Full-automatic handwork-imitating pancake machine

A technology that imitates handwork and pancake machines. It is applied in the direction of baking pancakes, oil/fat baking, etc. It can solve the problems of manpower consumption, time, bulky volume, complex structure, etc., to improve product quality and sanitation, good application prospects, and machines small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

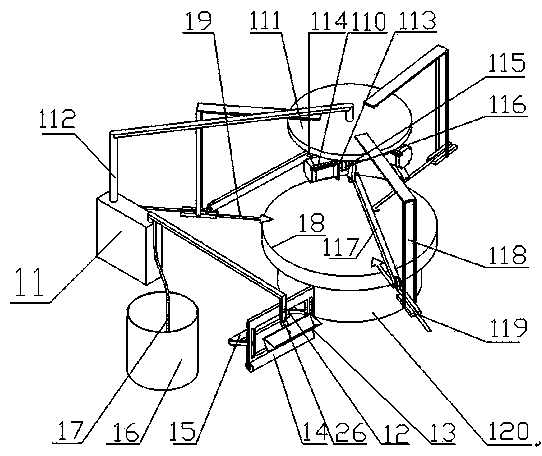

[0017] Embodiment 1: The present invention discloses a fully automatic hand-made pancake machine, which includes a frame, a battering part, a pancake lifting part, a griddle and an automatic control part. The pasting part includes: pasting cylinder 16, in which the prepared batter is installed; pasting pump is installed in the pasting cylinder 16, through which the batter is transported into the V-shaped groove through the pasting pipe 17 In 13; Paste drive rod 12; Oil wipe 15, V-shaped groove 13 and paste roll 14 installed on the paste drive rod 12 ends. Considering the shape of the griddle 18, in order to make the thickness of pancakes uniform, the closer to the edge of the griddle 18, the more batter should be provided. Therefore, the bottom of the V-shaped groove 13 is wide at one end and narrow at the other end, close to the edge of the griddle 18 The width of the bottom of the V-shaped groove 13 increases at the position. The groove bottom of V-shaped groove 13 can also...

Embodiment 2

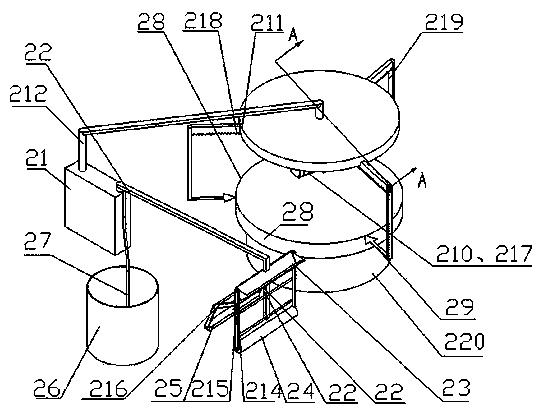

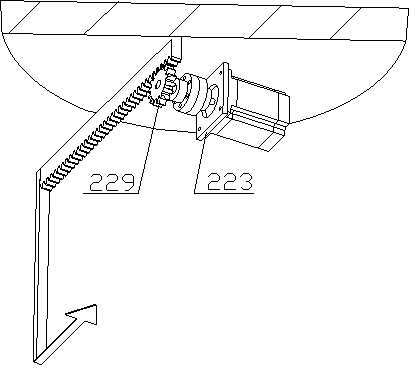

[0021]Embodiment 2: In this embodiment, the pasting part includes: the drive gear 228 installed in the control box, the drive gear 228 is connected and fixed with the bottom of the cabinet 21 through a rotatable connecting rod, and the left rack 223 meshes with the drive gear 228 respectively and the right rack 224, the right rack 224 is connected with the driving rod 11, the pull wire I 221, the pull wire II 222 and the curved rod 216; the oil wiper 25 is installed at the bottom of the connecting rod bracket, and the connecting rod bracket includes the connecting rod I 215 and the connecting rod II 214 One end of the pull wire I221 is connected with the left rack 223, the other end is connected with the connecting rod I215, one end of the spring I225 is connected with the connecting rod I215, and the other end is connected with the pasting drive rod 22; one end of the pull wire II222 is connected with the installation box, and the other end is connected with the Spring II 226 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com