Patents

Literature

30results about How to "Scrape thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

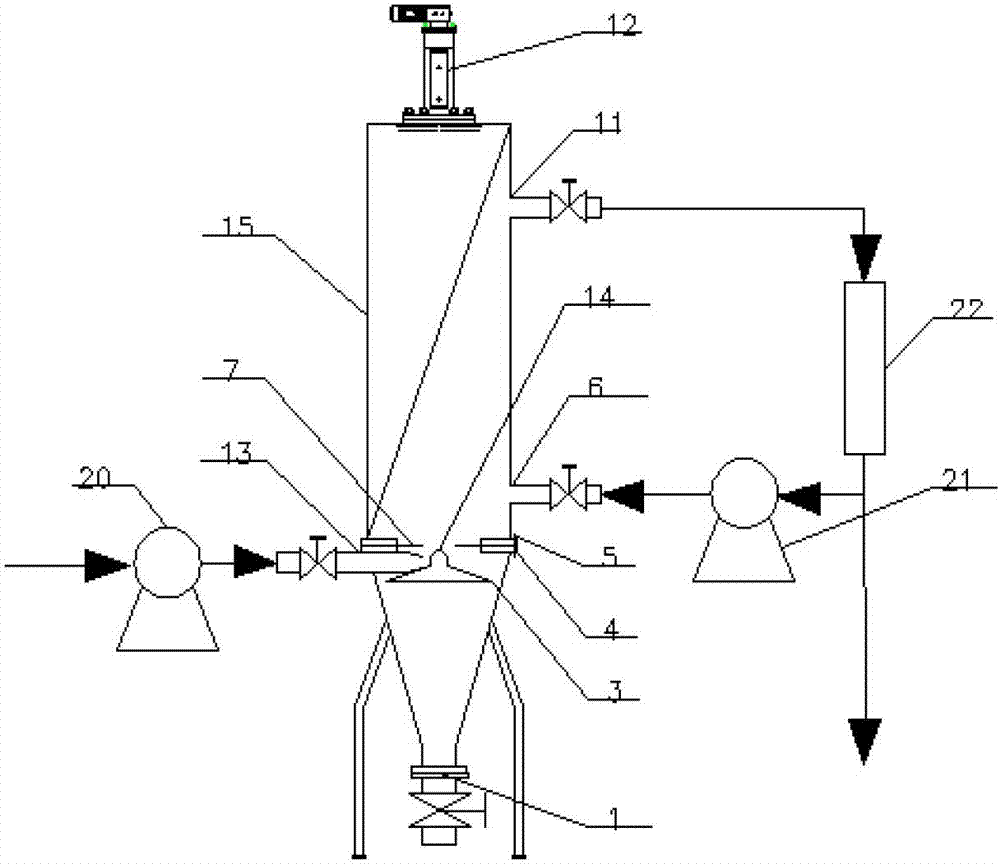

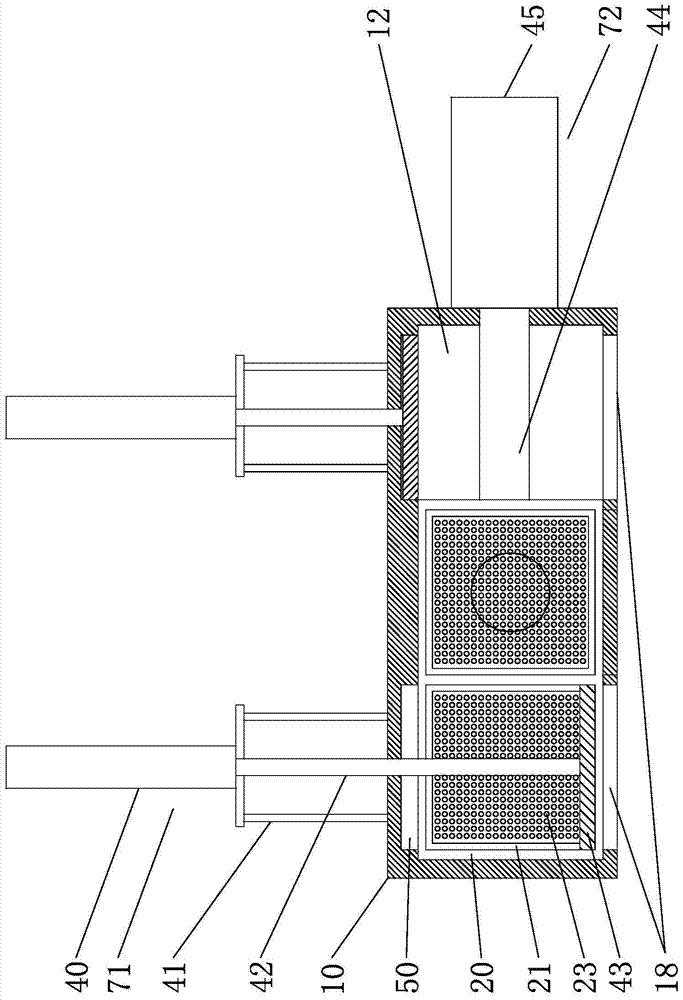

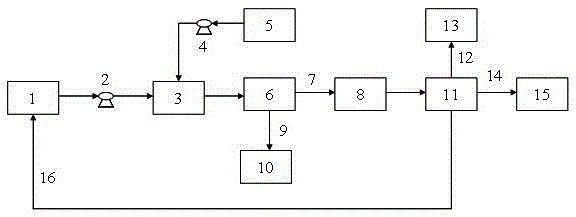

Oily sludge advanced treatment technology

ActiveCN104649563AGood demulsification effectGood biodegradabilitySludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesPetroleumSludge dewatering

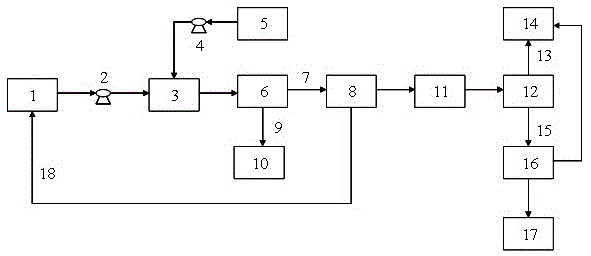

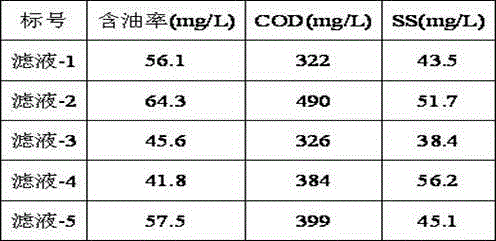

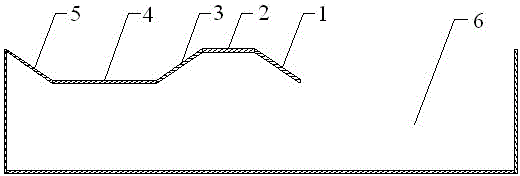

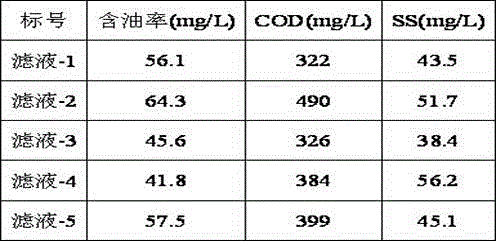

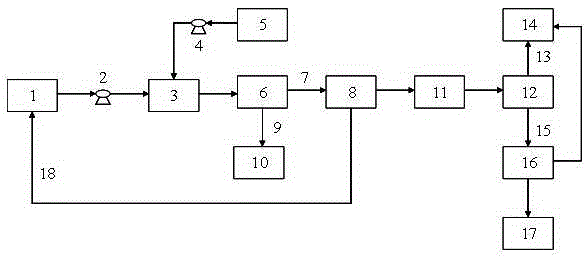

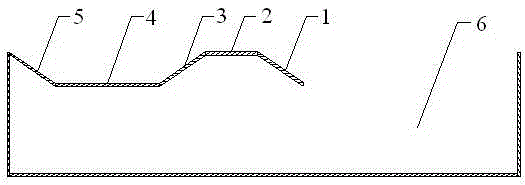

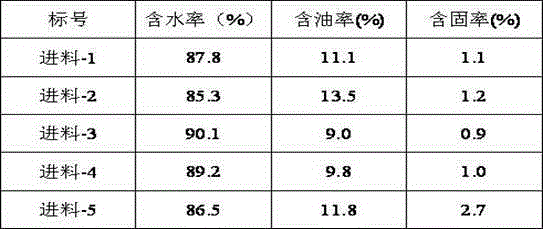

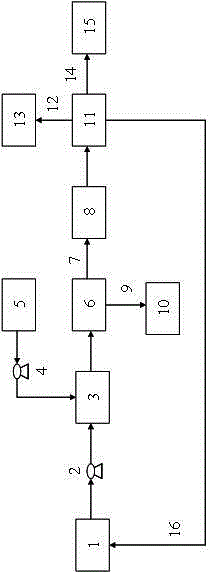

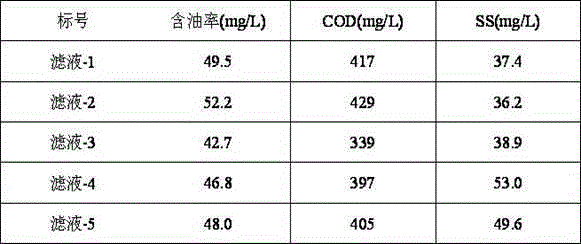

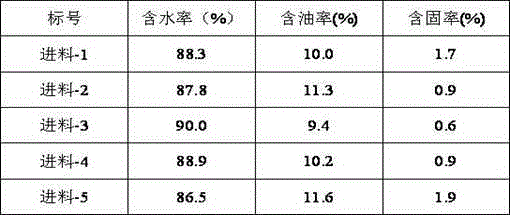

The invention discloses an oily sludge advanced treatment technology which comprises the following contents: oily sludge in a raw material storage sludge-tank enters a sludge mixing tank; a demulsifier is added to carry out demulsification treatment; demulsified oily sludge enters screw-type sludge dewatering equipment to undergo solid-liquid separation so as to obtain a filtrate and sludge cake; the filtrate enters a two-phase cyclone to be separated; after two-phase separation, excess sludge at the lower layer flows back to the raw material storage sludge-tank, a mixed liquor at the upper layer is sent into a gas-liquid mixing tank to be mixed with the air and then enters a separation pond to carry out primary separation of sump oil and sewage; sump oil is recovered to a sump oil tank by the use of a sludge scraper; sewage enters a filter to separate suspended particles and residual sump oil in the sewage from water; sump oil separated from the top of the filter is recovered to a sump oil recovery tank; and sewage discharged from the filter is sent to a sewage treatment plant to undergo subsequent processing. By the technology, water content of the oily sludge can be reduced from 80-98% to about 50%, and most crude oil in the oily sludge can be recovered. Thus, sludge subsequent processing difficulty is greatly reduced. The technology provided by the invention has a wide range of application, is especially suitable for processing of oily sludge at the bottom of an oil-tank, dross and activated sludge as well as processing of various oily sludge generated from oil exploitation and storage transportation enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil sludge demulsifier and oil sludge resourceful treatment process

ActiveCN104556626AImprove performanceMild performanceSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSludge cakeDemulsifier

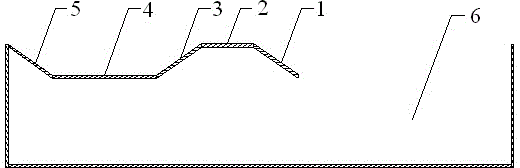

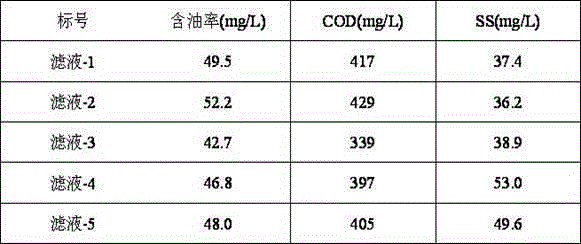

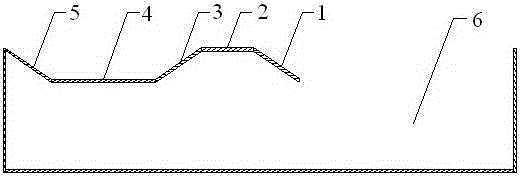

The invention discloses an oil sludge demulsifier and an oil sludge resourceful treatment process. The oil sludge demulsifier comprises the following components in parts by weight: 5-30 parts of fatty acid methyl ester sulfonate, 2-10 parts of alkyl polyglucoside, 0.5-2 parts of a green accessory ingredient and 58-92 parts of water. The oil sludge resourceful treatment process comprises the following steps: enabling oily sludge in a raw material storage sludge tank to enter a sludge mixing tank; adding the oil sludge demulsifier for demulsification treatment; enabling demulsified oily sludge to enter a stacked spiral type sludge dewatering machine for solid-liquid separation to obtain a filter liquor and a sludge cake; enabling the filter liquor to enter a gas-liquid mixing tank to be mixed with air; enabling the mixture to enter a separation tank for three-phase separation of oil, water and sludge. The oil sludge resourceful treatment process can reduce the moisture content of oily sludge from 80-98% to about 50%, can further recycle most crude oil in oily sludge, and greatly reduces the difficulty of sludge follow-up treatment. By combining the oil sludge demulsifier with the oil sludge demulsification process, the moisture content of oil sludge can be reduced from 80-98% to about 50%, most crude oil in oil sludge can be further recycled, and the difficulty of sludge follow-up treatment is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

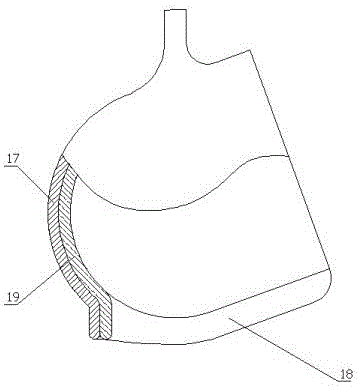

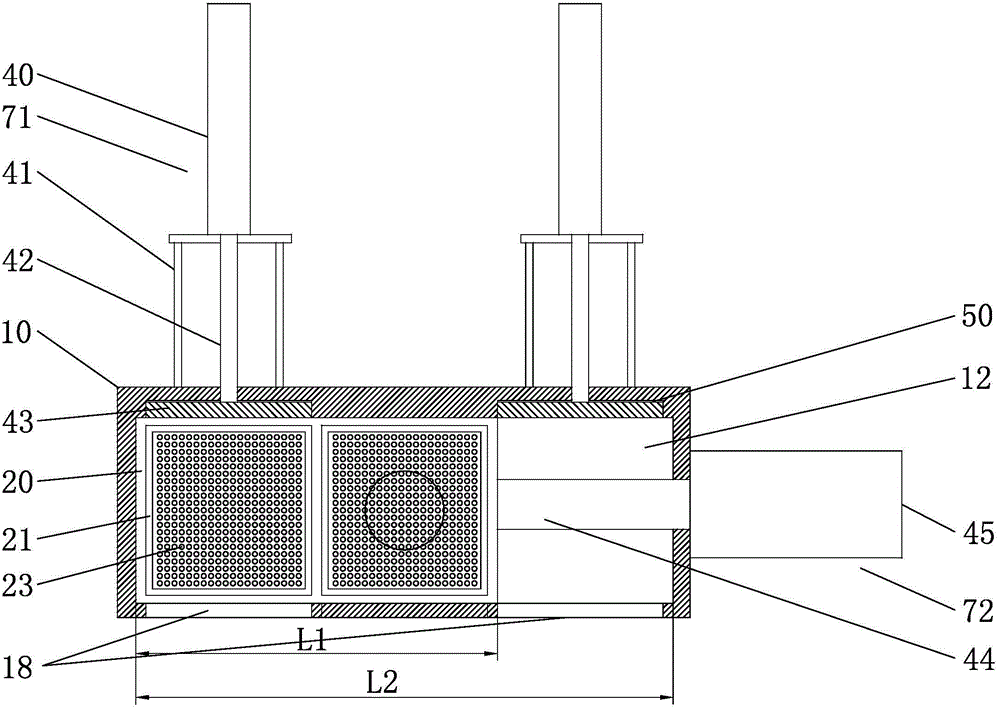

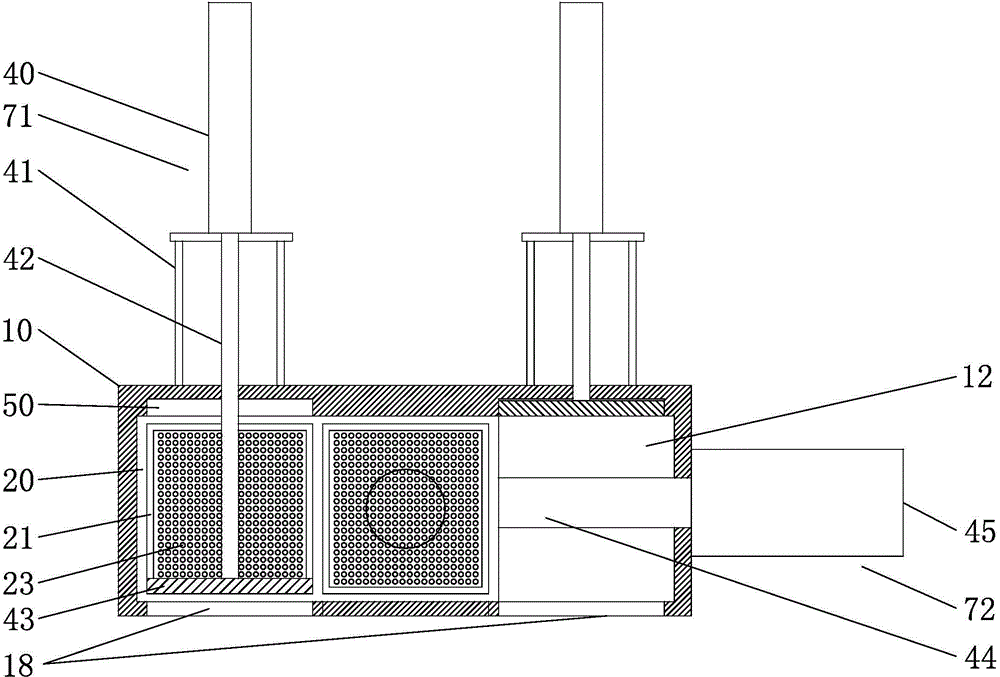

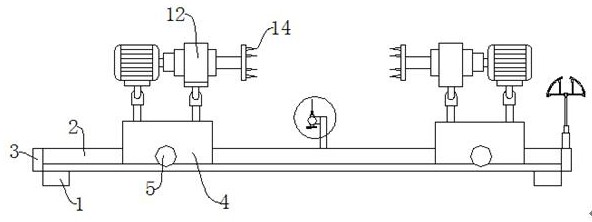

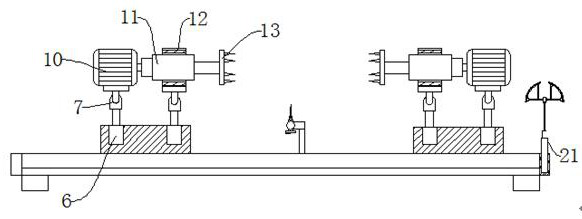

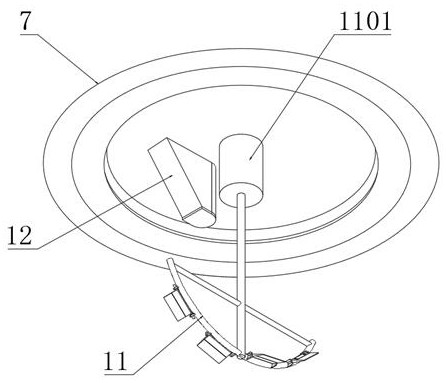

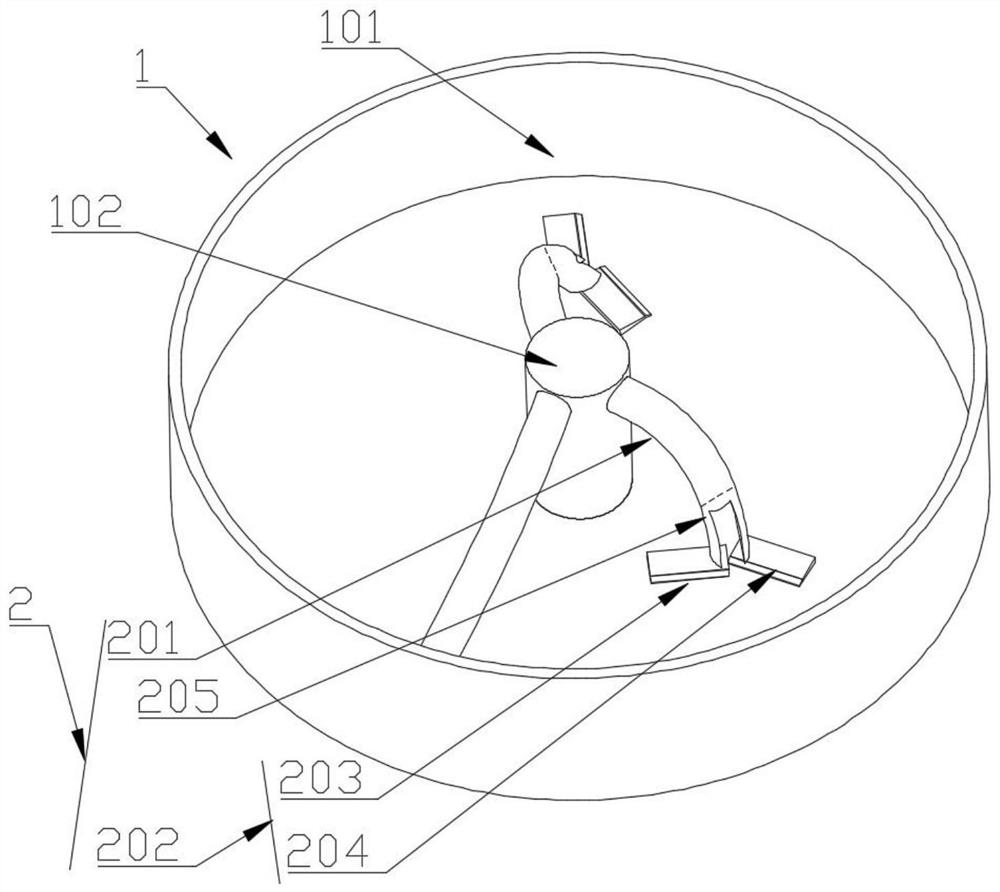

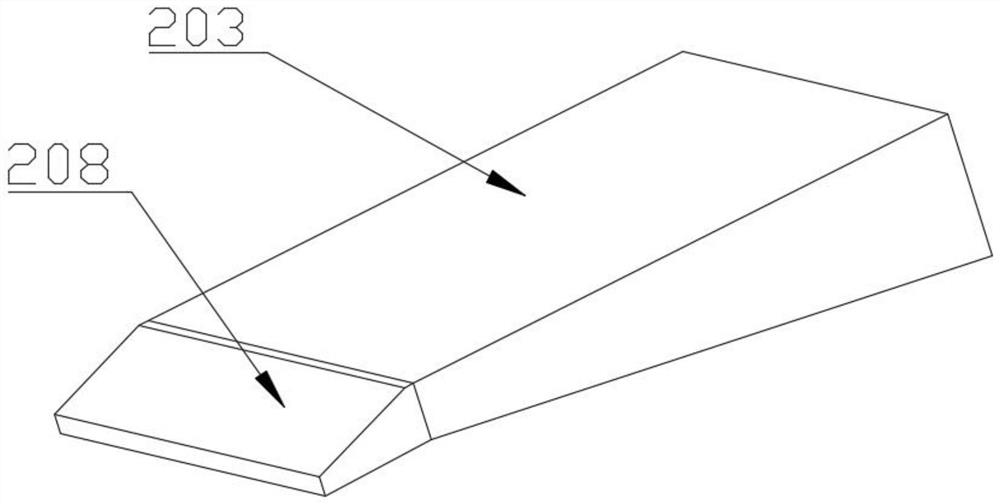

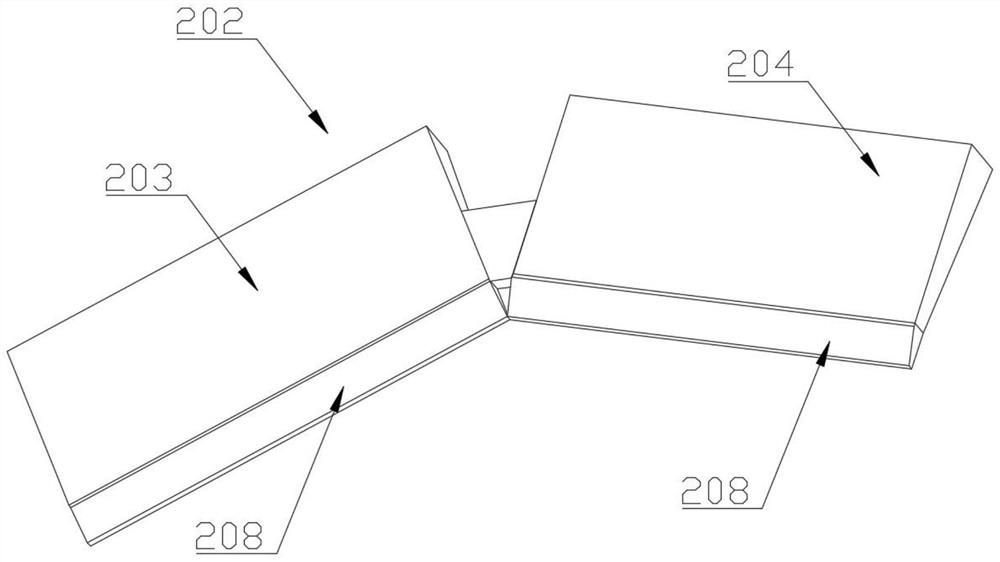

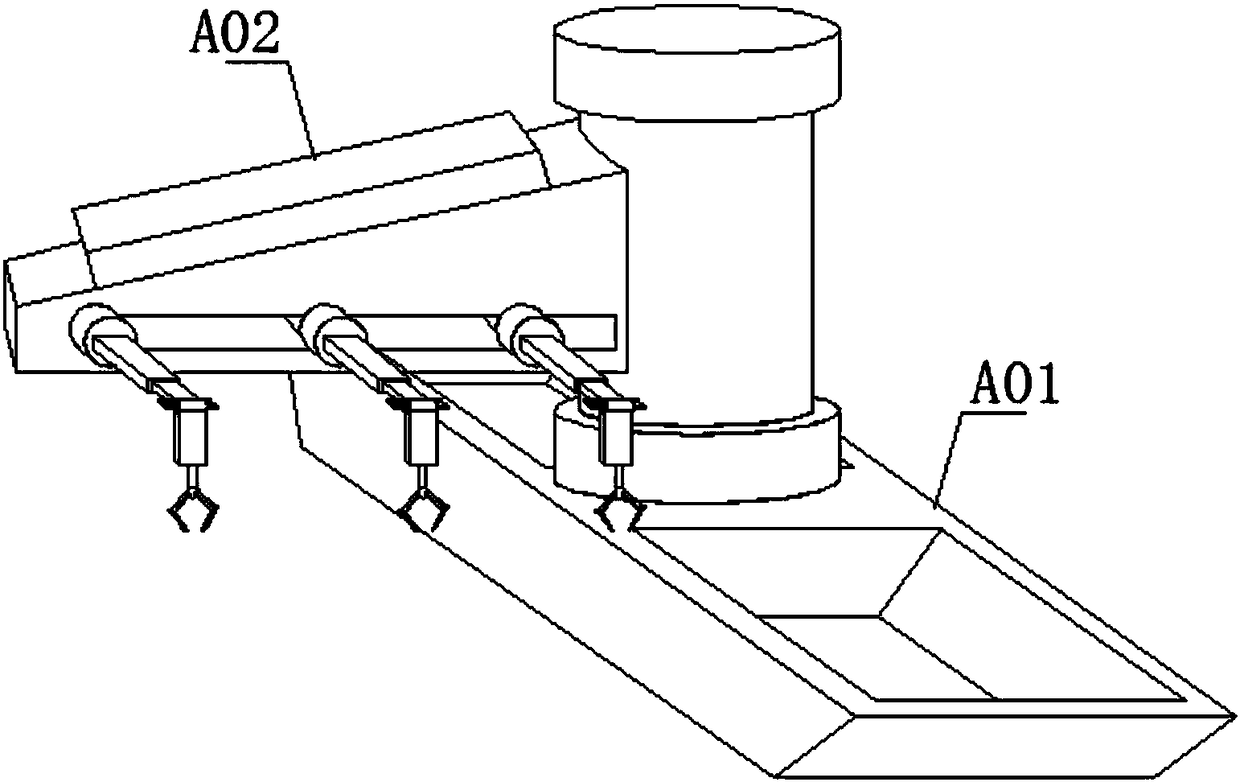

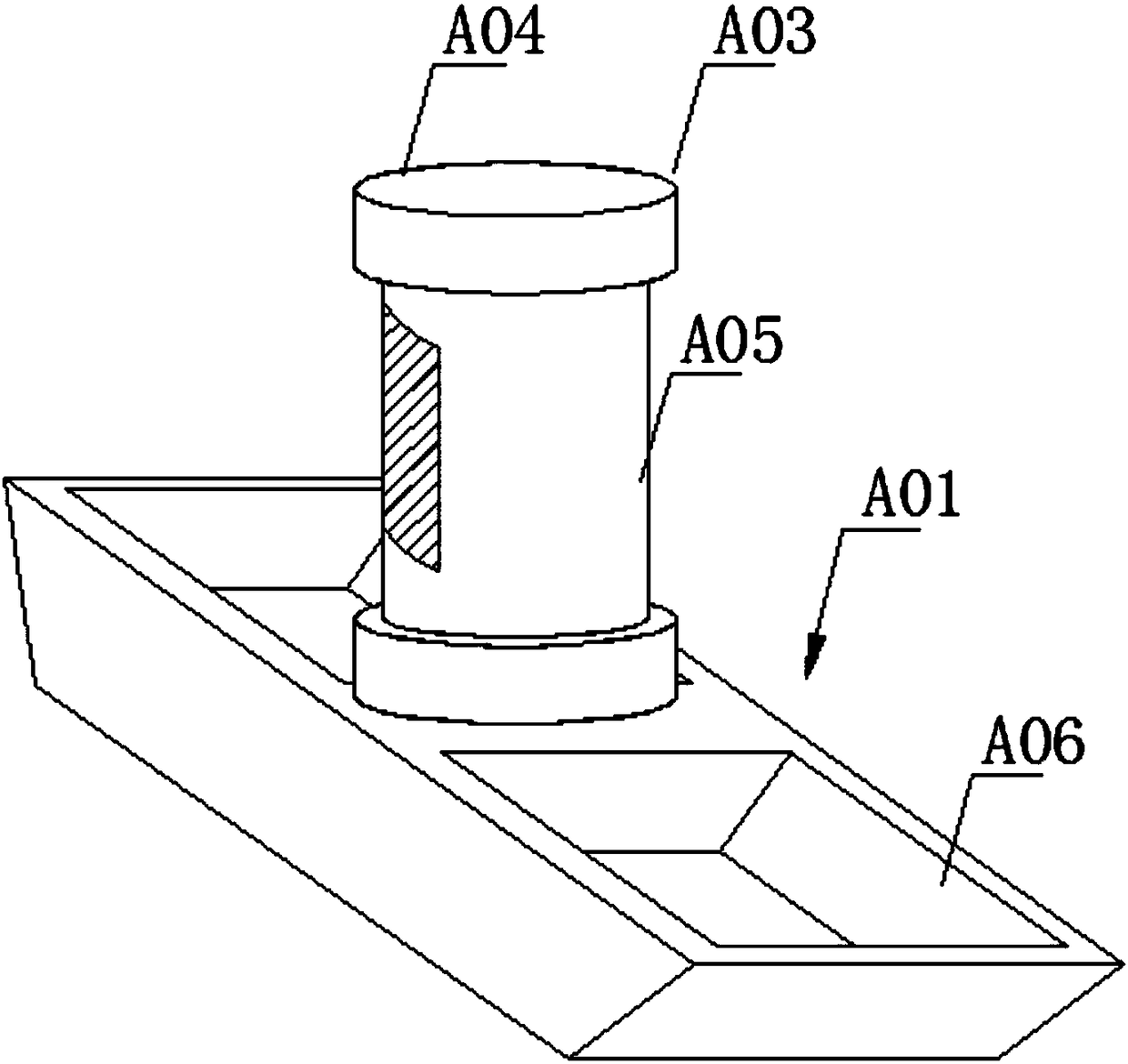

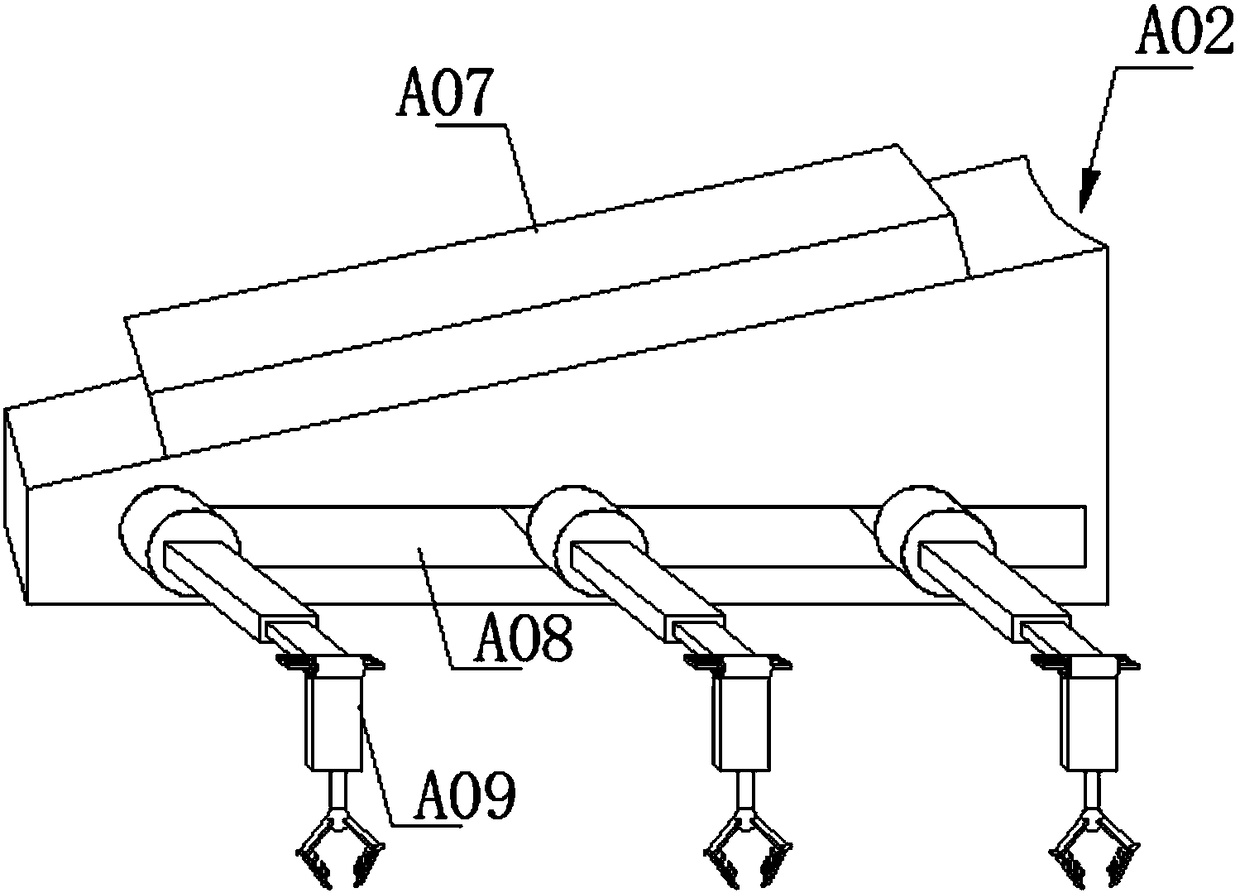

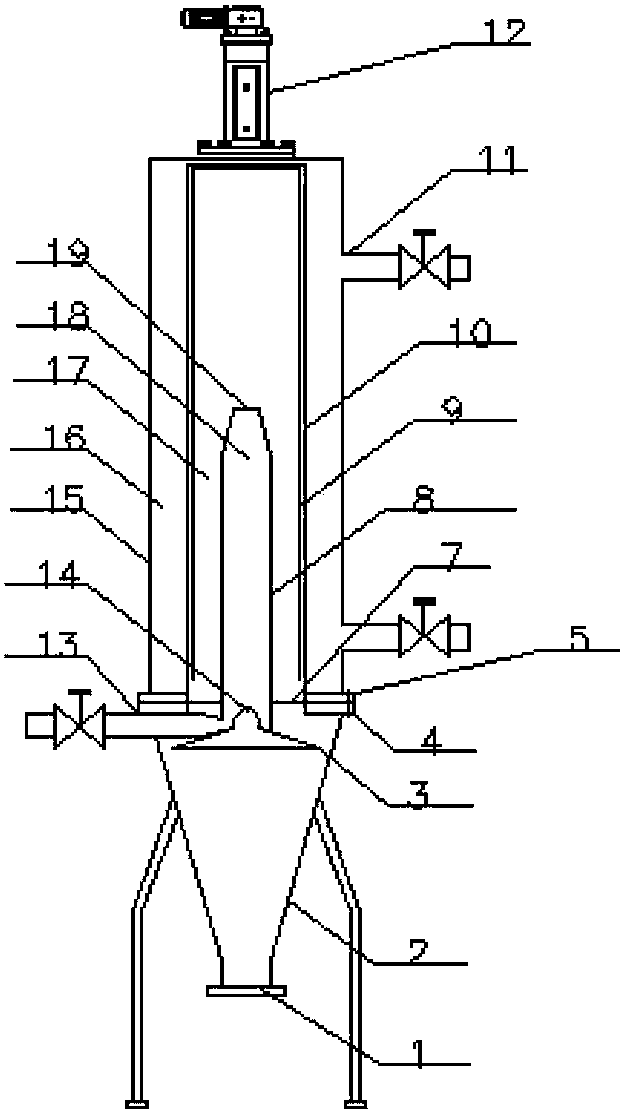

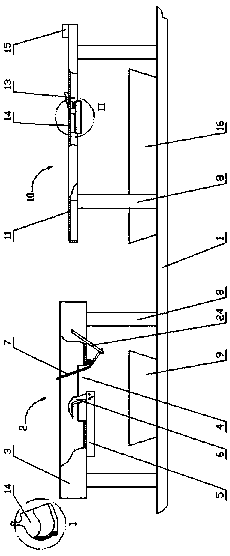

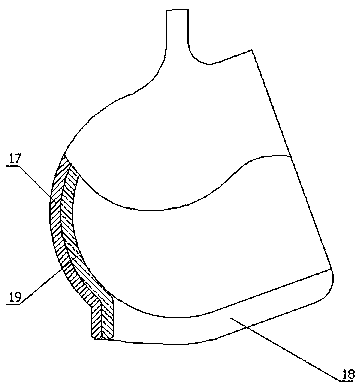

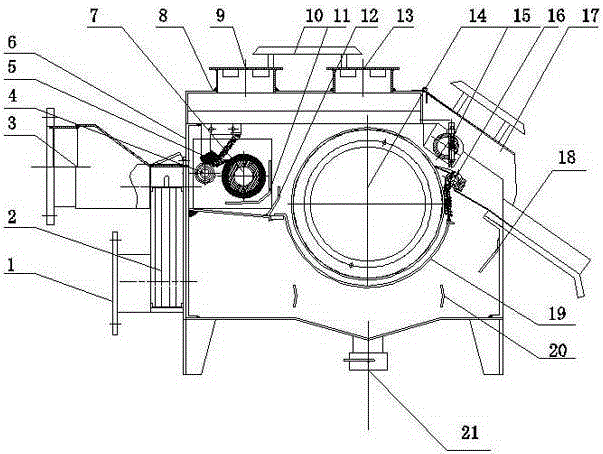

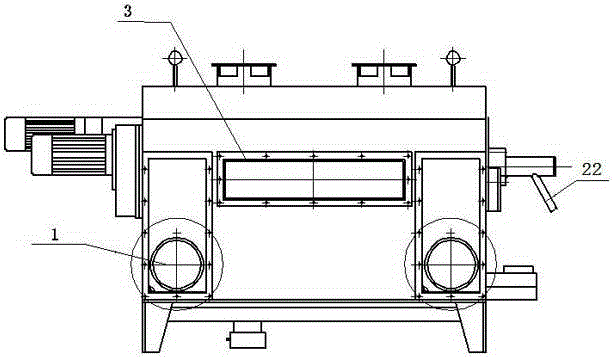

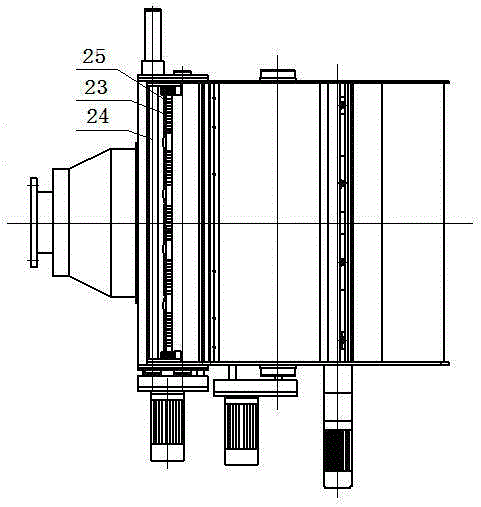

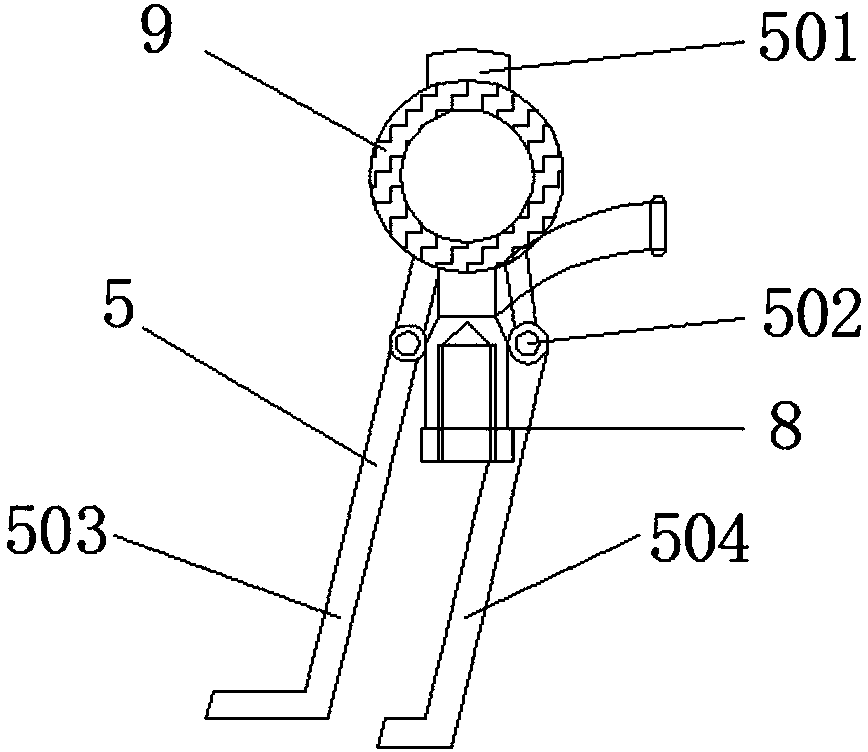

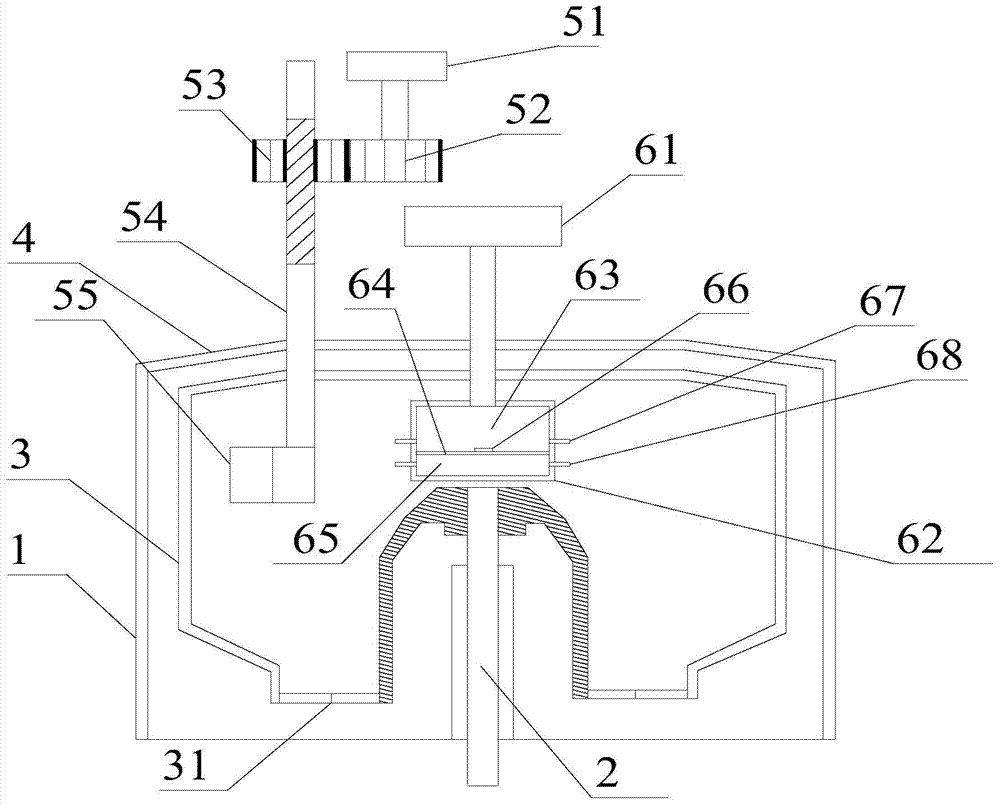

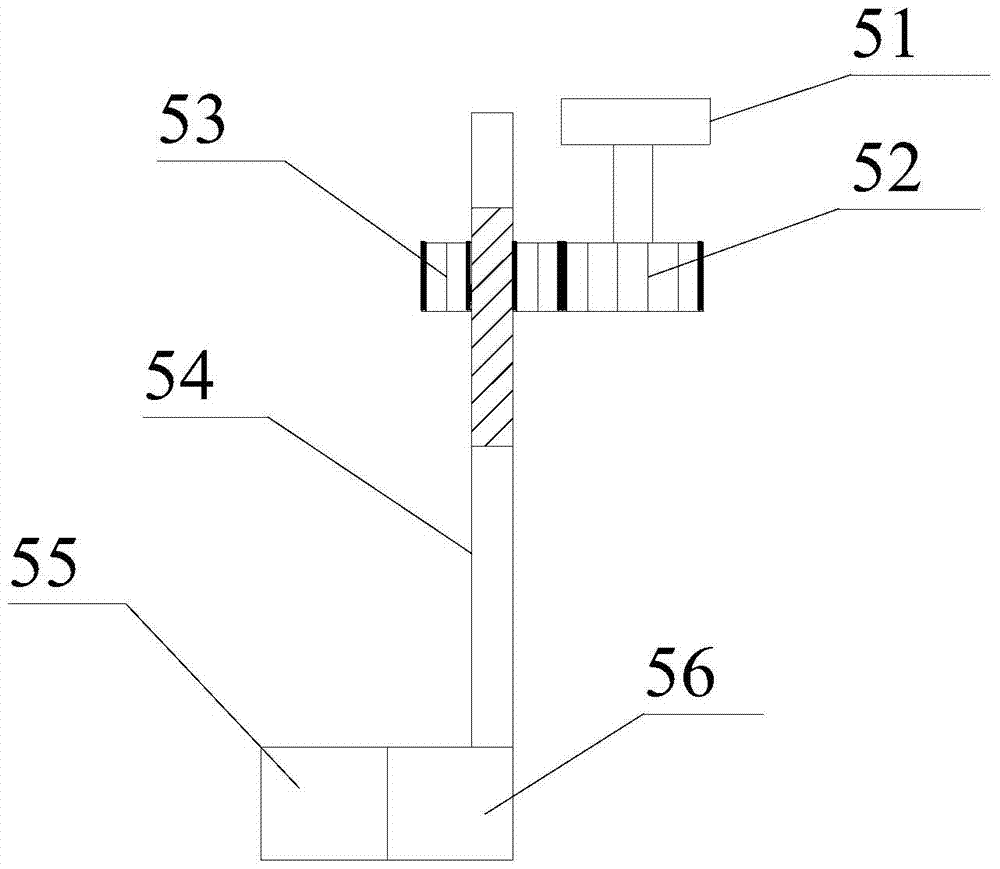

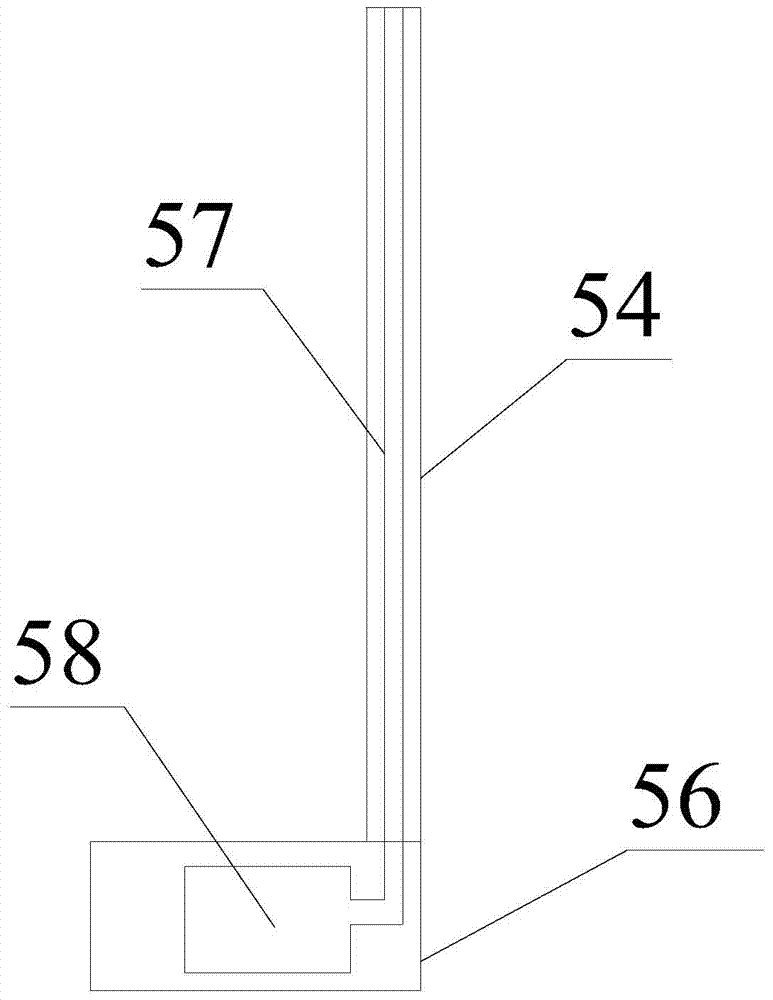

Automatic duck gizzard and duck glandular gastro-esophagus separation device

ActiveCN106720154AReliable split operationImprove permeabilityPoultry processingGizzardOesophageal tube

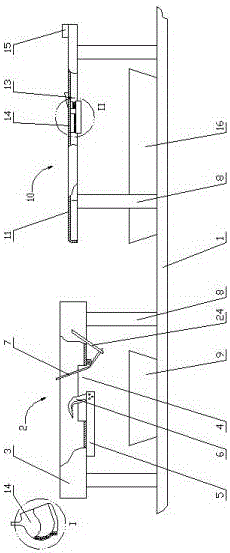

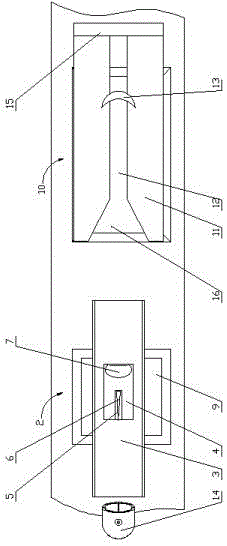

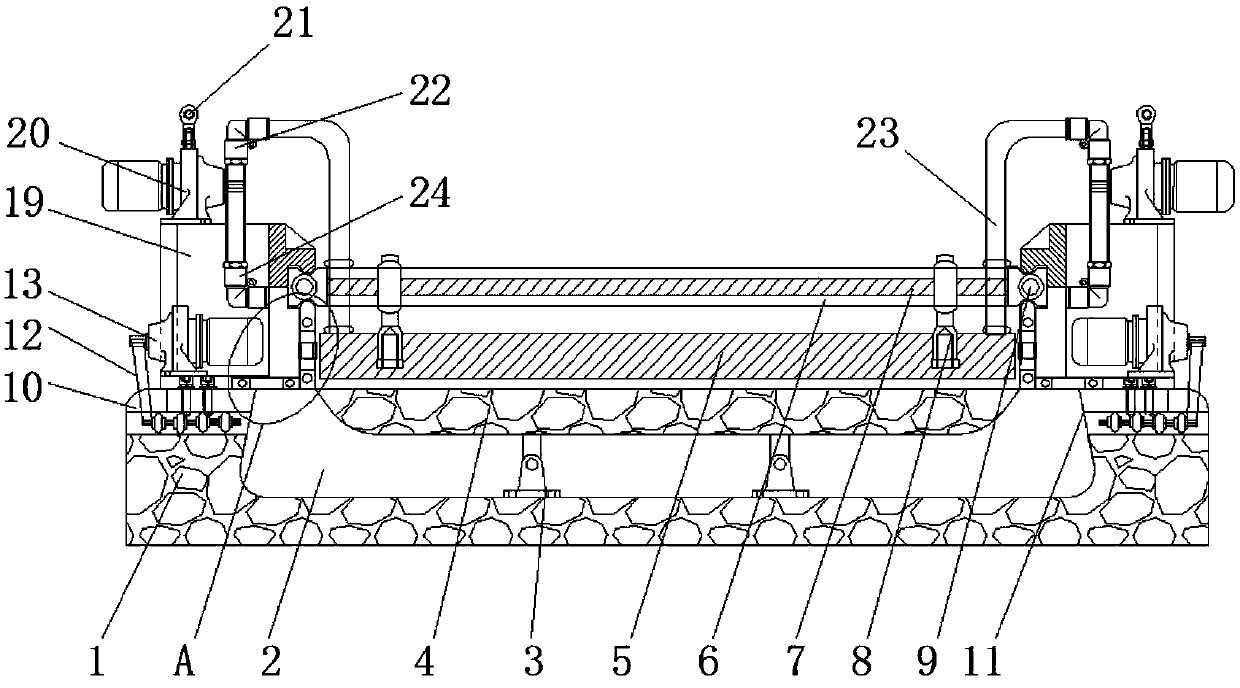

The invention discloses an automatic duck gizzard and duck glandular gastro-esophagus separation device. The automatic duck gizzard and duck glandular gastro-esophagus separation device comprises a duck gizzard bag driven by a chain, and a duck glandular gastro-esophagus and content separation mechanism and a duck gizzard and duck glandular gastro-esophagus separation mechanism, which are arranged on a working table and are connected end to end, wherein the duck glandular gastro-esophagus and content separation mechanism is provided with a blade I with a sharp end part and a food removing pulling sheet with the diameter more than a duck glandular gastro-esophagus, and the blade I is close to the food removing pulling sheet; the duck glandular gastro-esophagus can be cut apart very well, and contents in the duck glandular gastro-esophagus are scraped very well; the duck gizzard and duck glandular gastro-esophagus separation mechanism is provided with a guide platform for forming a gap and the gap is provided with a blade II; after the contents is separated from the duck glandular gastro-esophagus, the a duck gizzard can be separated from the duck glandular gastro-esophagus, without changing a container. The automatic duck gizzard and duck glandular gastro-esophagus separation device has the beneficial effects that according to the description, the automatic duck gizzard and duck glandular gastro-esophagus separation device is simple in structure and reasonable in design; the labor is released, the working efficiency is improved and the production quality is also improved.

Owner:单县六和饲料有限公司 +1

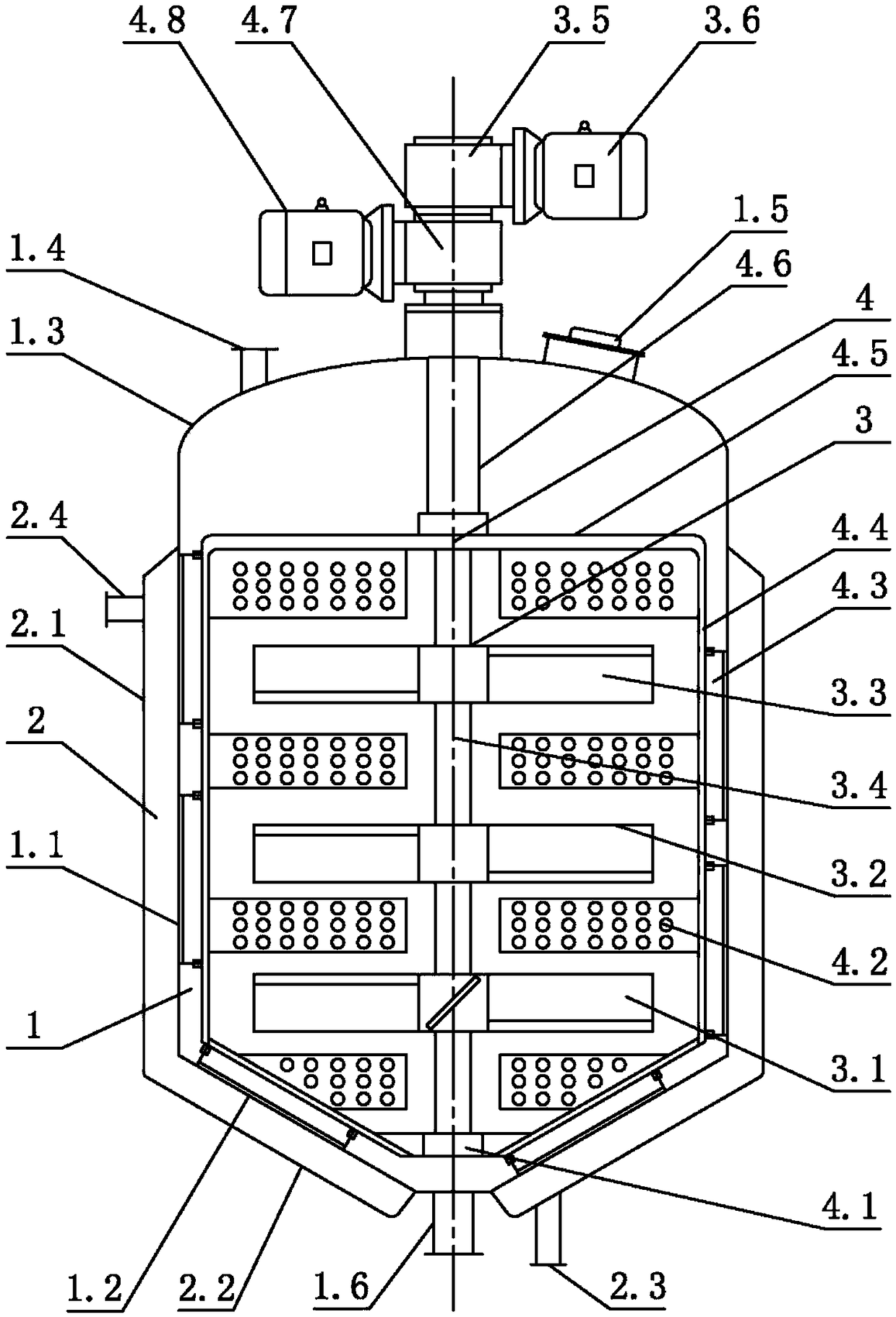

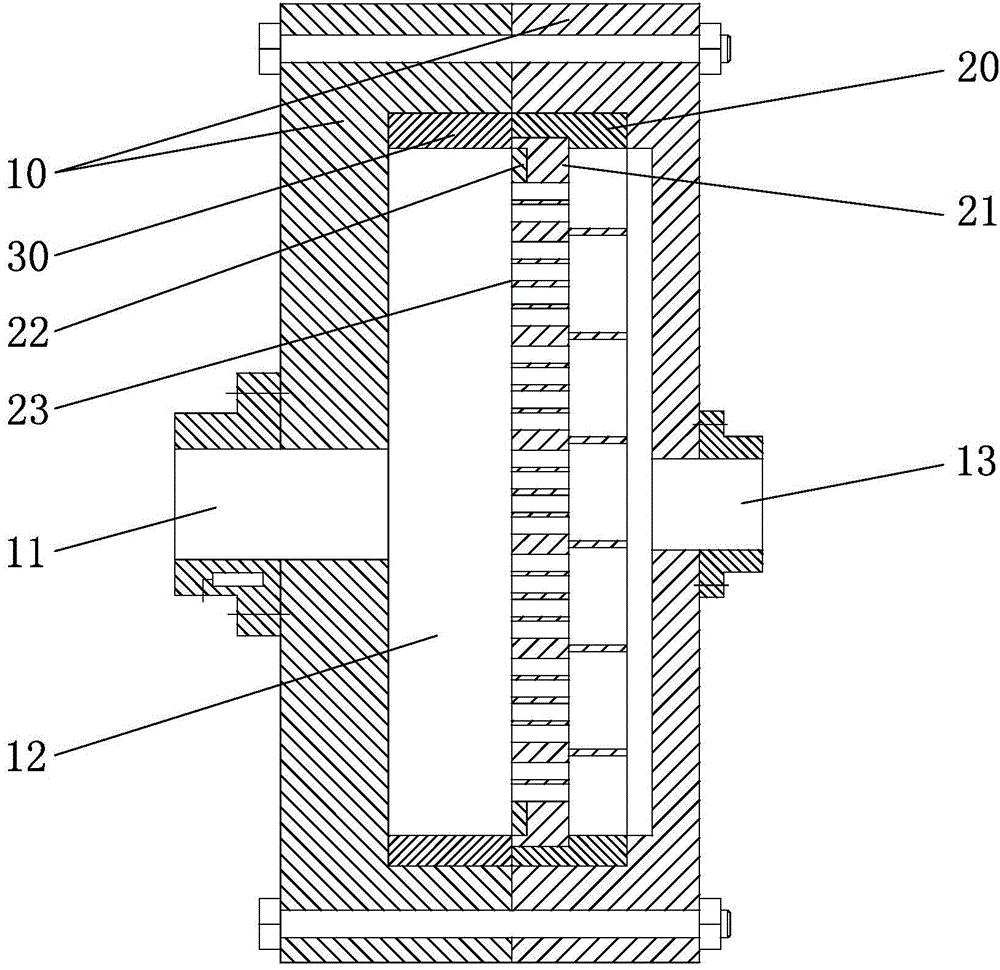

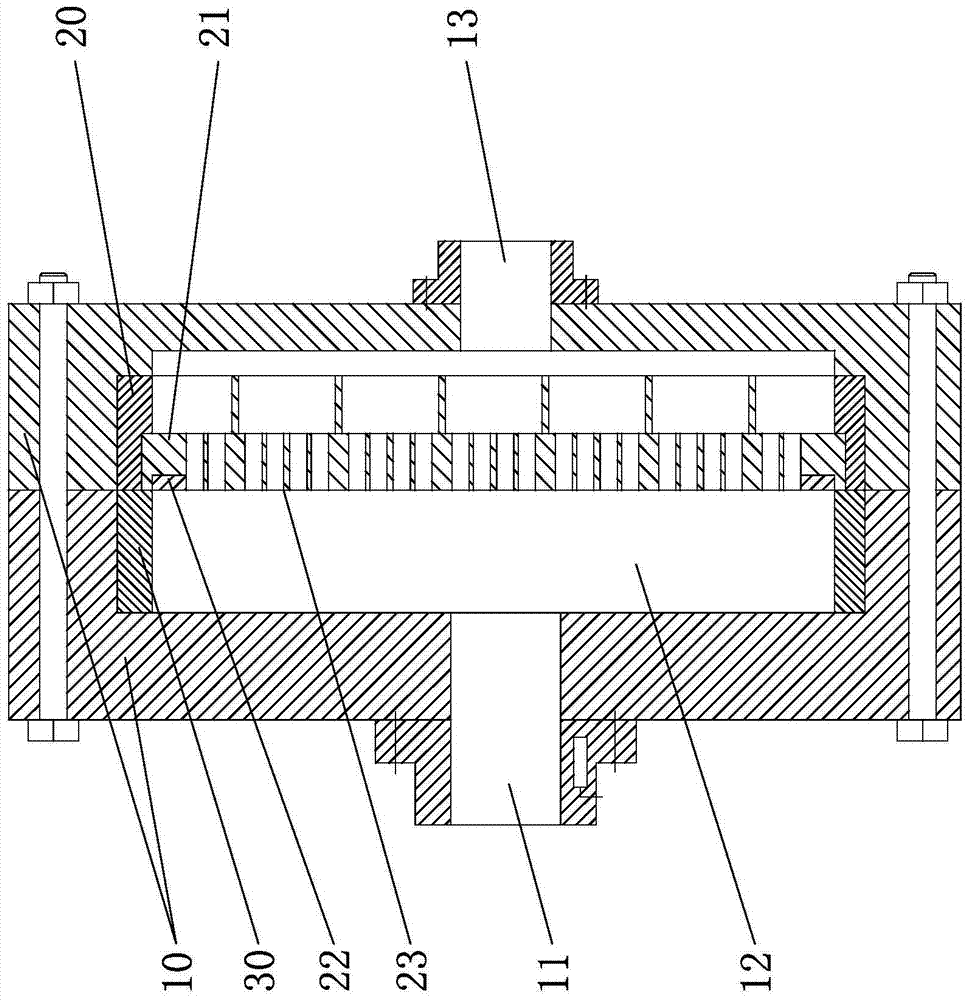

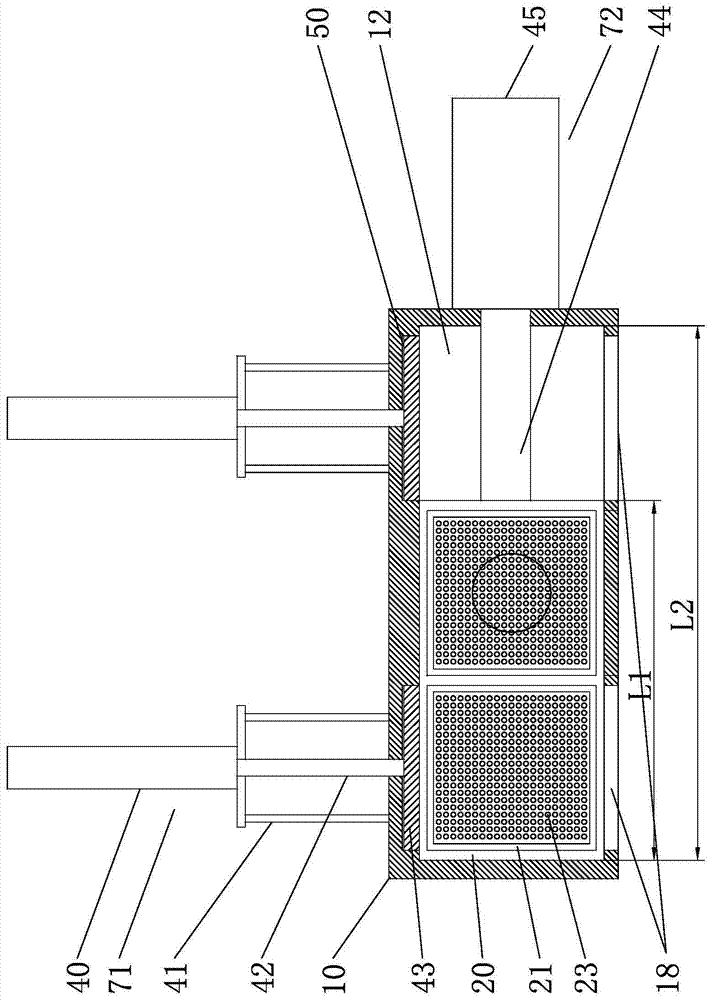

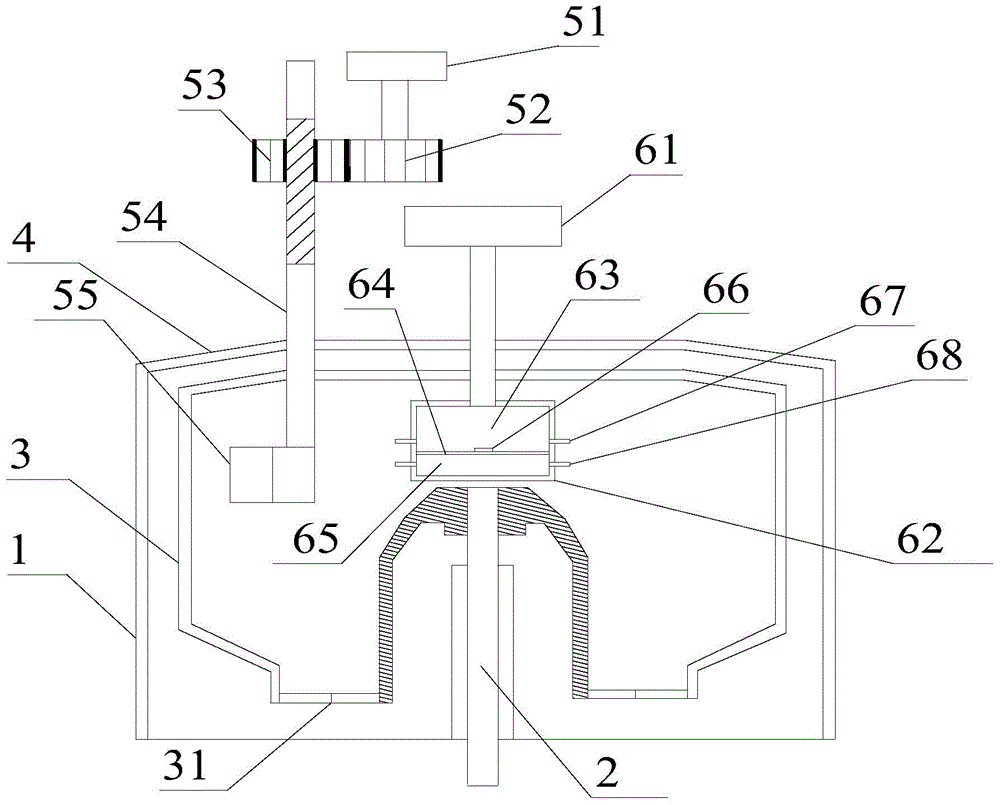

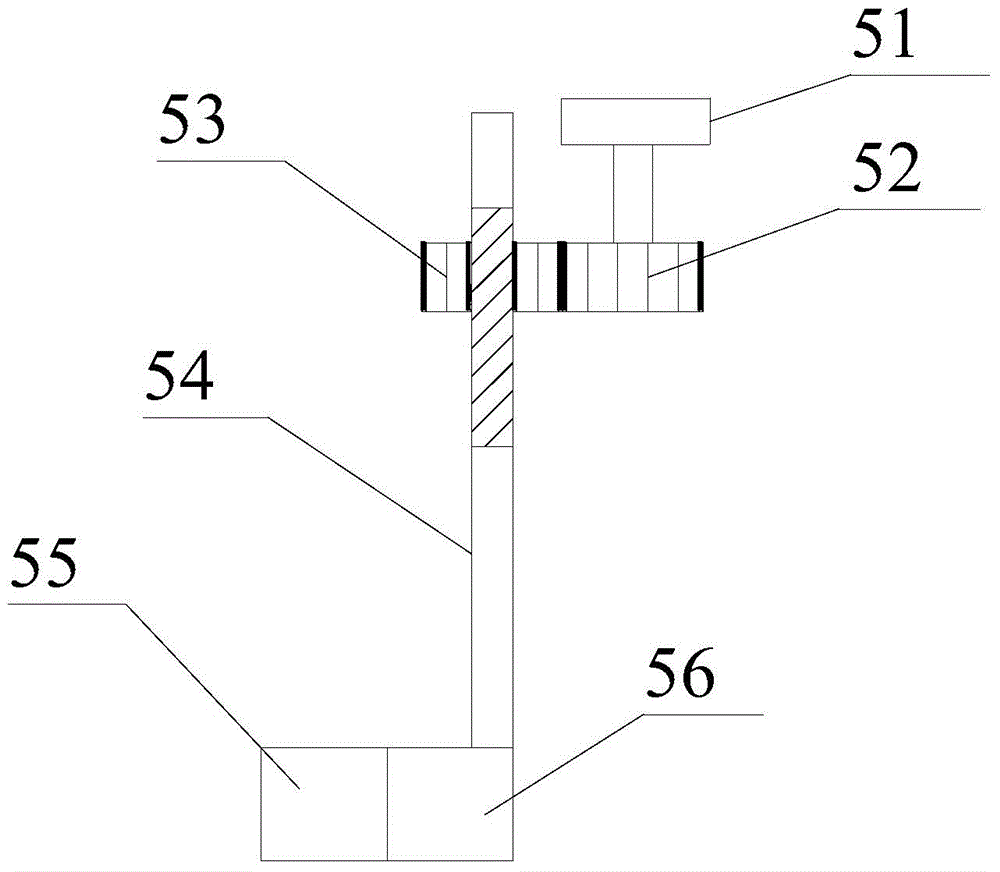

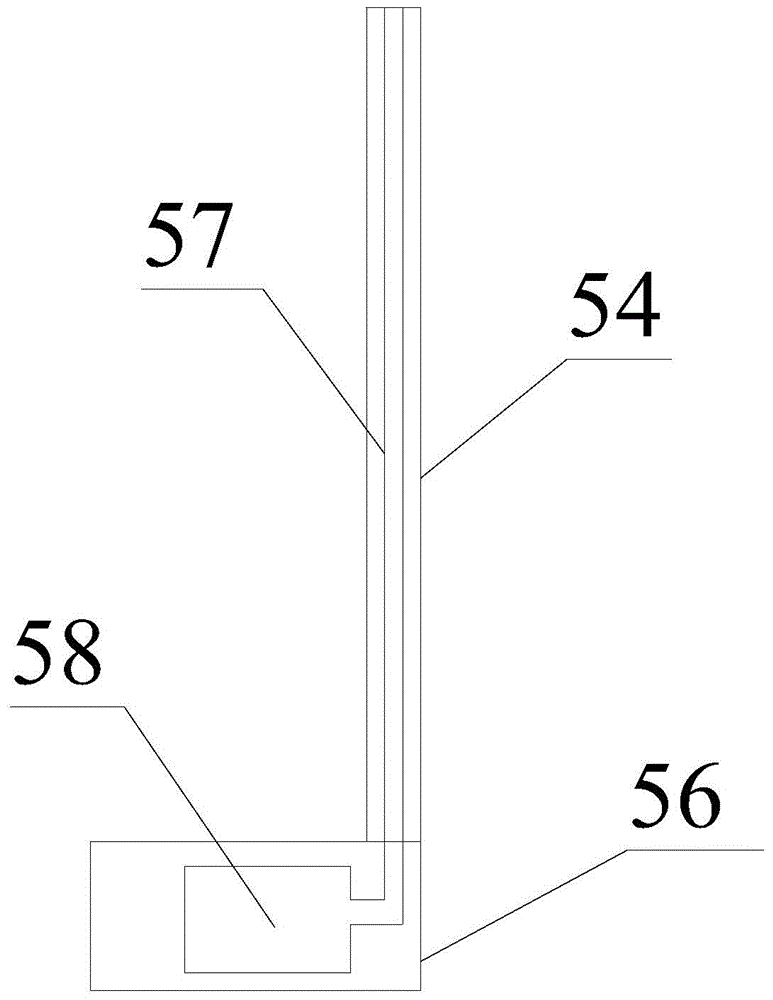

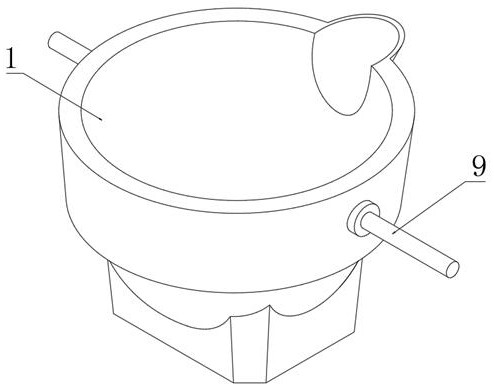

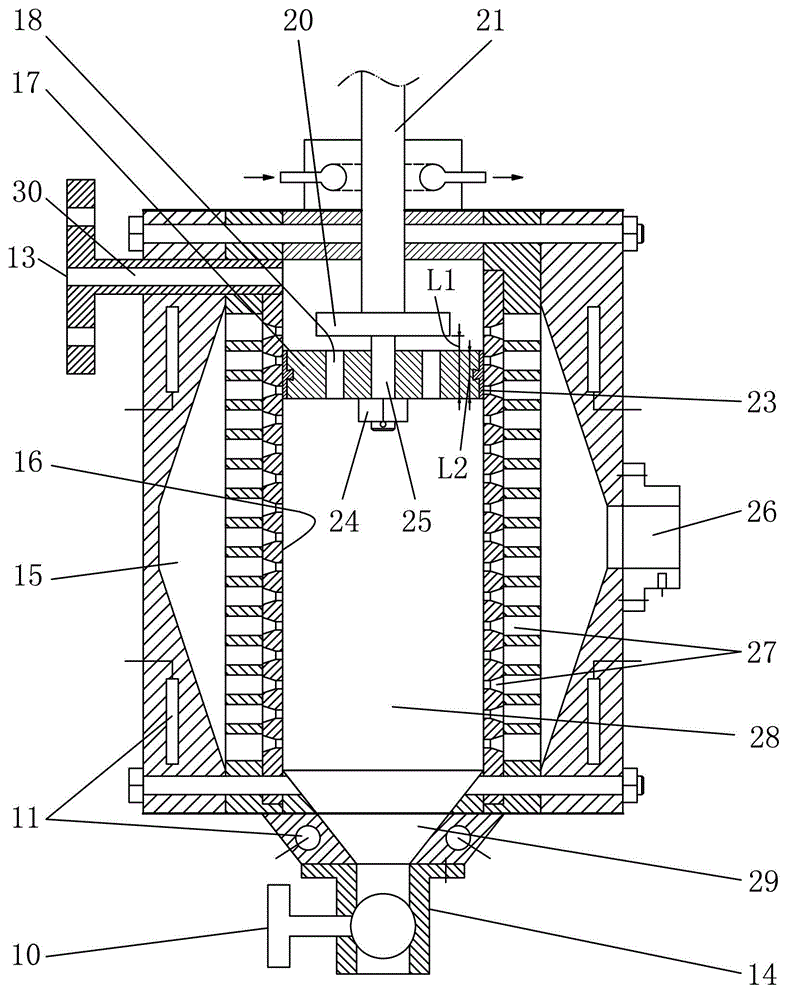

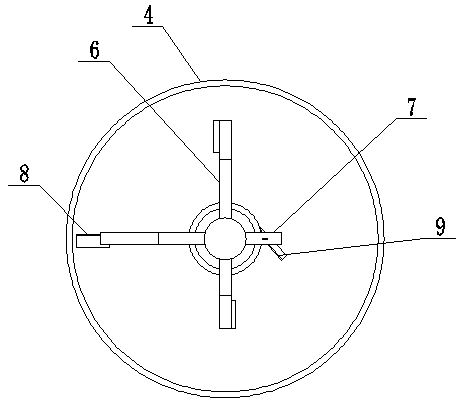

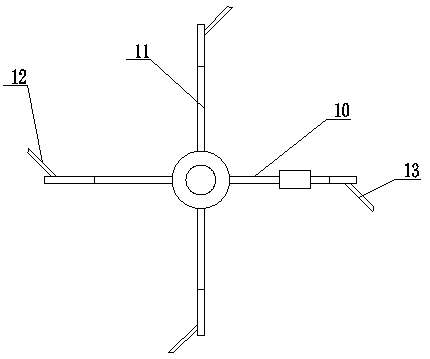

Amino-modified silicone oil emulsification reactor

InactiveCN108246133AImprove liquidityEasy to unloadTransportation and packagingMixing methodsMixed flowEngineering

The invention belongs to the technical field of novel emulsification, and particularly relates to an amino-modified silicone oil emulsification reactor. The reactor comprises a container main body, ajacket, a main stirrer and a porous shearing stirrer, wherein the main stirrer and porous shearing stirrer are mounted in a concentric-shaft form and can be operated at differential rotational speeds,and the main stirrer comprises three layers of paddles with different paddle-inclining angles; fluid force at the paddle-inclining angles are generated by a material under the action of the paddles,and flow impact in different directions are formed, so that full mixed flow is achieved; four layers of paddles of the porous shearing stirrer and the paddles of the main stirrer are staggered, convection impact is formed by fluid of the main stirrer and the paddles of the porous shearing sitter, and shearing is performed at a porous part; and in addition to the action of a mobile wall-scraping plate, the material adhered to a wall can be scraped off, so that the material is updated quickly, and emulsion is excellent. The prepared silicone oil emulsion has narrow particle size distribution, and the method is suitable for oil-in-water emulsion of different viscosities and particle sizes; the method can also be applied to the reaction process of other viscous material systems.

Owner:JIANGNAN UNIV

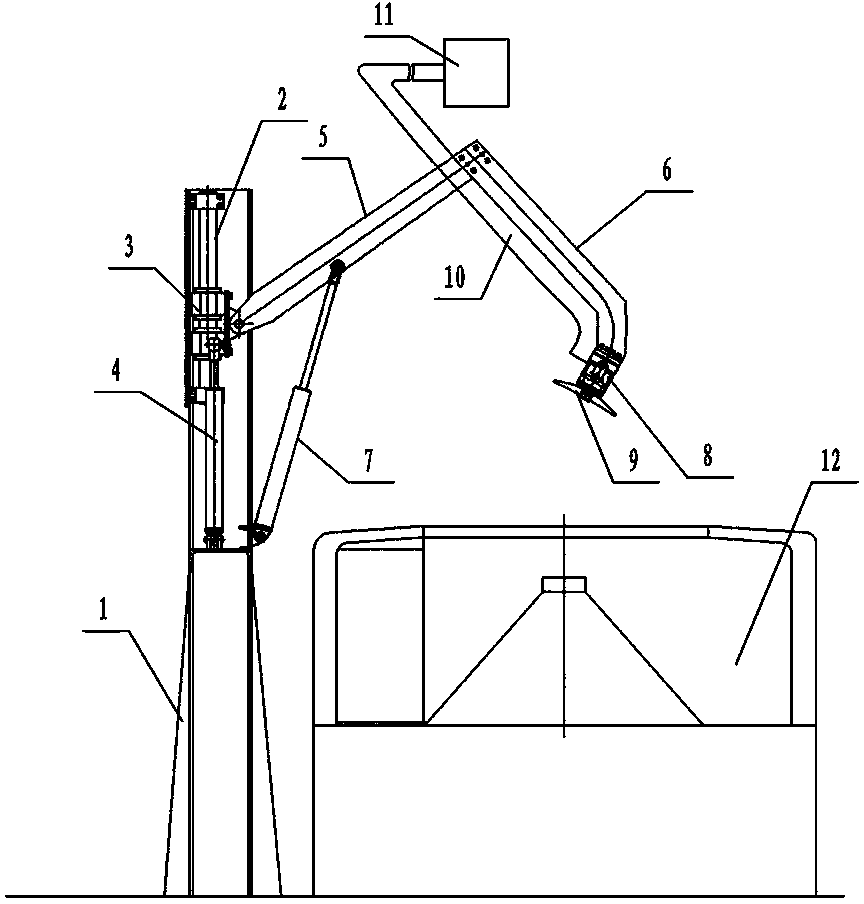

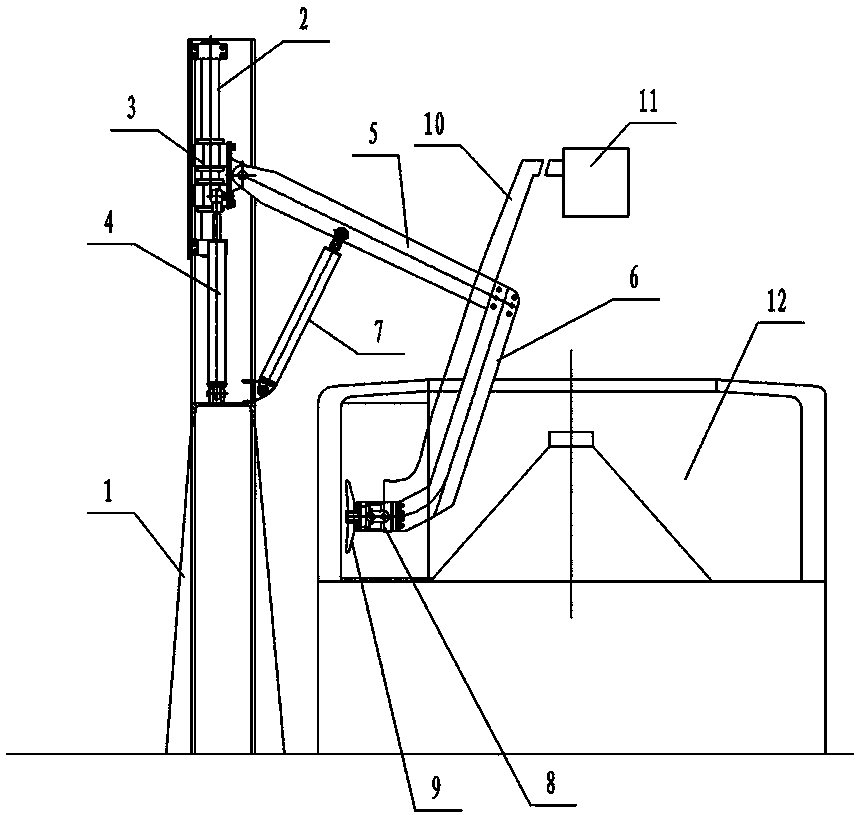

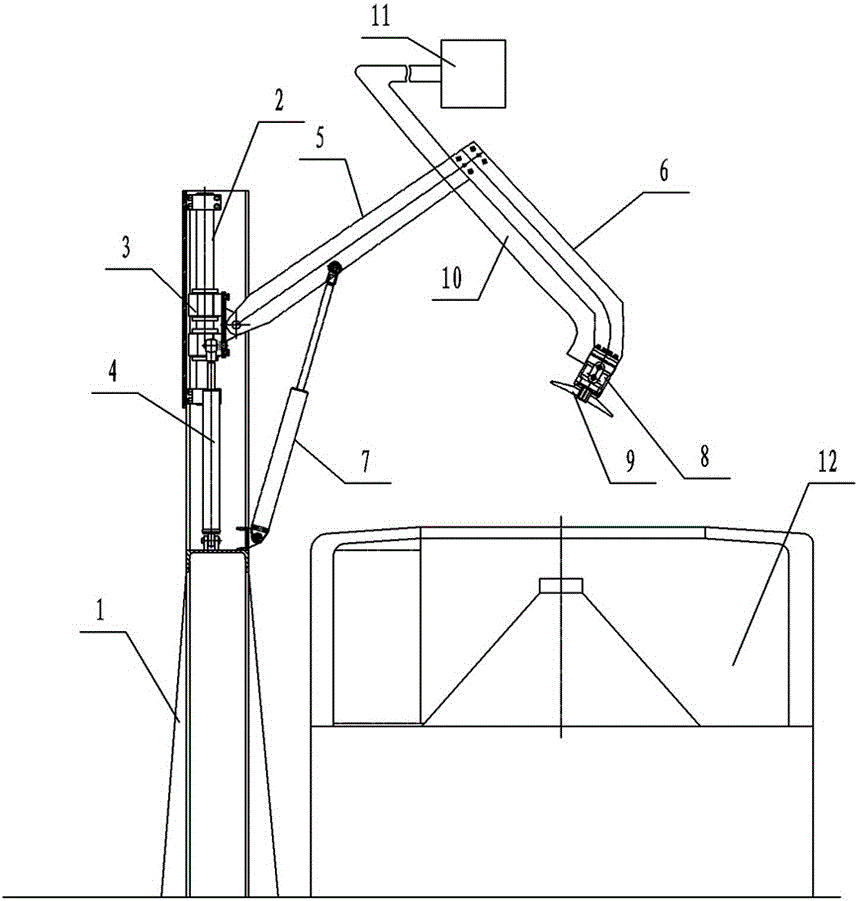

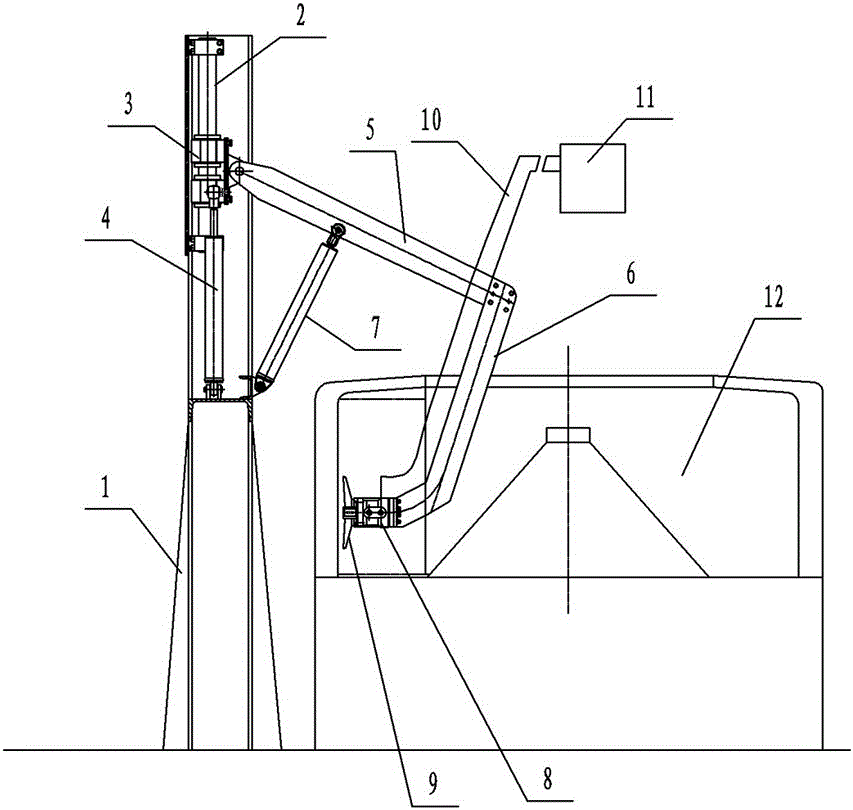

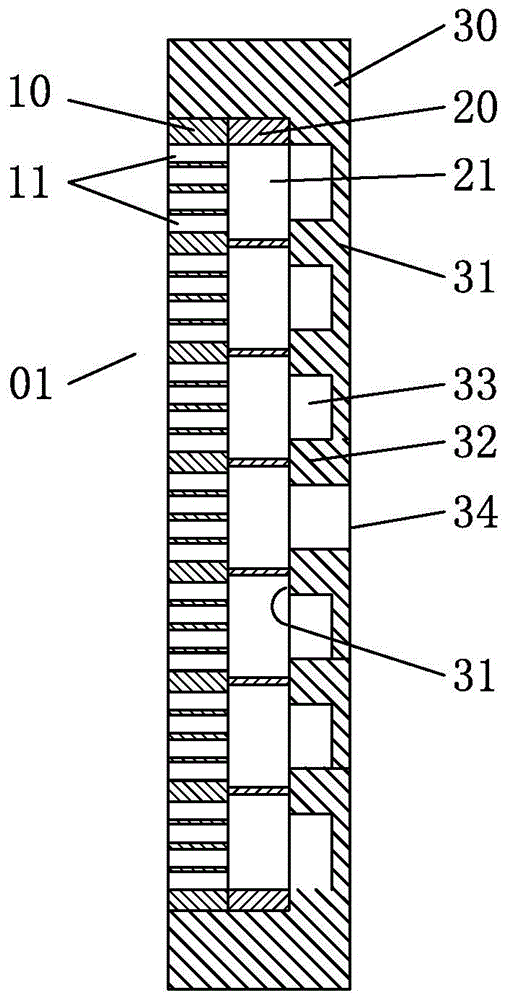

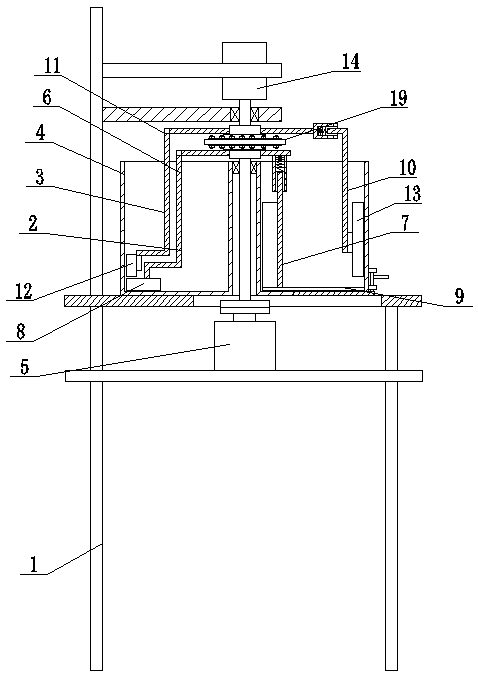

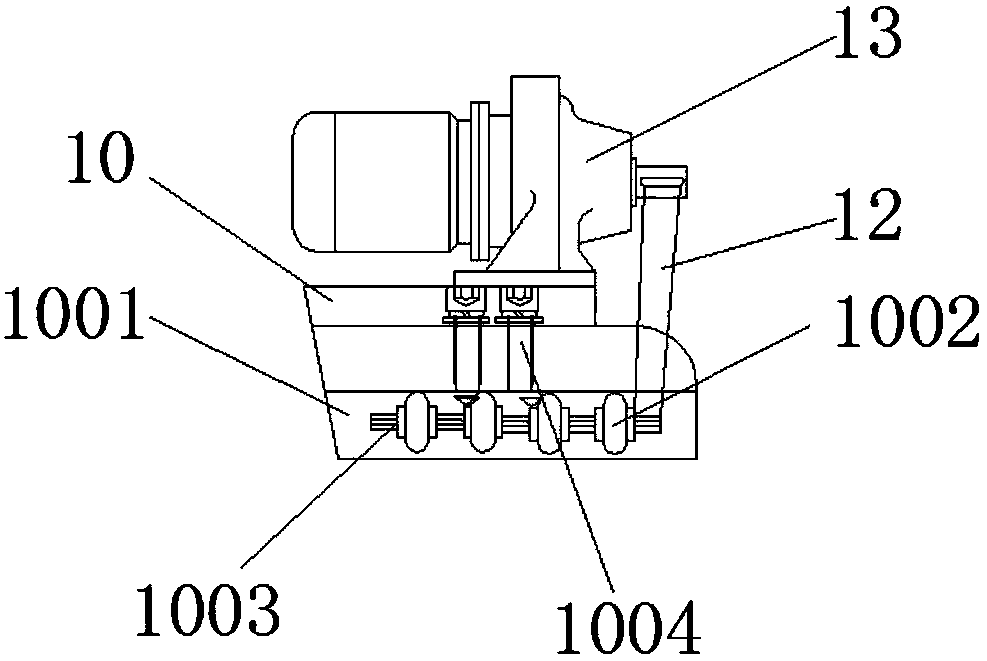

Scraping device for centrifugal machine

The invention relates to a centrifugal machine device, in particular to a scraping device for a centrifugal machine. The scraping device for the centrifugal machine comprises a base, wherein a vertical sliding rail is arranged on the upper portion of the base, a trolley is arranged on the sliding rail, the lower portion of the trolley is connected with a hydraulic device, a mechanical arm is hinged to the trolley and is composed of an upper section and a lower section, the middle of the upper portion of the mechanical arm is connected with a hydraulic overturning device, and a scraper is arranged at the tail end of the lower section of the mechanical arm. According to the scraping device for the centrifugal machine, automatic scraping can be achieved in the centrifugal machine, thorough and complete scraping is achieved, labor is saved, and cost is reduced.

Owner:HENAN PENGDA DOWN PROD

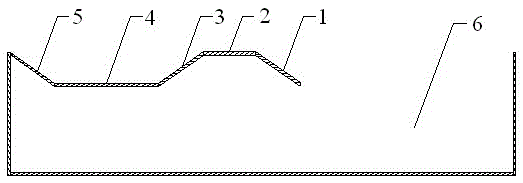

Quick foreign matter remover

ActiveCN104526908AOutstanding and Beneficial Technical EffectsIncrease productivityCleaning using toolsForeign matterFilter effect

The invention belongs to the technical field of a filtering device and relates to a quick foreign matter remover. The quick foreign matter remover is characterized in that a horizontal material collecting cavity is arranged in the middle of a shell; the front side and the rear side of the middle of the shell are respectively provided with a feeding opening and a discharging opening; the material collecting cavity is internally provided with a power device for driving a frame horizontally sliding; filtering nets are arranged in two small frames which are horizontally arranged in the frame in parallel; when the small frames are arranged at the central position of the material collecting cavity, the periphery of the small frame in the middle is connected with the shell in a sealing manner; the front side and the rear side of the filtering net on each small frame are respectively communicated with the feeding opening and the discharging opening; the upper end of each small frame is provided with a foreign matter scraper which is driven to slide up and down and scrape foreign matters by the power device; or groove holes formed in the two sides of the shell and the upper part of the material collecting cavity are internally provided with foreign matter scrapers which are driven to slide up and down by the power device. The quick foreign matter remover has the advantages that the filtering effect is good, and the foreign matter removal without stoppage can be realized, so that the quick foreign matter remover is applicable to various specifications and types of reclaimed plastic granulators.

Owner:陈艳

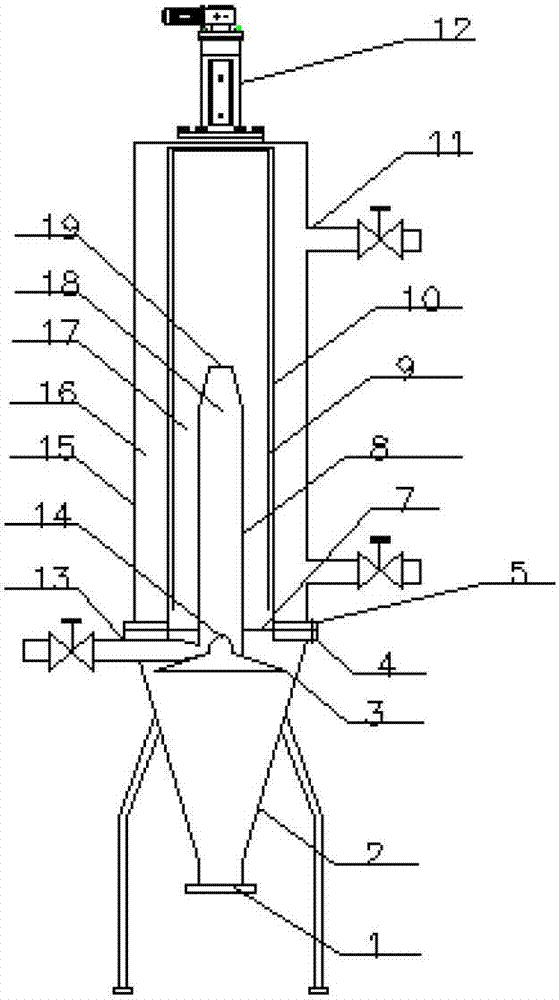

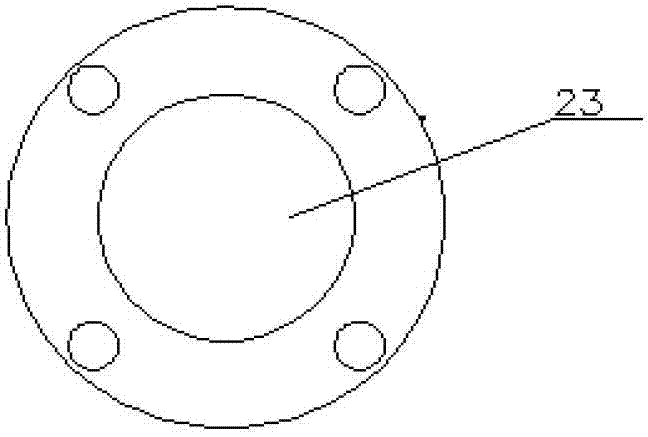

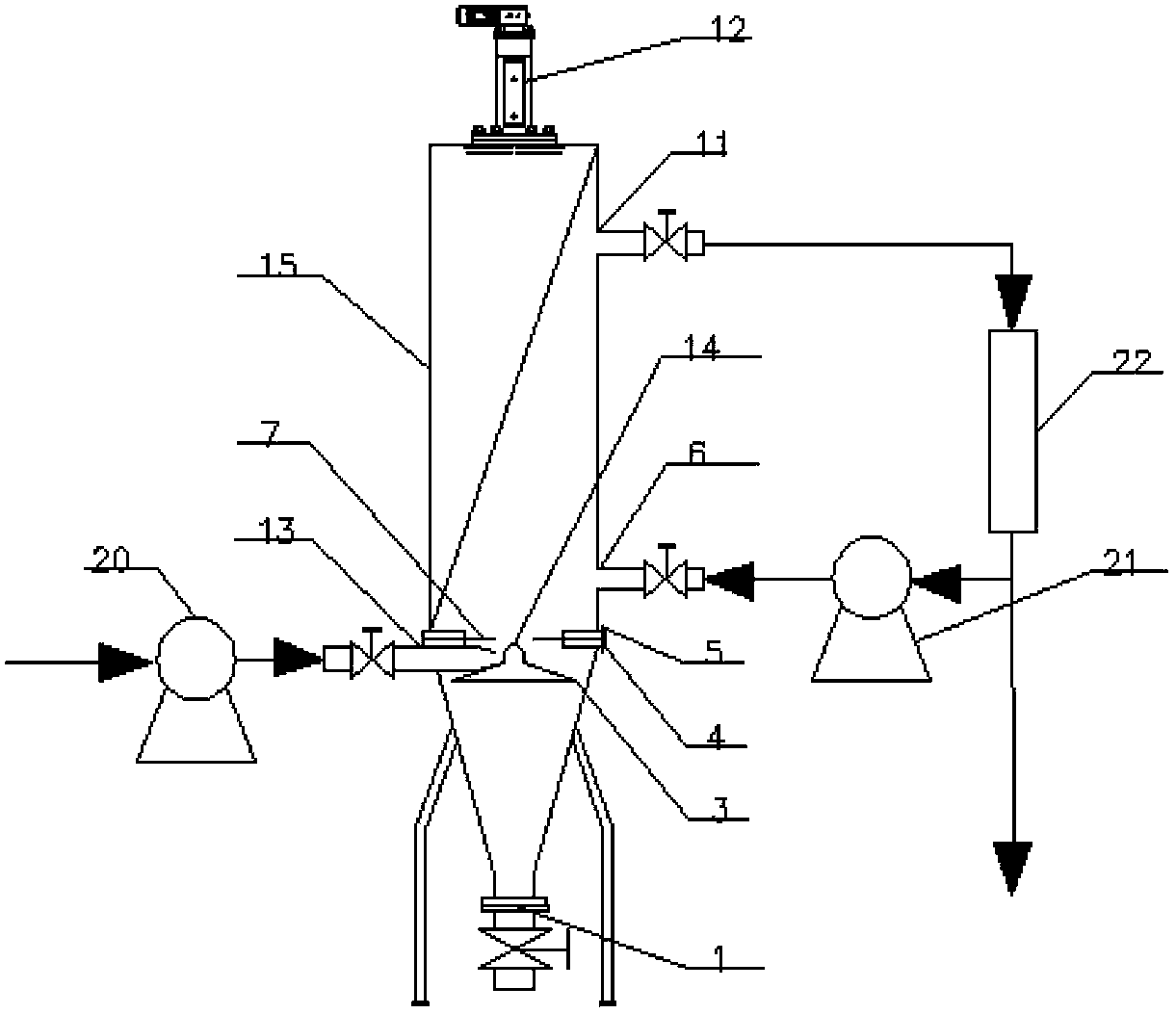

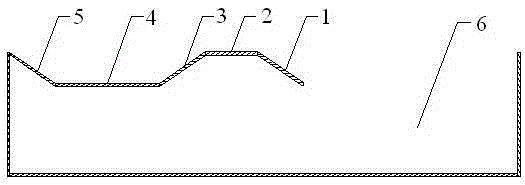

Cyclone separation filter

InactiveCN102815801AEfficient separationImprove separation efficiencyWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentSedimentEnergy consumption

The invention relates to a cyclone separation filter. The cyclone separation filter comprises a raw water inlet tube, a sediment storehouse, a cyclone tube, a cyclone chamber sediment discharge port, and a sediment storehouse sediment discharge port, wherein a housing is sleeved outside the cyclone tube; the housing is provided with a purified liquid outlet; a filter screen cover is arranged between the cyclone tube and the housing; and the housing and the filter screen cover are connected with the sediment storehouse through an upper ring flange and a lower ring flange. The cyclone separation filter enables the solid-liquid separation efficiency to be improved and especially the fine particle removal efficiency to be improved, and has the advantages of simple and compact structure, reduction of conveying pipelines and matching equipment, and realization of less energy consumption, low running cost, convenient operation and convenient cleaning.

Owner:董伟

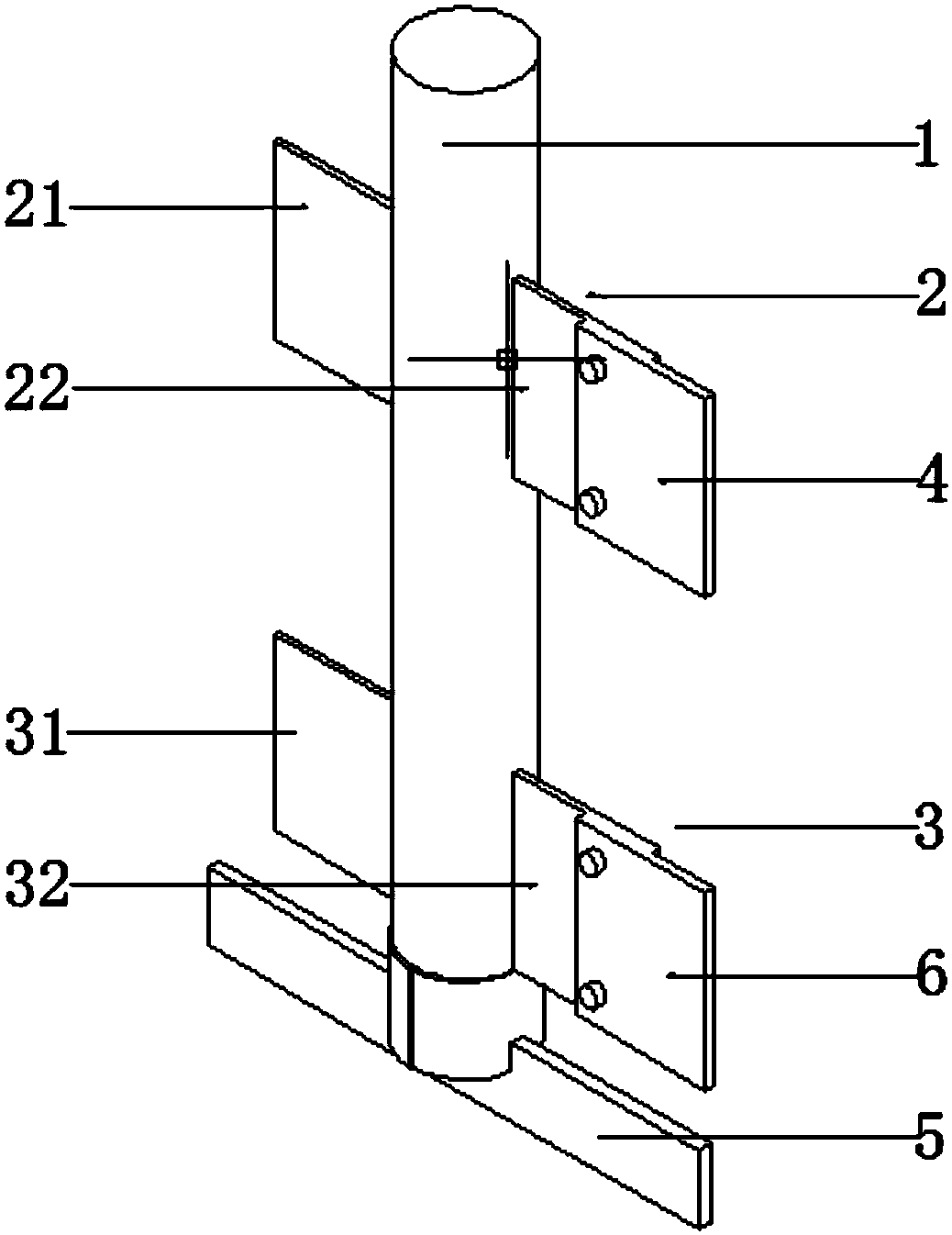

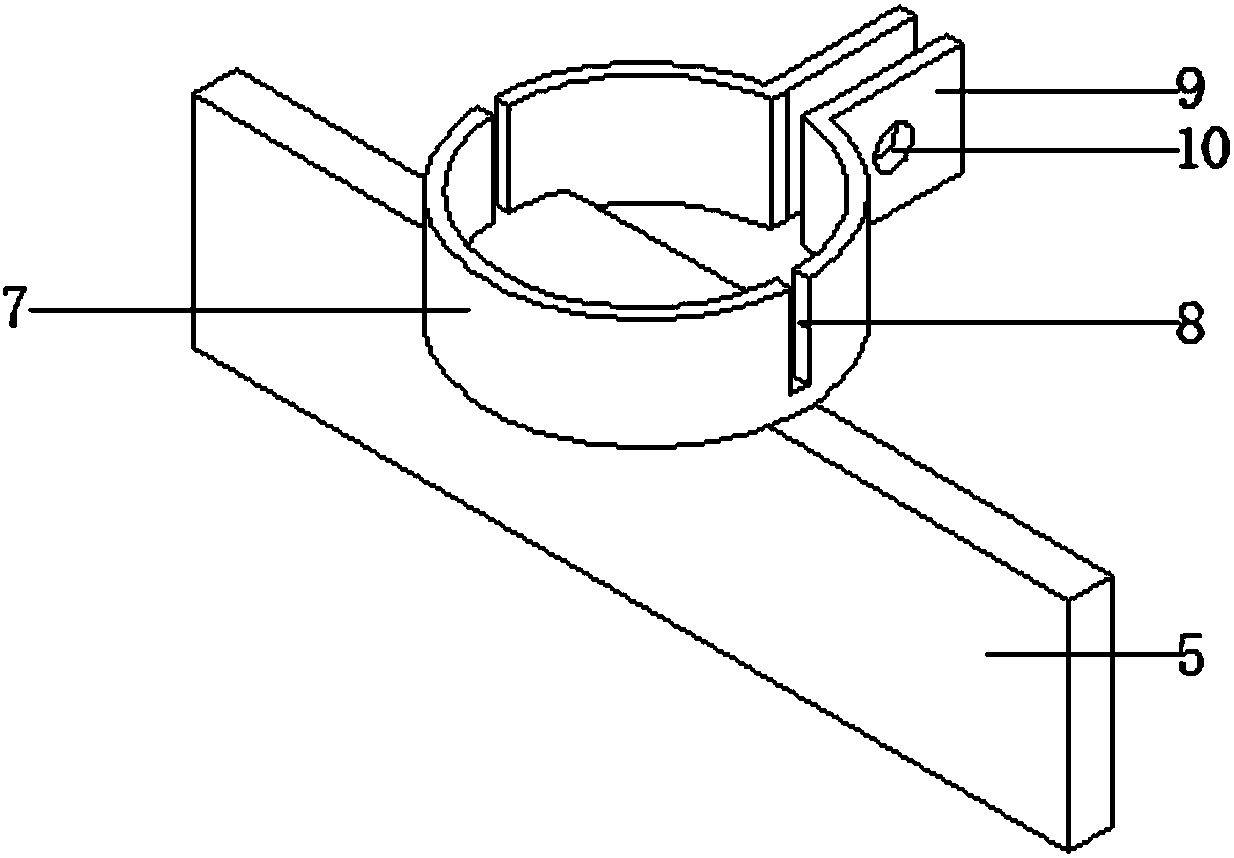

Stirring device for slurry mixing tank

InactiveCN107790001AEasy to disassemble and replaceAvoid stickingTransportation and packagingRotary stirring mixersEngineering

The invention provides a stirring device for a slurry mixing tank. The stirring device comprises a stirring shaft, wherein the stirring shaft is provided with first stirring paddles and second stirring paddles; the first stirring paddles are located on the upper part of stirring shaft; the second stirring paddles are located on the lower part of stirring shaft; the first stirring paddles are composed of a first left paddle and a first right paddle; the first right paddle is provided with positioning holes and is detachably connected with a first brushing plate via the positioning holes and bolts; the end part of the first brushing plate is provided with brushing hair; the lower end of the stirring shaft is provided with a second brushing plate; and the end part of the second brushing plateis provided with brushing hair. The stirring device for the slurry mixing tank in the invention can prevent materials from depositing on the bottom of the tank and adhering onto the sidewall of the tank and improves the utilization rate of the materials.

Owner:TIANJIN DONGDING TECH CO LTD

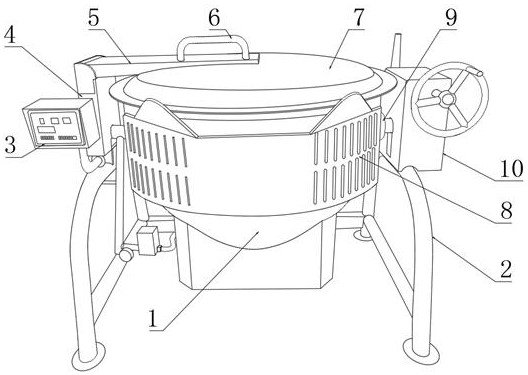

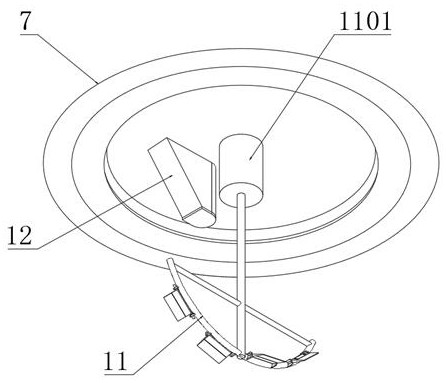

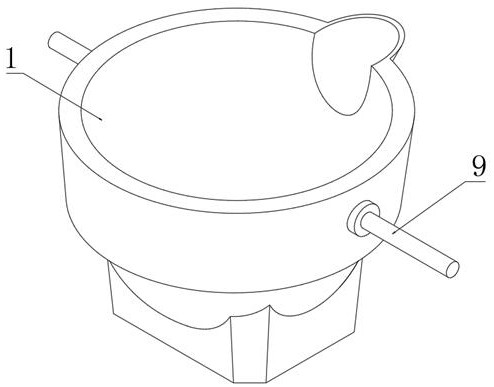

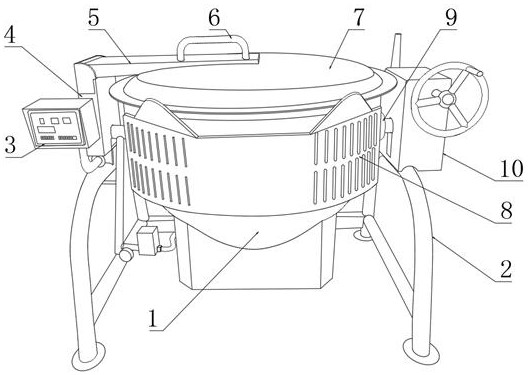

Intelligent control automatic cooker

ActiveCN112716266ANo stirring dead angleStir wellCooking insertsTime-controlled ignitorsTemperature controlElectric machinery

The invention discloses an intelligent control automatic cooker.The automatic cooker comprises a pot body, a pot frame is installed outside the pot body, a temperature control box is installed on one side of the top end of the pot frame, a supporting plate is installed at the position, corresponding to the temperature control box, of one side of the top end of the pot frame, a connecting plate is rotatably connected to the top end of the supporting plate, a pull rod is installed at the top end of one end of the connecting plate, a pot cover is installed at the bottom end of one end of the connecting plate, the pot body is sleeved with an external heat preservation cylinder, and rotating shafts are symmetrically installed on the outer end face of the pot body. By arranging a stirring motor, a stirring rod, a connecting cross rod, an arc-shaped rod, a connecting block, a rotating hole, a limit shaft, a clamping plate and a scraping plate, the stirring motor drives the arc-shaped rod and the scraping plate in the pot to rotate in the pot to stir and mix internal food materials, so that the internal food materials are stirred more uniformly, the scraping plate makes full contact with the pot body, the attachment degree is high, no stirring dead angle exists in the pot, bottom scraping is more thorough, and the pot pasting phenomenon is not likely to happen.

Owner:江门市永成厨具设备有限公司

Quick Cleaner

ActiveCN104526908BIncrease productivityReduce manufacturing costCleaning using toolsForeign matterEngineering

The invention belongs to the technical field of a filtering device and relates to a quick foreign matter remover. The quick foreign matter remover is characterized in that a horizontal material collecting cavity is arranged in the middle of a shell; the front side and the rear side of the middle of the shell are respectively provided with a feeding opening and a discharging opening; the material collecting cavity is internally provided with a power device for driving a frame horizontally sliding; filtering nets are arranged in two small frames which are horizontally arranged in the frame in parallel; when the small frames are arranged at the central position of the material collecting cavity, the periphery of the small frame in the middle is connected with the shell in a sealing manner; the front side and the rear side of the filtering net on each small frame are respectively communicated with the feeding opening and the discharging opening; the upper end of each small frame is provided with a foreign matter scraper which is driven to slide up and down and scrape foreign matters by the power device; or groove holes formed in the two sides of the shell and the upper part of the material collecting cavity are internally provided with foreign matter scrapers which are driven to slide up and down by the power device. The quick foreign matter remover has the advantages that the filtering effect is good, and the foreign matter removal without stoppage can be realized, so that the quick foreign matter remover is applicable to various specifications and types of reclaimed plastic granulators.

Owner:陈艳

A kind of oily sludge advanced treatment process

ActiveCN104649563BReduce manufacturing costEasy to prepareSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesCycloneActivated sludge

The invention discloses an oily sludge advanced treatment technology which comprises the following contents: oily sludge in a raw material storage sludge-tank enters a sludge mixing tank; a demulsifier is added to carry out demulsification treatment; demulsified oily sludge enters screw-type sludge dewatering equipment to undergo solid-liquid separation so as to obtain a filtrate and sludge cake; the filtrate enters a two-phase cyclone to be separated; after two-phase separation, excess sludge at the lower layer flows back to the raw material storage sludge-tank, a mixed liquor at the upper layer is sent into a gas-liquid mixing tank to be mixed with the air and then enters a separation pond to carry out primary separation of sump oil and sewage; sump oil is recovered to a sump oil tank by the use of a sludge scraper; sewage enters a filter to separate suspended particles and residual sump oil in the sewage from water; sump oil separated from the top of the filter is recovered to a sump oil recovery tank; and sewage discharged from the filter is sent to a sewage treatment plant to undergo subsequent processing. By the technology, water content of the oily sludge can be reduced from 80-98% to about 50%, and most crude oil in the oily sludge can be recovered. Thus, sludge subsequent processing difficulty is greatly reduced. The technology provided by the invention has a wide range of application, is especially suitable for processing of oily sludge at the bottom of an oil-tank, dross and activated sludge as well as processing of various oily sludge generated from oil exploitation and storage transportation enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

Scraping device for centrifuge

ActiveCN104190559BRealize automatic scrapingScrape thoroughlyCentrifugesEngineeringMechanical engineering

Owner:HENAN PENGDA DOWN PROD

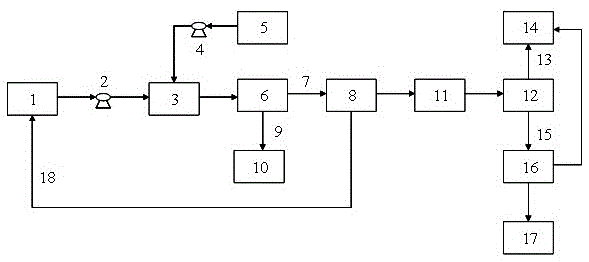

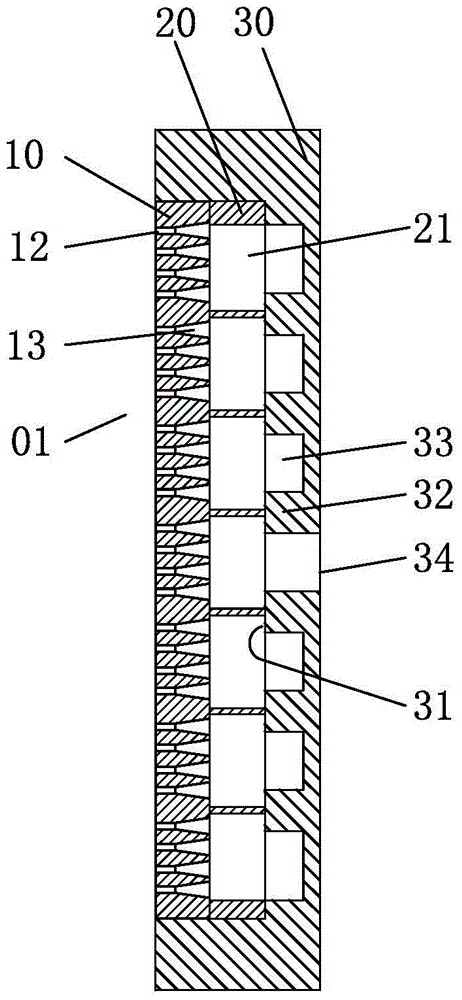

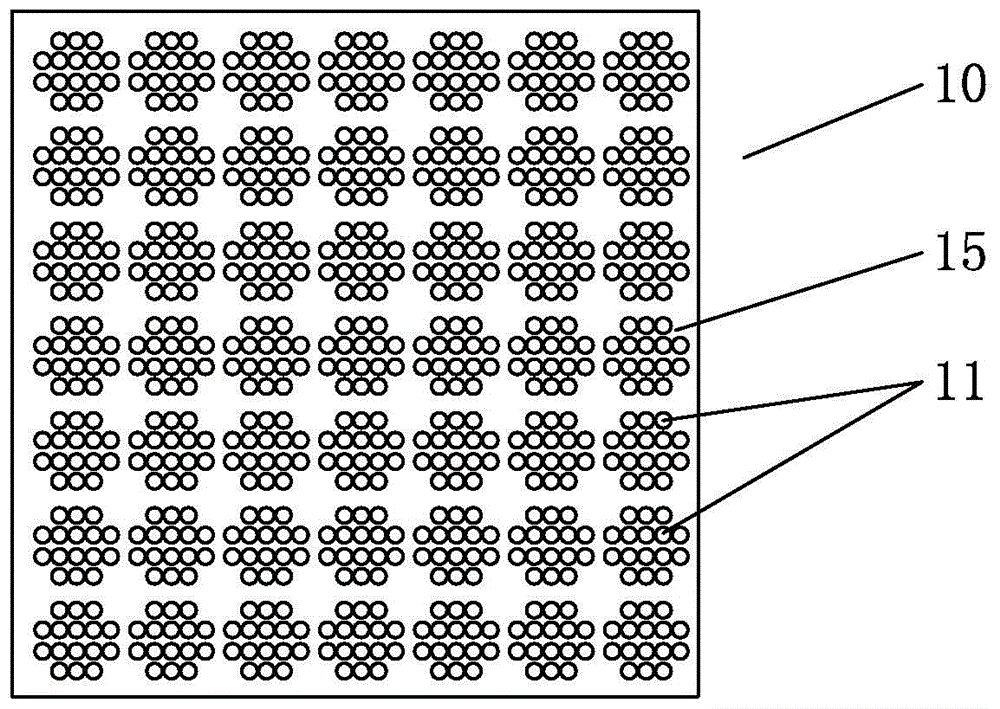

Filter device and filter extruder head containing the same

The invention belongs to the technical field of filter devices, and relates to a filter device for a plastic granulator and a filter extruder head containing the filter device: a filter device is formed by a plurality of filter groups evenly distributed on a substrate to form a filter net, and each filter group A number of filter holes are arranged at intervals, and the outer contour of each filter group is a geometric figure; the filter extrusion head is at least one side wall of a cylindrical or rectangular shell as the filter device, and the shell and filter device The inner filter cavity is formed, and the shell wall or / and the top cover of the shell are provided with a feed port or a feed channel, and a material extruding device is set in the filter cavity, and the underside of the shell is sequentially provided with a miscellaneous storage cavity, a discharge The miscellaneous port and the miscellaneous discharge valve are installed on the miscellaneous discharge port. There is a heating device inside or outside the shell wall. The advantages are: good filtering effect, non-stop cleaning, suitable for various specifications and models of recycled plastics Granulator.

Owner:郑建财

A small household pumpkin peeling and scraping device

ActiveCN107455769BFast peelingPeel and scrape cleanVegetable peelingMechanical engineeringElectrical and Electronics engineering

Owner:倪荷春

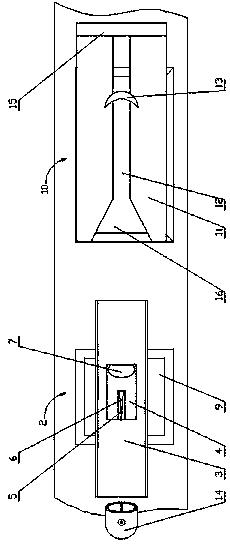

Automatic-unloading vertical centrifuge

The invention puts forward an automatic-unloading vertical centrifuge. A scraping device comprises a scraper shaft, a scraper base, a scraper, a driving gear, a driven gear, and a first drive device, wherein a controller is connected to the first drive device, the first drive device is connected to the driving gear to drive rotation of the driving gear, the driven gear is engaged with the driving gear, one end of the scraper shaft passes through the driven gear and is connected to the driven gear by threads, the other end of the scraper shaft passes through a machine cover and is stretched into a drum and connected with the scraper base, and the scraper is installed on the scraper base; and a first air duct is disposed inside the scraper shaft, a second air duct is disposed inside the scraper base, the first air duct is communicated with the second air duct, blowing nozzles which blow wind to the inner wall of the drum are disposed on two sides of the scraper on the scraper base, and the blowing nozzles are communicated with the second air duct. The automatic-unloading vertical centrifuge provided by the invention can realize lifting, descending and rotation of the scraper shaft by the drive device, the driving gear and the driven gear.

Owner:江苏颖盛化工有限公司

A kind of oil sludge demulsifier and oil sludge advanced treatment process

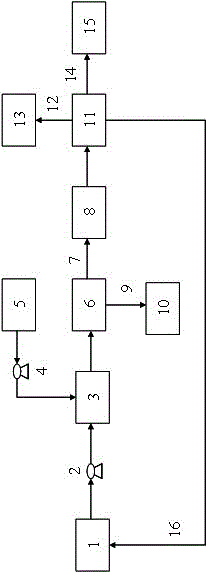

ActiveCN104556624BGood demulsification effectPromote degradationWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningActivated sludgeDemulsifier

The invention discloses an oil sludge demulsifier and an oil sludge advanced treatment process. The oil sludge demulsifier comprises the following components in parts by weight: 7-28 parts of polyglycerol fatty acid ester, 3-14 parts of oleic acid polyoxyethylene ester, 0.5-2 parts of a green accessory ingredient and 58-92 parts of water. The oil sludge advanced treatment process comprises the following steps: enabling oily sludge to enter a sludge mixing tank for demulsification treatment and then carrying out solid-liquid separation; enabling filter liquor to enter a two-phase swirler for separation; enabling lower-layer residual sludge to reflux to a sludge tank; enabling an upper-layer mixed liquor to enter a gas-liquid mixing tank to be mixed with air and to enter a separation tank for oil-water separation; recycling sump oil to a sump oil tank; performing following-up treatment on sewage. The oil sludge advanced treatment process can reduce the moisture content of oily sludge, recycles most crude oil in oil sludge, and reduces the difficulty of sludge follow-up treatment; the oil sludge advanced treatment process is wide in application rang, and is particularly applicable to treatment of tank-bottom oil sludge, scum and activated sludge, and treatment of various kinds of oily sludge generated by oil exploitation and storage and transportation companies.

Owner:CHINA PETROLEUM & CHEM CORP +1

Intelligent control automatic cooking machine

ActiveCN112716266BNo stirring dead angleStir wellCooking insertsTime-controlled ignitorsTemperature controlElectric machinery

The invention discloses an intelligently controlled automatic cooking machine, which comprises a pot body. A pot frame is installed on the outside of the pot body. A temperature control box is installed on the top side of the pot frame. The top side of the pot frame corresponds to the temperature control box. A support plate is installed at the position of the support plate, the top of the support plate is rotatably connected to a connecting plate, a pull rod is installed on the top of one end of the connecting plate, a pot cover is installed on the bottom of one end of the connecting plate, and the pot body The outside of the pot is provided with an external insulation tube, and the outer end surface of the pot body is symmetrically equipped with a rotating shaft. The present invention is provided with a stirring motor, a stirring rod, a connecting cross bar, an arc rod, a connecting block, a rotating hole, a limit shaft, The clamping plate and the scraper, the stirring motor drives the internal arc rod and the scraper to rotate in the pot to stir and mix the internal ingredients, so that the internal ingredients are stirred more evenly, and the scraper is in full contact with the pot body, and the fit is high , so that there is no dead angle of stirring in the pot, the scraping of the bottom is more thorough, and it is not easy to cause the phenomenon of sticking the pot.

Owner:江门市永成厨具设备有限公司

Scraper mechanism for paste mixer

PendingCN112755949AGood scraping effectIncrease temperature cooling effectRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a scraper mechanism for a paste mixer, and relates to the technical field of paste mixers. The device comprises a paste mixer and a scraper mechanism, the paste mixer comprises a stirring shell and a rotating shaft; a scraper mechanism is fixedly mounted at the top of the rotating shaft; the scraper mechanism comprises a fixed shaft and a scraper; the scrapers comprise a scraper A and a scraper B; a forked shaft is arranged at the tail end of the fixed shaft; and a scraper A and a scraper B are respectively fixed on two branches of the forked shaft. Under the action of the scraper mechanism, the mechanism has a better scraping effect on residual lead paste at the bottom of a pot, and has an effect of improving temperature reduction in a paste mixing process, so that the quality of the lead paste is improved.

Owner:TIANNENG BATTERY GRP ANHUI

Clearing device for sewage generated by printing and using method thereof

The invention discloses a clearing device for sewage generated by printing and a using method thereof. The clearing device comprises a carrying ship, a clearing rotary frame, a carrier tray, a first motor, a rotary connection column, a storage bin, a second motor, a rolling groove, clearing plates, rollers, swing grabbing frames, turning shafts, transmission swing frames, turning rings, turning blocks, telescopic connection rods, universal balls, rotary grabbing frames and inverted clamping hooks. The clearing device has the beneficial effects that during use, the rotary grabbing frame scrapsthe duckweed in a rotating mode by extending the telescopic connection rods in the clearing plates, the duckweed on the water surface is cleared and grabbed in the rolling groove by the clearing plates on the clearing rotary frame in a continuously reciprocating mode, so that the movement of the duckweed below the clearing rotary frame is higher, the duckweed is scrapped more comprehensively and thoroughly by the clearing plates, the rotary connection column is coordinated to continuously drive the clearing rotary frame to slowly rotate to scrape and clear the duckweed around the ship, and thereof the efficiency and comprehensiveness of the device for clearing the river water duckweed are guaranteed; and the clearing device has the advantages of being convenient to operate, and all the components are flexibly connected.

Owner:张良

Extrusion filter

The invention belongs to the technical field of plastic granulation and relates to an extrusion filter. The extrusion filter comprises a casing, a feeding connector arranged on the casing, a heating temperature control device and a material extrusion device; a discharging port of the material extrusion device is connected with an impurity filter with a filter screen; an impurity scraping and discharging device for scraping impurities on the filter screen into an impurity storage cavity and discharging the impurities to the outside of the impurity filter is arranged in an inner cavity of the impurity filter; the filter screen formed by a plurality of radially-arranged filtering holes is arranged on the side wall of the inner cavity of the impurity filter; and a discharging connector communicated with a discharging cavity at the outer side of the filter screen is arranged on the outer wall of the impurity filter. The extrusion filter has the benefits that the impurities generated in the granulation and the production of the extrusion filter can be cleared without machine halt; and the extrusion filter has the advantages of easiness in structure manufacture, high strength, uneasiness in blockage, long service life, high production efficiency and low production cost and is suitable for the granulation of waste plastics.

Owner:陈艳

Cyclone separation filter

InactiveCN102815801BEfficient separationImprove separation efficiencyWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentSedimentEnergy consumption

The invention relates to a cyclone separation filter. The cyclone separation filter comprises a raw water inlet tube, a sediment storehouse, a cyclone tube, a cyclone chamber sediment discharge port, and a sediment storehouse sediment discharge port, wherein a housing is sleeved outside the cyclone tube; the housing is provided with a purified liquid outlet; a filter screen cover is arranged between the cyclone tube and the housing; and the housing and the filter screen cover are connected with the sediment storehouse through an upper ring flange and a lower ring flange. The cyclone separation filter enables the solid-liquid separation efficiency to be improved and especially the fine particle removal efficiency to be improved, and has the advantages of simple and compact structure, reduction of conveying pipelines and matching equipment, and realization of less energy consumption, low running cost, convenient operation and convenient cleaning.

Owner:董伟

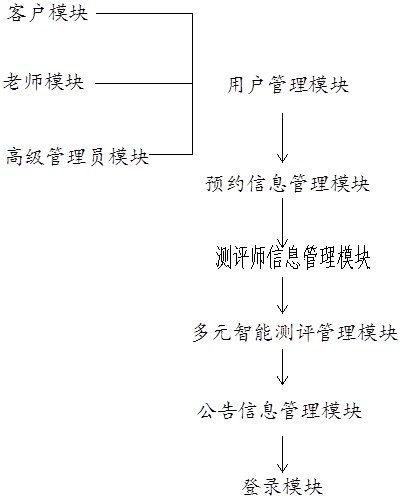

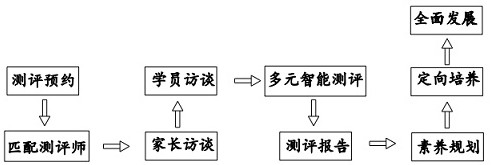

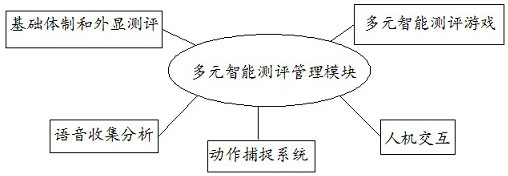

Teenager quality evaluation system based on multivariate intelligence theory

PendingCN113571185AEasy to make an appointmentPlay a protective effectHealth-index calculationReservationsPasswordCiphertext

The invention discloses a teenager quality evaluation system based on a multivariate intelligent theory, and relates to the technical field of multivariate intelligent evaluation. The system comprises a user management module which is used for distributing specific permissions and functions allowed to be realized to various roles according to business processing requirements, a client module, an evaluator module, a high-level administrator module, a reservation information management module, an evaluator information management module, a multi-element intelligent evaluation management module, an announcement information management module, and a login module which is used for calculating the user password through a certain algorithm when the user management module logs in through the password, storing the user password into a database, and then matching the user password and the initially stored ciphertext, and if the matching is successful, the login is successful. The teenager quality evaluation system in the prior art has certain defects, and the technical problems that parents are busy to work and inconvenient to make an appointment in an intelligent campus, and appointment is difficult are solved, remote appointment can be achieved by arranging a client module, and a favorite evaluator can be selected.

Owner:正艺星空(北京)教育科技有限公司

Special forced stirrer for normal-temperature asphalt mixture

PendingCN110624439AAvoid depositionImprove the mixing effectTransportation and packagingRotary stirring mixersEngineeringAsphalt

The invention discloses a special forced stirrer for a normal-temperature asphalt mixture. According to conventional stirrers for an asphalt mixture, a stirring arm is arranged in a stirring cylinder,the stirring arm is a bottom stirring arm, a large amount of asphalt adheres to the side face of the stirring arm after long-time work, cleaning is difficult, meanwhile, stirring of the stirring armis not thorough, and the situation that the stirring arm gets stuck occurs. The stirrer comprises a stirrer support (1) and a cylindrical stirring cylinder (4) fixed to the stirrer support, a lower gear motor (5) is fixed onto the stirrer support, and an output shaft of the lower gear motor penetrates through the center of the cylindrical stirring cylinder to be fixed to a cylinder bottom stirringarm (2); an upper gear motor (14) is fixed to the upper part of the stirrer support, and an output shaft of the upper gear motor is fixed to a side wall stirring arm (3). The forced mixer is specialfor the normal-temperature asphalt mixture.

Owner:杨墨义

An automatic separation device for duck gizzard and duck gland gastroesophagus

ActiveCN106720154BReliable split operationImprove permeabilityPoultry processingGizzardOesophageal tube

The invention discloses an automatic duck gizzard and duck glandular gastro-esophagus separation device. The automatic duck gizzard and duck glandular gastro-esophagus separation device comprises a duck gizzard bag driven by a chain, and a duck glandular gastro-esophagus and content separation mechanism and a duck gizzard and duck glandular gastro-esophagus separation mechanism, which are arranged on a working table and are connected end to end, wherein the duck glandular gastro-esophagus and content separation mechanism is provided with a blade I with a sharp end part and a food removing pulling sheet with the diameter more than a duck glandular gastro-esophagus, and the blade I is close to the food removing pulling sheet; the duck glandular gastro-esophagus can be cut apart very well, and contents in the duck glandular gastro-esophagus are scraped very well; the duck gizzard and duck glandular gastro-esophagus separation mechanism is provided with a guide platform for forming a gap and the gap is provided with a blade II; after the contents is separated from the duck glandular gastro-esophagus, the a duck gizzard can be separated from the duck glandular gastro-esophagus, without changing a container. The automatic duck gizzard and duck glandular gastro-esophagus separation device has the beneficial effects that according to the description, the automatic duck gizzard and duck glandular gastro-esophagus separation device is simple in structure and reasonable in design; the labor is released, the working efficiency is improved and the production quality is also improved.

Owner:单县六和饲料有限公司 +1

A magnetic roller filter

The invention relates to treatment equipment for a nonmetal liquid, in particular to a magnetic roller type filter for removing ferreous substances, surface oil dirt and the like of a nonmetal mixed liquid. The magnetic roller type filter comprises an accommodating cavity with a liquid inlet and a liquid outlet; a dustproof cover is arranged on the accommodating cavity; a magnetic roller and an oil removal roller are arranged in the accommodating cavity and both driven by a speed reducer motor to rotate; a slag scrapping device basically clung to the surface of the magnetic roller is arranged at the part, above a liquid level, of the magnetic roller; an oil scrapping device closely lung to the surface of the oil removal roller is arranged at the part, above the liquid level, of the oil removal roller; a flow guide plate for dividing the accommodating cavity into a slag removing cavity and a purification cavity is arranged below the magnetic roller and the oil removal roller. The magnetic roller type filter not only can remove the ferrous substances and the oil dirt, but also has a high filtration effect and a stable structure.

Owner:武汉斯蒂尔派科技有限公司

A sludge demulsifier and sludge recycling process

ActiveCN104556626BGood demulsification effectPromote degradationSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSludge cakeDemulsifier

The invention discloses an oil sludge demulsifier and an oil sludge resourceful treatment process. The oil sludge demulsifier comprises the following components in parts by weight: 5-30 parts of fatty acid methyl ester sulfonate, 2-10 parts of alkyl polyglucoside, 0.5-2 parts of a green accessory ingredient and 58-92 parts of water. The oil sludge resourceful treatment process comprises the following steps: enabling oily sludge in a raw material storage sludge tank to enter a sludge mixing tank; adding the oil sludge demulsifier for demulsification treatment; enabling demulsified oily sludge to enter a stacked spiral type sludge dewatering machine for solid-liquid separation to obtain a filter liquor and a sludge cake; enabling the filter liquor to enter a gas-liquid mixing tank to be mixed with air; enabling the mixture to enter a separation tank for three-phase separation of oil, water and sludge. The oil sludge resourceful treatment process can reduce the moisture content of oily sludge from 80-98% to about 50%, can further recycle most crude oil in oily sludge, and greatly reduces the difficulty of sludge follow-up treatment. By combining the oil sludge demulsifier with the oil sludge demulsification process, the moisture content of oil sludge can be reduced from 80-98% to about 50%, most crude oil in oil sludge can be further recycled, and the difficulty of sludge follow-up treatment is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Automatic excrement scraping machine with cleaning function for culture industry

InactiveCN107771682AWith cleaning functionAvoid breedingAnimal housingBird housingsAquaculture industryEngineering

The invention discloses an automatic excrement scraper with cleaning function for aquaculture, which comprises a concrete bottom plate, a beam arm, a left power box, a motor and an installation box, a collection tank is arranged inside the concrete bottom plate, and the A support plate is installed on the top, nozzles are installed on both sides of the manure scraping device, rotating shafts are installed on both sides of the beam arm, and motors are installed above the left power box and the right power box. Belts are installed on the outside of the collection tank, connection ports are provided on both sides of the collection tank, a first water pipe is installed above the first hydraulic switch door, a water pump is installed above the installation box, and the first water valve A second water pipe is installed on the right side. The aquaculture industry uses an automatic manure scraper with a cleaning function, which can scrape the manure more thoroughly during the manure scraping operation, and can clean and collect the breeding site during the manure scraping, so as to avoid the breeding of bacteria during long-term use.

Owner:金博

A kind of oil sludge demulsifier and oil sludge treatment process

ActiveCN104556625BGood demulsification effectPromote degradationSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSludge cakeDemulsifier

The invention discloses an oil sludge demulsifier and an oil sludge treatment process. The oil sludge demulsifier comprises the following components in parts by weight: 6-30 parts of fatty acid methyl ester ethoxylate, 2-13 parts of lauramidopropyl hydroxy sulfoBetaine, 0.5-1 part of a green accessory ingredient and 56-91 parts of water. The oil sludge treatment process comprises the following steps: enabling oil sludge in a raw material storage sludge tank to enter a sludge mixing tank; adding the oil sludge demulsifier for demulsification treatment; enabling demulsified oil sludge to enter a stacked spiral type sludge dewatering machine for solid-liquid separation to obtain a filter liquor and a sludge cake; enabling the filter liquor to enter a gas-liquid mixing tank to be mixed with air; enabling the mixture to enter a separation tank for three-phase separation of oil, water and sludge. The oil sludge treatment process can reduce the moisture content of oily sludge from 80-98% to about 50%, can further recycle most crude oil in the oily sludge, and greatly reduces the difficulty of sludge follow-up treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

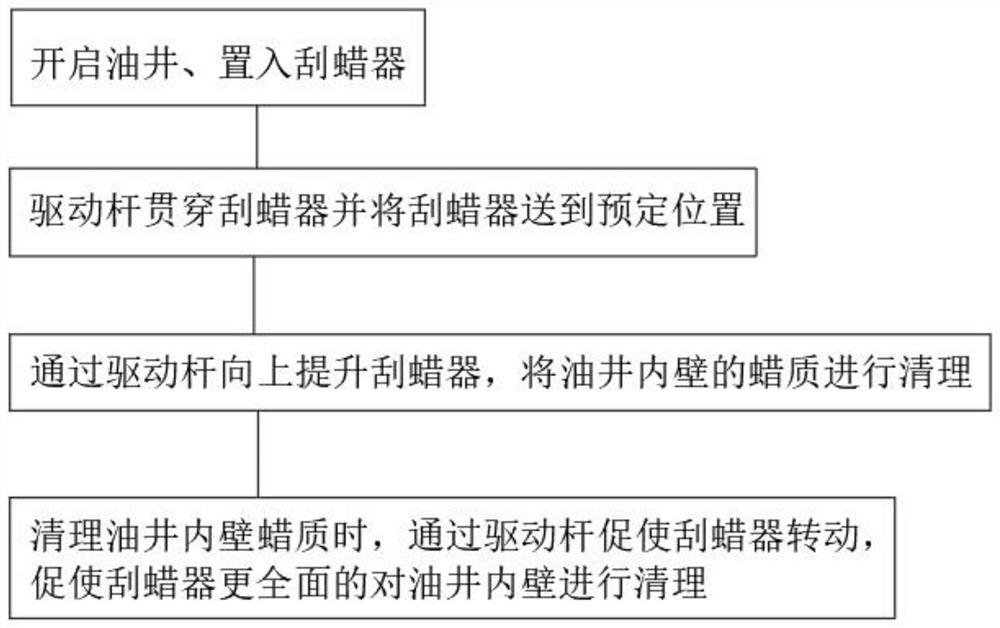

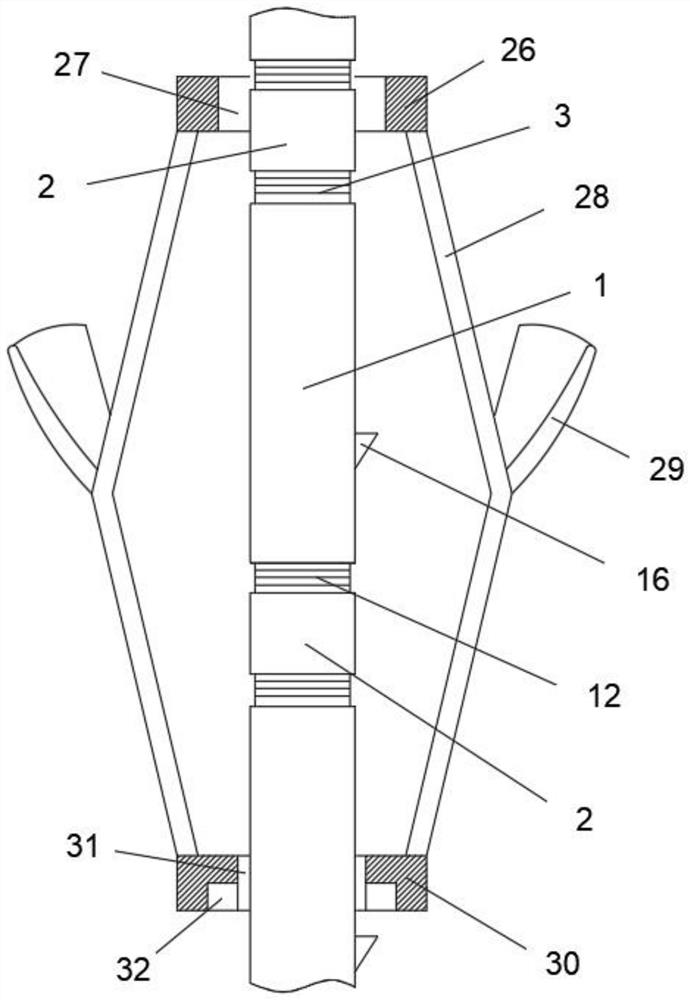

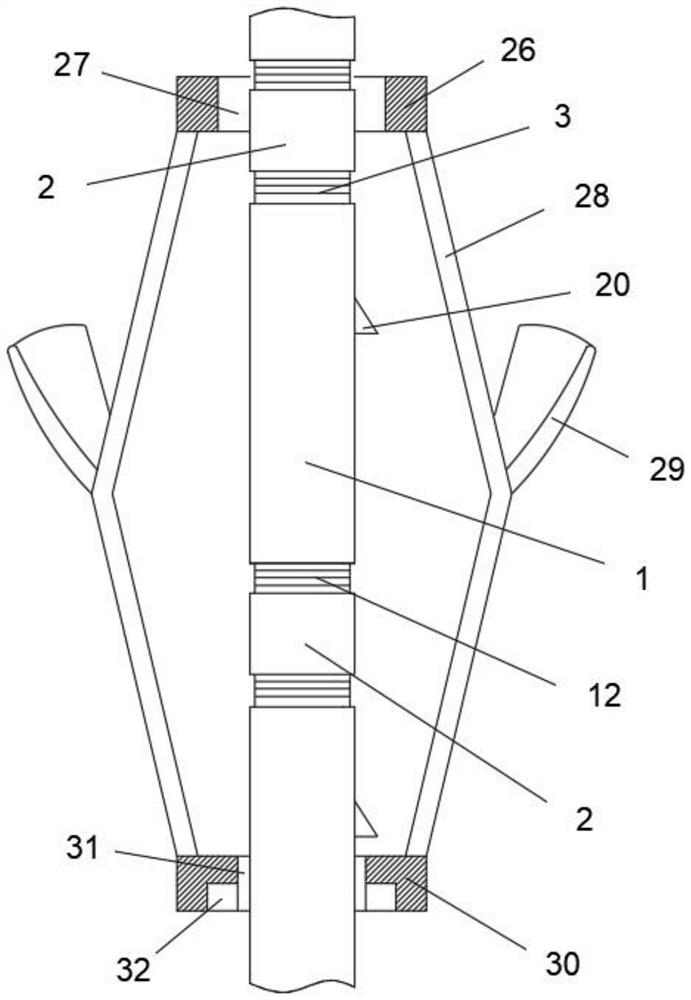

Oil well anti-blocking process for petroleum mechanical exploitation

The invention relates to the technical field of petroleum exploitation, and discloses an oil well anti-blocking process for petroleum mechanical exploitation, which comprises the following steps: S1, a paraffin scraper is arranged in an oil well; s2, a driving rod penetrates through the paraffin scraper and pushes the paraffin scraper to go deep into the oil well, a plurality of scrapers are obliquely arranged on the paraffin scraper through elastic connecting rods, and the scrapers are distributed in a circular array mode with the driving rod as the axis; and S3, when the paraffin scraper reaches a preset position, the paraffin scraper is lifted upwards through a driving rod. According to the oil well anti-blocking technology for petroleum mechanical exploitation, the scrapers are assembled through the elastic connecting rods, the elastic connecting rods are of a metal plate structure supported by elastic steel, and the scrapers are obliquely arranged upwards, so that when the scrapers make contact with wax on the inner wall of an oil well, the elastic connecting rods can adaptively deform towards the side close to the driving rod along with downward movement of the scrapers; and the scraper cannot scrape too much wax, so that a large amount of wax is prevented from falling into the oil well.

Owner:刘畅

An automatic unloading vertical centrifuge

The invention proposes an automatic unloading vertical centrifuge. The scraping device includes a scraper shaft, a scraper seat, a scraper, a driving gear, a driven gear, and a first driving device. The controller is connected to the first driving device. The first driving device The device is connected with the driving gear to drive the driving gear to rotate, the driven gear meshes with the driving gear, one end of the scraper shaft passes through the driven gear and is threadedly connected with the driven gear, and the other end of the scraper shaft passes through the machine cover and extends into the drum. It is connected with the scraper seat, and the scraper is installed on the scraper seat; there is a first air channel in the scraper shaft, and a second air channel in the scraper seat, the first air channel is connected with the second air channel, and the scraper seat is located on the two sides of the scraper. The side position is provided with an air blowing nozzle to blow the wind to the inner wall of the drum, and the air blowing nozzle is connected with the second air duct. The invention can realize the lift and rotation of the scraper shaft through the driving device, the driving gear and the driven gear.

Owner:江苏颖盛化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com