Bead elimination scheme of vehicle rearview mirror and vehicle window glass

A technology for automotive rearview mirrors and window glass, which is applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve the problems of imperfection, affect the appearance, and the liquid is not improved, and achieve a perfect solution, low cost, and appearance. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

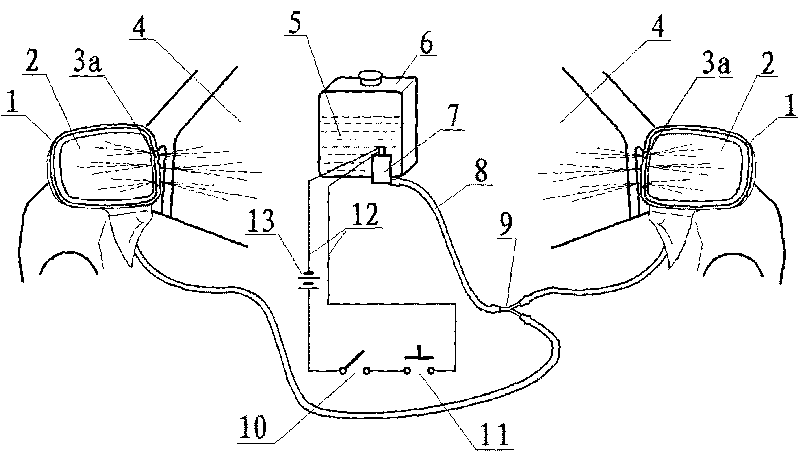

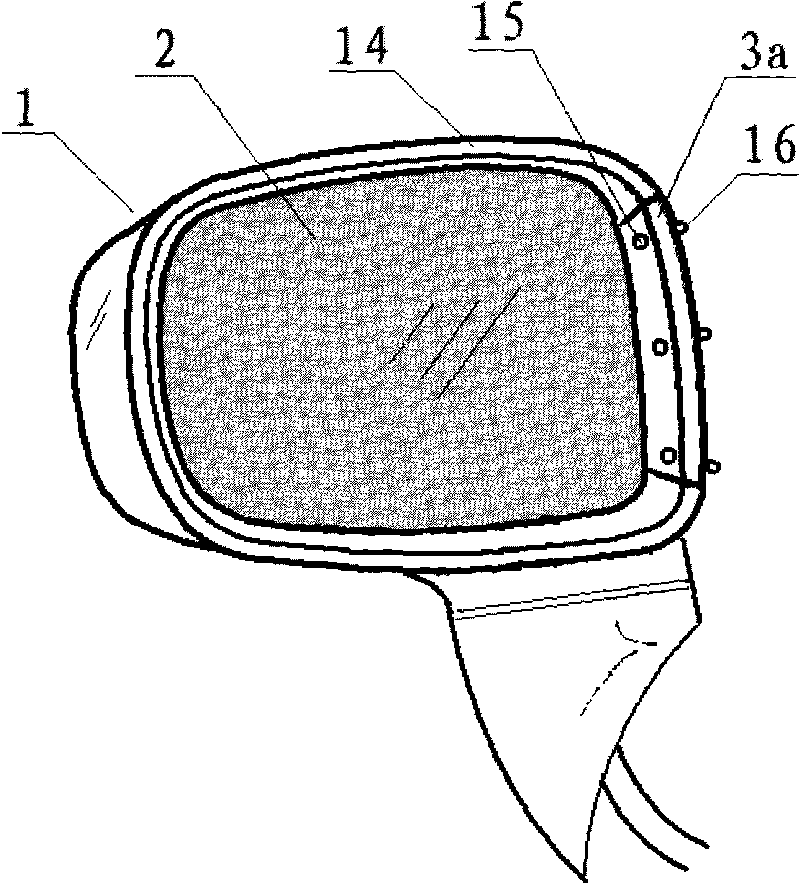

[0040] figure 1Among them, the hydrophilic liquid 5 is stored in the washer kettle 6, outputted by the washing pump 7, divided into two paths along the water pipe 8 through the tee 9, and flows to the left and right rearview mirrors 1 respectively, and then sprays to the mirror surface 2 and the mirror surface through the mirror housing nozzle 3a. Window glass 4. The control switch 11 is connected in series with the wiper switch 10, and the operation of the control switch 11 is effective only after the wiper switch 10 is activated. The scrubber kettle 6 generally has two positions for adorning the washing pump 7, and the sedan and the hatchback without the rear wiper only use one of them, and just utilize another position to install a pump for the present invention. For hatchback cars equipped with rear wipers, since there is no remaining pumping position, it may be considered to change the rear washer pump to remove water droplets, cancel the function of spraying washer flui...

Embodiment 2

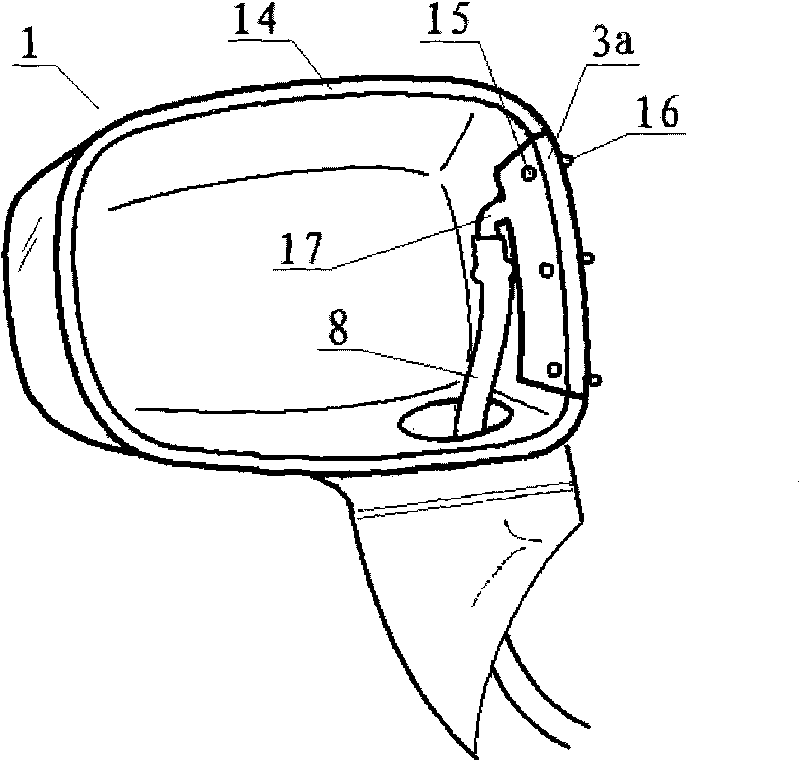

[0046] See Figure 6 The difference from Embodiment 1 is that there are two nozzles, that is, the window nozzle 3c for spraying the window glass 4 is installed on the window decoration cover plate 21, which completely solves the problem that the vehicle window glass 4 is sprayed when the car is running at high speed. The problem of placement. The rearview mirror 1 of some models is installed in the position of the decorative cover plate 21 (which is the bottom plate of the rearview mirror at this time), which is more convenient to implement this scheme. The mirror casing nozzle 3a still remaining on the mirror casing 14 is only responsible for spraying liquid to the mirror surface 2, and only the rearview mirror spout 15 is arranged on it, which can be considered to be embedded in other positions of the mirror casing 14.

Embodiment 3

[0048] This embodiment is the improvement of embodiment two, two nozzles are provided with, and the liquid spraying to the mirror surface 2 is realized by the mirror surface nozzle 3b, and there is a small hole in the inconspicuous place on the mirror surface 2 glass, and the mirror surface nozzle 3b is embedded in this hole (see Figure 7 ) and fixed on the plastic chassis of mirror 2 ( Figure 7 not shown in ) with chrome-plated exposed parts. The mirror shower head 3b can also be inlaid on the exposed edge of the plastic chassis 22 of the mirror 2 (see Figure 8 ), this method is not applicable if the edge of the rearview mirror plastic chassis 22 is not exposed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com