Decomposition and extraction method of active ingredients in purple sweet potatoes

A technology of active ingredients and extraction methods, applied in the field of natural product extraction, can solve the problems of purple sweet potato resource waste, environmental pollution, etc., and achieve the effects of high added value of products, easy control of production process, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

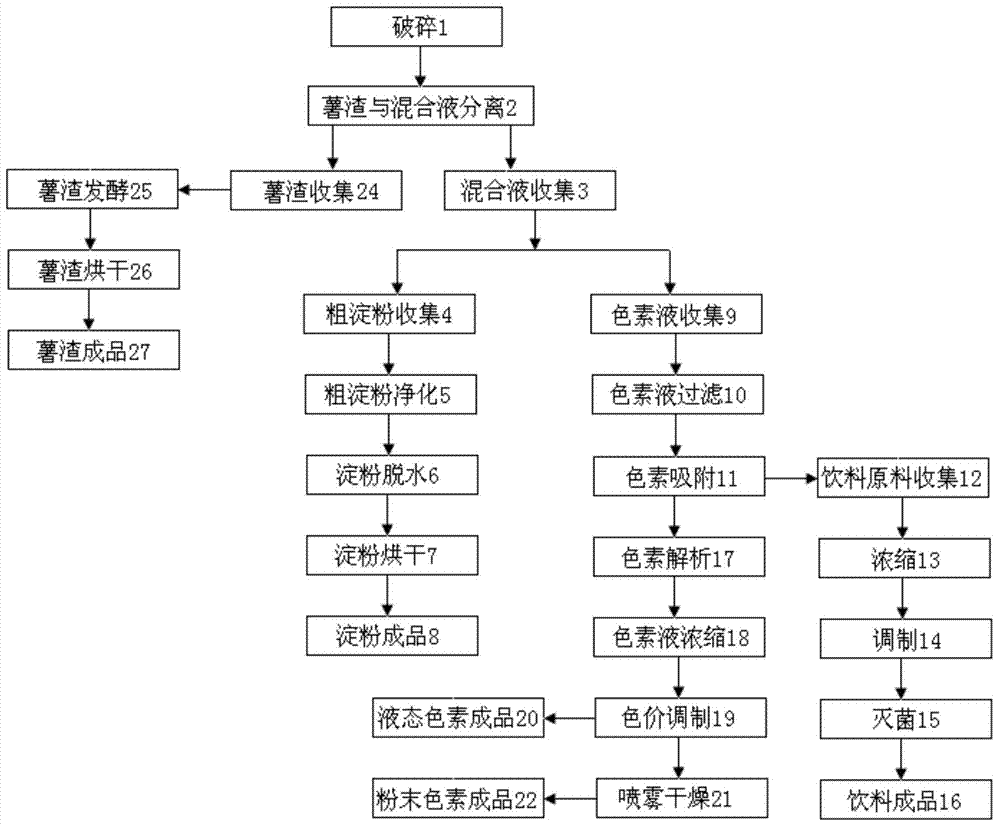

[0018] The concrete preparation process of this embodiment is by figure 1 As shown, the crushing device, filtering device, drying device, starch purification device, dehydration device, adsorption device, concentration device, spray drying device and sterilization device used in it are all conventional general-purpose devices, and their control parameters are controlled according to conventional Process selection can be realized; in this embodiment, the raw material purple sweet potato is firstly processed through three pretreatment processes of crushing 1, potato residue and mixed solution 2 and mixed solution collection 3, and then each product is prepared separately, wherein the preparation of potato residue includes potato residue Four processes of residue collection 24, potato residue fermentation 25, potato residue drying 26 and potato residue finished product 27; starch preparation includes crude starch collection 4, crude starch purification 5, starch dehydration 6, sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com