Low-temperature industrial continuous catalytic cracking method and equipment for waste organic polymer material

A technology of organic polymers and polymer materials, which is applied in the field of low-temperature industrial continuous catalytic cracking of waste organic polymer materials, and can solve the problems of slow stirring speed, poor jacket cooling effect, poor stirring uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

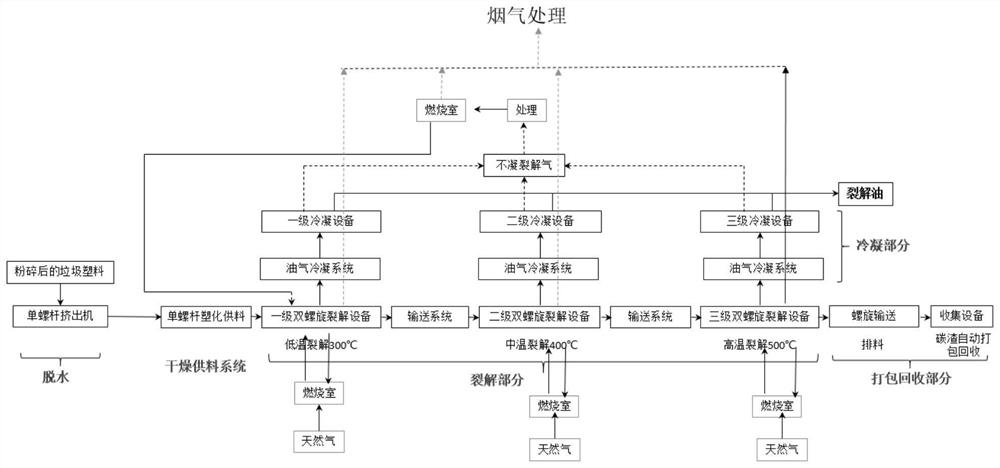

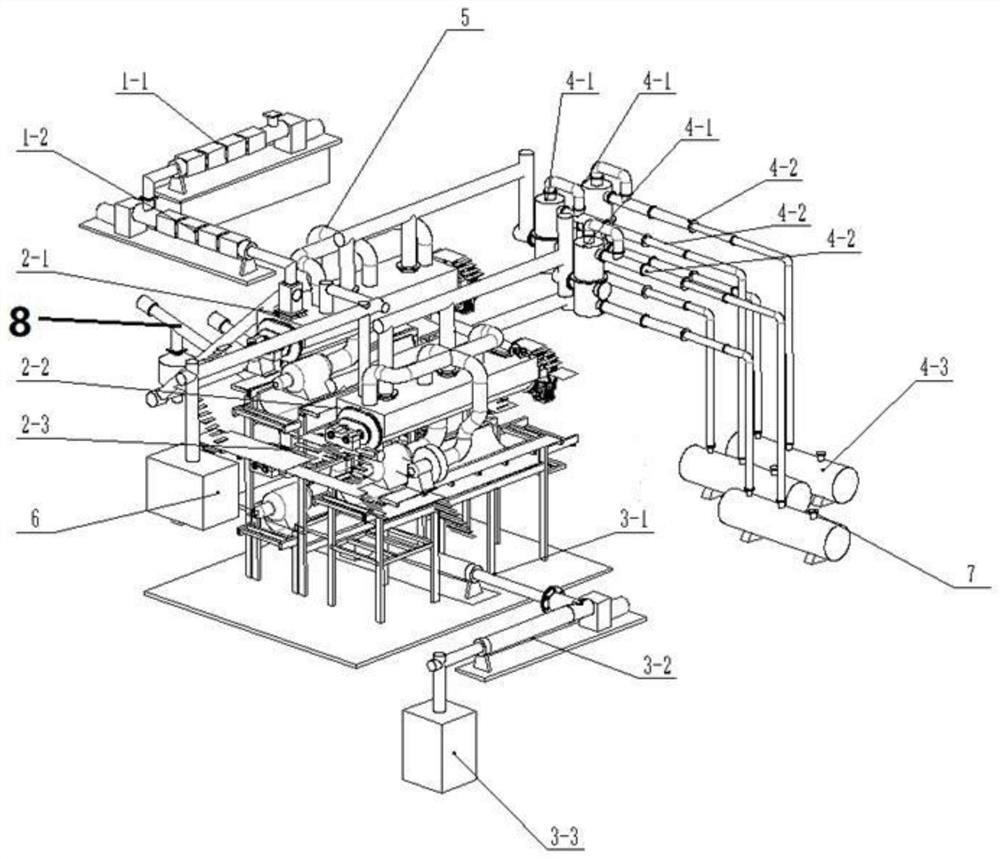

[0103] Such as Figure 1-13 Shown, a kind of low-temperature industrial continuous catalytic cracking method of waste organic polymer materials, comprises the following steps:

[0104] (1) Pre-treatment of waste organic polymer materials: waste organic polymer materials are screened out of other inorganic impurities such as stones and iron filings through winnowing, crushing and other processes;

[0105] (2) Dehydration and drying of waste organic polymer materials: The waste organic polymer materials that have been preliminarily screened are dehydrated and dried to reduce the impact of moisture in the materials on the quality of cracking products; this step is mainly through two special extruders in different Efficient dehydration and drying under process parameters.

[0106] Among them, the process includes a low-temperature high-efficiency dehydration process and a dry feed process;

[0107] Low-temperature and high-efficiency dehydration process: This process is mainly c...

Embodiment 2

[0180] The present invention also relates to a process for preparing chemical raw materials through low-temperature industrial continuous catalytic cracking of waste tires, which comprises the following steps:

[0181] (1) The waste tires recovered from the waste recycling plant are continuously transported into the crushing system through the conveyor belt, and then crushed into rubber blocks of a certain size;

[0182] (2) the rubber block after the splitting enters in the cracking reaction furnace through the drying system;

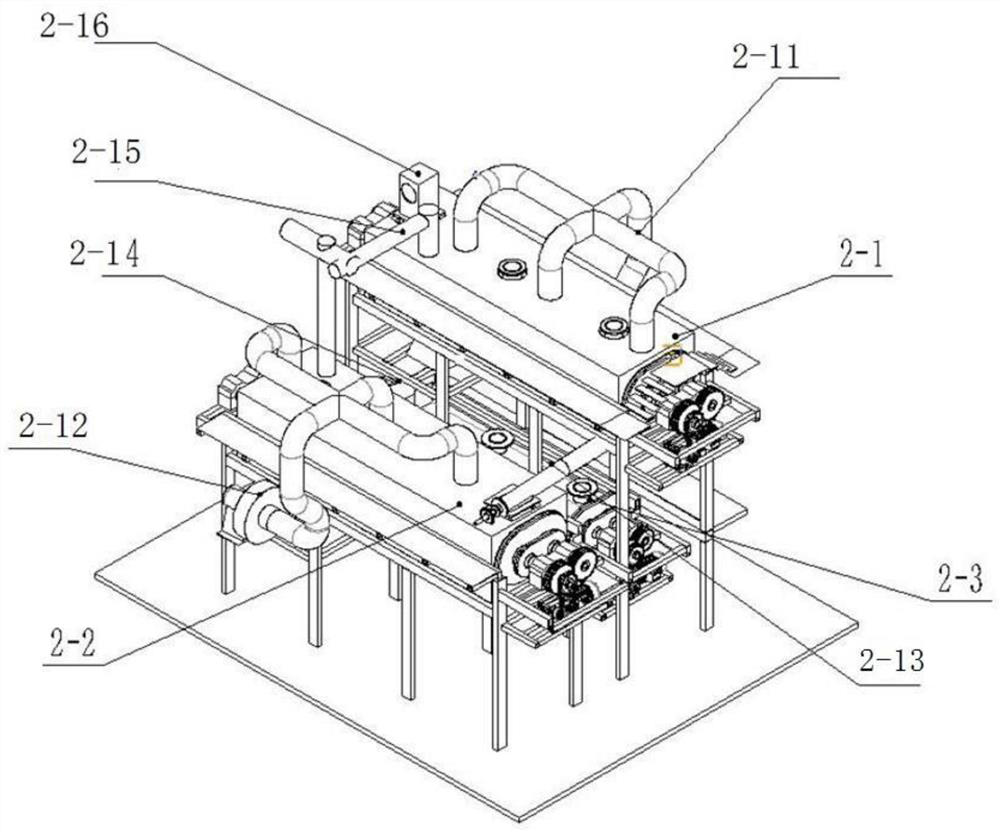

[0183] (3) The waste plastics that enter cracking reactor crack small molecular organic additive components in primary cracking reactor 2-1, crack components such as natural rubber, styrene-butadiene rubber in secondary cracking reactor 2-2, In the three-stage cracking reactor 2-3, the components with high cracking temperature such as cracking collection are cracked, and the oil and gas produced are collected by the subsequent tanks of each reactor aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com