Patents

Literature

59 results about "Solvay process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

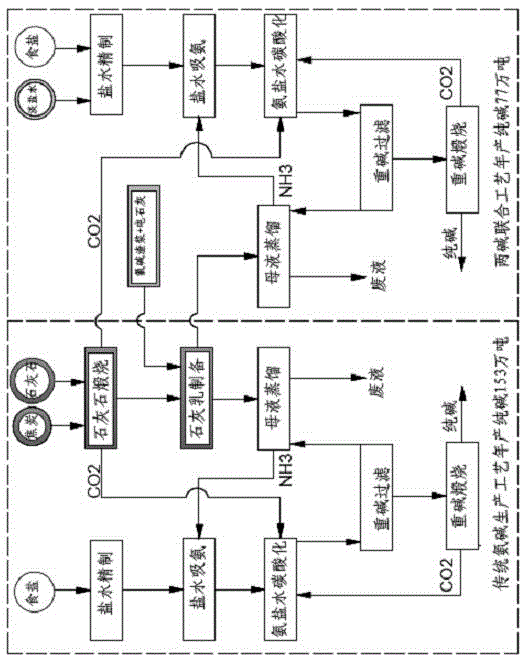

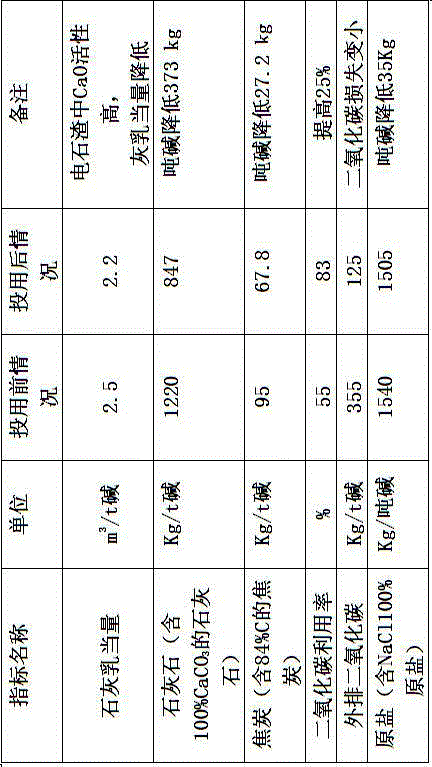

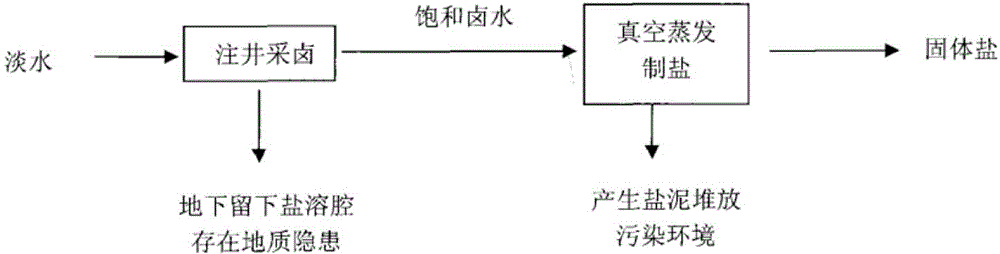

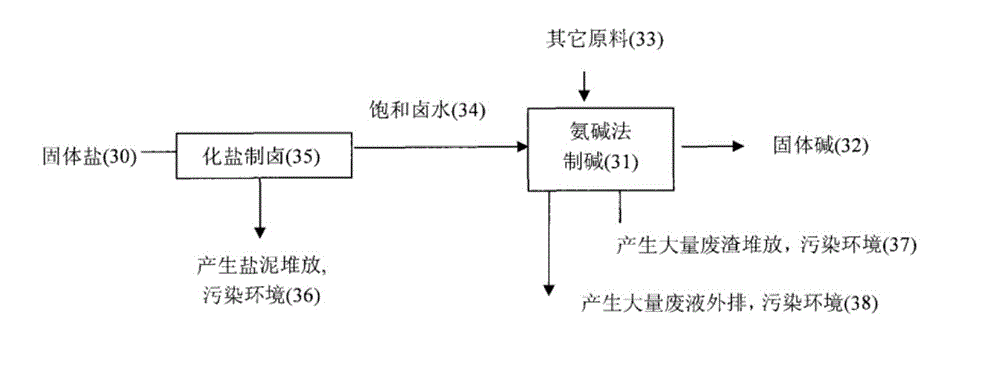

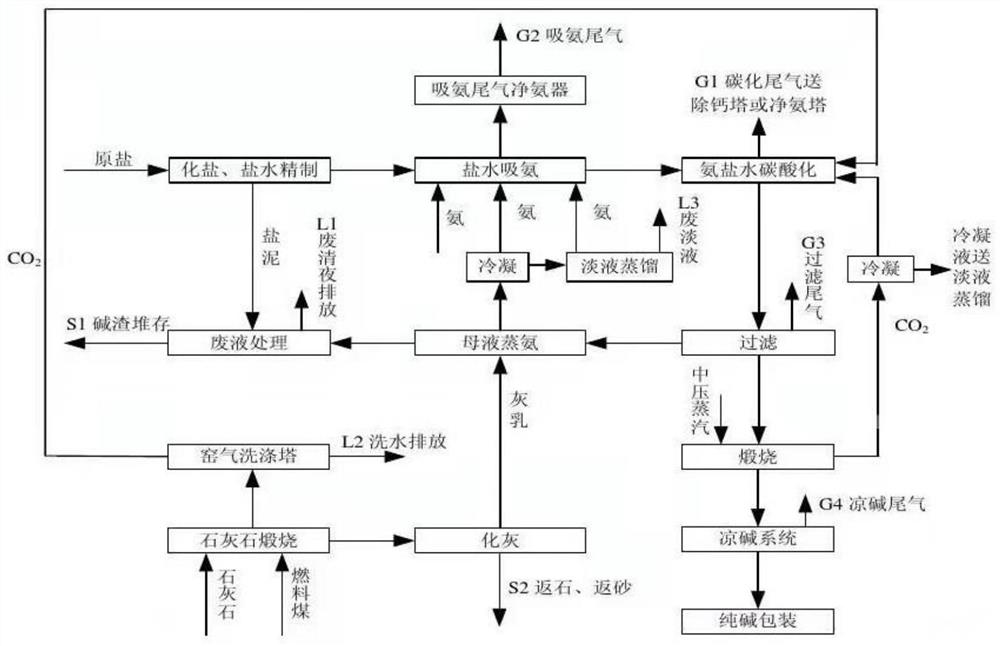

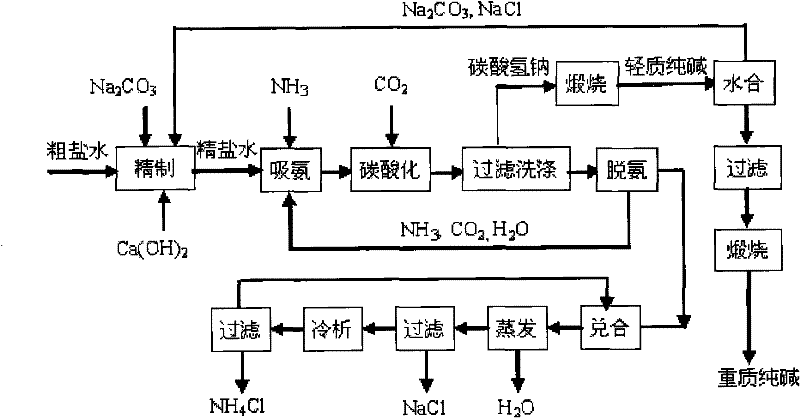

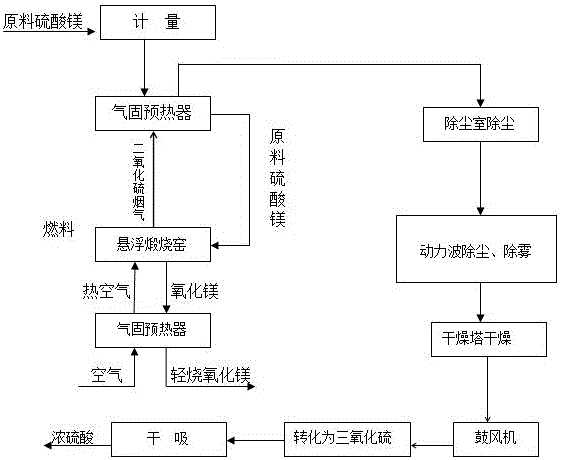

The Solvay process or ammonia-soda process is the major industrial process for the production of sodium carbonate (soda ash, Na₂CO₃). The ammonia-soda process was developed into its modern form by Ernest Solvay during the 1860s. The ingredients for this are readily available and inexpensive: salt brine (from inland sources or from the sea) and limestone (from quarries). The worldwide production of soda ash in 2005 has been estimated at 42 million metric tons, which is more than six kilograms (13 lb) per year for each person on Earth. Solvay-based chemical plants now produce roughly three-quarters of this supply, with the remaining being mined from natural deposits. This method superseded the Leblanc process.

Method for separatingcalcium chloride and sodium chloride in ammonia distillation waste clear solution with nanofiltration technology and application of production by the method

InactiveCN101219797AIncrease concentrationReduce consumptionCalcium/strontium/barium chloridesWater/sewage treatment bu osmosis/dialysisHigh concentrationDistillation

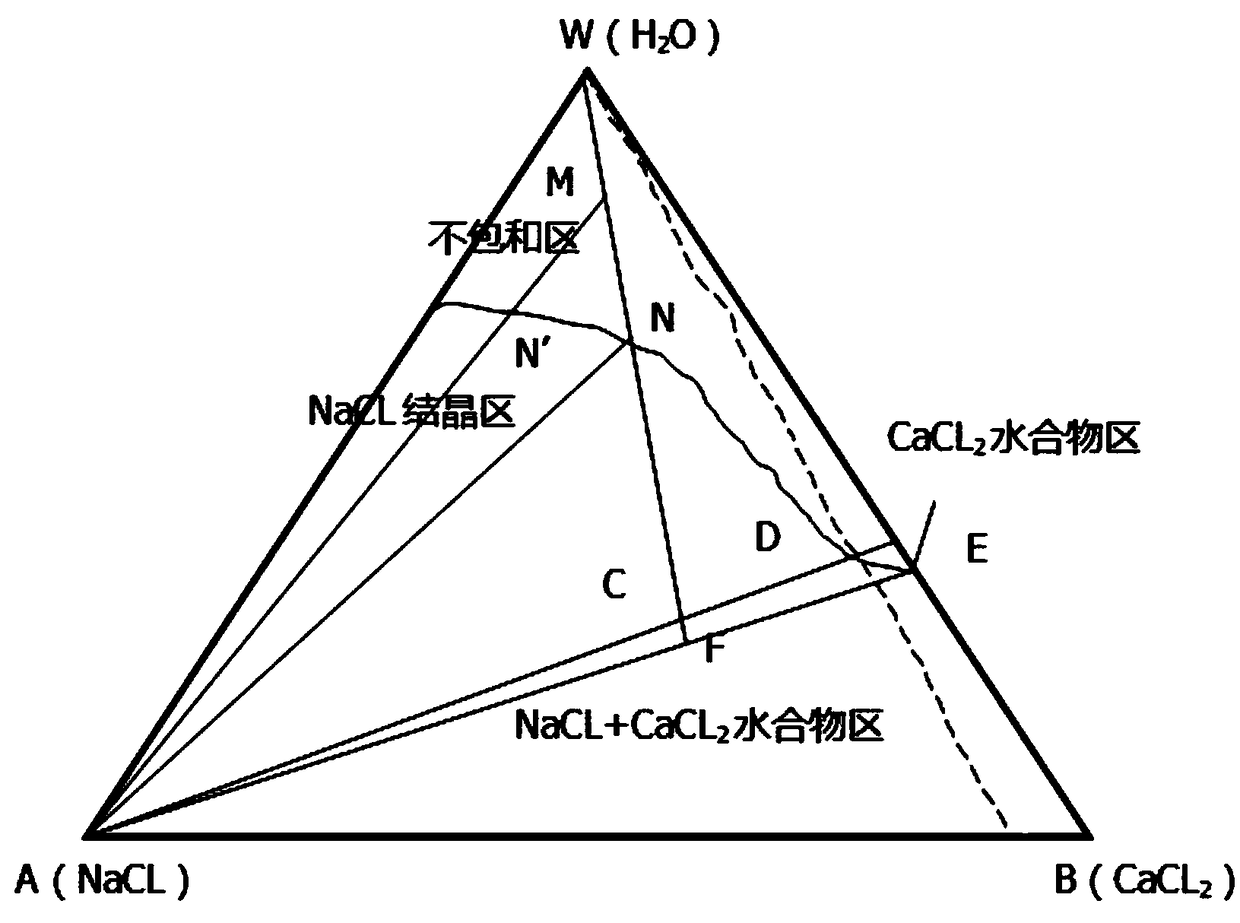

The invention discloses a method for separating calcium chloride and sodium chloride in ammonia distillation waste clear liquid by using nanofiltration membrane technology and application of product thereof, relating to a chemical field of preparing calcined soda by using an ammonia-soda process or a union alkali method; the method comprises that the ammonia distillation waste clear liquid is separated through a nanofiltration membrane filtering equipment to obtain concentrated solution mainly containing calcium chloride solution and penetrant mainly containing sodium chloride solution. The penetrant can be recycled for salt dissolving technology. The concentrated solution containing high-concentration calcium chloride can be used for producing calcium chloride product by adopting methods of evaporation and crystallization. The method leaves out processes of repeated sunning, heating and vacuum pumping, and most moisture can be reused; the invention reduces energy consumption and area occupation, saves a large amount of water resource, which create good condition for technology of subsequent salt dissolving and the calcium chloride production.

Owner:王晓璐

Method for combined production of ammonia and basic calcium chloride by decomposing ammonium chloride

InactiveCN101941719AReduce energy consumptionLess investmentCalcium/strontium/barium chloridesAmmonia preparation/separationChemical reactionSolvay process

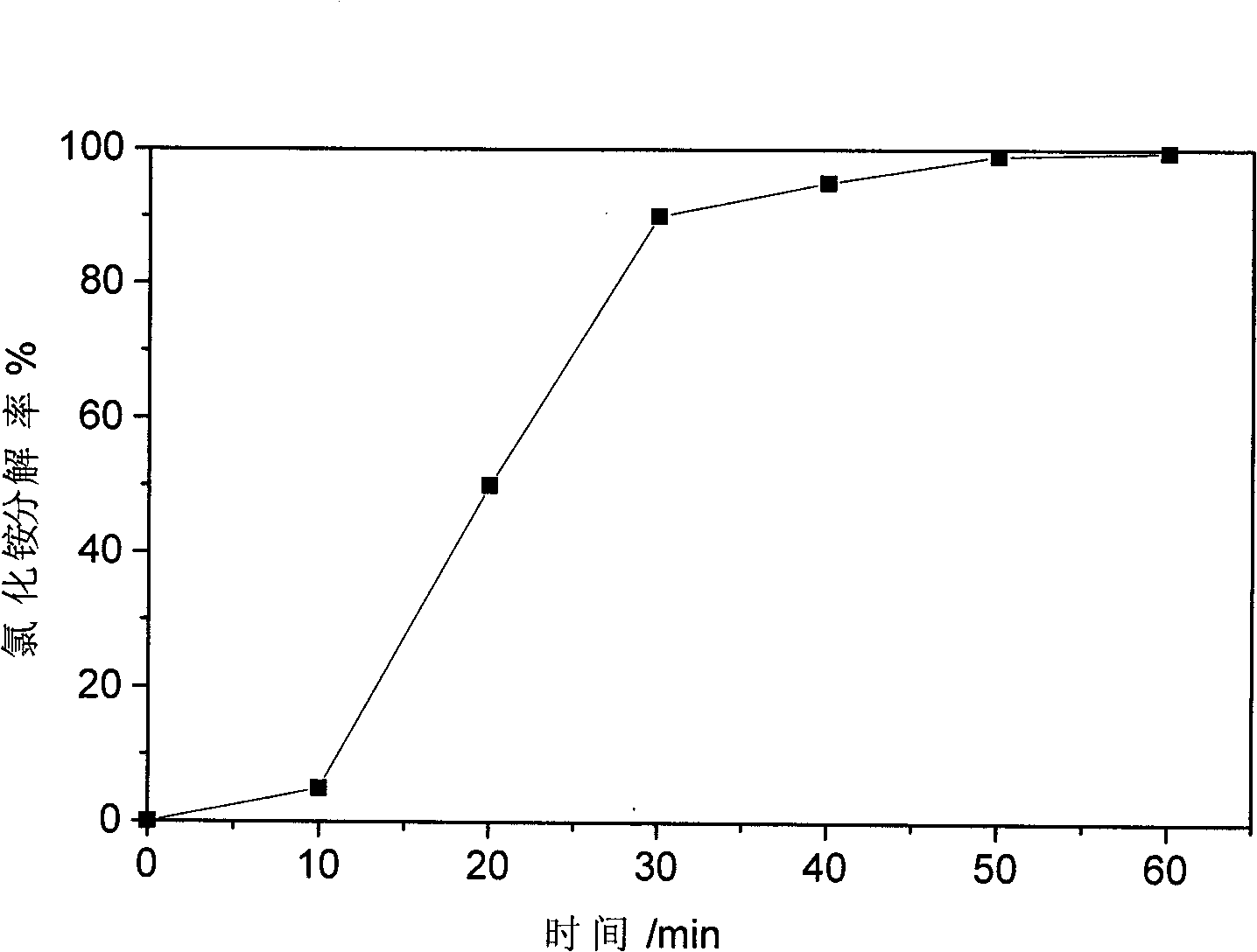

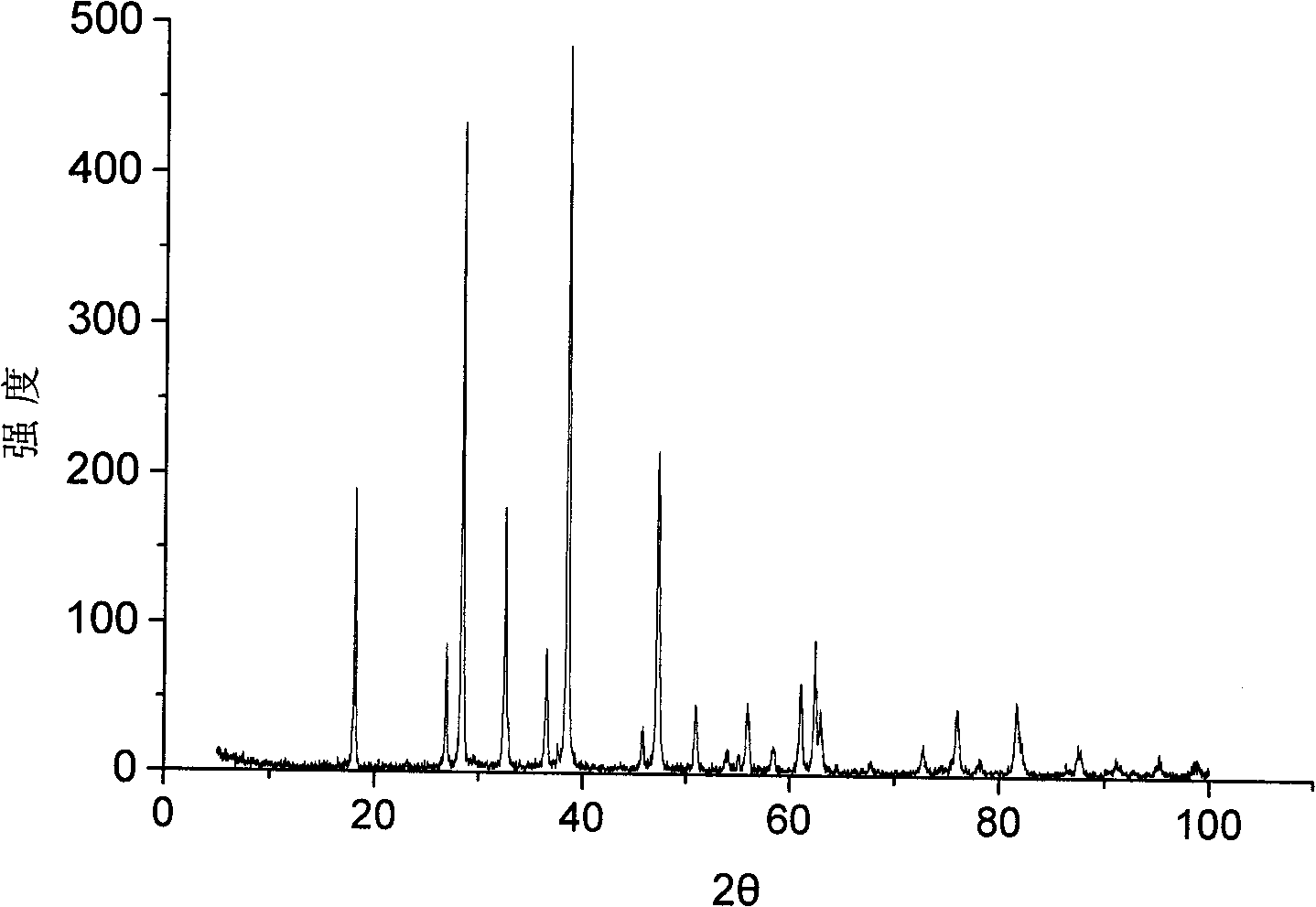

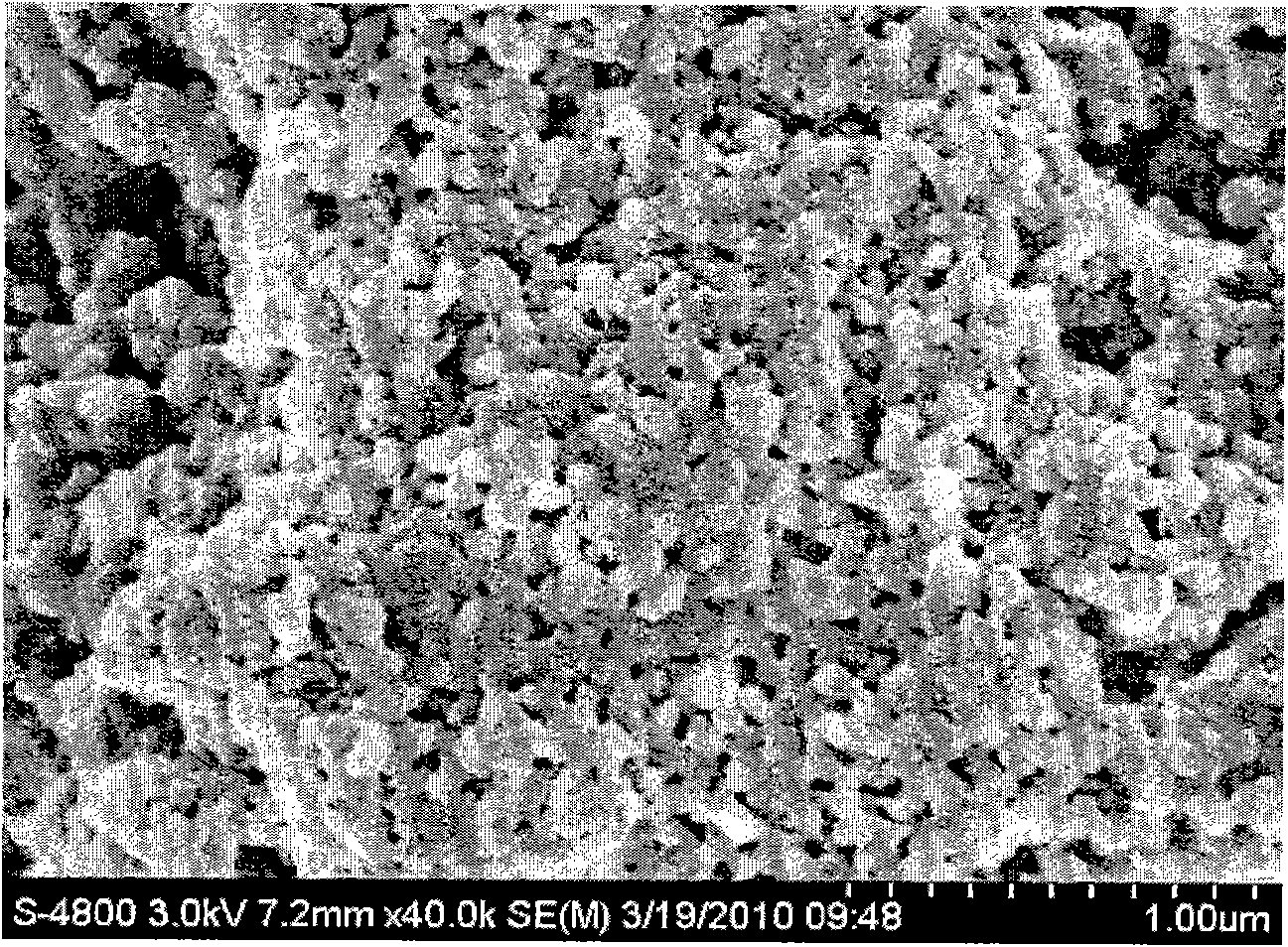

The invention provides a method for the combined production of ammonia and basic calcium chloride by decomposing ammonium chloride, which comprises the following steps: grinding or crushing calcareous materials and ammonium chloride according to a mol ratio of 1:0.5-2 in a ball grinder or a crusher at -20-200 DEG C, enabling the calcareous materials and the ammonium chloride to be subject to a chemical reaction to decompose the ammonium chloride so as to release ammonia gas and generate basic calcium chloride. The invention fully uses the large amount of ammonium chloride as the byproducts of the combined soda process and the ammonia soda process, realizes the recycling of ammonia and generates the basic calcium chloride as the byproduct. The invention has the characteristics of simple process, low investment, high conversion rate, no pollution and low energy consumption, is applicable to industrial production and meets the requirements green chemical development in the present society.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing chlorine-removal alkali residue mixture by utilizing alkali residues through ammonia-soda process and application of chlorine-removal alkali residue mixture

ActiveCN104190690AImprove dechlorination effectReduce Chloride ContentSolid waste managementSolid waste disposalChlorideEthyl Chloride

The invention discloses a method for preparing a chlorine-removal alkali residue mixture by utilizing alkali residues through an ammonia-soda process. The method comprises the following steps: step 1, crushing returned sand and returned stones, and grinding to obtain returned sand and returned stone powder; step 2, soaking the returned sand and returned stone powder in water for 0.5-14 days, digesting overburnt calcium oxide, mixing the digested returned sand and returned stone powder, alkali residues and water, wherein a ratio of dry mass of the digested returned sand and returned stone powder to the alkali residues is 2:8 to 5:5 based on the mass percentage of the materials, and the total mass of the water is 1.5 to 8 times that of total dry mass of the digested returned sand and returned stone powder and alkali residues; or mixing the returned sand and returned stone powder, the alkali residues and water, soaking the mixture for 0.5-14 days, and digesting the overburnt calcium oxide; and step 3, performing filter pressing treatment, thereby obtaining the chlorine-removal alkali residue mixture of which the chloride ion content is lower than 0.30 percent of the total mass of solids in the mixture. The invention also discloses application of the chlorine-removal alkali residue mixture. The method and application disclosed by the invention are good in chlorine removal effect, simple in process, energy-saving and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

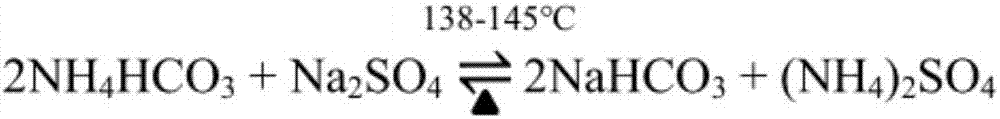

Method for preparation of sodium bicarbonate and ammonium sulfate from chemical strong brine

ActiveCN106865571ASolve processing problemsAchieve recyclingAlkali metal carbonatesAmmonia compoundsSodium bicarbonateProcess engineering

Belonging to the technical field of solid waste miscellaneous salt recycling treatment, the invention discloses a method for preparation of sodium bicarbonate and ammonium sulfate from chemical strong brine. According to the method, evaporated and concentrated chemical strong brine is subjected to hardness removal to obtain a delicate mirabilite solution, and then ammonia-soda process reaction is carried out to obtain sodium bicarbonate and ammonium sulfate products. The method provided by the invention solves the difficult treatment problem of chemical strong brine, realizes recycling of miscellaneous salt in strong brine, and meets the sustainable development requirements. At the same time, compared with the salt method for preparation of sodium bicarbonate, the method provided by the invention reduces the anti-corrosion requirement of equipment, saves the project investment for preparation of sodium bicarbonate, has the byproduct ammonium sulfate with a value higher than ammonium chloride, and has obvious advantages in economic benefits.

Owner:科莱环保(北京)有限公司

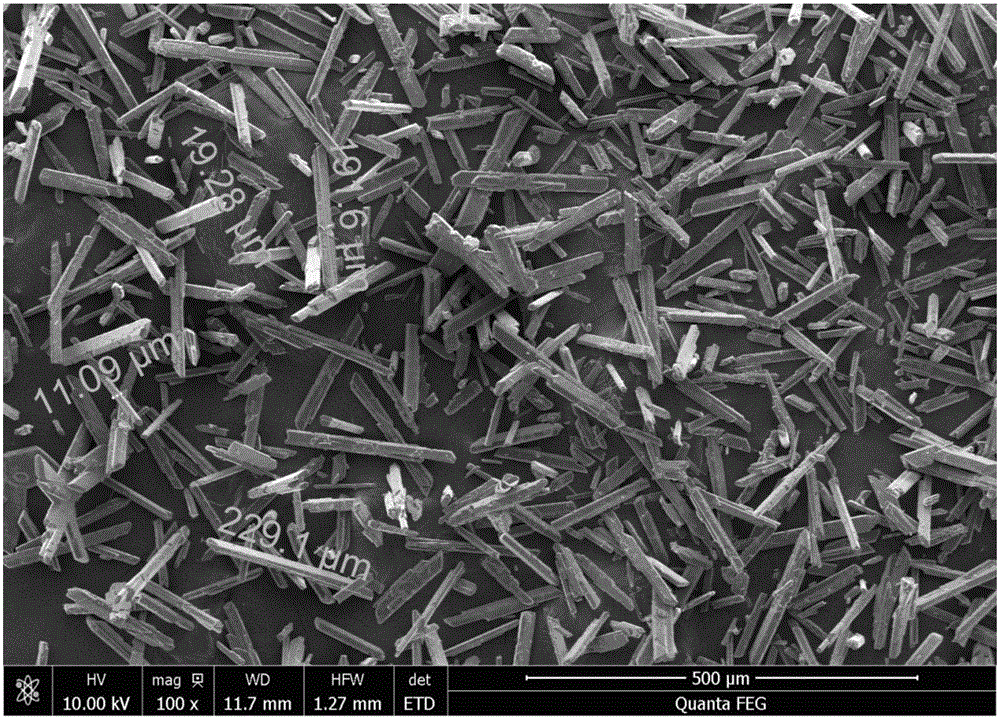

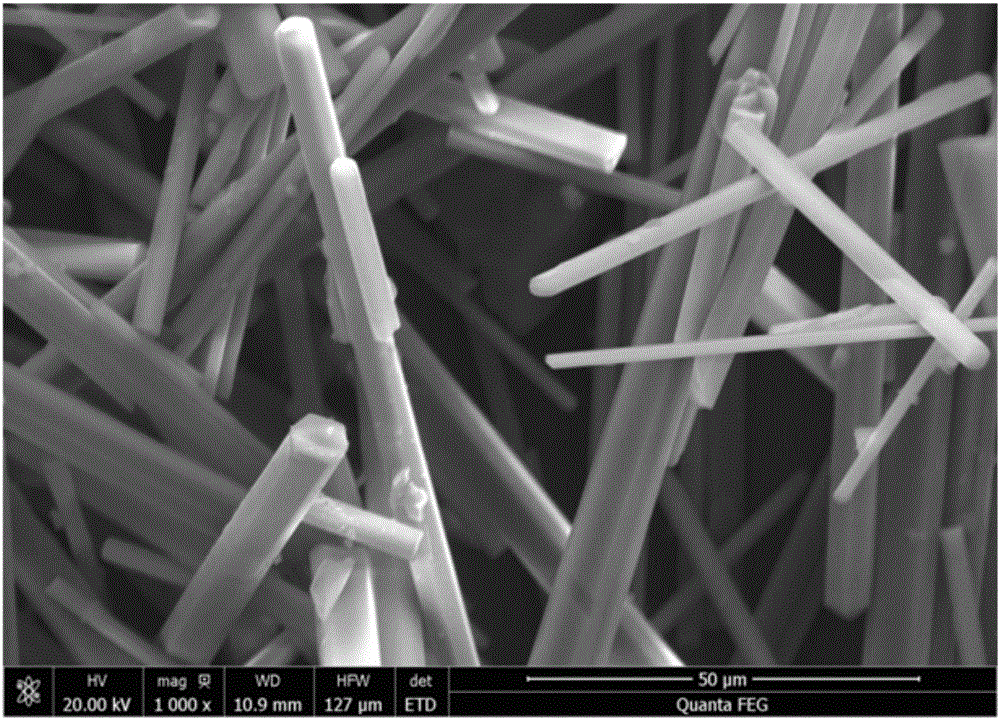

Method for preparing high-purity dihydrate gypsum whiskers by using industrial byproduct calcium chloride

InactiveCN105671627AIncrease productivityImprove the level ofPolycrystalline material growthFrom normal temperature solutionsChemical industryPapermaking

The invention relates to a method for preparing high-purity dihydrate gypsum whiskers by using an industrial byproduct calcium chloride. The method comprises the following steps: 1) preparing a calcium chloride solution from an ammonia-soda-process industrial byproduct calcium chloride slurry, heating the calcium chloride solution to 30-80 DEG C, and adding a nucleation accelerator and a crystal form control agent to obtain a reaction mother solution; and 2) adding a 40-60-DEG C sodium sulfate solution into the reaction mother solution, stirring to react for 30-40 minutes, keeping the temperature for 0.5-3 hours to obtain a dihydrate gypsum whisker slurry, and carrying out after-treatment to obtain the high-purity dihydrate gypsum whiskers. The surplus byproduct in the salt chemical industry production process is used as the raw material to prepare the dihydrate gypsum whiskers, of which the length-diameter ratio is 10-100, the crystal length is 50-500 mu m, the purity is 98% or above and the whiteness is 90 or above. The invention provides a high-added-value utilization scheme for the calcium chloride slurry byproduct; and the obtained gypsum whisker can be widely used in the fields of papermaking, chemical industry, novel construction materials, composite materials and the like.

Owner:WUHAN UNIV OF TECH

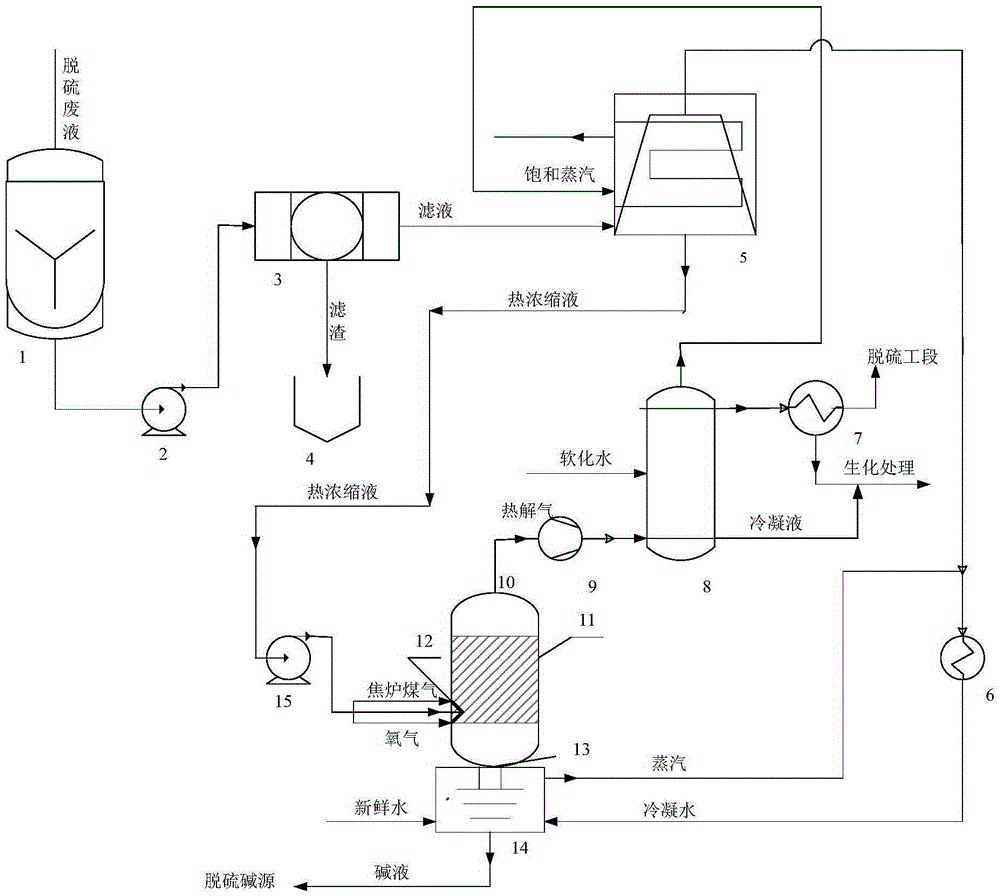

Method used for pyrolyzing wet oxidation desulfurization mixed waste liquid in partial oxidation environment

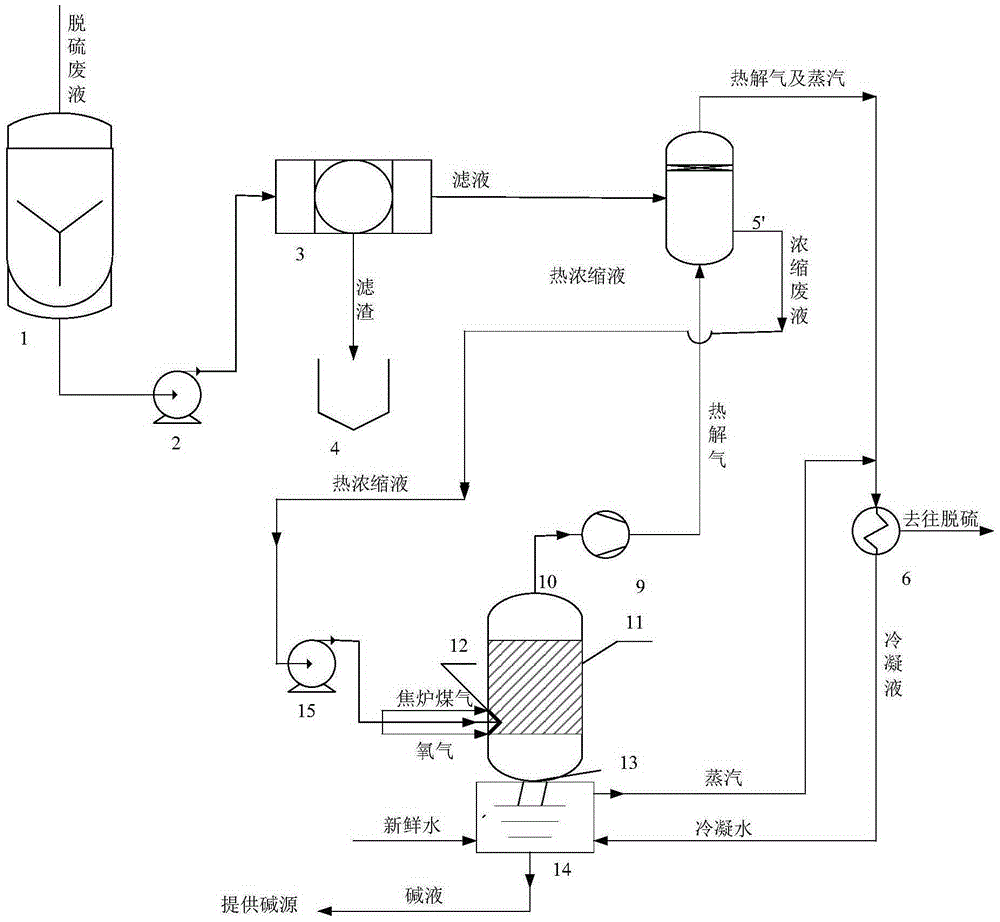

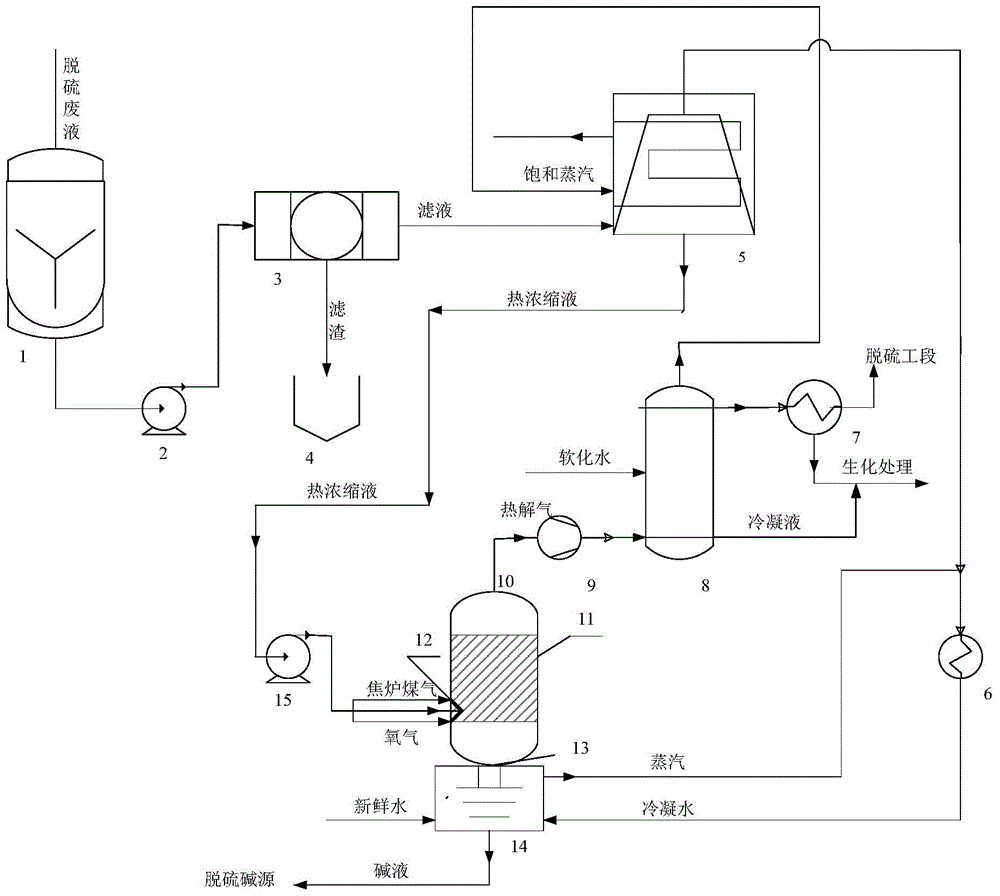

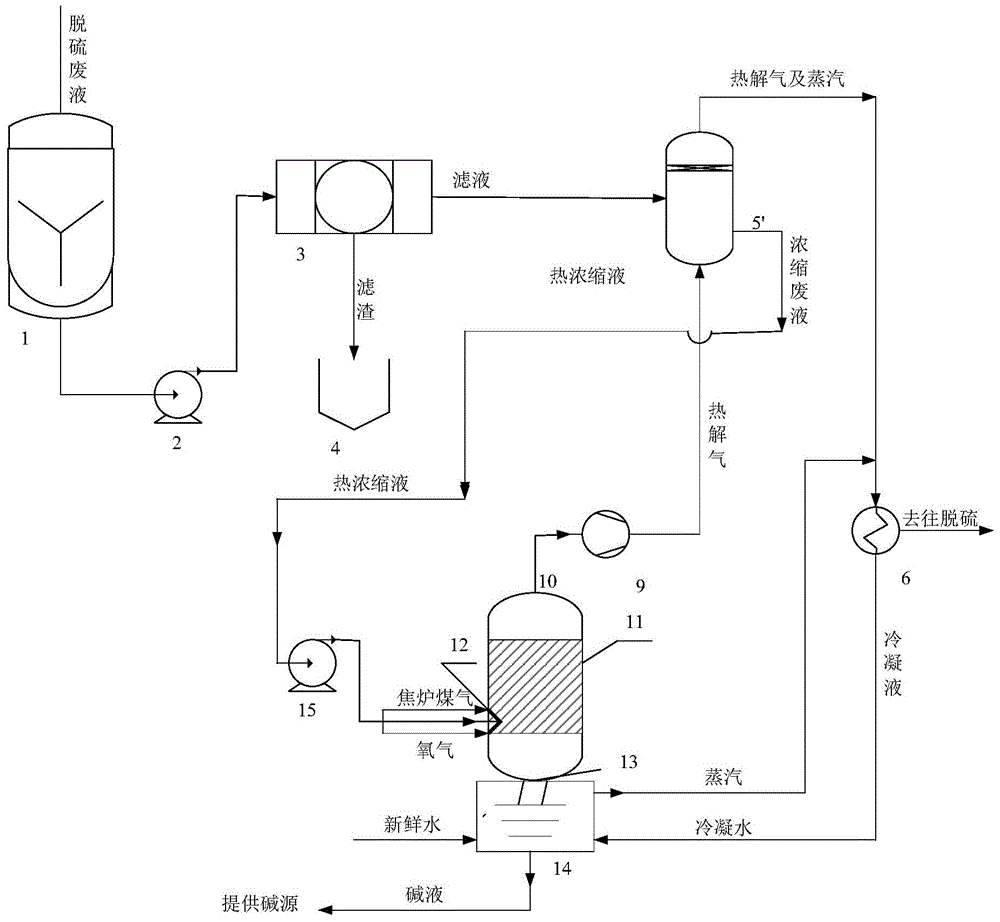

ActiveCN105236647AComply with relevant policy requirements for protectionRealize whole component processingEnergy inputWaste water treatment from gaseous effluentsPartial oxidationIndirect Method

The invention discloses a method used for pyrolyzing wet oxidation desulfurization mixed waste liquid in partial oxidation environment. According to the method, a desulfurization waste liquid mixture obtained via ammonia alkaline method and sodium alkali method is filtered; an obtained filtrate is subjected to reduced pressure vaporization preheating, a desulfurization waste liquid concentrated solution obtained via vaporization is subjected to pressurization, is subjected to atomization using a three-channel combined pressure atomization nozzle, and then is delivered into a pyrolysis reactor together with hydrogen-rich gas, such as coal gas, and oxygen for pyrolysis; pyrolysis gas obtained via pyrolysis is subjected to vaporization preheating of desulfurization waste liquid via a direct method or an indirect method; pyrolyzed molten salt obtained via pyrolysis is discharged via the bottom of the pyrolysis reactor, is cooled using a cooling system, and then is recycled back to a desulfurization workshop section to provide alkali sources. The method is simple; operation is continuous and stable; application range is wide; desulfurization waste liquid obtained via ammonia alkaline method and sodium alkali method, and a mixture of desulfurization waste liquid obtained via ammonia alkaline method and sodium alkali method can be processed effectively; all-component harmless treatment of waste liquid is realized, and problems that mixed waste liquid is difficult to process, processing processes are complicated, and application range is limited, are solved completely.

Owner:TAIYUAN UNIV OF TECH

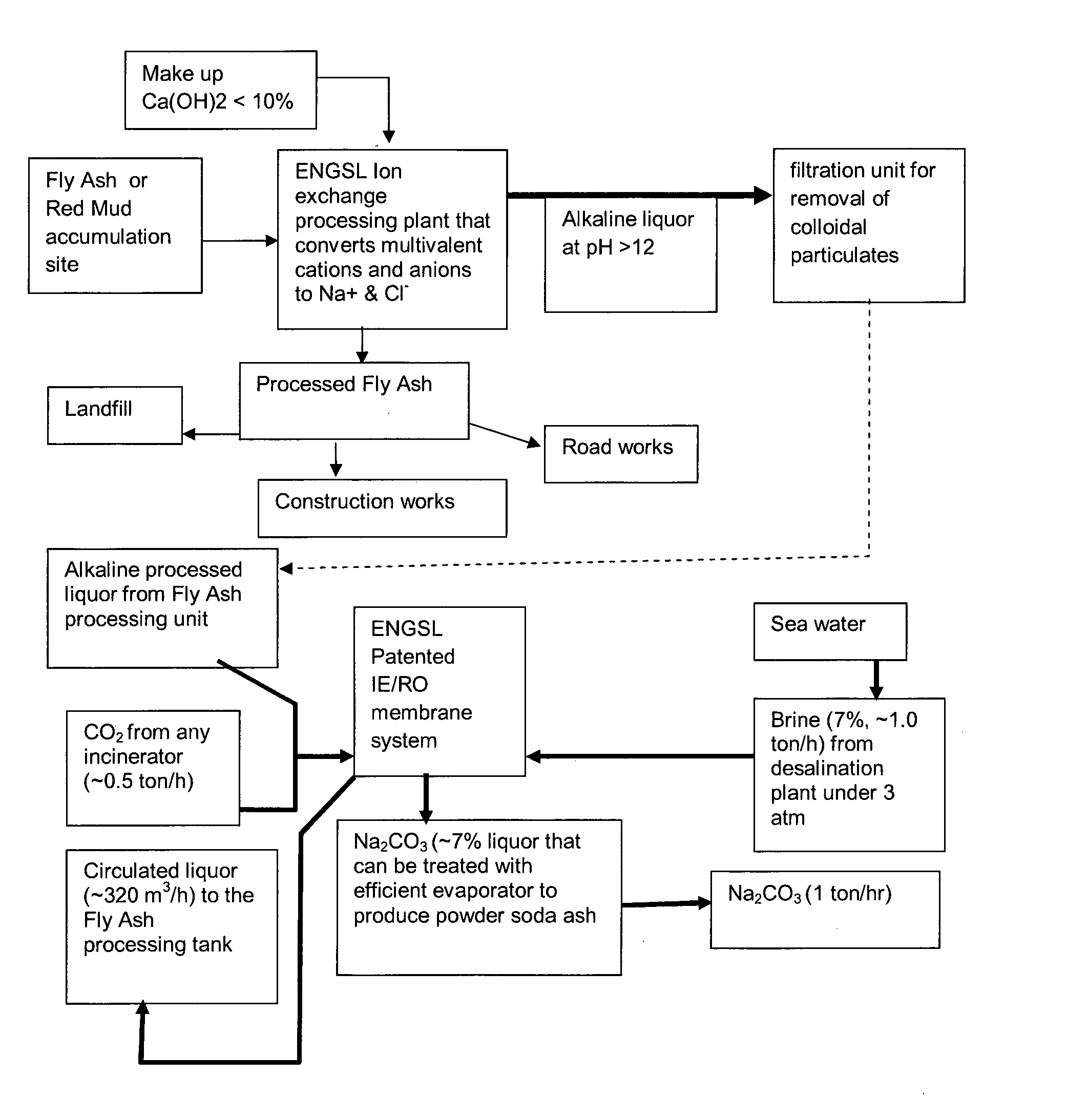

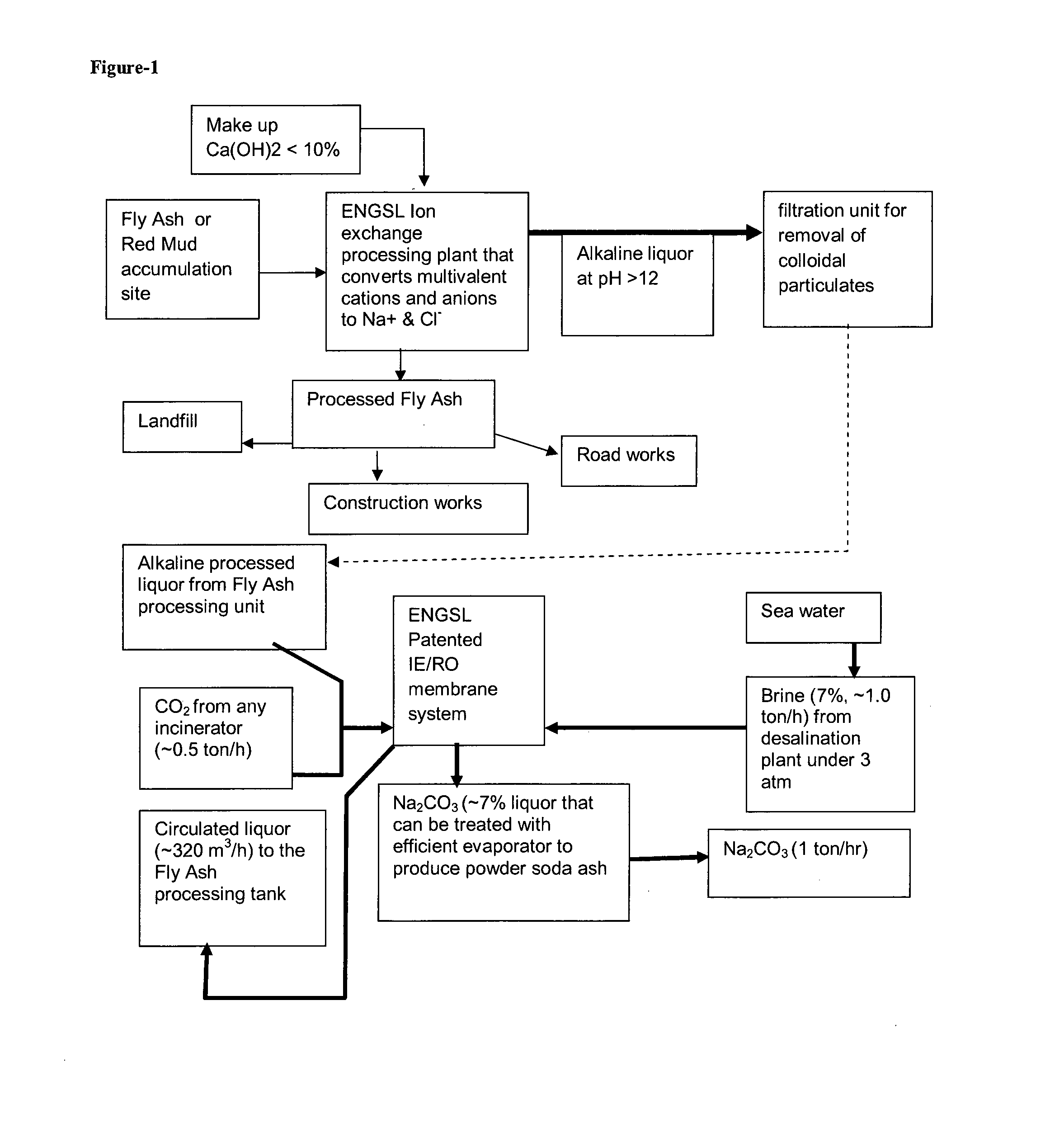

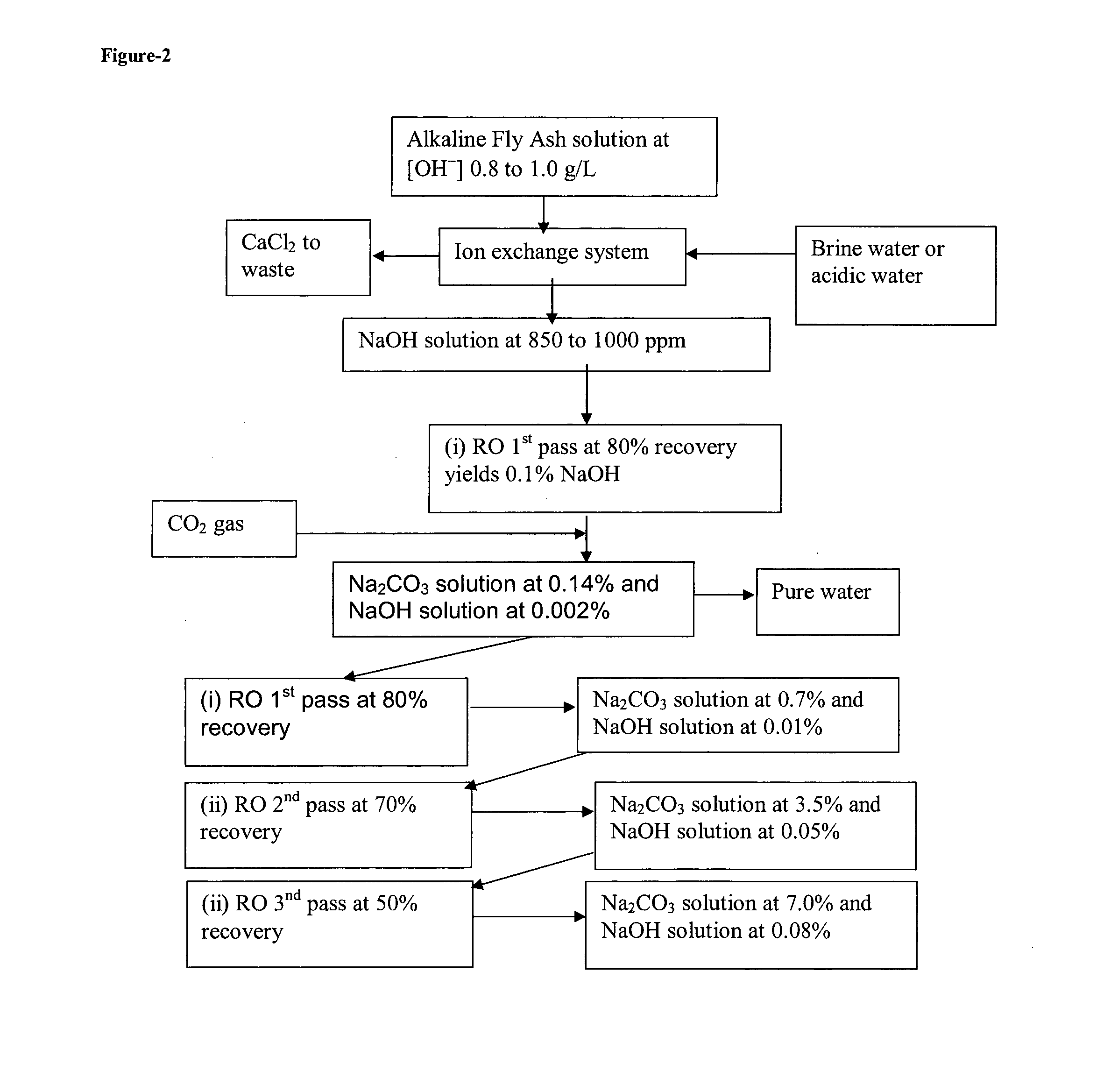

Using alkaline fly ash and similar byproducts in an ion-exchange/reverse osmosis process for the production of sodium carbonate

Owner:OLFI MOHAMMED +1

Method for removing chloride ions in waste alkaline residues

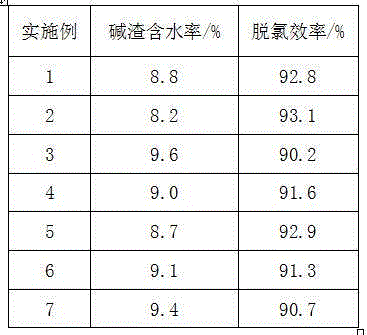

ActiveCN105032903AFast dechlorination efficiencyHigh dechlorination efficiencySolid waste disposalMagnetic separationMass ratioElution

The invention discloses a method for removing chloride ions in waste alkaline residues. The method specifically includes the steps that the waste alkaline residues and magnetic substances are evenly mixed according to the mass ratio of 100:0.1-1.5; water with the mass three to six times that of the waste alkaline residues is added; the mixture is fully stirred, water elution, dechlorination and solid-liquid separation are conducted, and then deposits and supernate are obtained; the deposits are dried; and the magnetic substances are removed through a magnet, and then dechlorinated alkaline residues with 90-93% of chloride removed is obtained. The method has the beneficial effects that the settling velocity of the alkaline residues is high, the alkaline residue dechlorination efficiency is high, and the water content of the dechlorinated alkaline residues is low. Meanwhile, the process and equipment are simple, operation is easy, and energy consumption is low. By means of the method, the waste alkaline residues in soda production by the ammonia-soda process are applied to broader fields in a large scale.

Owner:唐山睿壕科技有限公司

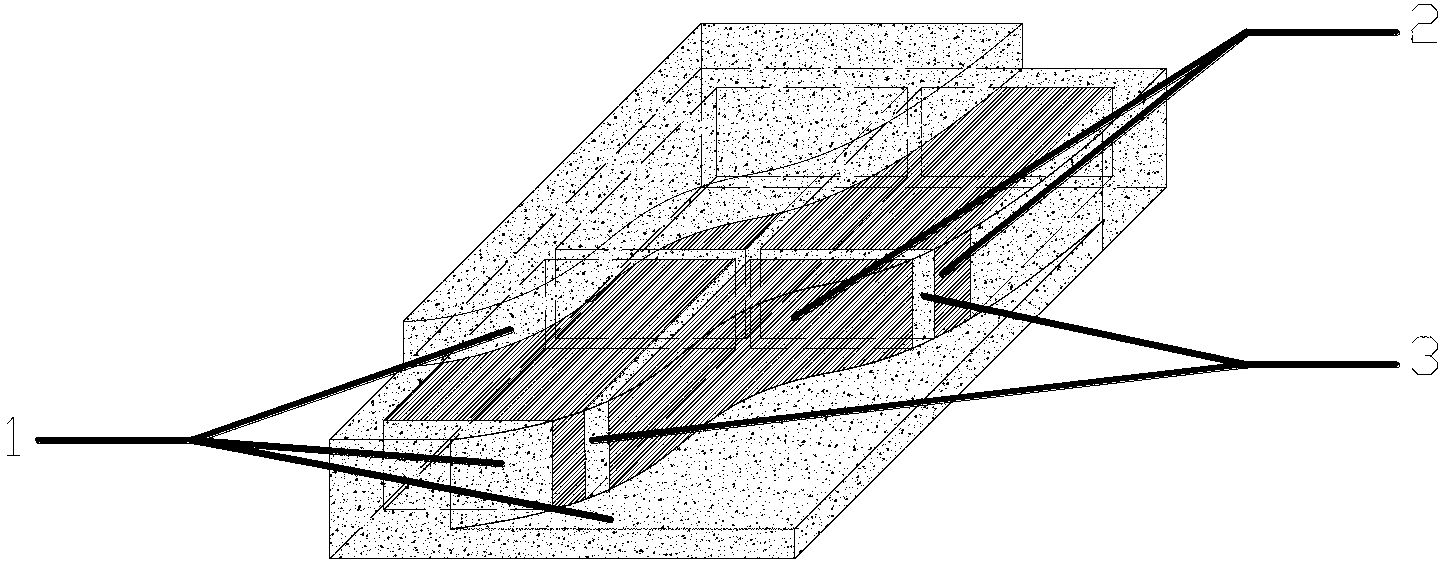

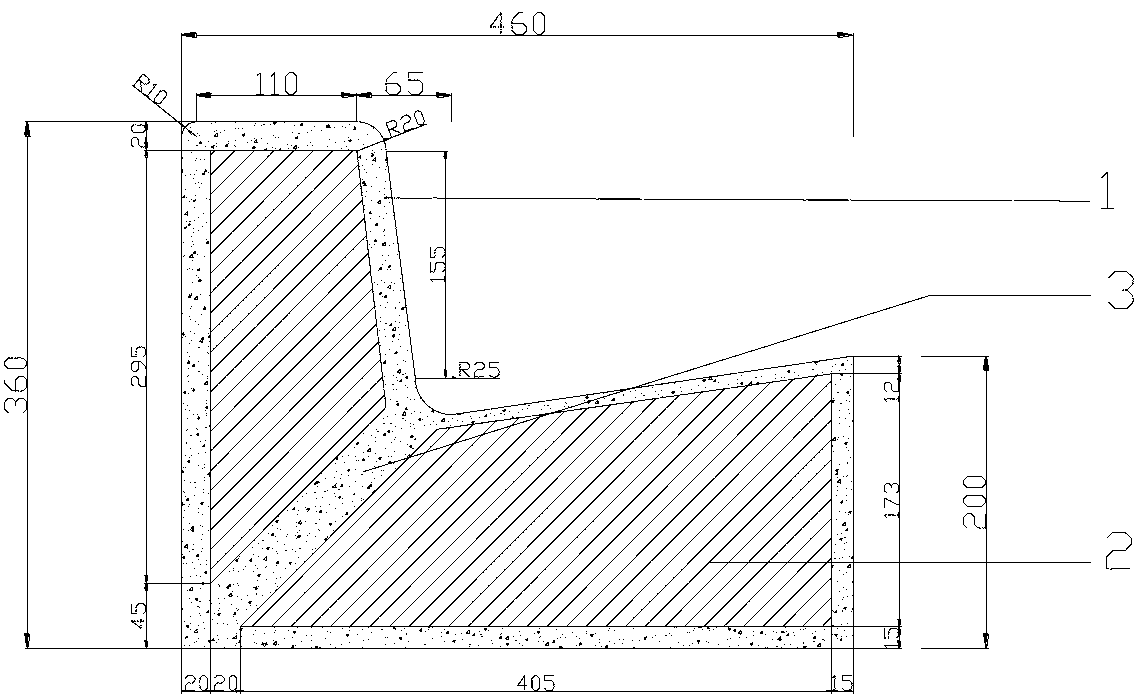

Method for making cored building material block by using solidified soda residue soil

The invention discloses a method for making a cored building material block by using solidified soda residue soil, belonging to the field of civil engineering. The cored building material block is prepared from a solidified soda residue soil core material, a mortar or concrete external coating material and an internal division wall through the steps of solidified soda residue soil core material making, mortar or concrete making, pressure forming, curing and the like. The solidified soda residue soil is a hardenite which has certain strength, is capable of fixing harmful substances in soda residue soil to reduce or eliminate the harmful substance leaching phenomenon along with water and is formed by uniformly blending a curing agent and soda residues (waste residues of waste liquid discharged in the process of producing soda by using an ammonia-soda process) and subjecting the curing agent and the soda residue soil to a physical-chemical reaction. Waste liquid and waste residues discharged in the industrial production process of soda are effectively utilized, and the reduction, harmlessness and reclamation of the soda residues are realized.

Owner:BEIHANG UNIV

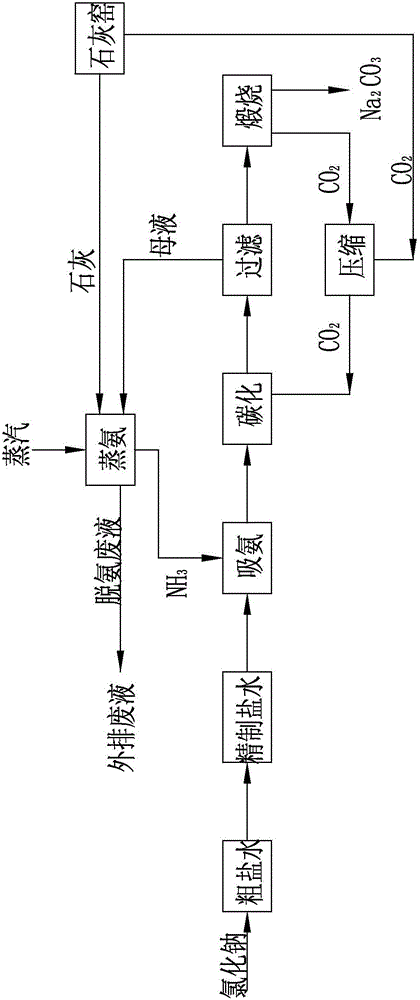

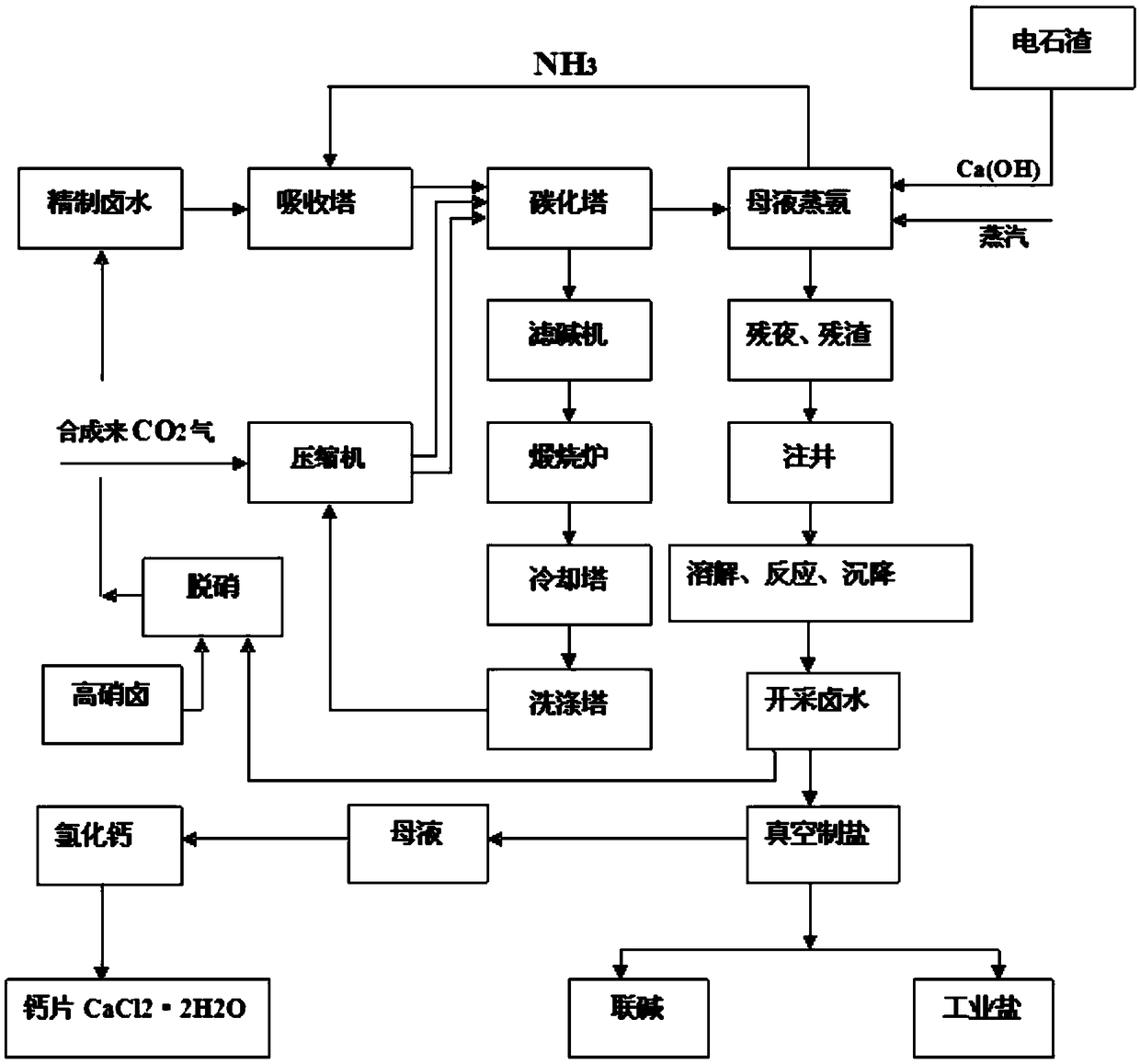

Method for producing sodium carbonate by utilizing chlor-alkali ammonia-alkali tailings

The invention relates to a method for producing sodium carbonate, in particular to a method for producing sodium carbonate by utilizing chlor-alkali ammonia-alkali tailings. Limestone burns to emit heat, and is resolved to generate carbon dioxide gas which is sent to a compressor; the acetylene sludge slurry of the chlor-alkali tailing and calcium carbide dust are mixed to prepare lime slurry; refined salt water is prepared through light salt brine after production of chlor-alkali and mirabilite; light ammoniacal brine is sent to an absorption tower to prepare ammoniacal brine; sodium bicarbonate slurry is sent to a filtering alkali vehicle for solid-liquid separation; the solid body is sent to a sodium bicarbonate calcination procedure; the liquid is sent to a mother liquid distillation procedure; the sodium bicarbonate is conducted by heating resolving in a sodium bicarbonate calcination furnace to generate sodium carbonate, and is sent to a sodium bicarbonate production and alkali cooling procedure; the generated carbon dioxide gas returns to a carbonizer. The method produces sodium carbonate by utilizing the carbon dioxide emitted by the ammonia-alkali and the acetylene sludge slurry emitted by the chlor-alkali, realizes combined production of the two alkalis, solves the problem of emission of the alkali wastes, reduces consumption of limestone and energy, improves the utilization ratio of the carbon dioxide, and improves the production of sodium carbonate through an ammonia soda process.

Owner:TANGSHAN SANYOU CHEM IND

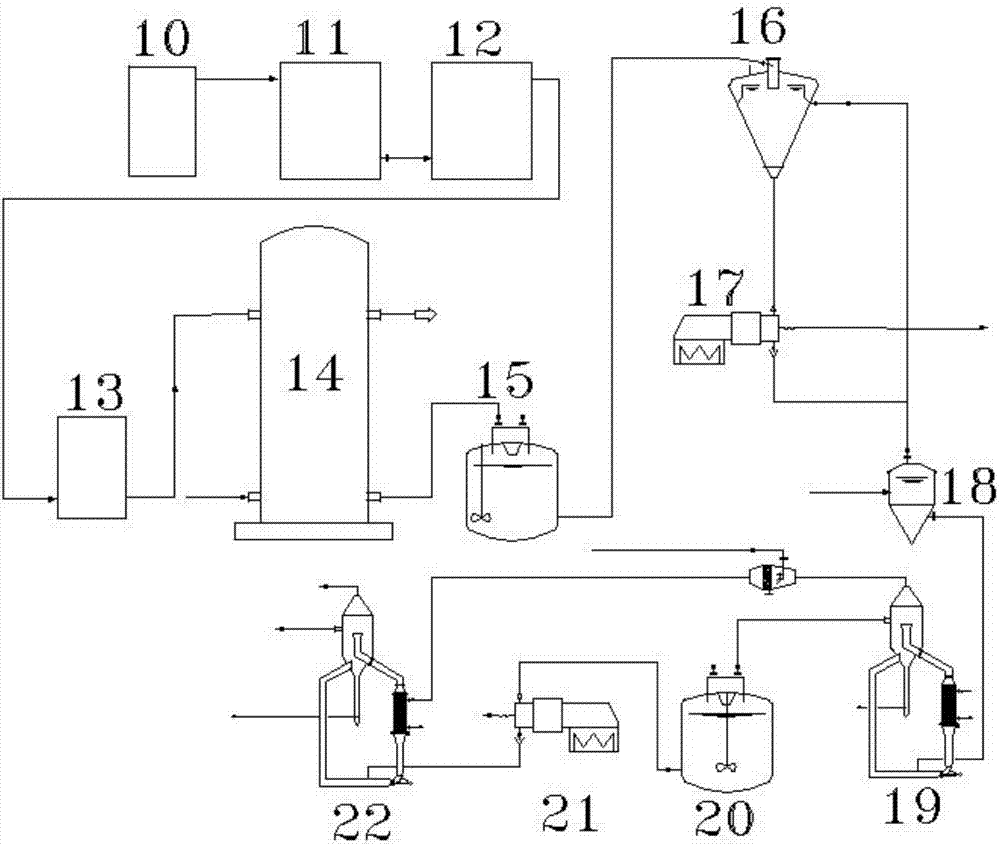

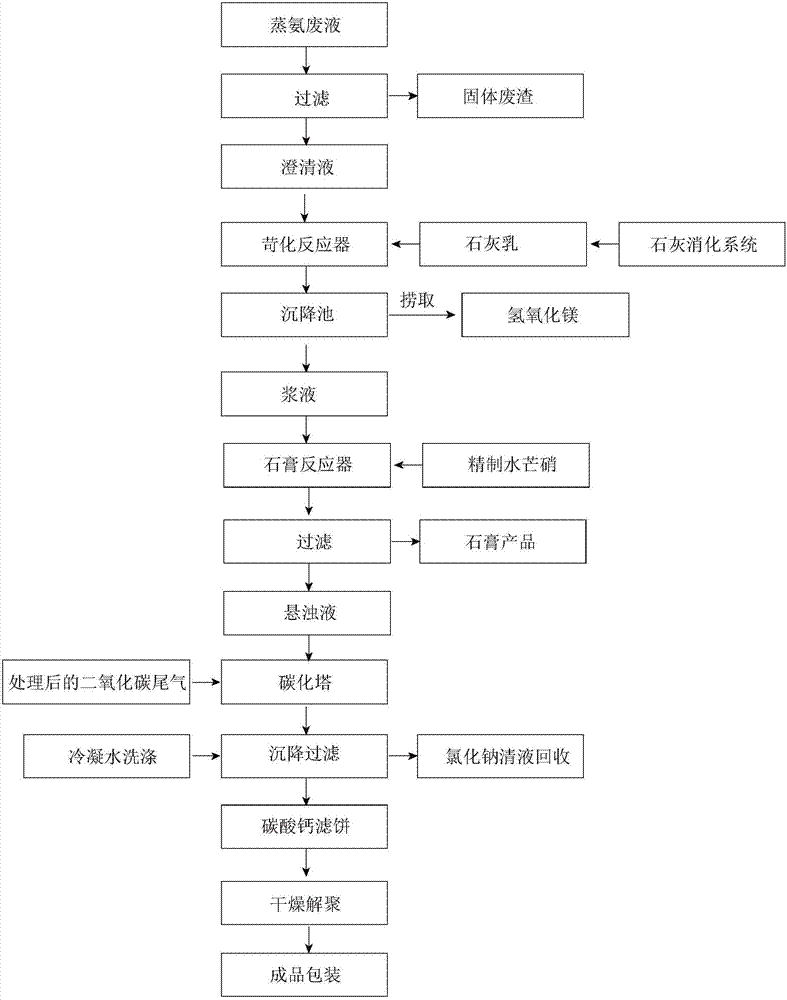

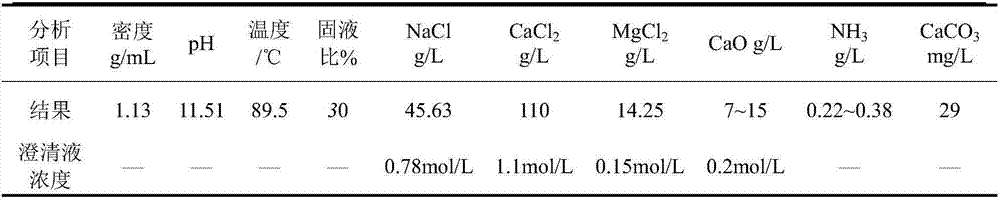

New method for recycling ammonia distillation wastewater discharged during production of soda ash by virtue of ammonia-soda process

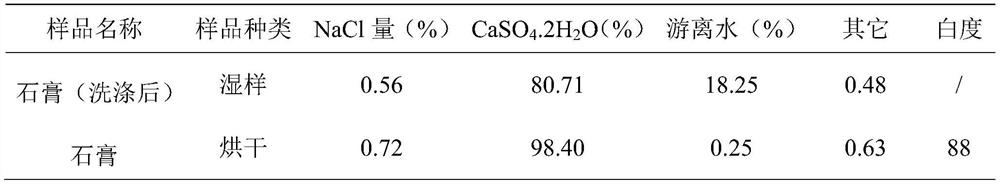

ActiveCN107089675AEasy to handleIncrease profitCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesDistillationCarbonization

The invention belongs to the technical field of wastewater treatment and provides a new method for recycling ammonia distillation wastewater discharged during production of soda ash by virtue of an ammonia-soda process. The new method comprises the following steps: clarifying the ammonia distillation wastewater, and filtering, so that clarified liquor and solid waste residue are obtained; adding excessive lime milk into the clarified liquor, carrying out causticizing reaction, and obtaining magnesium hydroxide floating on liquid surface and slurry after the causticizing reaction is finished; respectively adding the slurry and excessive refined mirabilite aqueous solution into a gypsum reactor, fully reacting, filtering products, and washing, so that a dehydrate gypsum filter cake and turbid liquid containing sodium chloride and calcium hydroxide are obtained; carrying out dust removal and desulfurization purification treatment on carbon dioxide waste gas, introducing into a carbonization tower, carrying out carbonation reaction with calcium hydroxide in the turbid liquid, settling, and filtering, so that a light calcium carbonate filter cake and sodium chloride clear liquid are obtained; and applying the sodium chloride clear liquid to an alkali making system, so that sodium chloride in the clear liquid is recycled. The new method provided by the invention solves the technical problem that waste produced in a soda ash production process by virtue of the ammonia-soda process in the prior art cannot be comprehensively utilized.

Owner:石家庄科林威尔环保科技有限公司

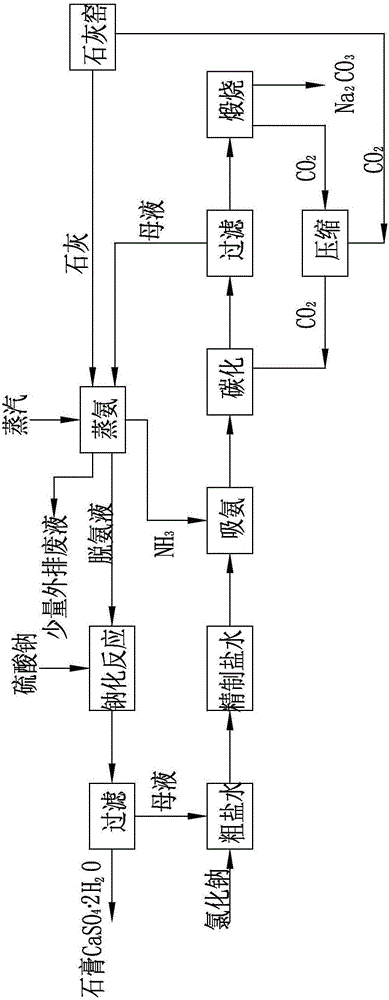

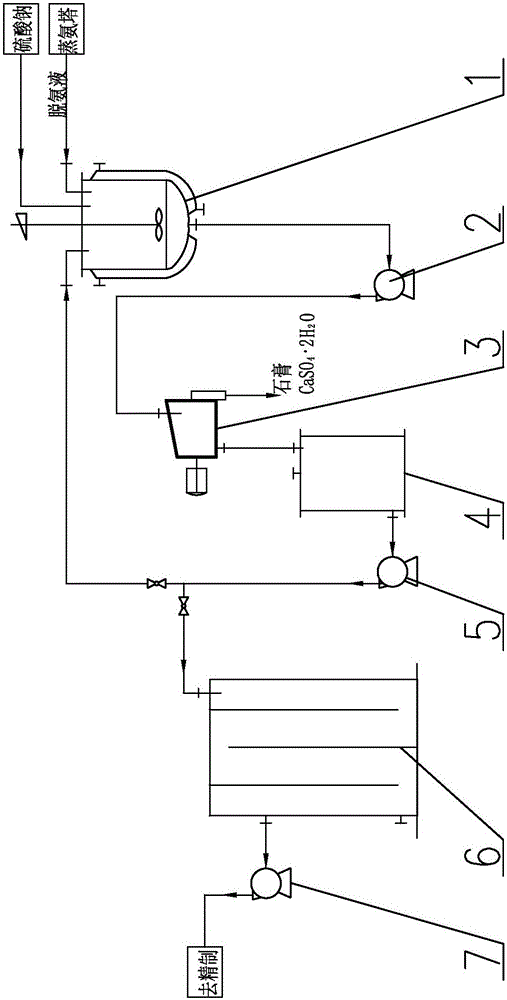

Method for preparing sodium carbonate from sodium sulfate

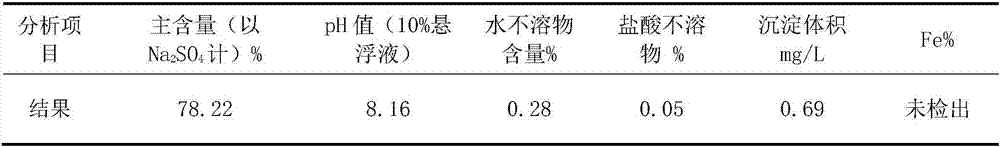

InactiveCN106082281ASolve resource problemsAchieve recyclingAlkali metal carbonatesWater dischargeDistillation

The invention relates to a method for preparing sodium carbonate from sodium sulfate. The method comprises, based on the original ammonia-soda process for sodium carbonate preparation, clarifying to remove impurities in an ammonia distillation mother liquor, stirring the ammonia distillation mother liquor at a temperature of 30-65 DEG C, according to calcium chloride content, adding sodium sulfate into the ammonia distillation mother liquor according to a mole ratio of calcium chloride to sodium sulfate of 1: 1-1.1, carrying out a reaction process to obtain sodium chloride and gypsum (CaSO4. 2H2O) precipitates, carrying out filtration to obtain unsaturated primary brine and carrying out later ammonia-soda process-based production. The method utilizes sodium sulfate as a raw material, utilizes chloride ions and ammonia as intermediate mediums, realizes resource cyclic utilization, reduces waste water generation and is very important. The method can reduce sodium carbonate production wastes, utilizes sodium sulfate or saltcake raw ore as production raw materials, reduces enterprise water consumption and waste water discharge, reduces solid waste production and improves enterprise economic benefits.

Owner:史永军 +1

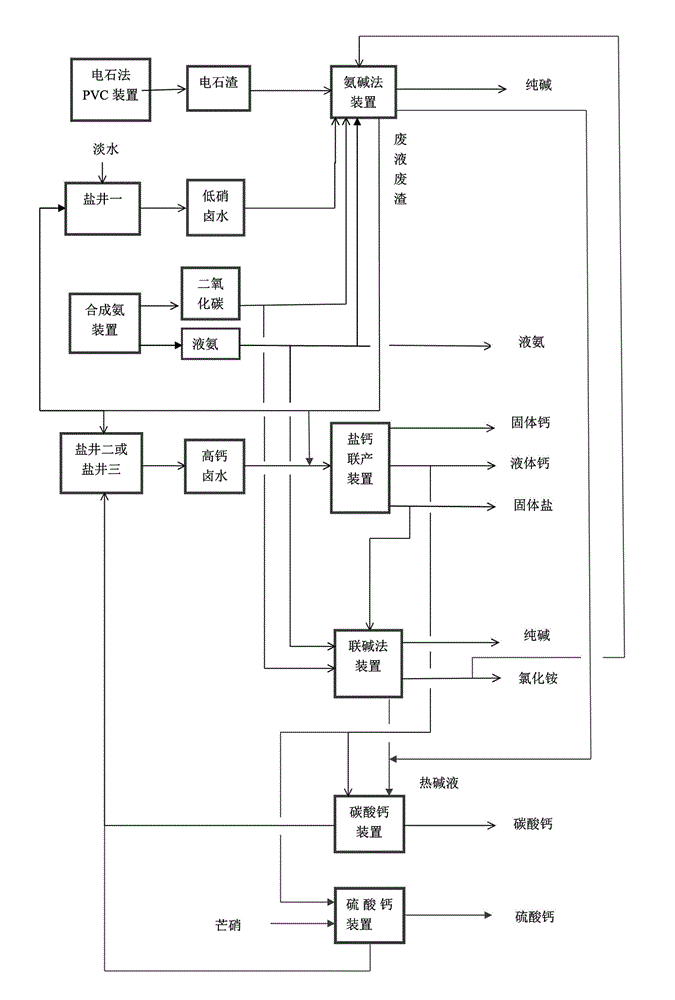

Ammonia-soda-combined-soda cyclic production process and application thereof

ActiveCN104528765AReduce pollutionReduce wasteCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesSludgeSalt calcium

The invention relates to a process of ammonia-soda-combined-soda cyclic production for sodium chloride, sodium carbonate, liquid ammonia, ammonium chloride, calcium chloride and calcium carbonate. The process comprises the following steps: using brine, carbon dioxide and acetylene sludge as raw materials for producing sodium carbonate by an ammonia-soda method, injecting the generated waste liquid in a salt well and extracting brine, leaving and storing the calcium sulphate generated after nitrate removal and the injected soda sludge in the salt well, conveying the extracted brine into a salt calcium co-production device, producing a solid salt, reacting a part of the remainder solution with sodium carbonate to produce calcium carbonate, using a part as liquid calcium chloride, and evaporating the other part to produce calcium chloride dehydrate; using the obtained solid salt, ammonia and carbon dioxide as raw materials for producing sodium carbonate and ammonium chloride by a combined-soda method; adding wet ammonium chloride in the ammonia-soda waste liquid and decomposing. According to the process, the efficiency and yield of cyclic production are increased, and environmental pollution is reduced; the purities of sodium carbonate, calcium carbonate, ammonium chloride and solid salt are up to 99.0%, 99.9%, 99.5% and 95% respectively, the content of solid calcium is 74%, liquid calcium can be optimally configured, and the particle size of calcium carbonate is nanometre-submicron order.

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD

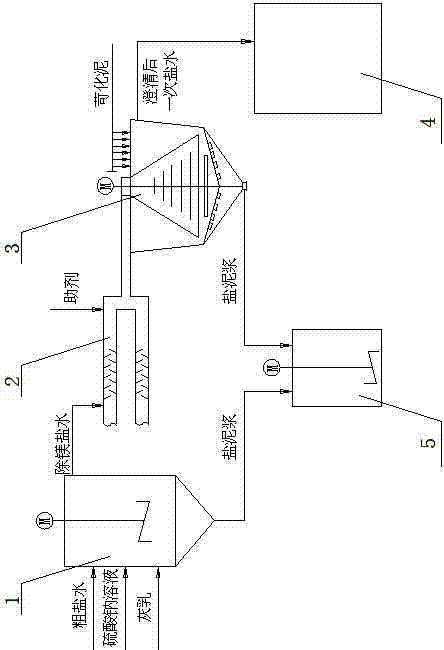

Brine refinement technique

ActiveCN103880042AReduce consumptionDesaturationAlkali metal halide purificationChemistrySolvay process

The invention relates to a brine preparation technique, particularly a brine refinement technique. The technique comprises the following steps: adding crude brine, lime milk and a sodium sulfate solution into a primary reactor, and mixing to react in the reactor; sending the reaction solution in the primary reactor to a primary brine settling tank through a chute, carrying out solid-liquid separation on primary refined brine and brine sludge in the primary brine settling tank, sending the clear primary refined brine from the upper part of the primary settling tank to a secondary refinement reactor to perform calcium removal; sending the brine sludge discharged from the top of the primary brine settling tank and silt discharged from the primary reactor into a sludge washing barrel to be washed, and recovering raw salt; and when different degrees of calcium sulfate scales are formed on the equipment and pipelines after the sulfate content in the sodium sulfate solution increases, adding causticized low-concentration alkali liquor into the primary brine settling tank to eliminate the scales. The technique avoids the scales of the production equipment system and improves the lime-sodium carbonate brine refinement method from sodium carbonate by an ammonia soda process.

Owner:TANGSHAN SANYOU CHEM IND

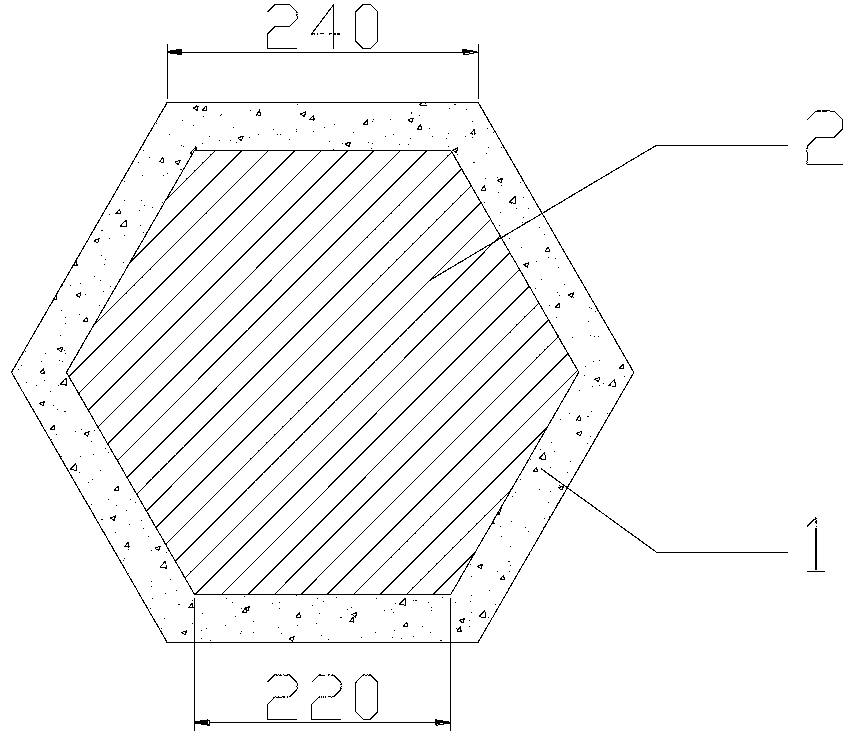

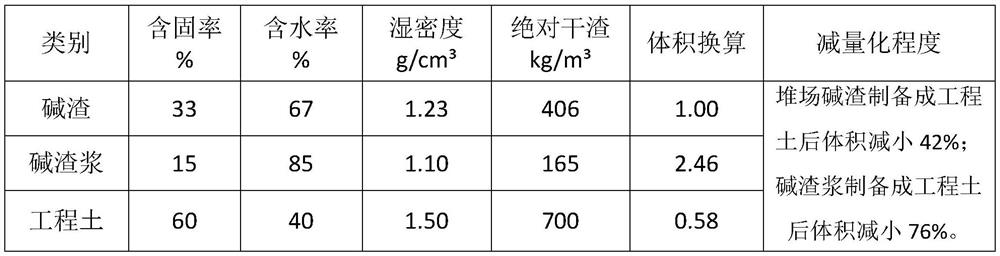

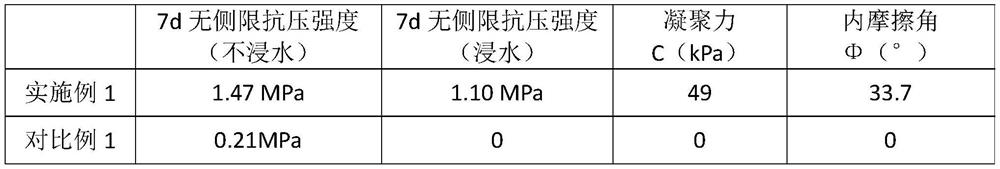

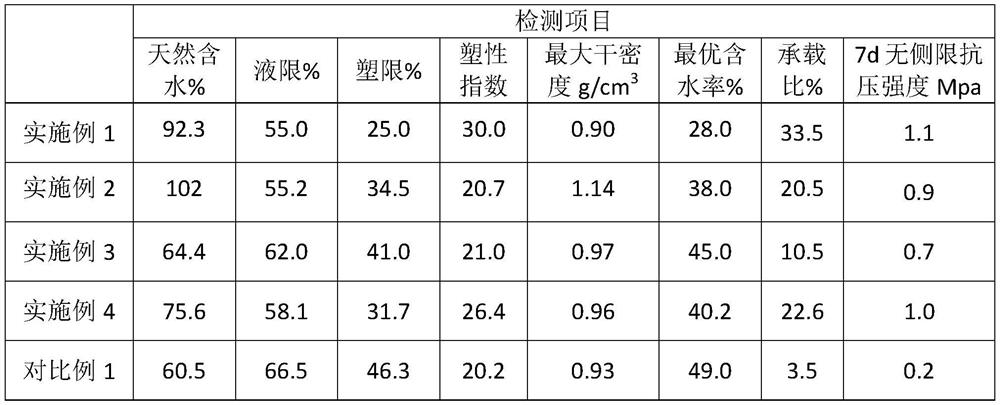

Method for preparing engineering soil from alkaline residues by ammonia-alkaline method

PendingCN111606635AImprove dehydration effectReduce moisture contentSoil scienceEnvironmental engineering

The invention discloses a method for preparing engineering soil from alkaline residues by an ammonia-alkaline process. The method comprises the step of: sequentially carrying out sediment treatment, concentration treatment, homogenization modification, dehydration treatment and stacking treatment on alkaline residues to obtain engineering soil, wherein the homogenizing modification comprises the following specific steps: adding a calcium material and a volcanic ash active material into the concentrated alkaline residues, and uniformly stirring the mixture; and the mass ratio of dry substancesin the calcium material, the volcanic ash active material and the concentrated alkaline residues is (0-15): (5-20): 100. The method has the advantage of improving the strength and water stability of the engineering soil prepared from the alkaline residues.

Owner:ROAD ENVIRONMENT TECH

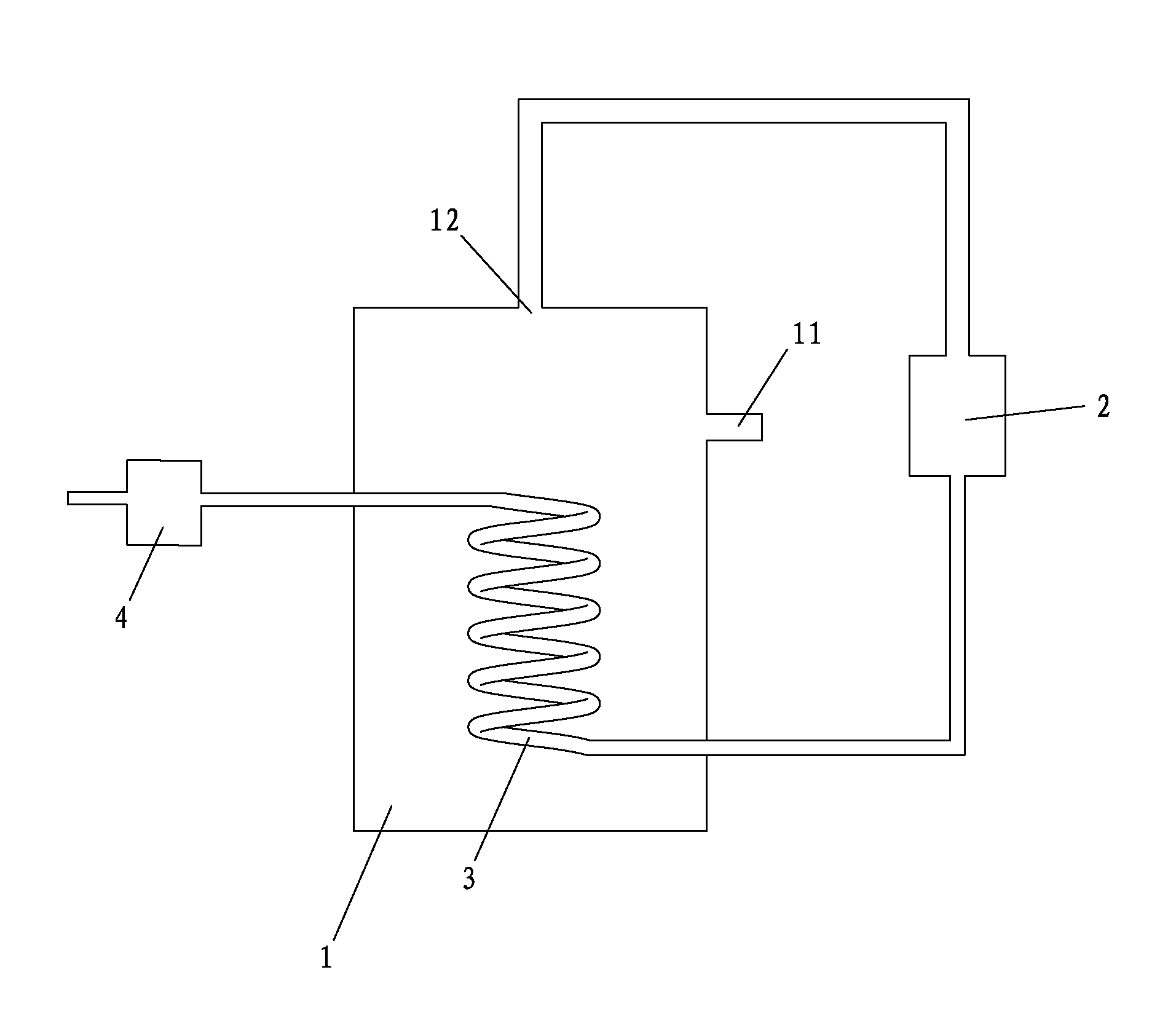

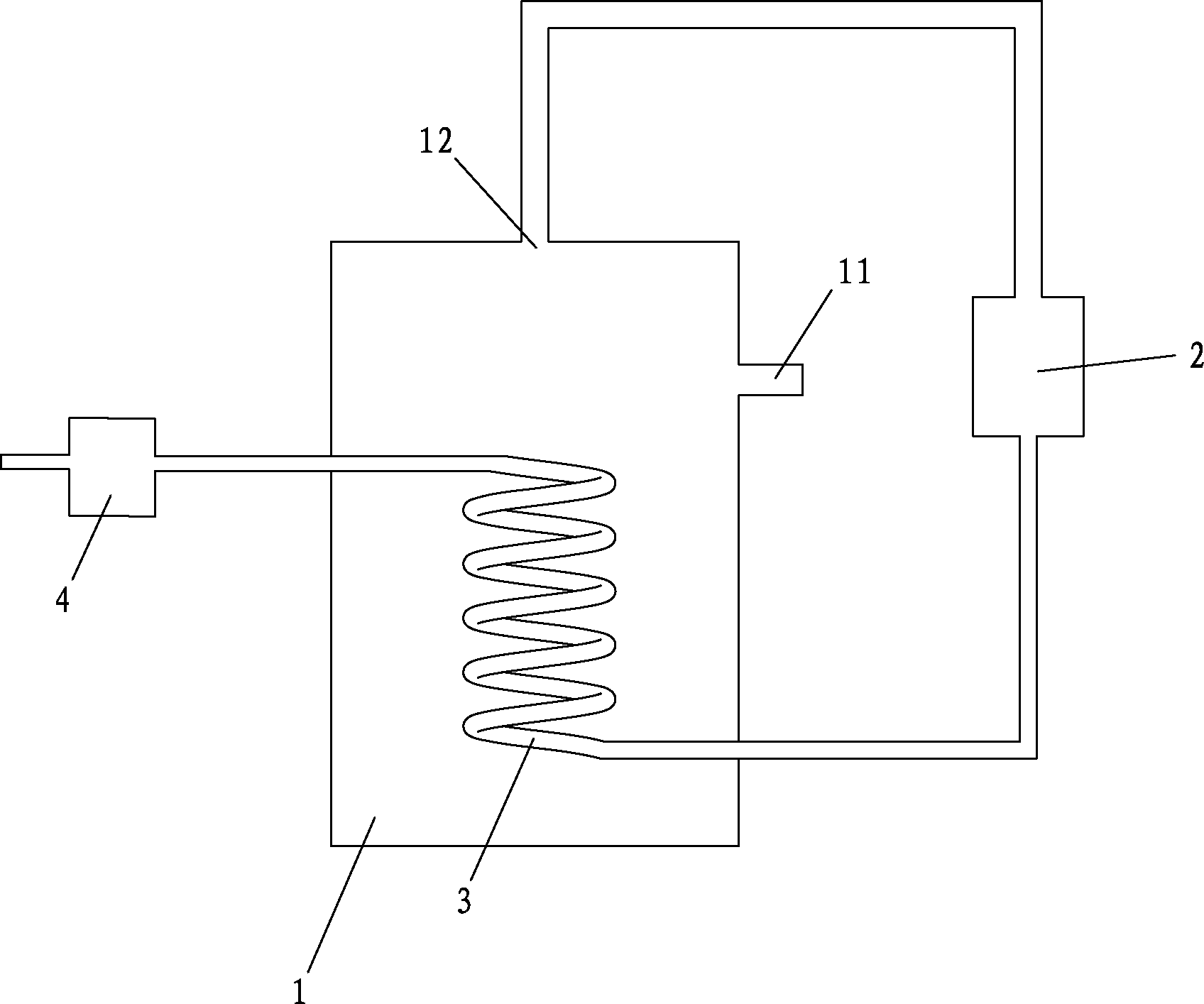

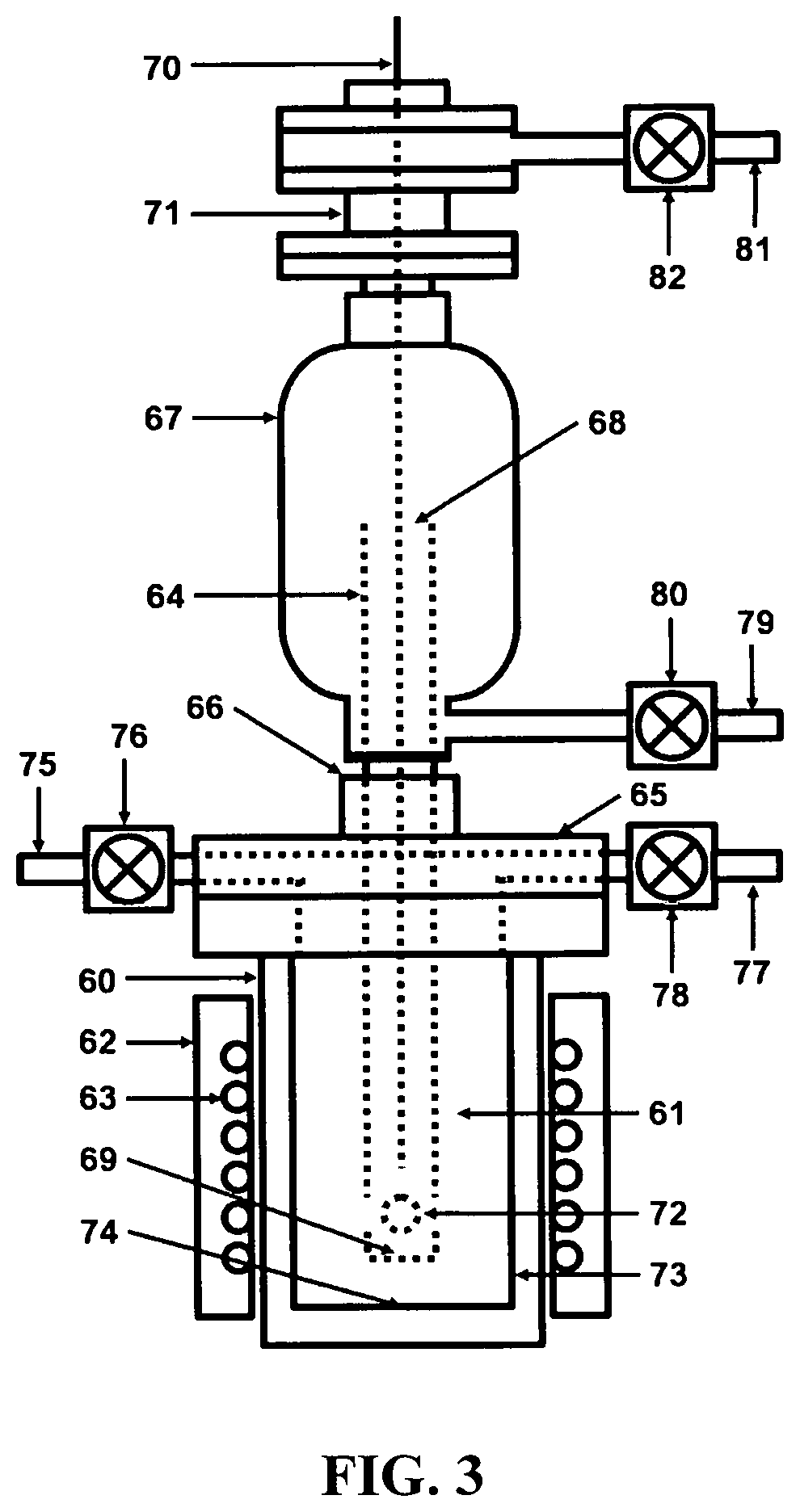

Method and device for recycling waste clear liquid produced in process for producing sodium carbonate by ammonia-soda process

ActiveCN102515201AAvoid the disadvantages of polluting the environmentHigh purityAlkali metal oxides/hydroxidesDistillationDistilled water

The invention relates to the technical field of soda production, in particular to a method and a device for recycling waste clear liquid produced in a process for producing sodium carbonate by an ammonia-soda process. The method for recycling the waste clear liquid comprises the following steps of: leading the waste clear liquid into a waste liquid tank; starting a compression device to ensure that negative pressure is formed in the waste liquid tank, and recycling according to a gas and liquid heat exchange principle to obtain distilled water; when water is evaporated to ensure the concentration of sodium chloride in the waste clear liquid is increased until sodium chloride precipitate is separated out, performing liquid-solid separation to obtain sodium chloride; and continuously pressurizing to compress the waste clear liquid to ensure that the concentration of calcium chloride in the waste clear liquid is increased until calcium chloride precipitate is separated out, performing solid-liquid separation to obtain calcium chloride. By the method, the chemical pollution of the waste clear liquid produced in the process for producing the sodium carbonate by the ammonia-soda process is eliminated, distillation waste liquid can be reformed into a chemical product with certain economic value, the negative pressure and pressurization principles are skillfully used, sodium chloride and calcium chloride in the waste clear liquid can be recycled, and distilled water can be extracted; and the method has the advantages of simplicity, low production cost, and high economic benefit.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

Method for comprehensively utilizing waste liquid generated in process of preparing alkali by ammonia-alkali method

ActiveCN112850770AGuarantee normal productionReduce accumulationCalcium/strontium/barium sulfatesFluid removalEngineeringSlurry pump

The invention belongs to the technical field of mineral development, and particularly relates to a method for cyclically and comprehensively utilizing waste liquid generated in the process of preparing an alkali by an ammonia-alkali method. The method for comprehensively utilizing the waste liquid generated in the process of preparing the alkali by the ammonia-alkali method comprises the following steps: naturally settling the pretreated alkali-making waste liquid, and separating to obtain a light calcium liquid; mixing the light calcium liquid with a salt-making discharged mother liquor, and reacting to generate mixed slurry of calcium sulfate dihydrate and sodium chloride; pumping the mixed slurry into a settling tank by using a slurry pump, and thickening the solid content of the slurry to obtain thick slurry; and carrying out solid-liquid separation on the thick slurry to obtain afiltrate II and filter residues II, and washing the filter residues II with water to obtain gypsum, wherein the filtrate II is a high-concentration NaCl solution, and is injected into a mine well to be extracted. By means of the method, the situation that calcium sulfate generated underground deposits and covers mineral resources at the bottom of the well can be reduced, calcium sulfate and calcium carbonate products can be obtained in the circulation process, and mineral resources are more fully utilized.

Owner:JIANGXI JINGHAO SALINIZATION

Circulating green production method for salt, alkali and calcium on and underneath ground

PendingCN111115674AImprove recovery rateLow in calciumCalcium/strontium/barium sulfatesAlkali metal chloridesResource recoveryWastewater

The invention relates to the technical field of salt chemical engineering resource recycling, and particularly discloses a circulating green production method for salt, alkali and calcium on and underneath the ground. According to the method, calcium chloride in ammonia-alkali waste liquid and sodium sulfate and glauberite in a mirabilite type rock salt resource are mixed; waste liquid is treatedon the ground in stages, meanwhile, waste resources are reasonably utilized, and all resources such as Ca<2+>, Cl<->, SO4<2-> and Na<+> are recycled; and the problem of pollution caused by discharge of wastewater from a traditional ammonia-alkali process is solved, and cyclic utilization and green production of the resources are achieved.

Owner:JIANGXI JINGHAO SALINIZATION

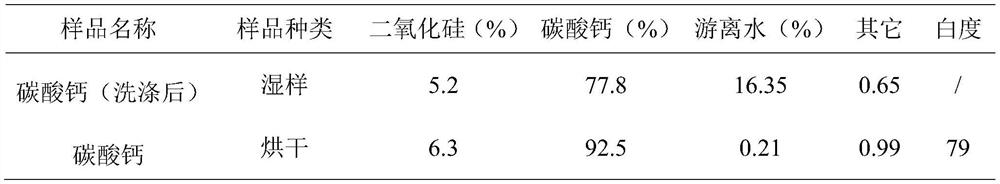

Method of recycling of by-products for the production of soda ash and ammonium sulphate

InactiveUS9193601B2Lower requirementEasy dischargeAmmonium sulfatesCarbonate preparationSolvay processCalcination

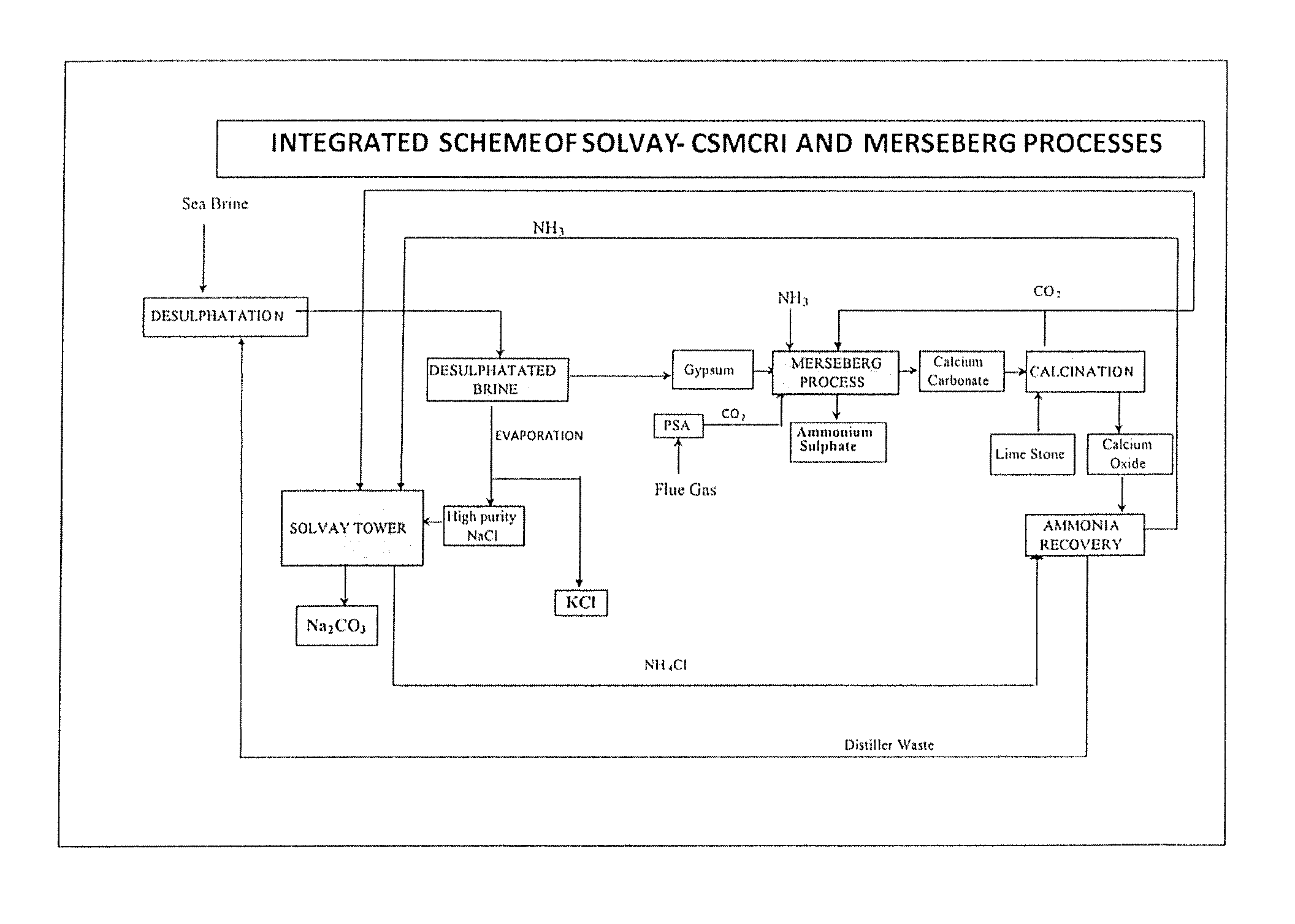

A method of producing soda ash and ammonium sulphate by recycling by-products of Merseberg and Solvay processes includes treating brine with soda ash distiller waste for desulphatation of the brine to obtain gypsum, recovering pure salt from the desulphated brine and utilizing it in manufacture of soda ash in a Solvay process, washing the gypsum and reacting it with liquor ammonia and carbon dioxide to obtain CaCO3 and ammonium sulphate, separating the CaCO3 from the ammonium sulphate solution and recovering solid ammonium sulphate, washing the CaCO3 followed by calcination to generate CO2 and lime, recycling the CO2 in the Solvay process to obtain soda ash, recycling the lime with ammonium chloride generated in the Solvay process to recover ammonia and obtain distiller waste containing CaCl2 as a by-product, recycling the by-product distiller waste for the desulphatation of the brine, and recycling the ammonia recovered.

Owner:COUNCIL OF SCI & IND RES

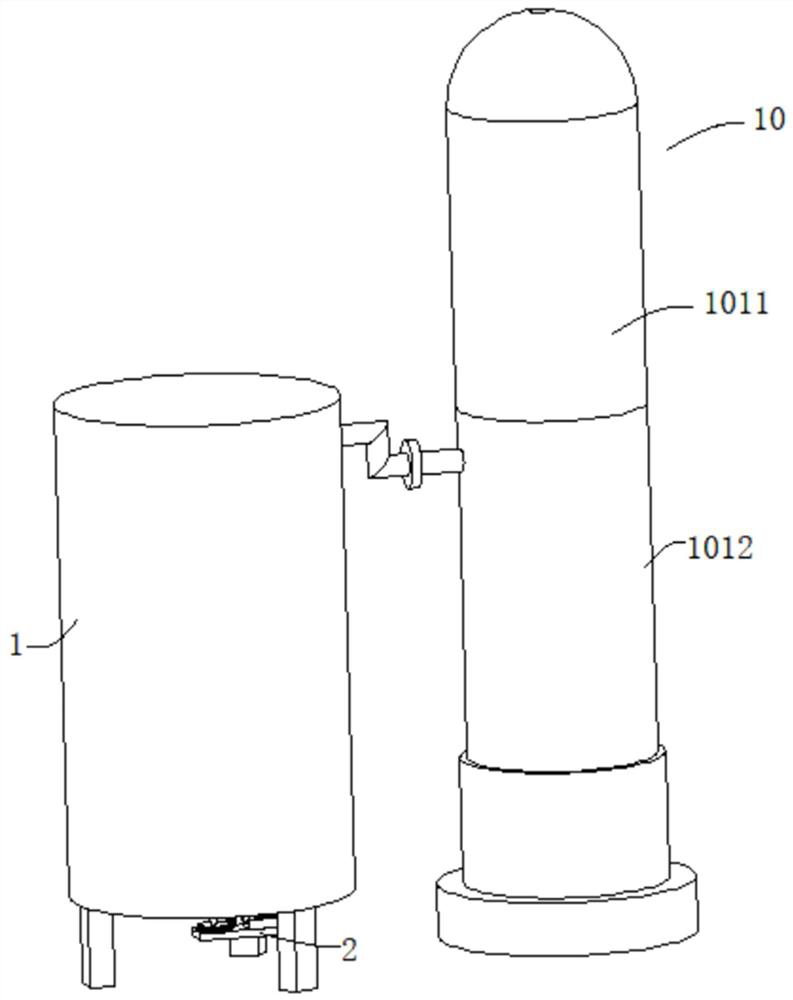

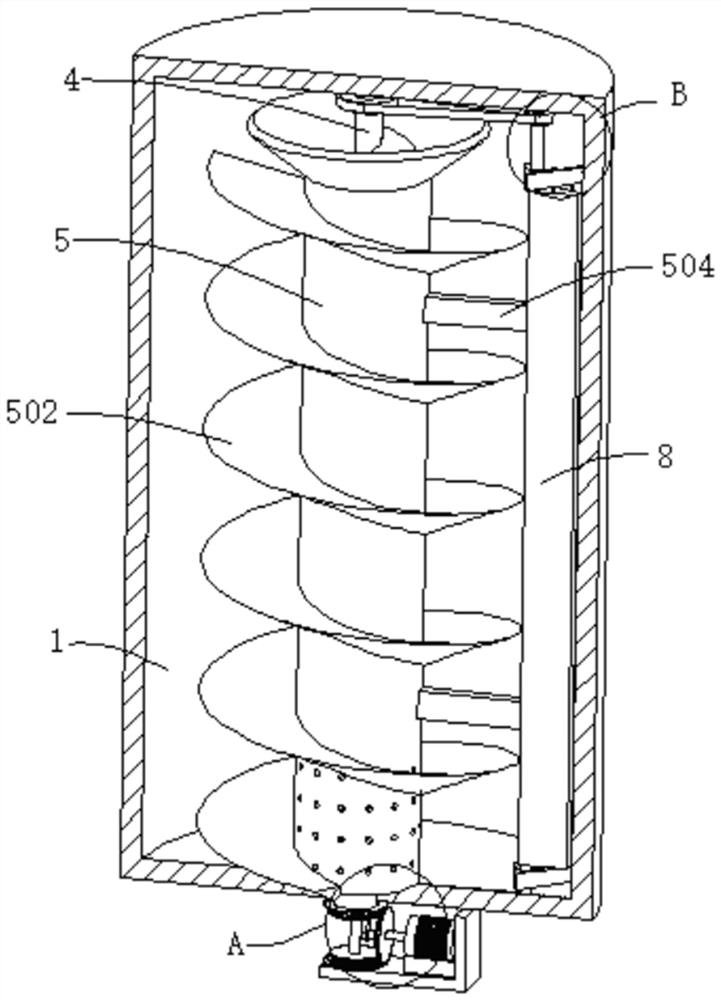

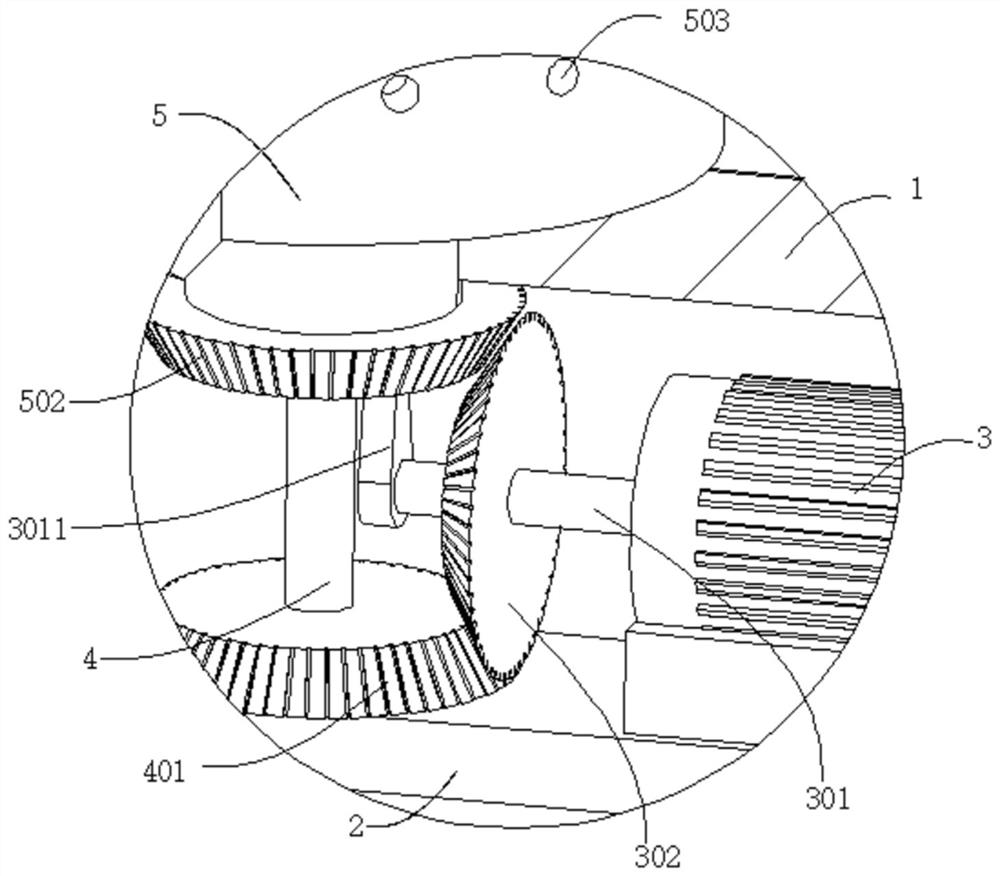

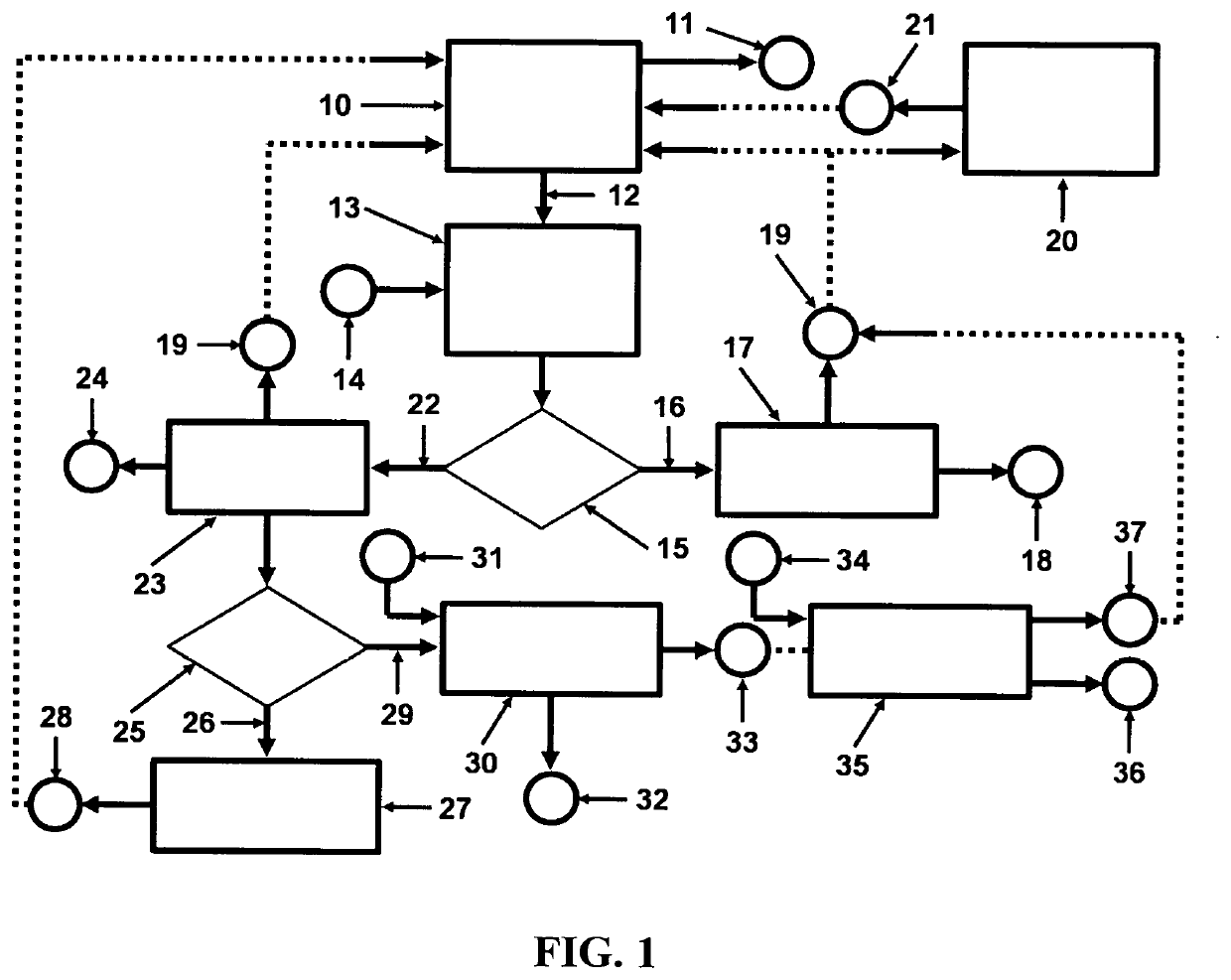

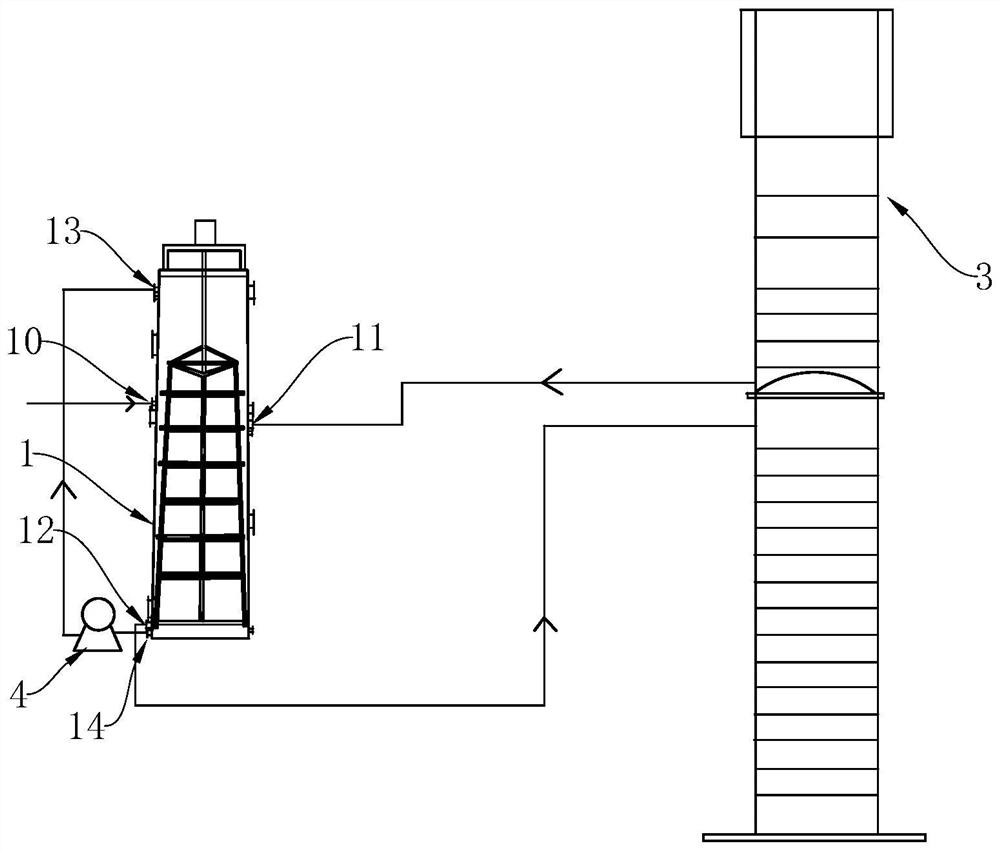

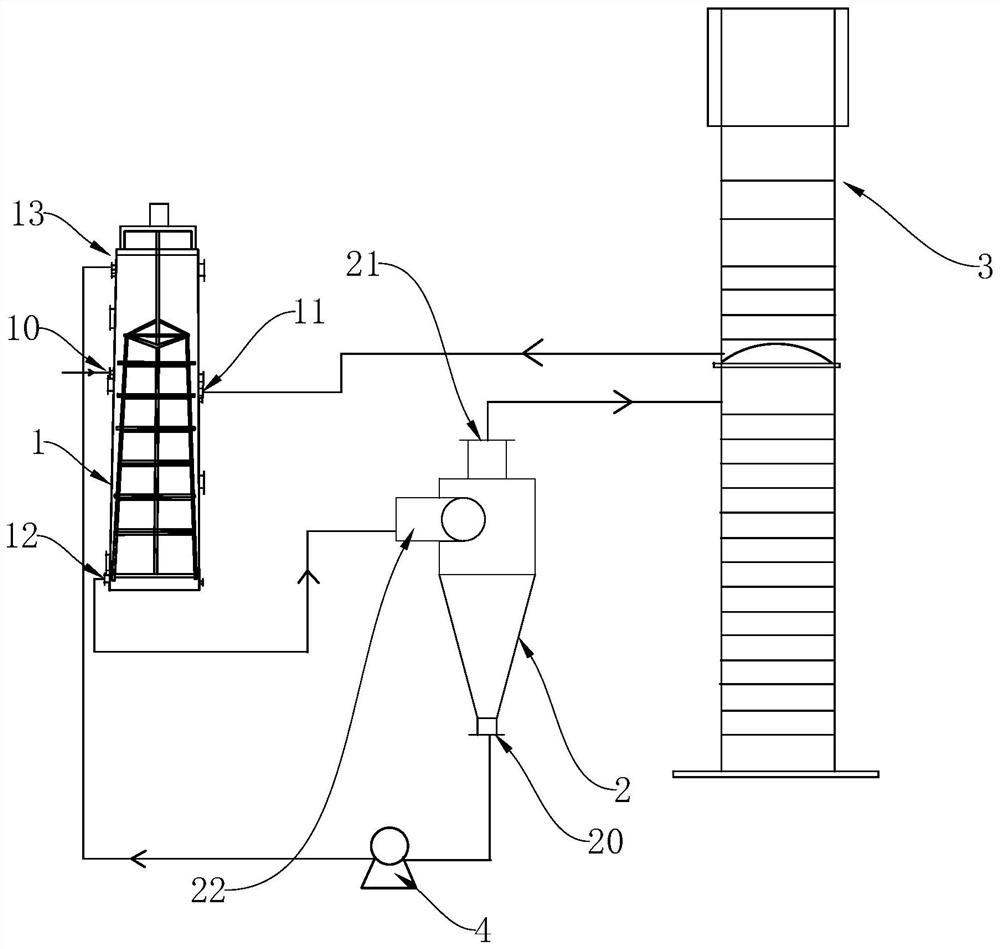

Ammonia-soda-process soda ash production process optimization system based on material balance

ActiveCN112573543AAvoid cloggingAvoid wear and tearCarbonate preparationParticulatesMaterial balance

The invention discloses an ammonia-soda-process soda ash production process optimization system based on material balance, and belongs to the technical field of ammonia-soda-process soda ash production. The ammonia-soda-process soda ash production process optimization system based on material balance comprises a preliming barrel and an ammonia distillation tower, the preliming barrel is connectedwith the ammonia distillation tower through a connecting pipe, the bottom of the preliming barrel is connected with a supporting base, the outer wall of the supporting base is connected with a motor,the output end of the motor is connected with a rotating shaft, and the end, away from the motor, of the rotating shaft is connected with a first bevel gear; particulate matter in the pre-liming barrel is conveyed to the top of the pre-liming barrel through the second spiral conveying blade, then the particulate matter moving to the top is conveyed into the filter screen cylinder through the firstspiral conveying blade, the particles in a solution are collected through the filter screen cylinder, equipment blockage and abrasion are avoided, and when the pre-liming barrel is cleaned, the pre-liming barrel is prevented from being blocked and abraded, only the filter screen cylinder needs to be cleaned, the maintenance time is shortened, the soda ash production capacity of equipment is further ensured, and the production cost is reduced.

Owner:安徽德邦化工有限公司

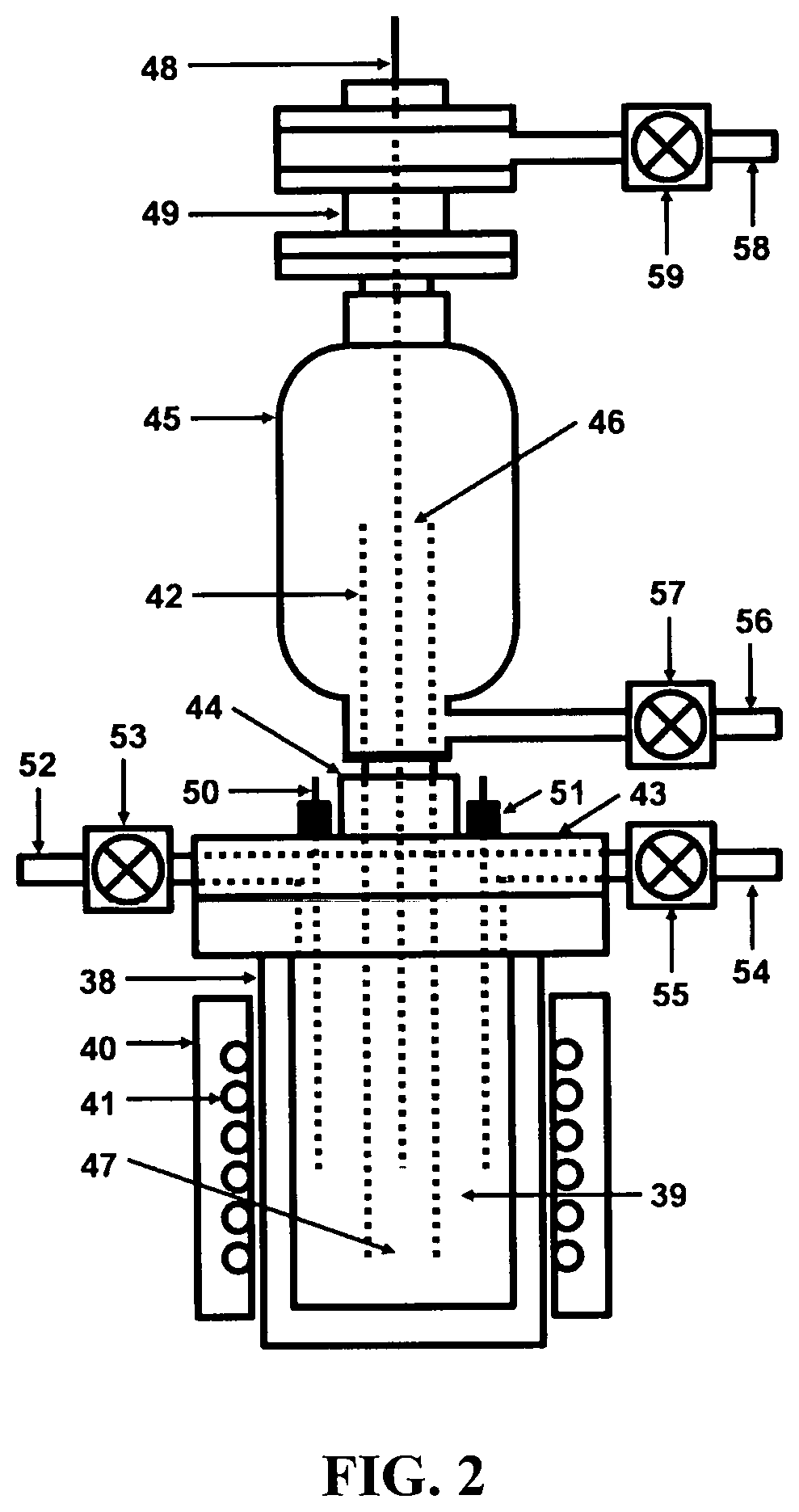

Comprehensive utilization method and equipment for producing soda ash residue by ammonia-soda process

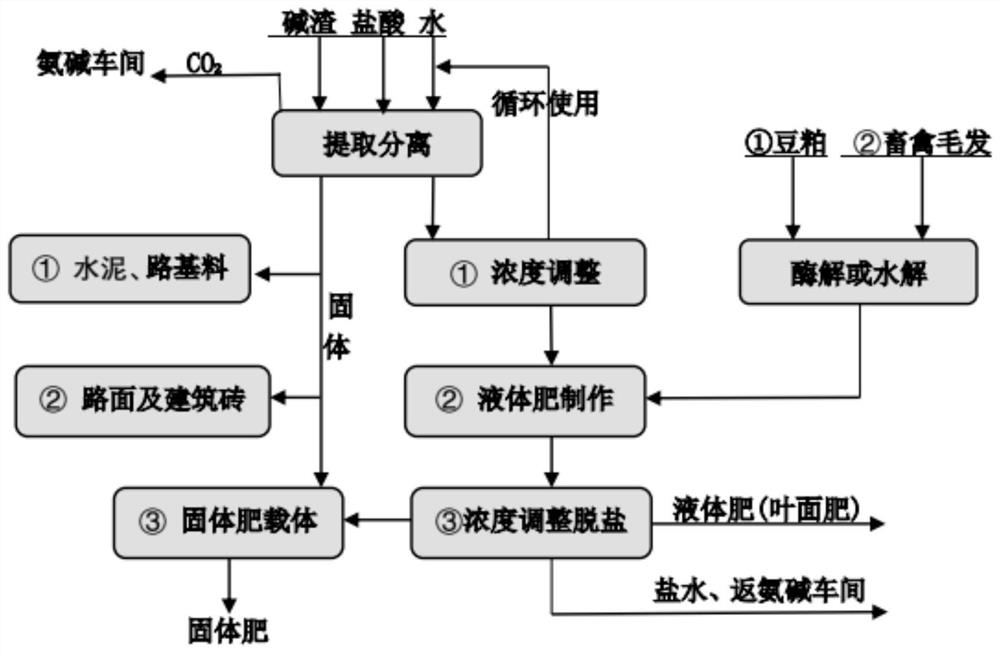

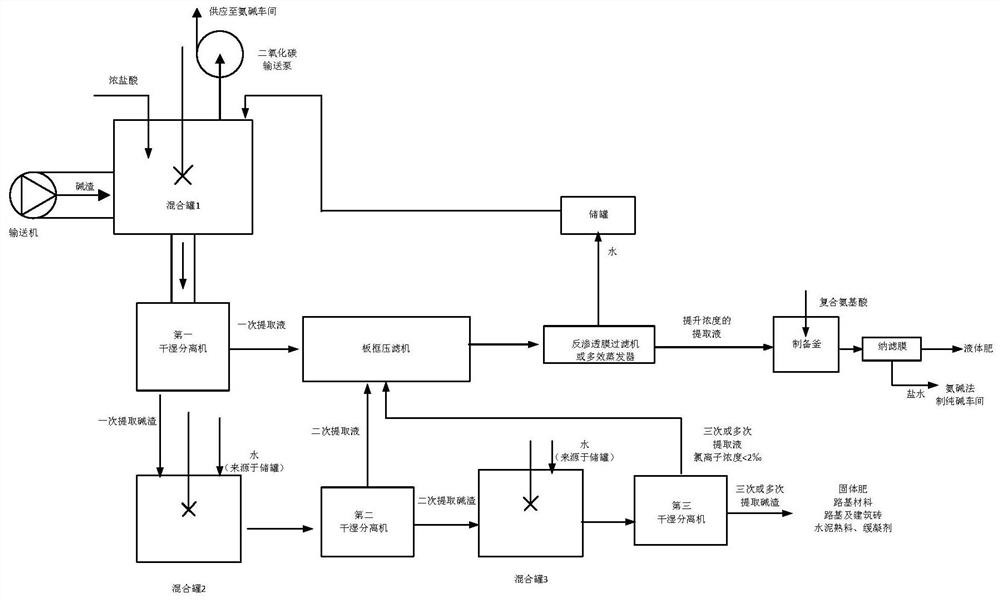

ActiveCN113976068ARealize comprehensive utilizationImprove processing efficiencySolid waste managementReverse osmosisClinker (waste)Solvay process

The embodiment of the invention provides a comprehensive utilization method and equipment for producing soda ash residue by using an ammonia-soda process, which comprises the steps of adjusting the pH value of the soda residue to 6.5-7.5 by using hydrochloric acid, and converting calcium-containing and magnesium-containing components in the soda residue into corresponding chlorides; and carrying out dry-wet separation, repeatedly washing solids until the chloride ion concentration is 0.2% or below, adjusting the concentration of the generated liquid, and chelating with compound amino acid to form a compound amino acid chelated liquid / solid / body fertilizer, wherein the obtained solid sand ash is used for manufacturing cement clinker, a retarder, a baking-free brick, a solid fertilizer and / or a roadbed material. Various components of the soda residue are comprehensively utilized, and waste is turned into wealth.

Owner:关祥瑞

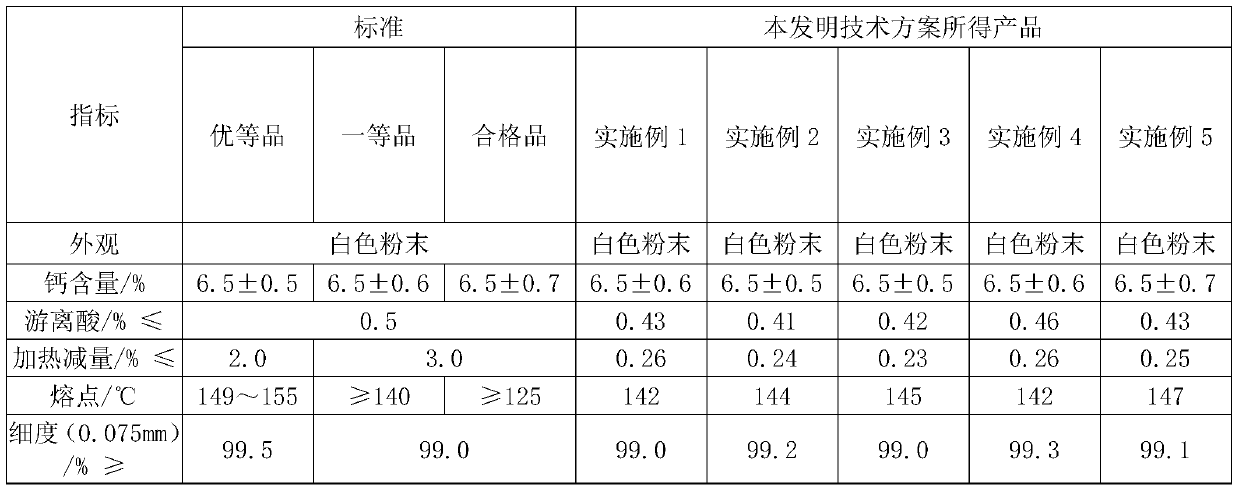

Method for producing low-salt high-quality dense soda ash

The invention provides an improved method for producing low-salt high-quality dense soda ash by using light soda ash produced by a hot method alkali combination process as a raw material. The method comprises the following steps: firstly, producing the light soda ash containing 0.5 to 0.9 percent of NaCl in mass fraction through hot method alkali combination; and secondly, producing the low-salt high-quality dense soda ash containing less than 0.3 percent of the NaCl in mass fraction by adopting a liquid-phase hydration method or a modified solid-phase hydration method, wherein in order to ensure the salinity in the product, a certain amount of saliferous mother liquor of 40 to 80 g / L is needed to be discharged from a hydration system continuously or discontinuously and the saliferous soda mother liquor is sent back into a brine refining system, a Na2CO3 component in the mother liquor serves as a calcium remover, and a NaCl component serves as a raw material component. The method overcomes the defects that an ammonia soda process for producing the low-salt dense soda ash has a large sewage discharge and a combination soda production method cannot normally produce the low-salt dense soda ash; the raw materials can be coarse sea salts and mine salts, or bitterns obtained through solution mining of salt mines can be used directly; and the method has the advantages of no sewage discharge, good product quality and extensive development prospect.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

Method and molten salt electrolytic cell for implementing a hydrogen fuel, sustainable, closed clean energy cycle on a large scale

ActiveUS20190348698A1Safe and reliable and cost-effectiveReduce production efficiency and product yieldElectrolysis componentsReactant parameters controlChemical reactionClean energy

A hydrogen fuel, sustainable, closed clean energy cycle based on green chemistry is presented for large scale implementation using a cost effective electrolytic cell. A chemical reaction between salinated (sea) or desalinated (fresh) water (H2O) and sodium (Na) metal produces hydrogen (H2) fuel and sodium hydroxide (NaOH) byproduct. The NaOH is reprocessed in a solar powered electrolytic Na metal production plant that can result in excess chlorine (Cl2) from sodium chloride (NaCl) in sea salt mixed with NaOH, used to effect freezing point lowering of seawater reactant for hydrogen generation at reduced temperatures. The method and molten salt electrolytic cell enable natural separation of NaCl from NaOH, thereby limiting excess Cl2 production. The recovered NaCl is used to produce concentrated brine solution from seawater for hydrogen generation in cold climates, or becomes converted to sodium carbonate (Na2CO3) via the Solvay process for electrolytic production of Na metal without Cl2 generation.

Owner:STERN ALVIN GABRIEL

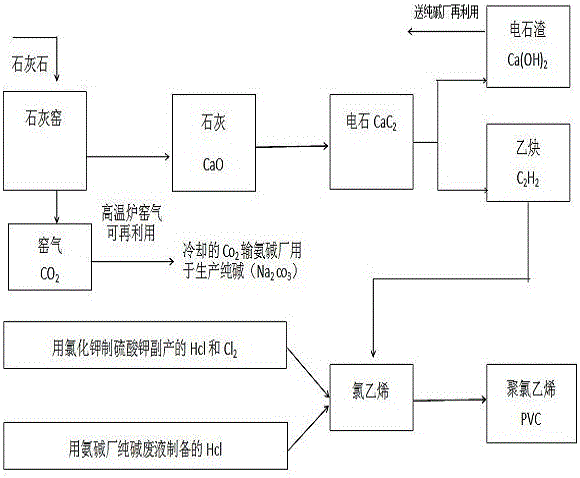

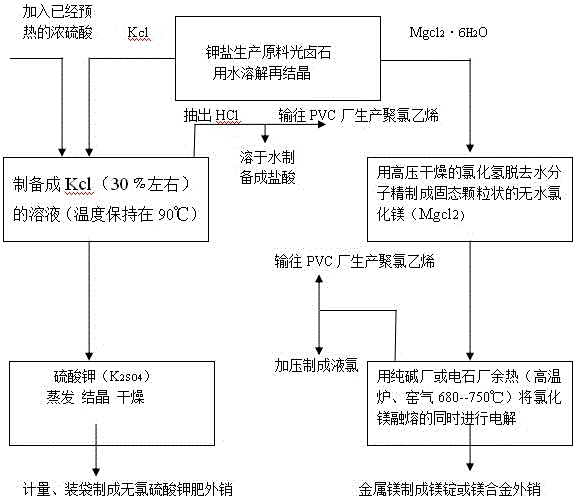

Method for producing potassium sulphate fertilizer magnesium metal PVC and liquid chlorine hydrochloric acid through carnallite

InactiveCN106083221AEmission reductionSave resourcesChlorine/hydrogen-chlorideElectrolysis componentsChemical reactionElectrolysis

The invention discloses a method for producing potassium sulphate fertilizer magnesium metal PVC and liquid chlorine hydrochloric acid through carnallite. According to the technical route, firstly, the carnallite is dissolved with water and then is crystallized, potassium chloride and magnesium chloride hexahydrate contained in the carnallite are separated and purified; then, the magnesium chloride hexahydrate is electrolyzed through the improved Norsk Hydro process to prepare magnesium metal and chlorine; thirdly, a potassium chloride solution and concentrated sulfuric acid are subjected to a chemical reaction under a heated condition to prepare potassium sulfate fertilizer and hydrogen chloride; finally, secondary products including chloride and hydrogen chloride are used for producing liquid chlorine PVC or hydrochloric acid; the sylvite production raw material carnallite can be comprehensively utilized fully. A method for producing sulfuric acid sodium carbonate through natural sulfate (magnesium sulfate and mirabilite) in sylvite residues, a solvay process for producing sodium carbonate and a calcium carbide method for producing PVC are commonly applied, a plant is reasonably planned and established beside a salt lake, scientific cooperative production is achieved, resources can be comprehensively and circularly utilized, energy is saved, emission is reduced, consumption is reduced, and the environment protection is achieved.

Owner:古舜起

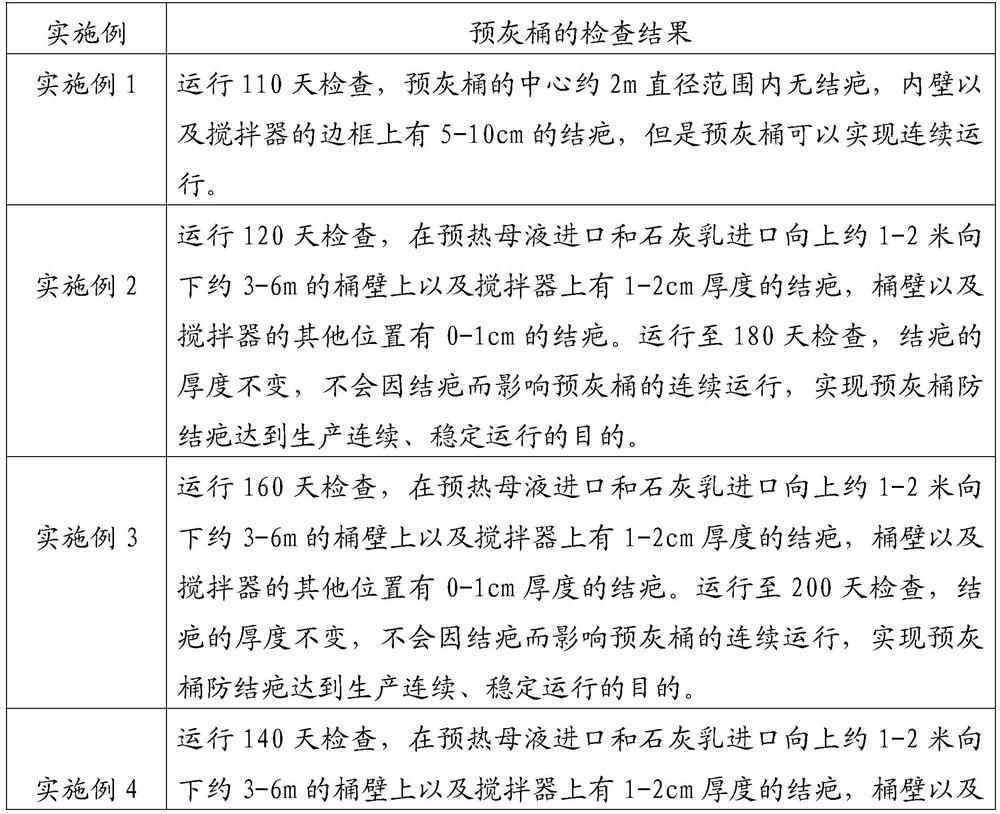

Method for preventing scabbing of pre-liming tank in distillation process in soda ash production by ammonia-soda process

ActiveCN111675227AEasy to separateEliminate surface tensionCarbonate preparationSolvay processProcess engineering

The invention relates to the technical field of soda ash production, and especially relates to a method for preventing the scabbing of a pre-liming tank in the distillation process in soda ash production by an ammonia-soda process. A return pipe is arranged on one side close to the bottom of a pre-liming tank. Lime milk and preheated mother liquor are stirred and mixed in the pre-liming tank to form blending liquid, which enters the pre-liming tank from a turbid liquid return pipe arranged at the upper part of the pre-liming tank through the return pipe. The method can prevent the pre-liming tank from scabbing, continuous and stable operation of the pre-liming tank is realized, the stability and continuity of a whole sodium carbonate production system are improved, the environmental protection risk is reduced, the equipment utilization rate is improved, the productivity is improved, and thus the manufacturing cost is reduced.

Owner:山东海天生物化工有限公司

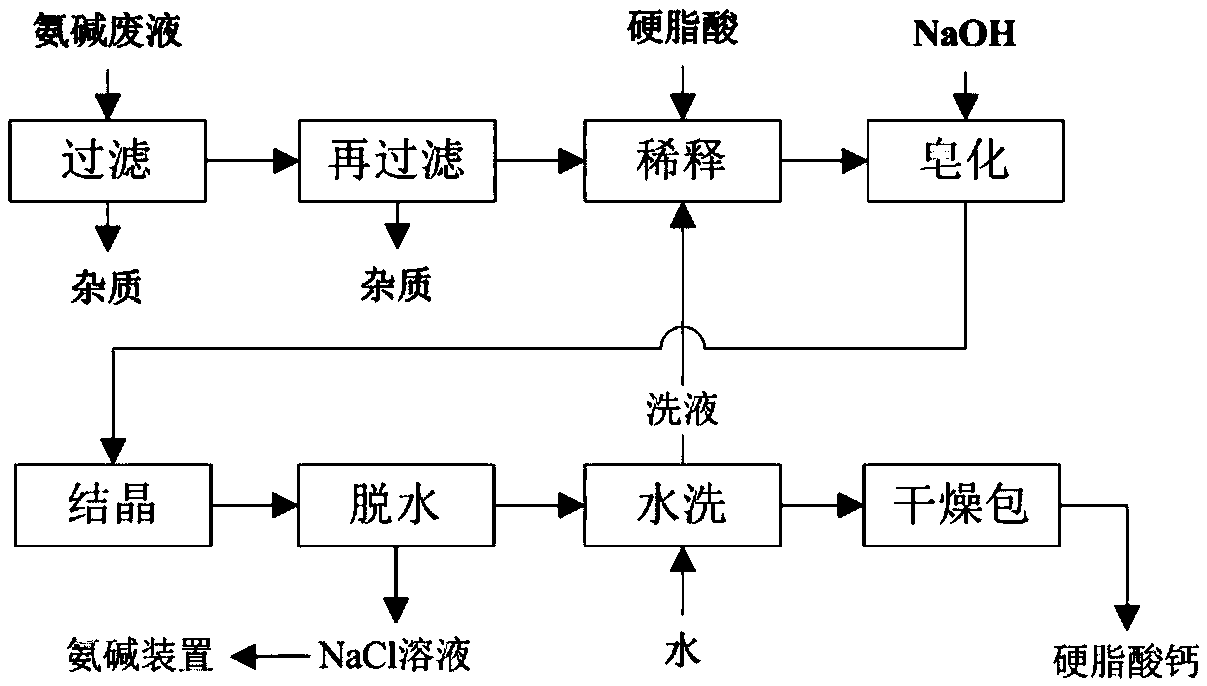

Treating and utilizing technology of waste liquid from Solvay process

ActiveCN105503570ARealize comprehensive utilizationSolve the emission problemOrganic compound preparationCarboxylic acid salt preparationCalcium chloride transformationStearic acid

The invention provides a treating and utilizing technology of waste liquid from Solvay process. The treating and utilizing technology adopts waste liquid from Solvay process, stearic acid and caustic soda as raw materials; calcium chloride in the waste liquid from Solvay process is converted into a high-value product, namely calcium stearate; filtered waste liquid from Solvay process is sufficiently utilized in the process. According to the invention, comprehensive utilization of the waste liquid from Solvay process is realized sufficiently; the cost of calcium serving as a raw material in the production process of calcium stearate is reduced; the waste liquid discharging problem of the production process of calcium stearate is solved. Practical production tests show that to produce 1 ton of calcium stearate, about 2 tons of the waste liquid from Solvay process can be treated. The treating and utilizing technology has the advantages that the raw materials are wide in sources, and low in cost; the operability is high; industrialization is easy to realize; in the whole technological process, water is saved, consumption is reduced, and a higher comprehensive economic benefit can be realized.

Owner:CHINA TIANCHEN ENG +1

Salt and alkali combined preparation process based on ammonia-soda method

InactiveCN109354038AReduce pollutionReduce manufacturing costCalcium/strontium/barium chloridesAlkali metal chloridesSolvay processCarbon dioxide

The invention belongs to the technical field of salt and alkali industry preparation, and discloses a salt and alkali combined preparation process based on an ammonia-soda method. The preparation process includes the steps: removing nitrate and refining the nitrate; leading in ammonia gas to reach saturation, and leading in carbon dioxide; filtering out crystals and calcining the crystals; addingacetylene sludge into mother liquor, and distilling ammonia; pouring the mother liquor into a salt well; extracting brine and preparing salt. The preparation process has the advantages that alkali preparation of the ammonia-soda method and a well slat preparation process are combined, recyclable comprehensive utilization of waste residue and waste liquid is achieved, environmental pollution is greatly reduced, production cost is greatly reduced, and huge economic benefits are brought.

Owner:湖北云应矿业技术开发有限公司

A process for pyrolysis of wet oxidative desulfurization mixed waste liquid in partial oxidation environment

ActiveCN105236647BComply with relevant policy requirements for protectionRealize whole component processingEnergy inputWaste water treatment from gaseous effluentsPartial oxidationPhysical chemistry

Owner:TAIYUAN UNIV OF TECH

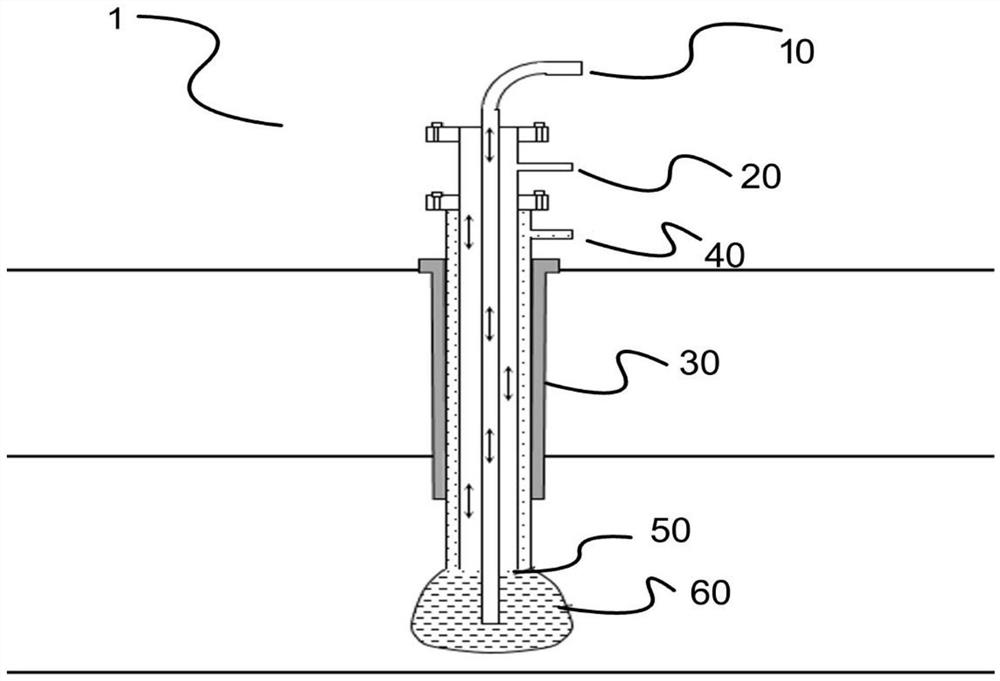

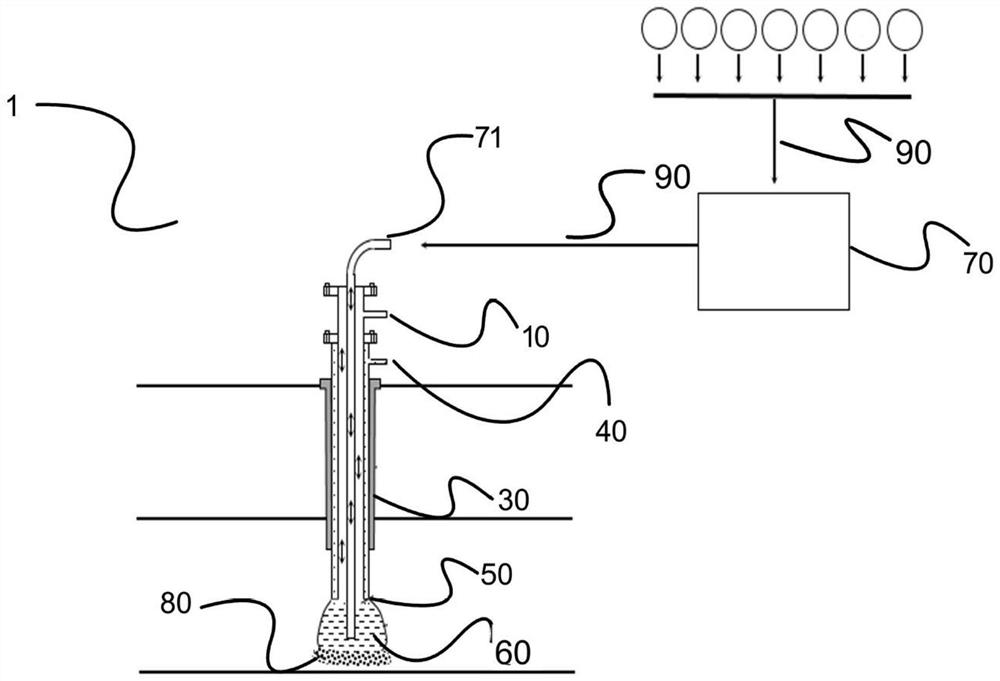

Application of liquid waste containing liquid and solid components obtained in process of producing sodium carbonate by ammonia-alkali method in production of saline water in underground caves

PendingCN112299447ATransportation and packagingMultistage water/sewage treatmentLiquid wasteSaline water

The invention relates to application of liquid waste containing liquid and solid components obtained in the process of producing sodium carbonate by adopting an ammonia-alkali method in the productionprocess of underground cave brine. Correspondingly, the invention provides application of liquid waste containing liquid and solid components obtained in the soda ash production process in the salinewater production process of the underground cave (1). Thus, recovery of soda ash and saline water mixed with a small amount of waste and recovery of liquid waste containing liquid and solid components obtained in the soda ash production process are provided.

Owner:伊利马特恩股份有限公司

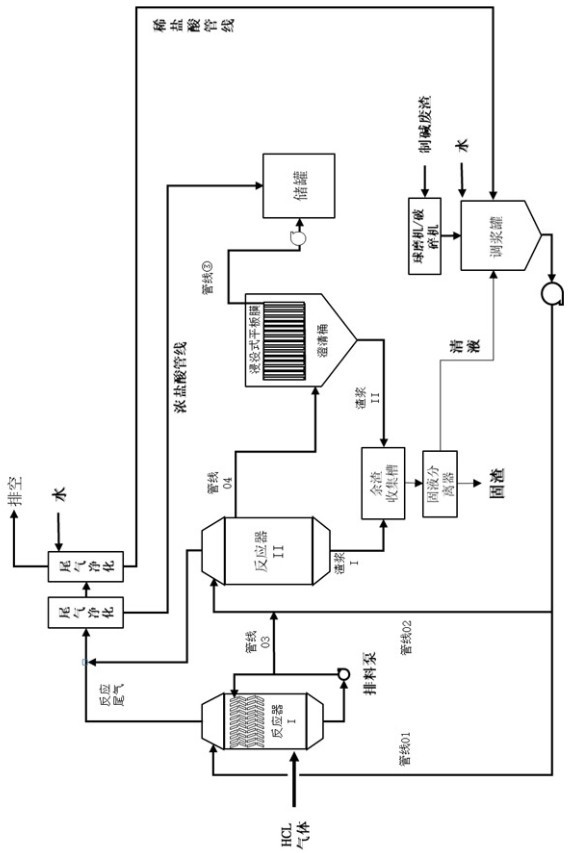

Method for producing calcium chloride solution from alkali waste residues produced by ammonia-alkali process

ActiveCN114159963AEmission reductionReduce consumptionGas treatmentCalcium/strontium/barium chloridesProcess engineeringEnvironmental engineering

The invention discloses a method for producing a calcium chloride solution by using alkali production waste residues in an ammonia-alkali process, hydrogen chloride gas and the alkali production waste residues in ammonia-alkali process sodium carbonate production are used as raw materials, the calcium chloride solution is prepared through crushing / grinding size mixing and reaction in a two-stage reactor, and the concentration of the prepared calcium chloride solution can reach more than 50%. The content of magnesium ions and sulfate ions is greatly reduced, the steam consumption is greatly reduced when solid calcium chloride is produced through subsequent evaporation, concentration and crystallization, and meanwhile, the discharge amount of solid alkaline residues is reduced.

Owner:SHANDONG HAIHUA GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com