Patents

Literature

87 results about "Scraping - action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

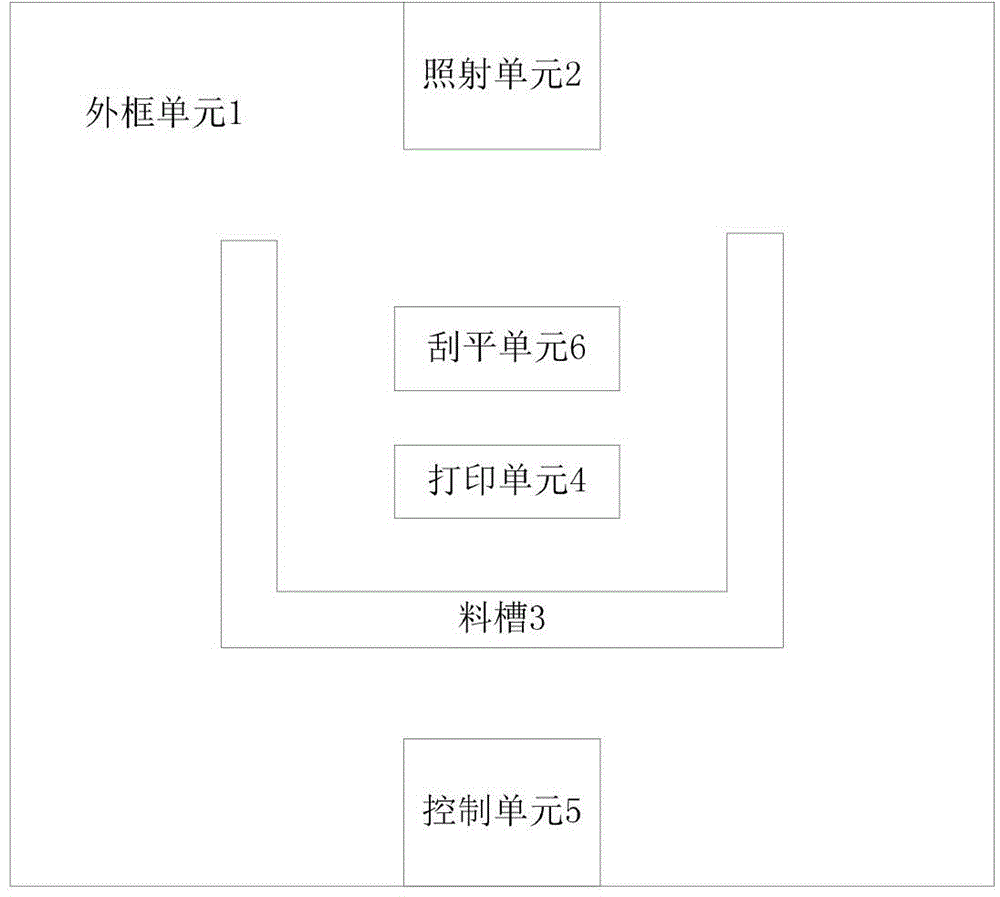

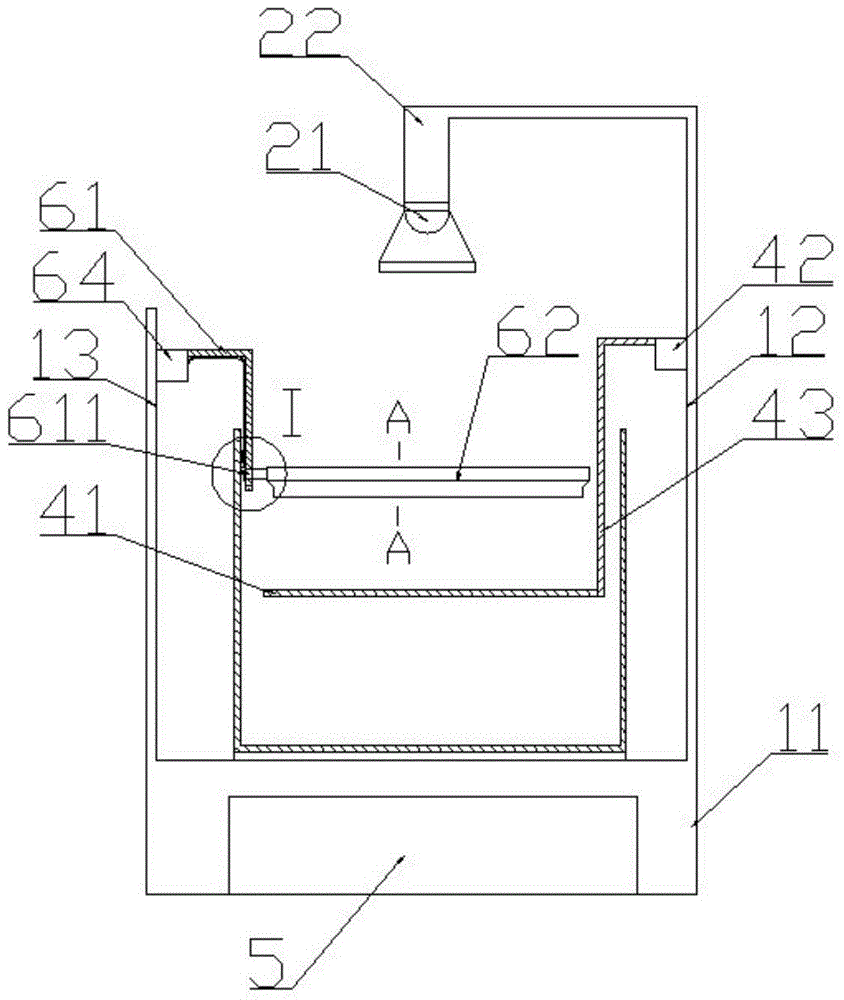

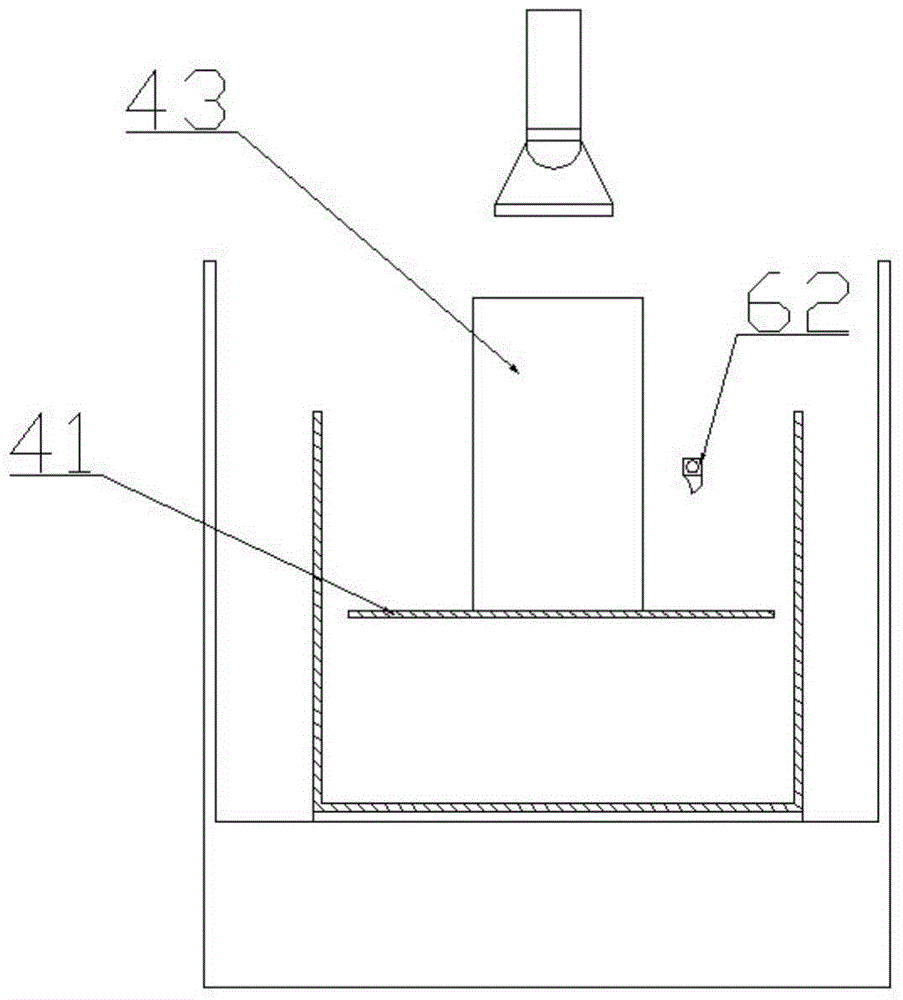

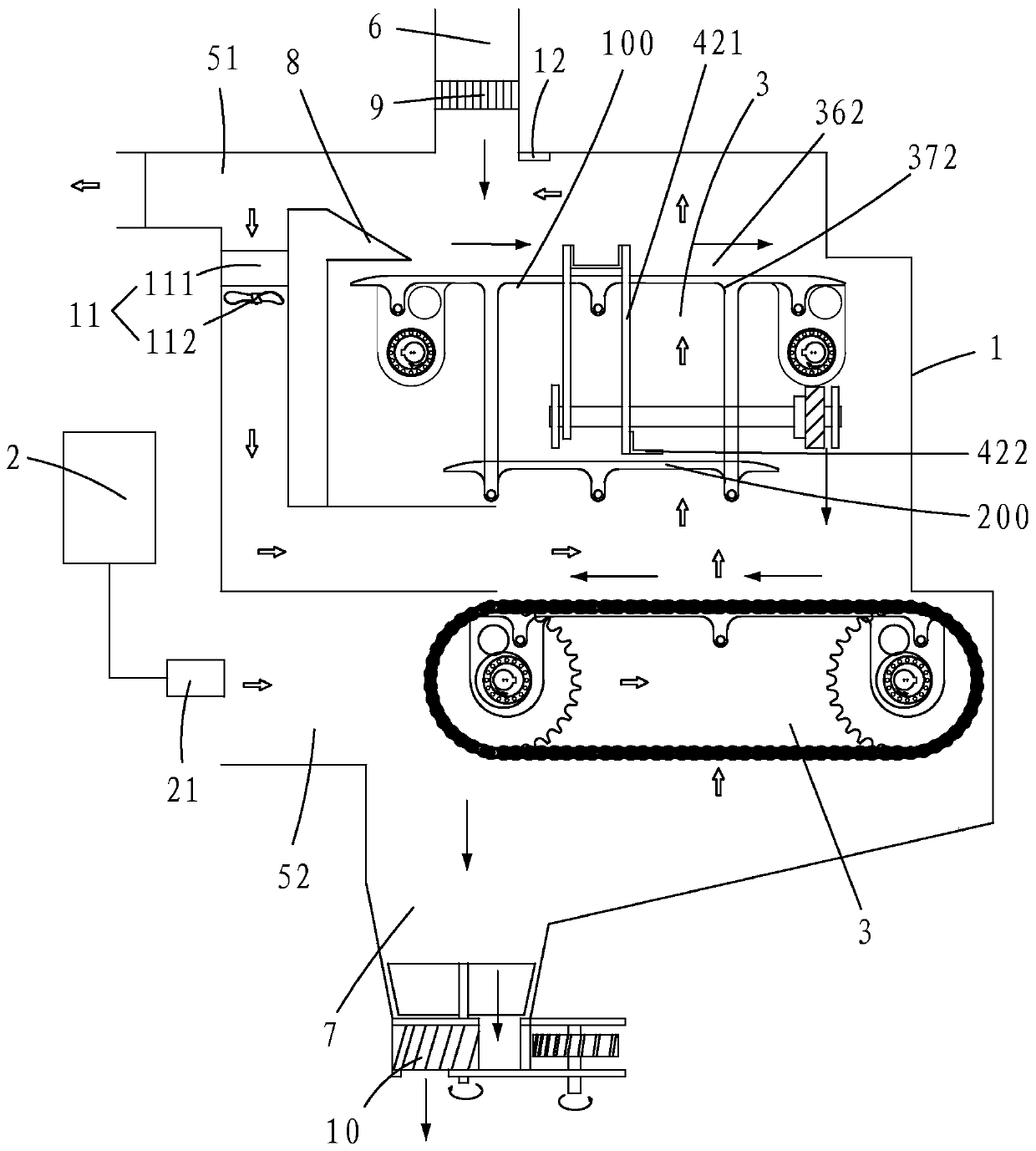

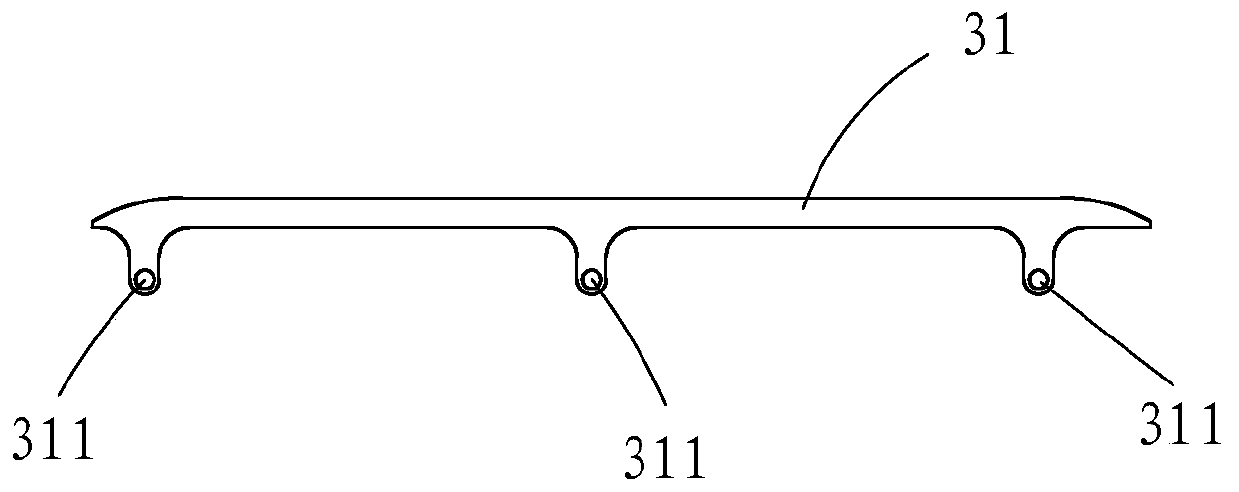

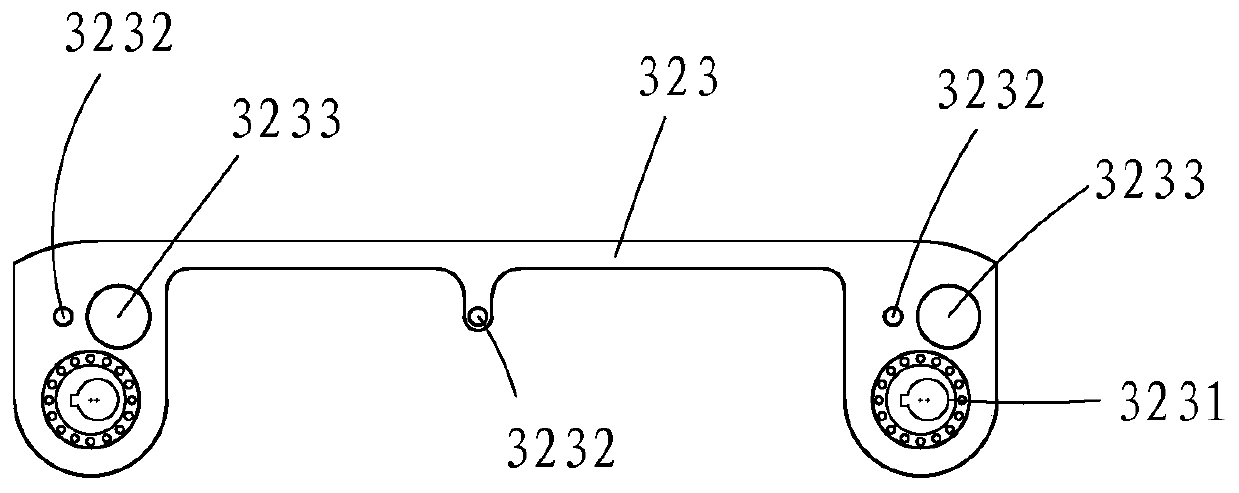

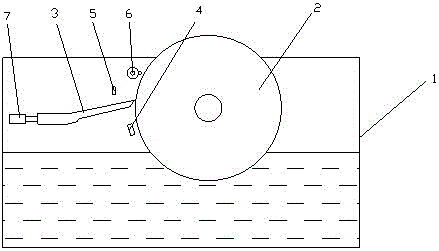

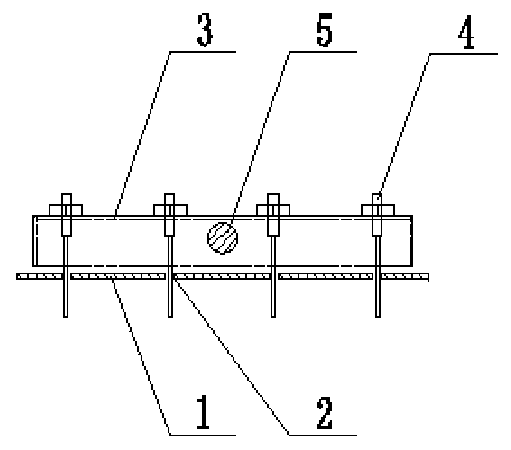

3D laser printer with leveling function and light-curing printing method thereof

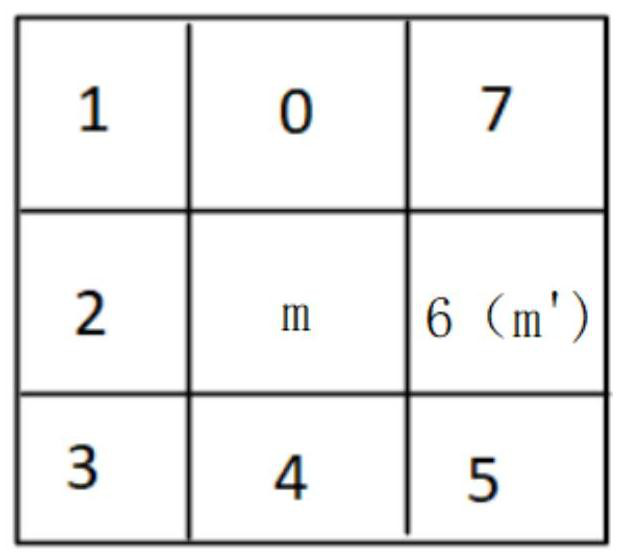

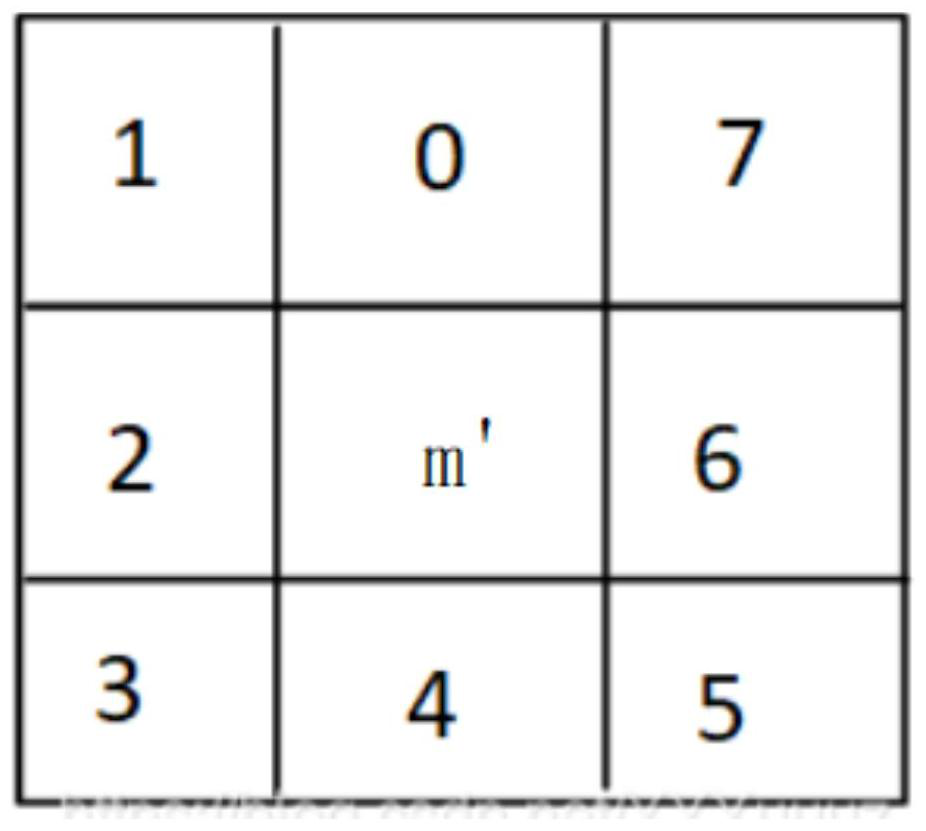

InactiveCN104527065AAvoid influenceExcellent printing surfaceAdditive manufacturing apparatusScraping - actionReciprocating motion

The invention discloses a 3D laser printer with a leveling function. The printer comprises an outer frame unit, a trough, a printing unit, an irradiation unit, a leveling unit and a control unit, wherein the outer frame unit is used for forming a low-cost framework; the trough is used for containing a printing stock solution; the printing unit can longitudinally move relative to the outer frame unit and is positioned at an operation station in the trough; the irradiation unit is used for providing a light-curing laser light source; the leveling unit is positioned between the printing unit and the irradiation unit and is used for leveling the printing surface; the control unit is used for controlling the operating state of each unit; and the leveling unit can longitudinally move, a leveling plate arranged on the leveling unit can horizontally and transversely move in the trough, and the scraping action and leveling action can be simultaneously finished in a reciprocating motion. The invention also discloses a light curing printing method suitable for the 3D printer. The printer disclosed by the invention is stable in printing and high in precision, the levelness of each section is well controlled, and the overall printing deformation rate is low.

Owner:NINGBO HI TECH ZONE TAIBO TECH CO LTD

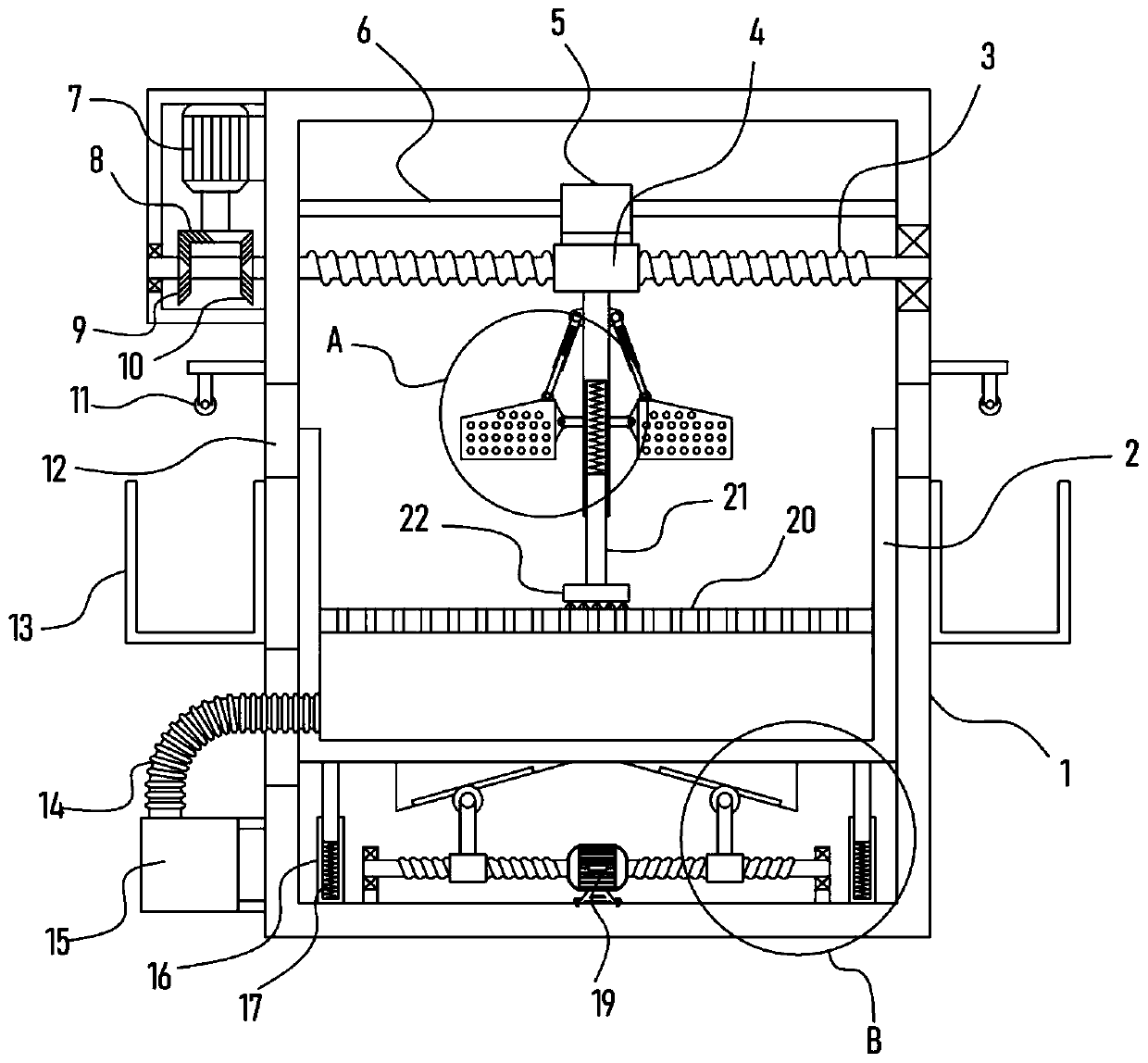

Filtering and impurity removing device for sewage treatment

InactiveCN111203014AEasy to cleanGuaranteed usuallyStationary filtering element filtersScraping - actionElectric machinery

The invention discloses a filtering and impurity removing device for sewage treatment. The invention relates to the technical field of sewage treatment. The device comprises a supporting frame, a threaded rod is rotationally installed on the supporting frame, a reversing mechanism used for driving the threaded rod to rotate clockwise and anticlockwise alternately is arranged on the supporting frame, a double-shaft motor is fixed to the bottom in the supporting frame, and a lifting mechanism used for driving a water tank to adjust the vertical height is connected to the double-shaft motor in adriving mode. The reversing mechanism can drive the threaded rod to alternately rotate clockwise and anticlockwise, and the threaded rod drives a threaded sleeve block to enable a scraping mechanism to collect and filter floating objects on the surface of sewage in the water tank. Arranged pushing wheels can push a mesh basket, so that the mesh basket rotates to pour floating objects in the mesh basket into a collecting tank, and a rapid cleaning effect for the floating objects is achieved. An arranged cleaning mechanism can conduct transverse back-and-forth scraping action on a filter screen,it is guaranteed that meshes in the filter screen are not blocked, and the efficient filtering effect of the filter screen on insoluble impurities in sewage is improved.

Owner:徐卫

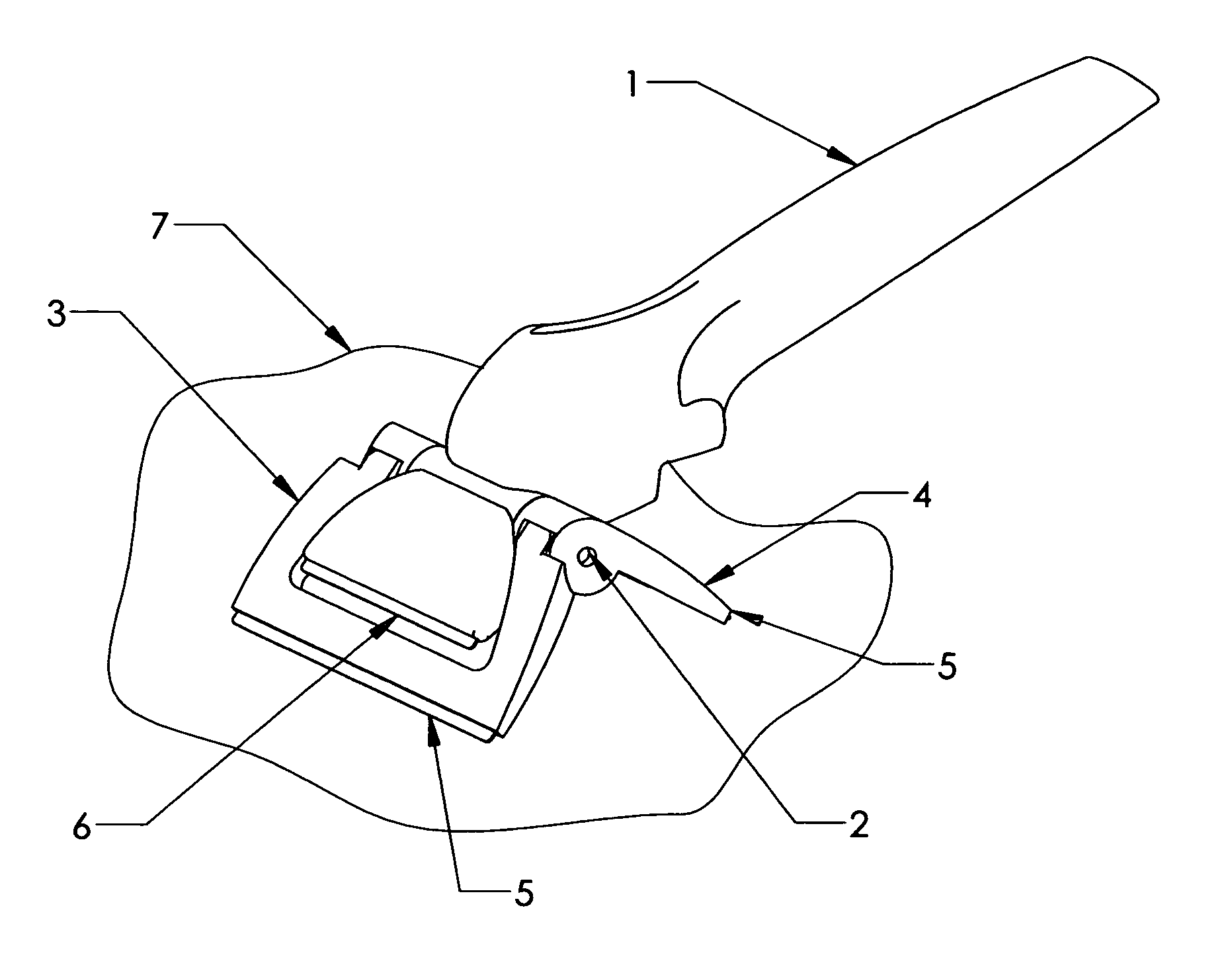

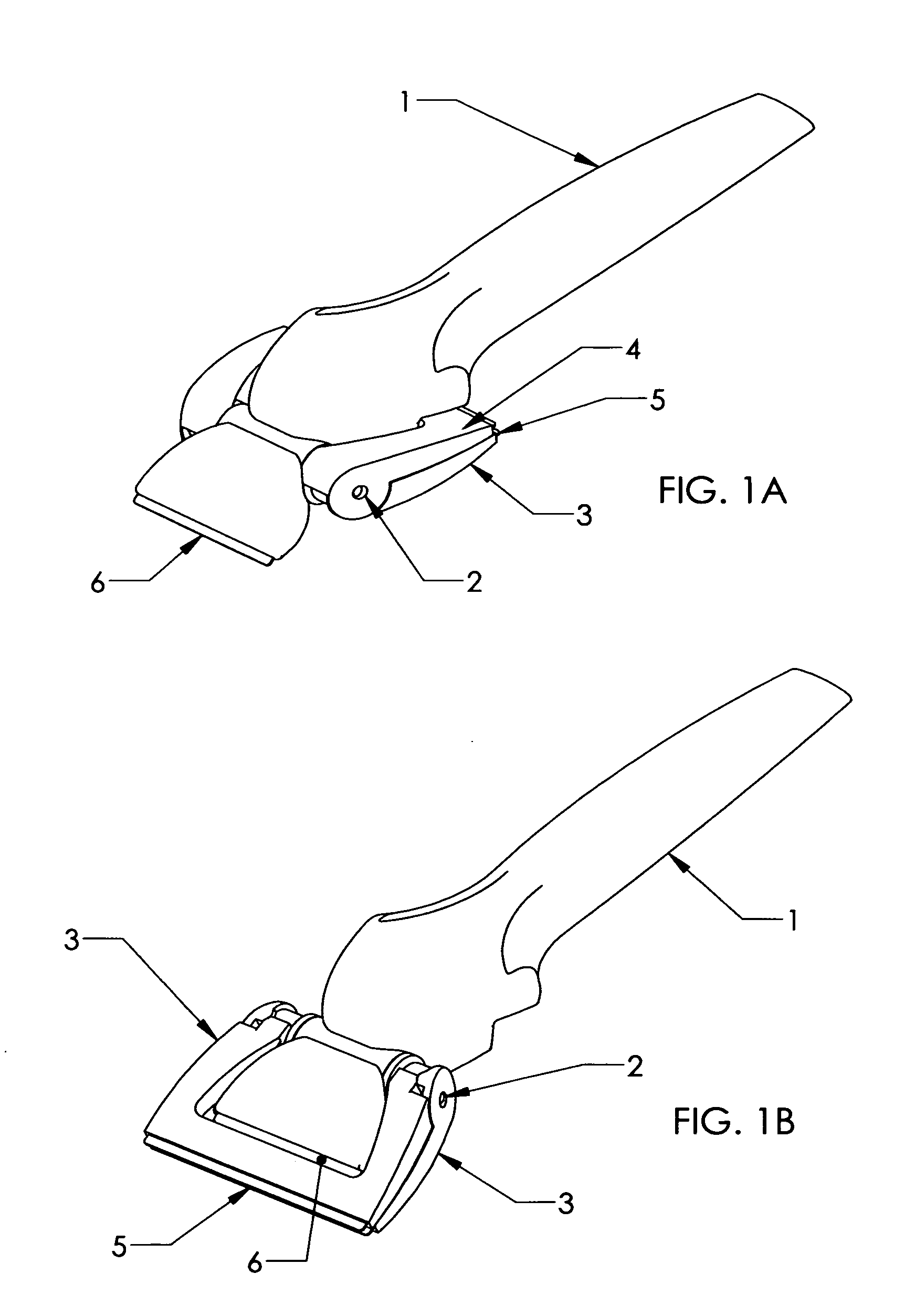

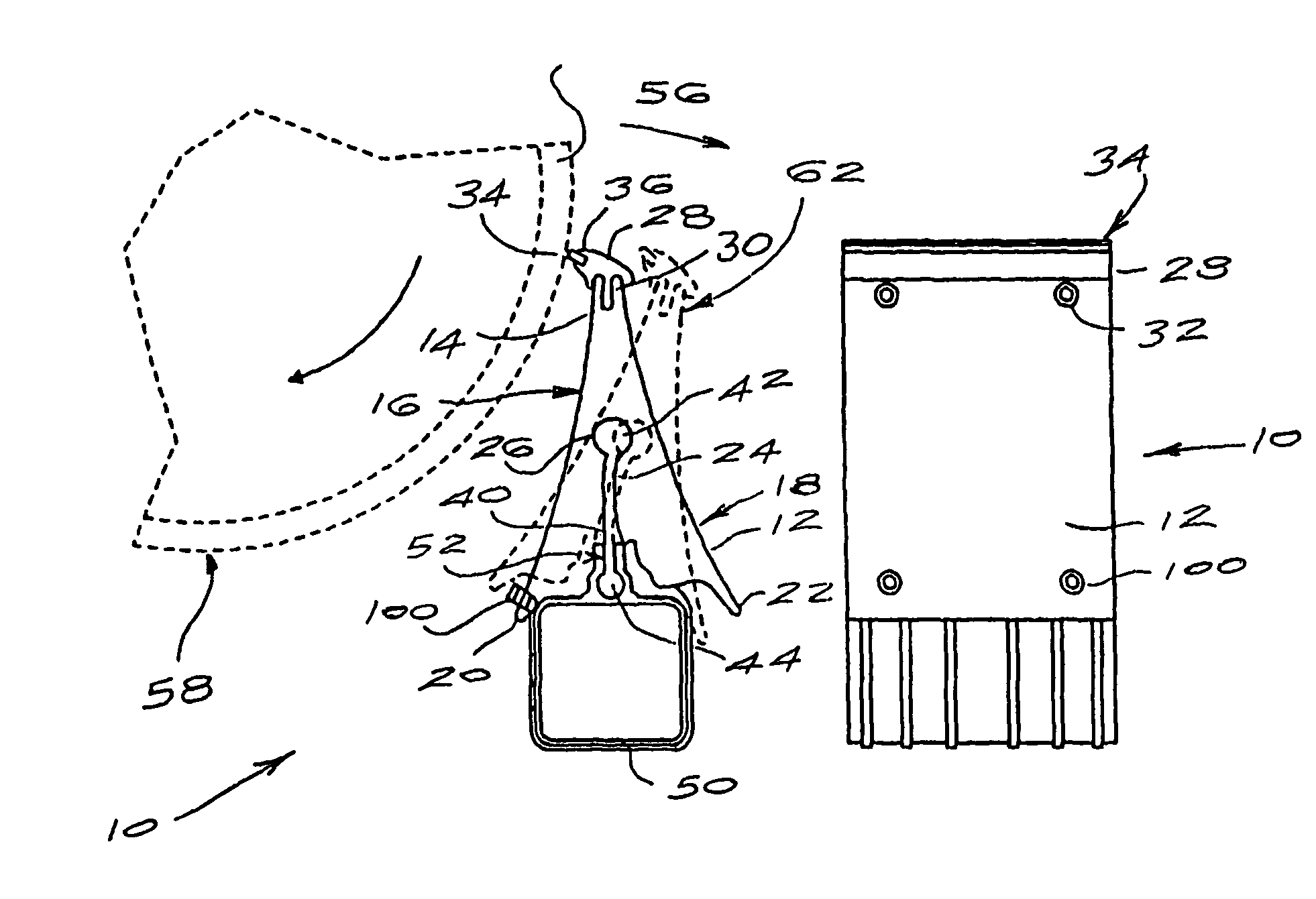

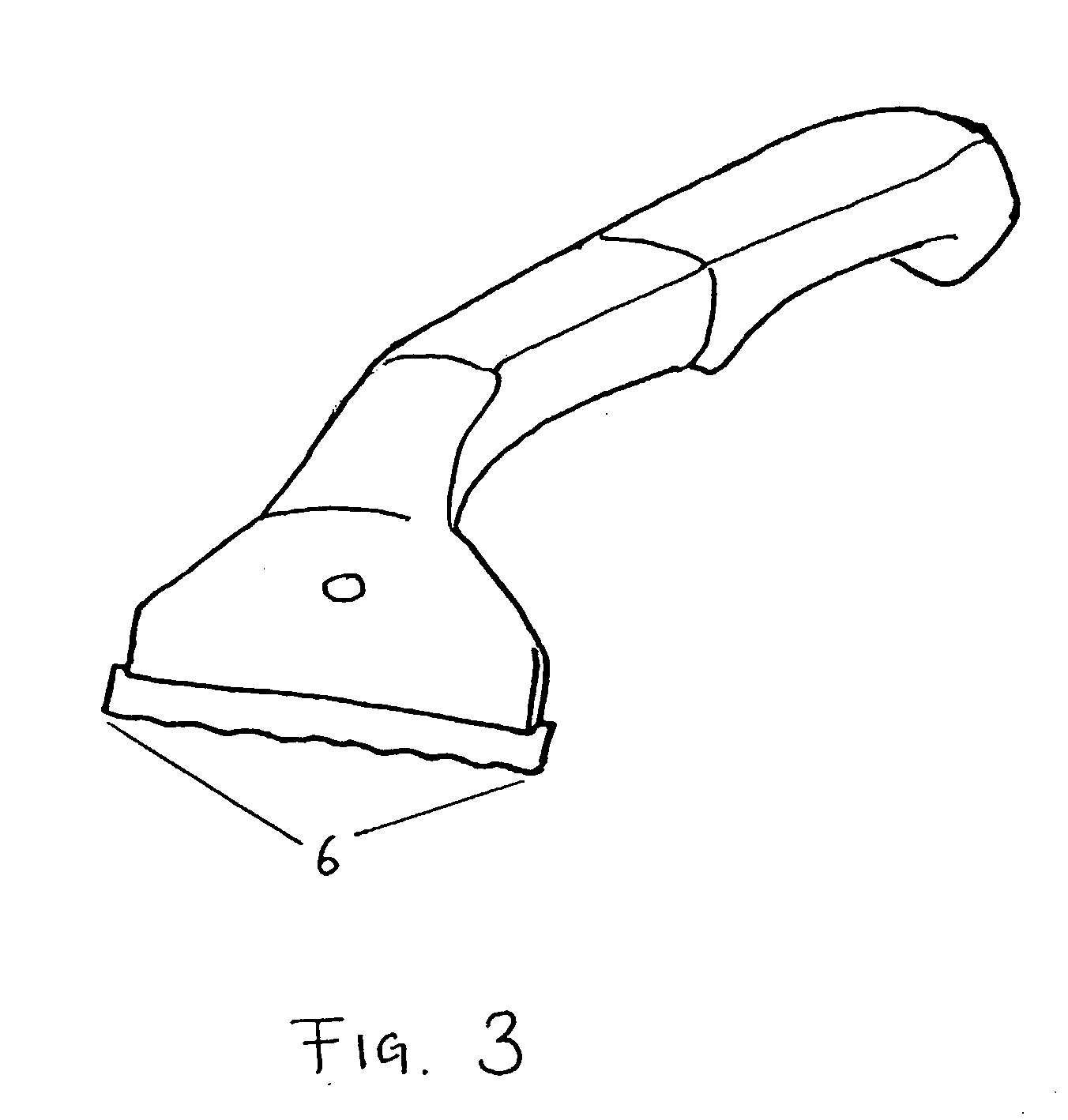

Two blade scraping device

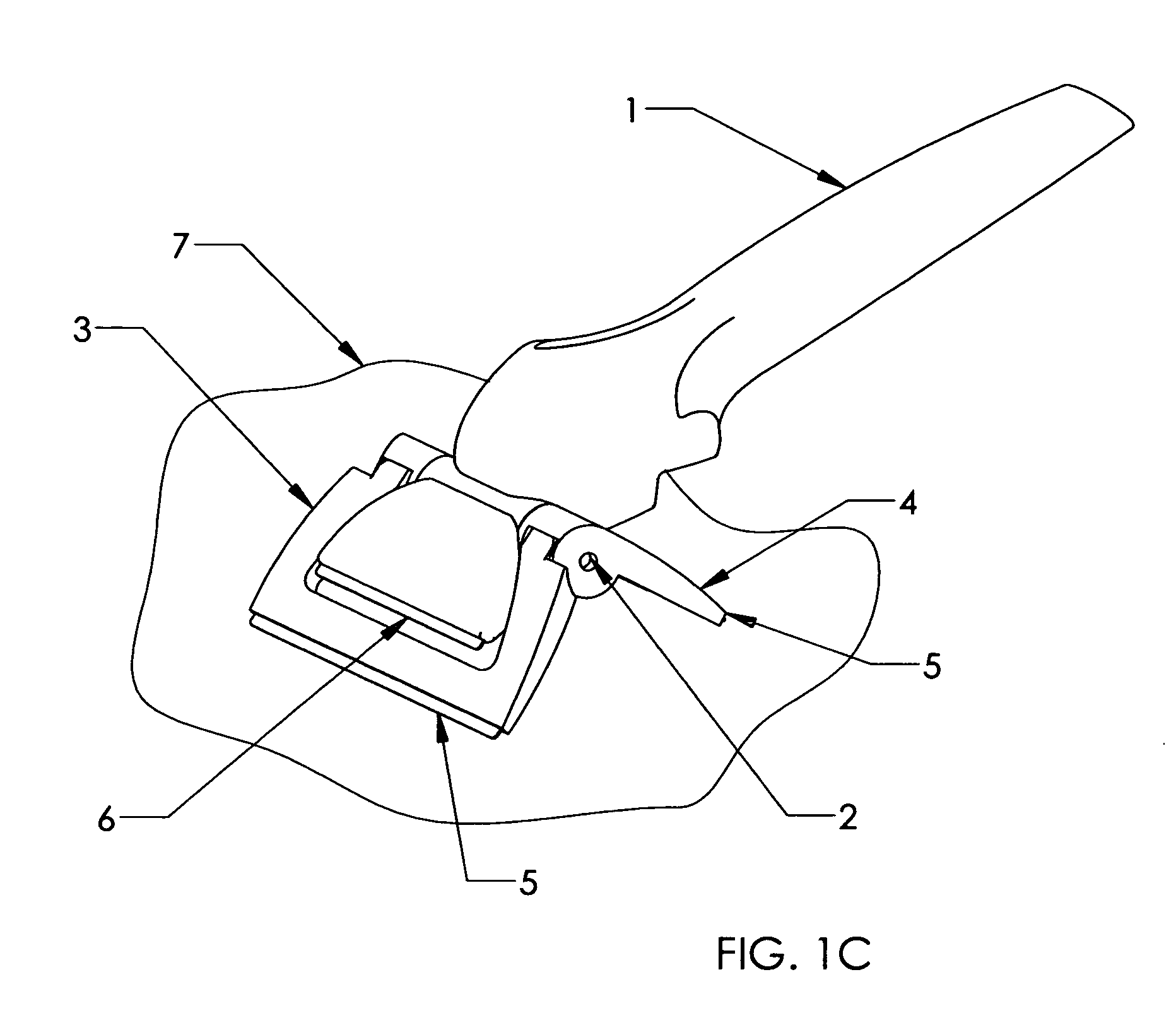

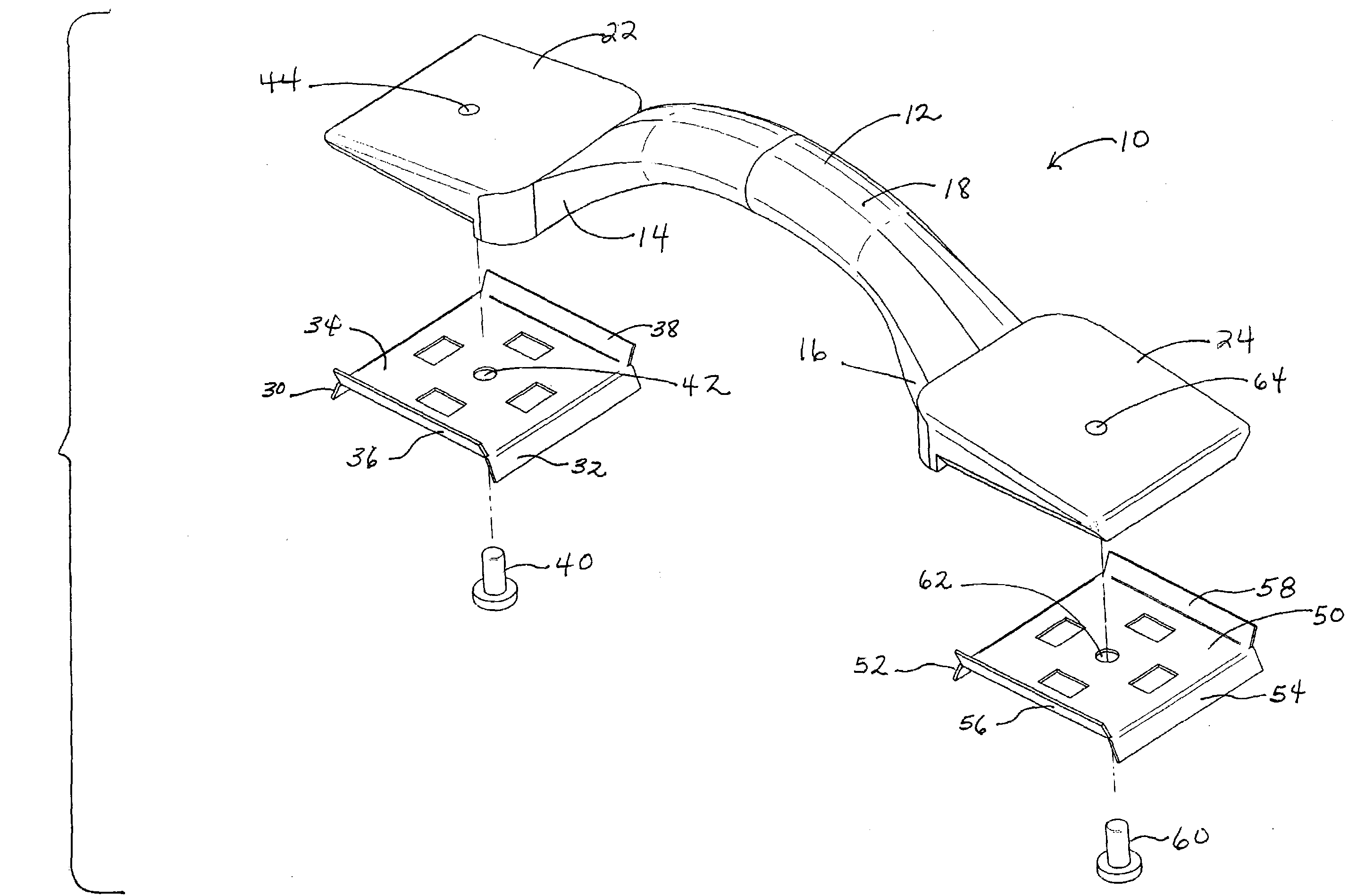

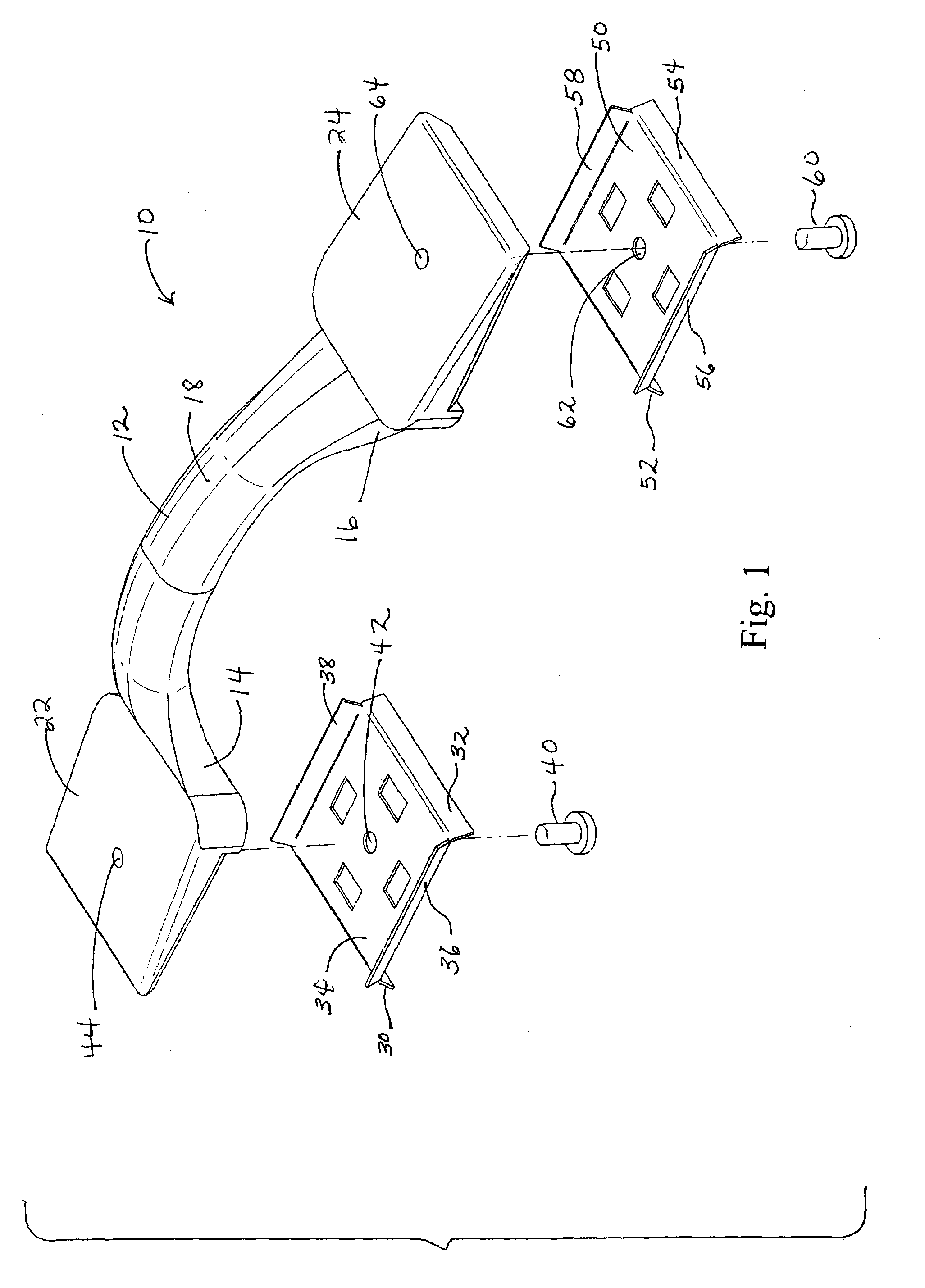

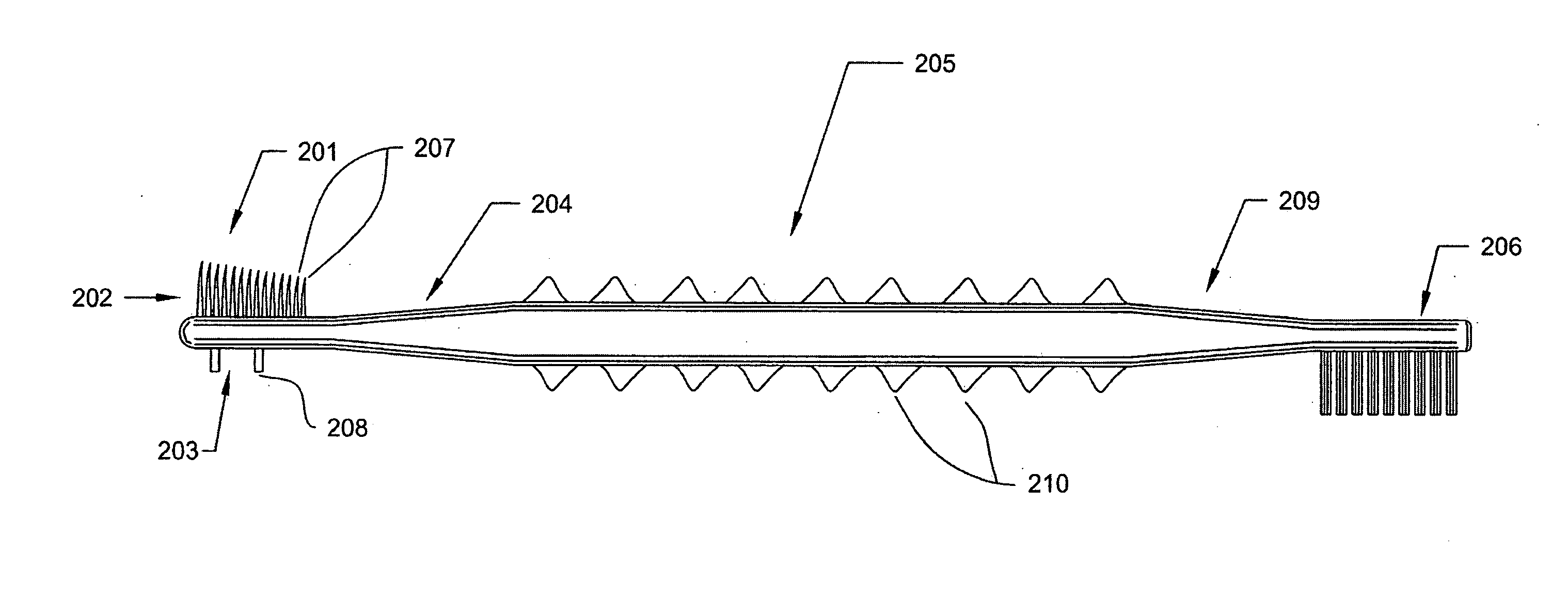

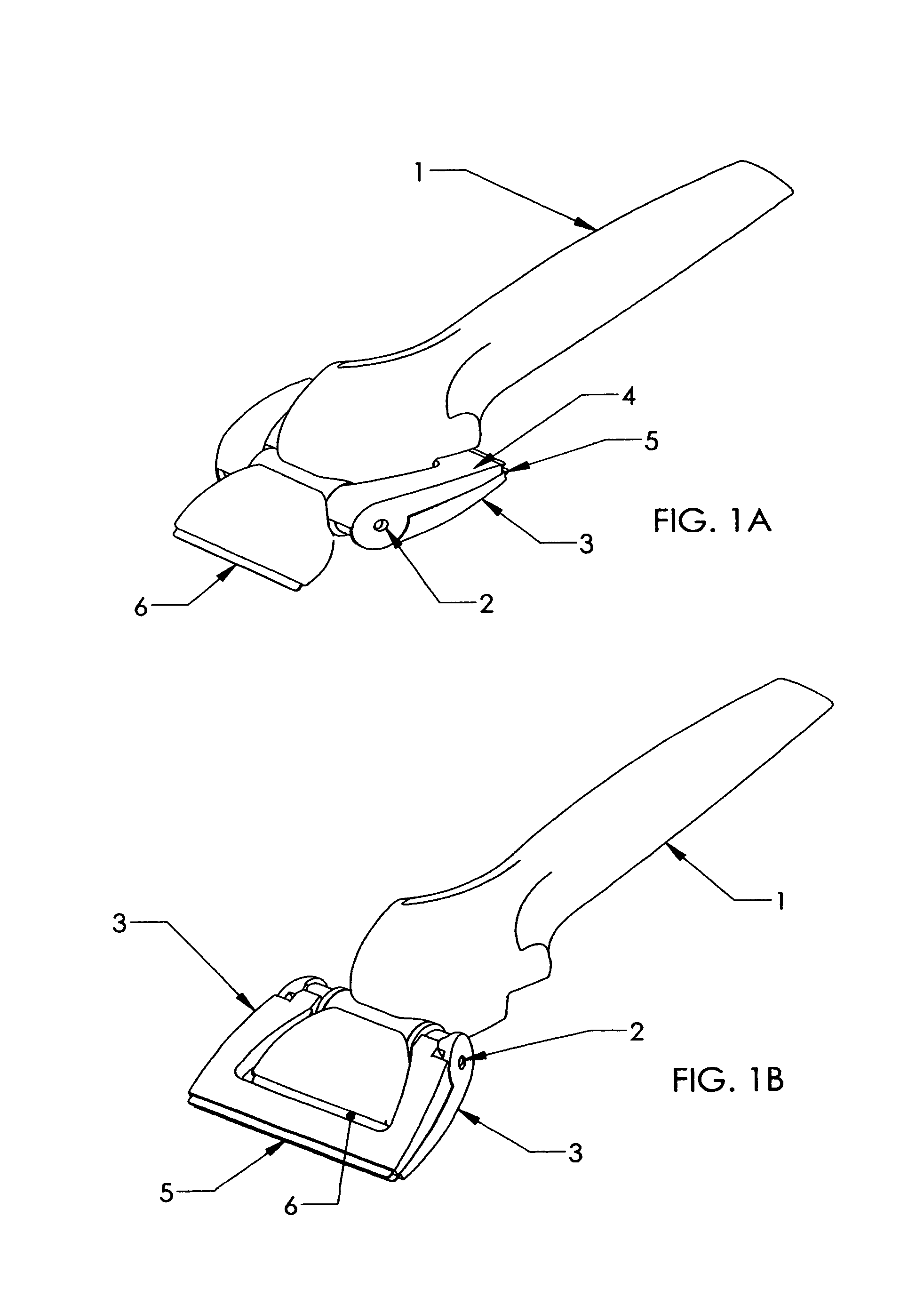

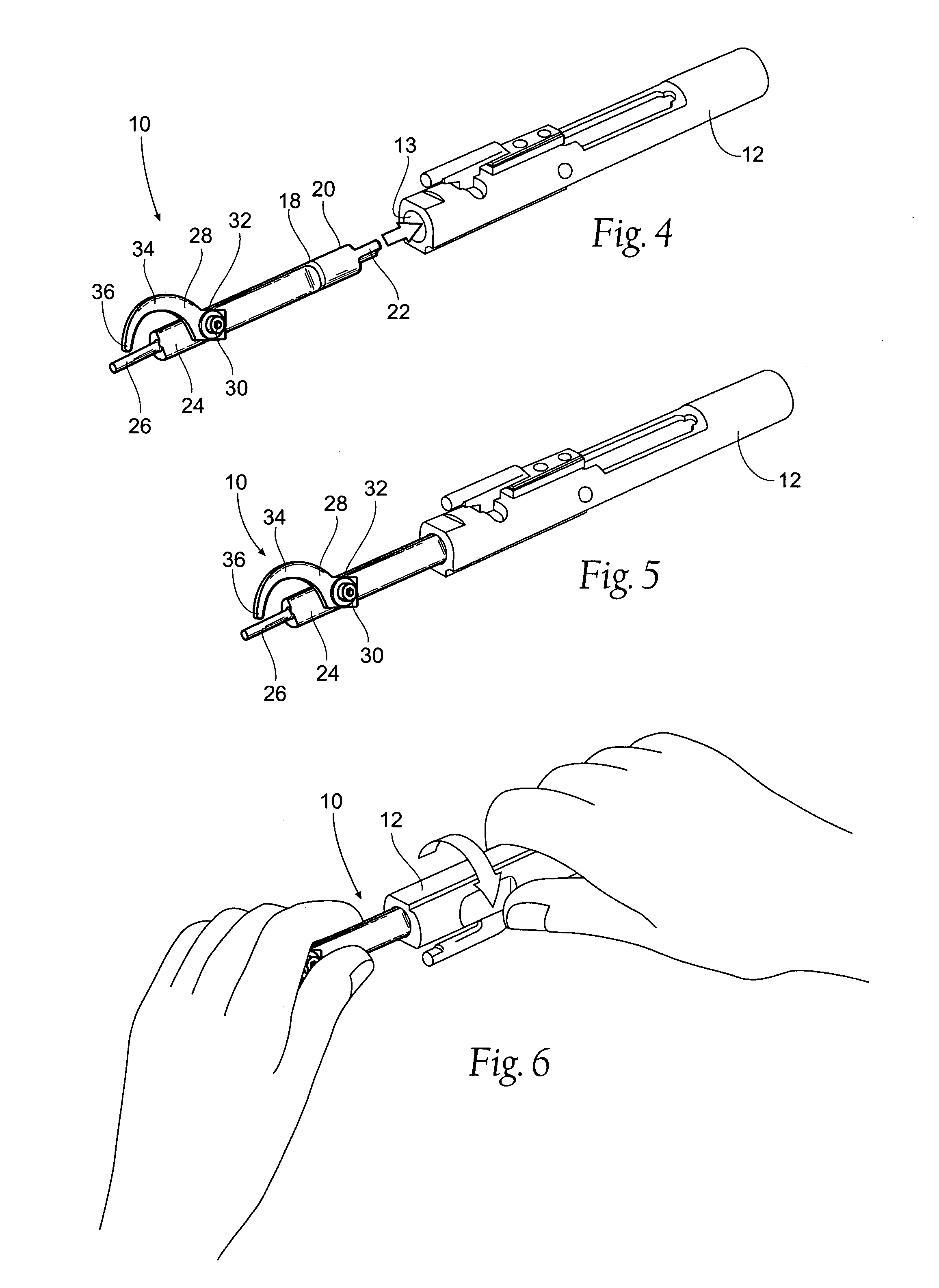

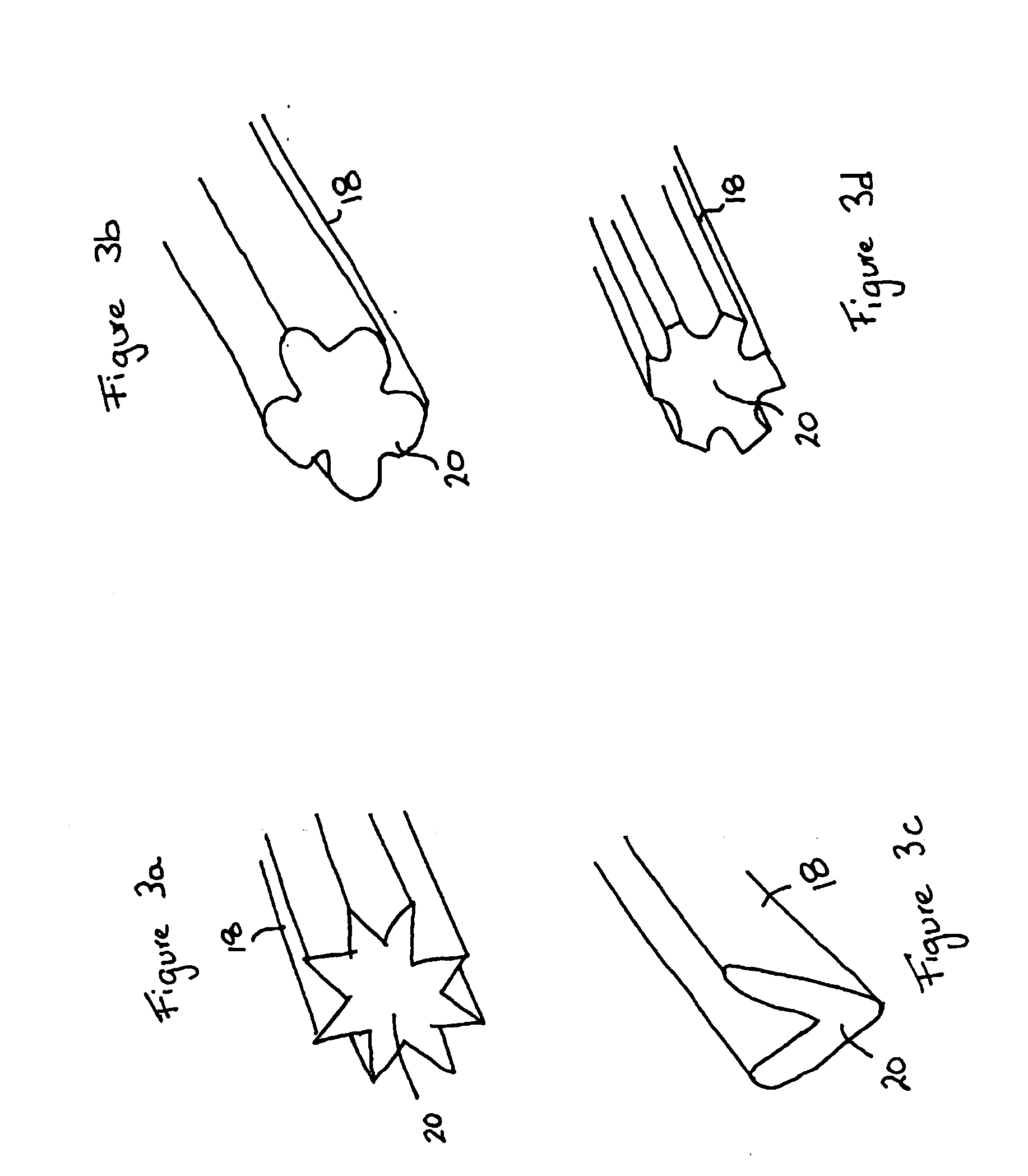

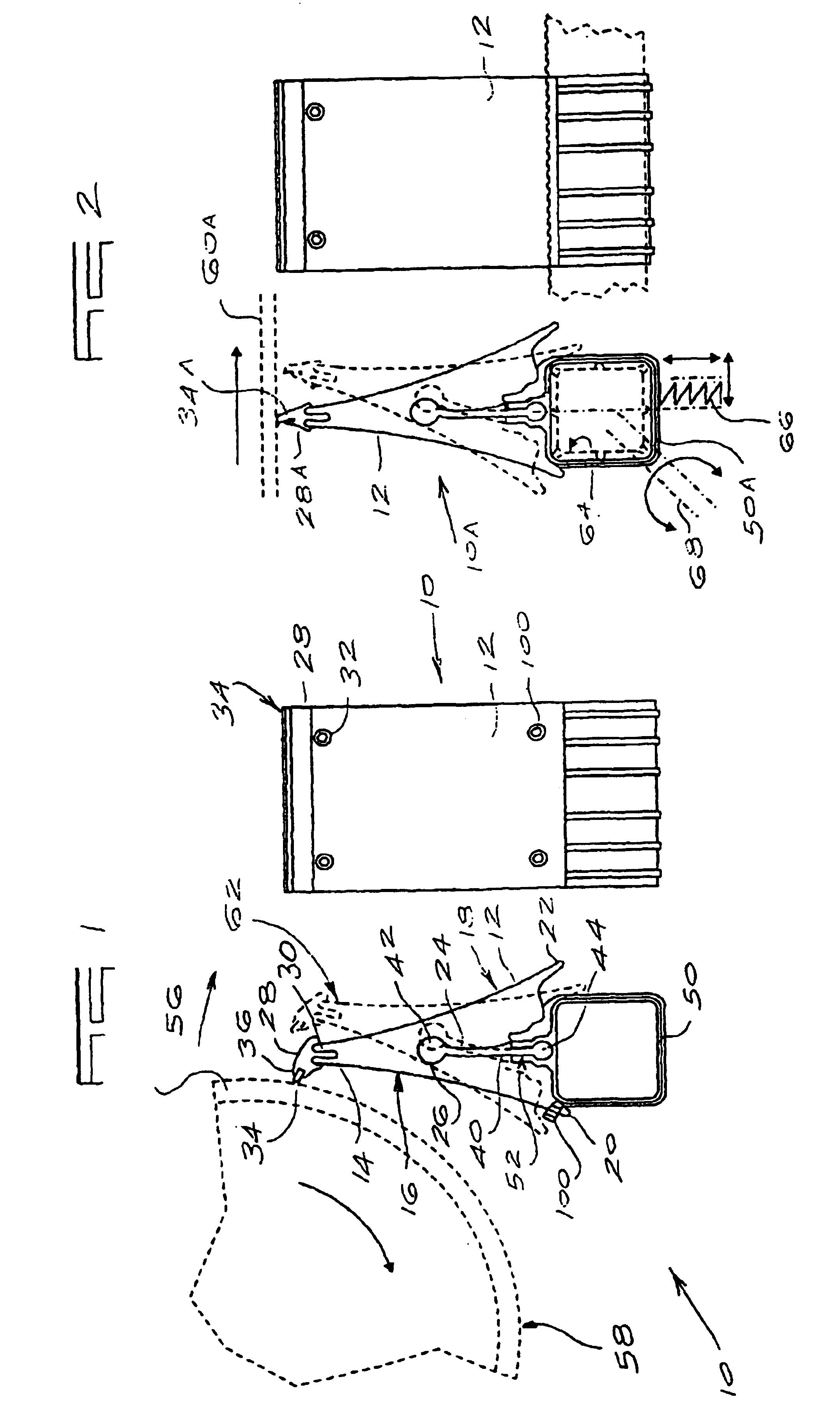

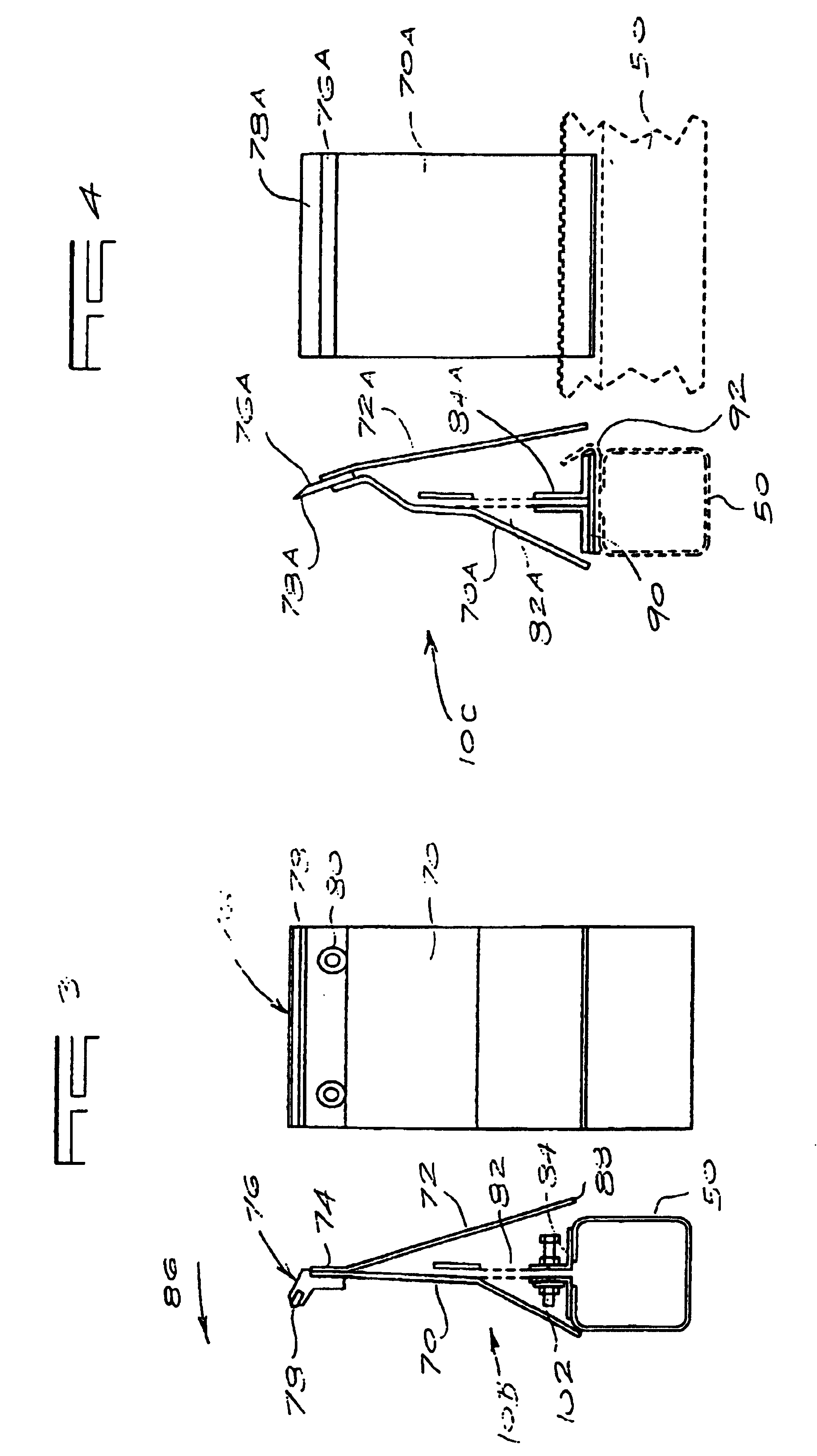

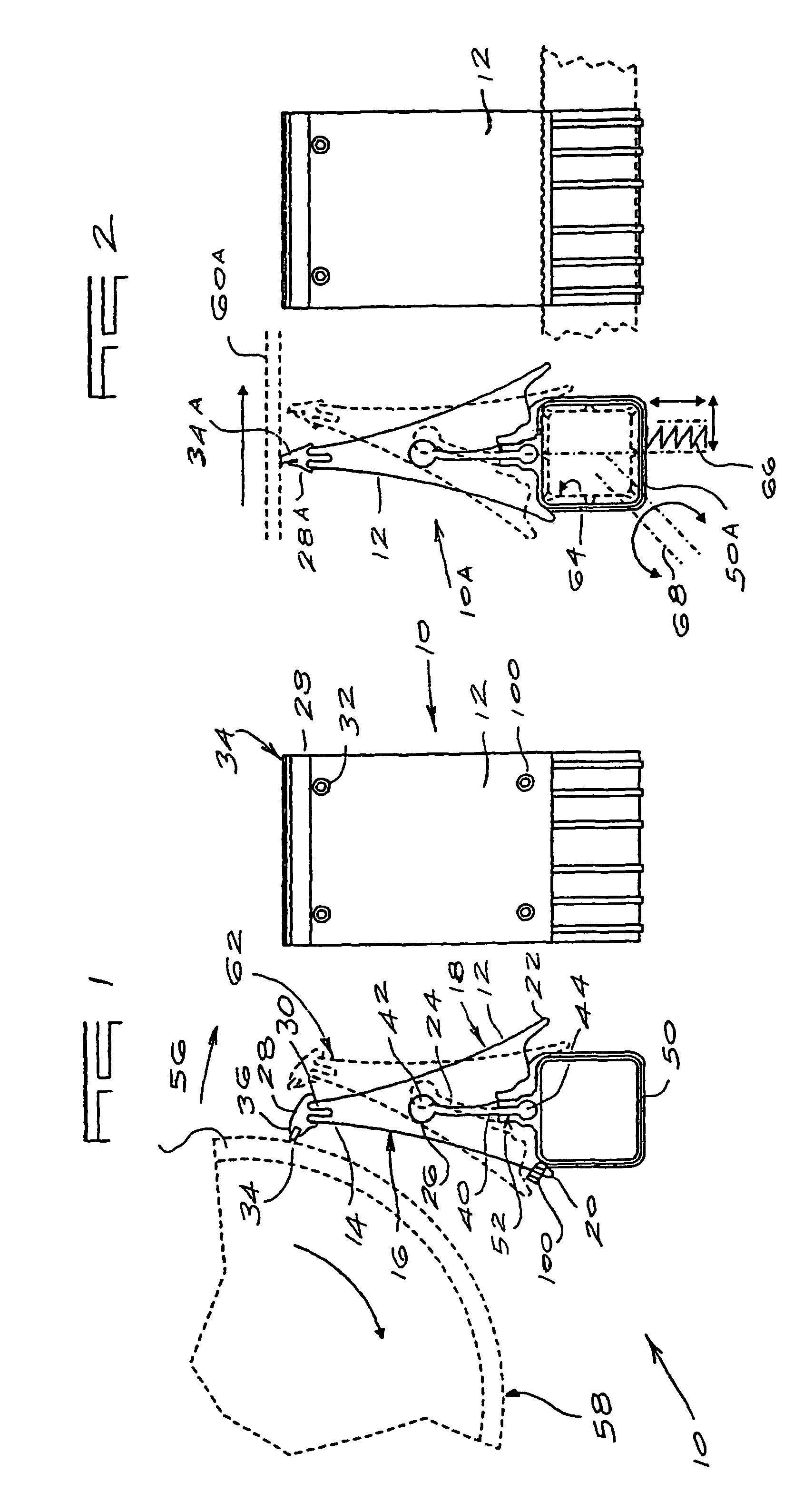

InactiveUS20060200932A1Few operator strokeEasy to storeLiquid surface applicatorsCarpet cleanersPush and pullScraping - action

A hand-held scraper device containing a stowable multi blade pivoting head. The pivoting head is comprised of at least two scraping elements which remain at a fixed angle relative to each other while still allowing a pivoting action of the head assembly independently from the handle. The angle of the scraping elements relative to each other is set such that as the two scraping elements are jointly presented against the work surface they will be maintained at an angular attitude conducive to a scraping action in both a push and pull direction. The pivoting head can be collapsed for more efficient stowage or as an alternate configuration for specific scraping applications.

Owner:BYRNES JAMES MICHAEL

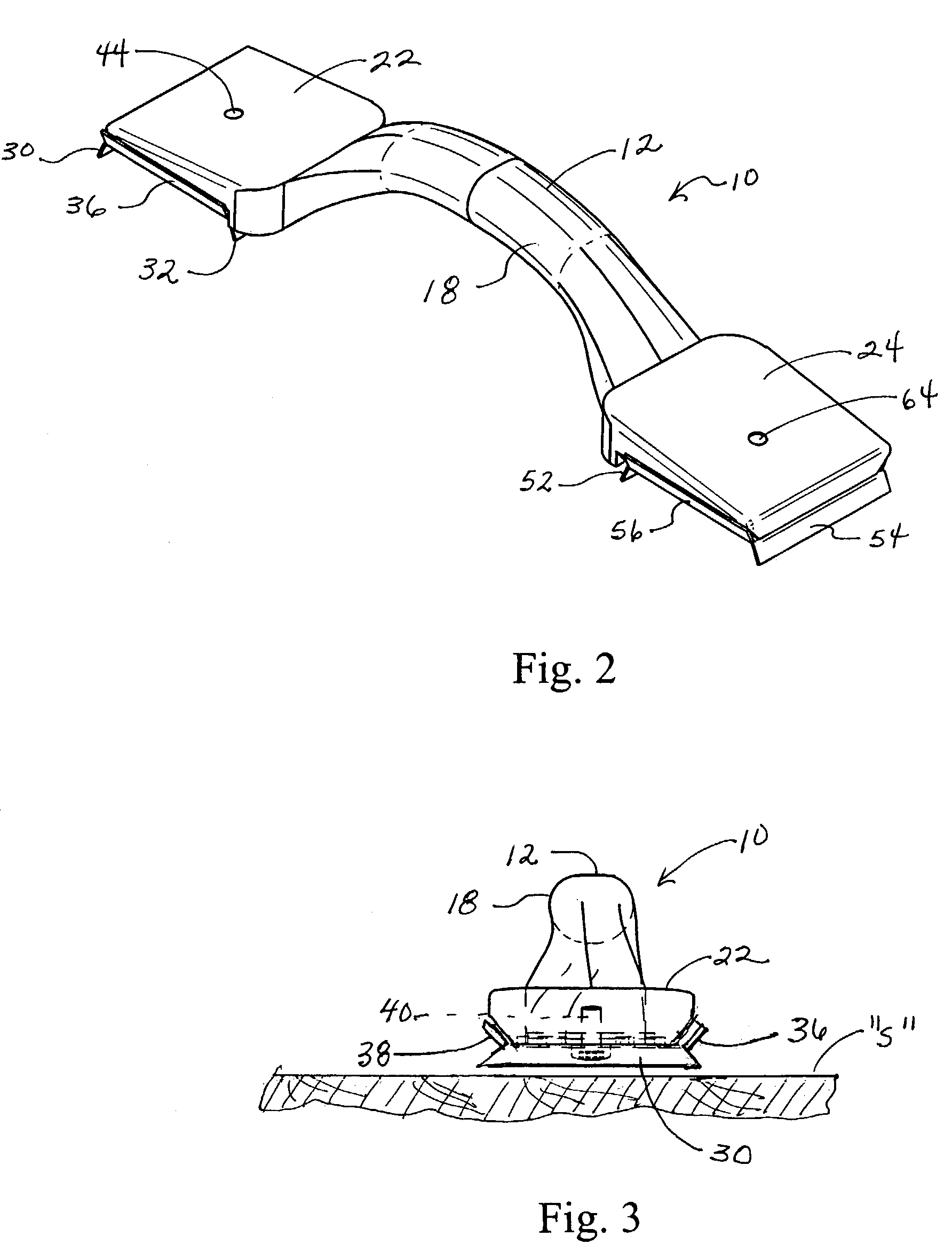

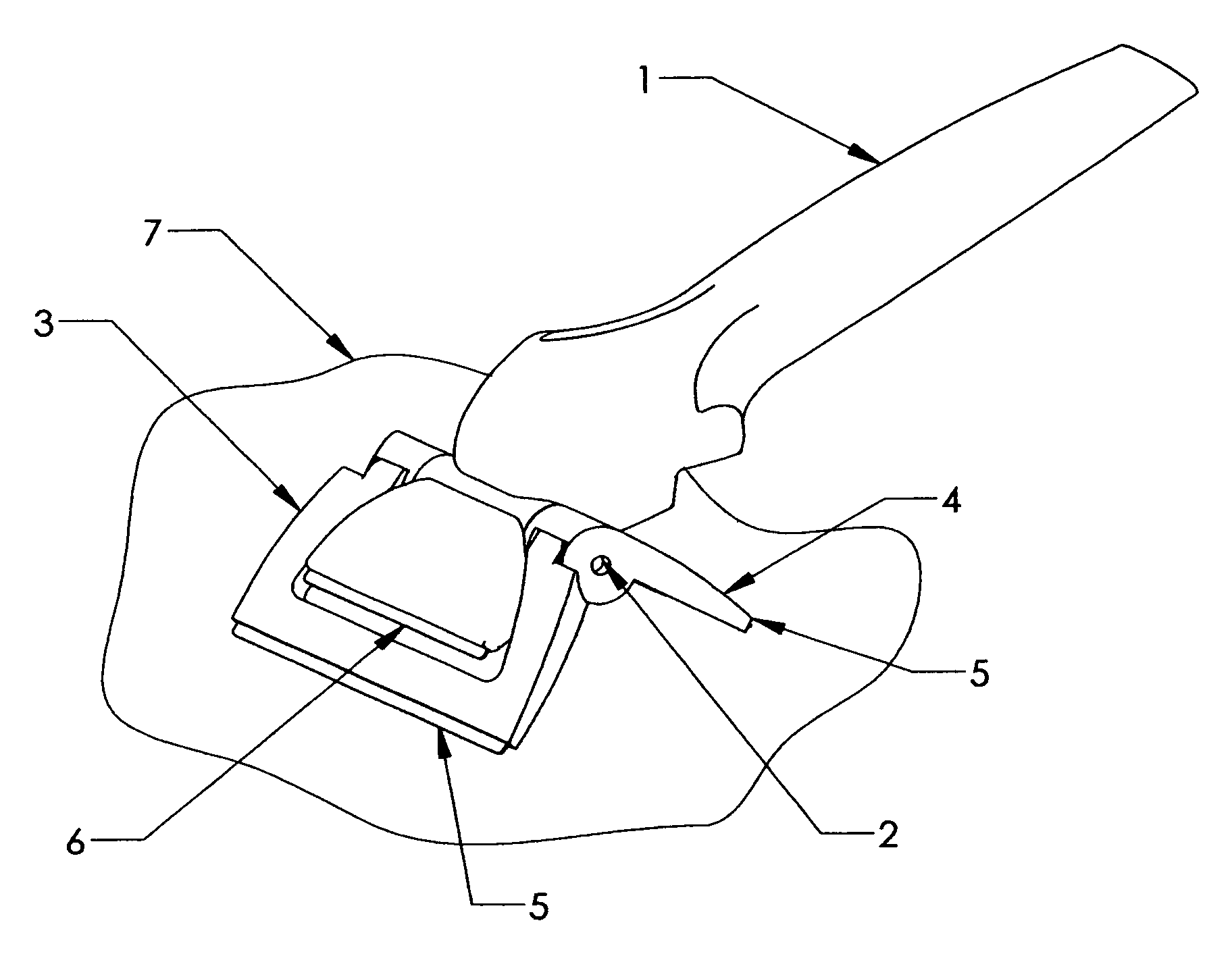

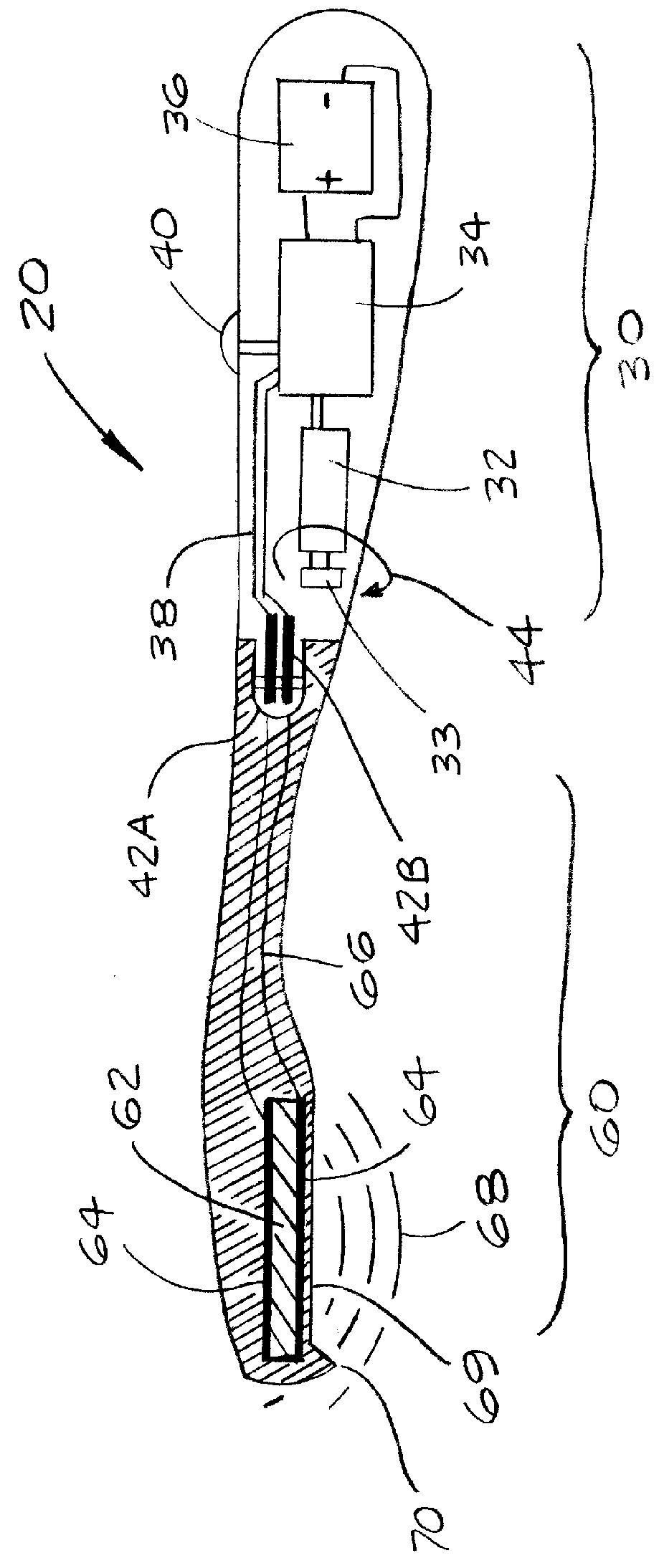

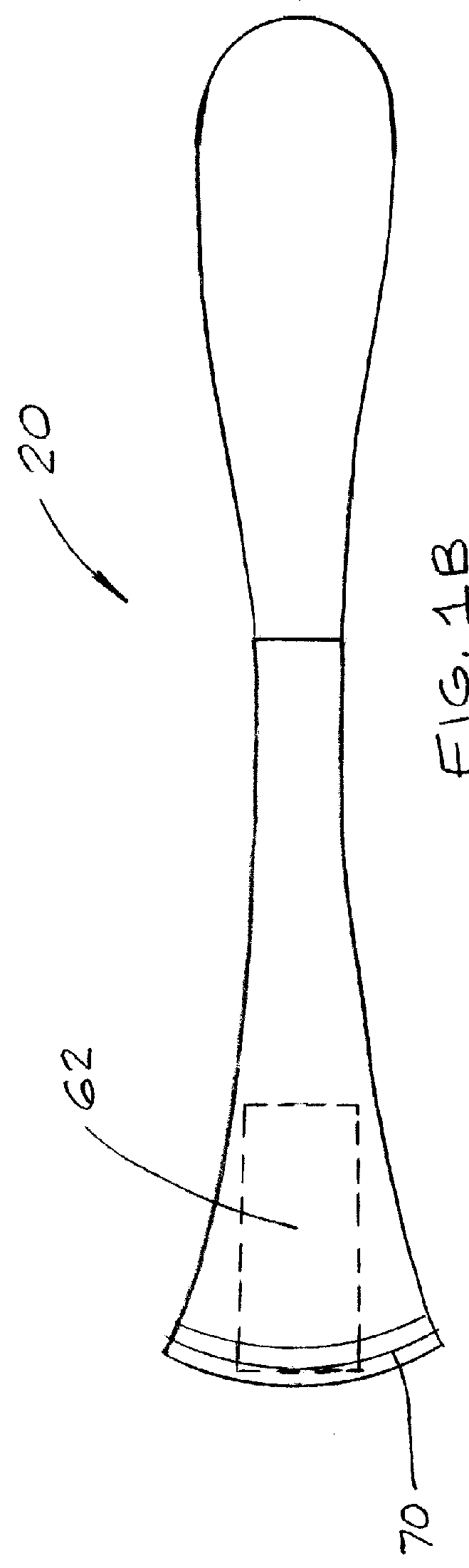

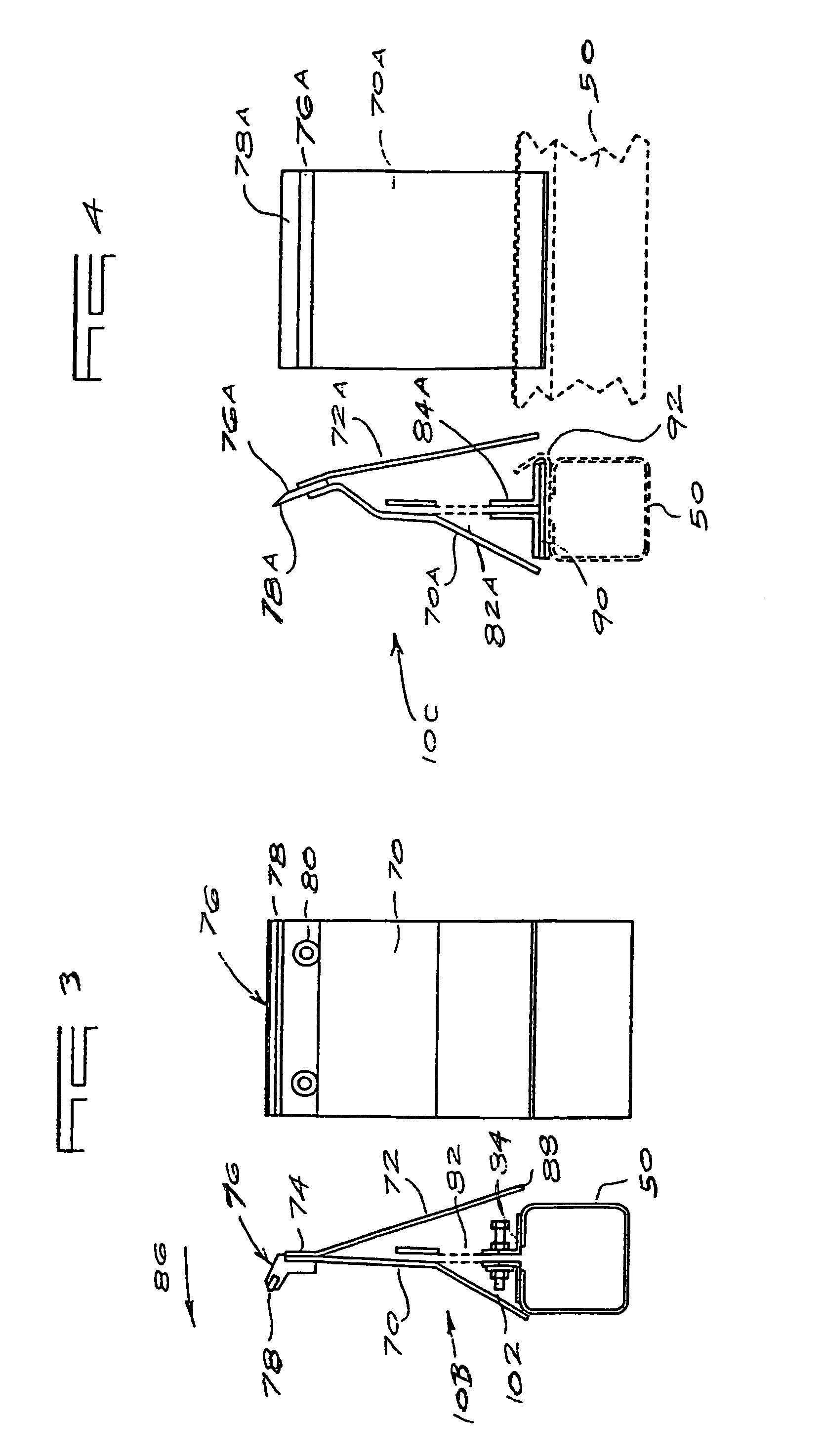

Push and pull shock absorbing scraper

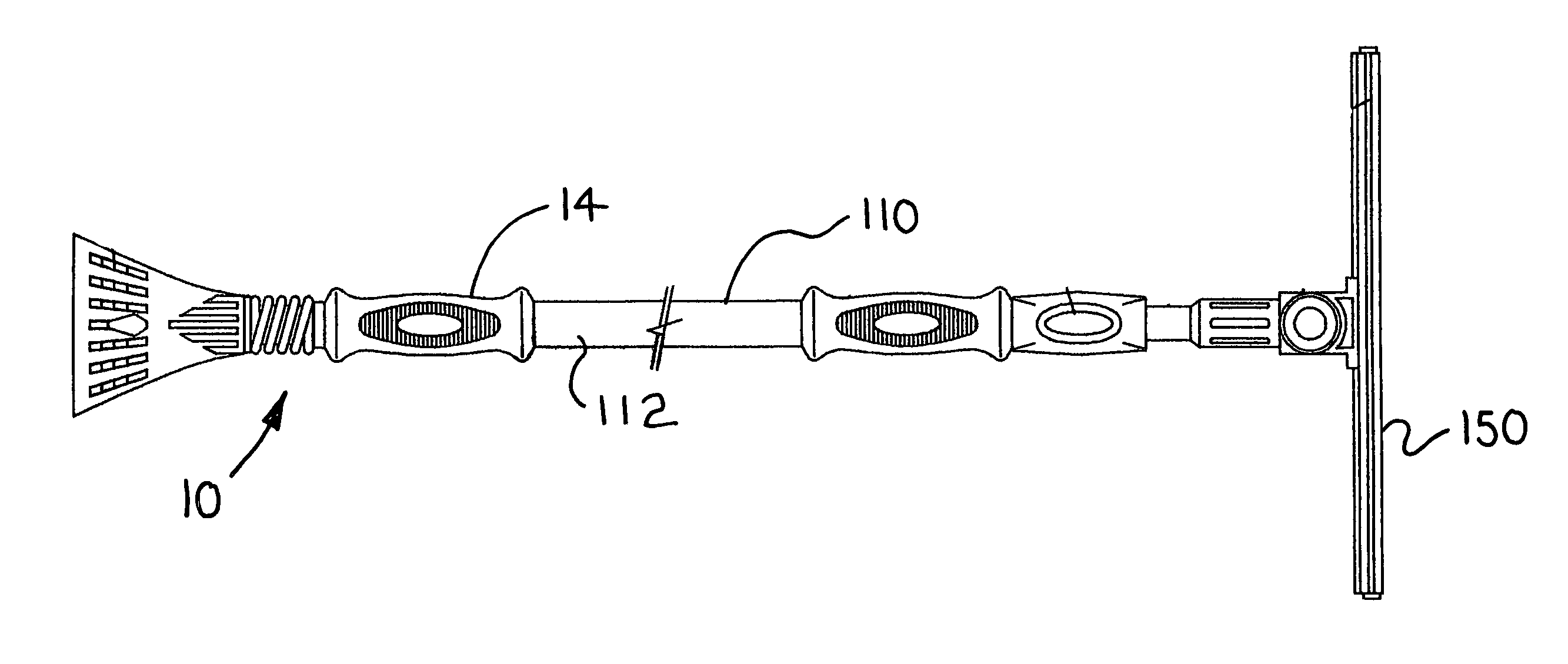

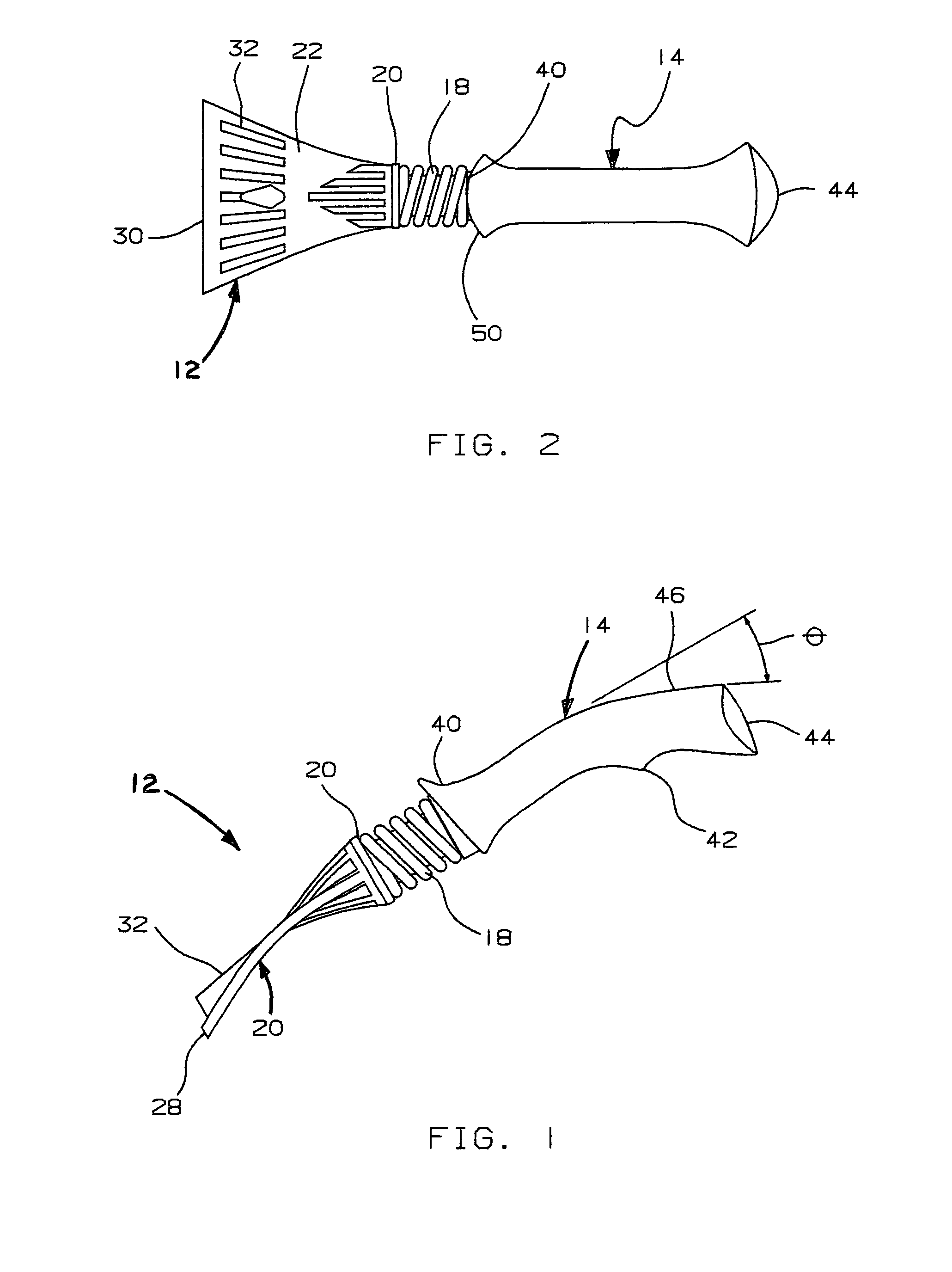

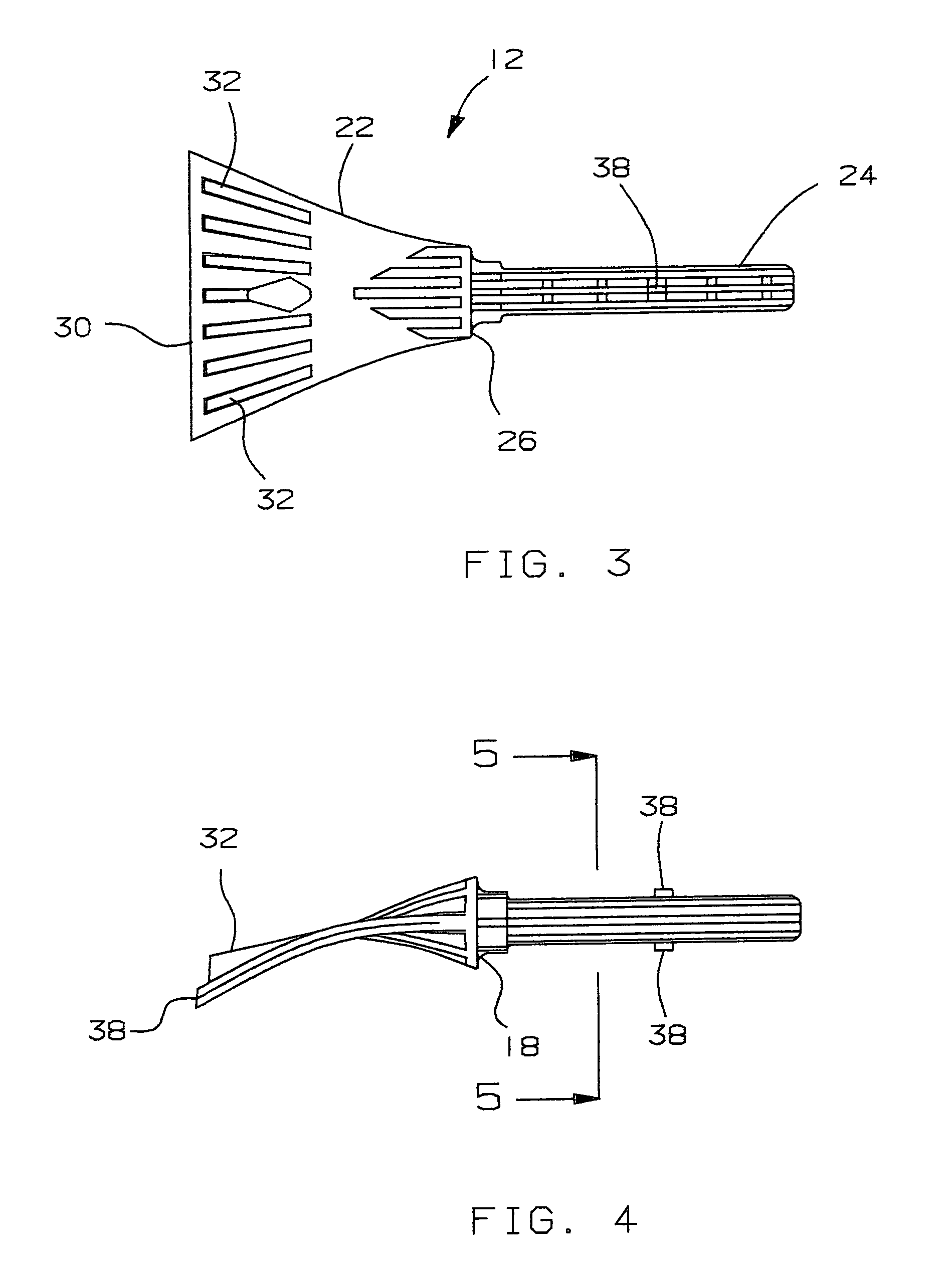

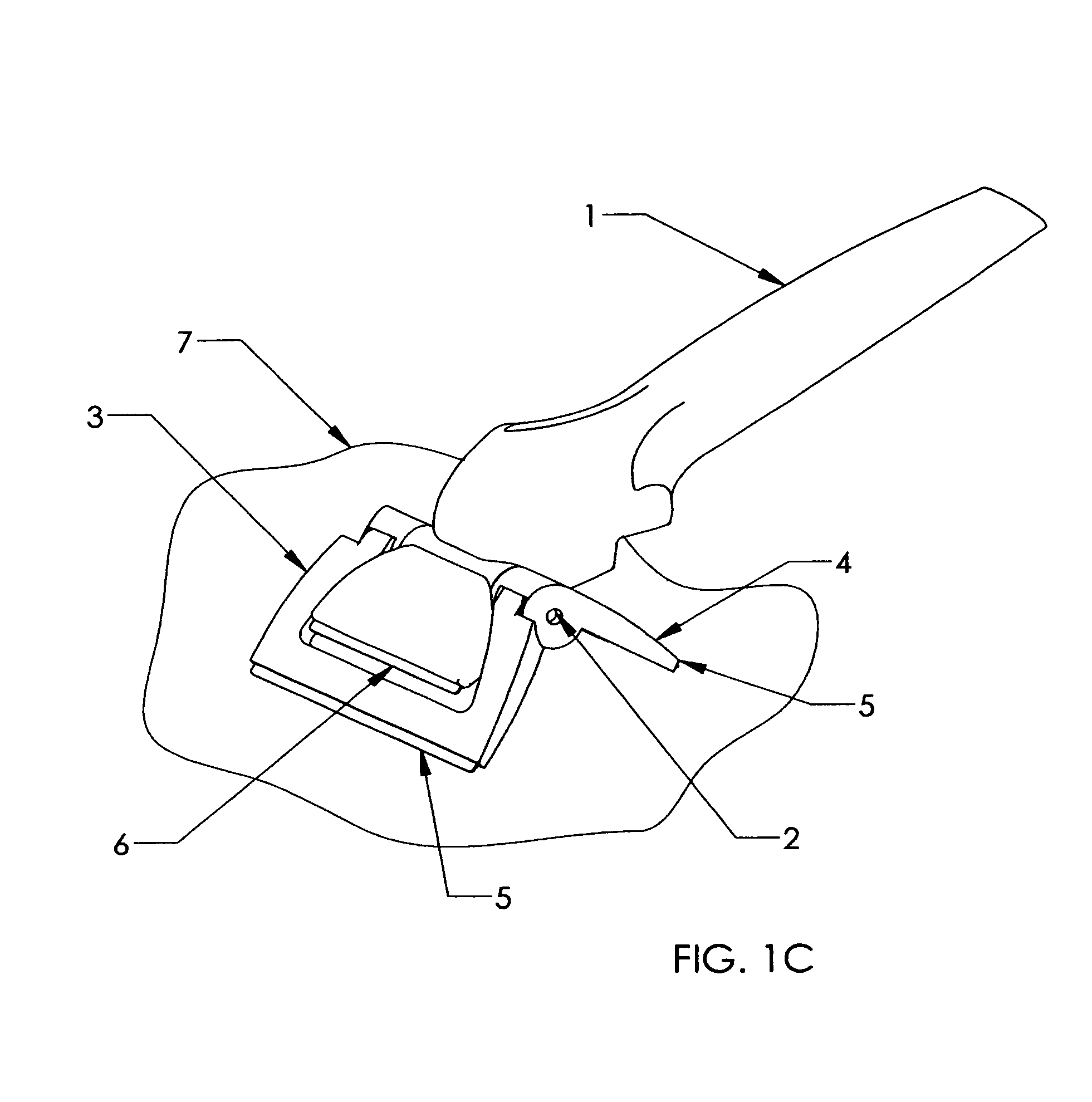

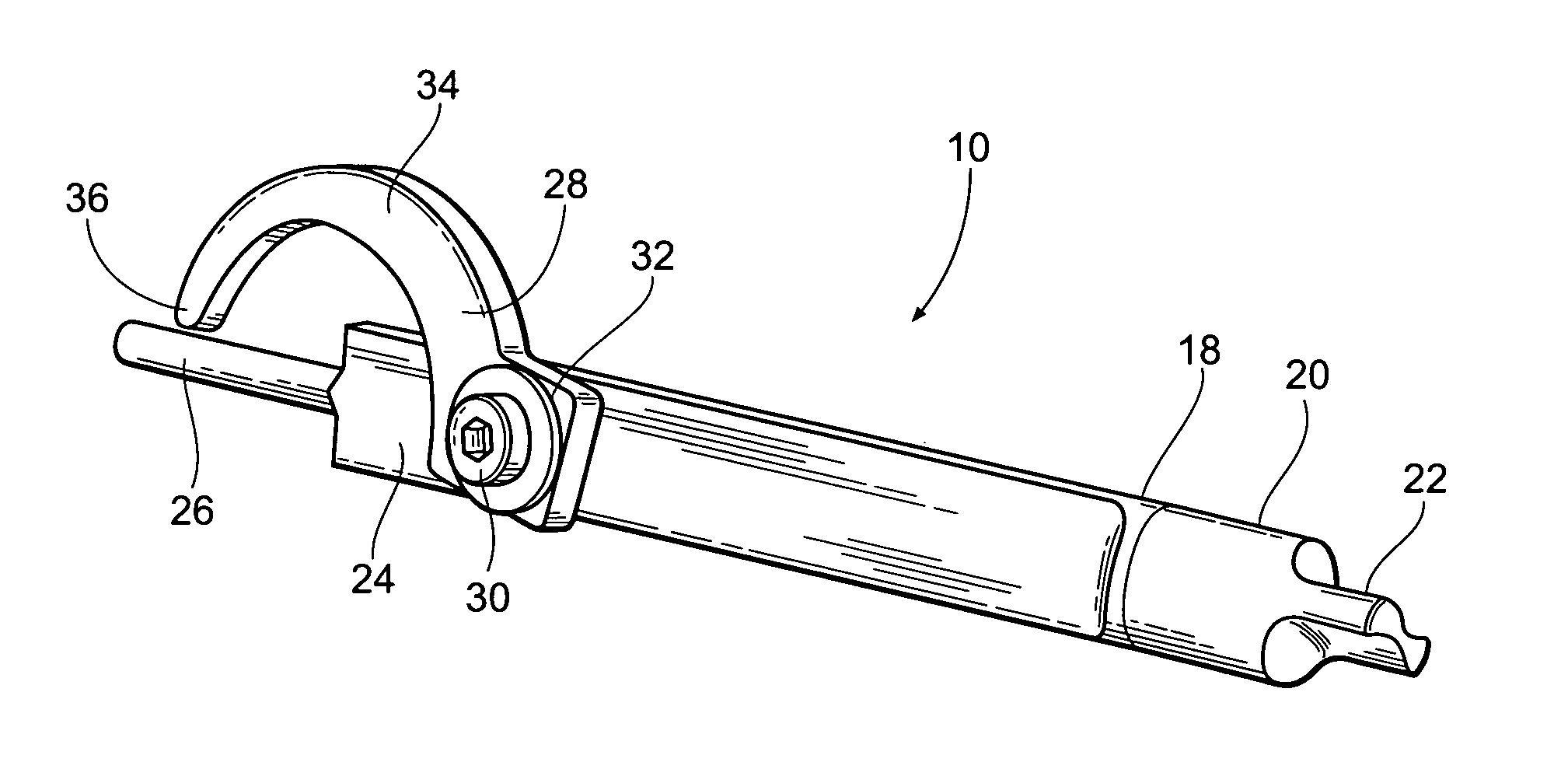

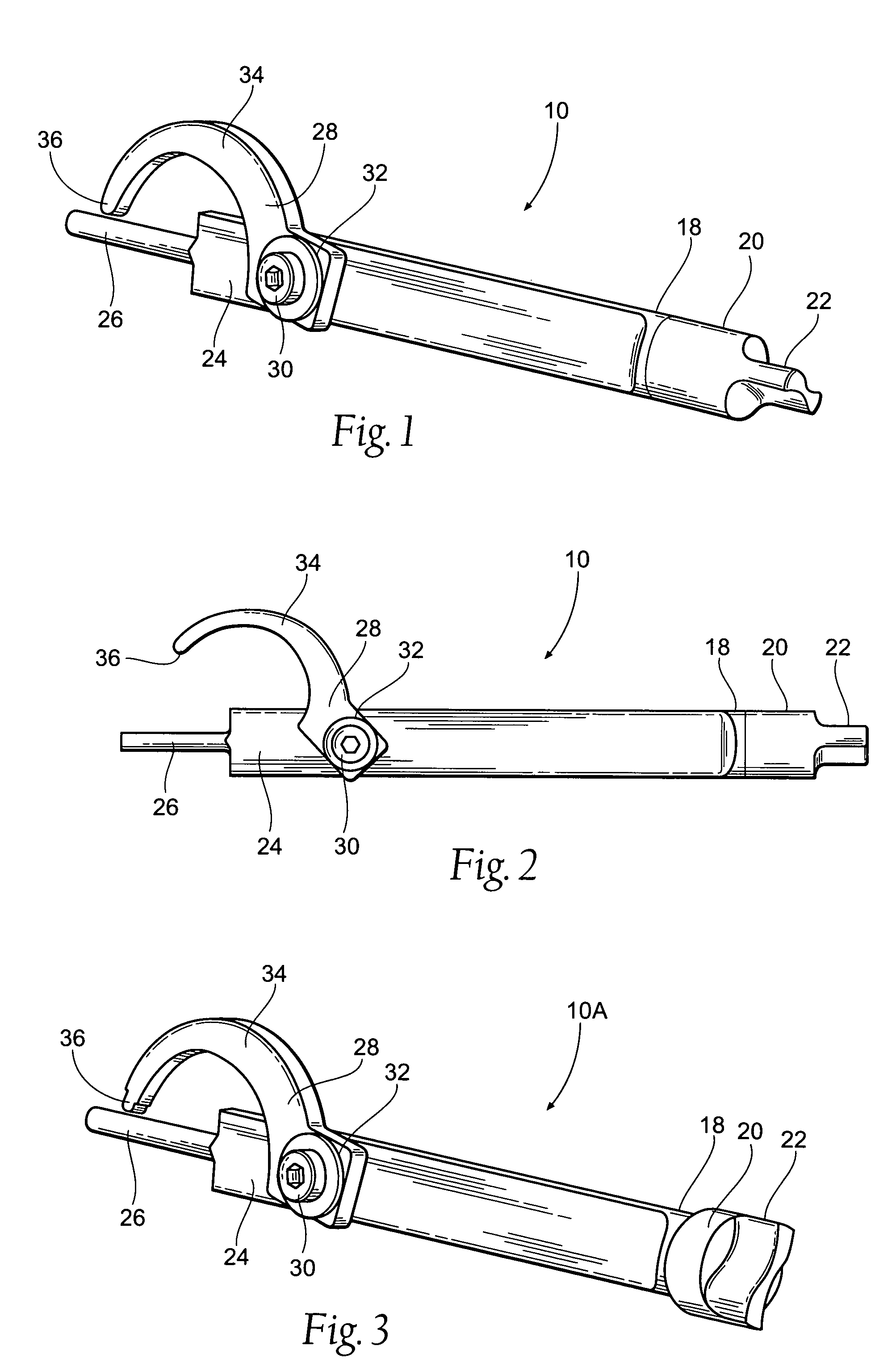

InactiveUS8312589B1Avoid injuryEasy to useLiquid surface applicatorsCarpet cleanersScraping - actionPush and pull

A push and pull shock absorbing scraper for selective scraping by a push and pull action includes an upper and lower scraper members for scraping ice, snow and frost from windows of a vehicle. The upper scraper member includes a head portion and a shaft portion, where head portion has a scraper blade. The lower scraper member is attached to the shaft portion of the upper scraper member to provide a double push scraping action. The lower scraper member includes a flexible front push blade, a rear pull blade and an attachment portion, where the attachment portion is attached to the shaft portion of the upper scraper member. The handgrip has a bore, where the insert is press-fitted within the bore of the handgrip and a pair of opposite protruding tabs extending outward for preventing transverse movement of the shaft portion of the scraper within the bore of the handgrip. The coil spring is located between the head portion and the handgrip for absorbing the impact force of the reciprocation movement of the head portion of the scraper. The O-ring is located between the head portion and the coil spring to further absorbs the impact force of the head portion of the scraper.

Owner:D2RM CORP

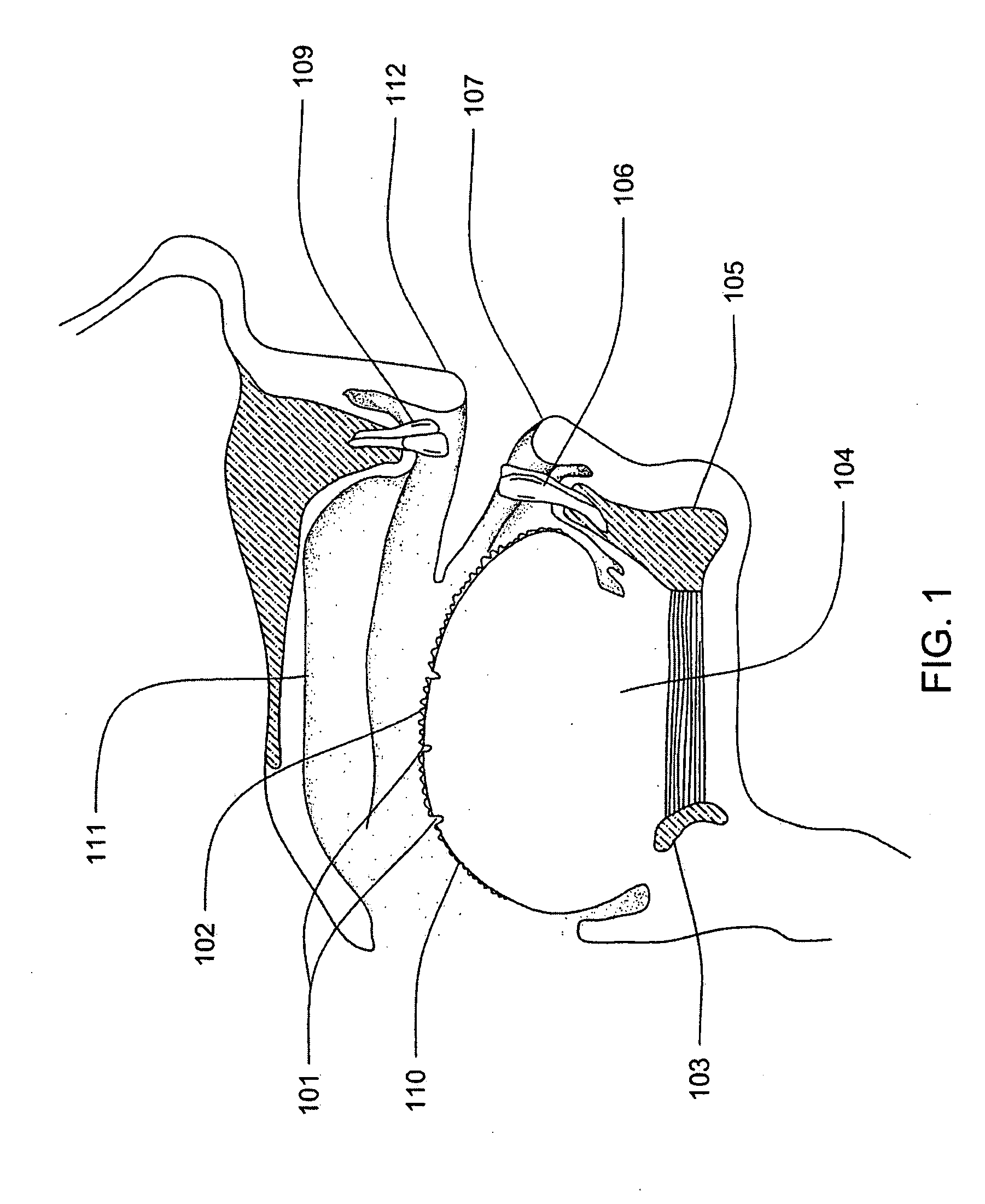

Tongue cleaning apparatus

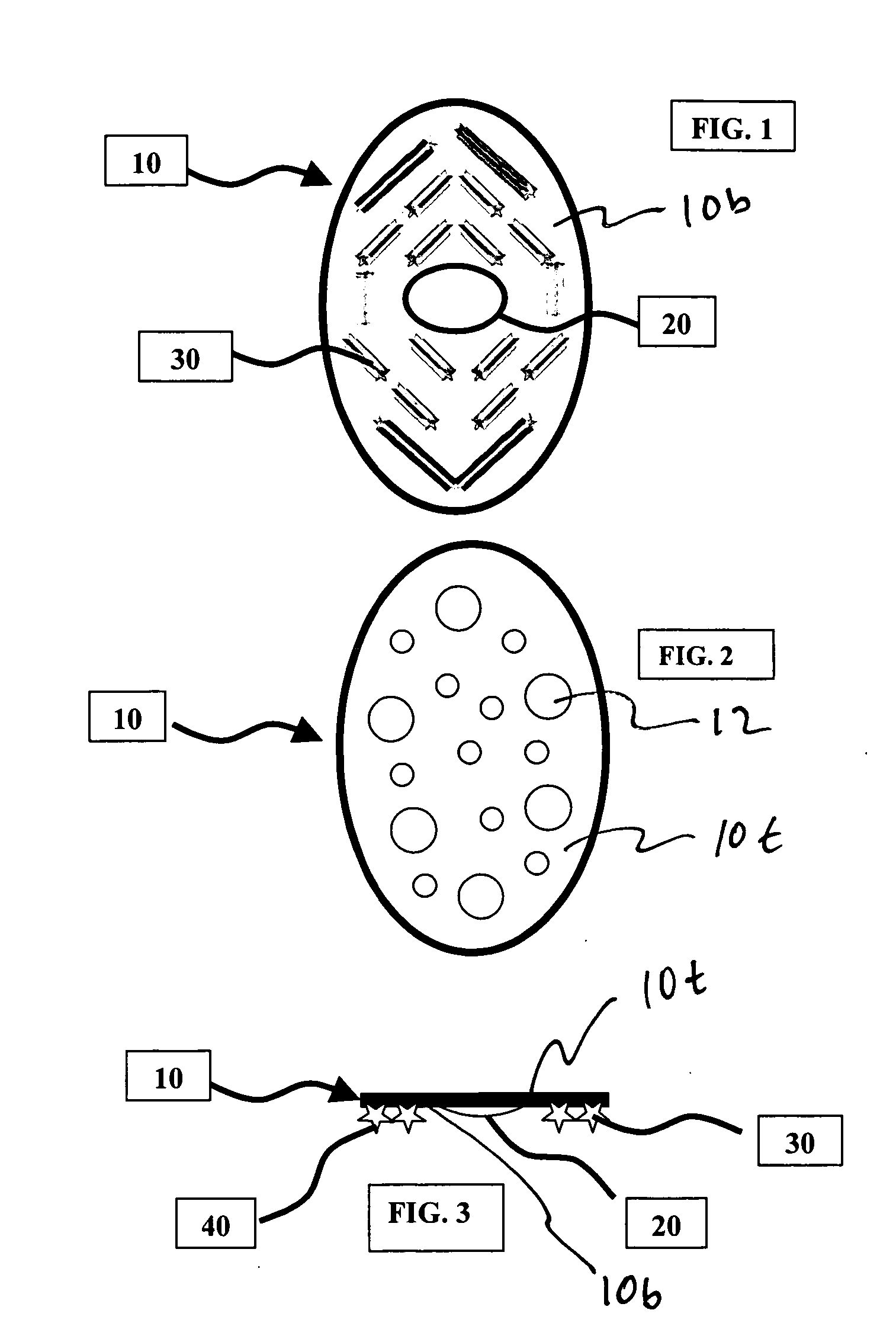

InactiveUS20060222683A1Effective tongue scraping actionImprove adhesionPharmaceutical delivery mechanismTongue cleaningScraping - action

The present invention is a dissolvable candy which provides effective tongue scraping action. The candy is a soft pliable edible dissolvable candy material, such as a GUMMI-BEAR type confection, having a generally oval shape. A plurality of segments are formed with hard candy in one surface of the soft candy. Preferably, the segments have raised ridges which are suitable for abrading the tongue. A blister have a freshening agent is formed on the same side as the hard candy segments. A plurality of depressions are formed in another side of the soft candy to facilitate adhering the soft candy to the roof of the mouth.

Owner:MYTHEN DANIEL RICHARD

Scraper

A wood scraper having two oppositely angled blades on a single head, and preferably two heads with two oppositely angled blades on each head. Thus, on both the forward and reverse stroke, there are two spaced apart blades scraping the work piece. This covers twice the surface area with the same effort as a single-bladed or single-headed scraper. All the blades are rigid and have a straight edge. All the blade edges are aligned with the planar surface of the work piece. This produces a level cut and makes the tool more stable, making gouging unlikely and enhancing the efficiency of the scraping action. The tool can be operated easily with one hand. In addition, the use of straight blades allows all the blades to be sharpened easily and quickly and at the same time using a belt sander or on a sheet of emery paper on a flat surface.

Owner:BRANDON L D

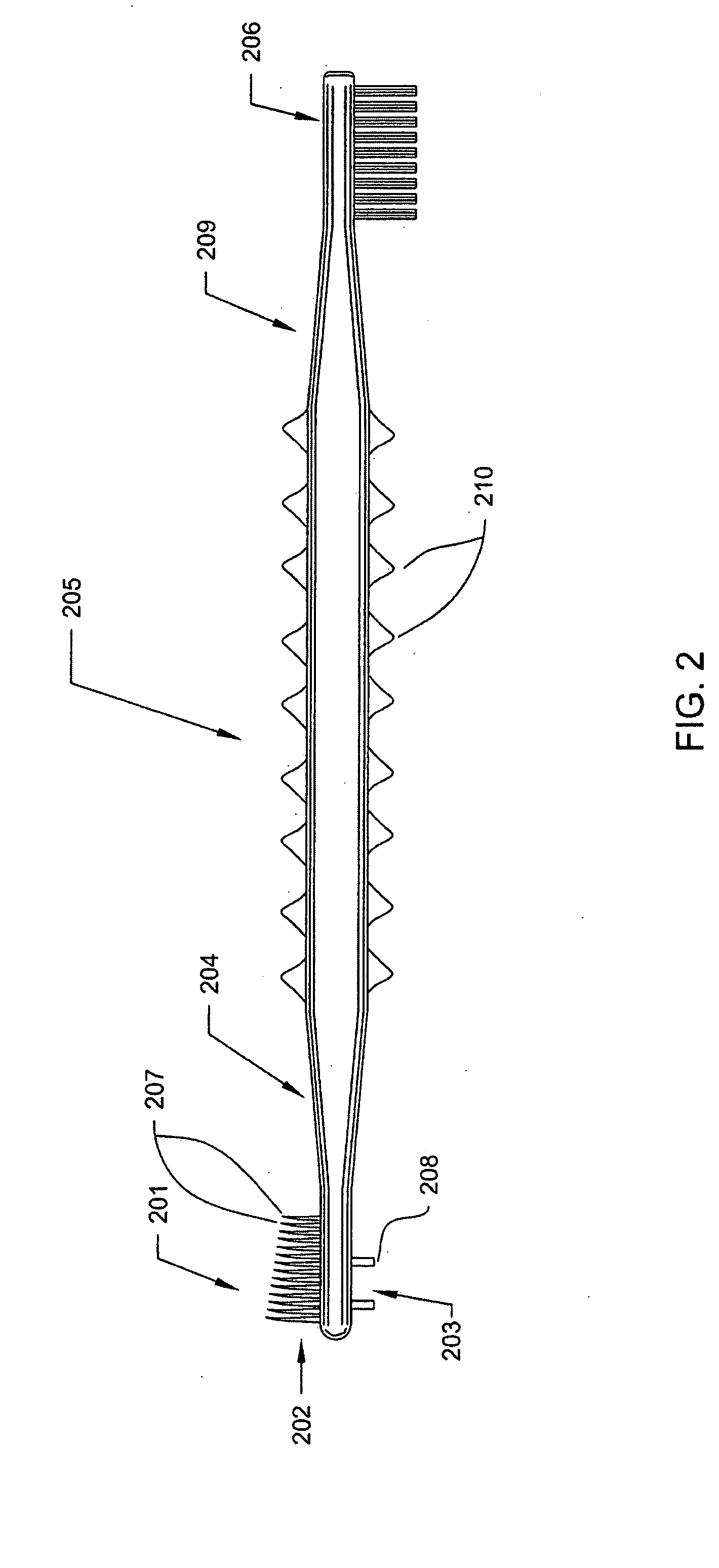

Tongue cleaning device

Devices for cleaning the human tongue and methods for making such devices are disclosed. The tongue cleaner may include a tongue brush and a tongue scraper. The tongue cleaner may be of unitary injection molded construction. The tongue cleaner bristles may be tapered to a point for cleaning crevices of a human tongue, and the bristles may be angled or curved. The tongue scraper contains at least one blade for removal of undesirable material from the tongue by a scraping action. The tongue brush and tongue scraper may be combined into one unit or may be made and used separately.

Owner:DR BOBS

Two blade scraping device

InactiveUS7913349B2Easy to storeEfficiency advantageLiquid surface applicatorsCarpet cleanersPush and pullScraping - action

A hand-held scraper device containing a stowable multi blade pivoting head. The pivoting head is comprised of at least two scraping elements which remain at a fixed angle relative to each other while still allowing a pivoting action of the head assembly independently from the handle. The angle of the scraping elements relative to each other is set such that as the two scraping elements are jointly presented against the work surface they will be maintained at an angular attitude conducive to a scraping action in both a push and pull direction. The pivoting head can be collapsed for more efficient stowage or as an alternate configuration for specific scraping applications.

Owner:BYRNES JAMES MICHAEL

Firearm cleaning tool and method of using

InactiveUS20100186769A1Easy to manufactureDurable and reliable constructionHollow article cleaningHair combsScraping - actionEngineering

A firearm cleaning tool and method of use is disclosed in which multiple firearm components may be cleaned using a single tool. The tool includes cutting or scraping edges to ream residue, such as carbon deposits through a scraping action. The proximal end includes a scraping head with a scraping edge, and the distal end includes pivotable scraper arm and longitudinally extending insertion pin. A method of use is also contemplated.

Owner:MAGNA MATIC CORP

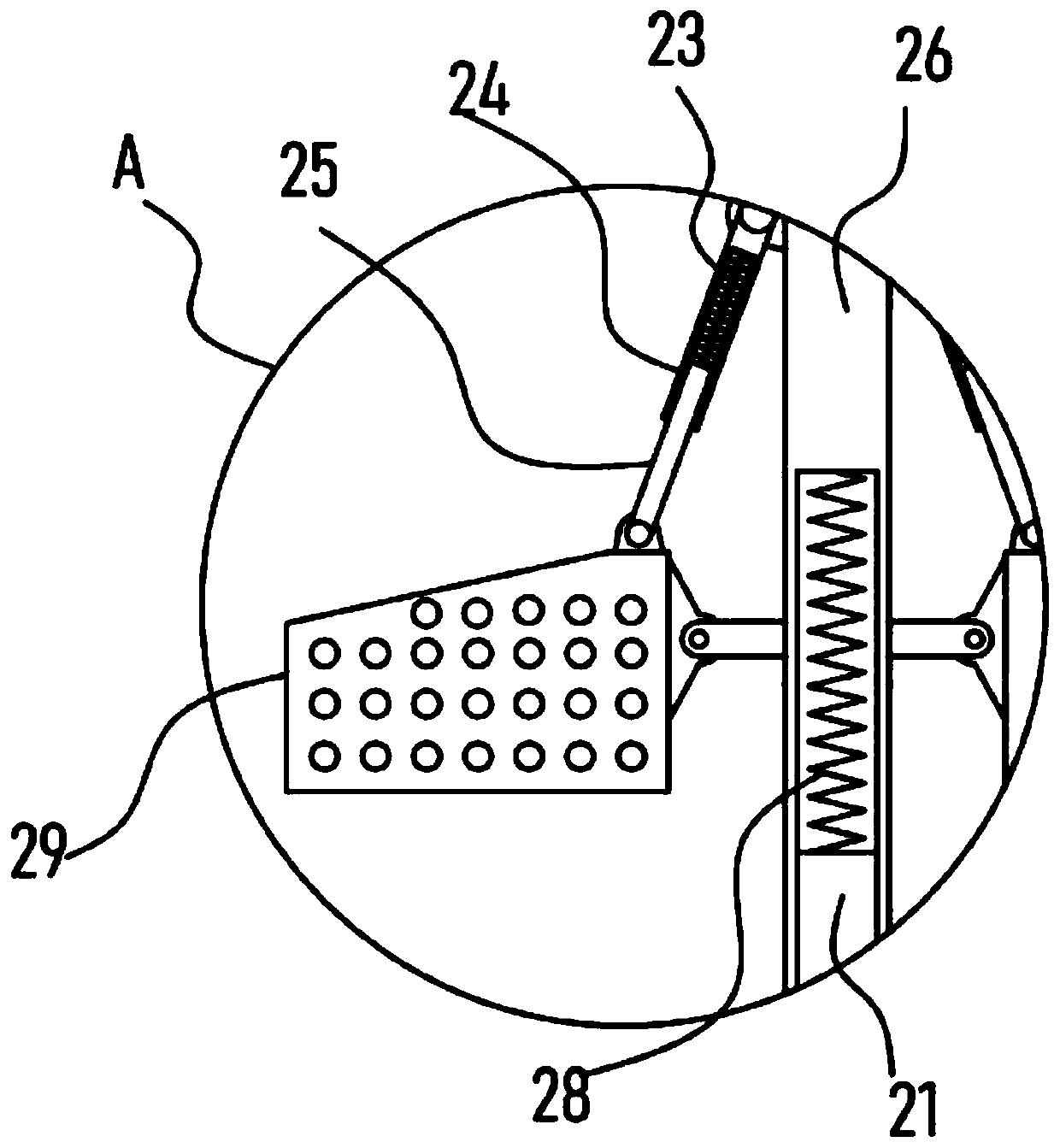

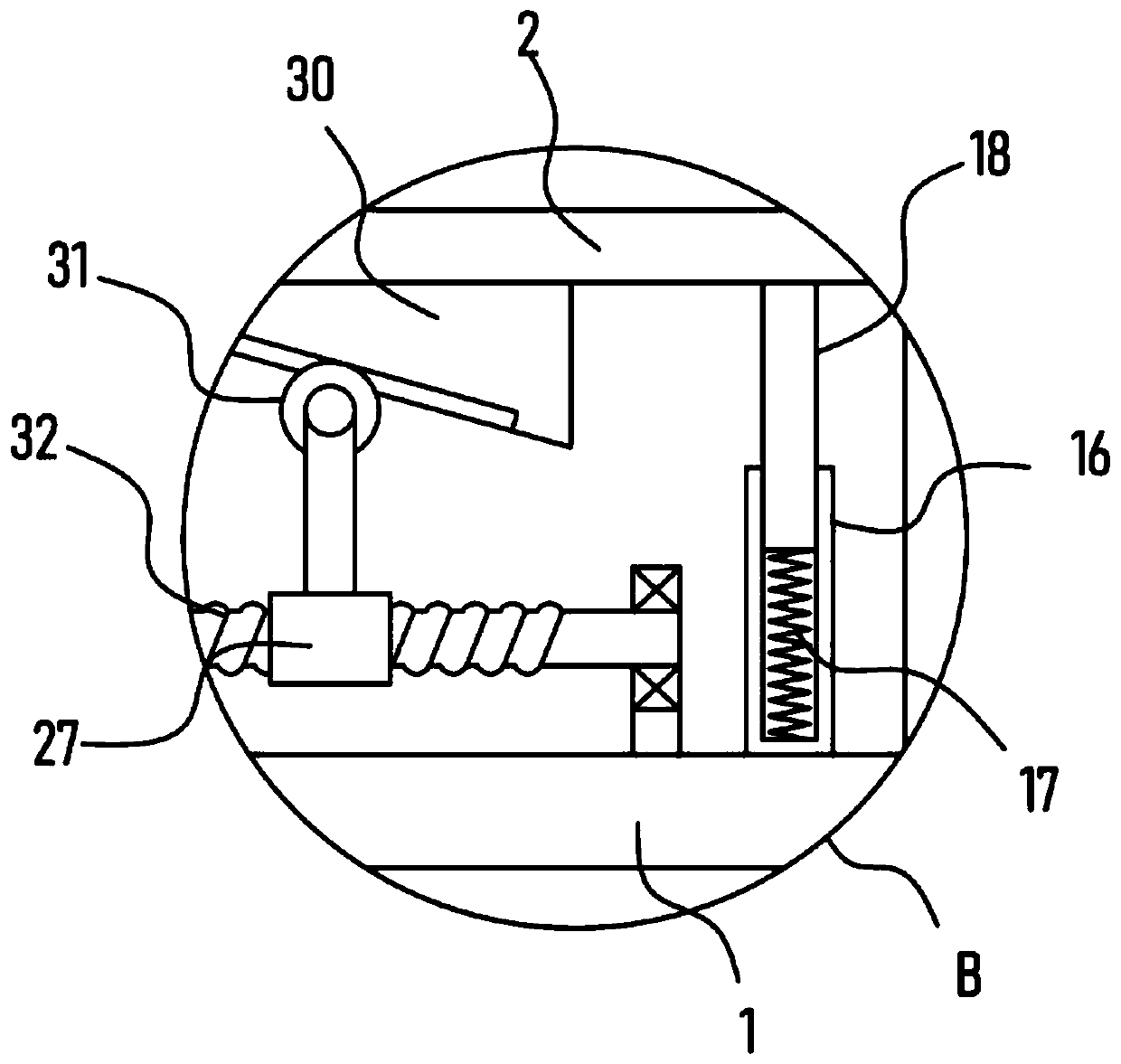

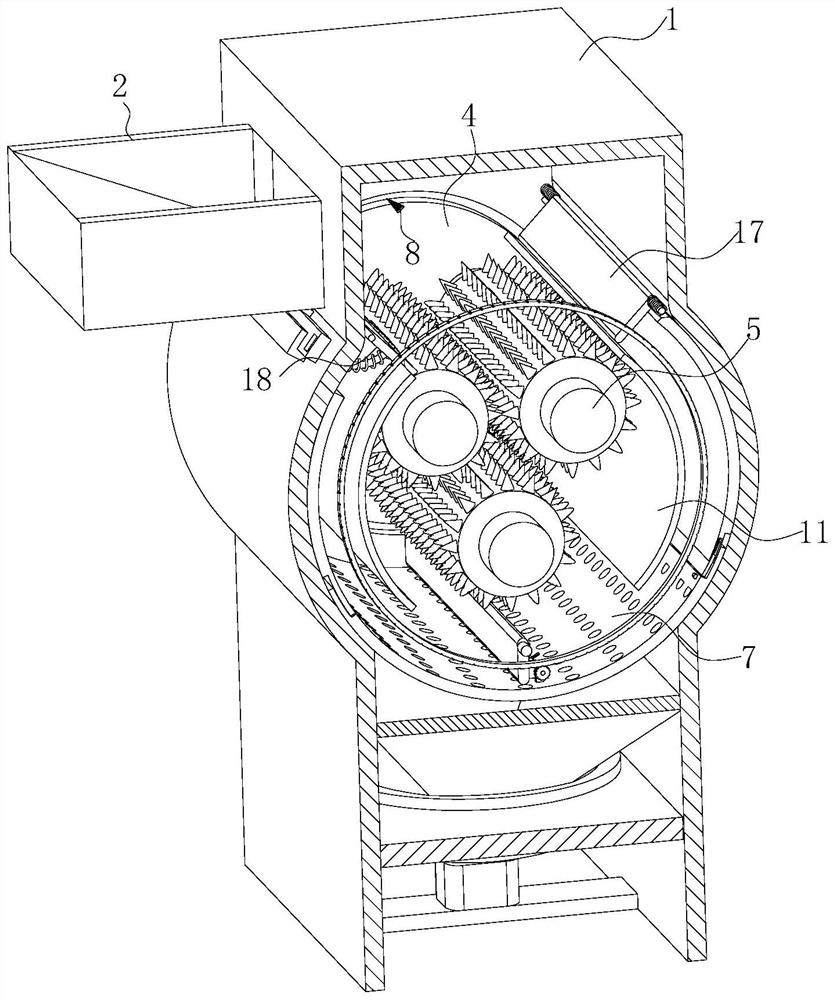

Drying equipment with grinding function for material conveying device

PendingCN110606644AEasy to dryEfficient dryingSludge treatment by de-watering/drying/thickeningScraping - actionReciprocating motion

Drying equipment with a grinding function for a material conveying device comprises a heat supply module, a drying chamber and the material conveying device arranged in the drying chamber. The dryingchamber is provided with a heat source inlet, a heat source outlet, a feeding port and a discharging port. A heat outlet point of the heat supply module is arranged at the heat source inlet and used for providing a heat source for the drying chamber. The material conveying device is used for providing a platform for flatly laying materials and pushing the materials; the material conveying device is provided with a material grinding device, the material grinding device is driven by a first driving device to do reciprocating motion, and a certain angle is formed between the material grinding device and the pushing direction of the materials, so that the materials on the platform are ground, flattened, extruded, sheared and scraped. In the material conveying process, the grinding device carries out grinding, smoothing, extruding, shearing and scraping actions on materials on the platform, the evaporation area of the materials is increased, drying is carried out more efficiently, and the equipment is also suitable for the materials which are high in water content and cannot be formed.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

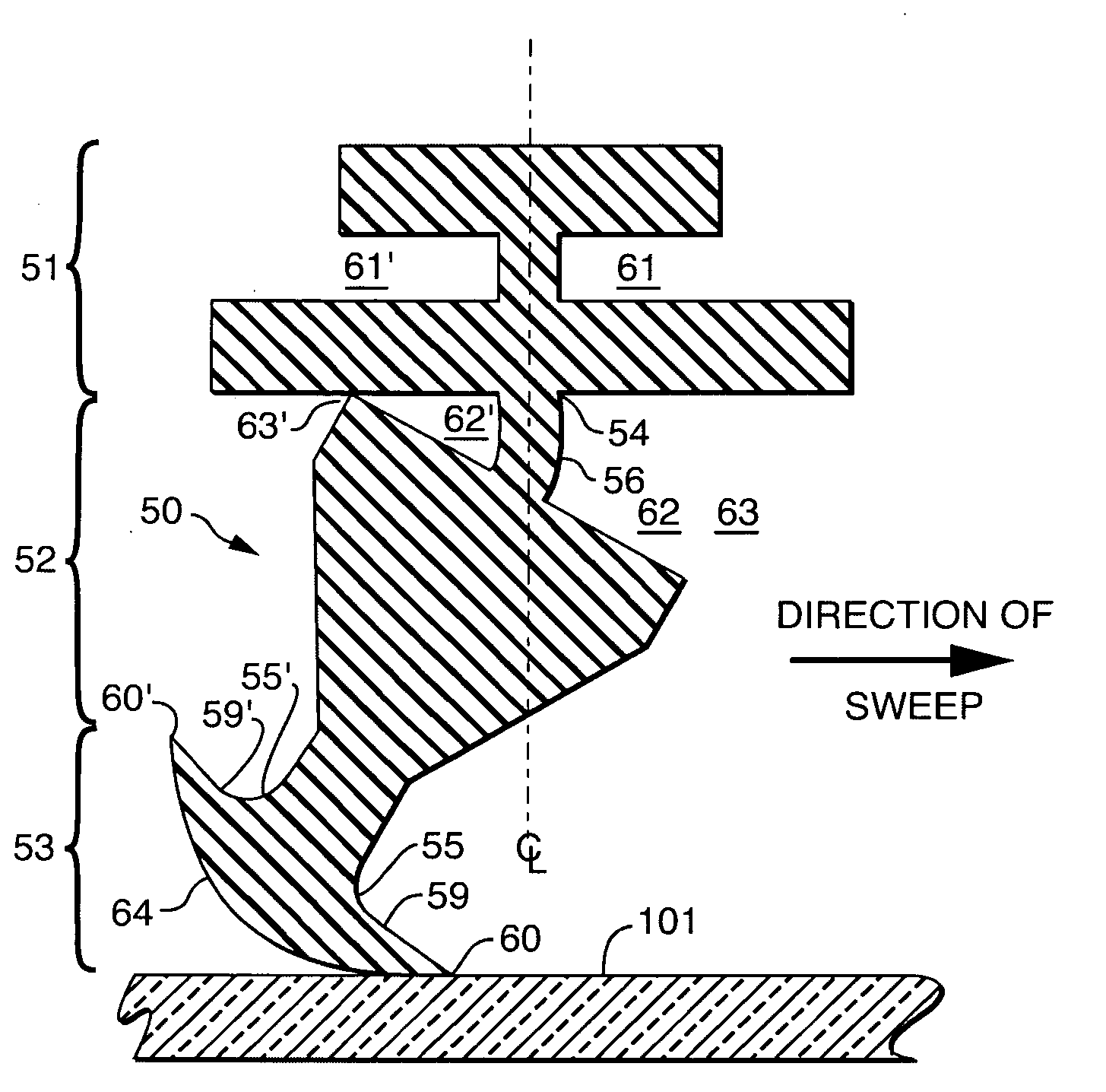

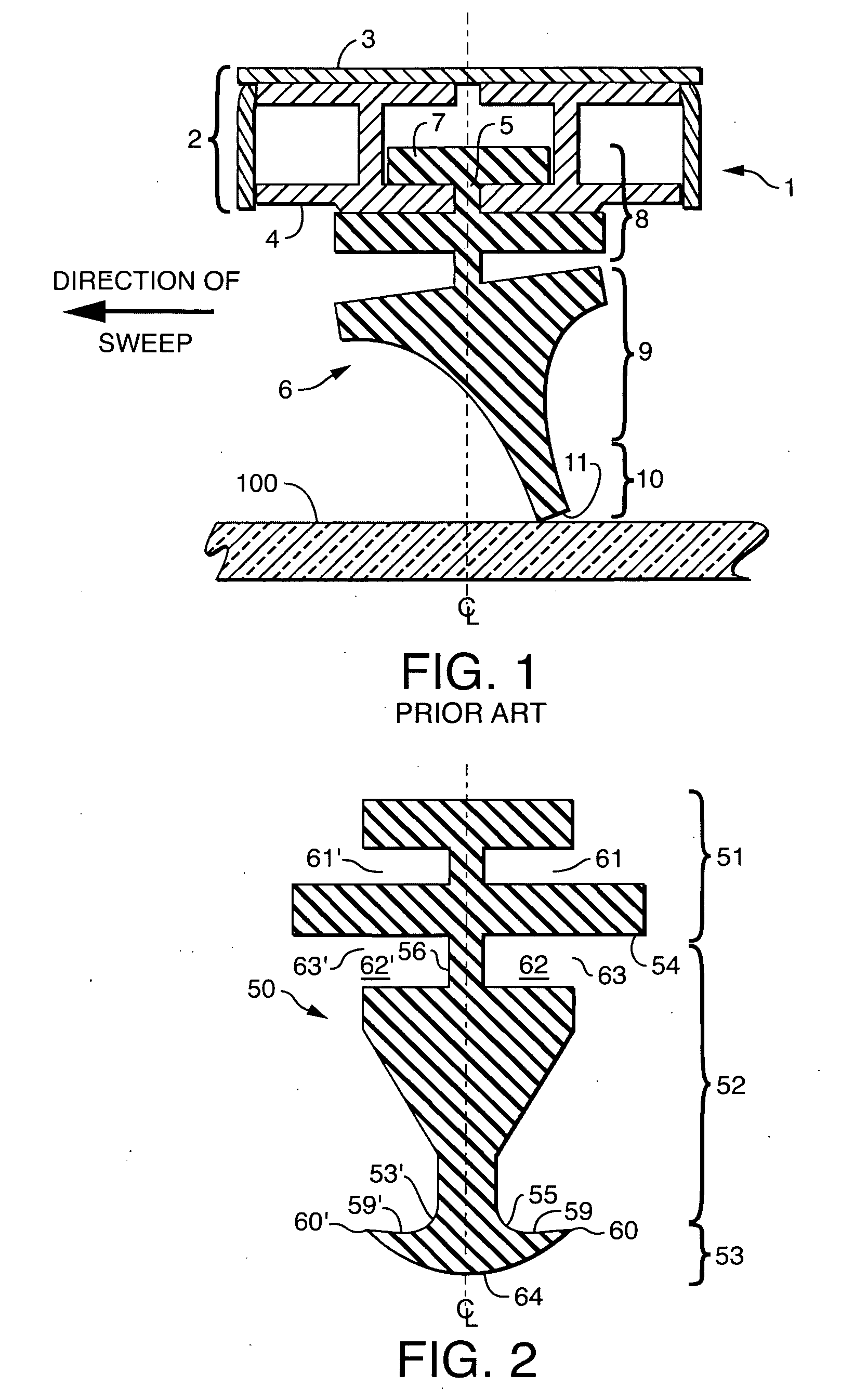

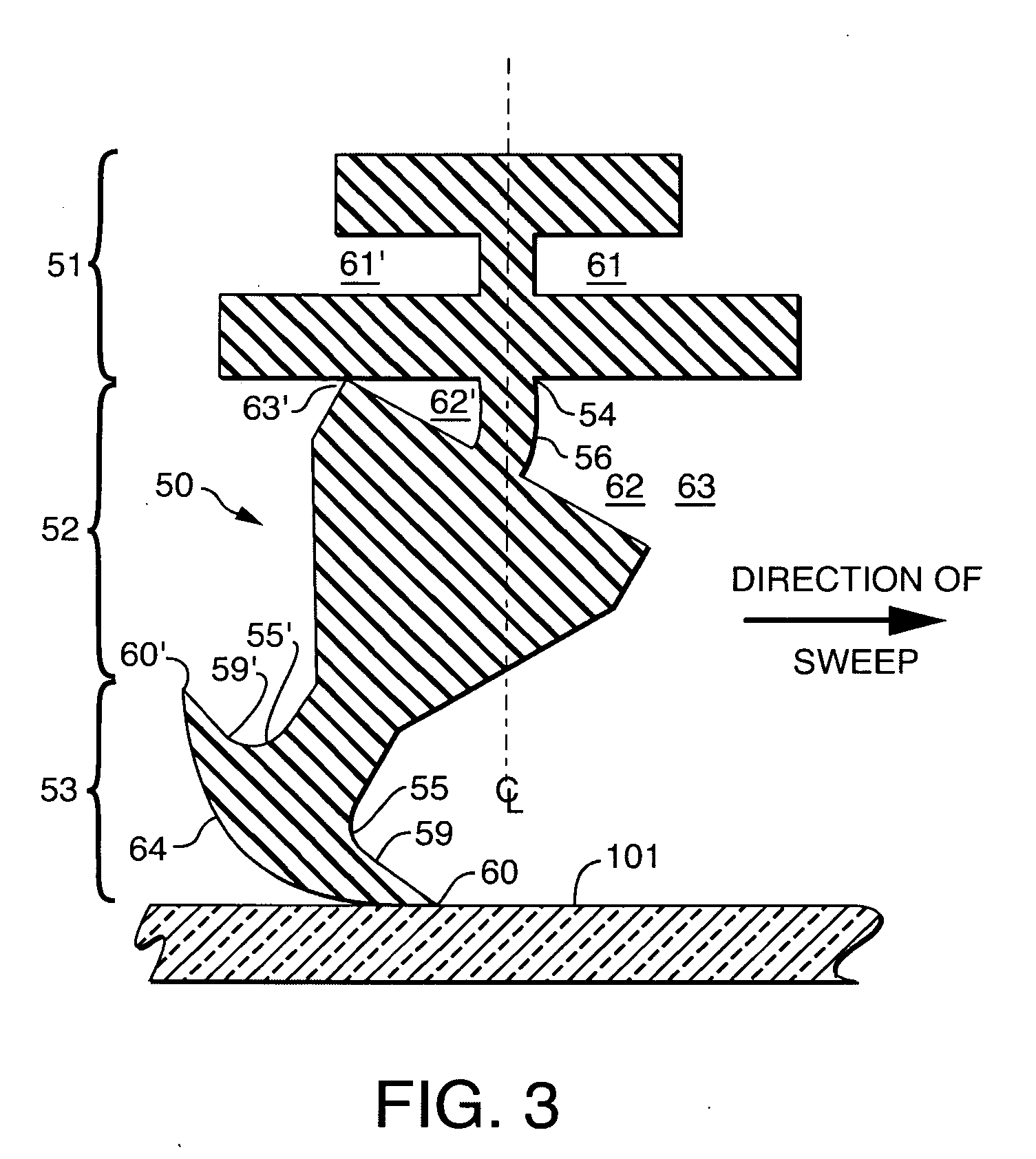

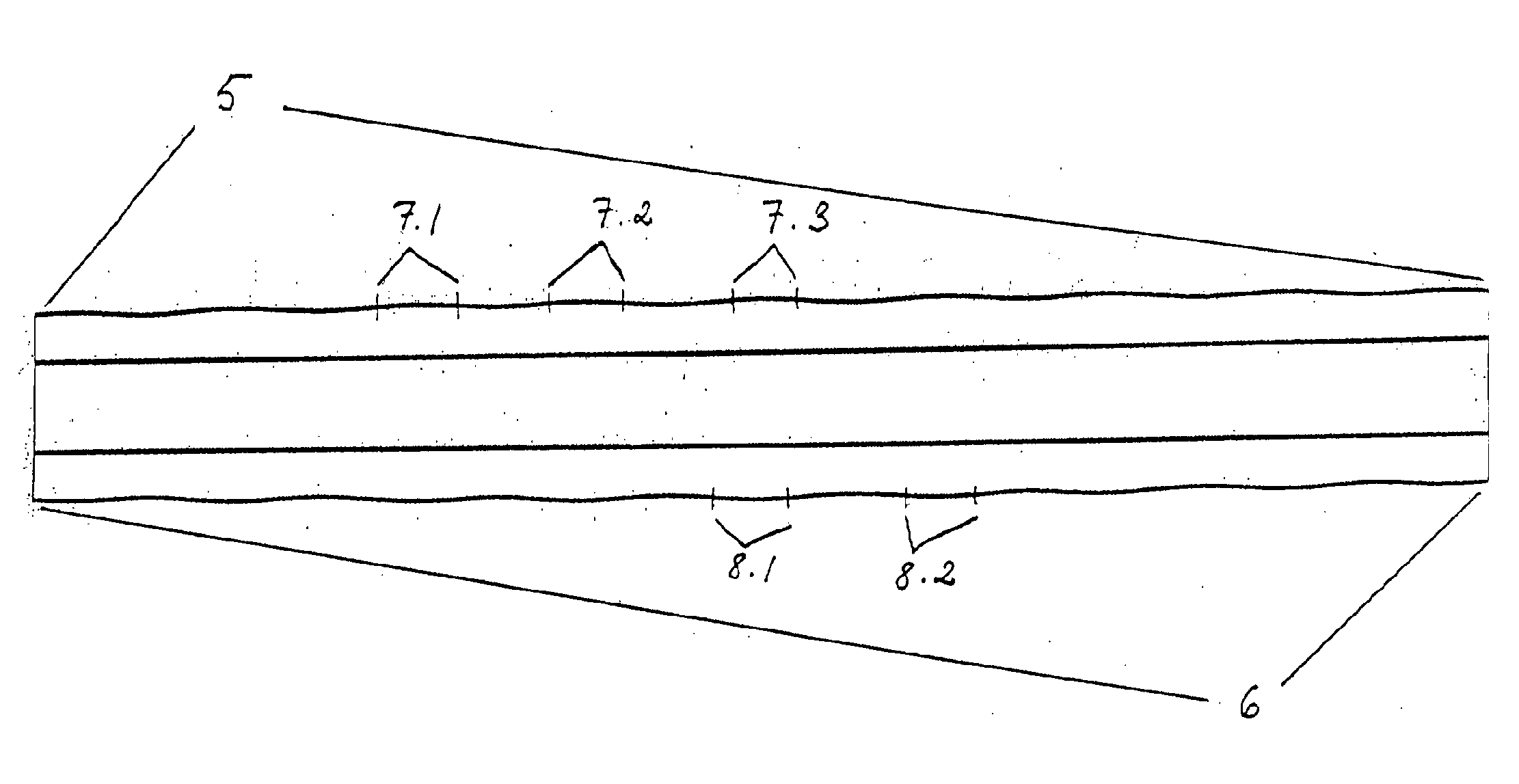

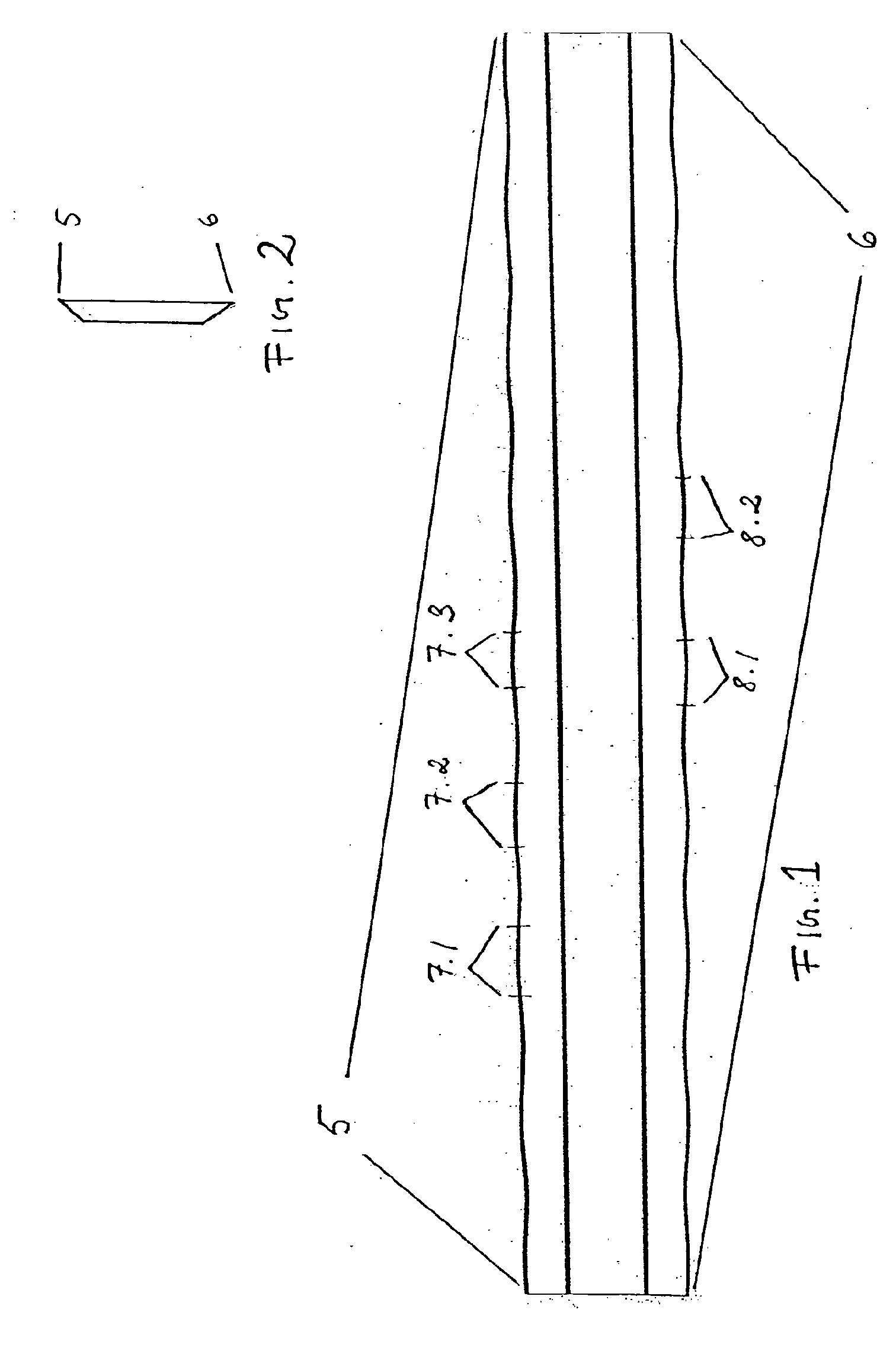

Windshield wiper blade element having improved anti-chatter properties

InactiveUS20090241282A1Extended service lifeWindow cleanersVehicle cleaningScraping - actionEngineering

Disclosed herein is a windshield wiper blade element having improved anti-chatter and cleansing properties. The elongate rubbery blade element has a pair of opposed channels to impart angular flexibility adjacent the blade root and a bottom edge section defining a squeegee element having the cross sectional geometry of a mature inverted mushroom cap. In use, the squeegee element having this geometry provides a beneficial scraping action during the cleansing sweep of the blade element over the glass surface, thereby aiding in the removal of soft detritus.

Owner:MARC MICHEL

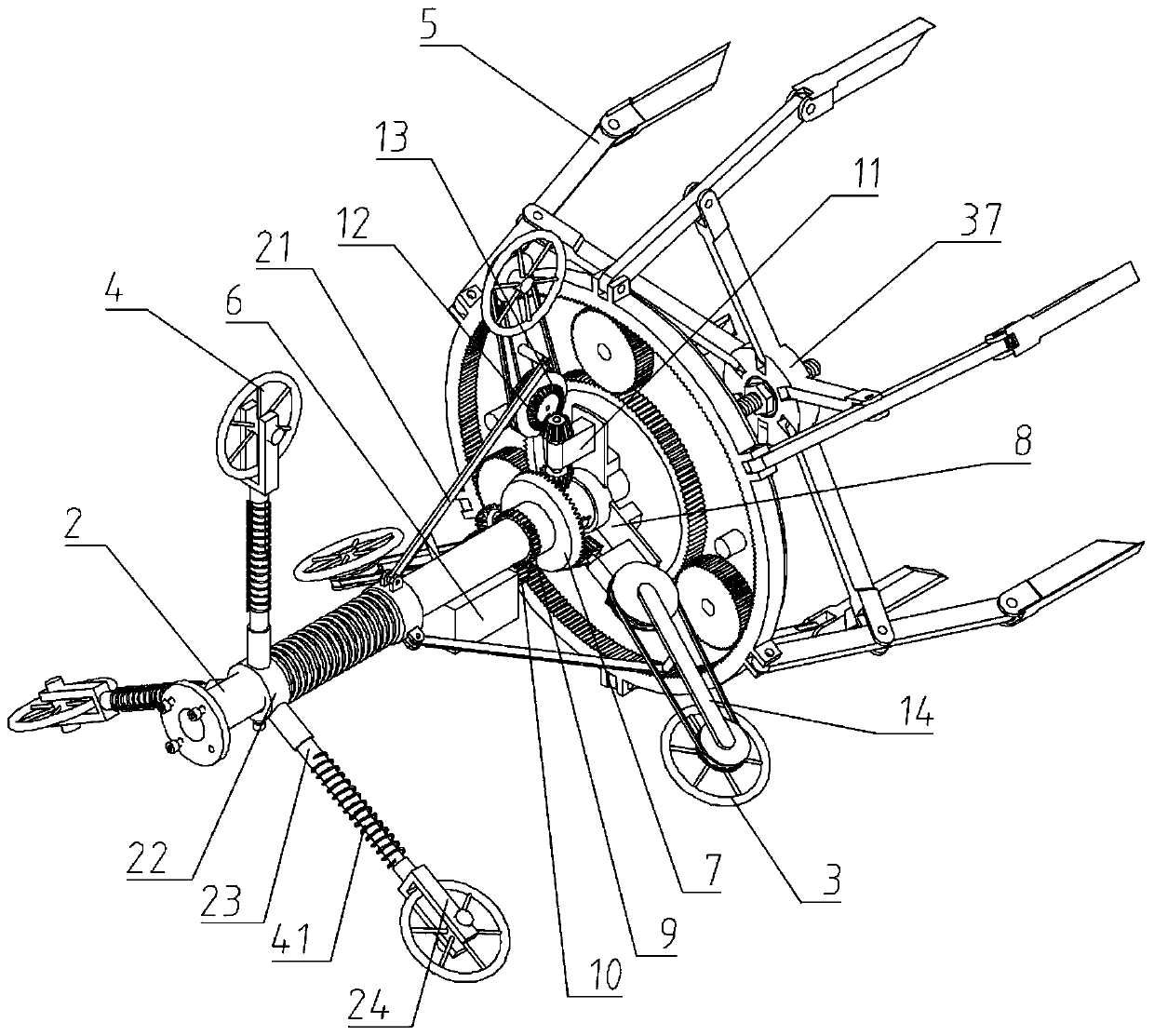

A deicing machine which performs omni-directional knocking on a high-voltage line based on the magnetic principle

The invention discloses a deicing machine for omni-directionally knocking high-voltage line based on magnetic principle, its structure includes de-icing driving mechanism, Connecting rod, deicing device, High-voltage wires, driving wheels, drive belt, a scraper, a deicing traveling power mechanism penetrating the high-voltage line and movably connecting the high-voltage line and the high-voltage line, in accordance with that prior art, the invention has the advantages that: the deicing device can be quickly installed on the high-voltage line, capable of knocking ice in turn, Percussion is morecomprehensive, with the scraping action of the scraper, can cause the ice to fall completely, so that within a certain range, which can be applied to the high-voltage wires with different ice diameters and different diameters, At that same time, the circular re and the knocking block are made of aluminum alloy, because the aluminum alloy has excellent heat conductivity, is conducive to the thermal intersection between the ice block and the surroundings, and is conducive to the melting of the ice; and the knocking can make the ice block be quickly broken, and the deicing efficiency is high.

Owner:东台市高科技术创业园有限公司

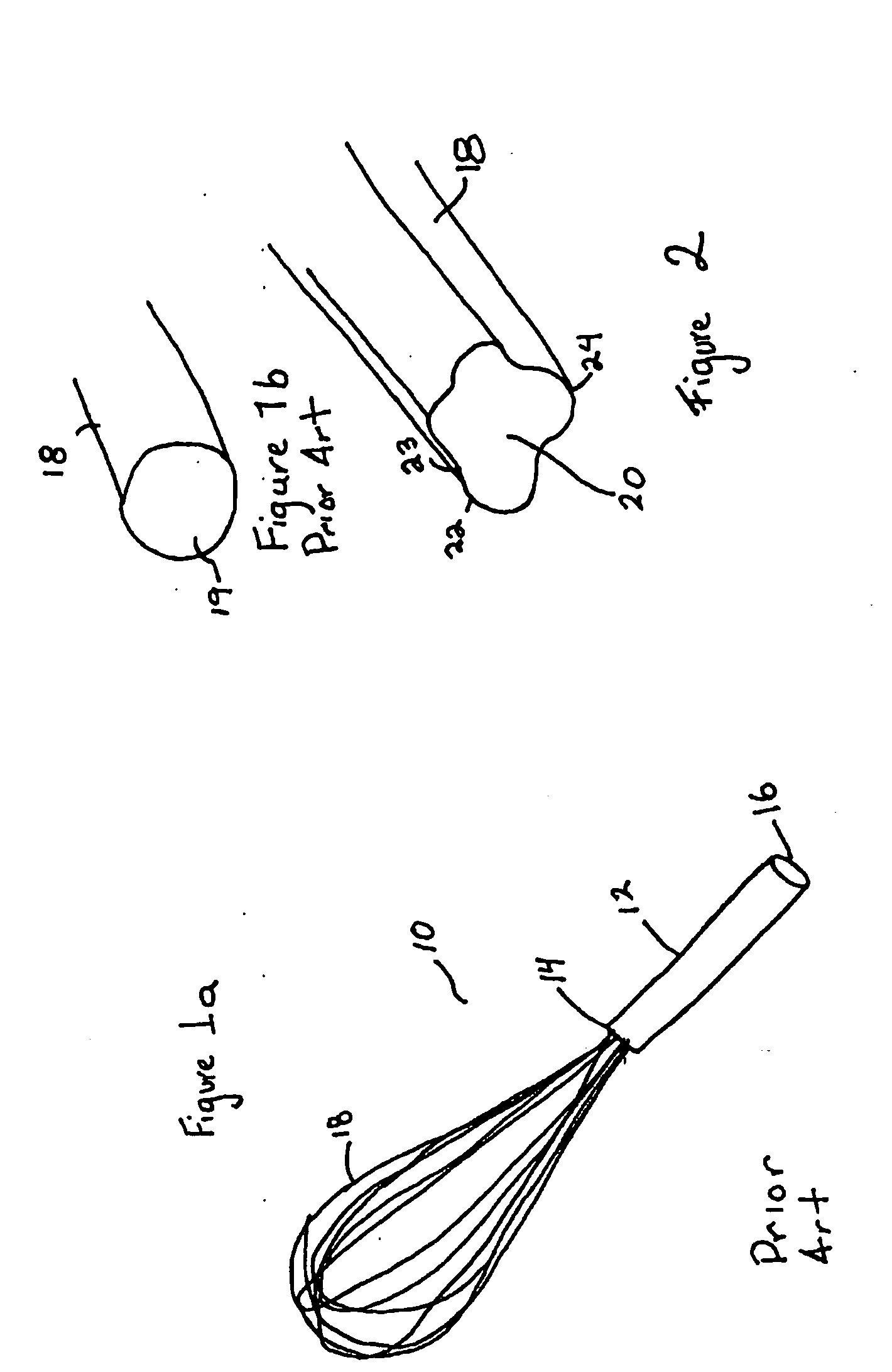

Covered kitchen utensil and a covering for a kitchen utensil

InactiveUS20050083777A1Maximising frictional contactMixer accessoriesKitchen equipmentScraping - actionKitchen utensils

The present invention relates to a kitchen utensil such as a whisk having a handle and at least one elongate member attached to the handle for contacting at least one of a food and a food preparation surface. The at least one elongate member has a cross-sectional profile that is non-round. Preferably, the elongate member comprises a central core and a resilient covering having a non-round peripheral cross-sectional shape at least one of V, flower, star, square and cog shapes. The elongate member may be shaped to conform to the internal profile of a vessel. Such kitchen utensils provide improved whisking, mixing, beating and scraping action.

Owner:BROWNE & CO LTD

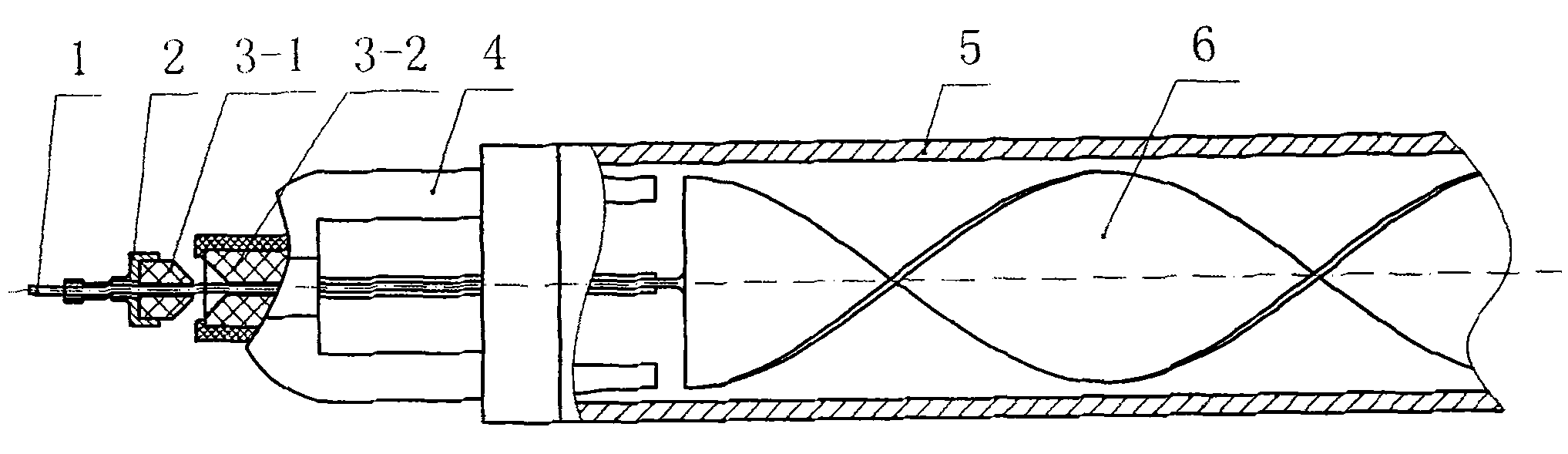

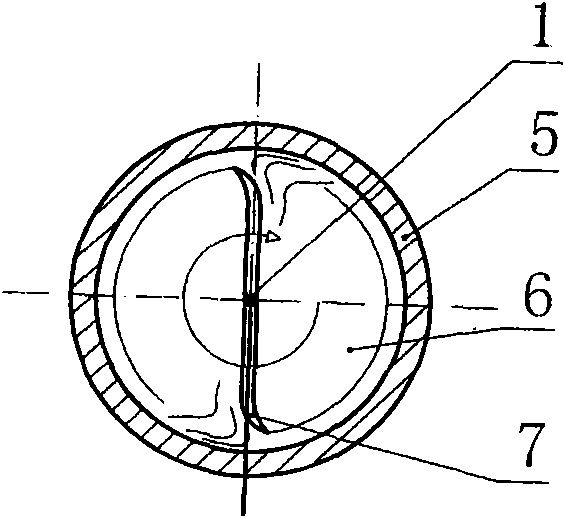

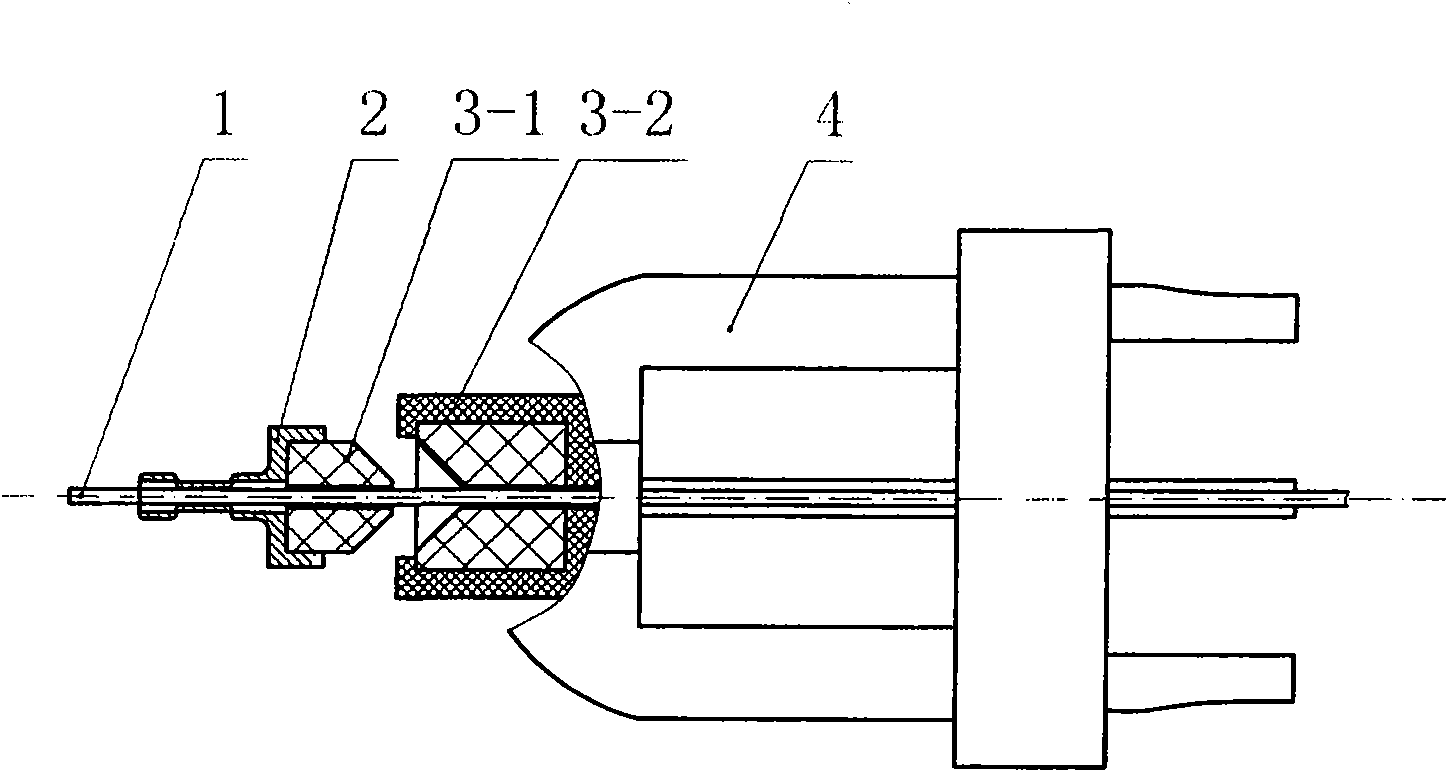

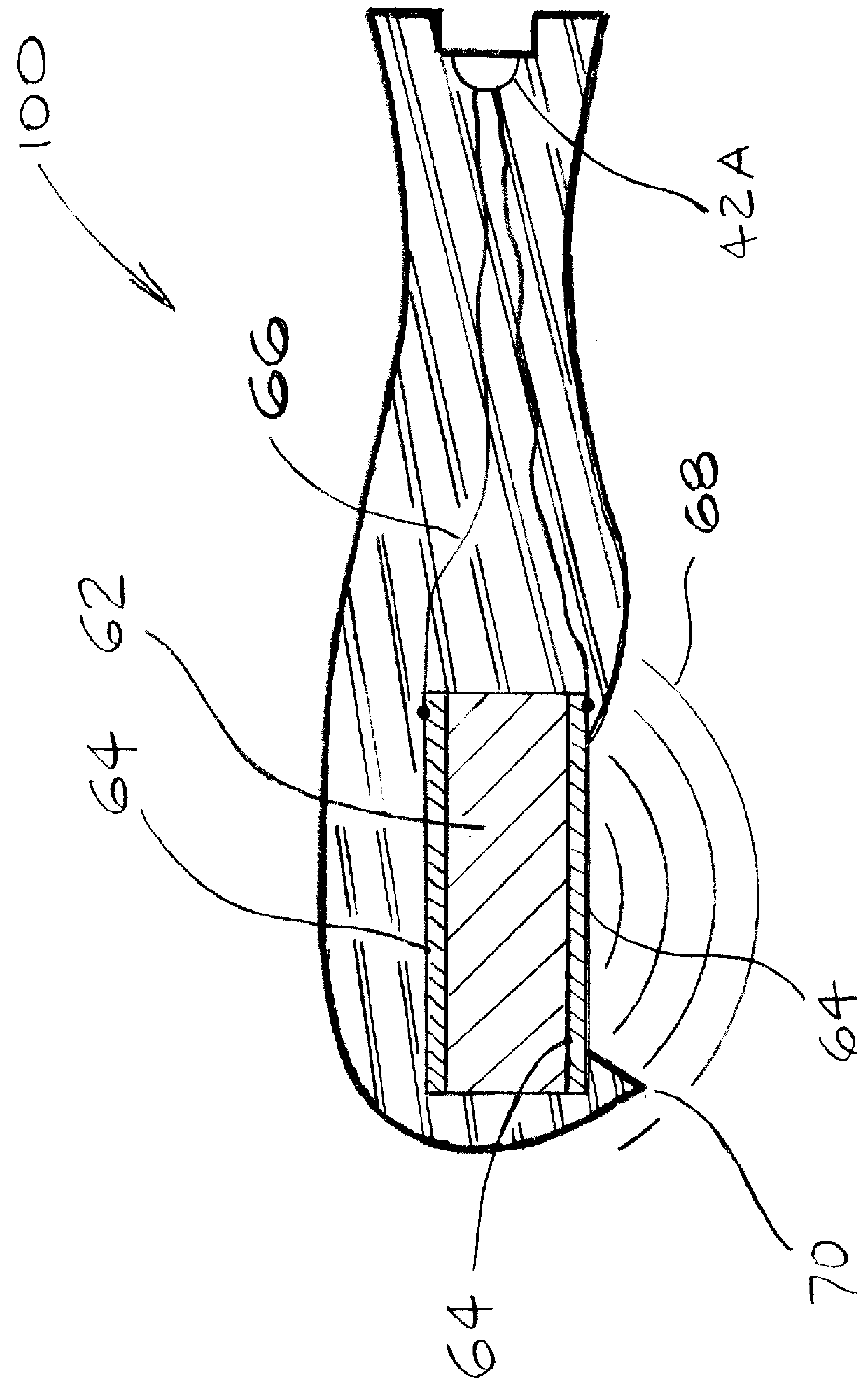

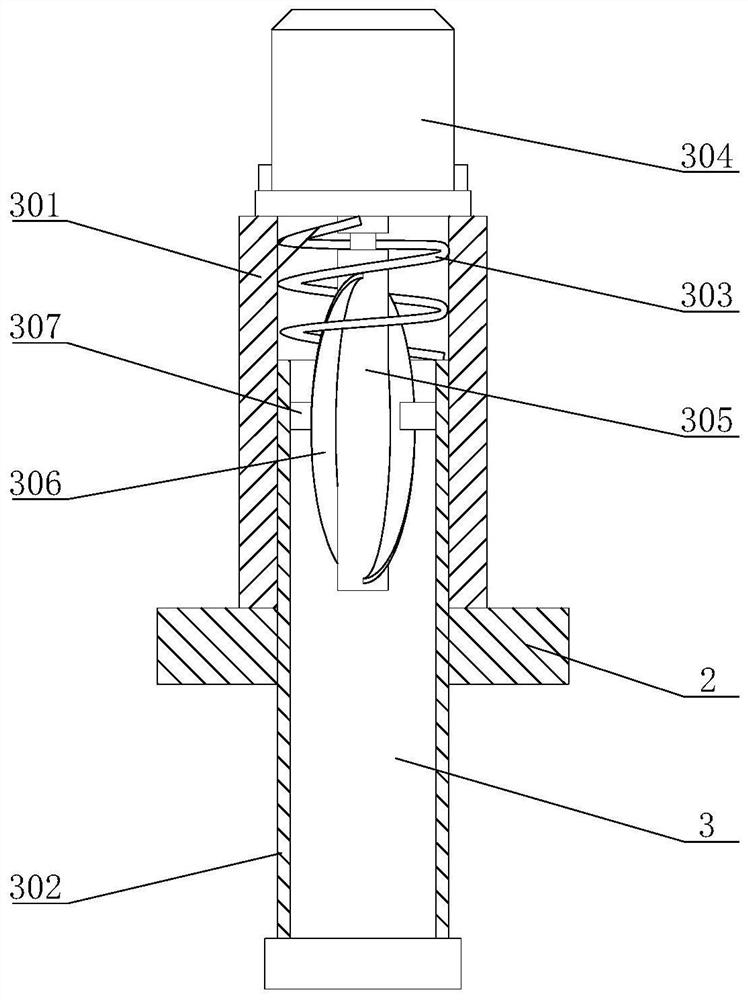

Self-cleaning enhanced heat-transfer magnetic suspension spiral twisted tape in heat-transfer tube

InactiveCN102032837ALow rotational resistanceSolve the problem of severe wear and tearRotary device cleaningScraping - actionEnhanced heat transfer

The invention relates to a magnetic suspension spiral twisted tape which comprises a spiral twisted tape and an axial locating device, wherein, the axial locating device is composed of a support frame and a magnet locating device; the magnet locating device is composed of a central conical magnet and an external conical sleeve magnet; the support frame is fixedly arranged on the liquid-inlet end of a heat-transfer tube; the external conical sleeve magnet is fixed with the support frame; the polarity of the central conical magnet is the same as that of the external conical sleeve magnet; one end of the spiral twisted tape is equipped with a pivot, and the pivot passes through the support frame and the external conical sleeve magnet; and the central conical magnet is fixed on the pivot. The magnetic suspension spiral twisted tape has the advantages that by adopting a magnetic suspension locating mode, the problem of severe wear caused by great contact force at a locating position of a liquid inlet is solved, and the service life of an axial locating element of the spiral twisted tape is prolonged; by utilizing a reinforced framework axis core, the strength of the spiral twisted tape can be enhanced; by means of a guide structure, the scraping action of the spiral twisted tape on a tube wall is reduced; and by means of a flow guide structure, fluid flow is further disturbed, the radial flow intensity and turbulent flow intensity of fluid are enhanced, and convective heat transfer is strengthened.

Owner:SINO ECO TECH

Conveyor belt scraper

A method of assembling a conveyor belt scraper which includes at least one scraping edge fixed to a support at least by means of a biasing member which includes the steps of prestressing the biasing member in a first sense, maintaining the biasing member prestressed, and mounting the conveyor belt scraper adjacent a surface of the belt whereby, in use, when the scraping edge exerts a scraping action on the belt and is deflected away from the belt, the biasing member is further stressed in the first sense.

Owner:SLIC TRADING

High Intensity Ultrasonic Tongue Cleaner

ActiveUS20160051271A1Efficiently neutralizedStop sulfur gas producing decompositionUltrasound therapyEar treatmentScraping - actionMedicine

An ultrasonic tongue cleaner applying high intensity non-attenuated ultrasound pressure waves to the tongue concurrently with the mechanical scraping action is disclosed. The ultrasound component is operative to damage and deactivate odor causing bacterial chains on the surface and in the folds of the tongue. A silver based antimicrobial attachment further enhances the performance of the tongue cleaner. Various configurations are disclosed, including user removable and replaceable tongue cleaner heads with and without antimicrobial silver. A motorized version featuring sonic frequency orbital vibration of the tongue cleaner head is described.

Owner:ROBERT T BOCK CONSULTANCY

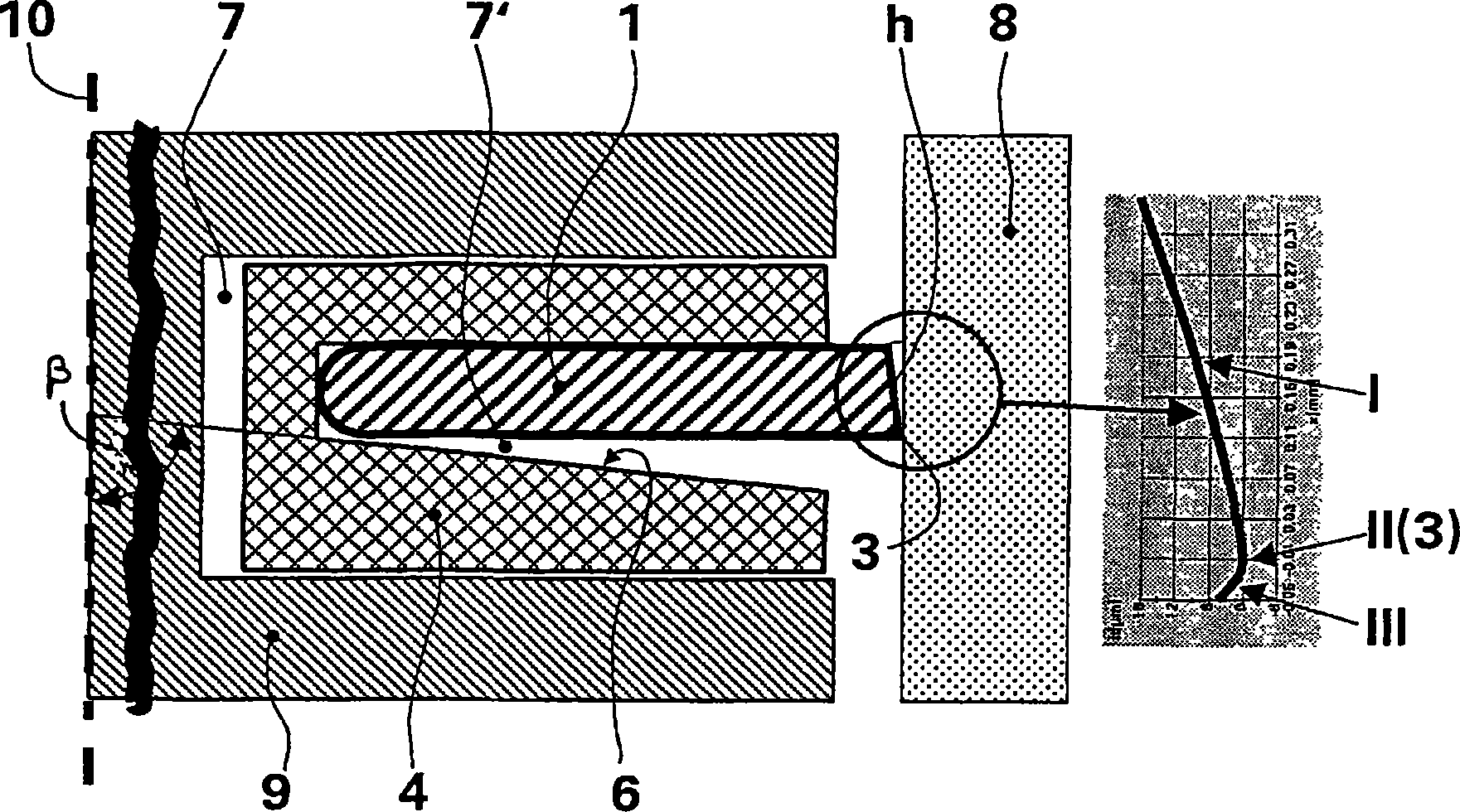

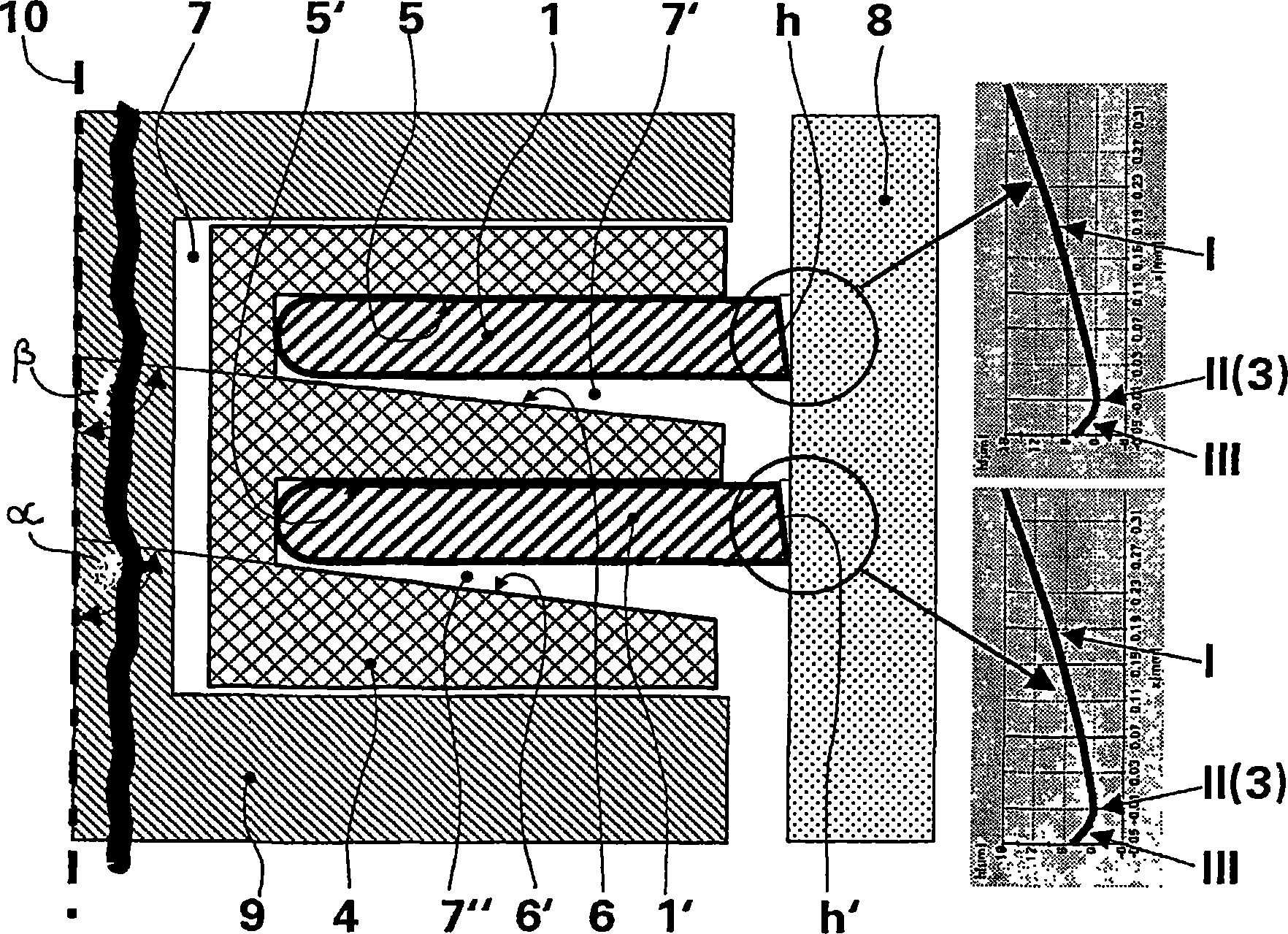

Oil scraper ring for pistons of internal combustion engines

The invention relates to an oil scraper ring for pistons of internal combustion engines, said oil scraper ring comprising a disc (1) that is provided with parallel flanks and a bearing surface (h) having an asymmetrical crowned form with a vertex line (3) extending over the periphery of the disc. A bracing spring (4) arranged in a ring groove (7) of the piston and comprising a spring groove side (6) opposing the piston head and a spring groove side (5) facing the piston head presses the disc (1) radially against the cylinder wall (8). The aim of the invention is to achieve an improved oil scraping action compared to that of prior art, while reducing the friction and the abrasion of the bearing surface. To this end, at least one of the spring groove sides (5, 6) extends at an angle (ss) in relation to the piston axis (10) in such a way that it is radially outwardly inclined to the bracing spring end oriented towards the cylinder, the bearing surface (h) of the disc (1) being embodied in such a way that it corresponds to an almost worn end contour in the started engine state, and, when the oil scraper ring (1) is mounted in the piston, the vertex line (3) of the bearing surface (h) is oriented in the direction of the ring groove side (6) opposing the piston head.

Owner:MAHLE GMBH

Conveyor belt scraper

A method of assembling a conveyor belt scraper which includes at least one scraping edge fixed to a support at least by means of a biasing member which includes the steps of prestressing the biasing member in a first sense, maintaining the biasing member prestressed, and mounting the conveyor belt scraper adjacent a surface of the belt whereby, in use, when the scraping edge exerts a scraping action on the belt and is deflected away from the belt, the biasing member is further stressed in the first sense.

Owner:SLIC TRADING

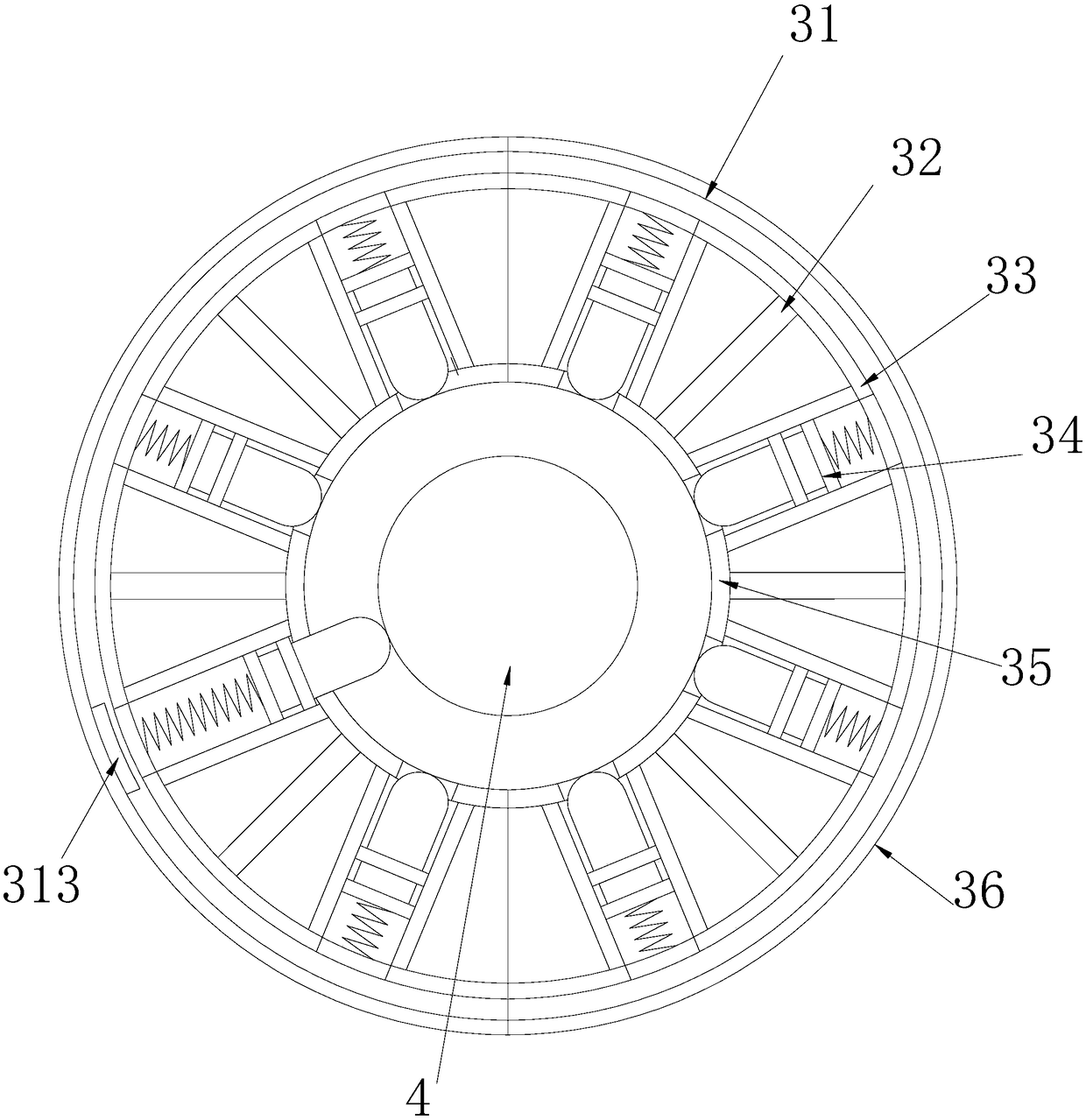

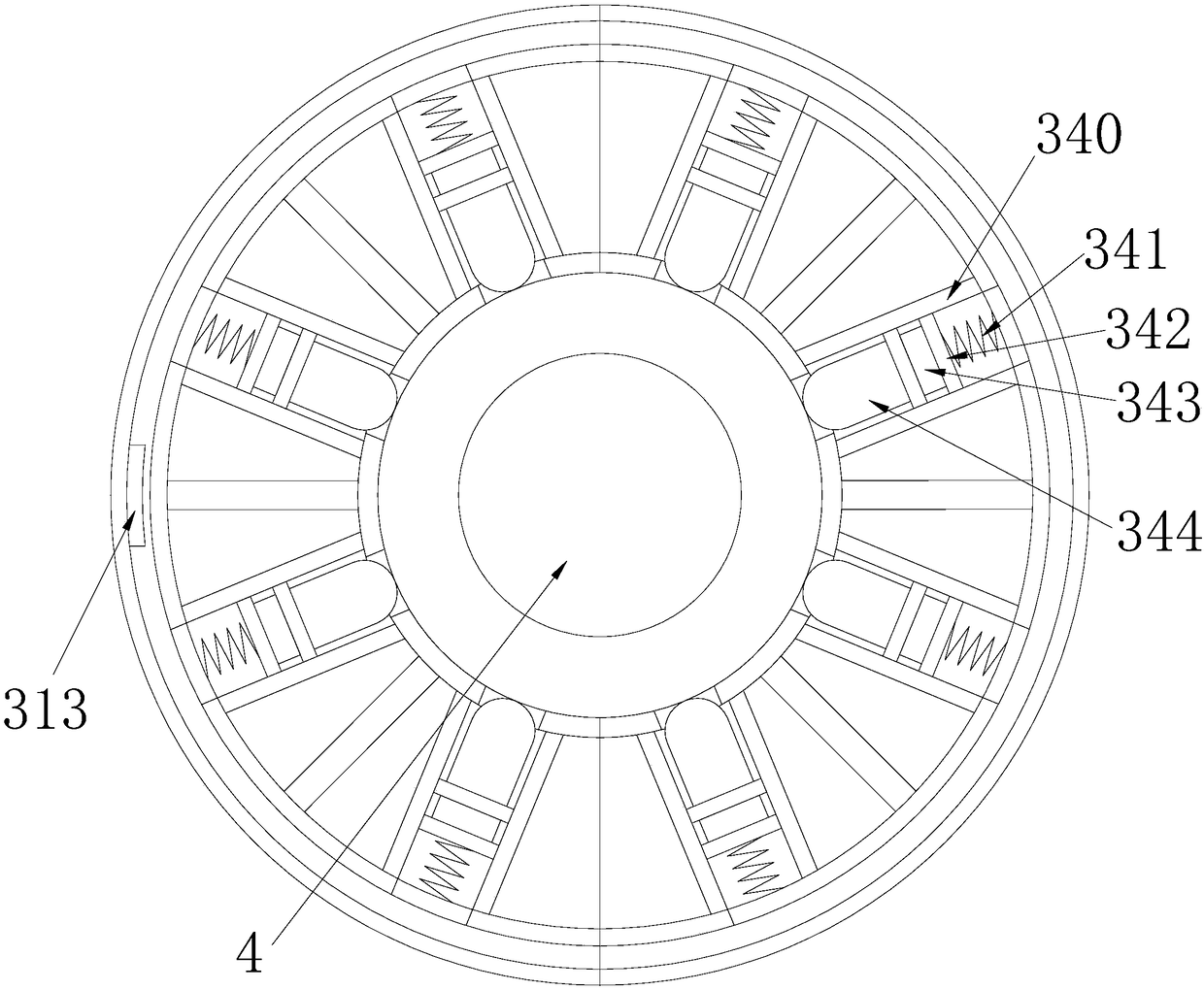

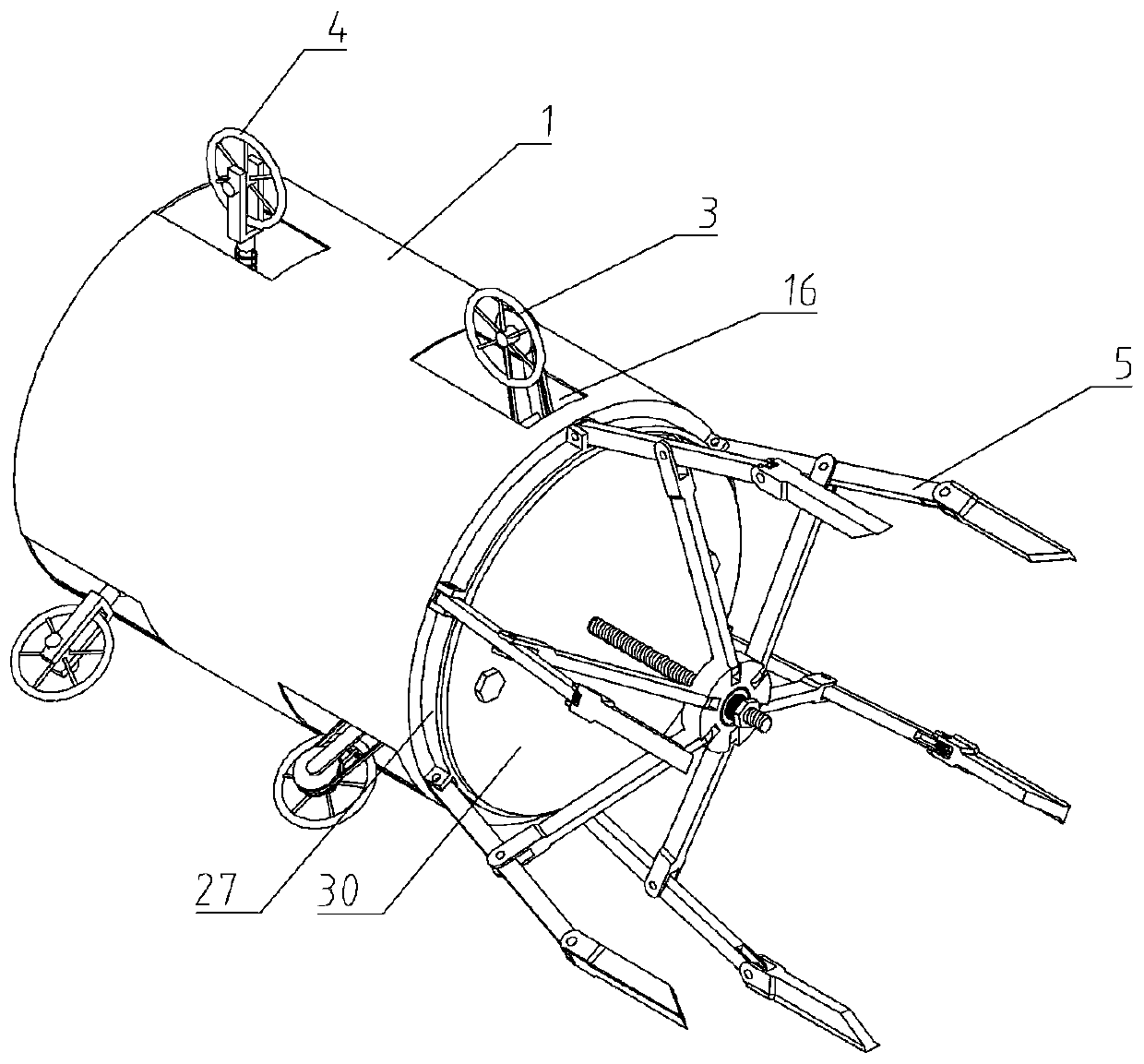

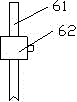

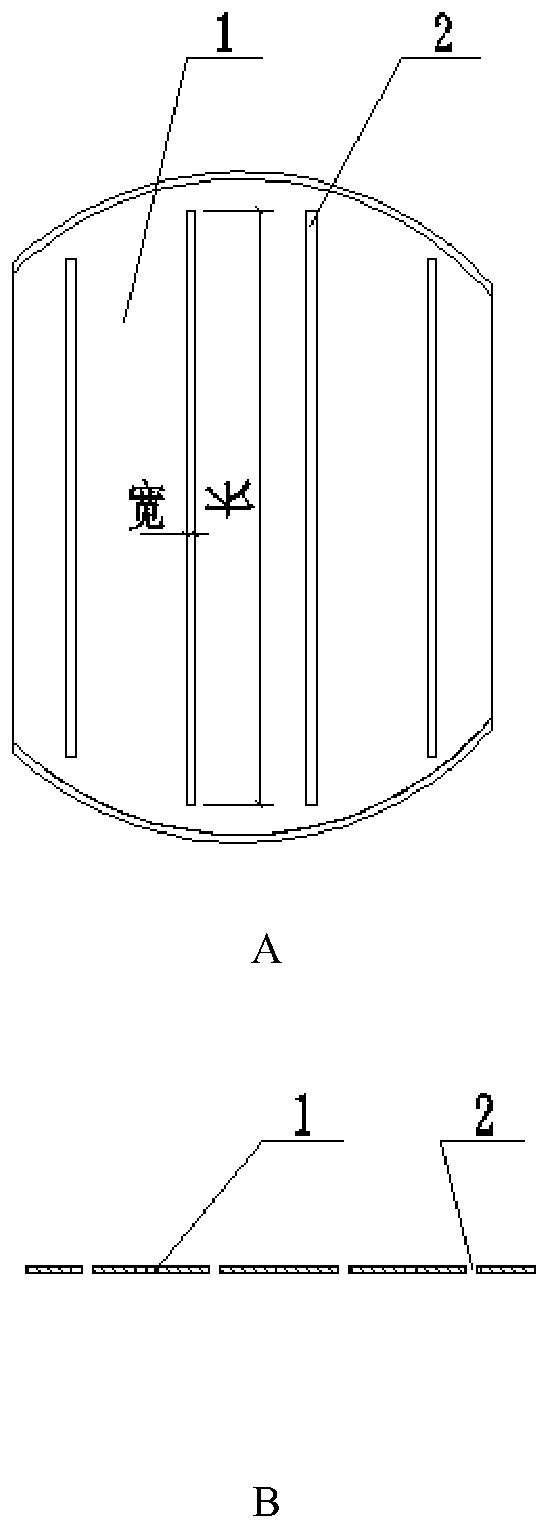

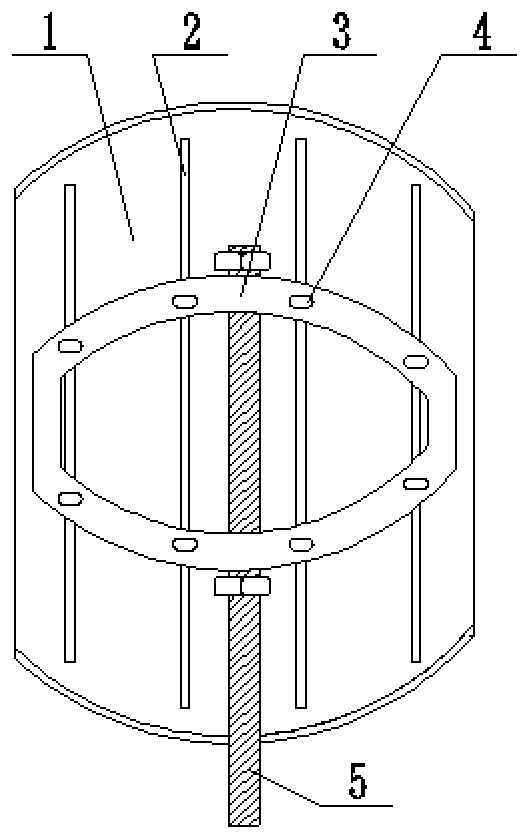

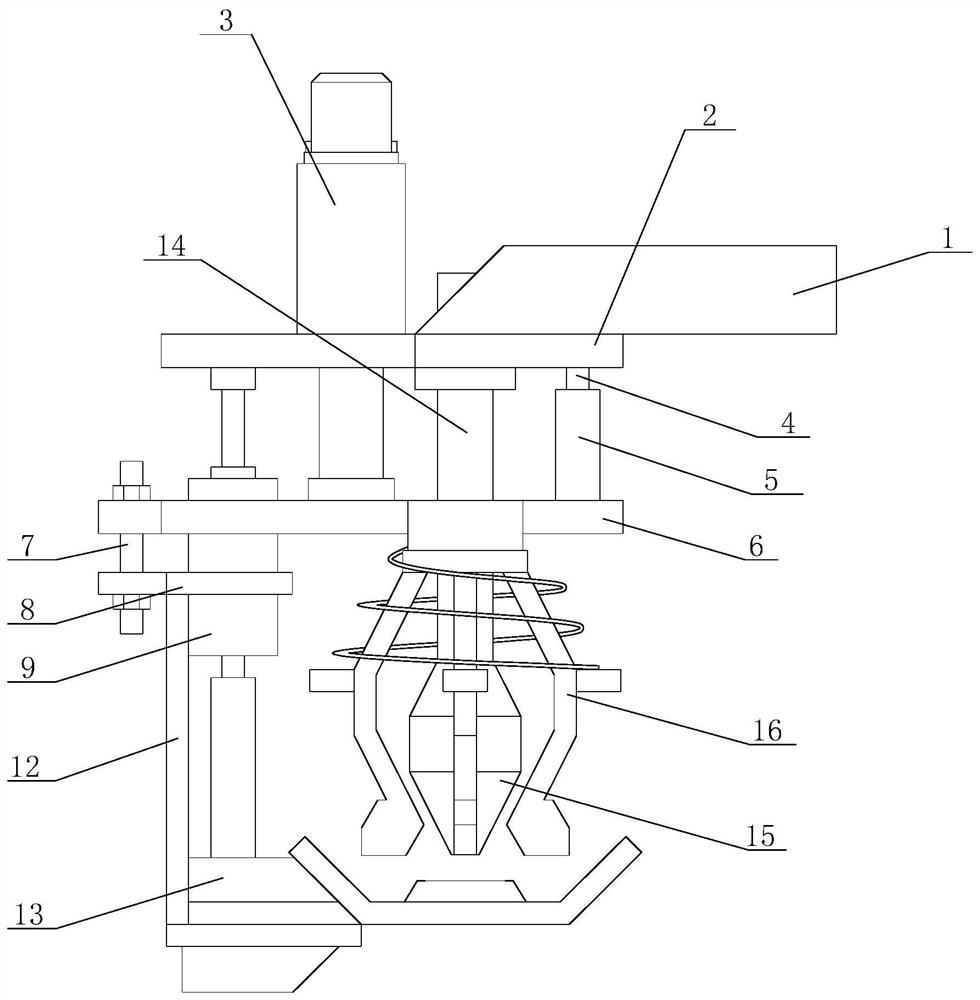

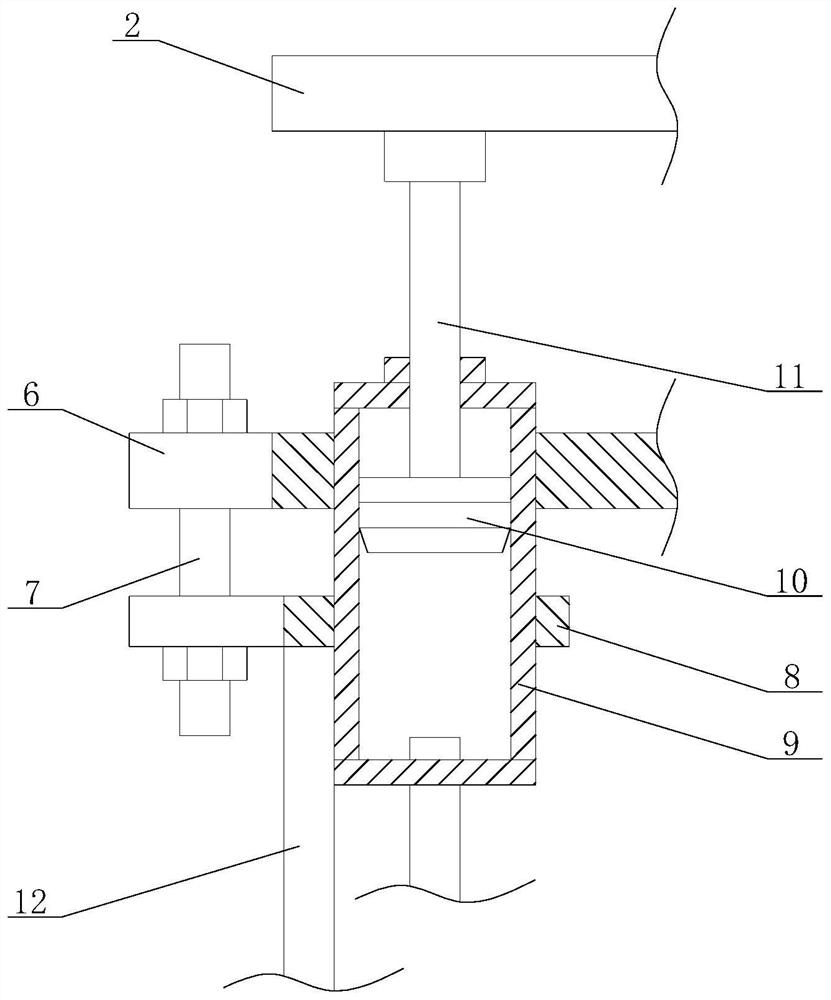

Automatic descaling equipment for large-mouth diameter tubular structure

The invention relates to the field of pipeline descaling, in particular to automatic descaling equipment for a large-mouth diameter tubular structure. The automatic descaling equipment comprises a wall scraping mechanism, a traveling mechanism, a first roller assembly and a second roller assembly, the wall scraping mechanism is used for scraping dirt on the inner wall of the tubular structure; thetraveling mechanism is connected with the wall scraping mechanism and used for driving the wall scraping mechanism to walk and complete scraping action; the traveling mechanism comprises a shell of acylindrical structure and a fixing shaft arranged in the shell and located on the axis of the shell, and the two ends of the fixing shaft are fixed to the two ends of the shell; the first roller assembly is arranged at one end of the fixing shaft and comprises a plurality of first rollers, the first rollers are arranged on the same circumference at equal angles relative to the axis of the fixingshaft, and the distance between each first roller and the axis of the fixing shaft is adjustable; the second roller assembly is arranged at the other end of the fixing shaft and comprises a pluralityof second rollers, the second rollers are arranged on the same circumference at equal angles relative to the axis of the fixing shaft, the distance between each second roller and the axis of the fixing shaft is adjustable, and the first roller and the second roller enable the traveling mechanism to walk along the axis direction of the fixing shaft. The automatic descaling equipment can automatically scrape dirt in tubular structures with different diameters.

Owner:黄惠惠

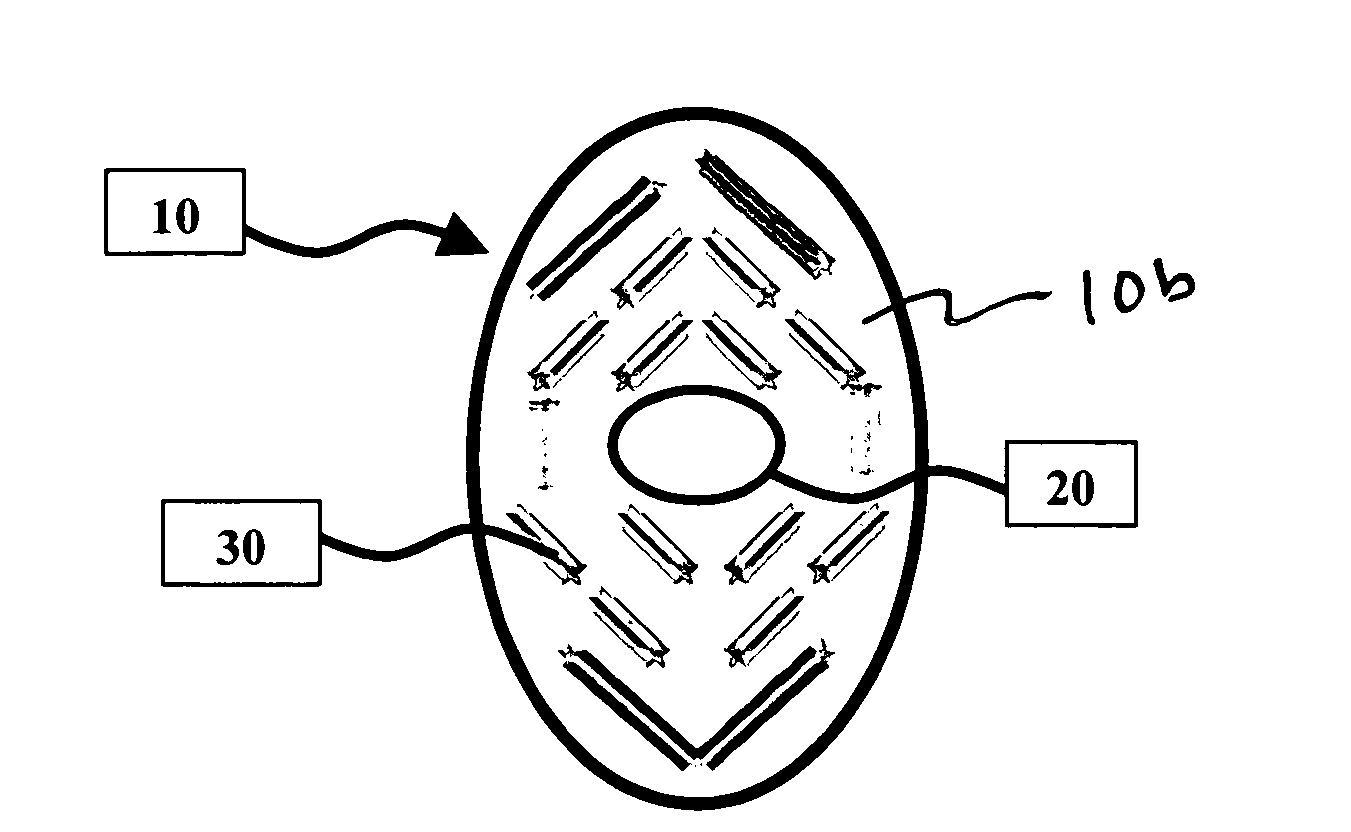

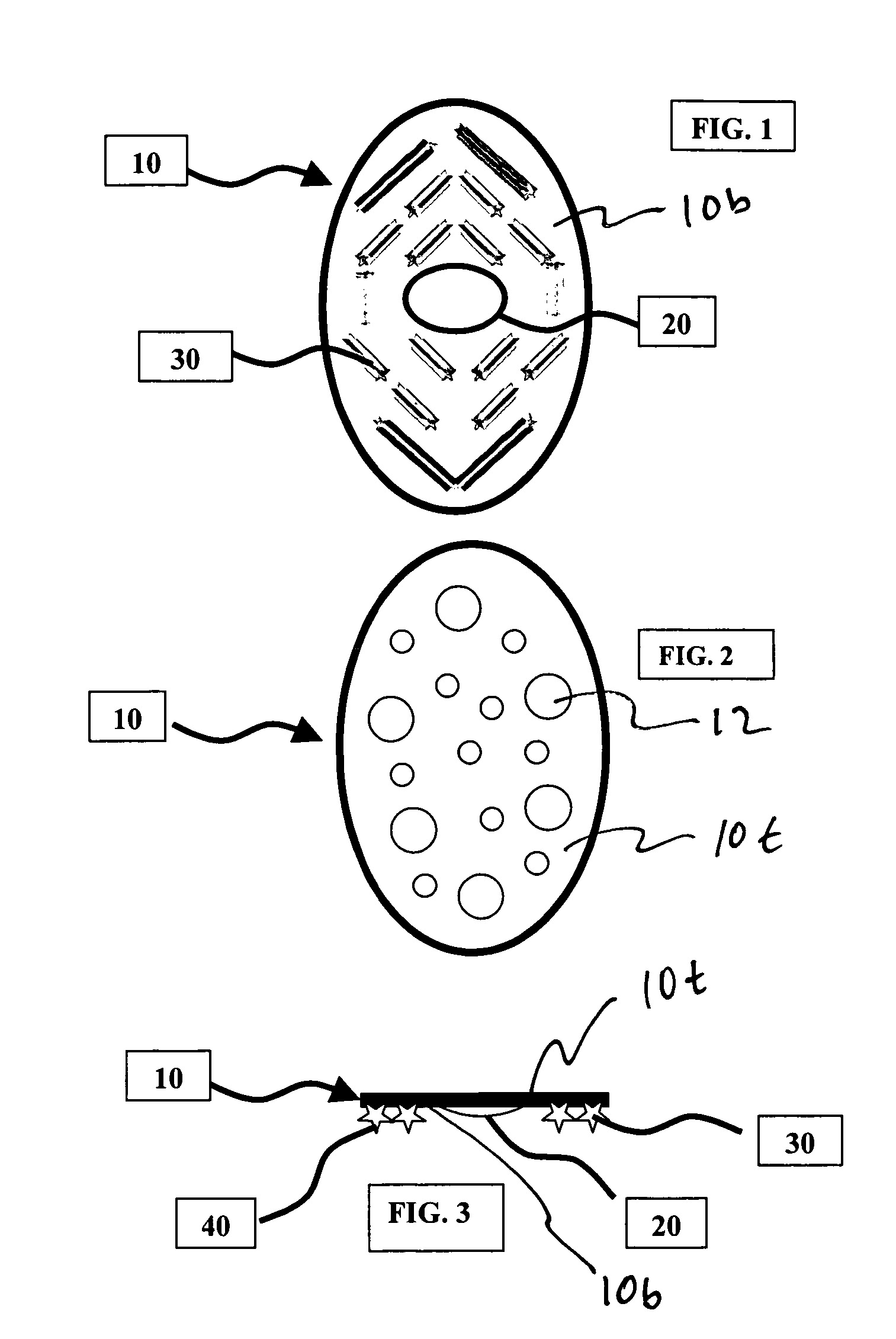

Tongue cleaning apparatus

InactiveUS7592018B2Effective tongue scraping actionImprove adhesionPharmaceutical delivery mechanismScraping - actionTongue cleaning

The present invention is a dissolvable candy which provides effective tongue scraping action. The candy is a soft pliable edible dissolvable candy material, such as a GUMMI-BEAR type confection, having a generally oval shape. A plurality of segments are formed with hard candy in one surface of the soft candy. Preferably, the segments have raised ridges which are suitable for abrading the tongue. A blister have a freshening agent is formed on the same side as the hard candy segments. A plurality of depressions are formed in another side of the soft candy to facilitate adhering the soft candy to the roof of the mouth.

Owner:MYTHEN DANIEL RICHARD

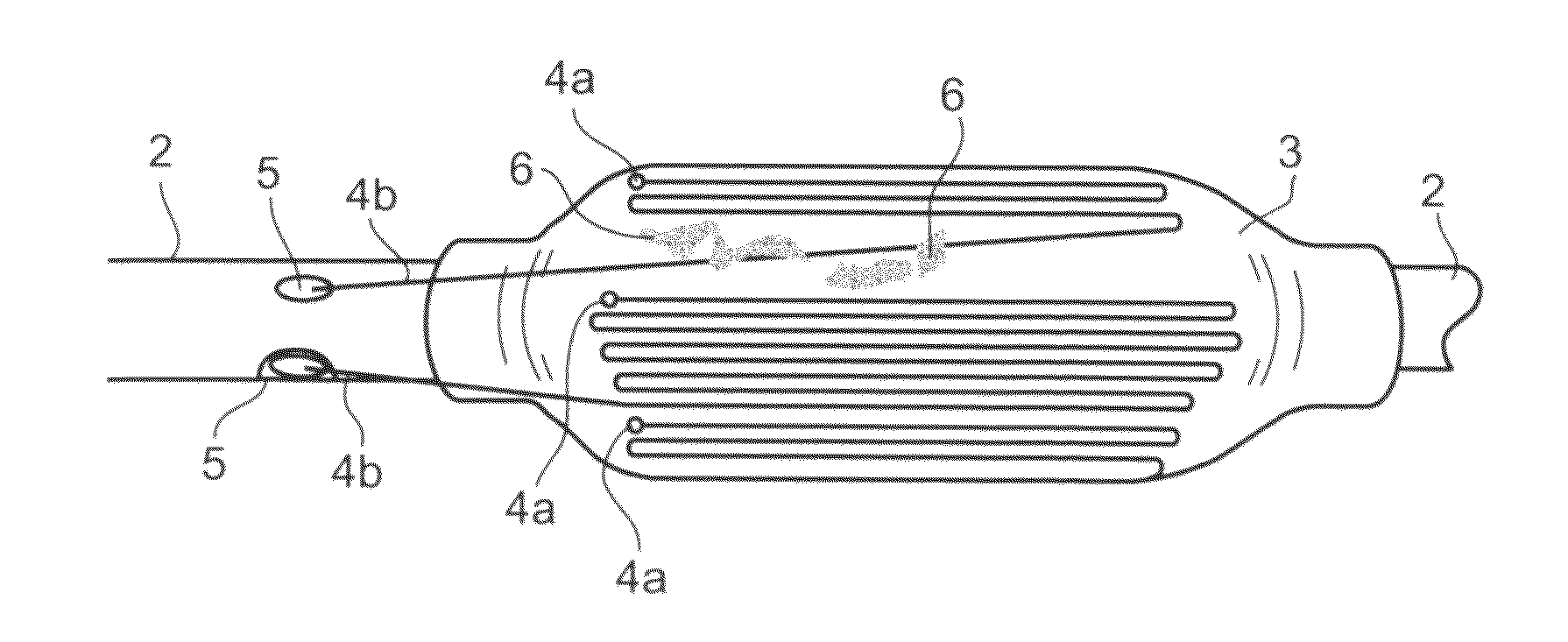

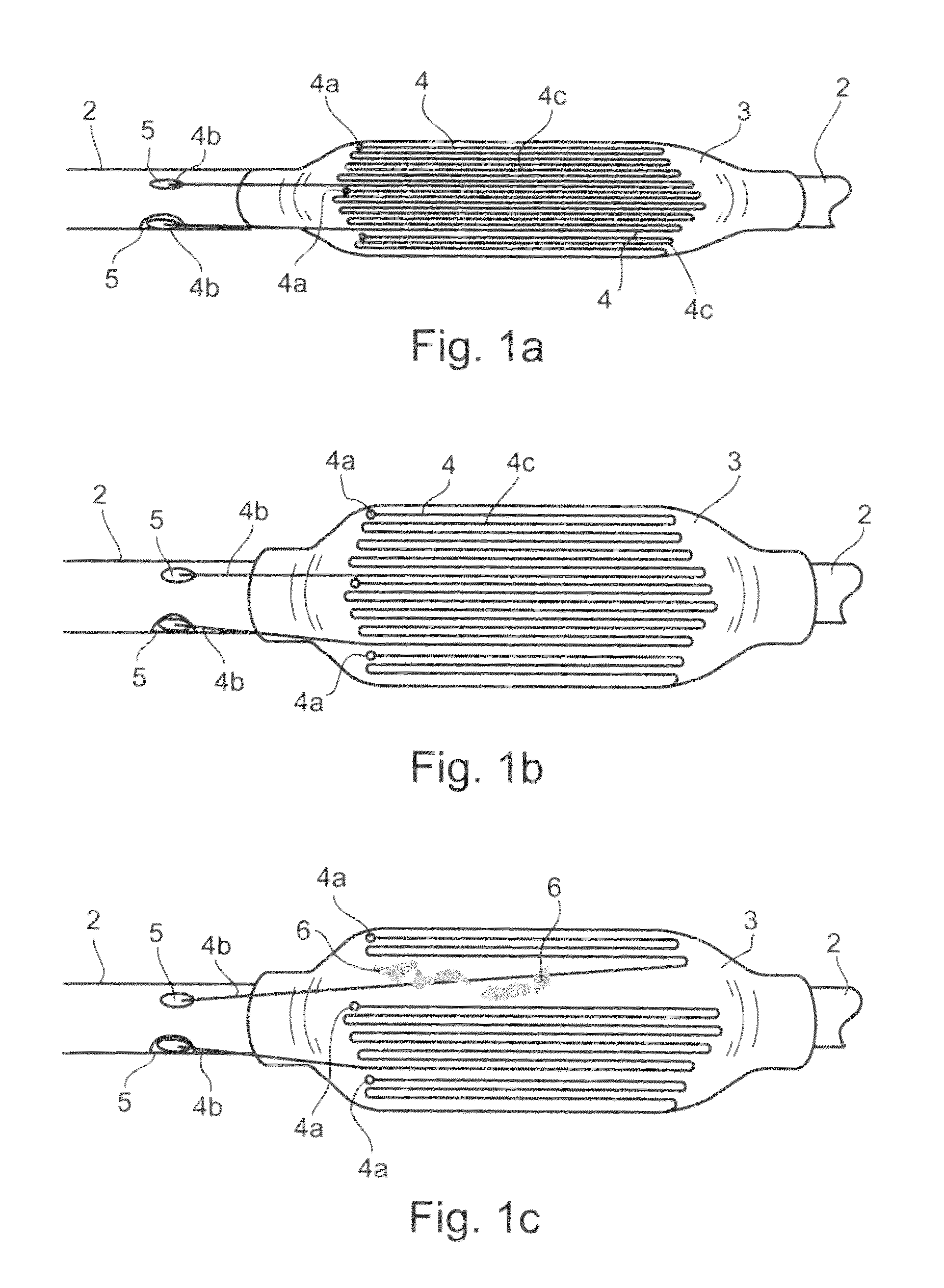

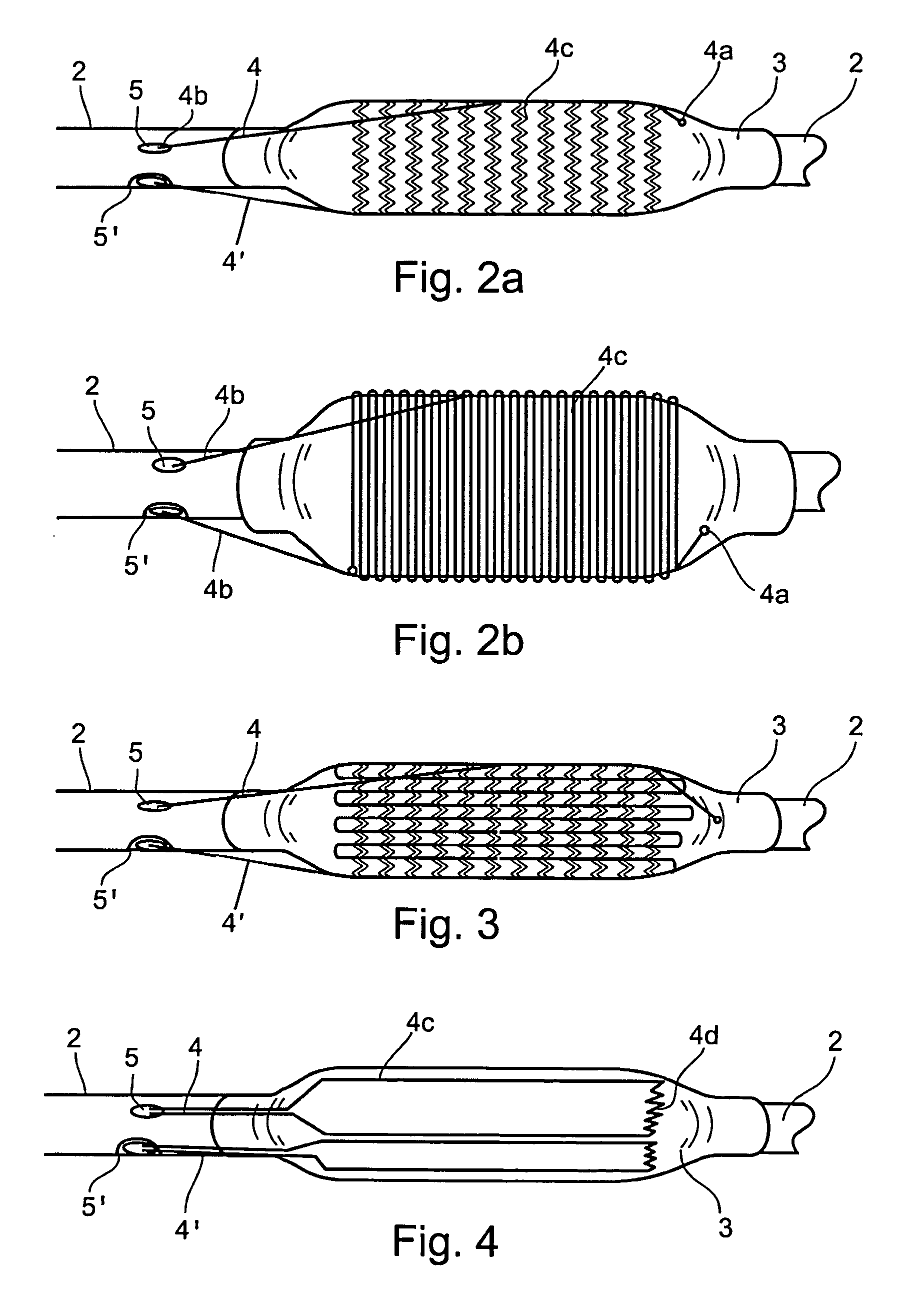

Apparatus and method for removing deposits from tubular structure, particularly atheroma from blood vessels

Apparatus for removing deposits from a selected location on the inner surface of a tubular structure, includes an expansible device introducible into the tubular structure, and at least one scraper cord carried on the outer surface of the expansible device so as to engage the inner surface of the tubular structure upon the expansion of the expansible device, and to be movable therealong to scrape away the deposits from the inner surface of the tubular structure. Preferred embodiments are described in the form of a catheter for removing atheroma or other undesirable deposits from blood vessels, wherein the expansible device is an inflatable balloon, and a flushing device is provided to flush out the scraped away deposits. The catheter preferably includes a plurality of such scraper cords occupying different portions of the inflatable balloon or different layers thereon, and individually movable over the outer surface thereof to produce a controlled and gentle scraping action.

Owner:NOVOSERT LTD

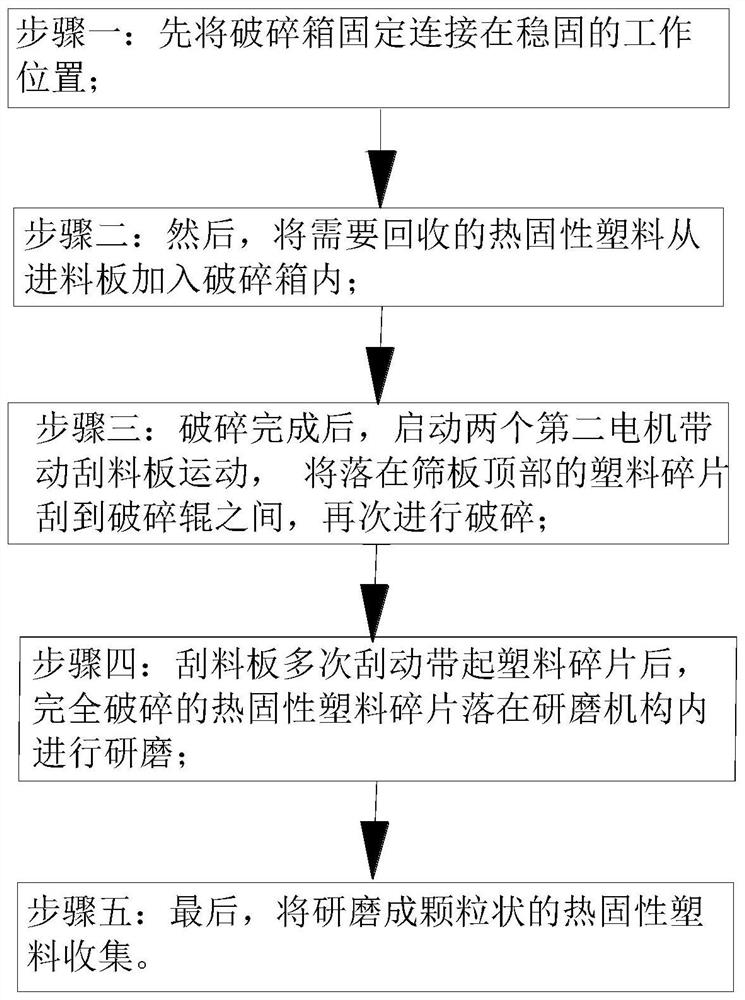

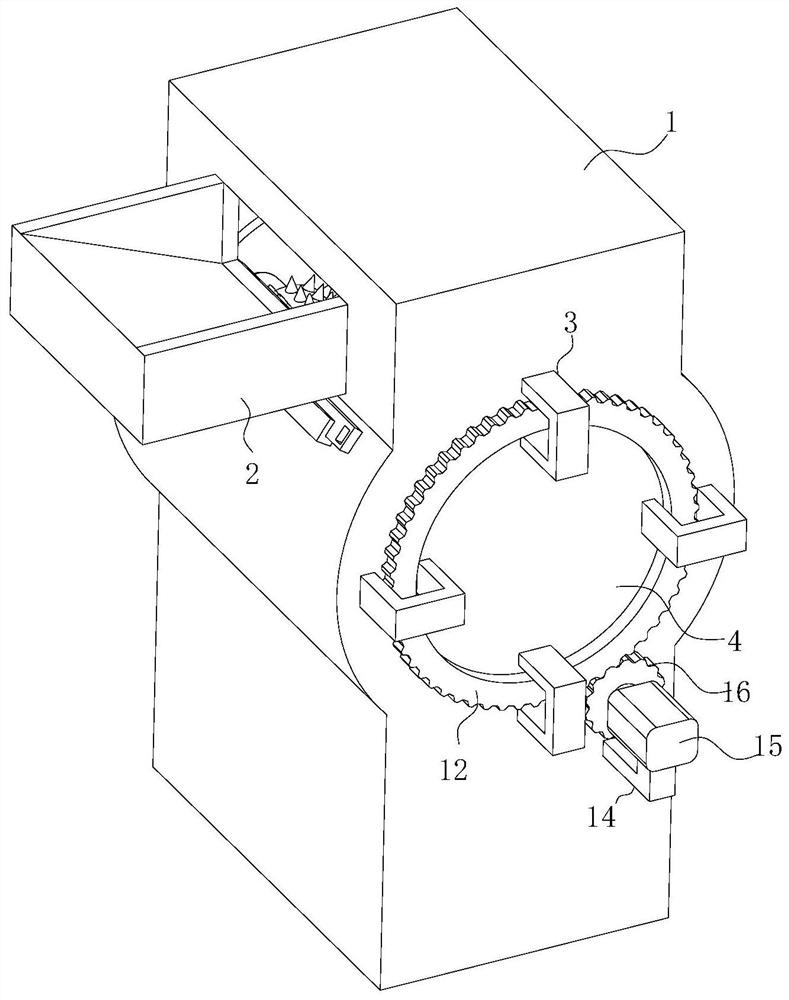

Waste thermosetting plastic regeneration device and regeneration process

ActiveCN112847937AAvoid repeated processingAvoid reprocessing problemsPlastic recyclingGrain treatmentsScraping - actionProcess engineering

The invention discloses waste thermosetting plastic regeneration device and regeneration process in the technical field of the waste thermosetting plastic regeneration device and regeneration process. The device comprises a crushing box, wherein the left side of the crushing box is fixedly connected to a feeding plate, and the front side wall and the rear side wall of the crushing box are fixedly connected to mounting discs through a plurality of U-shaped connecting blocks. When thermosetting plastic is crushed every time by the device, a scraping plate continuously rotates in the crushing box, thermosetting plastic fragments with insufficient crushing granularity are scraped and brought up, when the scraping plate moves and passes through a first baffle and a second baffle to open the first baffle and the second baffle in advance in cooperation with a rotating mechanism and an opening and closing mechanism, the scraping plate can move circumferentially to perform continuous scraping action, so that plastic particles which are not crushed completely can be crushed for multiple times thoroughly, and the thermosetting plastic can be recycled completely.

Owner:王雨田

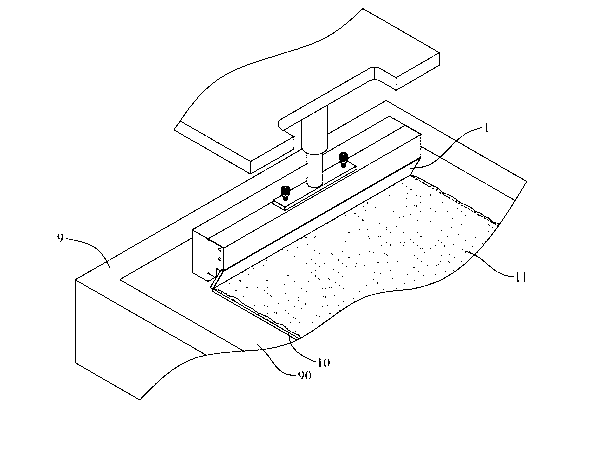

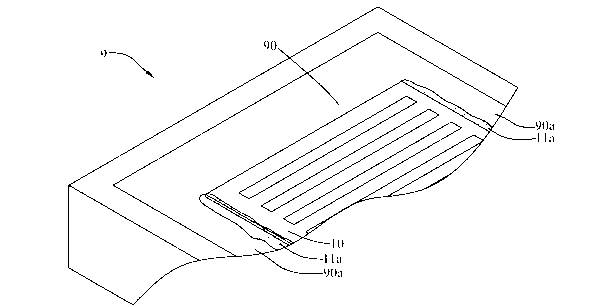

Scraper, solder paste coating machine with scraper and method for scraping solder paste

InactiveCN103144419AEfficient scrapingPrevent hardeningScreen printersScraping - actionStructural engineering

The invention discloses a scraper. The scraper is characterized in that second scraper blades are respectively arranged on two opposite sides of a first scraper blade. When the scraper executes the solder paste scraping action on a worktable of the solder paste coating machine, solder paste overflowing out of two sides of the first scraper blade is toggled into the inner side of the first scraper blade by the second scraper blades, so that the solder paste can be prevented from being resided on the outer side of the first scraper blade and further the phenomenon that the solder paste is hardened due to long-time accommodation on the worktable is avoided. In addition, the invention also discloses a solder paste coating machine with the scraper and a scraping method.

Owner:ASKEY TECH JIANGSU +1

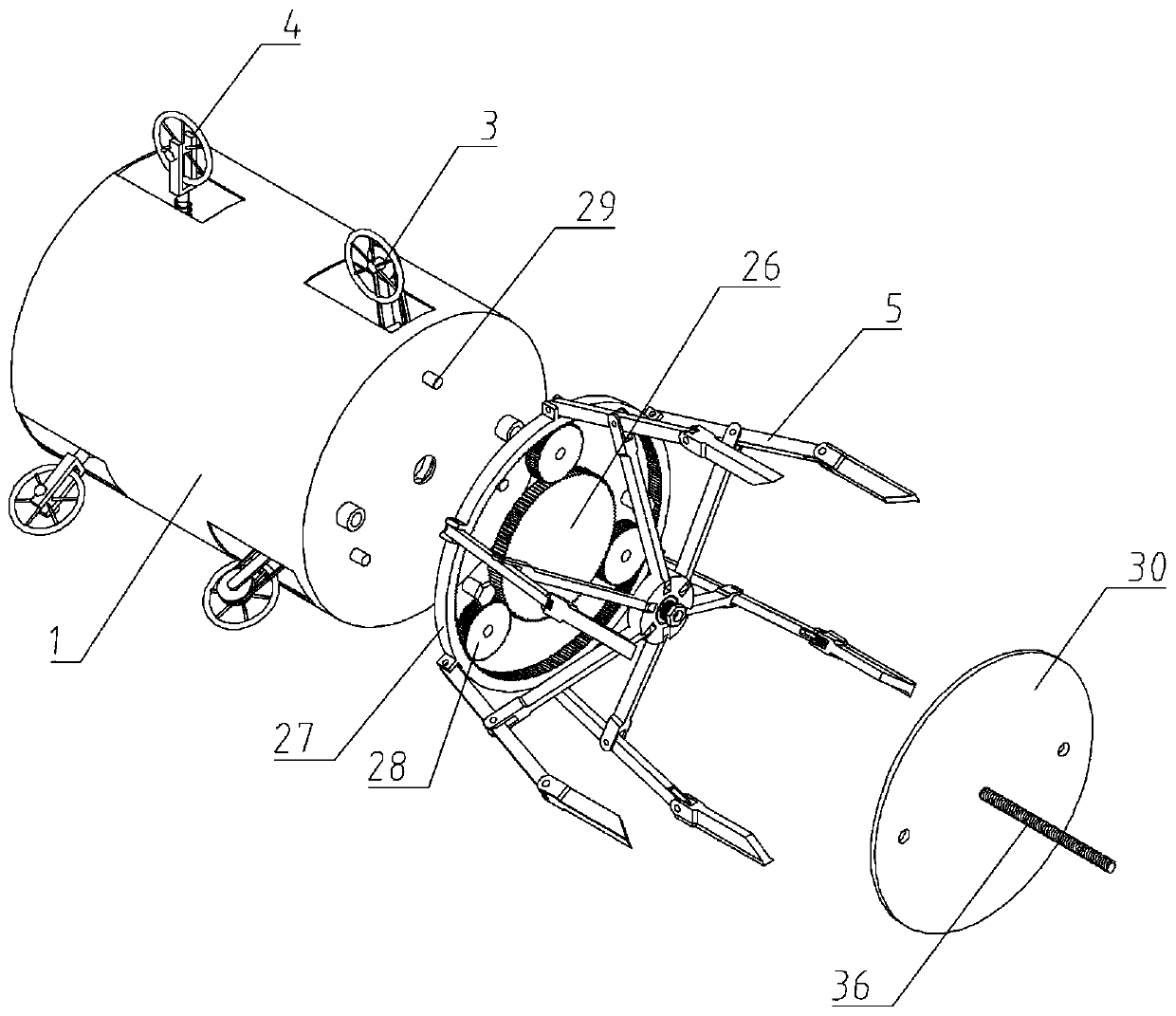

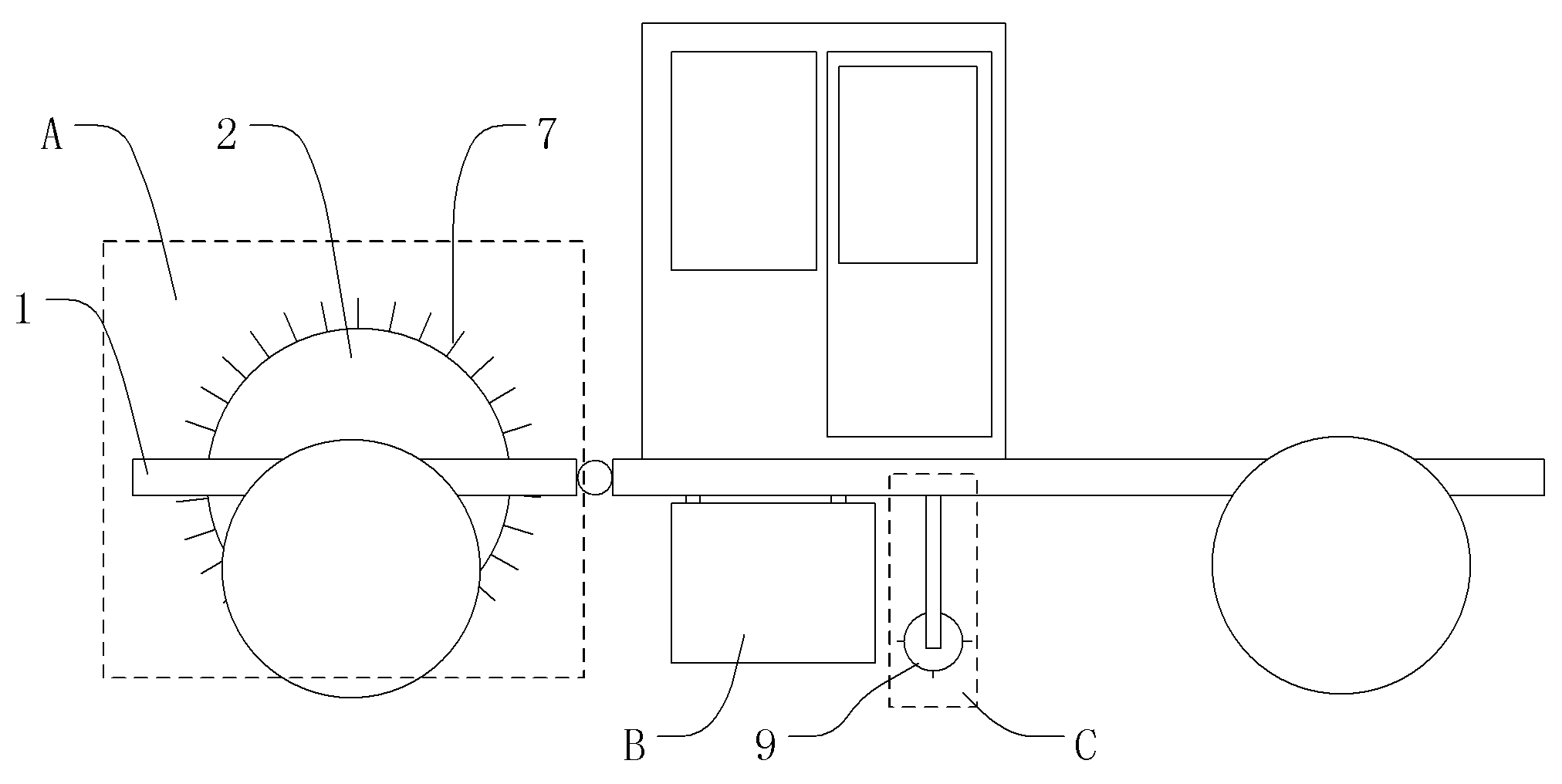

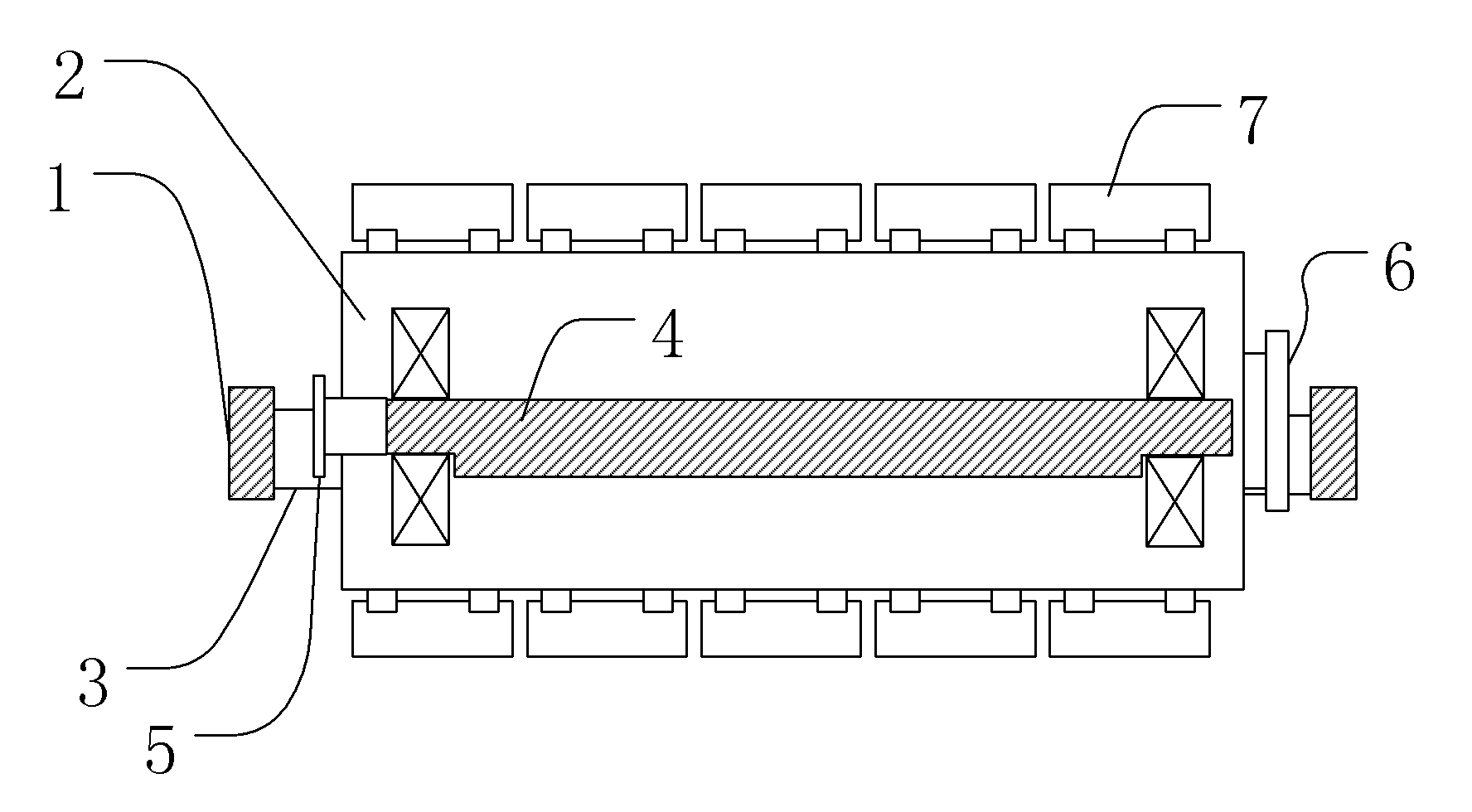

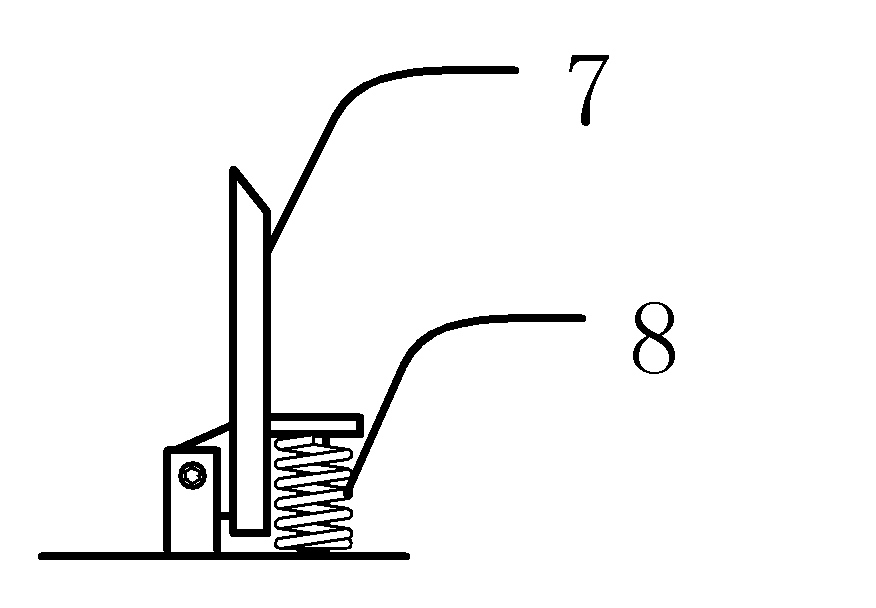

Vibration cutting deicing device

InactiveCN102535381ARealize the deicing functionGood deicing effectSnow cleaningScraping - actionEngineering

The invention belongs to the field of special equipment for engineering, and particularly relates to a vibration cutting deicing device. The device is mounted at the front part of a motor vehicle, and comprises three parts, namely a vibration cutting structure, a sweeping structure and an ice coating removing structure. The vibration cutting structure is mounted at the forefront of the motor vehicle; an eccentric shaft is arranged in the vibration cutting structure; elastic blades are arranged outside the vibration cutting structure; the vibration cutting structure vibrates while rotating to conduct ice cutting and scraping actions, and can effectively protect a pavement from damage under the premise of ensuring the ice crushing efficiency; the sweeping structure is responsible for sweeping cut off crushed ice; and metal nails flexibly connected with a housing are arranged on the surface of the ice coating removing structure, and are used for further cleaning the ice coating on the treated pavement, and removing residual ice in pits on the pavements through irregular impact, so as to achieve a fully cleaning effect.

Owner:纪成明

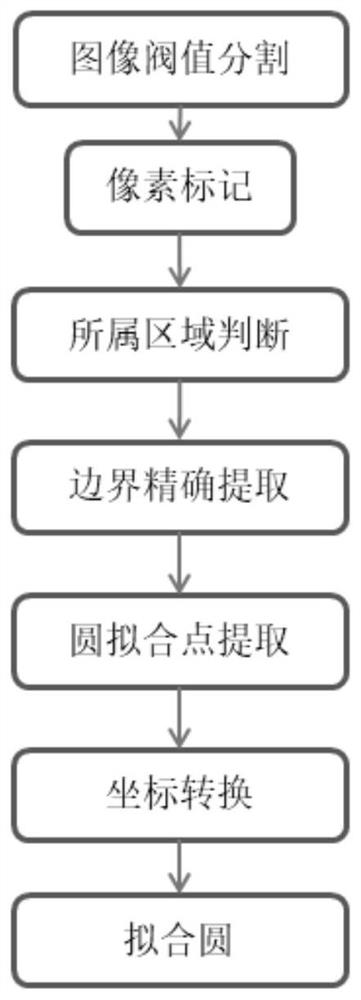

Robot glue scraping method based on visual identification

ActiveCN112172191ASolve the problem of uneven thickness and difficult scraping operationRealize automatic scrapingTubular articlesScraping - actionImaging processing

The invention discloses a robot glue scraping method based on visual identification, and belongs to the field of glue scraping methods. The robot glue scraping method comprises the following steps that a visual identification device obtains an image of a to-be-processed pipe, and the image is processed through a visual image processing algorithm to obtain the diameter and perimeter L of the to-be-processed pipe and the curvature of the circumference of the to-be-processed pipe; according to the curvature information, the position of a glue scraping mechanism on a mechanical arm in a glue scraping system is adjusted, so that a glue scraping roller brush is positioned at the topmost end of the to-be-processed pipe and moves downwards to the lowest point along the curvature path of the to-be-processed pipe from the topmost end to complete the first half-perimeter glue scraping action, a second driving device starts to drive the mechanical arm to move by the width of one roller brush and return to the first step for circular treatment again until glue scraping of the first half surface of the to-be-processed pipe is completed; and the to-be-processed pipe is rotated, and returns to thefirst step for circular treatment again until glue scraping of the second half surface of the to-be-processed pipe is completed. The robot glue scraping method can adopt the glue scraping system to automatically complete the glue scraping action, and is safe and environmentally-friendly.

Owner:江西省智能产业技术创新研究院

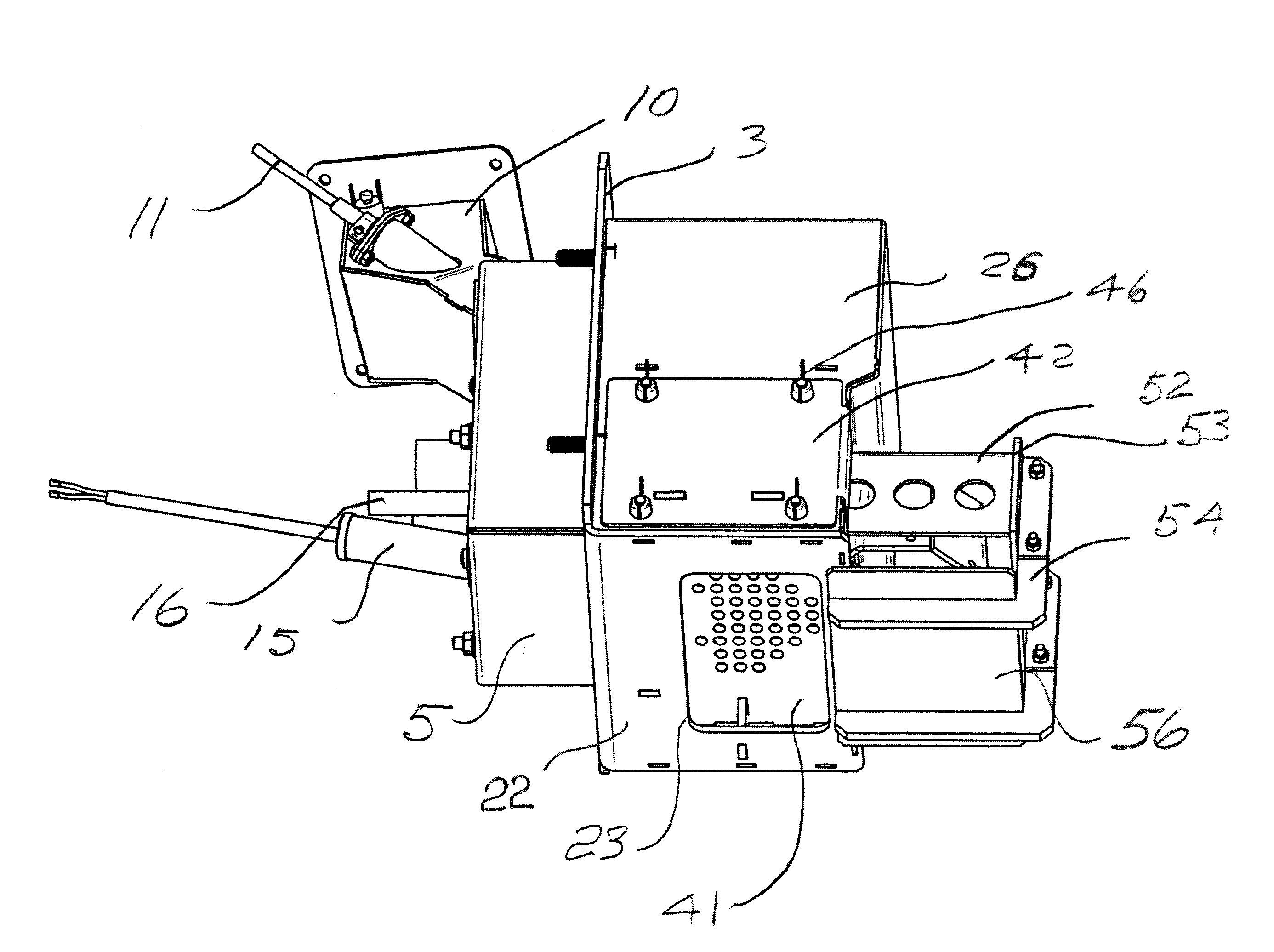

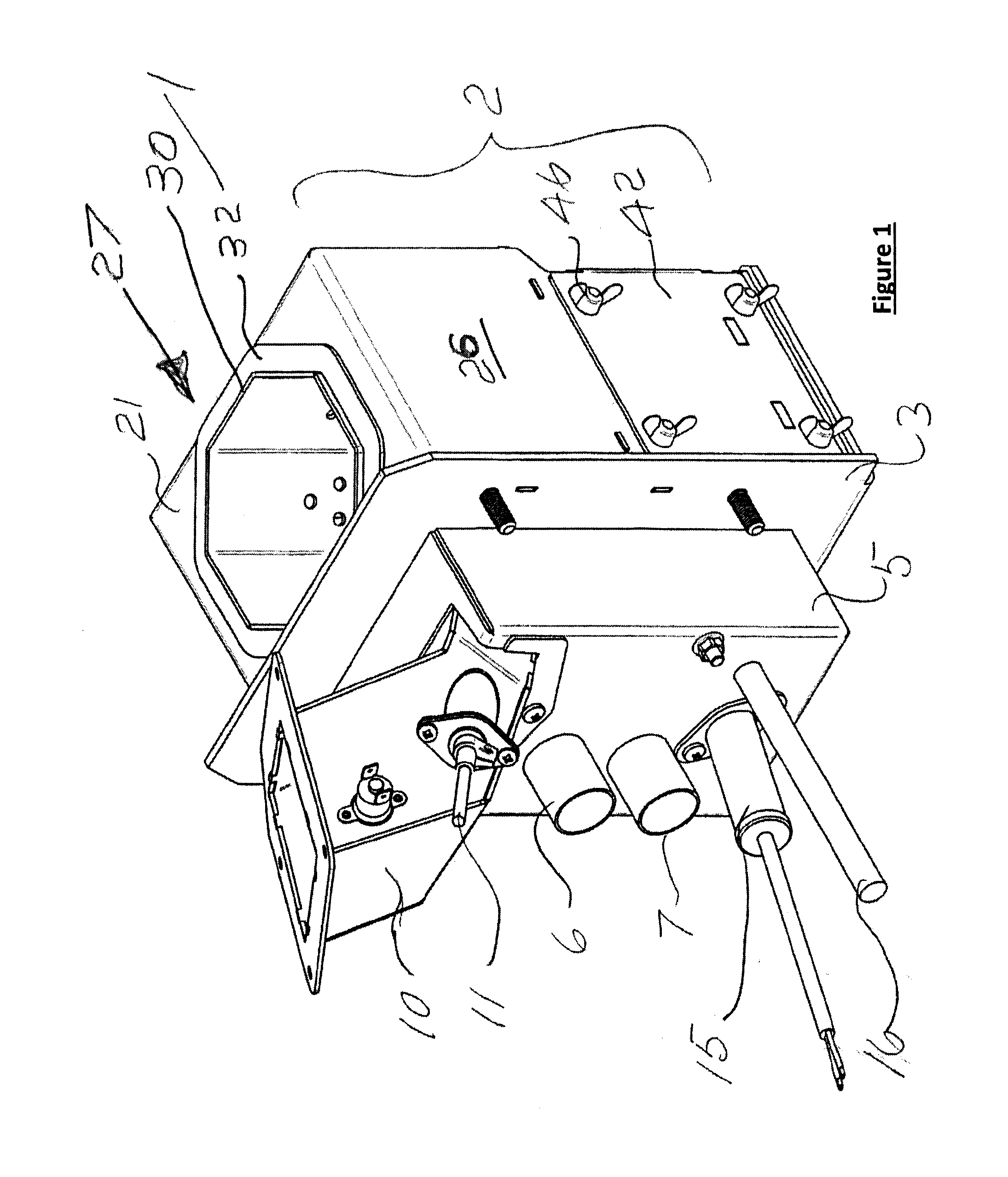

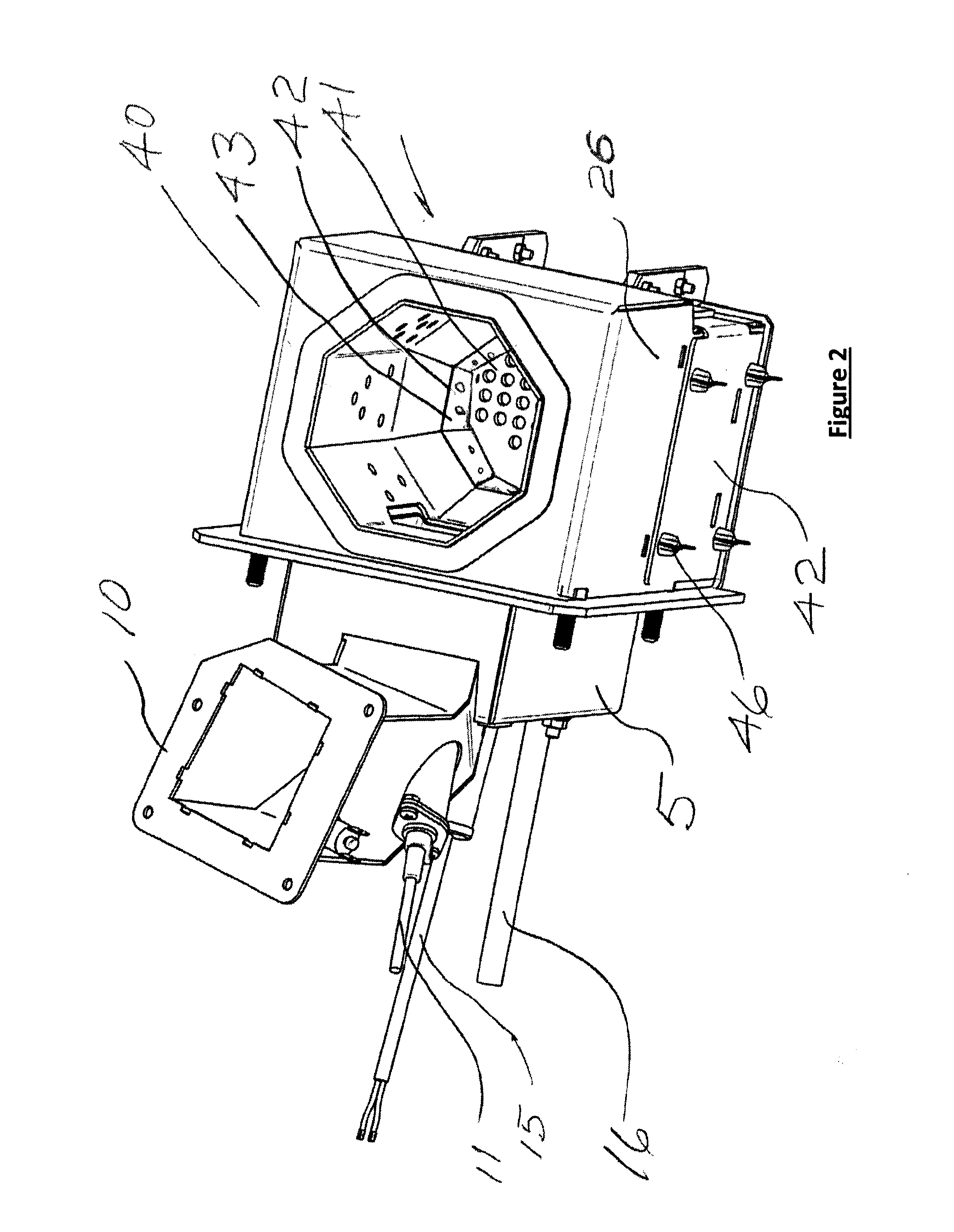

Wood pellet burner assembly

InactiveUS20150122241A1Low costSave spaceCombustion-air/flue-gas circulation for stovesGratesScraping - actionCombustor

There is provided a wood pellet burner assembly for a wood pellet boiler, not shown. There is a fixed and easily removable fuel apertured grate mounted above and spaced apart from a base wall forming part of a main support enclosure. A movable scraper subassembly carrying an apertured flame tube is provided which can be moved in and out of the main support enclosure to perform a scraping action on the fixed fuel apertured grate to deliver ash and clinker which have not fallen through the grate during combustion off the grate out of the main support enclosure. This cleaning operation can be carried out at suitable preset time intervals.

Owner:GRANT STEPHEN WILLIAM JOHN

Scraping Blade For Paint Scraper Intended For Removing Paint

InactiveUS20070209136A1Less forceGood effectLiquid surface applicatorsCarpet cleanersScraping - actionEngineering

A scraper blade for a paint scraper intended for removing paint from a surface includes at least one scraping edge. The scraping edge is divided into at least two abutting portions extending along the scraping edge, which, upon abutting scraping action, extend transversely to the direction of scraping, each abutting portion being convex in the plane of the scraping edge, whereby an effective scraping effect is provided.

Owner:KAPMAN

Ink scraping device

InactiveCN106042633AUniform roller surfaceSmooth roller surfacePrinting press partsScraping - actionPulp and paper industry

The invention provides an ink scraping device which is simple in structure, convenient to operate and capable of improving the ink scraping reliability. The ink scraping device comprises an ink disc, a roller wheel and a scraping knife. The ink disc is used for containing ink. The lower portion of the roller wheel is soaked in the ink in the ink disc. The scraping knife is arranged on the ink disc and located on one side of the roller wheel. The ink scraping device further comprises a heater, a controller, an imaging mechanism and an ink jet mechanism. By arranging the heater, the roller wheel is subjected to initial set through the heater, and then the ink scraping action is conducted through the scraping knife; when the protruding ink is scraped through the scraping knife, the ink connected with the protruding ink can be taken away by the scraping knife, and a recessed part is generated on the roller wheel; and acquisition is conducted through imaging, ink jet is conducted on the recessed part by controlling an ink jet box through the controller, and the surface of the roller wheel is made to be uniform and level.

Owner:长兴艾飞特科技股份有限公司

Method and device for preventing distillation scaling

PendingCN109771982AAchieve removalCleaning using toolsFractional distillationChemical industryScraping - action

The invention discloses a method and a device for preventing distillation scaling, and belongs to the fields of chemical industry and environmental protection. A tray with strip-shaped screen holes, provided in the invention, is combined with a self-cleaning mechanism, a frame connected with the shaft and protrusions connected with the frame reciprocatingly move along the strip-shaped screen holesunder the action of the cylinder in the running process of an ammonia distillation tower, the mechanical scraping action of the protrusions is used to remove scales adhered to the strip-shaped screenholes, and the scraped scales are powdery, flow with a liquid, and are finally discharged from the bottom of the tower; and the frame also removes scales adhered to the surface of the tray during reciprocating movement. The method and the device can be used for preventing the scaling problem in the distillation and deamination process of landfill leachate, anaerobic digestion liquids and other high-hardness and high-ammonia nitrogen wastewaters, and copper-ammonia complex and other metal-ammonia complex wastewaters.

Owner:JIANGSU WODEKAI ENVIRONMENTAL PROTECTION TECH CO LTD

3D printer with automatic clearing function

InactiveCN113320153AWith automatic cleaning functionRealize the scraping actionManufacturing recycling3D object support structuresScraping - actionComputer printing

The invention relates to the technical field of printer equipment, in particular to a 3D printer with an automatic clearing function. The 3D printer aims at solving the technical problems that an error is generated between the initial glue spraying moment of a nozzle and a program setting moment due to the fact that glue stock on the nozzle of an existing device is easily blocked, vibration is generated due to high-pressure release at the beginning moment of glue spraying, the quality of printing operation products is affected, waste is inconvenient to collect, clearing and maintenance are troublesome, and in order to solve the technical problem, the 3D printer with the automatic clearing function comprises a bearing arm, and the bearing arm is of a U-shaped structure. Through arrangement of a claw head and a scraping block, a moving plate and a bearing plate are driven by a step change device to generate separation action, so that the scraping block performs scraping action along the glue stock on the outer surface of the nozzle, blockage is avoided, stable and reliable operation is guaranteed, a piston plate instantly moves on the inner side of the piston pipe, negative pressure is generated at the position of an air inducing hole, and the scraped glue stock is collected.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com