Patents

Literature

1223results about "Oil/fat baking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

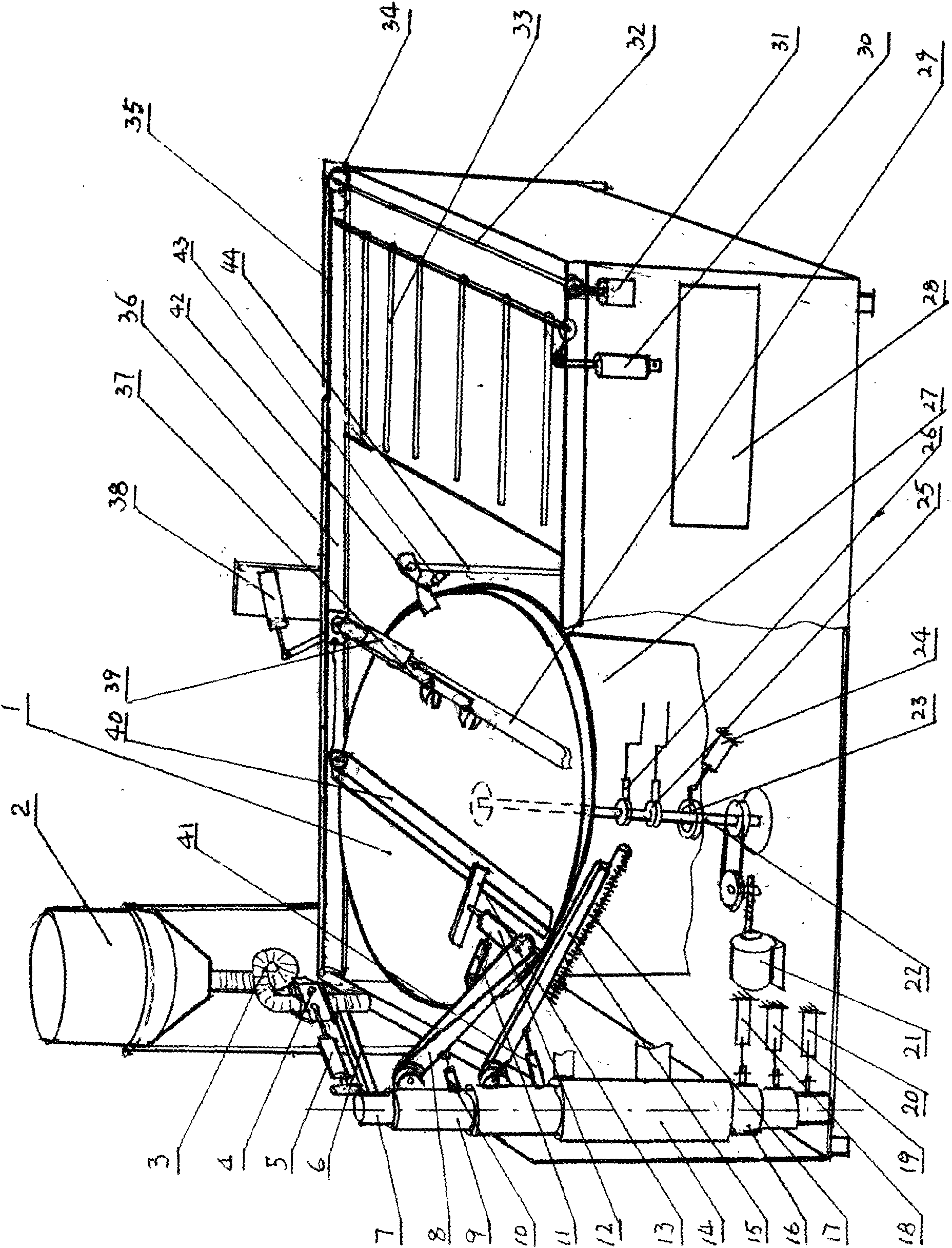

Full-automatic pancake machine

InactiveCN101584352AImprove processing efficiencyReduce labor intensityOil/fat bakingPancakes bakingRobot handElectric machinery

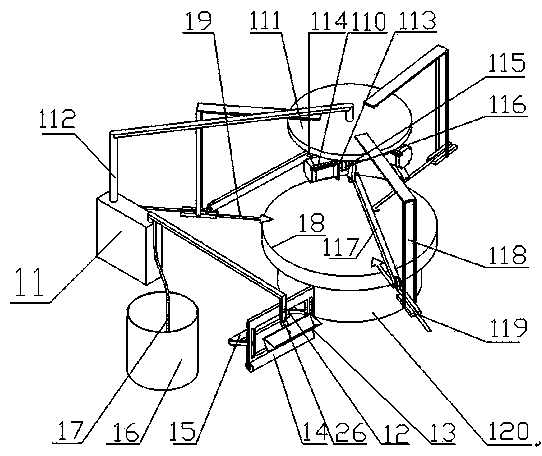

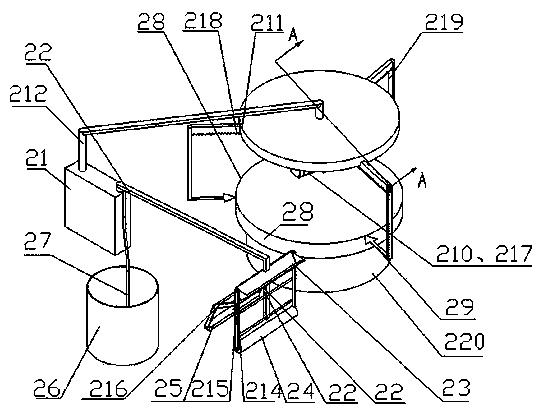

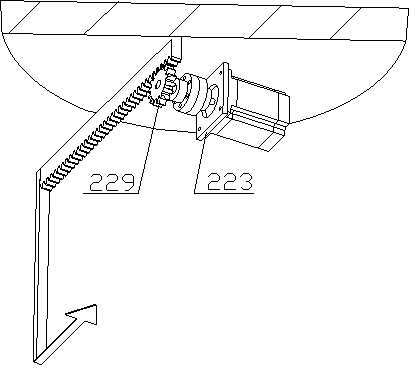

The invention discloses a full-automatic pancake machine, comprising a griddle heating and rotating under the drive of motor, an accumulator, a mechanical hand for polishing by simulating manual pancake making actions, a mechanical hand for feeding paste materials, a spreading mechanical hand, a raising mechanical hand, a pulling mechanical hand, a scraping mechanical hand, a turning-moving mechanical hand and an automatic controller. The automatic controller controls each mechanical hand to run according to program, thereby achieving the actions of simulating manual pancake making of the full-automatic pancake machine. All the manual operation procedures of pancake making in the invention are finished automatically, so that the pancake making is automatized, processing efficiency is improved, and labour intensity is reduced, besides, the made pancake still has the feeling of pancake made manually.

Owner:单传芹

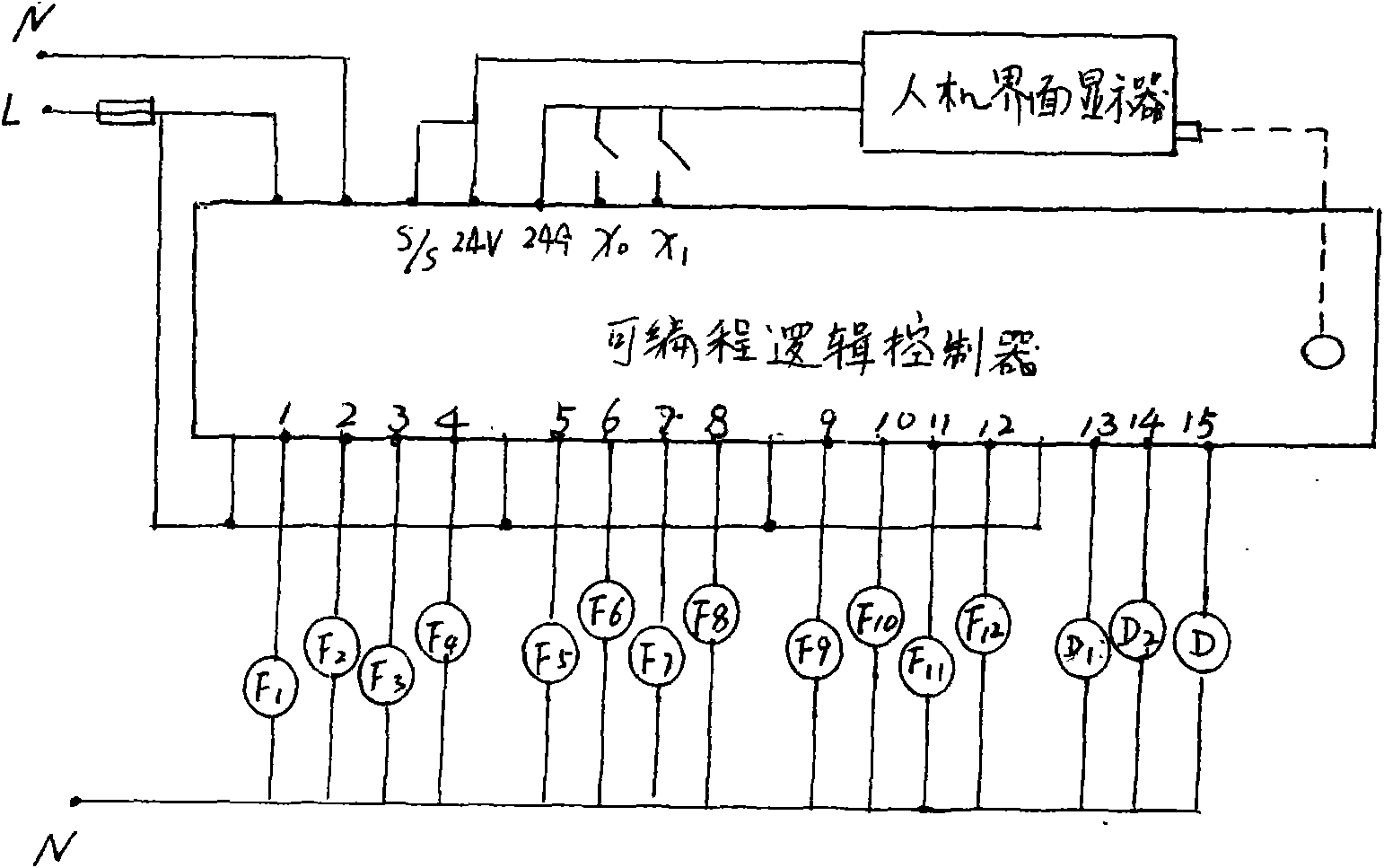

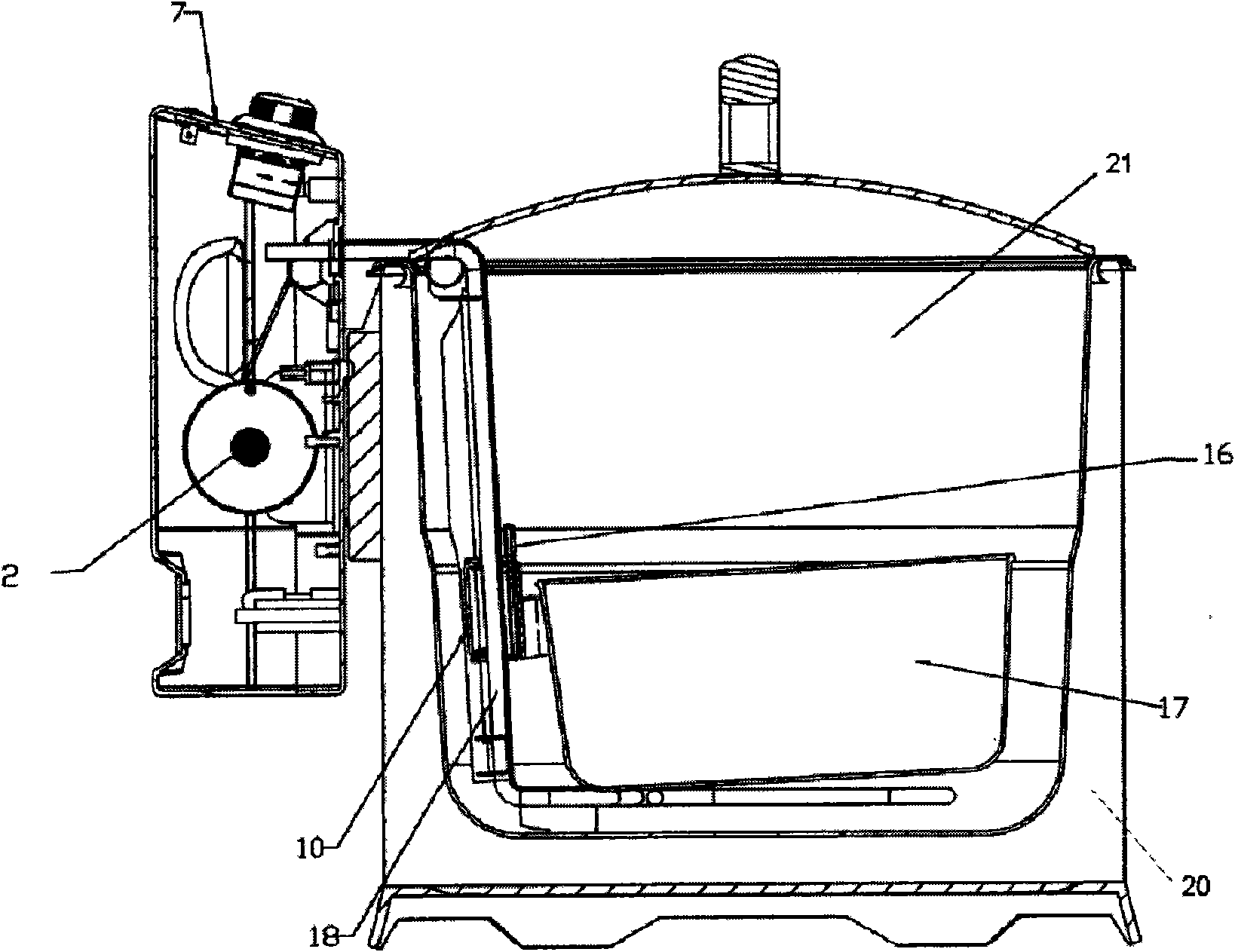

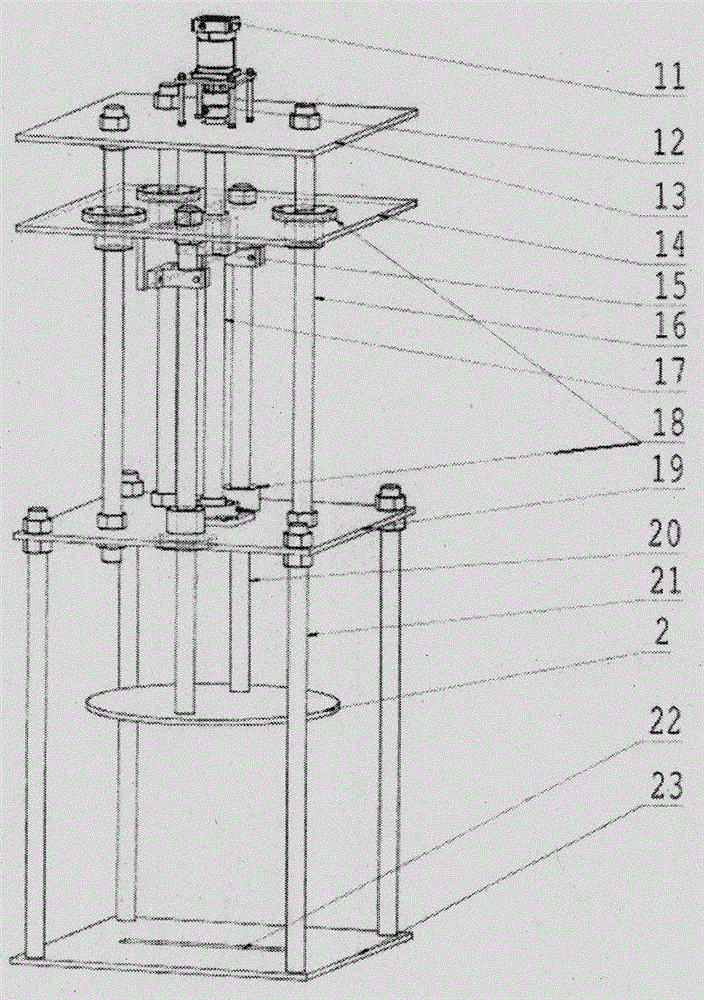

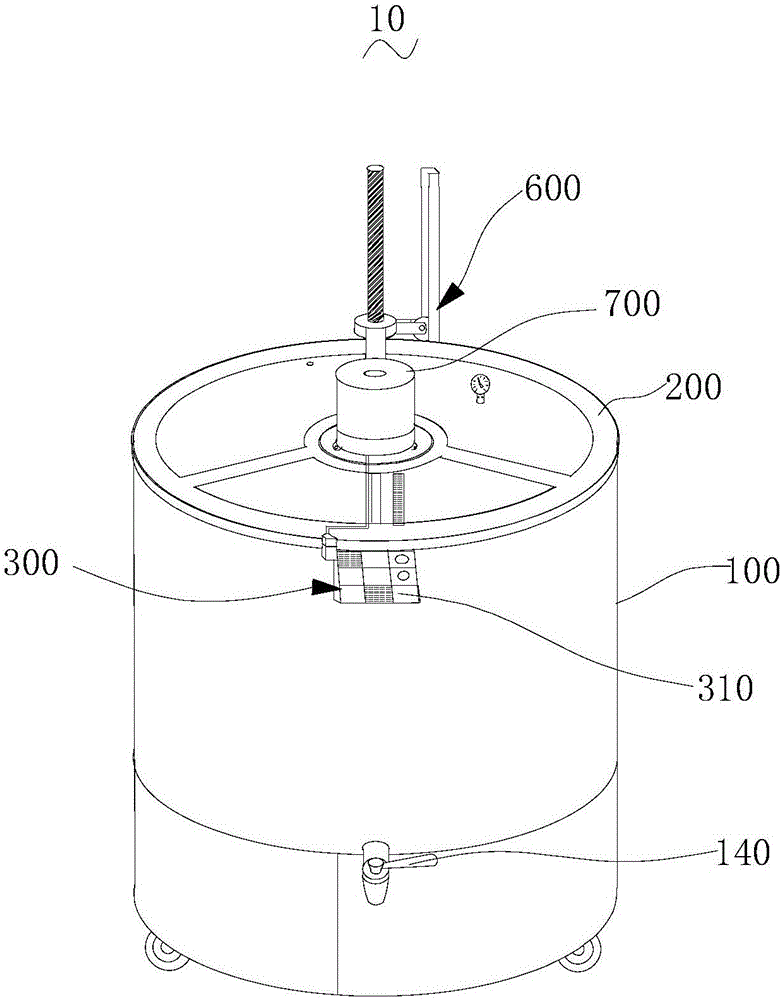

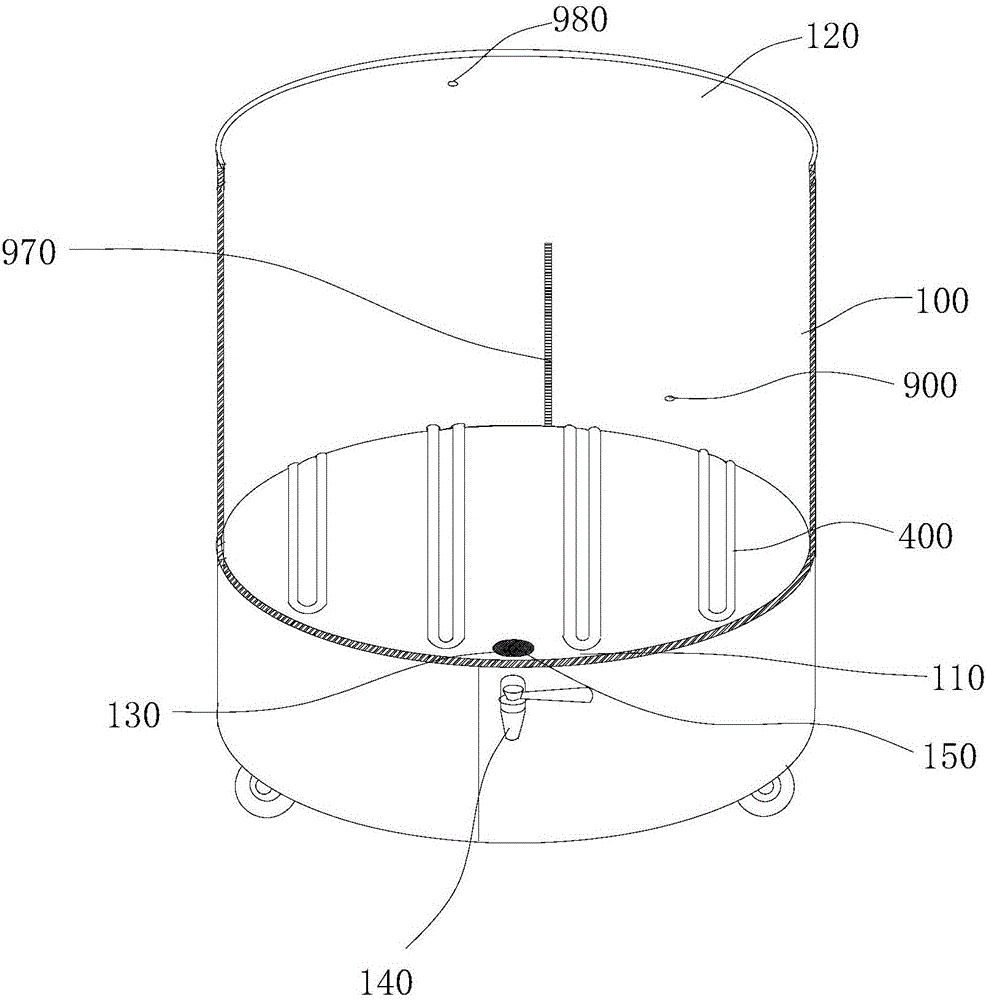

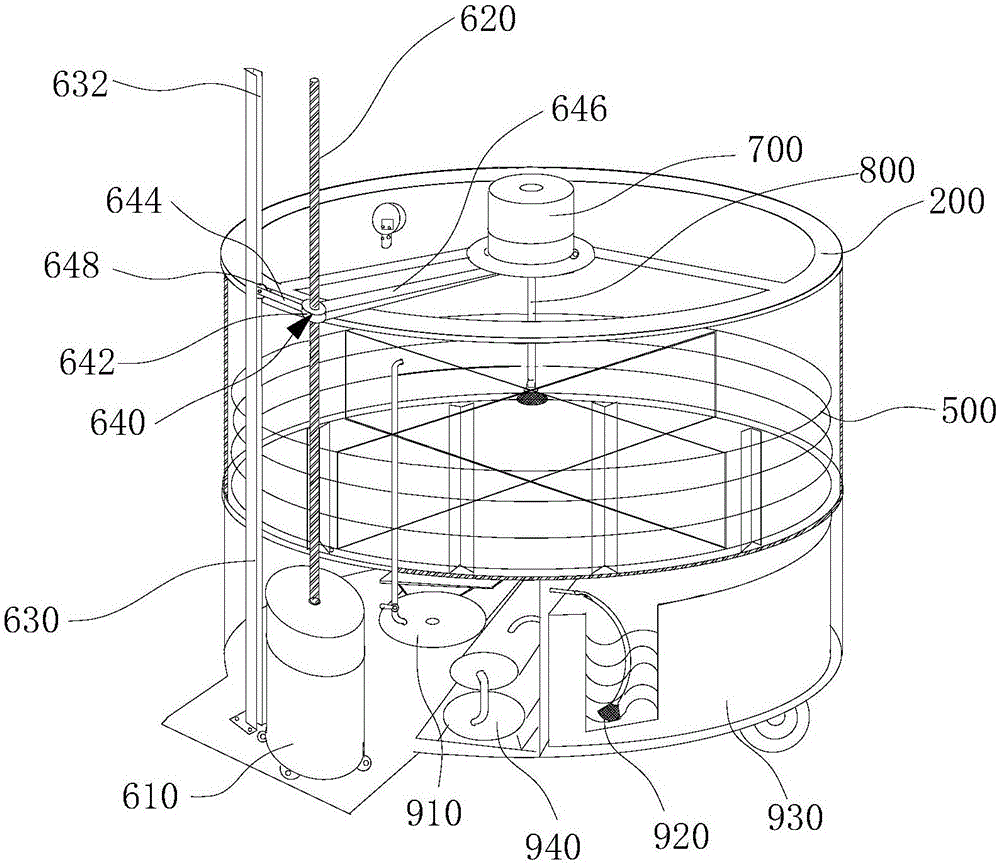

Microwave and vacuum frying integrating device for food processing, and efficient frying method

The invention relates to a microwave and vacuum frying integrating device for food processing and an efficient frying method, and belongs to the field of rapid frying, dewatering and drying devices for foods. The integrating device comprises a microwave heating cavity, a microwave generator, a microwave vacuum frying vessel, an oil storage tank, an oil pump, a hanging basket, a hanging basket rotating device, a condenser and a control panel, wherein the hanging basket is used for placing materials; the microwave generator is a variable-frequency microwave generator with high precision; the circumferences of the microwave generator are distributed evenly, vertically and spirally; the microwave generator adopts a waveguide feeding operation in a side part extending manner; the microwave vacuum frying vessel is used for frying the materials; and the oil pump is connected with the vacuum frying vessel, so that the materials are heated evenly in a pulse spouting manner. After the frying operation is finished, the frying oil is pumped back to the oil storage tank, and a vacuum de-oiling operation is carried out through the hanging basket rotating device. The integrating device has the advantages of high efficiency, rapidness, energy conservation and reduction in production cost. In order to realize an effect similar to a stirring effect, the pulse spouting manner is adopted, so that the frying effect is more uniform and the frying quality is very good. In addition, the flavor, the color and the nutritional ingredients of an original product are maintained when the materials are processed in the vacuum frying manner.

Owner:JIANGNAN UNIV

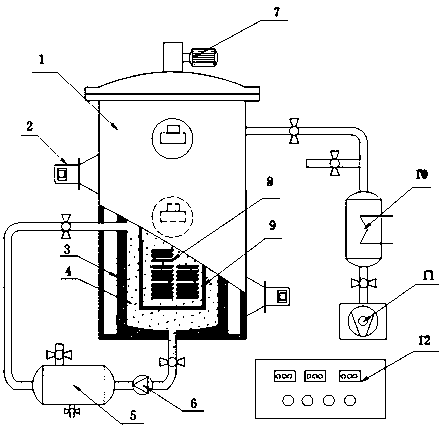

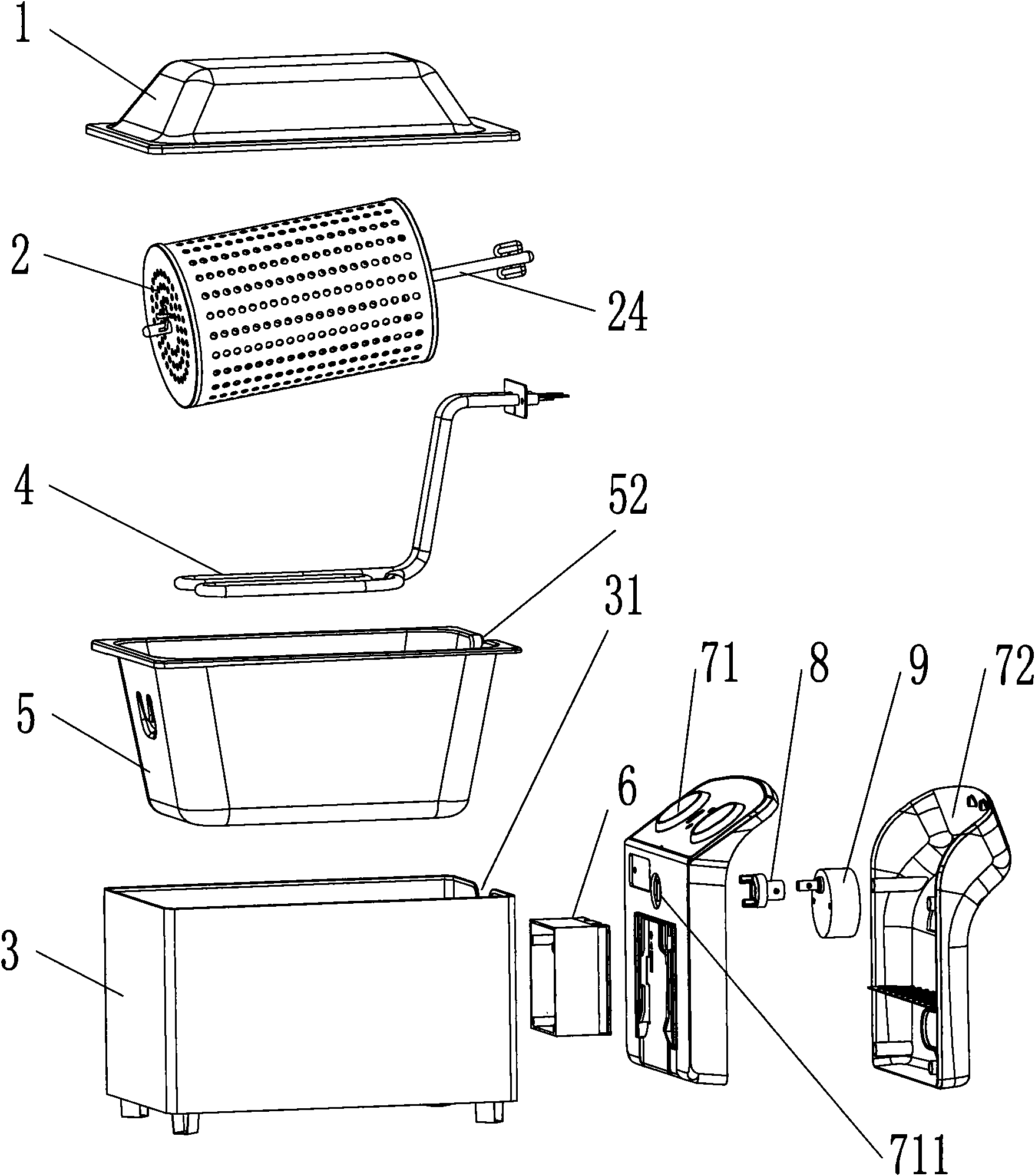

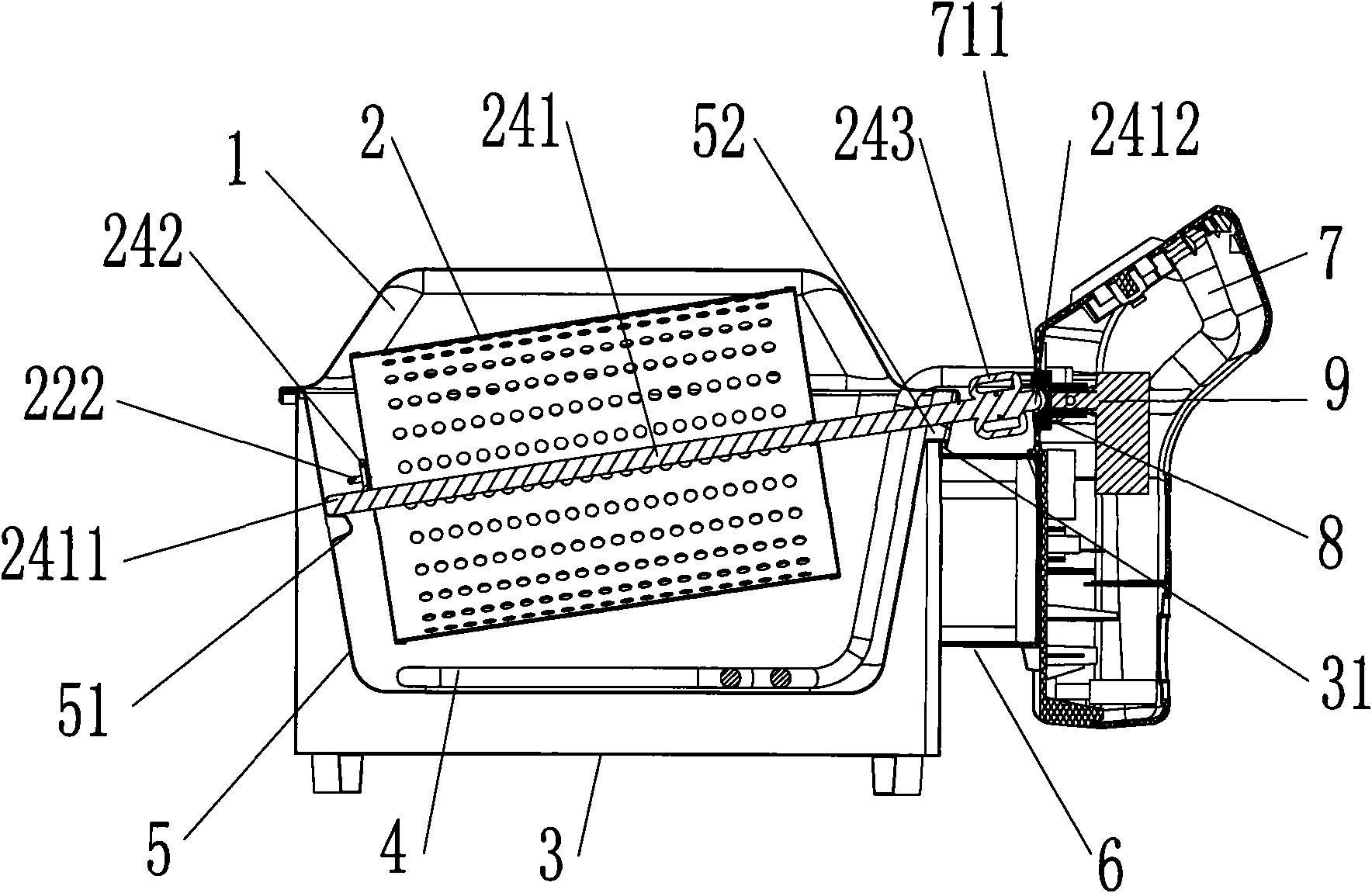

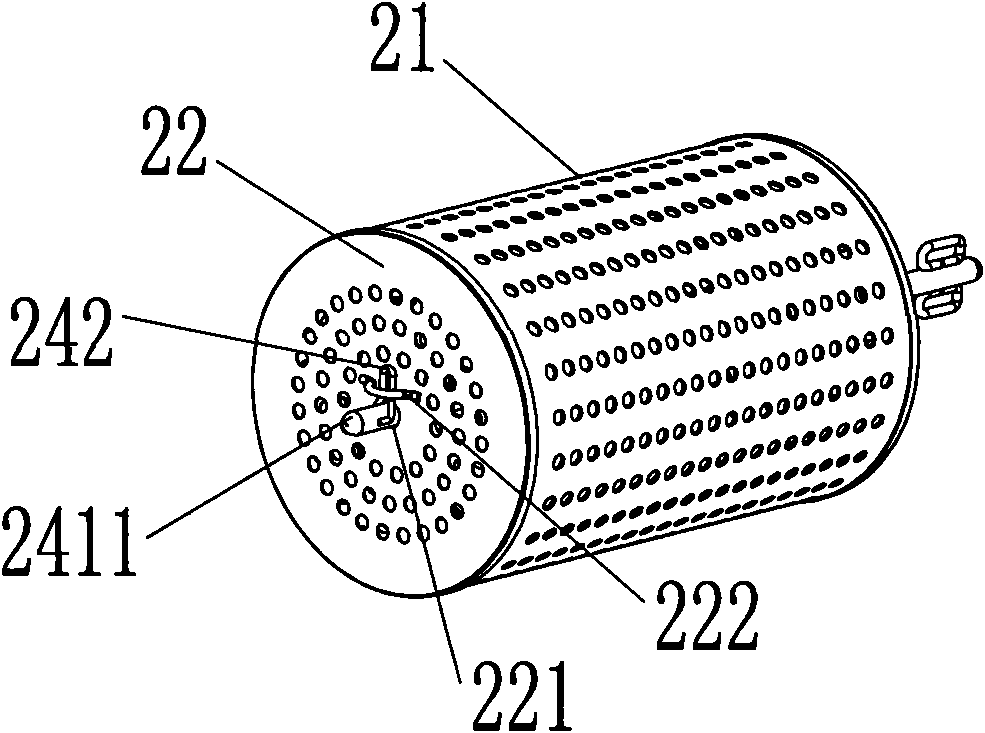

Deep fryer with rotatable frying cage

The invention discloses a deep fryer with a rotatable frying cage, which comprises an upper cover, the frying cage, a shell, an inner pot, a heater and a control box, wherein the frying cage is detachably suspended in the inner pot; the inner pot is placed in the shell; and the heater is placed at the inner bottom or the outer bottom of the inner pot. The deep fryer is characterized in that one lateral surface of the inner pot is provided with a step protruded to the center of the inner pot; a shaft assembly, a coupler and a motor which are connected together in turn are fixed on the lateral surface on the shell opposite to the step; and the shaft assembly passes through the frying cage, one end of the shaft assembly is placed on the lateral surface of the inner pot, and the other end of the shaft assembly is connected with the coupler. The frying cage can rotate in 360 degrees to fully turn food so as to save oil and improve the food frying effect; and a groove for connecting the frying cage and the motor does not need to be formed on the inner pot so as to avoid the problems of oil splash and cleaning difficulty.

Owner:MIDEA GRP CO LTD

Crayfish food as well as preparation method and production equipment thereof

InactiveCN103960697AGood health effectSilky meatWater/sewage treatmentOil/fat bakingVegetable oilAdditive ingredient

Crayfish food comprises ingredients in parts by weight as follows: 100 parts of crayfish, 50 parts of vegetable oil, 10.6-15.2 parts of spice, 0.3-0.5 parts of transglutaminase, 0.3-0.5 parts of nisin, 0.2-0.5 parts of konjac glucomannan, 0.2-0.4 parts of chitosan, 0.4-0.5 parts of lecithin and 0.08-0.16 parts of delta-gluconolactone. According to the crayfish food, crayfish balls are used for preparing instant food, crayfish shells are used for preparing chitosan, and raw materials are sufficiently utilized; transglutaminase in the raw materials prompts crosslinking of crayfish meat protein crosslinking amino acid, tenderness of a product is improved, natural food antiseptics such as nisin and the like meet requirements of people for food health, and at the same time, the guarantee period of the crayfish food is prolonged to 12 months; and defects that crayfish products which can be stored at the normal temperature are less, the guarantee period is short and the like are overcome, and the crayfish food has good market prospect.

Owner:顾炎林

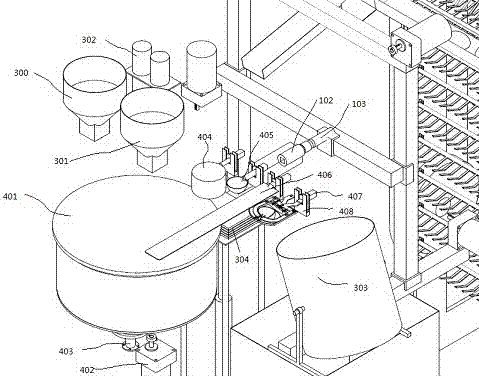

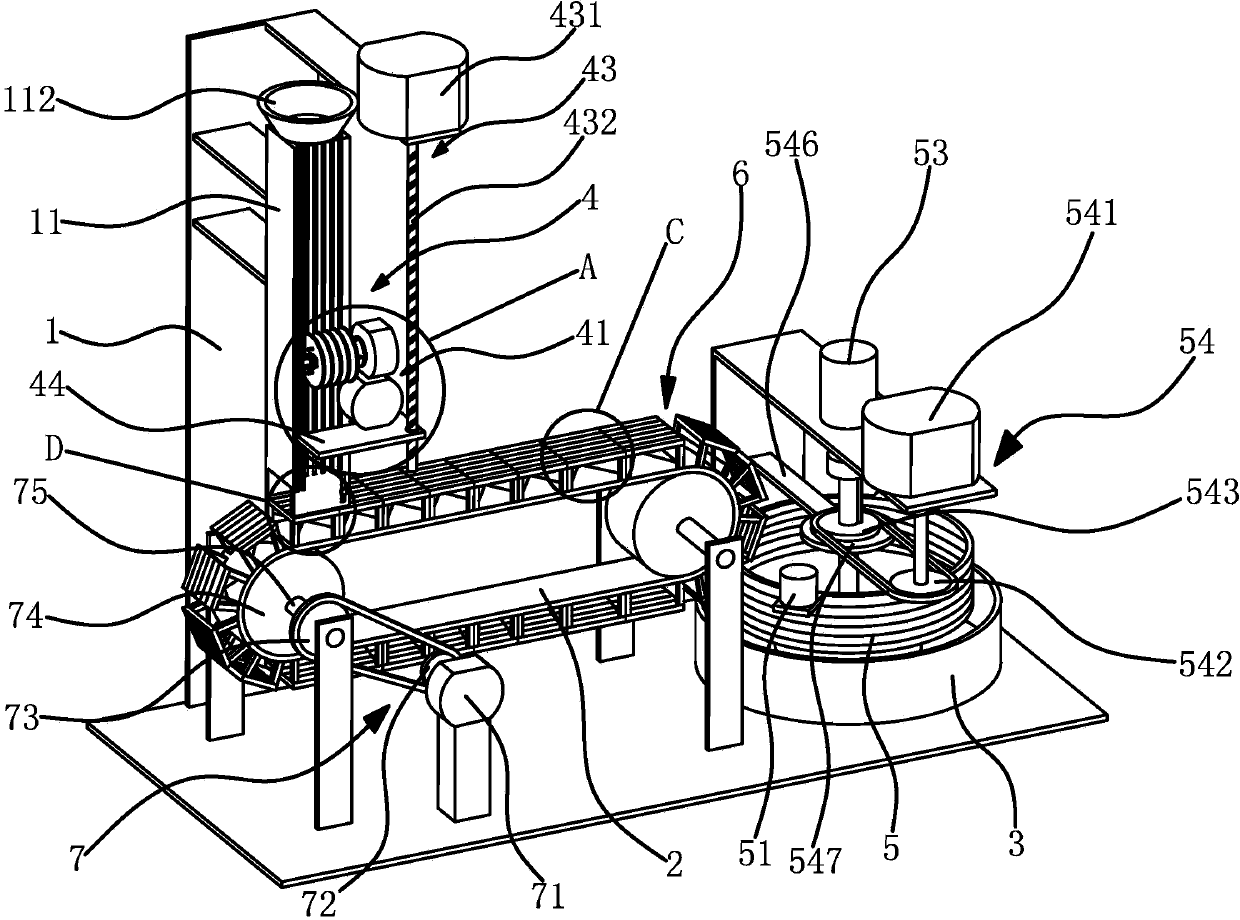

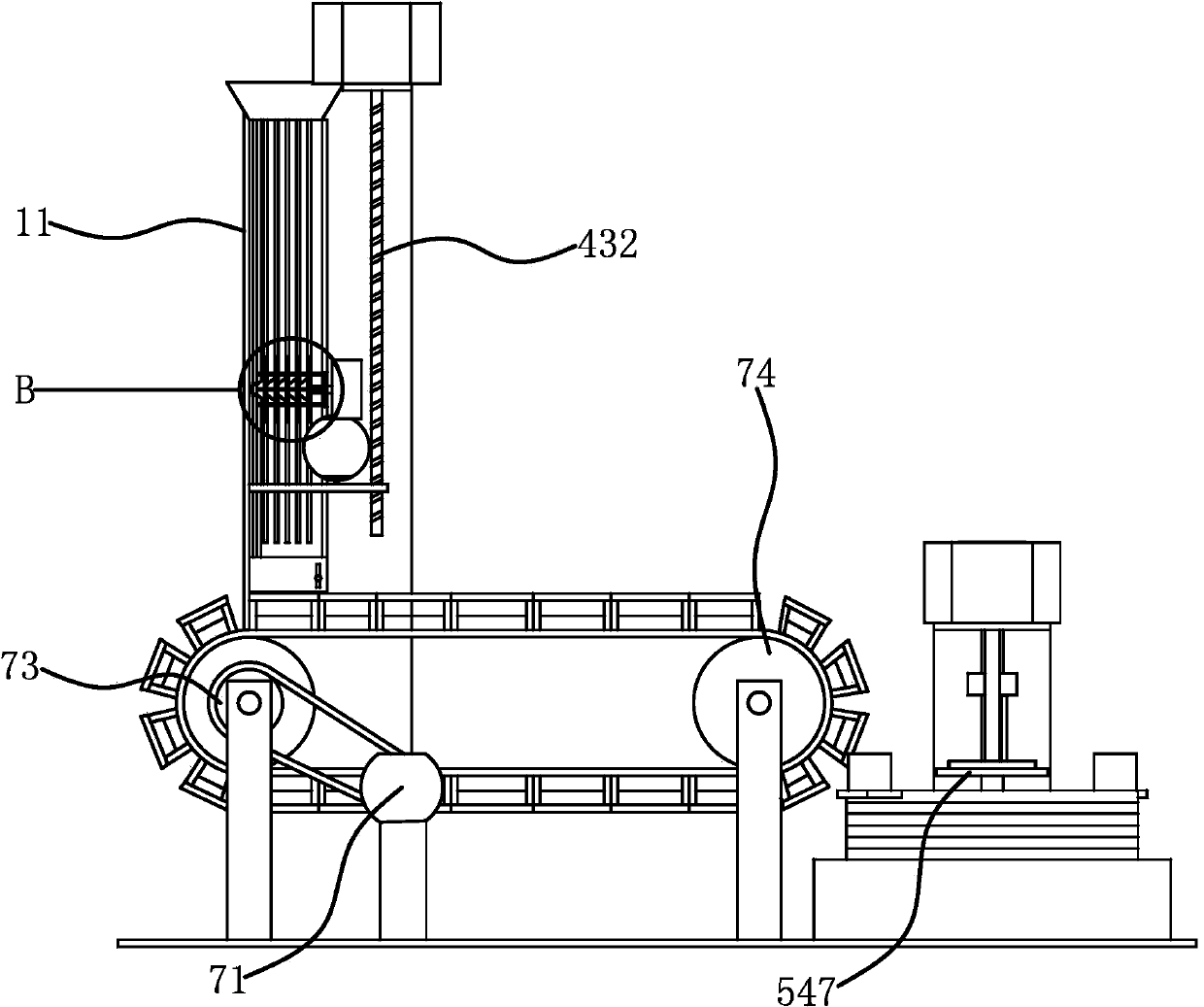

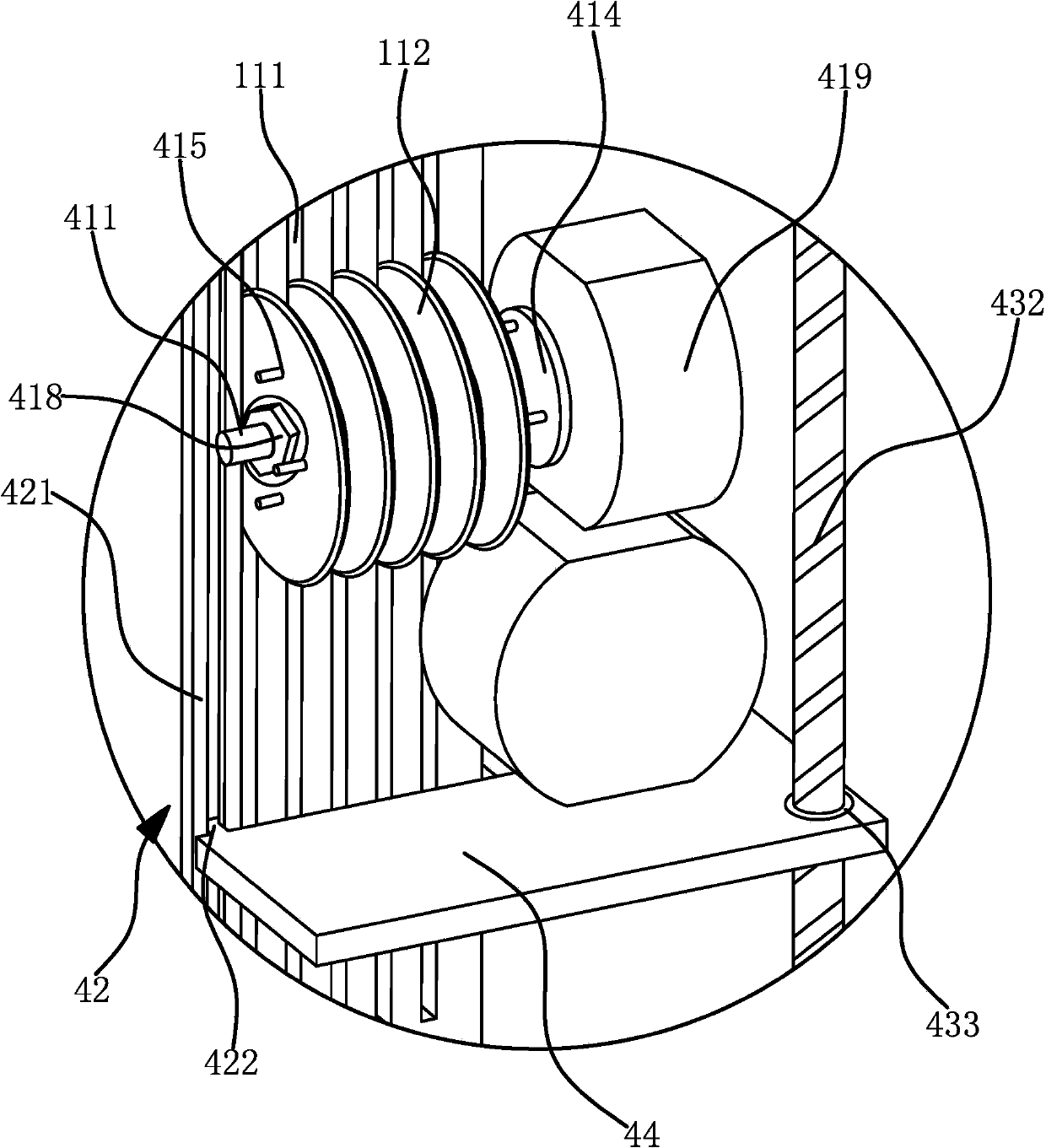

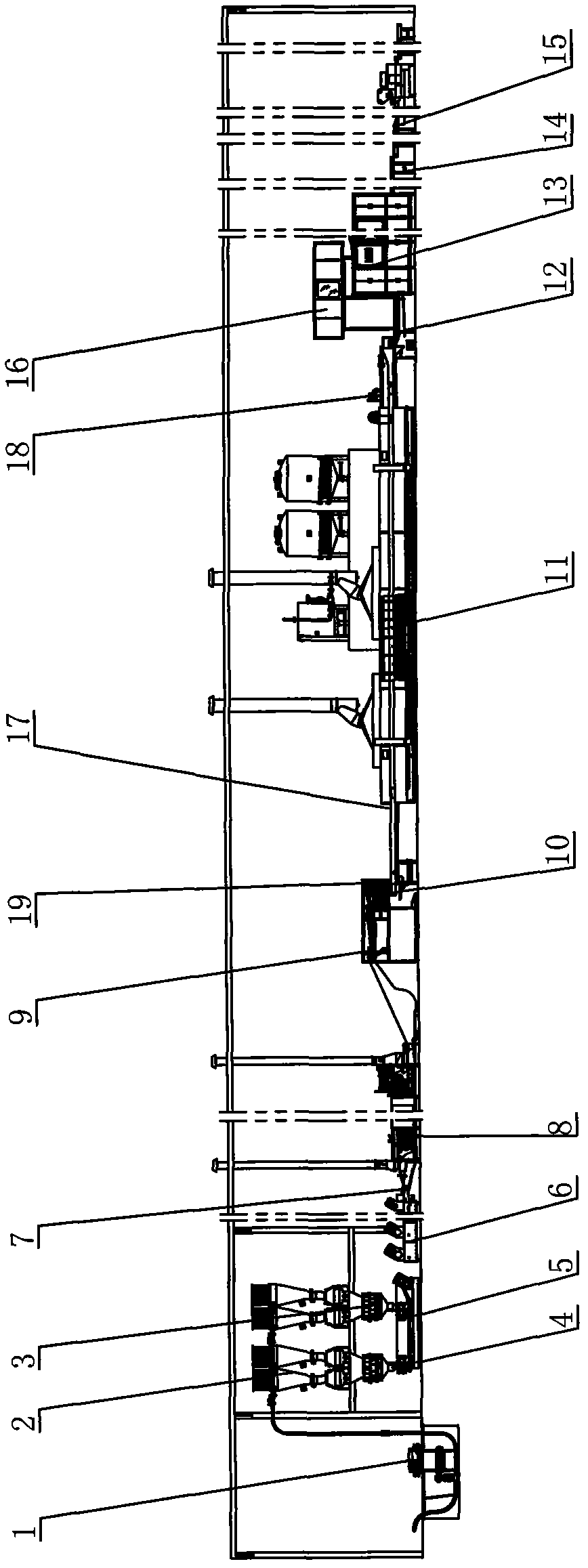

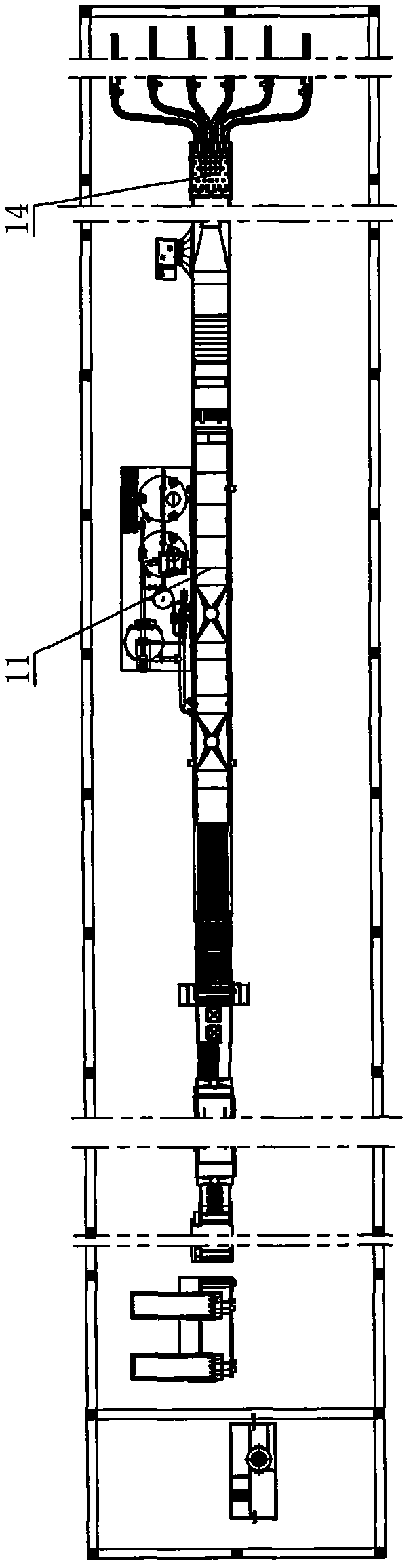

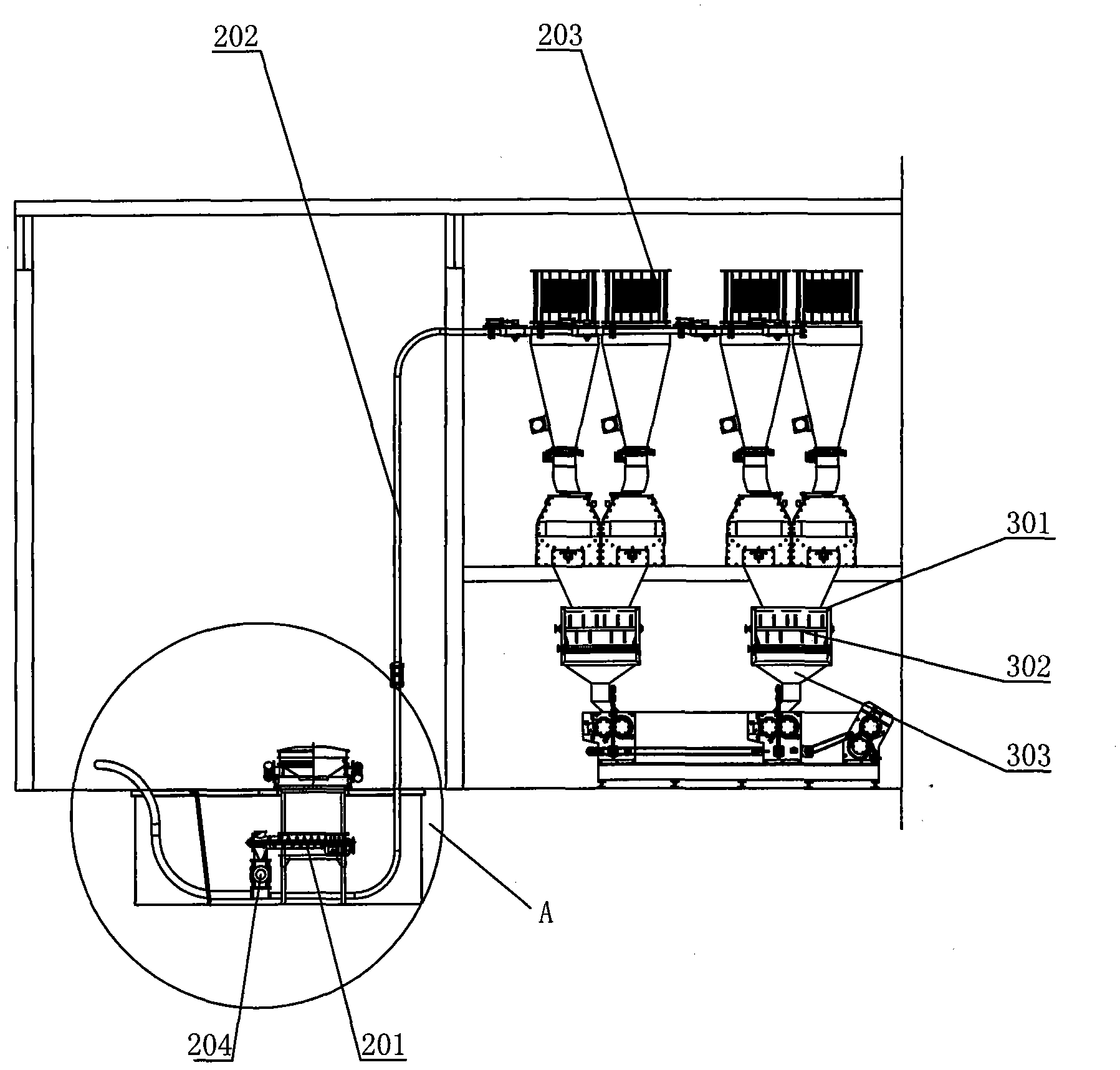

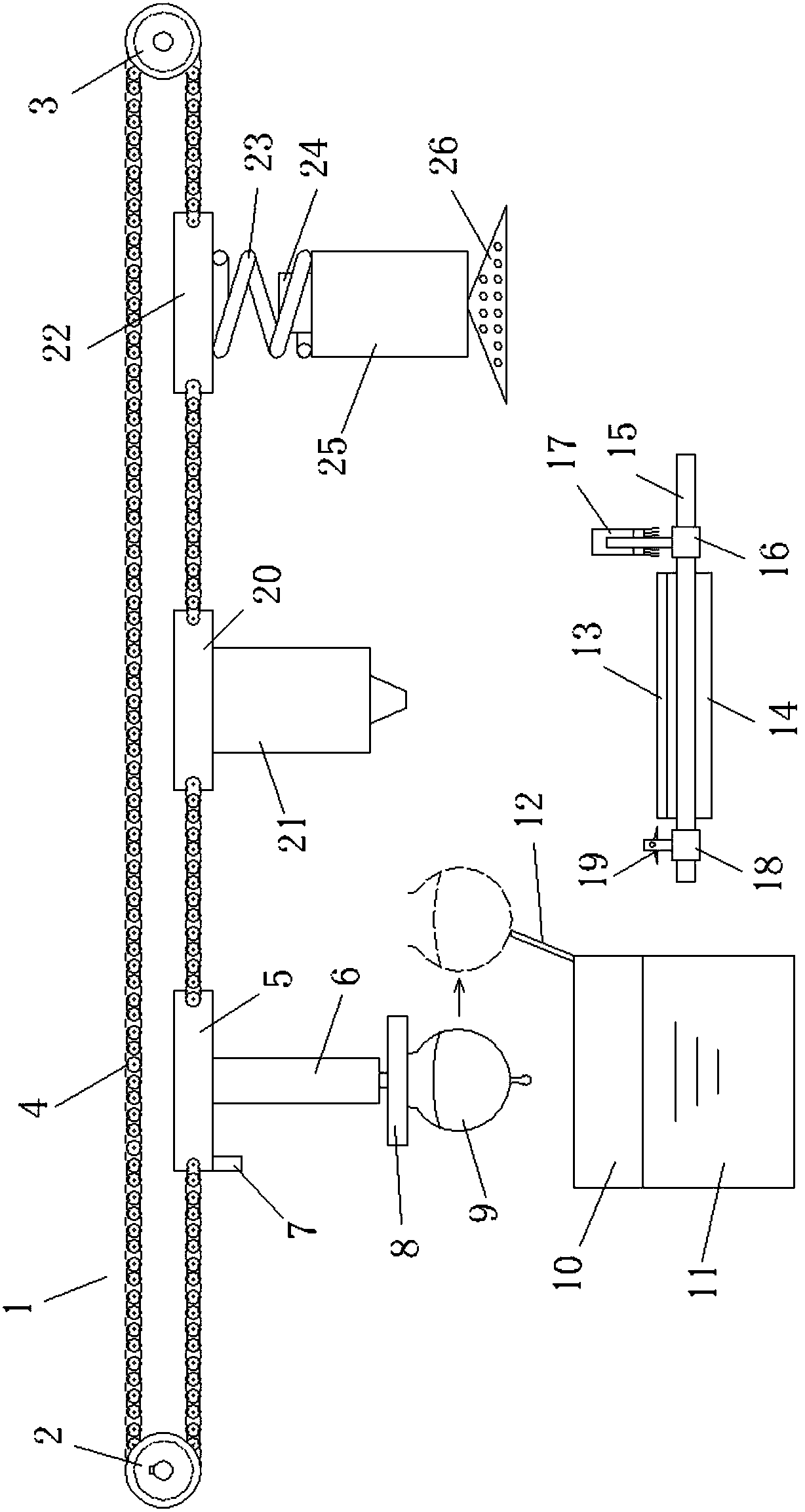

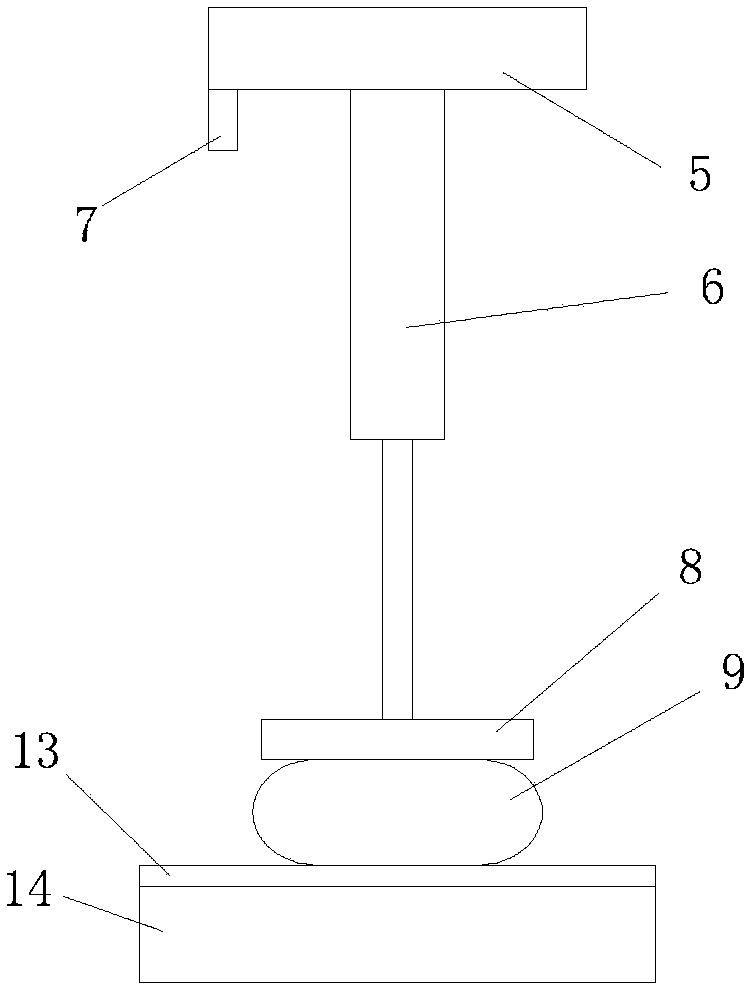

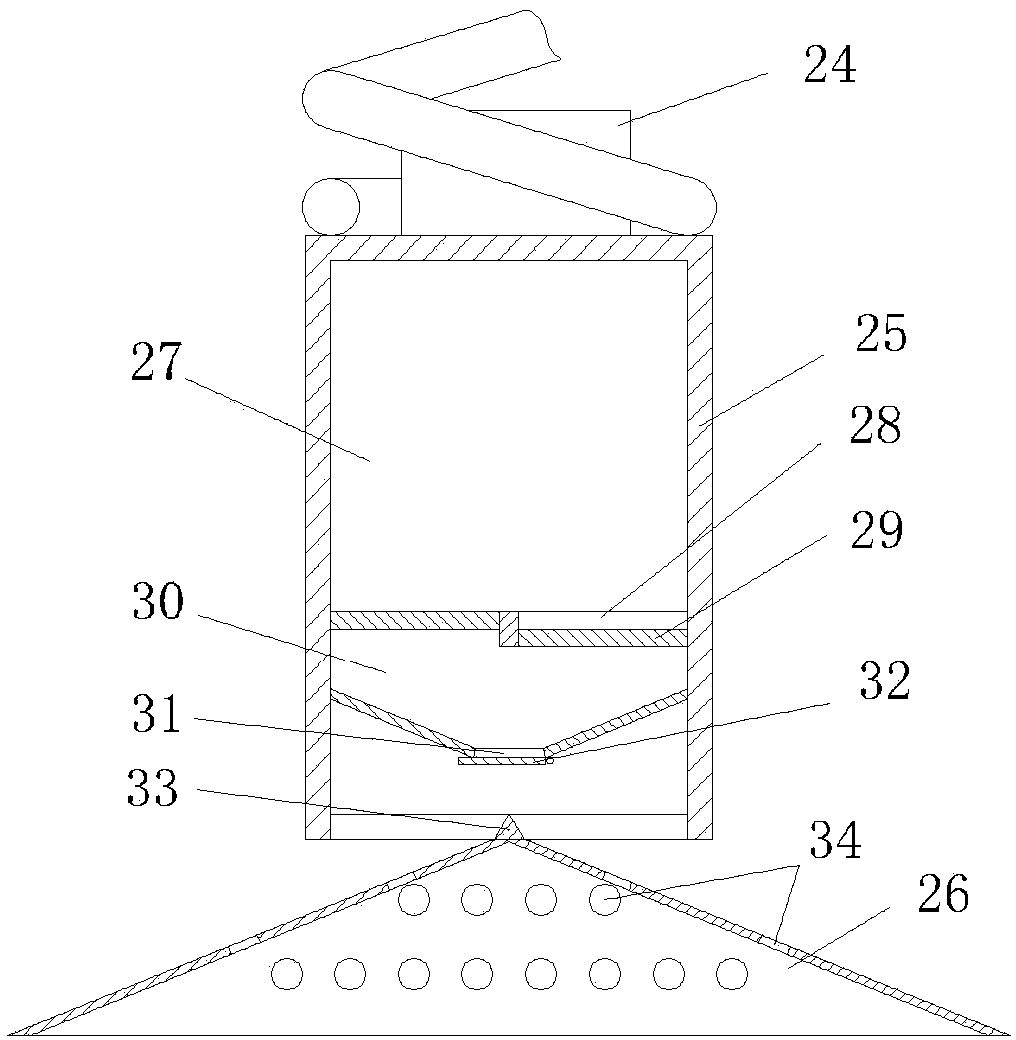

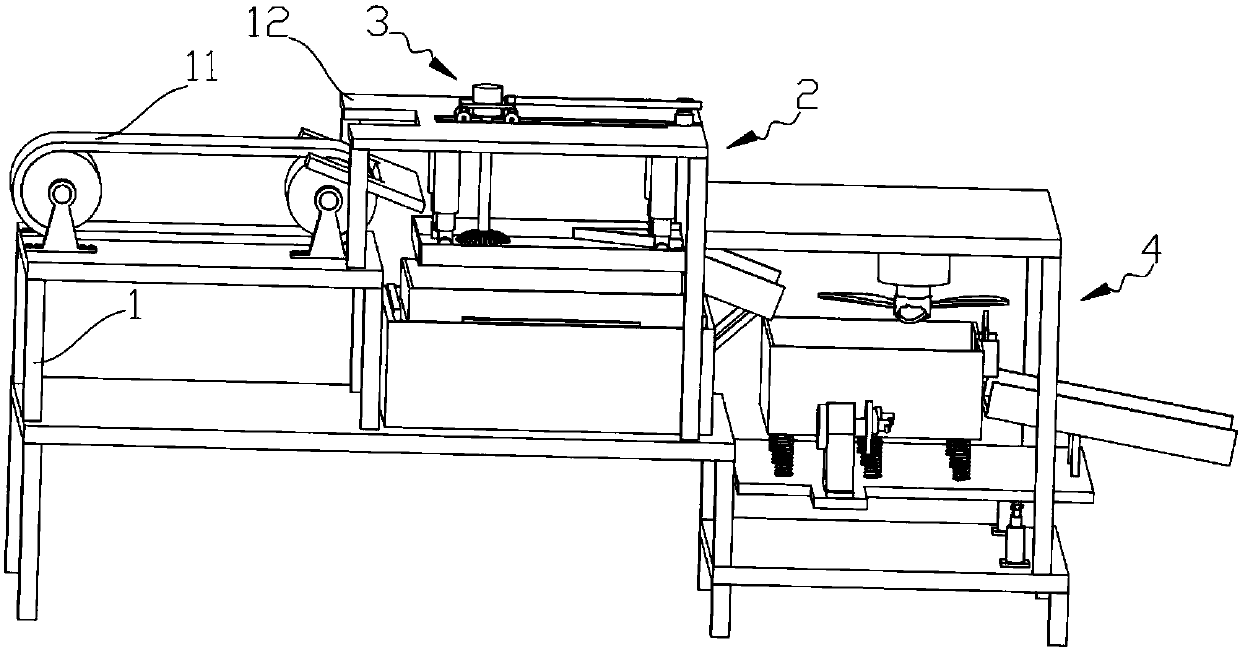

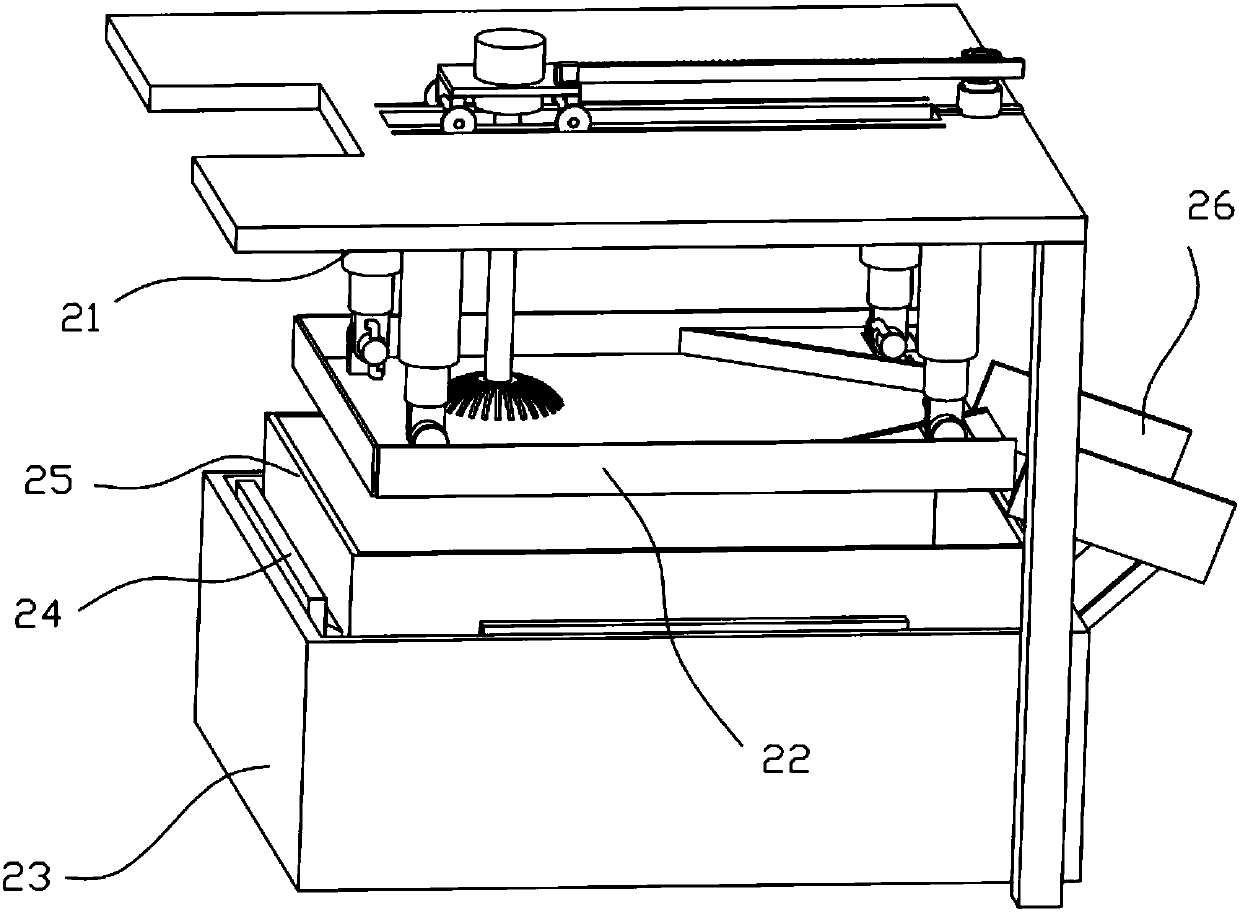

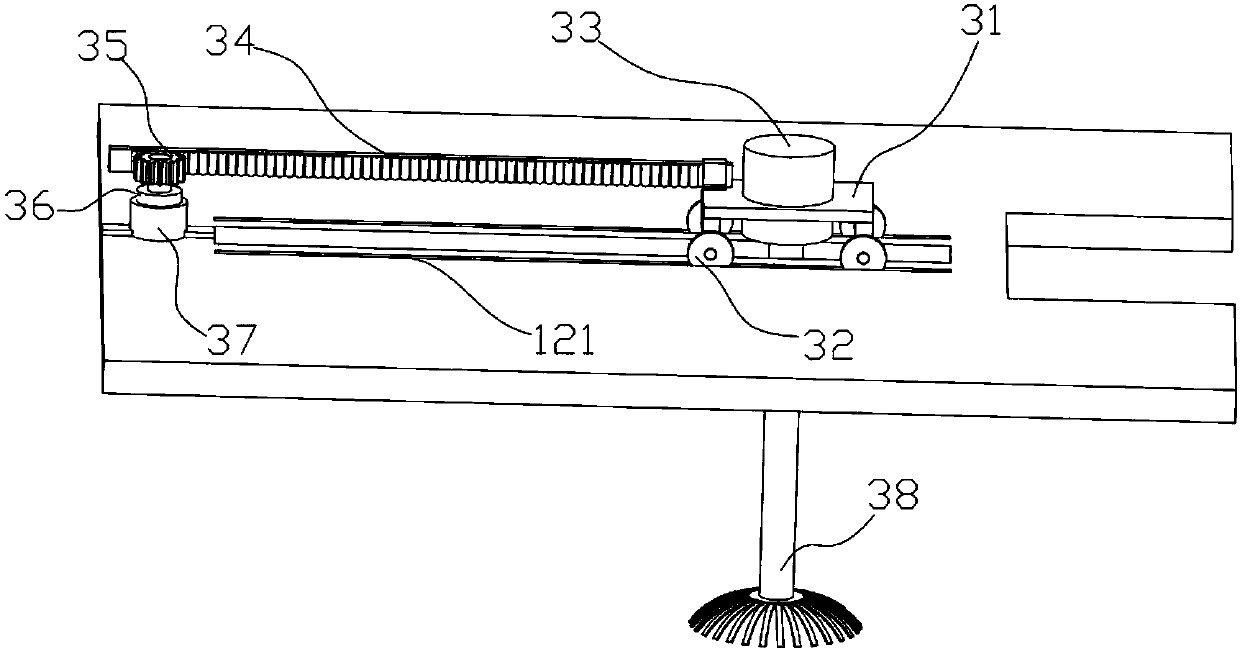

Pancake full automation joint production and network selling all-in-one machine

ActiveCN107114431ARealize online bookingAchieve interactionPaper-money testing devicesReservationsAdditive ingredientCash collection

The invention belongs to the technical field of food equipment, in particular relates to a pancake full automation joint production and network selling all-in-one machine. The machine comprises a machine body, wherein a pancake-making device is arranged on the machine body, an annular dual-channel storage egg shell removing and feeding device, a mobile wall hanging rail vehicle-mounted working platform device, a flipping folding end product packaging output device, fried pancake, fried fruit grate, sauces, a side ingredient storage alternative ration feeding device, and an electrical supply and control device; for solving the problems of complex pancake making process and labor expending, a full automation joint production and network selling all-in-one machine is provided, replacement of manual operations is achieved, all decentralized operations are combined together in one machine, and the production work of pancakes is completed. Cash is automatically collected by self-service under the intelligent control of an intelligent selling system, Internet lines are connected with the machine, online reservations, cash collections, and automatic vending are achieved through Internet, and online communication and interaction are achieved for the purchasers.

Owner:天津市津盈门科技研发有限公司

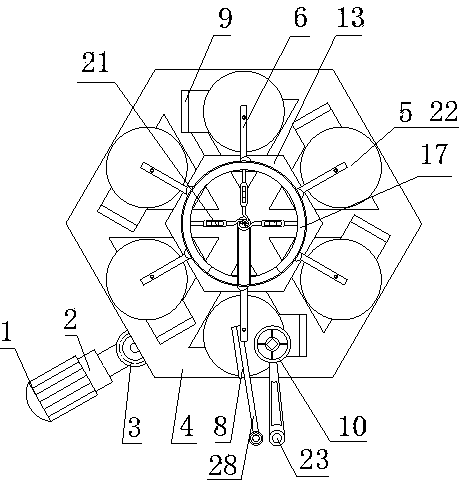

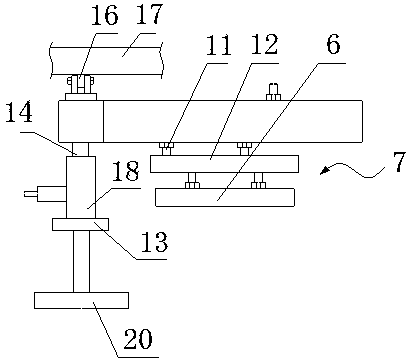

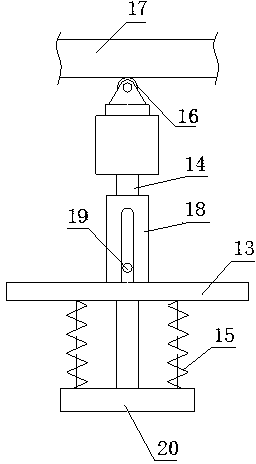

Automatic pancake machine

InactiveCN103734209AReduce thicknessTenacious feetOil/fat bakingPancakes bakingEngineeringHeating furnace

The invention relates to an automatic pancake machine which comprises a pancake spreading device, a heating and baking device and a power device, wherein the heating and baking device comprises more than one heating furnace; the heating furnace is fixedly arranged on a rotary disc, and is provided with flat plates; the pancake spreading device comprises scraping plates, and the scraping plates are respectively arranged at one side of each flat plate; the power device comprises a main driving part, a flat plate self-rotation driving part and a scraping plate lifting part, the main driving part is used for driving the rotary disc to rotate, and the flat plate self-rotation driving part is used for realizing the self-rotation of each plat plate; the lifting movement track line of each scraping plate comprises an ascending travel section track line and a return travel section track line; the return travel section track line at least comprises a return travel track line I and a return travel track line II; an included angle alpha between the return travel track line I and a time coordinate axis is greater than the included angle beta between the return travel track line II and the time coordinate axis. The automatic pancake machine has the advantages that the pancake is thin, the processing efficiency is high, the processing speed is high, and the scraping of pancake is complete.

Owner:尹相善

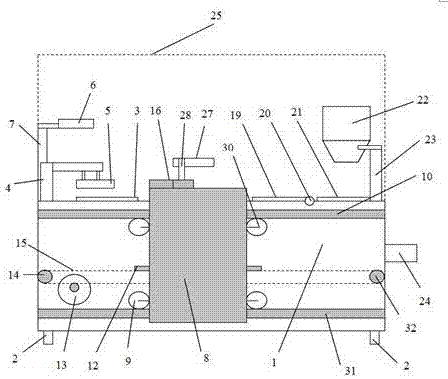

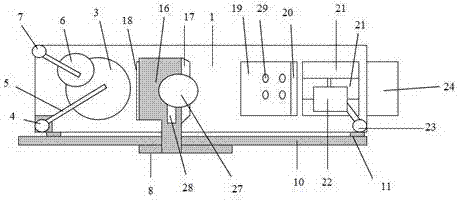

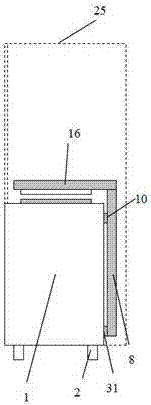

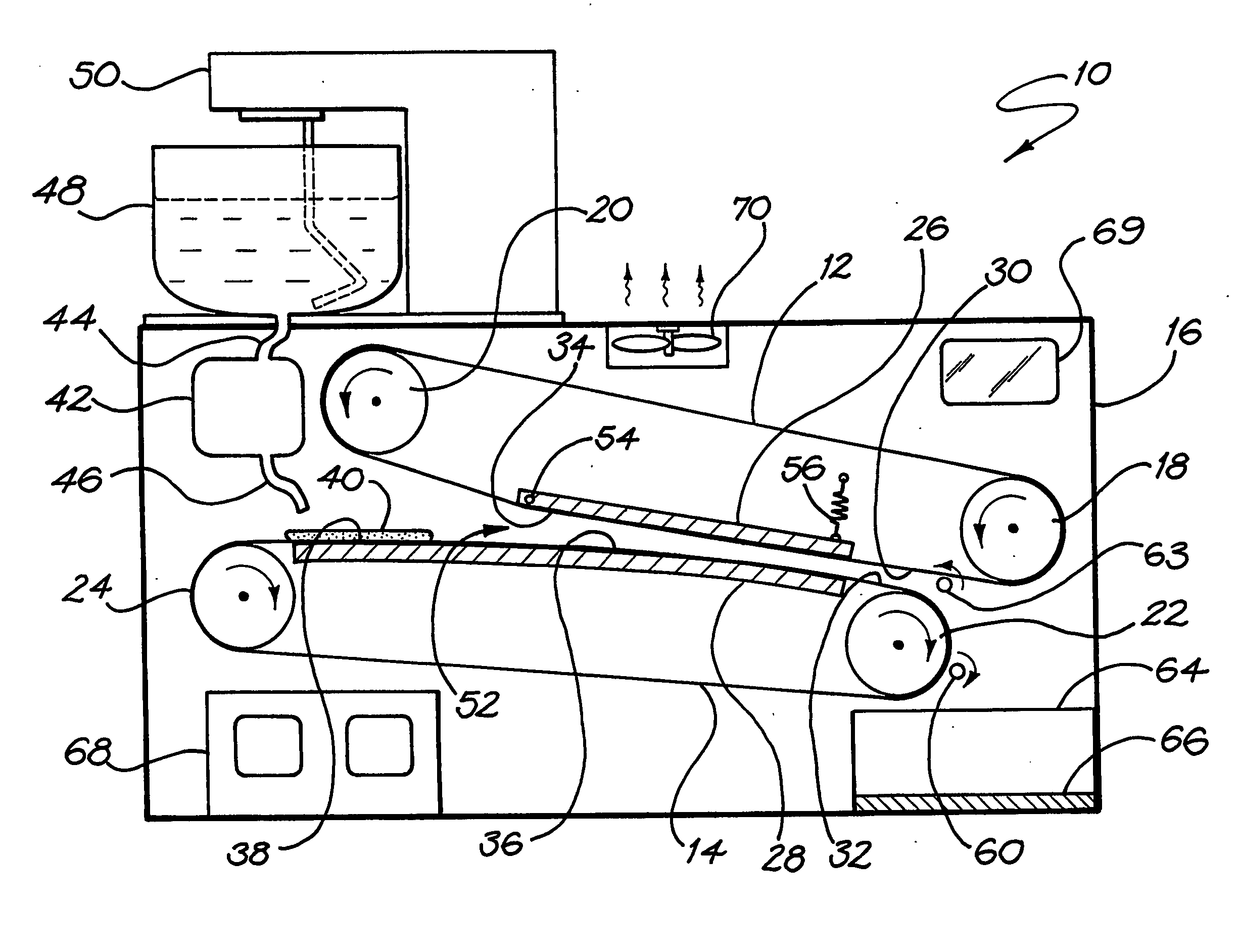

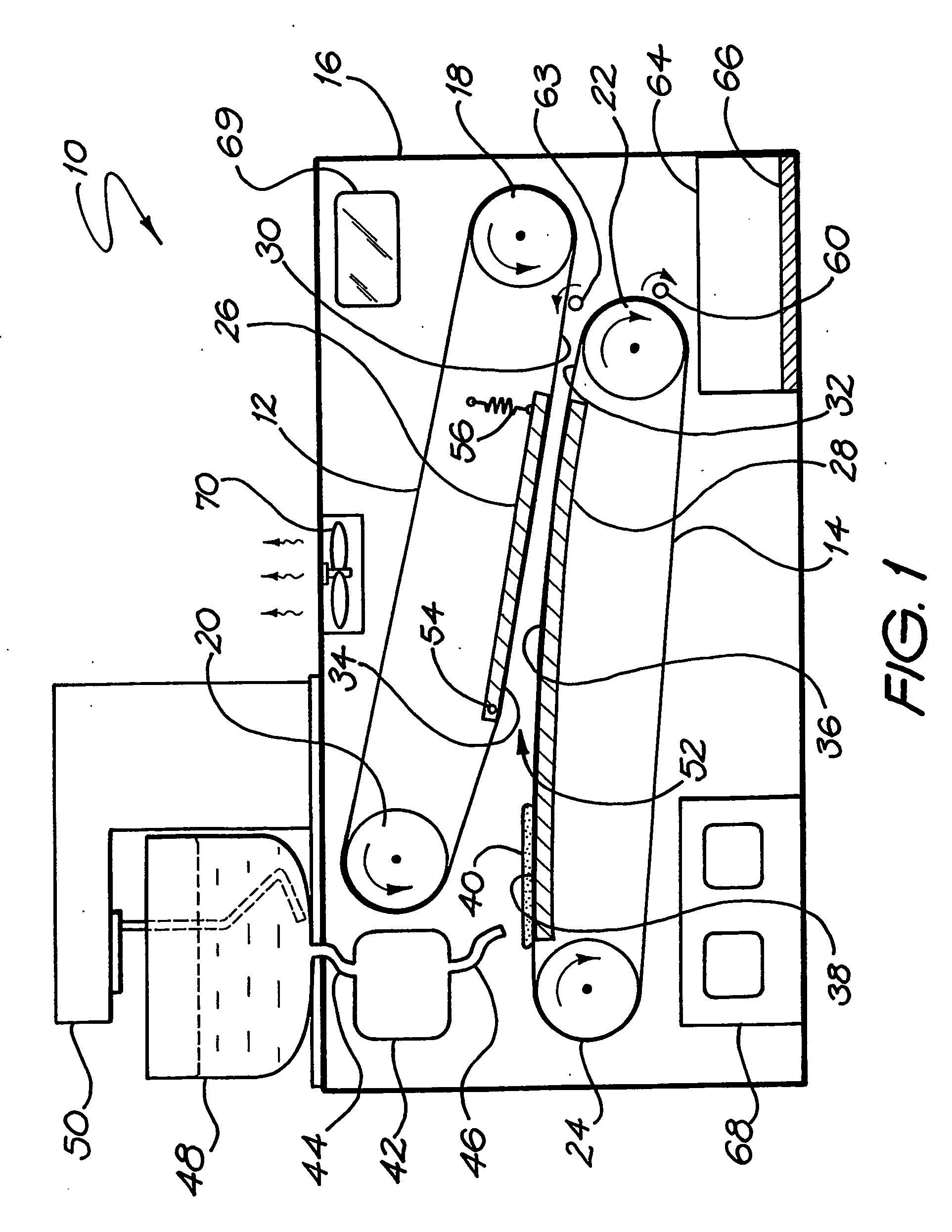

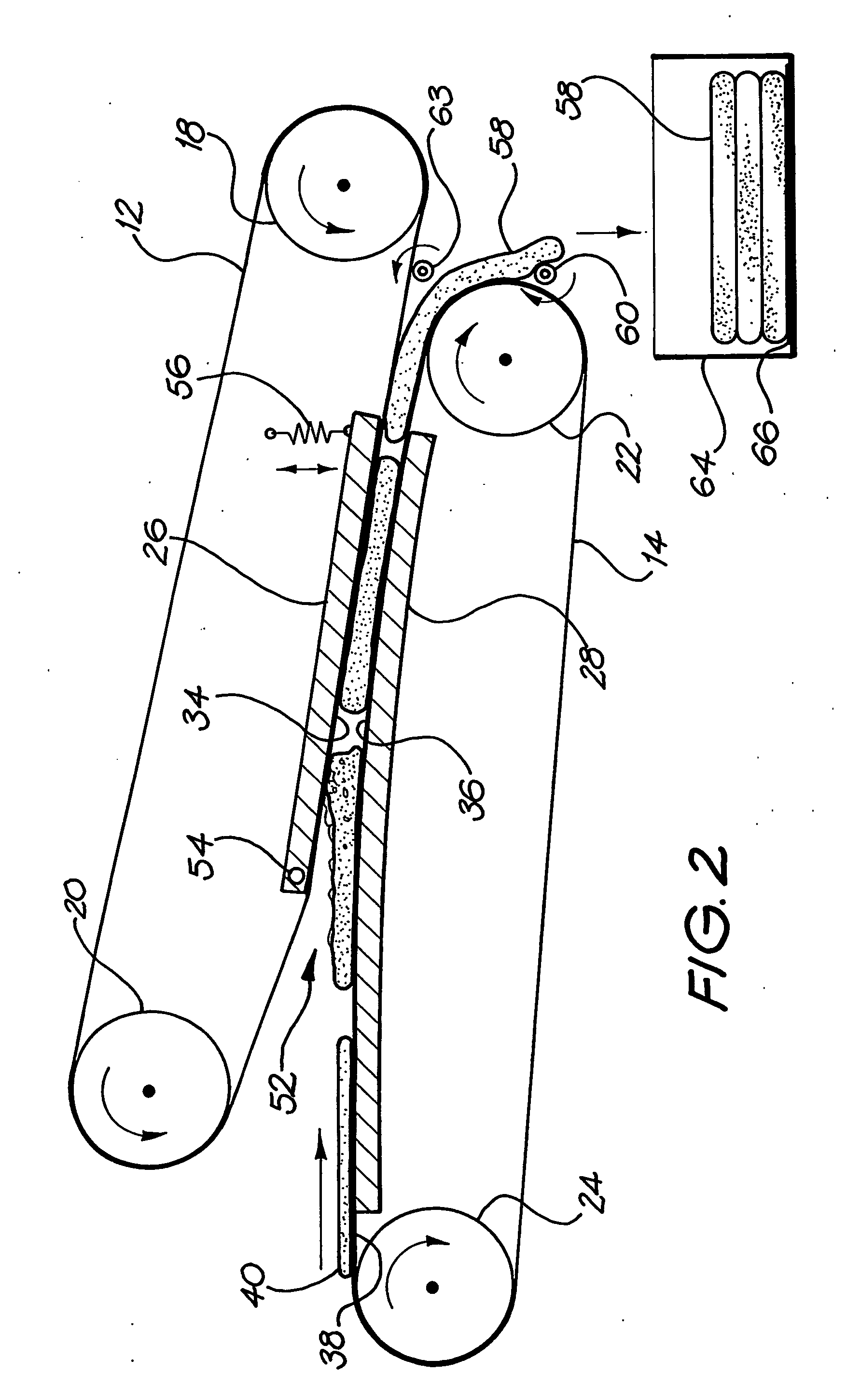

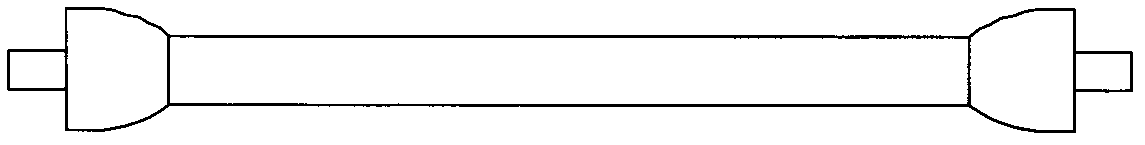

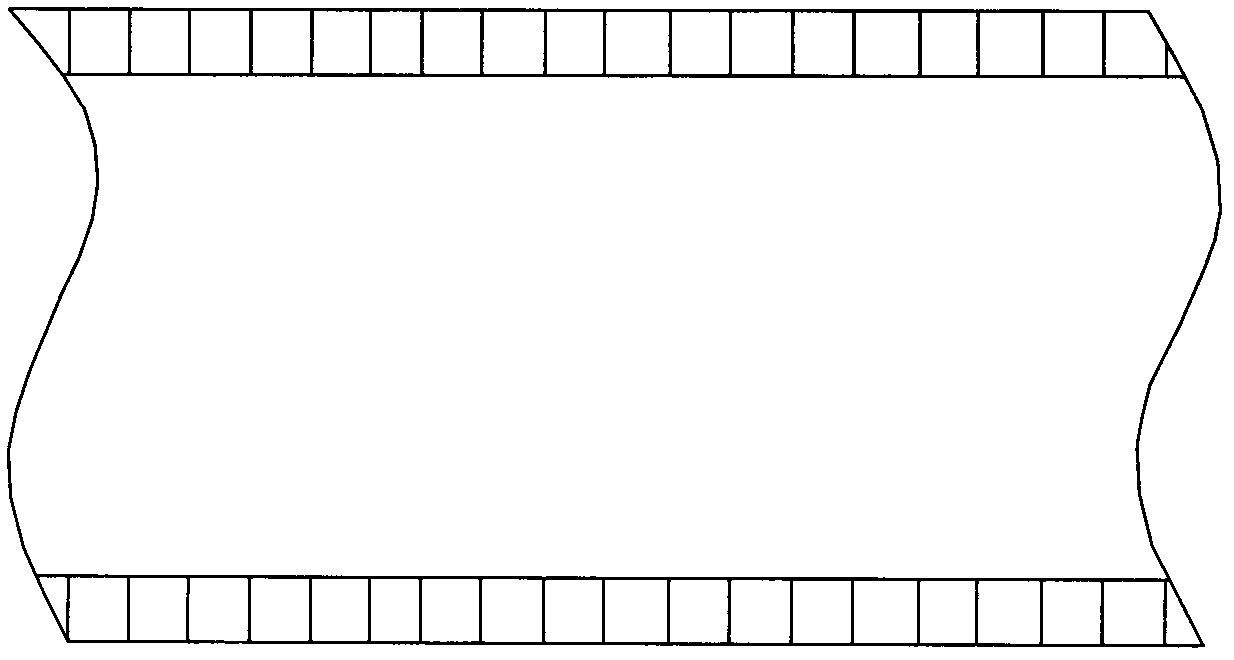

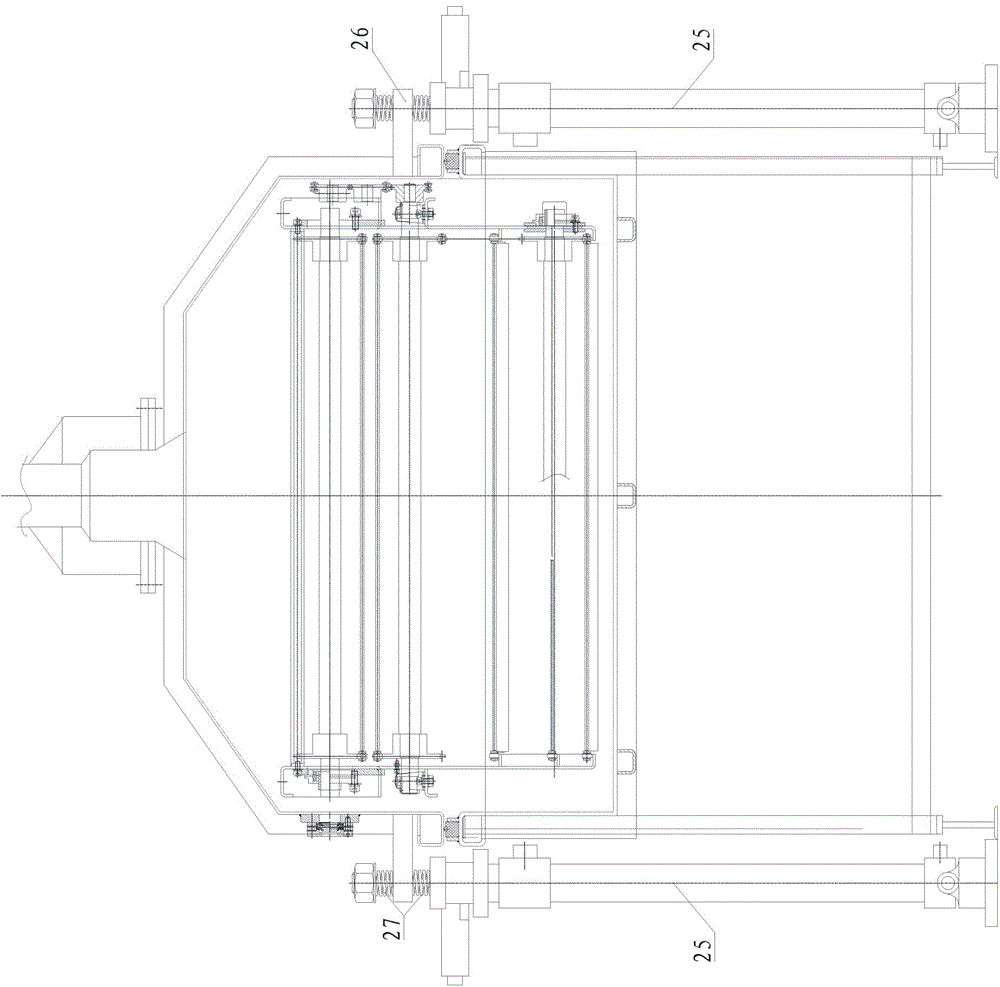

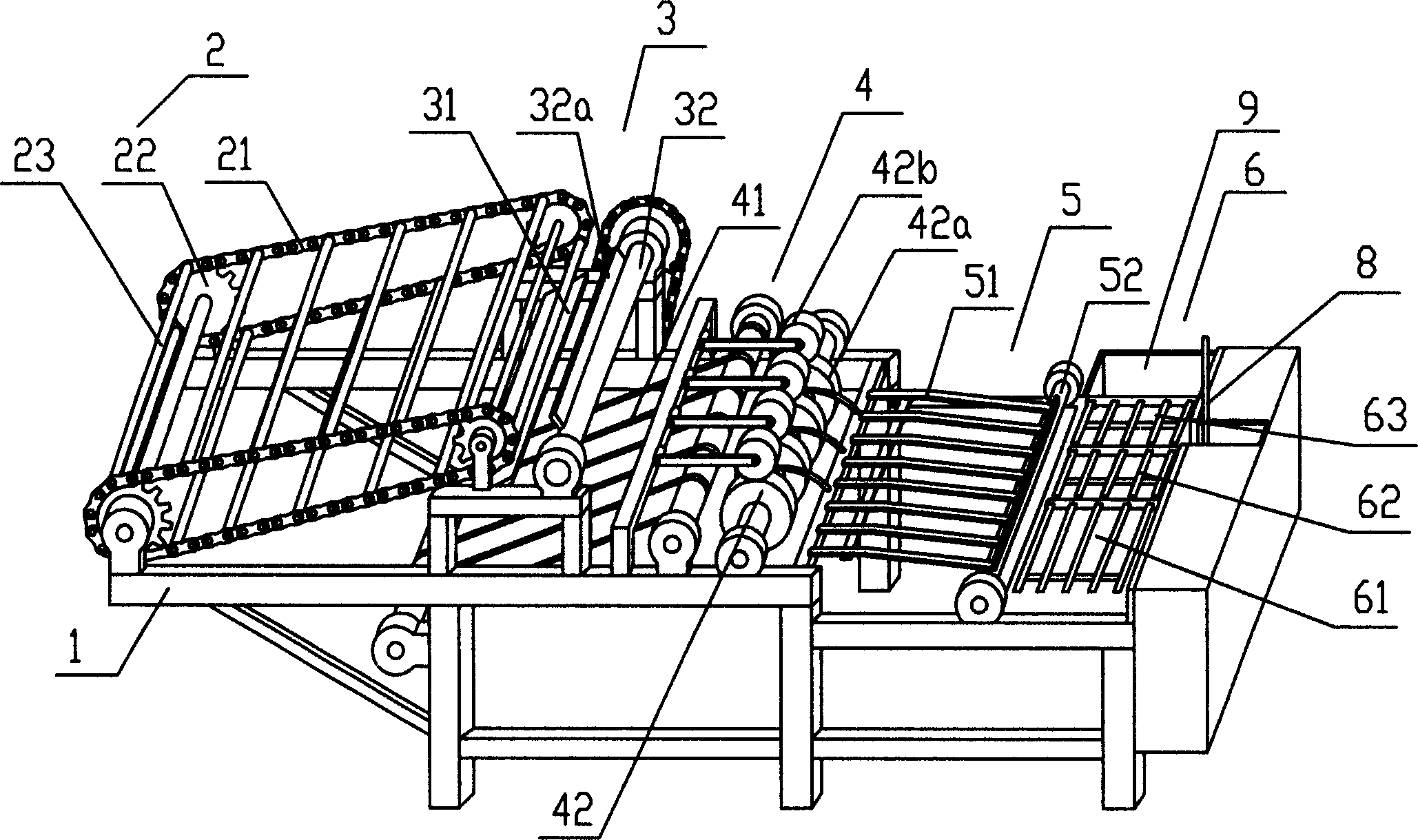

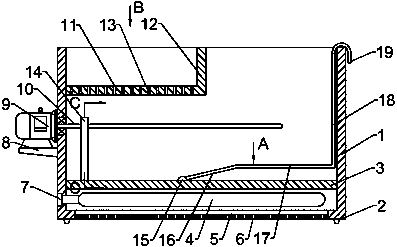

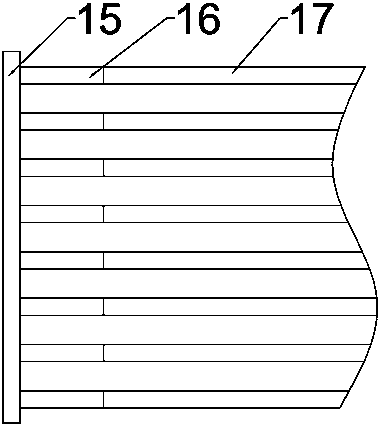

Automated belt cooking machine pancakes or the like

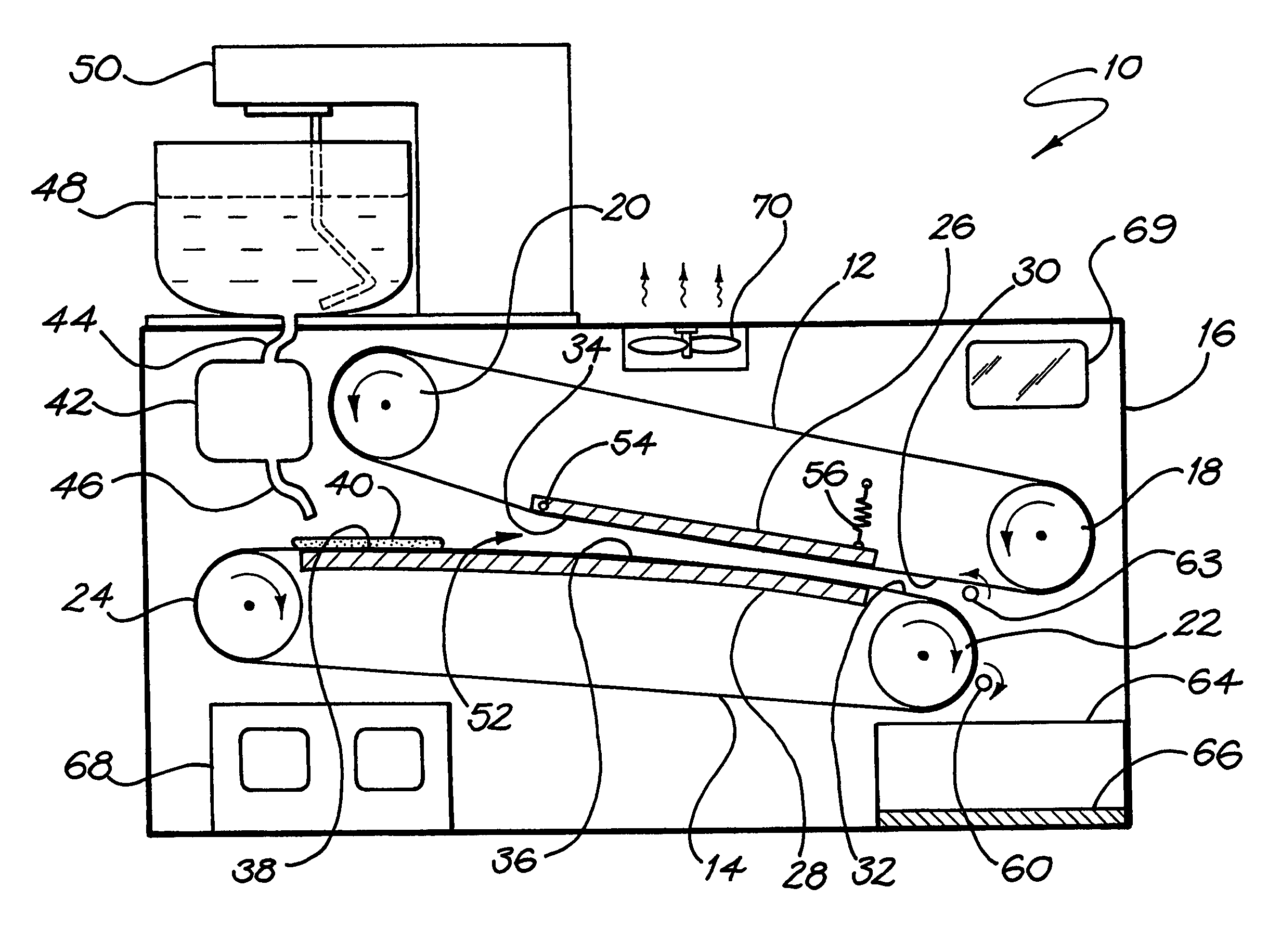

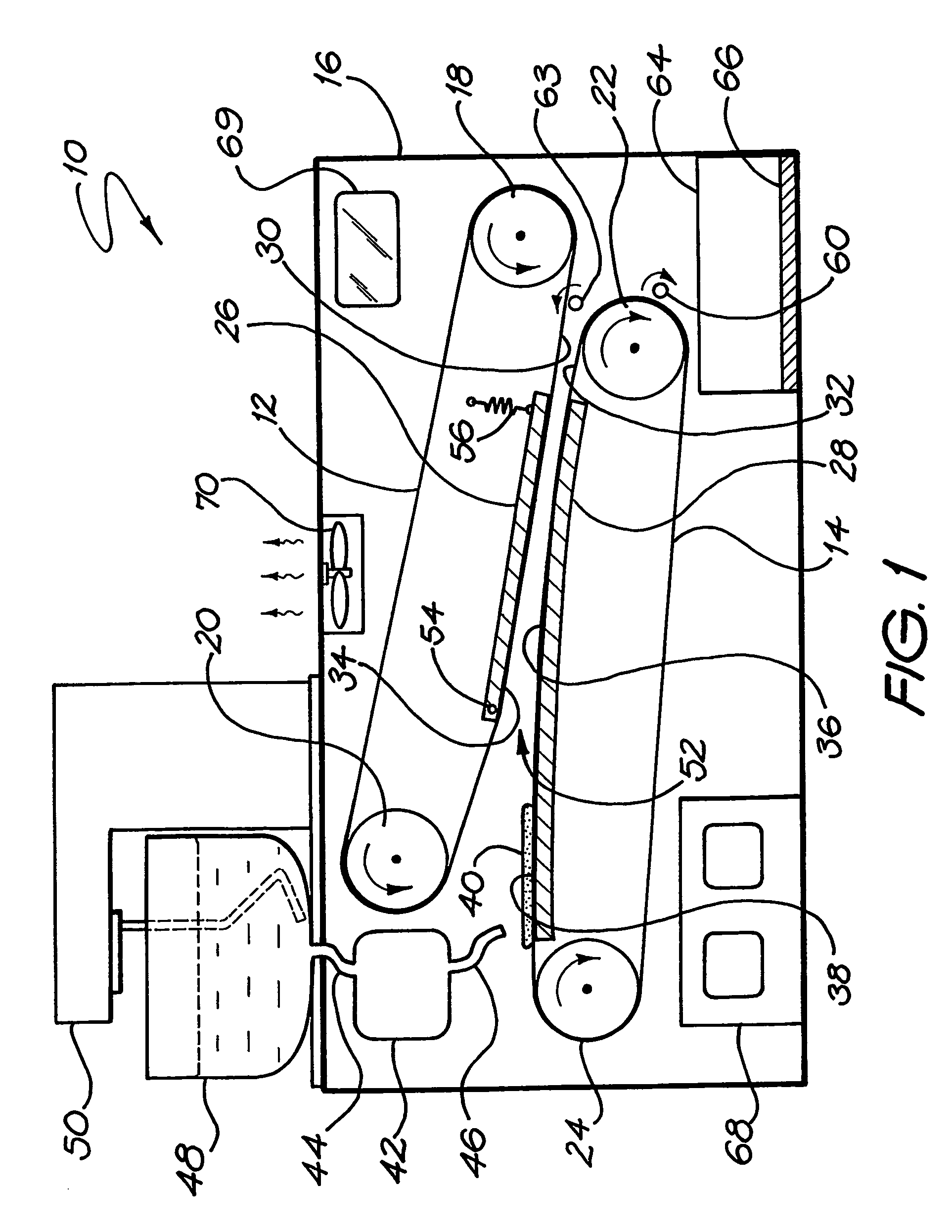

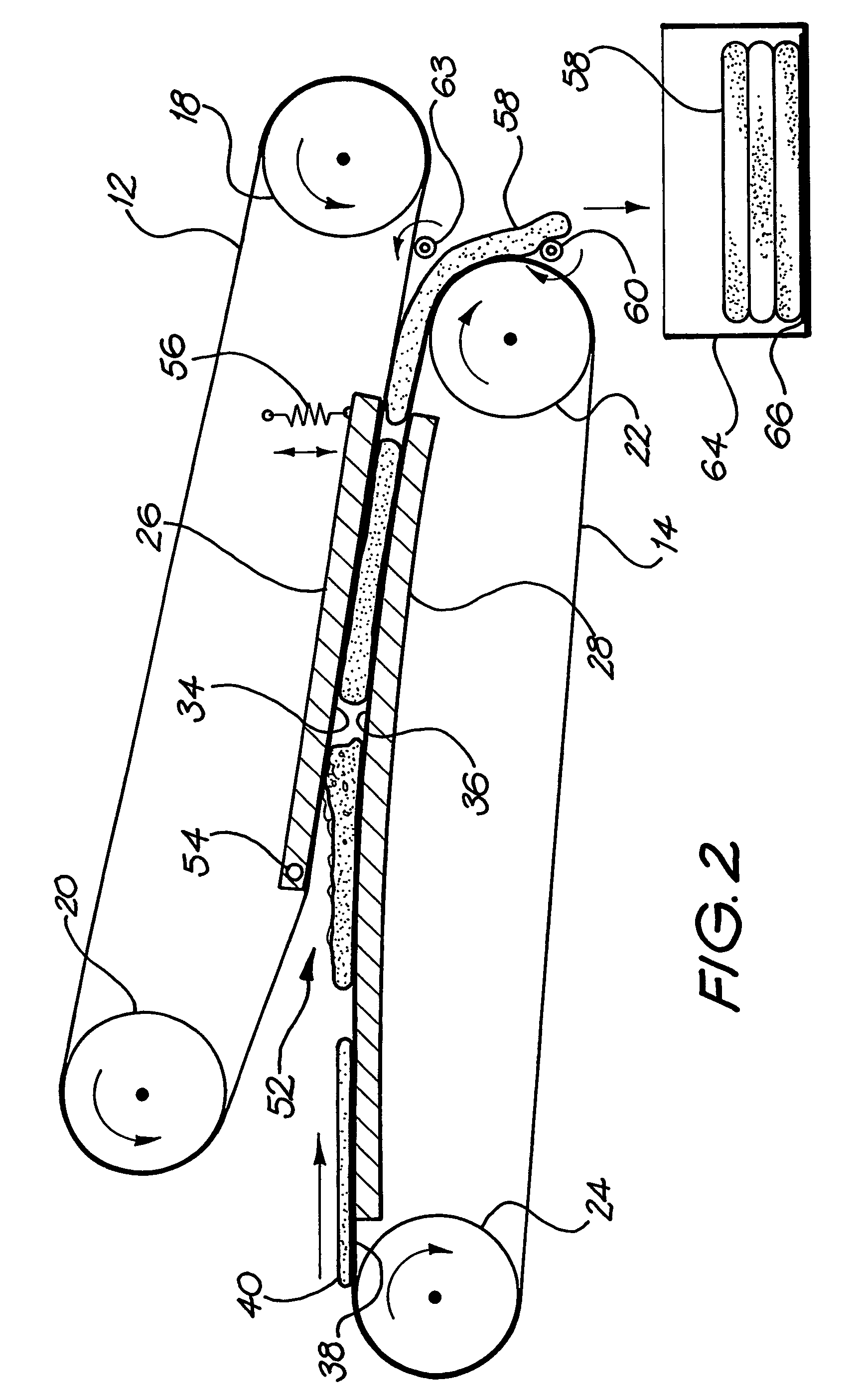

An automated belt cooking machine (10) for pancakes and the like food products has upper and lower overlapping, thermally conductive belts (12, 14), counter-rotatably mounted to a frame (16) so that, in use, a bottom run (30) of the upper belt (12) and a top run (32) of the lower belt (14) co-operate to convey food (40) to be cooked. The lower belt (14) extends a predetermined distance to one side of the upper belt (12) so as to provide a dispensing platform portion (38) for dispensing thereon the food to be cooked (40), so that the food (40) is conveyed towards a mouth (52) formed between the upper belt and lower belts (12, 14) and thereafter is conveyed sandwiched between the bottom and top run (30, 32). Upper and lower heating platens (26,28) are mounted to the frame (16) and are in thermal contact with the bottom and top run (30, 32), wherein the food to be cooked (40) is initially exposed to heat from the lower platen (28) conducted through the dispensing platform portion (38).

Owner:SZYMANSKI MAREK

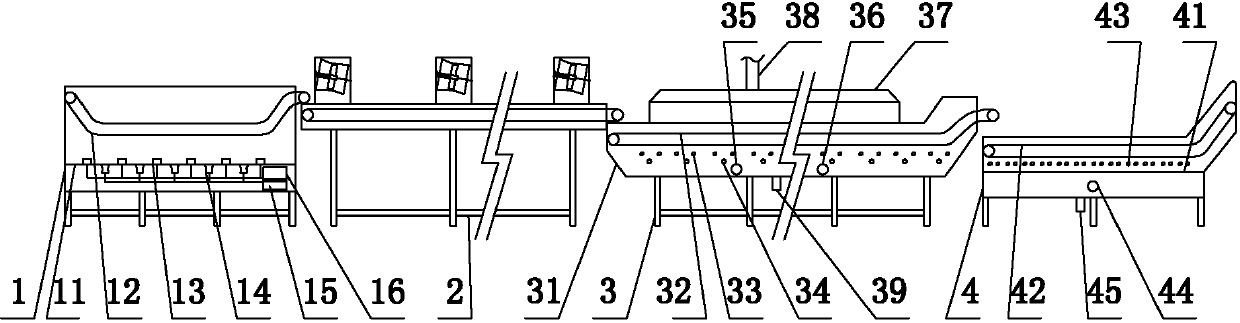

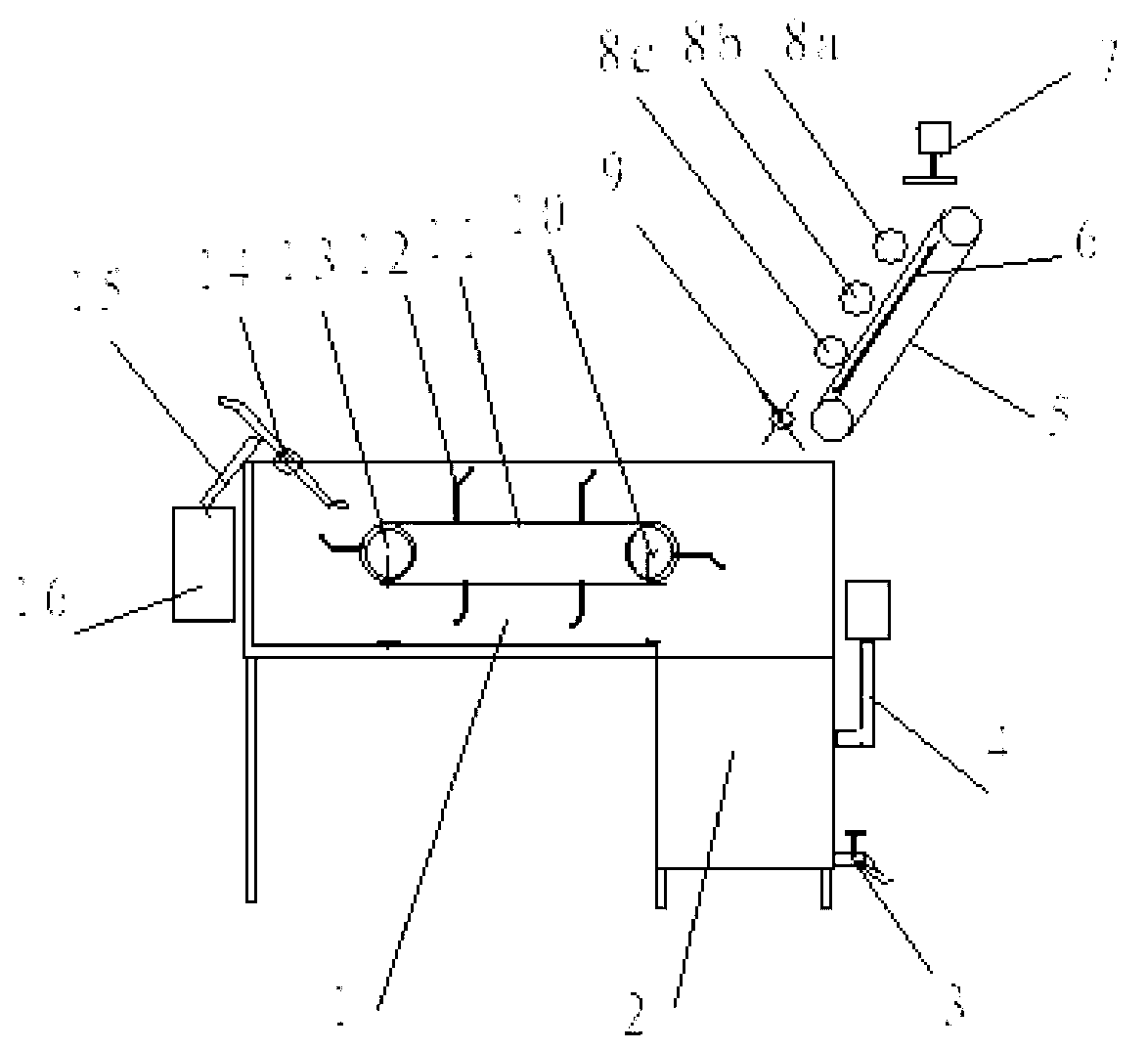

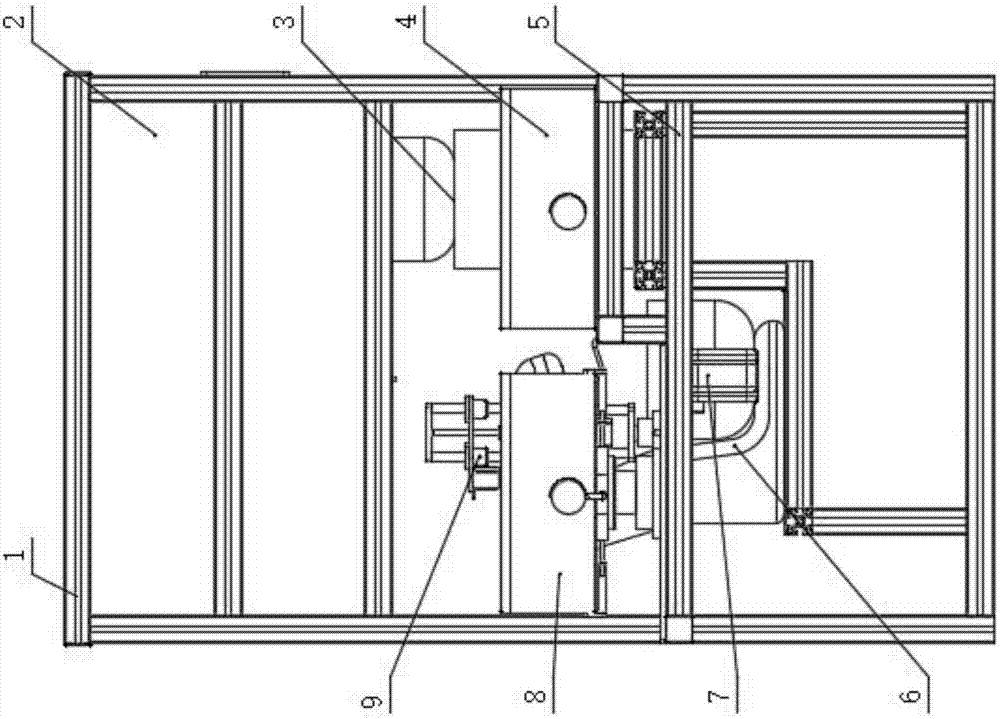

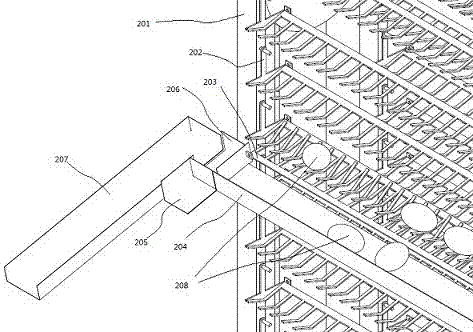

Full-automatic deep-fried twisted dough stick machine

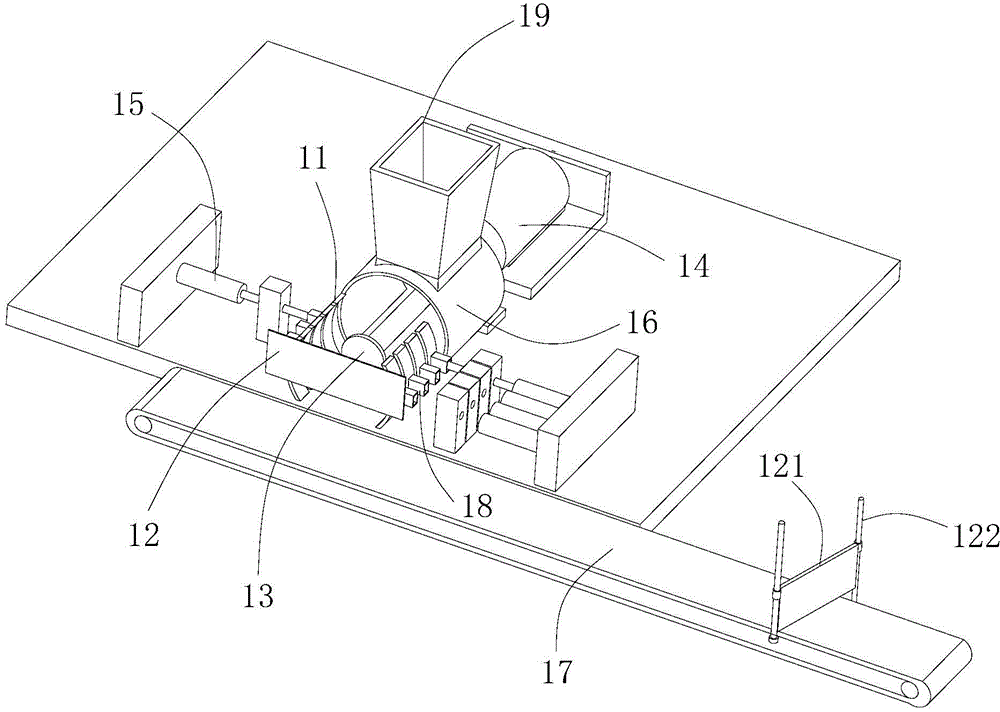

ActiveCN103181402AWell formedEmbryo making process is simpleOil/fat bakingConveyor beltPower transmission

The invention discloses a full-automatic deep-fried twisted dough stick machine, which comprises an embryo-making device, an electrical heating frying box with a double-layered heat-insulating structure, a transmission device driven by a motor, a deep-fried twisted dough stick conveying device, a deep-fried twisted dough stick scooping device and a power transmission device, wherein the embryo-making device adopts a mechanical structure composed of a conveyor belt and a plurality of compression rollers arranged in a matched manner; the frying box is the heat-insulating frying box with the double-layered heat-insulating structure; and the power transmission device is a chain transmission device driven by the motor and drives the embryo-making device, the deep-fried twisted dough stick conveying device and the deep-fried twisted dough stick scooping device to work through the chain transmission. The full-automatic deep-fried twisted dough stick machine, disclosed by the invention, involves no manual operation during the whole operational process, and thus is truly the full-automatic deep-fried twisted dough stick machine.

Owner:丁怀坤

Automated belt cooking machine pancakes or the like

Owner:SZYMANSKI MAREK

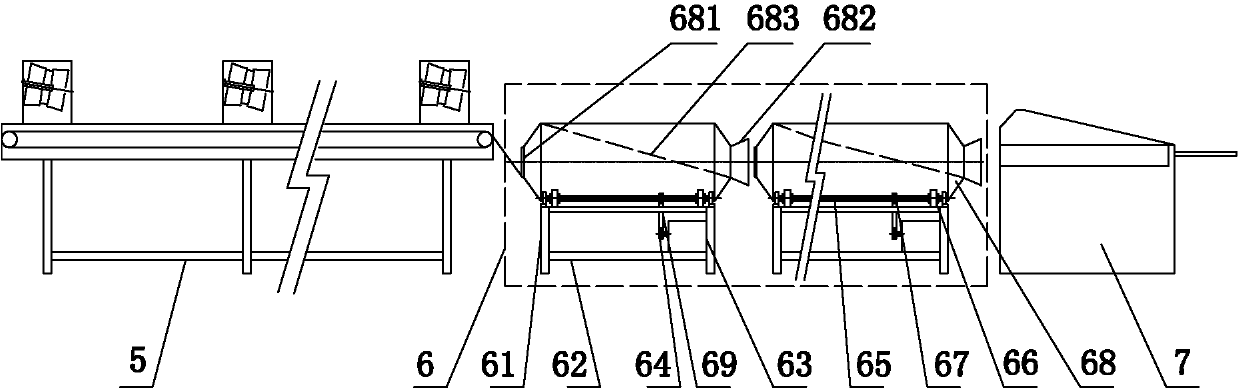

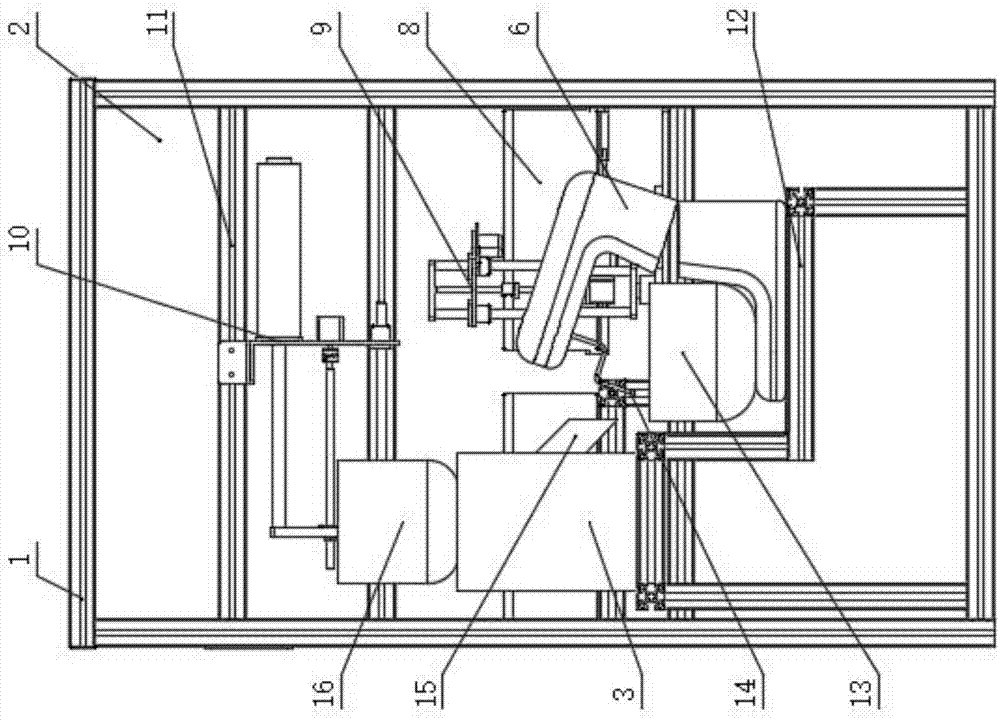

Double-layer fried bread stick machine and method of making fried bread sticks

ActiveCN107439626AEasy to startMeet size requirementsOil/fat bakingDough shaping and dividing combinationEngineeringConveyor belt

The invention discloses a double-layer fried bread stick machine. The method comprises a rack and a conveyor belt mounted on the rack, a front dough feeding mechanism located in a material feeding end of the conveyor belt, and a first dough pressing mechanism, an oil brushing mechanism, a water brushing mechanism, a second dough pressing mechanism, a round cutter mechanism, a medium press roller mechanism, a cutting table mechanism which are arranged from the material feeding end to a material discharging end; a rear dough feeding mechanism is located on the conveyor belt, and the output end of the rear dough feeding mechanism is located at an input end of the second dough pressing mechanism; a dough rolling mechanism and a three circular cutter mechanism are at least arranged on the front dough feeding mechanism. According to the double-layer fried bread stick machine, imitating manual rolling of the fried bread stick dough can be achieved; through brushing oil and water alternately, the edges of the fried bread sticks can rise easily when fried, the middle connections are good and do not explode, so that two layers of fried bread sticks stick well together, and it is not possible to cause dough stickiness for the fried bread sticks; the rising effect is good, it is ensured that the yield of finished products is 100%, the appearance is beautiful, the prepared double layer fried bread sticks are fed into a frying pan mechanism automatically, and the degree of automation is higher.

Owner:SUZHOU GUOEN FOOD MACHINERY

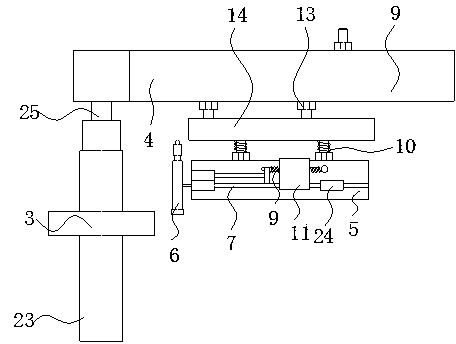

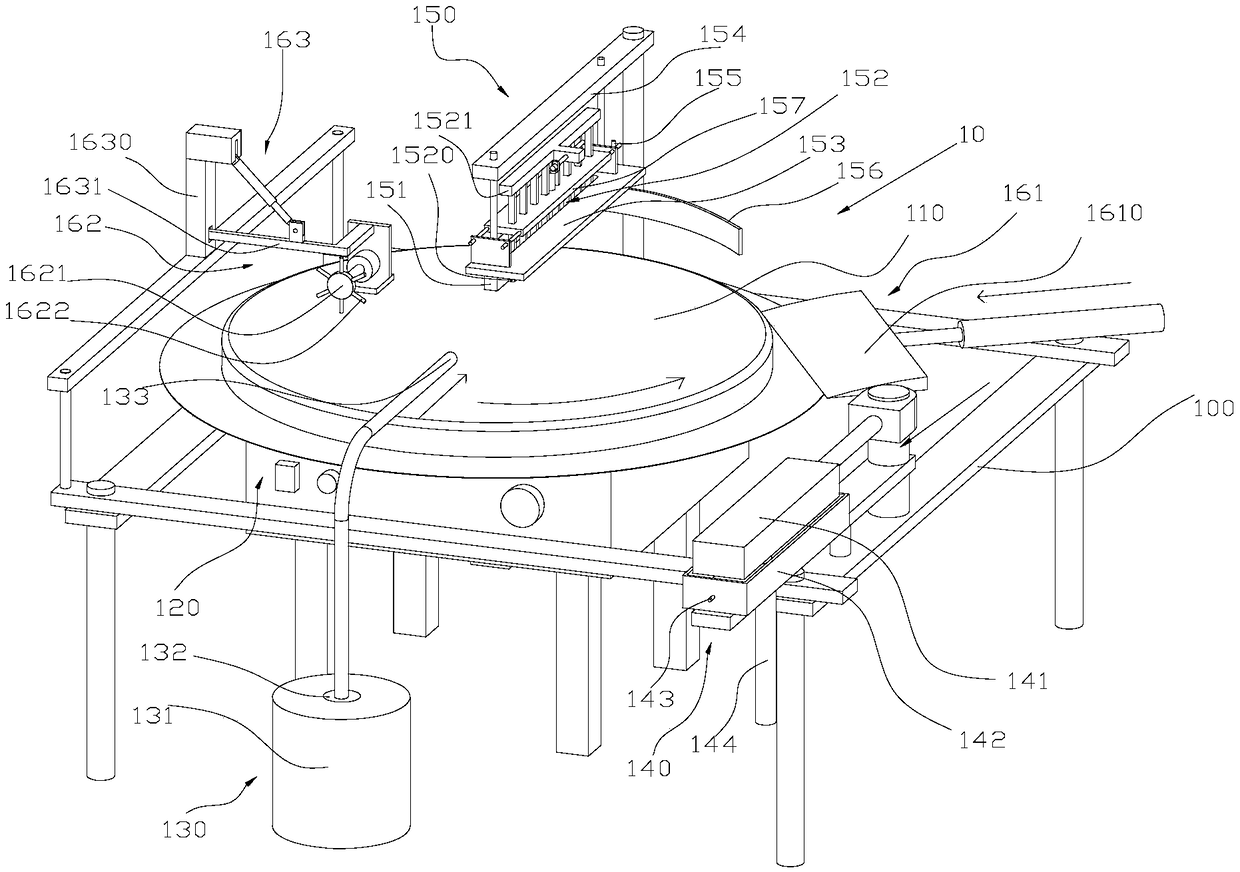

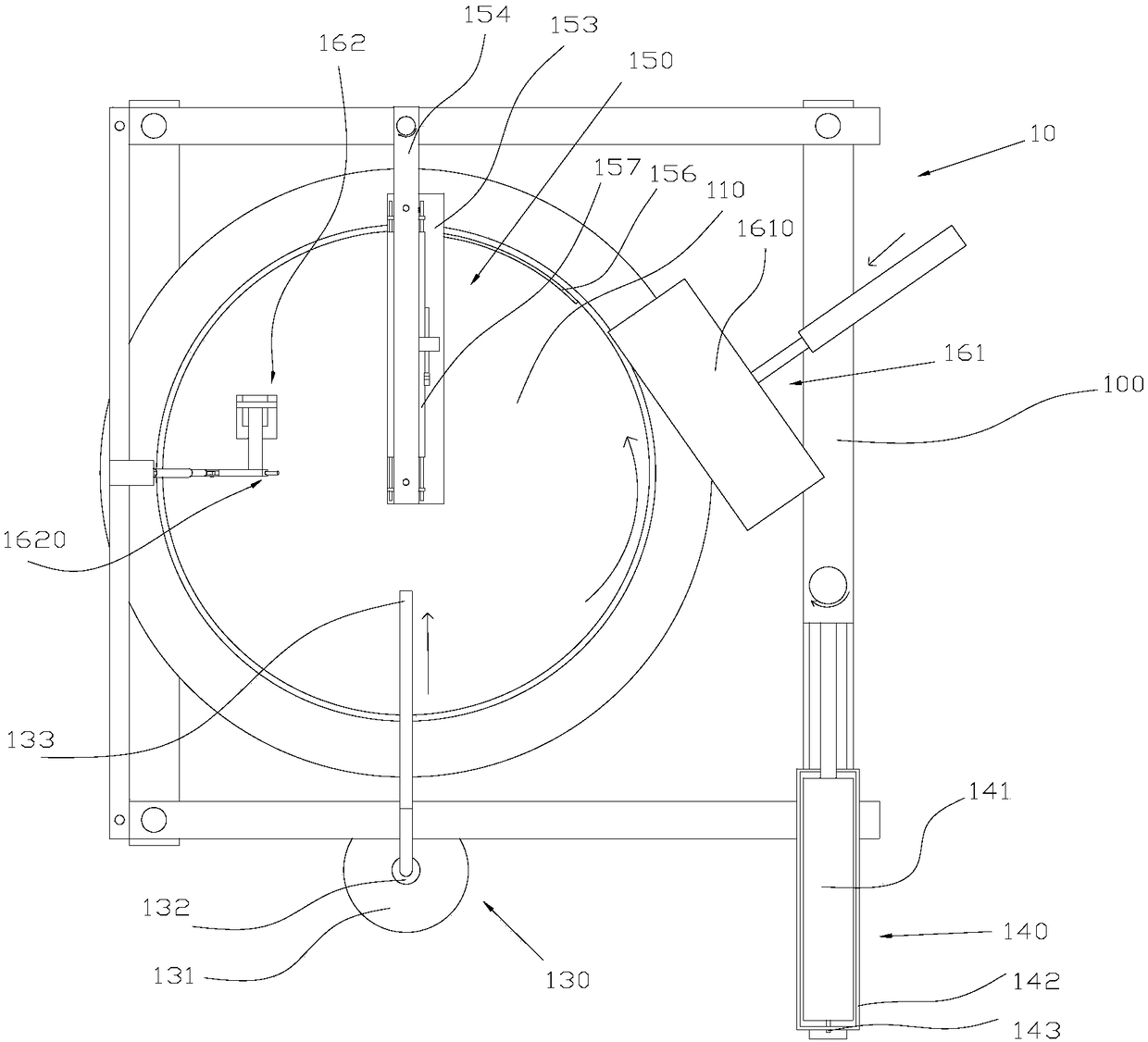

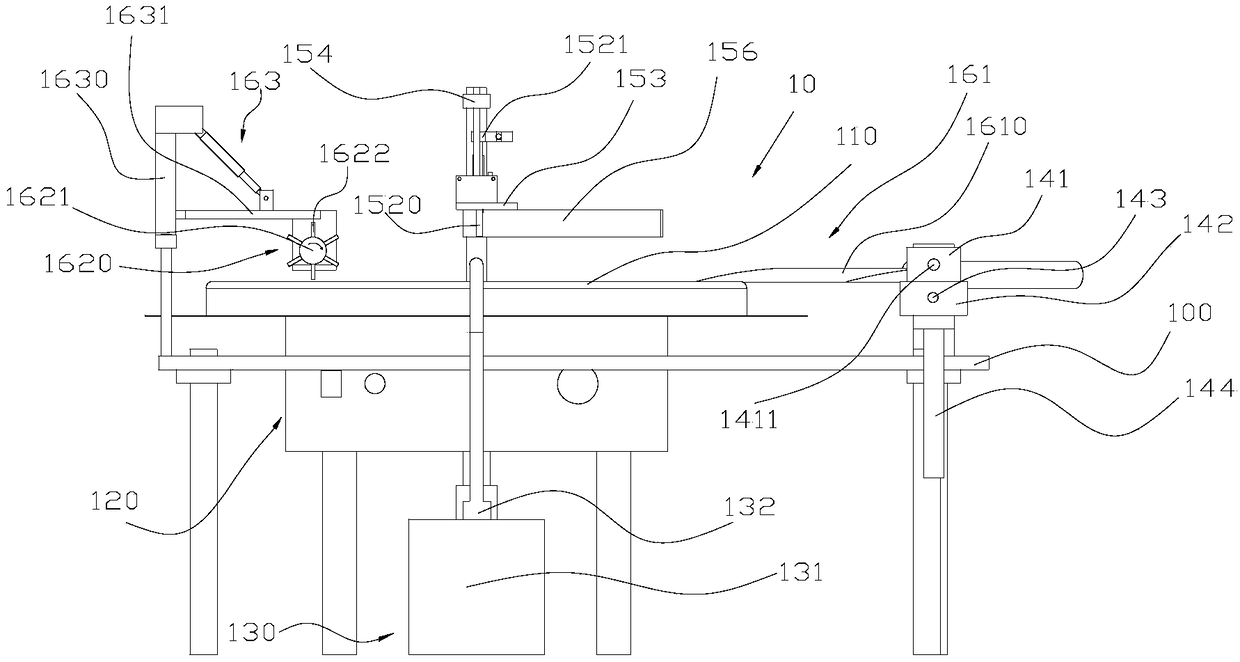

Chinese hamburger preparation system

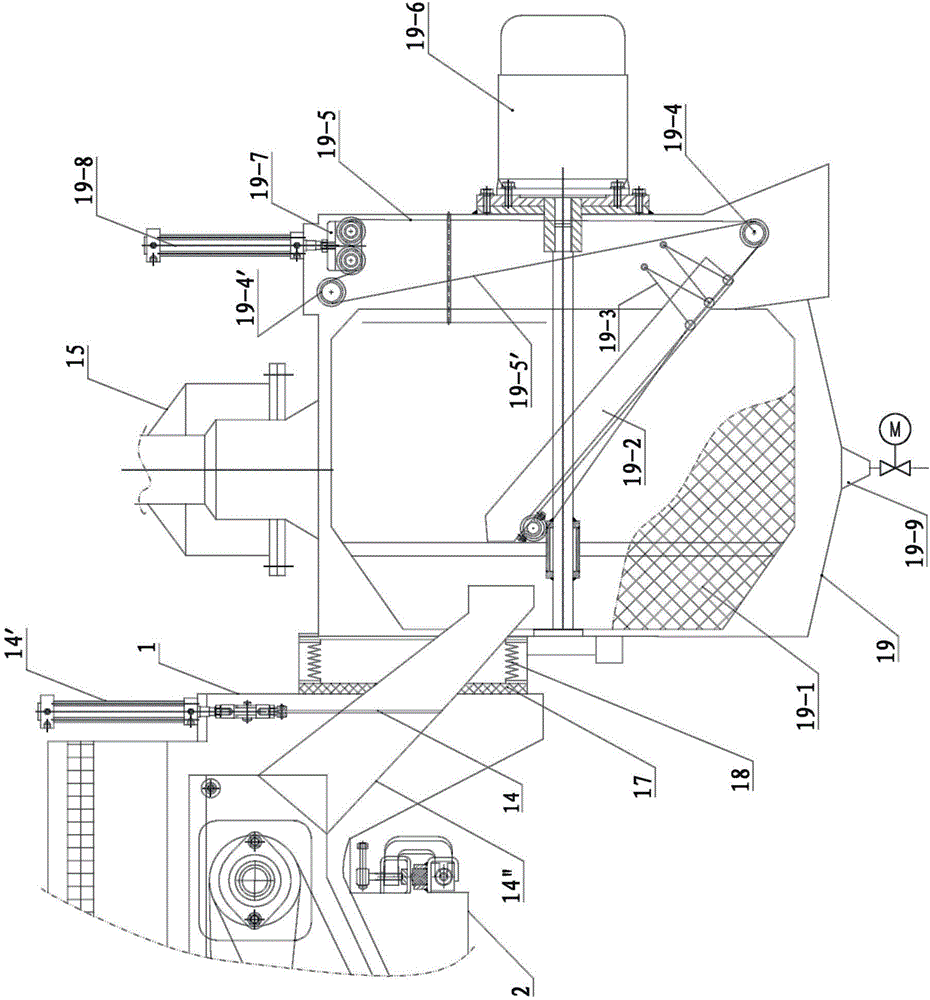

ActiveCN107396944AAccurate distanceSatisfy taste needsOil/fat bakingPancakes bakingMeat burgerMechanical engineering

The invention relates to a Chinese hamburger preparation system. The system is characterized in that a griddle surface rotating mechanism is arranged at the front end of a support; a batter scrapping mechanism is arranged on the support beside the griddle surface rotating mechanism; a batter supplying mechanism is arranged at any position on the support; a griddle surface automatically rotates, and the batter supplying mechanism automatically conveys batter to the griddle surface; after being automatically positioned, a scraper plate is used for flattening the batter on the griddle surface. According to the Chinese hamburger preparation system, vertical movement and horizontal movement of the scraper plate and a shoveling knife are driven by a stepping motor, so that the control accuracy is high; a piston in a material barrel is driven by the stepping motor, and quantitative battery conveying is achieved; the system is simple in structure, and convenient to mount and maintain; the griddle surface is driven through a belt, so that the noise is low, and the abrasion is small; the griddle surface can be axially and radially fixed through a fixing block and a mounting block on a supporting plate, steady mounting is ensured, and a fixing rod can be adjusted to fit the fixation of the griddle surface with different size; the structures are matched with each other, so that the whole system is convenient, practical, convenient to mount and maintain, and applicable to different users in different conditions.

Owner:TIANJIN CHUANGZHI ROBOT TECH CO LTD

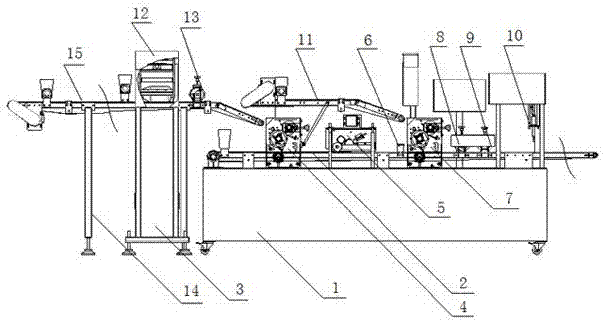

Full-automatic handwork-imitating pancake machine

ActiveCN103404547AReduce volumeIngenious ideaOil/fat bakingPancakes bakingAutomatic controlEngineering

The invention discloses a full-automatic handwork-imitating pancake machine which comprises a machine frame, a paste feeding part, a pancake raising part, a griddle and an automatic control part. The paste feeding part comprises a paste feeding tube and a paste feeding pipe communicated with the paste feeding tube which is connected with a paste feeding groove in the paste feeding part. The pancake raising part comprises a pancake scraper and a scraper moving part for driving the pancake scraper to move. The full-automatic handwork-imitating pancake machine is ingenious in design, finishes full-automatic pancake spreading operation through mechanical transmission and corresponding programs, is small in machine size and high in efficiency, effectively saves labor power, improves sanitary standard of pancakes and has good application prospects.

Owner:王同成

Pancake making device

InactiveCN103734210AAvoid breakingAvoid spillingOil/fat bakingPancakes bakingMechanical engineeringPhysics

A pancake making device comprises a support, wherein a scraper and a scraper lifting part which is used for driving the scraper to achieve a cyclical motion of rising and falling. The moving-track curve of the cyclical motion of rising and falling of the scraper comprises a rising part moving-track curve and a return part moving-track curve, wherein the return part moving-track curve comprises at least a return part moving-track curve I and a return part curve II. The alpha angle between the return part moving-track curve I and the time coordinate is larger than the beta angle between the return part moving-track curve II and the time coordinate. According to this arrangement, a plurality of functions such as the motion of rising and falling of the scraper, the transverse moving of a sub-scraper and the adjustment of heights of the scraper and the sub-scraper can be achieved. The pancake making device has the advantages of high integration and degree of automation, thereby effectively ensuring pancake making time by the scraper and uniformity of pancakes. Accordingly, pancakes made by the pancake making device are thin, tough and delicious. Compared with the prior art, cereal pancakes can be made by the pancake making device, which is an innovation in the industry.

Owner:尹相善

Pancake manufacturing device and operation method

InactiveCN107439624ABaked articles handlingOil/fat bakingMaterial resourcesUltimate tensile strength

The invention relates to a food processing equipment and its operating method, in particular to a pancake glutinous rice making equipment and its operating method. Present pancake glutinous rice balls are all artificially made, and there is a large labor intensity of personnel, and the human body as a potential source of pollution causes the pancake glutinous rice flour to have a hygienic hidden danger. The invention makes the pancake glutinous rice in a fully automatic way, without manual intervention in the production process to ensure hygiene, the thickness of the pancake is uniform, the production speed is fast, and it can be produced 24 hours a day, which greatly reduces the manpower and material resources required for making pancake glutinous rice Increased productivity and improved social efficiency.

Owner:邵萌

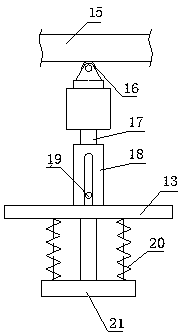

Double-sided heating type pancake machine

InactiveCN109122748ANice appearanceHeating evenlyOil/fat bakingPancakes bakingEngineeringSupport plane

The invention discloses a double-sided heating type pancake machine comprising a frame. A main bottom plate is fixed on the top surface of a top plate of the frame; a mounting groove is formed in themiddle part of the top surface of a main bottom frame; and heating blocks are fixed in the mounting groove. An upper support plate is fixed on the top surface of the main bottom frame; and the upper parts of the heating blocks extend out of a straight mounting slot of the upper support plate. Pancake bottom plates are fixed on the top surface of the upper support plate; and heating grooves are formed in the bottom of the pancake bottom plates. The upper part of the heating blocks are inserted and clamped into the heating grooves. Pancake top plates are hinged to the pancake bottom plates. An upper heating support frame is fixed on the top plate of the frame; adjusting motors are fixed to the top surfaces of two sides of a main connecting plate of the upper heating support frame; lower connecting plates are fixed to the lower parts of support plates at two sides of the upper heating support frame; lower ends of adjusting screw rods are hinged to the lower connecting plates; and upper ends of the adjusting screw rods are hinged to the main connecting plate. With the double-sided heating type pancake machine, a double-sided three-dimensional pancake can be made and has the beautiful appearance; and heating uniformity is ensured without overturning.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

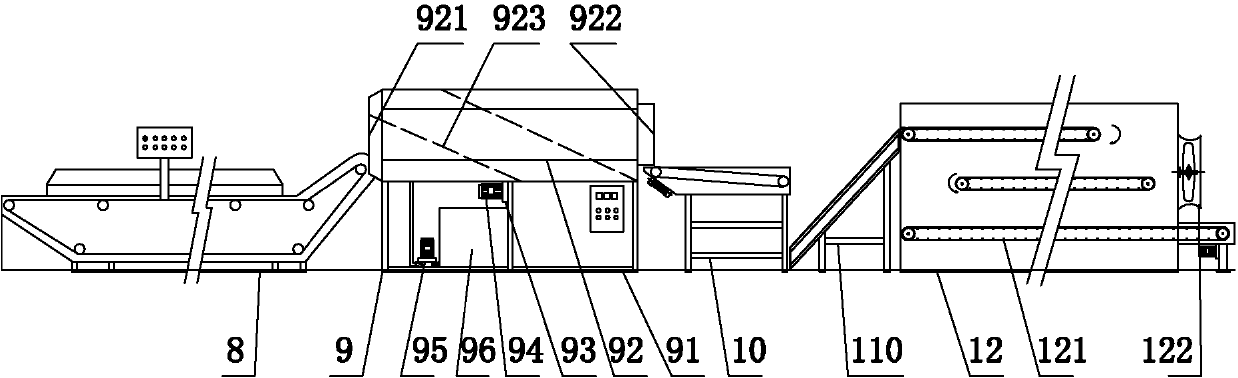

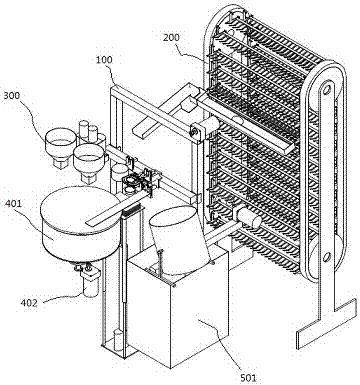

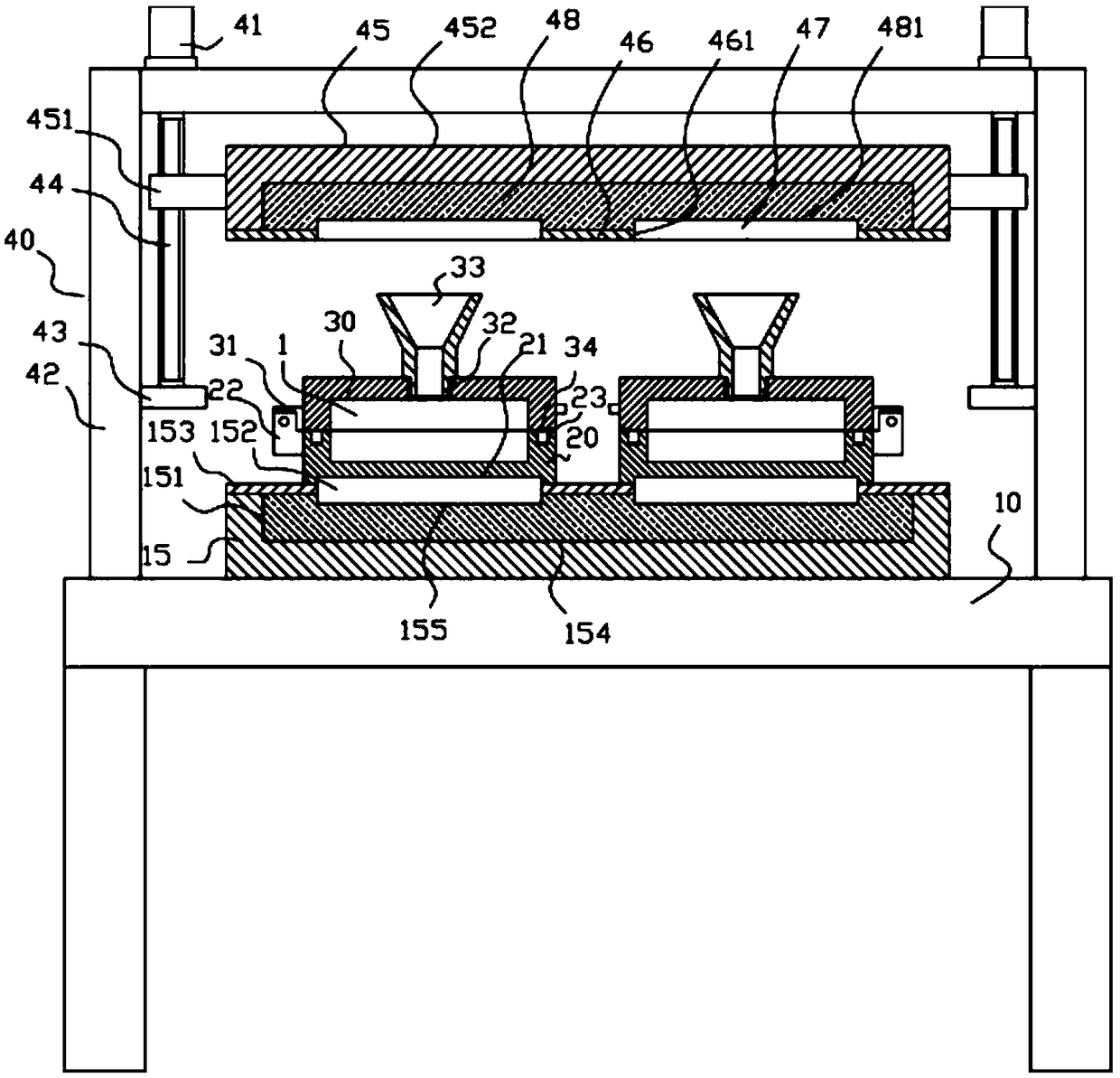

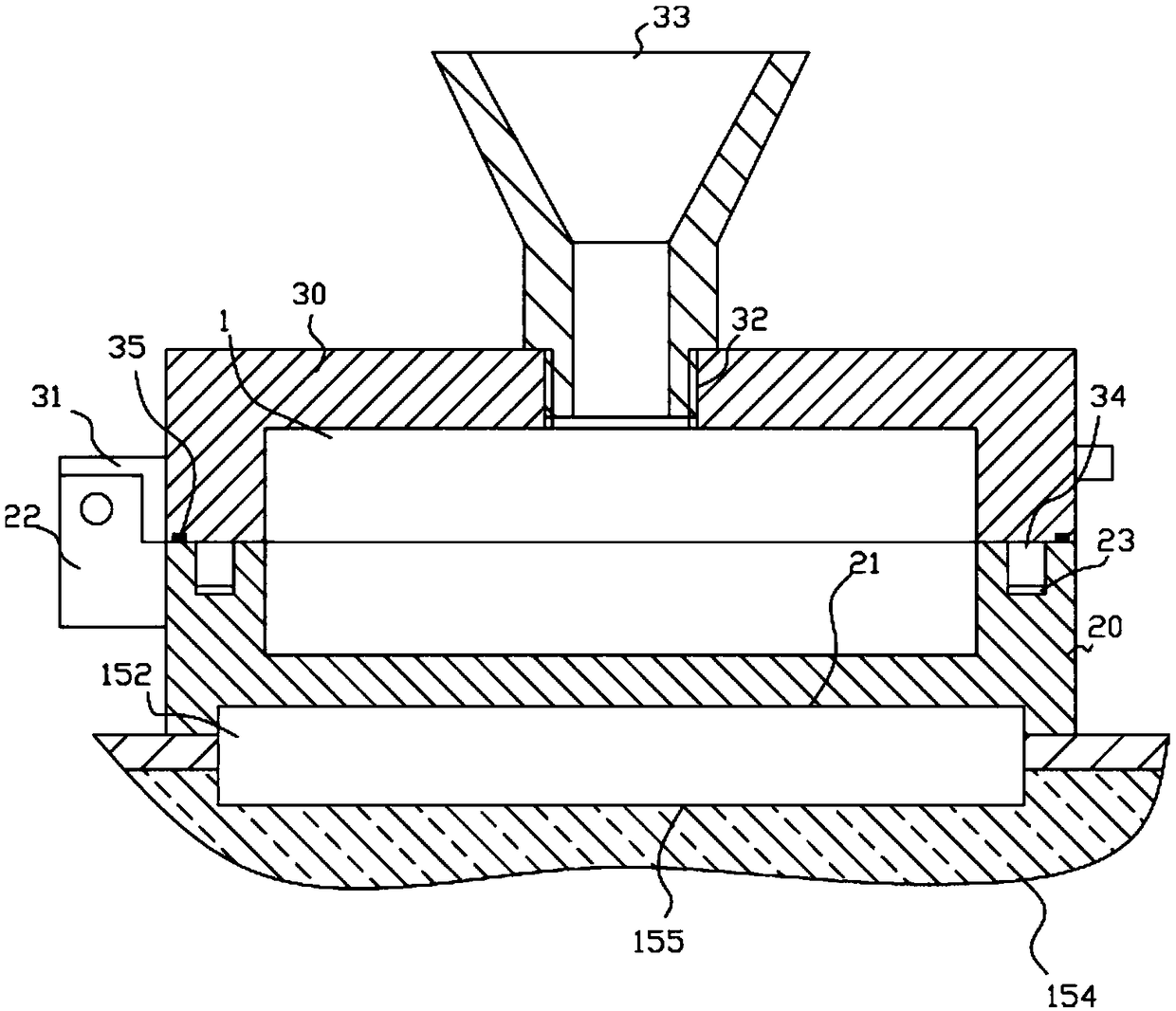

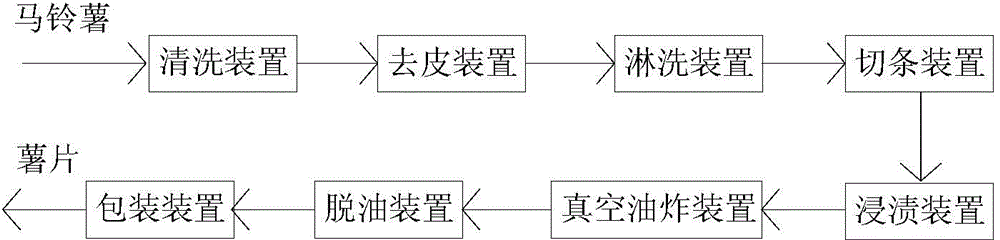

Processing equipment for preparing potato strips

Disclosed processing equipment for preparing potato strips comprises a cleaning device, a peeling device, a drip washing device, a strip cutting device, a dipping device, a vacuum frying device and a packaging device; the drip washing device comprises a conveying mechanism, and a conveying roll is fixedly disposed on a frame in a rotatable way; a water spray mechanism is arranged above the conveying roll, the outside of each end of the conveying roll is provided with a protection plate, and a material collection tank for collecting cleaned separated potato peel is arranged below the conveying mechanism; the groove bottom of the material collection tank is obliquely arranged, and the part, at the feeding end of the conveying mechanism, of the groove bottom is relatively lower; the material collection tank is inside provided with a filter screen; and the lowest position of the material collection tank is provided with a water outlet connected with a water storage tank via a connection pipe. By employing the above technical scheme, peeled potato can be cleaned, also potato peel and potato can be separated, so that the processing efficiency of potato is improved. By employing the above preliminary processing equipment, potato strips can be effectively rapidly prepared from potato, the processing efficiency of potato strips is improved, and labor cost is saved.

Owner:邯郸市永年区中原农副产品批发市场有限公司

Frying machine

ActiveCN103734211AMove forward at a constant speedAccurately guarantee the frying timeOil/fat bakingFuel tankEngineering

The invention relates to the frying machinery field and specifically relates to a frying machine. The frying machine comprises a main frame, a frying tank and a conveying chain. The frying machine is characterized in that the frying tank is mounted on the main frame and a heating tube is mounted at the bottom of the frying tank; the conveying chain is mounted at a side close to the frying tank inside the main frame, a separator is mounted on the conveying chain and a cylinder is mounted on the separator; a hot oil tank is mounted on the top support of the main frame, a power distribution box is fixed on the outer surface of the hot oil tank, a thyristor and a frequency converter are mounted in the power distribution box, respectively, the thyristor is connected with the heating tube, and the frequency converter is connected with the tachometer of the conveying chain; an oil injection tube is mounted at a side close to the outer surface of the hot oil tank, and a transmission chain is mounted at a side close to the conveying chain adjacent to the oil injection tube. The factor of poor conveying effect of the previous frying machine is overcome; the frying machine is not only convenient to operate and capable of realizing large-scale frying process, and also capable of saving oil and non-sticky to pan; the fried cakes are regular and beautiful in appearance.

Owner:PENGLAI JINGLU FISHERY

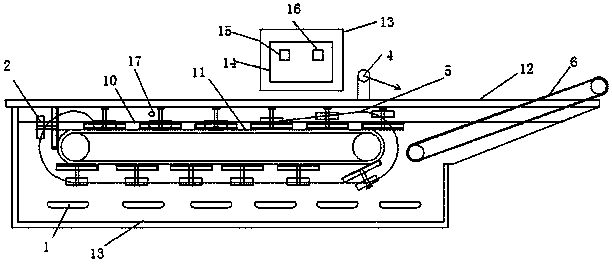

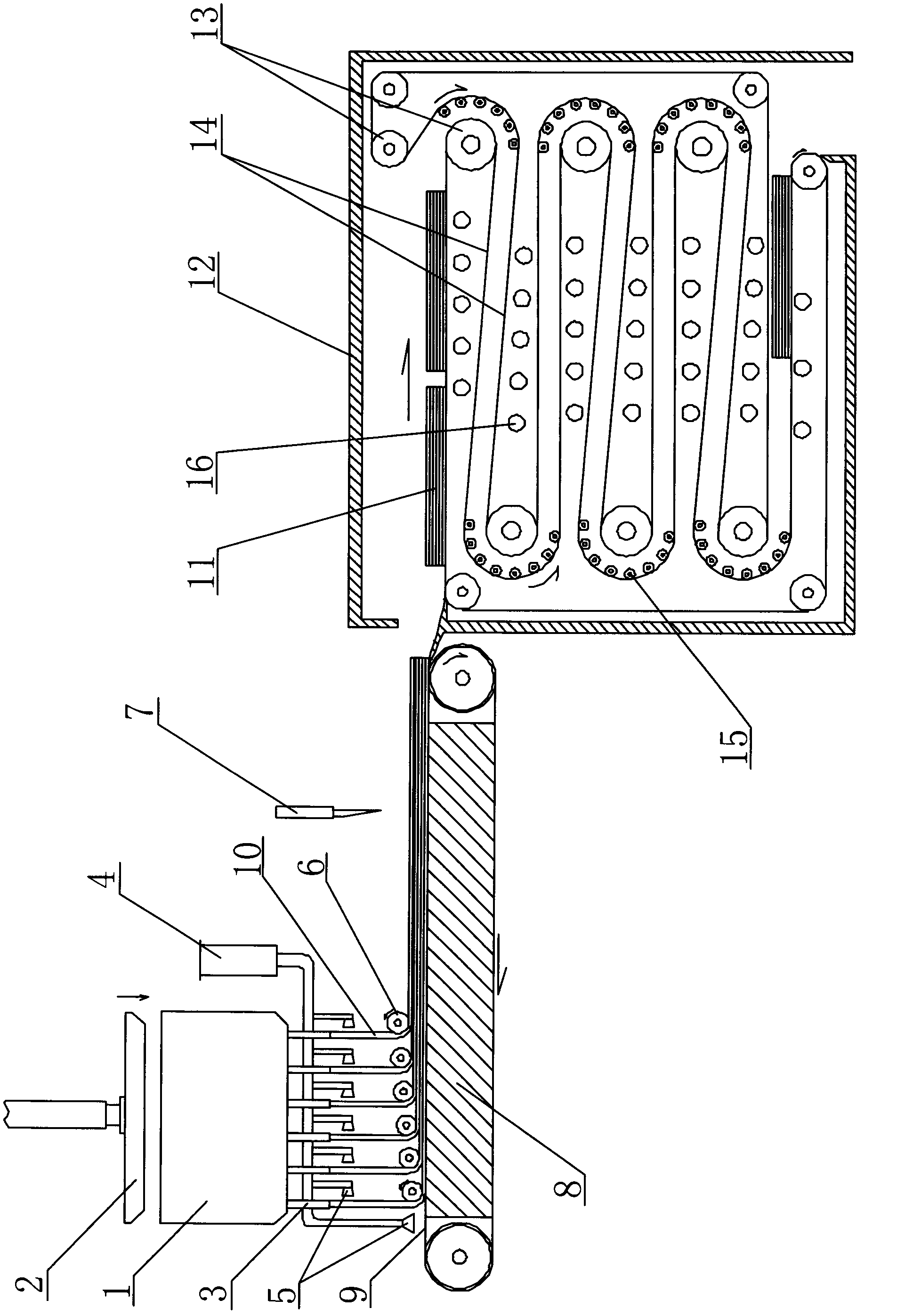

Fully automatic pancake cooking machine

InactiveCN102524344AAchieve mass productionGuaranteed tasteOil/fat bakingBakery productsButt jointSprocket

The invention relates to food processing equipment, in particular to a fully automatic pancake cooking machine, which mainly consists of a pancake making mechanism and a pancake cooking box, wherein the pancake making mechanism mainly comprises a facet making device, a facet oil spraying device, a facet guiding and pressing device, a transmission support table and a pancake fixing and cutting device, the pancake cooking box comprises a case with a pancake outlet and a pancake inlet, two parallel pancake conveying belts which are driven by a chain wheel and have a certain spacing are arranged in the case, and the two pancake conveying belts form continuous S-shaped paths through the chain wheel and a positioning supporting and pulling roller tooth, so a plurality of transmission layers are formed, electric heating pipes are arranged among all transmission layers, and the transmission tail end of the transmission support table of the pancake making mechanism is in butted joint with the pancake inlet of the pancake cooking box through connecting plates. The fully automatic pancake cooking machine has the effect and the obvious advantages that the traditional manual pancake making and pancake cooking processes can be completely replaced, the labor is saved, and in addition, the production efficiency is improved, so the mass production of the pancake cooking can be realized in a short time, and in addition, the mouth feeling and the quality can be ensured.

Owner:张志杰

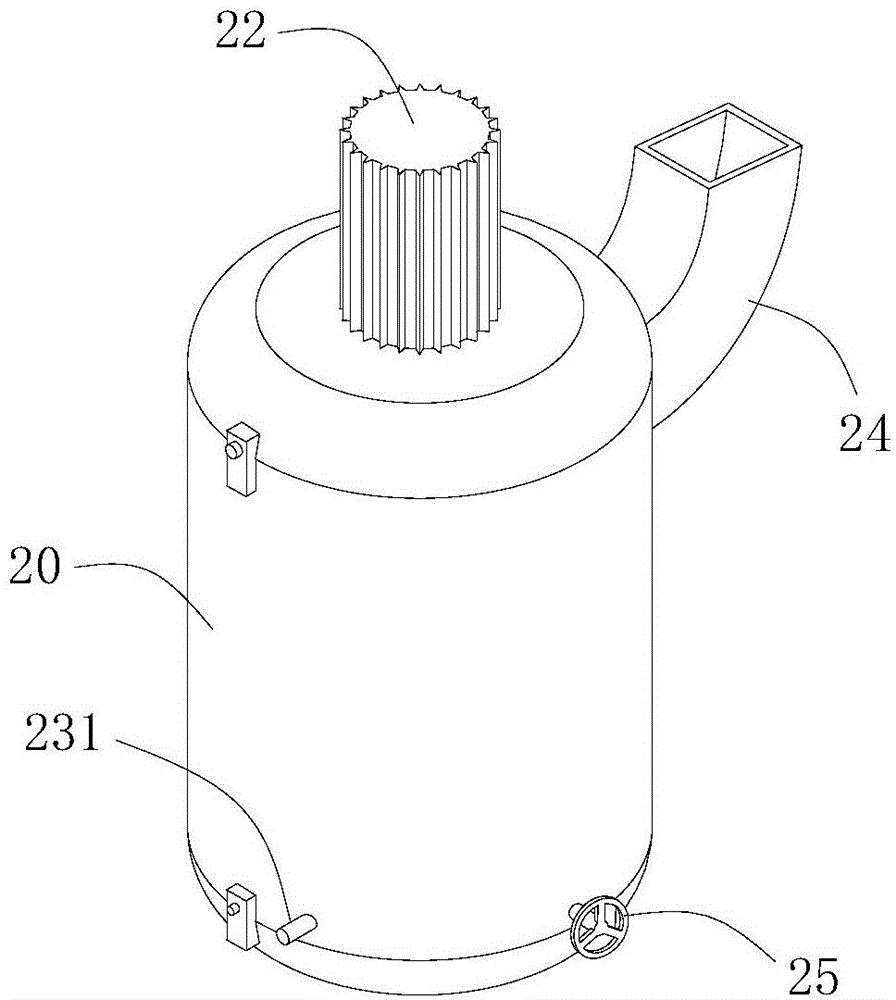

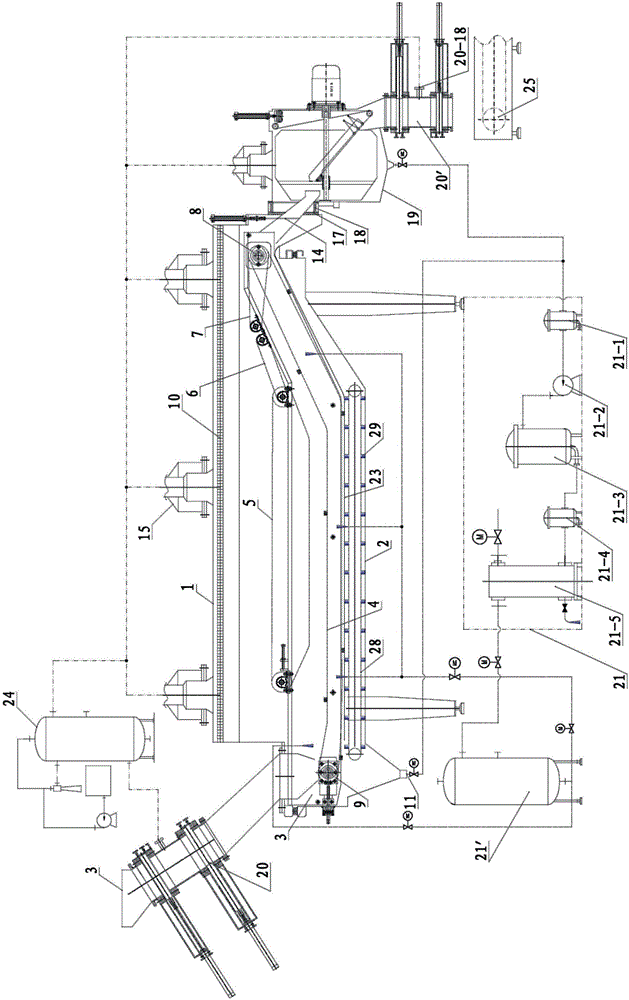

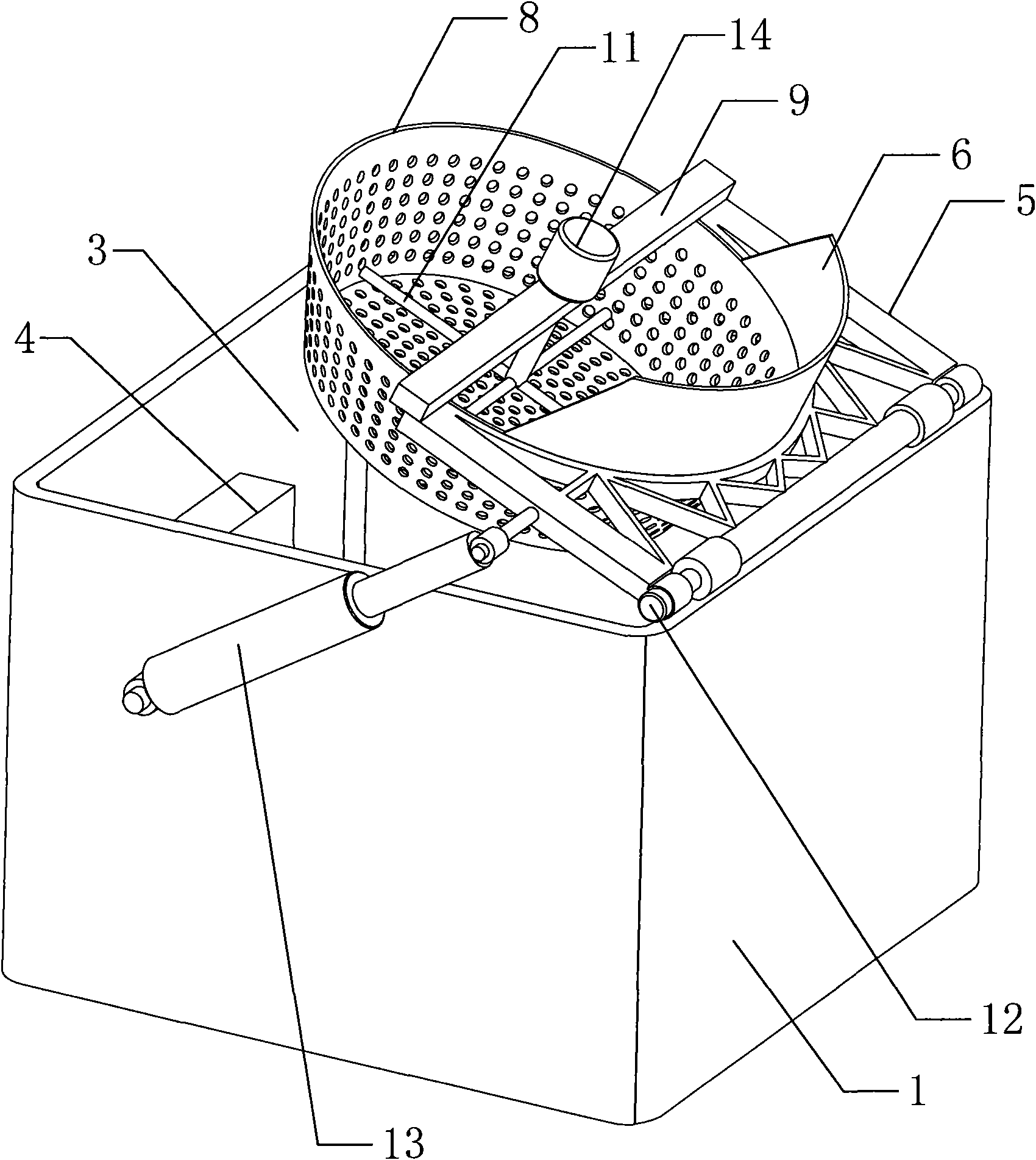

Continuous vacuum frying oil removing machine

The invention relates to a continuous vacuum frying oil removing machine capable of maintaining high-vacuum-degree stability under the continuous feeding and discharging conditions. The machine is provided with an upper frying bin, a lower frying bin, a wedge disc type feeding and discharging sealing device, a centrifugal oil removing machine device, a vacuum system, an oil filtering device, a cleaning system and an upper frying bin pressurizing device. The wedge disc type feeding and discharging sealing device is adopted as a feeding and discharging sealing device, or two vacuum valves are adopted to be combined into the feeding and discharging sealing device. The simple and high-speed centrifugal oil removing machine device is adopted. The machine is simple in structure, low in manufacturing cost, convenient to press and maintain, wide in application range, suitable for continuous vacuum frying processing of fruits, vegetables, dried fruits, cooked wheaten foods, aquatic products, livestock and poultry meat and other foods, applicable to frying processing equipment in large or medium or small food processing enterprises and large collective canteens, also applicable to continuous vacuum impregnating and capable of being wholly and automatically controlled.

Owner:陈长清

Oil frying equipment

InactiveCN101611733AAvoid the phenomenon of uneven raw and cookedQuality assuranceOil/fat bakingCharging/discharging ovensEngineeringMechanical engineering

Owner:ZHENGZHOU GUXIANGQING FOOD TECH

Potato chip frying machine

InactiveCN103689020AImprove efficiencyEasy to replace and maintainOil/fat bakingChipped potatoesEngineering

The invention provides a potato chip frying machine belonging to the technical field of food mechanical equipment. The potato chip frying machine solves the problem that the existing potato chip frying machine is low in efficiency. The potato chip frying machine provided by the invention comprises a frame, wherein a conveying belt is arranged on the frame and is connected with first driving mechanism; a feeding channel is vertically arranged above the input end of the conveying belt, and an oil cylinder is arranged below the output end of the conveying belt; a cutting device capable of cutting blocky potatoes into strips is arranged on the feeding channel; a drying device capable of heating and drying the potato strips is arranged on the conveying belt; a material supporting net for placing and frying the potato strips is arranged in the oil cylinder. The potato chip frying machine has functions of forming, drying and frying potatoes, is operated automatically from the blocky potatoes to the frying of the potato strips, and is high in efficiency.

Owner:崔亚静 +1

Equipment for cutting and folding flap jack

InactiveCN1600105AEasy to useReduce pollutionOil/fat bakingPancakes bakingProduction rateEngineering

A cutting-folding machine for thin pancake is composed of the first conveyer for conveying the thin pancake to cutting unit, the cutting unit for cutting the thin pancake by defined sizes, the second conveyer for conveying the cut pancake to its holder for pressing the pancake onto folding unit, and the folding unit with three folding plates for folding the pancake twice.

Owner:徐江军

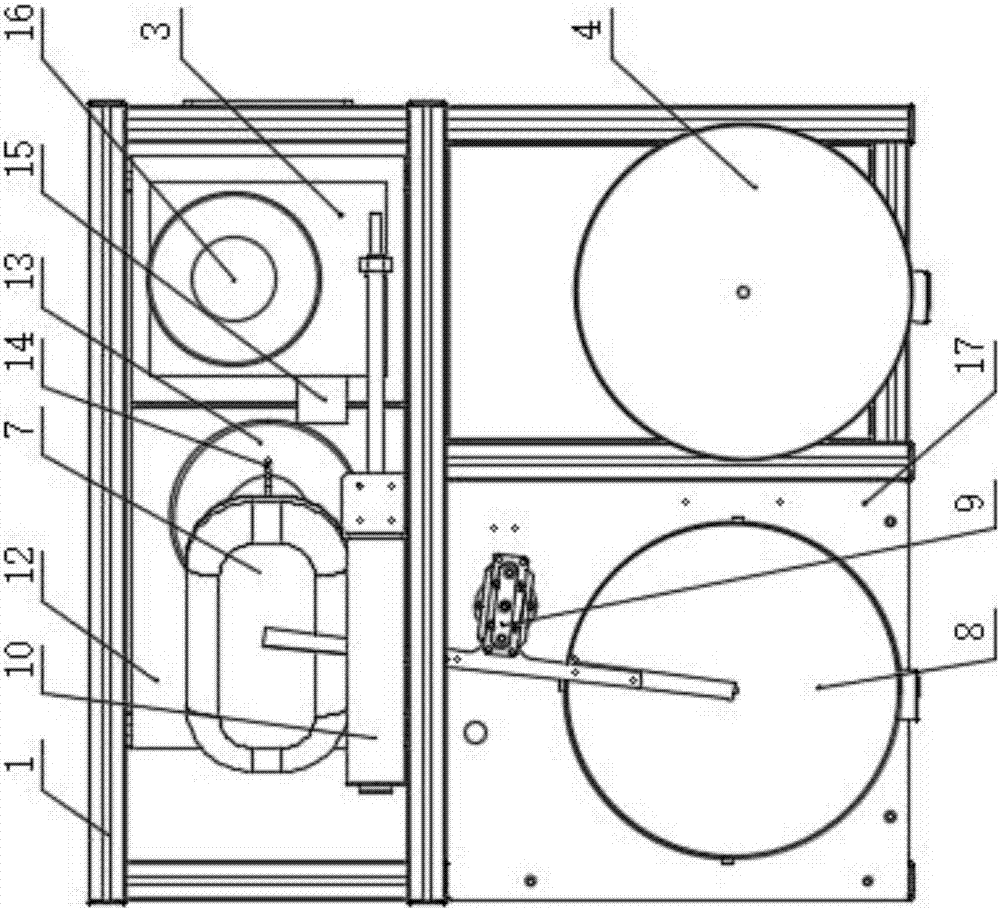

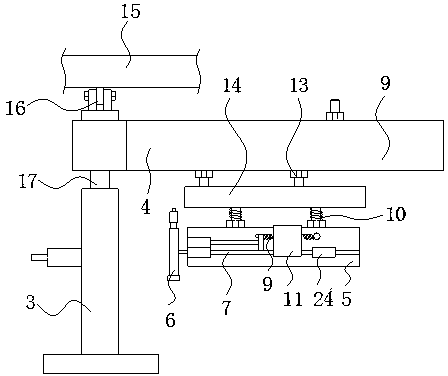

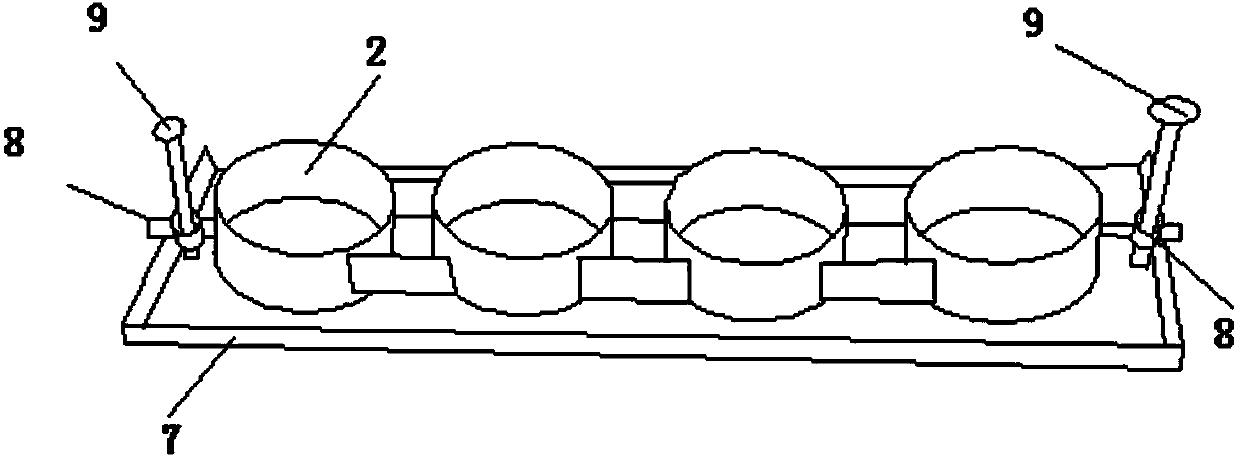

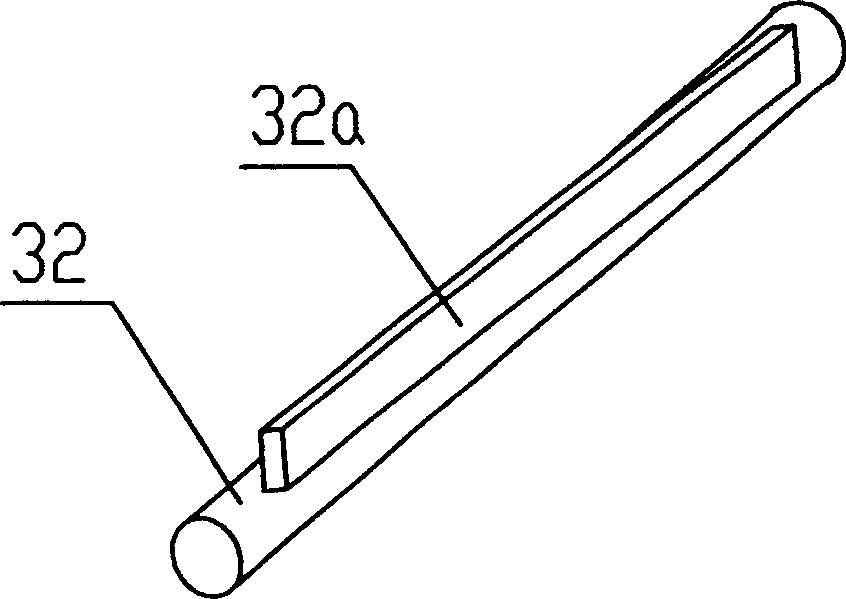

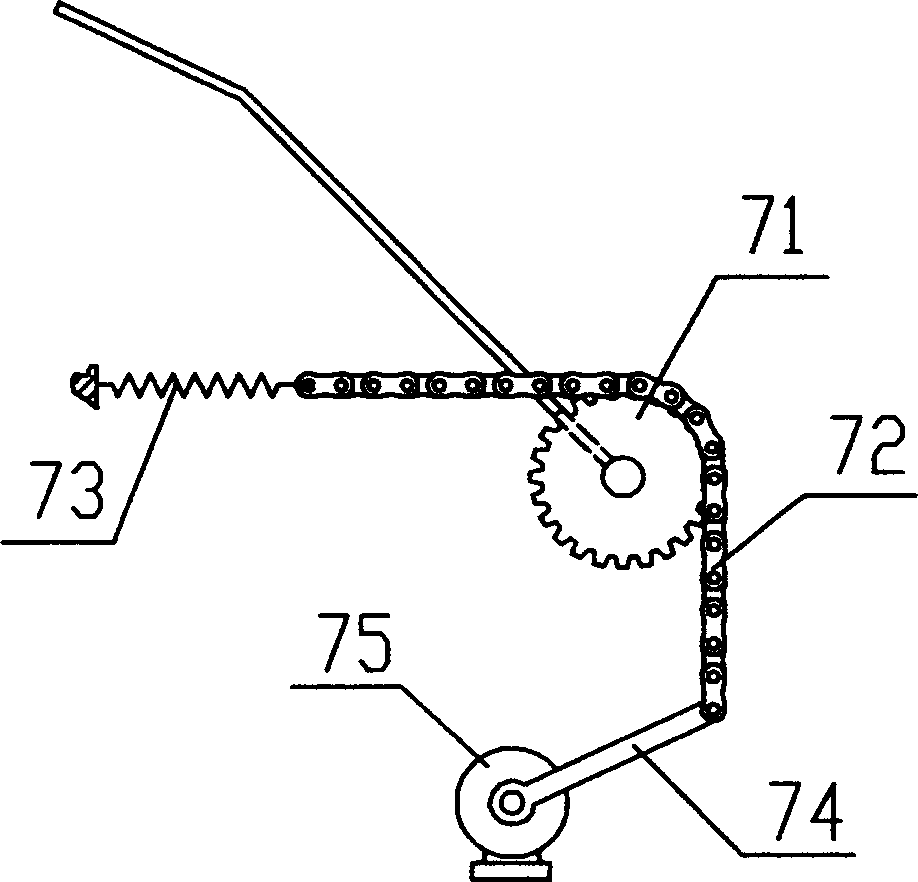

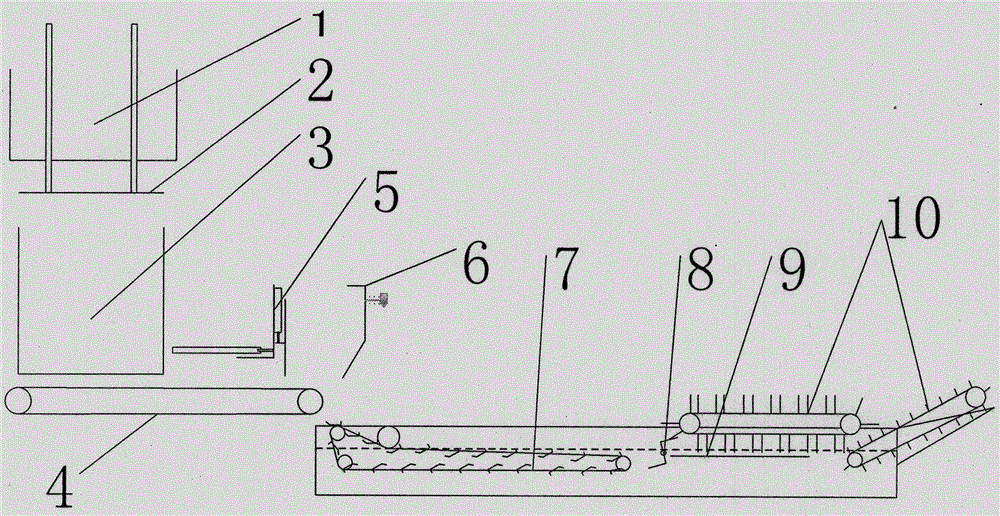

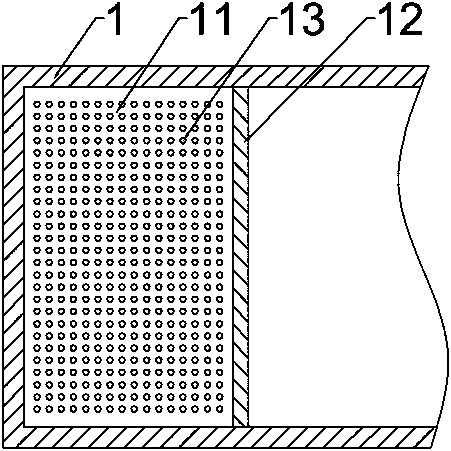

Combined fried bread stick machine

The invention relates to a combined fried bread stick machine and belongs to the field of food processing machines. According to the combined fried bread stick machine, double changes on a dough blank making method and a fried bread stick frying method, and structural design relying on the (blank making and frying) methods are carried out. According to the design, a screw mold set dough pressing device (1) drives a dough pressing plate (2) to make dough in a dough bucket (3) extruded out of a mold opening in the bottom of the dough bucket to form a sheet blank, the extruded sheet blank is conveyed to a pneumatic blank cutting part (5) through a combined conveying belt (4) and pneumatically pushed forwards after pneumatic cutting is carried out, and passes through a fried bread stick blank scraper (6) to make fried bread stick blanks fall, the fried bread stick blanks fall on fried bread stick supporting plates through related linkage, pass through a fried bread stick supporting driving part (7) and are fried into a related color and conveyed to a fried bread stick overturning part (8), fried bread sticks are overturned and rolled, the other sides of the fried bread sticks are fried through a rolling preventing design part (9), the fried bread sticks are discharged out of a pot through a related driving part (10), and the finished fried bread sticks are made.

Owner:皮常胜

Food folding equipment

ActiveCN108925596AImprove efficiencyImprove folding efficiencyConveyorsBaked articles handlingAssembly lineEngineering

The invention discloses food folding equipment. The food folding equipment comprises a cake transporting unit for transporting cakes and a cake folding unit for folding the cakes. Through adoption ofthe food folding equipment provided by the invention, the automation degree of the processing of the cakes is increased, the product quality is improved, and the processing and making cost of the products is reduced; and the food folding equipment is particularly suitable for assembly lines and large-scale production, and has favorable application prospect.

Owner:泾县集知佳工业设计有限公司

Production line and process of fried straight noodles

InactiveCN102144749AEasy to replaceImprove cleanlinessOil/fat bakingDough shaping and cutting apparatusProduction lineEngineering

The invention relates to a production line and a production process of fried straight noodles. The production line comprises a flour sieving and filtering machine, a flour air blower, a powder liquid mixing machine, a dough curing and conveying machine, a composite noodle press, a continuous noodle press, a shredding forming machine, a noodle steaming machine, a dry method differential fluffer, avibrating fluffer, a quantitative cut-off falling machine, a noodle oil-pouring machine, a frying machine, a dough deoiling machine, an arraying machine, an air cooled machine, a distributing conveyor and a packaging conveyer which are arranged sequentially. The production process comprises the following steps of: sieving and filtering flour; pneumatically conveying the flour; mixing powder and liquid; curing and conveying dough; performing composite noodle press; performing continuous noodle press; shredding and forming; steaming noodles; loosening the noodles by a dry method; loosening the noodles in a vibrating mode; quantitatively cutting off the noodles, so that the noodles fall into a box; pouring oil on the noodles; frying the noodles; deoiling the paste; arraying the noodles; performing air cooling; performing distributed conveying; and performing packaging conveying. By the production line and the production process of the fried straight noodles, the production efficiency is high; various types of noodles cam be produced on one production line; and the produced noodles are healthful and delicious.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

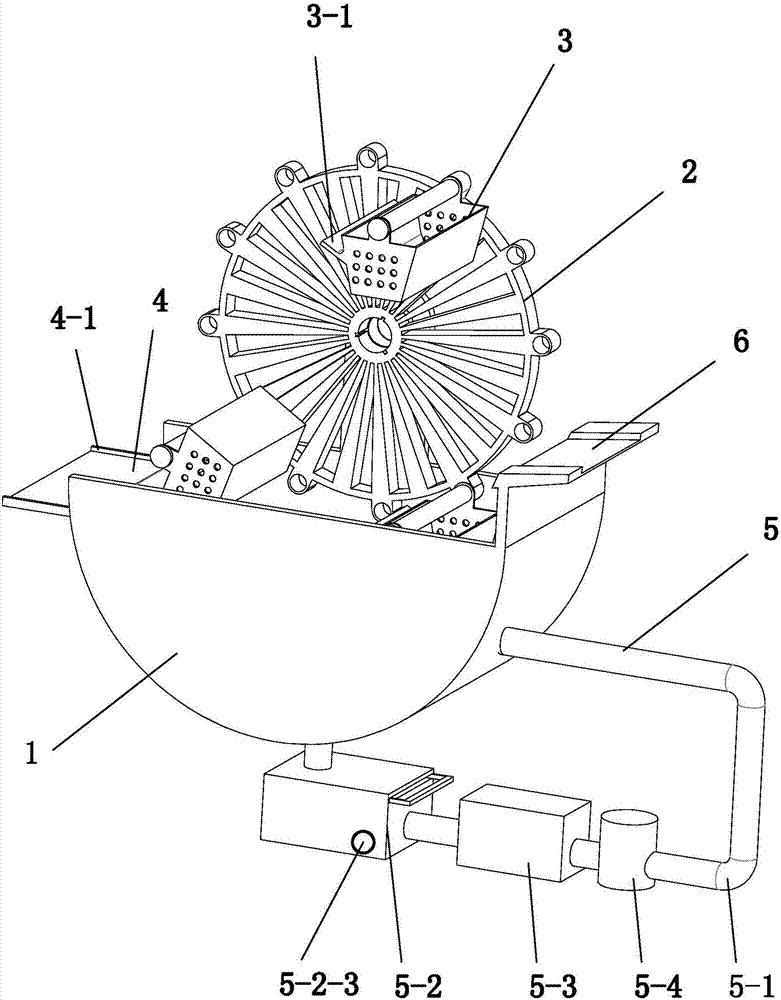

Small fryer capable of processing various types of food at the same time

PendingCN107318911AAvoid confusionThe way to separate oil residue is completeOil/fat bakingDeep fat fryersEngineeringEdible oil

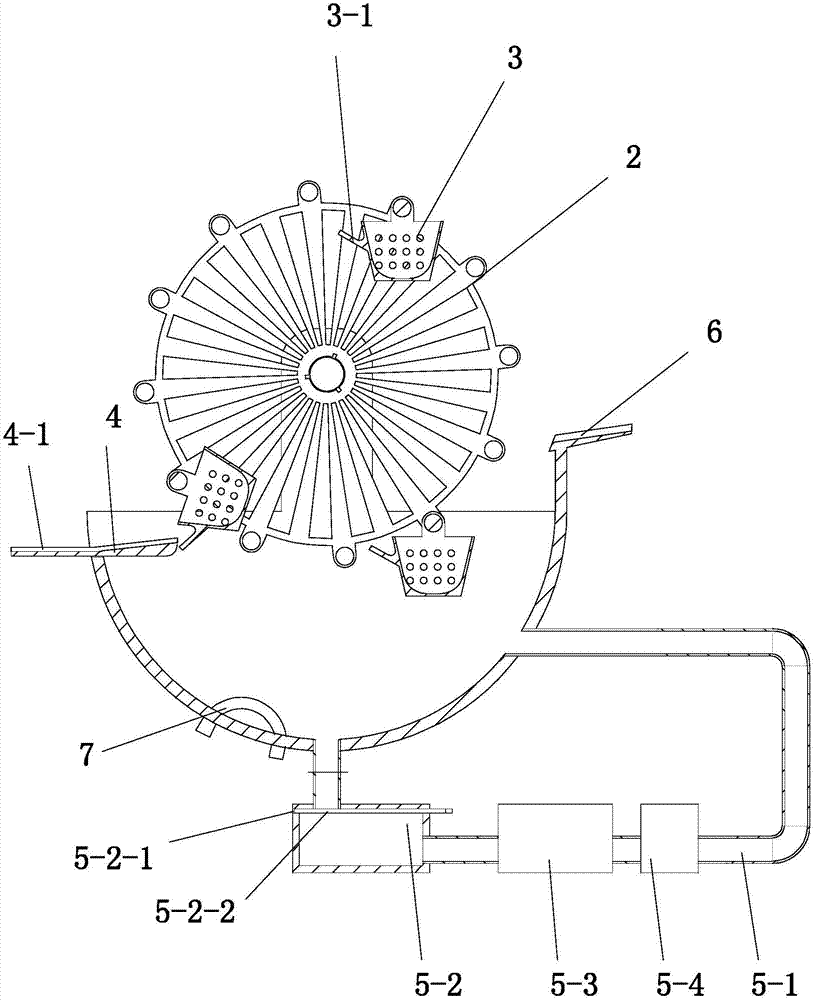

The invention provides a small fryer capable of processing various types of food at the same time. The small fryer comprises a pot body, an arc groove is formed in the top of the pot body, and a rotating wheel is connected to the groove wall in a rotatable mode; the rotating wheel is arranged in the vertical direction, multiple frying baskets are arranged along the edge of the rotating wheel in a hinged mode, and the frying baskets are at a certain distance from the bottom of the groove when located in the lowest position in a hung mode; the frying baskets are open containers which are large on the top and small on the bottom, one-side basket wall of each frying basket is arranged as a turnover assistant plate with a certain angle, and a turnover assistant pushing part corresponding to the action direction of the turnover assistant plate is arranged at the outlet of the arc groove; a discharging sliding groove is formed in the upper portion of the turnover assistant pushing part; the pot body is provided with an internal circulation residue removing device communicated with the pot bottom and the pot wall. By means of the small fryer, the purposes that different food is fried and divided at the same time and oil residues in cooking oil are well removed can be achieved.

Owner:浦北县龙腾食品有限公司

Thin pancake machine

The invention provides a thin pancake machine. The thin pancake machine comprises a flat iron plate, a starch adhesive barrel, a material dipping device and a conveying device, wherein the material dipping device is mounted on the conveying device, and comprises a material dipping head which can be extruded to be deformed and an extruding mechanism; micro holes which can adhere starch adhesive areformed in the surface of the material dipping head; and the extruding mechanism cooperates with the flat iron plate, so that the material dipping head can be extruded until the material dipping headis deformed, and the adhered starch adhesive is flat spread on the flat iron plate. Through adoption of the thin pancake machine disclosed by the invention, thin pancakes can be automatically made, sothat labor is saved, and the efficiency is high.

Owner:邵嘉阳

Oil-fried food processing apparatus

InactiveCN107788048AAvoid food spoilageTimely processingOil/fat bakingBaking plantsEngineeringEdible oil

The invention relates to the technical field of food processing, and especially discloses an oil-fried food processing apparatus. The oil-fried food processing apparatus comprises a machine frame, a processing mechanism, a dirt removing mechanism, and a cooling mechanism; the processing mechanism is used for performing oil-frying process on foods to be processed; the dirt removing mechanism is used for performing impurity treatment on a material plate; and the cooling mechanism is used for performing quick cooling on the oil-fried foods, as well as filtering edible oil on surfaces of the oil-fried foods. According to the oil-fried food processing apparatus, the processing mechanism is used for carrying out oil-frying on the foods to be processed, and the foods in an oil tank are fished outat the same time by adopting a hydraulic lifting way so as to avoid food deterioration caused by excessive long oil-frying time; impurities produced by oil-frying are timely treated by the dirt removing mechanism so that food quality is improved and utilization time of edible oil is prolonged; and quick cooling is carried out on the processed foods by the cooling mechanism so that subsequent packaging or future processing are facilitated, and oil is fully filtrated.

Owner:合肥岭启信息科技有限公司

Oil frying equipment

ActiveCN106172568ASmall footprintRealize the function of deoilingOil/fat bakingDeep fat fryersEngineeringMechanical engineering

The invention relates to oil frying equipment. The oil frying equipment comprises a pot body, a circuit control component, a heating part, a frying basket, a lifting device and a centrifugal motor; the frying basket is contained in the pot body and can slide in the direction close to or far away from the bottom of the pot body, the lifting device comprises a lifting motor, a screw, a guide part and a sliding component, the lifting motor can drive the screw to rotate, a guide groove extending in the direction from the bottom to the opening of the pot body is formed in the guide part, the sliding component is slidably arranged on the screw in a sleeving mode, part of the sliding component is contained in the guide groove, and the sliding component can slide in the extension direction of the guide groove; the centrifugal motor is fixedly installed on the sliding component, the centrifugal motor can slide along with the sliding component, the centrifugal motor is fixedly connected with the drying baskets so as to drive the frying basket to slide, the centrifugal motor can drive the frying basket to rotate, and the centrifugal motor is electrically connected with the circuit control component. The frying equipment can allow oil removing to be more convenient, and the occupied area is small.

Owner:徐州恒华包装科技有限公司

Fried peanut processing device

The invention discloses a fried peanut processing device which comprises a frying pan body, wherein a lower clapboard is fixedly connected below the inner part of the frying pan body; an electric heating plate is fixedly connected below the lower clapboard; an overhaul hole is formed below the electric heating plate; a radiating baffle is fixedly connected below the overhaul hole through a bolt; aplurality of radiating holes are formed above the radiating baffle; a connecting plug is fixedly connected on the left side of the frying pan body, and the connecting plug is electrically connected with the electric heating plate; and the middle part on the left side of the frying pan body is fixedly connected with a motor mounting frame, the upper part of the motor mounting frame is fixedly connected with a motor, and the output end of the motor is fixedly connected with a limited transmission shaft. Compared with the prior art, the fried peanut processing device has the beneficial effects that the fried peanut processing device has a simple structure, is convenient to use, can be used for frying peanuts, can be used for more intuitively and clearly understanding the frying condition ofthe peanuts when the peanuts are fried, can filter oil on the surfaces of the peanuts after frying, avoids excessive oil content of the peanuts, and is worthy of popularization.

Owner:泗水县锦川花生食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com