Method for preparation of sodium bicarbonate and ammonium sulfate from chemical strong brine

A technology of baking soda and concentrated brine, which is applied in chemical instruments and methods, ammonia compounds, inorganic chemistry, etc., can solve the problems of difficult treatment of chemical concentrated brine, achieve effective utilization, simple production process, and reduce anti-corrosion requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

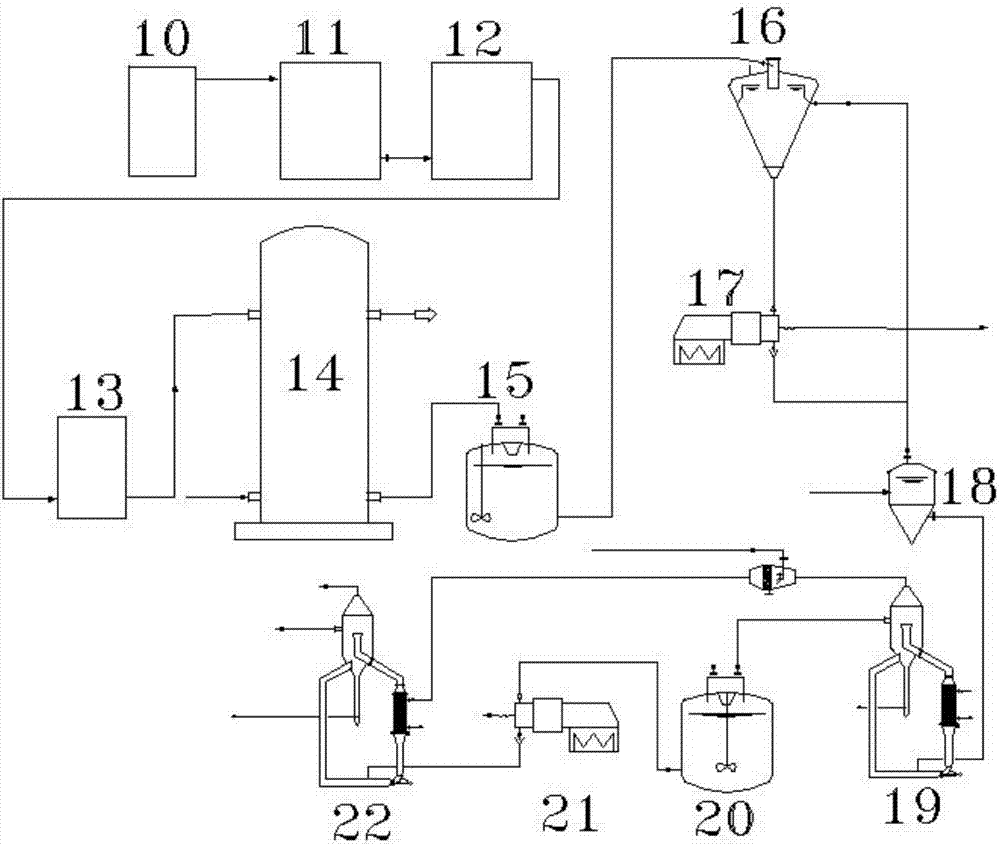

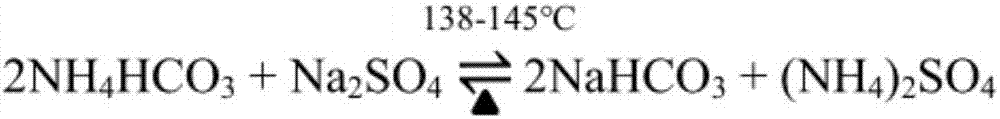

Method used

Image

Examples

Embodiment 1

[0044] 1) Pretreatment: Evaporating and concentrating chemical concentrated brine to obtain a 91% sodium sulfate solution by mass percentage, passing 150t of 91% sodium sulfate solution into a raw material tank for storage;

[0045]2) Remove calcium and magnesium ions: pass step 1) saturated sodium sulfate solution into the reaction tank, add 2t sodium hydroxide and 8t sodium carbonate to the reaction tank, eliminate calcium and magnesium ions in the solution and make refined Glauber's salt liquid;

[0046] 3) Coagulation and clarification: pass the solution for removing calcium and magnesium ions in step 2) into the coagulation and clarification tank and add polyaluminum chloride to stir, stir for 13 minutes and then let stand for 30 minutes to clarify to obtain the supernatant;

[0047] 4) Preparation of ammonium bicarbonate: passing the supernatant in step 3) into a refined Glauber's salt tank, passing ammonia and carbon dioxide gas into the refined Glauber's salt tank to re...

Embodiment 2

[0058] On the basis of Example 1, this example modifies the conditions of some steps in Example 1, and the remaining parts are completely the same as Example 1.

[0059] 5) carbonization reaction: pass the solution after the fully mixed reaction in step 4) into the carbonization tower for carbonization reaction, continuously add carbon dioxide gas during the reaction, the pressure of the carbonization tower is 0.4MPa, and feed CO 2 75% by volume, CO 2 The temperature of entering the tower is 45°C, and the carbonization time takes 4 hours. The sodium bicarbonate crystals generated by the reaction are precipitated from the bottom of the tower and passed into the salt slurry tank;

[0060] 8) Ammonia and carbon dioxide recovery: store the supernatant obtained in step 6) and the mother liquor obtained in step 7) in a centrifuge bucket, add sulfuric acid to adjust the pH to 4, and recover ammonia and carbon dioxide;

[0061] The purity of the sodium bicarbonate prepared by the abo...

Embodiment 3

[0063] On the basis of Example 1, this example modifies the conditions of some steps in Example 1, and the remaining parts are completely the same as Example 1.

[0064] 5) carbonization reaction: pass the solution after the fully mixed reaction in step 4) into the carbonization tower for carbonization reaction, continuously add carbon dioxide gas during the reaction process, the pressure of the carbonization tower is 0.35MPa, and feed CO 2 Volume content is 65%, CO 2 The temperature of entering the tower is 40°C, and the carbonization time takes 3 hours. The sodium bicarbonate crystals generated by the reaction are precipitated from the bottom of the tower and passed into the salt slurry tank;

[0065] 8) Ammonia and carbon dioxide recovery: store the supernatant obtained in step 6) and the mother liquor obtained in step 7) in a centrifuge bucket, add sulfuric acid to adjust the pH to 2.5, and recover ammonia and carbon dioxide;

[0066] The purity of the sodium bicarbonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com