Fuel supply-vaporization-pressure regulation-full premixed combustion system, thermoelectric power generation device with same and method for thermoelectric power generation

A technology of combustion system and thermoelectric power generation, applied in combustion methods, combustion engines, gas fuel burners, etc., can solve the problems of high maintenance cost, high noise, complex structure and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

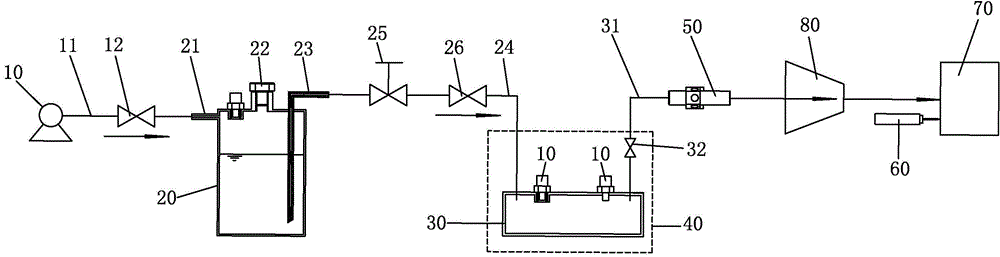

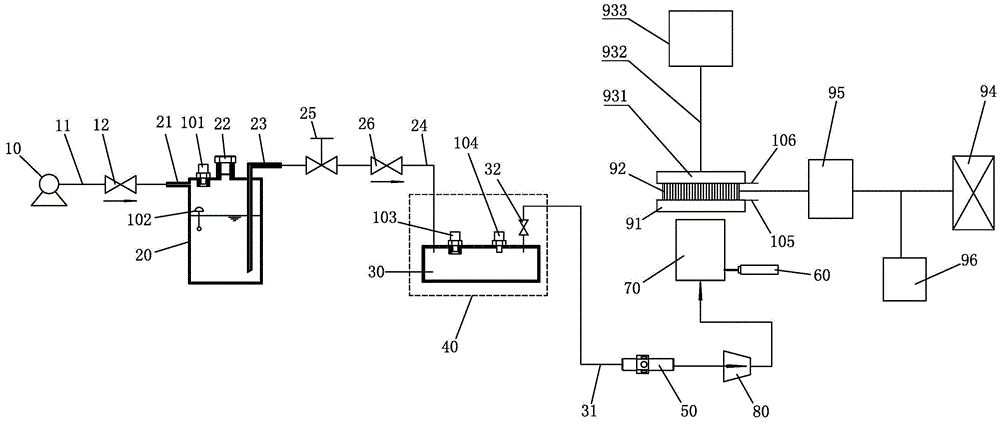

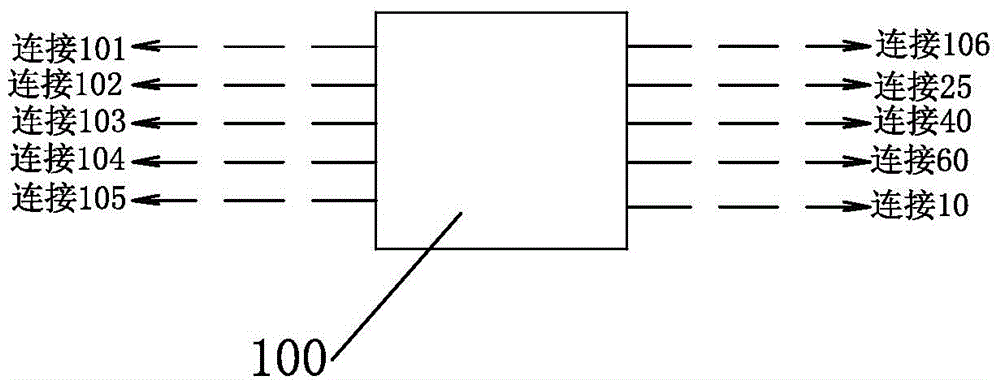

[0079] see figure 1 , figure 2 As shown, a fuel supply-vaporization-pressure regulation-full premix combustion system of the present invention includes an air pump 10, a fuel tank 20, a gasification chamber 30, a preheating heater 40, a premix nozzle 50, and an ignition device 60 , full premix burner 70 and air intake guiding device 80;

[0080] The air pump 10 communicates with the air inlet 21 of the fuel tank 20 through the first pipeline 11, and the fuel tank 20 is provided with a fuel inlet 22 and an oil outlet pipe 23; The fuel oil inlet of the chamber 30 is connected, and the gasification chamber 30 is provided with a preheating heater 40 for heating the gasification chamber 30; The air inlet is connected and communicated, and the air outlet of the premix nozzle 50 leads to the air intake guide device 80, and the outlet of the air intake guide device 80 is connected and communicated with the full premix burner 70, and the full premix burner 70 is provided with There...

Embodiment 2

[0087] Repeat embodiment 1, its difference is only: the inner diameter of one end of the trumpet-shaped through hole 81 of the air guiding device 80 is 25cm, and the inner diameter of the other end is 16cm; the diameter of the cavity 51 at the left end is 6mm; The diameter of the cavity 52 at the right end is 8 mm; the diameter of the reduced diameter hole 53 is 0.5 mm; the diameter of the air inlet hole 54 is 6 mm.

Embodiment 3

[0089] Repeat Example 1, the difference is only: the inner diameter of the trumpet-shaped through hole 81 of the air guiding device 80 is 23cm at one end, and the inner diameter at the other end is 14cm; the diameter of the cavity 51 at the left end is 4mm; The diameter of the cavity 52 at the right end is 6 mm; the diameter of the reduced diameter hole 53 is 0.1 mm; the diameter of the air inlet hole 54 is 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com