolysis oil from the fan blade comprises a crushing system, a circulating fluidized bed boiler system, a fluidized bed pyrolyzing furnace, a non-contact heat exchanger, a pyrolysis gas-solid separation system and a pyrolysis oil separation system. According to the system, the composite materials in the waste blades can be effectively pyrolyzed, the glass fiber and the pyrolysis oil can be recycled, the pyrolysis gas is pumped to a hearth to be effectively incinerated, the contained heat value is effectively utilized, and pollutants generated by combustion can be discharged in a standard reaching mode by means of an environmental protection device arranged in an original boiler system; and a pyrolysis reaction in the fluidized bed pyrolyzing furnace under the oxygen deficit atmosphere effectively avoids the potential problems of dioxin generation and emission and the like caused by direct incineration of the waste blades, and harmless and resourceful treatment of the waste fan blades is achieved. Before the comprehensive recycling technology of the blade material is mature and is utilized on a large scale, the system for extracting the glass fiber and the pyrolysis oil from the fan blade can effectively solve the influence of the waste blades on the environment, and generate good environmental protection and economic benefits.

Owner:HUANENG CLEAN ENERGY RES INST

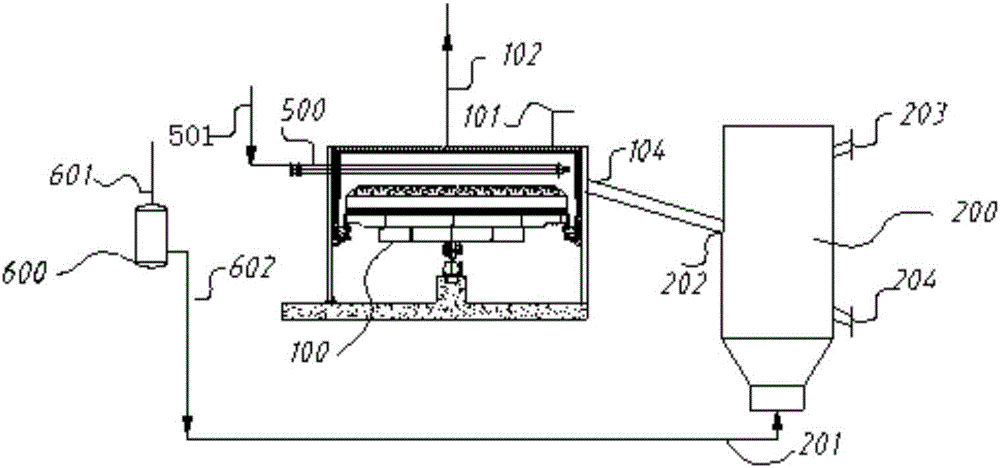

System and method for preparing active carbon by biomass

PendingCN106629715ASolve the blockageSolve heavy dustCarbon compoundsSpecial form destructive distillationCombustorWater vapor

The invention relates to a system and a method for preparing active carbon by biomass. The system comprises a pyrolyzing furnace, a combustor, a steam boiler and a fluidized bed, wherein the pyrolyzing furnace is used for pyrolyzing raw material biomass to generate pyrolyzed oil gas and carbon residue; the combustor is used for heating the raw material biomass to pyrolyze the raw material biomass; the steam boiler is used for heating water to obtain steam; and the fluidized bed is used for activating the carbon residue to generate active carbon. According to the system and the method, the existing fluidized bed does not need to be transformed, heat loss is reduced, energy consumption is reduced, the productivity of the pyrolyzing furnace is improved, and reduction, harmless treatment and resource utilization of the materials is realized.

Owner:SHENWU TECH GRP CO LTD

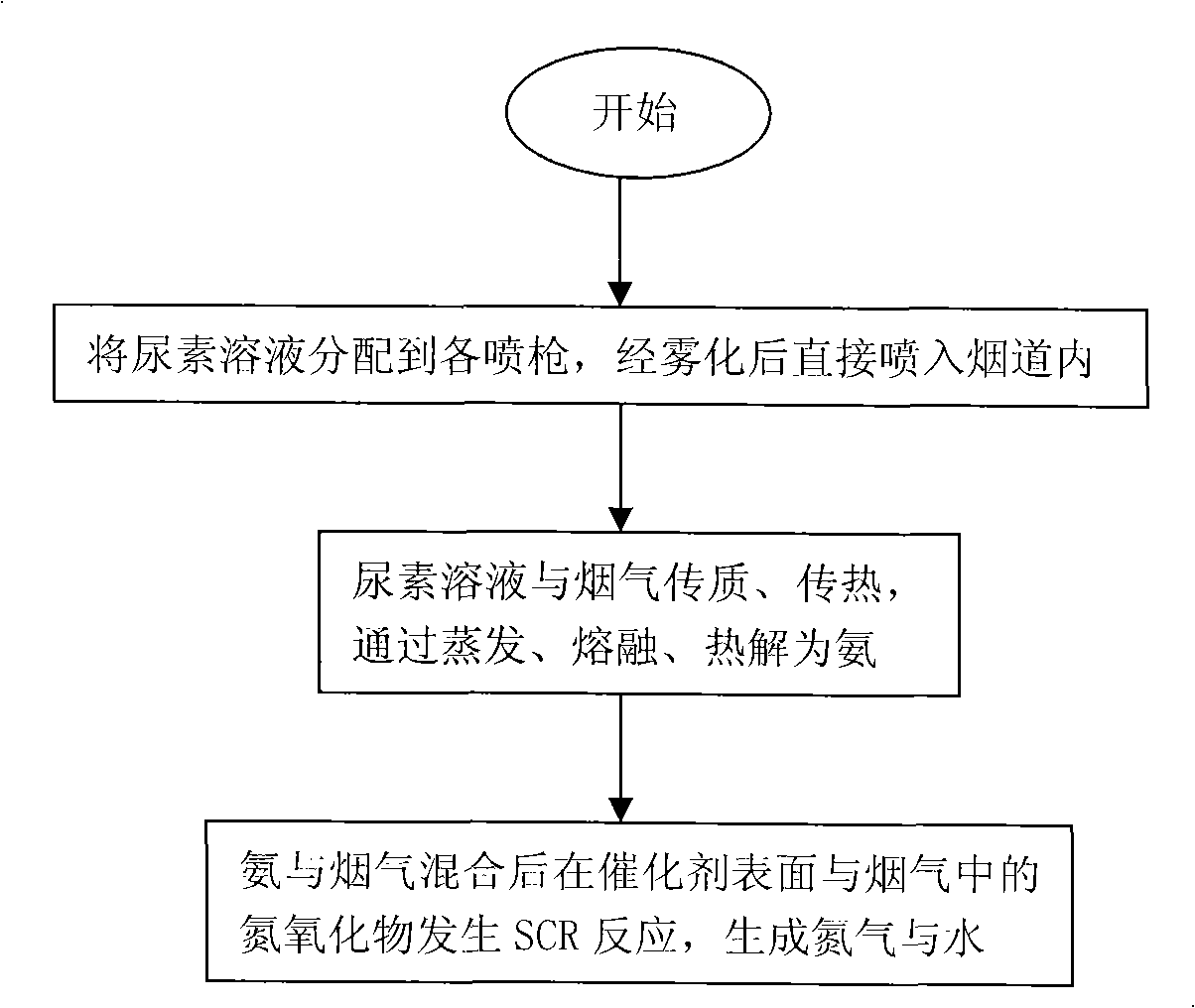

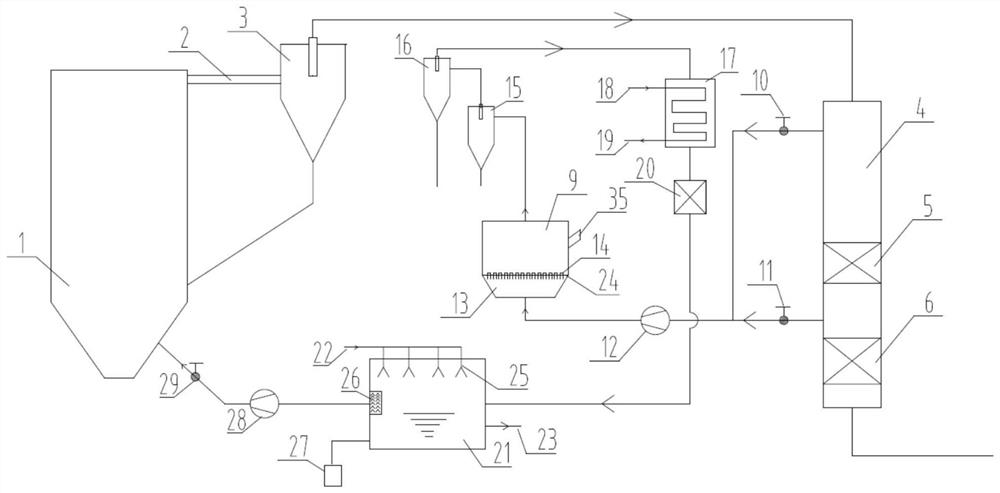

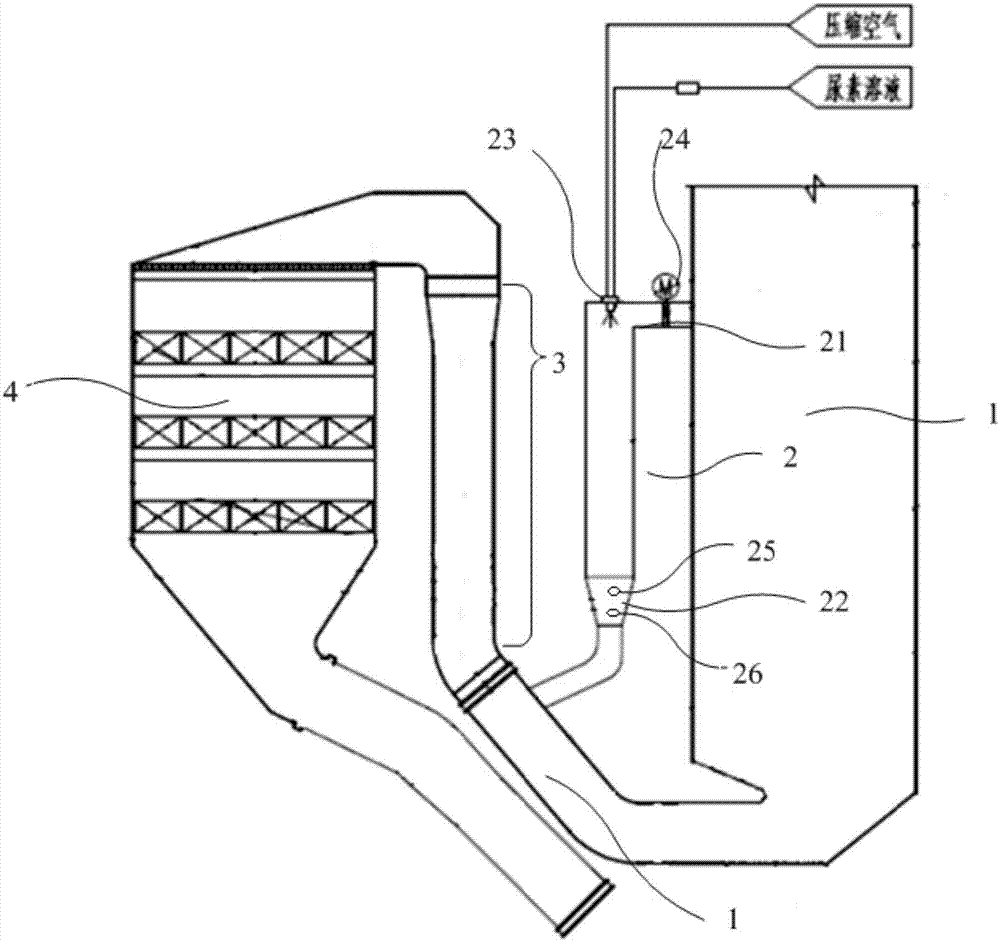

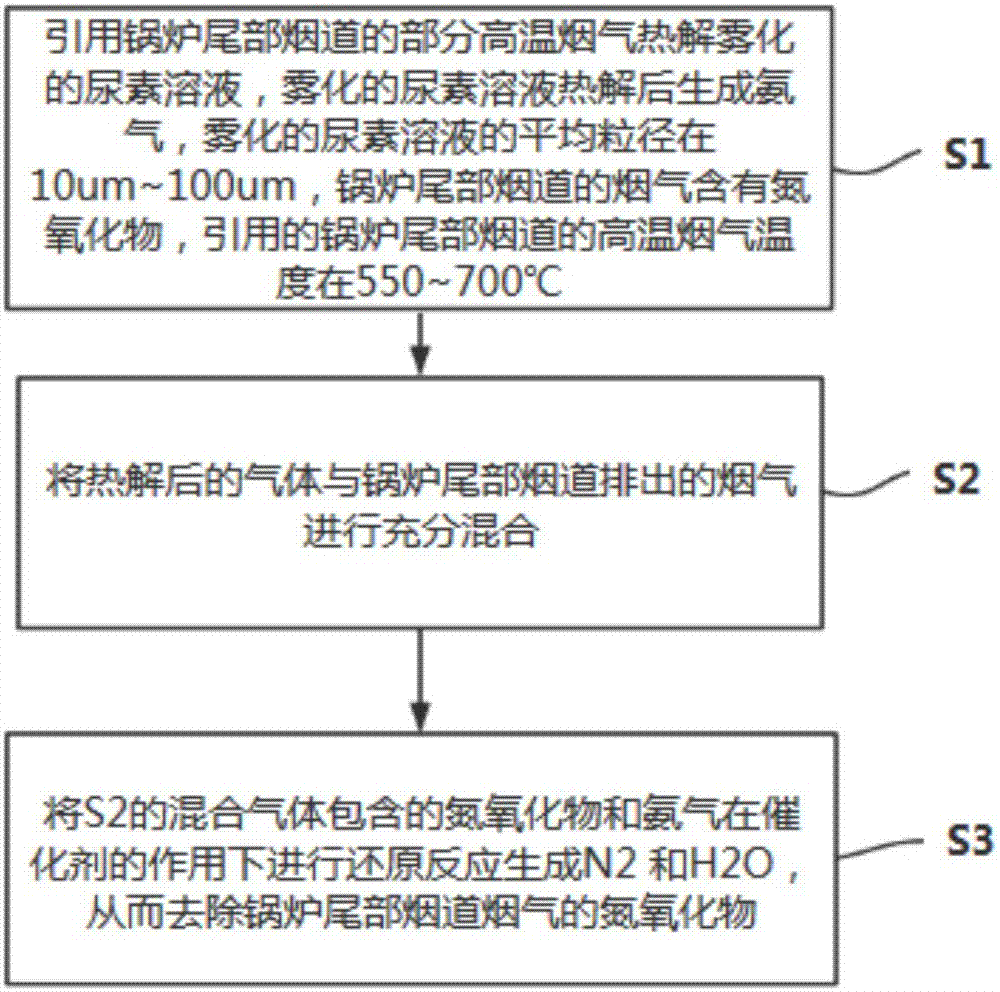

Denitration device and process for introducing high temperature flue gas for urea pyrolysis for ammonia production

PendingCN107261837AFully pyrolyzedPrevent crystallizationGas treatmentDispersed particle separationAir preheaterAmmonia production

The invention discloses a denitration device and process for introducing high temperature flue gas for urea pyrolysis for ammonia production, part of the high temperature flue gas in a boiler rear smoke channel is introduced into pyrolyzers for pyrolysis of an atomized urea solution, after pyrolysis of the atomized urea solution, ammonia gas is generated; gases after the pyrolysis are fully mixed with flue gas discharged from the boiler rear smoke channel; and N2 and H2O are generate by reduction reaction of the nitrogen oxides and the ammonia gas contained in the mixed gas under the effect of a catalyst, and so that the nitrogen oxides in the flue gas discharged from the boiler rear smoke channel can be removed. The beneficial effects are that: same denitrification effect can be achieved without an additional electric heater and steam heating, energy consumption can be saved to the maximum extent, cost is reduced, the urea pyrolysis is full, urea crystallization on the catalyst and an air preheater can be prevented, and urea corrosion of the heating surface and the heat transfer surface of the boiler rear smoke channel caused by urea direct injection can be prevented.

Owner:中节环立为(武汉)能源技术有限公司

Preparation method for biological oil

ActiveCN104549098AMitigate or even avoid the phenomenon of secondary crackingAvoid the phenomenon of secondary crackingBiofuelsLiquid hydrocarbon mixture productionMicrowave pyrolysisReactive distillation

The invention discloses a preparation method for biological oil. The preparation method comprises the following steps: uniformly mixing a biomass raw material with a microwave additive; performing microwave preheating treatment; performing microwave pyrolysis; condensing a generated pyrolysis volatile component; performing oil-water separation to obtain an oil phase which is biological heavy oil and a water phase which is water containing biological light oil; performing reactive distillation on the water phase to remove the moisture to obtain low-moisture biological light oil. The biological oil obtained by the method is high in yield, low in moisture content and high in heat value, and can be directly used as fuel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for removing a separator in a waste lithium ion power battery

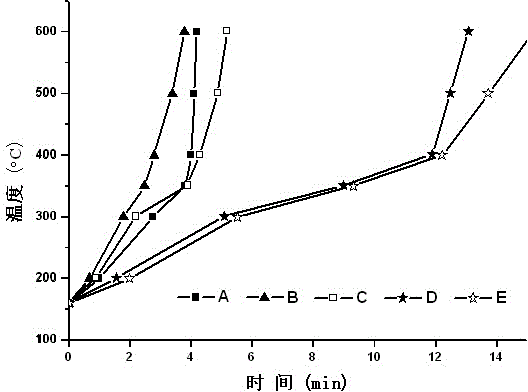

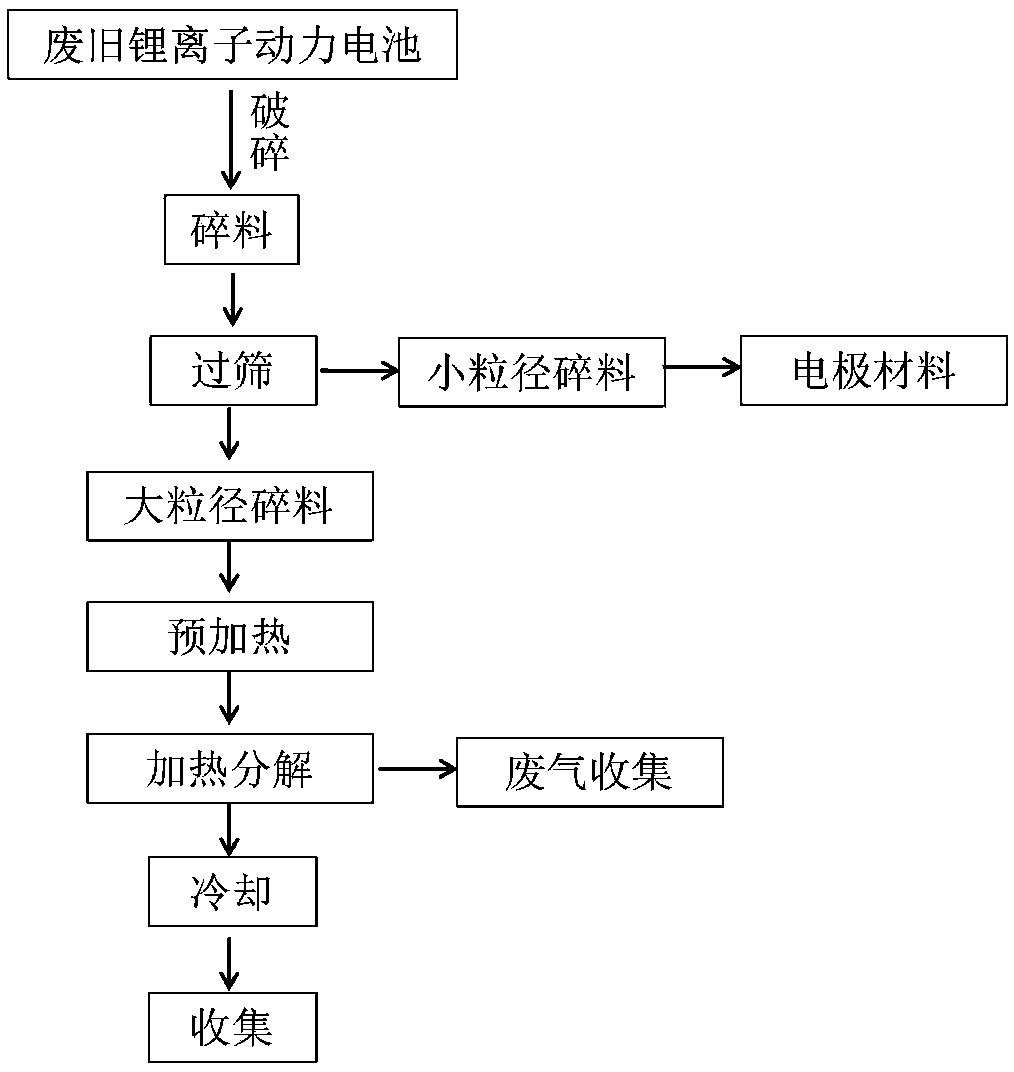

ActiveCN109273791AImprove pyrolysis efficiencySolve removal puzzlesWaste accumulators reclaimingBattery recyclingDecompositionScrap

The invention discloses a method for removing a separator in a waste lithium ion power battery, which comprises the following steps: crushing the waste lithium ion power battery into crumbs and passing through a 5-mesh screen to obtain small crumbs with a particle size less than 5 mesh and large crumbs with a particle size greater than 5 mesh; Preheating the large particle size crushed material, and controlling the preheating temperature at 100-300 DEG C; Heating and decomposing the crumbs obtained after the preheating is completed until the thermal decomposition of the diaphragm in the crumbsis complete and the temperature of the thermal decomposition is controlled at 300 to 500 DEG C; cooling and recovering The scrap obtained after decomposition. The method adopts two-stage heating design, improves the pyrolysis efficiency of the separator in the scrap material, the pyrolysis of the separator is more complete, the separator in the waste lithium ion power battery can be directly decomposed and removed, and the problem of removing the separator in the scrap material after the scrap material of the waste power battery is broken is solved; At that same time, the process method is simple to operate and easy to industrialize.

Owner:ZHUZHOU DINGDUAN EQUIP CO LTD

Method and device for microwave pyrolysis of sludge

ActiveCN107200452AFully pyrolyzedFull pyrolysisSpecific water treatment objectivesSludge treatment by pyrolysisCondensation processMicrowave pyrolysis

The invention discloses a method and a device for microwave pyrolysis of sludge. The device for microwave pyrolysis of sludge comprises a microwave reaction device, a vapor recovery device and an oil gas recovery device in communication. The microwave reaction device comprises a microwave reaction cavity, and a first microwave generator arranged in a microwave reaction cavity enables the microwave reaction cavity to have a plurality of temperature areas in sequential temperature rise in the direction from an inlet of the microwave reaction cavity to an outlet. Microwaves serve as a heat source to substitute for a traditional heating method for microwave pyrolysis of sludge, water, pyrolysis gas and pyrolysis residues are obtained sectionally by means of sectional heating and condensation, and heat energy in a condensation process is completely used as a heat source for sludge drying, so that energy saving, environment friendly and sludge recycling are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

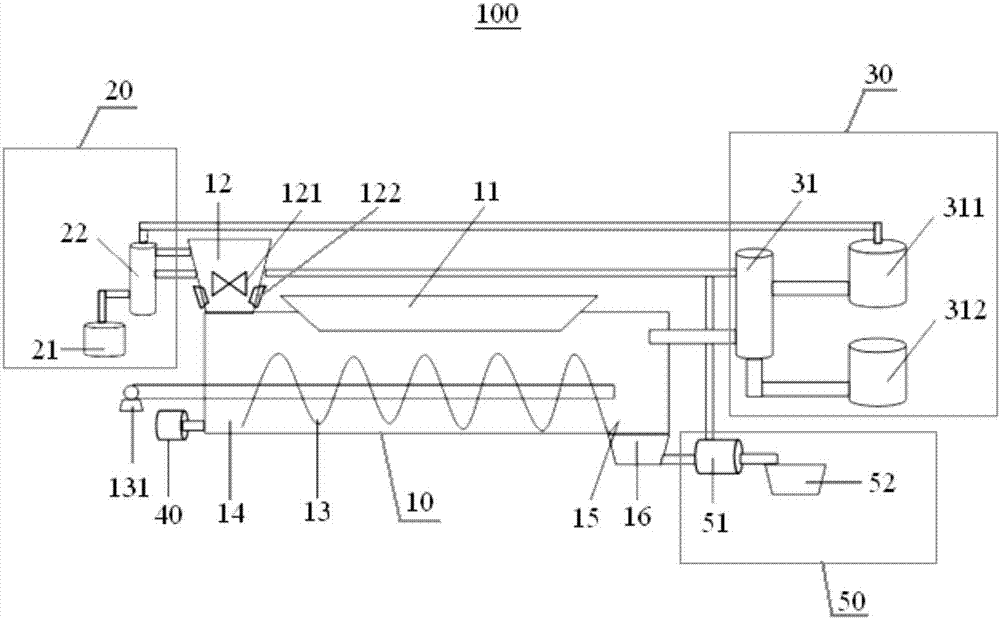

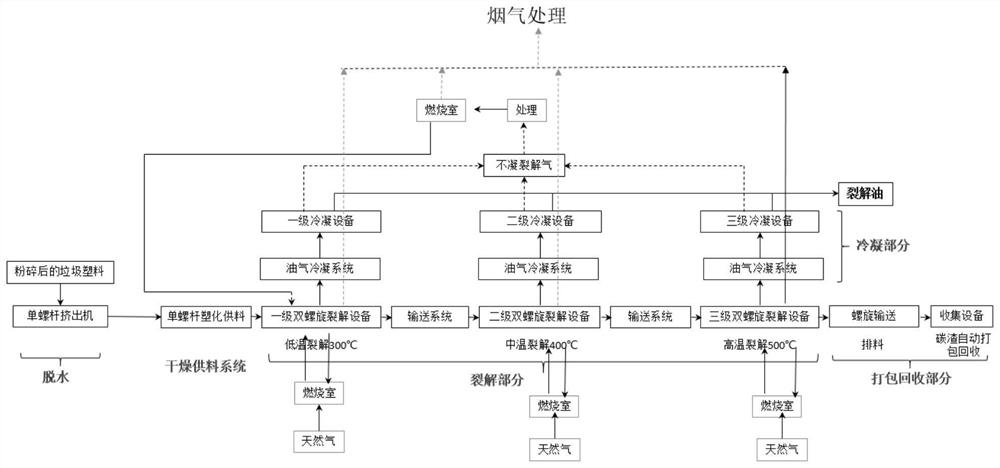

Low-temperature industrial continuous catalytic cracking method and equipment for waste organic polymer material

ActiveCN112029524ARealize deliveryAchieve serializationProductsGas treatmentThermodynamicsCombustible gas

The invention discloses a low-temperature industrial continuous catalytic cracking method and equipment for a waste organic polymer material. The method comprises the following steps: 1) carrying outearlier-stage treatment on a waste organic polymer material, 2) dehydrating and drying the waste organic polymer material, 3) carrying out a sectional catalytic cracking process on the waste high polymer material, 4) condensing and collecting cracking gas, 5) driving the melt material to move through an anti-coking heat-conducting medium, so that the heat and mass transfer effect is enhanced, 6) continuously discharging the pyrolysis carbon, 7) by non-condensable combustible gas generated by cracking supplies, heating the third-stage cracking reactor, 8) dividing the high-temperature flue gasinto three parts to be recycled, and discharging redundant parts through a tail gas treatment device, and 9) discharging tail gas. According to the invention, graded cracking of mixed waste organic polymer materials can be realized, cracked oil products are respectively recycled according to different decomposition temperatures of all the components, the maximum economic benefit of cracking products is realized, and the equipment is reasonable in structural design, can improve the production efficiency and realizes automatic production.

Owner:QINGDAO UNIV OF SCI & TECH

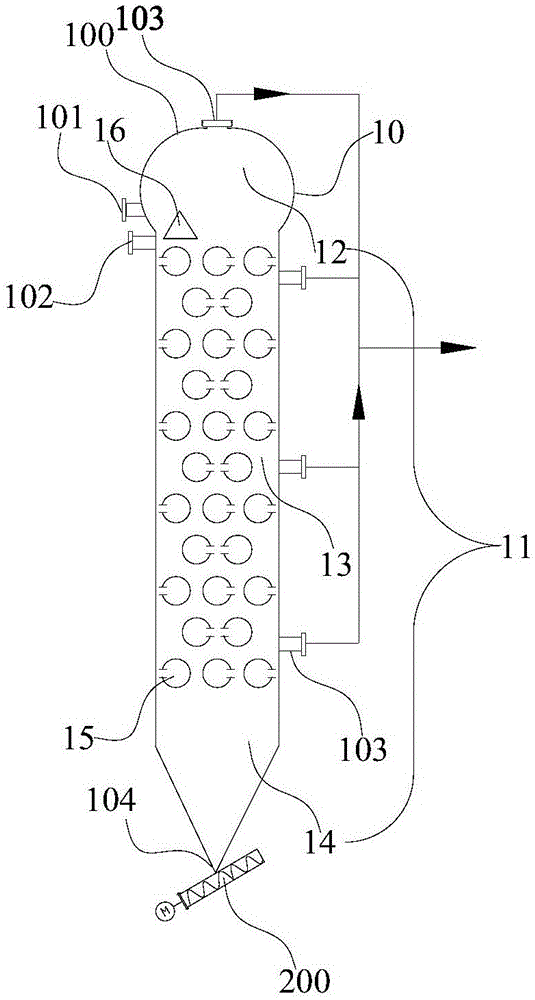

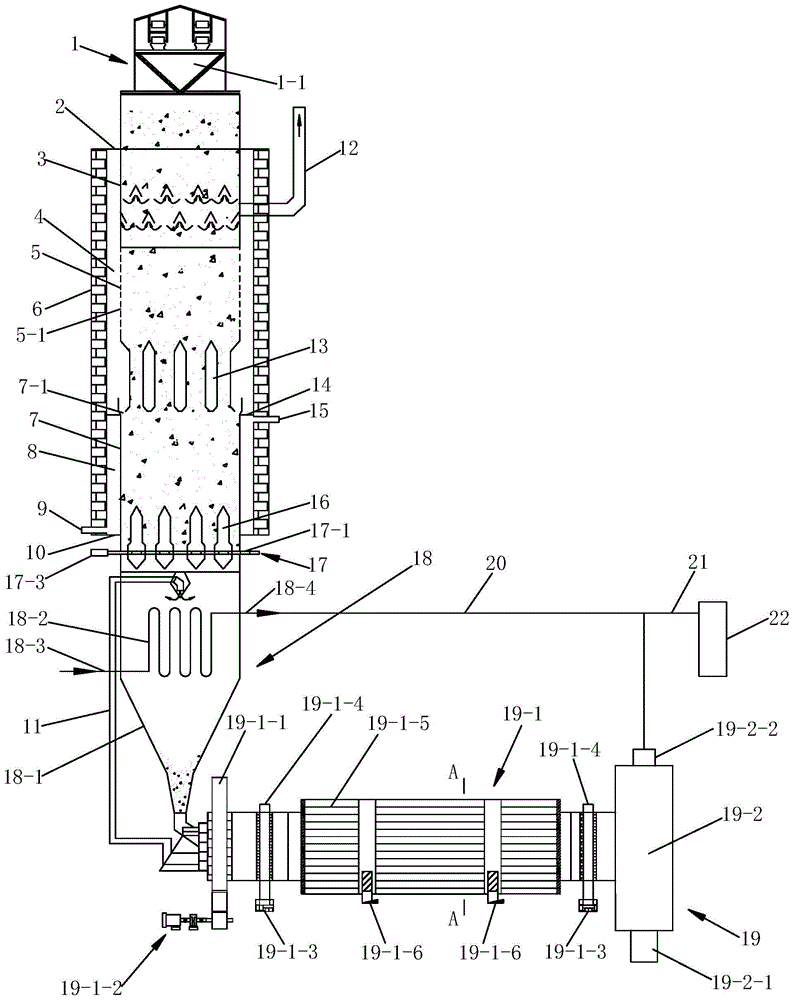

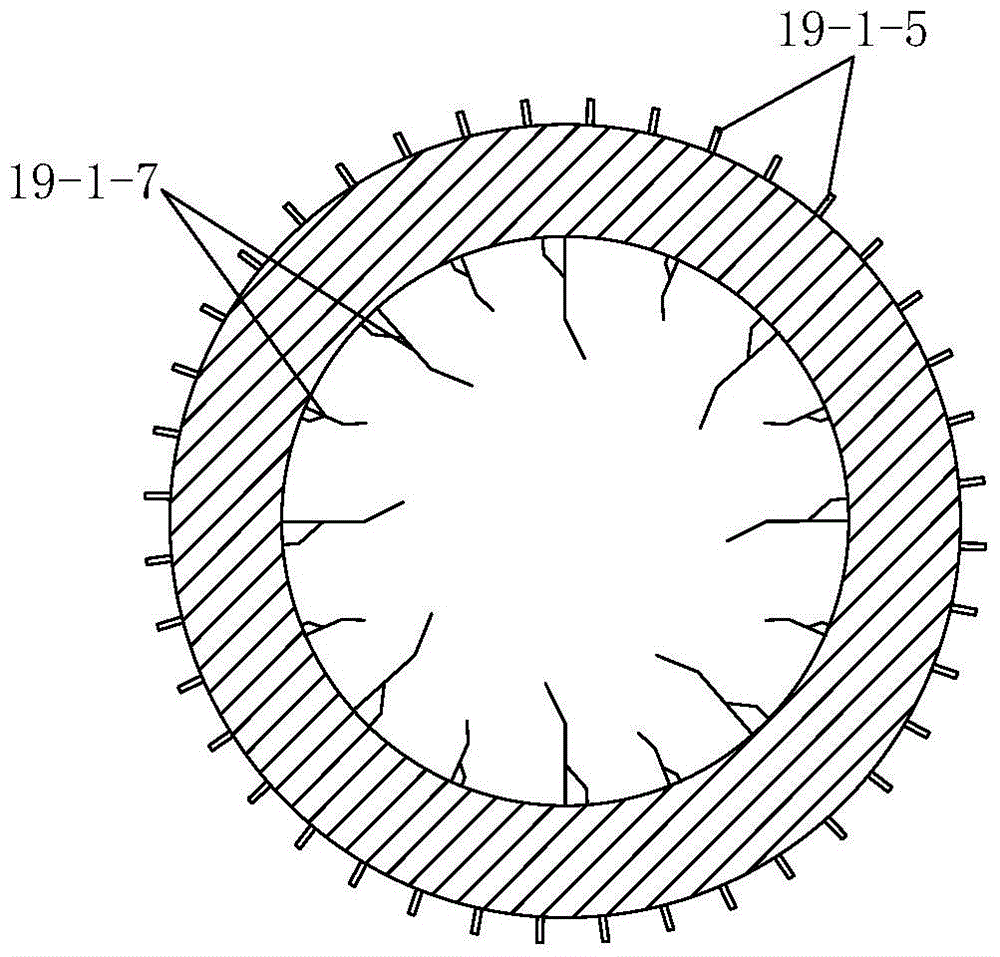

Small-size oil shale dry distillation system heated based on heat accumulation type gas radiation pipe

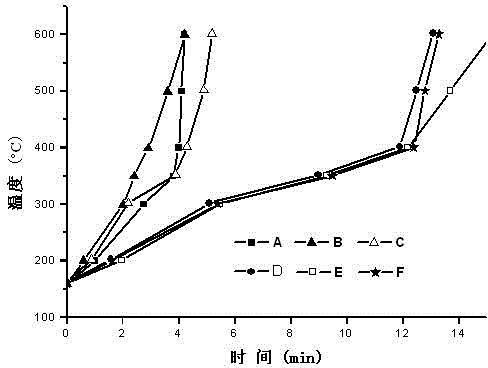

ActiveCN103087740AEvenly heatedFully pyrolyzedCombustible gas coke oven heatingEnergy inputThermal efficiencyEnergy consumption

The invention relates to a small-size oil shale dry distillation system heated based on a heat accumulation type gas radiation pipe. The system serves as a stepping type furnace; oil shale is heated to be at 180-220 DEG C through radiation heat provided by the heat accumulation type gas radiation pipe to be dried and then is heated to be at 480-520 DEG C to be subjected to dry distillation at low temperature, so that the oil shale is pyrolyzed to generate products, such as the shale oil, dry distillation gas and semi-coke; and a waste heat recycling section is used for enabling cold gas generated by the dry distillation of the oil shale to perform absorption and dry distillation on waste heat of semi-coke to generate hot gas as fuel of the heat radiation pipe. The small-size oil shale dry distillation system disclosed by the invention has the advantages of being simple in process, high in heat efficiency, low in energy consumption and the like.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com