Patents

Literature

54results about How to "Realize automatic scraping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

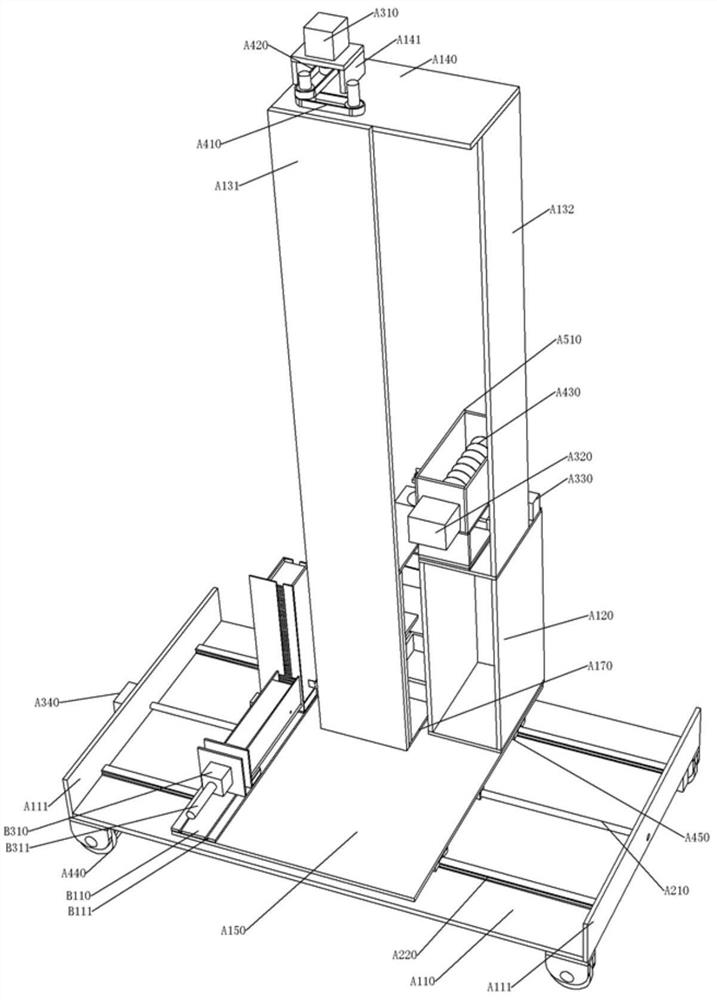

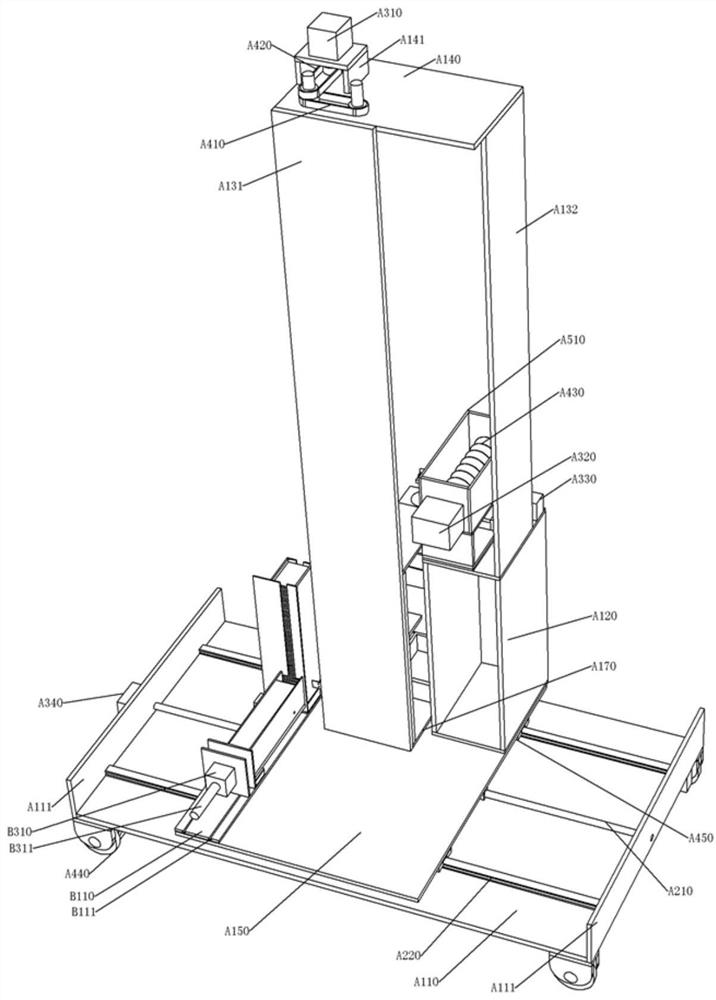

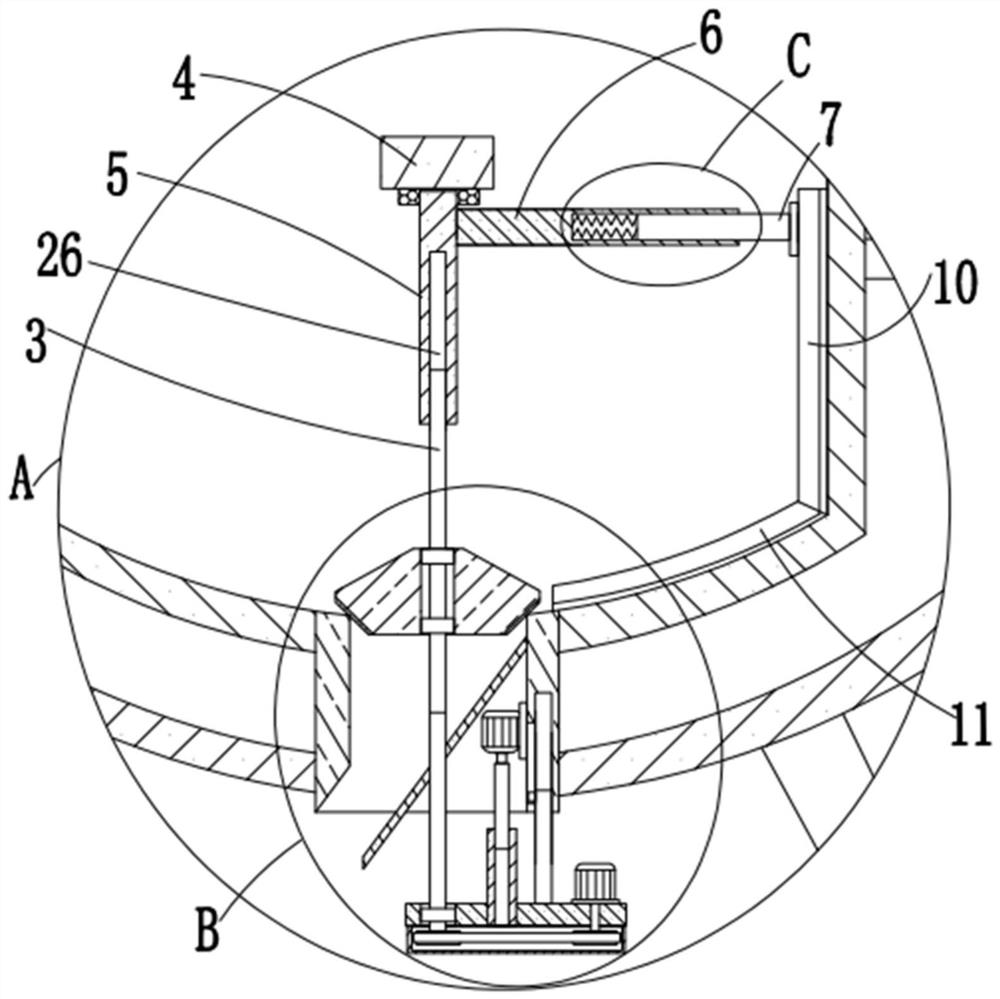

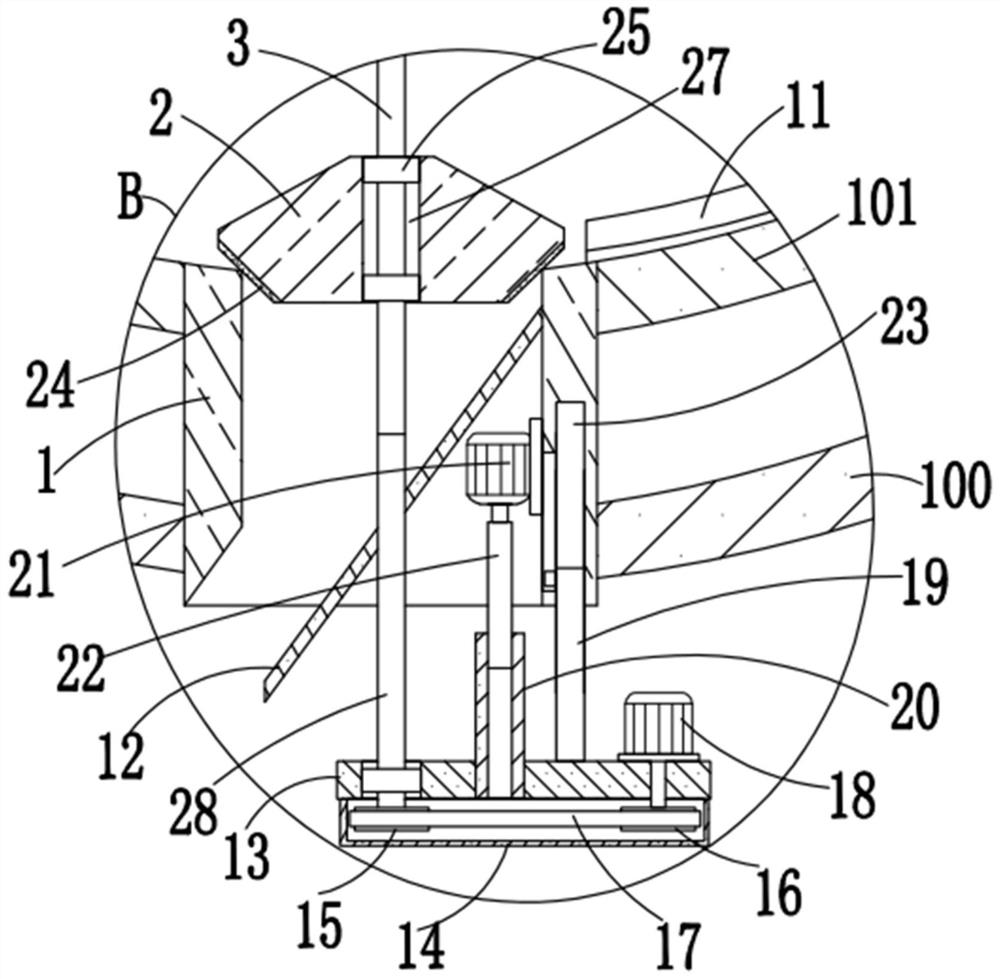

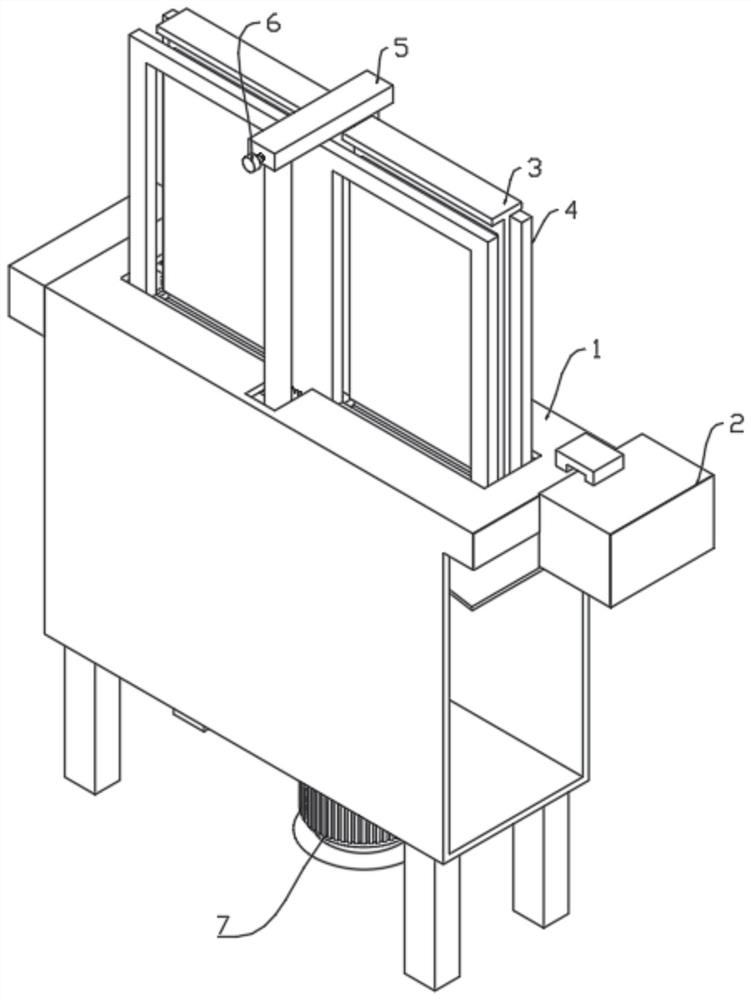

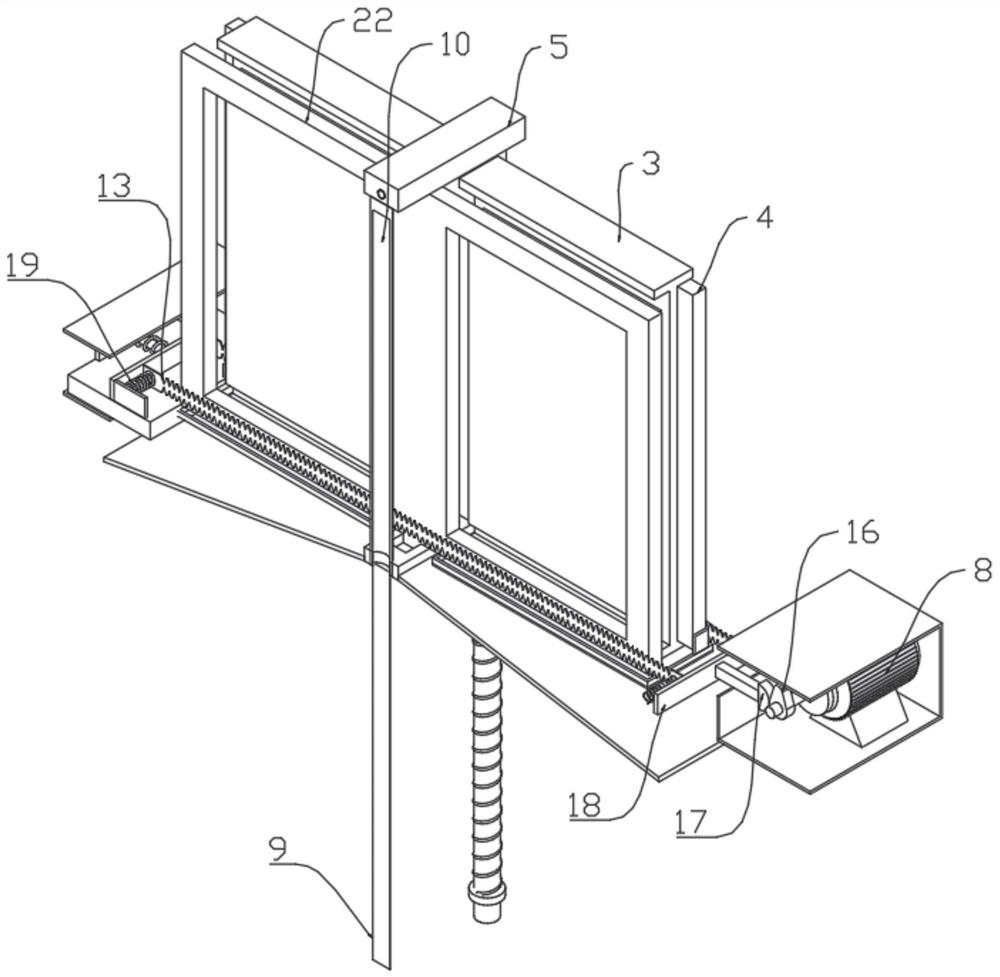

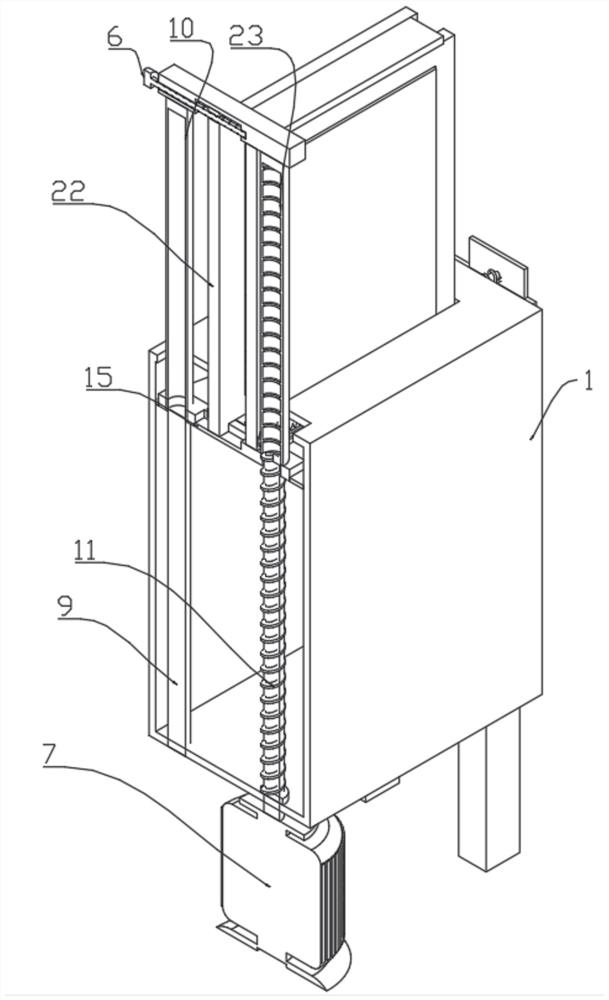

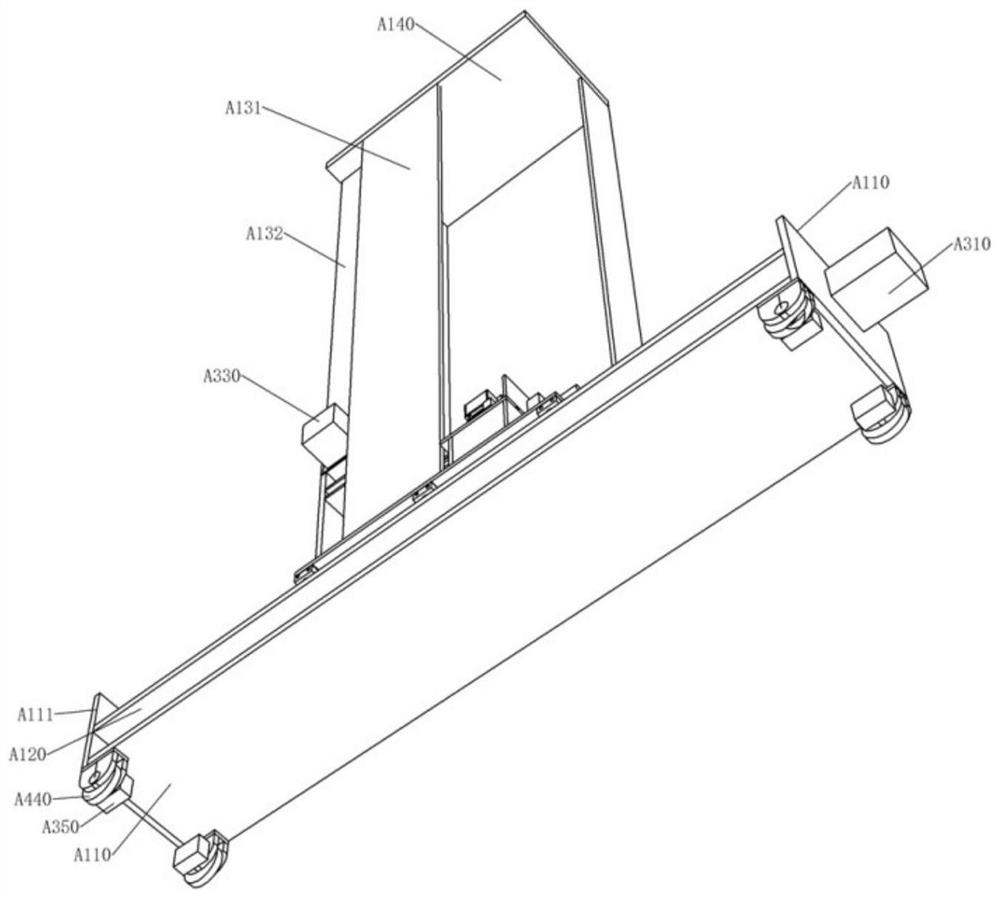

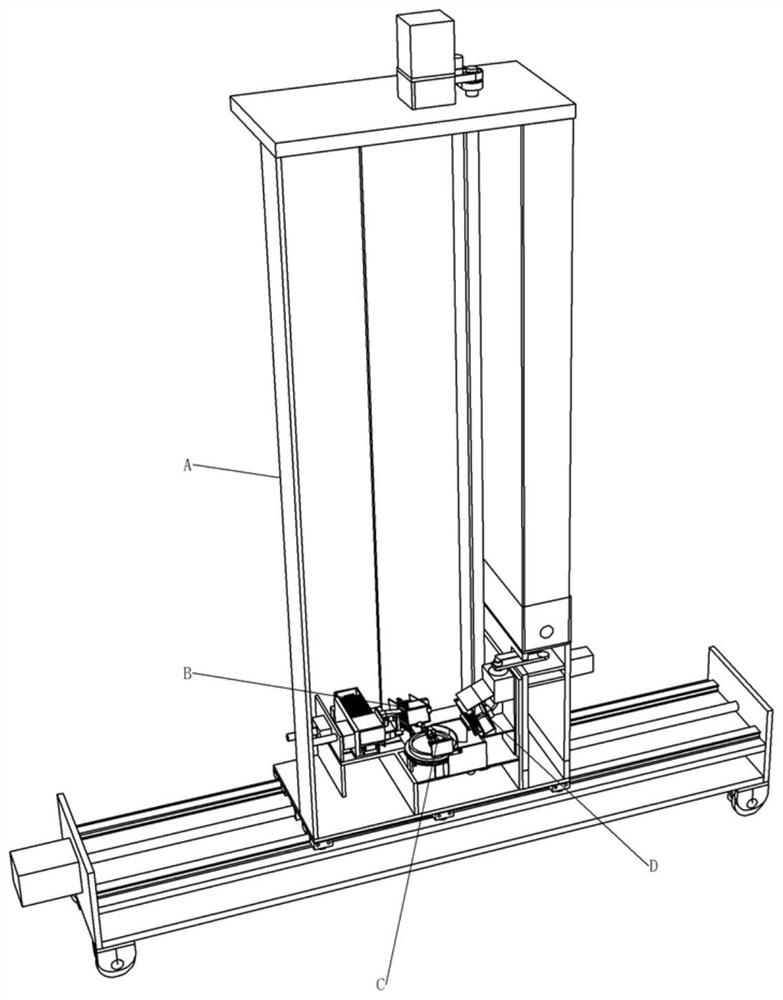

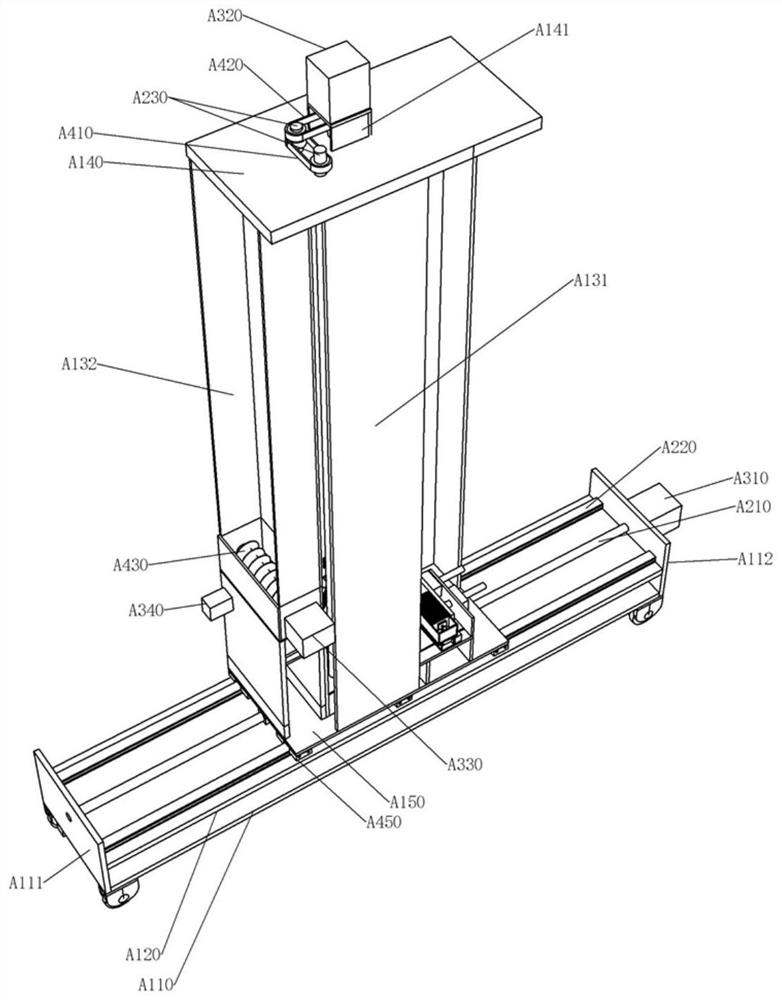

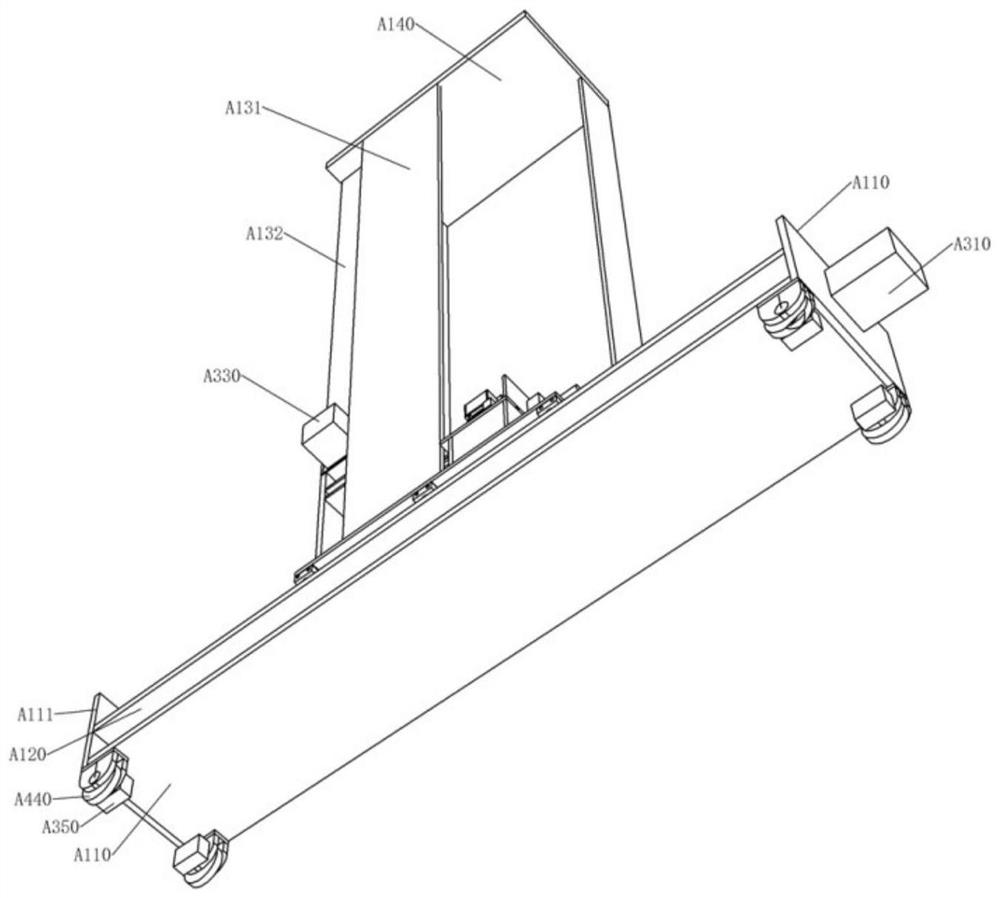

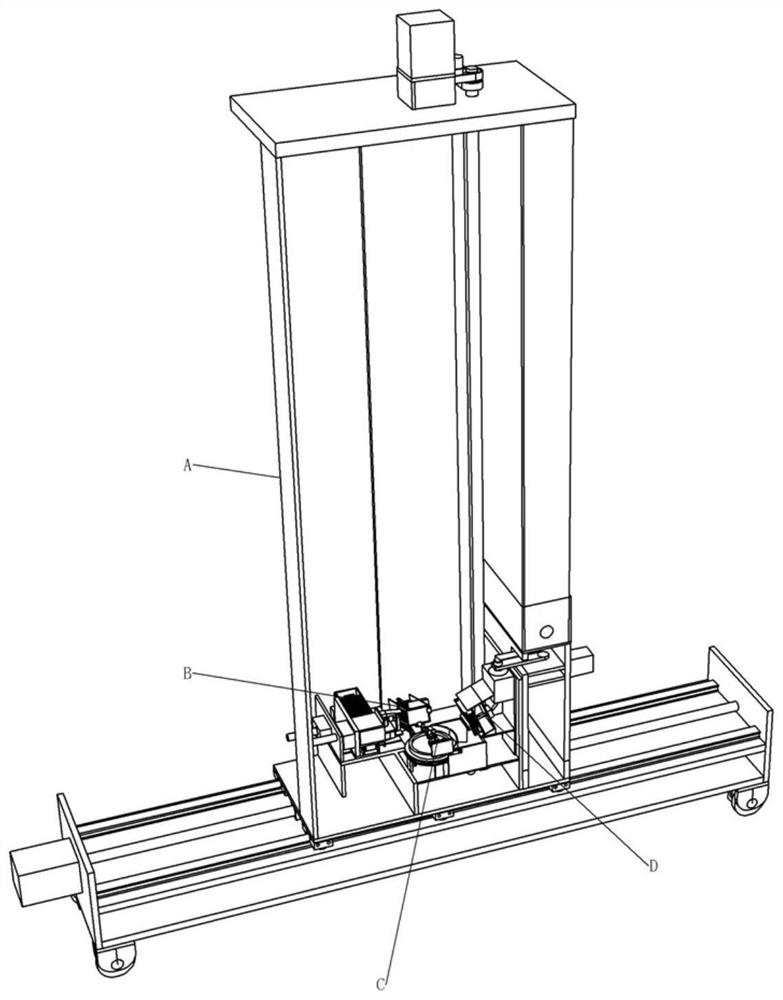

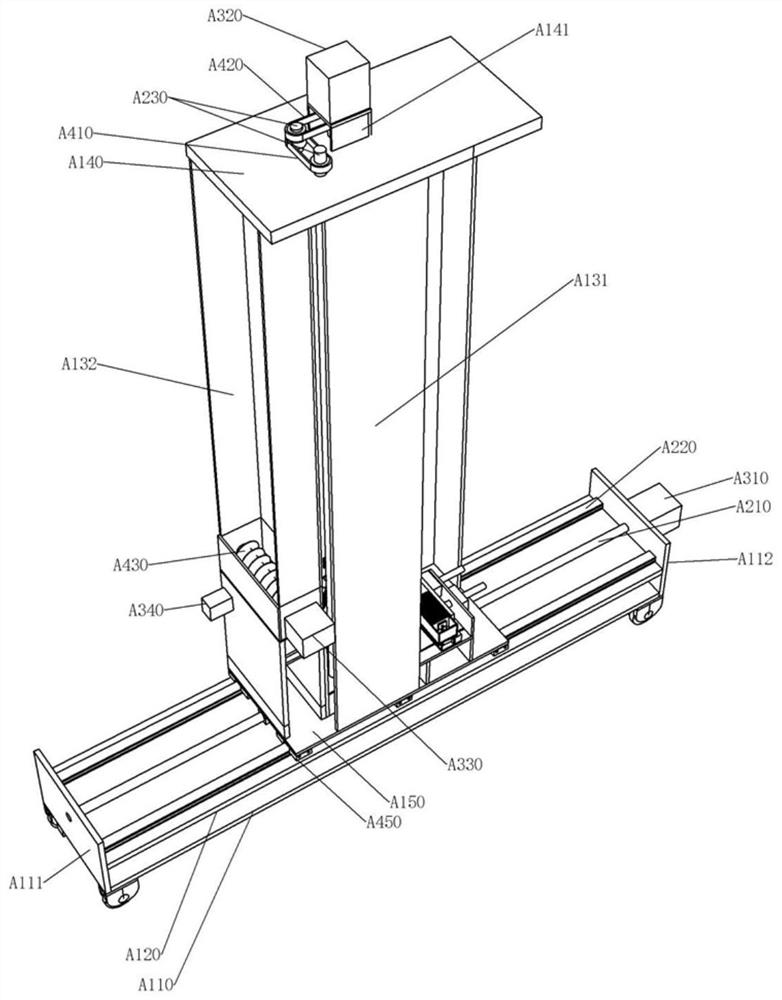

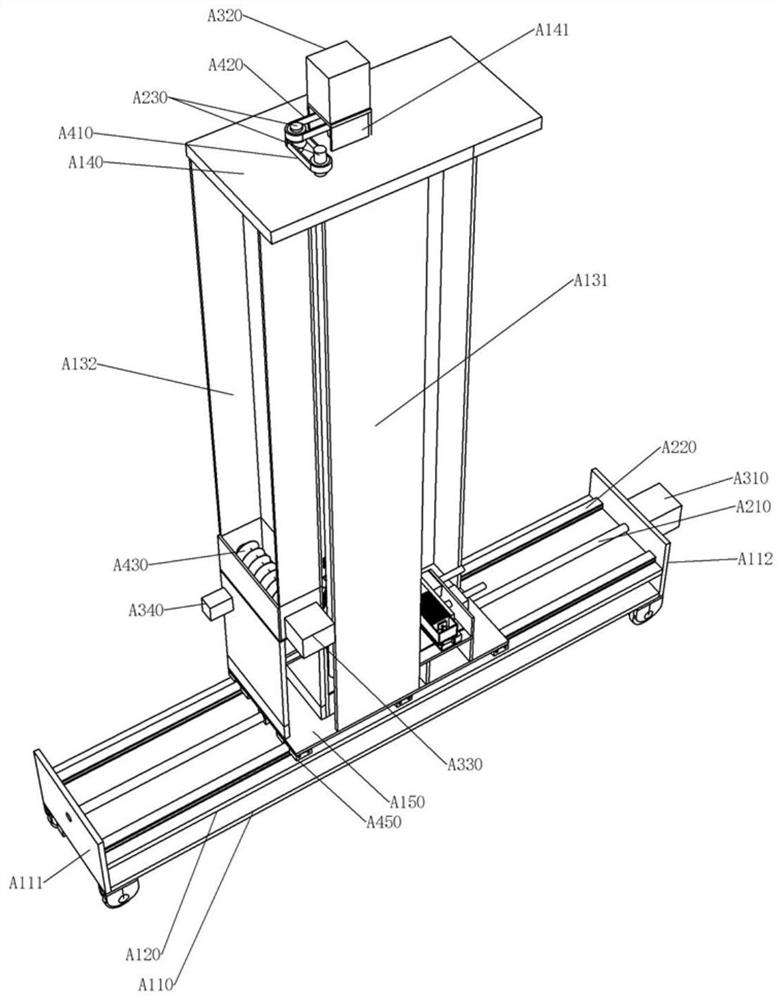

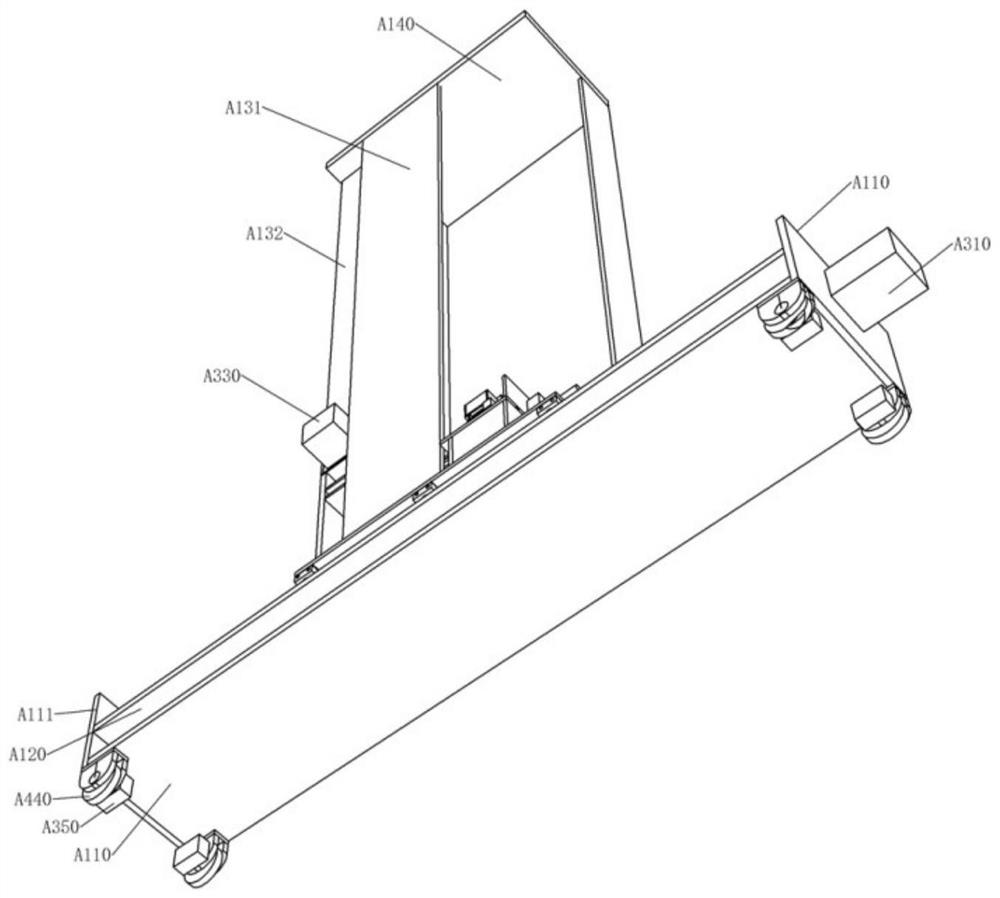

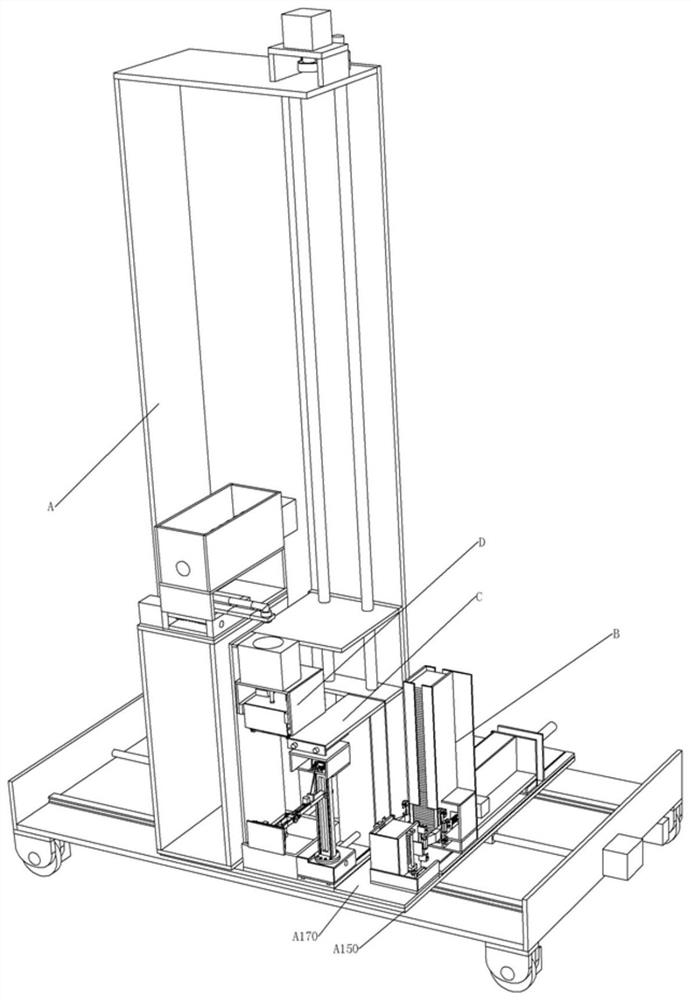

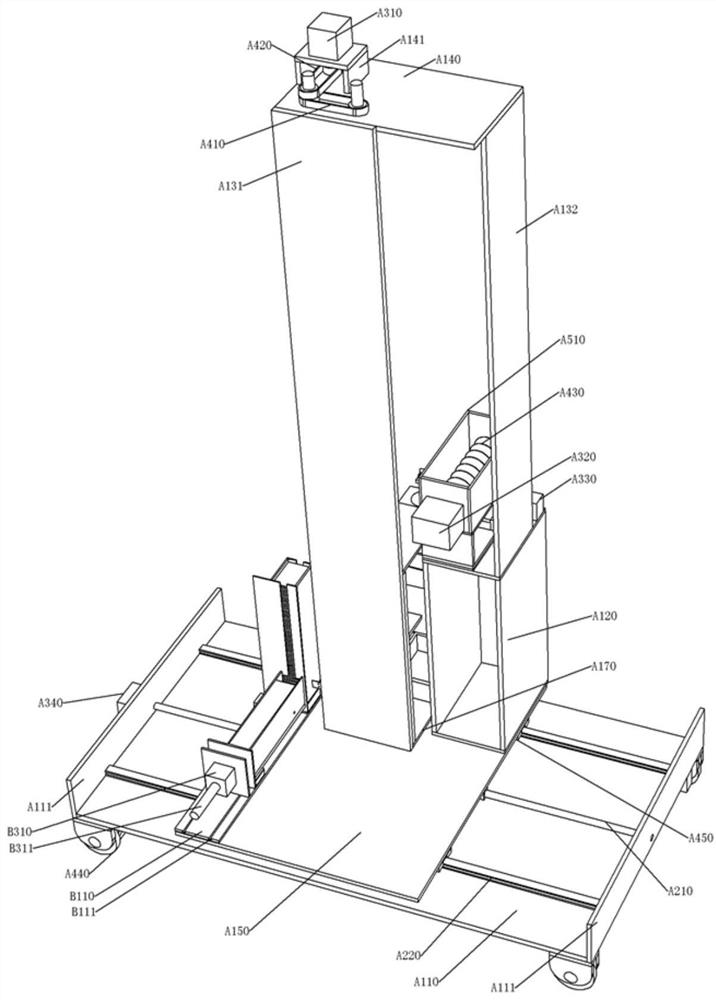

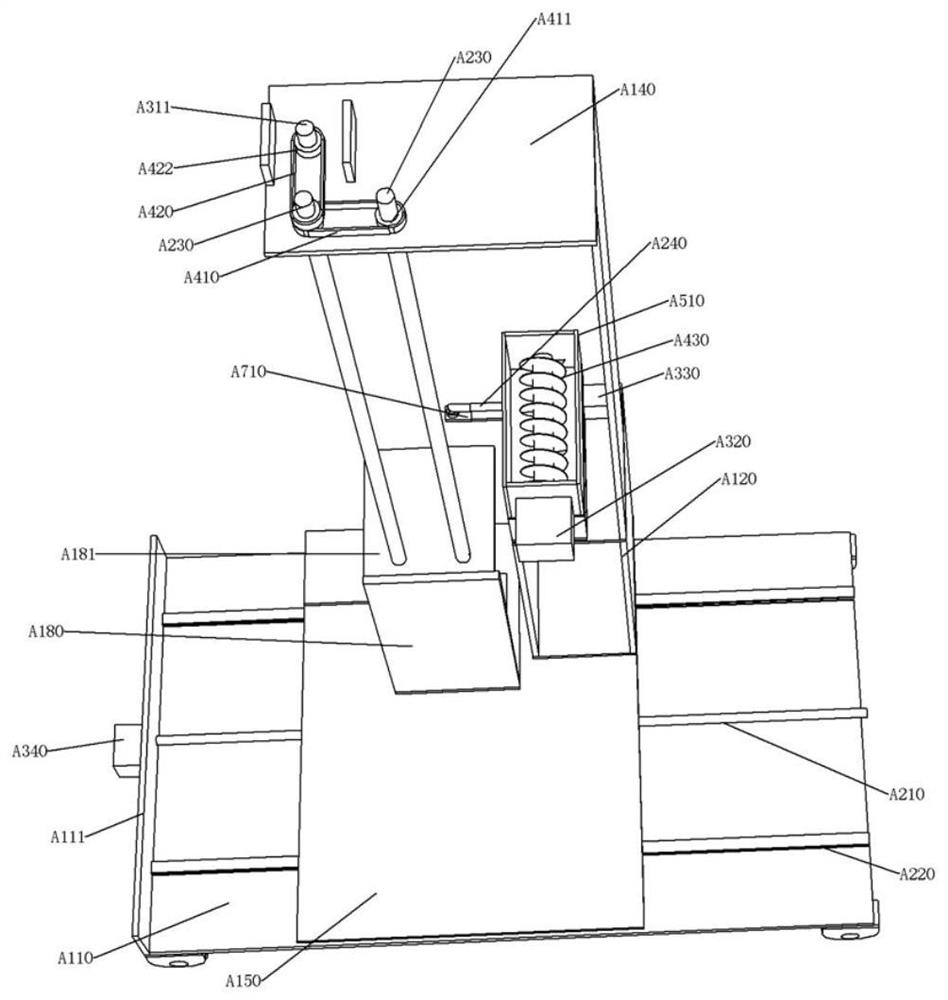

Rack module and intelligent tiling robot thereof

ActiveCN112031368AFully automated tilingVersatileBuilding constructionsEngineeringImage identification

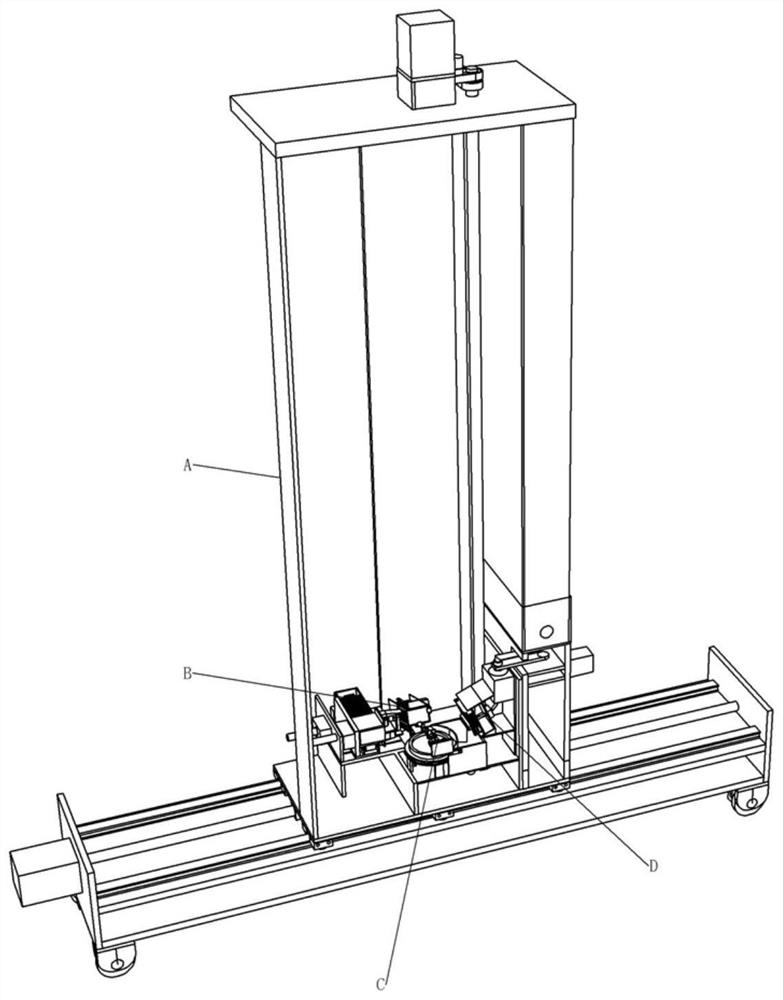

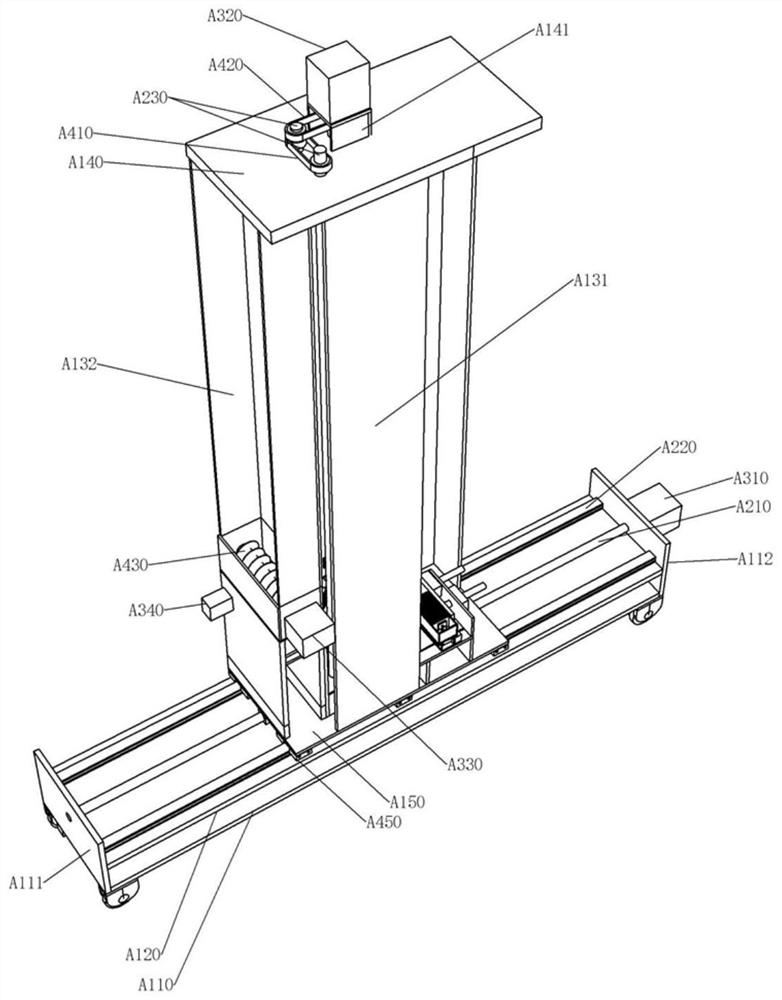

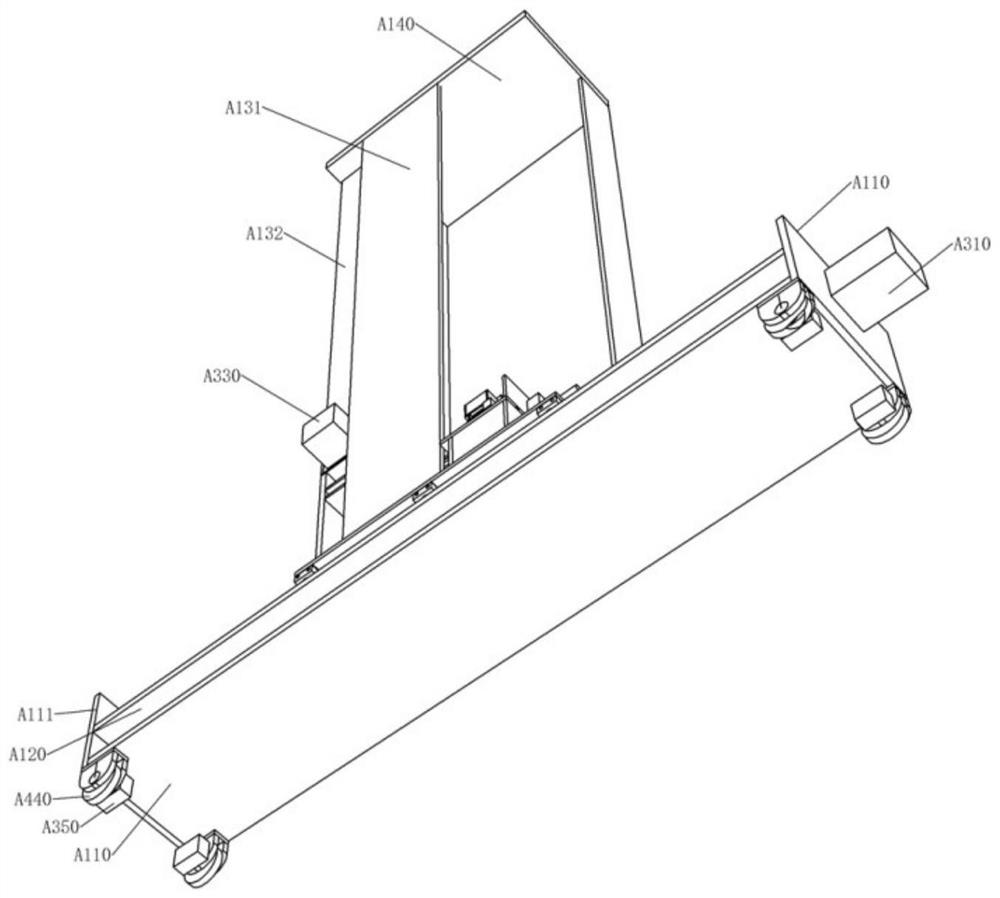

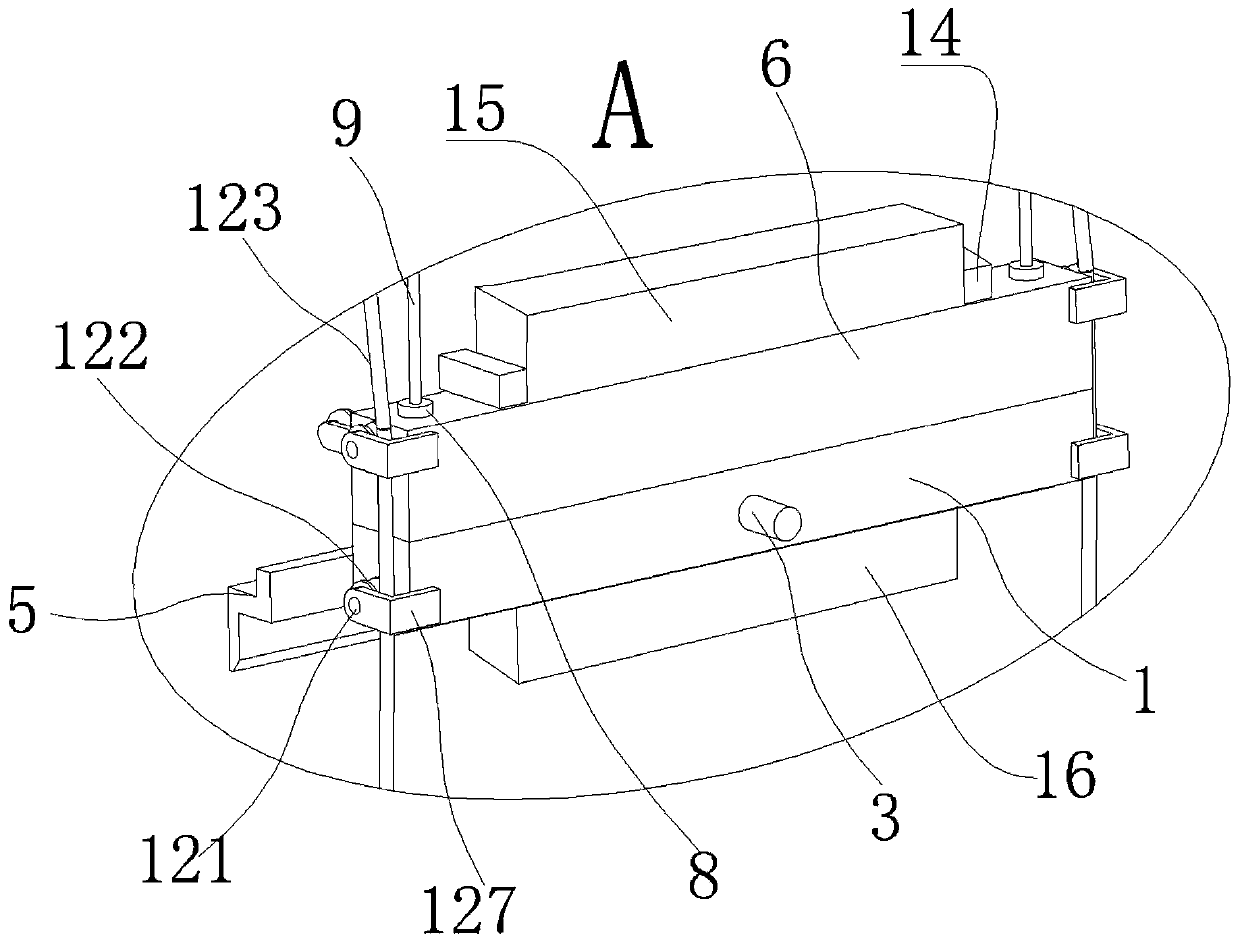

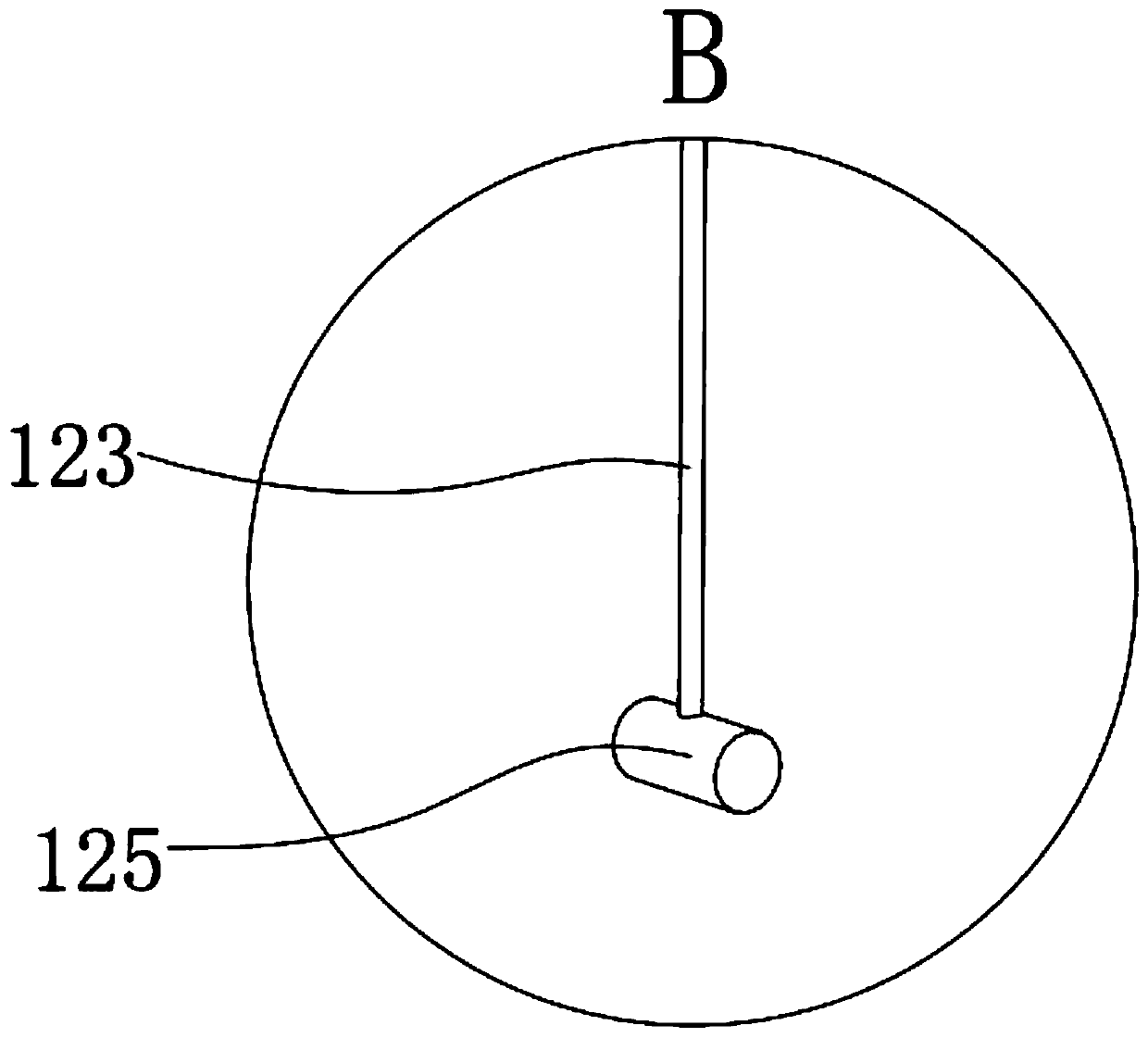

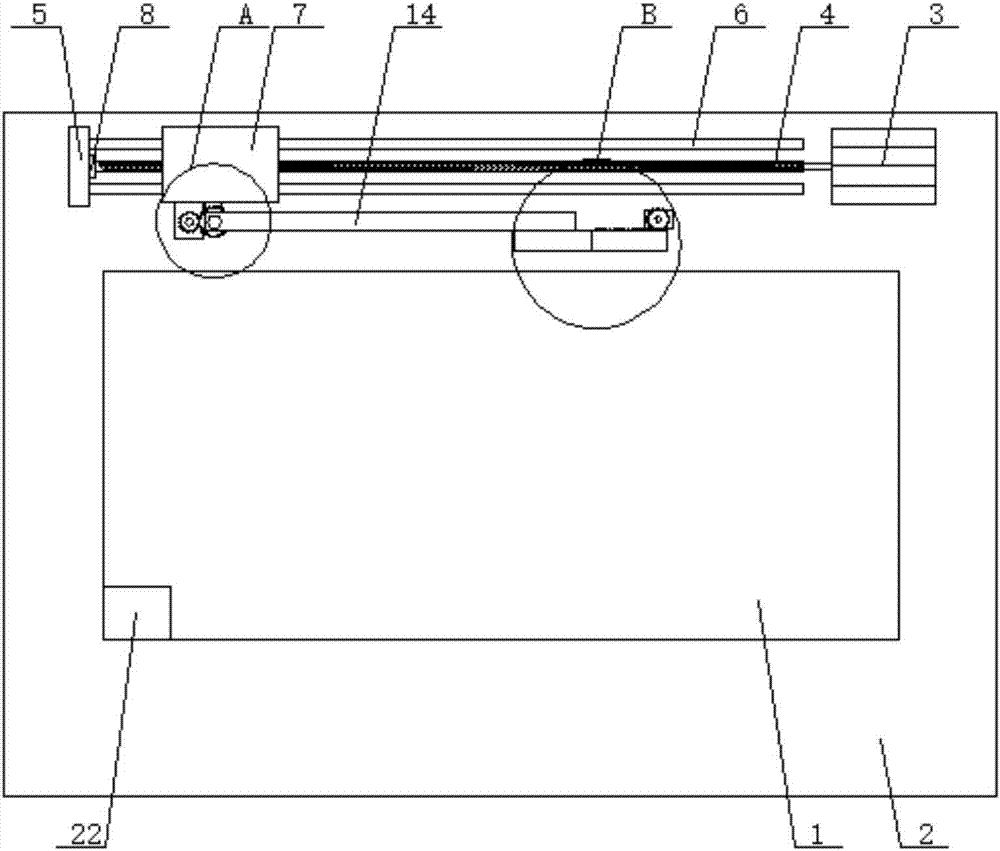

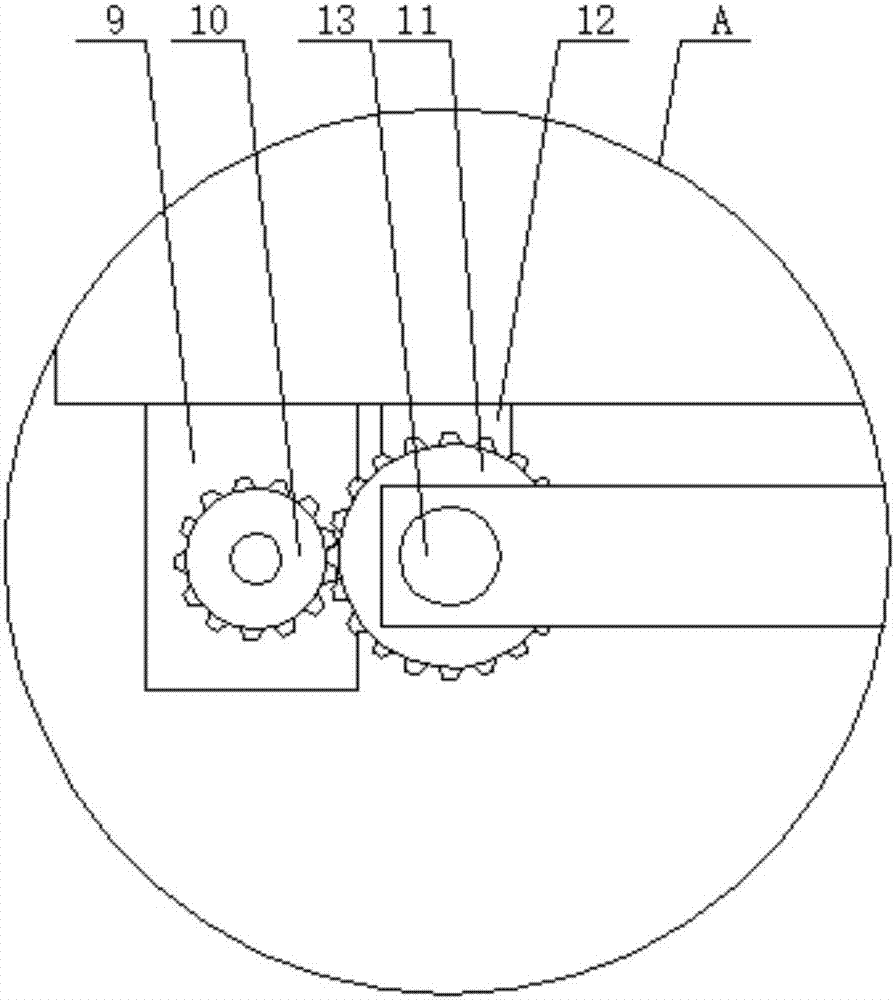

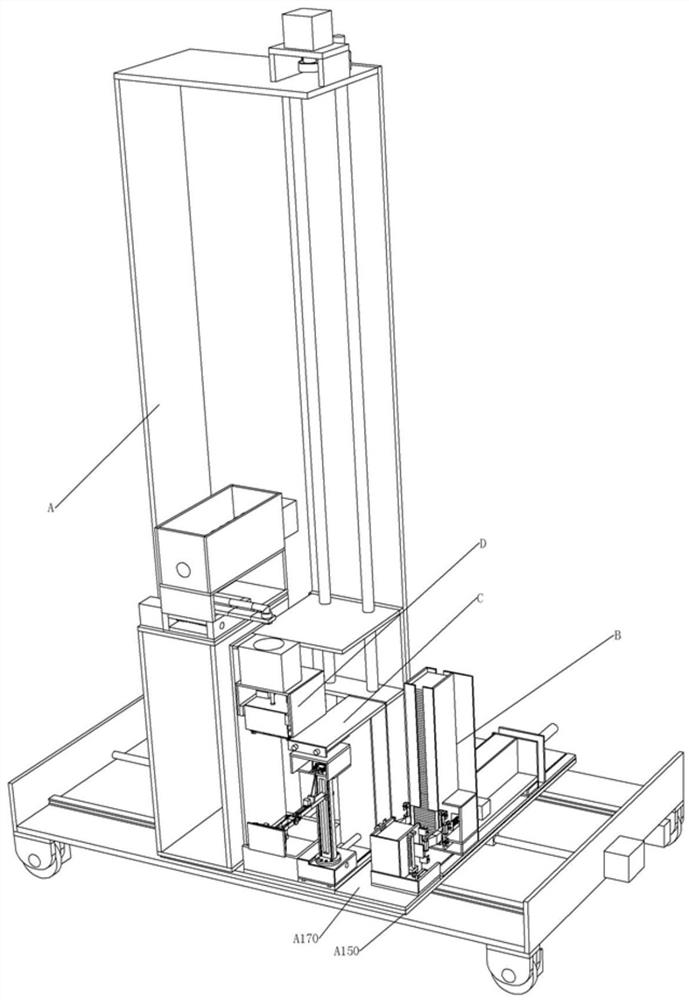

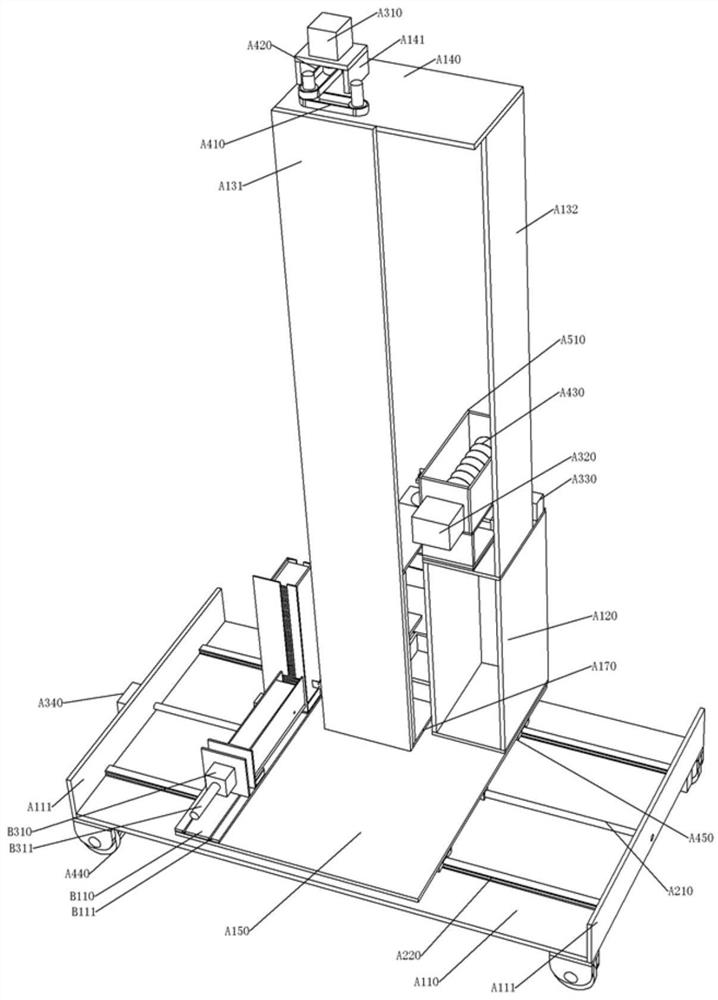

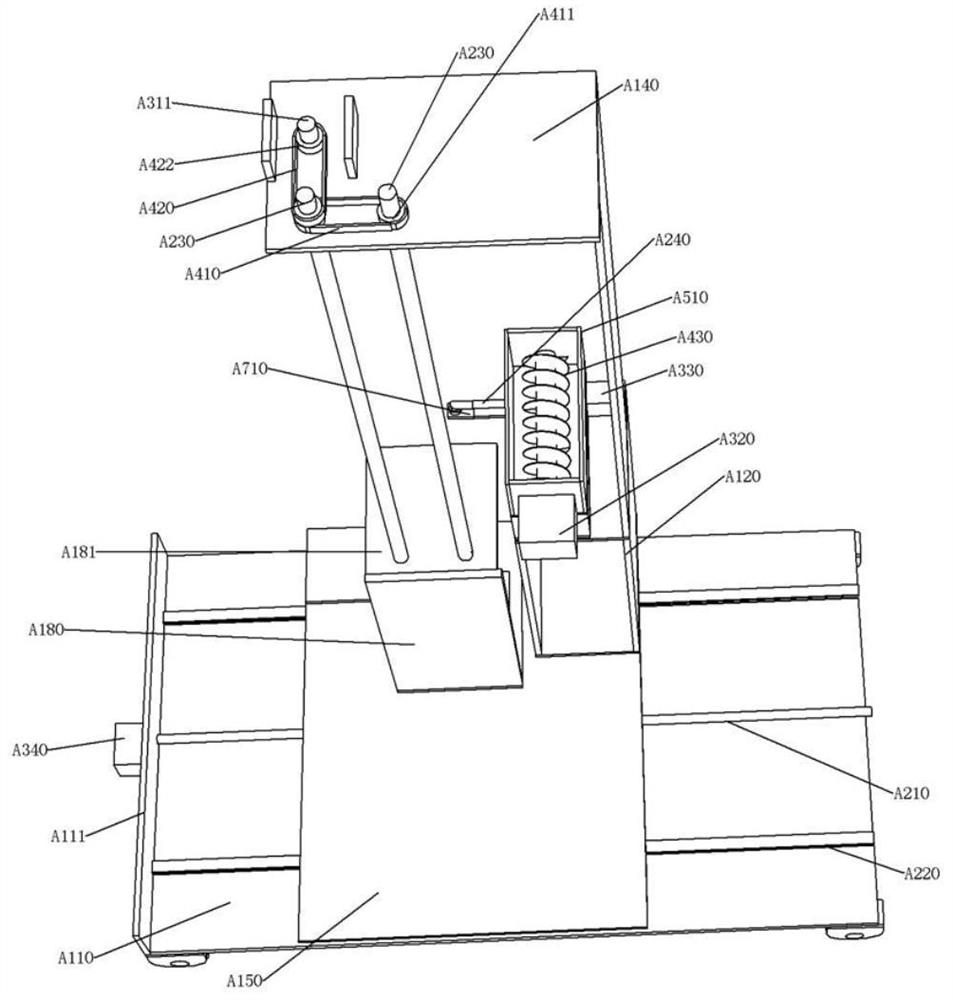

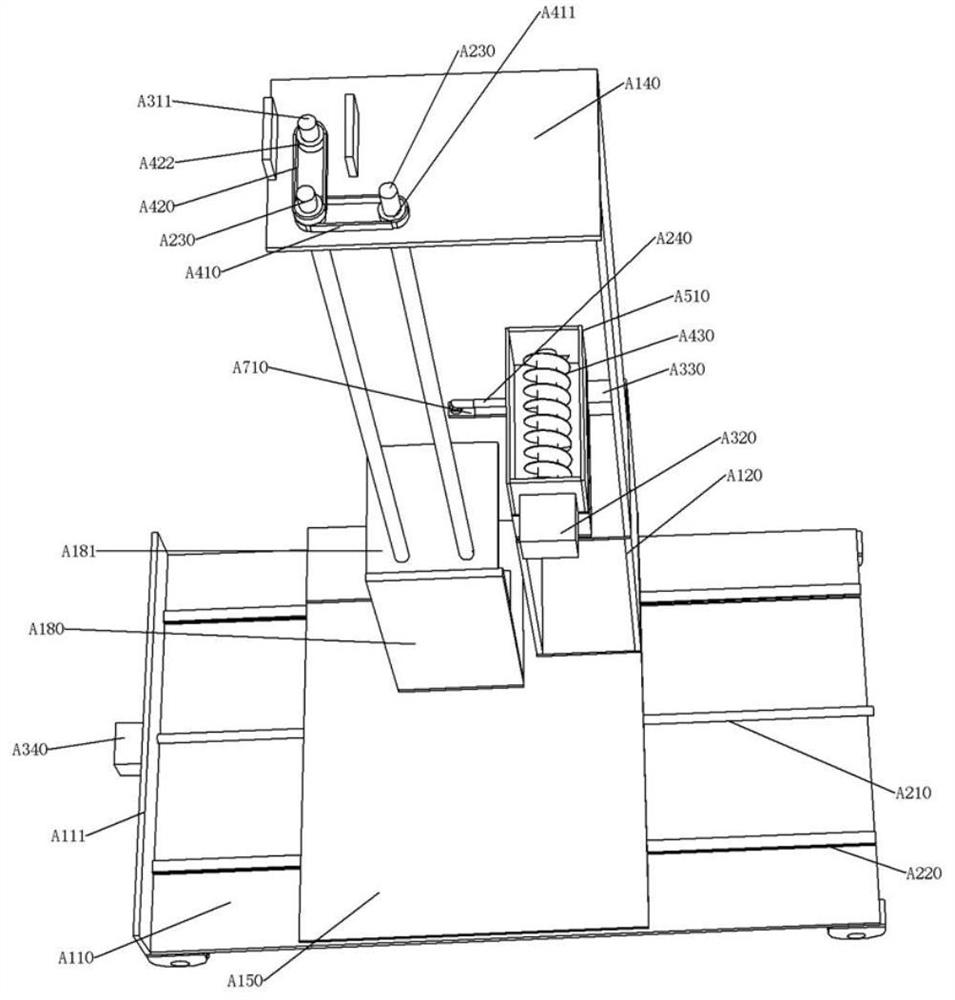

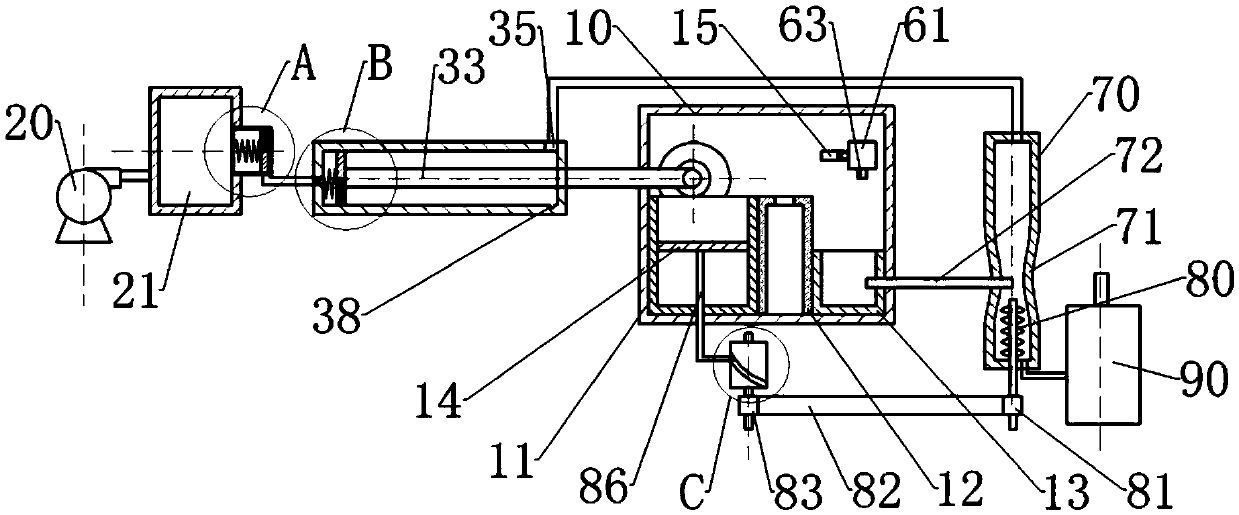

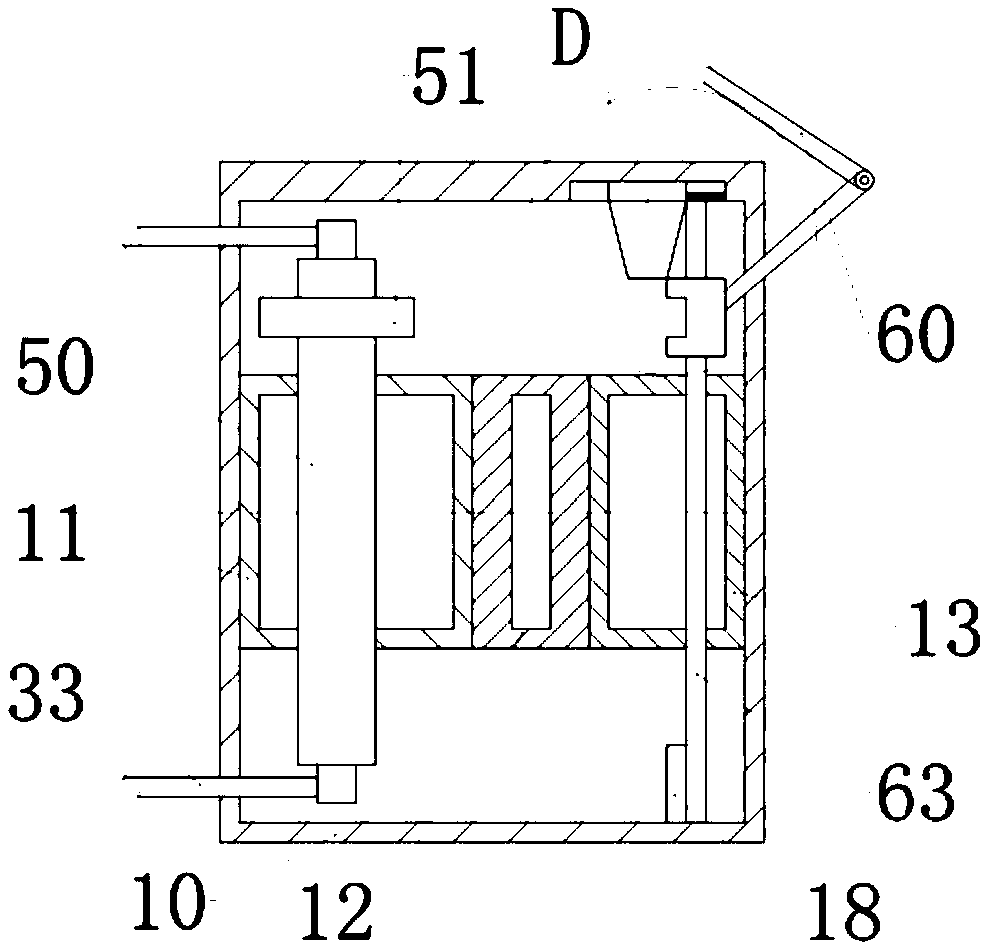

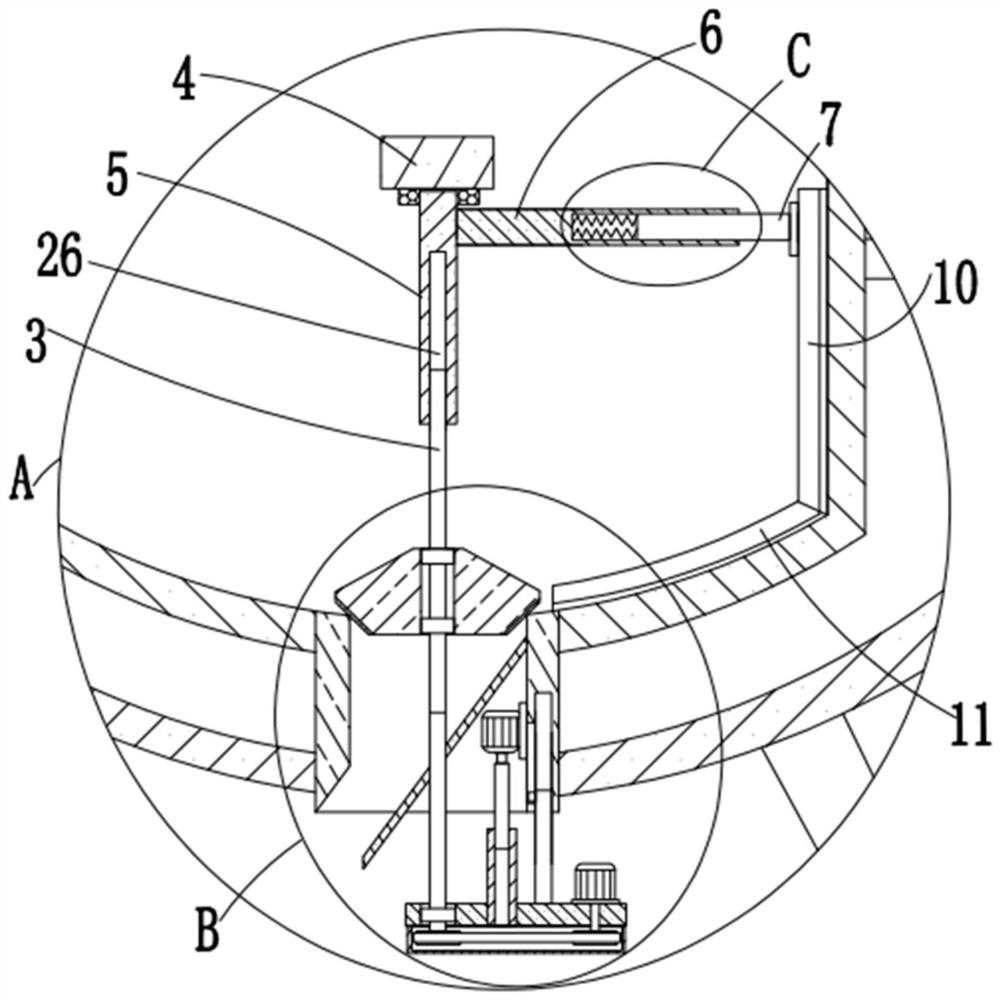

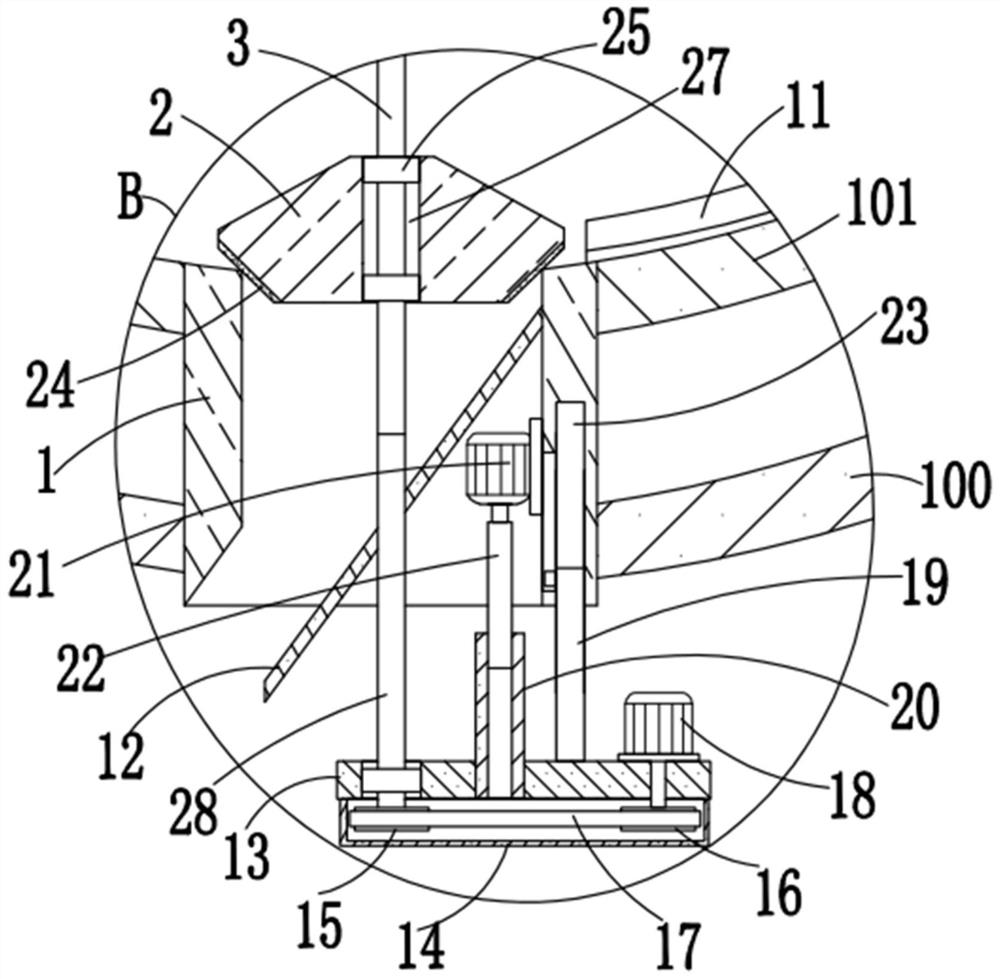

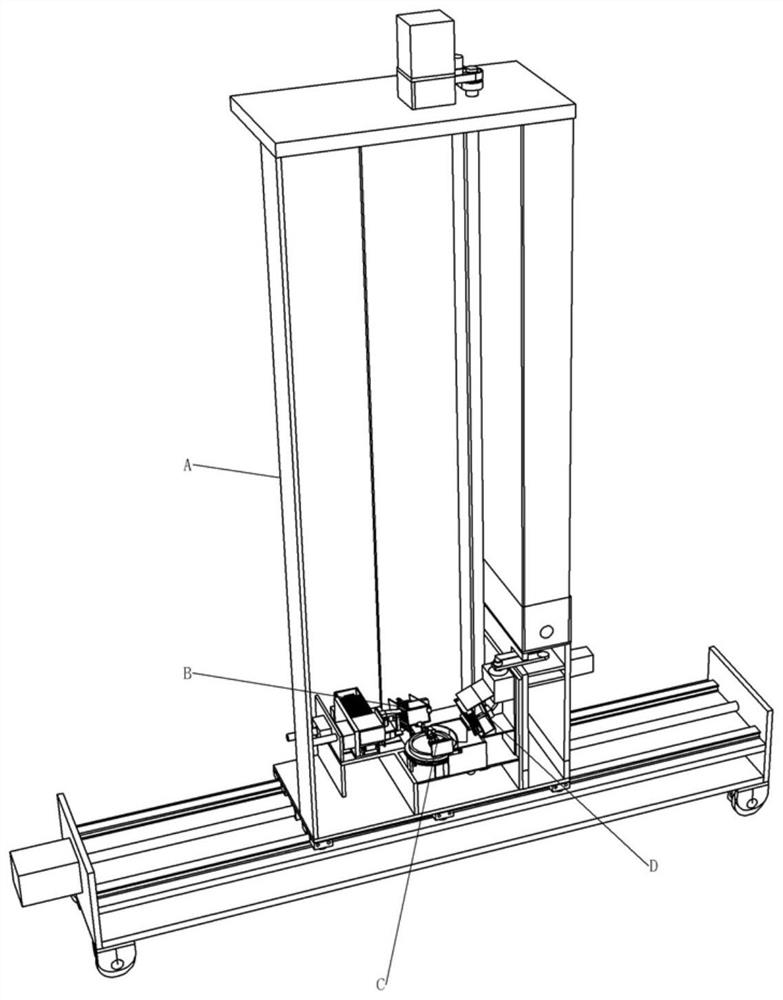

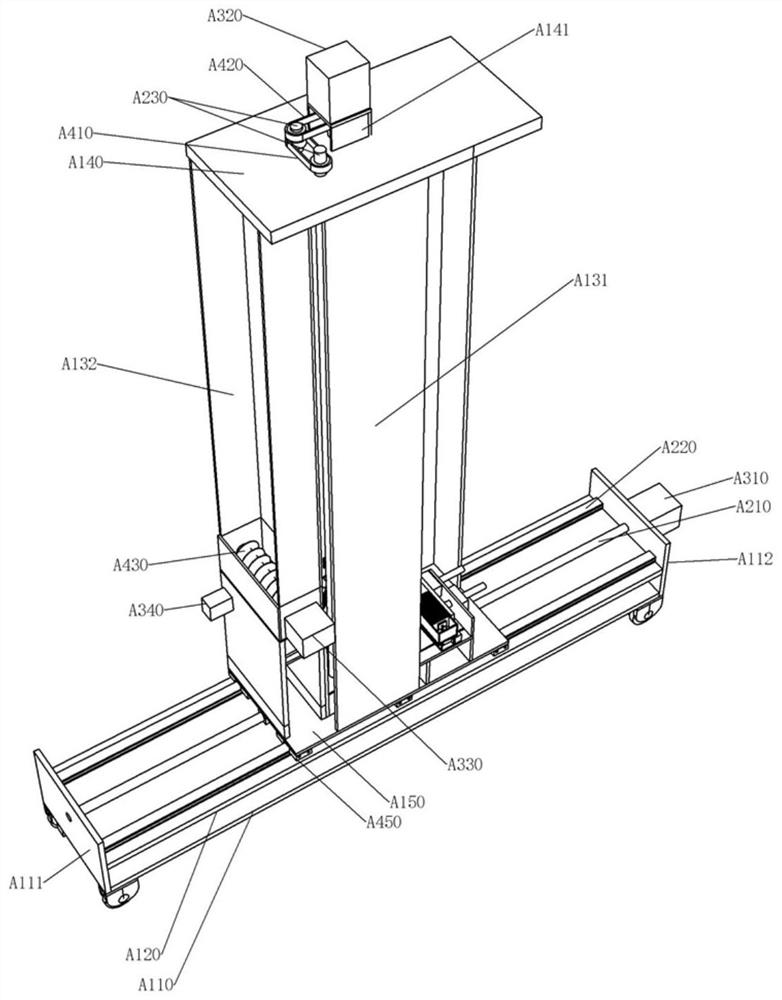

The invention discloses a rack module and an intelligent tiling robot thereof. The intelligent tiling robot comprises the rack module, a tile supply module, a tile suction module and a slurry scrapingmodule, wherein the rack module is used for mounting, moving and positioning the tile supply module, the tile suction module and the slurry scraping module; the tile supply module is used for continuously supplying wall tiles to the tile suction module so as to facilitate suction of the tile suction module; the tile suction module is used for sucking the wall tiles, then feeding the wall tiles into the slurry scraping module for slurry scraping, conveying the wall tiles to be parallel to a tiling wall surface and then pasting the wall tiles to the tiling wall surface; and the slurry scrapingmodule is used for scraping slurry on the wall tiles so as to facilitate subsequent pasting of the wall tiles to the tiling wall surface. The intelligent tiling robot has complete functions and can realize automatic slurry scraping, wall tile suction, wall tile rotation, wall tile pasting and detection of whether the wall tiles are laid flat and simultaneously lay flat, the whole process can realize full automation, a basis can be provided for a subsequent full-automatic wall tile pasting technology, that is, a technical basis is provided for a subsequent AI tiling technology. Particularly, after an intelligent image recognition and planning technology is added, AI tiling can be basically realized.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

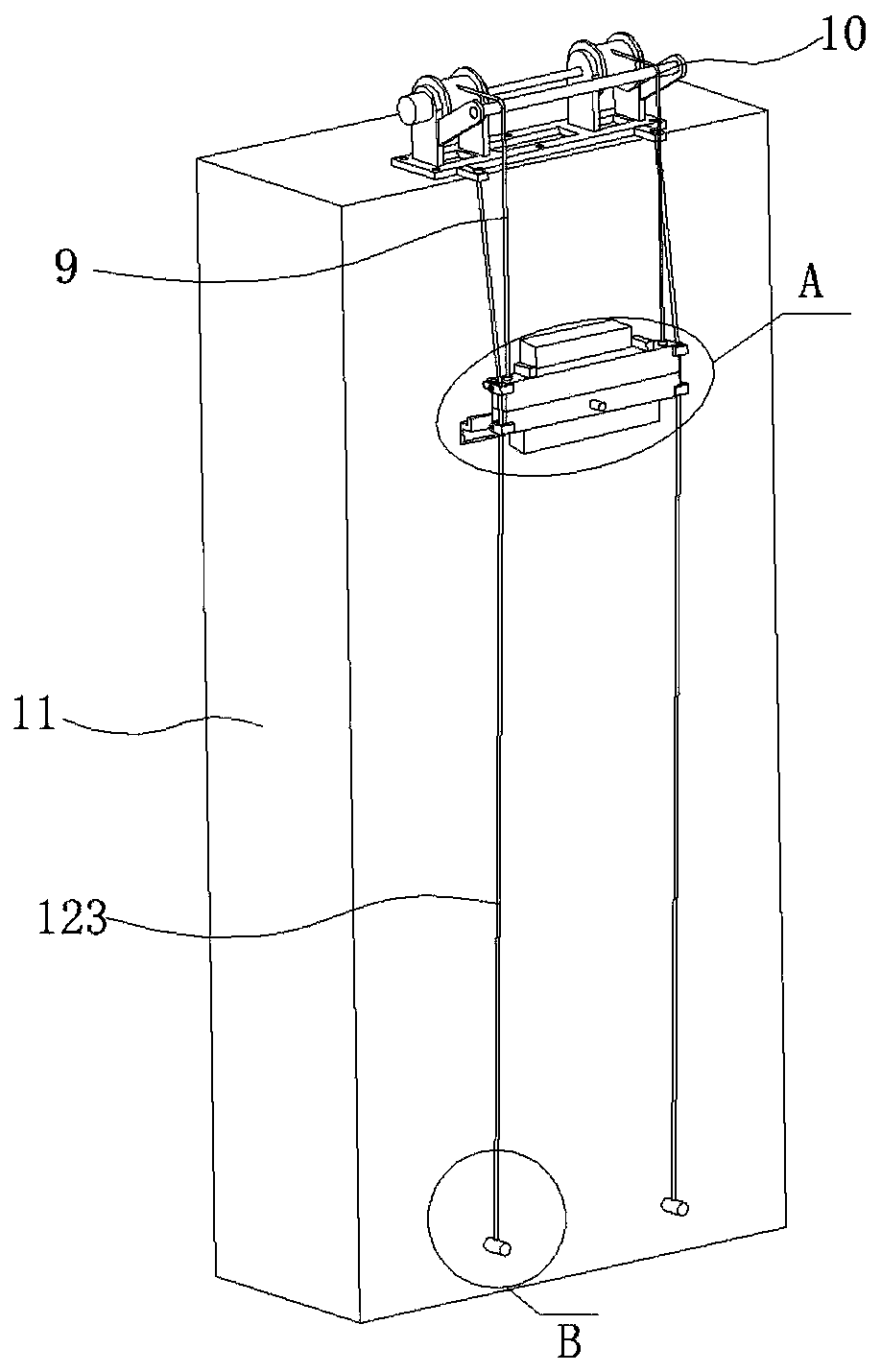

Automatic cleaning platform for insulating layer of external wall of building construction

The invention discloses an automatic cleaning platform for an insulating layer of an external wall of building construction. The automatic cleaning platform comprises a first installation box, a second installation box is fixed on the first installation box, a storage battery is fixed in the second installation box, the storage battery is electrically connected with an electric push rod, the electric push rod is fixed on the first installation box, a piston rod of the electric push rod is in threaded connection with a pushing block, a scraping knife is fixedly connected on the pushing block, the scraping knife is positioned on the outer portion of the front side of the first installation box, the front end of the scraping knife is in close contact with a wall, supporting mechanisms are arranged on two sides of the upper portion of the scraping knife, the supporting mechanisms are installed at the front end of the second installation box, connecting seats are welded on two sides of thetop end of the second installation box, lifting steel wire ropes are fixed on the connecting seats, a lifting mechanism is arranged at one end, far away from the corresponding connecting seat, of eachlifting steel wire rope, and platform limiting mechanisms are symmetrically arranged at the ends of the left end and the right end of the first installation box and the second installation box. The insulating layer on the wall can be automatically removed without labor, the safety is good, and the working efficiency is high.

Owner:左雪云

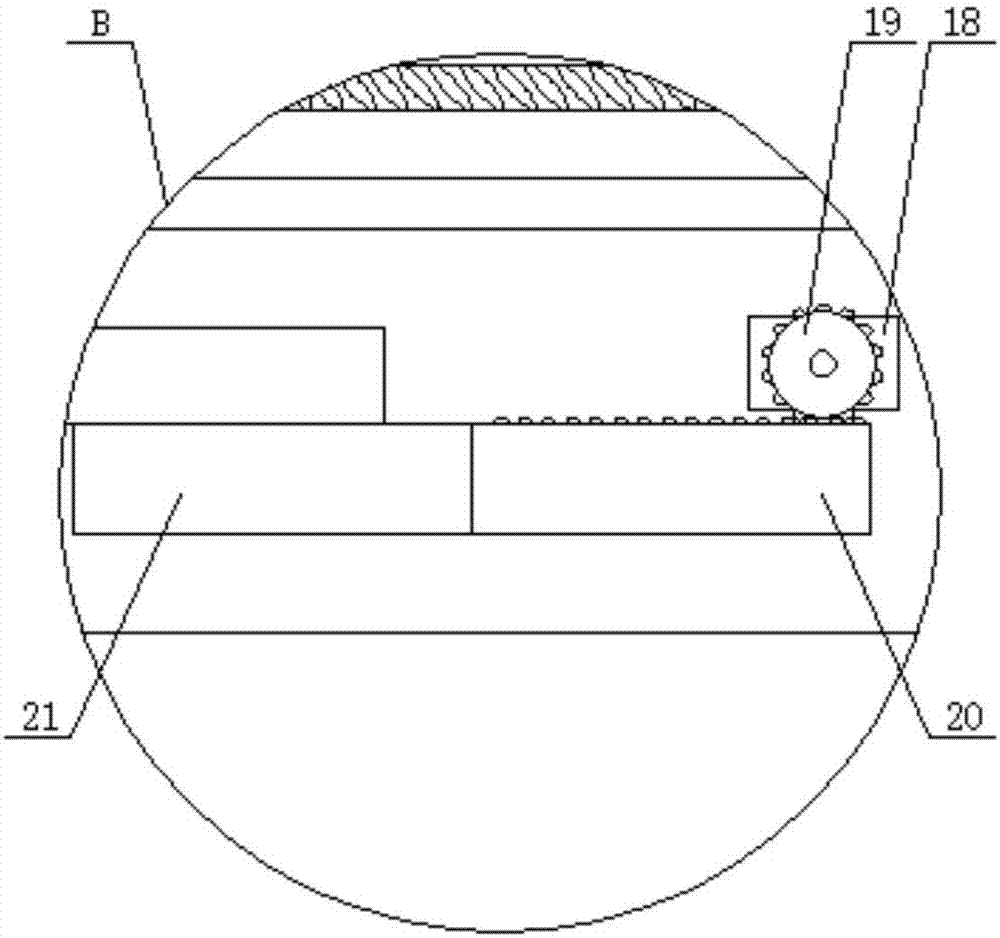

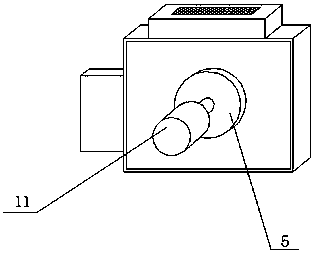

Mirror with automatic mist cleaning function

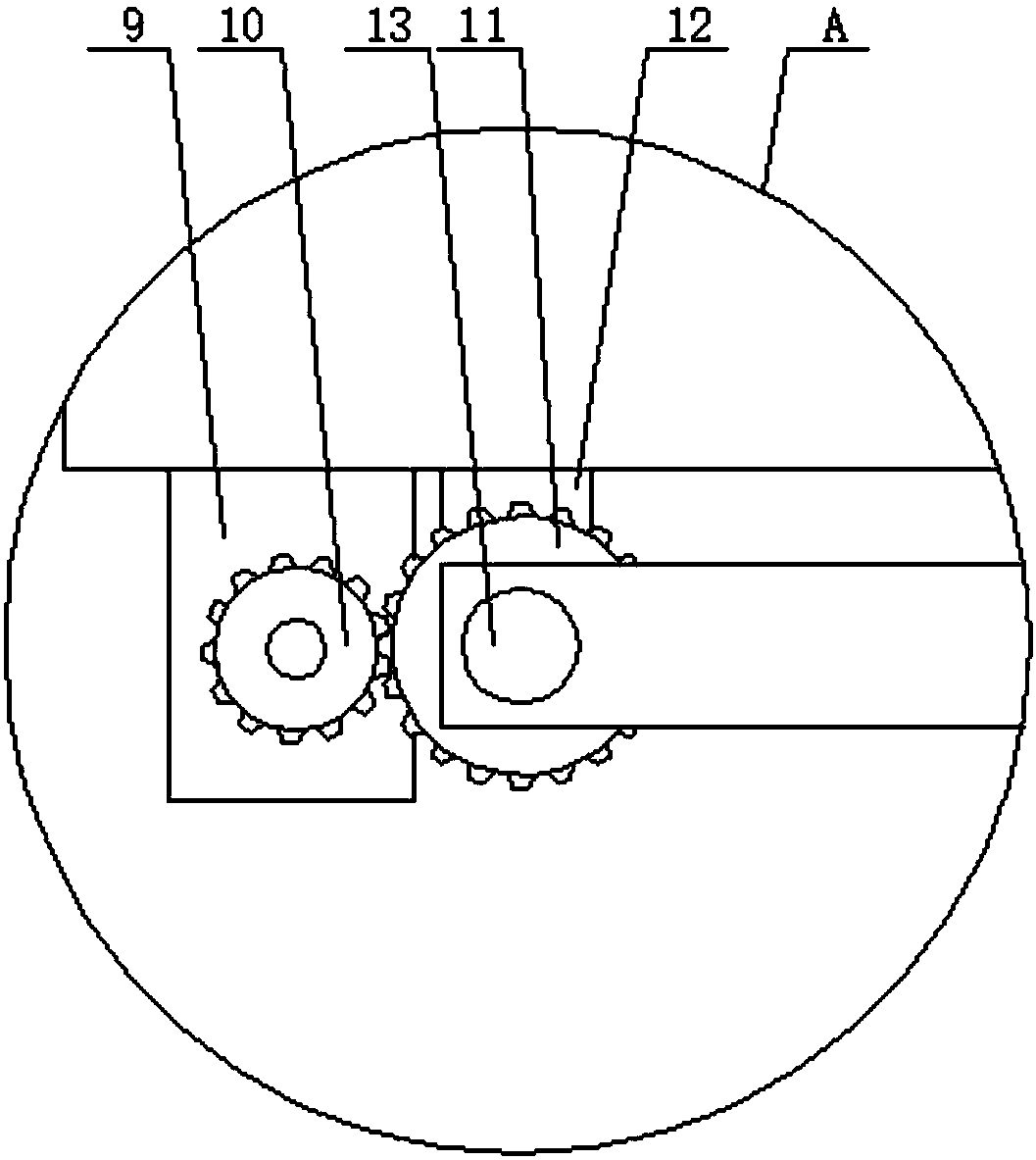

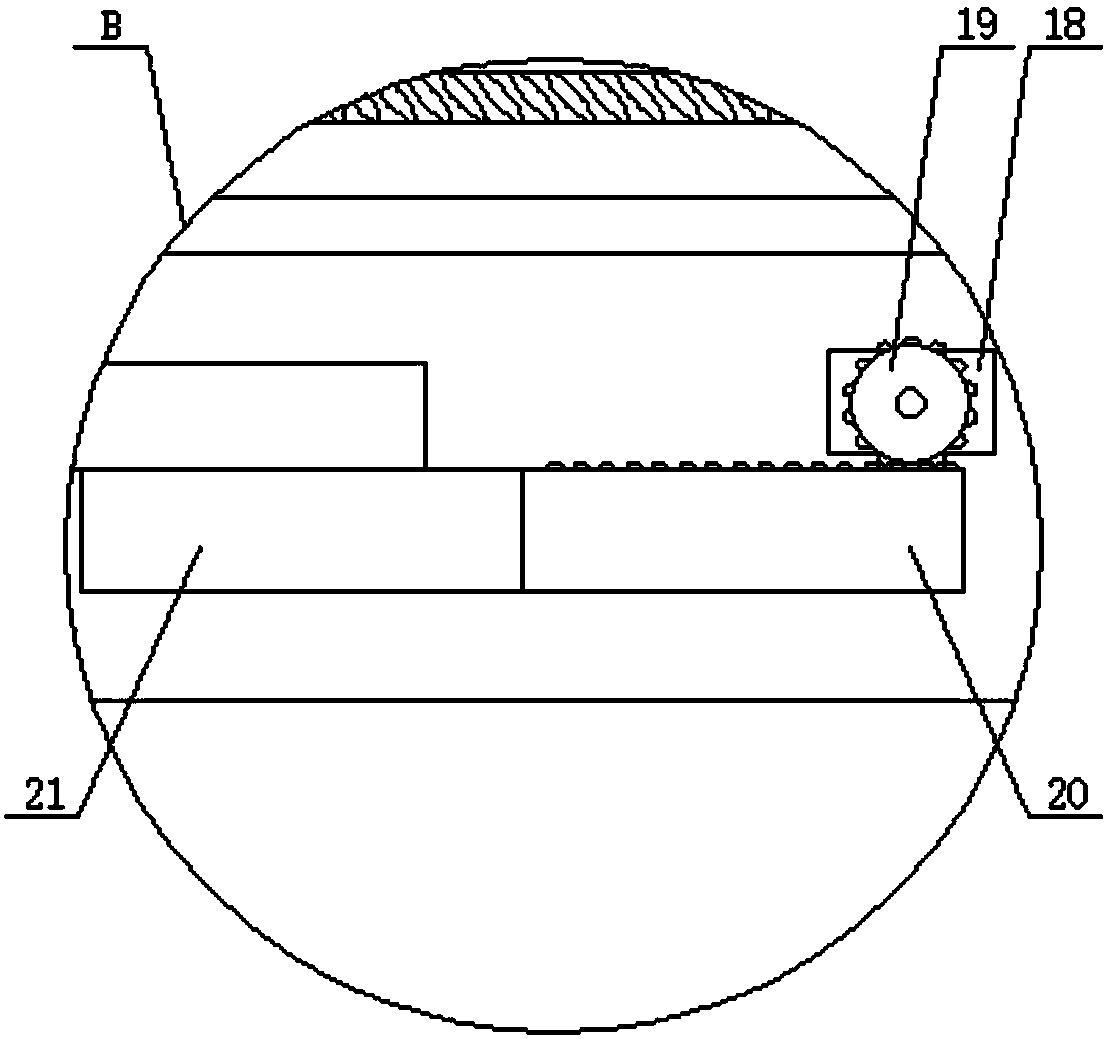

ActiveCN106880229ARealize automatic scrapingWith automatic cleaning mist functionCarpet cleanersPicture framesEngineeringMechanical engineering

The invention relates to a mirror with an automatic mist cleaning function. The mirror comprises a mirror face and a mirror frame; the mirror frame further comprises a cleaning device, the cleaning device comprises a moving mechanism, a rotating mechanism and a cleaning mechanism, the moving mechanism comprises a first motor, a lead screw, a fixing block, a sliding rod and a sliding block, the rotating mechanism comprises a second motor, a first cylindrical gear, a second cylindrical gear, a second bearing and a rotating shaft, the cleaning mechanism comprises a cleaning rod, a rubber strip and a compressing assembly, and the compressing assembly comprises a spring and a supporting rod. According to the mirror with the automatic mist cleaning function, when much mist exists on the mirror face, the cleaning rod located on the upper portion of the mirror face drives the rubber strip to rotate so that the rubber strip can abut against the mirror face and be arranged vertically, and then the moving mechanism drives the rubber strip to be attached to the mirror face and move back and forth so that the mist can be scrapped automatically; compared with manual wiping, the mode saves time and labor, the mirror is cleaned more thoroughly without water stain, and great convenience is brought to life of people.

Owner:宿州市徽腾知识产权咨询有限公司

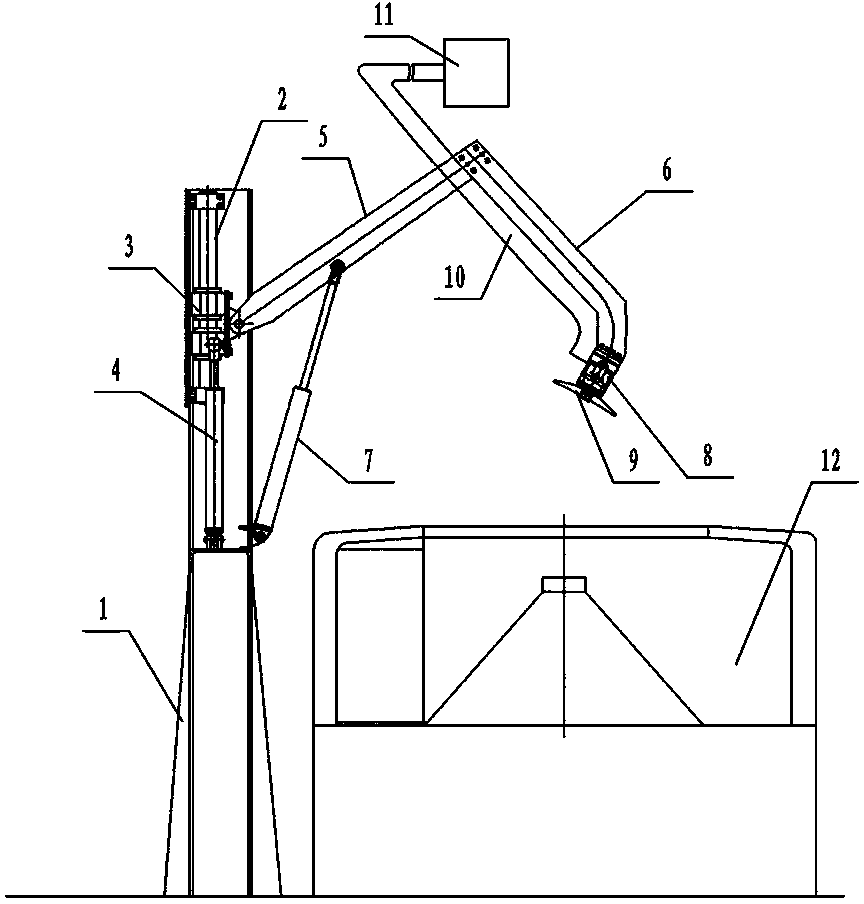

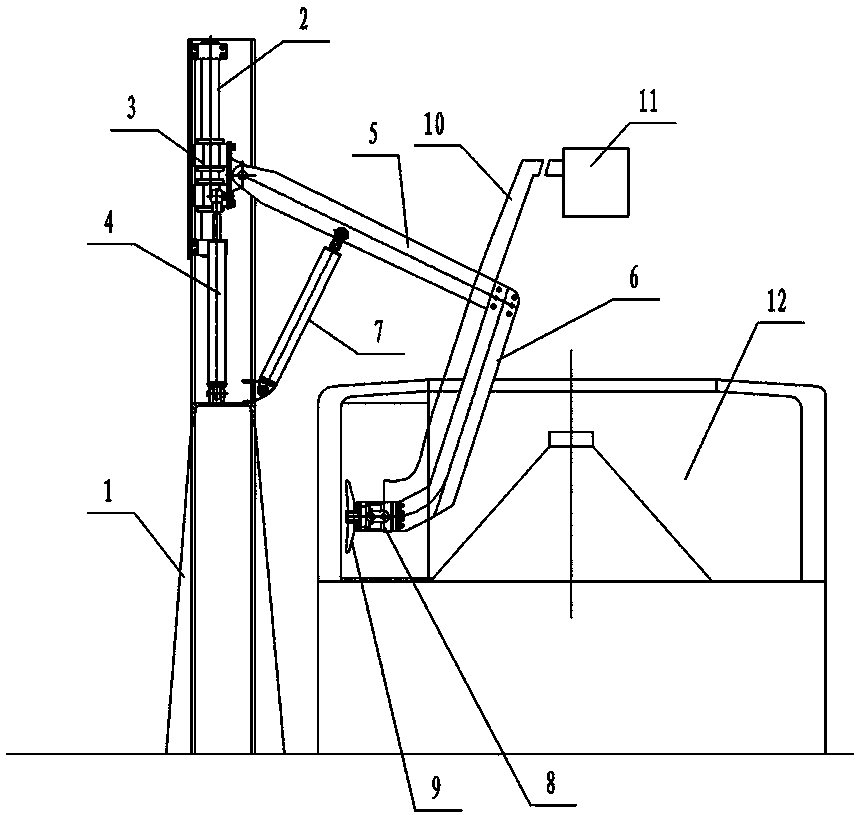

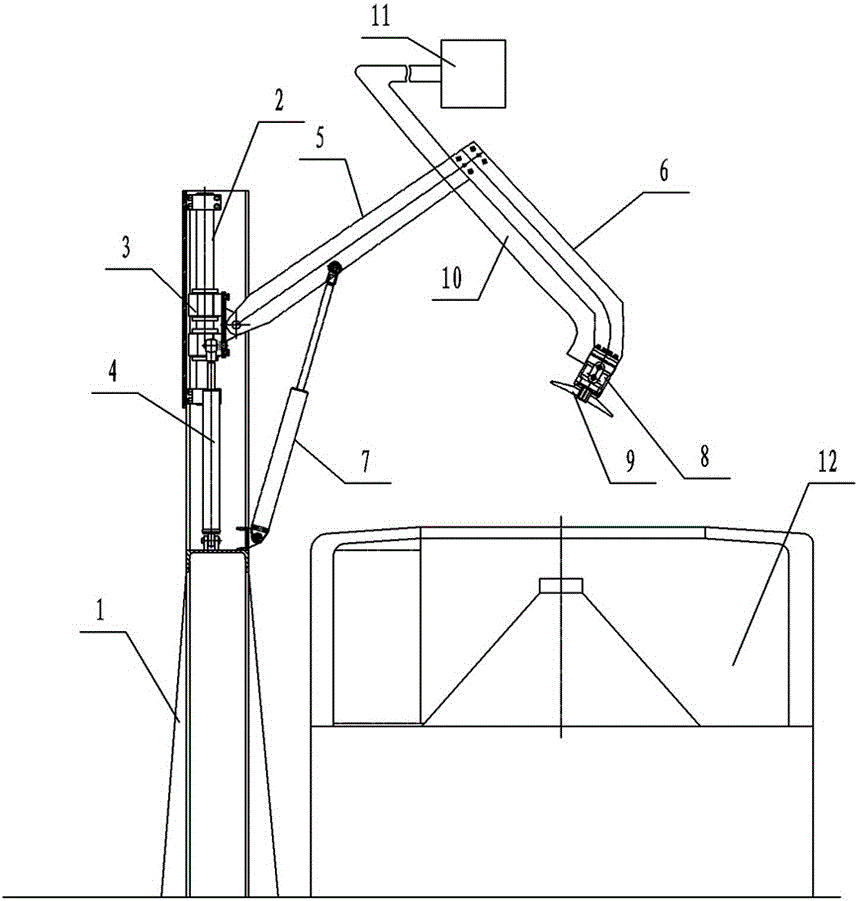

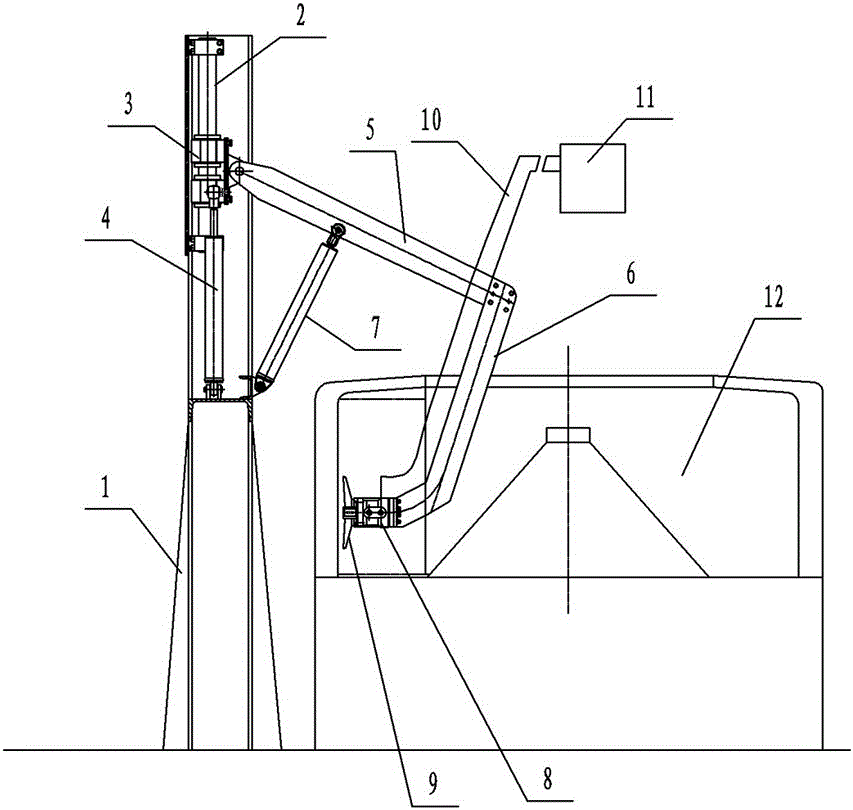

Scraping device for centrifugal machine

The invention relates to a centrifugal machine device, in particular to a scraping device for a centrifugal machine. The scraping device for the centrifugal machine comprises a base, wherein a vertical sliding rail is arranged on the upper portion of the base, a trolley is arranged on the sliding rail, the lower portion of the trolley is connected with a hydraulic device, a mechanical arm is hinged to the trolley and is composed of an upper section and a lower section, the middle of the upper portion of the mechanical arm is connected with a hydraulic overturning device, and a scraper is arranged at the tail end of the lower section of the mechanical arm. According to the scraping device for the centrifugal machine, automatic scraping can be achieved in the centrifugal machine, thorough and complete scraping is achieved, labor is saved, and cost is reduced.

Owner:HENAN PENGDA DOWN PROD

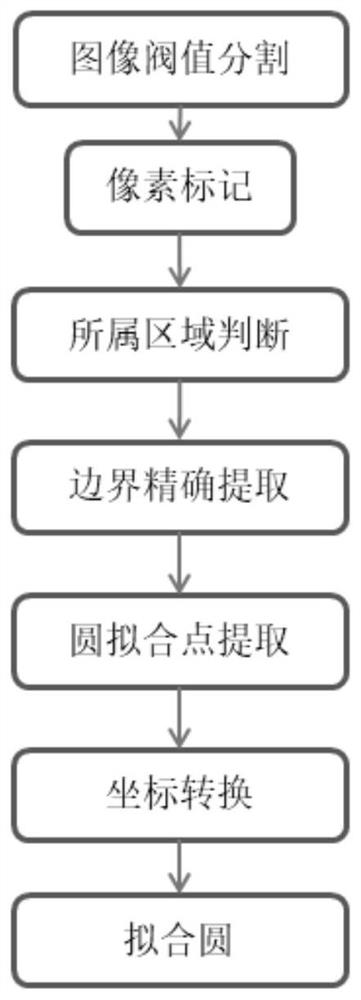

Robot glue scraping method based on visual identification

ActiveCN112172191ASolve the problem of uneven thickness and difficult scraping operationRealize automatic scrapingTubular articlesScraping - actionImaging processing

The invention discloses a robot glue scraping method based on visual identification, and belongs to the field of glue scraping methods. The robot glue scraping method comprises the following steps that a visual identification device obtains an image of a to-be-processed pipe, and the image is processed through a visual image processing algorithm to obtain the diameter and perimeter L of the to-be-processed pipe and the curvature of the circumference of the to-be-processed pipe; according to the curvature information, the position of a glue scraping mechanism on a mechanical arm in a glue scraping system is adjusted, so that a glue scraping roller brush is positioned at the topmost end of the to-be-processed pipe and moves downwards to the lowest point along the curvature path of the to-be-processed pipe from the topmost end to complete the first half-perimeter glue scraping action, a second driving device starts to drive the mechanical arm to move by the width of one roller brush and return to the first step for circular treatment again until glue scraping of the first half surface of the to-be-processed pipe is completed; and the to-be-processed pipe is rotated, and returns to thefirst step for circular treatment again until glue scraping of the second half surface of the to-be-processed pipe is completed. The robot glue scraping method can adopt the glue scraping system to automatically complete the glue scraping action, and is safe and environmentally-friendly.

Owner:江西省智能产业技术创新研究院

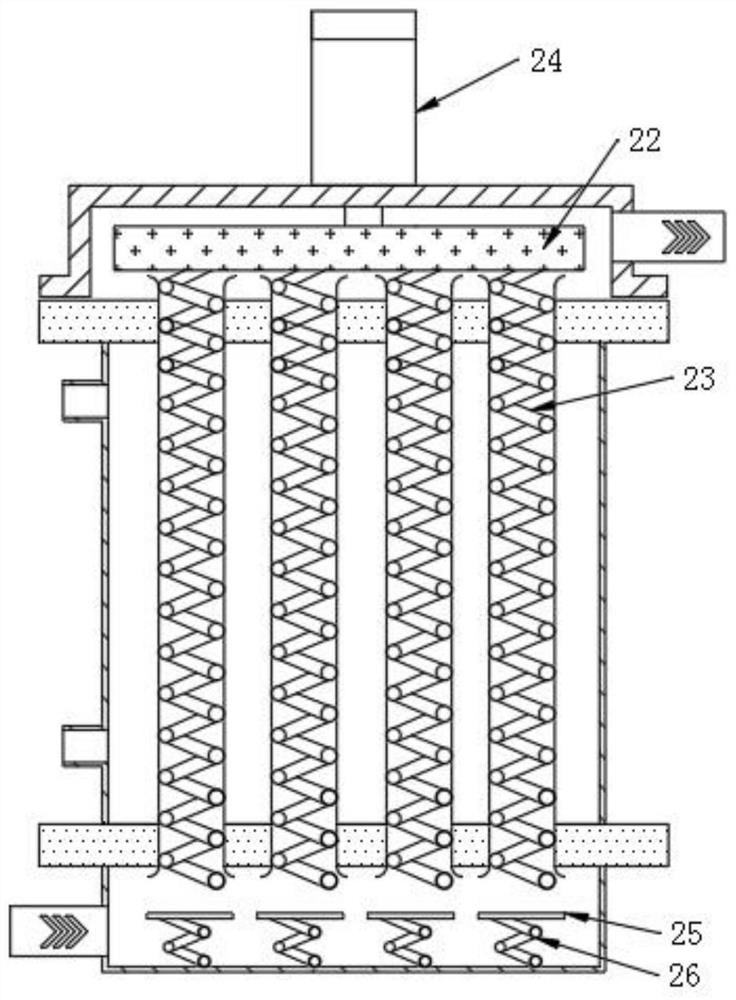

Electrolysis device capable of automatically scraping away electrode impurities

InactiveCN104986832AGuaranteed work efficiencyRealize automatic scrapingWater/sewage treatmentElectrolysisEngineering

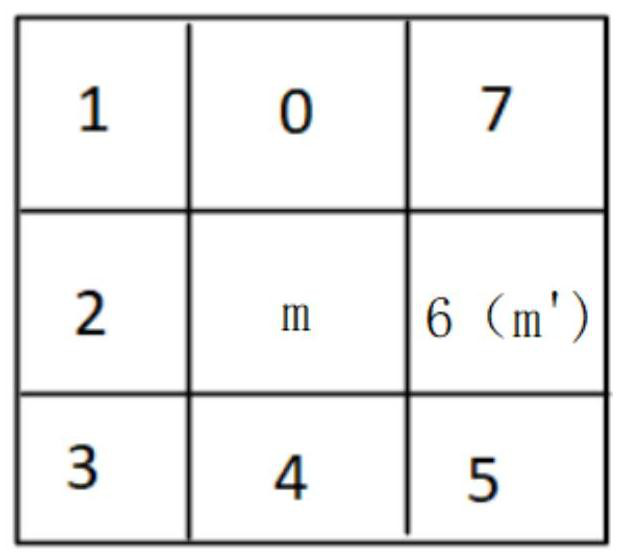

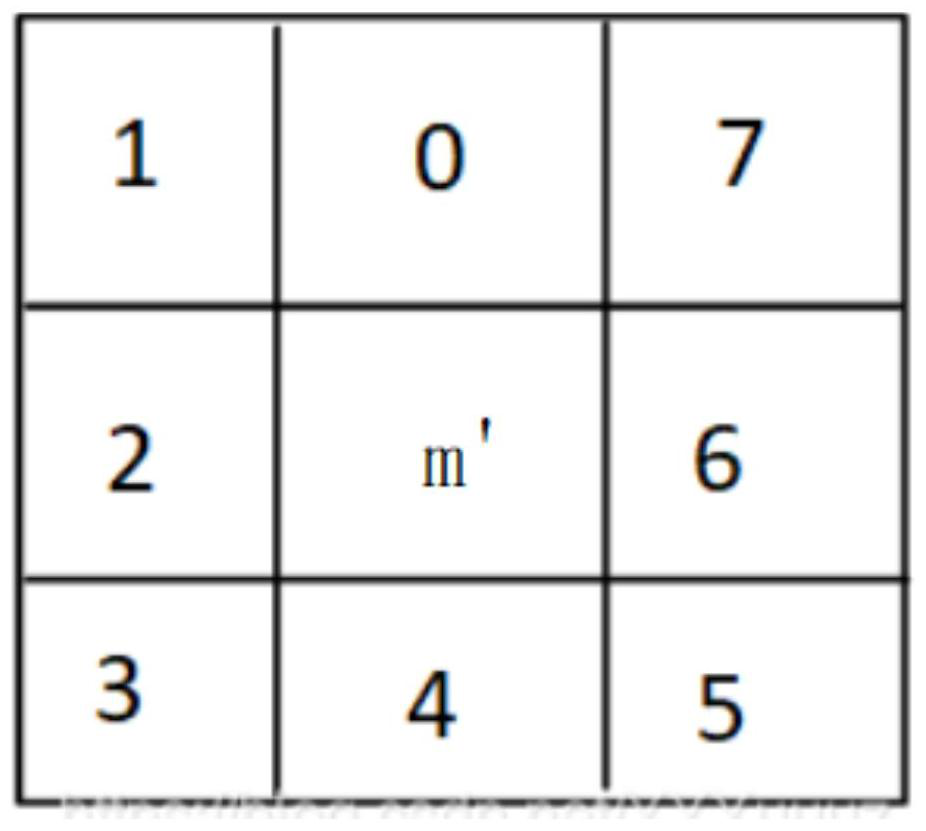

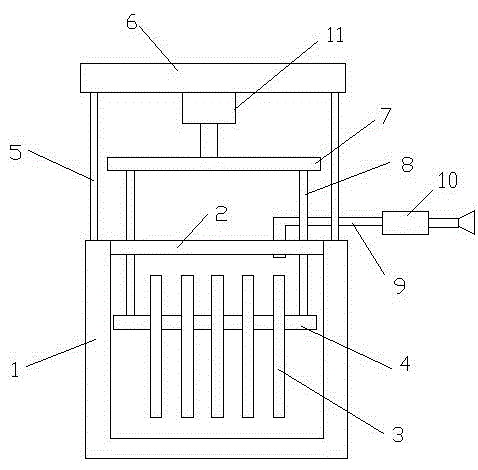

The invention discloses an electrolysis device capable of automatically scraping away electrode impurities. The electrolysis device comprises an electrolysis box and a box cover. A scraper and a plurality of electrodes are arranged in the electrolysis box. The electrodes all penetrate through the scraper. A supporting plate which can vertically move relative to the box cover is arranged above the box cover. The supporting plate and the scarper are connected through a guide rod penetrating through the box cover. An upper bottom plate is fixed to the upper portion of the supporting plate through a stand column. A drive device used for driving the supporting plate to vertically move is arranged between the upper bottom plate and the supporting plate. By driving the supporting plate to vertically move through the drive device, the guide rod drives the scraper to vertically move relative to the electrodes, and therefore the impurities on the surfaces of the electrodes are scraped away in an automated mode, and the work efficiency of the electrodes in the electrolysis process is ensured.

Owner:宋萌瑶

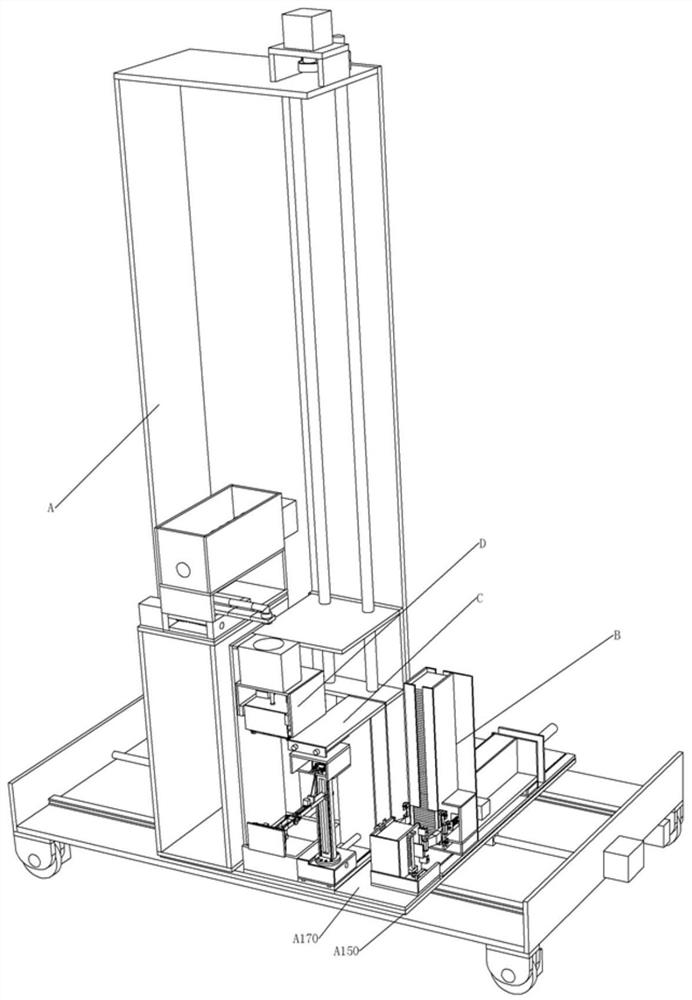

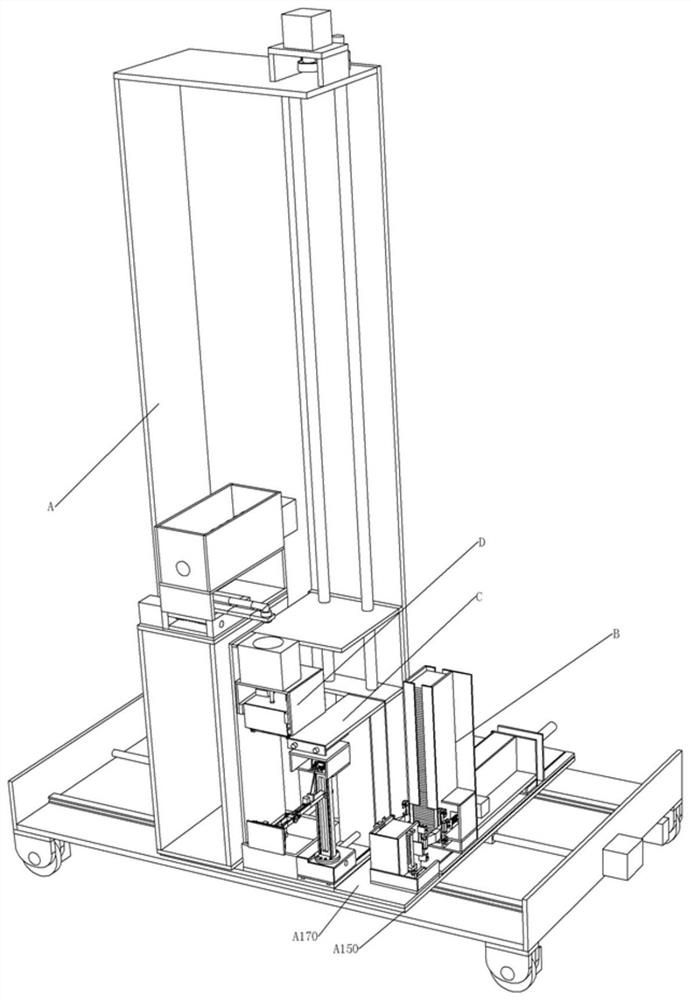

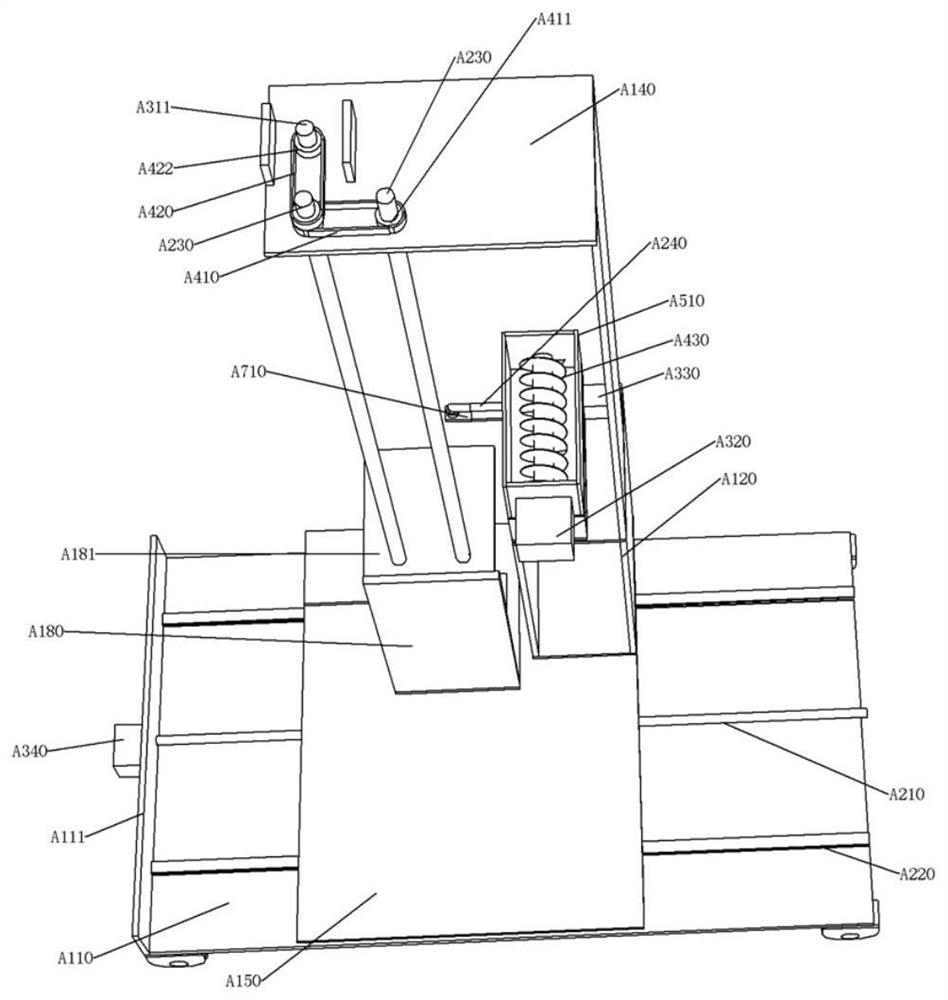

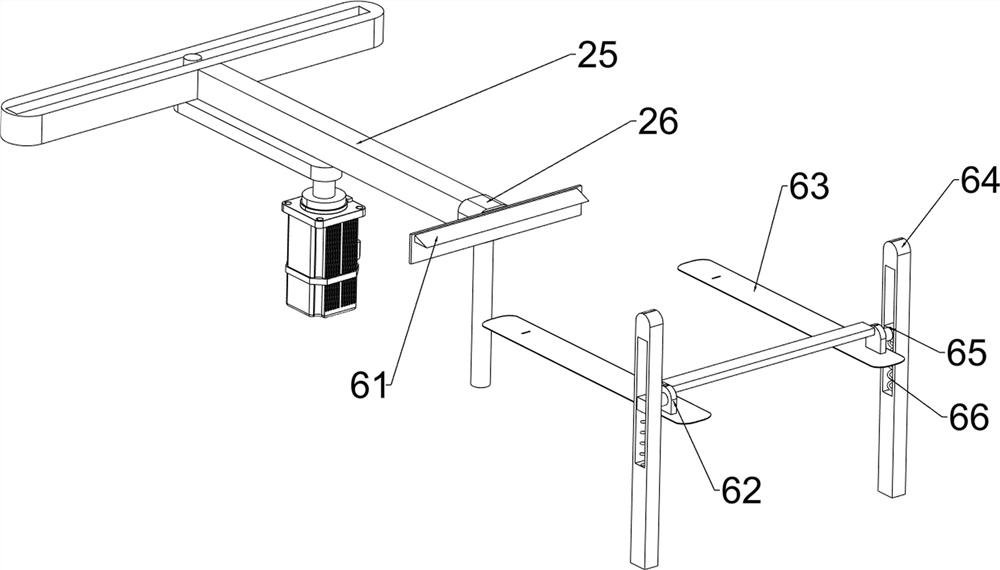

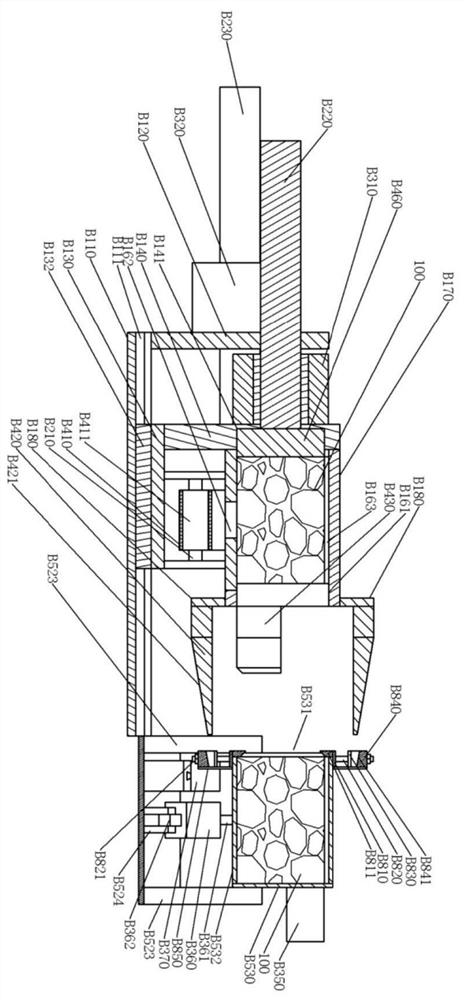

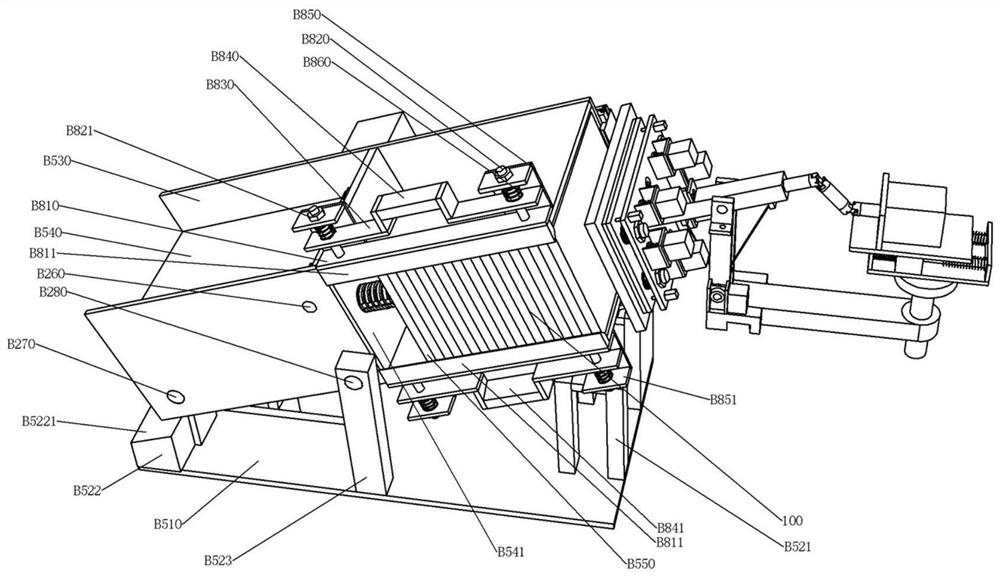

Suction mechanism and full-automatic tiling robot thereof

ActiveCN112031366AFully automated tilingVersatileBuilding constructionsStructural engineeringMechanical engineering

The invention discloses a suction mechanism and a full-automatic tiling robot thereof. The full-automatic tiling robot comprises a rack module, a tile supply module, a tile suction module and a slurryscraping module, wherein the tile supply module is used for mounting, moving and positioning the tile supply module, the tile suction module and the slurry scraping module; the tile supply module isused for continuously supplying wall tiles to the tile suction module so as to facilitate suction of the tile suction module; the tile suction module is used for sucking the wall tiles, then feeding the wall tiles into the slurry scraping module for slurry scraping, conveying the wall tiles to be parallel to a tiling wall surface and then pasting the wall tiles to the tiling wall surface; and theslurry scraping module is used for scraping slurry on the wall tiles so as to facilitate subsequent pasting of the wall tiles to the tiling wall surface. The full-automatic tiling robot has complete functions and can realize automatic slurry scraping, wall tile suction, wall tile rotation, wall tile pasting and detection of whether the wall tiles are laid flat and simultaneously lay flat, and thewhole process can realize full automation. The full-automatic tiling robot can realize full-automatic tiling of the wall tiles, so that a basis can be provided for a subsequent full-automatic tiling technology, that is, a technical basis is provided for a subsequent AI tiling technology.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

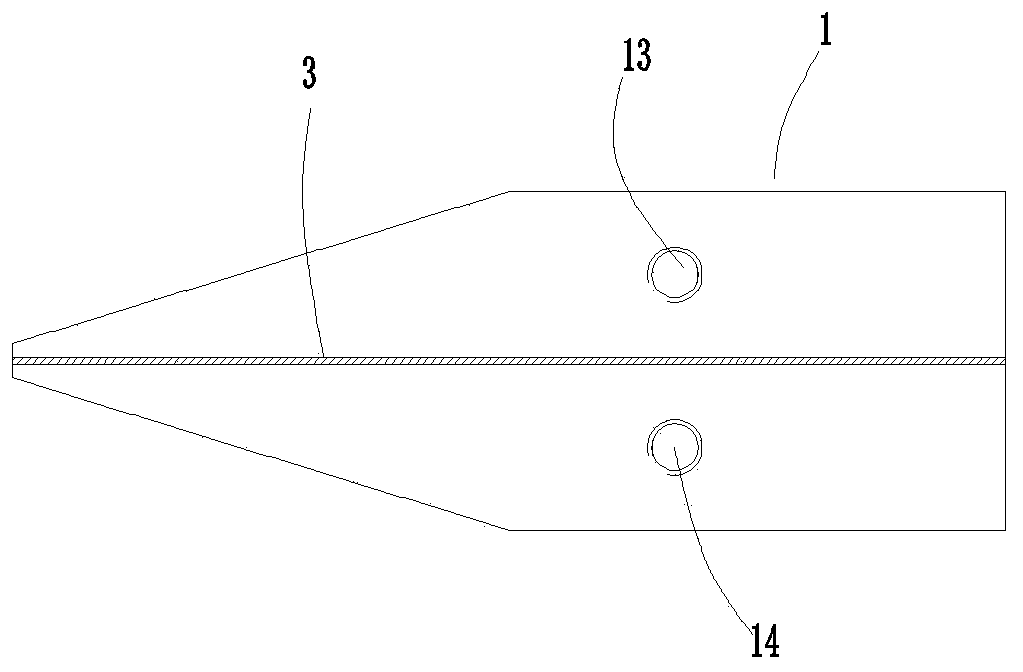

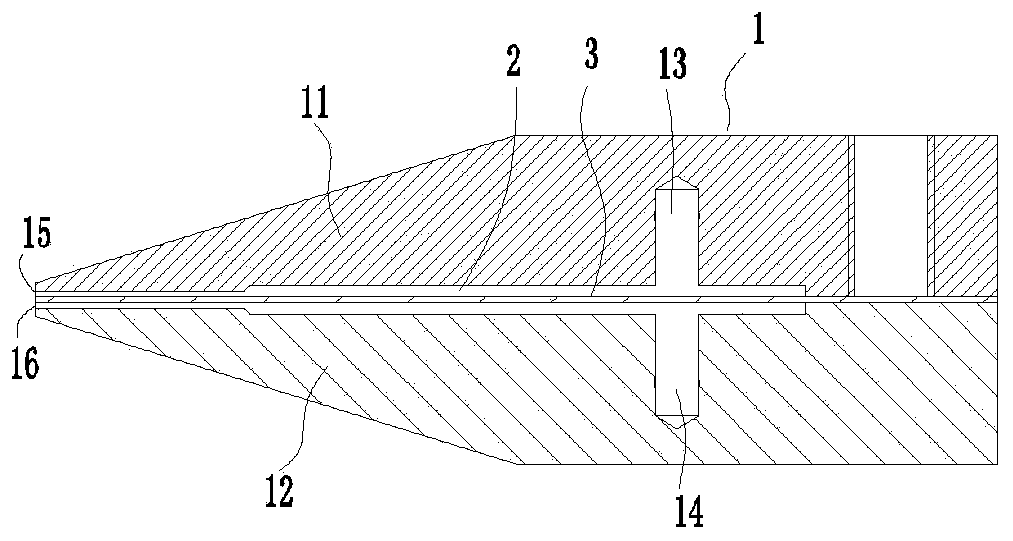

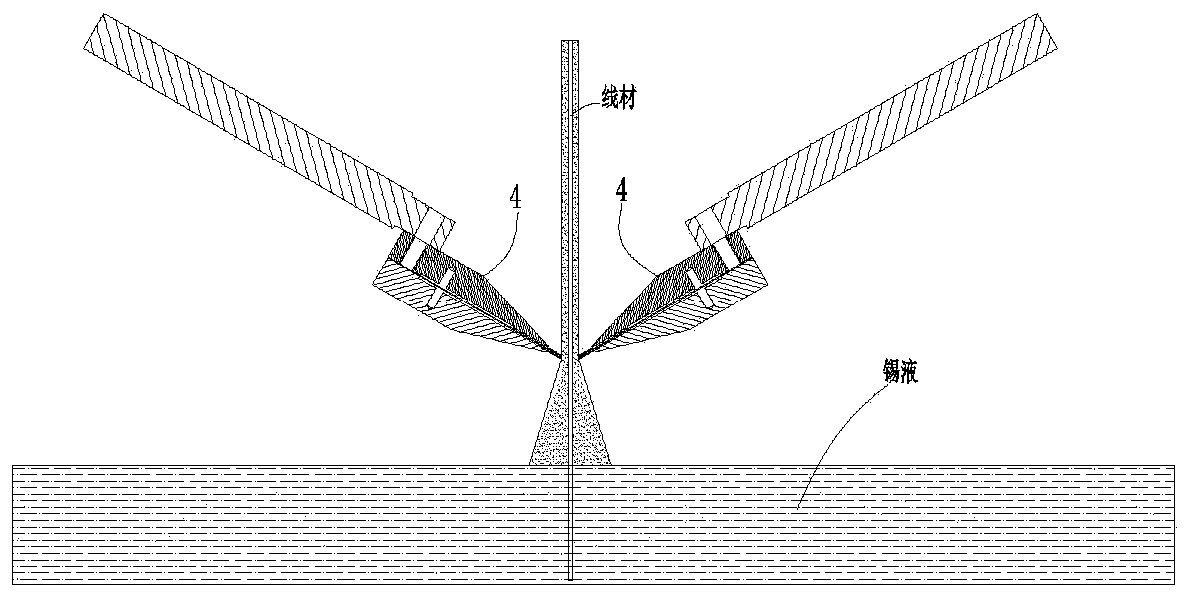

Triangular welding strip production system, tin coating device thereof, air knife system of tin coating device and air knife of air knife system

PendingCN111188003AAchieve windRealize closed windHot-dipping/immersion processesFurnace typesWire rodEngineering

The invention discloses a triangular welding strip production system, a tin coating device thereof, an air knife system of the tin coating device and an air knife of the air knife system. The air knife comprises a body, the body is internally provided with two independent air cavities, each air cavity is provided with an air knife air inlet communicating with the air cavity, and each air knife airinlet is used for being connected with an air source; and each air cavity is further provided with an air knife air outlet. The body is internally provided with an air knife partition piece which divides the space in the body into the two independent air cavities, and the air knife air outlets of the two air cavities are adjacent. Aiming at wire rods of a segmented triangular welding strip, whenthe wire rods are coated with tin, tin layers can be scraped with different air force for parts in different section shapes, and thus, it is ensured that the tin layers at the parts in the different section shapes are uniform.

Owner:SHENZHEN KEPSUN PRECISION TECH CO LTD

Attachment cleaning device for ocean platform

ActiveCN112550590APrevent fallingReduce labor intensityVessel cleaningArtificial islandsMarine terraceMarine engineering

Owner:WEIHAI OCEAN VOCATIONAL COLLEGE

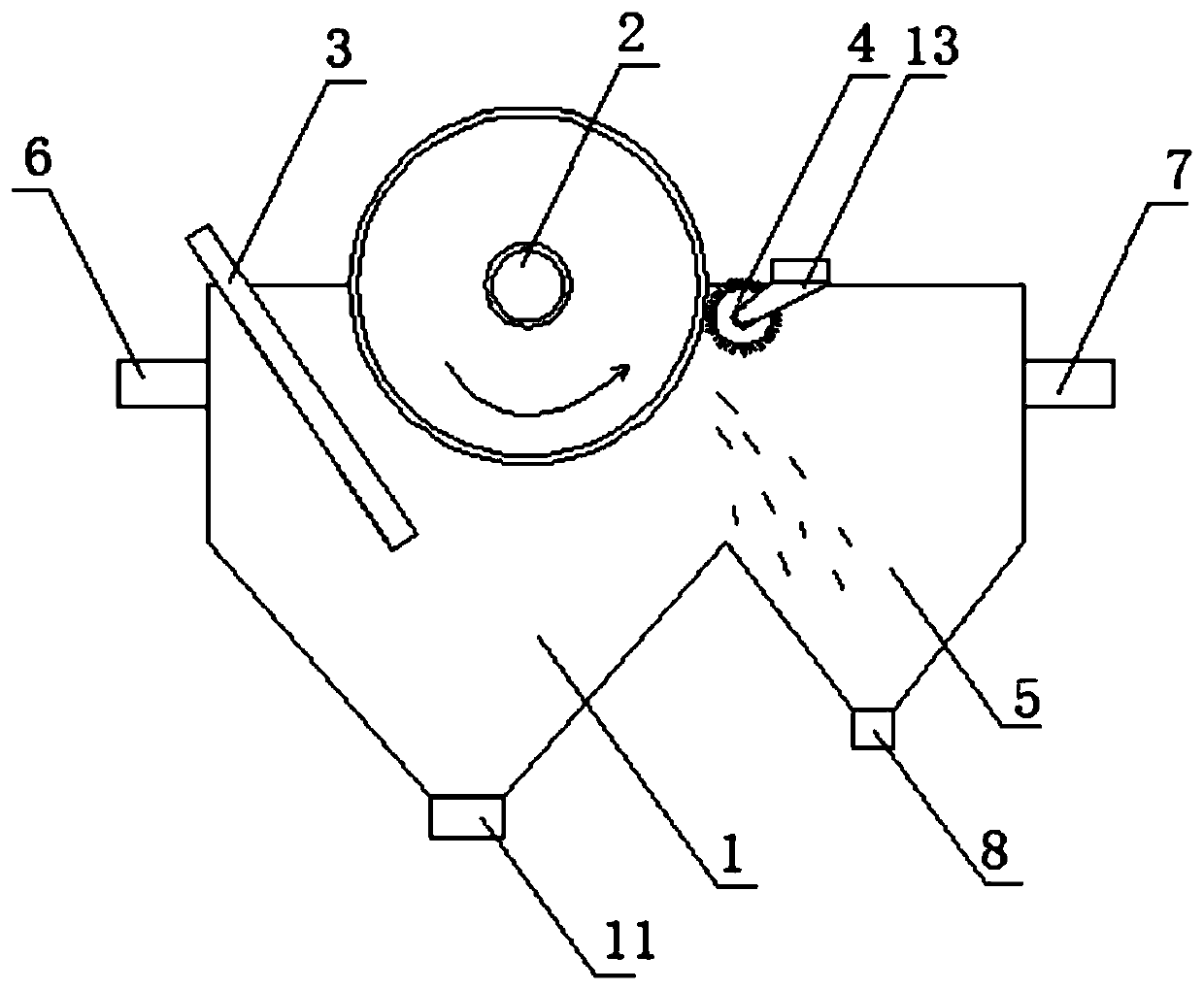

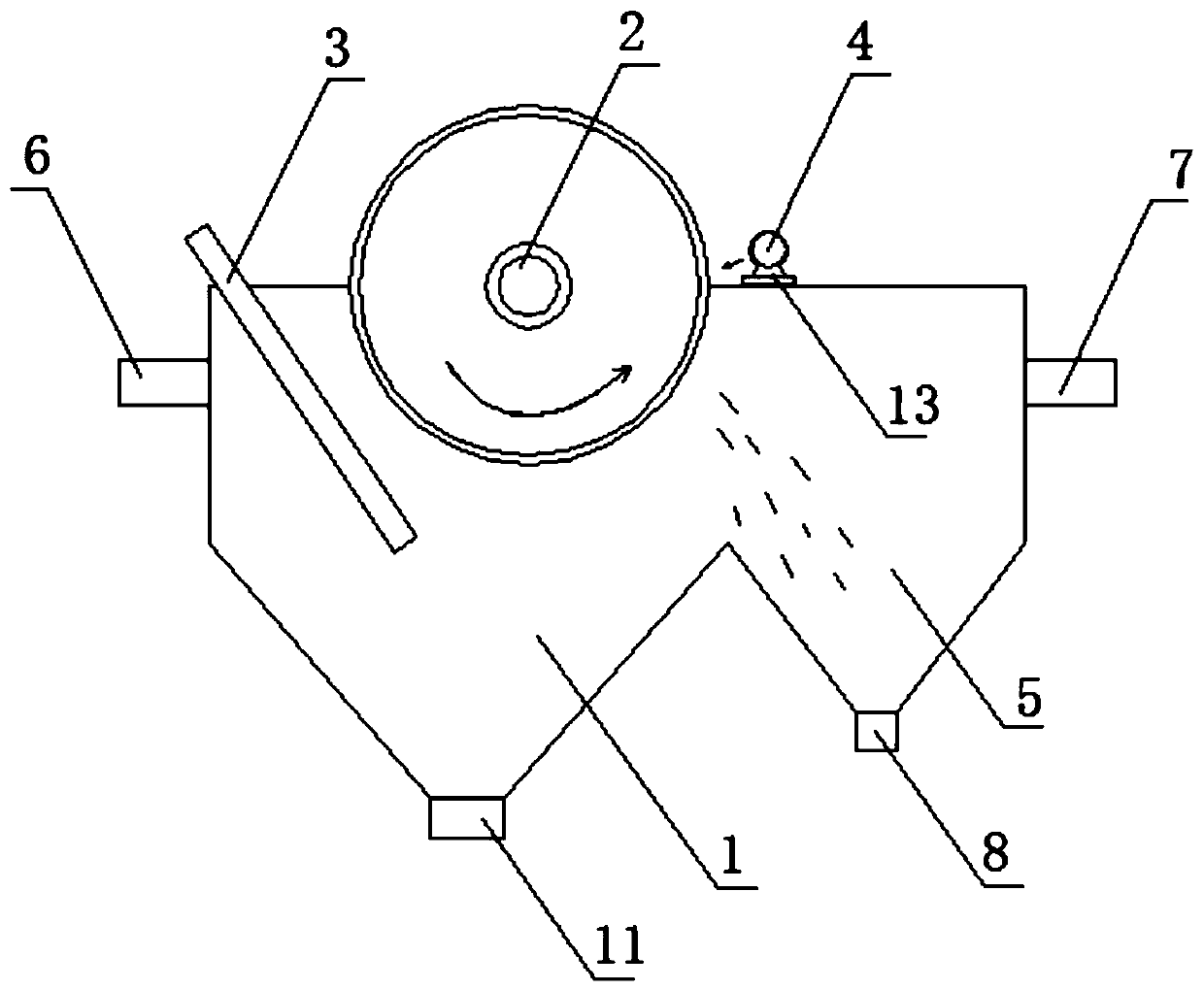

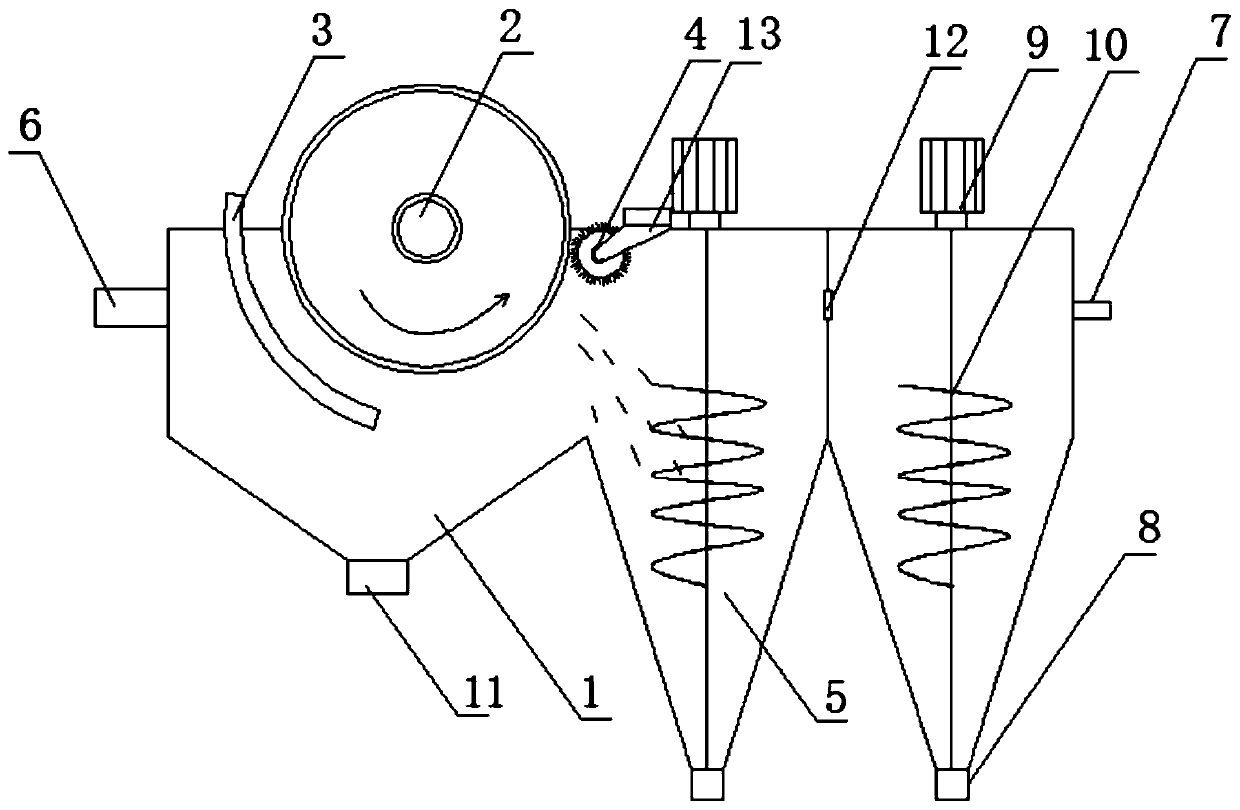

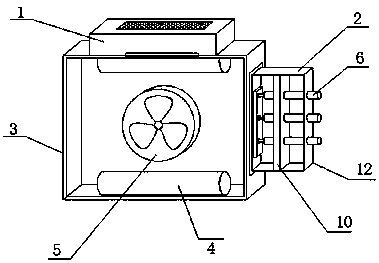

Copper powder preparation device and preparation method thereof

PendingCN110067010ARealize automatic scrapingAvoid different grain sizesElectrolysis componentsApparent densityElectrolysis

The invention provides a copper powder preparation device and a preparation method thereof. The copper powder preparation device comprises an electrolysis reaction tank, and further comprises a coppercathode drum which is arranged in the electrolysis reaction tank; a soluble copper anode board is arranged in the side, opposite to the copper cathode drum, of the electrolysis reaction tank; a copper powder scouring device is arranged on the other side opposite to the copper cathode drum; a copper powder collection tank connected with the electrolysis reaction tank is arranged below the side close to the copper powder scouring device; a liquid inlet is arranged on one side of the electrolysis reaction tank; a liquid outlet is arranged on one side of the copper powder collection tank; and a copper powder collection opening is further arranged at the lower end of the copper powder collection tank. The copper powder preparation device has the effects that the structure of the electrolysis reaction tank and the installation way of a cathode and an anode are improved, so that the automatic scraping of copper powder on the copper cathode drum can be achieved; the powder scraping speed is controlled; the different sizes of the copper powder caused by the uneven powder scraping time control is avoided; the particle sizes can be controlled; apparent density of the copper powder is small and the specific surface area of the copper powder is large; consecutive powder preparation is achieved; and the production efficiency is improved significantly.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

LED ceiling lamp for conveniently cleaning kitchen

InactiveCN108194867AEasy to cleanEffective disinfectionLighting elementsCleaning using toolsUv disinfectionPush pull

The invention relates to the field of LED lamp equipment, in particular to an LED ceiling lamp for conveniently cleaning a kitchen. The LED ceiling lamp comprises an atomizing device, a lamp shell anda push-pull lamp tube, the atomizing device is arranged at the top of the lamp shell, and a first groove is formed in one side of the lamp shell; the push-pull lamp tube is arranged in the first groove, a cavity is formed in one side of the atomizing device and internally provided with a pull plate, and a spray opening is formed in the top of the atomizing device; the lamp shell is internally provided with the lamp tube, a vent opening is formed in the inner side of the lamp shell, a fan is arranged at the vent opening, and the fan is mounted on an output shaft of an electromotor through a rotating shaft; and the push-pull lamp tube comprises an ultraviolet disinfection lamp, a lamp tube frame and a fixing plate, and the ultraviolet disinfection lamp is mounted on the lamp tube frame through the fixing plate. The LED ceiling lamp for conveniently cleaning the kitchen is reasonable in design and high in functionality, and is suitable for mass promotion.

Owner:广东韩星健康家居科技有限公司

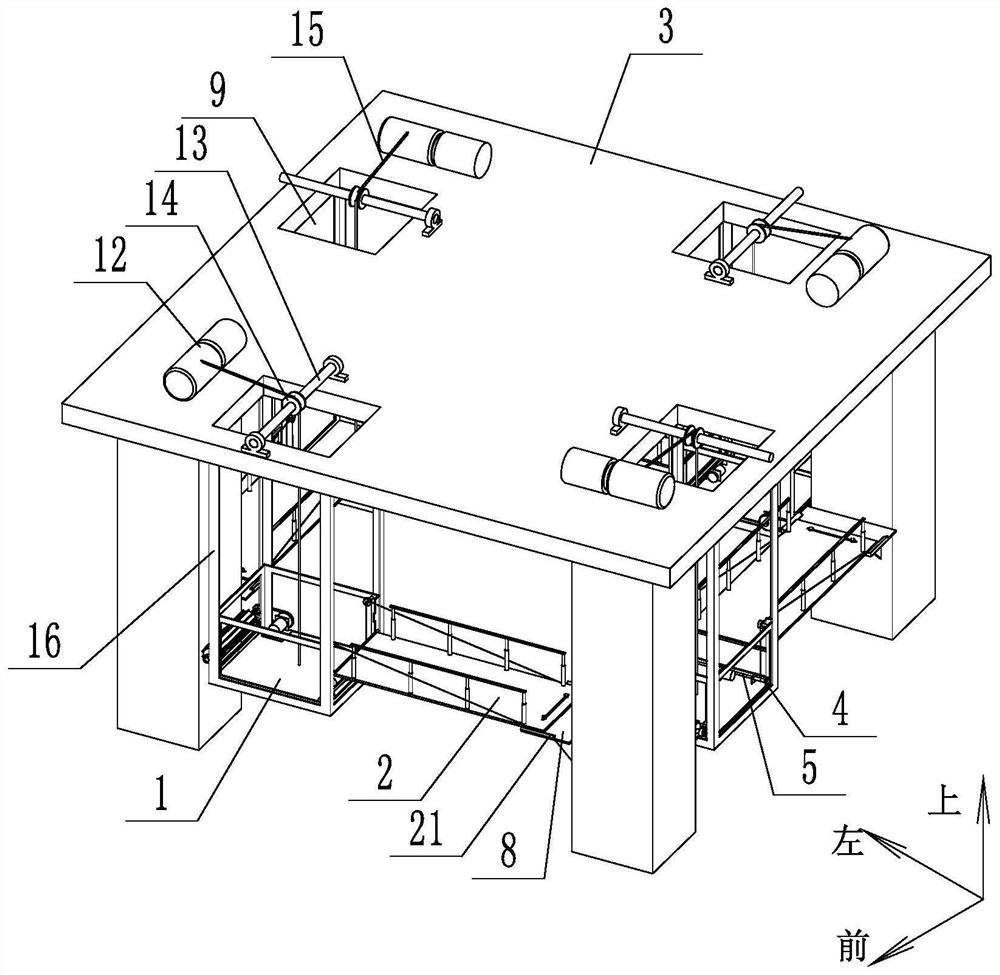

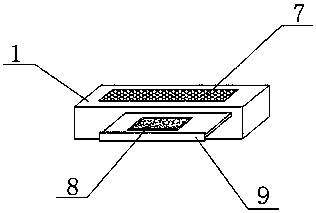

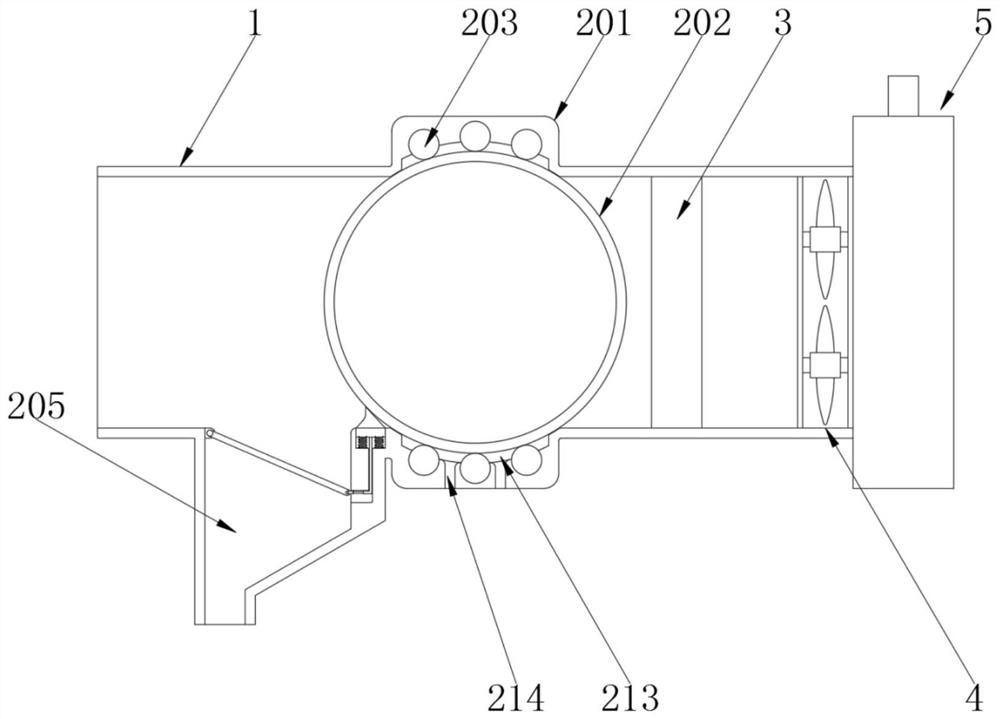

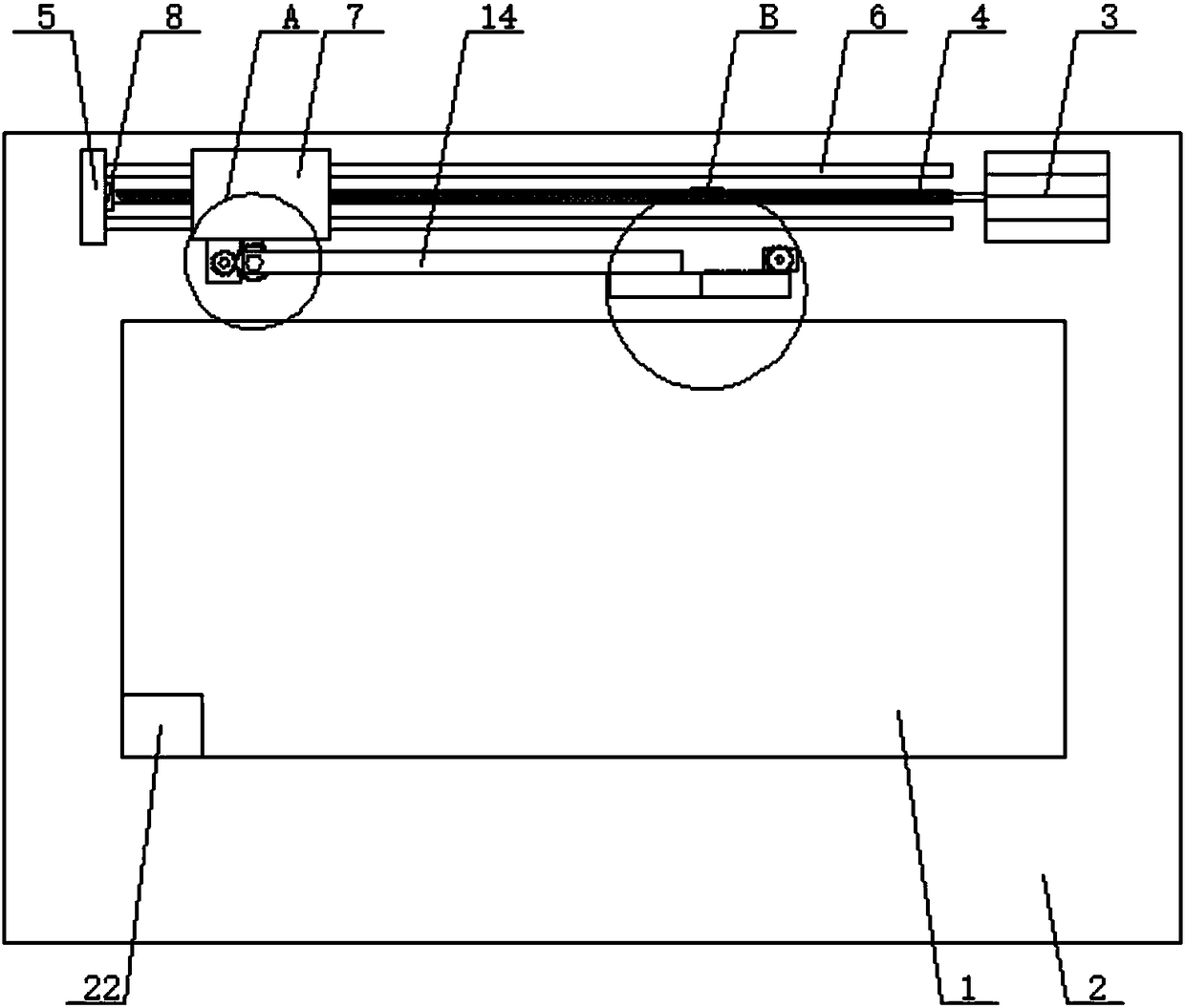

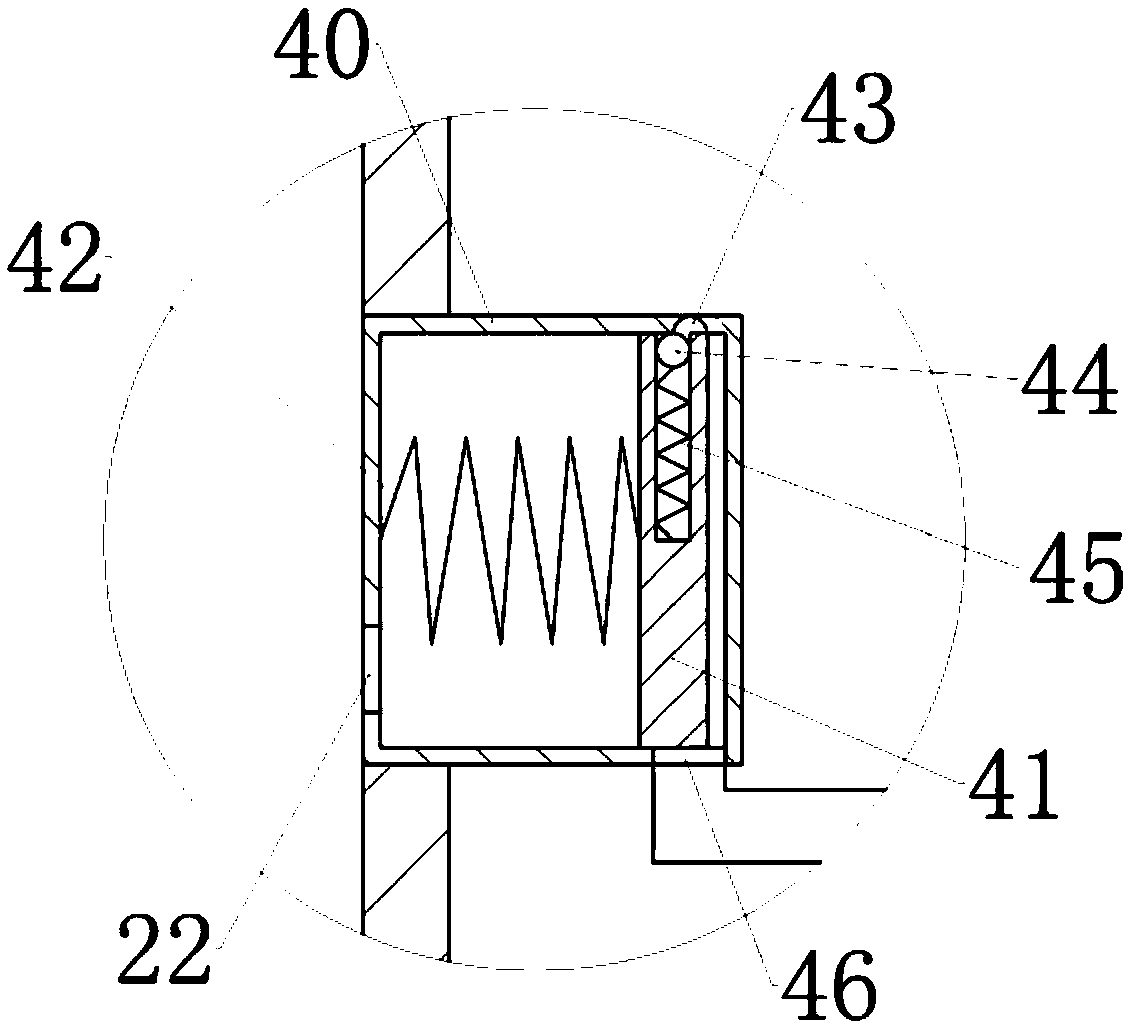

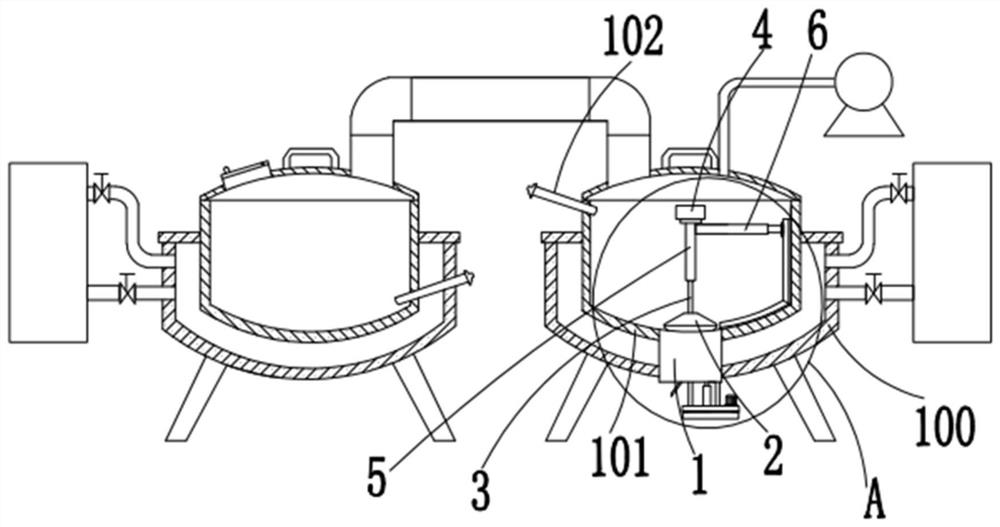

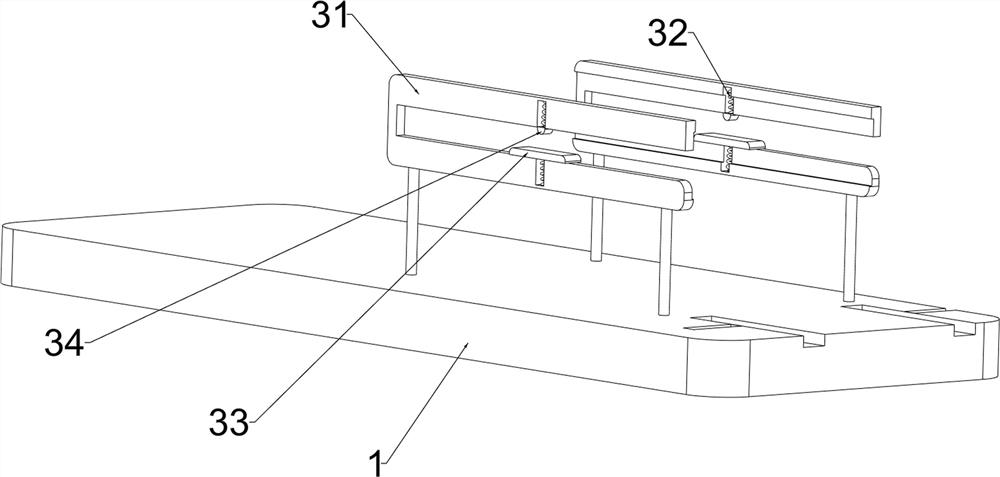

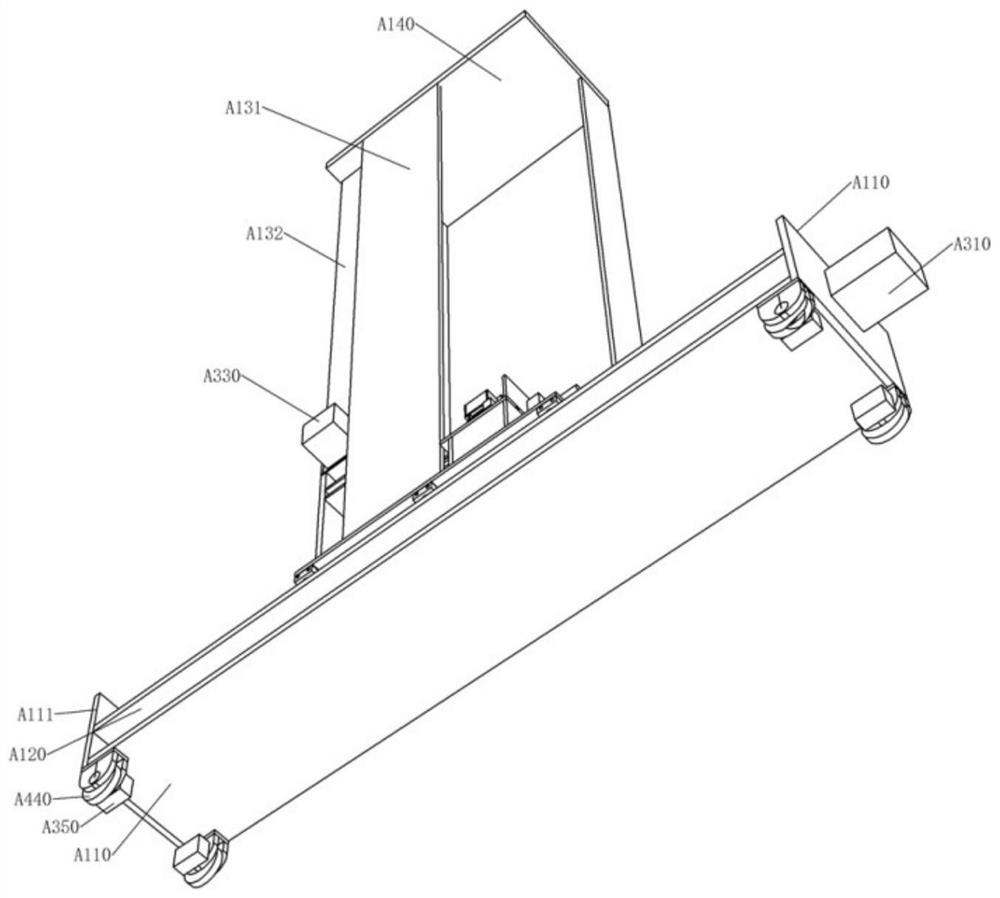

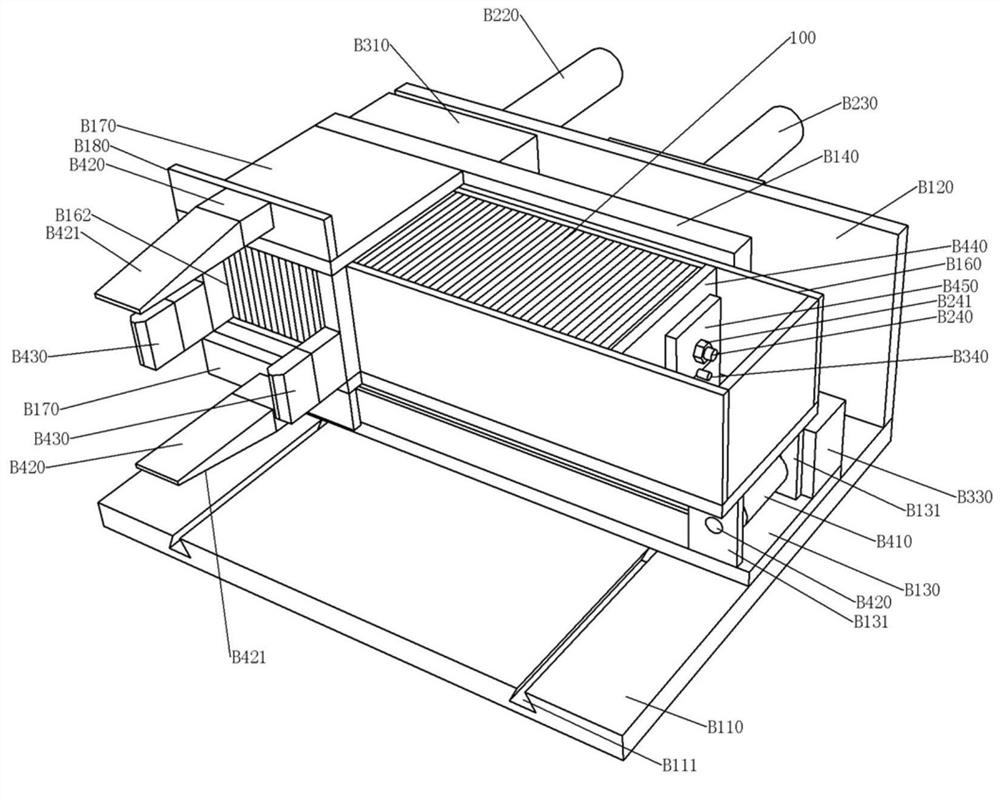

Tile supply module and full-automatic tiling robot with same

ActiveCN112049379AFully automated tilingVersatileBuilding constructionsMechanical engineeringFully automated

The invention discloses a tile supply module and a full-automatic tiling robot with the same. The full-automatic tiling robot comprises a rack module used for installing, moving and positioning the tile supply module, a tile suction module and a slurry scraping module, the tile supply module, the tile suction module and the slurry scraping module. The tile supply module is used for continuously supplying wall tiles to the tile suction module, so that the tile suction module sucks the wall tiles conveniently; the tile suction module is used for sucking the wall tiles, conveying the wall tiles into the slurry scraping module for slurry scraping, conveying the wall tiles to be parallel to the tile sticking wall surface, and sticking the wall tiles to the tile sticking wall surface; and the slurry scraping module is used for scraping the slurry on the wall tiles so as to facilitate sticking of the wall tiles on the tile sticking wall surface in the follow-up process. The robot is completein function, can achieve automatic slurry scraping, wall tile sucking, wall tile rotating, wall tile sticking, detecting whether the wall tiles are paved or not and wall tile paving at the same time,and can achieve full automation in the whole process. By means of the robot, full-automatic tiling of the wall tiles can be achieved, a foundation can be provided for the follow-up full-automatic tiling technology, and in other words, a technical foundation is provided for the follow-up AI tiling technology.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

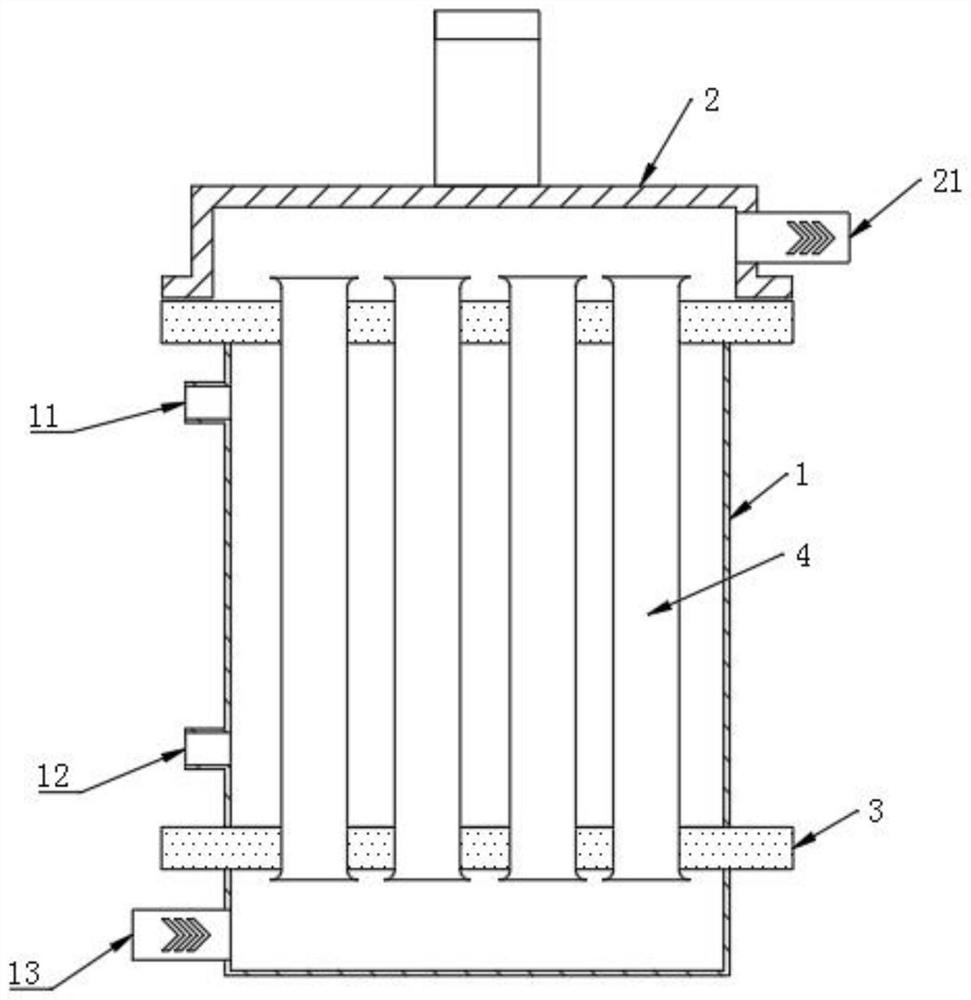

Low-temperature evaporator for automatically treating sewage scales

PendingCN111892111ARealize automatic scrapingFor quick replacementSpecific water treatment objectivesWater/sewage treatment by heatingThermodynamicsEngineering

The invention relates to an evaporator, which has the effect of being easy and convenient to maintain. The invention discloses a low-temperature evaporator capable of automatically treating sewage scales. The low-temperature evaporator comprises a shell, wherein a plurality of water pipes parallel to the length direction of the shell are uniformly arrayed in the shell, the upper end and the lowerend in the shell are each provided with a partition plate for sealing the inner cavity of the shell, the water pipes penetrate through the two partition plates in an attached mode and are welded and fixed to the partition plates, the shell is provided with a refrigerant inlet and a refrigerant outlet which are located between the two partition plates, the shell is provided with a water inlet and awater outlet which are located outside the two partition plates respectively, a lifting plate which is located outside the partition plate and parallel to the partition plate is arranged in the shell, a plurality of scale scraping springs which are attached to and inserted into the water pipes respectively are arranged on the lifting plate, and an air cylinder which drives the lifting plate to ascend and descend in the length direction of the shell is arranged outside the shell. By means of cooperation of the scale scraping spring and the water pipes, automatic scale scraping is achieved, andregular cleaning is not needed.

Owner:无锡德华仕环境科技有限公司

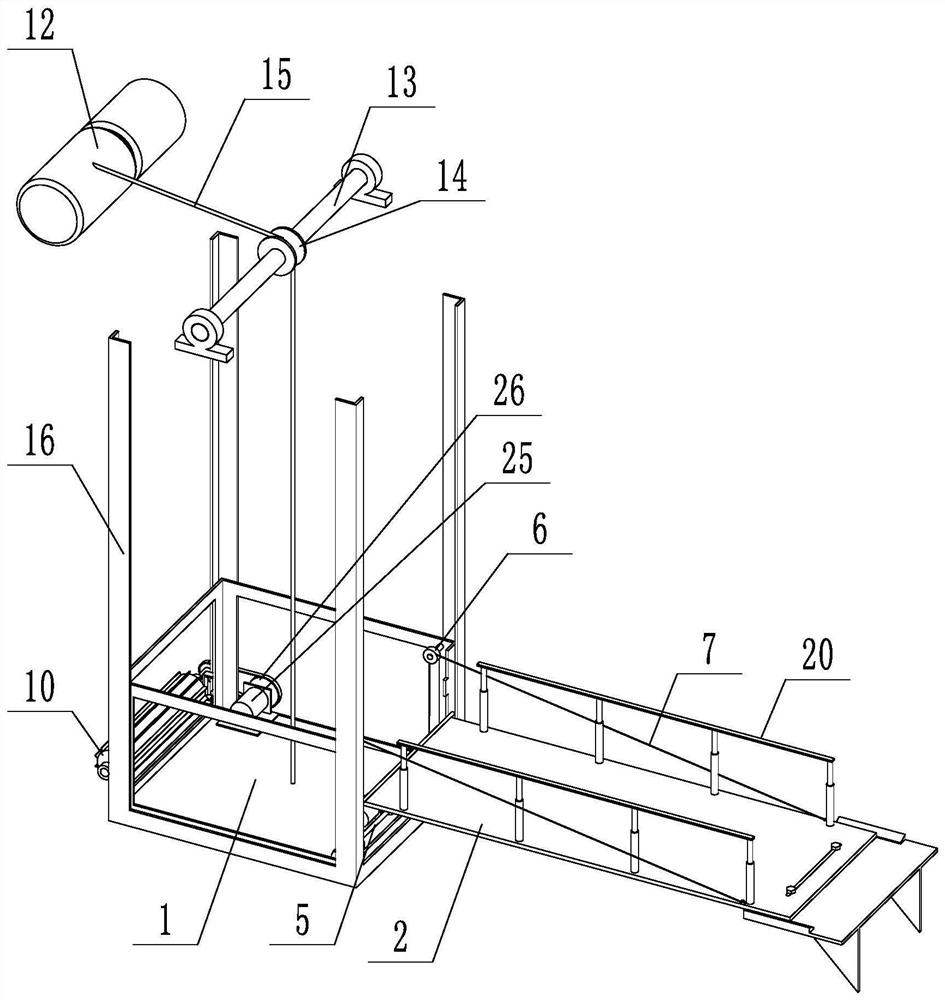

Suction module and full-automatic tiling robot with same

ActiveCN112031363AFully automated tilingVersatileBuilding constructionsMechanical engineeringFully automated

The invention discloses a suction module and a full-automatic tiling robot with the same. The full-automatic tiling robot comprises a rack module used for mounting, moving and positioning a tile supply module, the tile suction module and a slurry scraping module, the tile supply module, the tile suction module and the slurry scraping module. The tile supply module is used for continuously supplying wall tiles to the tile suction module, so that the tile suction module sucks the wall tiles conveniently; the tile suction module is used for sucking the wall tiles, conveying the wall tiles into the slurry scraping module for slurry scraping, conveying the wall tiles to be parallel to the tile sticking wall surface, and sticking the wall tiles to the tile sticking wall surface; and the slurry scraping module is used for scraping the slurry on the wall tiles so as to enable the wall tiles to be conveniently stuck on the tile sticking wall surface in the follow-up process. The full-automatictiling robot is complete in function, automatic slurry scraping, wall tile sucking, wall tile rotating, wall tile sticking, detection of whether the wall tiles are paved and simultaneous wall tile paving can be achieved, full automation can be achieved in the whole process, full-automatic tiling of the wall tiles can be achieved, a foundation can be provided for the follow-up full-automatic tilingtechnology, and in other words, a technical foundation is provided for the follow-up AI tiling technology.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

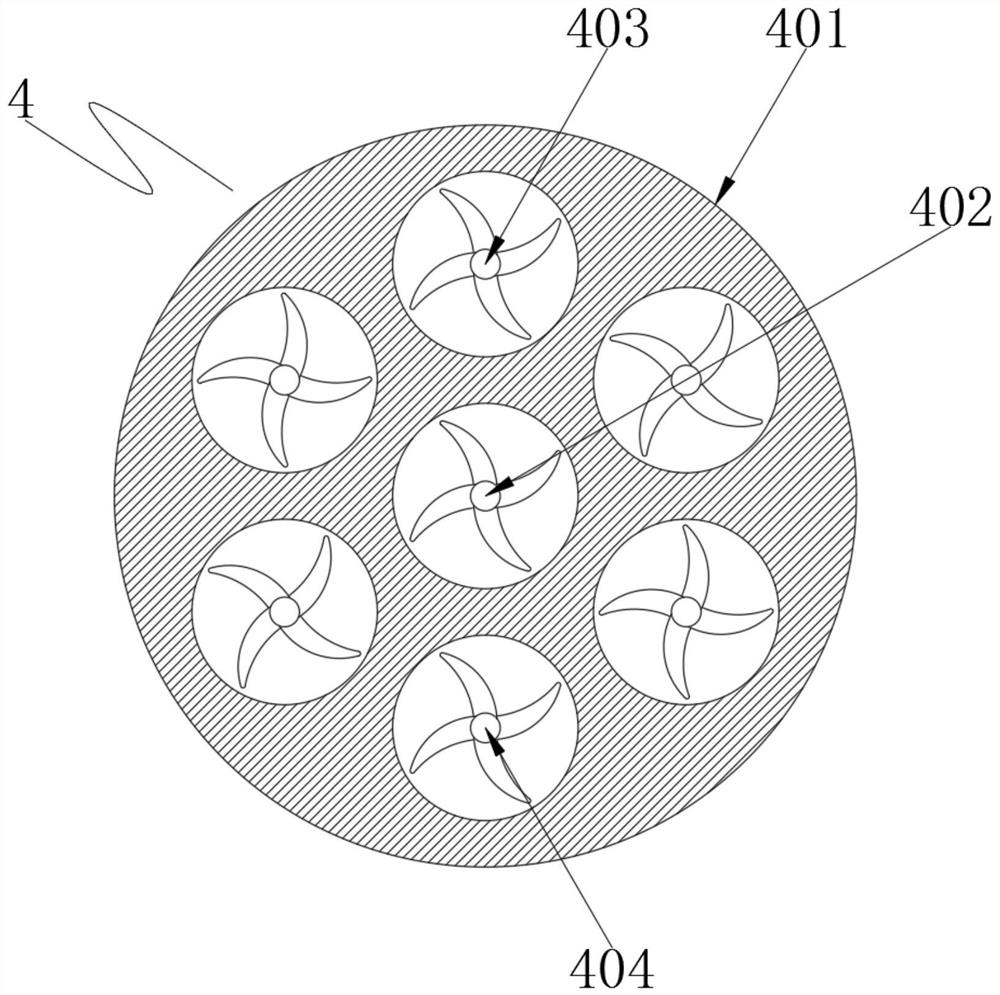

Integral dust falling and purification device applied to underground coal mine

ActiveCN111608718AIncrease profitAvoid frequent replacementCombination devicesDispersed particle filtrationFiltrationCoal dust

The invention discloses an integral dust falling and purification device applied to an underground coal mine and belongs to the technical field of gas purification. The integral dust falling and purification device comprises a dust falling and purification pipe, a dust falling and purification device, an activated carbon purification plate, a negative pressure fan set and a water curtain dust falling device, wherein the dust falling and purification device is installed at the center inside the dust falling and purification pipe; the activated carbon purification plate and the negative pressurefan set are successively installed on one side of the dust falling and purification device; and the water curtain dust falling device is installed on the end, close to the negative pressure fan set,of the dust falling and purification pipe. The device disclosed by the invention is scientific and rational and safe and convenient in use; the device greatly increases a use rate of a filtering mesh;meanwhile, dust falling and purification effects of coal dust in air are ensured; the coal dust can be scrapped automatically after filtration; efficiency is higher; and effects are better

Owner:府谷县中联矿业有限公司

Scraping device for centrifuge

ActiveCN104190559BRealize automatic scrapingScrape thoroughlyCentrifugesEngineeringMechanical engineering

Owner:HENAN PENGDA DOWN PROD

A mirror with self-cleaning mist function

ActiveCN106880229BRealize automatic scrapingWith automatic cleaning mist functionPicture framesCarpet cleanersGear wheelEngineering

The invention relates to a mirror with an automatic mist cleaning function. The mirror comprises a mirror face and a mirror frame; the mirror frame further comprises a cleaning device, the cleaning device comprises a moving mechanism, a rotating mechanism and a cleaning mechanism, the moving mechanism comprises a first motor, a lead screw, a fixing block, a sliding rod and a sliding block, the rotating mechanism comprises a second motor, a first cylindrical gear, a second cylindrical gear, a second bearing and a rotating shaft, the cleaning mechanism comprises a cleaning rod, a rubber strip and a compressing assembly, and the compressing assembly comprises a spring and a supporting rod. According to the mirror with the automatic mist cleaning function, when much mist exists on the mirror face, the cleaning rod located on the upper portion of the mirror face drives the rubber strip to rotate so that the rubber strip can abut against the mirror face and be arranged vertically, and then the moving mechanism drives the rubber strip to be attached to the mirror face and move back and forth so that the mist can be scrapped automatically; compared with manual wiping, the mode saves time and labor, the mirror is cleaned more thoroughly without water stain, and great convenience is brought to life of people.

Owner:宿州市徽腾知识产权咨询有限公司

Energy-saving and environment-friendly 3D printing powder conveying device

ActiveCN109648853ARealize automatic scrapingEasy to operateAdditive manufacturing apparatusManufacturing recyclingPistonElectric heating

The invention belongs to the technical field of 3D printing, and particularly relates to an energy-saving and environment-friendly 3D printing powder conveying device. A box is included. The inner side of the bottom face of the box is sequentially and fixedly connected with a discharging box, a workbench and a material receiving box from left to right. An electric heating plate is in sliding connection in the discharging box. The top end face of the discharging box is in sliding connection with a roller, one end of the outer side of the roller is in sliding connection with a scraping plate, and a first piston cylinder is arranged at the outer portion of the box and provided with a one-way air inlet valve and a first piston cylinder exhaust port. The outer portion of the box is provided with a venturi tube. The first piston cylinder exhaust port communicates with an air inlet of the venturi tube. The bottom of the right side wall of the material receiving box communicates with the throat of the venturi tube through a suction pipe. According to the purpose, the problem that after dust on a roller of a 3D printer powder conveying device is scraped down, treatment is not conducted, andenvironment pollution can be caused is solved.

Owner:贵阳金汉诚广告器材有限公司

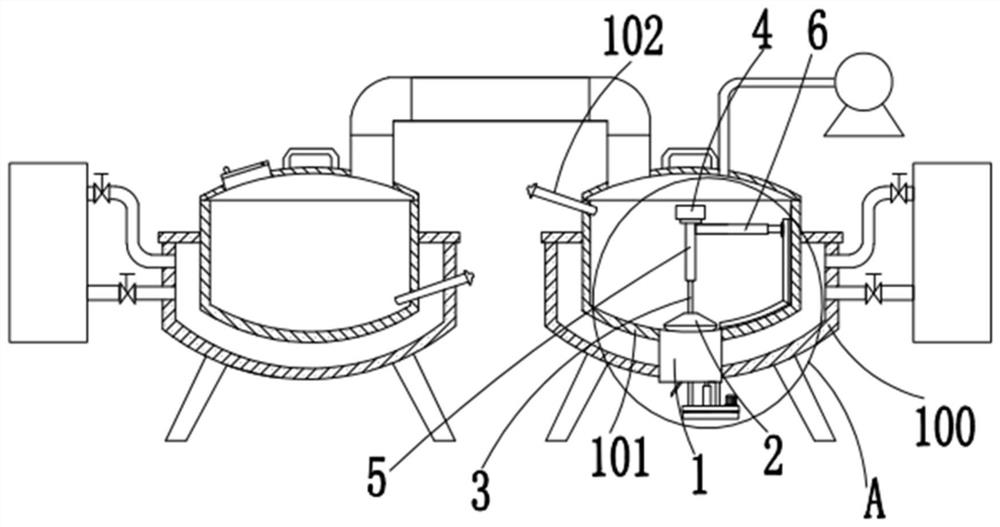

A sublimation crystallization device for testing the purity of chemical components of traditional Chinese medicine preparations

ActiveCN112843770BRealize automatic dischargeClose contactChemical industrySublimationProcess engineeringThermocouple device

The invention discloses a sublimation crystallization device for testing the purity of chemical components of traditional Chinese medicine preparations, comprising a sublimation crystallization device body. The temperature measuring thermocouple at the top of the side, the bottom inner wall of the crystallizer is set as an arc mechanism, the crystallizer is provided with an automatic discharging mechanism, and the automatic discharging mechanism includes a connected and fixed on the bottom inner wall of the crystallizer. The discharge pipe, the shell is fixedly sleeved on the discharge pipe, and a square rod is arranged in the discharge pipe, and the top end of the square rod extends into the crystallizer. The design of the invention is reasonable, it is convenient to automatically discharge the crystallized material in the crystallizer, and it is convenient to automatically scrape and discharge the crystallized material adhered to the inner wall of the crystallizer, so as to realize the purpose of automatic discharging and scraping, and save time and effort. , reduce labor intensity, improve discharge efficiency, meet the needs of use, and is conducive to use.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Honey extraction device with scraping structure

InactiveCN113615603AImplement automatic scrapingRealize automatic scrapingHoney collectionScrew threadBeeswax

The invention relates to a honey extraction device with a scraping structure. The honey extraction device with the scraping structure comprises a box body, the box body is a cuboid which is through left and right, and a driving box is mounted at the side end of the box body. When honey combs on a honey plate need to be scraped, a movable clamping plate is moved through a thread assembly, the honey plate is fixed between the fixed clamping plate and the movable clamping plate, and a limiting spring releases elastic potential energy to enable scrapers to be attached to the side ends of the two clamping plates; then an upper box plate drives the honey plate to move downwards by driving a lifting mechanism, and the scrapers move left and right at the side ends of the two clamping plates in a reciprocating mode through an elastic rotating mechanism, so that beeswax at the side ends of the honey plate is scraped; and when the upper box plate moves into the box body, the lifting mechanism drives the upper box plate to drive the honey plate to move upwards, the scrapers repeatedly scrape the honey plate, the two clamping plates release fixation of the honey plate through a threaded assembly, and finally beewax is automatically scraped.

Owner:湖南蜂窝窝科技有限公司

Sublimation crystallization device for purity inspection of chemical components of traditional Chinese medicine preparation

ActiveCN112843770ARealize automatic dischargeEasy dischargeChemical industrySublimationProcess engineeringMechanical engineering

The invention discloses a sublimation crystallization device for purity inspection of chemical components of a traditional Chinese medicine preparation, the sublimation crystallization device comprises a sublimation crystallization device body, the sublimation crystallization device body comprises a crystallizer, a shell fixedly sleeving the crystallizer and a temperature thermocouple fixed at the top of the left side of the crystallizer, and the inner wall of the bottom of the crystallizer is arranged to be an arc-shaped mechanism. The crystallizer is provided with an automatic discharging mechanism, the automatic discharging mechanism comprises a discharging pipe which is communicated and fixed on the inner wall of the bottom of the crystallizer, the shell is fixedly arranged on the discharging pipe in a sleeving manner, a square rod is arranged in the discharging pipe, and the top end of the square rod extends into the crystallizer. The sublimation crystallization device is reasonable in design, crystallization materials in the crystallizer can be conveniently and automatically discharged, the crystallization materials attached to the inner wall of the crystallizer can be conveniently and automatically scraped and discharged, the purposes of automatic discharging and material scraping are achieved, time and labor are saved, the labor intensity is reduced, the discharging efficiency is improved, the use requirement is met, and use is facilitated.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Tile supply module and intelligent tiling robot with same

ActiveCN112031362AFully automated tilingVersatileBuilding constructionsStructural engineeringMechanical engineering

The invention discloses a tile supply module and an intelligent tiling robot with the same. The intelligent tiling robot comprises a rack module used for installing, moving and positioning the tile supply module, a tile suction module and a slurry scraping module, the tile supply module, the tile suction module and the slurry scraping module. The tile supply module is used for continuously supplying wall tiles to the tile suction module, so that the tile suction module sucks the wall tiles conveniently; the tile suction module is used for sucking the wall tiles, conveying the wall tiles into the slurry scraping module for slurry scraping, conveying the wall tiles to be parallel to the tile sticking wall surface, and sticking the wall tiles to the brick sticking wall surface; and the slurryscraping module is used for scraping the slurry of the wall tiles so as to enable the wall tiles to be conveniently stuck on the tile sticking wall surface in the follow-up process. The intelligent tiling robot is complete in function, automatic slurry scraping, wall tile sucking, wall tile rotating, wall tile sticking, detection of whether the wall tiles are paved and simultaneous wall tile paving can be achieved, full automation can be achieved in the whole process, a foundation can be provided for the follow-up full-automatic wall tile tile technology, and namely a technical foundation isprovided for the follow-up AI tile technology. Particularly, after an intelligent image recognition and planning technology is added, AI tiling can be basically realized.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

Blueberry yolk soluble bean finished product collecting device

ActiveCN112623785ARealize automatic scrapingImprove work efficiencyLoading/unloadingConveyor partsBiotechnologyEngineering

The invention relates to a collecting device, in particular to a blueberry yolk soluble bean finished product collecting device. The blueberry yolk soluble bean finished product collecting device is capable of achieving automatic scraping, screening and collecting. The blueberry yolk soluble bean finished product collecting device comprises a base, a shoveling device and a clamping device, the shoveling device is arranged on one side of the top of the base, and the clamping device is arranged on the side portion of the top of the base. Through cooperation of the shoveling device and the clamping device, yolk soluble beans can be automatically scraped off, a plate of the yolk soluble beans can be fixed, in this way, manual work can be replaced to collect the yolk soluble beans, the work efficiency of people is improved, and through cooperation of the collecting device and a shaking device, the scraped yolk soluble beans can be screened and collected so that people can conveniently collect the complete yolk soluble beans.

Owner:蔡龙

A brick supply module and its intelligent tiling robot

The invention discloses a brick supply module and its intelligent tile-laying robot. The intelligent brick-laying robot includes a frame module for installing, moving, and positioning a brick supply module, a brick suction module, and a slurry scraping module; the brick supply module is used for To continuously supply wall tiles to the brick-absorbing module, so that the brick-absorbing module can absorb them; The wall tiles are attached to the tiled wall; the scraper module is used to scrape the wall tiles so as to be attached to the tiled wall later. The invention has complete functions, and can realize automatic scraping, absorbing wall tiles, rotating wall tiles, pasting wall tiles, detecting whether the wall tiles are paved and paving the wall tiles at the same time. The wall tile technology provides the foundation, which is to provide the technical basis for the subsequent AI tile technology. Especially after adding intelligent image recognition and planning technology, AI tiling can basically be realized.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

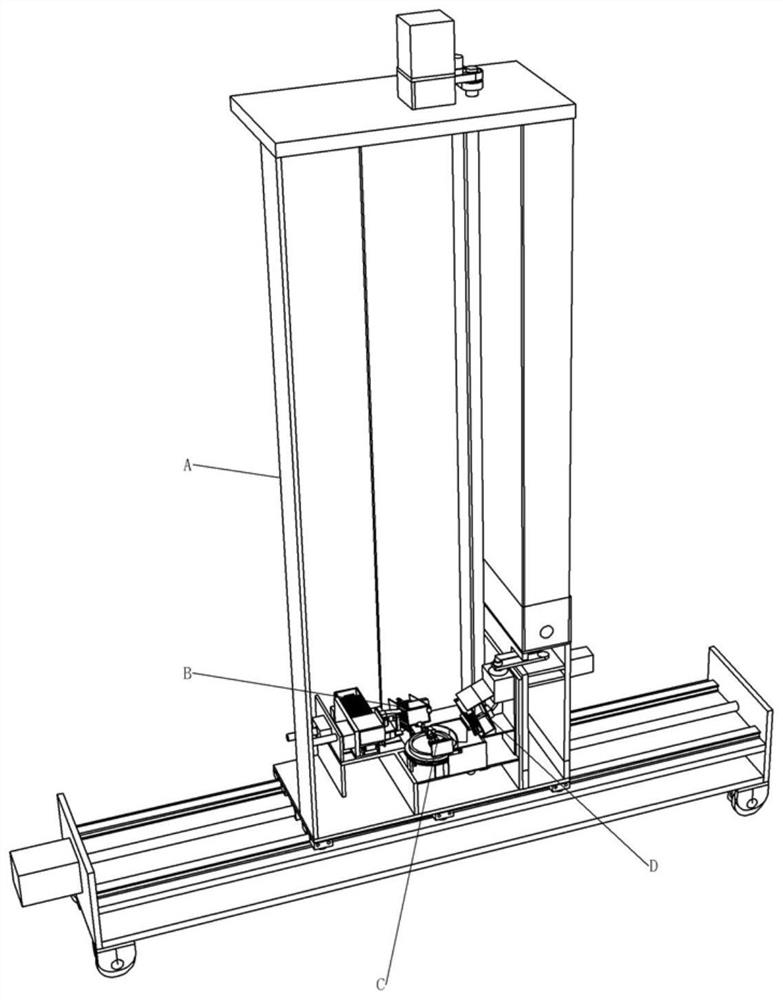

A rack module and its intelligent tiling robot

The invention discloses a frame module and an intelligent tile-laying robot thereof. The intelligent tile-laying robot includes a frame module for installing, moving, and positioning a brick supply module, a brick suction module, and a scraper module; the brick supply module is used for To continuously supply wall tiles to the brick-absorbing module, so that the brick-absorbing module can absorb them; The wall tiles are attached to the tiled wall; the scraper module is used to scrape the wall tiles so as to be attached to the tiled wall later. The invention has complete functions, and can realize automatic scraping, absorbing wall tiles, rotating wall tiles, pasting wall tiles, detecting whether the wall tiles are paved and paving the wall tiles at the same time. The wall tile technology provides the foundation, which is to provide the technical basis for the subsequent AI tile technology. Especially after adding intelligent image recognition and planning technology, AI tiling can basically be realized.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

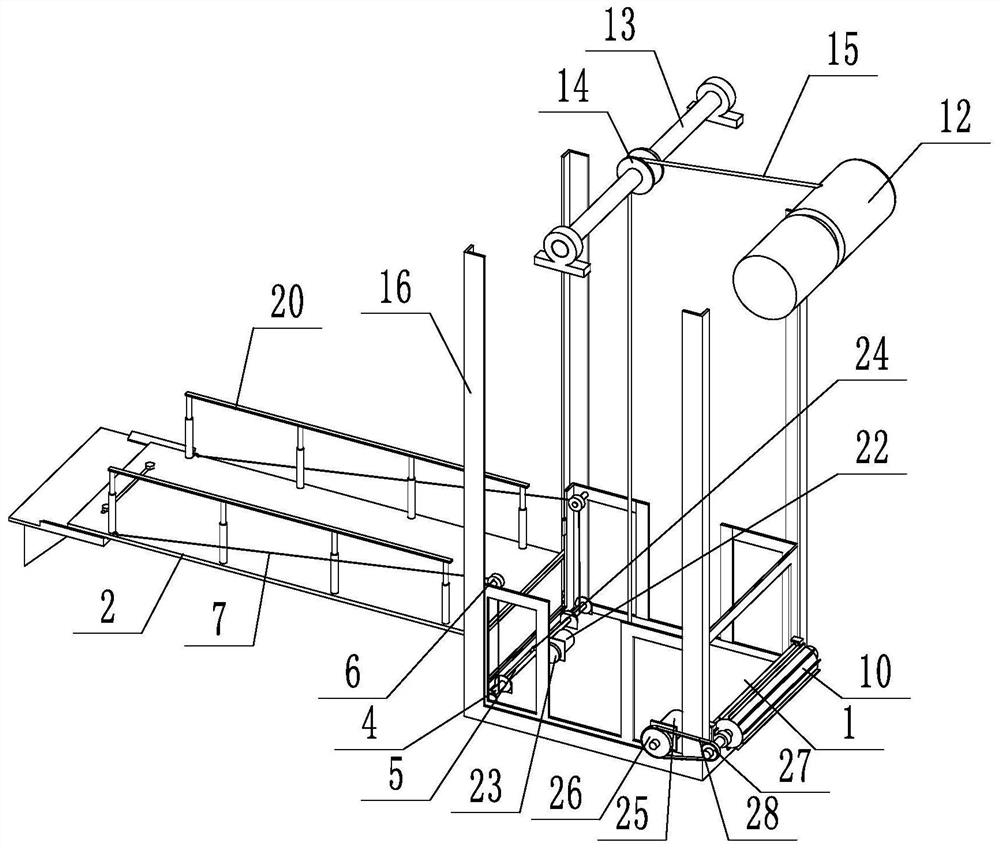

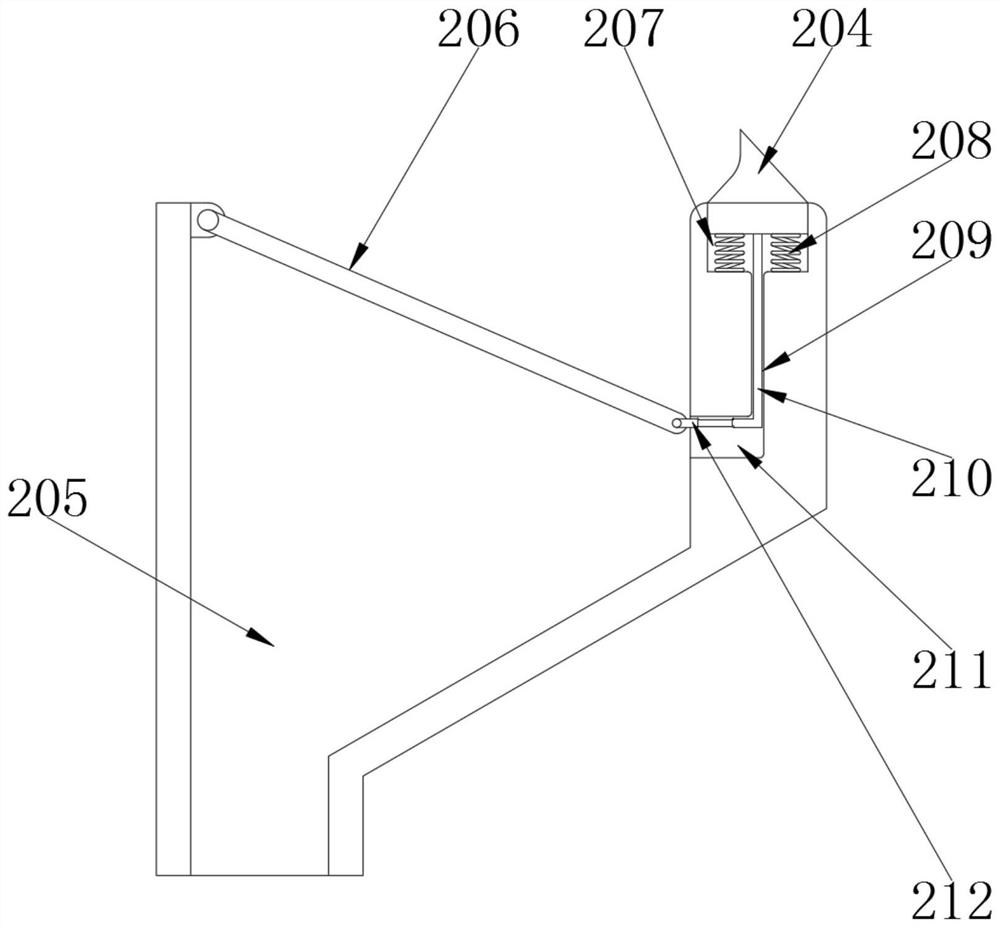

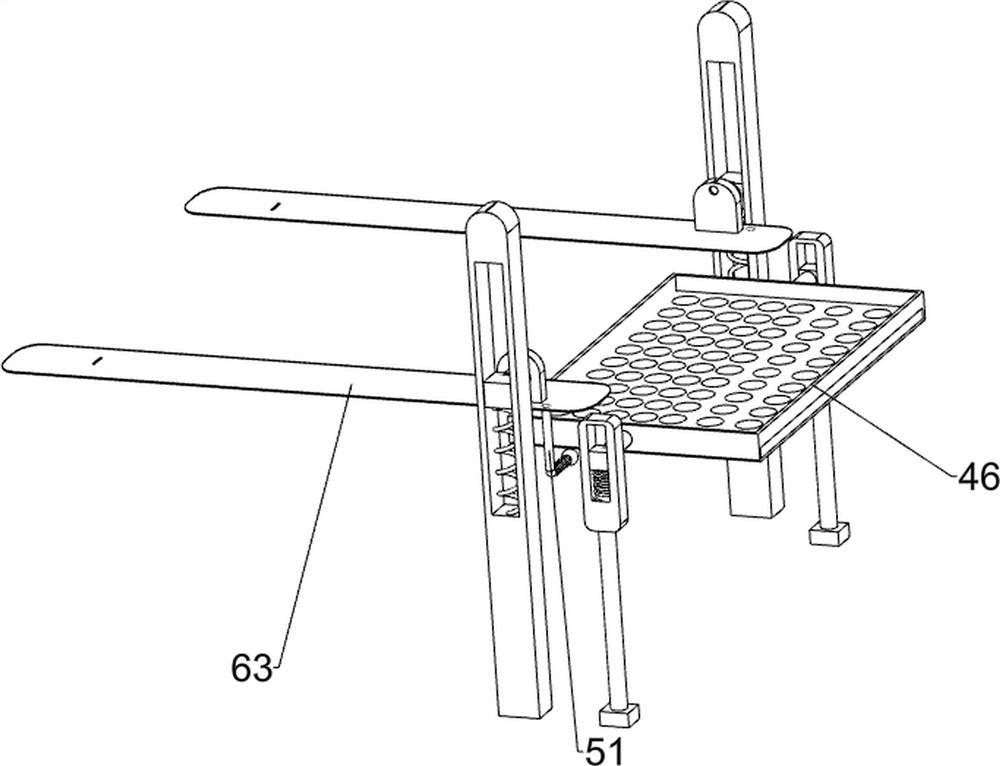

A squeegee module and its intelligent tiling robot

The invention discloses a scraper module and an intelligent tile-laying robot thereof. The intelligent tile-laying robot includes a frame module for installing, moving, and positioning a brick supply module, a brick suction module, and a scraper module; the brick supply module is used for To continuously supply wall tiles to the brick-absorbing module, so that the brick-absorbing module can absorb them; The wall tiles are attached to the tiled wall; the scraper module is used to scrape the wall tiles so as to be attached to the tiled wall later. The invention has complete functions, and can realize automatic scraping, absorbing wall tiles, rotating wall tiles, pasting wall tiles, detecting whether the wall tiles are paved and paving the wall tiles at the same time. The wall tile technology provides the foundation, which is to provide the technical basis for the subsequent AI tile technology. Especially after adding intelligent image recognition and planning technology, AI tiling can basically be realized.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

A brick filling mechanism and its intelligent tiling robot

The invention discloses a brick repairing mechanism and an intelligent brick tiling robot thereof. The intelligent brick tiling robot includes a frame module for installing, moving and positioning a brick supply module, a brick suction module and a slurry scraping module; the brick supply module is used for To continuously supply wall tiles to the brick-absorbing module, so that the brick-absorbing module can absorb them; The wall tiles are attached to the tiled wall; the scraper module is used to scrape the wall tiles so as to be attached to the tiled wall later. The invention has complete functions, and can realize automatic scraping, absorbing wall tiles, rotating wall tiles, pasting wall tiles, detecting whether the wall tiles are paved and paving the wall tiles at the same time. The wall tile technology provides the foundation, which is to provide the technical basis for the subsequent AI tile technology. Especially after adding intelligent image recognition and planning technology, AI tiling can basically be realized.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

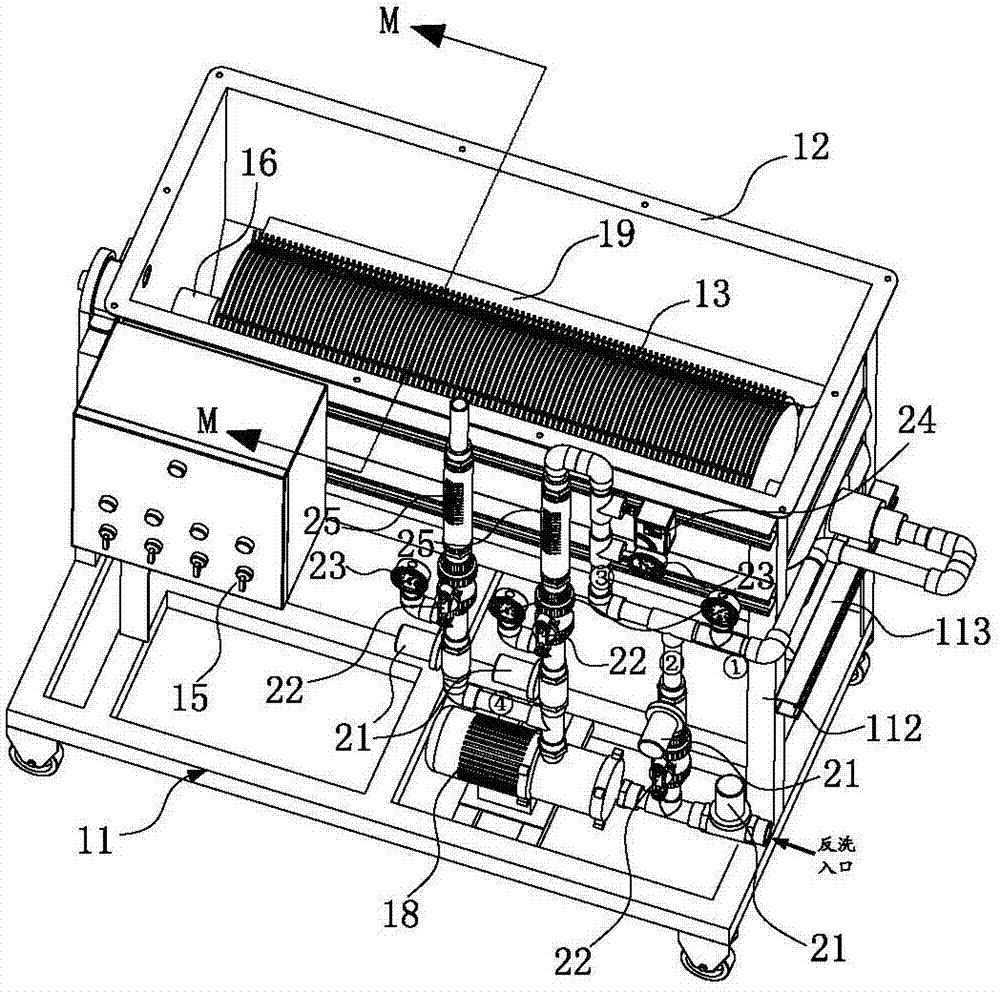

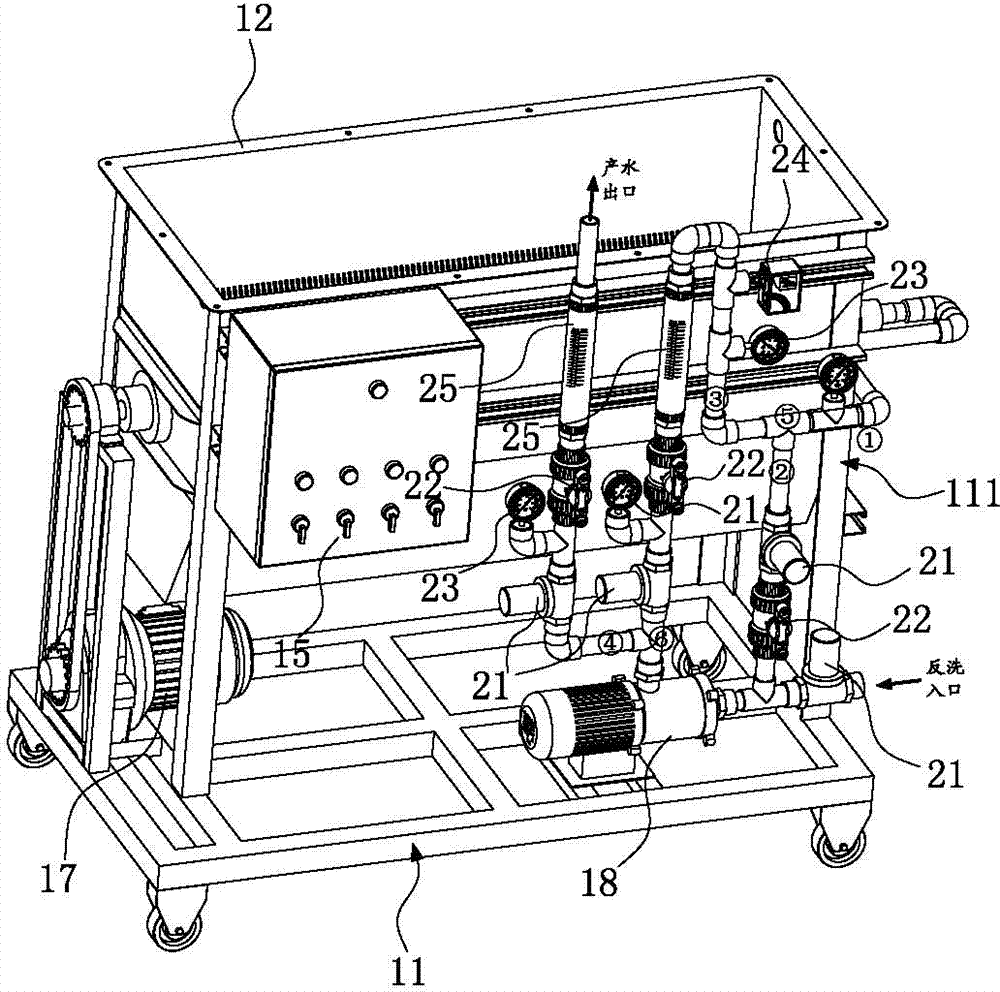

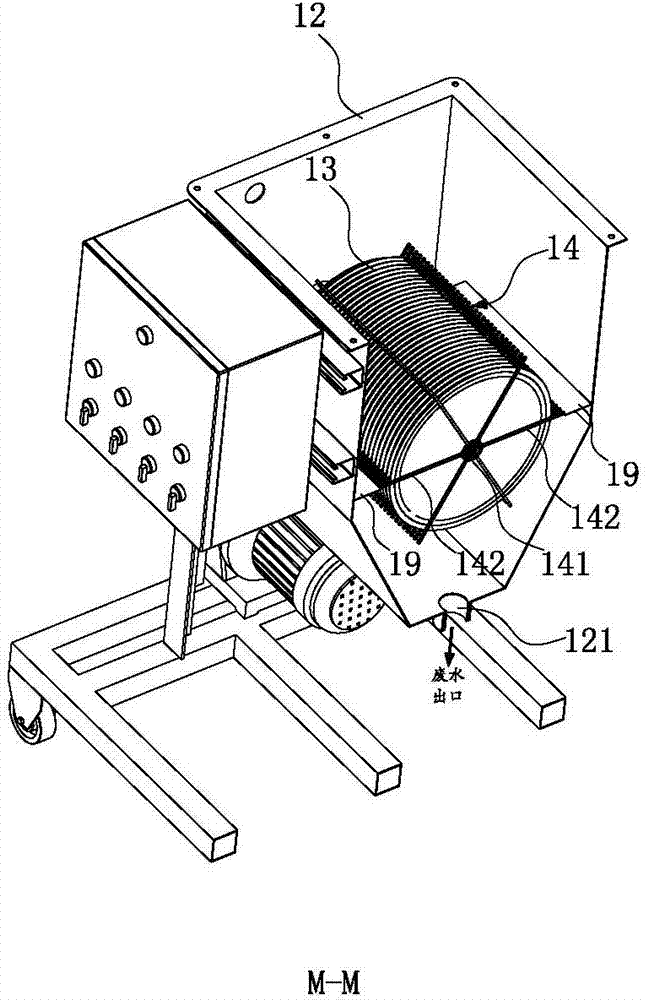

Water treatment equipment

ActiveCN102674504BSimple structureHigh efficiency water productionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltrationWater production

The invention discloses water treatment equipment comprising a base, a water tank, a filtration film device, a scraping piece, a water production pipeline component, a backwashing pipeline component and a control box, wherein the water production pipeline component comprises a rotating shaft type water production pipe in the water tank and a transmission pipeline component outside the water tank; the rotating shaft type water production pipe is connected with a driving motor; an electromagnetic valve, a pressure gauge, a pressure switch and a flowmeter are arranged on the water production pipeline component; the backwashing pipeline component is connected to the water production pipeline component; under the forward pumping of a water production water pump, sewage in the water tank is filtered through the filtration film device to form water product which enters a rotating shaft type water production pipe; and during backwashing, the sewage in the water tank is pumped in a reverse direction through a backwashing water pump, so as to backwash the filtration film device. Therefore, the water treatment equipment has the advantages that the structure is simple; through the matching of components, efficient water production is realized; the water production quality and the water production efficiency are guaranteed; the whole operation process is controlled fully automatic; and the operation is safe and reliable. Moreover, the arrangement of the pipeline components is reasonable and compact, so as to save occupied area.

Owner:DONGGUAN DONGYUAN ENVIRONMENTAL TECH CO LTD

A suction module and its fully automatic tile-laying robot

The invention discloses a suction module and a fully automatic tile-laying robot thereof. The fully-automatic tile-laying robot includes a frame module for installing, moving, and positioning a brick supply module, a brick suction module, and a slurry scraping module; the brick supply module is used for To continuously supply wall tiles to the brick-absorbing module, so that the brick-absorbing module can absorb them; The wall tiles are attached to the tiled wall; the scraper module is used to scrape the wall tiles so as to be attached to the tiled wall later. The invention has complete functions, and can realize automatic scraping, absorbing wall tiles, rotating wall tiles, affixing wall tiles, detecting whether the wall tiles are paved or not, and simultaneously paving the wall tiles. The whole process can realize full automation. The present invention can realize the fully automatic tiling of wall tiles, which can provide the basis for the subsequent fully automatic tiling technology, that is, provide the technical basis for the subsequent AI tiling technology.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

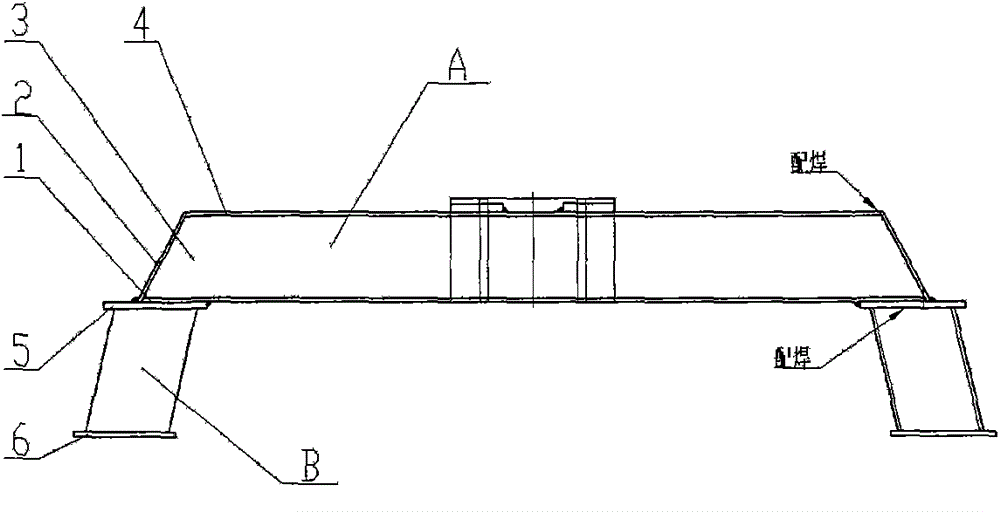

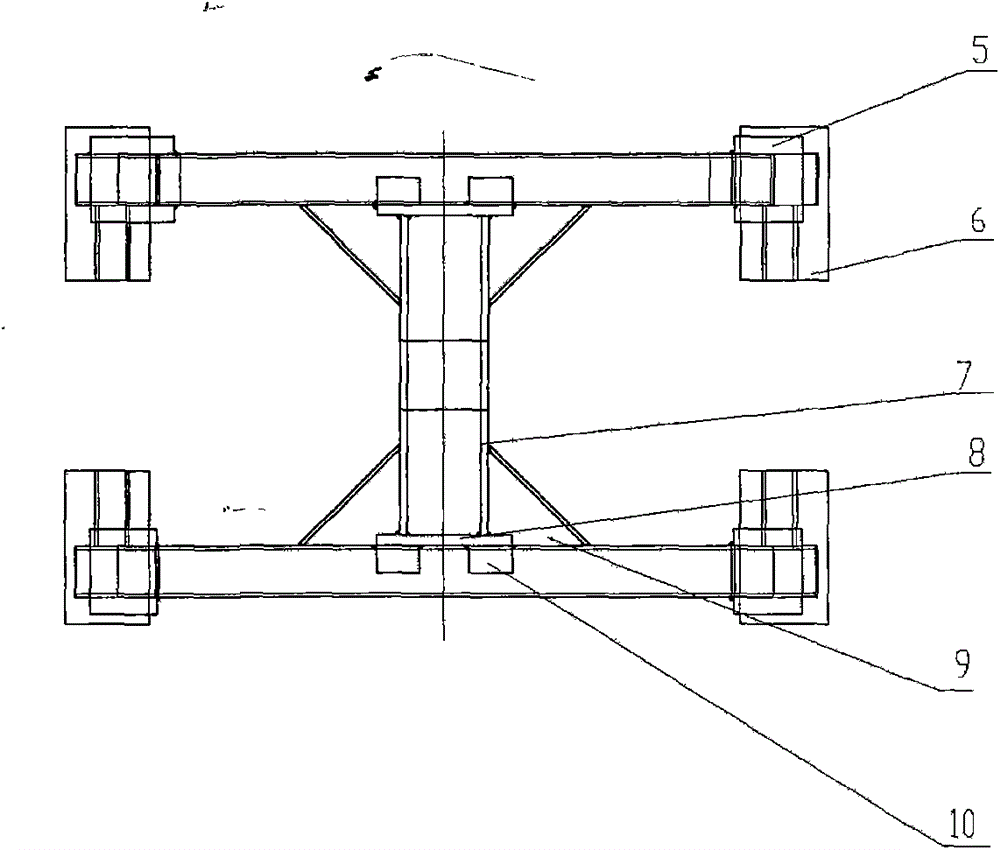

Automatic material returning device on engineering mechanical grab bucket

In order to solve the problem that when an engineering mechanical grab bucket grabs viscous materials, the materials will be attracted to the inner wall of a shell of the grab bucket, the invention provides an automatic material returning device on the engineering mechanical grab bucket. Energy and the circular-arc radius obtained when the grab bucket stretches out are utilized, and the viscous materials attached to the inner wall of the shell of the grab bucket can be automatically scraped when the grab bucket is stretched out, and the equipment working efficiency is improved; and the device is simple in structure, convenient to use, low in production cost and convenient to use and popularize. According to the technical scheme, the two ends of front and back material returning square boxes (A) are provided with front, back, left and right scraper square boxes (B) respectively in a welded manner; the material returning square boxes (A) and the scraper square boxes (B) which are completely welded are welded with a supporting plate (7) together, welding of the material turning device is completed, and then the material returning device is welded to a stand column of the grab bucket; and the aim that the energy and the circular-arc radius obtained when the grab bucket stretches out are utilized for achieving the aim that when the grab bucket stretches out, the viscous materials attached to the inner wall of the grab bucket can be automatically scraped.

Owner:徐礼龙 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com