Water treatment equipment

A technology of water treatment equipment and water tanks, which is applied in the direction of osmosis/dialysis water/sewage treatment, semi-permeable membrane separation, chemical instruments and methods, etc., which can solve the problems of large overall floor area and space, difficulty in stabilizing the quality of produced water, and reliable operation Insufficient performance and other problems, to save production costs, ensure the quality and efficiency of water production, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

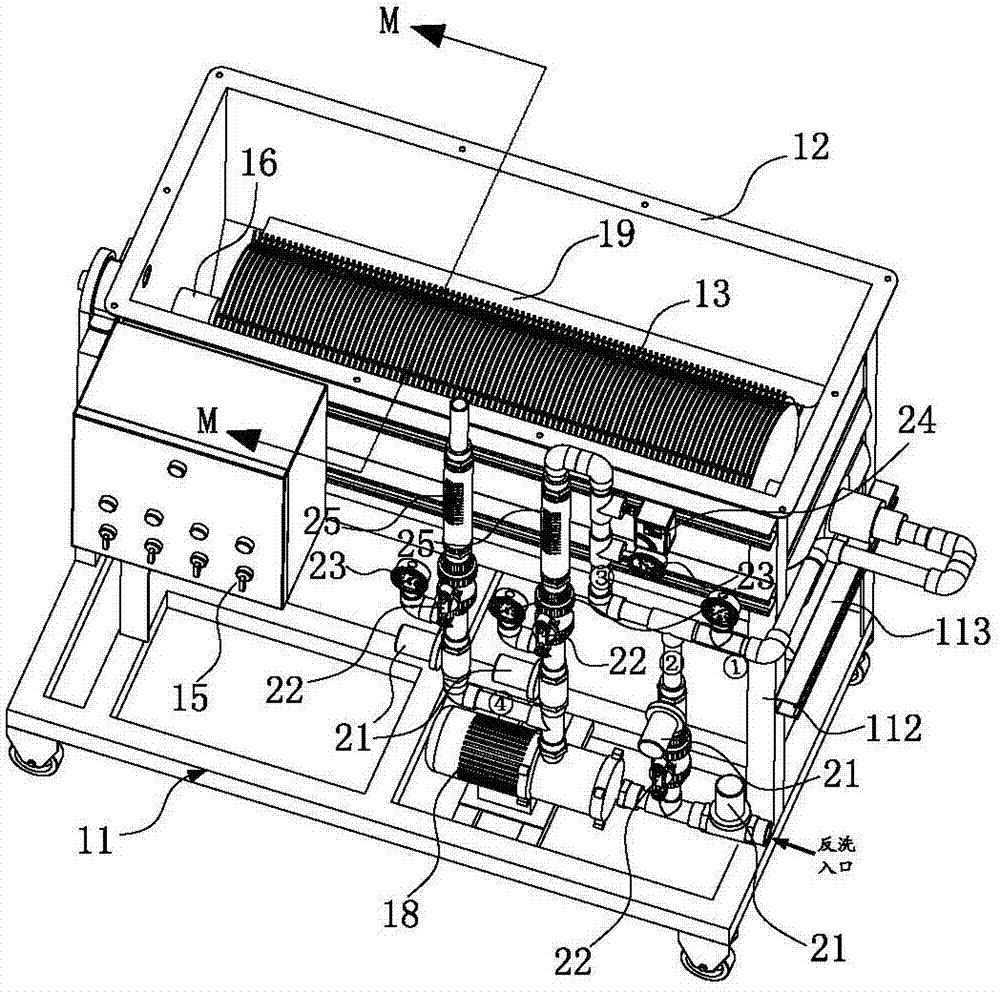

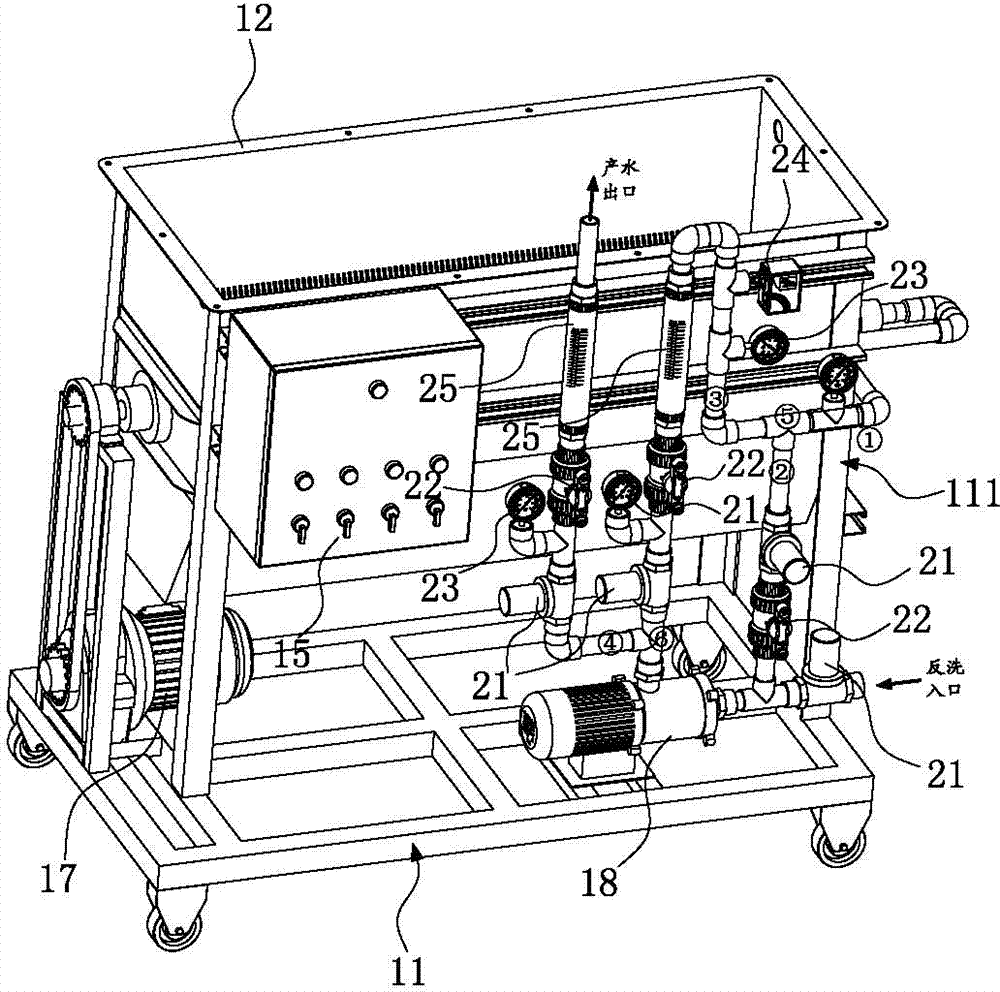

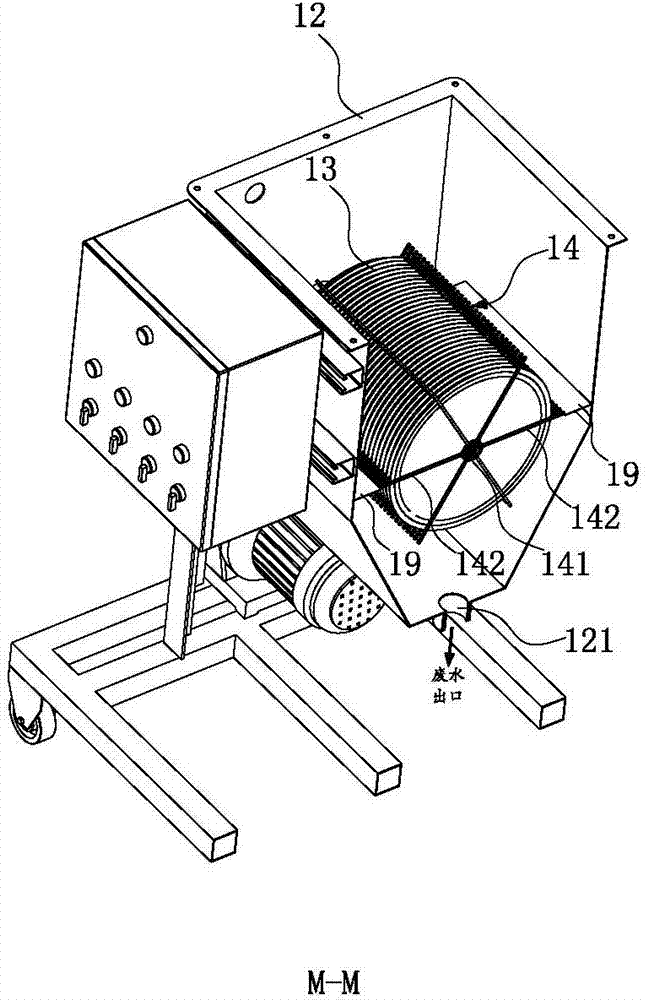

[0041] See Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a base 11, a water tank 12, a membrane filter device 13, a scraper 14, a water production pipeline assembly and a control box 15.

[0042] The water tank 12 is located on the base 11, usually the water tank 12 is a sealed container, which includes a main body and a cover plate detachably locked on the main body. The cover plate is not shown in the figure, and the water tank 12 is opened outwardly. Waste water discharge port 121, such as image 3 As shown, the waste water discharge port 121 is opened at the bottom of the water tank 12.

[0043] The water production pipeline assembly includes a rotary shaft-type water production pipe 16 disposed in the water tank 12 and a delivery pipe assembly located outside the water tank 12; the rotary shaft-type water production pipe 16 is arranged in a horizontal direction, and one end is provided with a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com