Automatic material returning device on engineering mechanical grab bucket

A technology for construction machinery and material return, which is applied in the direction of cleaning devices, transportation and packaging, and conveyor objects, and can solve problems such as waste of fuel, inability to return materials, and poor results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

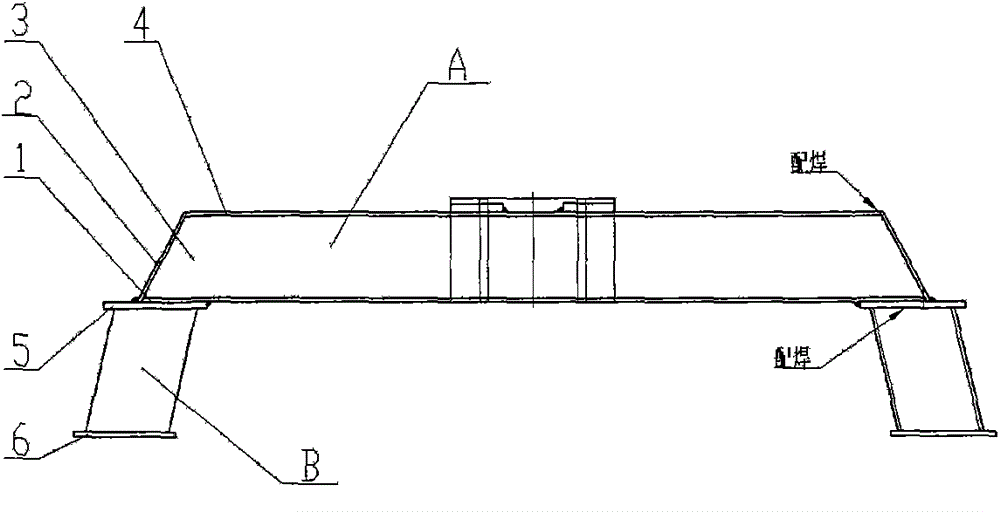

[0009] right figure 1 Each part is described as follows: 1. Bottom plate, 2. Inclined cover plate, 3. Vertical plate, 4. Top cover plate, 5. Scraper 1, 6. Scraper 2, A. Return material square box, B. Scraper square box.

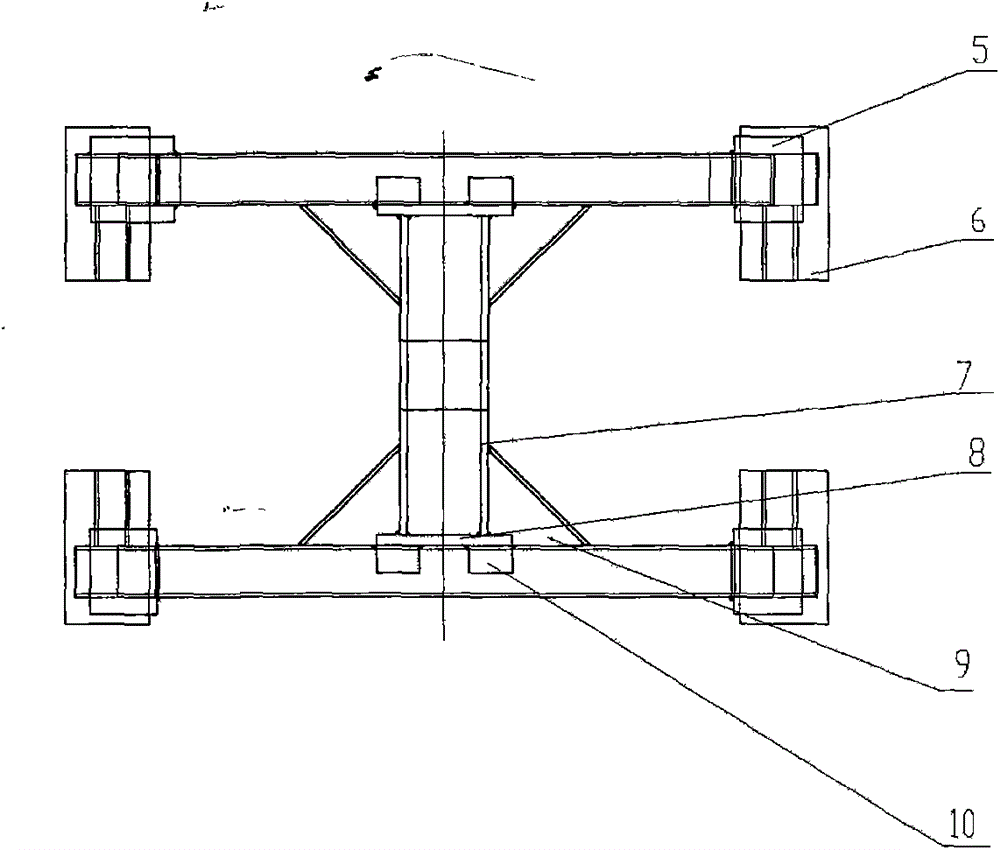

[0010] right figure 2 Each part is described as follows: 5. Scraper 1, 6. Scraper 2, 7. Support plate, 8. Positioning plate, 9. Rib 1, 10. Pressure plate.

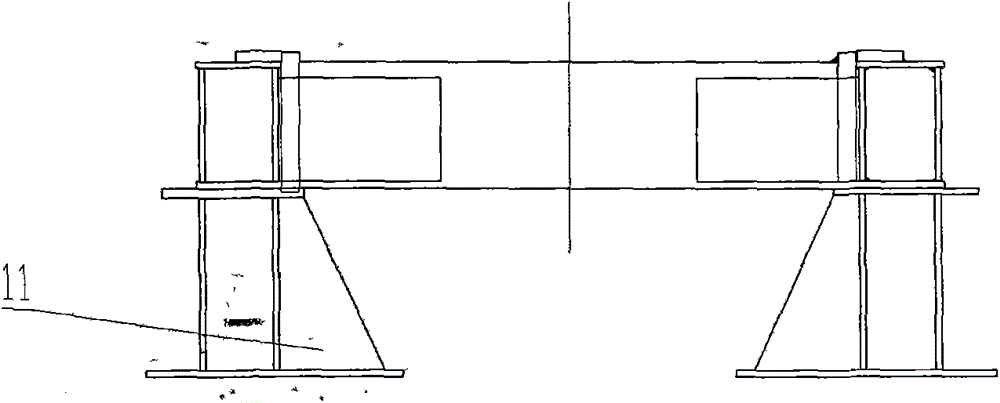

[0011] right image 3 Each part is described as follows: 11. Rib 2.

[0012] right Figure 4 Each part is described as follows: 12. Grab column.

[0013] Depend on figure 1 Shown: the material return square box (A) is formed by welding the bottom plate (1), inclined cover plate (2), vertical plate (3) and top cover plate (4), and the upper end of the scraper square box (B) is welded with a scraper Plate 1 (5), the lower end is welded with scraper 2 (6), and the welded scraper square box (B) is welded to the bottom of both ends of the scraper square box (A) respectively.

[0014] Depend on figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com