Patents

Literature

44results about How to "Good dehydration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of demulsifier for oil fields

ActiveCN102093526AGood dehydration effectHigh molecular weightDewatering/demulsification with chemical meansSolventToluene

The invention discloses a preparation method of a demulsifier for oil fields. In the method, fatty alcohol is used as a raw material, and the demulsifier is prepared by crosslinking and modifying after reacting the fatty alcohol with oxirane and epoxypropane. First, the fatty alcohol is used as an initiator, and a polyether demulsifier A is prepared by reacting the fatty alcohol with propylene oxide and ethylene oxide in the presence of a basic catalyst. Then, a product B is prepared by carrying out self-crosslinking reaction on the polyether demulsifier A with polycarboxylic acid under the action of the catalyst. Finally, a final product, i.e. the high-performance demulsifier, is prepared by carrying out self-crosslinking reaction on the polyether demulsifier A and the product B in a solvent with adoption of toluene diisocynate. The demulsifier prepared with the method has the advantages of high relative molecular weight, ideal dewatering effect and good broad spectrum property, and can be used for demulsifying and dewatering oil field crude oil. Separated water is clear, and the use amount of the demulsifier is small.

Owner:JURONG NINGWU CHEM

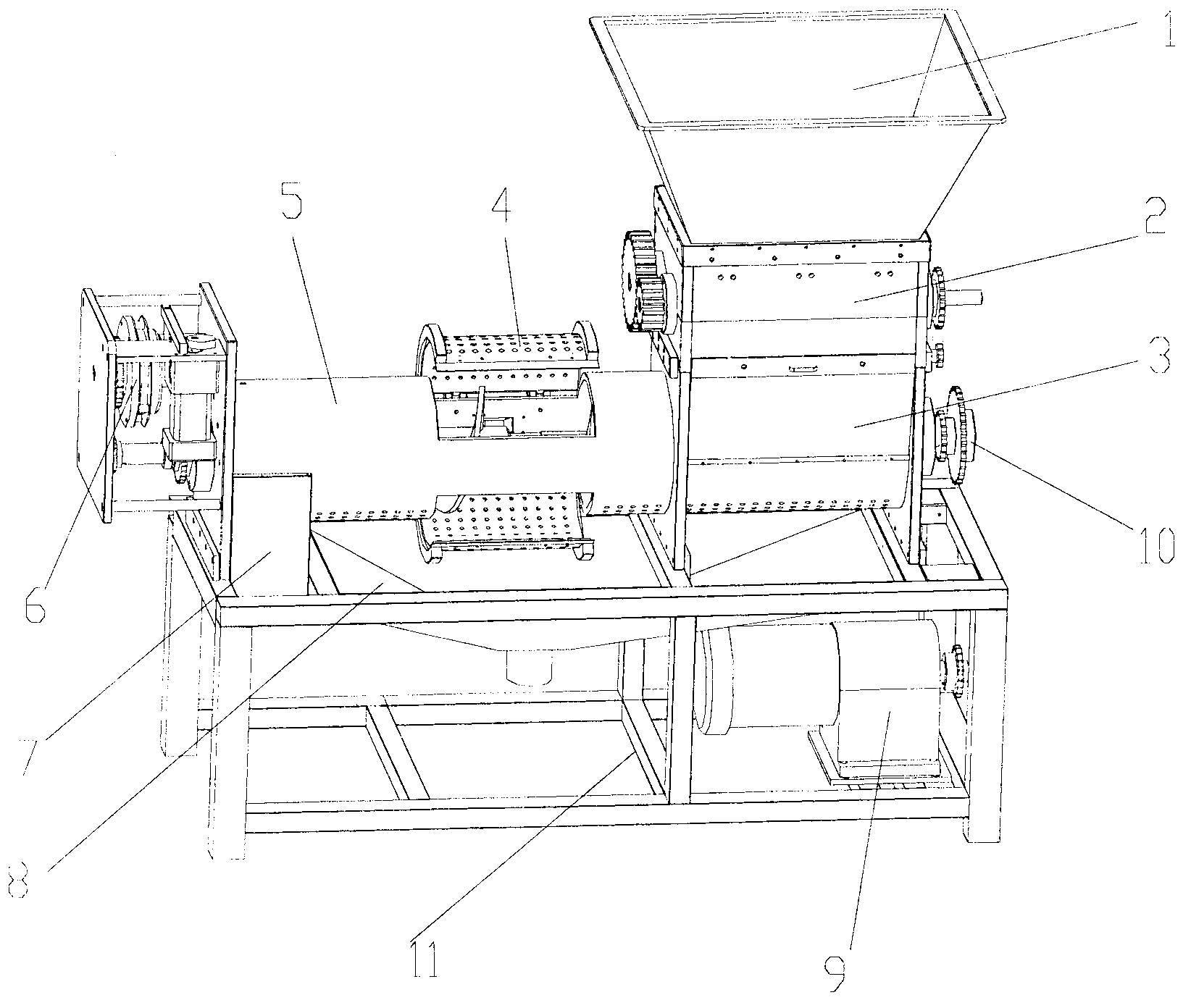

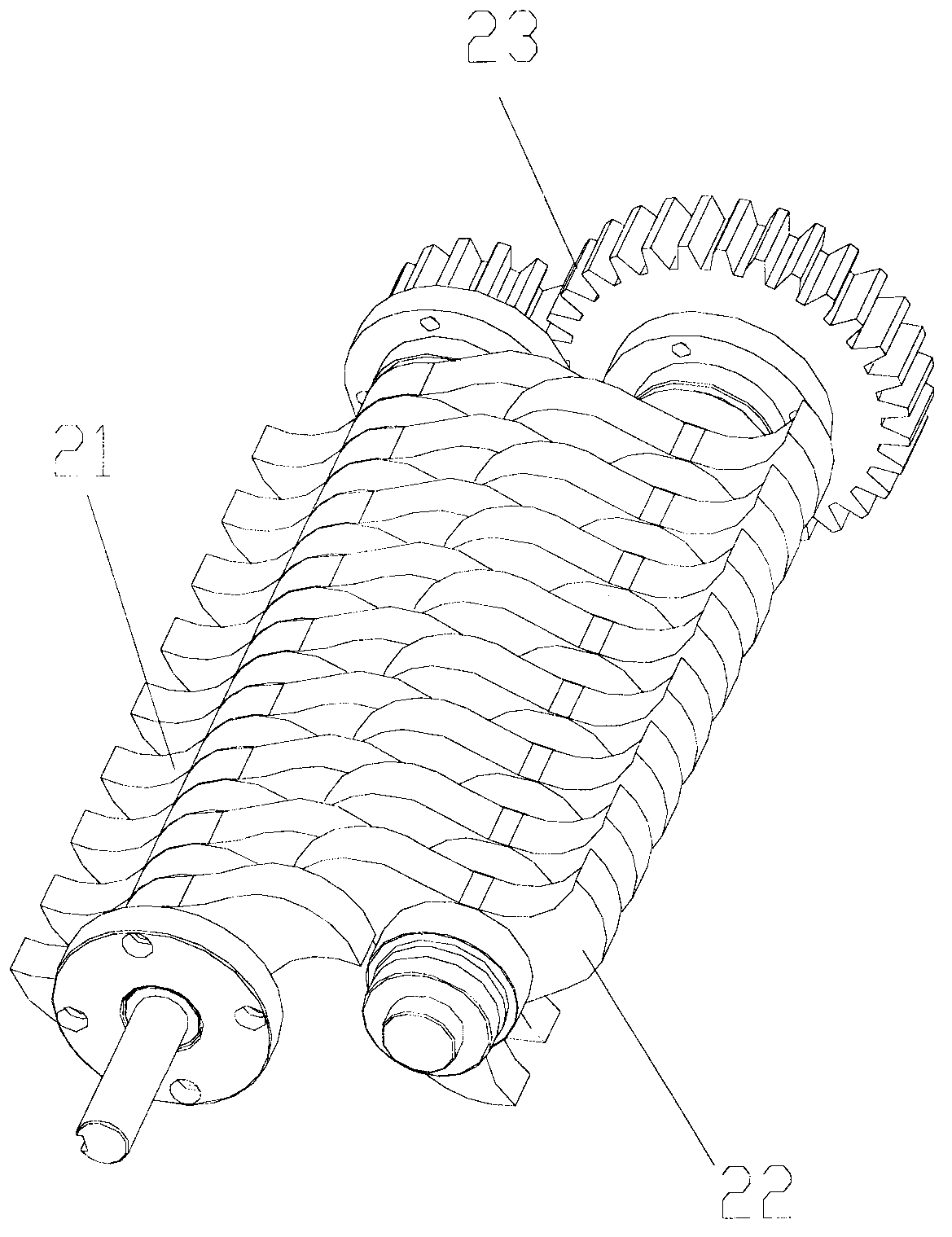

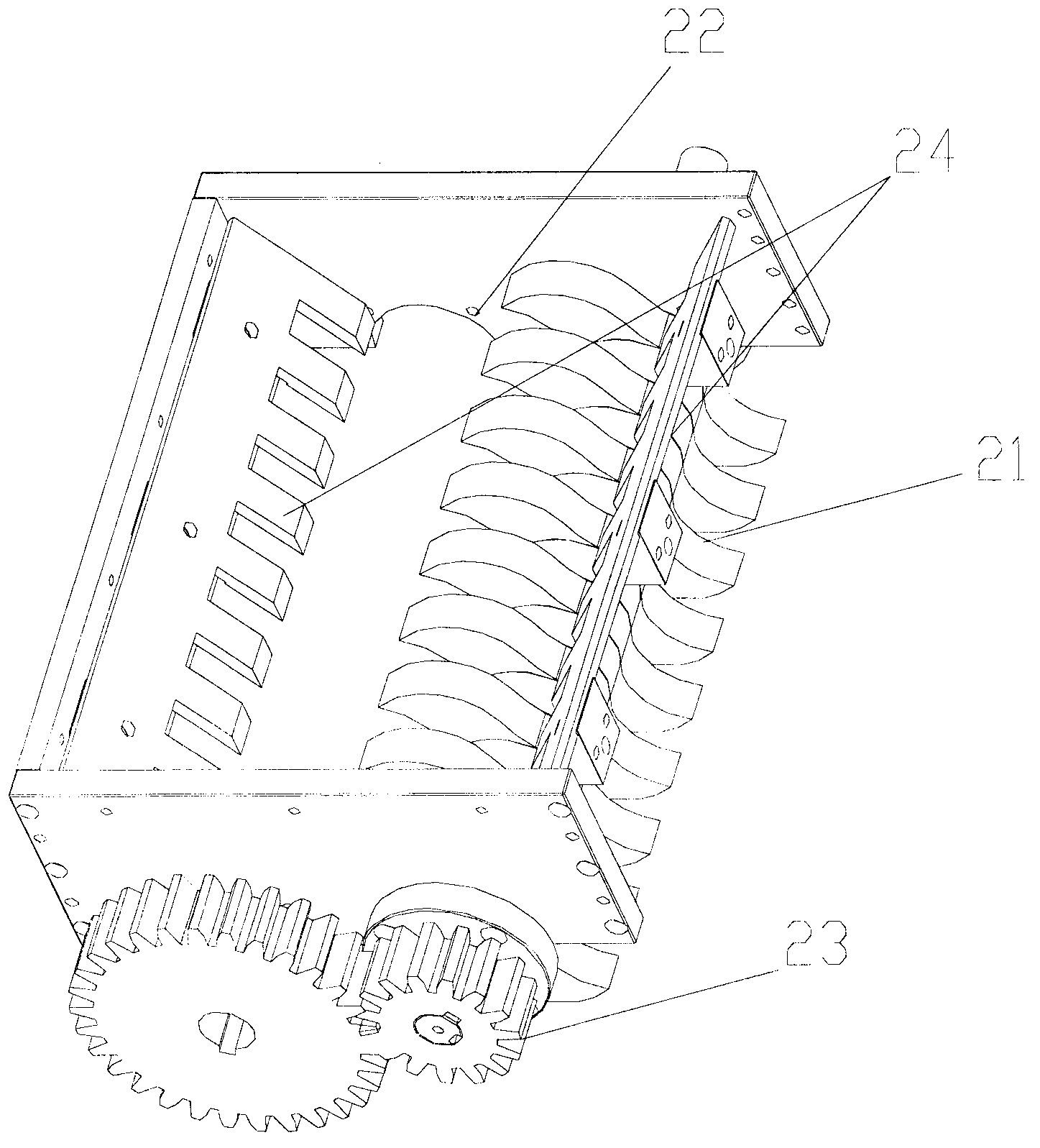

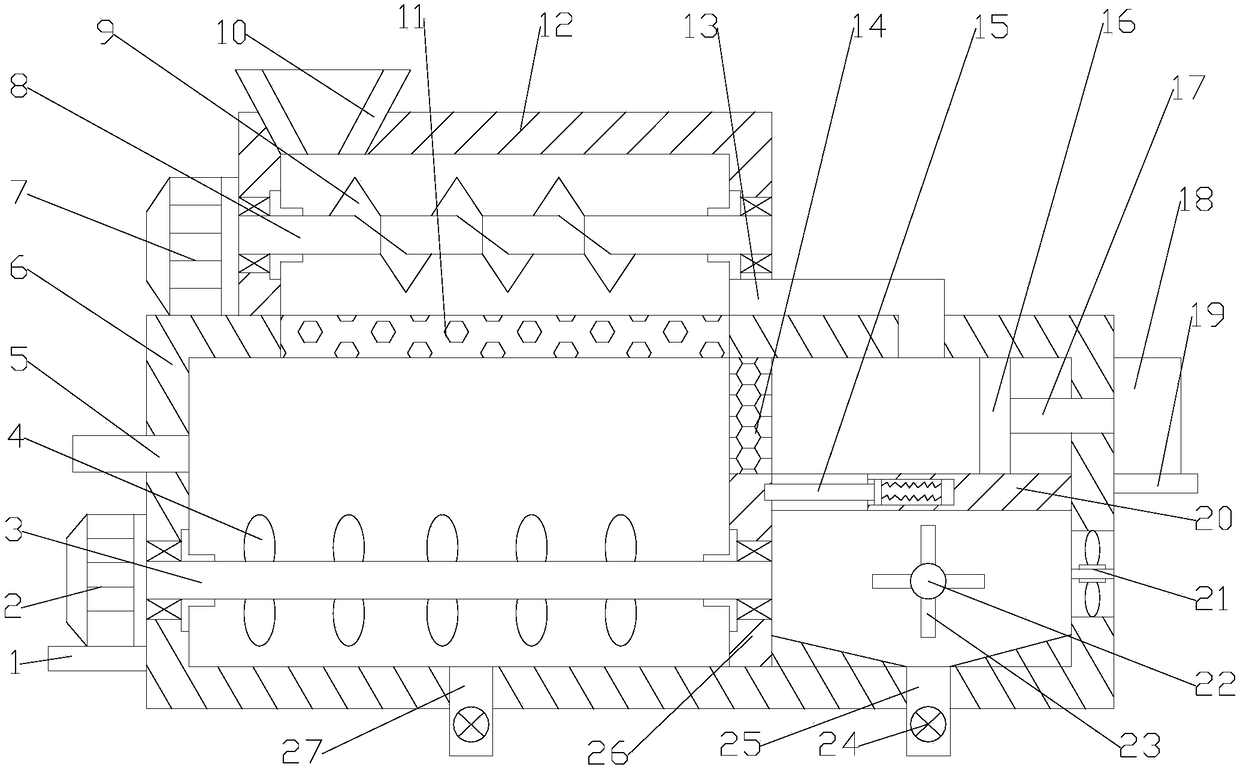

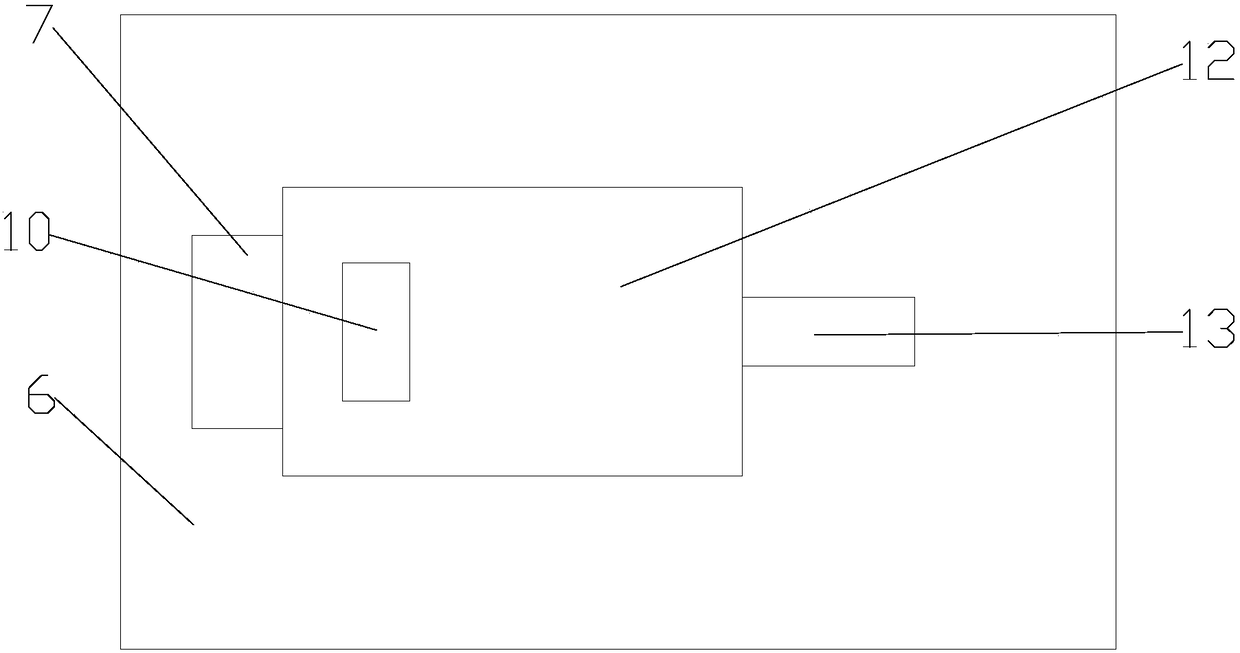

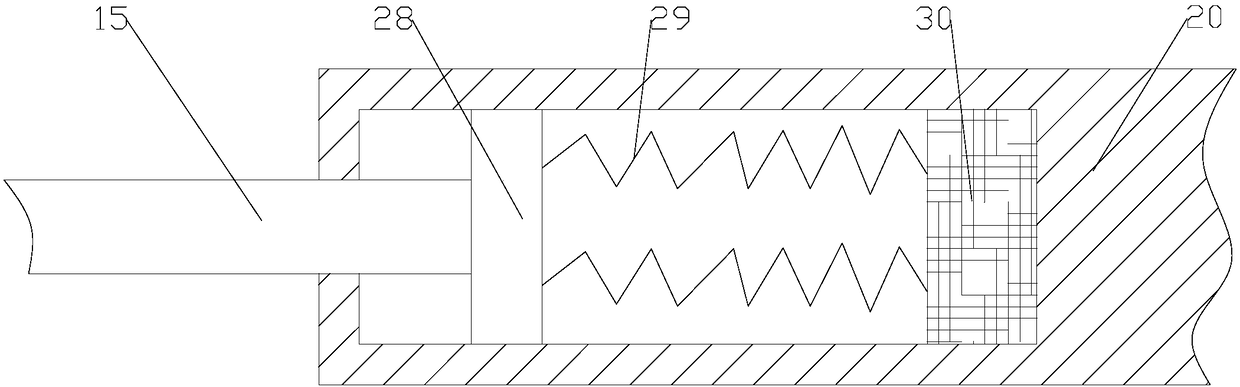

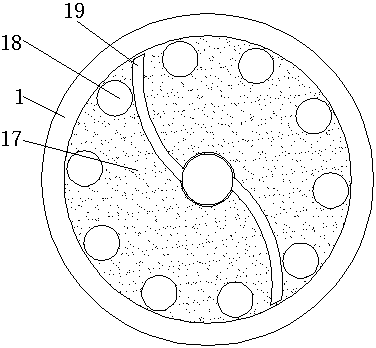

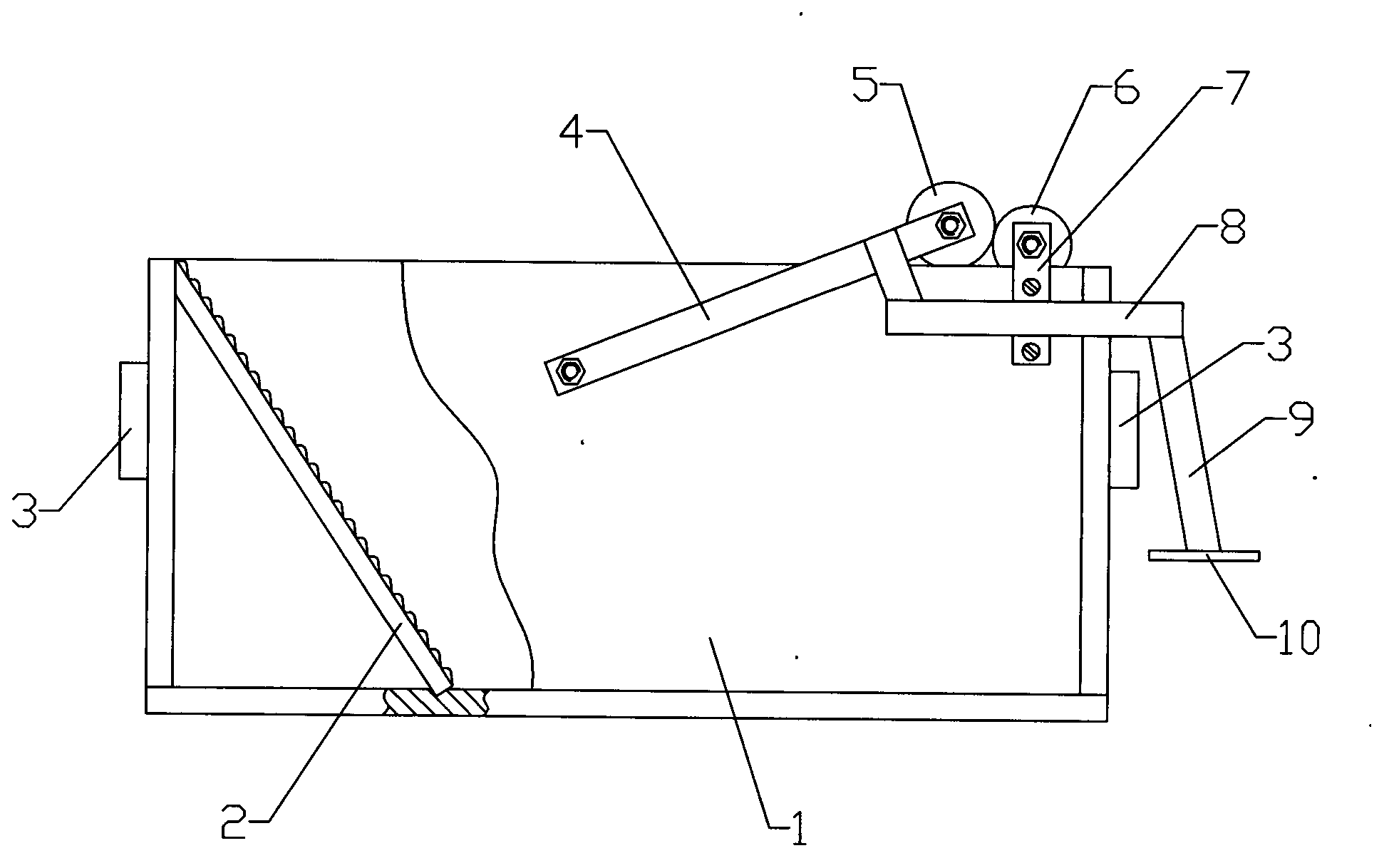

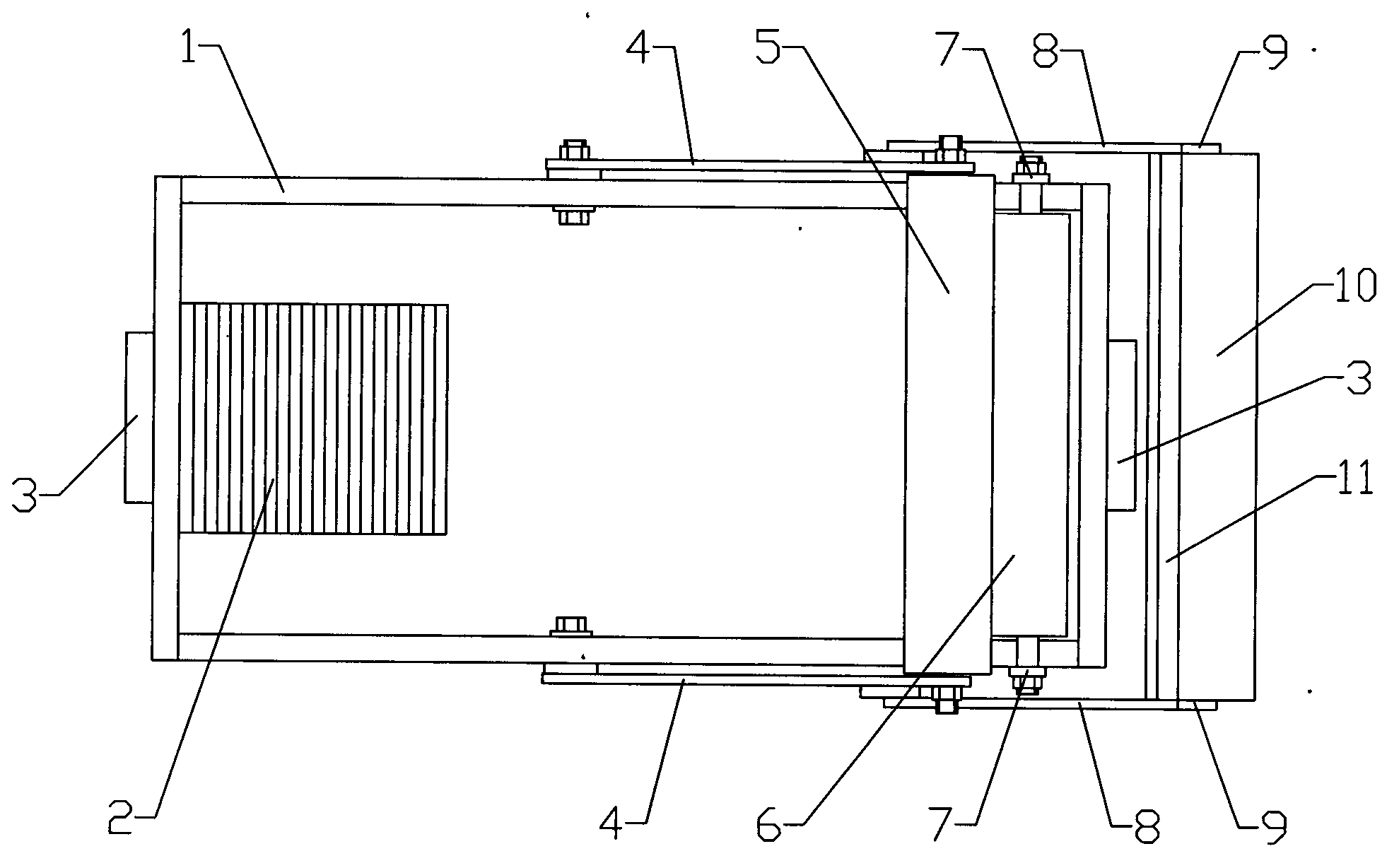

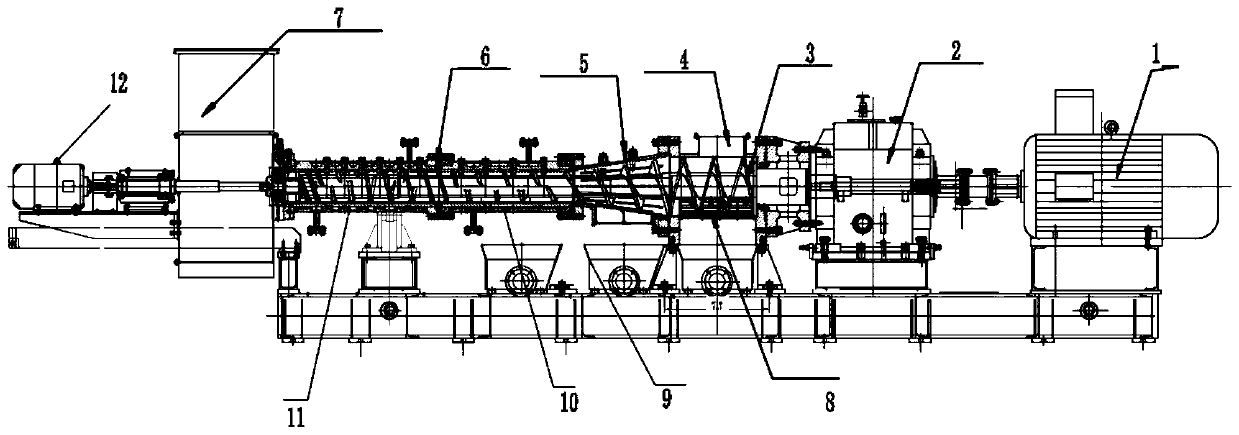

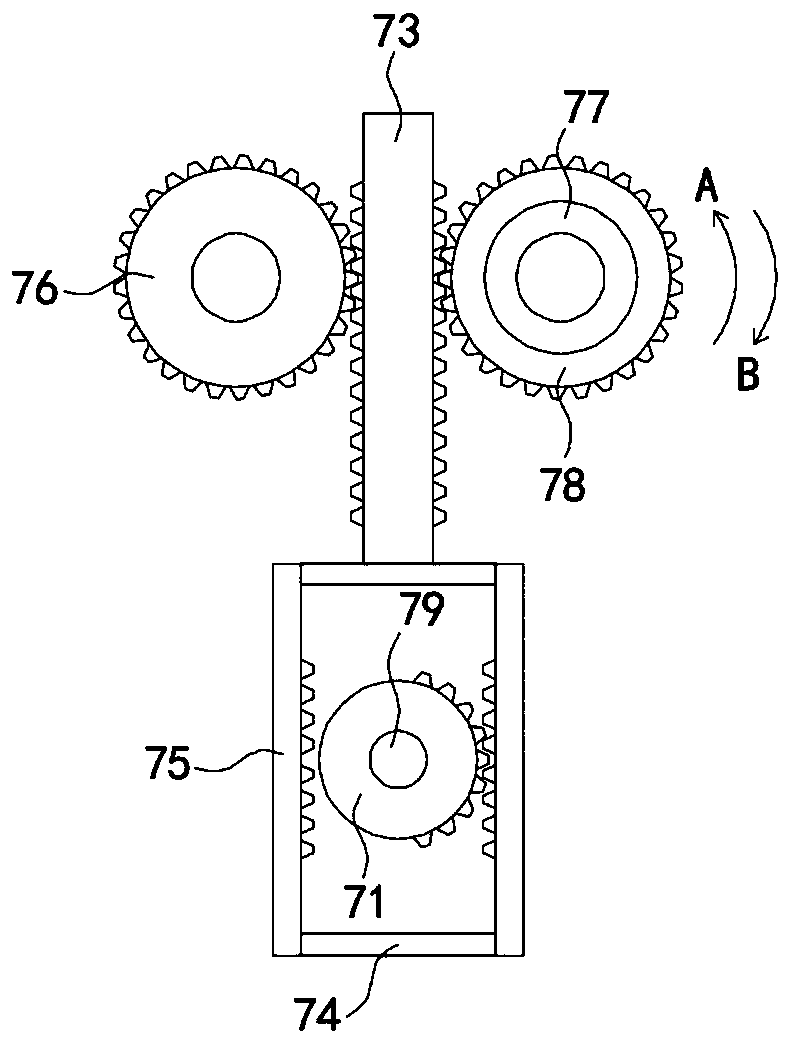

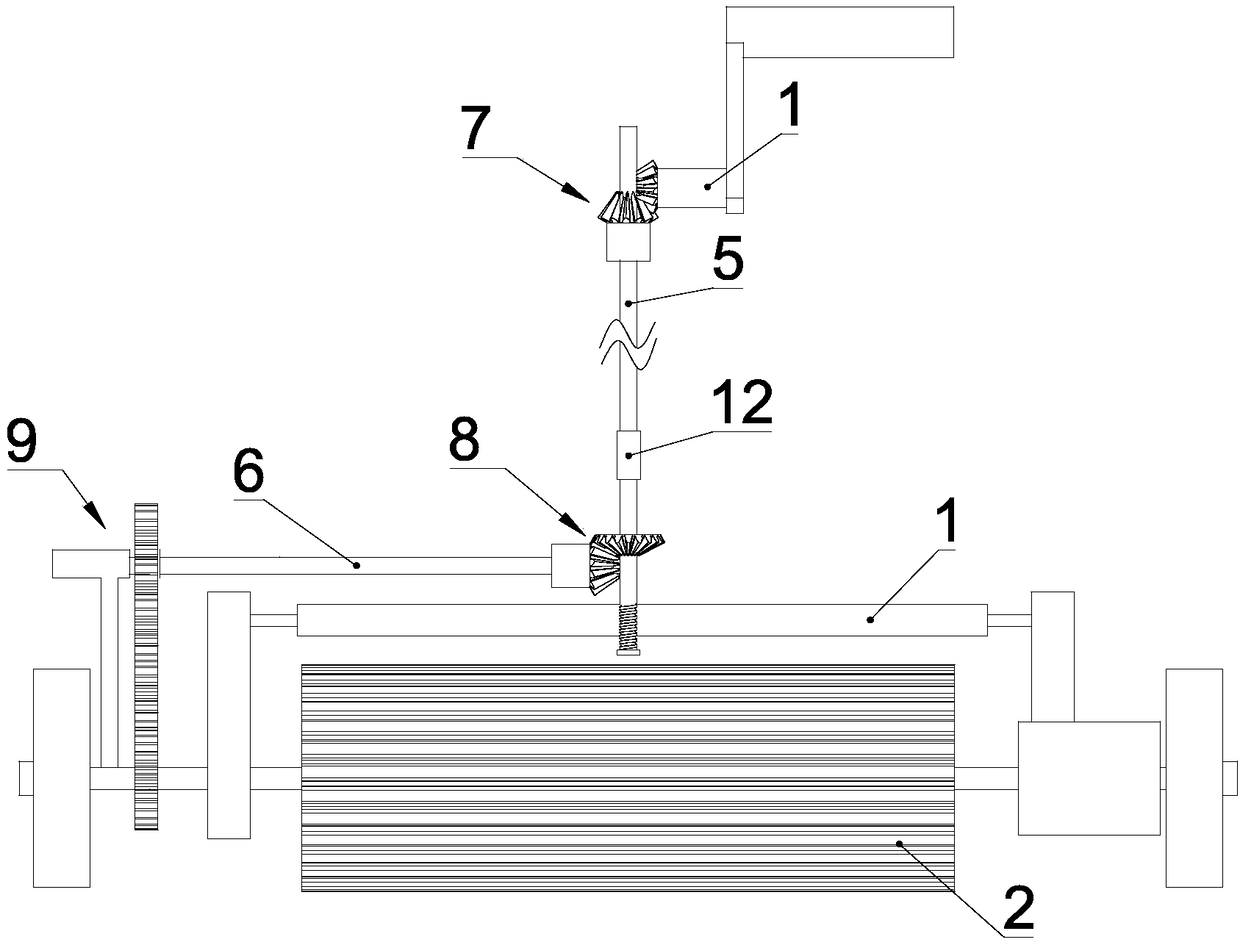

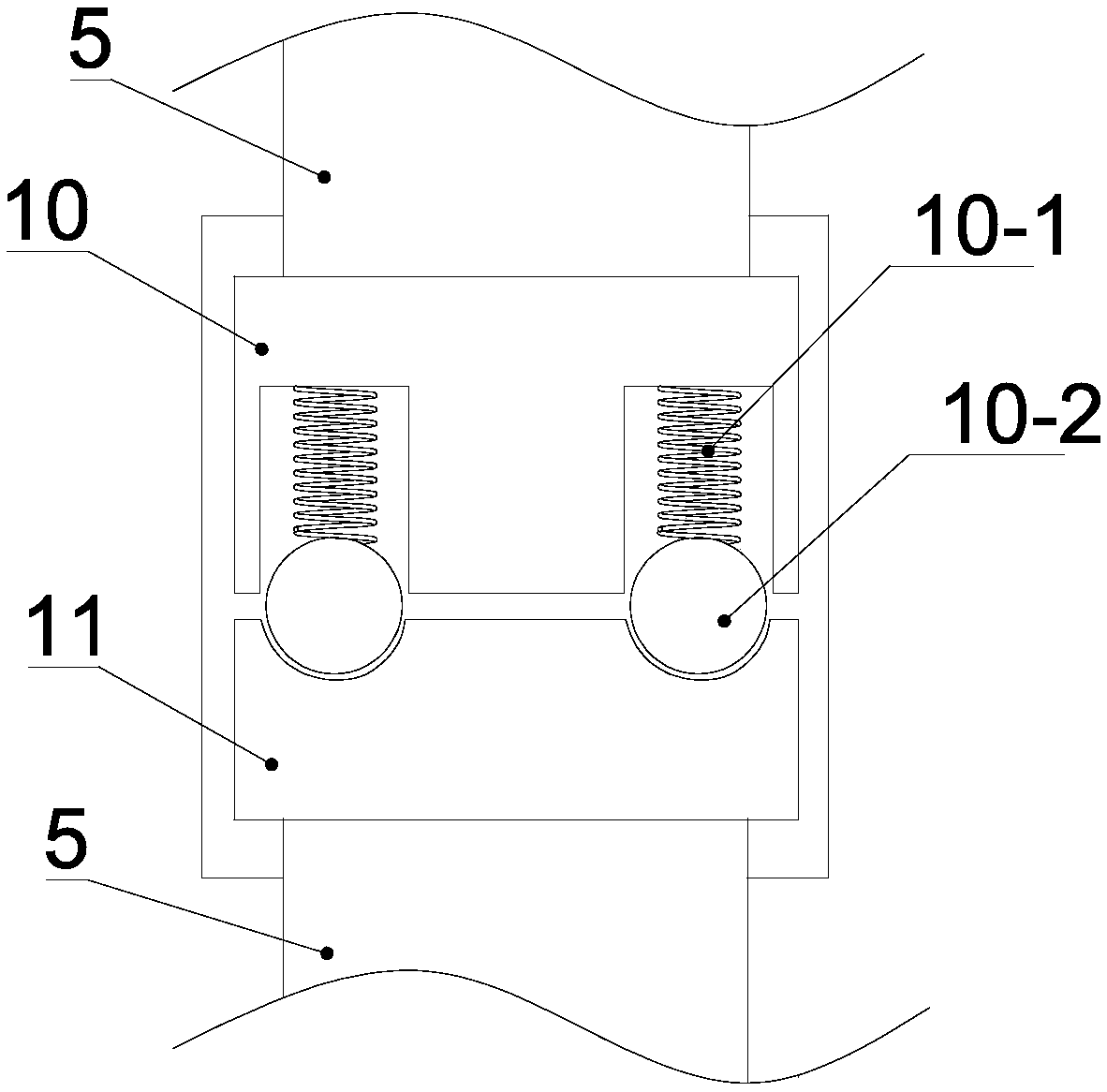

Automatic organic material crushing and dewatering machine and crushing and dewatering method

The invention discloses an automatic organic material crushing and dewatering machine which comprises a base frame, a feeding bucket, a hob crushing device, a driving chain wheel, a spiral feeding bin, an extruding dewatering bin, a spiral discharge bin, a discharge variable speed link group, a discharge port and a main motor, wherein the driving chain wheel, the spiral feeding bin, the extruding dewatering bin, the spiral discharge bin and the discharge variable speed link group are connected in sequence by screw rods; a water collecting bucket is arranged below the extruding dewatering bin; the hob crushing device is composed of a set of special crossed hobs with double blades and three blades and driven to operate by a pair of variable gears connected with the hobs; and screw rod structures are arranged in the spiral feeding bin and the spiral discharge bin, and spiral blade structures are arranged on screw rods to continuously push materials. The invention further discloses a crushing and dewatering method which uses the automatic organic material crushing and dewatering machine; different organic materials can be crushed and dewatered; the defects of the existing equipment available on the market are overcome; the automatic organic material crushing and dewatering machine has the advantages of simplicity and convenience in operation and maintenance; the service efficiency and the working efficiency of the equipment are improved; additionally, the operating environment is improved; and the wear of the equipment is reduced.

Owner:深圳市三盛环保科技有限公司

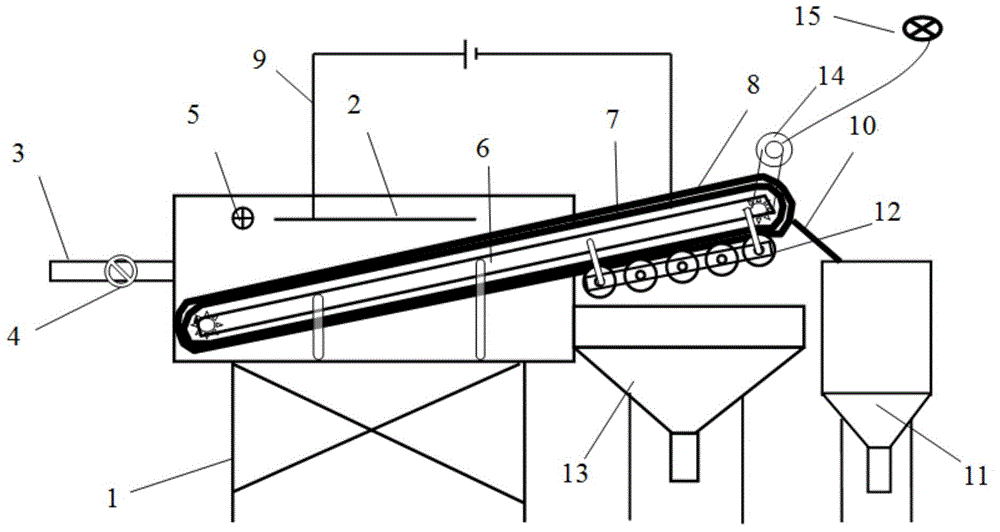

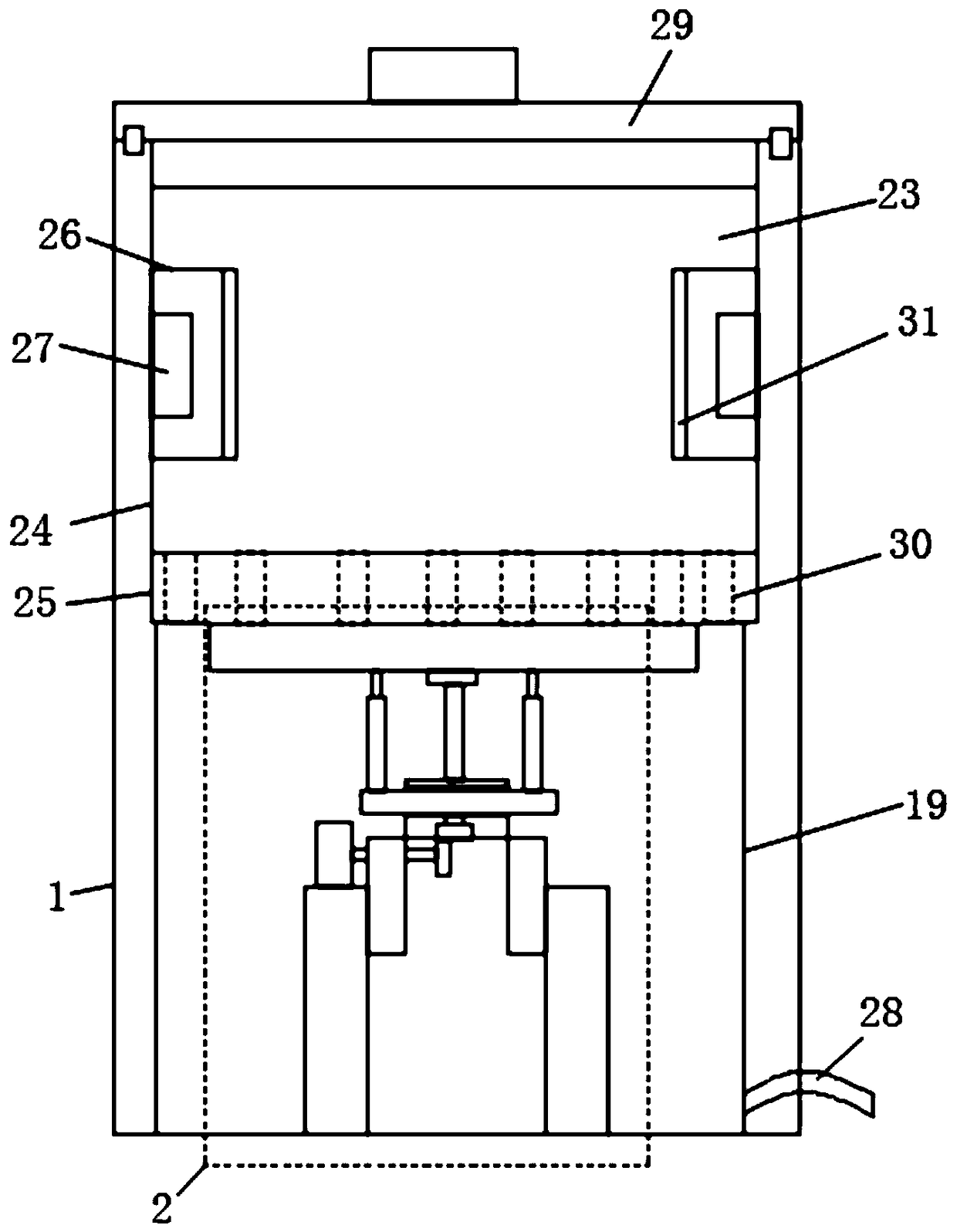

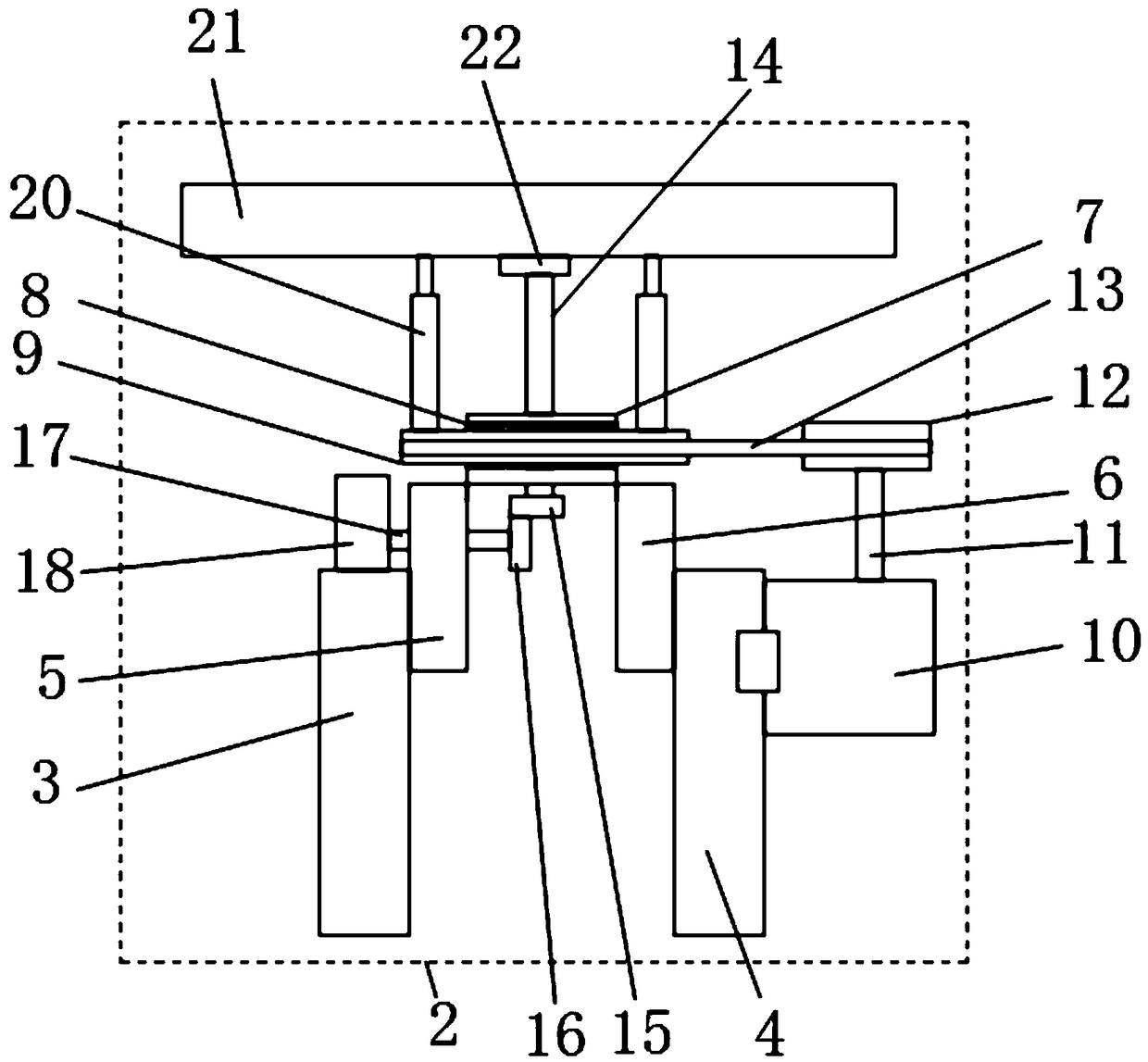

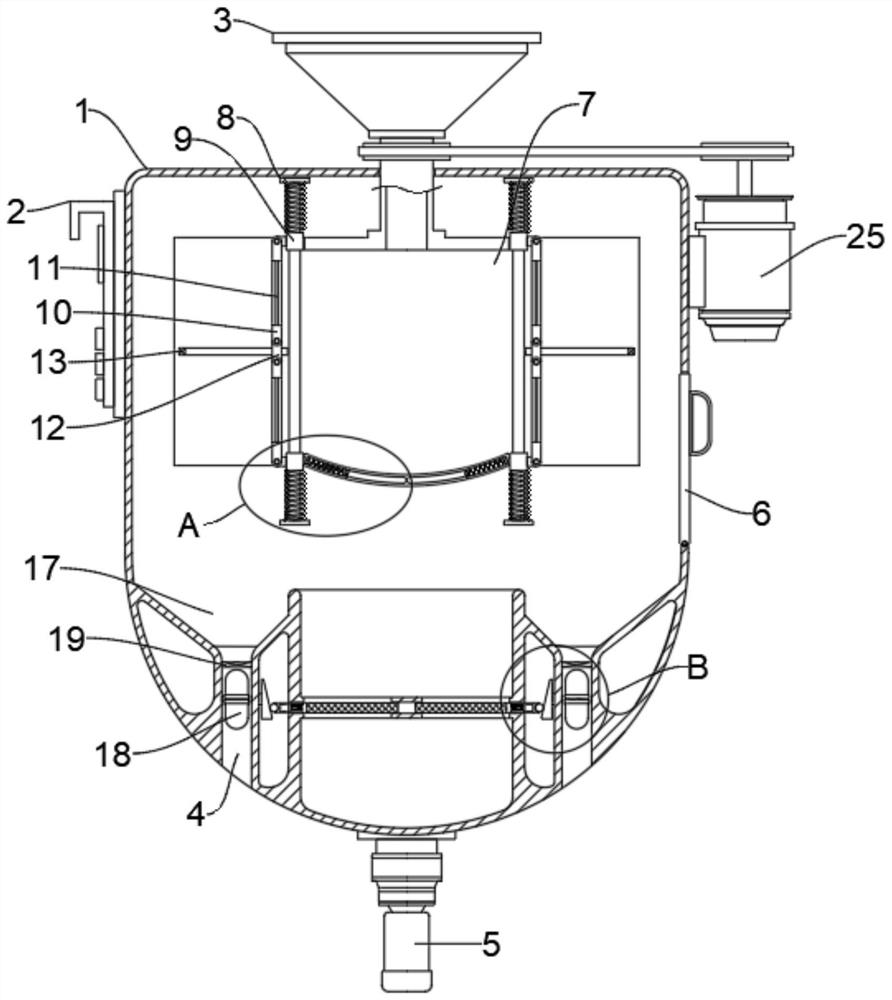

Rapid dehydration device for mud with high water content

InactiveCN104803577AGood dehydration effectReduce energy consumptionSludge treatment by de-watering/drying/thickeningDischarge efficiencyEngineering

The invention provides a rapid dehydration device for mud with a high water content. The rapid dehydration device comprises a muddy water storage component, a mud inlet component, a liquid level measurement component, an inlet mud control component, an electric osmosis component, a conveying support component, a conveying component, a water absorption component, a mud scraping component, a mud receiving component, a dehydration component and a water receiving component. When muddy water moves to the top end of the device along with the conveying component, mud on the surface of a water absorption belt is scraped away through the mud scraping component, while the scraped mud falls into the mud receiving component; the water absorption component is extruded with the dehydration component after scraping of the mud, so as to remove moisture in the water absorption component, while the extruded water falls into the water receiving component. The rapid dehydration device has the advantages that the discharging efficiency is improved; the mud dehydration efficiency is improved remarkably.

Owner:SHANGHAI JIAO TONG UNIV +1

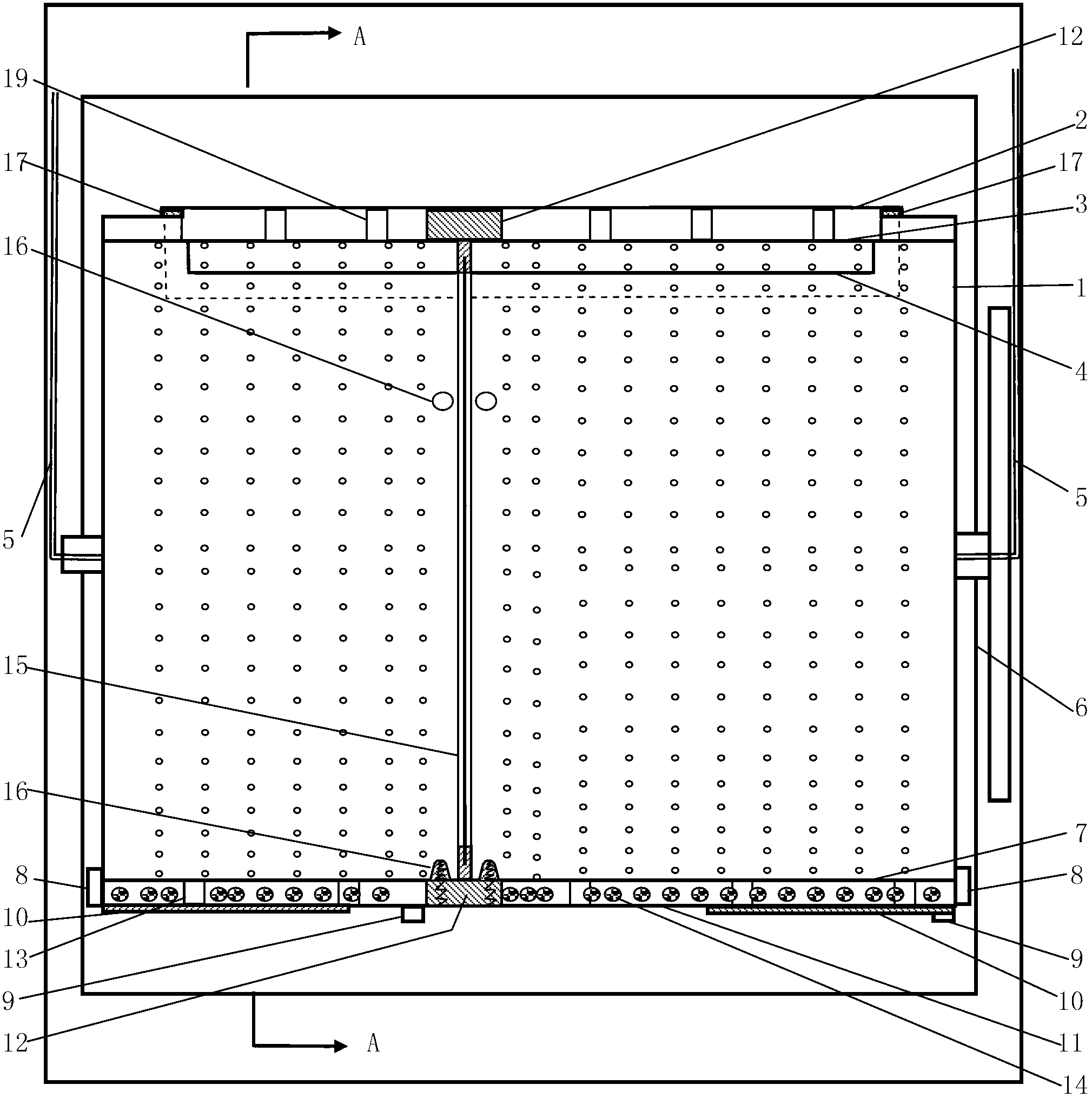

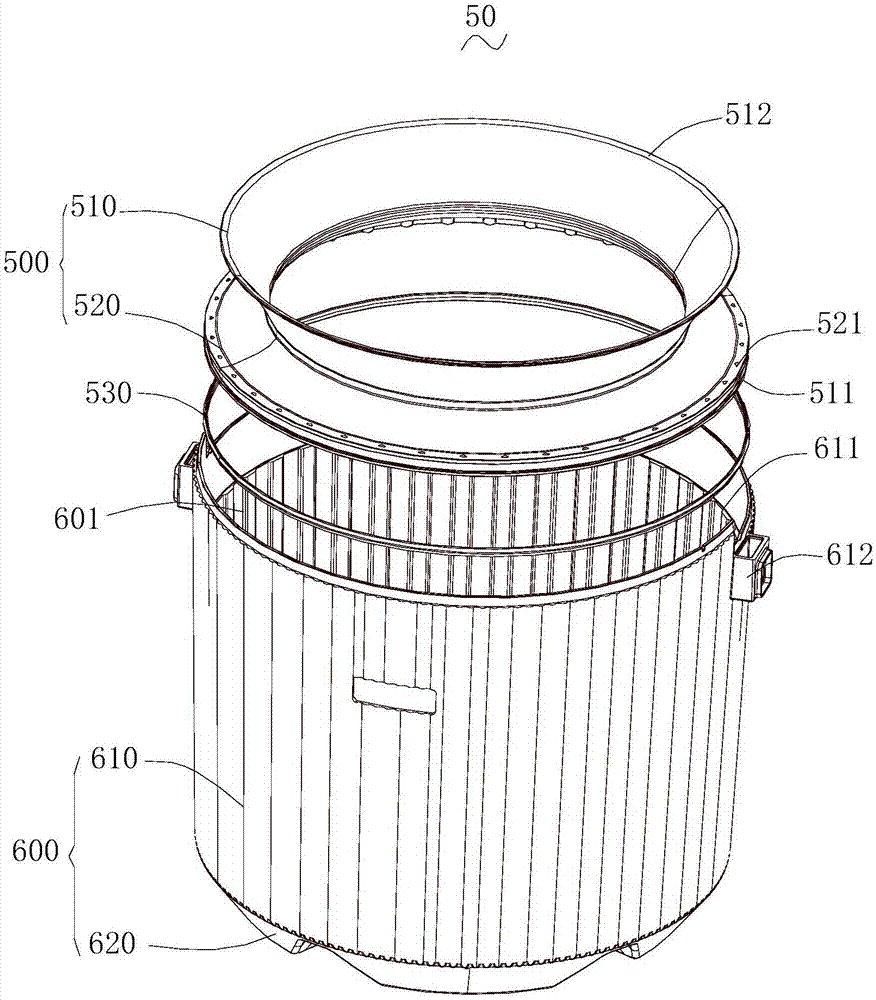

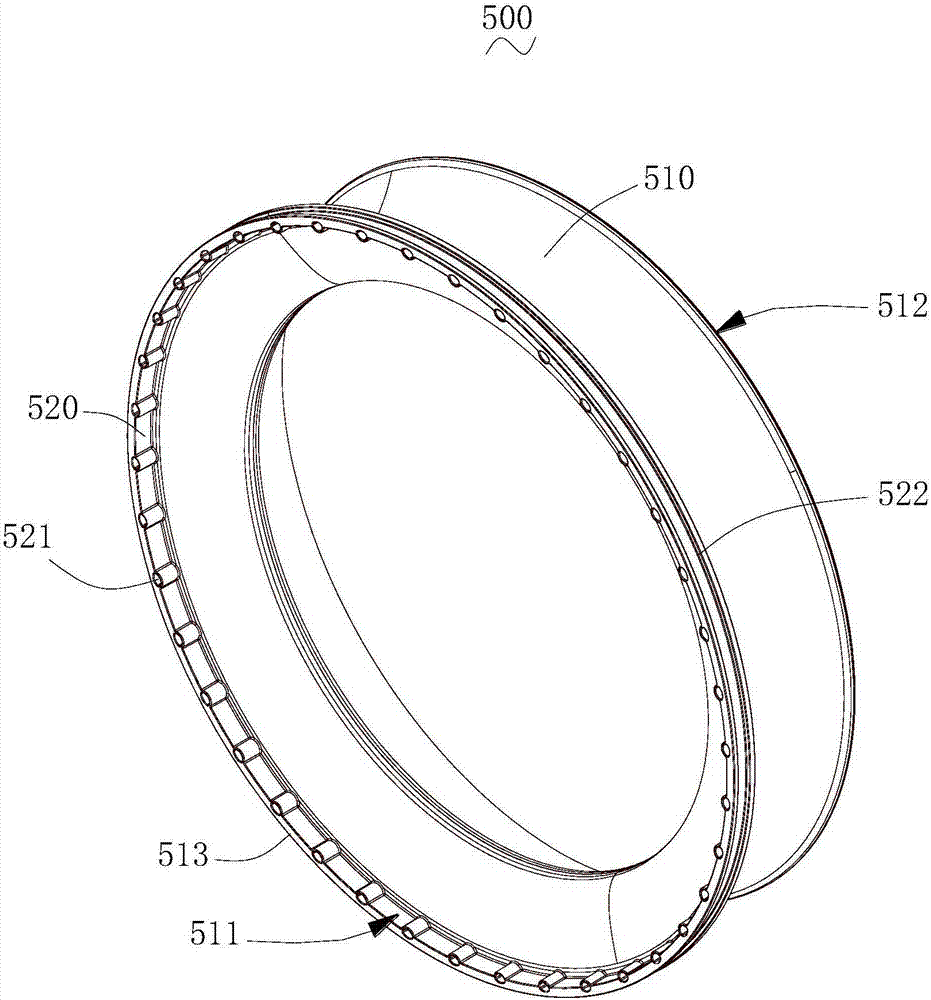

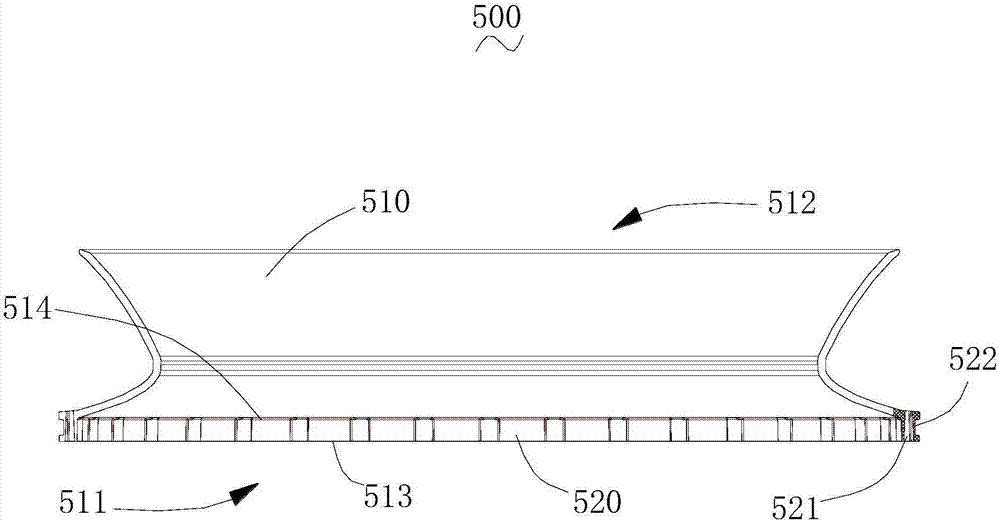

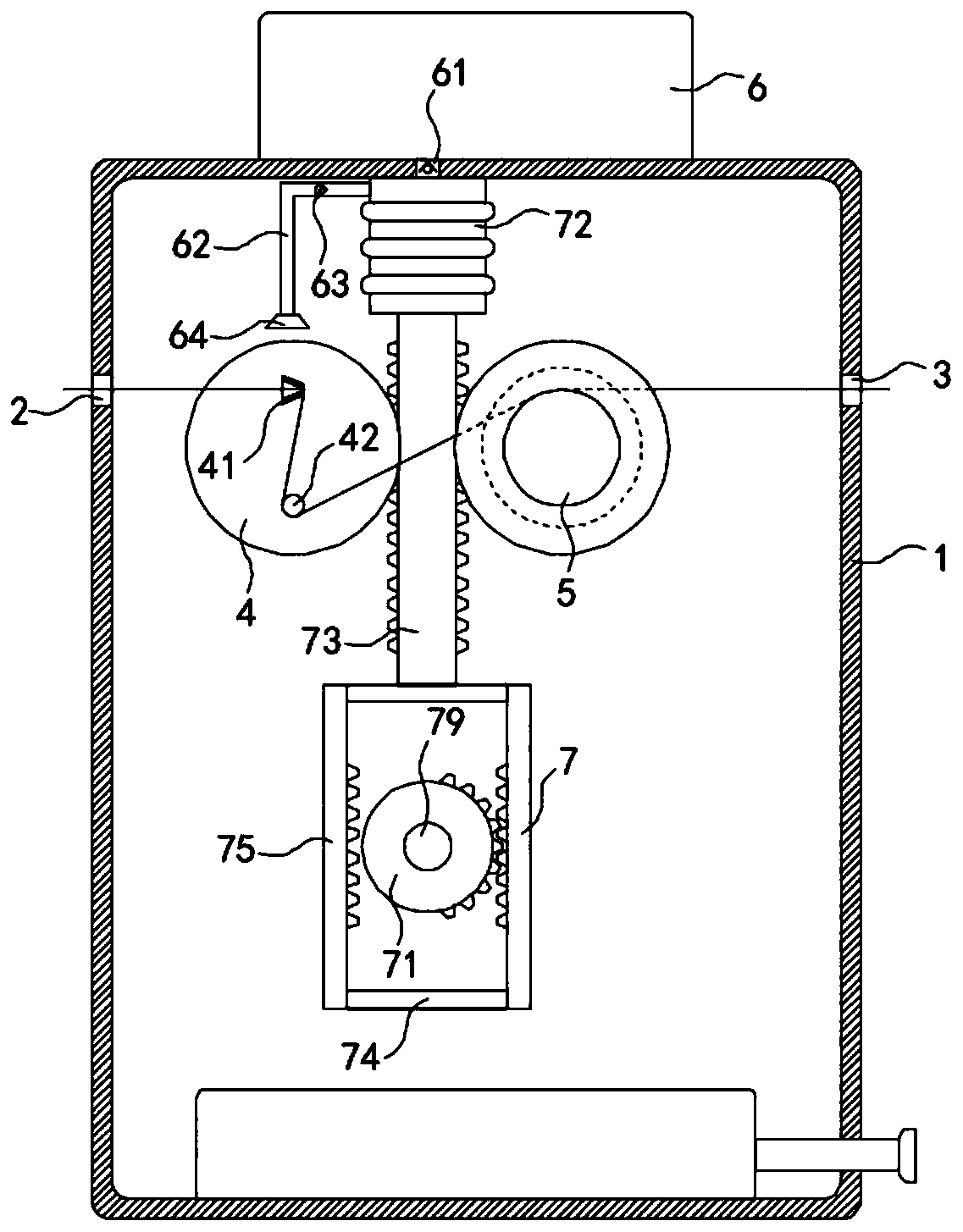

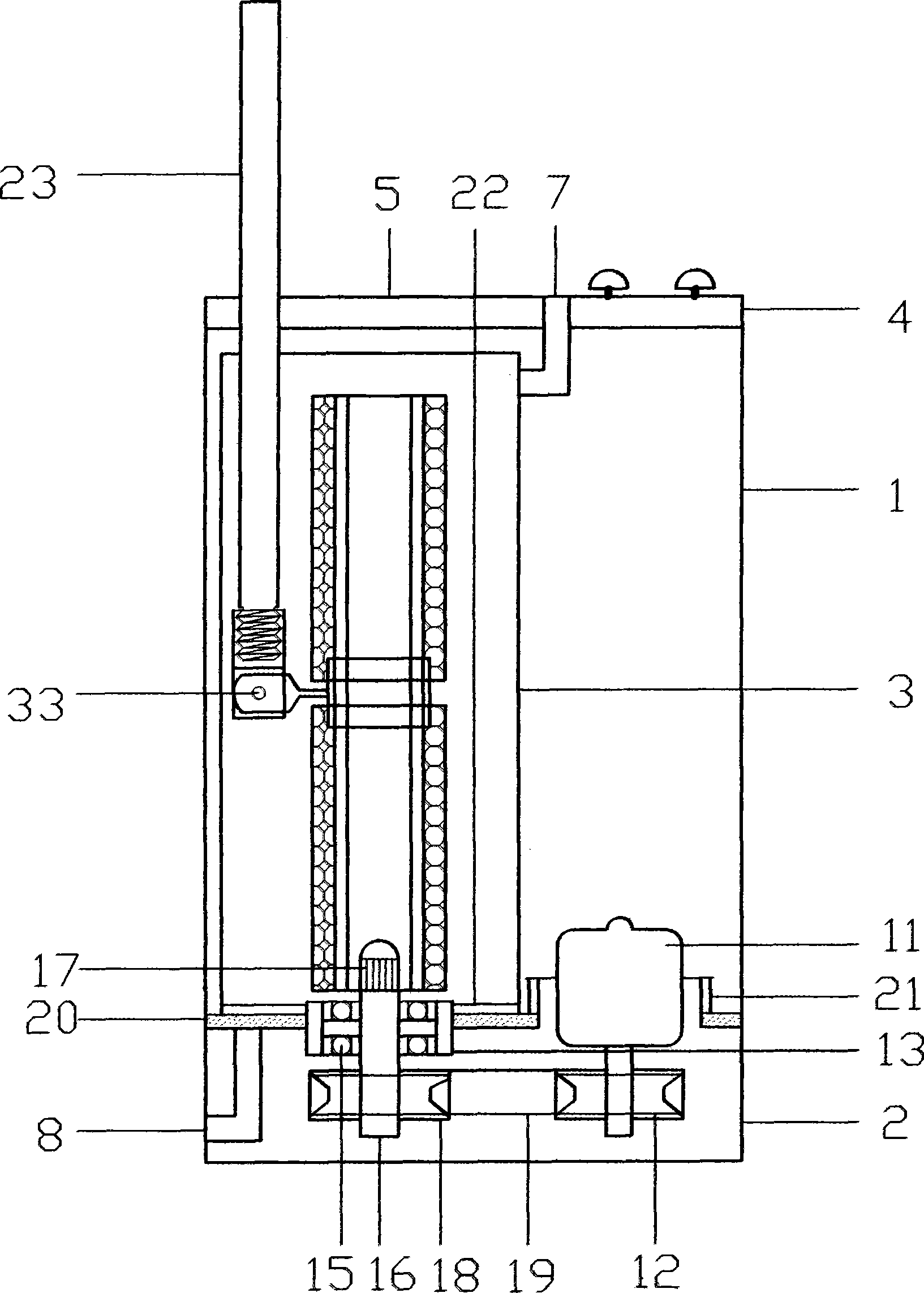

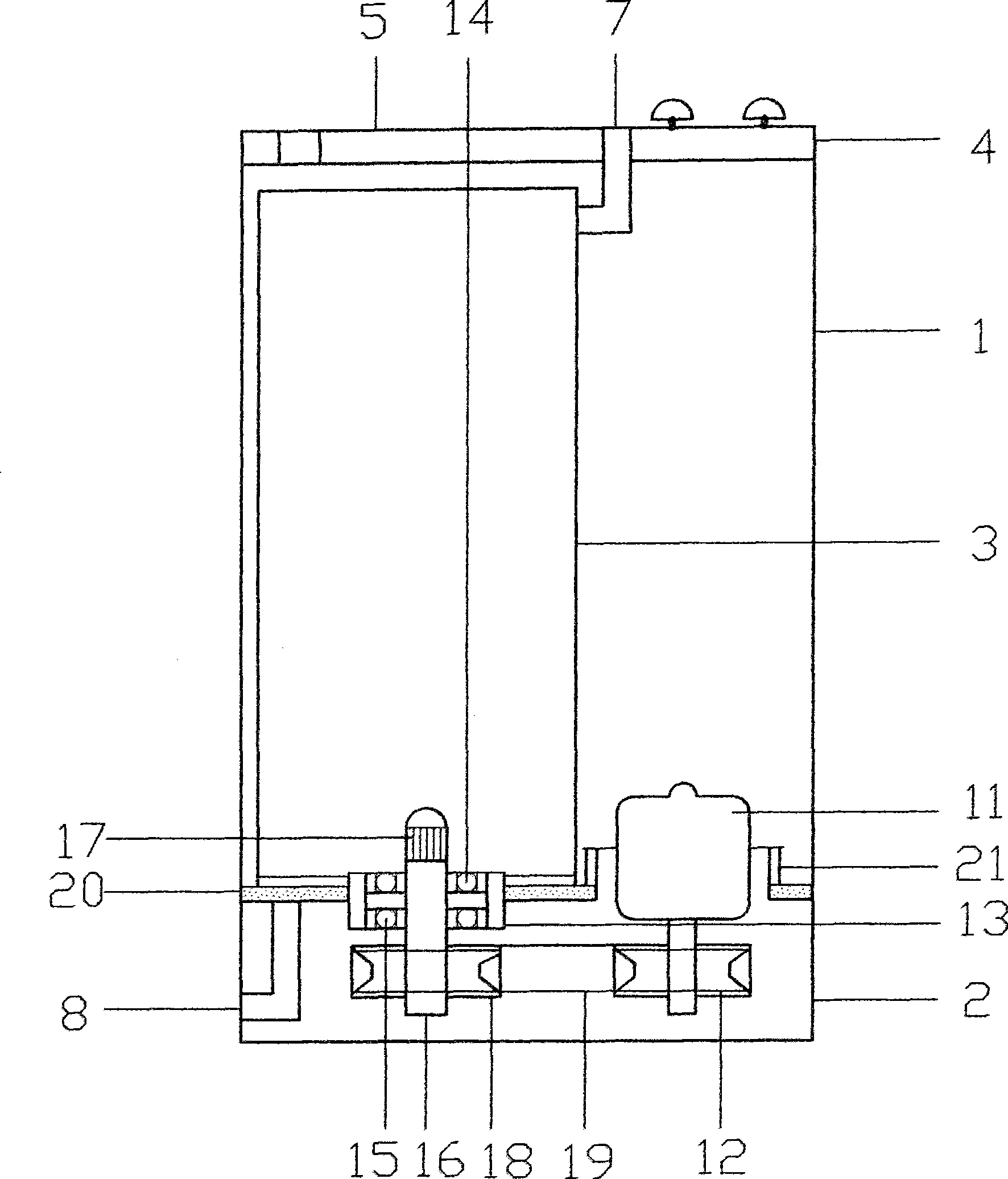

Roller washing machine washing clothes separately

InactiveCN103255598AGood dehydration effectReduce moisture contentOther washing machinesWashing machine with receptaclesLaundry washing machinePulp and paper industry

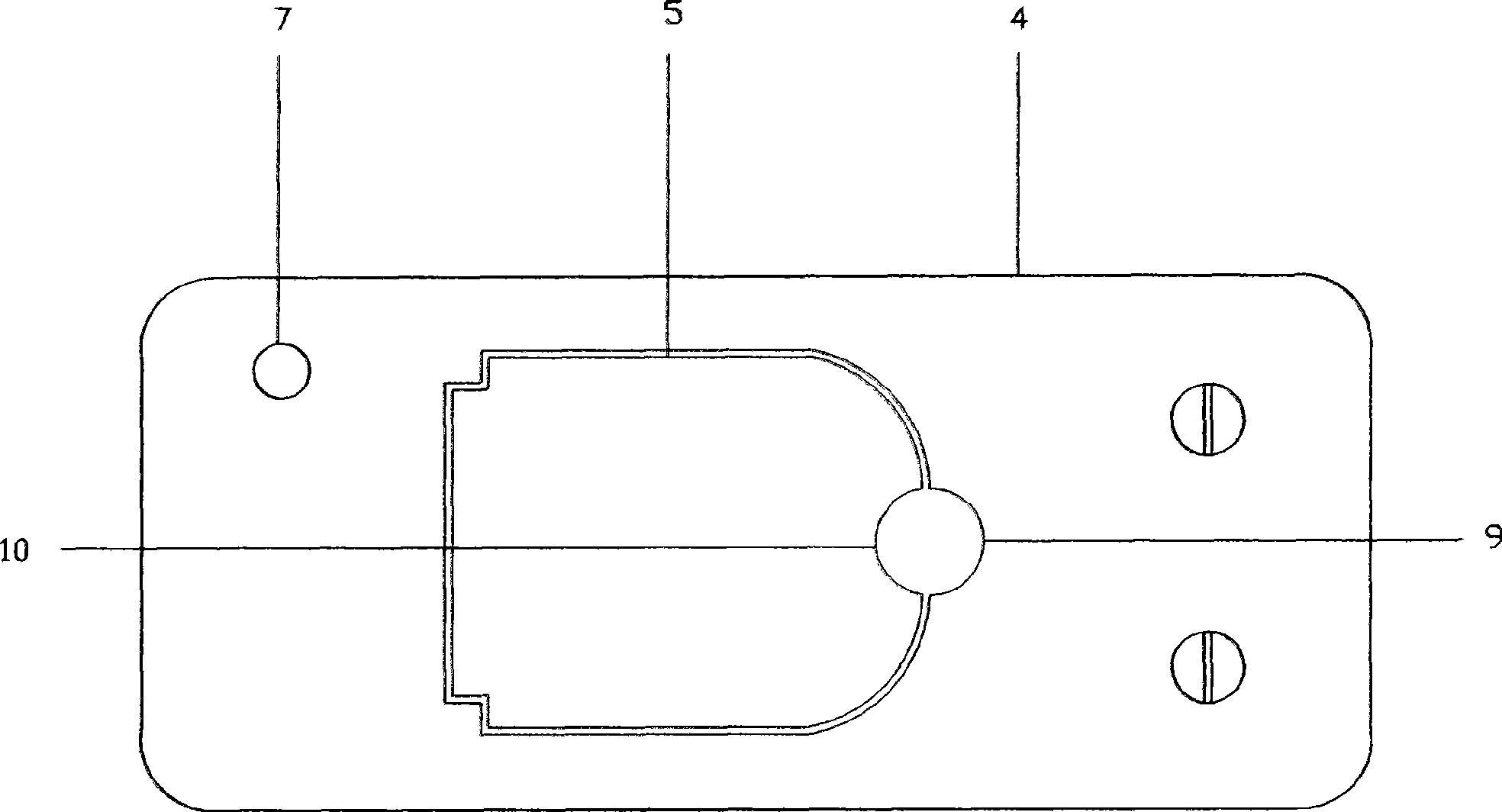

The invention relates to improvement of a roller washing machine washing clothes separately. People hope to simultaneously and separately wash underwear and outerwear and simultaneously and separately wash discoloring clothes and colourfast clothes. As for an existing roller washing machine washing clothes separately, a roller is of a single-barrel structure, a few dewatering holes are formed in the barrel wall, and dewatering effects are poor. According to the roller washing machine washing clothes separately, a roller 1 is of a double-layer barrel wall structure and is composed of a sealed outer roller 11 and an inner roller 7 provided with a lot of dewatering holes, a round sealing ring 12 is sleeved between the inner roller and the outer roller, a detachable sealing partition plate 15 is additionally installed in the inner roller, the round sealing ring 12 and the sealing partition plate 15 divide inside space of the double-layer roller into two small independent rollers, and different types of clothes are placed in the different small rollers to be washed. A plurality of cleaning balls 14 are placed in a gap of the double-layer roller and used for cleaning the barrel walls in the gap. The roller washing machine washing clothes separately can simultaneously and separately wash different types of clothes, is very good in dewatering effect, and cannot cause secondary pollution to washed clothes.

Owner:任文涛

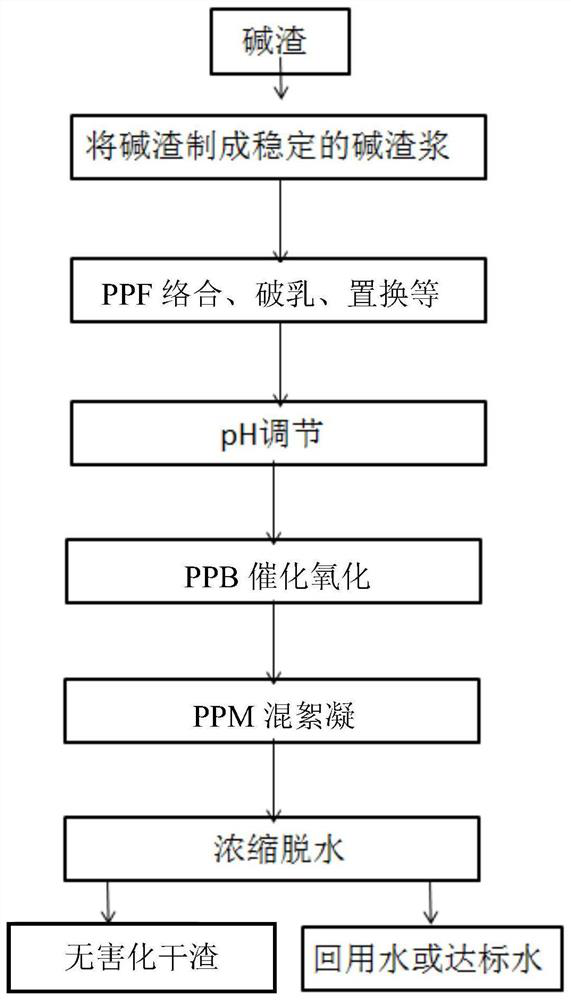

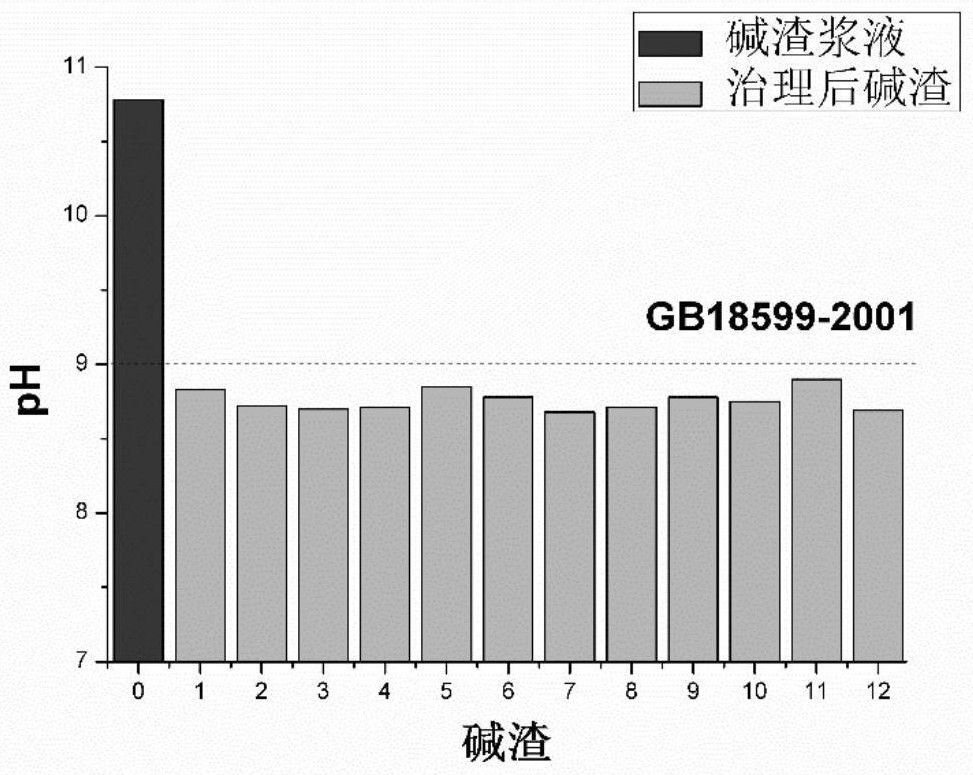

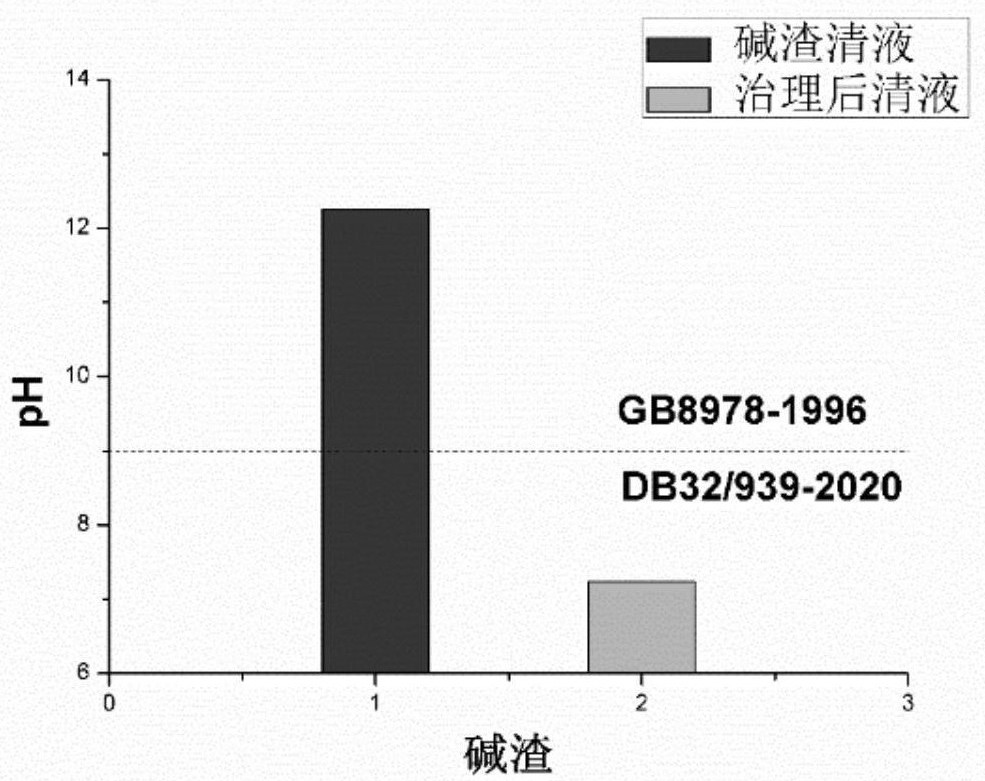

Harmless treatment and resource utilization method for alkaline residue of soda ash prepared by ammonia-alkali process

ActiveCN112546530AReduce corrosionGood dehydration effectChemical protectionIndustrial wasteSolvay process

The invention belongs to the technical field of comprehensive treatment of industrial waste, and particularly relates to a harmless treatment and resource utilization method for alkaline residue of soda ash prepared by ammonia-alkali process. Directed at the characteristics of high salinity, high ammonia nitrogen, high chloride ions, high viscosity and high moisture content of alkaline residue generated by soda ash preparation by an ammonia-alkali process, harmless and resourceful treatment is very difficult at present. The invention provides the harmless treatment method for alkaline residueof soda ash prepared by ammonia-alkali process, and the method comprises the following steps of: concentrating alkaline residue generated by soda ash prepared by the ammonia-alkali process and / or adding water to a mean value, sequentially adding a composite physicochemical treatment agent and a flocculating agent, and conducting concentrating and dehydrating to obtain treated harmless, reduced andrecycled alkaline residue and reuse water or standard water. The method is suitable for treating the alkaline residue generated in the process of preparing soda ash by the ammonia-alkali process, andparticularly aims at treatment and resource utilization of the alkaline residue with high alkalinity, high ammonia nitrogen, high salinity, high water content, high colloid property, high viscosity,much bound water and high hydrophilicity.

Owner:李开春 +1

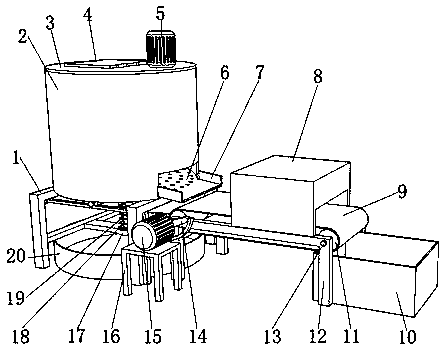

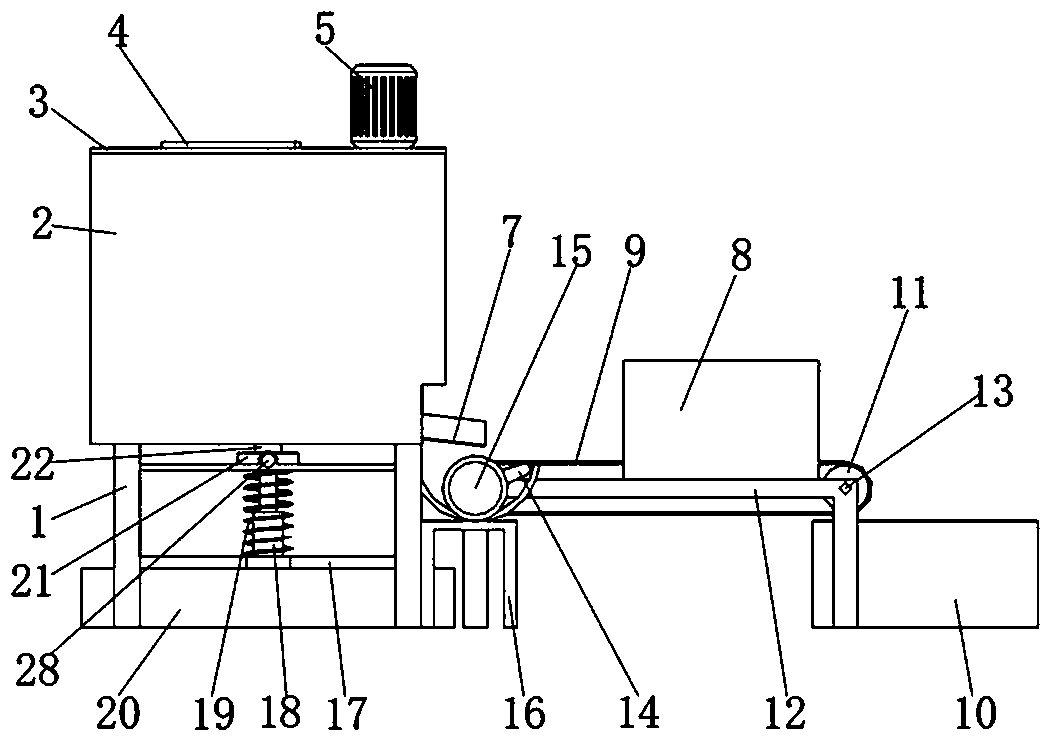

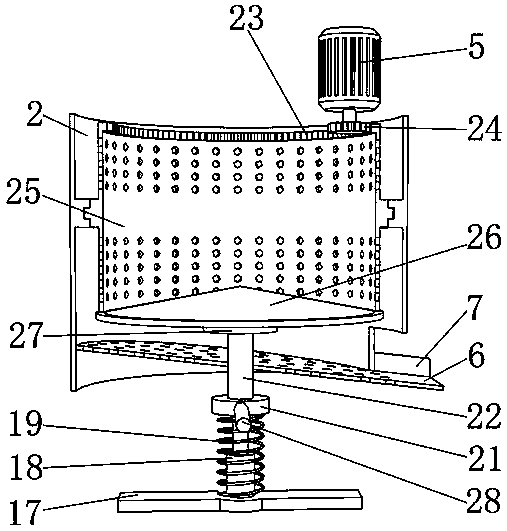

Blue-green algae dehydration device

InactiveCN108444255AEasy to operateGood dehydration effectDrying gas arrangementsWater/sewage treatmentFeeding tubeEngineering

The invention provides a blue-green algae dehydration device. The blue-green algae dehydration device comprises a box, wherein a loading box is fixedly welded to the upper side of the box; a feeding opening is formed in the upper side of the loading box; helical blades are arranged on the lower side of the feeding opening; a filtering plate is arranged below the helical blades; a liquid feeding tube is arranged in the left lower direction of the filtering plate; a stirring motor is arranged below the liquid feeding tube; the right side of the stirring motor is connected with a stirring shaft;stirring blades are welded to the surface of the stirring shaft; a feeding tube is mounted in the right side wall of the loading box in an embedded manner; a pressure plate is arranged in the right lower direction of the feeding tube; a filter pressing plate is arranged on the right side of the pressure plate, and is fixedly connected to the upper side of a vertical plate; a door panel is arrangedon the right side of the vertical plate; the right side of the door panel is connected with a magnet; the right side of the magnet is connected with a reset spring; and the right side of the reset spring is connected with an electromagnet. The blue-green algae dehydration device is simple in structure, reasonable in design and good in dehydration effect, and has quite high practicability.

Owner:杭州爵沸网络科技有限公司

Continuous dehydrating production process and device for nitro-cotton

InactiveCN101830987AGood dehydration effectSimple production processLow nitrogenContinuous production

The invention discloses a continuous dehydrating production process and a continuous dehydrating production device for nitro-cotton. The process comprises the following steps of: conveying hydrous nitro-cotton to a horizontal centrifugal defiberizer for the first dehydration defibering process by using a cotton-conveying pump, wherein the horizontal centrifugal defiberizer is that at least one defibering hook is arranged at the outlet end of a horizontal centrifuge, the defibering hook is that a hook head is arranged on the end part of a rod body, the tail end of the rod body is fixed on a shell of the centrifuge and the hook head extends inside a sieve; collecting the nitro-cotton output from a discharge outlet of the horizontal centrifugal defiberizer into a weak liquor container for stirring and alcoholizing; inputting the nitro-cotton output from the weak liquor container into a horizontal centrifugal defibering alcoholizing machine for alcoholizing and defibering; arranging an alcohol spraying pipe on the top of the shell of the centrifuge; and packaging the nitro-cotton prepared conventionally. Aiming at the nitro-cotton products, such as the nitro-cotton for L-type coatings with low nitrogen content and high hydrophilism, the nitro-cotton for celluloid and the like, which cannot be produced qualifiedly by the continuous production process, qualified products meeting the quality requirement can be manufactured by the process.

Owner:FUCHENG CHENGXIN CELLULOSE

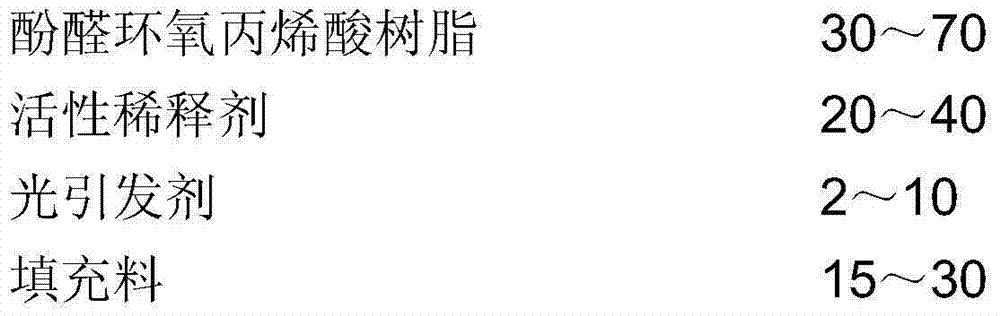

Acid resistance type protective ink and preparation method thereof

ActiveCN104845441AGood resistance to hydrofluoric acidGood dehydration effectInksHydrofluoric acidEpoxy

The invention discloses acid resistance type protective ink and a preparation method thereof. Phenolic epoxy acrylic resin which comprises a multi-reaction functional group and a hydrophilic group is synthesized, the screening of filling materials, a defoaming agent and other additives is integrated with the phenolic epoxy acrylic resin as a main body, and the acid resistance type protective ink with the good hydrofluoric acid resistance and the dehydration effect is prepared. According to the acid resistance type protective ink and the preparation method thereof, the superior adhesion is presented on OGS (One Glass Solution) touch screen glass, the time of the resistance to the 20% of hydrofluoric acid can reach more than 30 minutes, the film stripping can be achieved through the ordinary hot water, the harm to the glass is not produced, a protective film falls off in a flaked mode during film stripping, the filtration and the separation are easy, the degree of automation of the process is high, and the safe and environment-friendly effect is achieved.

Owner:国科广化(南雄)新材料研究院有限公司 +1

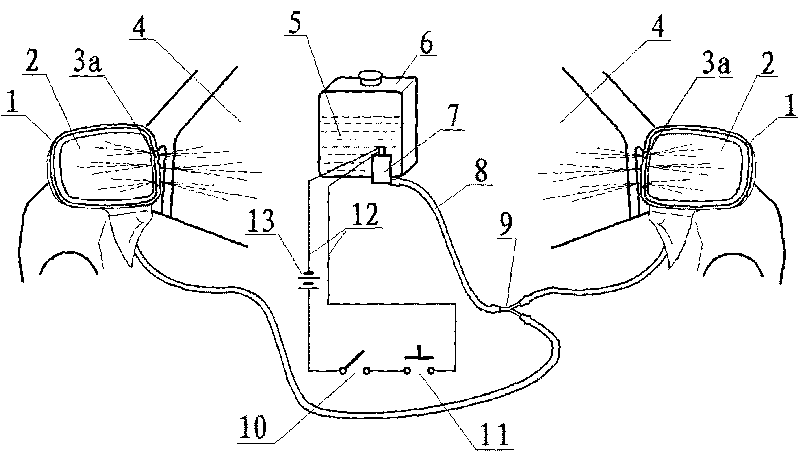

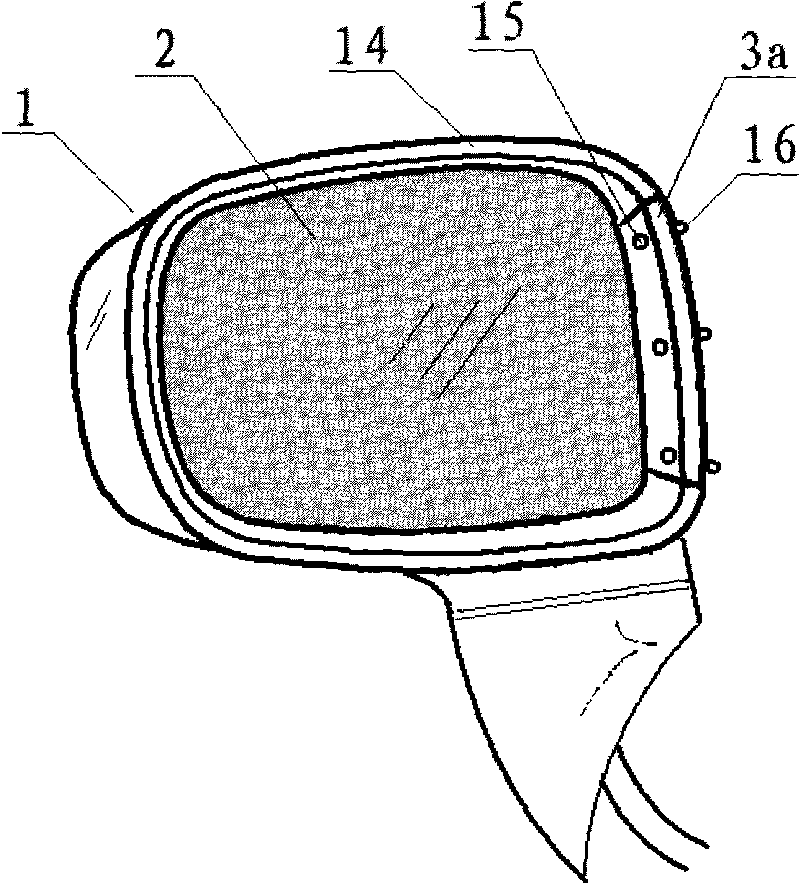

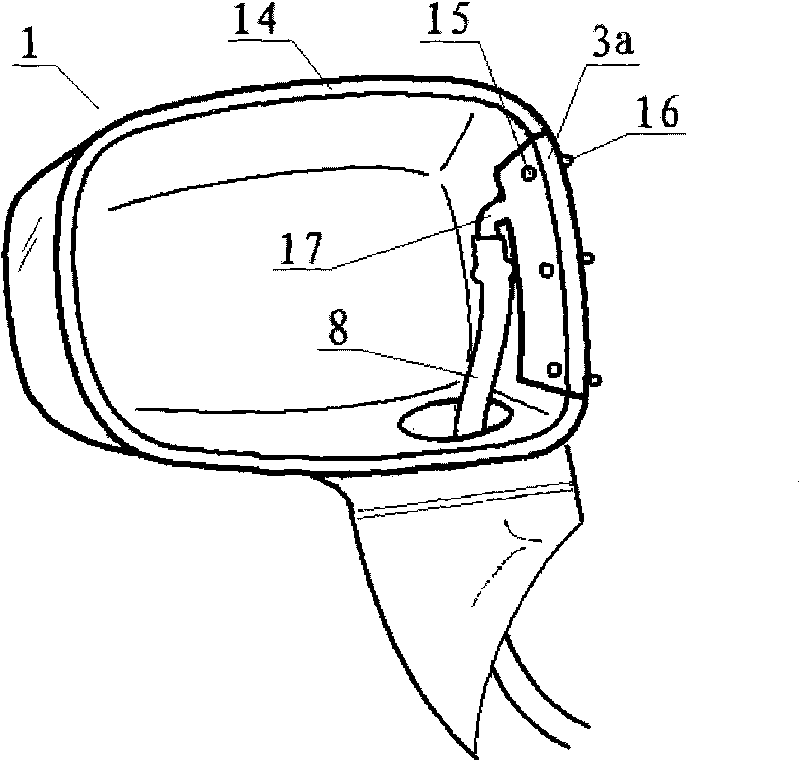

Bead elimination scheme of vehicle rearview mirror and vehicle window glass

The invention relates to a bead elimination scheme of a vehicle rearview mirror and vehicle window glass, wherein a hydrophilic washing liquid which is rich in a surfactant, has good water affinity and can markedly reduce the interfacial tension of water is used for eliminating beads, a spray device is formed by adding a washing pump, a water pipe, a cable, a spray head and a control switch to a traditional washer kettle on a vehicle, the spray head is arranged on a rearview mirror and / or a vehicle window decorative cover plate, the appearance problem of the spray head is solved through an inlaid or built-in mode, and the hydrophilic liquid is simultaneously sprayed on the rearview mirror and the vehicle window glass to immediately eliminate the beads and keep no sticking of the beads within a period of time.

Owner:何启航

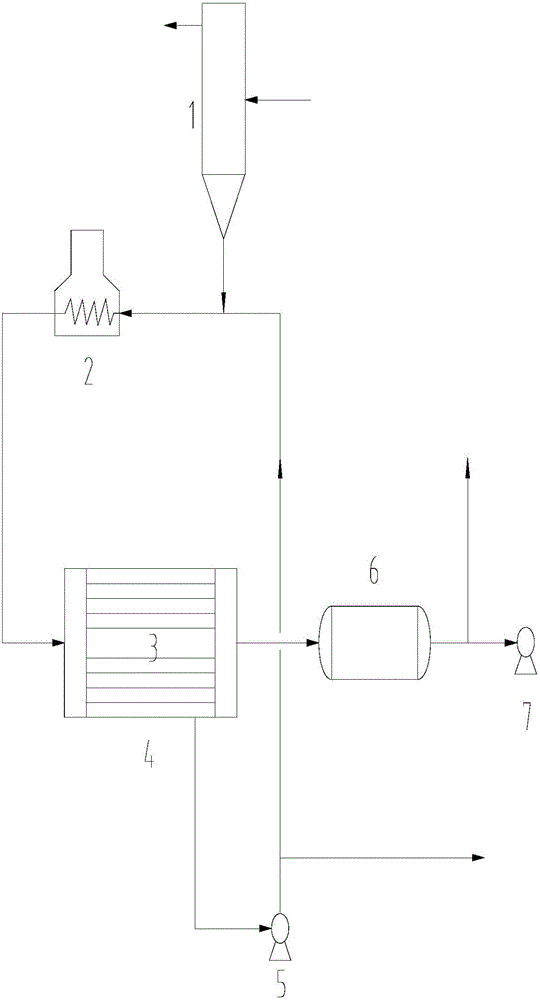

Coke tar distillation process

InactiveCN107699266AReduce usageGood dehydration effectTar working-up by water removalTar working-up by distillationTarElectric field

The invention discloses a coke tar distillation process. The coke tar distillation process comprises the following steps: (1) mixing raw material coke tar with a dehydrating agent, heating the mixture, carrying out dehydrating treatment under the condition that the electric field intensity is 2,000-3,000 V / cm for 60-75 min, and removing liquid supernatant after layering to obtain dehydrated coke tar; (2) placing the dehydrated coke tar in a 1# distillation tower, carrying out distillation under the condition of normal pressure, removing light oil distillate, then heating, producing carbolic oil fraction on the top of the tower, and cutting naphthalene oil fraction on a side line; and (3) heating mixed oil obtained from the bottom of the 1# distillation tower via a tubular heating furnace,then feeding the mixed oil into a 2# distillation tower, producing heavy scrubbing oil fraction on the top of the tower under the condition of reduced pressure, cutting first anthracene oil fraction and second anthracene oil fraction from a side line, and producing medium-temperature pitch from the bottom of the tower. The distillation process is good in dehydrating effect, simple to operate and low in cost, is energy-saving and environmentally friendly, and is suitable for large-scale coke tar processing engineering.

Owner:CHENGDU ARITIME INTELLIGENT CONTROL

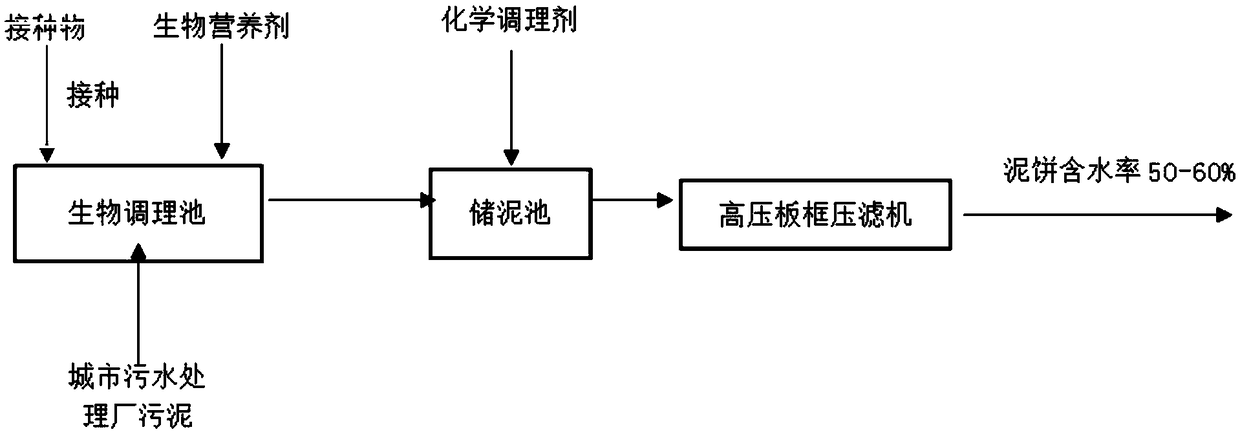

Method for improving dewatering property of sludge by biological conditioning

ActiveCN108706848AGood dehydration effectSignificant volume lossSludge treatment by de-watering/drying/thickeningWater treatment compoundsContinuous flowChemistry

The invention discloses a method for improving the dewatering property of sludge by biological conditioning. In the method, the effect of compound biological florae is utilized for reducing the content of sludge extracellular polymers and the sludge viscidity and accelerating the endogenous digestion of the sludge, so that the dewatering property of the sludge is greatly improved, and the moisturecontent of the sludge is reduced to 60% or below after the conditioned sludge is subjected to high-pressure plate-frame pressure filtration. The method includes the steps that the sewage of an urbansewage treatment plant is taken, an inoculum and a biological nutritional agent are added, the mixture is introduced into a biological conditioning tank in a continuous flow manner and is continuouslystirred, then the sludge is discharged into a sewage storage tank, a chemical conditioning agent is added according to a conventional conditioning method, and the mixture is conveyed to a high-pressure plate-frame filter press for pressure filtration treatment. The method is high in dewatering rate, low in operation cost and easy to operate and provides a new technical choice for low-cost and high-efficiency dewatering of the sewage treatment plant.

Owner:SHANGHAI JIAO TONG UNIV

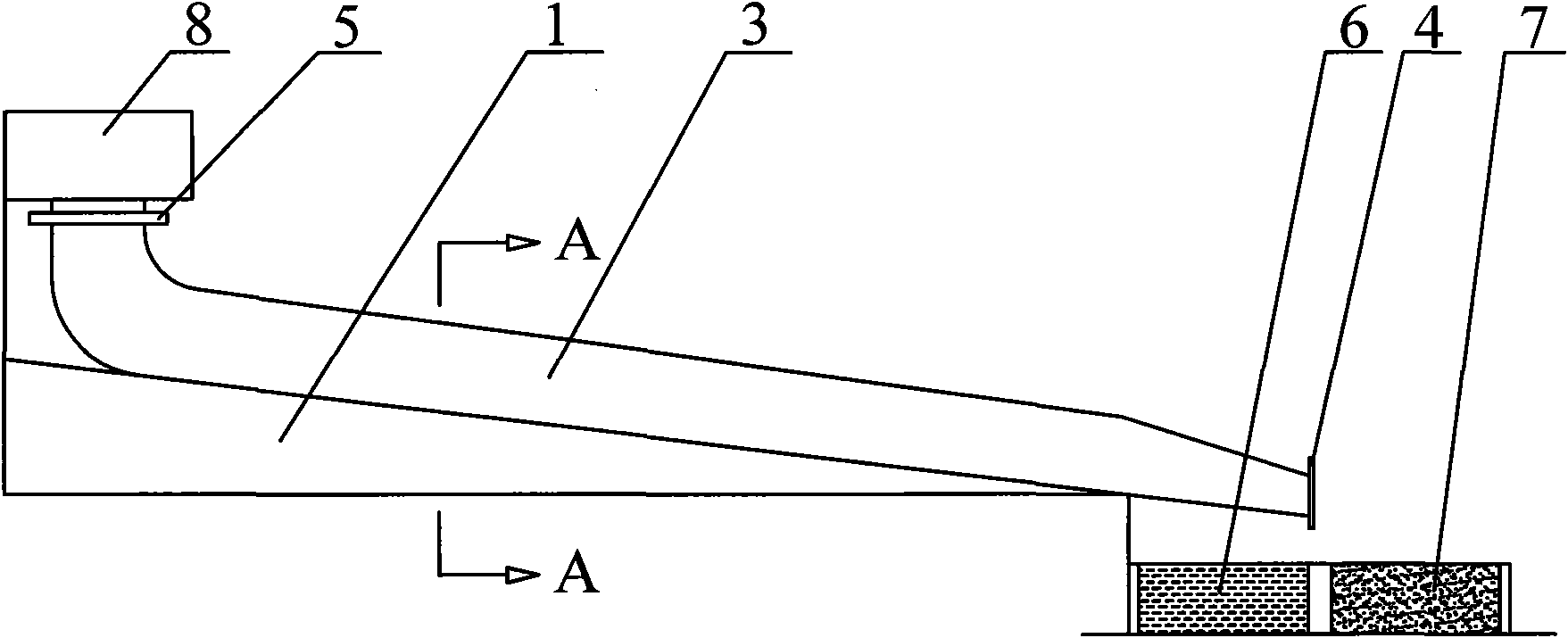

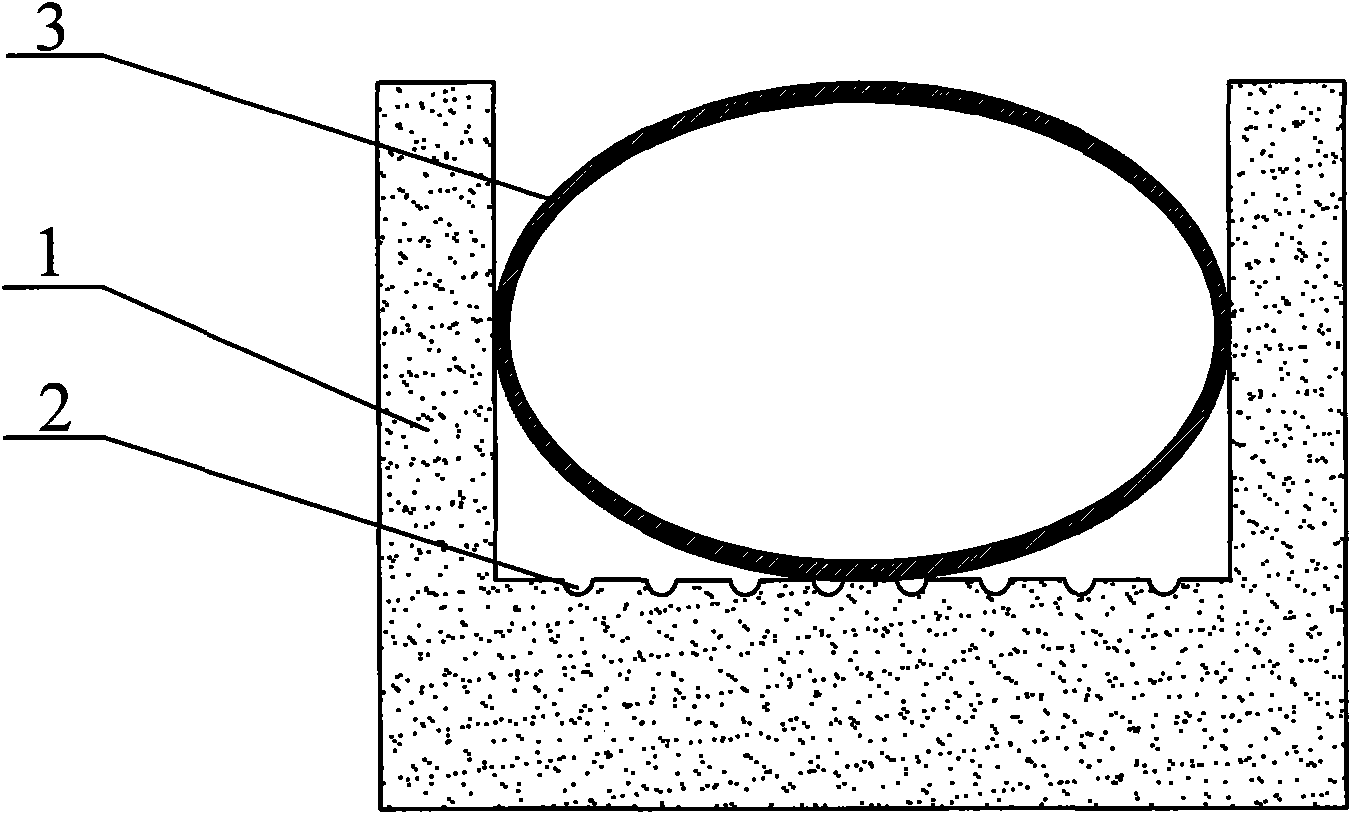

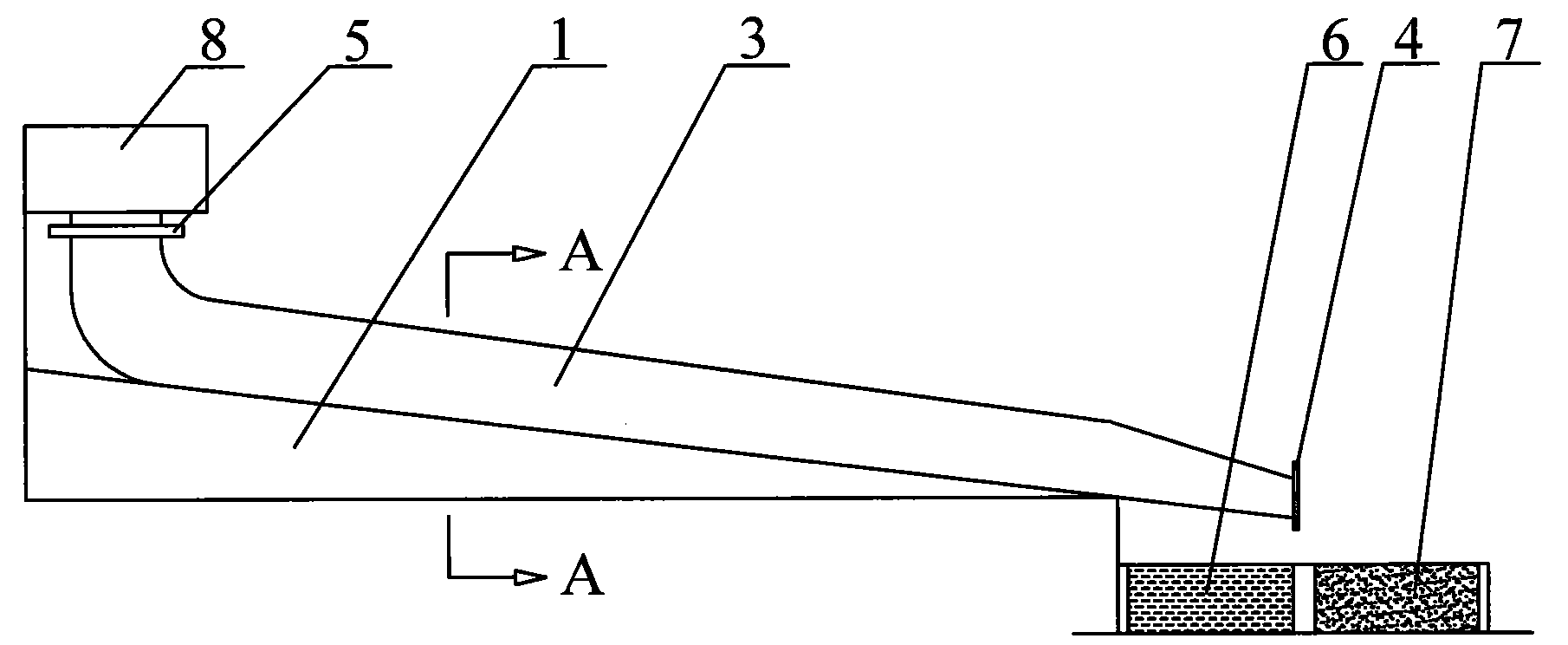

Unpowered sludge dehydration device

InactiveCN101774744AGood dehydration effectSimple structureSludge treatment by de-watering/drying/thickeningSlagWater storage tank

The invention relates to an unpowered sludge dehydration device, comprising a fluid bath arranged on the upper surface of the tank bottom of a dehydration tank; wherein the upper surface of the tank bottom of the dehydration tank is obliquely arranged with the horizontal plane, a dehydration woven bag is arranged on the upper surface of the tank body of the dehydration tank, the length direction of the dehydration woven bag is the same as the length direction of the dehydration tank, an outlet end of the dehydration woven bag stretches out of the dehydration tank and the inlet height of the dehydration woven bag is higher than the outlet height of the dehydration woven bag; the inlet end of the dehydration woven bag is arranged above a high end of the dehydration tank, a tying belt is arranged at the outlet of the dehydration woven bag and a water storage tank and a slag storage tank are arranged at the outside of a low end of the dehydration tank; wherein the distance between the water storage tank and the low end of the dehydration tank is smaller than the distance between the slag storage tank and the low end of the dehydration tank. After being installed, the unpowered sludge dehydration device can automatically carry out dehydration without external power, features good dehydration effect, simple structure, small volume, low manufacturing cost and conservation of massive funds and energy.

Owner:无锡光初科技服务有限公司

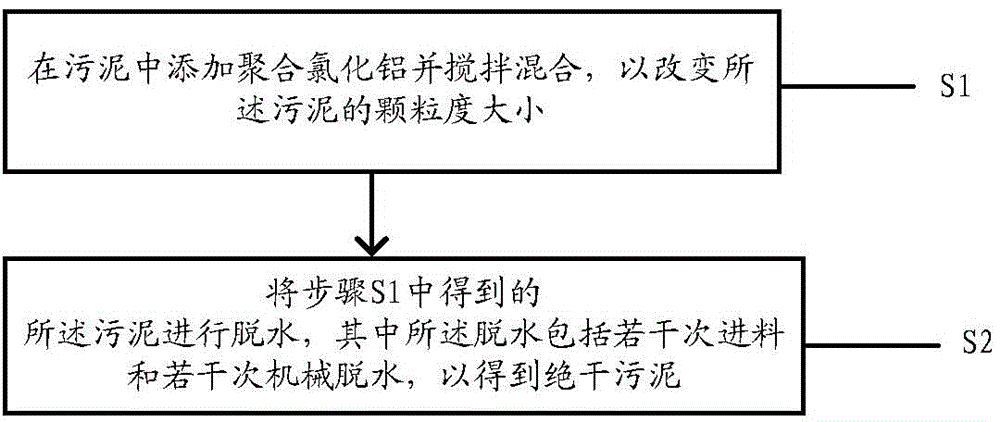

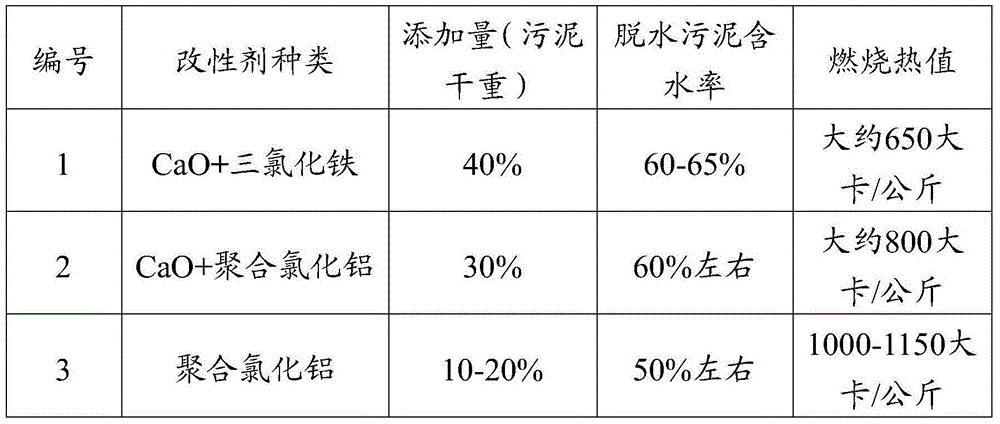

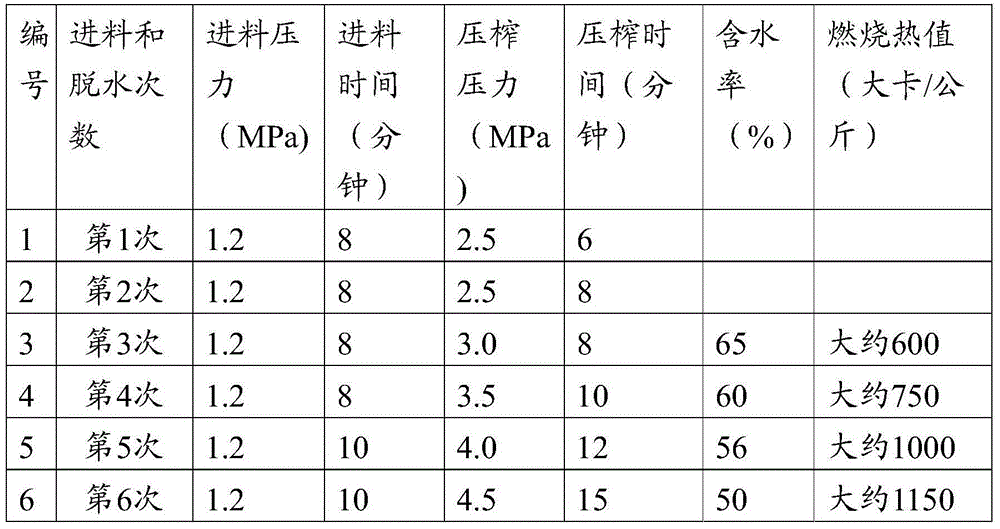

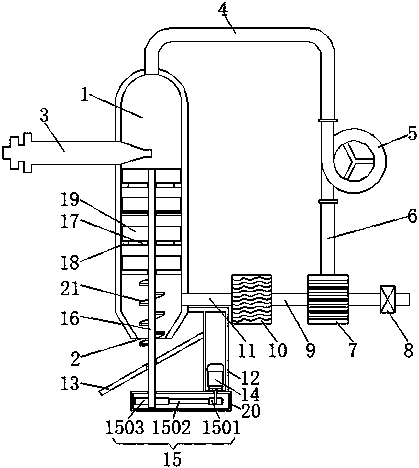

Sludge treatment method

ActiveCN104556621ASimple processGood dehydration effectSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesWater contentChemistry

The invention provides a sludge treatment method. The method comprises the following steps: step one, adding polychloride aluminum in the sludge, stirring and mixing to change the granularity size of the sludge; and step two, dehydrating the sludge obtained in the S1, wherein the dehydrating comprises repeatedly feeding materials and repeatedly mechanically dehydrating so as to obtain the dehydrated sludge. The method provided by the invention has the effect that the sludge with water content of 80% can be dehydrated to about 50% through the mode of adding less medicaments and using a high-pressure plate frame, the process is simple, and the dehydrating effect is good. Furthermore, the dosage of a conditioner is greatly reduced, especially the lime is unnecessary, the heat value of the sludge cannot be influenced, and the dehydrated sludge has high heat value, and is especially suitable for incineration disposition.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD +2

Centrifugal dewatering and drying integrated machine

PendingCN109970308AGood dispersionIncrease moisture contentSludge treatment by de-watering/drying/thickeningWaste heat recovery unitPulp and paper industry

The invention discloses a centrifugal dewatering and drying integrated machine, and relates to the technical field of dehydration and drying devices. The centrifugal dewatering and drying integrated machine comprises a tank body, a discharging outlet is formed in the bottom of the tank body, a centrifugal dewatering machine is arranged on the lateral surface of the tank body, the top of the tank body is provided with a steam collecting pipe, and a steam outlet end of the steam collecting pipe is fixedly connected with an air inlet end of a negative pressure blower. An air outlet end of the negative pressure blower is fixedly connected with an air inlet end of a round pipe, an air outlet end of the round pipe is fixedly connected with an air inlet end of a waste heat recovery device, the other air inlet end of the waste heat recovery device is provided with a control valve, and an air outlet end of the waste heat recovery device is fixedly connected with an air inlet end of a heating device through a first connecting pipe. By arranging the negative air blower, the waste heat recovery device, a motor, a disc and a sludge scraping plate, the problem that an existing sludge treatment device is poor in sludge dewatering and drying effect is solved.

Owner:厦门鹭昆机电设备有限公司

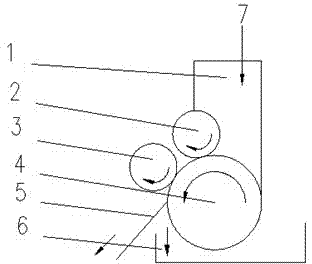

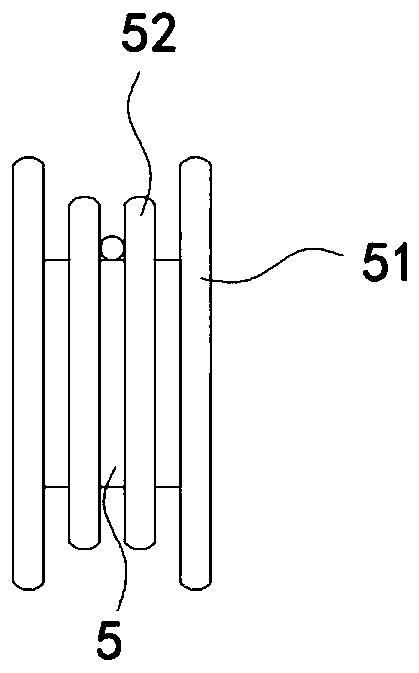

Green-quality resource solid-liquid separation equipment and feed producing method

InactiveCN103879009AGood solid-liquid separation effectGood dehydration effectFeeding-stuffAnimal feeding stuffAgricultural engineeringAgricultural science

A set of green-quality resource solid-liquid separation equipment comprises a first pressing roller, a second pressing roller and a third pressing roller, wherein a feeding port is formed in the first pressing roller; the second pressing roller and the third pressing roller are sequentially arranged in the rotating direction of the first pressing roller, both the second pressing roller and the third pressing roller are meshed with the first pressing roller, the gap between the second pressing roller and the first pressing roller is larger than the gap between the third pressing roller and the first pressing roller, and the diameter of the first pressing roller is larger than that of the second pressing roller and that of the third pressing roller. The diameter of the first pressing roller is large, so that the rotating speed of the first pressing roller is low, liquid pressed out of forage freely falls into a liquid collecting groove under the action of gravity, the forage with liquid removed falls outside the liquid collecting groove through a scraper blade, and therefore solid and liquid separation can be automatically completed. Besides, because the gap between the second pressing roller and the first pressing roller is larger than the gap between the third pressing roller and the first pressing roller, the feeding effect is good, the forage is roughly and fine pressed, the solid and liquid separation effect is better, the dehydration effect is better, and the equipment is simple in structure, convenient to move and suitable for all-weather operation.

Owner:云南绿博生物产业有限公司

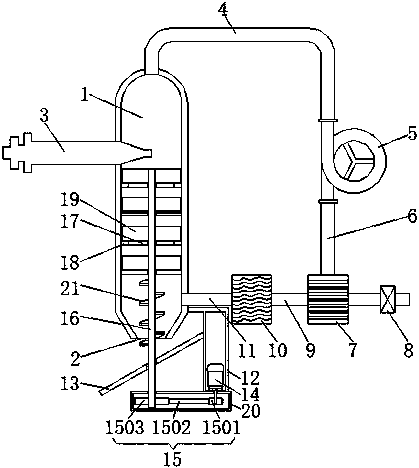

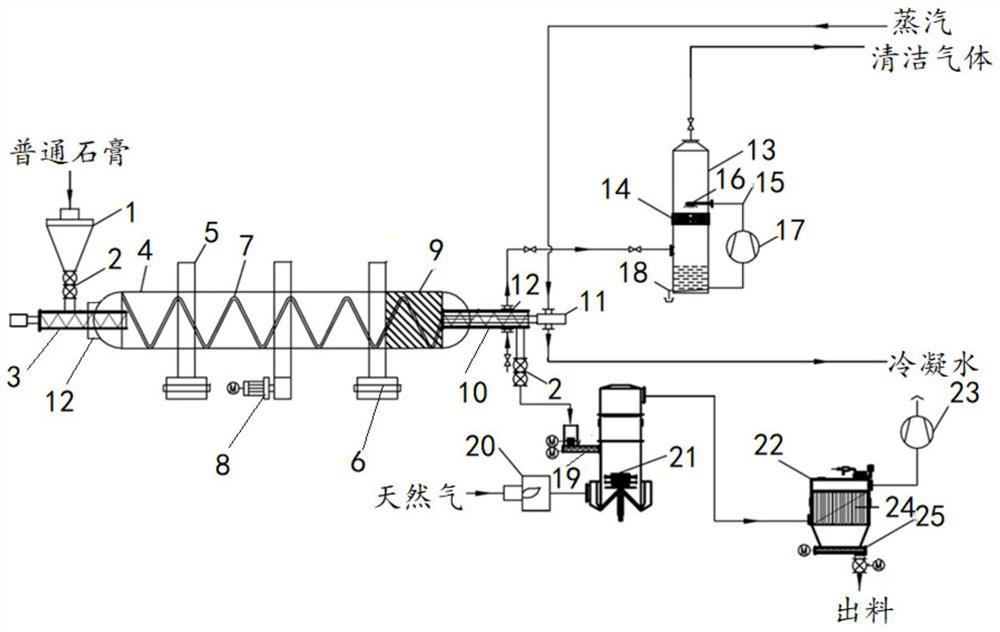

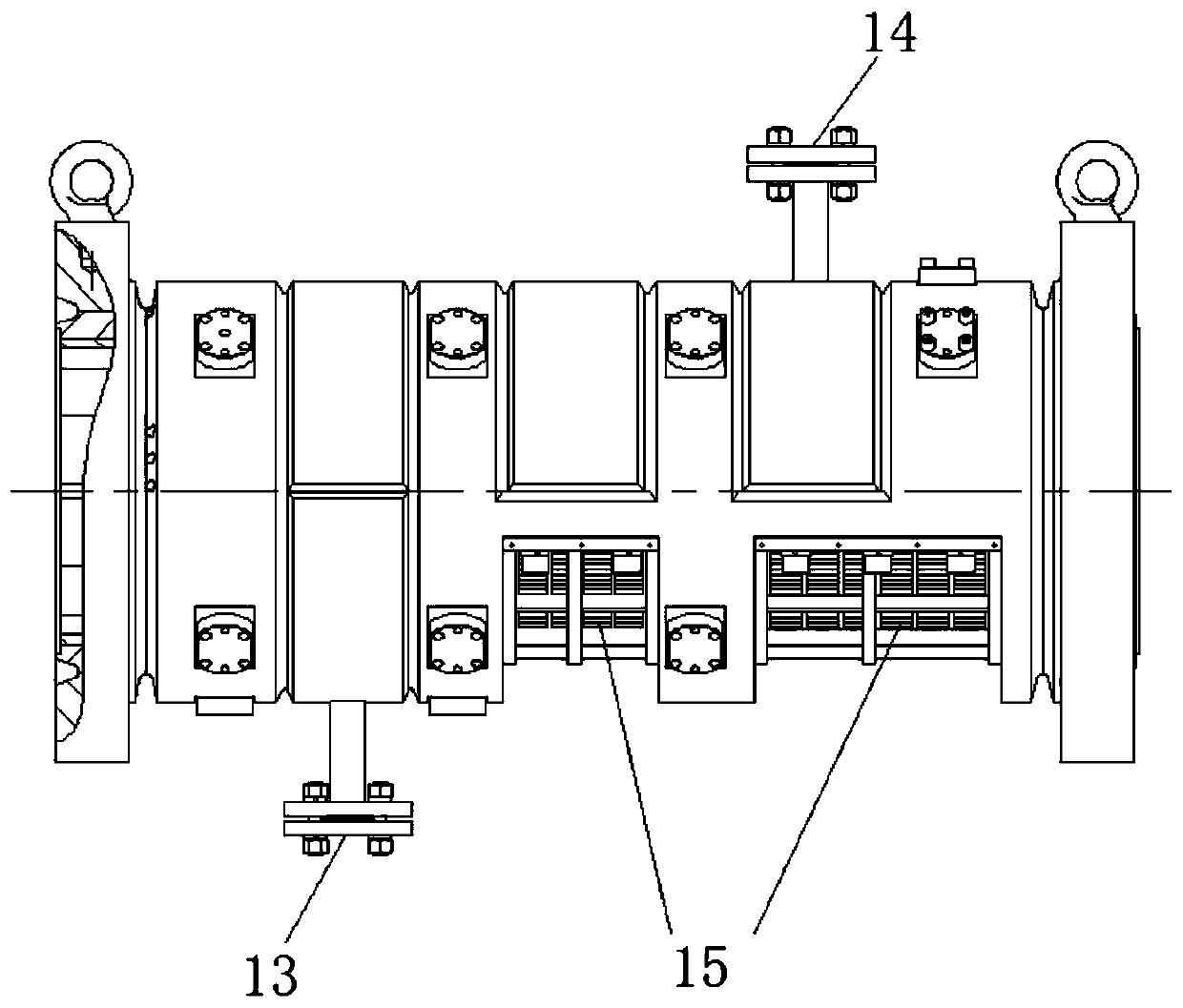

Horizontal continuous crystal transformation device, system and method for preparing high-strength gypsum

The invention discloses a horizontal continuous crystal transformation device, system and method for preparing high-strength gypsum, and the device comprises a horizontal crystal transformation cylinder, and the two ends of the horizontal crystal transformation cylinder are respectively connected with a feed conveying screw and a spiral guide device through high-pressure dynamic and static seals. A feed port of the feed conveying screw and a discharge port of the spiral guide device are respectively connected with a pressure-maintaining discharge valve; a spiral steam pipe is arranged in the horizontal crystal transformation cylinder, and the materials can be subjected to crystal phase transformation under the conditions of continuous feeding and discharging of the materials and pressure maintaining by controlling the steam temperature. Through the pressure-maintaining discharge valve and the high-pressure dynamic and static seal, the barrel can enable materials to continuously enter and exit while the materials are subjected to crystal transformation.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

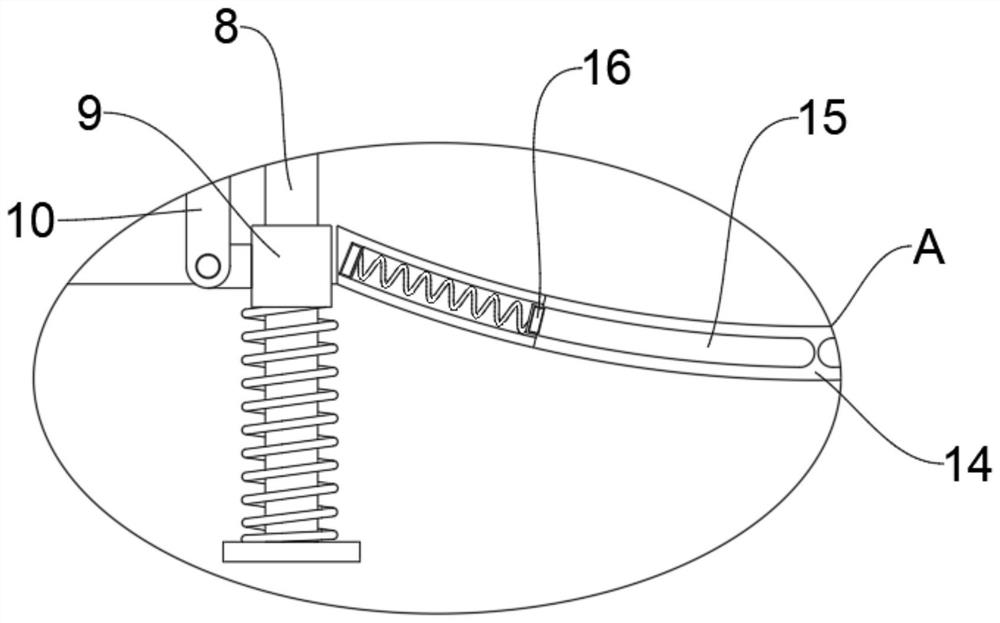

Mop dehydrating device

InactiveCN102934977AGood dehydration effectDehydration fastCarpet cleanersFloor cleanersMechanical engineeringEngineering

Owner:李建美

Coal tar dehydration method and coal tar dehydration device

ActiveCN105778964AGood dehydration effectHigh separation factorTar working-up by water removalWater contentChemistry

The invention relates to a coal tar dehydration method and a coal tar dehydration device, and belongs to the technical field of coal tar dehydration. The coal tar dehydration method comprises the following steps: preheating crude coal tar to be 80 to 90 DEG C, and performing membrane separation, wherein membrane separation is implemented by performing vacuumizing on the osmosis side of a separation membrane to osmose and evaporate water in the crude coal tar to the osmosis side of the separation membrane to obtain dehydrated coal tar on the osmosis residual side. According to the coal tar dehydration method, a separation process is high in separation coefficient, and has good separation effects, and the water content of the coal tar can be reduced to be 0.1 percent or lower; distillation is avoided in the separation process, so that energy consumption is greatly reduced; the method is easy to operate and lower in cost; moreover, an operating condition is mild, and introduction of a third component is avoided to achieve environment friendliness.

Owner:ZHENGZHOU SIWEI SPECIAL MATERIALS CO LTD

Textile processing and dewatering device

InactiveCN108826892AGood dehydration effectImprove dehydration effectDrying chambers/containersDrying machines with non-progressive movementsEngineeringTextile processing

The invention discloses a textile processing and dewatering device. The device comprises a dewatering shell, wherein a rotating device is arranged at the bottom of the inner side of the dewatering shell; the rotating device comprises a first supporting column and a second supporting column which are symmetrically arranged, and a first mounting plate and a second mounting plate are correspondinglyarranged on one sides, close to each other, of the first supporting column and the second supporting column; a mounting ring is arranged between the first mounting plate and the second mounting plate,a threaded sleeve is arranged in the middle of the outer surface of the mounting ring, and the threaded sleeve is fixedly connected to the mounting ring; the threaded sleeve is sleeved with a rotating disc which is in threaded connection with the threaded sleeve, one side of the second supporting column is provided with a first motor, and the top of the first motor is provided with a first screwrod; and the first motor is in transmission connection with a first gear through the first screw rod, and the first gear and the rotating disc are in transmission connection through a belt. The devicehas the beneficial effects that the dewatering effect of textile articles is better.

Owner:芜湖瀚德信息科技有限公司

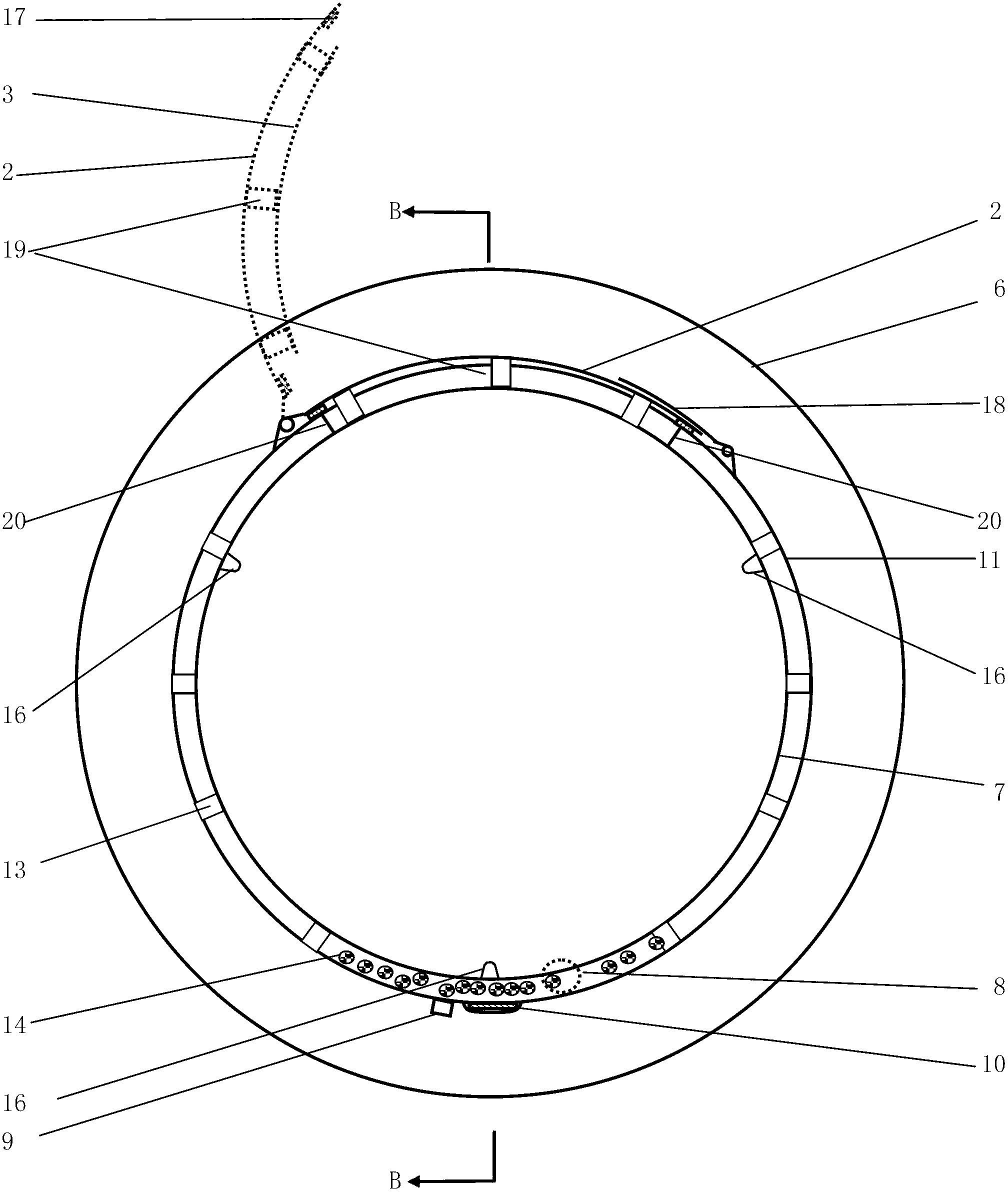

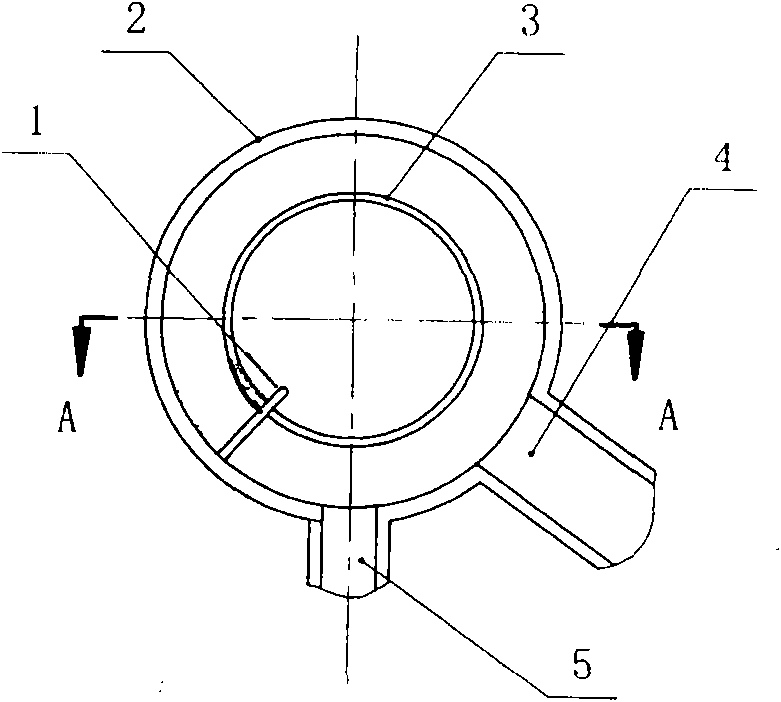

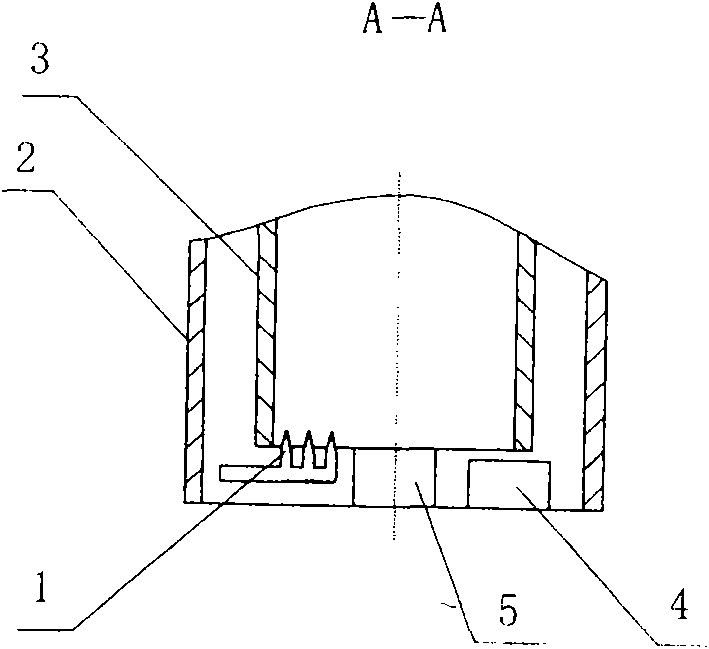

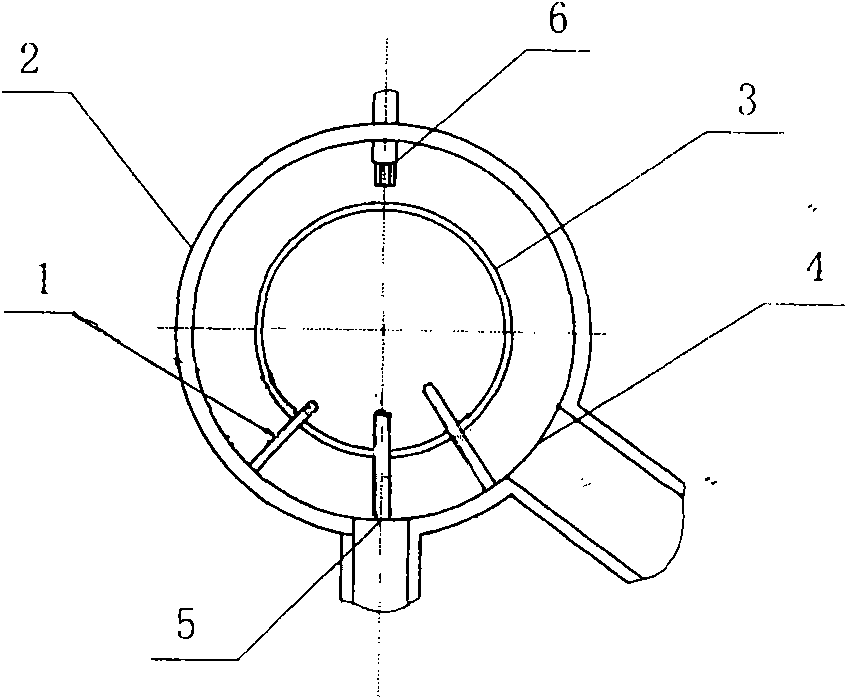

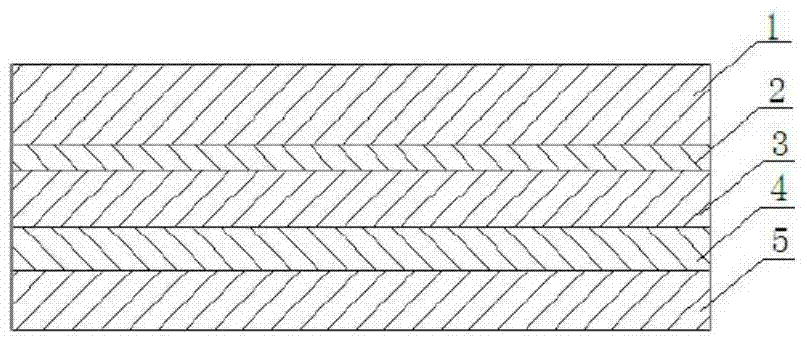

Washing machine and water retaining ring thereof

ActiveCN107059342APrevent throwingGood washingOther washing machinesTextiles and paperLow speedEngineering

The invention relates to a washing machine and a water retaining ring thereof. The water retaining ring comprises a ring body and a drainage portion, the ring body is provided with a first end and a second end, the inner diameter of the ring body is gradually enlarged from the middle of the ring body to the first end and the second end, the drainage portion is connected with the first end of the ring body and the wall of a small barrel and provided with a drainage hole, the water retaining ring is placed on the wall of the small barrel close to a barrel port, so that the outer side of the port of the small barrel is retained by the water retaining ring, the height of the small barrel limiting clothes is increased, water cannot thrown by the water retaining ring when the small barrel rotates at the low speed, throwing of the clothes can be effectively prevented as the middle inner diameter of the water retaining ring is small when the small barrel rotates at the high speed, water can be drained along the drainage hole, and drainage efficiency is effectively improved, so that washing and dewatering effects of the small barrel are better.

Owner:TCL HOME APPLIANCES (HEFEI) CO LTD

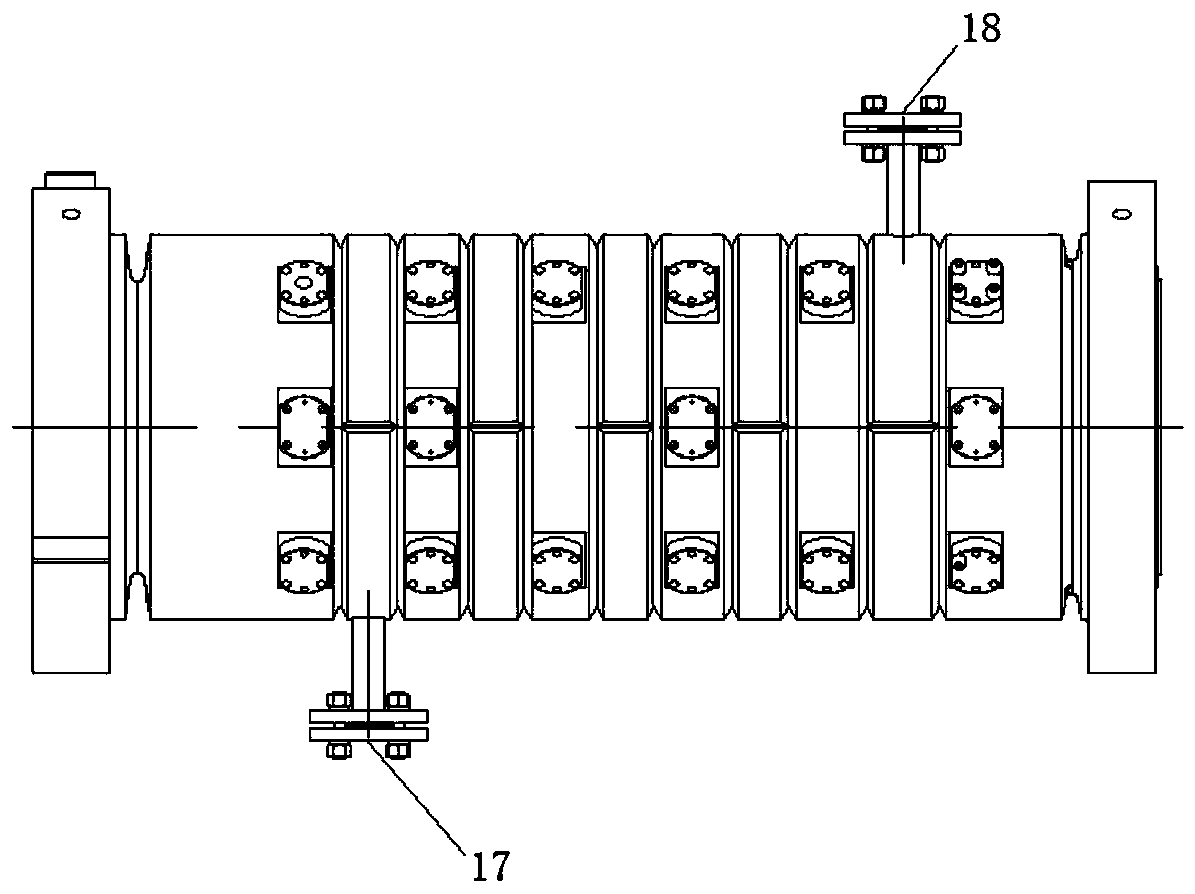

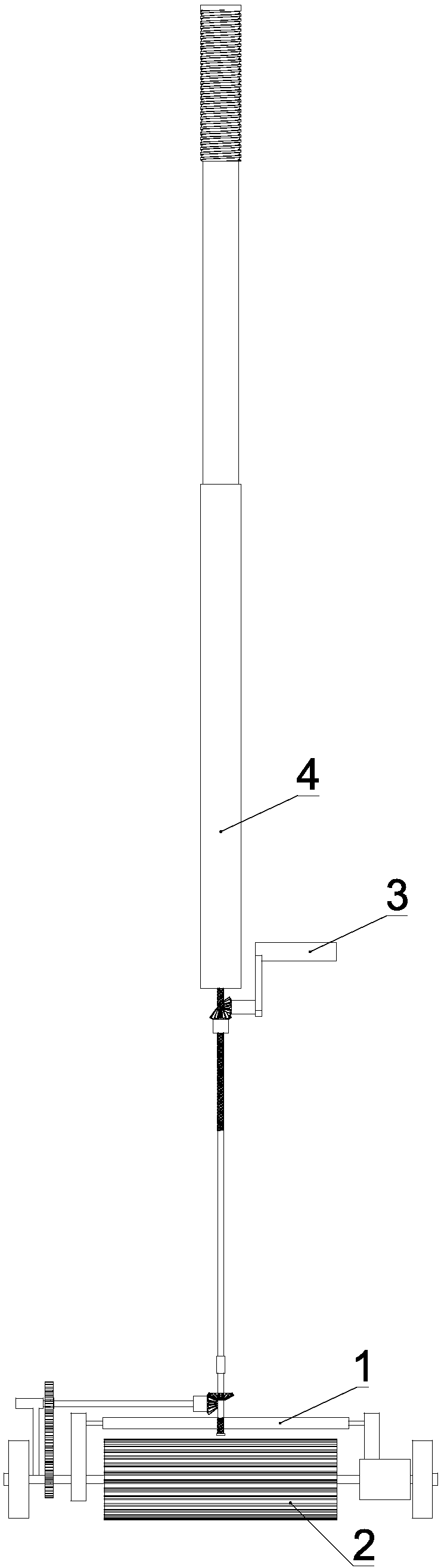

Natural rubber extrusion, dehydration, expansion and drying all-in-one machine

PendingCN111267261AGood dehydration effectImprove heating efficiencyDrying solid materials without heatHeating arrangementNatural rubberMechanical engineering

The invention discloses a natural rubber extrusion, dehydration, expansion and drying all-in-one machine, and is applied to the field of natural rubber production. The natural rubber extrusion, dehydration, expansion and drying all-in-one machine comprises a screw rod connected with a main motor, the screw rod sequentially penetrates through a charging cylinder, a cone machine cylinder and a straight machine cylinder and then is connected to the inner side of a template, and a cutting mechanism is arranged on the outer side of the template; a first water leakage sieve is arranged at the bottomend of the charging cylinder; a second water leakage sieve is arranged at the bottom end of the cone machine cylinder; the straight machine cylinder is formed by connecting a first straight machine cylinder and a second straight machine cylinder; a third water leakage sieve is arranged at the bottom of the first straight machine cylinder; a first temperature measuring screw, a first heat conduction oil outlet and a first heat conduction oil inlet are arranged on the first straight machine cylinder, and the first heat conduction oil outlet is in communication with the first heat conduction oilinlet through a first heat conduction oil channel; the second straight machine cylinder is provided with a second temperature measuring screw, a second heat conduction oil outlet and a second heat conduction oil inlet, and the second heat conduction oil outlet in communication with the second heat conduction oil inlet through a second heat conduction oil channel. Compared with the prior art, theall-in-one machine has the advantage that the temperature of the natural rubber treatment process can be better controlled.

Owner:DALIAN TIANSHENG GENERAL MACHINERY

Efficient washing equipment for textile thread materials

ActiveCN110541263AImprove automationEasy to cleanTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationEngineeringTextile

The invention belongs to the technical field of textile equipment, and particularly relates to efficient washing equipment for textile thread materials. The equipment comprises a box body, a thread inlet and a thread outlet are respectively formed in the two side walls of the box body, and a turntable and a pushing roller are rotatably connected with the inner side wall of the box body; a thread penetrating tube is fixedly connected with the surface of the turntable, the thread penetrating tube is arranged to be conical, and openings are formed in the two ends of the thread penetrating tube; the surface of the turntable is rotatably connected with a fixed pulley, the thread penetrating tube and the fixed pulley are symmetrically arranged on the turntable, a motor is fixedly installed on the side wall of the box body, and an output shaft of the motor penetrates through the side wall of the box body and extends into the box body. According to the efficient washing equipment, the turntable and the pushing roller can be driven by the motor to cooperatively rotate, segment-by-segment conveying of linen threads is achieved, and the automation degree is high; the linen threads are washedby an air bag and a washing brush, the washing effect is good, the linen threads are stirred by arranging stirring pieces, water on the linen threads can be quickly removed through vibration, and thework efficiency is improved.

Owner:安徽东至双江纺织有限公司

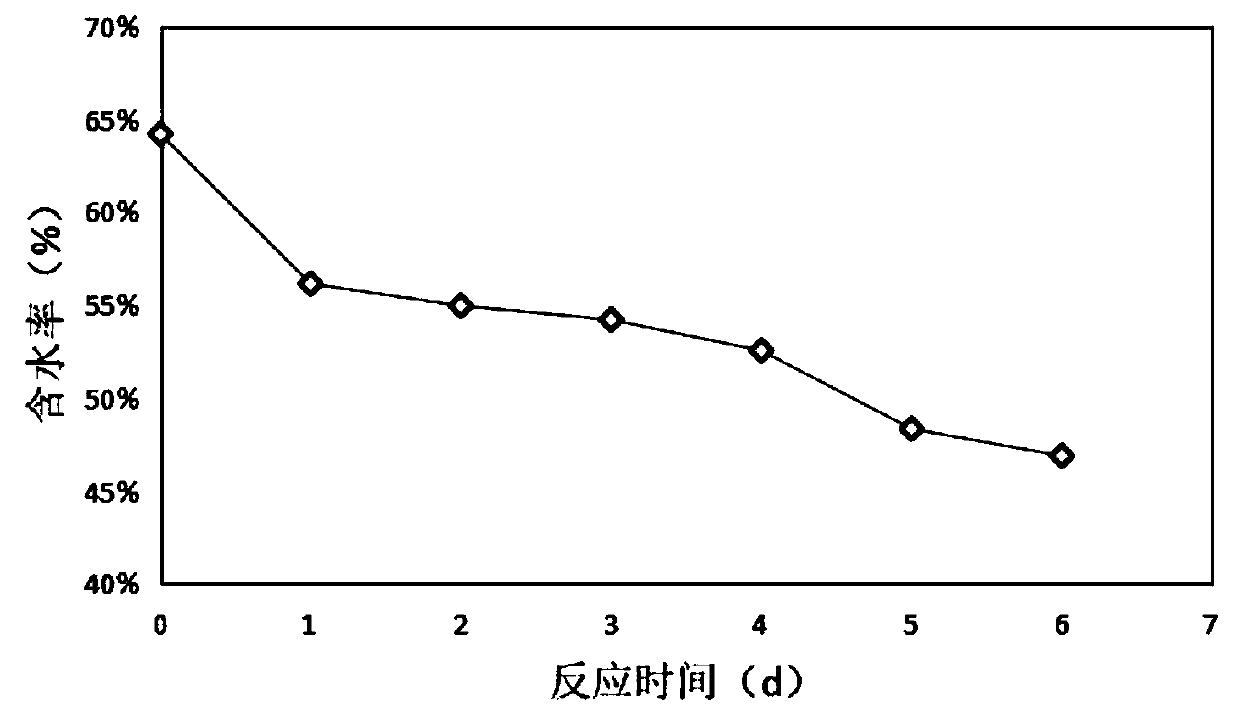

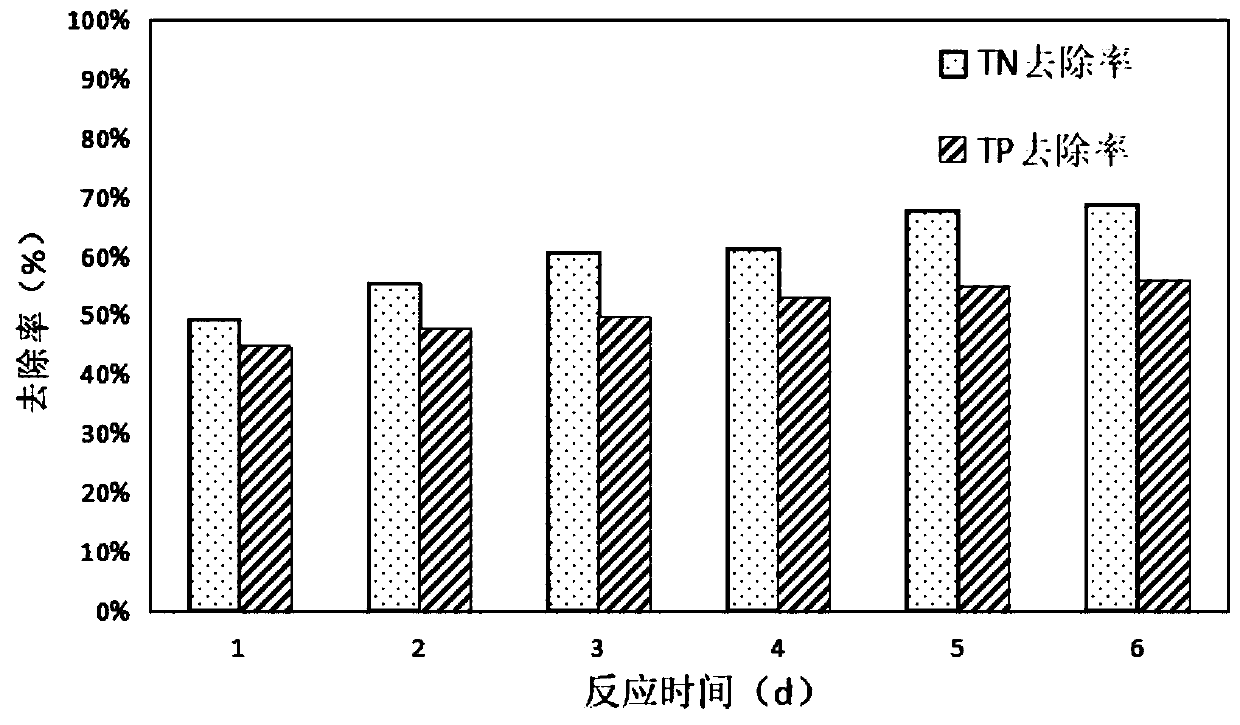

Method for treatment of sediment in black-odor water body

PendingCN110054382AReduce moisture contentGood dehydration effectSludge treatment by oxidationWater contaminantsTotal phosphorusChemistry

The invention provides a method for treatment of sediment in the black-odor water body. The moisture content of the sediment can be reduced remarkably by improving types and proportion of key reagentsadded to the sediment, and the total nitrogen (TN) and total phosphorus (TP) in the sediment can be effectively removed. The method includes the steps of 1), laying flat the sediment in the black-odor water body, discharging overlaying water and removing impurities prior to mixing evenly; 2), adding persulfate and a hydrogen peroxide solution to the evenly mixed sediment prior by turning in sunlight and mixing, and effectively treating the sediment in the black-odor water body after reaction under natural conditions.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

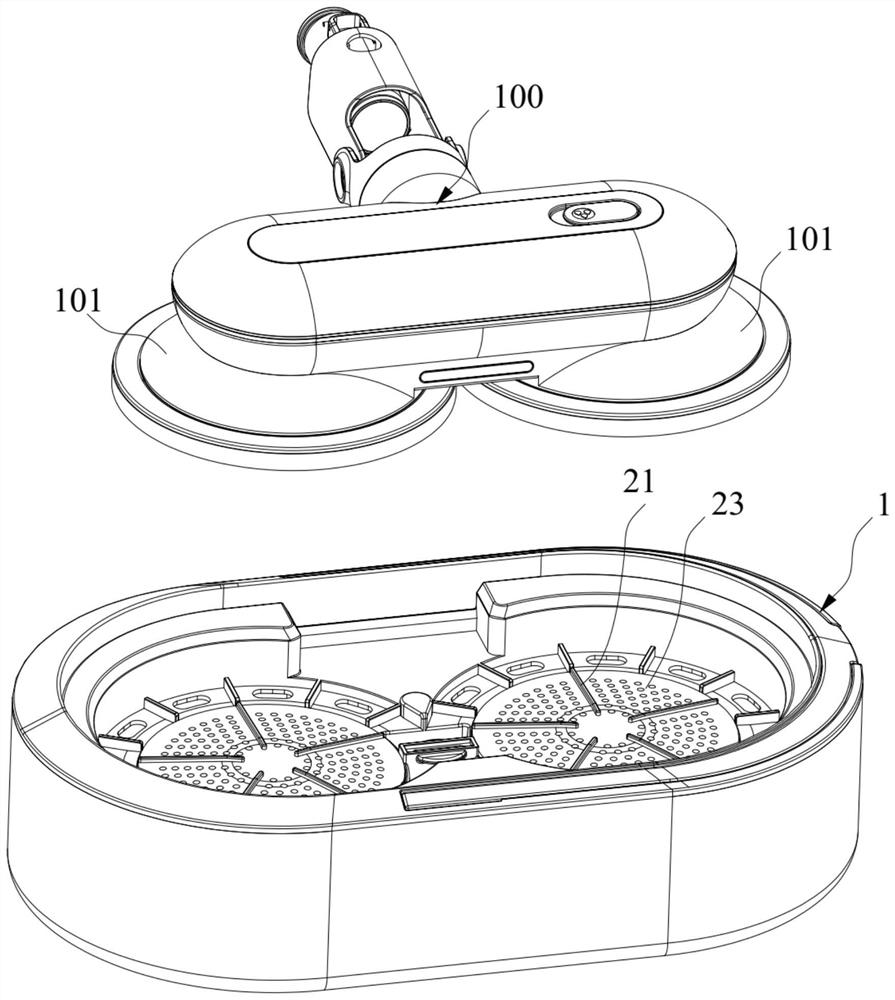

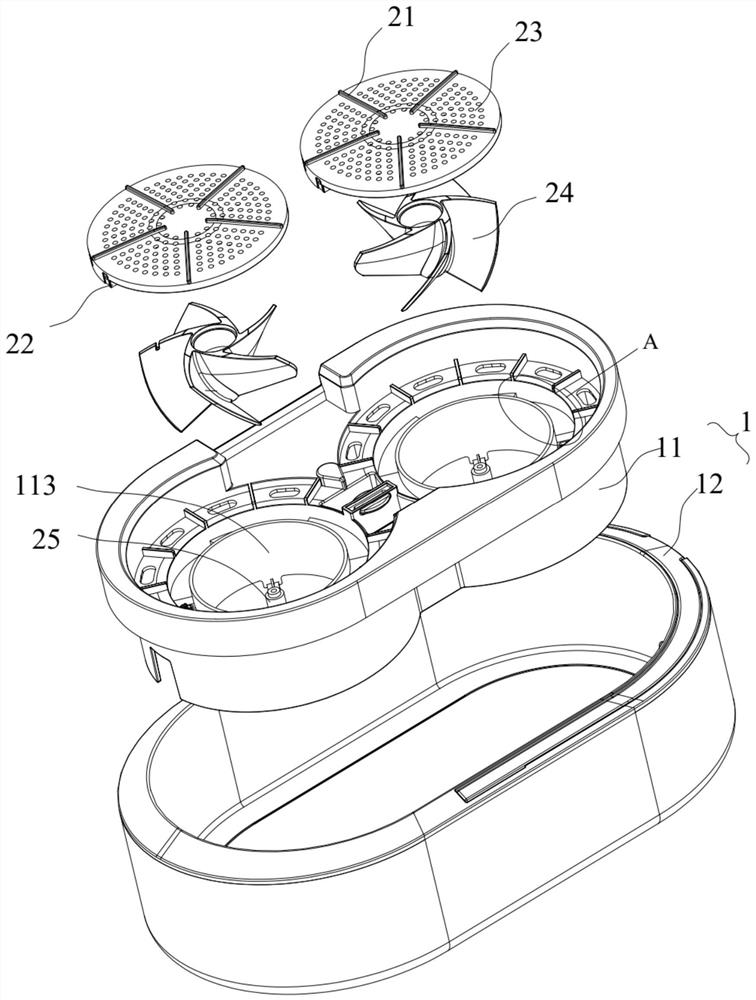

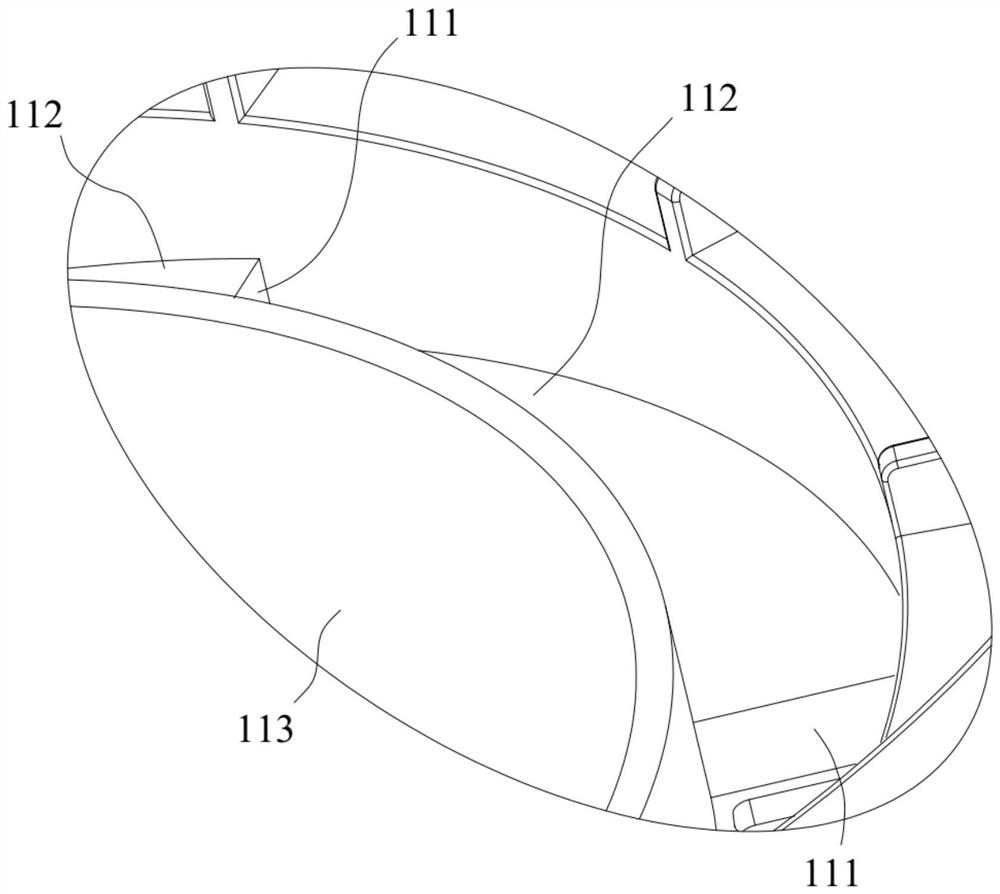

Floor mopping machine cleaning device

ActiveCN112493947AGood dehydration effectClean upCarpet cleanersFloor cleanersEngineeringWater leakage

The invention belongs to the technical field of cleaning devices, and discloses a floor mopping machine cleaning device which comprises a barrel body and a cleaning assembly, the barrel body comprisesa cleaning tank concavely arranged downwards from the top of the barrel body, a retaining part is arranged on the barrel body, the cleaning assembly comprises a cleaning disc, a scraping part and a stopping part, and a through water leakage hole is formed in the cleaning disc. The cleaning disc is rotationally arranged at the bottom of the cleaning tank, the scraping part is connected to the upper side face of the cleaning disc, the stopping part is connected to the cleaning disc, when forward driving force is applied to the cleaning disc, the stopping part slides relative to the retaining part, the cleaning disc rotates in the forward direction relative to the barrel body, and when reverse driving force is applied to the cleaning disc, the stopping part is clamped to the retaining part.The cleaning disc is braked relative to the barrel body. According to the cleaning device of the floor mopping machine, a good dehydration effect can be achieved, dirt adhering to the rag disc can bescraped off, and therefore the rag disc can be cleaned more thoroughly.

Owner:WUXI PURELIFE HEALTHY TECH

Water squeezing device suitable for rolling mop

ActiveCN108354544AGood dehydration effectGood rinsing effectCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a water squeezing device suitable for a rolling mop. The water squeezing device comprises a water squeezing part, a pressing switching mechanism for controlling contact or separation of a water squeezing part and a cleaning roller, a rocking handle and a rocking rotation mechanism arranged between the rocking handle and a rotary shaft of the cleaning roller and used for transferring power so as to drive the cleaning roller to rotate, wherein the rocking handle is arranged on a push rod of the rolling mop. The water squeezing device achieves dewatering of the cleaning roller in the water squeezing mode of rotary pressing. Due to the fact that in the dewatering process, the rotating cleaning roller can make the water squeezing part to be in contact with and squeeze all cleaning face on the cleaning roller for dewatering, a dewatering effect is good. In addition, the water squeezing device can also complete the rinsing task of the cleaning roller by rocking the rocking handle to make the cleaning roller rotate and has the advantages of being simple and convenient to operate and good in rinsing effect.

Owner:陈滨

Vertical type mop-cleaning machine and mop matched therewith

The invention relates to a vertical mop washing machine and a matched mop thereof. The mop washing machine comprises a machine body, a pedestal, an inner barrel, a machine cover, a cover plate and a transmission device, and is characterized in that the pedestal is connected with the machine body into a whole; the inner barrel is fixed on the pedestal; the upper opening of the machine body is provided with the machine cover; and the transmission device is fixed inside the pedestal. The matched mop comprises a mop rod, a rotating connection device and a mop head, and is characterized in that the shape of the lower end of the mop rod is matched with an inner hole formed when a back bayonet of the machine cover is matched with a front bayonet of the cover plate; the lower end of the mop rod is connected with the rotating connection device; and the mop head is sleeved on the lower part of the rotating connection device. The vertical mop washing machine not only ensures ideal effects and quick speed of cleaning and dewatering the mop, but also has smart design, small volume, light weight, simple structure, convenient operation, elegant appearance and high safety.

Owner:刘和法

Dehydrating and drying device for processing of Pleurotus geesteranus

The invention relates to the technical field of Pleurotus geesteranus processing devices, and discloses a dehydrating and drying device for processing of Pleurotus geesteranus. The dehydrating and drying device comprises a supporting frame and a mounting frame, wherein a shell is fixed to the top of the supporting frame through bolts; a cover plate is fixed to the top of the shell through bolts; afeeding port is formed in one side of the cover plate; a feeding plate is connected to one side of the feeding port through hinges; a first motor is fixed to one side of the cover plate through a bolt; a gear is fixed to an output shaft of the first motor through a bolt; a dehydrating barrel is rotationally connected to the inner side of the shell; multiple filtering holes are formed in one sideof the dehydrating barrel; and a gear ring is welded to the top of the dehydrating barrel. According to the invention, the dehydrating barrel is matched with a dryer, so Pleurotus geesteranus can be centrifugally dehydrated and then dried; Pleurotus geesteranus can be rapidly dehydrated and dried through dehydration and drying operation; and compared with a traditional dehydrating device, the dehydrating and drying device is better in dehydrating effect, higher in drying degree and less in consumed time, and improves the dehydrating and drying quality of Pleurotus geesteranus.

Owner:福建省罗源创鲜农业科技有限公司

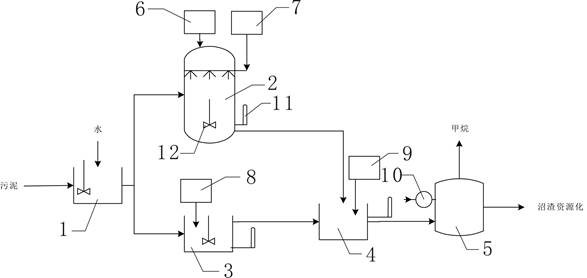

Sludge anaerobic treatment system and method

PendingCN114275983AHigh degree of stabilizationGood dehydration effectBiological sludge treatmentBiogasProcess engineering

The invention provides a sludge anaerobic treatment system and method, and relates to the field of sludge treatment.The sludge anaerobic treatment system comprises a hardening and tempering tank, a sterilization tank, an alkali washing tank, a neutralizing tank and an anaerobic fermentation tank, sludge enters the hardening and tempering tank, and the hardening and tempering tank adjusts the water content of the sludge; inlets of the sterilization tank and the alkali washing pool are connected in parallel to an outlet of the conditioning pool, and outlets of the sterilization tank and the alkali washing pool are connected in parallel to an inlet of the neutralization pool; the inlet of the anaerobic fermentation tank is connected with the outlet of the neutralization tank, the system can improve the sterilization rate of sludge to 90-100% through flow design, the biogas residue after anaerobic treatment is high in stabilization degree, good in dehydration effect and high in subsequent resource utilization rate; the COD content of the treated sludge solution is increased, the anaerobic digestion and decomposition rate is high, and the organic matter degradability is high.

Owner:TIANJIN ENEW ENVIRONMENTAL PROTECTION ENGCO LTD

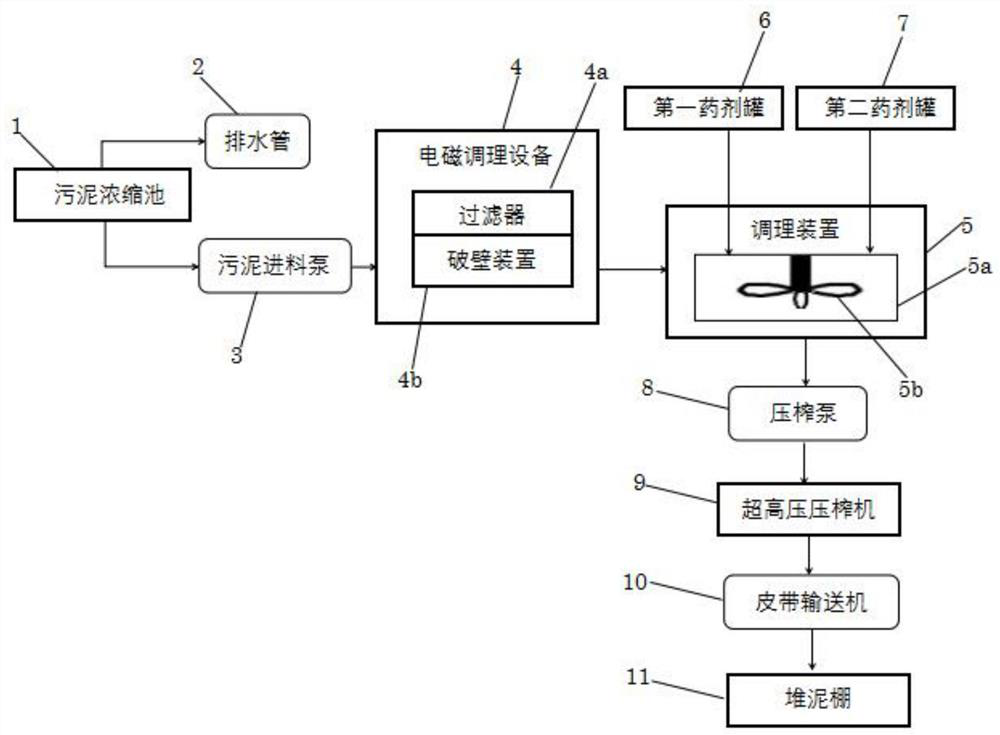

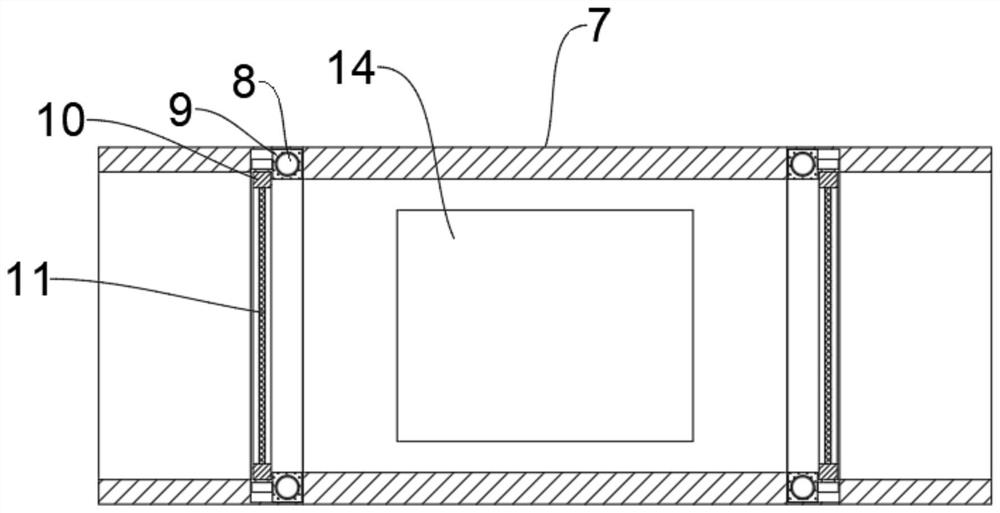

Sludge dewatering process and system employing combination of sludge wall-breaking and ultrahigh-pressure squeezer

PendingCN113716822AGood dehydration effectImprove filter press effectSludge treatment by de-watering/drying/thickeningPressesProcess engineeringUltra high pressure

The invention discloses a sludge dewatering process and system employing a combination of sludge wall-breaking and an ultrahigh-pressure squeezer. The sludge dewatering process comprises the following steps: 1) performing sludge wall-breaking treatment on raw sludge with a moisture content of 97%; 2) carrying out dosing flocculation conditioning on the sludge having been subjected to the sludge wall-breaking treatment; and 3) carrying out ultrahigh-pressure squeezing on the flocculated and conditioned sludge under a squeezing pressure of 2-10 Mpa until the water content of the squeezed sludge is lower than 50%, and then conveying the sludge for outward transportation treatment. The sludge dewatering process employing the combination of sludge wall-breaking and the ultrahigh-pressure squeezer has the advantages that chemical consumption is low; dehydration effect is good; and batch operation time is shortened, and operation efficiency is improved.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

Sludge treatment equipment for river regulation

ActiveCN113860692AHigh degree of automationGood dehydration effectSludge treatmentClimate change adaptationSludgeRiver regulation

The invention relates to the technical field of river regulation, in particular to sludge treatment equipment for river regulation. The equipment comprises a treatment box, a controller, a feeding hopper, a water outlet and a sludge discharge port, the controller, the feeding hopper, the water outlet and the sludge discharge port are arranged on the treatment box, a time delayer is arranged in the controller, and the sludge treatment equipment further comprises a dehydration box movably arranged in the treatment box and communicating with the feeding hopper, a power element arranged on the treatment box and connected with the dehydration box, at least one group of dehydration modules movably arranged in the dehydration box and used for assisting the dehydration box in dehydrating water in the sludge, a valve unit arranged in a discharging window formed in the dehydration box and capable of controlling opening and closing of the discharging window, and a screening module movably arranged in the treatment box. The whole process is high in automation degree, and compared with a traditional mode that dehydration is conducted only under the action of centrifugal force, the equipment is better in dehydration effect and shorter in dehydration period.

Owner:盐城市盐都区水务局新区水务站

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com