Glass ceramic mainly prepared from coal gangue and rice husk ash and preparation method thereof

A technology of glass-ceramics and main raw materials, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problem that iron oxide has not been utilized as a resource, the raw material processing process is complicated, and the transparency and gloss of glass-ceramics are affected and other issues, to achieve the effect of promoting healthy ecological development, good liquidity, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

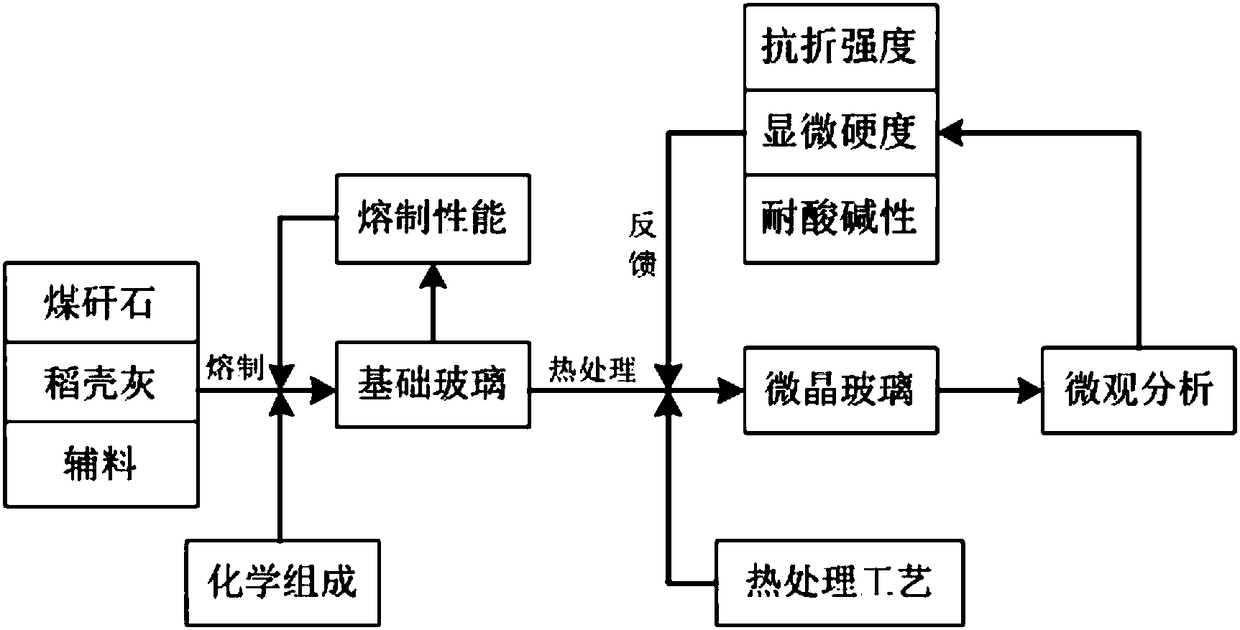

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of rice husk ash:

[0040] Introduce nitric acid with a volume ratio of 10% into the dried rice husk, place it in a constant temperature water bath at 100°C and heat it for 2 hours. During the heating process, make the nitric acid fully contact with the rice husk. After heating and drying, place it in a resistance furnace to raise the temperature to 650 ℃ for 9 hours to prepare rice husk ash.

[0041] What the present embodiment adopts is that the volume ratio is 10% nitric acid, the effect of nitric acid: remove the small amount of metal impurity elements such as Ca, Na, K, Mg, Fe etc. contained in the rice husk by acid treatment, improve SiO 2 The purity of the particles, and destroy the tissue structure of the rice husk, so that the rice husk is more fully pyrolyzed in the same time; those skilled in the art should understand that the acid treatment can also use inorganic acids such as hydrochloric acid and sulfuric acid.

Embodiment 1

[0043] (1) Ingredients

[0044] Coal gangue 28.5g, rice husk ash 4.20g, sodium carbonate 4.3g, calcium carbonate 7.5g, magnesium oxide 2.5g, titanium dioxide 3g.

[0045] (2) Experimental process

[0046] A. Mix the ingredients fully and evenly, place them in a corundum crucible, put them in a silicon-molybdenum rod high-temperature furnace, heat them to 900°C and keep them warm for 30 minutes, so that the volatile components in the mixture can be dispersed as much as possible, and the formation of bubbles in the glass liquid can be reduced, and then continue to heat up Melting at a high temperature of 1450°C for 2 hours to obtain a glass melt;

[0047] B. Immediately put the molten glass obtained above into cold water for quenching to obtain basic glass particles, then dry the basic glass particles, put them into a ball mill for ball milling, and pass through a 200-mesh sieve to obtain basic glass powder.

[0048] C. Mix the basic glass powder obtained above with polyvinyl ...

Embodiment 2

[0053] (1) Ingredients

[0054] Coal gangue 28.70g, rice husk ash 4.5g, sodium carbonate 4.1g, calcium carbonate 7.2g, magnesium oxide 2.5g, titanium dioxide 3g;

[0055] (2) Experimental process

[0056] A. Mix the ingredients fully and evenly, put them in a corundum crucible, put them in a silicon-molybdenum rod high-temperature furnace, heat them to 900°C and keep them warm for 30 minutes, so that the volatile components in the mixture can be dispersed as much as possible, and the formation of bubbles in the glass liquid can be reduced. Then continue to heat up to 1400 ° C for 2 hours to melt at a high temperature to obtain a glass melt;

[0057] B. Immediately put the molten glass obtained above into cold water for quenching to obtain basic glass particles. Then the basic glass particles are dried, added to a ball mill for ball milling, and passed through a 200-mesh sieve to obtain the basic glass powder.

[0058] C. Mix the basic glass powder obtained above with polyvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com