Patents

Literature

425results about How to "No discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

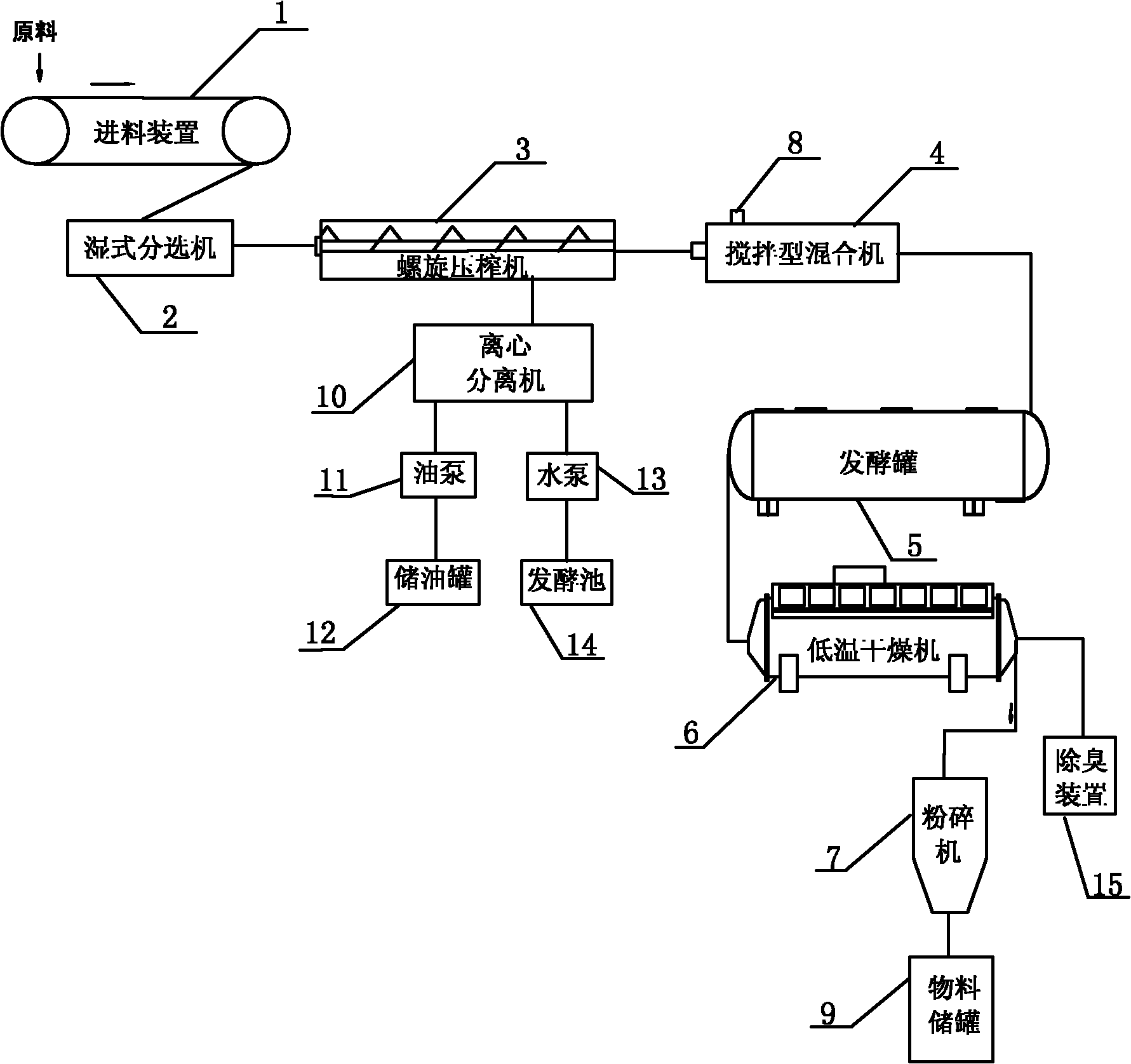

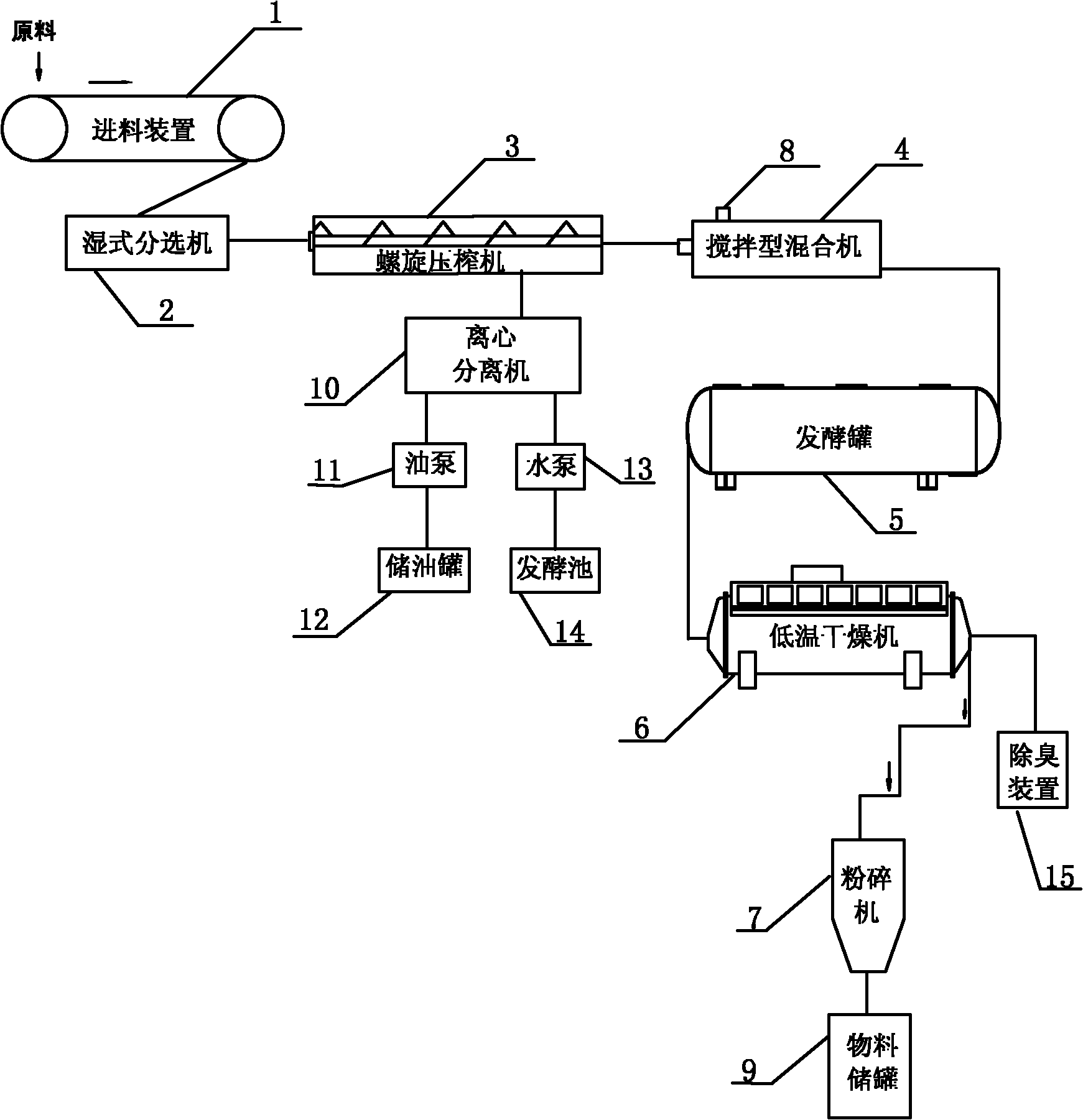

Method and system for preparing restaurant-kitchen wastes into livestock and poultry feed

InactiveCN102125166AGood flavor and colorImprove fermentation effectFeeding-stuffFood processingMixed materialsCrusher

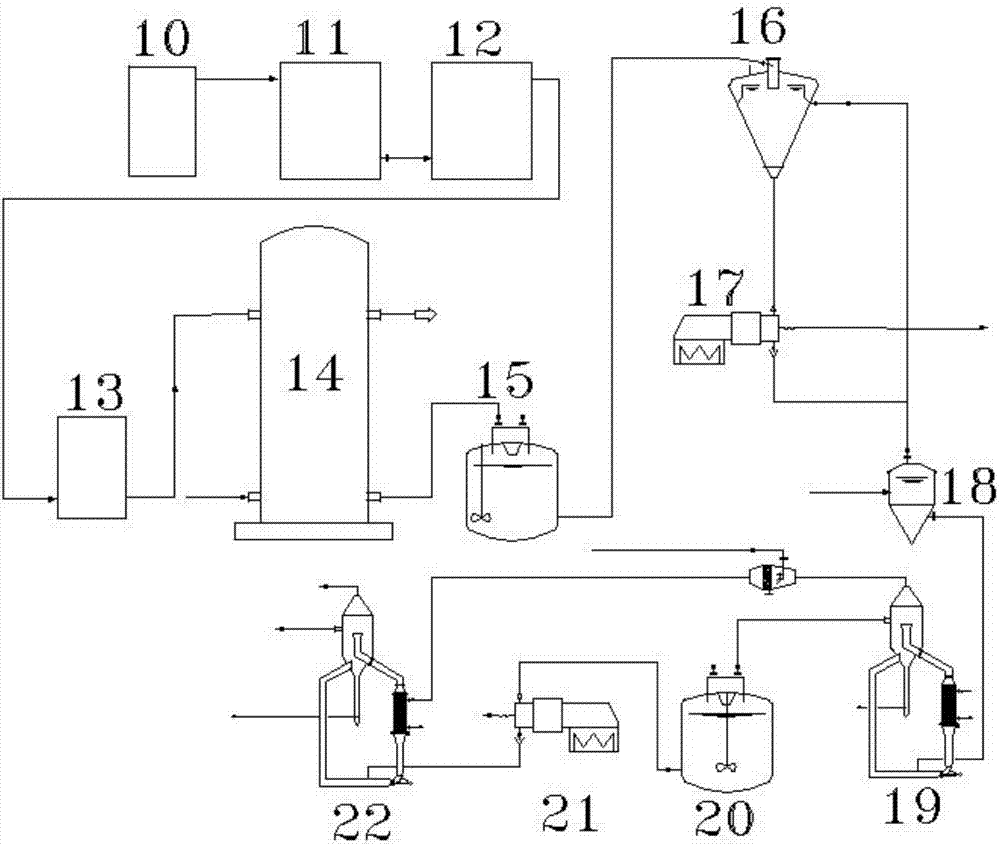

The invention discloses a method and a system for preparing restaurant-kitchen wastes into a livestock and poultry feed, wherein the method comprises the following steps: carrying out sorting preprocessing on restaurant-kitchen wastes so as to obtain biodegradable restaurant-kitchen wastes; carrying out solid-liquid separation on the obtained biodegradable restaurant-kitchen wastes; adding bran, corn flour and coarse meal into the obtained product so as to obtain a mixed material; adding composite fungicides into the mixed material according to the inoculum concentration (8-20 wt%) so as to ferment the mixed material; and finally, drying and cooling the fermented mixture, then packing the obtained object so as to obtain a livestock and poultry feed product. The system comprises a feed device, a wet sorting machine, a pressafiner, an agitated mixer, a fermentation tank, a low-temperature drying machine, a crusher and a finished product material storage tank which are sequentially connected; and the system has the advantages that the growth of putrefying bacterias and the reproduction of pathogenic microorganisms in restaurant-kitchen wastes can be inhibited, and the freshness retaining effect and organoleptic quality of the livestock and poultry feed are good; meanwhile, the protein content of the livestock and poultry feed can be improved; in addition, the system is low in used equipment cost, small in energy consumption, high in production efficiency and beneficial to environmental protection.

Owner:张荣尚

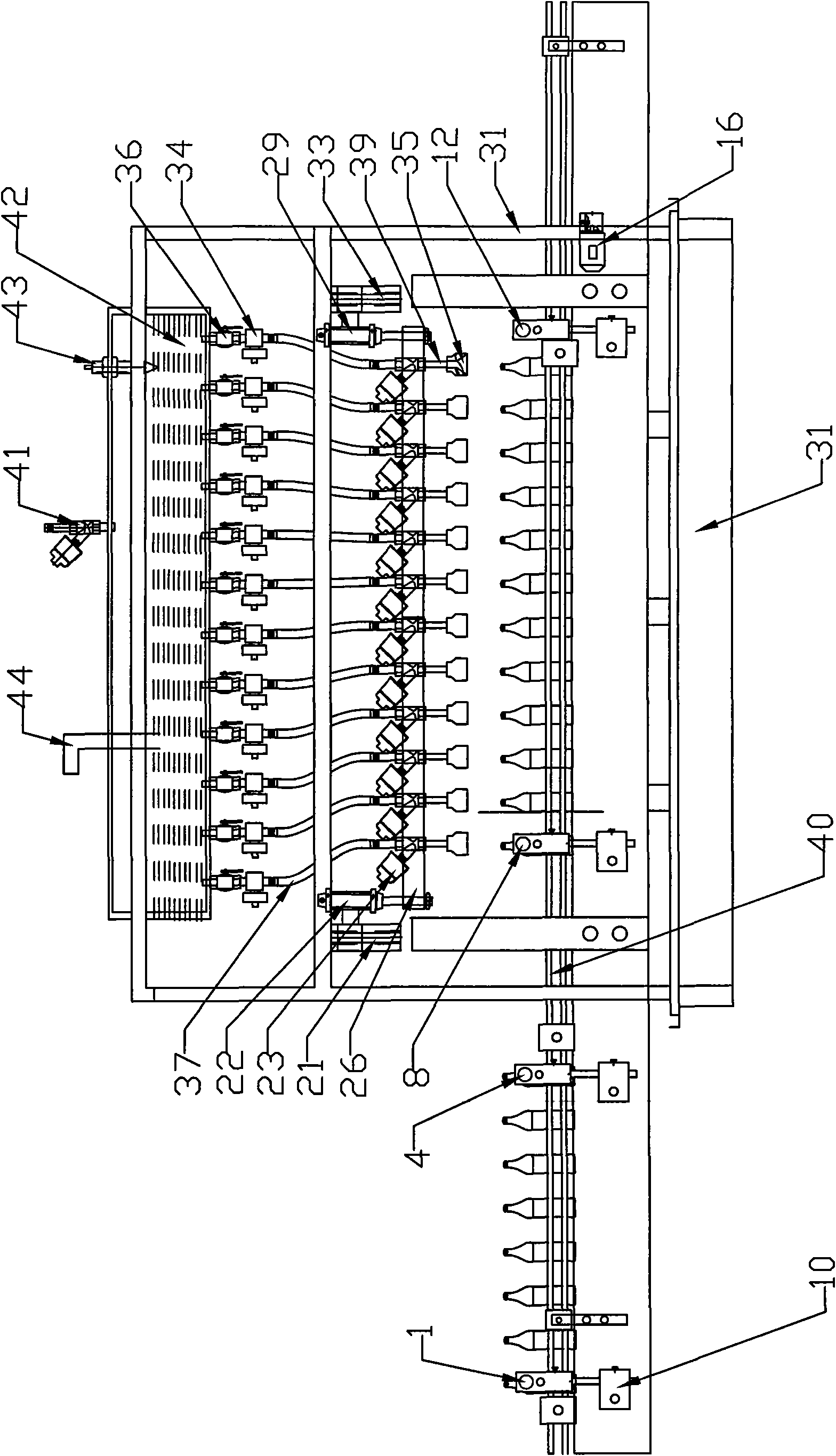

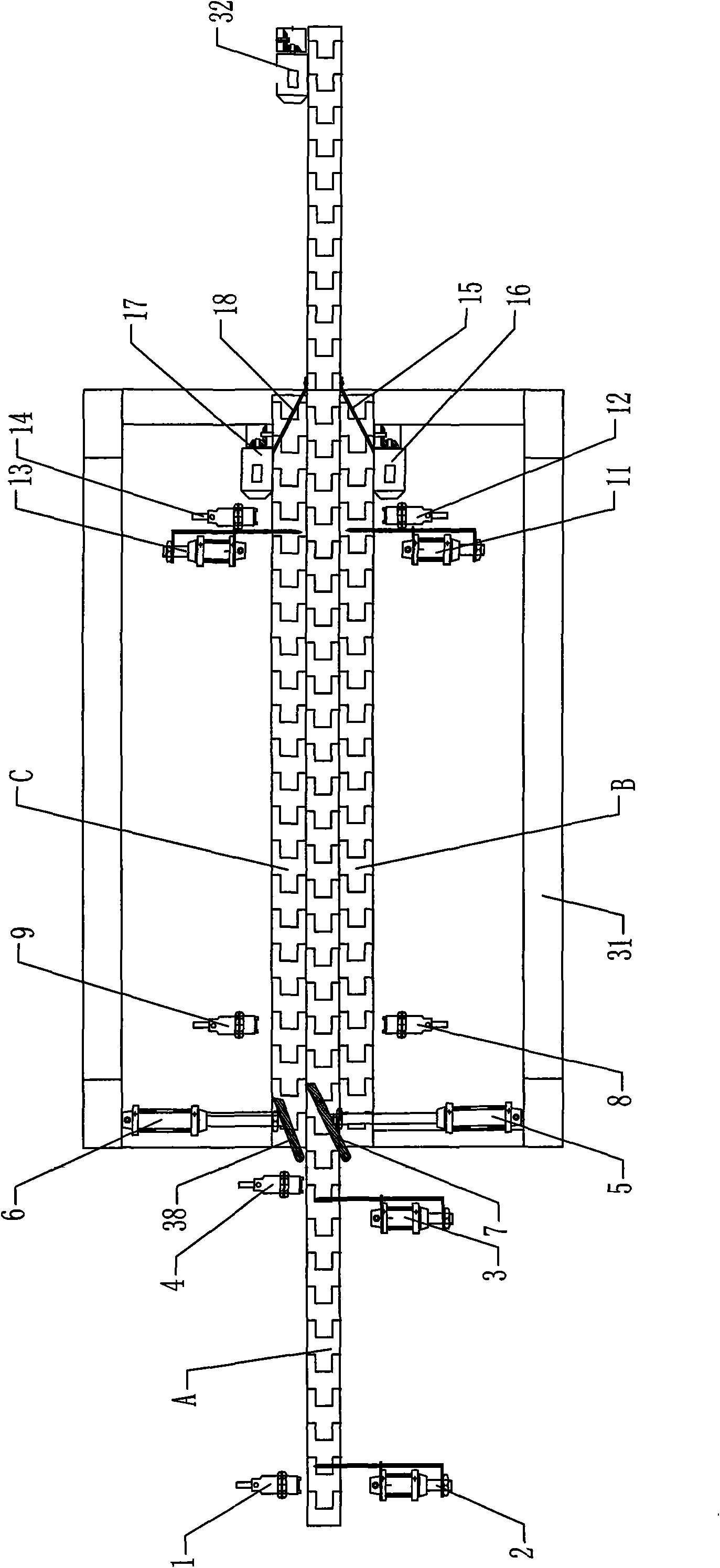

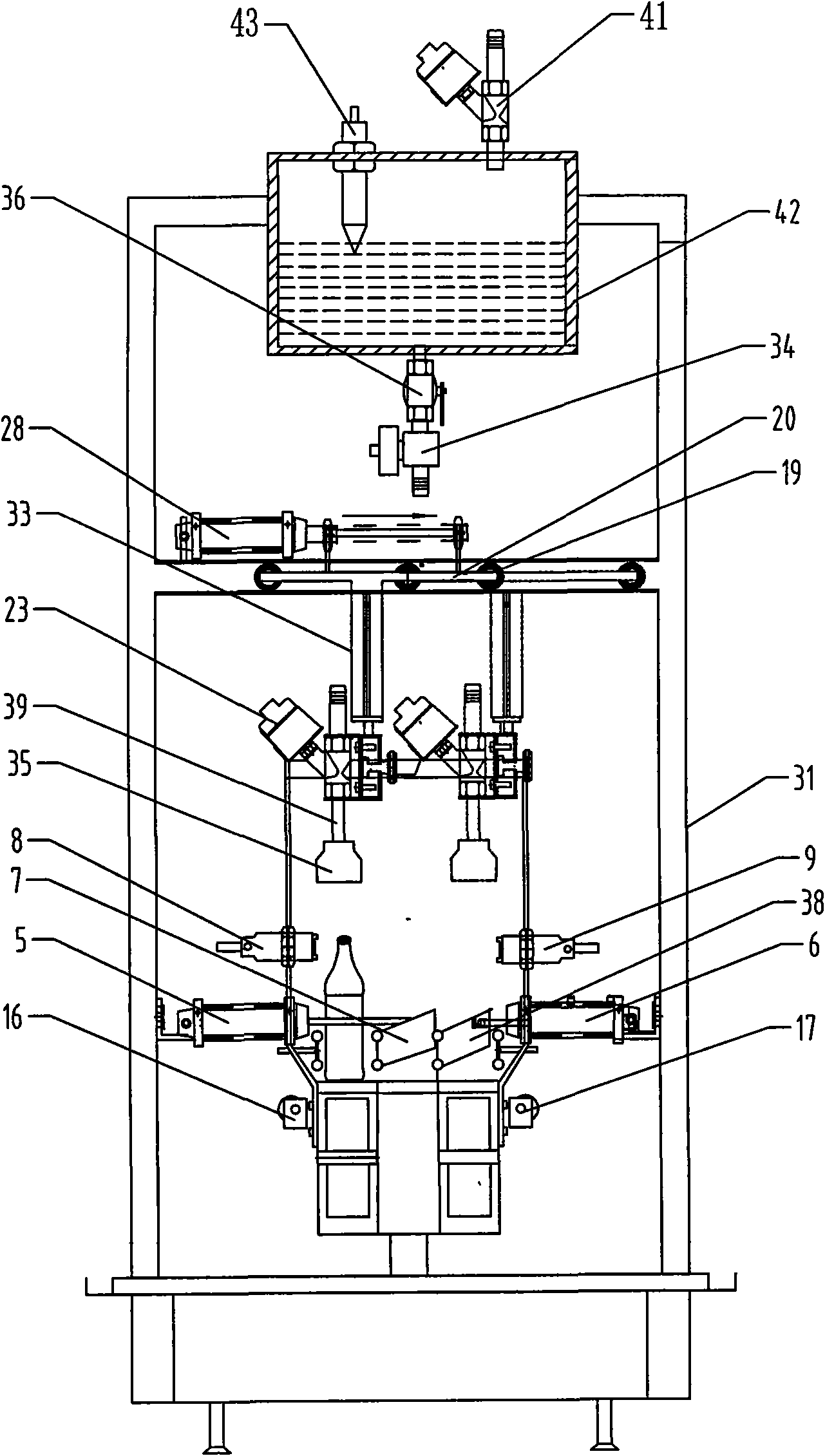

Three-row double-wire linear filling machine

InactiveCN101618845AShorten the intervalImprove filling efficiencyLiquid fillingAbnormal shapedEngineering

The invention discloses a three-row double-wire linear filling machine, comprising a frame. A bottle finishing and bottle conveying device and a liquid filling device are arranged on the frame, the bottle finishing and bottle conveying device comprises three rows of conveyer belts arranged in parallel, line exchanging devices are arranged between the three rows of conveyer belts, the bottle body can be continuously filled by carrying out line exchange on the bottle body, thereby overcoming the defect that the feeding of bottle needs to be waited when filling the bottle body by a traditional filling machine, shortening interval time between fed bottles and improving filling efficiency; the filling machine has the advantages of reasonable structure, high degree of automation, high precision, no drop leak, no discharge, simple capacity set, no bottle piling, strong applicability to abnormal shapes and high stability.

Owner:李真中

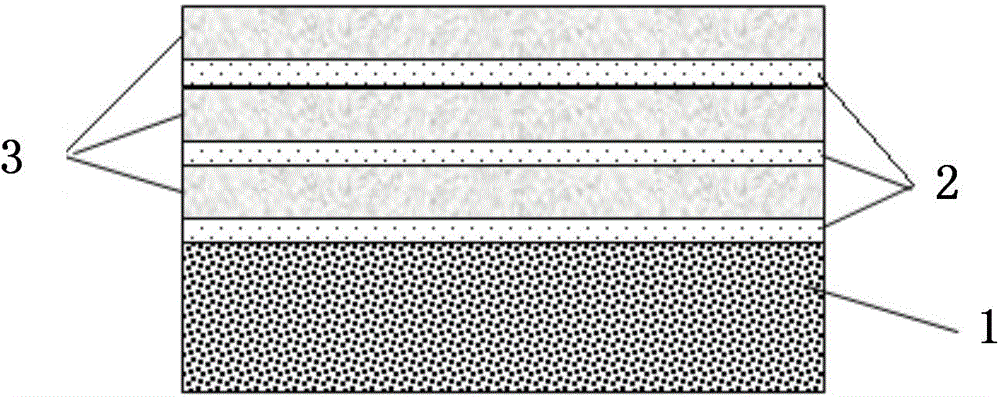

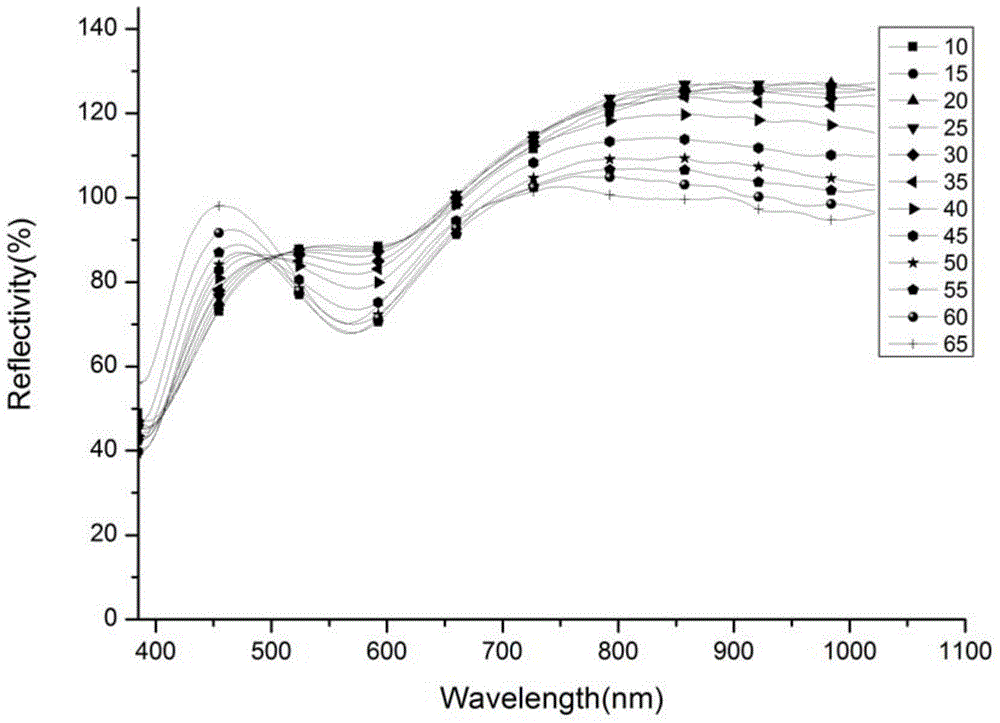

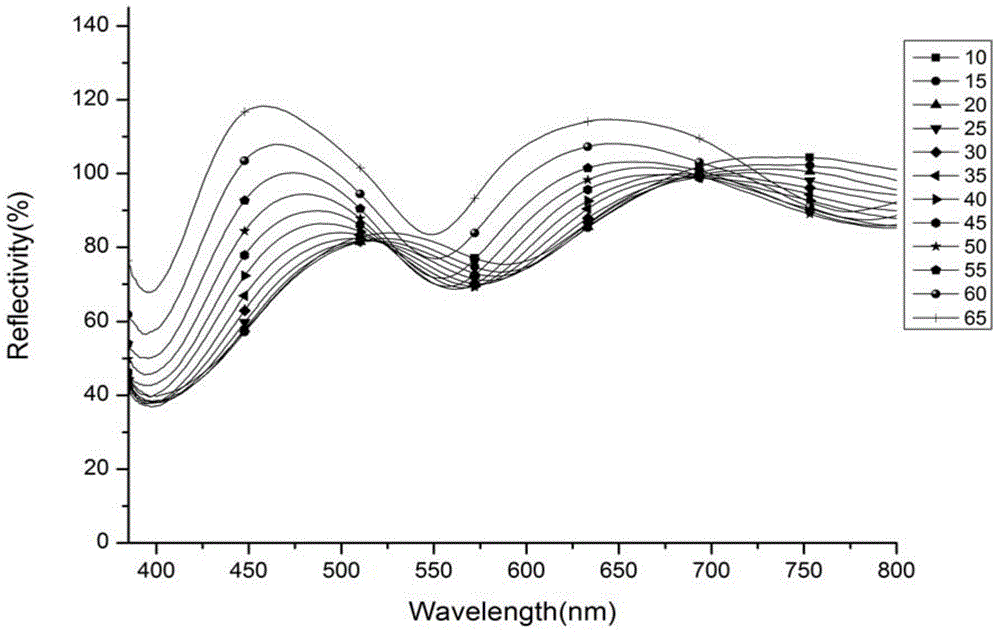

Fabric structure color preparation method

ActiveCN105603715AWide adaptabilityNo dischargeMaterial nanotechnologyVacuum evaporation coatingSputteringHigh energy

The present invention relates to a fabric structure color preparation method. According to the present invention, a magnetron sputtering radio frequency method is used, TiO2, SiO2 and the like are adopted as targets, sputtering is performed on a base cloth, the TiO2 and SiO2 (or other materials) targets are subjected to alternate sputtering on the surface of a fabric to form a nanometer period film on the fabric surface, the fabric presents a bright structure color due to light interference and other optical principles, the fabric surface color is determined by the sputtering material, the number of the sputtering layers and the thickness of each sputtering layer, the fabric color is changed along with the change of the observation angle, and the fabric does not fade if the film structure is not damaged; and the structure color fabric researched and developed through the preparation method has characteristics of uniform film, controllable film thickness and no requirement of any dye auxiliary agents, the method is the environmentally friendly dyeing method, and the defects of high pollution and high energy consumption in the traditional dyeing and finishing industry are expected to be solved.

Owner:GUANGDONG XINFENG TECH

Method for preparing carbon and producing controlled-release fertilizer by utilizing crop straws and controlled-release fertilizer prepared by using same

ActiveCN102211964AEffective return to fieldTo achieve a sustained release effectSolid waste disposalFertilizer mixturesEnvironmental resistanceCombustion

The invention discloses a method for preparing carbon and producing a controlled-release fertilizer by utilizing crop straws and the controlled-release fertilizer prepared by using the method, solving the problem that the straws can not be effectively utilized. The method mainly comprises the three steps of straw granulation, combustion carbon discharge and fertilizer preparation. By using the method, batch processing and effective utilization are carried out on the straws; the method is easy to grasp, has strong environmental suitability and is suitable for large-scale popularization and usein countries; by using the method, carbon can be prepared from the straws and then is used for preparing the fertilizer and the straws can also be prepared into biomass fuel for use; and production process is environmentally-friendly, thereby achieving cyclic utilization of energy and relieving the critical conditions of fertilizers and fuels in countries.

Owner:ZHEJIANG BULAIMENG AGRI SCI & TECH

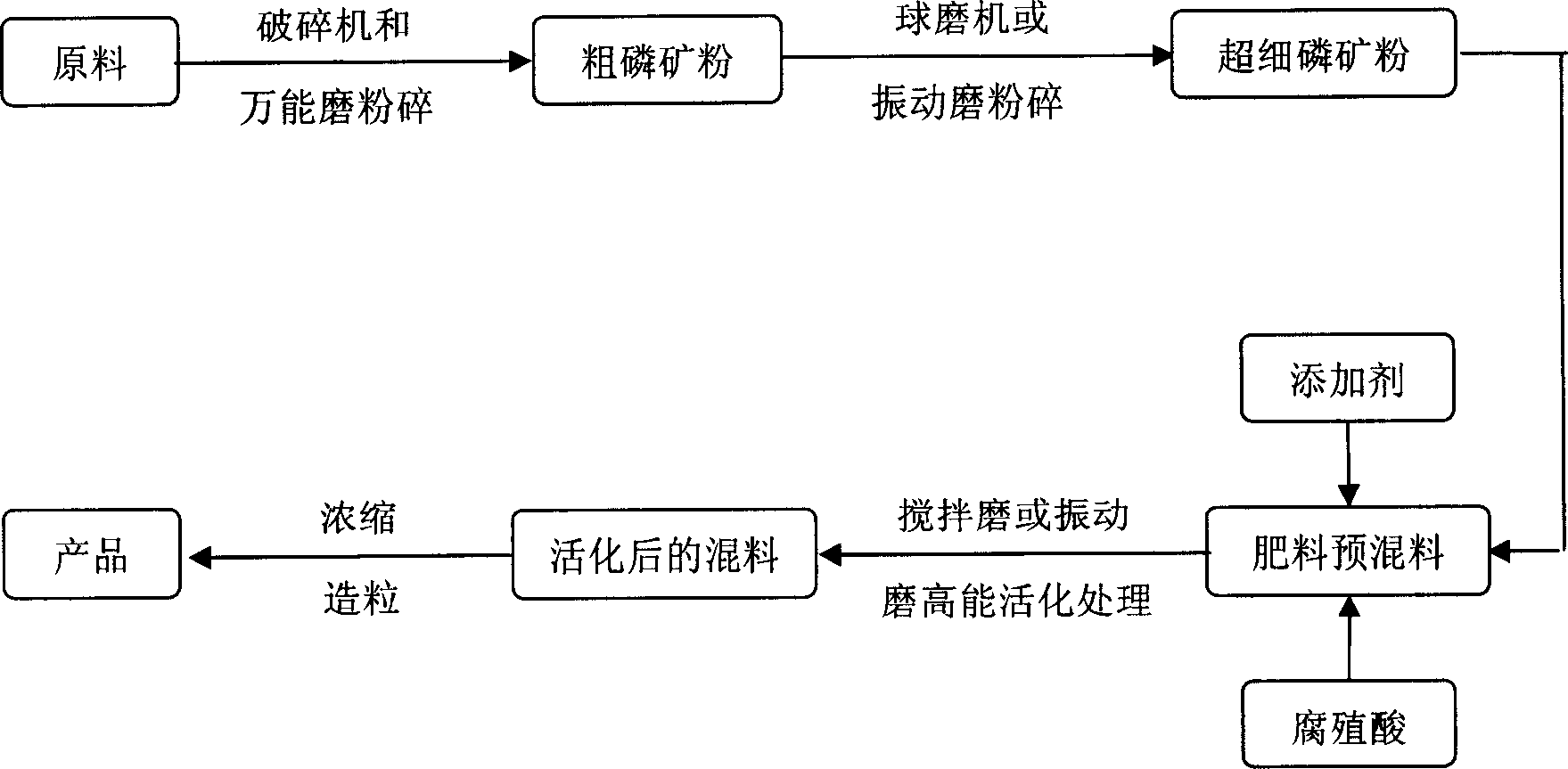

Method for preparing ultrafine activated phosphorusore compound fertilizer

InactiveCN1935749AGood effectPrevent compactionFertilisers by pryogenic processesFertilizer mixturesApatiteHigh energy

The invention is an ultrafine activated phosphorite compound fertilizer preparing method, crushing raw material into coarse powder by crusher and universal mill, and then crushing the coarse powder into ultrafine phosphorite powder as premix by ball mill or vibration mill; adding additive and humic acid in the premix and making high energy activation treatment by blending mill or vibration mill, making concentrated prilling and making the product. And the invention mechanically mills phosphorite by high input energy, improves chemical activity of apatite in phosphorite by mechano-chemical activation, and improves the releast- sustained speed of phosphor compounds in soil. And the prepared compound fertilizer has fast effect, long-time stability, and soil improving effect. And the invention is a good phosphorite compound fertilizer preparing method.

Owner:TSINGHUA UNIV

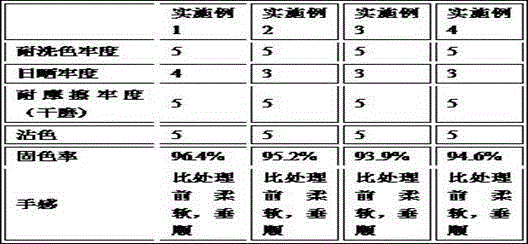

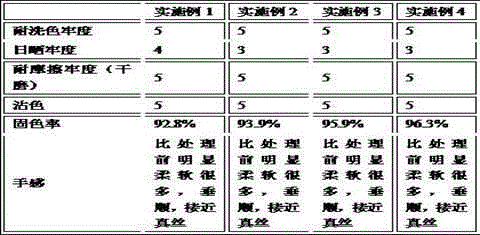

Silk digital ink-jet printing method

InactiveCN105002762ANo dischargeNo pollutionDyeing processAnimal fibresTextile printerPolymer science

The invention discloses a novel silk digital ink-jet printing method. The novel silk digital ink-jet printing method comprises carrying out fabric pre-treatment: heating a silk fabric to a temperature of 30-35 DEG C for pre-treatment, carrying out sizing on the pre-treated silk fabric by a sizing machine at a sizing temperature of 50-60 DEG C, carrying out drying at a drying temperature of 80-95 DEG C by an infrared drying device, making a file, carrying out ink-jet printing by a digital ink-jet printing device and carrying out dye fixation under saturated vapor at a temperature of 60-65 DEG C for 10-15min. The silk digital ink-jet printing method improves printing effects and color fastness, is free of special treatment on ink, does not need a high heating temperature, produces small damage to the fabric and realizes good hand feeling.

Owner:浙江宝石蝶围巾有限公司

Bamboo pulp sponge product and preparation method thereof

ActiveCN101942112AImprove performanceWide range of applicationsNon-woody plant/crop pulpCarbon disulfideChemistry

The invention discloses a bamboo pulp sponge product and a preparation method thereof. Bamboo pulp is used as a main raw material. The method comprises the following steps of: 1) soaking, namely adding sodium hydroxide solution into the bamboo pulp raw material at the temperature of between 25 and 35 DEG C, and reacting the mixture to generate AC alkali cellulose and water; 2) squeezing, namely squeezing the AC alkali cellulose through a squeezer, filtering the redundant sodium hydroxide solution to form cakes, and crushing the cakes into granules or blocks of 5 to 10 millimeters; 3) yellowing, namely reacting the granular or block alkali cellulose and carbon disulfide at the temperature of between 25 and 40 DEG C under vacuum to obtain xanthate; 4) gluing, namely adding bamboo pulp or wood pulp into the xanthate, and soaking the mixture into water to form a glue; and 5) molding, namely adding an inorganic acid salt pore-forming agent of alkali metal or alkaline earth metal into the glue, standing the mixture for 5 to 7 hours after mixing, then putting the mixture into a mold for molding, condensing by using current and foaming to prepare the sponge product consisting of 92 to 94 weight percent of methylcellulose, 4.5 to 5.5 weight percent of S10 cellulose and 0.5 to 3.5 weight percent of reinforced cellulose. The sponge product has the characteristics of strong water absorption, soft texture, strong dire and oil removing capability, long-time storage and accommodation, unchanged quality, pure natural and unpolluted product and the like.

Owner:NINGBO NECO SPONGE TECHONOLOGY CO LTD

Novel preparation method for water-soluble nano silver on large scale

InactiveCN102218541AThe implementation process is simpleLow equipment requirementsSolventReducing agent

The invention discloses a novel preparation method for water-soluble nano silver on a large scale. The preparation method comprises the following steps: stirring and dissolving silver salt, a protective agent and a stabilizing agent into a solvent (water) at 30-70DEG C; adjusting the pH value; when a solution system is clarified and vitrified for 5-20 minutes, adding a reducing agent into a reaction system; and continuously stirring and reacting for 5-30 minutes. The method disclosed by the invention has the advantages of low equipment requirement, simple technology, moderate reaction, short reaction time, high efficiency, low preparation cost and low energy consumption, is simple and convenient to operate and is suitable for large-scale production; and the product performance is good, the average particle diameter of the nano silver is less than 20nm, the blending concentration can be diluted by tap water, no harmful waste is generated, and the method conforms to the modern production requirements of environmentally-friendly production and energy conservation.

Owner:上海赛瓦纳米银材料科技有限公司

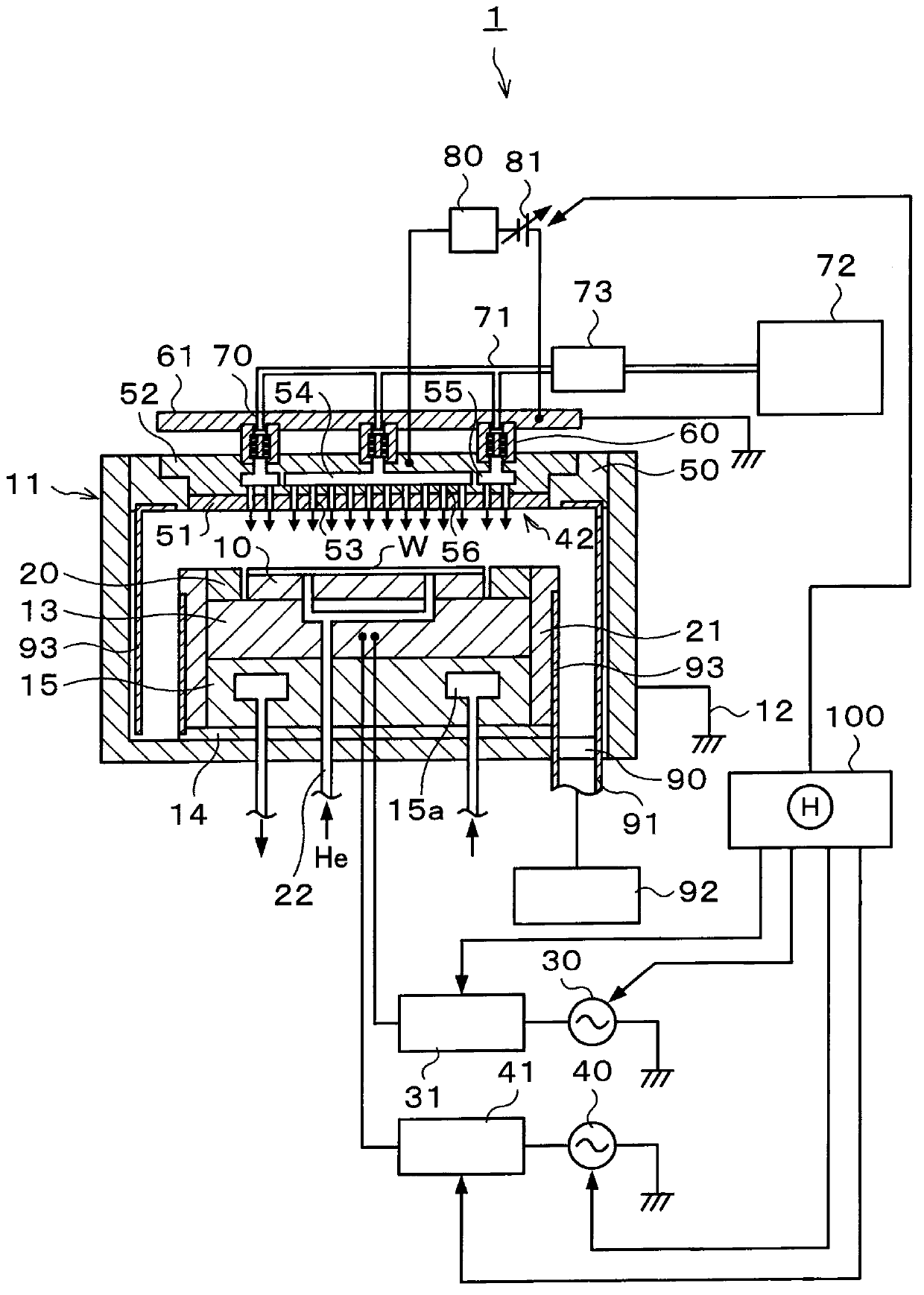

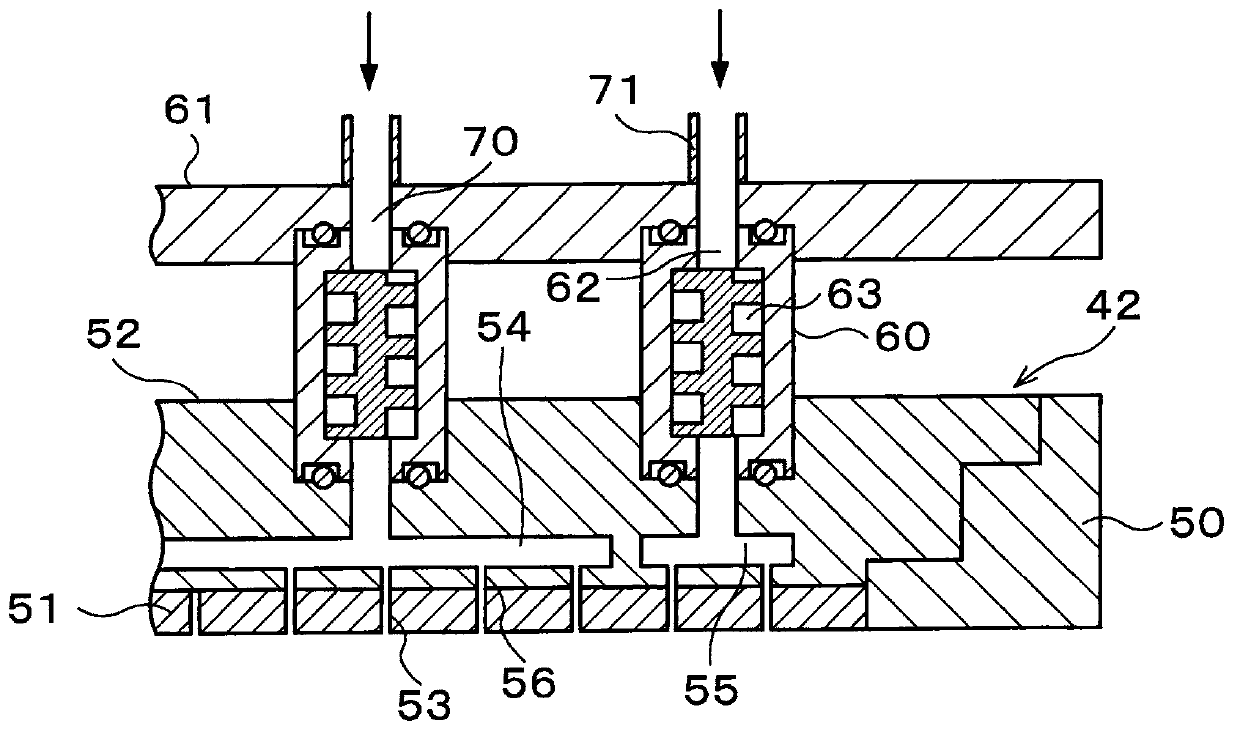

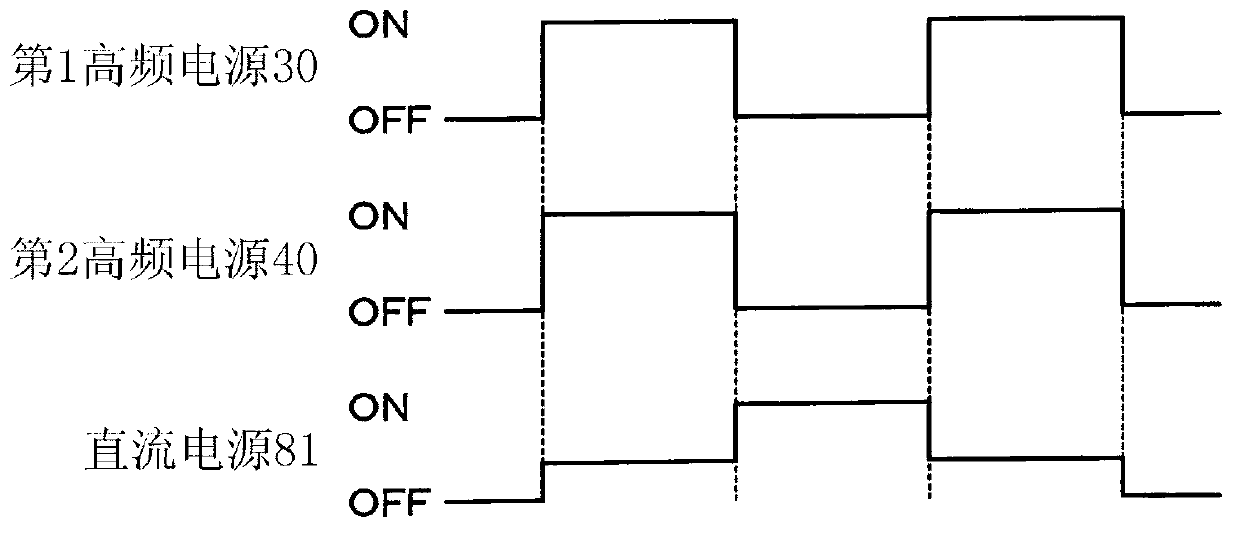

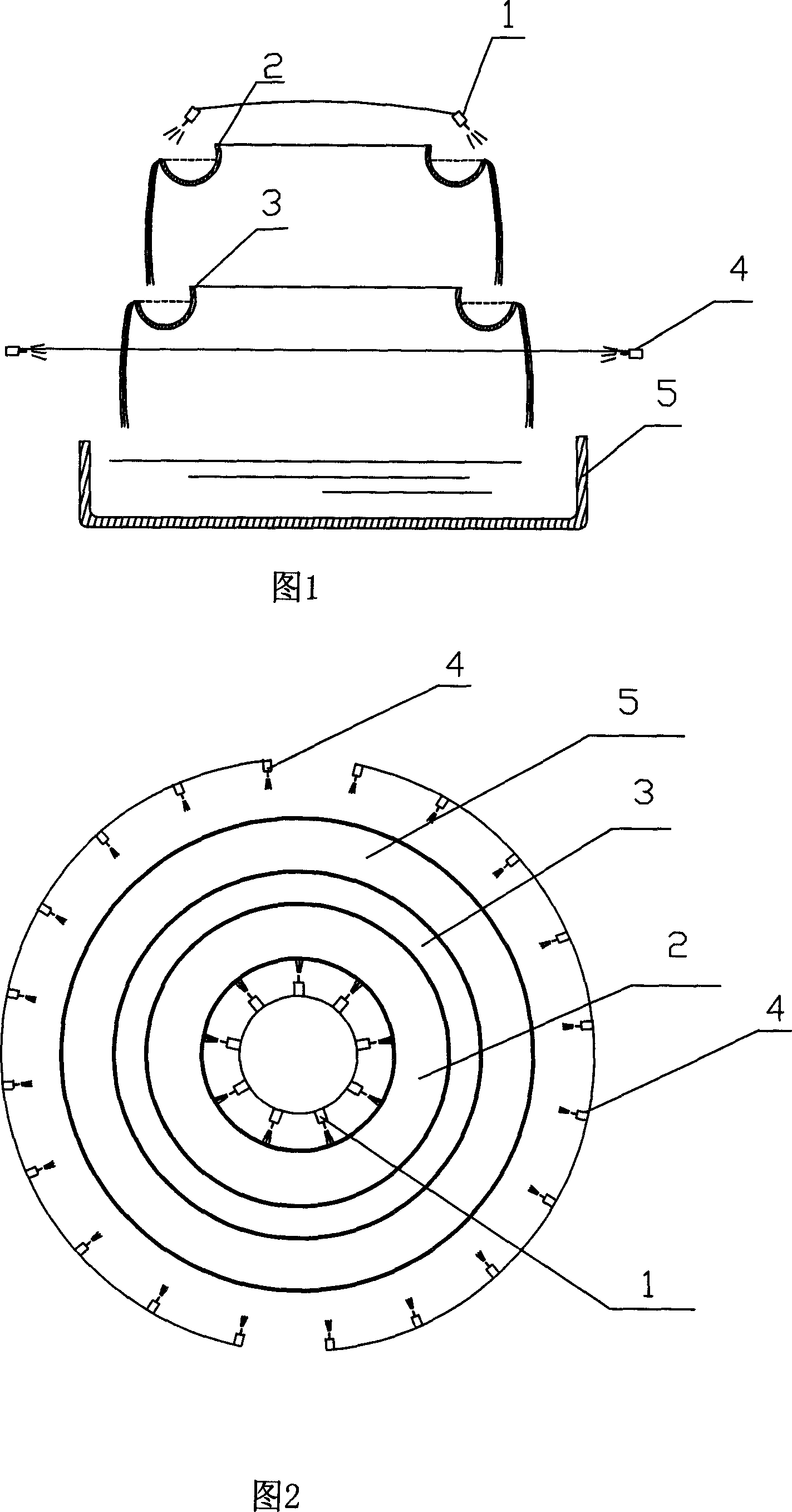

Plasma processing apparatus

ActiveCN103219216ANo dischargeElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringGas supply

A plasma processing apparatus comprises an upper electrode 42, a lower electrode, a grounding member 61 provided above the upper electrode 42 via an insulating member 60; and a DC power supply for applying a DC voltage to the upper electrode 42. Gas diffusion rooms 54 and 55 communicating with a gas supply opening 53 formed at a lower surface of the upper electrode 42 are formed in the upper electrode 42 and a gas flow path 62 communicating with the gas diffusion rooms 54 and 55 is formed in the insulating member 60. A bent portion 63 for allowing a gas within the gas flow path to flow in a direction having at least a horizontal component is formed at the gas flow path 62 such that an end of the gas flow path 62 cannot be seen from the other end thereof when viewed from the top.

Owner:TOKYO ELECTRON LTD

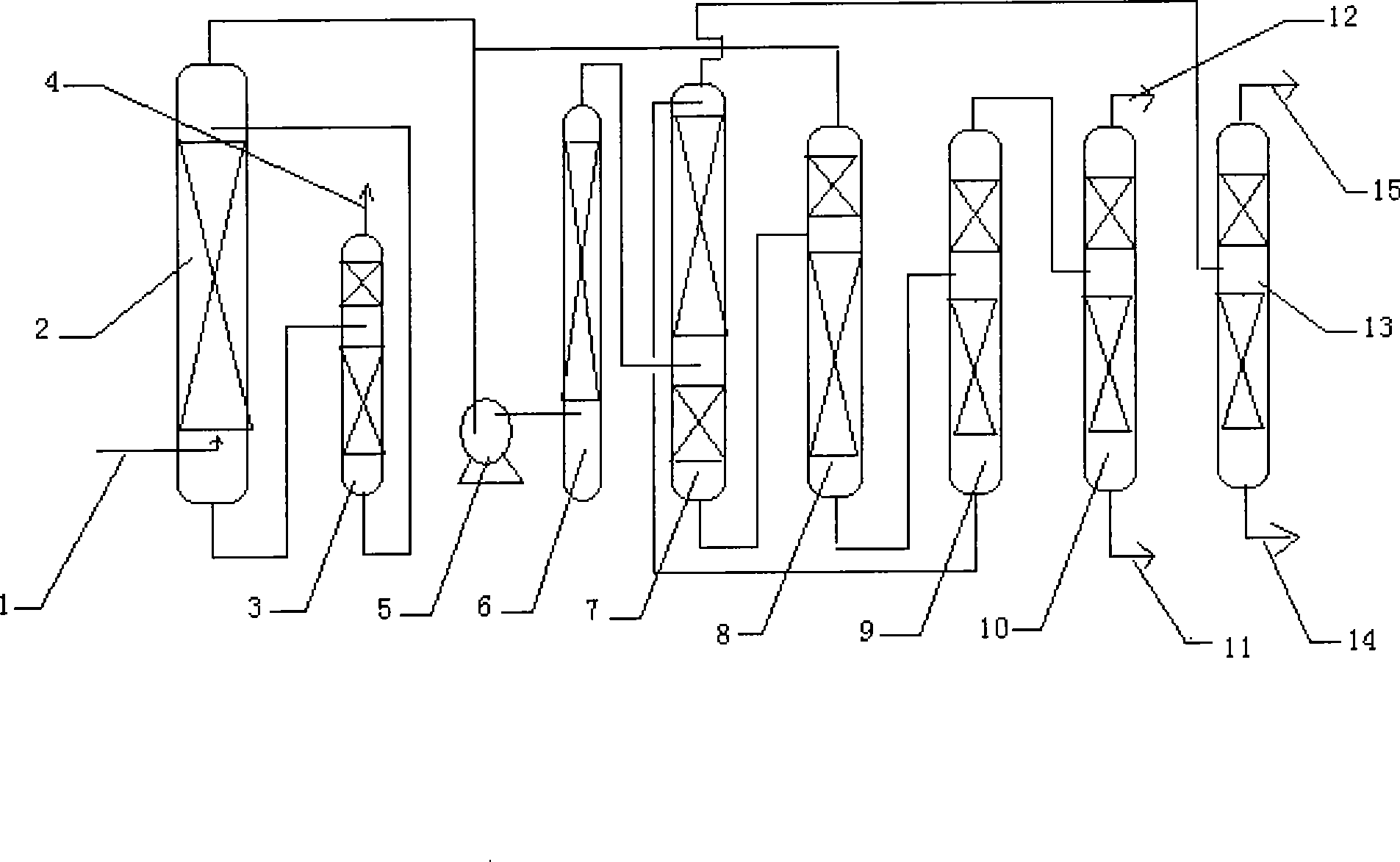

Fractionation process for cracking gas from oxidation pyrolysis of gaseous hydrocarbon

InactiveCN101486625ANo dischargeReasonable workmanshipDistillation purification/separationHydrocarbonsDesorptionFractionation

The invention provides a fractionation technique for the cracking gas obtained through the oxidation thermal decomposition of gaseous hydrocarbon and used for preparing acetylene. The cracking gas obtained through the oxidation thermal decomposition of gaseous hydrocarbon and used for preparing acetylene first goes through an oil washing tower to remove higher alkyne, C3 hydrocarbon and carbon black, and is pressurized to 0.4MPa to 1.5MPa through a compressor and deoiled through an activated carbon adsorption tower, thus dissolving acetylene and a few other indissoluble components through an absorbed solvent in the adsorption tower; the rest gases go in an ethylene separation tower to recycle concentrated ethylene products and tail gas is taken as synthesis gas; after the solvent dissolving acetylene and a few other indissoluble components enters a flashing tower to remove the indissoluble components, crude acetylene gas is obtained through the separation of an acetylene desorption tower; the indissoluble components are cycled before returning to the compressor and pure acetylene products are obtained after the crude acetylene gas is refined in a carbon dioxide tower; the wash oil saturated with higher alkyne, C3 hydrocarbon and carbon black goes back to normal pressure, flows to a wash oil purifying tower and higher alkyne and C3 hydrocarbon are obtained at the top of the tower and return to serve as gaseous hydrocarbon raw material.

Owner:SHANDONG UNIV OF SCI & TECH

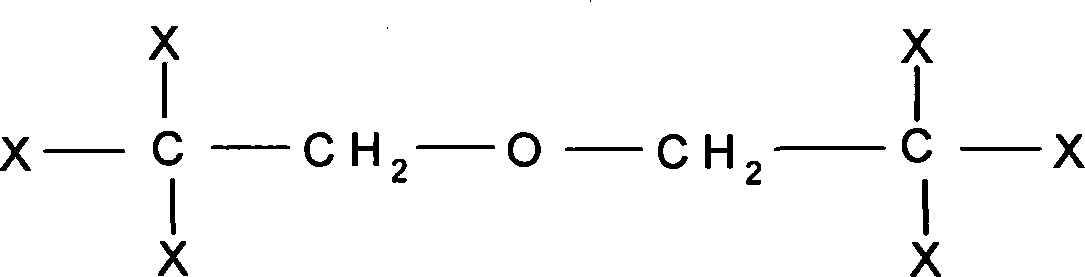

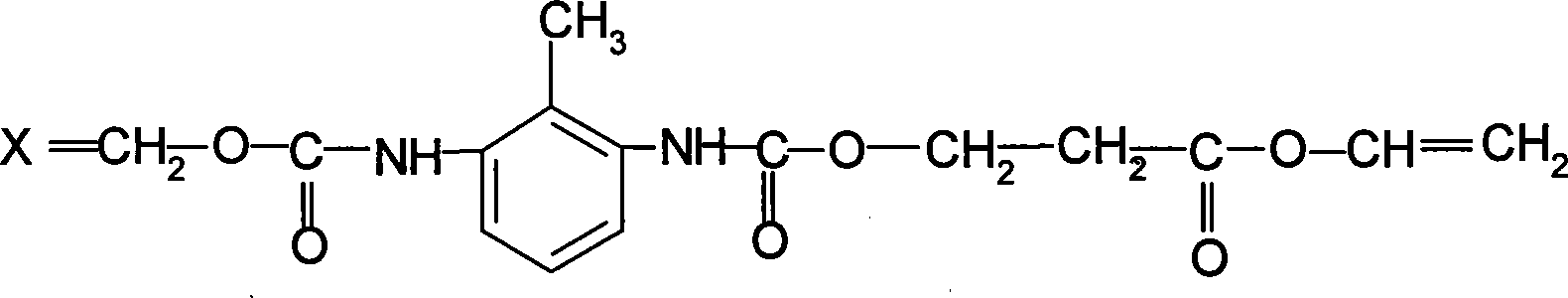

Acrylic polyurethane having star-structure six functional groups and synthesizing method thereof

InactiveCN101157640AFast curingMake up for water resistanceCarbamic acid derivatives preparationOrganic compound preparationPentaerythritol(Hydroxyethyl)methacrylate

The invention relates to an acrylic polyurethane containing stelliform-structure six functional groups and synthetic method, wherein, the compound is made through combining dipentaerythritol, diisocyanate and hydroxyethyl methacrylate. The synthetic method is that the dipentaerythritol and the diisocyanate are put in a reactor, the catalyst is put in then and stirred to increase the temperature, with the temperature is 10 to 90 DEG C and the period of the reaction is 30 to 100 minutes. When the content (quality consistency) of the isocyanate acid sampled and tested reaches 13.8 percent to 22 percent, the hydroxyethyl methacrylate and inhibitive substance are put in when the reaction temperature is between 20 and 100 DEG C and the temperature lasts for 1 to 5 hours. When the content of the isocyanate acid sampled and tested is less than 0.2 percent, the reaction is stopped the material is discharged. The resin of typically stelliform. The structure is innocuous and nonirritating, and having the advantages of good stability, well performance, simple synthetic method and easy operation causing no environmental pollution.

Owner:HUNAN UNIV

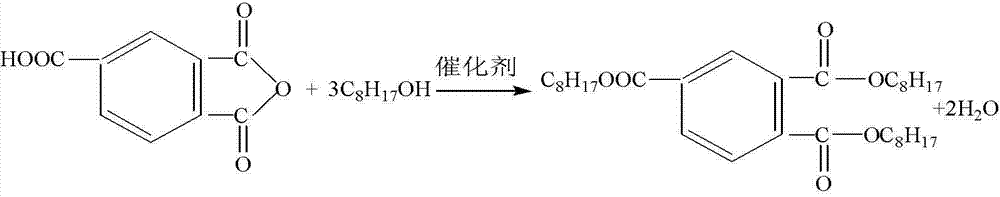

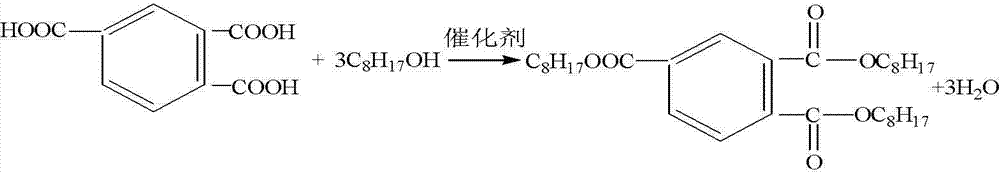

Catalytic synthesis method of tri-octyl tri-meta-benzoate

ActiveCN102924279AGood catalytic effectLight colorOrganic compound preparationCarboxylic acid esters preparationOxideTrioctyl trimellitate

The invention discloses a catalytic synthesis method of tri-octyl tri-meta-benzoate. A solid oxide is adopted as a catalyst and has a better catalysis effect; the catalytic synthesis method is an innovative novel catalytic synthesis process; the catalyst can be recycled; and the obtained tri-octyl tri-meta-benzoate is light in color and has high mass resistivity. Non-acid catalysis is adopted, and operations of neutralization and water washing are not needed in a production process, therefore, an aftertreatment procedure is simplified, and no wastewater is discharged in a production process; and the catalytic synthesis method is a cleaner production process, and accords with the requirement of relevant industrial policies for encouraging energy saving and emission reduction in the chemical engineering industry in China.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

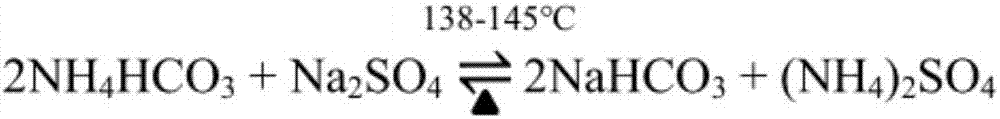

Method for preparation of sodium bicarbonate and ammonium sulfate from chemical strong brine

ActiveCN106865571ASolve processing problemsAchieve recyclingAlkali metal carbonatesAmmonia compoundsSodium bicarbonateProcess engineering

Belonging to the technical field of solid waste miscellaneous salt recycling treatment, the invention discloses a method for preparation of sodium bicarbonate and ammonium sulfate from chemical strong brine. According to the method, evaporated and concentrated chemical strong brine is subjected to hardness removal to obtain a delicate mirabilite solution, and then ammonia-soda process reaction is carried out to obtain sodium bicarbonate and ammonium sulfate products. The method provided by the invention solves the difficult treatment problem of chemical strong brine, realizes recycling of miscellaneous salt in strong brine, and meets the sustainable development requirements. At the same time, compared with the salt method for preparation of sodium bicarbonate, the method provided by the invention reduces the anti-corrosion requirement of equipment, saves the project investment for preparation of sodium bicarbonate, has the byproduct ammonium sulfate with a value higher than ammonium chloride, and has obvious advantages in economic benefits.

Owner:科莱环保(北京)有限公司

Method for preparing vegetable seedling culture substrate from agricultural wastes

ActiveCN104982252AImprove digestion efficiencyReduce processingGrowth substratesCulture mediaNutrientLivestock

The present invention provides a method for preparing a vegetable seedling culture substrate from agricultural wastes. The agricultural wastes comprise organic solid wastes and crop straws; and the method comprises the following steps of: (1) performing digestion and conversion on the organic solid wastes by earthworms; (2) composting the crop straws; (3) preparing the vegetable seedling culture substrate; and (4) optimizing the ratio of the vegetable seedling culture substrate. According to the method provided by the present invention, a technology of biologically digesting the agricultural wastes by the earthworms and fermenting and composting the crop straws by a straw composting agent is used so that efficient conversion of the agricultural wastes of a livestock and poultry culture farm and the crop straws is realized; a semi-decomposed organic material with good physical, chemical and biological properties is obtained according to the ratio; according to requirements on the vegetable seedling culture substrate, a novel vegetable seedling culture substrate with convenient mechanical work, good ventilation and water permeability, a balanced nutrient ratio, rapid-slow complementation of supply and strong buffering power is prepared.

Owner:临沂高盛肥业有限公司

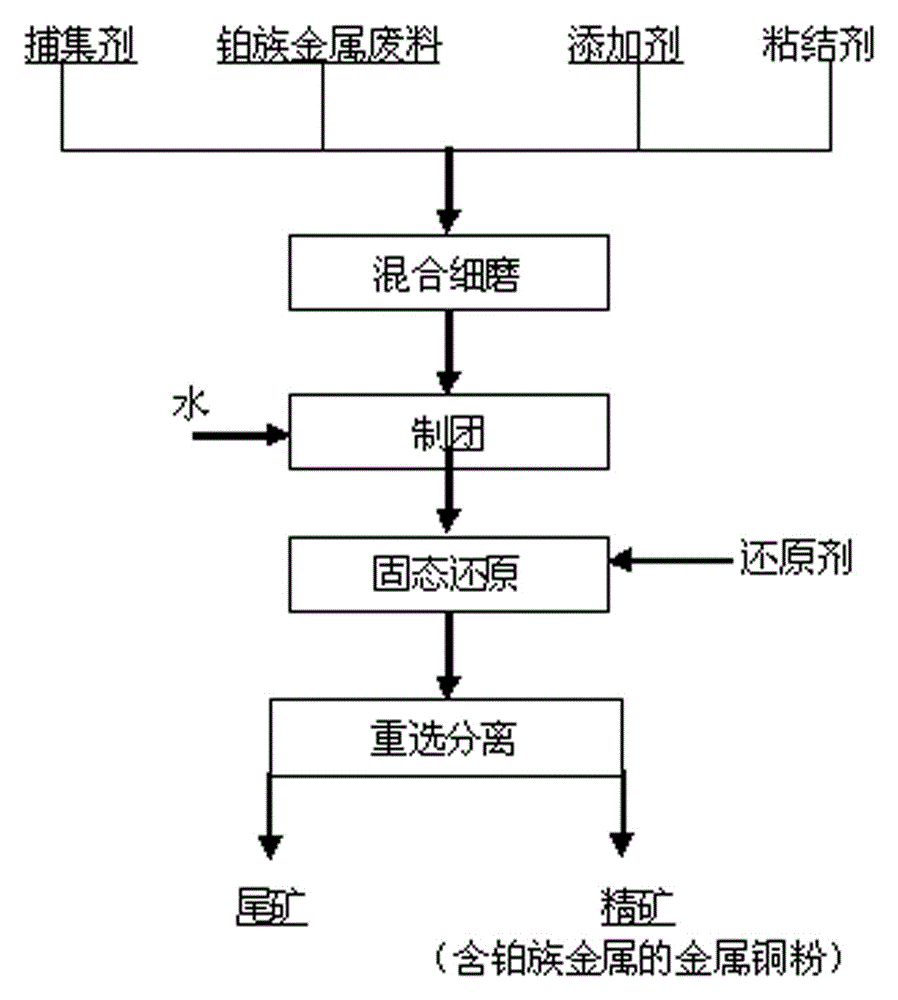

Method of recovering platinum group metals based on copper capture

InactiveCN104988314AEfficient recyclingHigh recovery rateProcess efficiency improvementPetrochemicalMetal recycling

The invention discloses a method of recovering platinum group metals based on copper capture. The method comprises the steps that platinum group metal contained waste is proportionally mixed with a copper capturing agent, an additive and a binding agent, and is subjected to fine grinding and then water adding to be pelletized, dried, placed in a crucible, and reduced at a certain temperature after certain reducing coal is added; metallized pellets obtained by reduction are broken, and the broken metalized pellets are subjected to ball milling and then gravity separation; and obtained ore concentrate is metal copper powder containing the platinum group metals, thereby realizing the recovery of the platinum group metals. The method is simple in technological process; and the reduction temperature is low; used equipment is conventional metallurgy and ore-dressing equipment, so that the method is easy to implement; a recovery rate of the platinum group metals is greater than 99%; the content of the platinum group metals in gravitation separation tailings is less than 10g / t; with the adoption of the method, the platinum group metals can be effectively recovered from spent auto-catalysts, catalysts for petrochemical industry and catalysts for fine chemicals; no harmful gas is discharged; the tailings can serve as raw building materials; and the whole process is clean and pollution-free.

Owner:KUNMING INST OF PRECIOUS METALS

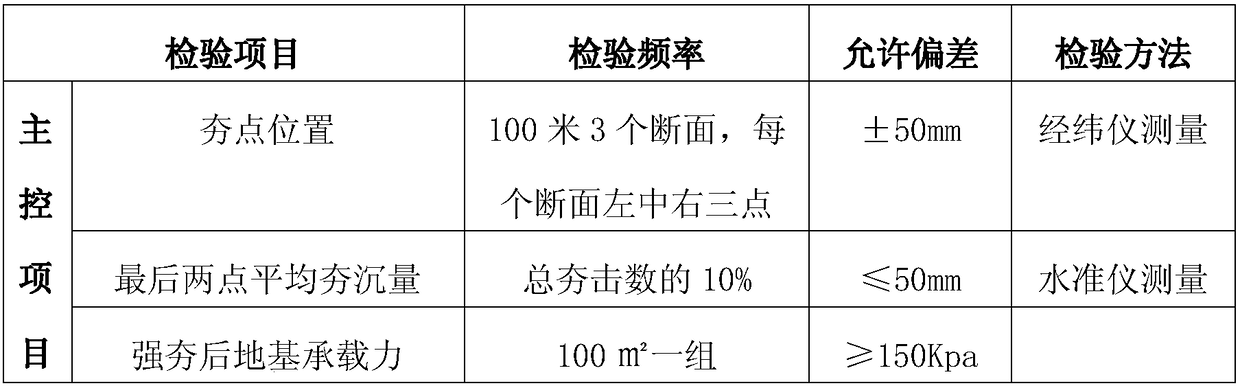

Foundation treatment construction method with column hammer dynamic-consolidation replacement effect

InactiveCN108914912AReduce environmental pollutionReduce engineering costsSoil preservationIndustrial wasteConstruction aggregate

The invention discloses a foundation treatment construction method with column hammer dynamic-consolidation replacement effect. According to the geological conditions of different projects, the different replacement materials and the dynamic pressure equivalent are selected; the foundation of a building is tamped to form holes; the industrial waste aggregate, local waste sandstone or gravel mixture, and waste building wastes are used for backfilling and tamping the pit; the tamping and backfilling are performed for multiple times; finally, the lower hammer common tamping is performed, so as toform a dense replacement pier meeting the foundation, thereby reaching the purpose of consolidating the loose soil body of the foundation. The foundation treatment construction method has the advantages that the wastes are used as the replacement materials to fill the tamped holes, so that while the pollution to environment is reduced, the project cost is greatly reduced; in the whole construction process, the soil body consolidating depth and the soil body bearing capacity are improved, the application range is broad, and the social and economic benefits are good.

Owner:ANHUI ELECTRIC POWER DESIGN INST CEEC

Microwave radioradiation crosslinked complete biodegradable material and its processing method

The invention relates the microwave radio-frequency radiation cross-linking biodegradation material, comprising starch, cellulose, A, aminocaprolactam or polyatomic alcohol, B, coupling agent, C, nucleation agent, D, undecylenic acid, calcium carbonate, natrii chloridum, and urea. The method comprises the following steps: mixing the raw material, cross linking with microwave radio-frequency device, foaming, forming, and getting the product. The invention solves the problems of no degradation, complex procedure, high cost and hard technology. The product has the advantages of good draftability, suppleness and obstructing property. The invention has the advantages of wide application area, completely degradation and non pollution. The invention also has the advantages of simple technology, easy operation and low cost.

Owner:杨军现

P-type solar cell grade polycrystalline silicon preparing process

InactiveCN1935647AMeet technical requirementsNo dischargeSiliconPhotovoltaic energy generationMedium frequencyReducer

The invention discloses a p-type solar battery graded polycrystalline silicon preparing method, comprising the steps of: (1) selecting high- grade silica as raw material; (2) using mixture of highly pure petroleum coke and coal as reducer to reduce the silica; (3) refining by medium frequency furnace in temperature subregions; (4) electromagnetically blending at high temperature and centrifugally purifying; (5) vibrating at high temperature and medium-middle frequency to purify; (6) dephosphorizing; and (7) ingoting. And it has simple process, low power consumption, and high yield, and can largely reduce the raw material costs of the current solar batteries.

Owner:高文秀

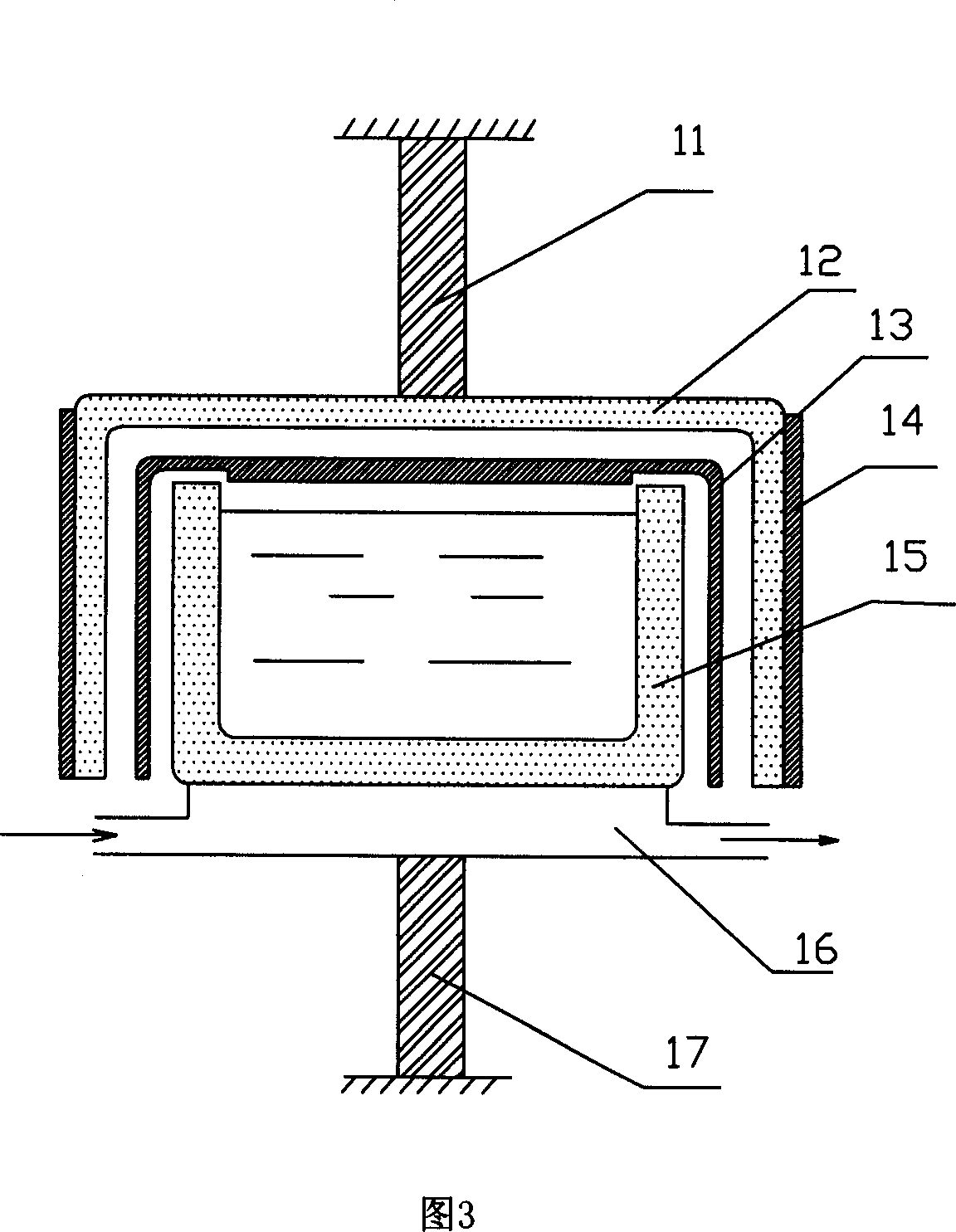

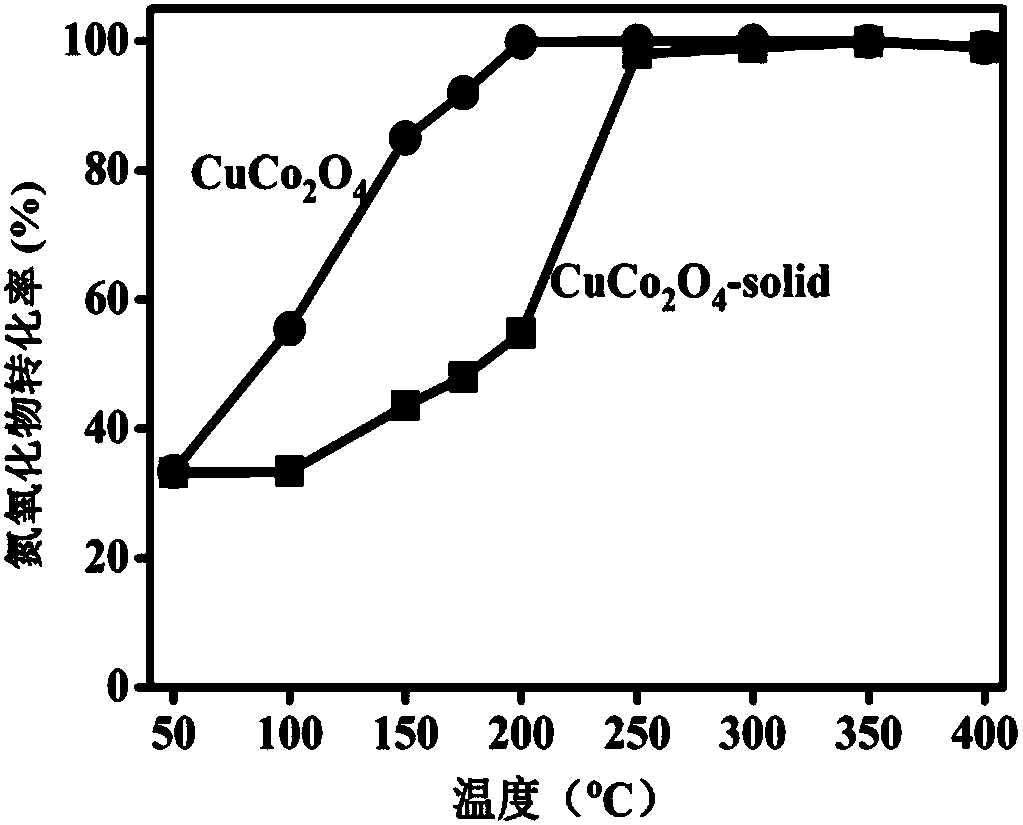

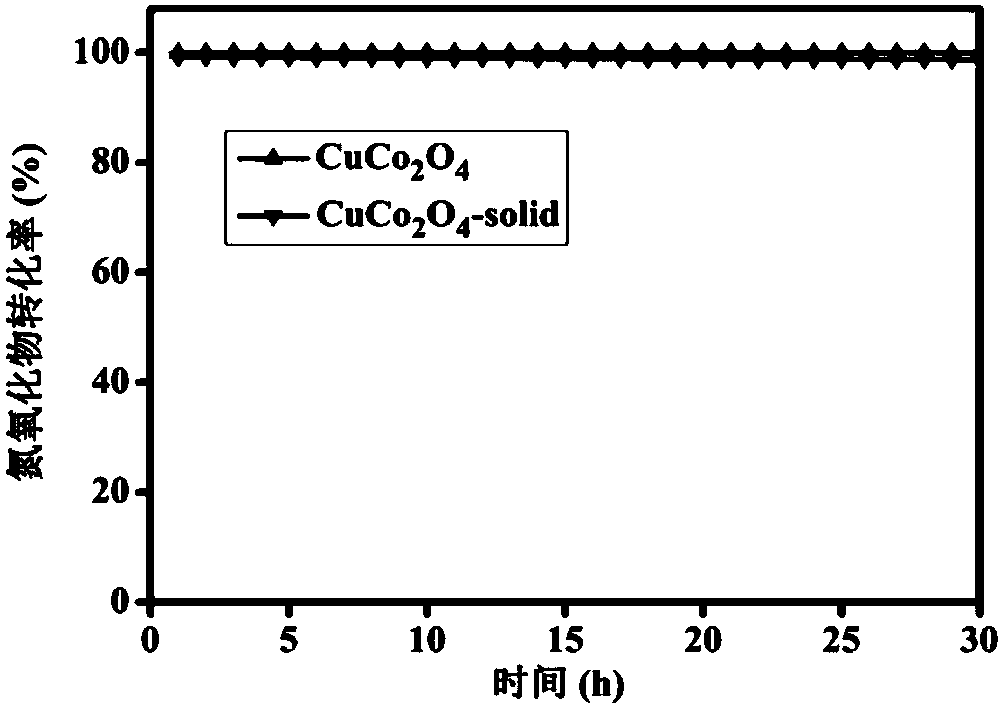

Preparation of spinel catalyst and application thereof to elimination of nitrogen oxides

InactiveCN107790116AUniform shapeControllable facetGas treatmentDispersed particle separationHigh pressureHigh voltage

The present invention provides a highly active spinel-type catalyst for elimination of nitrogen oxides from coal-fired flue gas emissions from thermal power plants and nitric acid plants. The catalystexhibits a high NOx conversion rate in a wide air-fuel ratio range and exhibits excellent low-temperature activity. The prepared catalyst is prepared by a high-voltage electrospinning method. The spinel components mainly include CuCo2O4, NiCo2O4, FeCo2O4, CoMn2O4, CoFe2O4, etc. The morphology of the prepared catalyst, such as crystal faces and size, can be controlled by combination of the electrospinning method and a heat treatment process. The performance of hollow tubular spinel in NOx elimination is much better than that of solid nanorods. The denitration effect of the catalyst provided bythe present invention is superior to that of a conventional NOx elimination catalyst. The preparation method is simple, the operation is convenient, the cost is low, the NOx conversion rate is high,and obvious industrial application value is provided.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

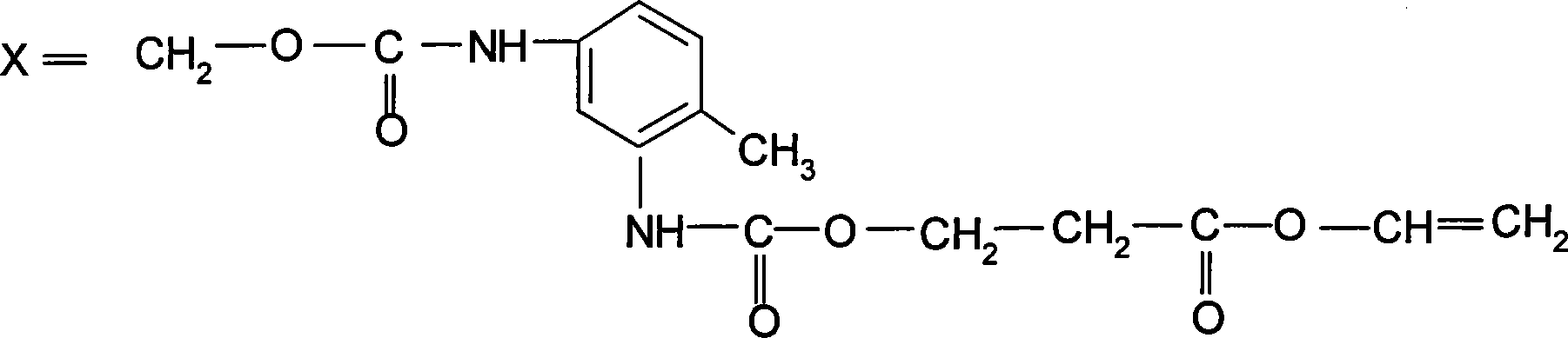

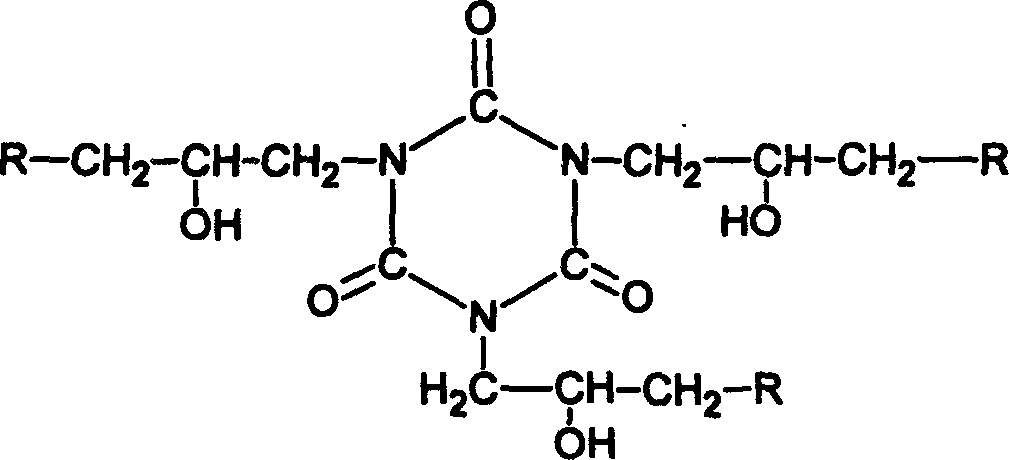

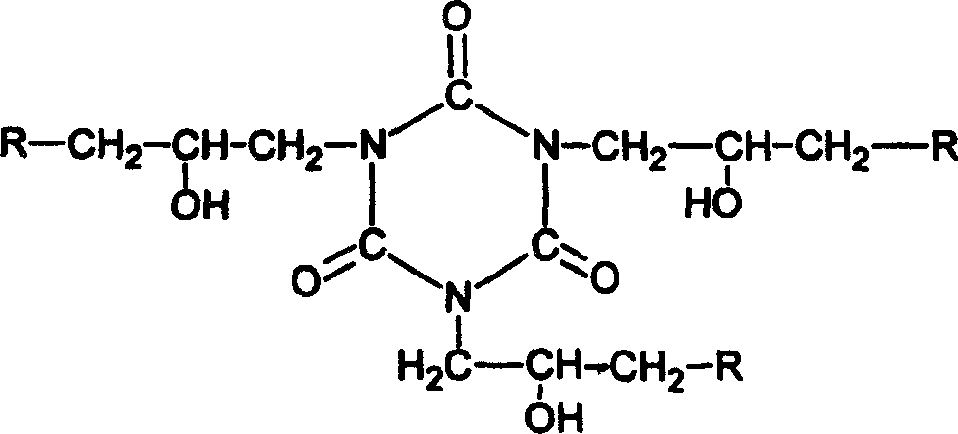

Tri(methyl)epoxy acrylate isocyanurate and synthesizing process thereof

InactiveCN1560039ANo dischargeNo pollution in the processOrganic chemistryEpoxy acrylateMethyl group

The invention is a tri(methyl)epoxy acrylate isocyanurate (TGICA), and its synthesizing metehod: (1) batching ratio: triepoxypropyl isocyanurate (TGIC) to (methyl)crylic acid = 1 : 2.85-3.15 (mol); the dosage of catalyst is 0.4-0.8% (reference toTGIC), that of anti-aggregative agent 0.5-1.5 % (AA, abbreviated for H2-C=CH-COO, or MAA, abbreviated for CH2=C-COO(CH2) ), and that of antioxidant 0.05-0.08% (total material quantity); (2) process course and conditions: casting the AA / MAA, anti-aggregative agent, and catalyst in a reactor, stirring and raising temperatue to 80 deg.C, then casting in TGIC in batches, after TGIC fully dissolves, controlling at 100-110 deg.C and reacting for 1 hour, raising and controlling temperature at 100-120 deg.C to react for 4 hours; stop stirring, sampling at 1 hour intervals to determine until the acid value < 5 mgKOH / g, cooling to under 80 deg.C, and taking out material and packing. The invenrtion is a quickly-curable, excellent-thermal stability and -outdoor weatherability, cost-reducible TGICA and its synthesizing method.

Owner:HUNAN UNIV

Medicine for preventing fowl plague

The invention discloses a medicine for preventing fowl plague, which is prepared by the following raw materials according to the weight portion: 5-15 of peach kernel, 3-10 of safflower, 5-15 of red paeonia, 5-15 of cortex moutan, 5-15 of trihosanthes root, 10-20 of ordate houttuynia, 5-15 of balloon flower, 5-15 of almond, 5-15 of liquorice, 5-15 of burdock, 10-20 of chrysanthemum, 10-20 of mulberry leaf, 5-15 of peppermint, 5-15 of radix bupleuri, 10-30 of dyers woad leaf, 10-30 of dandelion, 10-30 of radix isatidis, 10-30 of honeysuckle, 10-30 of forsythia, 5-15 of alisma orientale, 5-15 of betelnut and 5-15 of radix sileris. The invention has reasonable medicine formulation, low cost and remarkable treatment effect, and is easy to largely popularize and use.

Owner:许云生

Water column forming method of spherical molecular sieve

ActiveCN104383967AImprove adhesionReduce production process stepsCatalyst carriersCatalyst activation/preparationNano al2o3Manganese

The invention relates to a water column forming method of a spherical molecular sieve. The water column forming method is characterized by comprising the following steps: 1, beating a molecular sieve, a binding agent and water uniformly; 2, adding an alginate solution, and stirring uniformly at high speed to prepare a suspended sizing agent; 3, dropping the suspended sizing agent to a polyvalent metal cation water solution to form gel particles; and 4, taking the gel particles out, drying and roasting to obtain the product, wherein the dry-basis mass rate of the molecular sieve to the binding agent in the step 1 is (0.2-3):1, and the binding agent is alumina hydrogel, nanometer aluminum oxide sol or silica sol; the soluble alginate in the step 2 is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate, the content of alginate in the suspended sizing agent is 0.3-5w%, and total dry-basis content of the molecular sieve and the binding agent in the suspended sizing agent is 5-30w%; the polyvalent metal cation water solution in the step 3 is a saline solution containing aluminum, zinc, calcium, copper, ferrum, ferrous, cobalt, manganese or nickel ions, with the saturation concentration being 0.1mol / L.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

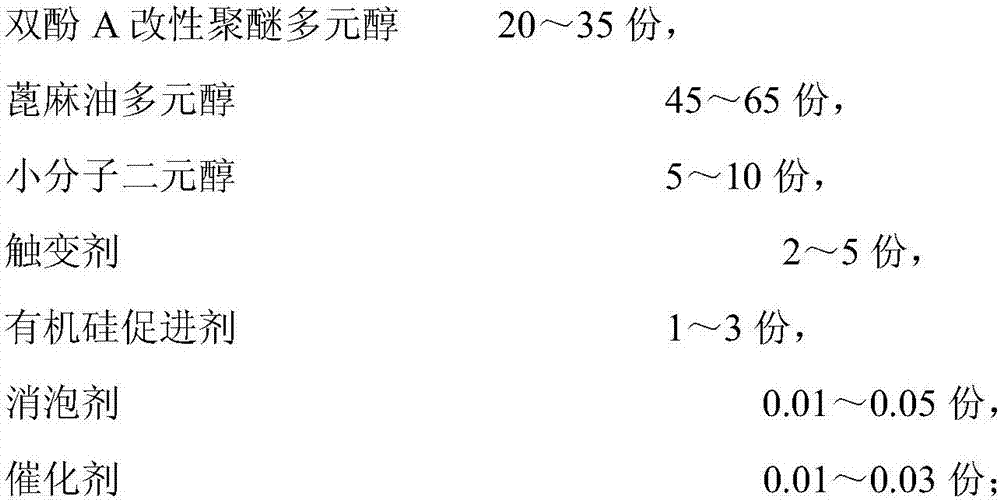

Preparation method of bi-component polyurethane pouring sealant for water treatment membrane

ActiveCN107083229AIncreased shear strengthFast curingSemi-permeable membranesNon-macromolecular adhesive additivesAging resistanceUltimate tensile strength

The invention discloses a preparation method of a bi-component polyurethane pouring sealant for a water treatment membrane. The pouring sealant comprises a component A and a component B; when the pouring sealant is stored, the component A and the component B are stored separately; when the pouring sealant is used, the component A and the component B are compounded; after the component A and the component B are mixed according to a mass ratio of (1.0 to 1.2):(0.8 to 1.0), the bi-component polyurethane pouring sealant for the water treatment membrane is obtained. According to the method, the obtained bi-component polyurethane pouring sealant for the water treatment membrane has a quicker curing speed, a bonding effect is achieved within 30 minutes in case of normal temperature bonding, the defect of slow curing of a common polyurethane pouring sealant can be overcome, complete curing can be realized within 24 hours, and the production efficiency is improved; meanwhile, a bi-component product is stronger in bonding force, higher in shear strength and excellent in ageing resistance, and has a good bonding effect on a hollow fiber membrane, and the service life of a membrane assembly can be longer.

Owner:南京威邦新材料有限公司

Method for producing white carbon black and active carbon by using residual rice hull ash after gasification

InactiveCN101704526AGood effectGood impregnation absorption performanceSilicaSilicon dioxidePermeation

The invention provides a method for producing white carbon black and active carbon by using residual rice hull ash after gasification, which comprises the following steps of: performing alkali solution impregnation, drying and roasting on the residual rice hull ash after the gasification, which serves as a raw material, to obtain a mixture of powdery water glass and carbon powder; adding water into the mixture to dissolve the mixture and boiling the mixture to obtain a water glass solution and the carbon powder; performing the reaction of the water glass solution and soluble alkali metal acid carbonate to obtain silicon dioxide hydrate; filtering the silicon dioxide hydrate; washing and drying a precipitate to obtain the white carbon black; and washing and activating filter residue of the carbon powder to obtain the active carbon, wherein an alkali solution can be recycled. In the method, silicon dioxide in raw materials can well react with alkali, the impregnating absorption performance is good, the uniform permeation is achieved quickly, and the drying link can be switched immediately, so that the large silo capacity for storing impregnated rice hull ash is unnecessary; the anoxic roasting temperature is low, so that the high-temperature corrosion of a furnace body is avoided; the alkali solution can be recycled, so that the loss of chemical raw materials is reduced; the intermediate product powder, which is the mixture of the water glass and the carbon powder, is easy to be separated and filtered; and a prepared white carbon black product is high in purity and strong in activity.

Owner:李洪锡 +2

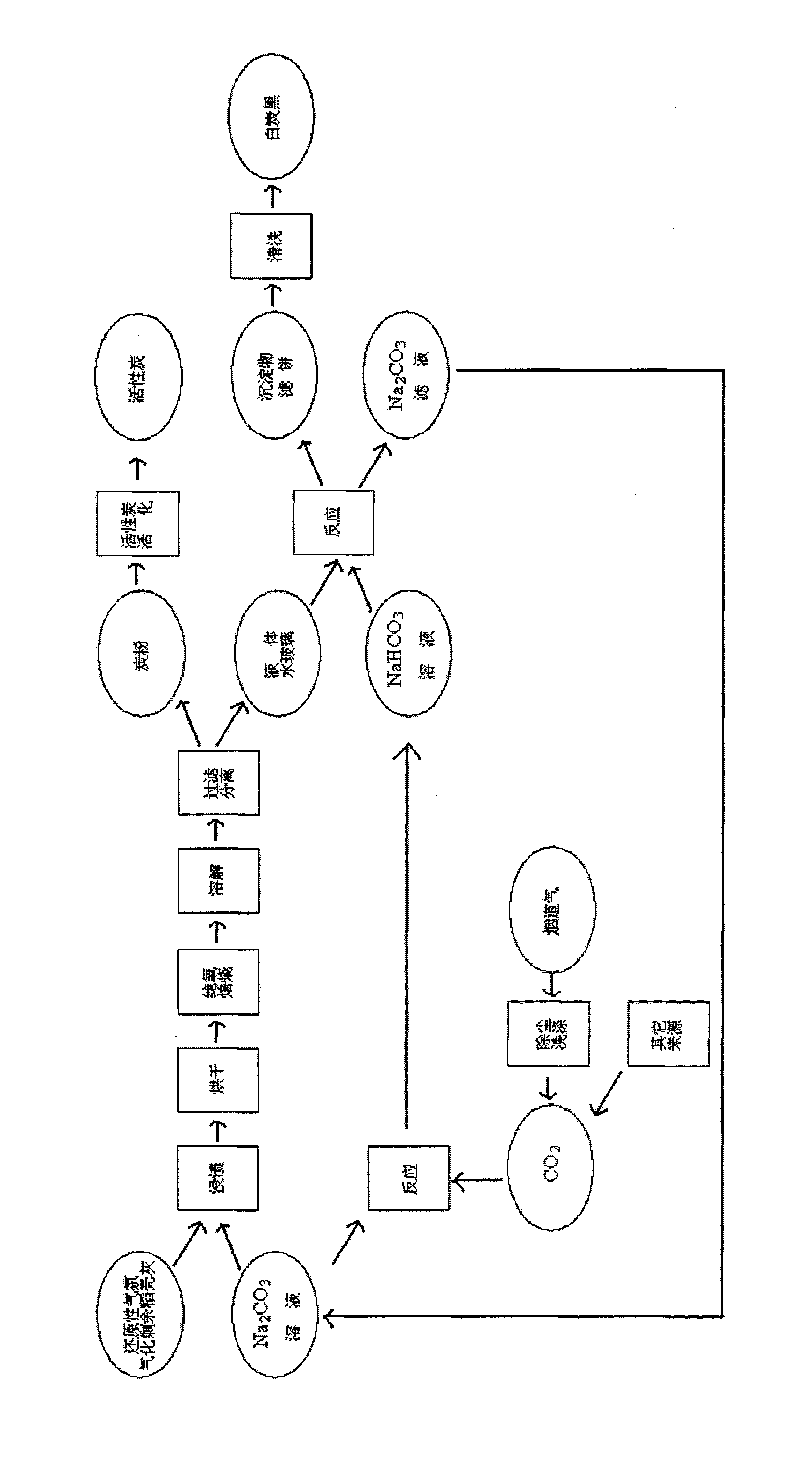

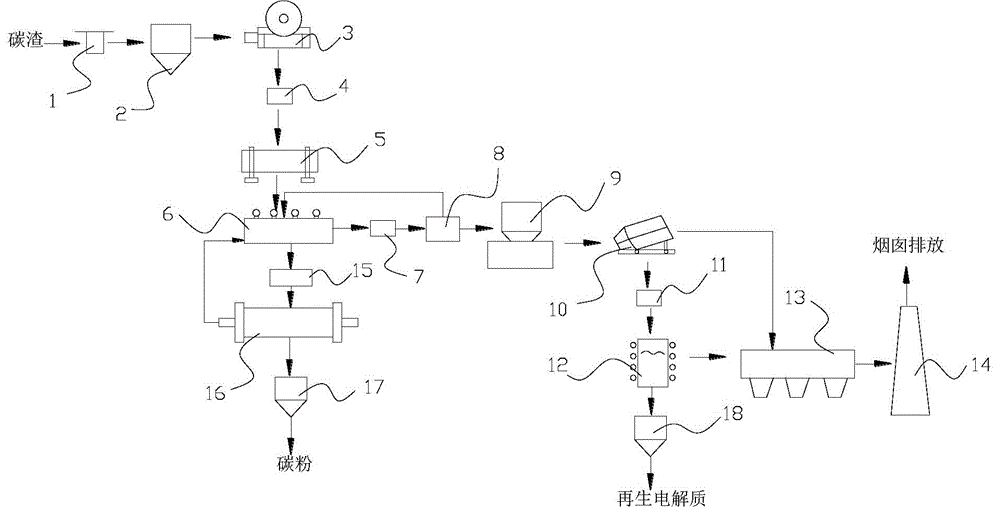

Device and method for producing regenerative electrolyte from aluminum-electrolysis carbon residues

InactiveCN103949460ANo dischargeSimple processSolid waste disposalIntermediate frequencyProcessing cost

The invention relates to a device and a method for producing regenerative electrolyte from aluminum-electrolysis carbon residues. The device comprises a sorting platform, a carbon residue stock bin, a crushing device, a first magnetic separation device, a ball milling device, a flotation tank, a second magnetic separation device, a sedimentation basin, a feeding device, a drying device, a third magnetic separation device, an intermediate frequency furnace, a dust-removal device and a chimney, which are sequentially connected with one another, wherein a carbon powder tank, a filter-press device and a carbon powder bin are further sequentially connected to the flotation tank, and a regenerative electrolyte bin is connected to the intermediate frequency furnace. The method comprises the following steps: (a) raw material sorting, (b) carbon residue crushing, (c) ball-milling, (d) flotation, (e) drying, (f) regenerative electrolyte refining, and (g) tail gas treatment. The method has the beneficial effects that the carbon residues are sorted to be a utilizable value resource, and basically no industrial waste residue is generated; the process is simple, the processing cost is low, the industrialized application is easily realized, the production water supply is completely recycled in the whole process, no polluted gas is discharged, and the method is a brand new method for processing and comprehensively utilizing the carbon residues and has a high promotional value.

Owner:JIANSHUI DEFU RENEWABLE RESOURCES

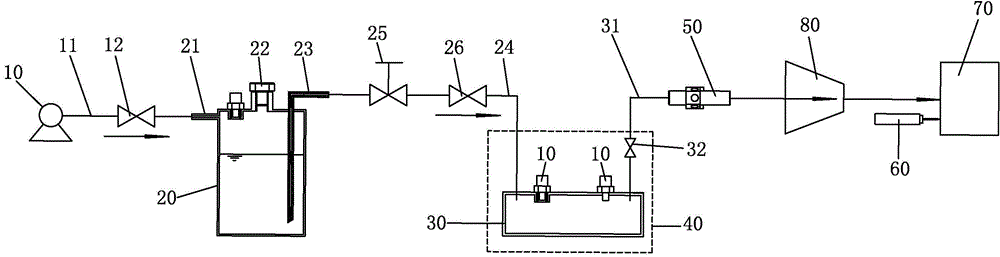

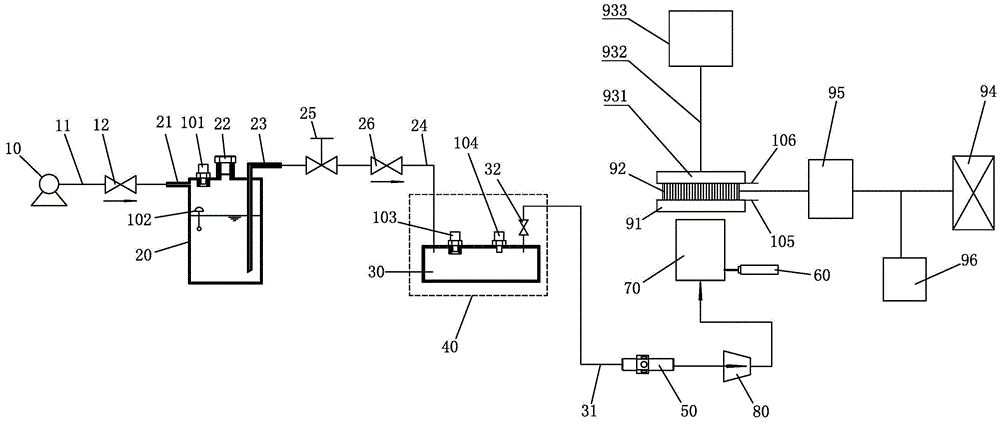

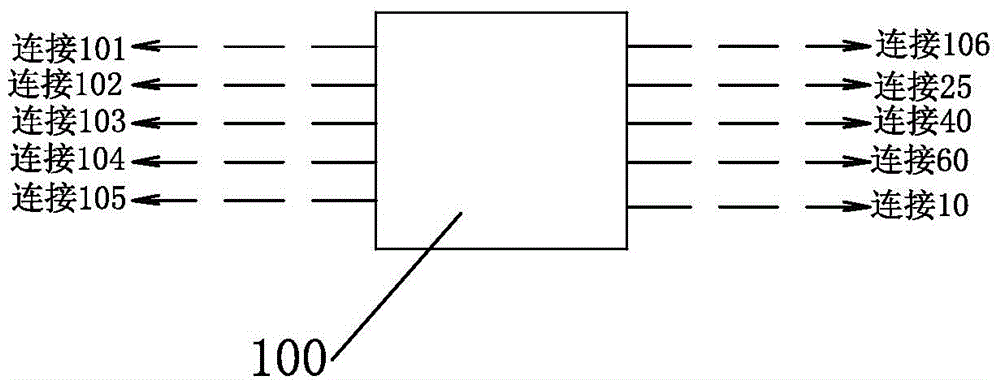

Fuel supply-vaporization-pressure regulation-full premixed combustion system, thermoelectric power generation device with same and method for thermoelectric power generation

ActiveCN103939895ANo noiseNo pollution in the processLiquid fuel feeder/distributionInternal combustion piston enginesCombustion systemFuel tank

The invention discloses a fuel supply-vaporization-pressure regulation-full premixed combustion system, a thermoelectric power generation device with the system and a method for thermoelectric power generation. The fuel supply-vaporization-pressure regulation-full premixed combustion system comprises an air pump, a fuel tank, a vaporizing chamber, a preheating heater, a premixing nozzle, an inflow air guide device, an ignition device and a full premixed combustor. The air pump is connected and communicated with the fuel tank through a first pipeline. The fuel tank is provided with a fuel inlet and a fuel outlet pipe. The fuel outlet pipe is connected and communicated with a fuel inlet of the vaporizing chamber through a second pipeline. The preheating heater heating the vaporizing chamber is arranged on the vaporizing chamber. The inflow air guide device is arranged between an air outlet of the premixing nozzle and the full premixed combustor. When the system is in work, combustion is thorough without black smoke, harmful gas is not exhausted, the speed is controllable, and noise is avoided; the structure is simple and the service life is over ten years. When the output power is 50 W, the fuel consumption is below 70 g / h, so that the economic benefit is good.

Owner:陈光宁

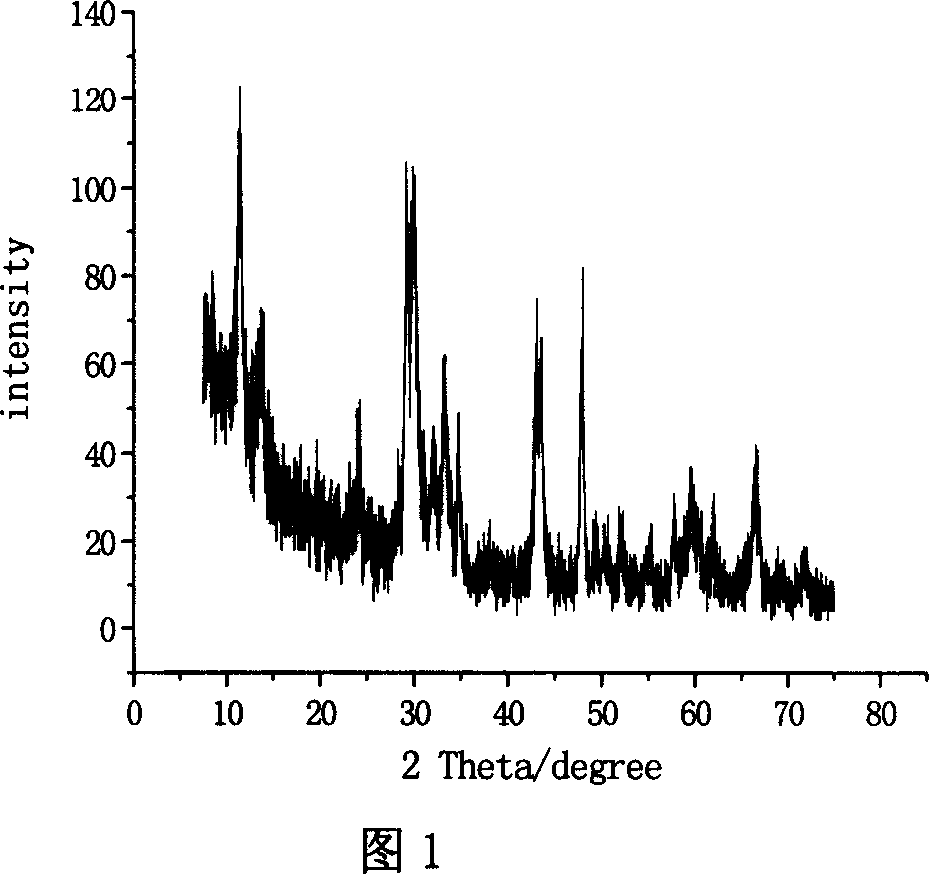

Potassium hexatitanate whisker and its prepn process

InactiveCN1974889AUniform diameterGood lookingPolycrystalline material growthFrom normal temperature solutionsDiameter ratioPotassium

The present invention relates to potassium hexatitanate whisker and its hydrothermal preparation process, and belongs to the field of material technology. The potassium hexatitanate (K2Ti6O13) whisker has diameter of 200-500 nm and length of 20000-30000 nm. It is prepared with titanium compound and potassium compound with the corresponding K2O / TiO2 molar ratio of 2-20, and through the technological steps of reaction, solid-liquid separation, washing, ultrasonic dispersion, drying, etc. The preparation process of the present invention has mild reaction condition, great operation flexibility, simple course and easy control, and the synthesized potassium hexatitanate whisker has high dispersion, homogeneous diameter, great length / diameter ratio and whisker yield over 83 %.

Owner:SICHUAN UNIV

Imitated silk fabric reactive printing method

InactiveCN105019277ANo dischargeNo pollutionFibre treatmentDyeing processTextile printerColour fastness

The invention discloses an imitated silk fabric reactive printing method which comprises the following steps: pretreatment of fabrics: imitated silk fabric cloth is put into a pretreating agent to be pretreated; sizing: the pretreated imitated silk fabric cloth undergoes sizing by a sizing machine; heat shaping; making of print files; jet-printing: jet-printing is carried out by a digital ink-jet printing machine; and streaming drying is carried out to obtain a finished product. By the method for reactive ink-jet printing of imitated silk fabric cloth, printing effect and colour fastness are both improved greatly, and there is no need to specially process ink. The machine is not easy to damage, and hand feeling of the product is also improved obviously.

Owner:浙江银梭织染股份有限公司

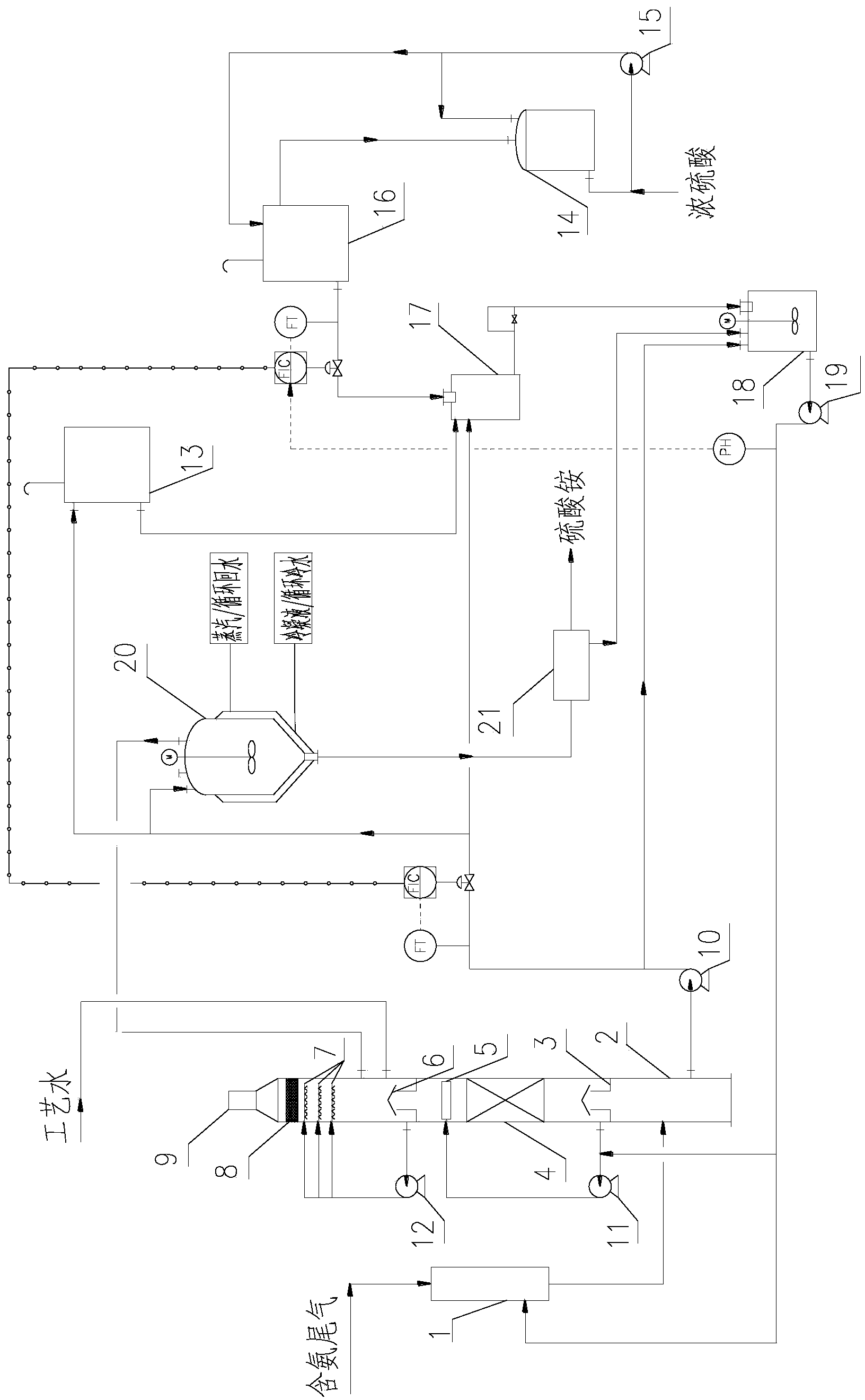

Method for treating low-concentration ammonia-containing tail gas

ActiveCN103894048APromote absorptionReduce pollutionDispersed particle separationHydrogen SulfateAfter treatment

The invention belongs to the field of environmental protection, and discloses a method for treating low-concentration ammonia-containing tail gas. The method for treating the low-concentration ammonia-containing tail gas comprises the following steps: low-concentration ammonia-containing tail gas enters an efficient absorber from the top, an ammonium hydrogen sulfate mother liquor is jetted to the lower part of the efficient absorber so as to be in sufficient contact reversely, and ammonia in tail gas is absorbed primarily; the ammonia-containing tail gas absorbed primarily and the ammonium hydrogen sulfate mother liquor enter the lower part of the absorption tower together, the ammonium hydrogen sulfate mother liquor is left at the bottom of the absorption tower, the tail gas ascends to the middle part of the absorption tower, acid dilute phase ammonium hydrogen sulfate mother liquor is sprayed, and ammonia in the tail gas is absorbed for a secondary stage; the tail gas after second-stage absorption continues to ascend to the upper part of the adsorption tower, a washing liquid is sprayed, ammonia in the tail gas is absorbed for a third stage, and the tail gas after third-stage absorption and replacement bypasses a demister and is discharged from the top of the absorption tower; ammonium sulfate mother liquor at the bottom of the absorption tower is conveyed to a crystallizing evaporator, concentrated mother liquor is evaporated firstly, and then is cooled down and crystallized, and separated to obtain ammonium sulfate. The method for treating low-concentration ammonia contained tail gas, which is provided by the invention, is suitable for producing solid ammonium sulfate in a small scale, and the ammonia content in the tail gas after treatment is lower than 10mg / Nm<3>.

Owner:SINOPEC NANJING ENG & CONSTR +1

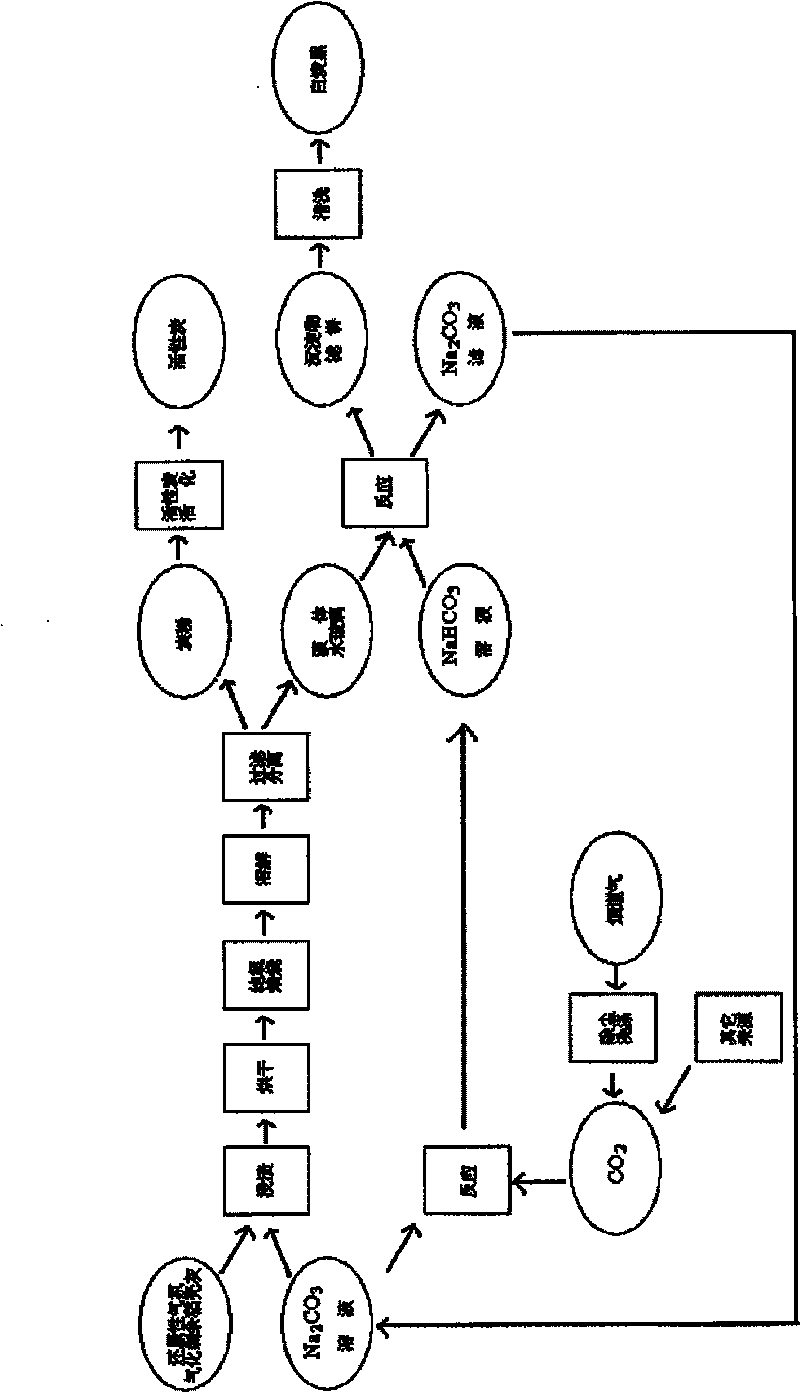

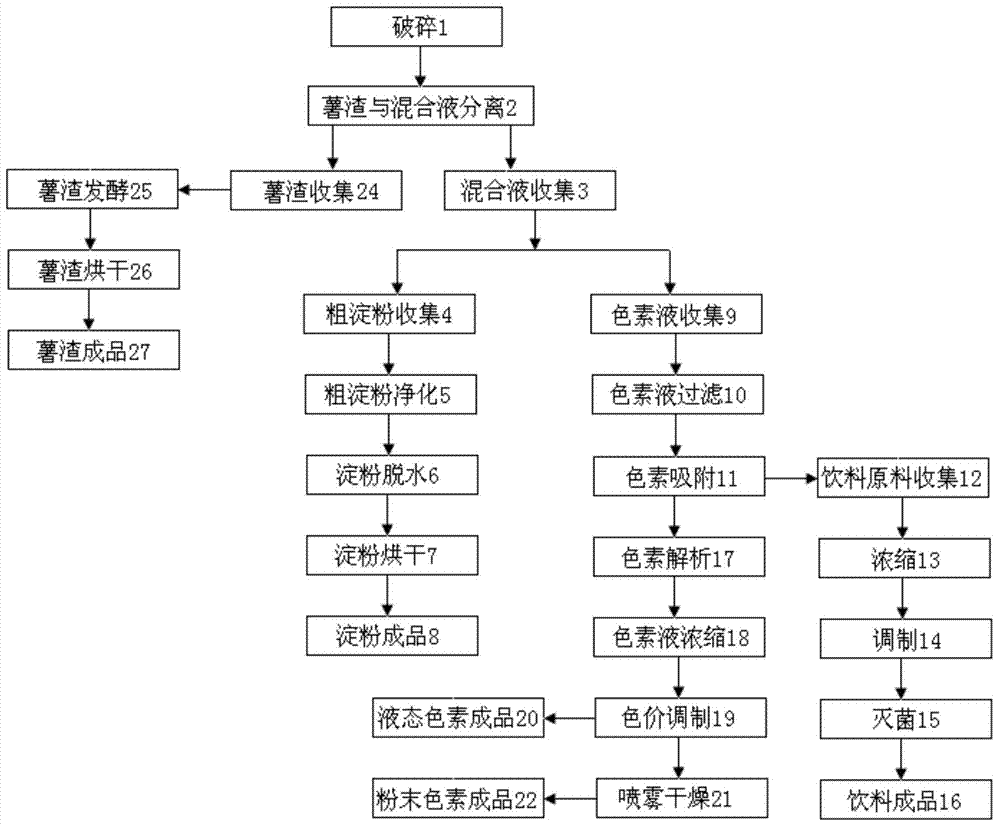

Decomposition and extraction method of active ingredients in purple sweet potatoes

InactiveCN103788218AHigh extraction rateNo dischargeAnimal feeding stuffNatural dyesDecompositionActive ingredient

The invention belongs to the technical field of natural product extraction, and relates to a decomposition and extraction method of active ingredients in purple sweet potatoes. The decomposition and extraction method comprises the following steps: firstly carrying out pre-treatment technologies such as purple sweet potato breaking, potato residue and mixed liquid separation and mixed liquid collection, and then respectively preparing products, wherein the potato slag preparation technology comprises four technological processes of potato residue collection, potato residue fermentation, potato residue drying and potato residue finished product, the starch preparation technology comprises five technological processes of raw starch collection, raw starch purification, starch dehydration, starch drying and starch product, the pigment preparation technology comprises nine technological processes of pigment liquid collection, pigment filtered liquid, pigment adsorption, pigment desorption, pigment liquid concentration, color value modulation, liquid pigment product, spray drying and powdery pigment product, and the beverage preparation technology comprises five technological processes of beverage raw material collection, concentration, modulation, sterilization and beverage finished product. The decomposition and extraction method has the advantages that the preparation technologies are simple, the rate of comprehensive utilization is high, the extraction rate of natural pigment is high, the production technology is easy to control, the added value of the product is high, and the decomposition and extraction method is simple to operate and environment-friendly.

Owner:日照瑞奥生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com