Tri(methyl)epoxy acrylate isocyanurate and synthesizing process thereof

A technology of epoxy acrylate and isocyanurate, applied in organic chemistry and other directions, can solve the problems of unsatisfactory thermal stability and outdoor weather resistance, and achieve the effects of easy control, simple operation, and no environmental pollution problems.

Inactive Publication Date: 2005-01-05

HUNAN UNIV

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing UV film-forming resin acrylate bisphenol A epoxy ester, acrylic polyurethane, acrylic polyester are not ideal enough for thermal stability and outdoor weather resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Pencil hardness | aaaaa | aaaaa |

Login to View More

Abstract

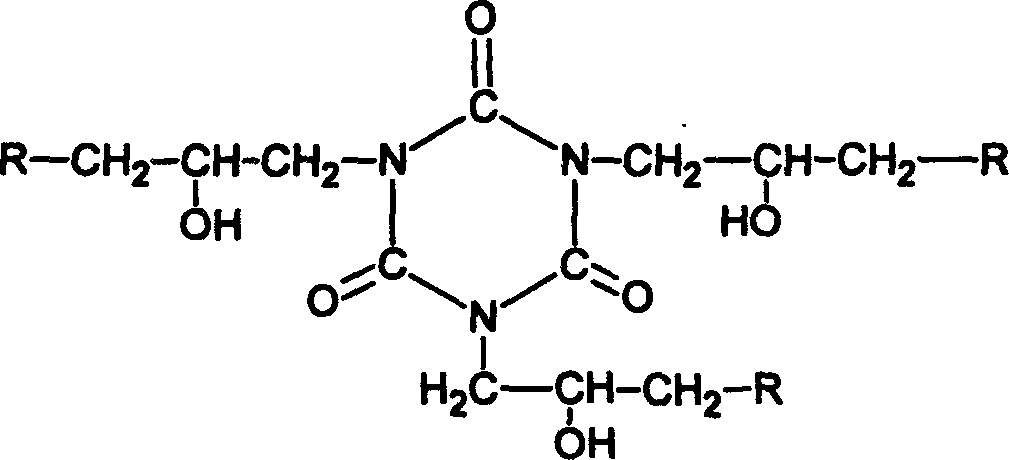

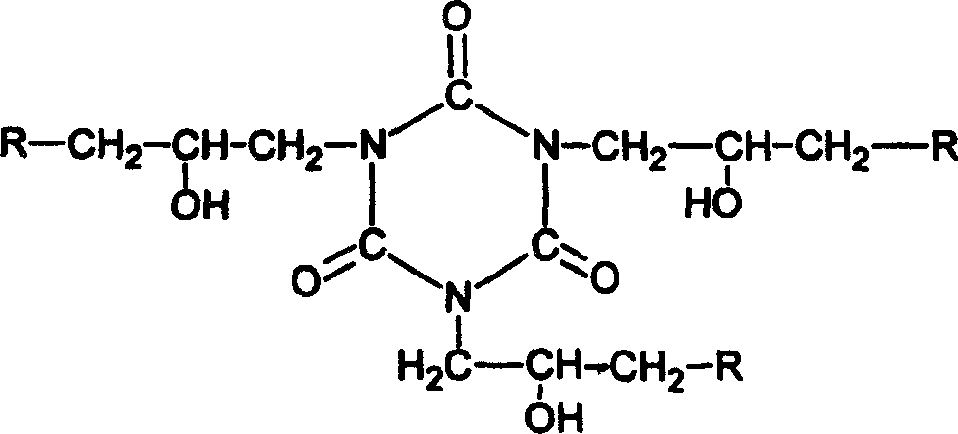

The invention is a tri(methyl)epoxy acrylate isocyanurate (TGICA), and its synthesizing metehod: (1) batching ratio: triepoxypropyl isocyanurate (TGIC) to (methyl)crylic acid = 1 : 2.85-3.15 (mol); the dosage of catalyst is 0.4-0.8% (reference toTGIC), that of anti-aggregative agent 0.5-1.5 % (AA, abbreviated for H2-C=CH-COO, or MAA, abbreviated for CH2=C-COO(CH2) ), and that of antioxidant 0.05-0.08% (total material quantity); (2) process course and conditions: casting the AA / MAA, anti-aggregative agent, and catalyst in a reactor, stirring and raising temperatue to 80 deg.C, then casting in TGIC in batches, after TGIC fully dissolves, controlling at 100-110 deg.C and reacting for 1 hour, raising and controlling temperature at 100-120 deg.C to react for 4 hours; stop stirring, sampling at 1 hour intervals to determine until the acid value < 5 mgKOH / g, cooling to under 80 deg.C, and taking out material and packing. The invenrtion is a quickly-curable, excellent-thermal stability and -outdoor weatherability, cost-reducible TGICA and its synthesizing method.

Description

technical field The present invention relates to a novel compound-tri(meth)acrylic acid epoxy ester isocyanurate (TGICA) and its synthesis method. Background technique In recent years, UV-curable coatings (hereinafter referred to as UV coatings) have been widely used in many industrial and civil fields as a kind of green environmental protection coatings because they do not contain volatile organic solvents, and are an important aspect of clean production in the coatings industry. UV coatings are mainly composed of four major parts, namely film-forming resin, diluent monomer, photosensitizer and additives. The performance and application of UV coatings depend entirely on the performance and composition of the above substances. Existing UV film-forming resin acrylic bisphenol A epoxy ester, acrylic polyurethane, its thermal stability and outdoor weather resistance of acrylic polyester are not ideal enough. Contents of the invention The technical problem to be solved by ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07D251/34

Inventor 单文伟曾光明汤杨彭敏

Owner HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com